Page 1

SEMICONDUCTOR TECHNICAL DATA

1

REV 2

Motorola, Inc. 1997

1/97

The MC1648 requires an external parallel tank circuit consisting of the

inductor (L) and capacitor (C). For Maximum Performance QL ≥ 100 at

Frequency of Operation.

A varactor diode may be incorporated into the tank circuit to provide a

voltage variable input for the oscillator (VCO). The MC1648 was

designed for use in the Motorola Phase–Locked Loop shown in Figure 9.

This device may also be used in many other applications requiring a fixed

or variable frequency clock source of high spectral purity. (See Figure 2)

The MC1648 may be operated from a +5.0Vdc supply or a –5.2Vdc

supply, depending upon system requirements.

NOTE: The MC1648 is NOT useable as a crystal oscillator.

Pinout: 14–Lead Package (Top View)

1314 12 11 10 9 8

21 34567

VCCNC TANK NC BIAS NC V

EE

VCCNC OUT NC AGC NC V

EE

Pin assignment is for Dual–in–Line Package.

For PLCC pin assignment, see the MC1648 Non–Standard Pin Conversion T able below.

MC1648 NON–STANDARD PIN CONVERSION DATA

Package TANK V

CCVCC

OUT AGC V

EEVEE

BIAS

8 D 1 2 3 4 5 6 7 8

14 L,P 12 14 1 3 5 7 8 10

20FN 18 20 2 4 8 10 12 14

*NOTE – All unused pins are not connected.

Supply Voltage

GND Pins Supply Pins

+5.0Vdc 7,8 1,14

–5.2Vdc 1,14 7,8

5

AGC

LOGIC DIAGRAM

3

TANK 12

BIAS POINT 10

OUTPUT

•

Input Capacitance = 6.0pF (TYP)

•

Maximum Series Resistance for L (External Inductance) = 50

Ω

(TYP)

•

Power Dissipation = 150mW (TYP)/Pkg (+5.0Vdc Supply)

•

Maximum Output Frequency = 225MHz (TYP)

V

CC1

= Pin 1

V

CC2

= Pin 14

VEE = Pin 7

VOLTAGE

CONTROLLED

OSCILLATOR

FN SUFFIX

20–LEAD PLCC PACKAGE

CASE 775–02

L SUFFIX

14–LEAD CERAMIC PACKAGE

CASE 632–08

P SUFFIX

14–LEAD PLASTIC PACKAGE

CASE 646–06

D SUFFIX

8–PIN PLASTIC SOIC PACKAGE

CASE 751–05

Not Recommended for New Designs

Page 2

MC1648

MOTOROLA HIPERCOMM

BR1334 — Rev 4

2

Figure 1. Circuit Schematic

5

AGC

8

V

EE

12

TANK

10

BIAS

POINT

7

V

EE1

V

CC2

14

V

CC1

1

Q4

Q3 Q2

Q1

Q5

D1

Q8

Q7 Q6

Q9

Q10Q11

D2

3

OUTPUT

TEST VOLTAGE/CURRENT VALUES

@ Test

(Volts) mAdc

Temperature

V

IHmax

V

ILmin

V

CC

I

L

MC1648

–30°C +2.0 +1.5 +5.0 –5.0

+25°C +1.85 +1.35 +5.0 –5.0

+85°C +1.7 +1.2 +5.0 –5.0

Note: SOIC “D” package guaranteed –30°C to +70°C only

ELECTRICAL CHARACTERISTICS (Supply Voltage = +5.0V)

–30°C +25°C +85°C

Symbol Characteristic Min Max Min Max Min Max Unit Condition

I

E

Power Supply Drain Current – – – 41 – –

mAdc

Inputs and outputs open

V

OH

Logic “1” Output Voltage 3.955 4.185 4.04 4.25 4.11 4.36 Vdc V

ILmin

to Pin 12, IL @ Pin 3

V

OL

Logic “0” Output Voltage 3.16 3.4 3.2 3.43 3.22 3.475 Vdc V

IHmax

to Pin 12, IL @ Pin 3

V

BIAS

1

Bias Voltage 1.6 1.9 1.45 1.75 1.3 1.6 Vdc V

ILmin

to Pin 12

Min Typ Max Min Typ Max Min Typ Max Unit Condition

V

P–P

Peak–to–Peak Tank Voltage – – – – 400 – – – – mV See Figure 3

Vdc Output Duty Cycle – – – – 50 – – – – %

f

max

2

Oscillation Frequency – 225 – 200 225 – – 225 – MHz

1. This measurement guarantees the dc potential at the bias point for purposes of incorporating a varactor tuning diode at this point.

2. Frequency variation over temperature is a direct function of the ∆C/∆ Temperature and ∆L/∆ Temperature.

Page 3

MC1648

HIPERCOMM

BR1334 — Rev 4

3 MOTOROLA

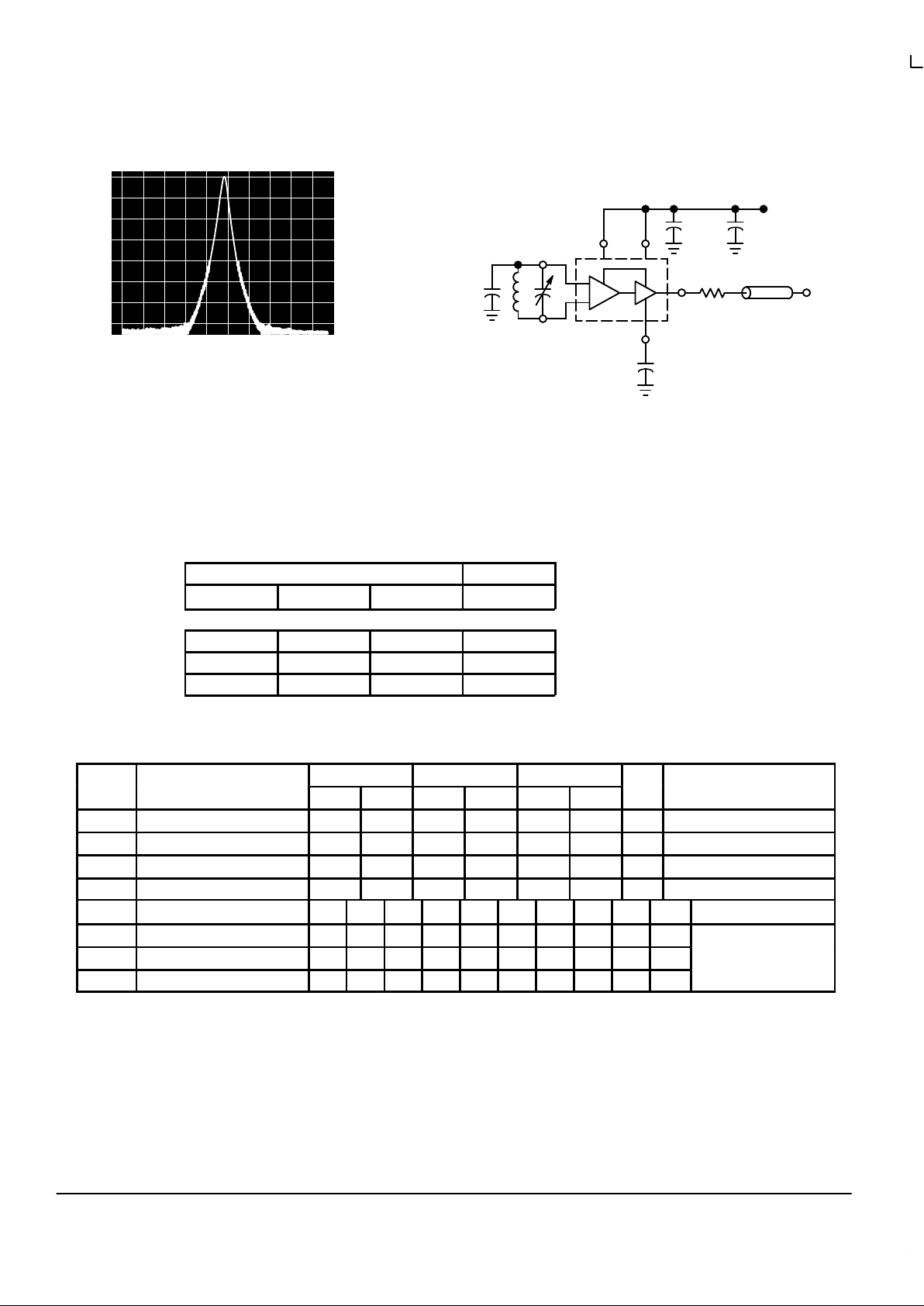

Figure 2. Spectral Purity of Signal Output for 200MHz Testing

B.W. = 10 kHz

Center Frequency = 100 MHz

Scan Width = 50 kHz/div

Vertical Scale = 10 dB/div

0.1µF

1200*

CL

10

12

5

0.1

µ

F

3

SIGNAL

UNDER

TEST

10µF0.1µF

114

L=40nH

C=10pF

+5.0Vdc

L: Micro Metal torroid #T20–22, 8 turns #30 Enameled Copper wire.

C = 3.0–35pF

* The 1200 ohm resistor and the scope termination impedance constitute a 25:1

attenuator probe. Coax shall be CT–075–50 or equivalent.

TEST VOLTAGE/CURRENT VALUES

@ Test

(Volts) mAdc

Temperature

V

IHmax

V

ILmin

V

EE

I

L

MC1648

–30°C –3.2 –3.7 –5.2 –5.0

+25°C –3.35 –3.85 –5.2 –5.0

+85°C –3.5 –4.0 –5.2 –5.0

Note: SOIC “D” package guaranteed –30°C to +70°C only

ELECTRICAL CHARACTERISTICS (Supply Voltage = –5.2V)

–30°C +25°C +85°C

Symbol Characteristic Min Max Min Max Min Max Unit Condition

I

E

Power Supply Drain Current – – – 41 – –

mAdc

Inputs and outputs open

V

OH

Logic “1” Output Voltage –1.045 –0.815 –0.96 –0.75 –0.89 –0.64 Vdc V

ILmin

to Pin 12, IL @ Pin 3

V

OL

Logic “0” Output Voltage –1.89 –1.65 –1.85 –1.62 –1.83 –1.575 Vdc V

IHmax

to Pin 12, IL @ Pin 3

V

BIAS

1

Bias Voltage –3.6 –3.3 –3.75 –3.45 –3.9 –3.6 Vdc V

ILmin

to Pin 12

Min Typ Max Min Typ Max Min Typ Max Unit Condition

V

P–P

Peak–to–Peak Tank Voltage – – – – 400 – – – – mV See Figure 3

Vdc Output Duty Cycle – – – – 50 – – – – %

f

max

2

Oscillation Frequency – 225 – 200 225 – – 225 – MHz

1. This measurement guarantees the dc potential at the bias point for purposes of incorporating a varactor tuning diode at this point.

2. Frequency variation over temperature is a direct function of the ∆C/∆ Temperature and ∆L/∆ Temperature.

Page 4

MC1648

MOTOROLA HIPERCOMM

BR1334 — Rev 4

4

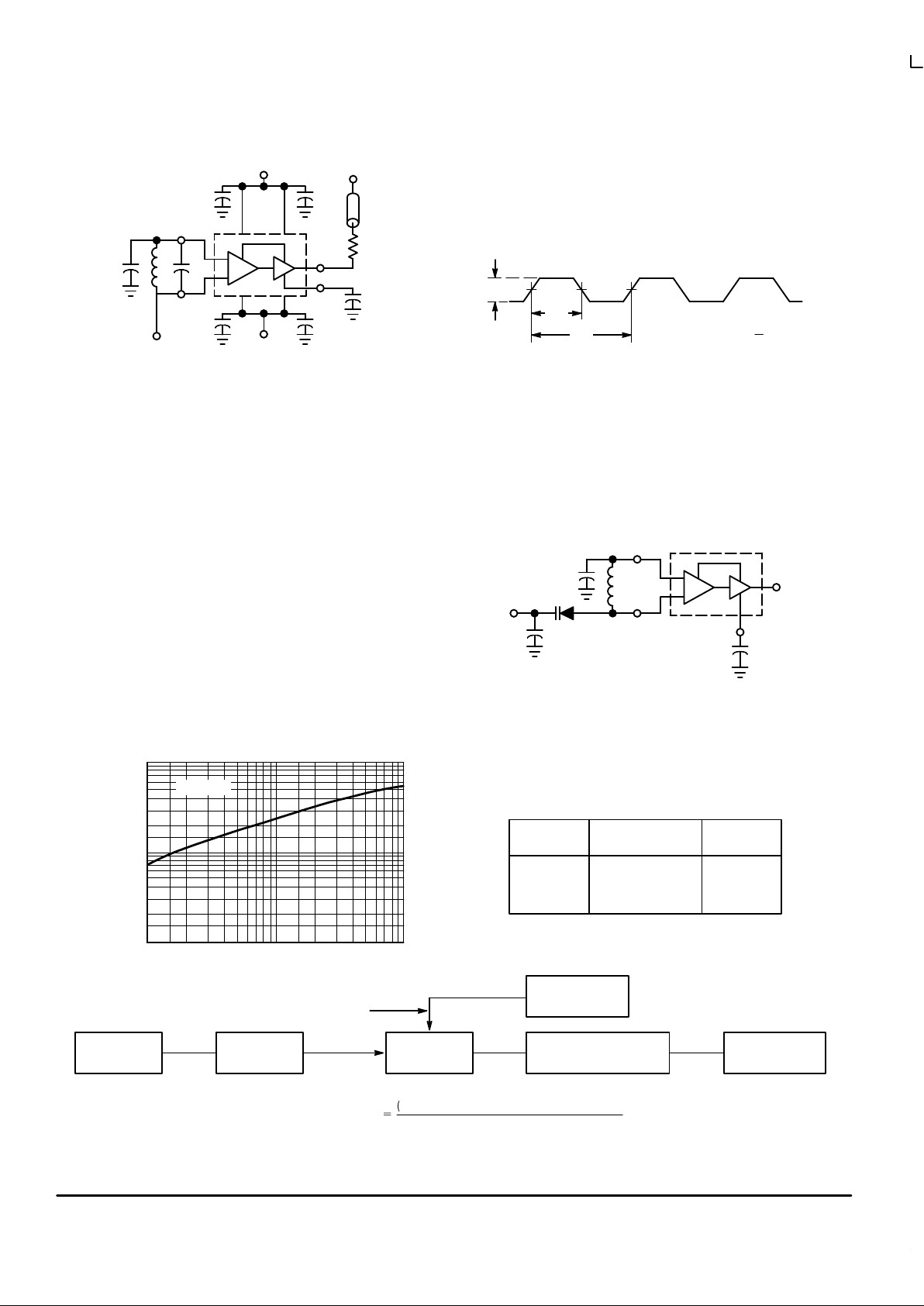

Figure 3. Test Circuit and Waveforms

0.1µF

1200

CL

10

12

0.1µF

3

*

V

CC

**

***

5

V

EE

QL

≥

100

* Use high impedance probe (>1.0 Megohm must be used).

** The 1200 ohm resistor and the scope termination impedance constitute

a 25:1 attenuator probe. Coax shall be CT–070–50 or equivalent.

***Bypass only that supply opposite ground.

50%

t

a

t

b

V

P–P

PRF = 1.0MHz

Duty Cycle (Vdc) –

t

a

t

b

7 8

114

0.1µF 0.1µF

***

OPERA TING CHARACTERISTICS

Figure 1 illustrates the circuit schematic for the MC1648.

The oscillator incorporates positive feedback by coupling the

base of transistor Q6 to the collector of Q7. An automatic gain

control (AGC) is incorporated to limit the current through the

emitter–coupled pair of transistors (Q7 and Q6) and allow

optimum frequency response of the oscillator.

In order to maintain the high Q of the oscillator, and

provide high spectral purity at the output, transistor Q4 is

used to translate the oscillator signal to the output differential

pair Q2 and Q3. Q2 and Q3, in conjunction with output

transistor Q1, provides a highly buffered output which

produces a square wave. Transistors Q9 and Q11 provide

the bias drive for the oscillator and output buffer. Figure 2

indicates the high spectral purity of the oscillator output

(pin 3).

When operating the oscillator in the voltage controlled

mode (Figure 4), it should be noted that the cathode of the

varactor diode (D) should be biased at least “2” VBE above

VEE (≈1.4V for positive supply operation).

When the MC1648 is used with a constant dc voltage to

the varactor diode, the output frequency will vary slightly

because of internal noise. This variation is plotted versus

operating frequency in Figure 5.

Figure 4. The MC1648 Operating in the

Voltage Controlled Mode

0.1µF

L

10

12

C2

3

5

QL

≥

100

Output

V

in

C1

D

1.0–10

10–60

60–100

f

MHz

Figure 5. Noise Deviation Test Circuit and Waveform

100

1

f, OPERATING FREQUENCY (MHz)

VCC = 5 Vdc

f, FREQUENCY DEVIA TION, RMS (Hz)

10

1

10 100

∆

Frequency Deviation

+

(HP5210A output voltage) (Full Scale Frequency)

1.0Volt

MV2115

MV2115

MV2106

D

100

2.3

0.15

L

µH

Oscillator Tank Components

(Circuit of Figure 4)

BW=1.0kHz Frequency

Meter HP5210A or Equiv

Voltmeter RMS

HP3400A or Equiv

MC1648

Frequency (f)

MC1648

Under Test

Attenuator

Product

Detector

Signal Generator

HP608 or Equiv

10mV 20kHz

300mV

20kHz above MC1648 Frequency

Page 5

MC1648

HIPERCOMM

BR1334 — Rev 4

5 MOTOROLA

* The 1200 ohm resistor and the scope termination impedance consti-

tute a 25:1 attenuator probe. Coax shall be CT–070–50 or equivalent.

NOT used in normal operation.

** Input resistor and cap are for test only. They are NOT necessary for

normal operation.

* The 1200 ohm resistor and the scope termination impedance consti-

tute a 25:1 attenuator probe. Coax shall be CT–070–50 or equivalent.

NOT used in normal operation.

** Input resistor and cap are for test only. They are NOT necessary for

normal operation.

Figure 6

Figure 7

Figure 8

Vin, INPUT VOLTAGE (VOLTS)

Vin, INPUT VOLTAGE (VOLTS)

18

0

8

10

190

50

64

0

Vin, INPUT VOLTAGE (VOLTS)

8

10

56

48

40

32

24

16

2468

f

out

, OUTPUT FREQUENCY (MHz)f

out

, OUTPUT FREQUENCY (MHz)f

out

, OUTPUT FREQUENCY (MHz)

16

14

12

10

24 68

0102468

170

150

130

110

90

70

0.1µF

L

10

12

0.1

µ

F

3

5

V

CC1

= V

CC2

= +5.0Vdc

V

EE1

= V

EE2

= GND

f

out

V

in

MV1401

1200*

5.0µF

L = 0.13

µ

H

QL

≥

100

L: Micro Metal Toroidal Core #T44–10,

4 turns of No. 22 copper wire.

0.1µF

L

10

12

0.1

µ

F

3

5

V

CC1

= V

CC2

= +5.0Vdc

V

EE1

= V

EE2

= GND

f

out

V

in

MV1401

1200*

5.0µF

QL ≥100

C = 500pF

L = 1.58

µ

H

L: Micro Metal Toroidal Core #T44–10,

20 turns of No. 22 copper wire.

C

1.0k

1.0k

* The 1200 ohm resistor and the scope termination impedance consti-

tute a 25:1 attenuator probe. Coax shall be CT–070–50 or equivalent.

NOT used in normal operation.

** Input resistor and cap are for test only. They are NOT necessary for

normal operation.

0.1µF

L

10

12

0.1

µ

F

3

5

V

CC1

= V

CC2

= +5.0Vdc

V

EE1

= V

EE2

= GND

f

out

V

in

1200*

QL ≥100

L = 0.065

µ

H

L: Micro Metal Toroidal Core #T30–12,

6 turns of No. 22 copper wire.

51k

MV1404

5.0µF

**

**

**

**

**

**

Page 6

MC1648

MOTOROLA HIPERCOMM

BR1334 — Rev 4

6

Typical transfer characteristics for the oscillator in the

voltage controlled mode are shown in Figure 6, Figure 7 and

Figure 8. Figure 6 and Figure 8 show transfer characteristics

employing only the capacitance of the varactor diode (plus

the input capacitance of the oscillator, 6.0pF typical).

Figure 7 illustrates the oscillator operating in a voltage

controlled mode with the output frequency range limited. This

is achieved by adding a capacitor in parallel with the tank

circuit as shown. The 1.0kΩ resistor in Figure 6 and Figure 7

is used to protect the varactor diode during testing. It is not

necessary as long as the dc input voltage does not cause the

diode to become forward biased. The larger–valued resistor

(51kΩ) in Figure 8 is required to provide isolation for the

high–impedance junctions of the two varactor diodes.

The tuning range of the oscillator in the voltage controlled

mode may be calculated as:

f

max

f

min

+

CD(max))C

S

Ǹ

CD(min))C

S

Ǹ

where f

min

+

1

2pL(CD(max))CS)

Ǹ

CS = shunt capacitance (input plus external capacitance)

CD = varactor capacitance as a function of bias voltage

Good RF and low–frequency bypassing is necessary on

the power supply pins. (See Figure 2)

Capacitors (C1 and C2 of Figure 4) should be used to

bypass the AGC point and the VCO input (varactor diode),

guaranteeing only dc levels at these points.

For output frequency operation between 1.0MHz and

50MHz a 0.1µF capacitor is sufficient for C1 and C2. At

higher frequencies, smaller values of capacitance should be

used; at lower frequencies, larger values of capacitance. At

high frequencies the value of bypass capacitors depends

directly upon the physical layout of the system. All bypassing

should be as close to the package pins as possible to

minimize unwanted lead inductance.

The peak–to–peak swing of the tank circuit is set internally

by the AGC circuitry. Since voltage swing of the tank circuit

provides the drive for the output buffer, the AGC potential

directly affects the output waveform. If it is desired to have a

sine wave at the output of the MC1648, a series resistor is

tied from the AGC point to the most negative power potential

(ground if +5.0 volt supply is used, –5.2 volts if a negative

supply is used) as shown in Figure 10.

At frequencies above 100 MHz typ, it may be desirable to

increase the tank circuit peak–to–peak voltage in order to

shape the signal at the output of the MC1648. This is

accomplished by tying a series resistor (1.0kΩ minimum)

from the AGC to the most positive power potential (+5.0 volts

if a +5.0 volt supply is used, ground if a –5.2 volt supply is

used). Figure 11 illustrates this principle.

APPLICATIONS INFORMATION

The phase locked loop shown in Figure 9 illustrates the

use of the MC1648 as a voltage controlled oscillator. The

figure illustrates a frequency synthesizer useful in tuners for

FM broadcast, general aviation, maritime and landmobile

communications, amateur and CB receivers. The system

operates from a single +5.0Vdc supply, and requires no

internal translations, since all components are compatible.

Frequency generation of this type offers the advantages of

single crystal operation, simple channel selection, and

elimination of special circuitry to prevent harmonic lockup.

Additional features include dc digital switching (preferable

over RF switching with a multiple crystal system), and a

broad range of tuning (up to 150MHz, the range being set by

the varactor diode).

The output frequency of the synthesizer loop is

determined by the reference frequency and the number

programmed at the programmable counter; f

out

= Nf

ref

. The

channel spacing is equal to frequency (f

ref

).

For additional information on applications and designs for

phase locked–loops and digital frequency synthesizers, see

Motorola Brochure BR504/D, Electronic Tuning Address

Systems, (ETAS).

Figure 10 shows the MC1648 in the variable frequency

mode operating from a +5.0Vdc supply . T o obtain a sine wave

at the output, a resistor is added from the AGC circuit (pin 5)

to VEE.

Figure 11 shows the MC1648 in the variable frequency

mode operating from a +5.0Vdc supply . To extend the useful

range of the device (maintain a square wave output above

175Mhz), a resistor is added to the AGC circuit at pin 5 (1.0

kohm minimum).

Figure 12 shows the MC1648 operating from +5.0Vdc and

+9.0Vdc power supplies. This permits a higher voltage swing

and higher output power than is possible from the MECL

output (pin 3). Plots of output power versus total collector

load resistance at pin 1 are given in Figure 13 and Figure 14

for 100MHz and 10MHz operation. The total collector load

includes R in parallel with Rp of L1 and C1 at resonance. The

optimum value for R at 100MHz is approximately 850 ohms.

Page 7

MC1648

HIPERCOMM

BR1334 — Rev 4

7 MOTOROLA

Figure 9. Typical Frequency Synthesizer Application

Phase

Detector

MC4044

f

ref

Counter Control

Logic

MC12014

MC12012

÷

P, ÷(P+1)

÷

N

p

Programmable

Counter MC4016

÷

A

Programmable

Counter MC4016

Low Pass

Filter

Voltage Controlled

Oscillator

MC1648

Modulus Enable Line

Zero Detect Line

f

out

N = Np

•

P + A

Counter Reset Line

f

out

f

out

= Nf

ref

where

N = Np

•

P + A

Figure 10. Method of Obtaining a Sine–Wave Output Figure 11. Method of Extending the Useful Range

of the MC1648 (Square Wave Output)

10

12

78

3

5

Output

+5.0Vdc

10

12

78

3

5

Output

+5.0Vdc

114

114

1.0k min

Page 8

MC1648

MOTOROLA HIPERCOMM

BR1334 — Rev 4

8

Figure 12. Circuit Used for Collector Output Operation

10

12

0.1

µ

F

3

5

Bias Point

L2* T ank

C2

1.0

µ

F

V

CC2

14 1V

CC1

C1

L1

+5.0V

C3

R

0.01µF

+9.0V

AGC

+5.0V

1.0µF

1.2k

8V

EE2

7V

EE1

* QL ≥ 100

Output

Figure 13. Power Output versus Collector Load Figure 14. Power Output versus Collector Load

TOTAL COLLECT OR LOAD (OHMS)

7

10

TOTAL COLLECT OR LOAD (OHMS)

POWER OUTPUT (mW RMS)

0

10,000

6

5

4

3

2

1

100 1000

POWER OUTPUT (mW RMS)

10 10,000100 1000

14

0

12

10

8

6

4

2

See test circuit, Figure 12, f = 100MHz

C3 = 3.0–35pF

Collector Tank

L1 = 0.22µH C1 = 1.0–7.0pF

R = 50Ω–10kΩ

RP of L1 and C1 = 11kΩ @ 100MHz Resonance

Oscillator Tank

L2 = 4 turns #20 AWG 3/16” ID

C2 = 1.0–7.0pF

See test circuit, Figure 12, f = 10MHz

C3 = 470pF

Collector Tank

L1 = 2.7µH C1 = 24–200pF

R = 50Ω–10kΩ

RP of L1 and C1 = 6.8kΩ @ 10MHz Resonance

Oscillator Tank

L2 = 2.7µH

C2 = 16–150pF

Page 9

MC1648

HIPERCOMM

BR1334 — Rev 4

9 MOTOROLA

OUTLINE DIMENSIONS

P SUFFIX

PLASTIC PACKAGE

CASE 646–06

ISSUE L

18.16

6.10

3.69

0.38

1.02

1.32

0.20

2.92

0°

0.39

19.56

6.60

4.69

0.53

1.78

2.41

0.38

3.43

10

°

1.01

2.54 BSC

7.62 BSC

0.715

0.240

0.145

0.015

0.040

0.052

0.008

0.115

0

°

0.015

SEATING

PLANE

0.100 BSC

0.300 BSC

MIN MINMAX MAX

INCHES MILLIMETERS

DIM

0.770

0.260

0.185

0.021

0.070

0.095

0.015

0.135

10

°

0.039

A

B

C

D

F

G

H

J

K

L

M

N

NOTES:

1. LEADS WITHIN 0.13 (0.005) RADIUS OF TRUE

POSITION AT SEATING PLANE AT MAXIMUM

MATERIAL CONDITION.

2. DIMENSION L TO CENTER OF LEADS WHEN

FORMED PARALLEL.

3. DIMENSION B DOES NOT INCLUDE MOLD

FLASH.

4. ROUNDED CORNERS OPTIONAL.

17

14 8

B

A

F

HG D

N

K

C

L

J

M

MIN MINMAX MAX

INCHES MILLIMETERS

DIM

A

B

C

D

F

G

J

K

L

M

N

0.785

0.280

0.200

0.020

0.065

0.015

0.170

15

°

0.040

0.750

0.245

0.155

0.015

0.055

0.008

0.125

0

°

0.020

19.94

7.11

5.08

0.50

1.65

0.38

4.31

15

°

1.01

19.05

6.23

3.94

0.39

1.40

0.21

3.18

0

°

0.51

0.100 BSC

0.300 BSC

2.54 BSC

7.62 BSC

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEAD WHEN

FORMED PARALLEL.

4. DIMESNION F MAY NARROW TO 0.76 (0.030)

WHERE THE LEAD ENTERS THE CERAMIC

BODY.

14 8

17

-A-

-B-

-T-

SEATING

PLANE

FG

N

K

C

L

M

0.25 (0.010) T A

M

S

0.25 (0.010) T B

M

S

J 14 PL

D 14 PL

L SUFFIX

CERAMIC PACKAGE

CASE 632–08

ISSUE Y

D SUFFIX

PLASTIC SOIC PACKAGE

CASE 751–05

ISSUE R

SEATING

PLANE

1

4

58

A0.25MCB

SS

0.25MB

M

h

q

C

X 45

_

L

DIM MIN MAX

MILLIMETERS

A 1.35 1.75

A1 0.10 0.25

B 0.35 0.49

C 0.18 0.25

D 4.80 5.00

E

1.27 BSCe

3.80 4.00

H 5.80 6.20

h

0 7

L 0.40 1.25

q

0.25 0.50

__

NOTES:

1. DIMENSIONING AND TOLERANCING PER ASME

Y14.5M, 1994.

2. DIMENSIONS ARE IN MILLIMETERS.

3. DIMENSION D AND E DO NOT INCLUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 PER SIDE.

5. DIMENSION B DOES NOT INCLUDE MOLD

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 TOTAL IN EXCESS

OF THE B DIMENSION AT MAXIMUM MATERIAL

CONDITION.

D

E

H

A

B

e

B

A1

C

A

0.10

Page 10

MC1648

MOTOROLA HIPERCOMM

BR1334 — Rev 4

10

OUTLINE DIMENSIONS

FN SUFFIX

PLASTIC PLCC PACKAGE

CASE 775–02

ISSUE C

A

B

C

E

F

G

H

J

K

R

U

V

W

X

Y

Z

G1

K1

MIN MINMAX MAX

INCHES MILLIMETERS

DIM

9.78

9.78

4.20

2.29

0.33

0.66

0.51

0.64

8.89

8.89

1.07

1.07

1.07

—

2

°

7.88

1.02

10.03

10.03

4.57

2.79

0.48

0.81

—

—

9.04

9.04

1.21

1.21

1.42

0.50

10

°

8.38

—

0.385

0.385

0.165

0.090

0.013

0.026

0.020

0.025

0.350

0.350

0.042

0.042

0.042

—

2

°

0.310

0.040

0.395

0.395

0.180

0.110

0.019

0.032

—

—

0.356

0.356

0.048

0.048

0.056

0.020

10

°

0.330

—

1.27 BSC0.050 BSC

NOTES:

1. DATUMS -L-, -M-, AND -N- DETERMINED WHERE

TOP OF LEAD SHOULDER EXITS PLASTIC BODY

AT MOLD PARTING LINE.

2. DIM G1, TRUE POSITION TO BE MEASURED AT

DATUM -T-, SEATING PLANE.

3. DIM R AND U DO NOT INCLUDE MOLD FLASH.

ALLOWABLE MOLD FLASH IS 0.010 (0.250) PER

SIDE.

4. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

5. CONTROLLING DIMENSION: INCH.

6. THE PACKAGE TOP MAY BE SMALLER THAN THE

PACKAGE BOTTOM BY UP TO 0.012 (0.300).

DIMENSIONS R AND U ARE DETERMINED AT THE

OUTERMOST EXTREMES OF THE PLASTIC BODY

EXCLUSIVE OF MOLD FLASH, TIE BAR BURRS,

GATE BURRS AND INTERLEAD FLASH, BUT

INCLUDING ANY MISMATCH BETWEEN THE TOP

AND BOTTOM OF THE PLASTIC BODY.

7. DIMENSION H DOES NOT INCLUDE DAMBAR

PROTRUSION OR INTRUSION. THE DAMBAR

PROTRUSION(S) SHALL NOT CAUSE THE H

DIMENSION TO BE GREATER THAN 0.037 (0.940).

THE DAMBAR INTRUSION(S) SHALL NOT CAUSE

THE H DIMENSION TO BE SMALLER THAN 0.025

(0.635).

-N-

Y BRK

-M-

-L-

W

V

D

D

20

1

A

R

Z

C

G

G1

E

J

VIEW S

B

U

Z

G1

X

H

F

VIEW S

K

K1

VIEW D-D

0.007 (0.180) T L

–M

SNSM

0.007 (0.180) T L

–M

SNSM

SEATING

PLANE

-T-

0.010 (0.250) T L

–M

SNSS

0.007 (0.180) T L

–M

SNSM

0.007 (0.180) T L

–M

SNSM

0.010 (0.250) T L

–M

SNSS

0.007 (0.180) T L

–M

SNSM

0.007 (0.180) T L

–M

SNSM

0.004 (0.100)

Page 11

MC1648

HIPERCOMM

BR1334 — Rev 4

11 MOTOROLA

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

How to reach us:

USA/EUROPE/Locations Not Listed: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, 6F Seibu–Butsuryu–Center,

P.O. Box 5405; Denver, Colorado 80217. 303–675–2140 or 1–800–441–2447 3–14–2 Tatsumi Koto–Ku, Tokyo 135, Japan. 81–3–3521–8315

Mfax: RMFAX0@email.sps.mot.com – TOUCHTONE 602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://Design–NET.com 51 Ting Ko k Road, Tai Po, N.T., Hong Kong. 852–26629298

MC1648/D

◊

Loading...

Loading...