Page 1

MC145750MOTOROLA

1

Product Preview

The MC145750 is a silicon gate HCMOS device designed to encode π/4–shift

QPSK baseband signals. The device contains two 10–bit DACs for the I/Q

signal, Root–Nyquist digital filtering, and burst rising and falling e dge

processing for digital RF communication equipment. Primary applications for

this device are in products that will be used in PHS (384 kbps) and PDC

(42 kbps). It will perform up to 800 kbps data rate. It also contains PN511

random pattern generator and timing generator with PLL.

• Root–Nyquist Digital Filtering (Coefficient = 0.5)

• Burst Edge Processing Circuitry (Ramp–Up and –Down)

• Two 10–Bit DACs for I/Q Output

• Operating Voltage Range: 2.7 to 5.5 V

• PN511 Random Pattern Generator

• Conformance to RCR Standard for PHS, PDC

• Variable Data Transmission Rate up to 800 kbps (VDD = 5 V)

• Timing Generator with PLL

• QPSK Mode, Burst, and Continuous I/Q Signal Output is Performed

• Companion Device is MRFIC0001

PIN ASSIGNMENT

NC

CF

PCO

PB1

PLL

ECLK

DV

DD

DV

SS

DCLK

DS/STBY

TXD

MODE1

MODE0

TEST

NC

DRATE

QPSK

PB2NCNC

TB0

TB1

NC

TB7

BW/TB9

TNO/TB8

I

out

DAref2

DAref3

DAref

DAref1

Q

out

DAV

SS

DV

DD

NC

TB2

TB4

TB5

TB6

NC

NC

MODE2

ERST/PDN

DAV

DD

TB3

DV

SS

NC

DAb

1

48

37

36

25

24

13

12

NC = NO CONNECTION

This document contains information on a product under development. Motorola reserves the right to change or discontinue this product without notice.

Order this document

by MC145750/D

SEMICONDUCTOR TECHNICAL DATA

VFU SUFFIX

PLASTIC VQFP

CASE 932

ORDERING INFORMATION

MC145750VFU VQFP

Motorola, Inc. 1995

REV 2

10/95

Page 2

MC145750 MOTOROLA

2

BLOCK DIAGRAM

PNO/TB8

TXD

DS/STBY

DCLK

PLL

ECLK

I

out

Q

out

BW/TB9

TEST TB7:0 M2:0 QPSK DRATE DAb DAref DAref3:1

PN PATTERN

GENERATOR

TEST

CIRCUIT

π

/4–SHIFT

QPSK

ENCODER

INTERFACE

CIRCUIT

ROLL–OFF

FILTERS

10–BIT

DAC

10–BIT

DAC

DPLL

TIMING

GENERATOR

DVDDDV

SS

ERST

/PDN Cf PC0 PB1 PB2 DAV

DD

DAV

SS

I

Q

INPUT/OUTPUT TIMING RELATIONS

DS

(INPUT)

DCLK

(INPUT)

TXD

(INPUT)

BW

(OUTPUT)

I

out/Qout

(OUTPUT)

RAMP–UP

(TWO SYMBOL LENGTH)

100% OUTPUT SWING LEVEL

RAMP–DOWN

(TWO SYMBOL LENGTH)

FIRST SYMBOL

LAST SYMBOL

DON’T CARE

1 2 3 4 5 6 7 8 9

n – 1

n 1 2 3 11 14 15 16

9 10

n BIT

Page 3

MC145750MOTOROLA

3

MAXIMUM RATINGS

Parameter

Symbol

Value

Unit

DC Supply Voltage

V

DD

– 0.5 to + 7

V

DC Input Voltage

V

in

– 0.5 to VDD + 0.5

V

Power Dissipation

P

D

500

mW

Storage Temperature

T

stg

– 65 to +150

°C

RECOMMENDED OPERATING CONDITIONS

Parameter Symbol Min Typ Max Unit

DC Supply Voltage V

DD

2.7 3.3 5.5 V

DC Input Voltage V

in

0 — V

DD

V

Operating Temperature Range T

A

– 20 25 85 °C

ELECTRICAL CHARACTERISTICS (T

A

= 25°C, TXD = L, Normal Mode)

Parameters

Symbol Condition Min Typ** Max Unit

DC Supply Current

I

dd1

ERST = L — 0.25 0.5

mA

VDD = 3 V

DRATE = L I

dd2

DS = L

— 5.0 6.0

DRATE = H I

dd3

— 1.5 1.8

DRATE = L I

dd4

DS = Burst Input*

— 5.0 6.0

DRATE = H I

dd5

— 1.5 1.8

DRATE = L I

dd6

DS = Continual Input

— 8.0 10.0

DRATE = H I

dd7

— 2.0 2.6

DC Supply Current

I

dd1

ERST = L — 0.5 3.0

mA

VDD = 5 V

DRATE = L I

dd2

DS = L

— 27.0 33.0

DRATE = H I

dd3

— 17.0 19.0

DRATE = L I

dd4

DS = Burst Input*

— 30.0 33.0

DRATE = H I

dd5

— 18.0 20.0

DRATE = L I

dd6

DS = Continual Input

— 33.0 37.0

DRATE = H I

dd7

— 18.0 20.0

*625 µs burst/5 ms period (DRATE = L) at DCLK = 384 kHz.

6.6 ms burst/20 ms period (DRATE = H) at DCLK = 42 kHz.

**Typical numbers are not guaranteed.

ANALOG CHARACTERISTICS (T

A

= 25°C)

Parameters

Symbol Condition Min Typ** Max Unit

Output Swing Level

VDD = 3 V

V

out

RL = k

Ω, TXD = L

500 550 600

mV p–p

I/Q Out

VDD = 5 V

Normal Mode

520 570 620

Output Swing Imbalance ∆V

out

– 0.5 0 0.5 dB

Output DC Level

VDD = 3 V

V

out

DS = L

800 820 840

mV

I/Q Out

VDD = 5 V 780 800 820

Output Swing Imbalance ∆V

DD

— — 20

Out–of–Band Noise Level VDD = 5 V V

in

600 kHz — – 50 —

dB

900 kHz — – 55 —

DC Output Resistance R

out

I

out/Qout

— 50 100 Ω

*DAref1 = H at VDD = 3 V, DAref3 = H at VDD = 5 V

**Typical numbers are not guaranteed.

Page 4

MC145750 MOTOROLA

4

SWITCHING CHARACTERISTICS (T

A

= 25°C)

Parameters Symbol Condition Min Typ* Max Unit

Input Voltage

High–Level V

IH

VDD x 0.7 — —

V

Low–Level V

IL

— — VDD x 0.3

Output Voltage

High–Level V

OH

BW, PNO

VDD x 0.9 — —

Low–Level V

OL

— — VDD x 0.1

Data Set–Up Time t

su

TXD, DS, STBY 10 — —

ns

Data Hold Time t

h

TXD, DS, STBY 10 — —

Data Output Propagation Delay t

pd

BW, PNO — 1.5 3

µs

I/Q Output Propagation Delay T

D

I

out

, Q

out

— 4 6

Data Rate VDD = 3 V

DRATE = L — — 450

kbps

DRATE = H — — 55

VDD = 5 V

DRATE = L — — 800

DRATE = H — — 100

Clock Input Duty Cycle DCLK 45 50 55 %

VCO Oscillation Frequency

VDD = 3 V f

VCO1

— — 20

MHz

VDD = 5 V f

VCO2

— — 32

* Typical numbers are not guaranteed.

Figure 1. Timing Diagram

DS

DCLK

TXD

BW

I

out/Qout

PNO

t

su

t

su

1/fclk

t

PD

t

h

t

su

t

h

t

PD

t

su

t

h

t

D

t

PD

t

D

Page 5

MC145750MOTOROLA

5

PIN DESCRIPTIONS

POWER SUPPLY

V

SS

Digital Ground (Pins 6, 44)

These are the negative power supply input pins to the digi-

tal portion of the device and are connected to ground (0 V).

V

DD

Positive Power Supply Input (Pins 7, 43)

These are the positive power supply input pins to the digi-

tal portion of the device. Typical operating voltage range is

3.3 V at DAref3 = H, 5.0 V at DAref1 = H. Power should be

fed simultaneously with DA VDD pin in order to avoid any possible damage to the device.

DAV

DD

Positive Power Supply Input for DACs (Pin 13)

This is the positive power supply input pin to the analog

portion of the device. Typical operating voltage range is 2.7 V

to 5.5 V.

DAV

SS

Analog Ground for DACs (Pin 14)

This is the negative power supply pin to the analog portion

of the device and is connected to ground.

MODE CONTROL AND TEST

MODE0 – MODE2

Normal/Test Mode Select (Pins 1, 2, 3)

These pins must be connected to ground for normal operation. For system test, PN pattern generation mode will be

performed when MODE0 = H and MODE1, MODE2 = L.

PN511 signal is fed to the encoder instead of input data from

TXD pin. Data shift timing is the same as the normal operation mode and burst timing indicated by DS pin is still valid for

the device. The PN511 signal is monitored at the PNO pin.

TEST

Test Mode (Pin 4)

The device operates normally while this pin is held low.

When this signal is high, the device enters into factory test

mode. Only one mode is allowed to be enacted by user for

PN Mode.

DRATE

Data–Rate Select (Pin 9)

This pin can select high data rate when it is low , such as in

PHS applications.

QPSK

(D)QPSK/π/4–Shift QPSK Mode Select (Pin 10)

The device operates as a π/4–QPSK Encoder when this

pin is held high. By making this pin low, it functions as non–

shift differential QPSK Encoder. All of the functions are the

same in both modes.

PN0/TB8

PN511 Test Pattern Output/Test Bus 8 (Pin 23)

This is the output data of PN511 test–pattern in normal

mode. When the PN pattern generator outputs to this pin, it

can be output I/Q pins and data from TXD pin may be ignored. If the DS signal is L, I/Q pins stop but PN data stream

may be output.

TB0 – TB7

Test Bus (Pins 24, 26 – 32)

These pins are used in factory test and should be connected to ground for normal operation.

PLL

Int/Ext PLL Clock Select (Pin 41)

When this pin is connected to ground, the PLL is active

and timing will be generated internally. When this pin is connected to VDD, timing should be applied to the ECLK pin.

DIGITAL INTERFACE PINS

BW/TB9

Burst Window Output/Test Bus 9 (Pin 22)

This output indicates when modulated baseband I/Q signals are output from this device. This pin is used as the transmission control signal for saving power for RF.

ECLK

External Clock Input (Pin 42)

When the internal timing generator with PLL is not used in

the system, this pin must have 15.36 MHz applied as a system clock for this device. This pin is connected to ground for

normal operation.

DCLK

Data Shift Clock Input (Pin 45)

This is the shift clock input for the transmit data input and is

typically 384 kHz for the PHS (DRATE Pin = L) and 42 kHz

for the PDC (DRATE Pin = H) application. The data input occurs at the rising edge of the DCLK. For burst–type systems

such as the TDMA data transmission applications, this signal

must be synchronized with the rising/falling edge of the DS

pin (Data Slot Timing Input).

DS/STBY

Data Slot Timing/Standby Input (Pin 46)

For burst–type, this input signal indicates when transmit

data are valid for the device. Its duration must be equal with

the number of input data to the device, and its transition must

be aligned with the rising edge of the DCLK signal.

When a logic L is applied to this pin, all digital portions except the timing generator are not clocked and the device is in

a low power dissipation mode. When a logic H is applied continuously, all input data are encoded as valid data.

TXD

Transmit Data Input (Pin 47)

Data bit streams to be transmitted are input to this pin. The

data is valid only when the DS (Pin 46) is asserted (high). Its

transition should be s ynchronized with rising edge of the

DCLK (Pin 45).

Page 6

MC145750 MOTOROLA

6

ERST/PDN

External Reset/Power Down Input (Pin 48)

When a logic L is applied to this pin, it forces a complete

power down. When at start up, VDD goes high, it is recommended that a logic L, then a logic H be applied to this pin to

start up and reset all digital portions.

ANALOG INTERFACE PINS

Q

out

Filtered Quadrature–Phase Output (Pin 15)

This is the modulated quadrature–phase signal output and

the amplitude is typically 550 mV p–p at VDD = 3 V in PN test

mode. The output dc resistance is approximately 50 Ω.

I

out

Filtered In–Phase Output (Pin 20)

This is the modulated in–phase signal output and amplitude is typically 500 mV p–p at VDD = 3 V in PN test mode.

The output dc resistance is approximately 50 Ω.

DAC AND PLL SETTING

DAb

Reference Bias Setting Pin to DACs (Pin 12)

A resistor connected to ground from this pin determines

the reference current value for internal DACs. This resistor’s

value is 200 kΩ typically.

DAref

Ripple Filter Capacitor (Pin 16)

A capacitor connected to ground from this pin acts as a ripple filter for the internal DACs’ reference voltage. This capacitor’s value is 0.1µF, typically.

DAref1 – DAref3

Reference Bias Setting to DACs (Pin 17 – 19)

These pins determine the reference voltage for internal

DACs in conjunction with DAb pin. At 3 V operation, DAref1

pin should be connected to VDD. DAref2 pin should be connected to VDD at 3.3 V. DAref3 pin should be connected to

VDD at 5 V . The two other pins for the respective cases must

be left open.

PB1, PB2

PLL Bias (Pins 35, 38)

This pin determines the bias of the PLL. Its recommended

values are shown in T able 1 and it depends on operating voltage.

Cf

Loop Filter Capacitor (Pin 39)

Input from Cf pin is fed directly as the internal VCO control

signal.

PCO

Phase Comparator Output (Pin 40)

Connect an LPF as loop filter for the PLL. Refer to the application figure for recommended values.

Table 1. Function Table

Pin L H Remarks

3 MODE0 Normal Mode PN Pattern

These settings are independent of power supply.

10 QPSK Non–Shift /4–Shift

9 DRATE High Speed Low Speed To be determined setting high or low speed data rate.

17 DAref1 — VDD = 5 V

These pins should be held high depending on power supply voltage and

18 DAref2 — VDD 3.3 V

others should be left open.

19 DAref3 — VDD 3.0 V

41 PLL PLL Operation

Mode

Ext Clock Mode In case of external clock mode, TX data rate must be set to a frequency

of 1/40 when DRATE = L, and must be set to a frequency of 1/320

when DRATE = H. Max data rate is limited by power supply.

48 ERST/PDN Power Down Normal Operation Digital circuits reset condition will be released by rising edge of this

input.

Figure 2. DQPSK Baseband Signal Generation

SERIAL TO

PARALLEL

CONVERSION

DIFFERENTIAL

ENCODING

ROLL–OFF

FILTER

ROLL–OFF

FILTER

SERIAL DATA IN

Xk

Yk

Qk

Ik

TO DAC

TO DAC

Page 7

MC145750MOTOROLA

7

DEVICE DESCRIPTION

π/4–Shift QPSK Encoding

RCR standard (STD–28) specifies the basic configuration

of this modulation scheme as shown in Figure 2. First, serial

data input is converted to Xk/Yk parallel streams. Then its

value is compared with one previous symbol Ik/Qk, respectively, whether or not there is a change of polarity. If there is a

change, result is coded as 1. This two–bit πr (di–bit) is called

symbol, hence symbol rate is just half of the data input rate to

be modulated.

Phase transitions are determined as shown in Figure 3,

with respect to four di–bit values of Xk, Yk. (As is shown,

there should be at least π/4 of phase shift in each symbol timing unlike plain QPSK.) Actual in–phase outputs are fed to a

quadrature modulator circuit, and it is recommended that a

2– to 3–order LPF be used, which may be used as a level

shifter and dc offset compensation circuitry at the same time.

The reference voltage for the DACs is given by connecting

either of DAref1:3 to VDD according to the operating voltage

used. It is preferable not to have this voltage vary, since I/Q

output levels are affected.

Timing Generator

The PLL is intended in order to generate all required timing

signals for the devices. The VCO oscillating at the PN511

pattern rate is utilized when some characteristics are measured. By pulling MODE0 pin high, the device generates this

sequence. It is a useful simple measurement for the occupied power bandwidth and the out–of–band power level. The

sequence itself can also be monitored at the PNO pin.

This circuit is reset by an external reset signal while the

low–state of DS is not valid for initializing the generator.

START–UP SEQUENCE

To ensure stability and to initialize the internal ROM and

encoder, the start–up sequence should be done at power–

up. Refer to Figure 4.

Di–Bit Input

Xk Yk

Phase Shift

0 0

0 1

1 0

1 1

π/4

3π/4

– π/4

– 3π/4

Figure 3. Phase Diagram

Q

00

01

11

10

I

22.5

°

Figure 4. Start–Up Sequence

V

DD

REST

/PDN

DS

90%

> 100

µ

s

1 s

Page 8

MC145750 MOTOROLA

8

Figure 5. DRATE Equals L: 5 V Operation

NC

CF

PCO

PB1

PLL

ECLK

DV

DD

DV

SS

DCLK

DS/STBY

TXD

M1M0TEST

NC

DRATE

QPSK

PB2

NC

NC

TB0

TB1

NC

TB7

BW/TB9

PNO/TB8

I

out

DAref2

DAref3

DAref

DAref1

Q

out

DAV

SS

DV

DD

NC

TB2

TB4

TB5

TB6

NC

NC

M2

ERST/PDN

DAV

DD

TB3

DV

SS

NC

DAb

3635343332313029282726

25

CP

2

3

4

5

678

9

101112

24

23

22

21

20

19

18

17

16

15

14

13

37

38

39

40

41

42

43

44

45

46

47

48

47 k

I OUTPUT

Q OUTPUT

5 V

0.1

µ

10

µ

10 k

384 kHz

BURST TIMING OUTPUT

BURST TIMING INPUT

TX DATA INPUT

EXTERNAL RESET INPUT

1

µ

0.1

µ

10

µ

33 k

33 k

220 k

100 p

0.1

µ

1000 p

2.2 k

0.1

µ

0.1 µ10

µ

MC145750

Figure 6. DRATE Equals H: 3 V Operation

NC

CF

PCO

PB1

PLL

ECLK

DV

DD

DV

SS

DCLK

DS/STBY

TXD

M1M0TEST

NC

DRATE

QPSK

PB2

NC

NC

TB0

TB1

NC

TB7

BW/TB9

PNO/TB8

I

out

DAref2

DAref3

DAref

DAref1

Q

out

DAV

SS

DV

DD

NC

TB2

TB4

TB5

TB6

NC

NCM2

ERST/PDN

DAV

DD

TB3

DV

SS

NC

DAb

3635343332

31302928272625

CP

2

3

4

5

6

7

8

9

101112

24

23

22

21

20

19

18

17

16

15

14

13

37

38

39

40

41

42

43

44

45

46

47

48

47 k

I OUTPUT

Q OUTPUT

3 V

0.1

µ

10

µ

220 k

384 kHz

BURST TIMING OUTPUT

BURST TIMING INPUT

TX DATA INPUT

EXTERNAL RESET INPUT

1

µ

0.1

µ

10

µ

33 k

33 k

47 k

100 p

0.1

µ

1000 p

2.2 k

0.1

µ

0.1 µ10

µ

MC145750

Page 9

MC145750MOTOROLA

9

Figure 7. I/Q Output Interface Circuit 1

MC145750

I/Q OUTPUT

LEVEL SHIFT

BALANCE CONTROL

TO MRFIC0001

MODULATOR

R

R

R

R

+

–

+

–

Figure 8. I/Q Output Interface Circuit 2

MC145750

I/Q OUTPUT

LEVEL SHIFT

BALANCE CONTROL

TO MRFIC0001

MODULATOR

R

R

R

R

+

–

+

–

Figure 9. Modulation Accuracy Measurement Schematic

Measurement Equipment: Advantest Spectrum Analyzer R3365

Advantest Modulation Accuracy Analyzer R3541A

Rohde & Schwarz Modulation Unit SMHU–58

Conditions: Internal PLL mode, 384 kbps (PHS), TA = 25°C

220 µF

220 µF

100 k

100 k

+ 5 V

– 5 V

+ 5 V

– 5 V

I

in

Q

in

MODULATION UNIT

SMHU–58

(Zin = 50

Ω

)

IF

(240 MHz)

SPECTRUM

ANALYZER

R3365

MODULATION

ACCURACY

ANALYZER

R3541A

MC145750

I

out

+

–

Q

out

+

–

Motorola cannot recommend one supplier over another and in no way suggests

that this is a complete listing of measurement equipment suppliers.

Page 10

MC145750 MOTOROLA

10

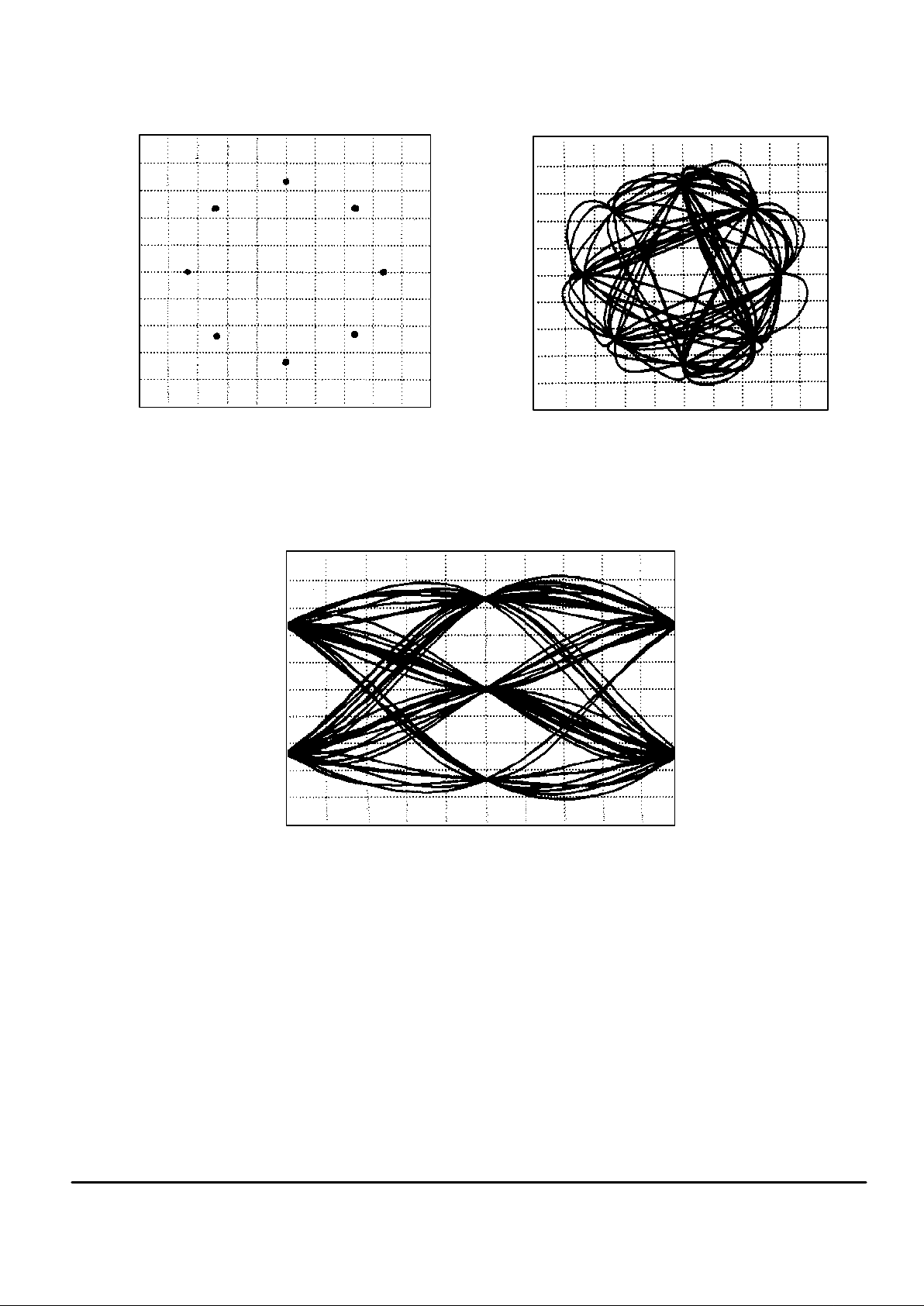

Figure 10. I–Q Pattern

1.5

1.2

0.9

0.6

0.3

0.0

– 0.3

– 0.6

– 0.9

– 1.2

– 1.5 – 1.2 – 0.9 – 0.6 – 0.3 0.0 0.3 0.6 0.9 1.2 1.5

ERR VEC : 0.982% rms

Q (t)

I (t)

Figure 11. I–Q Pattern

1.5

1.2

0.9

0.6

0.3

0.0

– 0.3

– 0.6

– 0.9

– 1.2

– 1.5 – 1.2 – 0.9 – 0.6 – 0.3 0.0 0.3 0.6 0.9 1.2 1.5

ERR VEC : 0.982% rms

I (t)

– 1.5

Q (t)

Figure 12. Q–Eye Pattern

1.5

1.2

0.9

0.6

0.3

0.0

– 0.3

– 0.6

– 0.9

– 1.2

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

ERR VEC : 0.982% rms

TIME

– 1.5

Q (t)

Page 11

MC145750MOTOROLA

11

PACKAGE DIMENSIONS

VFU SUFFIX

PLASTIC VQFP

CASE 932–02

DIMAMIN MAX MIN MAX

INCHES

7.000 BSC 0.276 BSC

MILLIMETERS

A1 3.500 BSC 0.138 BSC

B 7.000 BSC 0.276 BSC

B1 3.500 BSC 0.138 BSC

C 1.400 1.600 0.055 0.063

D 0.170 0.270 0.007 0.011

E 1.350 1.450 0.053 0.057

F 0.170 0.230 0.007 0.009

G 0.500 BASIC 0.020 BASIC

H 0.050 0.150 0.002 0.006

J 0.090 0.200 0.004 0.008

K 0.500 0.700 0.020 0.028

M 12 REF 12 REF

N 0.090 0.160 0.004 0.006

P 0.250 BASIC 0.010 BASIC

Q 1 5 1 5

R 0.150 0.250 0.006 0.010

S 9.000 BSC 0.354 BSC

S1 4.500 BSC 0.177 BSC

V 9.000 BSC 0.354 BSC

V1 4.500 BSC 0.177 BSC

W 0.200 REF 0.008 REF

X 1.000 REF 0.039 REF

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DATUM PLANE –AB– IS LOCATED AT BOTTOM OF

LEAD AND IS COINCIDENT WITH THE LEAD

WHERE THE LEAD EXITS THE PLASTIC BODY AT

THE BOTTOM OF THE PARTING LINE.

4. DATUMS –T–, –U–, AND –Z– TO BE DETERMINED

AT DATUM PLANE –AB–.

5. DIMENSIONS S AND V TO BE DETERMINED AT

SEATING PLANE –AC–.

6. DIMENSIONS A AND B DO NOT INCLUDE MOLD

PROTRUSION. ALLOWABLE PROTRUSION IS

0.250 (0.010) PER SIDE. DIMENSIONS A AND B DO

INCLUDE MOLD MISMATCH AND ARE

DETERMINED AT DATUM PLANE –AB–.

7. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. DAMBAR PROTRUSION SHALL

NOT CAUSE THE D DIMENSION TO EXCEED

0.350 (0.014).

8. MINIMUM SOLDER PLATE THICKNESS SHALL BE

0.0076 (0.0003).

9. EXACT SHAPE OF EACH CORNER IS OPTIONAL.

_ _

_ _ _ _

ÉÉÉ

ÉÉÉ

ÉÉÉ

A

A1

–T–

Z0.200 (0.008) AB T–U

–U–

4X

Z0.200 (0.008) AC T–U

4X

B

B1

1

12

13

24

25

36

37

48

–Z–

S1

S

V

V1

P

AE AE

–T–, –U–, –Z–

DETAIL Y

DETAIL Y

BASE METAL

N

J

F

D

S

T–U

M

0.080 (0.003) Z

S

AC

SECTION AE–AE

–AB–

–AC–

AD

G

0.080 (0.003) AC

M

_

TOP & BOTTOM

Q

_

W

K

X

E

C

H

0.250 (0.010)

GAUGE PLANE

R

9

DETAIL AD

Page 12

MC145750 MOTOROLA

12

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit,

and specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters can and do vary in different

applications. All operating parameters, including “T ypicals” must be validated for each customer application by customer’s technical experts. Motorola does

not convey any license under its patent rights nor the rights of others. Motorola products are not designed, intended, or authorized for use as components in

systems intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of

the Motorola product could create a situation where personal injury or death may occur. Should Buyer purchase or use Motorola products for any such

unintended or unauthorized application, Buyer shall indemnify and hold Motorola and its officers, employees, subsidiaries, affiliates, and distributors harmless

against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that Motorola was negligent regarding the design or manufacture of the part.

Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal Opportunity/Affirmative Action Employer.

How to reach us:

USA/EUROPE: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, Toshikatsu Otsuki,

P.O. Box 20912; Phoenix, Arizona 85036. 1–800–441–2447 6F Seibu–Butsuryu–Center, 3–14–2 Tatsumi Koto–Ku, Tokyo 135, Japan. 03–3521–8315

MFAX: RMFAX0@email.sps.mot.com – TOUCHTONE (602) 244–6609 HONG KONG: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://Design–NET.com 51 Ting Kok Road, Tai Po, N.T., Hong Kong. 852–26629298

MC145750/D

*MC145750/D*

◊

Loading...

Loading...