Page 1

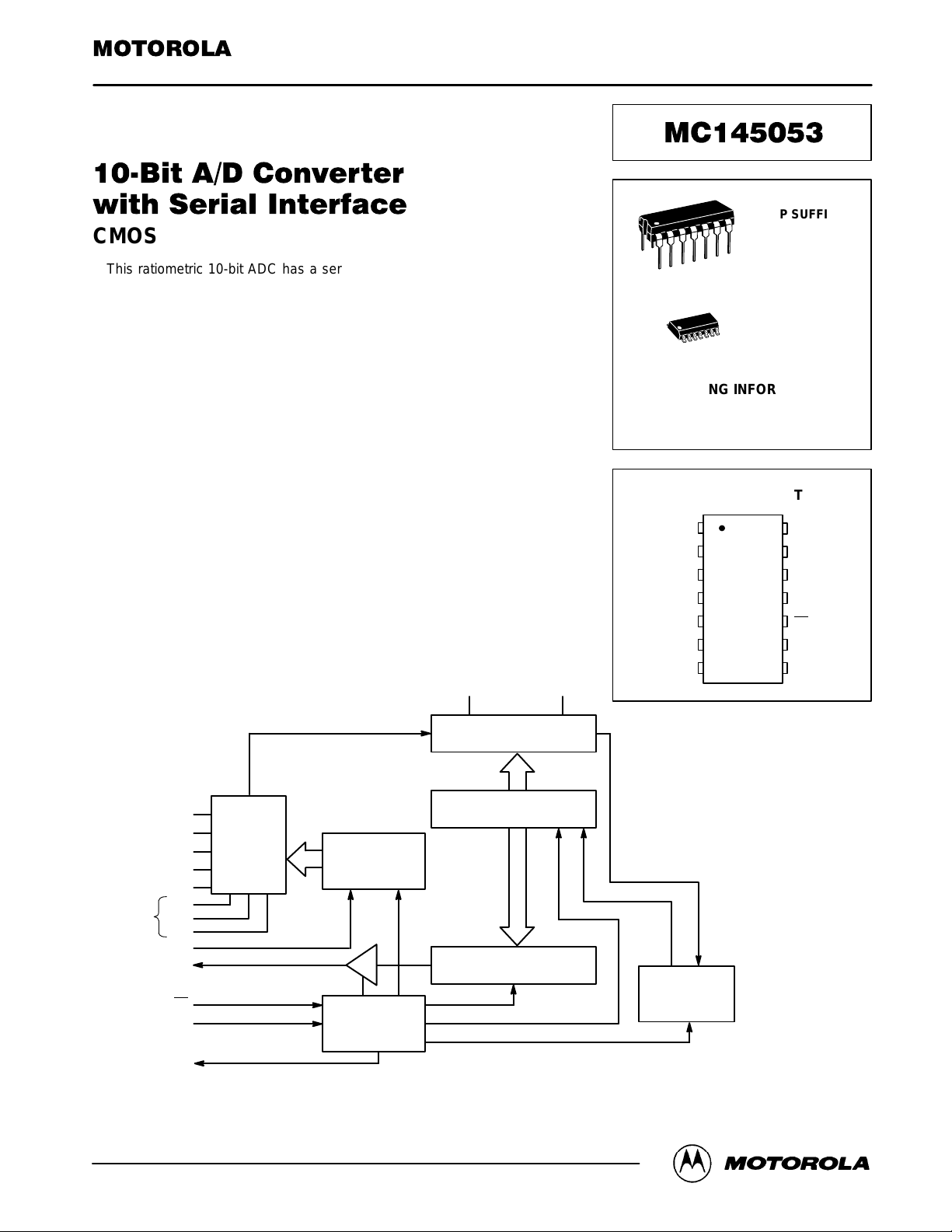

SEMICONDUCTOR TECHNICAL DATA

Order this document

by MC145053/D

CMOS

This ratiometric 10-bit ADC has a serial interface port to provide communi-

cation with MCUs and MPUs.

Either a 10- or 16-bit format can be used

16-bit format can be one continuous 16-bit stream or two intermittent 8-bit

streams. The converter operates from a single power supply with no external

trimming required. Reference voltages down to 4.0 V are accommodated.

The MC145053 has an internal clock oscillator to operate the dynamic A/D

conversion sequence and an end-of-conversion (EOC) output.

• 5 Analog Input Channels with Internal Sample-and-Hold

• Operating Temperature Range: – 40 to 125° C

• Successive Approximation Conversion Time: 44 µs Maximum

• Maximum Sample Rate: 20.4 ks/s

• Analog Input Range with 5-Volt Supply: 0 to 5 V

• Monotonic with No Missing Codes

• Direct Interface to Motorola SPI and National MICROWIRE Serial Data

Ports

• Digital Inputs/Outputs are TTL, NMOS, and CMOS Compatible

• Low Power Consumption: 14 mW

• Chip Complexity: 1630 Elements (FETs, Capacitors, etc.)

• See Application Note AN1062 for Operation with QSPI

BLOCK DIAGRAM

V

ref

98

MUX OUT

10-BIT RC DAC

WITH SAMPLE AND HOLD

. The

V

AG

P SUFFIX

PLASTIC

CASE 646

D SUFFIX

SOG

CASE 751A

ORDERING INFORMATION

MC145053P Plastic DIP

MC145053D SOG Package

PIN ASSIGNMENT

EOC

AN0

AN1

AN2

AN3

AN4

V

SS

1

2

3

4

6

7

14

13

12

11

105

V

DD

SCLK

D

in

D

out

CS

9

V

ref

V

8

AG

2

AN0

3

AN1

AN2

AN3

AN4

INTERNAL

TEST

VOLTAGES

MICROWIRE is a trademark of National Semiconductor Corp.

REV 2

1/99

MOTOROLA WIRELESS SEMICONDUCTOR

Motorola, Inc. 1998

SOLUTIONS DEVICE DA TA

AN5

AN6

AN7

D

in

D

out

CS

SCLK

EOC

4

5

6

12

11

10

13

ANALOG

MUX

1

MUX ADDRESS

REGISTER

DIGITAL CONTROL

LOGIC

SUCCESSIVE APPROXIMA TION

REGISTER

DATA REGISTER

PIN 14 = V

DD

PIN 7 = V

SS

AUTO-ZEROED

COMPARATOR

MC145053

1

Page 2

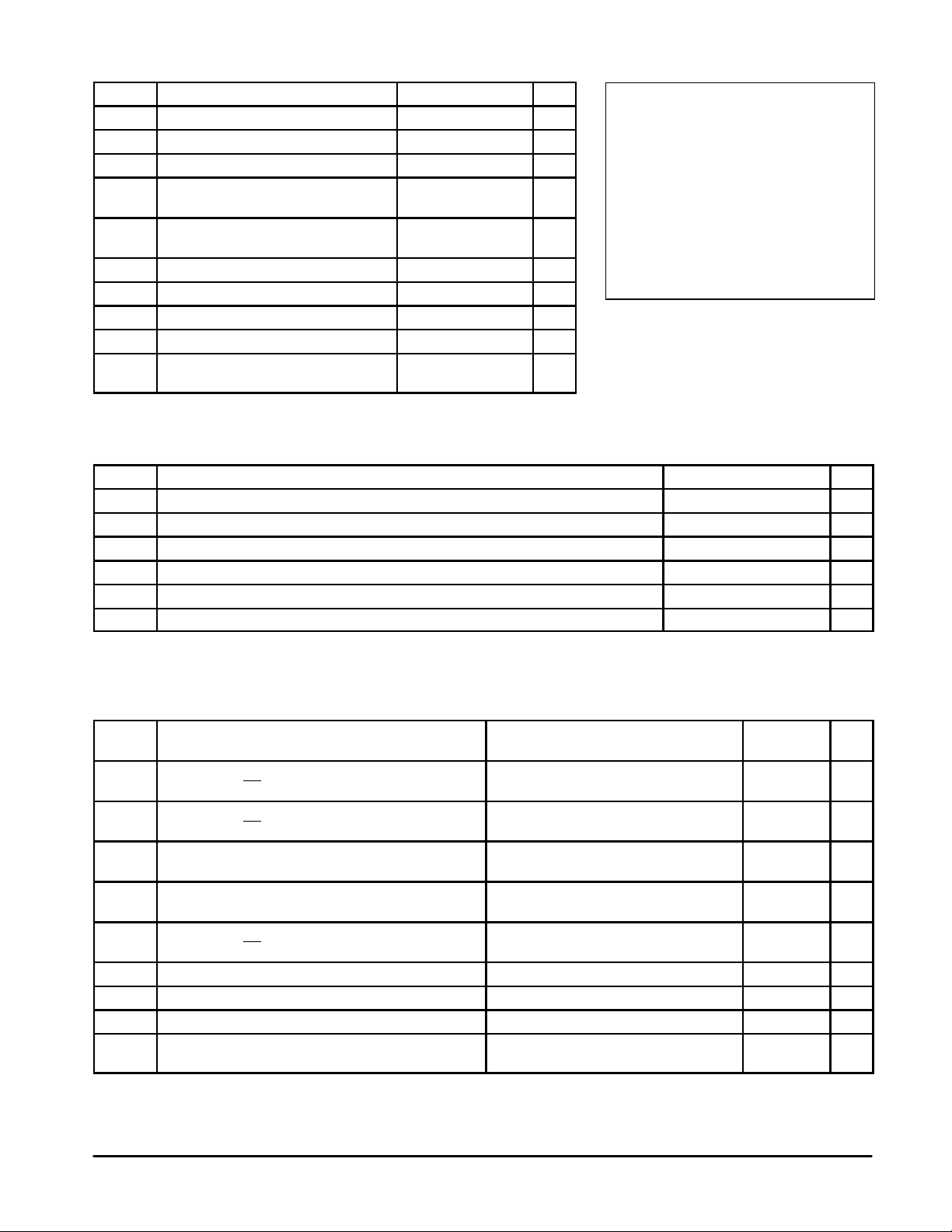

MAXIMUM RATINGS*

Symbol Parameter Value Unit

V

V

V

V

I

IDD, ISSDC Supply Current, VDD and VSS Pins ± 50 mA

T

*Maximum Ratings are those values beyond which damage to the device may occur. Func-

tional operation should be restricted to the Operation Ranges below..

DC Supply Voltage (Referenced to VSS) – 0.5 to + 6.0 V

DD

DC Reference Voltage VAG to VDD + 0.1 V

ref

Analog Ground VSS – 0.1 to V

AG

V

DC Input Voltage, Any Analog or Digital

in

Input

DC Output Voltage VSS – 0.5 to

out

I

DC Input Current, per Pin ± 20 mA

in

DC Output Current, per Pin ± 25 mA

out

Storage Temperature – 65 to 150 °C

stg

T

Lead Temperature, 1 mm from Case for

L

10 Seconds

VSS – 0.5 to

VDD + 0.5

VDD + 0.5

260 °C

ref

V

V

V

OPERATION RANGES (Applicable to Guaranteed Limits)

Symbol

V

V

V

Vin, V

NOTE: Analog input voltages greater than V

DC Supply Voltage, Referenced to V

DD

DC Reference Voltage VAG + 4.0 to VDD + 0.1 V

ref

Analog Ground VSS – 0.1 to V

AG

V

Analog Input Voltage (See Note) VAG to V

AI

Digital Input Voltage, Output Voltage VSS to V

out

T

Ambient Operating Temperature – 40 to 125 °C

A

descriptions.

Parameter Value Unit

SS

convert to full scale. Input voltages less than VAG convert to zero. See V

ref

This device contains protection circuitry to

guard against damage due to high static

voltages or electric fields. However, precautions must be taken to avoid applications

of any voltage higher than maximum rated

voltages to this high-impedance circuit. For

proper operation, Vin and V

constrained to the range VSS ≤ (Vin or V

VDD.

Unused inputs must always be tied to an

appropriate logic voltage level (e.g., either

VSS or VDD). Unused outputs must be left

open.

4.5 to 5.5 V

should be

out

– 4.0 V

ref

ref

DD

and VAG pin

ref

out

) ≤

V

V

DC ELECTRICAL CHARACTERISTICS

(Voltages Referenced to VSS, Full T emperature and Voltage Ranges per Operation Ranges T able, unless otherwise indicated)

Guaranteed

Symbol

V

IH

V

IL

V

OH

V

OL

I

in

I

OZ

I

DD

I

ref

I

Al

Parameter Test Condition

Minimum High-Level Input Voltage

(Din, SCLK, CS

Maximum Low-Level Input Voltage

(Din, SCLK, CS

Minimum High-Level Output Voltage

(D

, EOC)

out

Minimum Low-Level Output Voltage

(D

, EOC)

out

Maximum Input Leakage Current

(Din, SCLK, CS

Maximum Three-State Leakage Current (D

Maximum Power Supply Current Vin = VSS or VDD, All Outputs Open 2.5 mA

Maximum Static Analog Reference Current (V

Maximum Analog Mux Input Leakage Current between all

deselected inputs and any selected input (AN0 – AN4)

)

)

I

= – 1.6 mA

out

I

= – 20 µA

out

I

= + 1.6 mA

out

I

= + 20 µA

out

)

) V

out

) V

ref

Vin = VSS or V

= VSS or V

out

= VDD, VAG = V

ref

VAl = VSS to V

DD

DD

SS

DD

Limit

VDD – 0.1

Unit

2.0 V

0.8 V

2.4

0.4

0.1

± 2.5 µA

± 10 µA

100 µA

± 1 µA

V

V

MC145053

2

MOTOROLA WIRELESS SEMICONDUCTOR

SOLUTIONS DEVICE DA TA

Page 3

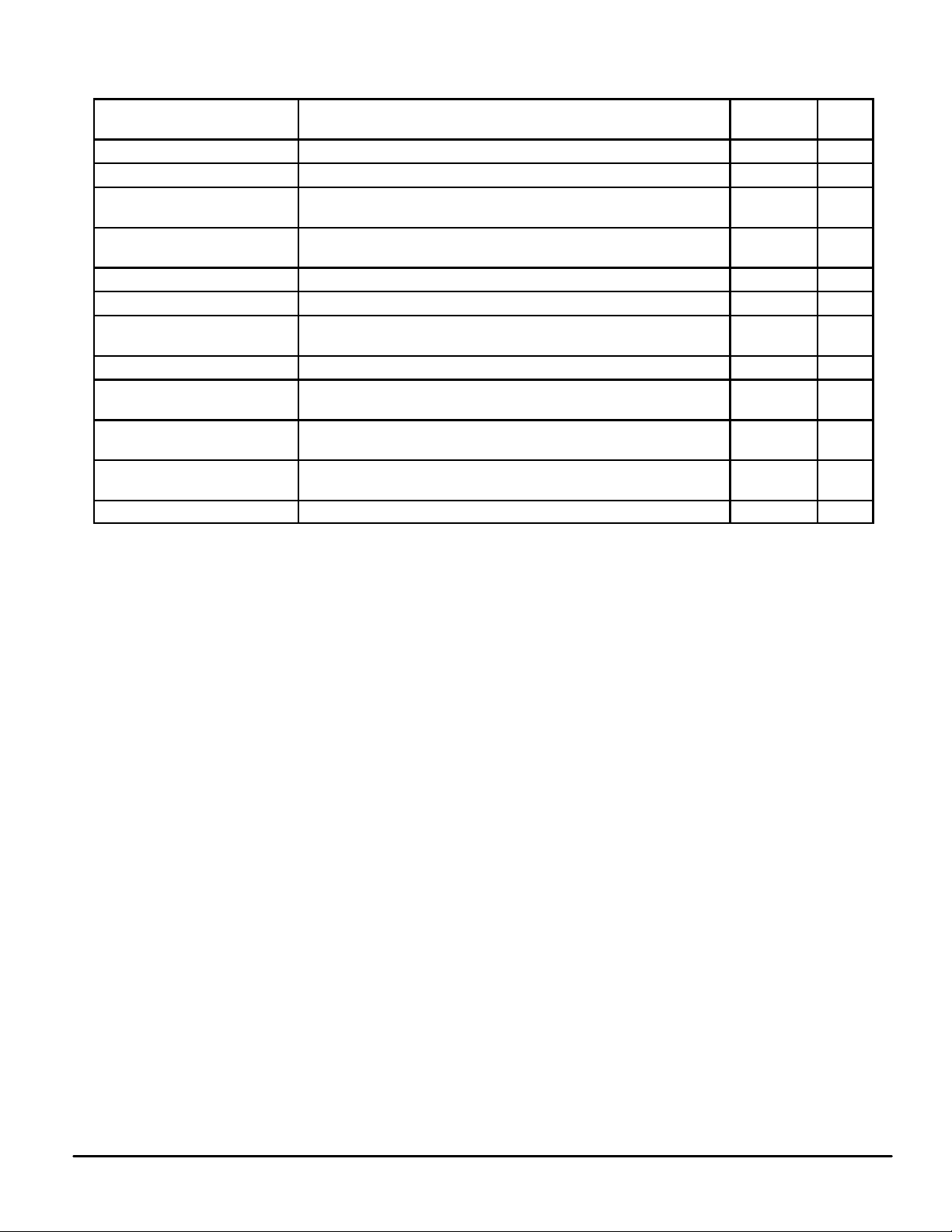

A/D CONVERTER ELECTRICAL CHARACTERISTICS

(Full Temperature and Voltage Ranges per Operation Ranges Table)

Guaranteed

Characteristic

Resolution Number of bits resolved by the A/D converter 10 Bits

Maximum Nonlinearity Maximum difference between an ideal and an actual ADC transfer function ± 1 LSB

Maximum Zero Error Difference between the maximum input voltage of an ideal and an actual

ADC for zero output code

Maximum Full-Scale Error Difference between the minimum input voltage of an ideal and an actual

ADC for full-scale output code

Maximum Total Unadjusted Error Maximum sum of nonlinearity, zero error, and full-scale error ± 1 LSB

Maximum Quantization Error Uncertainty due to converter resolution ± 1/2 LSB

Absolute Accuracy Difference between the actual input voltage and the full-scale weighted

equivalent of the binary output code, all error sources included

Maximum Conversion Time Total time to perform a single analog-to-digital conversion 44 µs

Data Transfer Time Total time to transfer digital serial data into and out of the device 10 to 16 SCLK

Sample Acquisition Time Analog input acquisition time window 6 SCLK

Minimum Total Cycle Time Total time to transfer serial data, sample the analog input, and perform the

conversion; SCLK = 2.1 MHz

Maximum Sample Rate Rate at which analog inputs may be sampled; SCLK = 2.1 MHz 20.4 ks/s

Definition and Test Conditions

Limit

± 1 LSB

± 1 LSB

± 1-1/2 LSB

49 µs

Unit

cycles

cycles

MOTOROLA WIRELESS SEMICONDUCTOR

SOLUTIONS DEVICE DA TA

MC145053

3

Page 4

AC ELECTRICAL CHARACTERISTICS

(Full Temperature and Voltage Ranges per Operation Ranges Table)

Figure

1 f Clock Frequency, SCLK (10-bit xfer) Min

1 t

1 t

1, 7 t

1, 7 t

2, 7 t

2, 7 t

3 t

3 t

4, 7, 8 t

5 t

— t

— t

5 t

6, 8 t

1 tr, t

1, 4, 6 – 8 t

— C

— C

NOTES:

1. After the 10th SCLK falling edge (≤ 2 V), at least 1 SCLK rising edge (≥ 2 V) must occur within 18.5 µs.

2. A CS

Symbol Parameter

Note: Refer to twH, twL below (10- to 16-bit xfer) Max)

wH

wL

, t

PLH

h

, t

PLZ

, t

PZL

su

h

d

su

CSd

CAs

h

PHL

, t

TLH

out

edge may be received immediately after an active transition on the EOC pin.

Minimum Clock High Time, SCLK 190 ns

Minimum Clock Low Time, SCLK 190 ns

Maximum Propagation Delay, SCLK to D

PHL

Minimum Hold Time, SCLK to D

Maximum Propagation Delay, CS to D

PHZ

Maximum Propagation Delay, CS to D

PZH

Minimum Setup Time, Din to SCLK 100 ns

Minimum Hold Time, SCLK to D

Maximum Delay Time, EOC to D

Minimum Setup Time, CS to SCLK 2.425 µs

Minimum Time Required Between 10th SCLK Falling Edge (≤ 0.8 V) and

CS

to Allow a Conversion

Maximum Delay Between 10th SCLK Falling Edge (≤ 2 V) and CS to

Abort a Conversion

Minimum Hold Time, Last SCLK to CS 0 ns

Maximum Propagation Delay, 10th SCLK to EOC 2.35 µs

Maximum Input Rise and Fall Times SCLK

f

Maximum Output Transition Time, Any Output 300 ns

THL

Maximum Input Capacitance AN0 – AN4

in

Maximum Three-State Output Capacitance D

out

in

out

High-Z 150 ns

out

Driven 2.3 µs

out

(MSB) 100 ns

out

(11- to 16-bit xfer) Min

Din, CS

SCLK, CS

, D

out

Guaranteed

Limit

0

Note 1

2.1

125 ns

10 ns

0 ns

Note 2

9 µs

1

10

55

in

15

15 pF

Unit

MHz

ms

µs

pF

MC145053

4

MOTOROLA WIRELESS SEMICONDUCTOR

SOLUTIONS DEVICE DA TA

Page 5

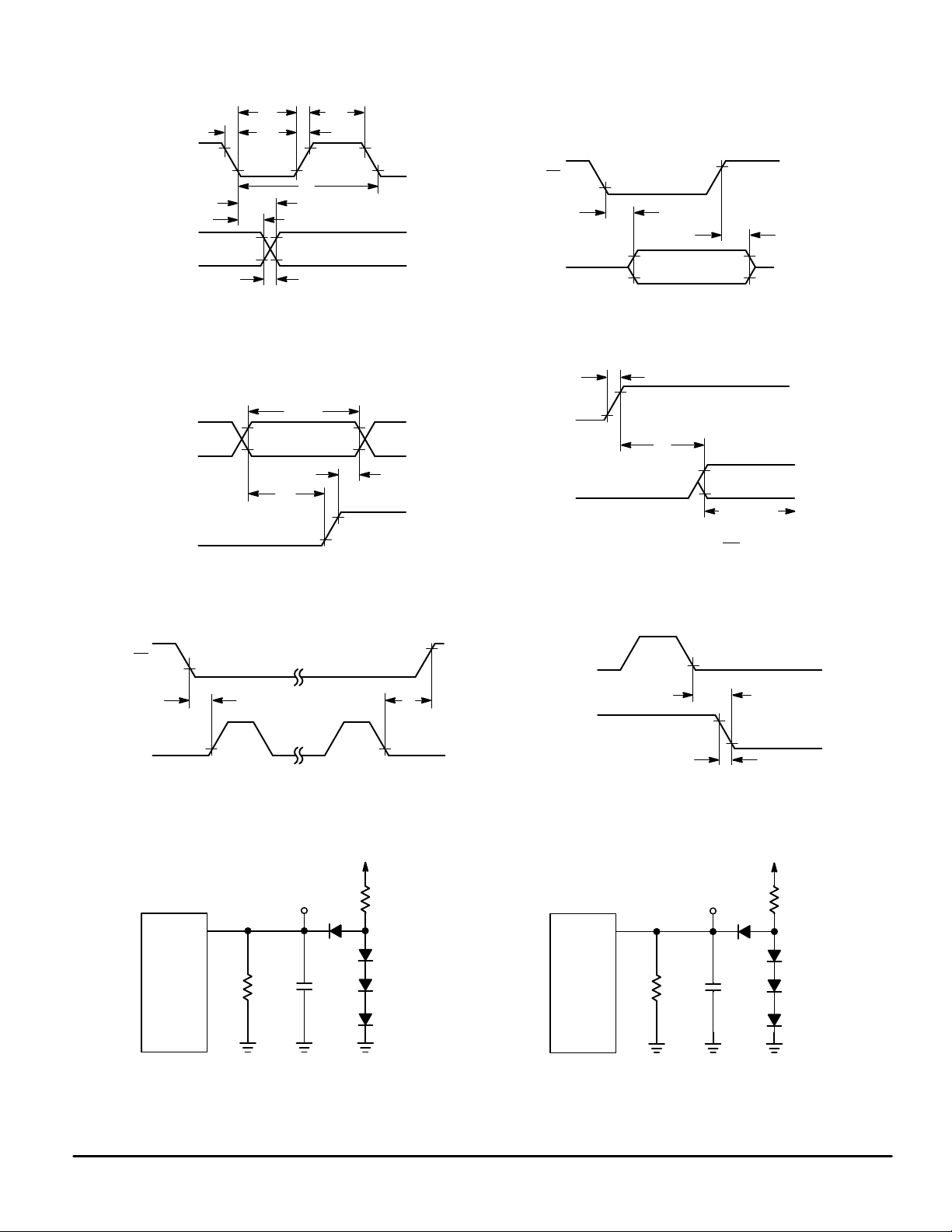

SWITCHING WAVEFORMS

SCLK

D

out

D

SCLK

in

t

f

2.0 V

t

h

t

wL

0.8 V

2.4 V

0.4 V

Figure 1.

VALID

2.0 V

0.8 V

t

su

1/f

t

PLH

t

TLH

, t

t

wH

PHL

, t

t

r

THL

0.8 V

2.0 V

PZL

2.0 V

90%

10%

t

PHZ

, t

PLZ

CS

D

out

0.8 V

2.4 V

0.4 V

t

PZH

, t

Figure 2.

t

TLH

EOC

0.4 V

t

h

D

out

NOTE: D

2.4 V

t

d

2.4 V

0.4 V

VALID MSB

is driven only when CS is active (low).

out

CS

SCLK

DEVICE

UNDER

TEST

0.8 V

D

Figure 3.

t

su

FIRST

CLOCK

Figure 5.

out

12 k 100 pF

TEST

POINT

LAST

CLOCK

V

DD

0.8 V0.8 V

2.18 k

2.0 V

t

h

SCLK

EOC

DEVICE

UNDER

TEST

10TH

CLOCK

EOC

Figure 4.

0.8 V

2.4 V

t

THL

Figure 6.

TEST

POINT

12 k 50 pF

t

0.4 V

PHL

V

DD

2.18 k

Figure 7. T est Circuit

MOTOROLA WIRELESS SEMICONDUCTOR

SOLUTIONS DEVICE DA TA

Figure 8. T est Circuit

MC145053

5

Page 6

PIN DESCRIPTIONS

DIGITAL INPUTS AND OUTPUT

The various serial bit-stream formats for the MC145053

are illustrated in the timing diagrams of Figures 9 through 14.

Table 1 assists in selection of the appropriate diagram. Note

that the ADC accepts 16 clocks which makes it SPI (Serial

Peripheral Interface) compatible.

T able 1. Timing Diagram Selection

No. of Clocks in

Serial Transfer

10 Yes Don’t Care 9

10 No Don’t Care 10

11 to 16 Yes Shorter than Conversion 11

16 No Shorter than Conversion 12

11 to 16 Yes Longer than Conversion 13

16 No Longer than Conversion 14

CS

Active-Low Chip Select Input (Pin 10)

Chip select initializes the chip to perform conversions and

provides 3-state control of the data output pin (D

inactive high, CS

and disables the data input (Din) and serial clock (SCLK)

pins. A high-to-low transition on CS

port and synchronizes it to the MPU data stream. CS

main active during the conversion cycle and can stay in the

active low state for multiple serial transfers or CS

active high after each transfer. If CS

tween transfers, the length of each transfer is limited to either

10 or 16 SCLK cycles. If CS

tween transfers, each transfer can be anywhere from 10 to

16 SCLK cycles long. See the SCLK pin description for a

more detailed discussion of these requirements.

Spurious chip selects caused by system noise are minimized by the internal circuitry. Any transitions on the CS

are recognized as valid only if the level is maintained for

about 2 µs after the transition.

If CS

is inactive high after the 10th SCLK cycle

and then goes active low before the A/D conversion is complete, the conversion is aborted and

the chip enters the initial state, ready for another

serial transfer/conversion sequence. At this point,

the output data register contains the result from

the conversion before the aborted conversion.

Note that the last step of the A/D conversion sequence is to update the output data register with

the result. Therefore, if CS

attempt to abort the conversion too close to the

end of the conversion sequence, the result register may be corrupted and the chip could be thrown

out of sync with the processor until CS

again (refer to the AC Electrical Characteristics in

the spec tables).

Using

CS

forces D

Serial Transfer

Interval

to the high-impedance state

out

out

Figure

No.

). While

resets the serial data

can re-

can be in-

is kept active low be-

is in the inactive high state be-

NOTE

goes active low in an

is toggled

pin

D

out

Serial Data Output of the A/D Conversion Result

(Pin 11)

This output is in the high-impedance state when CS

is in-

active high. When the chip recognizes a valid active low on

, D

CS

is taken out of the high-impedance state and is driv-

out

en with the MSB of the previous conversion result. (For the

first transfer after power-up, data on D

entire transfer.) The value on D

out

is undefined for the

out

changes to the second

most significant result bit upon the first falling edge of SCLK.

The remaining result bits are shifted out in order, with the

LSB appearing on D

upon the ninth falling edge of SCLK.

out

Note that the order of the transfer is MSB to LSB. Upon the

10th falling edge of SCLK, D

allowed by CS

) so that transfers of more than 10 SCLKs read

is immediately driven low (if

out

zeroes as the unused LSBs.

When CS

is held active low between transfers, D

out

is driven from a low level to the MSB of the conversion result for

three cases: Case 1 — upon the 16th SCLK falling edge if

the transfer is longer than the conversion time (Figure 14);

Case 2 — upon completion of a conversion for a 16-bit transfer interval shorter than the conversion (Figure 12); Case 3

— upon completion of a conversion for a 10-bit transfer (Figure 10).

D

in

Serial Data Input (Pin 12)

The four-bit serial input stream begins with the MSB of the

analog mux address (or the user test mode) that is to be converted next. The address is shifted in on the first four rising

edges of SCLK. After the four mux address bits have been

received, the data on Din is ignored for the remainder of the

present serial transfer. See Table 2 in Applications In-

formation.

SCLK

Serial Data Clock (Pin 13)

This clock input drives the internal I/O state machine to

perform three major functions: (1) drives the data shift registers to simultaneously shift in the next mux address from the

Din pin and shift out the previous conversion result on the

D

pin, (2) begins sampling the analog voltage onto the RC

out

DAC as soon as the new mux address is available, and (3)

transfers control to the A/D conversion state machine after

the last bit of the previous conversion result has been shifted

out on the D

out

pin.

The serial data shift registers are completely static, allowing SCLK rates down to the dc. There are some cases, however, that require a minimum SCLK frequency as discussed

later in this section. At least ten SCLK cycles are required for

each simultaneous data transfer. If the 16-bit format is used,

SCLK can be one continuous 16-bit stream or two intermittent 8-bit streams. After the serial port has been initiated to

perform a serial transfer*, the new mux address is shifted in

*The serial port can be initiated in three ways: (1) a recognized CS

falling edge, (2) the end of an A/D conversion if the port is performing either a 10-bit or a 16-bit “shorter-than-conversion” transfer

with CS

active low between transfers, and (3) the 16th falling edge

of SCLK if the port is performing 16-bit “longer-than-conversion”

transfers with CS

active low between transfers.

MC145053

6

MOTOROLA WIRELESS SEMICONDUCTOR

SOLUTIONS DEVICE DA TA

Page 7

on the first four rising edges of SCLK, and the previous 10-bit

conversion result is shifted out on the first nine falling edges

of SCLK. After the fourth rising edge of SCLK, the new mux

address is available; therefore, on the next edge of SCLK

(the fourth falling edge), the analog input voltage on the

selected mux input begins charging the RC DAC and continues to do so until the tenth falling edge of SCLK. After this

tenth SCLK edge, the analog input voltage is disabled from

the RC DAC and the RC DAC begins the “hold” portion of the

A/D conversion sequence. Also upon this tenth SCLK edge,

control of the internal circuitry is transferred to the internal

clock oscillator which drives the successive approximation

logic to complete the conversion. If 16 SCLK cycles are used

during each transfer, then there is a constraint on the minimum SCLK frequency. Specifically, there must be at least

one rising edge on SCLK before the A/D conversion is complete. If the SCLK frequency is too low and a rising edge

does not occur during the conversion, the chip is thrown out

of sync with the processor and CS

der to restore proper operation. If 10 SCLKs are used per

transfer, then there is no lower frequency limit on SCLK. Also

note that if the ADC is operated such that CS

between transfers, then the number of SCLK cycles per

transfer can be anything between 10 and 16 cycles, but the

“rising edge” constraint is still in effect if more than 10 SCLKs

are used. (If CS

number of SCLK cycles must be either 10 or 16.)

EOC

End-of-Conversion Output (Pin 1)

EOC goes low on the tenth falling edge of SCLK. A low-tohigh transition on EOC occurs when the A/D conversion is

complete and the data is ready for transfer.

stays active low for multiple transfers, the

needs to be toggled in or-

is inactive high

and leakage currents through the ESD protection diodes on

the selected channel occur. These leakage currents cause

an offset voltage to appear across any series source resistance on the selected channel. Therefore, any source resistance greater than 1 kΩ (Motorola test condition) may induce

errors in excess of guaranteed specifications.

There are three tests available that verify the functionality

of all the control logic as well as the successive approximation comparator. These tests are performed by addressing

$B, $C, or $D and they convert a voltage of (V

VAG, or V

ly by sampling V

the RC DAC during the sample phase. Addressing $B, $C, or

$D produces an output of $200 (half scale), $000, or $3FF

(full scale), respectively, if the converter is functioning properly. However, deviation from these values occurs in the

presence of sufficient system noise (external to the chip) on

VDD, VSS, V

POWER AND REFERENCE PINS

VSS and V

Device Supply Pins (Pins 7 and 14)

VSS is normally connected to digital ground; VDD is connected to a positive digital supply voltage. Low frequency

(VDD – VSS) variations over the range of 4.5 to 5.5 volts do

not affect the A/D accuracy. (See the Operations Ranges

Table for restrictions on V

VSS.) Excessive inductance in the VDD or VSS lines, as on

automatic test equipment, may cause A/D offsets > ± 1 LSB.

Use of a 0.1 µF bypass capacitor across these pins is recommended.

, respectively. The voltages are obtained internal-

ref

DD

or VAG onto the appropriate elements of

ref

, or VAG.

ref

and VAG relative to VDD and

ref

+ VAG)/2,

ref

ANALOG INPUTS AND TEST MODES

AN0 through AN4

Analog Multiplexer Inputs (Pins 2 – 6)

The input AN0 is addressed by loading $0 into the mux

address register. AN1 is addressed by $1, AN2 by $2, AN3

by $3, and AN4 by $4. Table 2 shows the input format for a

16-bit stream. The mux features a break-before-make

switching structure to minimize noise injection into the analog inputs. The source resistance driving these inputs must

be v 1 kΩ.

During normal operation, leakage currents through the

analog mux from unselected channels to a selected channel

VAG and V

Analog Reference V oltage Pins (Pins 8 and 9)

Analog reference voltage pins which determine the lower

and upper boundary of the A/D conversion. Analog input voltages ≥ V

≤ VAG produce an output of zero. CAUTION: The analog

input voltage must be ≥ VSS and ≤ VDD. The A/D conversion

result is ratiometric to V

noise-free as possible to avoid degradation of the A/D

conversion. Ideally , V

nected to the voltage supply driving the system’s transducers. Use of a 0.22 µF bypass capacitor across these pins is

strongly urged.

ref

produce a full scale output and input voltages

ref

– VAG. V

ref

and VAG should be single-point con-

ref

and VAG must be as

ref

MOTOROLA WIRELESS SEMICONDUCTOR

SOLUTIONS DEVICE DA TA

MC145053

7

Page 8

CS

D

out

SCLK

D

in

EOC

CS

D9 – MSB

MSB

D8 D7 D6 D5 D4 D3 D2 D1 D0 D9

12345678910 1

SAMPLE ANALOG INPUT

A3 A2 A1 A0

SHIFT IN NEW MUX ADDRESS,

SIMULTANEOUSLY SHIFT OUT PREVIOUS CONVERSION VALUE

HIGH IMPEDANCE

A/D CONVERSION

INTERV AL

RE-INITIALIZEINITIALIZE

Figure 9. Timing for 10-Clock Transfer Using CS

MUST BE HIGH ON POWER UP

A3

D

SCLK

EOC

D9 – MSB D8 D7 D6 D5 D4 D3 D2 D1 D0 D9

out

12345678910 1

SAMPLE ANALOG INPUT

D

in

INITIALIZE

A3 A2 A1 A0 A3

MSB

SHIFT IN NEW MUX ADDRESS,

SIMULTANEOUSLY SHIFT OUT PREVIOUS CONVERSION VALUE

Figure 10. Timing for 10-Clock Transfer Not Using CS

NOTES:

1. D9, D8, D7, D6, D5, …, D0 = the result of the previous A/D conversion.

2. A3, A2, A1, A0 = the mux address for the next A/D conversion.

LOW LEVEL

A/D CONVERSION

INTERV AL

MC145053

8

MOTOROLA WIRELESS SEMICONDUCTOR

SOLUTIONS DEVICE DA TA

Page 9

D9

HIGH

IMPEDANCE

LOW

LEVEL

1

D9

1

A3

RE-INITIALIZE

INTERV AL

A/D CONVERSION

LOW LEVEL

12 13 14 15

A3A3 A2 A1 A0

A/D CONVERSION INTERV AL

CS

D8 D7 D6 D5 D4 D3 D2 D1 D0

D9 – MSB

out

D

SAMPLE ANALOG INPUT

123456789101116

SCLK

SHIFT IN NEW MUX ADDRESS,

SIMULTANEOUSLY SHIFT OUT PREVIOUS CONVERSION VALUE

A3 A2 A1 A0

Figure 11. T iming for 11- to 16-Clock Transfer Using CS* (Serial Transfer Interval Shorter than Conversion)

in

D

EOC

INITIALIZE

MUST BE HIGH ON POWER UP

D9 – MSB D8 D7 D6 D5 D4 D3 D2 D1 D0

CS

D

out

SAMPLE ANALOG INPUT

1234567891011 16

SCLK

SHIFT IN NEW MUX ADDRESS,

SIMULTANEOUSLY SHIFT OUT PREVIOUS CONVERSION VALUE

MSB

in

D

EOC

Figure 12. Timing for 16-Clock Transfer Not Using CS* (Serial Transfer Interval Shorter Than Conversion)

INITIALIZE

D9, D8, D7, . . . , D0 = the result of the previous A/D conversion.

A3, A2, A1, A0 = the mux address for the next A/D conversion.

NOTES:

*This figure illustrates the behavior of the MC145051. The MC145050 behaves identically except there is no EOC signal and the conversion time is 44 ADCLK cycles (user-controlled time).

MOTOROLA WIRELESS SEMICONDUCTOR

SOLUTIONS DEVICE DA TA

MC145053

9

Page 10

D9

HIGH

IMPEDANCE

LOW

LEVEL

1

D9

1

2

NOTE

A3

RE-INITIALIZE

A/D

INTERVAL

CONVERSION

LOW LEVEL

A3

NOTE 2

CS

D8 D7 D6 D5 D4 D3 D2 D1 D0

D9 – MSB

out

D

SAMPLE ANALOG INPUT

123456789101116

SCLK

12 13 14 15

SHIFT IN NEW MUX ADDRESS,

SIMULTANEOUSLY SHIFT OUT PREVIOUS CONVERSION VALUE

A3 A2 A1 A0

Figure 13. Timing for 1 1- to 16-Clock Transfer Using CS* (Serial Transfer Interval Longer Than Conversion)

in

D

EOC

INITIALIZE

MUST BE HIGH ON POWER UP

D8 D7 D6 D5 D4 D3 D2 D1 D0

D9 – MSB

SAMPLE ANALOG INPUT

1234567891011 16

A3 A2 A1 A0

MSB

INTERV AL

A/D CONVERSION

SHIFT IN NEW MUX ADDRESS,

Figure 14. Timing for 16-Clock T ransfer Not Using CS* (Serial Transfer Interval Longer Than Conversion)

SIMULTANEOUSLY SHIFT OUT PREVIOUS CONVERSION VALUE

MC145053

10

CS

D

out

SCLK

in

D

EOC

INITIALIZE

MOTOROLA WIRELESS SEMICONDUCTOR

SOLUTIONS DEVICE DA TA

D9, D8, D7, . . . , D0 = the result of the previous A/D conversion.

A3, A2, A1, A0 = the mux address for the next A/D conversion.

NOTES:

1. This figure illustrates the behavior of the MC145051. The MC145050 behaves identically except there is no EOC signal and the conversion time is 44 ADCLK cycles (user-controlled time).

2. The 11th SCLK rising edge must occur before the conversion is complete. Otherwise the serial port is thrown out of sync with the microprocessor for the remainder of the transfer.

*NOTES:

Page 11

APPLICATIONS INFORMATION

DESCRIPTION

This example application of the MC145053 ADC interfaces

four analog signals to a microprocessor.

Figure 15 illustrates how the MC145053 is used as a costeffective means to simplify this type of circuit design. Utilizing

one ADC, four analog inputs are interfaced to a CMOS or

NMOS microprocessor with a serial peripheral interface

(SPI) port. Processors with National Semiconductor’s

MICROWIRE serial port may also be used. Full duplex

operation optimizes throughput for this system.

DIGITAL DESIGN CONSIDERATIONS

Motorola’s MC68HC05C4 CMOS MCU may be chosen to

reduce power supply size and cost. The NMOS MCUs may

be used if power consumption is not critical. A VDD or V

0.1 µF bypass capacitor should be closely mounted to the

ADC.

The MC145053 has the end-of-conversion (EOC) signal at

output pin 1 to define when data is ready.

ANALOG DESIGN CONSIDERATIONS

Analog signal sources with output impedances of less than

1 kΩ may be directly interfaced to the ADC, eliminating the

need for buffer amplifiers. Separate lines connect the V

and VAG pins on the ADC with the controllers to provide

isolation from system noise.

Although not indicated in Figure 15, the V

output lines may need to be shielded, depending on their

length and electrical environment. This should be verified

during prototyping with an oscilloscope. If shielding is

required, a twisted pair or foil-shielded wire (not coax) is

appropriate for this low frequency application. One wire of

the pair or the shield must be VAG.

and sensor

ref

SS

ref

A reference circuit voltage of 5 volts is used for the application shown in Figure 15. However, the reference circuitry

may be simplified by tying VAG to system ground and V

the system’s positive supply. (See Figure 16.)

A bypass capacitor of approximately 0.22 µF across the

V

and VAG pins is recommended. These pins are adjacent

ref

on the ADC package which facilitates mounting the capacitor

very close to the ADC.

SOFTWARE CONSIDERATIONS

The software flow for acquisition is straightforward. The

four analog inputs, AN0 through AN3, are scanned by reading the analog value of the previously addressed channel

into the MCU and sending the address of the next channel to

be read to the ADC, simultaneously .

The designer utilizing the MC145053 has the end-of-conversion signal (at pin 1) to define the conversion interval.

EOC may be used to generate an interrupt, which is serviced

by reading the serial data from the ADC. The software flow

should then process and format the data.

When this ADC is used with a 16-bit (2-byte) transfer, there

are two types of offsets involved. In the first type of offset, the

channel information sent to the ADCs is offset by 12 bits.

That is, in the 16-bit stream, only the first 4 bits (4 MSBs)

contain the channel information. The balance of the bits are

don’t cares. This results in 3 don’t-care nibbles, as shown in

Table 2. The second type of offset is in the conversion result

returned from the ADC; this is offset by 6 bits. In the 16-bit

stream, the first 10 bits (10 MSBs) contain the conversion

result. The last 6 bits are zeroes. The hexadecimal result is

shown in the first column of Table 3. The second column

shows the result after the offset is removed by a microprocessor routine. If the 16-bit format is used, the ADC can

transfer one continuous 16-bit stream or two intermittent 8-bit

streams.

ref

to

MOTOROLA WIRELESS SEMICONDUCTOR

SOLUTIONS DEVICE DA TA

MC145053

11

Page 12

Table 2. Programmer’s Guide for 16-Bit Transfers:

Input Code

Table 3. Programmer’s Guide for 16-Bit Transfers:

Output Code

Input

Address

in Hex

$0XXX

$1XXX

$2XXX

$3XXX

$4XXX

$5XXX

$6XXX

$7XXX

$8XXX

$9XXX

$AXXX

$BXXX

$CXXX

$DXXX

$EXXX

$FXXX

Channel to be

Converted Next

AN0

AN1

AN2

AN3

AN4

None

None

None

None

None

None

AN5

AN6

AN7

None

None

Comment

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Not Allowed

Not Allowed

Not Allowed

Not Allowed

Not Allowed

Not Allowed

Half Scale Test: Output = $8000

Zero Test: Output = $0000

Full Scale Test: Output = $FFC0

Not Allowed

Not Allowed

0.22 µF

ANALOG

SENSORS,

ETC.

Conversion

Result Without

Offset Removed

V

ref

AN0

AN1

MC145053

ADC

AN2

AN3

$0000

$0040

$0080

$00C0

$0100

$0140

$0180

$01C0

$0200

$0240

$0280

$02C0

L

$FF40

$FF80

$FFC0

+ 5 V

V

DD

Conversion

Result With

Offset Removed

$0000

$0001

$0002

$0003

$0004

$0005

$0006

$0007

$0008

$0009

$000A

$000B

$03FD

$03FE

$03FF

0.1

µ

F

CS

D

in

SCLK

D

out

EOC

Value

Zero

Zero + 1 LSB

Zero + 2 LSBs

Zero + 3 LSBs

Zero + 4 LSBs

Zero + 5 LSBs

Zero + 6 LSBs

Zero + 7 LSBs

Zero + 8 LSBs

Zero + 9 LSBs

Zero + 10 LSBs

L

Zero + 11 LSBs

L

Full Scale – 2 LSBs

Full Scale – 1 LSB

Full Scale

µ

P

SPI PORT

5 VOLT

REFERENCE

CIRCUIT

AN4

V

AG

Figure 15. Example Application

V

SS

MC145053

12

MOTOROLA WIRELESS SEMICONDUCTOR

SOLUTIONS DEVICE DA TA

Page 13

DIGITAL + V

Instruction

SPI

Device

ANALOG + V

DO NOT CONNECT

AT IC

V

ref

V

DD

5 V

SUPPLY

TO

SENSORS,

ETC.

ANALOG GND

DIGITAL GND

V

AG

MC145053

V

SS

DO NOT CONNECT

AT IC

0.1 µF0.22 µF

Figure 16. Alternate Configuration Using the Digital Supply for the Reference Voltage

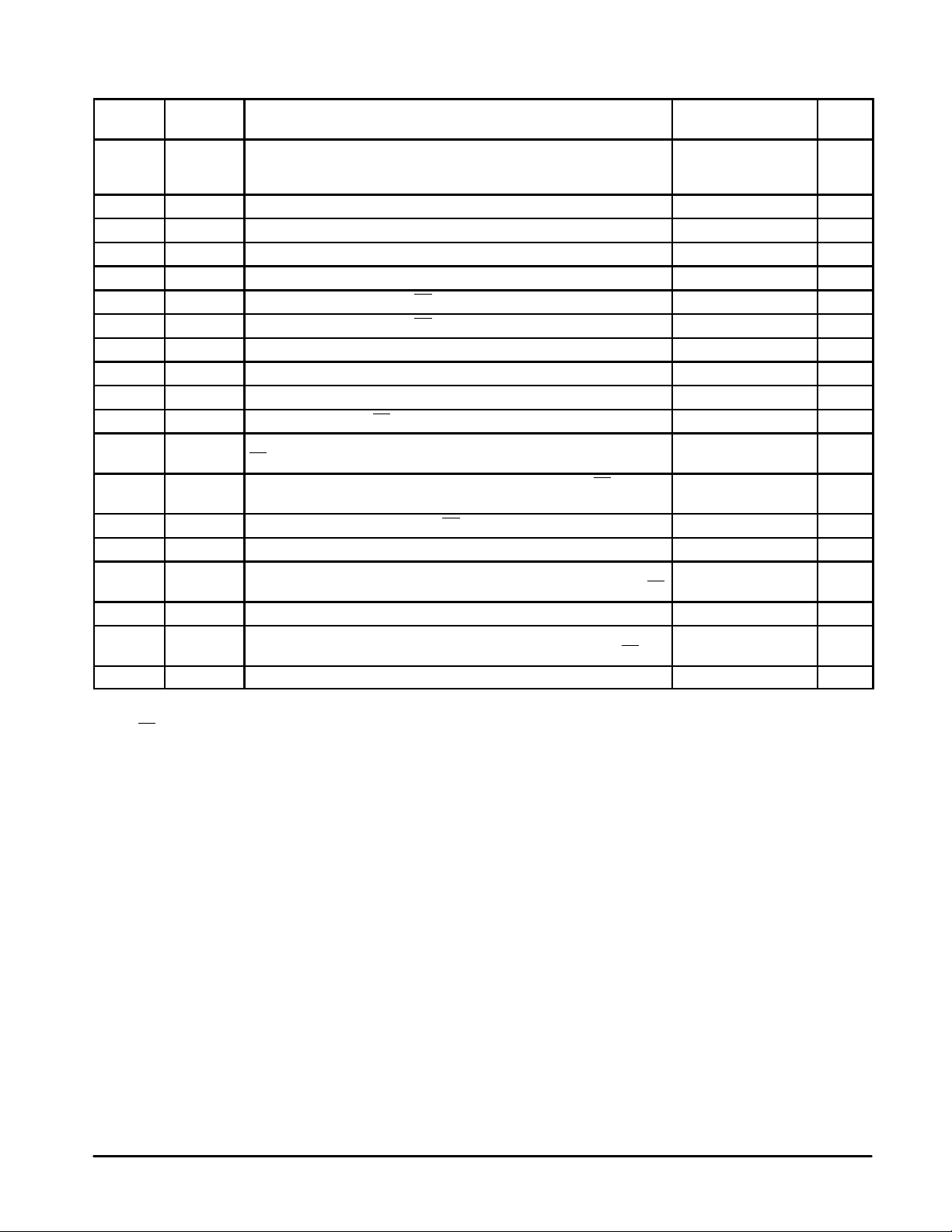

Compatible Motorola MCUs/MPUs

This is not a complete listing of Motorola’s MCUs/MPUs.

Contact your Motorola representative if you need

Instruction

Set

M6805 2096

M68000 — — — MC68HC000

SPI = Serial Peripheral Interface.

SCI = Serial Communication Interface.

High Speed.

Low Power.

additional information.

Memory (Bytes)

ROM EEPROM

2096

4160

4160

8K

4160

8K

7700

—

—

—

—

—

—

—

—

—

4160

SPI

SCI

Yes

Yes

Yes

Yes

Yes

Yes

Yes

—

—

Device

Number

MC68HC05C2

MC68HC05C3

MC68HC05C4

MC68HSC05C4

MC68HSC05C8

MC68HCL05C4

MC68HCL05C8

MC68HC05C8

MC68HC805C4

MOTOROLA WIRELESS SEMICONDUCTOR

SOLUTIONS DEVICE DA TA

MC145053

13

Page 14

P ACKAGE DIMENSIONS

14 8

B

17

A

F

C

N

SEATING

HG D

PLANE

K

PLASTIC DIP

P SUFFIX

CASE 646-06

L

J

M

NOTES:

1. LEADS WITHIN 0.13 (0.005) RADIUS OF TRUE POSITION

AT SEATING PLANE AT MAXIMUM MATERIAL

CONDITION.

2. DIMENSION L TO CENTER OF LEADS WHEN FORMED

PARALLEL.

3. DIMENSION B DOES NOT INCLUDE MOLD FLASH.

4. ROUNDED CORNERS OPTIONAL.

INCHES MILLIMETERS

MIN MINMAX MAX

DIM

A

B

C

D

F

G

H

J

K

L

M

N

0.715

0.240

0.145

0.015

0.040

0.100 BSC

0.052

0.008

0.115

0.300 BSC

°

0

0.015

0.770

0.260

0.185

0.021

0.070

0.095

0.015

0.135

10

0.039

°

18.16

6.10

3.69

0.38

1.02

2.54 BSC

1.32

0.20

2.92

7.62 BSC

0°

0.39

19.56

6.60

4.69

0.53

1.78

2.41

0.38

3.43

10

1.01

°

MC145053

14

MOTOROLA WIRELESS SEMICONDUCTOR

SOLUTIONS DEVICE DA TA

Page 15

SEATING

PLANE

SOG PACKAGE

D SUFFIX

CASE 751A-03

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

-A-

814

-B- P 7 PL

M M

1

G

D 14 PL

0.25 (0.010)

7

M

K

T

C

S S

BA

R

X 45°

B0.25 (0.010)

F

M

J

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006) PER

SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL IN

EXCESS OF THE D DIMENSION AT MAXIMUM

MATERIAL CONDITION.

MILLIMETERS INCHES

MIN MINMAX MAX

DIM

A

8.55

B

3.80

C

1.35

D

0.35

F

0.40

1.27 BSC 0.050 BSC

G

J

0.19

K

0.10

M

0

°

P

5.80

R

0.25

8.75

4.00

1.75

0.49

1.25

0.25

0.25

7

6.20

0.50

°

0.337

0.150

0.054

0.014

0.016

0.008

0.004

0

0.228

0.010

0.344

0.157

0.068

0.019

0.049

0.009

0.009

7

°

°

0.244

0.019

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty, representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

Mfax is a trademark of Motorola, Inc.

How to reach us:

USA/EUROPE/Locations Not Listed: Motorola Literature Distribution; JAPAN: Motorola Japan Ltd.; SPD, Strategic Planning Office, 141,

P.O. Box 5405, Denver, Colorado 80217. 1–303–675–2140 or 1–800–441–2447 4–32–1 Nishi–Gotanda, Shinagawa–ku, Tokyo, Japan. 81–3–5487–8488

Customer Focus Center: 1–800–521–6274

Mfax: RMFAX0@email.sps.mot.com – TOUCHTONE 1–602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

Moto rola Fax Back Sys tem – US & Canada ONLY 1–800–774–1848 51 T ing Kok Road, Tai Po, N.T., Hong Kong. 852–26629298

– http://sps.motorola.com/mfax/

HOME PAGE: http://motorola.com/sps/

MOTOROLA WIRELESS SEMICONDUCTOR

◊

MC145053

MC145053/D

SOLUTIONS DEVICE DA TA

15

Loading...

Loading...