Page 1

MC145402MOTOROLA

1

Advance Information

The MC145402 is a 13–bit linear monotonic digital–to–analog and analog–

to–digital converter implemented in a single silicon–gate CMOS IC. Potential

applications include analog interface for Digital Signal Processor (DSP)

applications, high speed modems, telephone systems, SONAR, Adaptive

Differential Pulse Code Modulation (ADPCM) converters, echo cancellers,

repeaters, voice synthesizers, and music synthesizers.

• 60 dB Signal–to–(Noise Plus Distortion) Ratio Typical

• On–Chip Precision Voltage Reference

• Serial Data Ports

• Two’ s Complement Coding

•± 5 V Supply Operation

• Sample Rates from 100 Hz to 16 kHz (Both A/D and D/A), 100 Hz to

21.3 kHz (A/D Only), and 100 Hz to 64 kHz (D/A Only)

• Input Sample and Hold Provided On–Chip

• 5 V CMOS Inputs; Outputs Capable of Driving Two LSTTL Loads

• Available in a 16–Pin DIP

• Low Power Consumption: 50 mW Typical, 1 mW Power–Down

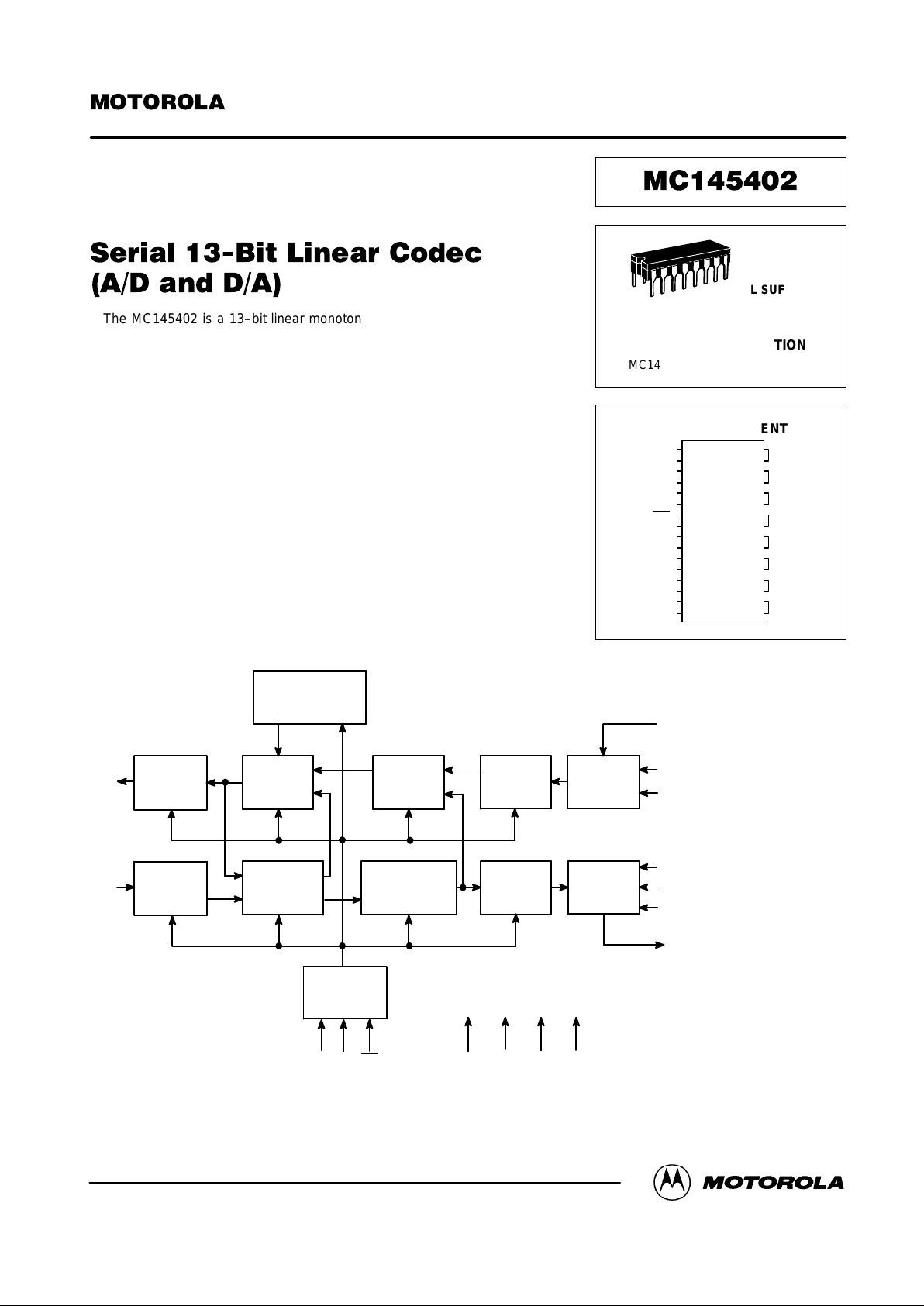

BLOCK DIAGRAM

BANDGAP VOLTAGE

REFERENCE

SAMPLE

AND HOLD

D/A

CONVERTER

DATA

SELECTOR

RECEIVE

LATCH

RECEIVE

SHIFT

REGISTER

15

RDD

13

14

RDC

RCE

2

3

A

out

A

in

7

10

12

11

TDF

TDE

TDC

TDD

65 4 16 8 1 9

VDDVSSVAGV

DG

MSI CCI PDI

SEQUENCE

CONTROLLER

SAMPLE

AND HOLD

COMPARATOR/

OP AMP

SUCCESSIVE

APPROXIMA TION

REGISTER

TRANSMIT

LATCH

TRANSMIT

SHIFT

REGISTER

This document contains information on a new product. Specifications and information herein are subject to change without notice.

Order this document

by MC145402/D

SEMICONDUCTOR TECHNICAL DATA

PIN ASSIGNMENT

L SUFFIX

CERAMIC PACKAGE

CASE 620

ORDERING INFORMATION

MC145402L Ceramic Package

16

1

16

15

14

13

12

11

10

9

V

AG

A

out

A

in

PDI

CCI

MSI

TDF

V

SS

V

DD

RDD

RCE

RDC

TDC

TDE

V

DG

TDD

•

1

2

3

4

5

6

7

8

Motorola, Inc. 1995

Page 2

MC145402 MOTOROLA

2

ABSOLUTE MAXIMUM RATINGS (Voltages Referenced to V

SS

)

Rating Symbol Value Unit

DC Supply Voltage VDD – V

SS

– 0.5 to 11 V

Voltage, Any Pin to VSS V – 0.5 to VDD + 0.5 V

DC Current Drain per Pin (Excluding

VDD, VSS)

I 10 mA

Operating Temperature Range T

A

– 40 to + 85

°C

Storage Temperature Range T

stg

– 85 to + 150

°C

RECOMMENDED OPERATING CONDITIONS

Parameter Pins

0 to 70°C

Min

25°C

Typ

0 to 70°C

Max

Unit

DC Supply Voltage VDD to V

SS

9.5 10 10.5 V

Power Dissipation, PDI = 1 VDD to V

SS

— 50 80 mW

Power Dissipation, PDI = 0 VDD to V

SS

— 1 5 mW

Conversion Rate Full Cycle A/D and D/A

Short Cycle A/D

Short Cycle D/A

MSI 0.1

0.1

0.1

—

—

—

16

21.3

64

kHz

Conversion Sequence Rate CCI 3.2 — 512 kHz

Data Rate TDC, RDC 16 x f

MSI

— 4096 kHz

Full Scale Analog Levels (Referenced to 600 Ω) AI, AO —

—

3.27

9.5

—

—

Vp

dBm

DIGITAL ELECTRICAL CHARACTERISTICS (V

DD

= 5 V, VSS = – 5 V, VAG = VDG = 0 V, TA = 0 to 70°C)

Characteristic Symbol Min Max Unit

High Level Input Voltage V

IH

3.5 — V

Low Level Input Voltage V

IL

— 1.5 V

Input Current I

in

— ± 1.0 µA

Input Capacitance C

in

— 10 pF

High Level Output Voltage TDD I

out

= – 20 µA

I

out

= – 1 mA

V

OH

4.9

4.3

—

—

V

Low Level Output Voltage TDD I

out

= – 20 µA

I

out

= – 1 mA

V

OL

—

—

0.1

0.4

V

This device contains circuitry to protect the

inputs against damage due to high static

voltages or electrical fields; however, it is

advised that normal precautions be taken to

avoid applications of any voltage higher than

maximum rated voltages to this high impedance circuit. For proper operation it is recommended that Vin and V

out

be constrained to

the range VSS ≤ (Vin or V

out

) ≤ VDD on analog

inputs/outputs and VDG

≤ (V

in

or V

out

) ≤ V

DD

on digital inputs/outputs. Reliability of operation is enhanced if unused digital inputs are tied

to an appropriate logic voltage level (e.g.,

either VDG or VDD) and unused analog Inputs

are tied to VAG.

Page 3

MC145402MOTOROLA

3

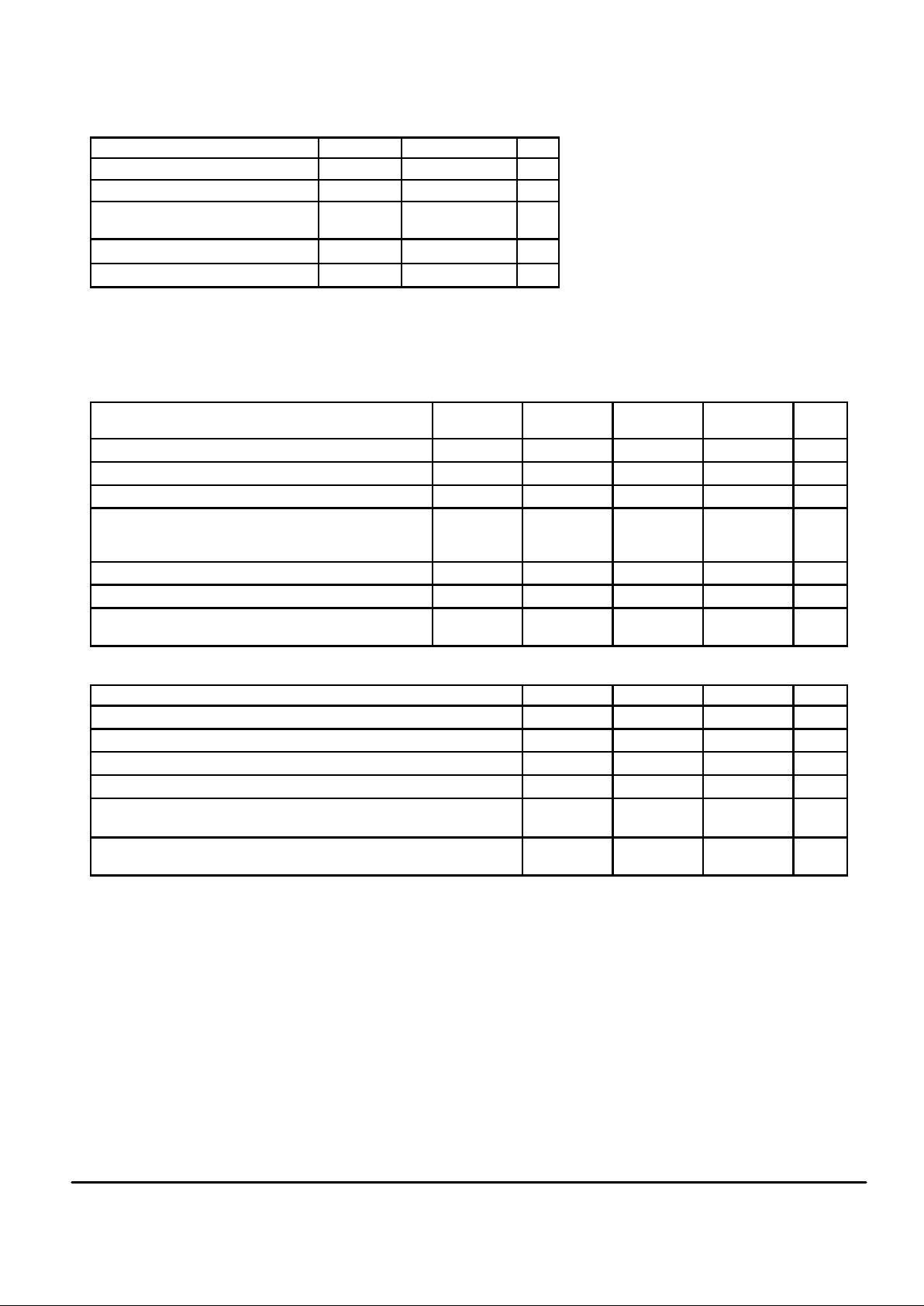

CODER AND DECODER PERFORMANCE (V

DD

= 5 V ± 5%, VSS = – 5 V ± 5%, VAG = VDG = 0 V,

0 dBm0 = 1.60 Vrms = 6.30 dBm (600 Ω), TA = 0 to 70°C, MSI = TDE = RCE = 8 kHz, TDC = RDC = 2.048 MHz, CCI = 256 kHz)

Coder (A/D) Decoder (D/A)

Characteristic

Min Typ Max Min Typ Max

Unit

Resolution 13 — 13 13 — 13 Bits

Conversion Time Full Cycle A/D and D/A

Short Cycle A/D

Short Cycle D/A

62.5

46.9

—

—

—

—

10,000

10,000

—

62.5

—

15.6

—

—

—

10,000

—

10,000

µs

Differential Nonlinearity — — ± 1 — — ± 1 LSB

Gain Error – 0.35 — + 0.35 – 0.35 — + 0.35 dB

Offset – 15

—

—

—

+ 15

—

—

– 20

—

—

—

+ 20

LSB

mV

Idle Channel Noise, 3 kHz Low–Pass — – 75 — — –79 — dBm0

Signal–to–Noise 3.2 dBm0

(Referenced to 1.02 kHz through 0 dBm0

a f

MSI

/2 Low–Pass Filter) – 10 dBm0

– 20 dBm0

– 30 dBm0

– 40 dBm0

– 50 dBm0

—

—

—

—

—

—

—

61

60

57

50

40

30

20

—

—

—

—

—

—

—

—

—

—

—

—

—

—

62

60

59

52

42

32

22

—

—

—

—

—

—

—

dB

ANALOG ELECTRICAL CHARACTERISTICS (V

DD

= 5 V ± 5%, VSS = – 5 V ± 5%, VAG = VDG = 0 V,

0 dBm0 = 1.60 Vrms = 6.30 dBm (600 Ω), TA = 0 to 70°C, MSI = TDE = RCE = 8 kHz, TDC = RDC = 2.048 MHz, CCI = 256 kHz)

Characteristic Pin Symbol Min Typ Max Unit

Input Current AI I

in

— 0.01 ± 1 µA

AC Input Impedance AI Z

in

0.5 — — MΩ

Input Capacitance AI C

in

— — 15 pF

Output Voltage Range AO V

out

– 3.4 — 3.4 V

Power Supply Rejection Ratio

(100 mV RMS on VDD or VSS, 0 – 50 kHz)

AO, TDD PSRR — 40 — dB

Crosstalk, Ain to A

out

and RDD to TDD Referenced to

0 dBm0 @ 1.02 kHz

AO, TDD — — – 90 – 75 dB

Slew Rate AO SR 1.5 3 — V/µs

Settling Time (Full Scale) AO t

settle

— 8 — µs

Page 4

MC145402 MOTOROLA

4

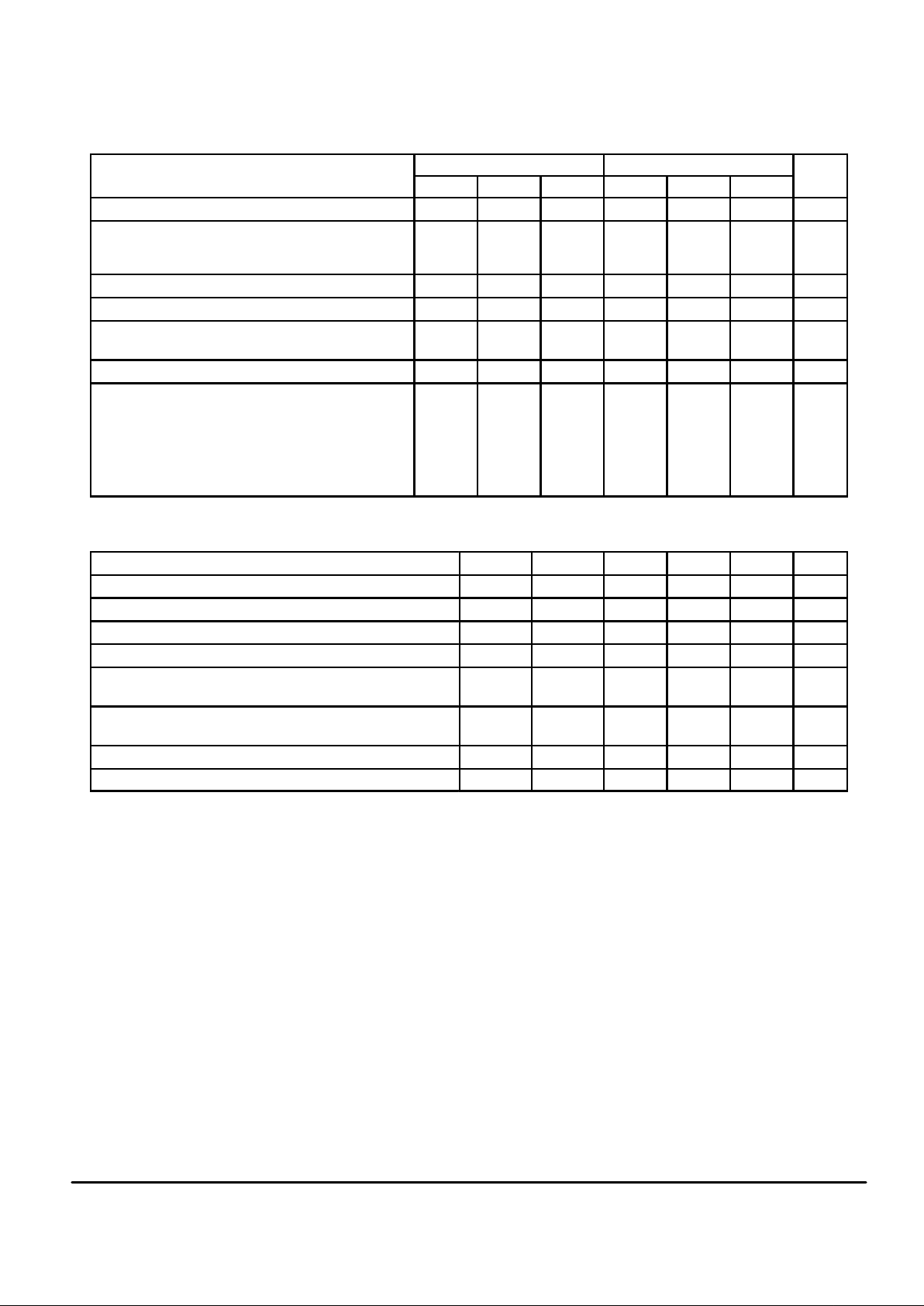

SWITCHING CHARACTERISTICS

(VDD = + 5 V ± 5%, VSS = – 5 V ± 5%, VAG = VDG = 0 V, TA = 0 to 70°C, CL = 50 pF, See Figure 1)

Characteristic Symbol Min Max Unit

Input Rise Time RCE, RDC, TDC, TDE, CCI, MSI t

r

— 100 ns

Input Fall Time RCE, RDC, TDC, TDE, CCI, MSI t

f

— 100 ns

Output Rise Time TDD t

r

— 80 ns

Output Fall Time TDD t

f

— 80 ns

Pulse Width High RDC, MSI, CCI, TDC, RCE t

wH

100 — ns

Pulse Width Low TDE, MSI, TDC, RCE, RDC t

wL

100 — ns

CCI Pulse Width Low t

wL

500 — ns

MSI Clock Frequency f

MSI

0.1 64 kHz

CCI Clock Frequency f

CCI

3.2 512 kHz

TDC and RDC Clock Frequency f

DC

16 x f

MSI

4.1 MHz

TDC Rising Edge to TDD Data Valid During TDE High t

p1

— 150 ns

TDE Rising Edge to TDD Data Valid During TDC High t

p2

— 150 ns

TDE Rising Edge to TDD Low–Impedance Propagation Delay t

p3

0 100 ns

TDE Falling Edge to TDD High–Impedance Propagation Delay t

p4

— 40 ns

TDE Rising Edge to TDC Falling Edge Setup Time t

su1

t

su2

20

100

—

—

ns

RDC Bit 0 Falling Edge to Last CCI Falling Edge Prior to MSI t

su3

20 — ns

MSI Rising Edge to CCI Falling Edge Setup Time t

su4

t

su5

20

100

—

—

ns

Last CCI Rising Edge (Prior to MSI) to TDE Rising Edge t

su6

100 — ns

Last CCI Rising Edge (Prior to MSI) to First TDC Rising Edge t

su6’

100 — ns

First TDC Falling Edge to Last CCI Rising Edge Prior to MSI t

su7

0 — ns

RCE Rising Edge to RDC Falling Edge Setup Time t

su8

t

su9

20

100

—

—

ns

RDD Valid to RDC Falling Edge Setup T ime t

su10

60 — ns

RDD Hold Time from RDC Falling Edge t

h

100 — ns

Page 5

MC145402MOTOROLA

5

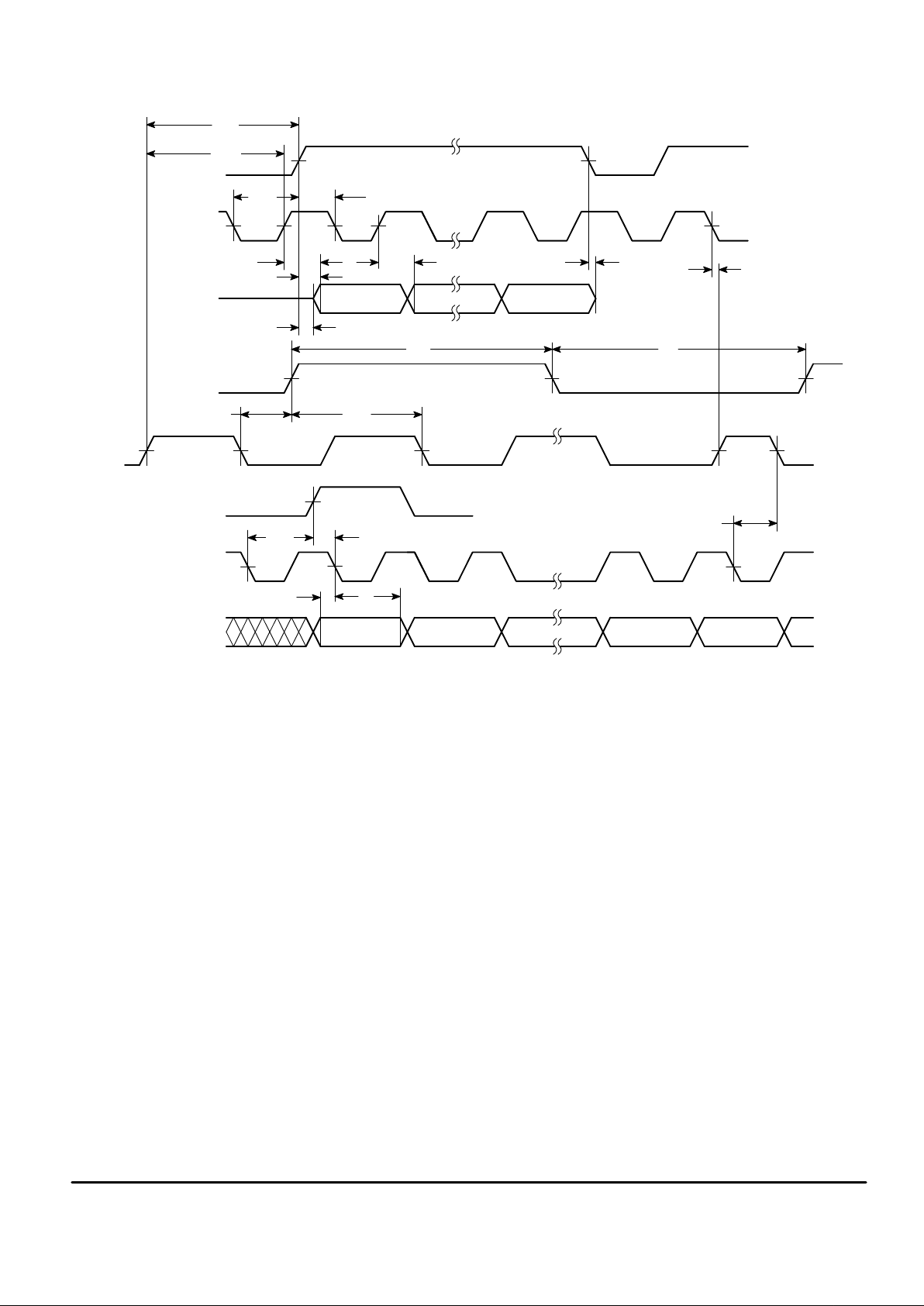

t

su1

TDE

TDC

TDD

MSI

CCI

RCE

RDD

t

su6

t

su2

t

p1

t

p2

t

p1

t

p4

t

su7

t

p3

t

wH

t

wL

t

su4

t

su5

t

su8

t

su9

t

su10

t

h

t

su3

S B11 B10 B1 B0

t

su6

′

CCI

LAST

CCI

LAST

Figure 1. AC Timing Diagram

LAST

BIT

CLOCK

RDC

Page 6

MC145402 MOTOROLA

6

PIN DESCRIPTIONS

V

DD

Positive Supply (Pin 16)

The most positive power supply, typically + 5 V in split

power supply configurations, or + 10 V in single supply

systems.

V

SS

Negative Supply (Pin 8)

The most negative power supply, typically – 5 V in split

power supply configurations, or 0 V in single supply systems.

V

AG

Analog Ground (Pin 1)

This is the analog signal reference point. This pin is normally tied to 0 V in split supply operation or VDD/2 in single

supply systems.

V

DG

Digital Ground (Pin 9)

This is the ground reference for all of the digital input and

output pins. CMOS compatible logic signals swing from V

DG

to VDD where VDG can be established anywhere from VDD –

4.75 V to VSS.

A

out

Analog Output (Pin 2)

This is the output of the decoder’s sample and hold circuit

and is a 100% duty cycle analog output of the last digital

word received and decoded by the decoder. A

out

is updated

approximately 60 ns after the rising edge of the last CCI prior

to MSI (see Figure 2). A

out

is capable of driving a 10 kΩ,

50 pF load.

A

in

Analog Input (Pin 3)

This is the high–impedance input to the coder. An A/D

cycle begins on the first falling edge of CCI following the rising edge of MSI. Ain is sampled approximately 50 ns after the

rising edge of CCI prior to the start of the A/D cycle.

PDI

Power–Down Input (Pin 4)

In normal operation this Input should be tied high. A logic

low on this input puts the device into a minimum power dissipation mode. During power–down, all functions stop. Two

complete MSI conversion cycles are required to establish

normal operation after leaving the power–down mode.

CCI

Convert Clock Input (Pin 5)

This input controls the complete conversion sequence during one MSI cycle and must receive a clock which is 32 times

the frequency of MSI. The only exception to 32 times the frequency of MSI is during short–cycle operation. See General

Modes of Operation section. CCI must be synchronous and

approximately rising edge aligned with MSI.

MSI

Master Sync Input (Pin 6)

This pin determines the conversion rate for both the coder

and the decoder. One A/D and D/A conversion takes place

during each period of the digital clock applied to this input

(except in short–cycle operation, see General Modes of

Operation section). MSI must be synchronous and approximately rising edge aligned with CCI.

TDC

Transmit Data Clock (Pin 12)

Digital data from the coder is serially transmitted from TDD

on rising TDC edges whenever TDE is a logic high. TDC

must be approximately rising edge aligned with TDE. Generally, if TDC is low when TDE rises, the first rising edge of

TDC clocks the first data bit. If TDC is high when TDE rises,

the first bit will be clocked by TDE and the first rising edge of

TDC after TDE rises will clock out the second data bit.

TDE

Transmit Data Enable (Pin 10)

This pin is used to initiate the serial transfer of data from

the coder and provides three–state control of the TDD pin.

The rising edge of TDE (or TDC if it follows TDE) signals the

start of data transfer from the TDD pin. A resulting high logic

level on TDE also releases TDD from its high–impedance

state. TDE must remain high throughout the data transfer to

keep TDD in the low–impedance state and must return to a

low state prior to each data transfer. If TDE remains high for

more than 16 TDC clocks, the 16 bits of TDD data will be recirculated. (Note: The A/D cycle begins on the first falling

edge of CCI after the rising edge of MSI. The internal transmit latch is updated one and one half CCI periods prior to the

start of the A/D cycle. A pulse generated by the logical AND

of TDE and the first TDC transfers data to the transmit shift

register, and this pulse must not occur when the transmit

latch is updated. See Figure 2 and see t

su6

, t

su6′

, and t

su7

of Figure 1.

TDD

Transmit Digital Data (Pin 11)

This is the three–state output data pin from the coder and

is controlled by the TDE and TDC pins. TDD is in the high–

impedance state whenever TDE is a logic low. The first data

bit is output from TDD on the rising edge of TDE (or TDC if it

follows TDE) and each subsequent bit is output on rising

edges of TDC. Two output data formats are available as described in the TDF pin description below.

TDF

Transmit Data Format (Pin 7)

The 13–bit digital output of the coder is available in one of

two 16–bit two’s complement formats as determined by the

state of this pin. A logic 0 at this pin causes the data from

TDD to be in a 16–bit sign–extended format as follows:

SSSSM ... L where S, M, and L represent the sign, most significant bit, and the least significant bit, respectively . A logic 1

on this pin formats the data as follows: SM ... LSSS (see Figure 3). RDD data is not affected by the state of this pin and if

a “digital loopback” is needed (TDD data looped back into

RDD), this pin should be high.

Page 7

MC145402MOTOROLA

7

RDC

Receive Data Clock (Pin 13)

Receive digital data is accepted by the decoder on the first

13 falling edges of RDC after an RCE rising edge.

RCE

Receive Clock Enable (Pin 14)

This pin identifies the beginning of a data transfer into the

RDD pin of the decoder. The first 13 falling edges of RDC after an RCE rising edge will clock data into the decoder data

input, RDD. RCE must return low prior to each data transfer.

Since receive data is latched into the receive latch on the last

CCI falling edge prior to MSI, data transfers may not span

this falling edge of CCI without loss of data.

RDD

Receive Digital Data (Pin 15)

This pin is the data input to the decoder and is controlled

by the RDC and RCE pins described above. Two’s complement data are loaded in the following sequence: SM ... L

where S, M, and L represent the sign, most significant bit,

and the least significant bit, respectively. Only the first 13 bits

clocked by RDC after RCE rises will be accepted for decoding. Any additional bits will be ignored (see Figure 3).

GENERAL INFORMATION

GENERAL MODES OF OPERATION

The MC145402 has three modes of operation; a “full” cycle

mode and two ‘‘short” cycle modes. The full cycle mode allows simultaneous analog–to–digital (A/D) and digital–to–

analog (D/A) operation. The short cycle modes allow either

A/D only or D/A only operation. Two MSI cycles are required

for the MC145402 to detect which operating mode has been

selected. See Figure 2 for full versus short cycle clocking.

Full Cycle Operation

When operating in the full cycle mode, the MC145402 performs a 13–bit A/D conversion followed by a 13–bit D/A con–

version. Full cycle operation is selected by using a CCI

frequency that is 32 times the frequency of MSI. MSI is the

sample rate frequency.

Short Cycle Analog–to–Digital Operation

If CCI is 24 times the frequency of MSI, short cycle analog–to–digital operation is selected. This allows a 13–bit A/D

conversion only. In this mode, the D/A is not operational and

any data applied to the RDD input is ignored.

Short Cycle Digital–to–Analog Operation

Short cycle digital–to–analog operation is selected by

using a CCI clock frequency that is eight times the MSI sample rate. During short cycle D/A operation, A/D operation is

disabled and digital data read from TDD is not valid.

CLOCKING RECOMMENDATIONS

For optimum differential nonlinearity performance, all data

transitions on TDD and RDD should be limited to the first four

CCI cycles following the rising edge of MSI. This may be

achieved by setting MSI = TDE = RCE having a duration of

16 da ta clo ck cy cles , and TD C = RDC

≥ 4 x CCI c lock

frequency. Figure 6 shows a circuit that generates this clocking configuration; see Application Circuits section.

SIGNAL TO DISTORTION RATIO

Figures 4 and 5 show graphs of typical signal to distortion

ratios versus signal level for the MC145402. The presented

data is referenced to a 1020 Hz input sinusoidal frequency

with signal levels referenced to 600 Ω and transmission level

point adjusted (e.g., 0 dBm0 at 600 Ω with a TLP of 6.30 dB

is 4.53 V peak–to–peak). For comparison, ideal signal to

noise ratios for 9–, 10–, 11–, 12–, and 13–bit A/D and D/A

converters are also shown. The equation used for an ideal

RMS to RMS signal to distortion ratio is:

S/D = N x 6 dB + 1.76 dB

where N is the number of bits of resolution, 6 dB per bit, and

1.76 = 20

log

(√3

/√2).

(√3

/√2) is approximately the RMS to RMS ratio of a sine

wave to white noise.

The signal to noise plus distortion ratio is measured

through a brickwall low–pass filter set to the Nyquist frequency of the A/D and D/A sample rate. For an 8 kHz sample rate,

the low–pass filter is set to block all signals above 4 kHz.

APPLICATION CIRCUITS

Figure 6 shows a typical circuit for generating the clock

frequencies for the MC145402. This circuit uses an

MC74HC4040 and a 2.048 MHz crystal to generate the

256 kHz frequency for internal sequencing, 1.024 MHz for

the date clocks, and an 8 kHz sample frequency. A

4.096 MHz crystal could be used for a sample rate of 16 kHz.

Figure NO TAG shows the MC145402 interfaced to the

DSP56000 digital signal processor. The DSP56000 can internally generate the clocks for the MC145402 using the SSI

serial interface. SCK provides the sequencing and data

clocks (non–gated continuous dock) and SC2 (setup as the

Frame Sync Out, FSL = 0) provides the sample rate and data

enables for the MC145402. The divide–by–four circuit to

generate the CCI clock is recommended for optimum

MC145402 performance, and allows the DSP56000 to clock

data in and out of the MC145402 quickly, leaving time available for processing by the DSP before another sample is

available. SC0 and SC1 could be used to gate the enables to

select up to four devices on the SSI bus.

TELEPHONE SYSTEM TRANSMISSION LEVEL POINT

FOR A LINEAR A/D OR D/A CONVERTER

REFERENCED TO MU–LAW COMPANDING

Mu–Law companding, as specified by AT&T and CCITT,

requires 8159 quantization levels to implement both A/D and

D/A conversion schemes. This is to be mirrored about signal

ground for the negative part of the wave form.

To implement a 13–bit (± 12–bit) linear converter scheme

requires 8192 quantization levels mirrored about signal

ground. To specify this converter such that it can be used to

interface with, or as an alternative to, telephony based Mu–

Law applications, the following is an explanation of the gain

translation.

A 13–bit linear converter scheme has 8192 quantization

levels. The goal is to be able to convert between these two

encoding schemes with minimal distortion. This dictates setting the LSBs to the same level. For this to be achieved requires the reference voltage of the linear converter to be

Page 8

MC145402 MOTOROLA

8

8192/8159 times the reference voltage of the Mu–Law

converter. The peak amplitude of a Mu–Law converter is

3.17 dBm0. The peak level of the linear converter will be

8192/8159 times the peak level of the Mu–Law converter,

which is 8192/8159 x 3.17 dBm0. However, you cannot multiply a gain factor by a dBm value without using common term

units and math (i.e., we must convert this gain factor to a dB

equivalent), which is:

20 log10 (8192/8159) = 0.03 dB

With the gain factor in dB, we can add it to the Mu–Law

peak level:

3.17 dBm0 + 0.03 dB = 3.20 dBm0

Therefore, the linear converter peak level is 3.20 dBm0.

This is another way of saying the 0 dBm0 level for the linear converter is 3.20 dB below the maximum amplitude.

To determine the absolute 0 dBm0 level for the linear converter from the peak level, we calculate the peak level in dBm

by:

10 log

10

3.27 VpK

/√2 )/(600 Ω)

1 mW

= 9.50 dBm (600 Ω)

and 3.20 dB below this level is the 0 dBm0 absolute amplitude, which is

9.50 dBm – 3.20 dB = 6.30 dBm (600 Ω)

Therefore, the calibration level, or transmission level point

(TLP), for this part is 6.30 dBm (600 Ω), which is 1.6 Vrms

based on the reference voltage of 3.27 V.

Page 9

MC145402MOTOROLA

9

AO UPDATED AND

FULL CYCLE A/D–D/A

SHORT CYCLE A/D ONLY

SHORT CYCLE D/A ONLY

A/D CONVERSION

A/D CONVERSION A/D CONVERSION

AI SAMPLED

AI SAMPLED

AO UPDATED

1 8 16 24 32

MSI

MSI

MSI

CCI

CCI

CCI

TDD DATA TRANSFERRED INT O

D/A

CONVERSION

D/A

CONVERSION

D/A

CONVERSION

D/A

CONVERSION

D/A

CONVERSION

RDD DATA LATCHED INTO

THE RECEIVE LATCH

RDD DATA LATCHED INTO

THE RECEIVE LATCH

THE TRANSMIT LATCH

TDD DATA TRANSFERRED

INTO THE TRANSMIT LA TCH

CLOCK

CYCLE

Figure 2. MC145402 Full and Short Cycle Timing

Page 10

MC145402 MOTOROLA

10

TDE

TDC

RCE

RDC

RDD

TDD

(TDF = 1)

TDD

(TDF = 0)

S

S

SS

S

SSSS b0b9b11 b10 b8 b7 b6 b5 b4 b3 b2 b1

b0b9b11 b10 b8 b7 b6 b5 b4 b3 b2 b1

b0b9b11 b10 b8 b7 b6 b5 b4 b3 b2 b1

Figure 3. MC145402 Digital Data Timing

Page 11

MC145402MOTOROLA

11

(1020 Hz REFERENCED TO 600

INPUT LEVEL (dBm0)

Ω

)

80

70

60

50

40

30

20

10

0

– 60 – 50 – 40 – 30 – 20 – 10 0 10

13–BIT

12–BIT

11–BIT

10–BIT

9–BIT

RMS SIGNAL TO RMS (NOISE + DIST ORTION) (dB)

f

MSI

/2

COMPARED TO 9–13 BIT IDEAL A/D; MSI = 8 kHz;

MEASURED THROUGH A LOW–P ASS FIL TER

WITH A BANDWIDTH OF

Figure 4. MC145402 Encoder (A/D) Signal to Noise Plus Distortion Ratio

(1020 Hz REFERENCED TO 600

INPUT LEVEL (dBm0)

Ω

)

80

70

60

50

40

30

20

10

0

– 60 – 50 – 40 – 30 – 20 – 10 0 10

13–BIT

12–BIT

11–BIT

10–BIT

9–BIT

RMS SIGNAL TO RMS (NOISE + DIST ORTION) (dB)

f

MSI

/2

COMPARED TO 9–13 BIT IDEAL D/A; MSI = 8 kHz;

MEASURED THROUGH A LOW–P ASS FIL TER

WITH A BANDWIDTH OF

Figure 5. MC145402 Decoder (D/A) Signal to Noise Plus Distortion Ratio

Page 12

MC145402 MOTOROLA

12

A/D

2.048 MHz

15 M

20 pF 20 pF

MC74HCU04

+ 5 V

0 V

V

DD

V

CC

16

10

8

CLK

GND

R

9

6

2

4

13

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

Q9

Q10

Q11

Q12

V

SS

V

DG

15

13

14

7

11

12

10

5

6

4

+ 5 V

8 kHz

256 kHz

+ 5 V

MC145402

CONTROL

2

3

16

8

9

1

out

RDD

RDC

RCE

TDF

TDD

TDC

TDE

CCI

MIS

PDI

+ 5 V

–5 V

0 V

µ

F0.1

µ

F0.1

V

CC

GND, PIN 7 = 0 V

, PIN 14 = + 5 V

13–BIT

POWER CONNECTIONS

MC74HCU04 AND MC74HC11

MC74HC1 1

1/3

MHz

1.024

DAT A

SERIAL

IN

DAT A

SERIAL

OUT

VOLT AGE

ANALOG

OUT

VOLT AGE

ANALOG

IN

D/A

13–BIT

11

MC74HC4040

V

AG

A

in

A

Ω

Figure 6. Typical MC145402 Configuration

Page 13

MC145402MOTOROLA

13

+ 5 V

128 f

sample

32 f

samplefsample

+ 5 V

+ 5 V

+ 5 V

V

CC

V

SS

256

kHz

1.024

MHz

8 kHz

DSP56000

1/2 MC74HC74

1/2 MC74HC73

1/2 MC74HC731/2 MC74HC74

SCK

SC2

SRD

STD

PDI

A

in

A

out

TDF

V

AG

V

DG

CCI

TDC

RDC

TDE

RCE

MSI

TDD

RDD

CLK

CLK

CLK

CLK

D

D

R

R R

R

J

J

K

K

Q

Q

Q

Q

Q

Q Q

Q

V

out

V

in

V

SS

V

DD

MC145402

– 5 V

Figure 7. The MC145402, 13–Bit Linear Codec, Interfaced to a Motorola DSP56000,

Digital Signal Processor, SSI Port

Page 14

MC145402 MOTOROLA

14

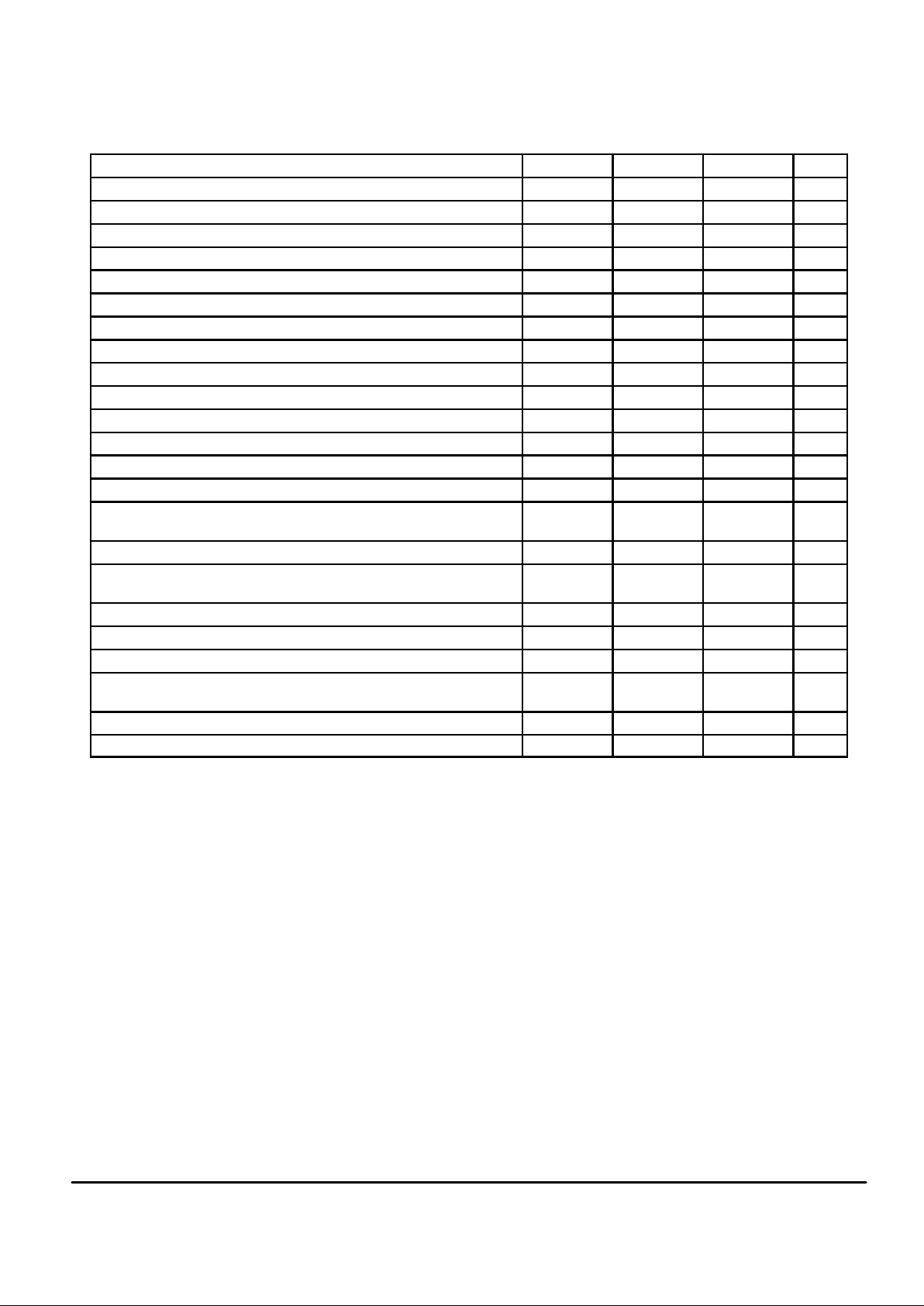

P ACKAGE DIMENSIONS

L SUFFIX

CERAMIC

CASE 620–09

MIN MINMAX MAX

INCHES MILLIMETERS

DIM

19.05

6.10

—

0.39

1.40

0.23

—

0

°

0.39

19.55

7.36

4.19

0.53

1.77

0.27

5.08

15

°

0.88

0.750

0.240

—

0.015

0.055

0.009

—

0

°

0.015

0.770

0.290

0.165

0.021

0.070

0.011

0.200

15

°

0.035

1.27 BSC

2.54 BSC

7.62 BSC

0.050 BSC

0.100 BSC

0.300 BSC

A

B

C

D

E

F

G

J

K

L

M

N

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEAD WHEN

FORMED PARALLEL.

4. DIMENSION F MAY NARROW TO 0.76 (0.030)

WHERE THE LEAD ENTERS THE CERAMIC

BODY.

D 16 PL

J 16 PL

SEATING

PLANE

0.25 (0.010) T A

M

S

0.25 (0.010) T B

M

S

18

916

-A-

-B-

K

C

N

G

E

F

-T-

M

L

Page 15

MC145402MOTOROLA

15

This page intentionally left blank.

Page 16

MC145402 MOTOROLA

16

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit,

and specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters can and do vary in different

applications. All operating parameters, including “T ypicals” must be validated for each customer application by customer’s technical experts. Motorola does

not convey any license under its patent rights nor the rights of others. Motorola products are not designed, intended, or authorized for use as components in

systems intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of

the Motorola product could create a situation where personal injury or death may occur. Should Buyer purchase or use Motorola products for any such

unintended or unauthorized application, Buyer shall indemnify and hold Motorola and its officers, employees, subsidiaries, affiliates, and distributors harmless

against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that Motorola was negligent regarding the design or manufacture of the part.

Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal Opportunity/Affirmative Action Employer.

How to reach us:

USA/EUROPE: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, Toshikatsu Otsuki,

P.O. Box 20912; Phoenix, Arizona 85036. 1–800–441–2447 6F Seibu–Butsuryu–Center, 3–14–2 Tatsumi Koto–Ku, To kyo 135, Japan. 03–3521–8315

MFAX: RMF AX0@email.sps.mot.com – T OUCHTONE (602) 244–6609 HONG KONG: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://Design–NET.com 51 Ting Kok Road, Tai Po, N.T., Hong Kong. 852–26629298

MC145402/D

*MC145402/D*

◊

Loading...

Loading...