Page 1

MC145149MOTOROLA

1

Interfaces with Dual–Modulus Prescalers

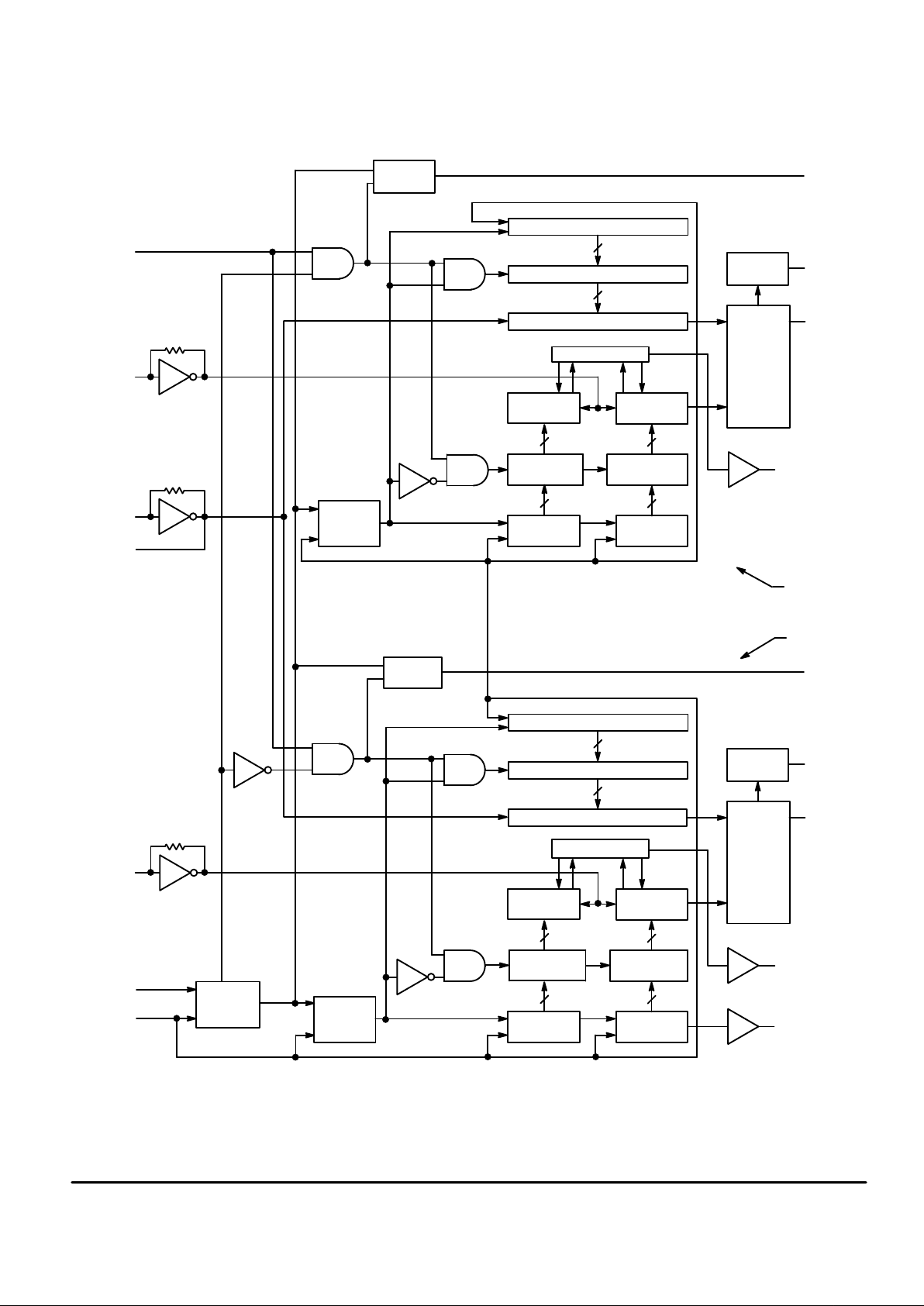

The MC145149 contains two PLL Frequency Synthesizers which share a

common serial data port and common reference oscillator. The device

contains two 14–stage R counters, two 10–stage N counters, and two

7–stage A counters. All six counters are fully programmable through a serial

port. The divide ratios are latched into the appropriate counter latch

according to the last data bits (control bits) entered.

When combined with external low–pass filters and voltage controlled

oscillators (VCOs), the MC145149 can provide all the remaining functions

for two PLL frequency synthesizers operating up to the device’s frequency

limit. For higher VCO frequency operation, a down mixer or dual–modulus

prescaler can be used between the VCO and the synthesizer IC.

• Low Power Consumption Through Use of CMOS Technology

• Wide Operating Voltage Range: 3 to 9 V

• Operating Temperature Range: – 40 to + 85°C

•÷ R Range = 3 to 16,383

•÷ N Range = 3 to 1023

•÷ A Range = 0 to 127

• Two “Linearized” Three–State Digital Phase Detectors with No Dead Zone

• Two Lock Detect Signals (LD1 and LD2)

• Two Open–Drain Port Expander Outputs (SW1 and SW2)

• Compatible with the Serial Peripheral Interface (SPI) on CMOS MCUs

Order this document

by MC145149/D

SEMICONDUCTOR TECHNICAL DATA

P SUFFIX

PLASTIC DIP

CASE 738

DW SUFFIX

SOG PACKAGE

CASE 751D

ORDERING INFORMATION

MC145149P Plastic DIP

MC145149DW SOG Package

20

1

20

1

CLK

f

in1

ENB

MC1

LD1

LD2

MC2

S/R

out

f

in2

DATA 5

4

3

2

1

10

9

8

7

6

14

15

16

17

18

19

20

11

12

13

OSC

out

SW1

V

DD1

PD

out1

V

SS1

V

SS2

PD

out2

V

DD2

SW2

OSC

in

PIN ASSIGNMENT

Motorola, Inc. 1995

Page 2

MC145149 MOTOROLA

2

CLK

DATA

6

5

PLL2

PLL1

SW1

17

SW2

14

10

10

7

7

14

14

10

10

7

7

14

14

8

2–BIT

CONTROL

S/R

7

10–BIT S/R7–BIT S/R

÷

A COUNTER

LATCH

10–BIT ÷ N

COUNTER

7–BIT ÷ A

COUNTER

MODULUS

CONTROL 2

(MC2)

9

12

10

LOCK

DETECT

14–BIT

÷

R COUNTER

1–BIT

LATCH

1–BIT

CONTROL

S/R

REFERENCE COUNTER LATCH

CONTROL LOGIC

PHASE

DETECTOR

÷

N COUNTER

LATCH

14–BIT SHIFT REGISTER

16

15

4

ENB

3

10–BIT S/R7–BIT S/R

÷

A COUNTER

LATCH

10–BIT

÷

N

COUNTER

7–BIT ÷ A

COUNTER

MODULUS

CONTROL 1

(MC1)

2

19

1

LOCK

DETECT

14–BIT

÷

R COUNTER

1–BIT

LATCH

1–BIT

CONTROL

S/R

REFERENCE COUNTER LATCH

CONTROL LOGIC

PHASE

DETECTOR

÷

N COUNTER

LATCH

14–BIT SHIFT REGISTER

OSC

in

OSC

out

f

in1

f

in2

S/R

out

PD

out2

f

R

PIN 13

=

V

DD2

PIN 11

=

V

SS2

PD

out1

f

R

PIN 18

=

V

DD1

PIN 20

=

V

SS1

BLOCK DIAGRAM

f

V

f

V

LD2

LD1

Page 3

MC145149MOTOROLA

3

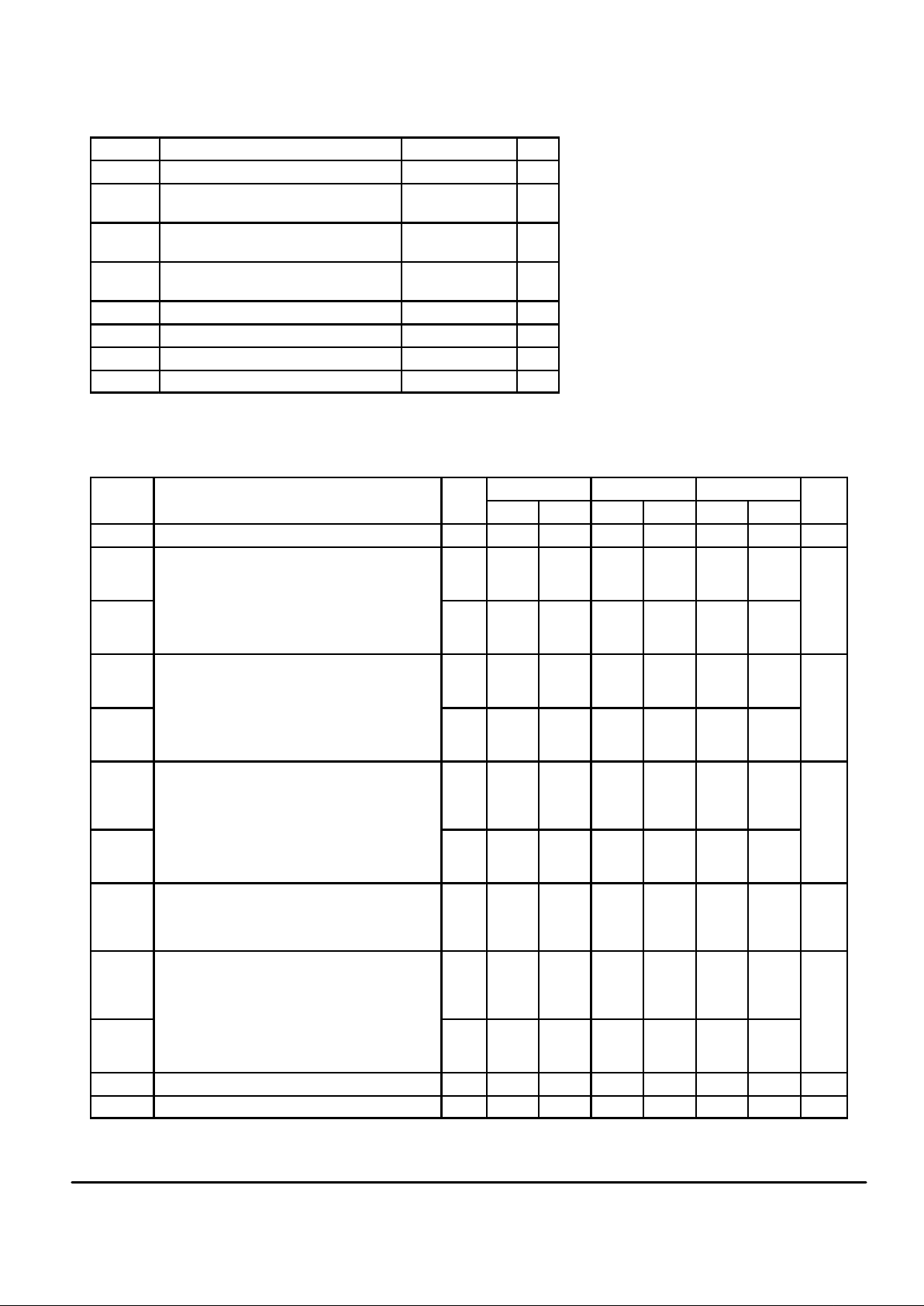

MAXIMUM RATINGS* (Voltages Referenced to V

SS

)

Symbol Rating Value Unit

V

DD

DC Supply Voltage – 0.5 to + 10 V

Vin, V

out

Input or Output Voltage (DC or T ransient)

except SW1, SW2

– 0.5 to VDD + 0.5 V

V

out

Output Voltage (DC or Transient) — SW1,

SW2

– 0.5 to 15 V

Iin, I

out

Input or Output Current (DC or Transient),

per Pin

± 10 mA

IDD, I

SS

Supply Current, VDD or VSS Pins ± 30 mA

P

D

Power Dissipation, per Package† 500 mW

T

stg

Storage Temperature – 65 to + 150 °C

T

L

Lead T emperature (8–Second Soldering) 260 °C

*Maximum Ratings are those values beyond which damage to the device may occur.

†Power Dissipation Temperature Derating:

Plastic DIP: – 12 mW/°C from 65 to 85°C

SOG Package: – 7 mW/°C from 65 to 85°C

ELECTRICAL CHARACTERISTICS (Voltages Referenced to V

SS

)

V

– 40°C 25°C 85°C

Symbol Characteristic

V

DD

V

Min Max Min Max Min Max

Unit

V

DD

Power Supply Voltage Range — 3 9 3 9 3 9 V

V

OL

Output Voltage 0 Level

Vin = 0 V or V

DD

I

out

= 0 µA

3

5

9

—

—

—

0.05

0.05

0.05

—

—

—

0.05

0.05

0.05

—

—

—

0.05

0.05

0.05

V

V

OH

1 Level 3

5

9

2.95

4.95

8.95

—

—

—

2.95

4.95

8.95

—

—

—

2.95

4.95

8.95

—

—

—

V

IL

Input Voltage 0 Level

V

out

= 0.5 V or VDD – 0.5 V

(All Outputs Except OSC

out

)

3

5

9

—

—

—

0.9

1.5

2.7

—

—

—

0.9

1.5

2.7

—

—

—

0.9

1.5

2.7

V

V

IH

1 Level 3

5

9

2.1

3.5

6.3

—

—

—

2.1

3.5

6.3

—

—

—

2.1

3.5

6.3

—

—

—

I

OH

Output Current — MC1, MC2

V

out

= 2.7 V Source

V

out

= 4.6 V

V

out

= 8.5 V

3

5

9

– 0.60

– 0.90

– 1.50

—

—

—

– 0.50

– 0.75

– 1.25

—

—

—

– 0.30

– 0.50

– 0.80

—

—

—

mA

I

OL

V

out

= 0.3 V Sink

V

out

= 0.4 V

V

out

= 0.5 V

3

5

9

1.30

1.90

3.80

—

—

—

1.10

1.70

3.30

—

—

—

0.66

1.08

2.10

—

—

—

I

OL

Output Current — SW1, SW2

V

out

= 0.3 V Sink

V

out

= 0.4 V

V

out

= 0.5 V

3

5

9

0.80

1.50

3.50

—

—

—

0.48

0.90

2.10

—

—

—

0.24

0.45

1.50

—

—

—

mA

I

OH

Output Current — Other Outputs

V

out

= 2.7 V Source

V

out

= 4.6 V

V

out

= 8.5 V

3

5

9

– 0.44

– 0.64

– 1.30

—

—

—

– 0.35

– 0.51

– 1.00

—

—

—

– 0.22

– 0.36

– 0.70

—

—

—

mA

I

OL

V

out

= 0.3 V Sink

V

out

= 0.4 V

V

out

= 0.5 V

3

5

9

0.44

0.64

1.30

—

—

—

0.35

0.51

1.00

—

—

—

0.22

0.36

0.70

—

—

—

I

in

Input Current — DATA, CLK, ENB 9 — ± 0.3 — ± 0.1 — ± 1.0 µA

I

in

Input Current — fin, OSC

in

9 — ± 50 — ± 25 — ± 22 µA

(continued)

This device contains circuitry to protect

against damage due to high static voltages or

electric fields, however, it is advised that normal

precautions be taken to avoid applications of any

voltage higher than maximum rated voltages to

this high–impedance circuit. For proper operation, it is recommended that Vin and V

out

be

constrained to the range VSS≤ (Vin or

V

out

) ≤ VDD except SW1 and SW2 which may

range up to 15 V.

Unused inputs must always be tied to an

appropriate logic voltage level (e.g., either V

SS

or VDD). Unused outputs should be left floating.

Page 4

MC145149 MOTOROLA

4

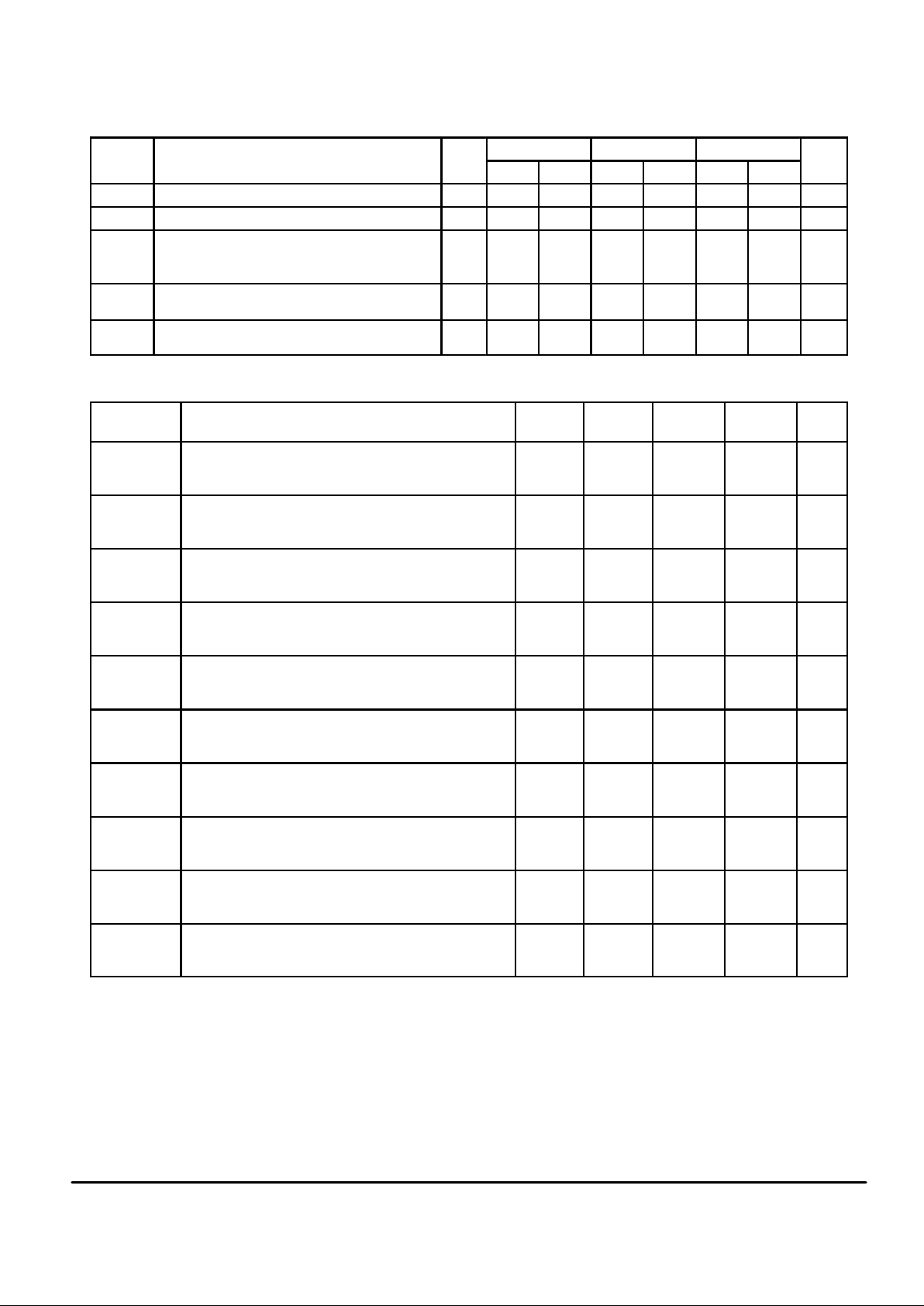

ELECTRICAL CHARACTERISTICS (continued)

V

– 40°C 25°C 85°C

Symbol Characteristic

V

DD

V

Min Max Min Max Min Max

Unit

C

in

Input Capacitance — — 10 — 10 — 10 pF

C

out

Three–State Output Capacitance — PD

out

— — 10 — 10 — 10 pF

I

DD

Quiescent Current

Vin = 0 V or V

DD

I

out

= 0 µA

3

5

9

—

—

—

800

1200

1600

—

—

—

800

1200

1600

— 1600

2400

3200

µA

I

OZ

Three–State Leakage Current — PD

out

V

out

= 0 V or 9 V

9 — ± 0.3 — ± 0.1 — ± 3.0 µA

I

OZ

Off–State Leakage Current — SW1, SW2

V

out

= 9 V

9 — 0.3 — 0.1 — 3.0 µA

SWITCHING CHARACTERISTICS (T

A

= 25°C, CL = 50 pF)

Symbol

Characteristic

Figure

No.

V

DD

V

Min Max Unit

t

TLH

Output Rise Time, MC1 and MC2 1, 6 3

5

9

—

—

—

115

60

40

ns

t

THL

Output Fall Time, MC1 and MC2 1, 6 3

5

9

—

—

—

60

34

30

ns

t

TLH

,

t

THL

Output Rise and Fall Time, LD and S/R

out

1, 6 3

5

9

—

—

—

140

80

60

ns

t

PLH

,

t

PHL

Propagation Delay Time, fin to MC1 or MC2 2, 6 3

5

9

—

—

—

125

80

50

ns

t

su

Setup Time, DATA to CLK 3 3

5

9

30

20

18

—

—

—

ns

t

su

Setup Time, CLK to ENB 3 3

5

9

70

32

25

—

—

—

ns

t

h

Hold Time, CLK to DATA 3 3

5

9

12

12

15

—

—

—

ns

t

rec

Recovery Time, ENB to CLK 3 3

5

9

5

10

20

—

—

—

ns

tr, t

f

Input Rise and Fall Times, Any Input 4 3

5

9

—

—

—

5

2

0.5

µs

t

w

Input Pulse Width, ENB and CLK 5 3

5

9

40

35

25

—

—

—

ns

Page 5

MC145149MOTOROLA

5

FREQUENCY CHARACTERISTICS (Voltages Referenced to V

SS

, CL = 50 pF, Input tr = tf = 10 ns unless otherwise indicated)

V

– 40°C 25°C 85°C

Symbol Parameter Test Conditions

V

DD

V

Min Max Min Max Min Max

Unit

f

i

Input Frequency

(fin, OSCin)

R ≥ 8, A ≥ 0, N ≥ 8

Vin = 500 mV p–p

ac coupled sine wave

3

5

9

—

—

—

6

15

15

—

—

—

6

15

15

—

—

—

6

15

15

MHz

R ≥ 8, A ≥ 0, N ≥ 8

Vin = VDD to V

SS

dc coupled square wave

3

5

9

—

—

—

6

15

15

—

—

—

6

15

15

—

—

—

6

15

15

MHz

SWITCHING W AVEFORMS

10%

90%

ANY

OUTPUT

t

TLH

t

THL

MC 50%

50%

t

PLHtPHL

V

DD

V

SS

f

in

Figure 1.

50%

50%

LAST

CLK

PREVIOUS DA TA

LATCHED

FIRST

CLK

ENB

CLK

DATA

50%

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

t

su

t

su

t

rec

t

h

10%

90%

ANY

INPUT

V

DD

V

SS

t

f

t

r

50%

ENB, CLK

V

DD

V

SS

t

w

OUTPUT

DEVICE

UNDER

TEST

C

L

*

Figure 2.

Figure 3.

Figure 4.

Figure 5. Figure 6.

* Includes all probe and fixture capacitance.

Page 6

MC145149 MOTOROLA

6

PIN DESCRIPTIONS

INPUT PINS

OSCin, OSC

out

Reference Oscillator Input/Output (Pins 15, 16)

These pins form a reference oscillator when connected to

terminals of an external parallel–resonant crystal. Frequency–setting capacitors of appropriate value must be connected from OSCin and OSC

out

to ground.

OSCin may also serve as input for an externally–generated

reference signal. The signal is typically ac coupled to OSCin,

but for signals with CMOS logic levels, dc coupling may be

used. When used with an external reference, OSC

out

should

be left open.

f

in1

, f

in2

Frequency Inputs (Pins 4, 7)

Input frequency from an external VCO output. Each rising–

edge signal on f

in1

decrements the N counter, and when ap-

propriate, the A counter of PLL 1. Similarly, f

in2

decrements

the counters of PLL 2.

These inputs have inverters biased on the linear region

which allows ac coupling for signals as low as 500 mV p–p.

With square wave signals which swing from VSS to VDD, dc

coupling may be used.

DATA, CLK

Data, Clock Inputs (Pins 5, 6)

Shift register data and clock inputs. Each low–to–high

transition on the clock pin shifts one bit of data into the on–

chip shift registers. Refer to Figure 7 for the following discussion.

The last bit entered is a steering bit that determines which

set of latches are activated. A logic high selects the latches

for PLL 1. A logic low selects PLL 2.

The second–to–last bit controls the appropriate port expander output, SW1 or SW2. A logic low forces the output

low. A logic high forces the output to the high–impedance

state.

The third–to–last bit determines which storage latch is activated. A logic low selects the ÷ A and ÷ N counter latches. A

logic high selects the reference counter latch.

When writing to either set of ÷ A and ÷ N counter latches,

20 clock cycles are typically used. However, if a byte–

oriented MCU is utilized, 24 clock cycles may be used with

the first 4 bits being “Don’t Care.”

When writing to either reference counter latch, 17 clock

cycles are typically used. However, if a byte–oriented MCU is

utilized, 24 clock cycles may be used with the first 7 bits

being “Don’t Care”.

ENB

Latch Enable Input (Pin 3)

A positive pulse on this input transfers data from the shift

registers to the selected latches, as determined by the control and steering data bits. A logic low level on this pin allows

the user to shift data into the shift registers without affecting

the data in the latches or counters. Enable is normally held

low and is pulsed high to transfer data into the latches.

OUTPUT PINS

PD

out1

, PD

out2

Single–Ended Phase Detector Outputs (Pins 19, 12)

Each single–ended (three–state) phase detector output

produces a loop error signal that is used with a loop filter to

control a VCO (see Figure 8).

Frequency fV > fR or fV Leading: Negative Pulses

Frequency fV < fR or fV Lagging: Positive Pulses

Frequency fV = fR and Phase Coincidence: High–Imped-

ance State

S/R

out

Shift Register Output (Pin 8)

This output can be connected to an external shift register

to provide band switching or control information. S/R

out

may

also be used to check the counter programming bit stream.

MC1, MC2

Modulus Control Outputs (Pins 2, 9)

Each output generates a signal by the on–chip control

logic circuitry for controlling an external dual–modulus

prescaler. The modulus control level is low at the beginning

of a count cycle and remains low until the ÷ A counter has

counted down from its programmed value. At this time,

modulus control goes high and remains high until the ÷ N

counter has counted the rest of the way down from its

programmed value (N–A additional counts since both ÷ N

and ÷ A are counting down during the first portion of the

cycle). Modulus control is then set back low, the counters are

preset to their respective programmed values, and the above

sequence is repeated. This provides for a total programmable divide value (NT) = N • P + A where P and P + 1 represent the dual–modulus prescaler divide values respectively

for high and low modulus control levels, N the number programmed into the ÷ N counter, and A the number programmed into the ÷ A counter.

Note that when a prescaler is needed, the dual–modulus

version offers a distinct advantage. The dual–modulus

prescaler allows a higher reference frequency at the phase

detector input, increasing system performance capability,

and simplifying the loop filter design.

LD1, LD2

Lock Detect Signals (Pins 1, 10)

Each output is essentially at a high logic level when the

corresponding loop is locked (fR and fV of the same phase

and frequency). Each output pulses low when the corresponding loop is out of lock (see Figure 8).

SW1, SW2

Latched Open–Drain Switch Outputs (Pins 17, 14)

The state of each output is controlled by the “SW STATE”

bit shown in Figure 7. If the bit is a logic high, the corresponding SW output assumes the high–impedance state. If the bit

is low, the SW output goes low.

To control output SW1, steering bit PLL 1/PLL 2 shown in

Figure 7 must be high. To control SW2, bit PLL 1/PLL 2 must

be low.

These outputs have an output voltage range of VSS to

15 V.

Page 7

MC145149MOTOROLA

7

POWER SUPPLY PINS

V

DD1

, V

DD2

Positive Power Supply (Pins 18, 13)

The most positive power supply potentials. Both of these

pins are connected to the substrate of the chip. Therefore,

both must be tied to the same voltage potential. This potential may range from 3 to 9 V with respect to the VSS pins.

For optimum performance, V

DD1

should be bypassed to

V

SS1

and V

DD2

bypassed to V

SS2

. That is, two separate

bypass capacitors should be utilized.

V

SS1

, V

SS2

Negative Power Supply (Pins 20, 11)

The most negative power supply potentials. Both of these

pins should be tied to ground.

Figure 7. Bit Stream Formats

÷

R

÷

A

÷

N

LAST BIT INTO

SHIFT REGISTER

LAST BIT INTO

SHIFT REGISTER

PLL 1/PLL 2

SW STATE

LOW OR “0”

LSB

MSB

LSB

PLL 1/PLL 2

SW STATE

HIGH OR “1”

LSB

MSB

MSB

NOTE: The PD output state is equal to either VDD or VSS when active. When not active, the output is high

impedance and the voltage at that pin is determined by the low–pass filter capacitor.

f

R

REFERENCE

(OSC

÷

R)

f

V

FEEDBACK

(fin

÷

N)

PD

out

LD

Figure 8. Phase Detector/Lock Detector Output Waveforms

Page 8

MC145149 MOTOROLA

8

F(s) =

ζ

=

ωn =

A)

NR1C

R1sC + 1

DEFINITIONS:

N = T otal Division Ratio in Feedback Loop

Kφ (Phase Detector Gain) = VDD/4π for PD

out

K

VCO

(VCO Gain) =

2π∆f

VCO

∆V

VCO

Damping Factor: ζ [ 1

1

C

VCOPD

out

N

ω

n

2K

φKVCO

F(s) =

ζ

=

ωn =

B)

(R1+R2)sC + 1

R2sC + 1

C

VCO

R

2

PD

out

R

1

R

1

NC(R1 + R2)

R2C+

N

K

φKVCO

0.5

ω

n

Ǔ

ǒ

KφK

VCO

K

φKVCO

RECOMMENDED READING:

Gardner, Floyd M.,

Phaselock Techniques (second edition).

New York, Wiley–Interscience, 1979.

Manassewitsch, Vadim,

Frequency Synthesizers: Theory and Design (second edition).

New York, Wiley–Interscience, 1980.

Blanchard, Alain,

Phase–Locked Loops: Application to Coherent Receiver Design.

New York, Wiley–Interscience, 1976.

Egan, William F.,

Frequency Synthesis by Phase Lock.

New York, Wiley–Interscience, 1981.

Rohde, Ulrich L.,

Digital PLL Frequency Synthesizers Theory and Design.

Englewood Cliffs, NJ, Prentice–Hall, 1983.

Berlin, Howard M.,

Design of Phase–Locked Loop Circuits, with Experiments.

Indianapolis, Howard W. Sams and Co., 1978.

Kinley, Harold,

The PLL Synthesizer Cookbook.

Blue Ridge Summit, PA, Tab Books, 1980.

AN535, Phase–Locked Loop Design Fundamentals, Motorola Semiconductor Products, Inc., 1970.

AR254, Phase–Locked Loop Design Articles, Motorola Semiconductor Products, Inc., Reprinted with permission from

Electronic Design,

1987.

for a typical design ωn (Natural Frequency)

≈

2πfr

10

(at phase detector input).

Figure 9. Phase–Locked Loop Low–Pass Filter Design

DESIGN CONSIDERA TIONS

CRYSTAL OSCILLATOR CONSIDERATIONS

The following options may be considered to provide a reference frequency to Motorola’s CMOS frequency synthesizers.

Use of a Hybrid Crystal Oscillator

Commercially available temperature–compensate crystal

oscillators (TCXOs) or crystal–controlled data clock oscillators provide very stable reference frequencies. An oscillator

capable of sinking and sourcing 50 µA at CMOS logic levels

may be direct or dc coupled to OSCin. In general, the highest

frequency capability is obtained utilizing a direct–coupled

square wave having a rail–to–rail (VDD to VSS) voltage

swing. If the oscillator does not have CMOS logic levels on

the outputs, capacitive or ac coupling to OSCin may be used.

OSC

out

, an unbuffered output, should be left floating.

For additional information about TCXOs and data clock

oscillators, please consult the latest version of the

eem Elec-

tronic Engineers Master Catalog,

the

Gold Book,

or similar

publications.

Design an Off–Chip Reference

The user may design an off–chip crystal oscillator using

ICs specifically developed for crystal oscillator applications,

such as the MC12061 MECL device. The reference signal

from the MECL device is ac coupled to OSCin. For large amplitude signals (standard CMOS logic levels), dc coupling is

used. OSC

out

, an unbuffered output, should be left floating.

In general, the highest frequency capability is obtained with a

direct–coupled square wave having rail–to–rail voltage

swing.

Use of the On–Chip Oscillator Circuitry

The on–chip amplifier (a digital inverter) along with an appropriate crystal may be used to provide a reference source

frequency. A fundamental mode crystal, parallel resonant at

Page 9

MC145149MOTOROLA

9

the desired operating frequency, should be connected as

shown in Figure 10.

For VDD= 5.0 V, the crystal should be specified for a loading capacitance, CL, which does not exceed 32 pF for frequencies to approximately 8 MHz, 20 pF for frequencies in

the area of 8 to 15 MHz, and 10 pF for higher frequencies.

These are guidelines that provide a reasonable compromise

between IC capacitance, drive capability, swamping variations in stray and IC input/output capacitance, and realistic

CL values. The shunt load capacitance, CL, presented

across the crystal can be estimated to be:

CL =

CinC

out

Cin + C

out

+ Ca + CO +

C1 • C2

C1 + C2

where

Cin= 5 pF (see Figure 11)

C

out

= 6 pF (see Figure 11)

Ca= 1 pF (see Figure 11)

CO= the crystal’s holder capacitance (see Figure 12)

C1 and C2 = external capacitors (see Figure 10)

The oscillator can be “trimmed” on–frequency by making a

portion or all of C1 variable. The crystal and associated components must be located as close as possible to the OSC

in

and OSC

out

pins to minimize distortion, stray capacitance,

stray inductance, and startup stabilization time. In some

cases, stray capacitance should be added to the value for C

in

and C

out

.

Power is dissipated in the effective series resistance of the

crystal, Re, in Figure 12. The drive level specified by the crystal manufacturer is the maximum stress that a crystal can

withstand without damaging or excessive shift in frequency.

R1 in Figure 10 limits the drive level. The use of R1 may not

be necessary in some cases (i.e., R1 = 0 Ω).

To verify that the maximum dc supply voltage does not

overdrive the crystal, monitor the output frequency as a function of voltage at OSC

out

. (Care should be taken to minimize

loading.) The frequency should increase very slightly as the

dc supply voltage is increased. An overdriven crystal will decrease in frequency or become unstable with an increase in

supply voltage. The operating supply voltage must be reduced or R1 must be increased in value if the overdriven

condition exists. The user should note that the oscillator

start–up time is proportional to the value of R1.

Through the process of supplying crystals for use with

CMOS inverters, many crystal manufacturers have developed expertise in CMOS oscillator design with crystals. Discussions with such manufacturers can prove very helpful

(see Table 1).

Figure 10. Pierce Crystal Oscillator Circuit

R1*

OSC

out

C2C1

R

f

FREQUENCY

SYNTHESIZER

*May be deleted in certain cases. See text.

OSC

in

Figure 11. Parasitic Capacitances of the Amplifier

C

in

C

out

C

a

NOTE: Values are supplied by crystal manufacturer

(parallel resonant crystal).

2

1

2

121

R

S

L

S

C

S

R

e

X

e

C

O

Figure 12. Equivalent Crystal Networks

RECOMMENDED READING

Technical Note TN–24, Statek Corp.

Technical Note TN–7, Statek Corp.

E. Hafner, “The Piezoelectric Crystal Unit – Definitions and

Method of Measurement”,

Proc. IEEE,

Vol. 57, No. 2 Feb.,

1969.

D. Kemper, L. Rosine, “Quartz Crystals for Frequency

Control”,

Electro–Technology

, June, 1969.

P. J. Ottowitz, “A Guide to Crystal Selection”,

Electronic

Design

, May, 1966.

Table 1. Partial List of Crystal Manufacturers

Name Address Phone

United States Crystal Corp.

Crystek Crystal

Statek Corp.

3605 McCart Ave., Ft. Worth, TX 76110

2351 Crystal Dr., Ft. Myers, FL 33907

512 N. Main St., Orange, CA 92668

(817) 921–3013

(813) 936–2109

(714) 639–7810

NOTE: Motorola cannot recommend one supplier over another and in no way suggests that this is a complete

listing of crystal manufacturers.

Page 10

MC145149 MOTOROLA

10

DUAL–MODULUS PRESCALING

OVERVIEW

The technique of dual–modulus prescaling is well established as a method of achieving high performance frequency

synthesizer operation at high frequencies. Basically, the

approach allows relatively low–frequency programmable

counters to be used as high–frequency programmable

counters with speed capability of several hundred MHz. This

is possible without the sacrifice in system resolution and performance that results if a fixed (single–modulus) divider is

used for the prescaler.

In dual–modulus prescaling, the lower speed counters

must be uniquely configured. Special control logic is necessary to select the divide value P or P + 1 in the prescaler

for the required amount of time (see modulus control definition). Motorola’s dual–modulus frequency synthesizers

contain this feature and can be used with a variety of dual–

modulus prescalers to allow speed, complexity, and cost to

be tailored to the system requirements. Prescalers having P,

P + 1 divide values in the range of ÷ 3/÷ 4 to ÷ 128/÷ 129 can

be controlled by most Motorola frequency synthesizers.

Several dual–modulus prescaler approaches suitable for

use with the MC145149 are:

MC12009

MC1201 1

MC12013

MC12015

MC12016

MC12017

MC12018

MC12022A

MC12032A

÷ 5/÷ 6

÷ 8/÷ 9

÷ 10/÷ 11

÷ 32/÷ 33

÷ 40/÷ 41

÷ 64/÷ 65

÷ 128/÷ 129

÷ 64/65 or ÷ 128/129

÷ 64/65 or ÷ 128/129

440 MHz

500 MHz

500 MHz

225 MHz

225 MHz

225 MHz

520 MHz

1.1 GHz

2.0 GHz

DESIGN GUIDELINES

The system total divide value, N

total

(NT) will be dictated by

the application, i.e.,

NT=

frequency into the prescaler

frequency into the phase detector

= N P + A

N is the number programmed into the ÷ N counter, A is the

number programmed into the ÷ A counter, P and P + 1 are

the two selectable divide ratios available in the dual–modulus prescalers. To have a range of NT values in sequence,

the ÷ A counter is programmed from 0 through P – 1 for a

particular value N in the ÷ N counter. N is then incremented

to N + 1 and the ÷ A is sequenced from 0 through P – 1

again.

There are minimum and maximum values that can be

achieved for NT. These values are a function of P and the

size of the ÷ N and ÷ A counters.

The constraint N ≥ A always applies. If A

max

= P – 1, then

N

min

≥ P – 1. Then N

Tmin

= (P – 1) P + A or (P – 1) P since A

is free to assume the value of 0.

N

Tmax

= N

max

P

+ A

max

To maximize system frequency capability, the dual–modulus prescaler output must go from low to high after each

group of P or P + 1 input cycles. The prescaler should divide

by P when its modulus control line is high and by P + 1 when

its modulus control is low.

For the maximum frequency into the prescaler (f

VCO

max),

the value used for P must be large enough such that:

1. f

VCO

max divided by P may not exceed the frequency

capability of fin (input to the ÷ N and ÷ A counters).

2. The period of f

VCO

divided by P must be greater than

the sum of the times:

a. Propagation delay through the dual–modulus

prescaler.

b. Prescaler setup or release time relative to its

modulus control signal.

c. Propagation time from fin to the modulus control

output for the frequency synthesizer device.

A sometimes useful simplification in the programming

code can be achieved by choosing the values for P of 8, 16,

32, or 64. For these cases, the desired value of NT results

when NT in binary is used as the program code to the ÷ N

and ÷ A counters treated in the following manner:

1. Assume the ÷ A counter contains “a” bits where 2a ≥ P.

2. Always program all higher order ÷ A counter bits above

“a” to 0.

3. Assume the ÷ N counter and the ÷ A counter (with all the

higher order bits above “a” ignored) combined into a

single binary counter of n + a bits in length (n = number

of divider stages in the ÷ N counter). The MSB of this “hypothetical” counter is to correspond to the MSB of ÷ N

and the LSB is to correspond to the LSB of ÷ A. The system divide value, NT, now results when the value of N

T

in binary is used to program the “new” n + a bit counter.

By using the two devices, several dual–modulus values

are achievable.

MC

DEVICE B

DEVICE A

DEVICE

B

MC12009 MC1201 1 MC12013DEVICE A

MC10131

MC10138

MC10154

÷

20/÷ 21

÷

50/÷ 51

÷

40/÷ 41

OR

÷

80/÷ 81

÷

64/÷ 65

OR

÷

128/÷ 129

÷

32/÷ 33

÷

80/÷ 81

÷

40/÷ 41

÷

100/÷ 101

÷

80/÷ 81

NOTE: MC12009, MC12011, and MC12013 are pin equivalent.

MC12015, MC12016, and MC12017 are pin equivalent.

Page 11

MC145149MOTOROLA

11

P ACKAGE DIMENSIONS

P SUFFIX

PLASTIC DIP

CASE 738–03

1.070

0.260

0.180

0.022

0.070

0.015

0.140

15°

0.040

1.010

0.240

0.150

0.015

0.050

0.008

0.110

0

°

0.020

25.66

6.10

3.81

0.39

1.27

0.21

2.80

0

°

0.51

27.17

6.60

4.57

0.55

1.77

0.38

3.55

15

°

1.01

0.050 BSC

0.100 BSC

0.300 BSC

1.27 BSC

2.54 BSC

7.62 BSC

MIN MINMAX MAX

INCHES MILLIMETERS

DIM

A

B

C

D

E

F

G

J

K

L

M

N

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEAD WHEN

FORMED PARALLEL.

4. DIMENSION B DOES NOT INCLUDE MOLD

FLASH.

-A-

C

K

N

E

GF

D

20 PL

J 20 PL

L

M

-T-

SEATING

PLANE

110

1120

0.25 (0.010) T A

M M

0.25 (0.010) T B

M M

B

D SUFFIX

SOG PACKAGE

CASE 751D–04

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.150

(0.006) PER SIDE.

5. DIMENSION D DOES NOT INCLUDE

DAMBAR PROTRUSION. ALLOWABLE

DAMBAR PROTRUSION SHALL BE 0.13

(0.005) TOTAL IN EXCESS OF D DIMENSION

AT MAXIMUM MATERIAL CONDITION.

–A–

–B–

20

1

11

10

S

A

M

0.010 (0.25) B

S

T

D20X

M

B

M

0.010 (0.25)

P10X

J

F

G

18X

K

C

–T–

SEATING

PLANE

M

R

X 45

_

DIM MIN MAX MIN MAX

INCHESMILLIMETERS

A 12.65 12.95 0.499 0.510

B 7.40 7.60 0.292 0.299

C 2.35 2.65 0.093 0.104

D 0.35 0.49 0.014 0.019

F 0.50 0.90 0.020 0.035

G 1.27 BSC 0.050 BSC

J 0.25 0.32 0.010 0.012

K 0.10 0.25 0.004 0.009

M 0 7 0 7

P 10.05 10.55 0.395 0.415

R 0.25 0.75 0.010 0.029

__

__

Page 12

MC145149 MOTOROLA

12

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit,

and specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters can and do vary in different

applications. All operating parameters, including “T ypicals” must be validated for each customer application by customer’s technical experts. Motorola does

not convey any license under its patent rights nor the rights of others. Motorola products are not designed, intended, or authorized for use as components in

systems intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of

the Motorola product could create a situation where personal injury or death may occur. Should Buyer purchase or use Motorola products for any such

unintended or unauthorized application, Buyer shall indemnify and hold Motorola and its officers, employees, subsidiaries, affiliates, and distributors harmless

against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that Motorola was negligent regarding the design or manufacture of the part.

Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal Opportunity/Affirmative Action Employer.

How to reach us:

USA/EUROPE: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, Toshikatsu Otsuki,

P.O. Box 20912; Phoenix, Arizona 85036. 1–800–441–2447 6F Seibu–Butsuryu–Center, 3–14–2 Tatsumi Koto–Ku, Tokyo 135, Japan. 03–3521–8315

MFAX: RMF AX0@email.sps.mot.com – T OUCHTONE (602) 244–6609 HONG KONG: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://Design–NET.com 51 Ting Kok Road, Tai Po, N.T., Hong Kong. 852–26629298

MC145149/D

*MC145149/D*

◊

Loading...

Loading...