Page 1

MOTOROLA

SEMICONDUCTOR TECHNICAL DATA

MC14LC5003

128 Segment LCD Drivers

CMOS

The MC14LC5003/5004 are 128-segment, multiplexed-by-four LCD Drivers. The two devices are functionally the same except for their data input

protocols. The MC14LC5003 uses a serial interface data input protocol. The

device may be interf aced to the MC68HCXX product families using a minimal

amount of software (see example). The MC14LC5004 has a IIC interface and

has essentially the same protocol, except that the device sends an ac knowledge bit back to the transmitter after each eight-bit byte is received.

MC14LC5004 also has a “read mode”, whereby data sent to the device ma y

be retrieved via the IIC bus.

The MC14LC5003/MC14LC5004 drives the liquid-crystal displays in a multiplexed-b y-four configuration. The device accepts data from a microprocessor or other serial data source to drive one segment per bit. The chip does

not have a decoder , allo wing f or the fle xibility of f ormatting the segment data

externally .

Devices are independently addressable via a two-wire (or three-wire) communication link which can be common with other peripheral devices.

The MC14LC5003/MC14LC5004 are low cost version of MC145003 and

MC145004 without cascading function.

• Drives 128 Segments Per Package

• May Be Used with the Following LCDs: Segmented Alphanumeric,

Bar Graph, Dot Matrix, Custom

• Quiescent Supply Current: 30 A @ 2.7 V V

• Operating Voltage Range: 2.7 to 5.5 V

• Operating Temperature Range: -40 to 85C

• Separate Access to LCD Drive Section’s Supply Voltage to Allow f or Tem-

perature Compensation

• See Application Notes AN1066 and AN442

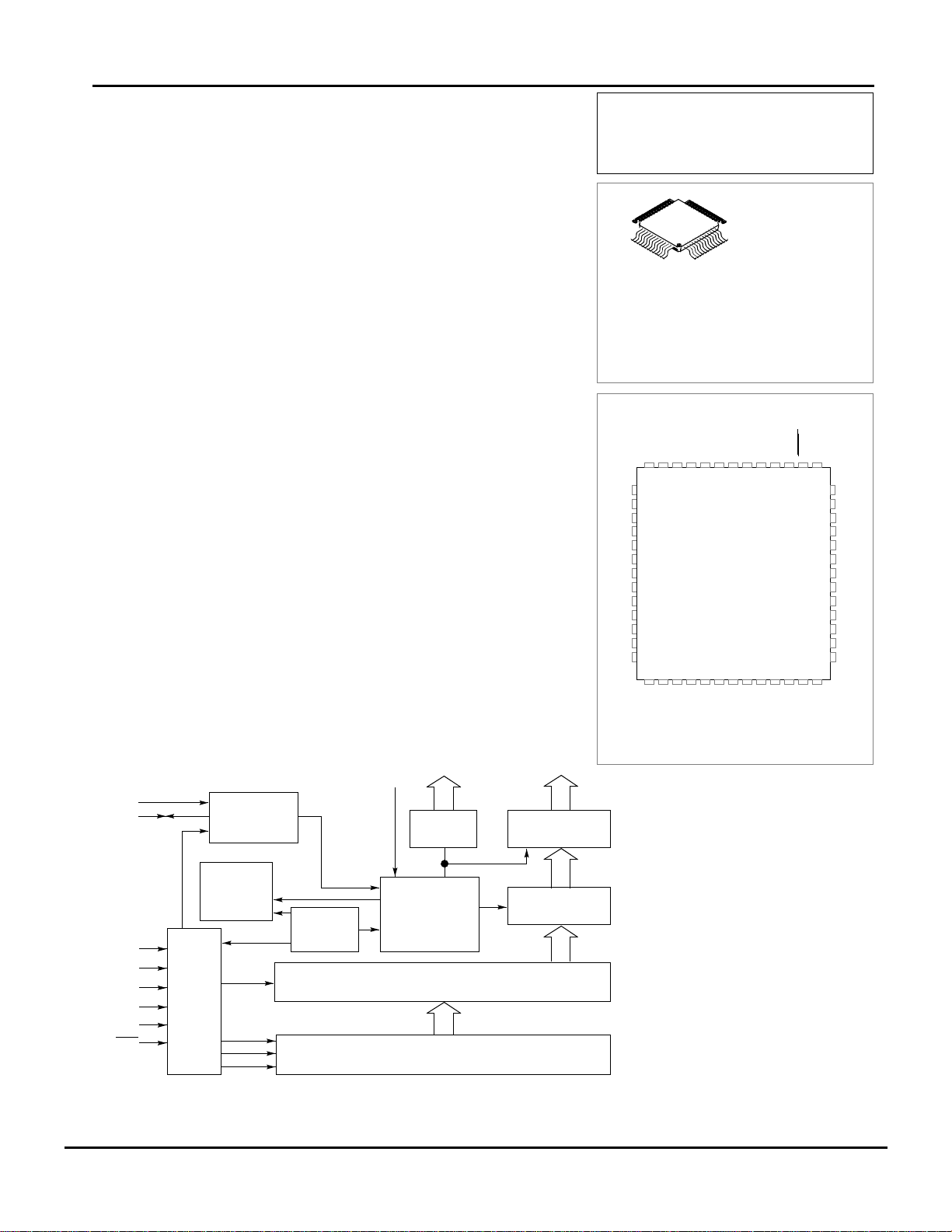

BLOCK DIAGRAM

OSC1

OSC2

OSCILLATOR

DD

BP1-BP4 FP1-FP32

V

LCD

DRIVERS

DRIVERS

MC14LC5004

1

52

ORDERING INFORMATION

MC14LC5003FU QFP

MC14LC5004FU QFP

MCC14LC5003 BARE DIE

MCC14LC5004 BARE DIE

PIN ASSIGNMENT

DD

OSC2

V

FP18

FP17

BP2

BP1

FP16

FP15

NC

OSC1

52 51 50 49 48 47 46 45 44 43 42 41 40

FP32

1

FP31

2

FP30

3

FP29

4

FP28

5

FP27

6

FP26

7

FP25

8

FP24

9

FP23

10

FP22

11

FP21

12

FP20

13

14 15 16 17 18 19 20 21 22 23 24 25 26

NC

FP19

NC=NO CONNECTION

BP3

LCD

V

BP4A0A1

SS

V

FP14

QFP

FU SUFFIX

CASE 848B

ENB

NC

A2

39

38

37

36

35

34

33

32

31

30

29

28

27

NC

FP11

FP13

FP12

Din

DCLK

NC

FP1

FP2

FP3

FP4

FP5

FP6

FP7

FP8

FP9

FP10

REV 2

10/96

DCLK

D

A0

A1

A2

ENB

FRAME

SYNC

GENERATOR

POR

in

DATA AND ADDRESS

CONTROL AND TIMING

LCD VOLTAGE

WAVEFORM

AND TIMING

GENERATOR

128-BIT LATCH

128-BIT SHIFT REGISTER

128 - 32

MULTIPLEX

MC14LC5003 • MC14LC5004MOTOROLA

3–3

Page 2

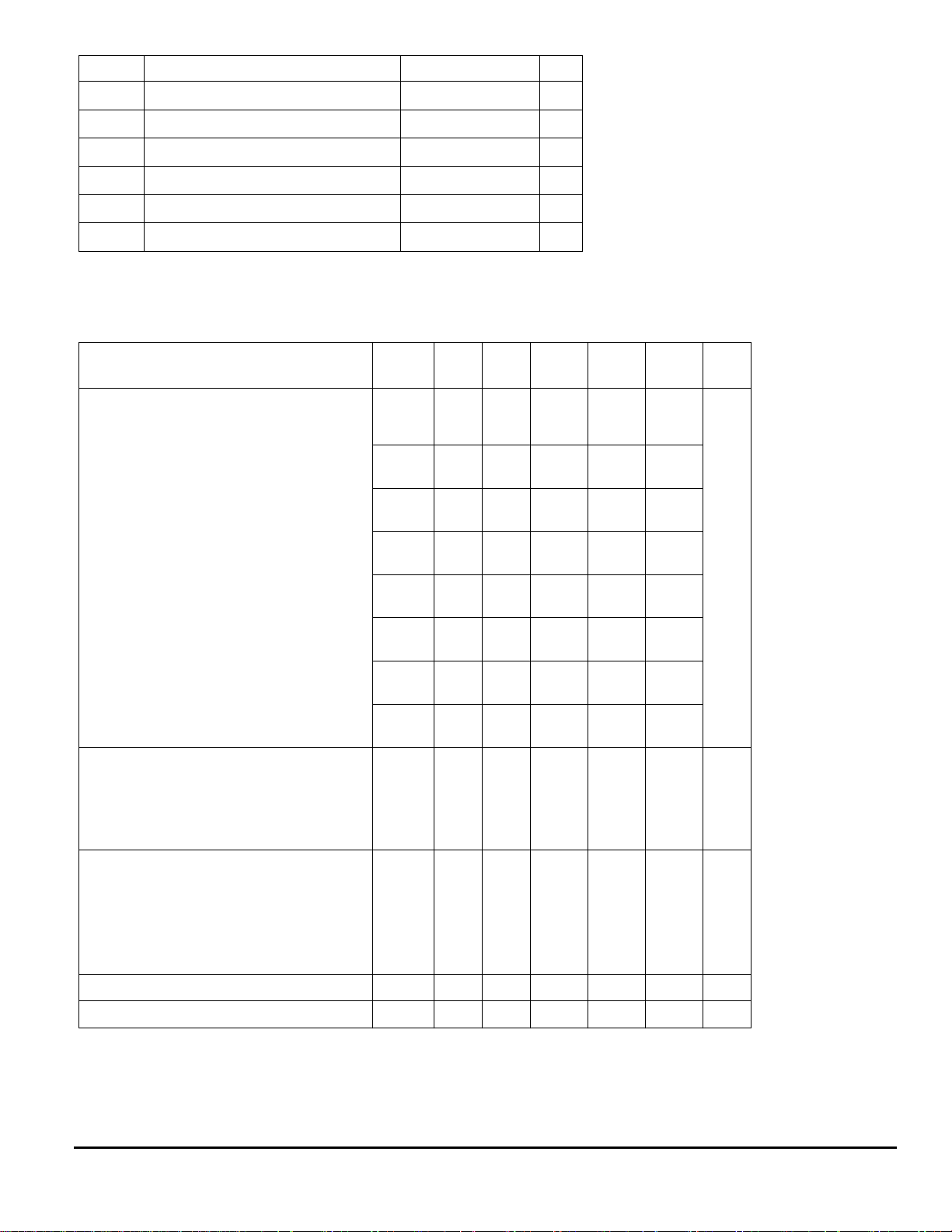

ABSOLUTE MAXIMUM RATINGS (Voltages Referenced to VSS)

Symbol Parameter Value Unit

V

V

V

in osc

T

DC Supply Voltage - 0.5 to + 6.5 V

DD

Input Voltage, Din, and Data Clock - 0.5 to 15 V

in

Input Voltage, OSCin of Master - 0.5 to VDD+ 0.5 V

I

DC Input Current, per Pin ± 10 mA

in

T

Operating Temperature Range - 40 to + 85 °C

A

Storage Temperature Range - 65 to + 150 °C

stg

* Maximum Ratings are those values beyond which damage to the device may occur. Func-

tional operation should be restricted to the limits in the Electrical Characteristics tables or

Pin Descriptions section.

This device contains protection circuitry

to guard against damage due to high static

voltages or electric fields. Howev er , precautions must be taken to avoid applications of

any voltage higher than maximum rated voltages to this high-impedance circuit. This

device may be light sensitive. Caution

should be taken to avoid exposure of this

device to any light source during normal operation. This device is not radiation protected.

ELECTRICAL CHARACTERISTICS (Voltages Referenced to V

Characteristic

Symbol

Output Drive Current — Frontplanes

VO = 0.15 V I

VO = 2.65 V I

VO = 1.72 V I

VO = 1.08 V I

VO = 0.15 V I

VO = 5.35 V I

VO = 3.52 V I

VO = 1.98 V I

FH

I

FL

FH

I

FL

FH

I

FL

FH

I

FL

FH

I

FL

FH

I

FL

FH

I

FL

FH

I

FL

Supply Standby Currents (No Clock)

IDD = Standby @ I

= Standby @ I

I

LCD

= Standby @ I

I

DD

= Standby @ I

I

LCD

out

out

out

out

= 0 µA

= 0 µA

= 0 µA

= 0 µA

I

DDS

I

LCDS

I

DDS

I

LCDS

, TA= 25C)

SS

V

DD

V

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

2.7

—

5.5

—

V

LCD

V Min Typical Max

2.7

2.7

2.7

2.7

2.7

2.7

2.7

2.7

5.5

5.5

5.5

5.5

5.5

5.5

5.5

5.5

—

2.7

—

5.5

260

260

-240

-240

-40

—

40

—

600

600

-520

-520

-35

—

55

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

Unit

µA

—

—

—

—

—

-1.5

—

2

—

—

—

—

—

-1.5

—

1

µA

30

800

50

1500

Supply Currents (f

= Quiescent @ I

I

DD

I

= Quiescent @ loading = 270pF

DD

= Quiescent @ I

I

DD

= Quiescent @ loading = 270pF

I

DD

= Quiescent @ I

I

LCD

= Quiescent @ I

I

LCD

) = 110 kHz

OSC

= 0 µA, no loading

out

= 0 µA, no loading

out

= 0 µA, no loading

out

= 0 µA, no loading

out

I

I

I

I

I

LCDQ

I

LCDQ

Input Current I

Input Capacitance C

MC14LC5003 • MC14LC5004

3–4

DDQ

DDQ

DDQ

DDQ

in

µA

2.7

2.7

5.5

5.5

—

—

—

—

—

—

2.7

5.5

—

—

—

—

—

—

30

—

170

—

—

—

—

70

—

400

40

70

— — -0.1 — 0.1 µA

in

— — — — 7.5 pF

(continued)

MOTOROLA

Page 3

ELECTRICAL CHARACTERISTICS (Continued)

V

V

DD

Characteristic

Symbol

Frequencies

OSC2 Frequency @ R1; R1 = 200 kΩ

BP Frequency @ R1

OSC2 Frequency @ R2; R2 = 996 kΩ

Average DC Offset Voltage (BP Relative to FP) V

Input Voltage “0” Level V

“1” Level V

f

OSC2

f

BP

f

OSC2

V

V

OO

2.8

IL

5.5

IL

2.8

IH

5.5

IH

Output Drive Current — Backplanes VO = 2.65 V IBH*

I

BL

VO = 0.15 V I

VO = 1.08V I

VO = 1.72 V I

VO = 5.35 V I

VO = 0.15 V I

VO = 1.98 V I

VO = 3.52 V I

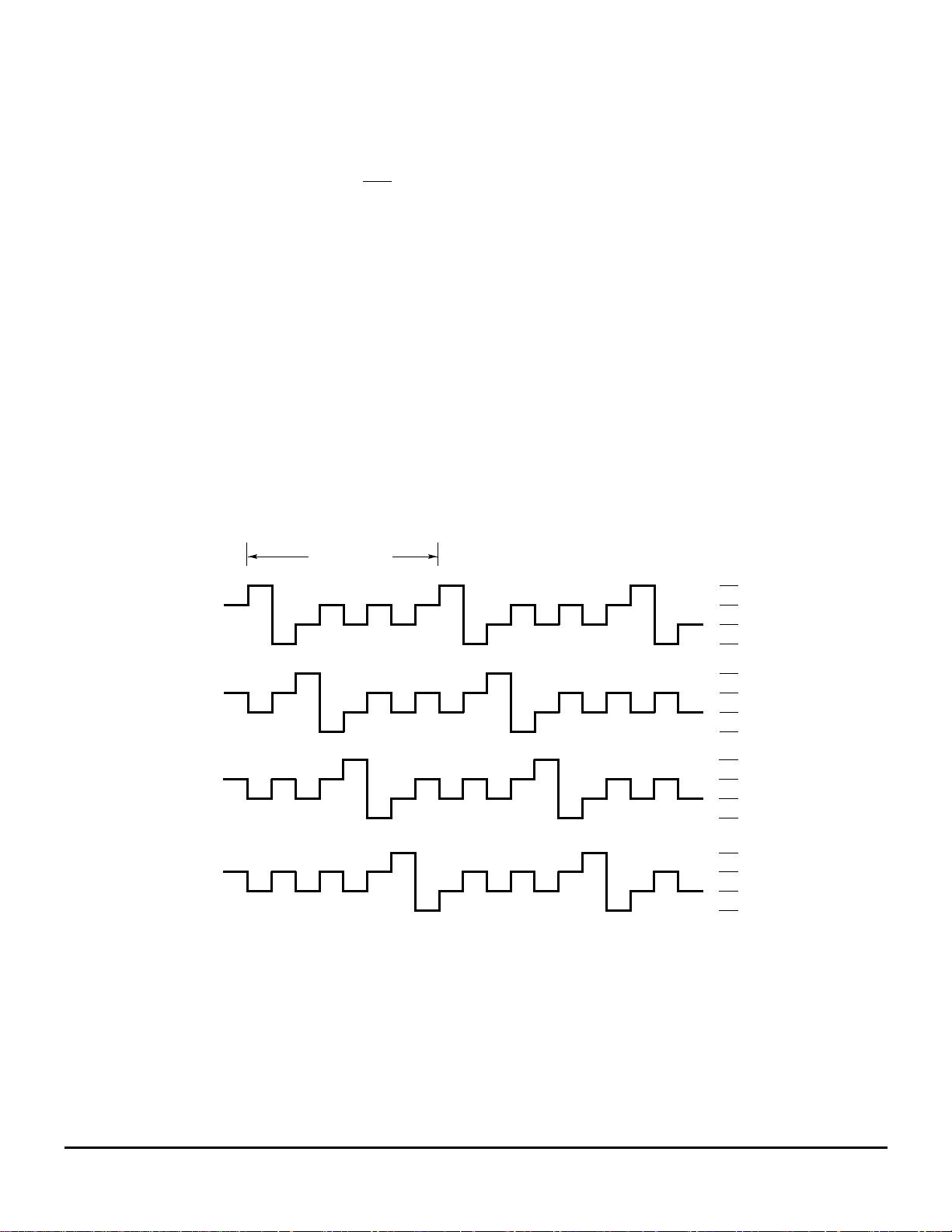

Pulse Width, Data Clock (Figure 1) t

DCLK Rise/Fall Time (Figure 1) tr, t

Setup Time, Din to DCLK (Figure 2) t

Hold Time, Din to DCLK (Figure 2) t

DCLK Low to ENB High (Figure 3) t

ENB High to DCLK High (Figure 3) t

ENB High Pulse Width (Figure 3) t

ENB Low to DCLK High (Figure 3) t

BH

I

BL

BH

I

BL

BH

I

BL

BH

I

BL

BH

I

BL

BH

I

BL

BH

I

BL

w

f

su

h

h

rec

w

su

NOTE: Timing for Figures 1, 2, and 3 are design estimates only.

* For a time (t = 4/OSC FREQ.) after the backplane waveform changes to a new voltage level, the circuit is maintained in the high-current state to

allow the load capacitances to charge quickly. The circuit is then returned to the low-current state until the next voltage change.

LCD

V

5

5

5

V Min Typical Max

5

5

5

100

100

23

—

—

—

150

150

33

Unit

kHz

Hz

kHz

5 2.8 -50 — +50 mV

5

5

5

5

5

2.8

5

2.8

5

2.8

5

2.8

5

2.8

5

2.8

5

2.8

5

2.8

5

5.5

5

5.5

5

5.5

5

5.5

5

5.5

5

5.5

5

5.5

5

5.5

5

3

5

3

5

3

5

3

5

3

5

3

5

3

5

3

—

—

2

3.85

-240

-240

260

260

40

—

-40

—

-520

-520

600

600

55

—

-35

—

50

100

—

—

0

0

30

60

10

20

10

20

50

100

10

20

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

0.85

1.65

—

—

—

—

—

—

—

2

—

-1

—

—

—

—

—

1

—

-1

—

—

20

120

—

—

—

—

—

—

—

—

—

—

—

—

V

µA

ns

µs

ns

ns

ns

ns

ns

ns

MC14LC5003 • MC14LC5004MOTOROLA

3–5

Page 4

SWITCHING WAVEFORMS

CLK

90%

50%

10%

t

f

t

r

V

DD

D

in

50%

GND

t

w

t

w

CLK

Figure 1. Figure 2.

ENB

CLK

50%

50%

FIRST

CLK

t

w

t

su

LAST

CLK

t

w

t

h

t

rec

V

DD

GND

V

DD

GND

Figure 3.

VALID

V

DD

GND

t

su

50%

t

h

V

DD

GND

MC14LC5003 • MC14LC5004

3–6

MOTOROLA

Page 5

FUNCTIONAL DESCRIPTION

The MC14LC5003/MC14LC5004 has essentially two sections which operate asynchronously from each other; the data

input and storage section and the LCD drive section. The LCD

drive and timing is derived from the oscillator, while the data

input and storage is controlled by the Data In (D

(DCLK), Address (A0, A1, A2), and Enable (

), Data Clock

in

ENB) pins.

Data is shifted serially into the 128-bit shift register and arranged into four consecutive b locks of 32 parallel data bits. A

time-multiplex of the four backplane drivers is made (each

backplane driver becoming active then inactive one after another) and, at the start of each backplane active period, the

corresponding block of 32 bits is made available at the frontplane drivers. A high input to a plane driver turns the driver

on, and a low input turns the driver off.

Figure 4 shows the sequence of backplanes. Figure 5 shows

the possible configurations of the frontplanes relative to the

backplanes. When a backplane driver is on, its output s witches

from V

to 2/3 V

output switches from 0 V to V

from 2/3 V

to 0 V, and when it is off, it switches from 1/3 V

LCD

. When a frontplane driver is on, its

LCD

, and when it is off, it switches

LCD

LCD

to 1/3 V

LCD

.

LCD

The LCD drive and timing section provides the multiplex signals and backplane driver input signals and formats the frontplane and backplane waveforms.

The address pins are used to uniquely distinguish LCD driver

from any other chips on the same bus and to define LCD driver

as the “master” in the system. There must be one master in any

system.

The enable pin may be used as a third control line in the

communication bus. It may be used to define the moment

when the data is latched. If not used, then the data is latched

after 128 bits of data have been received.

BP1

BP2

BP3

BP4

TIME FRAME

Figure 4. Backplane Sequence

V

LCD

2/3 (V

1/3 (V

0 V

V

LCD

2/3 (V

1/3 (V

0 V

V

LCD

2/3 (V

1/3 (V

0 V

V

LCD

2/3 (V

1/3 (V

0 V

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

)

)

)

)

)

)

)

)

MC14LC5003 • MC14LC5004MOTOROLA

3–7

Page 6

BP1

TIME FRAME

V

LCD

BP1

TIME FRAME

V

LCD

FP DATA

BITS

4321

0000

1000

0100

1100

0010

1010

0110

1110

0 V

V

LCD

2/3 (V

1/3 (V

0 V

V

LCD

2/3 (V

1/3 (V

0 V

V

LCD

2/3 (V

1/3 (V

0 V

V

LCD

2/3 (V

1/3 (V

0 V

V

LCD

2/3 (V

1/3 (V

0 V

V

LCD

2/3 (V

1/3 (V

0 V

V

LCD

2/3 (V

1/3 (V

0 V

V

LCD

2/3 (V

1/3 (V

0 V

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

LCD

0 V

V

FP DATA

)

)

)

)

BITS

4321

0001

1001

LCD

2/3 (V

1/3 (V

0 V

V

LCD

2/3 (V

1/3 (V

LCD

LCD

LCD

LCD

)

)

)

)

0 V

V

LCD

)

)

0101

2/3 (V

1/3 (V

LCD

LCD

)

)

0 V

V

LCD

)

)

1101

2/3 (V

1/3 (V

LCD

LCD

)

)

0 V

V

LCD

)

)

0011

2/3 (V

1/3 (V

LCD

LCD

)

)

0 V

V

LCD

)

)

1011

2/3 (V

1/3 (V

LCD

LCD

)

)

0 V

V

LCD

)

)

0111

2/3 (V

1/3 (V

LCD

LCD

)

)

0 V

V

LCD

)

)

1111

2/3 (V

1/3 (V

LCD

LCD

)

)

0 V

MC14LC5003 • MC14LC5004

3–8

Figure 5. Frontplane Combinations

MOTOROLA

Page 7

PIN DESCRIPTIONS

A0-A2

Address Inputs (Pins 42-44)

The devices hav e to receive a correct address before they

will accept data. Three address pins (A2, A1, A0) are used to

define the states of the three programmable bits of

MC14LC5003/MC14LC5004’s 8-bit address.

The address is 0111vwxy where v, w, x represent A2, A1,

and A0 respectively. Where v, w, x= 0, then A2, A1, and A0

should be tied to 0 V. Where v, w, x= 1, then A2, A1, and A0

should be tied to V

The address pins must be tied to V

device as a master.

Note: In applications where the circuit will be isolated from

external manual interference the system designer may take

advantage of the self-programming feature. Upon power-on,

address pins which are left open-circuit will be charged to VDD.

However, care must be taken not to inadvertently discharge

the pins after power-on since the address may then be lost. A

similar feature is also available on the

The configuration A0, A1, A2 = 000 should not be used. This

does not give a valid address and is reserved for Motorola’s

use only. All three address pins should never be tied to 0 V

simultaneously.

ENB

Enable Input (Pin 41)

If the

ENB pin is tied to VDD, the MC14LC5003/

MC14LC5004 will always latch the data after 128 bits have

been received. The latched data is multiplex ed and f ed to the

frontplane drivers for display. If external control of this latching

function is required, then the

followed by one high pulse on

quired. (This may be useful in a system where one MC145003/

MC145004 is permanently addressed and only the last 128

bits of data sent are required to be latched for display). The

pulse on the

DCLK, D

ENB pin must occur while DCLK is high.

in

Data Clock and Data Input (Pins 38, 39)

Address input and data input controls. SeeData Input Protocol sections for relevant option.

OSC1, OSC2

Oscillator Pins (Pins 51, 50)

To use the on-board oscillator, an external resistor should

be connected between OSC1 and OSC2. Optionally, the

OSC1 pin may be driven by an externally generated clock

signal.

A resistor of 680 k connected between OSC1 and OSC2

pins gives an oscillator frequency of about 30 kHz, giving

approximately 30 Hz as seen at the LCD driver outputs. A

resistor of 200 k gives about 100 kHz, which results in 100Hz

at the driver outputs. LCD manufacturers recommend an LCD

drive frequency of between 30 Hz and 100 Hz. See Figure 6.

DD

.

CAUTION

. This defines the

DD

NOTE

ENB pin.

ENB pin should be held low,

ENB when data display is re-

10 M

1 M

100 k

10 k

1 k 10 k 100 k 1 M

EXTERNAL RESISTOR VALUE

OSCILLATOR FREQUENCY

10 M

Figure 6. Oscillator Frequency vs. Load Resistance

(Approximate)

FP1-FP32

Frontplane Drivers (Pins 36-27, 25-22, 19-15, 13-1)

Frontplane driver outputs.

BP1-BP4

Backplane Drivers (Pins 48-45)

Backplane driver outputs.

V

LCD

LCD Driver Supply (Pin 20)

Power supply input for LCD drive outputs. May be used to

supply a temperature-compensated voltage to the LCD drive

section, which can be separate from the logic voltage supply,

V

.

DD

V

DD

Positive Power Supply (Pin 49)

This pin supplies power to the main processor interface and

logic portions of the device. The voltage range is 2.7 to 5.5 V

with respect to the V

For optimum performance, V

using a low inductance capacitor mounted very closely

V

SS

SS

pin.

should be bypassed to

DD

to these pins. Lead length on this capacitor should be minimized.

V

SS

Ground (Pin 21)

Common ground.

DATA INPUT PROTOCOL

Two-wire communication bus DCLK, Din; three-wire communication bus DCLK, D

MC14LC5003 — SERIAL INTERFACE DEVICE (FIGURE 7)

Before communication with an MC14LC5003 can begin, a

start condition must be set up on the bus by the transmitter.

To establish a start condition, the transmitter must pull the

data line low while the clock line is high. The “idle” state for

the clock line and data line is the high state.

After the start condition has been established, an eight-bit

address should be sent by the transmitter . If the address sent

corresponds to the address of the MC14LC5003 then on each

, ENB.

in

MC14LC5003 • MC14LC5004MOTOROLA

3–9

Page 8

successive clock pulse, the addressed device will accept a

data bit.

ENB pin is permanently high, then the addressed

If the

MC14LC5003’s internal counter latches the data to be displayed after 128 data bits hav e been received. Otherwise, the

control of this latch function may be overridden b y holding the

ENB line low until the new data is required to be displayed,

then a high pulse should be sent on the

pulse must be sent during DCLK high (clock idle).

To end communication with an MC14LC5003, a stop condition should be set up on the bus (or another start condition

may be set up if another communication is desired). Note that

the communication channel to an addressed device may be

left open after the 128 data bits have been sent by not setting

up a stop or a start condition. In such a case, the 129th rising

DCLK edge, which normally would be used to set up the stop

or start condition, is ignored by the MC14LC5003 and data

continues to be received on the 130th rising DCLK. The latch

function continues to work as normal (i.e., data is be latched

either after each block of 128 data bits has been received or

under external control as required).

At any time during data transmission, the transfer may be

interrupted with a stop condition. Data transmission may be

resumed with a start condition and resending the address.

MC14LC5004 — IIC DEVICE (FIGURE 8)

Before communication with an MC14LC5004 can begin, a

start condition must be set up on the bus by the controller. To

establish a start condition, the controller must pull the data

line low while the clock line is high.

After the start condition has been established, an eight-bit

address should be sent by the controller followed b y an e xtra

clock pulse while the data line is left high. In this option, only

the seven most significant bits of the address are used to

uniquely define devices on the bus, the least significant bit is

used as a read/write control: if the least significant bit is 0,

then the controller writes to the LCD driver; if it is 1, then the

ENB line. The high

controller reads from the LCD driver’s 128-bit shift register on

a first-in first-out basis. If the seven most significant address

bits sent correspond to the address of the LCD driver then the

addressed LCD driver responds by sending an “acknowledge”

bit back to the controller (i.e., the LCD driver pulls the data line

low during the extra clock pulse supplied by the controller). If

the least significant address bit was 0, then the controller

should continue to send data to the LCD driver in blocks of

eight bits followed by an extra ninth clock pulse to allow the

LCD driver to pull the data line D

If the least significant address bit was 1, then the LCD driver

sends data back to the controller (the clock is supplied by the

controller). After each successive group of eight bits sent, the

LCD driver leaves the data line high for one pulse.

ENB pin is permanently high, then the addressed

If the

MC14LC5004’s internal counter latches the data to be displayed after 128 data bits have been received. Otherwise the

control of this latch function may be overridden b y holding the

ENB line low until the new data is required to be displayed,

then a high pulse should be sent on the

pulse must be sent during DCLK high (clock idle).

T o end comm unication with an MC14LC5004, a stop condition should be set up on the bus (or another start condition

may be set up if another communication is desired). Note that

the communication channel to an addressed device may be

left open after the 128 data bits have been sent by not setting

up a stop or a start condition. In such a case the rising DCLK

edge which comes after all 128 data bits have been sent and

after the last acknowledge-related clock pulse has been made

is ignored; data continues to be received on the following

DCLK high. The latch function continues to work as normal

(i.e., data is latched either after each block of 128 data bits

has been received or under external control as required).

At any time during data transmission, the transfer may be

interrupted with a stop condition. Data transmission may be

resumed with a start condition and resending the address.

low as an acknowledgment.

in

ENB line. The high

MC14LC5003 • MC14LC5004

3–10

MOTOROLA

Page 9

129TH DCLK HIGH:

(DOES NOT SHIFT DATA)

START

BUT MUST BE DURING DCLK HIGH.

ENABLE PULSE MAY OCCUR AS REQUIRED

A2 A1 A0 BP4 BP3 BP2 BP1 BP4 BP3 BP2 BP1

FP1 FP2

Figure 7a. Data Input—MC14LC5003

BP

4321

432143214321432143214321

x

D

FP32

Figure 7b. Serial 128 Bits Data

FP1 FP2 FP3 FP4 FP5 FP6

(BPi, FPj) ON

(BPi, FPj) OFF

→

→

0

in

x: 1

START 8-BITS ADDRESS 128-BITS DATA

in

D

DCLK

ENB

(IF USED)

Figure 7. MC14LC5003(SERIAL INTERFACE DEVICE)

MC14LC5003 • MC14LC5004MOTOROLA

3–11

Page 10

LAST DCLK PULSE

(DOES NOT SHIFT DATA)

BUT MUST BE DURING DCLK HIGH.

ENABLE PULSE MAY OCCUR AS REQUIRED;

LAST DCLK PULSE

(DOES NOT SHIFT DATA)

ACKNOWLEDGE

ENTIRE CLK FOR

STOP

LEFT HIGH BY DRIVER

LEFT HIGH

BY CONTROLLER

FP1 FP2

LEFT HIGH

BY CONTROLLER

(LOW-ORDER BIT 02=0)

A2 A1 A0 BP4 BP3 BP2 BP1 BP4 BP3 BP2 BP1

ACKNOWLEDGE

ENTIRE CLK FOR

ACKNOWLEDGE

ENTIRE CLK FOR

CONTINUES TO CLOCK DATA AND ACKNOWLEDGE

PULLED LOW BY DRIVER STOP

PULLED LOW BY DRIVER

CONTINUES TO CLOCK DATA AND ACKNOWLEDGE

ACKNOWLEDGE

ENTIRE CLK FOR

ACKNOWLEDGE

ENTIRE CLK FOR

ADDRESS ACKNOWLEDGED BY DRIVER LEFT HIGH BY DRIVER

(LOW-ORDER BIT=1)

in

D

WRITE TO LCD DRIVER

(FROM

CONTROLLER)

DCLK

MC14LC5003 • MC14LC5004

3–12

START 8-BITS ADDRESS 8-BITS DATA

in

D

DRIVER)

(FROM LCD

ENB

(IF USED)

READ FROM LCD DRIVER

in

D

(FROM

Figure 8 . Data Input MC14LC5004 (IIC Device)

CONTROLLER)

DCLK

START 8-BITS ADDRESS 8-BITS DATA

in

D

DRIVER)

(FROM LCD

MOTOROLA

Page 11

BP1-BP4

680 k

ON BUS

FP1-FP32 BP1-BP4

LIQUID CRYSTAL DISPLAY

FP32

FP31

FP1-FP32

FP30

FP29

FP28

FP27

FP26

FP25

FP24

FP23

FP22

FP21

FP20

OSC1

FP19

OSC2

FP18

DD

V

FP17

BP1

FP16

BP2

FP15VV

A0A1A2

BP3

BP4

LCD DRIVER

LCD

SS

FP14

FP13

FP12

ENB

DCLK

FP10

FP11

D

FP1

FP2

FP3

FP4

FP5

FP6

FP7

FP8

FP9

in

CONTROLLER

Figure 9. Application Example

SS

DD

V

V

LCD

V

DATA

CLOCK

STROBE

MC14LC5003 • MC14LC5004MOTOROLA

3–13

Page 12

APPLICATION INFORMATION

Figure 10 shows an interface example.

Example shows a semi-automatic SPI Mode (only start and stop conditions are done in non-SPI Mode). It contains the software

to use HC11 with MC14LC5003 in manual SPI Mode.

V

DD

OSC1

OSC2

FP1-FP32

R = 470 k

MC68HC11

V

DD

MOSI

1 k

SCK

SS

BP1-BP4

1/4 MUX DISPLAY

D

in

DCLK

ENB

A0

A1 A2

MC14LC5003

Figure 10. Interface Example Between MC68HC11 and MC14LC5003

1

2 ;=======CONSTANTS=================================================

3 0000 T extram equ $A000 ;$A000 for 8K RAM

4 0000 T stack equ $00FF ;last RAM byte

5 0000 T intofs equ $1000 ;Internal Registers

6 0000 T data equ $08

7 0000 T clock equ $10

8 0000 T enable equ $20

9 0000 T portd equ 8

10

11

12 ;=======PROGRAM BEGIN=============================================

13 A000 T org extram ;Program into RAM

14 A000 N 8E00FF cold lds #stack ;set stack pointer

15 A003 M 8638 ldaa #$38 ;set of MOSI,SS,SCK

16 A005 T B71009 staa $1009 ;DDRD

17 A008 M C611 ldab #17

18 A00A N CEA05E ldx #send

19 A00D T BDA010 jsr spi

20 A010 T end cold

21

22 A010 U 18CE1000 spi ldy #intofs

23 A014 J 181D0820 bclr portd,y #enable ;EN = 0

24 A018 T BDA031 jsr start ;start condition

25 A01B X A600 again ldaa 0 , x ;SPI Mode Use

26 A01D T B7102A staa $102A ;SPDR

27 A020 L 181F2980FB brclr $29,y,#$80,*

28 A025 H 08 inx ;next DATA

29 A026 H 5A decb

30 A027 R 26F2 bne again

31 A029 J 181C0820 bset portd,y #enable

32 A02D T BDA04C jsr stop ;stop condition

33 A030 H 39 rts

34

35 A031 M 8633 start ldaa #$33 ;Normal Mode

36 A033 T B71028 staa $1028 ;SPCR

MC14LC5003 • MC14LC5004

3–14

MOTOROLA

Page 13

37 A036 J 181C0808 bset portd,y #data ;DATA = 1

38 A03A J 181C0810 bset portd,y #clock ;CLK = 1

39 A03E J 181D0808 bclr portd,y #data ;DATA = 0

40 A042 J 181D0810 bclr portd,y #clock ;CLK = 0

41 A046 M 8673 ldaa #$73 ;SPI Mode

42 A048 T B71028 staa $1028 ;SPCR

43 A04B H 39 rts

44 A04C M 8633 stop ldaa #$33 ;Normal Mode

45 A04E T B71028 staa $1028 ;SPCR

46 A051 J 181D0808 bclr portd,y #data ;DATA = 0

47 A055 J 181C0810 bset portd,y #clock ;CLK = 1

48 A059 J 181C0808 bset portd,y #data ;DATA = 0

49 A05D H 39 rts

50

51 A05E T 7E send fcb $007E ;LCD Driver Address

52 A05F T F0 fcb $00f0 ;Data to sent

53 A060 T F0 fcb $00f0

54 A061 T F0 fcb $00f0

55 A062 T F0 fcb $00f0

56 A063 T F0 fcb $00f0

57 A064 T F0 fcb $00f0

58 A065 T F0 fcb $00f0

59 A066 T F0 fcb $00f0

60 A067 T F0 fcb $00f0

61 A068 T F0 fcb $00f0

62 A069 T F0 fcb $00f0

63 A06A T F0 fcb $00f0

64 A06B T F0 fcb $00f0

65 A06C T F0 fcb $00f0

66 A06D T F0 fcb $00f0

67 A06E T F0 fcb $00f0

68 A06F H 39 rts

69

70 ;=======PROGRAM END===============================================

Example 1. Semi-Automatic SPI Method

Figure 11 shows another interface example.

Example 2 contains the software to use HC05 with MC14LC5003 in serial data interface.

V

DD

OSC1

OSC2

FP1-FP32

MC68HC05

V

DD

DOUT

SCK

STROBE

1 k

BP1-BP4

1/4 MUX DISPLAY

D

in

DCLK

ENB

A0

A1 A2

MC14LC5003

R = 470 k

Figure 11. Interface Example Between MC68HC05 and MC14LC5003

MC14LC5003 • MC14LC5004MOTOROLA

3–15

Page 14

PORTC EQU $02 PORTC

DDRC EQU $06 PORTDC

SEN EQU $07 ENABLE PIN, PC7

SCL EQU $06 CLOCK PIN, PC6

SDA EQU $05 DATA PIN, PC5

DOUT EQU $FF OUTPUT DATA

ORG $0050

W1 RMB 1

COUNT RMB 1

ORG $1FFE ADDRESS OF RESET VECTOR OF MC68HC805C4

FCB #$01 RESET VECTOR

FCB #$00

*** Main Program start at 0100 ***

ORG $0100

START LDA #DOUT SET DATA LINE OUTPUT

STA DDRC

AGAIN

LDX #$00

BSET SDA,PORTC IDLE STATE

BSET SCL,PORTC CLOCK AND DATA ARE HIGH

READY BSET SEN,PORTC EN=1

LDA #$11 SET ADDRESS AND 8 CHARACTERS

STA W1

BCLR SDA,PORTC START CONDITION, DATA LOW WHILE CLOCK HIGH

LBYTE CLC

LDA #$08

STA COUNT 8 BITS TO SHIFT

LDA SEND,X GET A BYTE

INCX

LBIT BCLR SCL,PORTC CLOCK LOW

ROLA

BCC DZERO DATA BIT=0 ?

BSET SDA,PORTC NO, BIT=1 AND DATA HIGH

JMP CLKHI

DZERO BCLR SDA,PORTC DATA LOW

CLKHI BSET SCL,PORTC CLOCK HIGH

DEC COUNT

BNE LBIT

DEC W1

BNE LBYTE LAST BYTE ?

STOP BCLR SCL,PORTC

BCLR SDA,PORTC STOP CONDITION

BSET SCL,PORTC DATA GOES HIGH WHILE CLOCK HIGH

BSET SDA,PORTC

BCLR SEN,PORTC EN=0

RTS

*** End of Program ***

*** LCD Address and Data ***

SEND

FCB $7E LCD DRIVER ADDRESS

FCB $FF, $FF, $FF, $FF, $FF, $FF, $FF, $FF DATA TO SENT

FCB $FF, $FF, $FF, $FF, $FF, $FF, $FF, $FF

RTS

MC14LC5003 • MC14LC5004

3–16

Example 2. Serial Data Interface Method

MOTOROLA

Page 15

PACKAGE DIMENSIONS

QFP

FU SUFFIX

CASE 848B-02

L

39

40

-A-

L

DETAIL A

52

27

26

0.05 (0.002) A-B

V

D

S S

A-B

C

M

0.20 (0.008)

D

S S

-D-

14

B

A-B

H

M

0.20 (0.008)

B

1

-D-

13

B

B

0.20 (0.008) A-B D

0.05 (0.002)

M

A-B

V

0.20 (0.008)

M

H

C

A-B D

S

S

-A,B,D-

DETAIL A

S

S

F

C

M

E

DETAIL C

J

N

-C-

SEATING

PLANE

DATUM

PLANE

-H-

H

DETAIL C

DATUM

-H-

PLANE

D

S

BASE METAL

0.10 (0.004)

G

M

0.02 (0.008) A-B

D

C

M

S

SECTION B-B

U

T

R

K

W

X

NOTES:

1.DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2.CONTROLLING DIMENSION: MILLIMETER.

3.DATUM PLANE -H- IS LOCATED A T BO TTOM OF

LEAD AND IS COINCIDENT WITH THE LEAD

WHERE THE LEAD EXITS THE PLASTIC BODY

AT THE BOTTOM OF THE PARTING LINE.

4.DATUMS -A-, -B- AND -D- TO BE DETERMINED

AT DATUM PLANE -H-.

Q

5.DIMENSIONS S AND V TO BE DETERMINED AT

SEATING PLANE -C-.

6.DIMENSIONS A AND B DO NOT INCLUDE MOLD

PROTRUSION. ALLOWABLE PROTRUSION IS

0.25 (0.010) PER SIDE. DIMENSIONS A AND B

DO INCLUDE MOLD MISMATCH AND ARE

DETERMINED AT DATUM PLANE -H-.

7.DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.08 (0.003) TOTAL IN

EXCESS OF THE D DIMENSION AT MAXIMUM

MATERIAL CONDITION. DAMBAR CANNOT BE

LOCATED ON THE LOWER RADIUS OR THE

FOOT.

MILLIMETERS INCHES

DIM MIN MAX MIN MX

A 9.90 10.10 0.390 0.398

B 9.90 10.10 0.390 0.398

C 2.10 2.45 0.083 0.096

D 0.22 0.38 0.009 0.015

E 2.00 2.10 0.079 0.083

F 0.22 0.33 0.009 0.013

G 0.65 BSC 0.026 BSC

H -- 0.25 -- 0.010

J 0.13 0.23 0.005 0.009

K 0.65 0.95 0.026 0.037

L 7.80 REF 0.307 REF

M 5˚ 10˚ 5˚ 10˚

N 0.13 0.17 0.005 0.007

Q0˚ 7˚ 0˚ 7˚

R 0.13 0.30 0.005 0.012

S 12.95 13.45 0.510 0.530

T 0.13 -- 0.005 -U0˚ -- 0˚ --

V 12.95 13.45 0.510 0.530

W 0.35 0.45 0.014 0.018

X 1.6 REF 0.063 REF

MC14LC5003 • MC14LC5004MOTOROLA

3–17

Page 16

PIN 1

+Y

-Y

BOND PAD LAYOUT

+X-X

HONG KONG I.C.

DESIGN CENTER

©

PIN NO. PIN NAME

1 FP32 -736.002 929.199

2 FP31 -736.002 781.999

3 FP30 -736.002 634.799

4 FP29 -736.002 487.599

5 FP28 -736.002 340.399

6 FP27 -736.002 193.199

7 FP26 -736.002 45.999

8 FP25 -736.002 -101.201

9 FP24 -736.002 -248.401

10 FP23 -736.002 -395.601

11 FP22 -736.002 -542.801

12 FP21 -736.002 -690.001

13 FP20 -736.002 -837.201

14 NC N/A N/A

15 FP19 -736.002 -1205.601

16 FP18 -588.802 -1205.601

17 FP17 -441.602 -1205.601

18 FP16 -294.402 -1205.601

19 FP15 -147.202 -1205.601

20 V

21 V

22 FP14 294.398 -1205.601

23 FP13 441.598 -1205.601

24 FP12 588.798 -1205.601

25 FP11 735.998 -1205.601

26 NC N/A N/A

LCD

SS

COORDINATES

XY

0.000 -1205.600

147.200 -1205.600

BOND PAD COORDINATES

PIN NO. PIN NAME

27 FP10 735.998 -837.201

28 FP9 735.998 -690.001

29 FP8 735.998 -542.801

30 FP7 735.998 -395.601

31 FP6 735.998 -248.401

32 FP5 735.998 -101.201

33 FP4 735.998 45.999

34 FP3 735.998 193.199

35 FP2 735.998 340.399

36 FP1 735.998 487.599

37 NC 736.000 634.800

38 DCLK 736.000 782.000

39 D

40 NC N/A N/A

41

42 A2 588.800 1205.600

43 A1 441.600 1205.600

44 A0 294.400 1205.600

45 BP4 147.198 1205.599

46 BP3 -0.002 1205.599

47 BP2 -147.202 1205.599

48 BP1 -294.402 1205.599

49 V

50 OSC2 -588.800 1205.600

51 OSC1 -736.000 1205.600

52 NC N/A N/A

IN

ENB 736.000 1205.600

DD

Die size : 78 x 119 mil

(1 mil ~ 25.4m)

COORDINATES

XY

736.000 929.200

-441.600 1205.600

2

MC14LC5003 • MC14LC5004

3–18

Dimemsions in m

MOTOROLA

Loading...

Loading...