Page 1

SEMICONDUCTOR TECHNICAL DATA

1

REV 1

Motorola, Inc. 1997

2/97

The MC12430 is a general purpose synthesized clock source targeting

applications that require both serial and parallel interfaces. Its internal

VCO will operate over a range of frequencies from 400 to 800MHz. The

differential PECL output can be configured to be the VCO frequency

divided by 1, 2, 4 or 8. With the output configured to divide the VCO

frequency by 2, and with a 16.000MHz external quartz crystal used to

provide the reference frequency, the output frequency can be specified in

1MHz steps. The PLL loop filter is fully integrated so that no external

components are required.

• 50 to 800MHz Differential PECL Outputs

• ±25ps Peak–to–Peak Output Jitter

• Fully Integrated Phase–Locked Loop

• Minimal Frequency Over–Shoot

• Synthesized Architecture

• Serial 3–Wire Interface

• Parallel Interface for Power–Up

• Quartz Crystal Interface

• 28–Lead PLCC Package

• Operates from 3.3V or 5.0V Power Supply

Functional Description

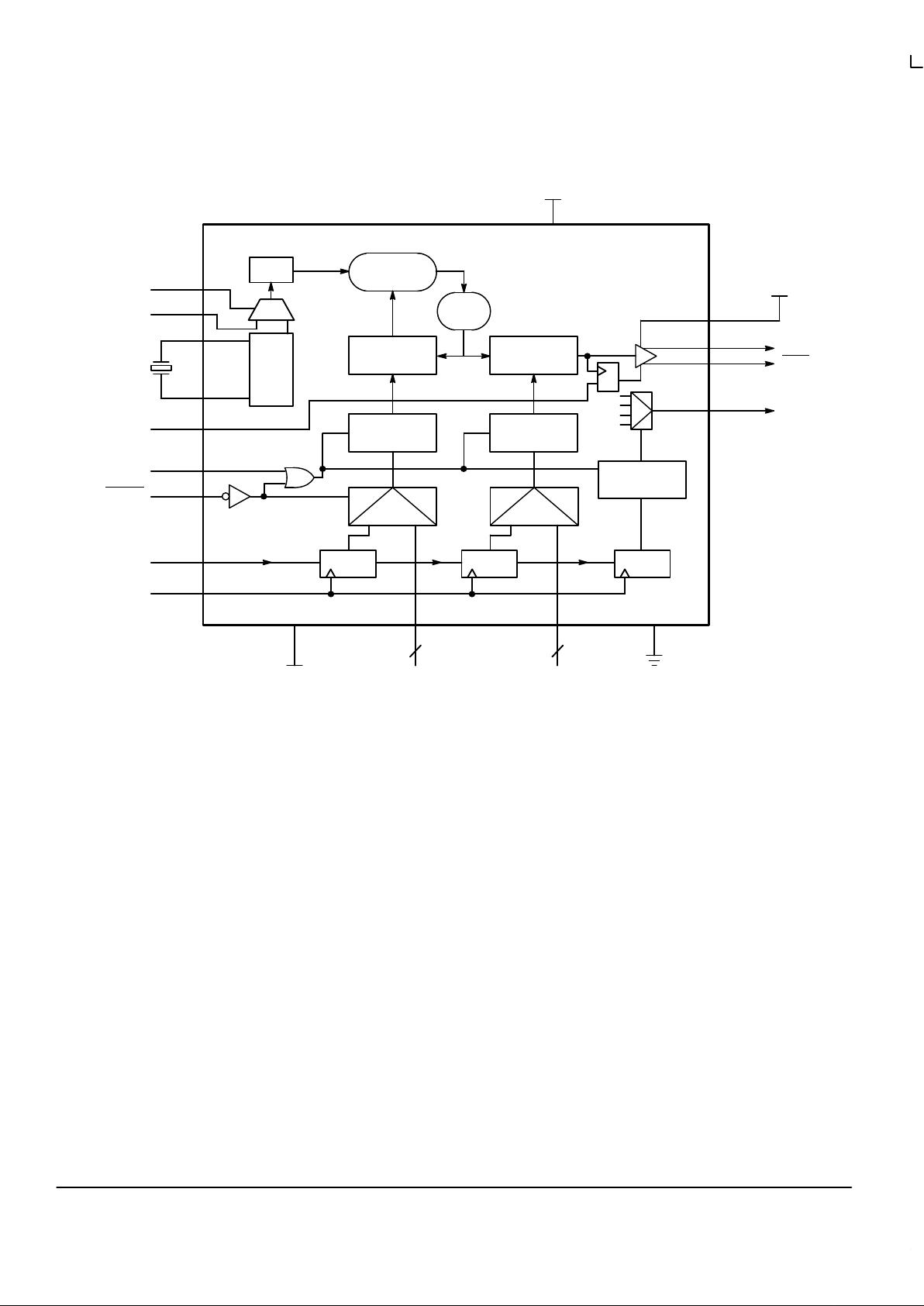

The internal oscillator uses the external quartz crystal as the basis of

its frequency reference. The output of the reference oscillator is divided

by 8 before being sent to the phase detector. With a 16MHz crystal, this

provides a reference frequency of 2MHz. Although this data sheet

illustrates functionality only for a 16MHz crystal, any crystal in the

10–20MHz range can be used.

The VCO within the PLL operates over a range of 400 to 800MHz. Its output is scaled by a divider that is configured by either

the serial or parallel interfaces. The output of this loop divider is applied to the phase detector.

The phase detector and loop filter attempt to force the VCO output frequency to be M times the reference frequency by

adjusting the VCO control voltage. Note that for some values of M (either too high or too low) the PLL will not achieve loop lock.

The output of the VCO is also passed through an output divider before being sent to the PECL output driver. This output divider

(N divider) is configured through either the serial or the parallel interfaces, and can provide one of four division ratios (1, 2, 4 or 8).

This divider extends performance of the part while providing a 50% duty cycle.

The output driver is driven differentially from the output divider, and is capable of driving a pair of transmission lines terminated

in 50Ω to VCC – 2.0. The positive reference for the output driver and the internal logic is separated from the power supply for the

phase–locked loop to minimize noise induced jitter.

The configuration logic has two sections: serial and parallel. The parallel interface uses the values at the M[8:0] and N[1:0]

inputs to configure the internal counters. Normally, on system reset, the P_LOAD

input is held LOW until sometime after power

becomes valid. On the LOW–to–HIGH transition of P_LOAD

, the parallel inputs are captured. The parallel interface has priority

over the serial interface. Internal pullup resistors are provided on the M[8:0] and N[1:0] inputs to reduce component count in the

application of the chip.

The serial interface centers on a fourteen bit shift register. The shift register shifts once per rising edge of the S_CLOCK input.

The serial input S_DATA must meet setup and hold timing as specified in the AC Characteristics section of this document. The

configuration latches will capture the value of the shift register on the HIGH–to–LOW edge of the S_LOAD input. See the

programming section for more information.

The TEST output reflects various internal node values, and is controlled by the T[2:0] bits in the serial data stream. See the

programming section for more information.

HIGH FREQUENCY PLL

CLOCK GENERATOR

FN SUFFIX

28–LEAD PLCC PACKAGE

CASE 776–02

FA SUFFIX

32–LEAD TQFP PACKAGE

CASE 873A–02

Page 2

MC12430

MOTOROLA TIMING SOLUTIONS

BR1333 — Rev 6

2

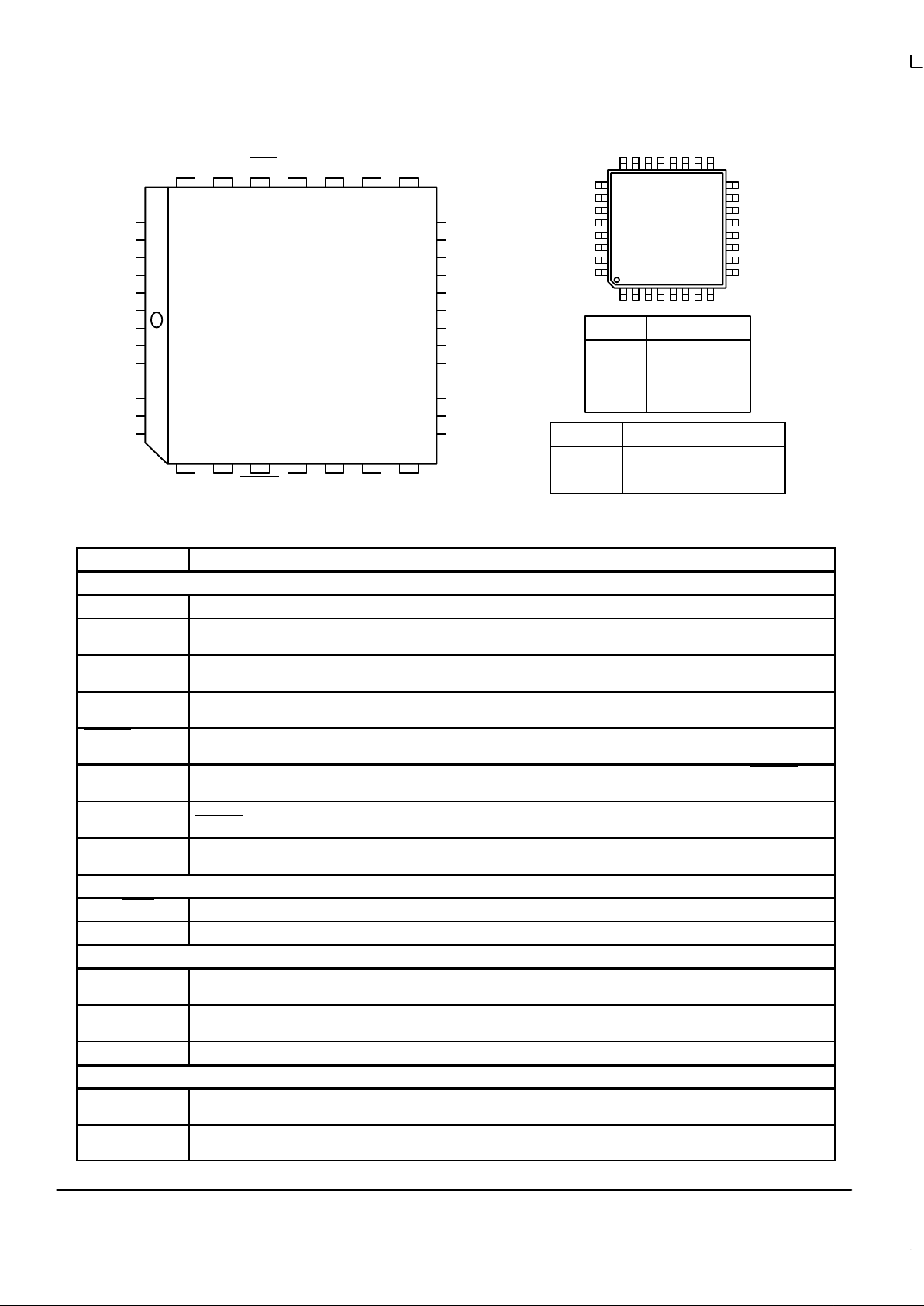

1

N[1]

N[0]

M[8]

M[7]

M[6]

M[5]

M[4]XTAL1

XTAL_SEL

FREF_EXT

PLL–V

CC

S_LOAD

S_DATA

S_CLOCK

4

3

2

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11109

7

8

6

5

28–Lead Pinout (Top View)

P_LOAD

VCCFOUT FOUT GND VCCTEST GND

M[3]M[2]M[1]M[0]

OE

XTAL2

N[1:0]

0 0

0 1

1 0

1 1

Output Division

2

4

8

1

Input

XTAL_SEL

OE

0

FREF_EXT

Disabled

1

XTAL

Enabled

32–Lead Pinout

TBD

PIN DESCRIPTIONS

Pin Name Function

Inputs

XTAL1, XTAL2 These pins form an oscillator when connected to an external series–resonant crystal.

S_LOAD

(Int. Pulldown)

This pin loads the configuration latches with the contents of the shift registers. The latches will be transparent when this

signal is HIGH, thus the data must be stable on the HIGH–to–LOW transition of S_LOAD for proper operation.

S_DATA

(Int. Pulldown)

This pin acts as the data input to the serial configuration shift registers.

S_CLOCK

(Int. Pulldown)

This pin serves to clock the serial configuration shift registers. Data from S_DATA is sampled on the rising edge.

P_LOAD

(Int. Pullup)

This pin loads the configuration latches with the contents of the parallel inputs .The latches will be transparent when this

signal is LOW, thus the parallel data must be stable on the LOW–to–HIGH transition of P_LOAD

for proper operation.

M[8:0]

(Int. Pullup)

These pins are used to configure the PLL loop divider. They are sampled on the LOW–to–HIGH transition of P_LOAD. M[8]

is the MSB, M[0] is the LSB.

N[1:0]

(Int. Pullup)

These pins are used to configure the output divider modulus. They are sampled on the LOW–to–HIGH transition of

P_LOAD

.

OE

(Int. Pullup)

Active HIGH Output Enable. The Enable is synchronous to eliminate possibility of runt pulse generation on the F

OUT

output.

Outputs

F

OUT

, F

OUT

These differential positive–referenced ECL signals (PECL) are the output of the synthesizer.

TEST The function of this output is determined by the serial configuration bits T[2:0]. The output is single–ended ECL.

Power

V

CC

This is the positive supply for the internal logic and the output buffer of the chip, and is connected to +3.3V or 5.0V

(VCC = PLL_VCC). Current drain through VCC ≈ 85mA.

PLL_V

CC

This is the positive supply for the PLL, and should be as noise–free as possible for low–jitter operation. This supply is

connected to +3.3V or 5.0V (VCC = PLL_VCC). Current drain through PLL_VCC ≈ 15mA.

GND These pins are the negative supply for the chip and are normally all connected to ground.

Other

FREF_EXT

(Int. Pulldown)

LVCMOS/CMOS input which can be used as the PLL reference.

XTAL_SEL

(Int. Pullup)

LVCMOS/CMOS input that selects between the crystal and the FREF_EXT source for the PLL reference signal. A HIGH

selects the crystal input.

Page 3

MC12430

TIMING SOLUTIONS

BR1333 — Rev 6

3 MOTOROLA

9–BIT SR 2–BIT SR 3–BIT SR

DIV 8

MC12430 BLOCK DIAGRAM

16MHz

S_LOAD

P_LOAD

S_DATA

S_CLOCK

XTAL1

XTAL2

OSC

4

5

PHASE

DETECTOR

28

7

9–BIT DIV M

COUNTER

LATCH

VCO

DIV N

(1, 2, 4, 8)

LATCH

400–800

MHz

FOUT

FOUT

+3.3 or 5.0V

25

24

23

V

CC0

LATCH

TEST

20

+3.3 or 5.0V

PLL_V

CC

2MHz

F

REF

01

27

26

01

V

CC1

+3.3 or 5.0V

M[8:0]

9

8:16

N[1:0]

2

17, 1821 22, 19

OE

6

FREF_EXT

2

XTAL_SEL

3

PROGRAMMING INTERF ACE

Programming the device amounts to properly configuring

the internal dividers to produce the desired frequency at the

outputs. The output frequency can by represented by this

formula:

FOUT = (F

XTAL

÷ 8) x M ÷ N (1)

Where F

XTAL

is the crystal frequency, M is the loop divider

modulus, and N is the output divider modulus. Note that it is

possible to select values of M such that the PLL is unable to

achieve loop lock. To avoid this, always make sure that M is

selected to be 200 ≤ M ≤ 400 for any input reference.

Assuming that a 16MHz reference frequency is used the

above equation reduces to:

FOUT = 2 x M ÷ N

Substituting the four values for N (1, 2, 4, 8) yields:

FOUT = 2M, FOUT = M,

FOUT = M ÷ 2 and FOUT = M ÷ 4

for 200 < M < 400

The user can identify the proper M and N values for the

desired frequency from the above equations. The four output

frequency ranges established by N are 400–800MHz,

200–400MHz, 100–200MHz and 50–100MHz respectively.

From these ranges the user will establish the value of N

required, then the value of M can be calculated based on the

appropriate equation above. For example if an output

frequency of 131MHz was desired the following steps would

be taken to identify the appropriate M and N values. 131MHz

falls within the frequency range set by an N value of 4 so N

[1:0] = 01. For N = 4 FOUT = M ÷ 2 and M = 2 x FOUT.

Therefore M = 131 x 2 = 262, so M[8:0] = 100000110.

Following this same procedure a user can generate any

whole frequency desired between 50 and 800MHz. Note that

for N > 2 fractional values of FOUT can be realized. The size

of the programmable frequency steps (and thus the indicator

of the fractional output frequencies acheivable) will be equal

to FXTAL ÷ 8 ÷ N.

For input reference frequencies other than 16MHz the set

of appropriate equations can be deduced from equation 1.

For computer applications another useful frequency base

would be 16.666MHz. From this reference one can generate

a family of output frequencies at multiples of the 33.333MHz

PCI clock. As an example to generate a 133.333MHz clock

Page 4

MC12430

MOTOROLA TIMING SOLUTIONS

BR1333 — Rev 6

4

from a 16.666MHz reference the following M and N values

would be used:

FOUT = 16.666 ÷ 8 x M ÷ N = 2.083333 x M ÷ N

Let N = 4, M = 133.3333 ÷ 2.083333 x 4 = 256

The value for M falls within the constraints set for PLL

stability, therefore N[1:0] = 01 and M[8:0} = 10000000. If the

value for M fell outside of the valid range a different N value

would be selected to try to move M in the appropriate

direction.

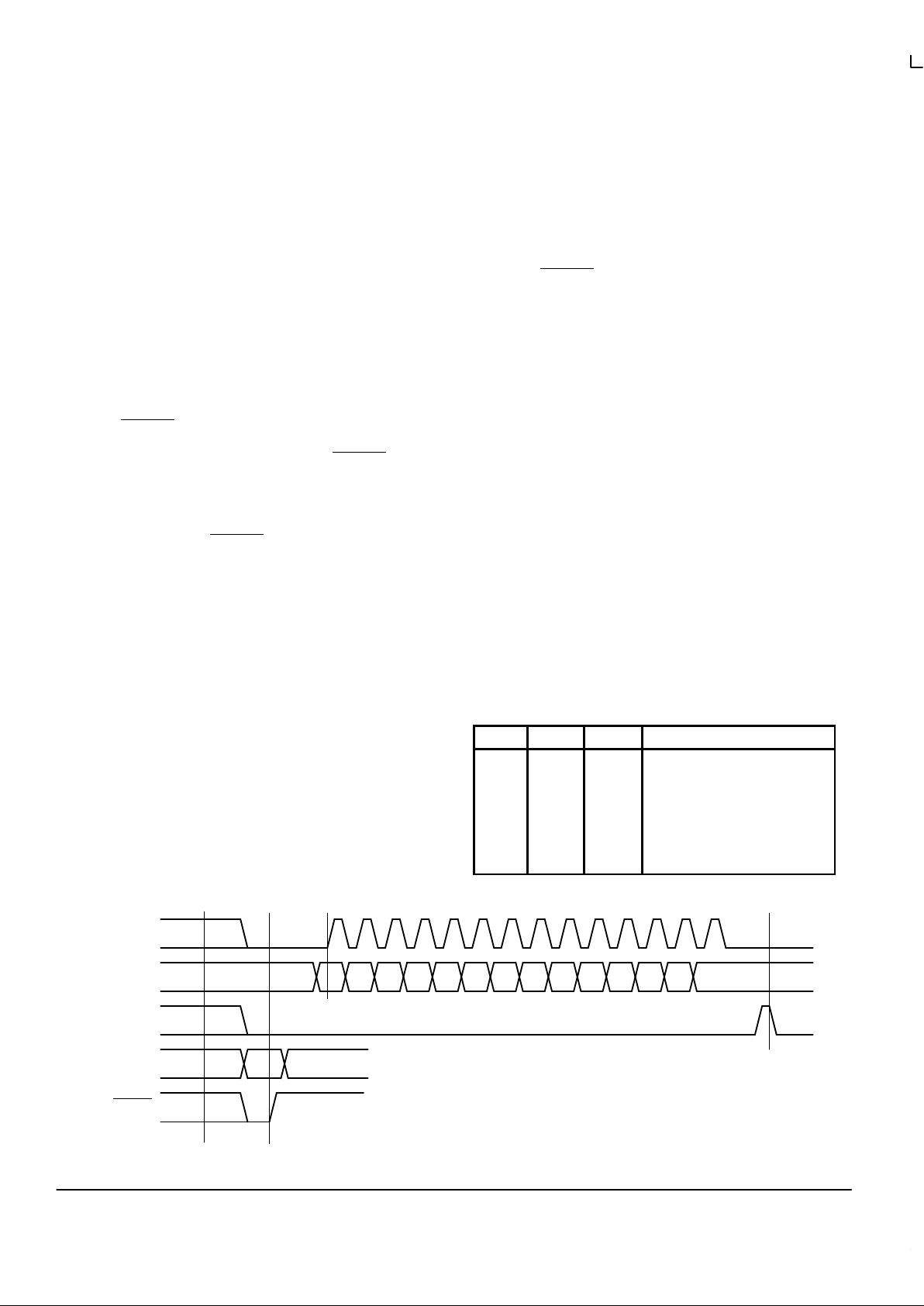

The M and N counters can be loaded either through a

parallel or serial interface. The parallel interface is controlled

via the P_LOAD

signal such that a LOW to HIGH transition

will latch the information present on the M[8:0] and N[1:0]

inputs into the M and N counters. When the P_LOAD

signal is

LOW the input latches will be transparent and any changes

on the M[8:0] and N[1:0] inputs will affect the FOUT output

pair. To use the serial port the S_CLOCK signal samples the

information on the S_DA TA line and loads it into a 14 bit shift

register. Note that the P_LOAD

signal must be HIGH for the

serial load operation to function. The Test register is loaded

with the first three bits, the N register with the next two and

the M register with the final eight bits of the data streeam on

the S_DATA input. For each register the most significant bit is

loaded first (T2, N1 and M8). A pulse on the S_LOAD pin

after the shift register is fully loaded will transfer the divide

values into the counters. The HIGH to LOW transition on the

S_LOAD input will latch the new divide values into the

counters. NO TAG illustrates the timing diagram for both a

parallel and a serial load of the MC12430 synthesizer.

M[8:0] and N[1:0] are normally specified once at power–up

through the parallel interface, and then possibly again

through the serial interface. This approach allows the

application to come up at one frequency and then change or

fine–tune the clock as the ability to control the serial interface

becomes available. To minimize transients in the frequency

domain, the output should be varied in the smallest step size

possible. The bandwidth of the PLL is such that frequency

stepping in 1MHz steps at the maximum S_CLOCK

frequency or less will cause smooth, controlled slewing of the

output frequency.

The TEST output provides visibility for one of the several

internal nodes as determined by the T[2:0] bits in the serial

configuration stream. It is not configurable through the

parallel interface. The T2, T1 and T0 control bits are preset to

‘000’ when P_LOAD

is LOW so that the PECL FOUT outputs

are as jitter–free as possible. Any active signal on the TEST

output pin will have detrimental affects on the jitter of the

PECL output pair. In normal operations, jitter specifications

are only guaranteed if the TEST output is static. The serial

configuration port can be used to select one of the alternate

functions for this pin.

Most of the signals available on the TEST output pin are

useful only for performance verification of the MC12430

itself. However the PLL bypass mode may be of interest at

the board level for functional debug. When T[2:0] is set to 110

the MC12430 is placed in PLL bypass mode. In this mode the

S_CLOCK input is fed directly into the M and N dividers. The

N divider drives the FOUT differential pair and the M counter

drives the TEST output pin. In this mode the S_CLOCK input

could be used for low speed board level functional test or

debug. Bypassing the PLL and driving FOUT directly gives

the user more control on the test clocks sent through the

clock tree. NO TAG shows the functional setup of the PLL

bypass mode. Because the S_CLOCK is a CMOS level the

input frequency is limited to 250MHz or less. This means the

fastest the FOUT pin can be toggled via the S_CLOCK is

250MHz as the minimum divide ratio of the N counter is 1.

Note that the M counter output on the TEST output will not be

a 50% duty cycle due to the way the divider is implemented.

T2 T1 T0 TEST (Pin 20)

0

0

0

0

1

1

1

1

0

0

1

1

0

0

1

1

0

1

0

1

0

1

0

1

SHIFT REGISTER OUT

HIGH

FREF

M COUNTER OUT

FOUT

LOW

PLL BYPASS

FOUT/4

Figure 1. Timing Diagram

S_CLOCK

S_DATA

S_LOAD

M[8:0]

N[1:0]

P_LOAD

T2 T1 T0 N1 N0 M8 M7 M6 M5 M4 M3 M2 M1

M0

M, N

First

Bit

Last

Bit

Page 5

MC12430

TIMING SOLUTIONS

BR1333 — Rev 6

5 MOTOROLA

Figure 2. Serial Test Clock Block Diagram

FDIV4

MCNT

LOW

FOUT

MCNT

FREF

HIGH

TEST

MUX

7

0

TEST

FOUT

(VIA ENABLE GATE)

N DIVIDE

(1, 2, 4, 8)

0

1

PLL 12430

LATCH

Reset

PLOADB

M COUNTER

SLOAD

T0

T1

T2

VCO_CLK

SHIFT

REG

14–BIT

DECODE

SDATA

SCLOCK

MCNT

FREF

SEL_CLK

•

T2=T1=1, T0=0: Test Mode

•

SCLOCK is selected, MCNT is on TEST output, SCLOCK DIVIDE BY N is on FOUT pin

PLOADB acts as reset for test pin latch. When latch reset T2 data is shifted out TEST pin.

DC CHARACTERISTICS (TA = 0° to 70°C, VCC = 3.3V to 5.0V ±5%)

Symbol Characteristic Min Typ Max Unit Condition

V

IH

Input HIGH Voltage 2.0 V VCC = 3.3 to 5.0V

V

IL

Input LOW Voltage 0.8 V VCC = 3.3 to 5.0V

I

IN

Input Current 1.0 mA

V

OH

Output HIGH Voltage 2.17 2.50 V V

CC0

= 3.3V

1

V

OL

Output LOW Voltage 1.41 1.76 V V

CC0

= 3.3V

1

I

CC

Power Supply Current V

CC

PLL_V

CC

85

15

100

20

mA

1. Output levels will vary 1:1 with V

CC0

variation.

Page 6

MC12430

MOTOROLA TIMING SOLUTIONS

BR1333 — Rev 6

6

AC CHARACTERISTICS (TA = 0° to 70°C, VCC = 3.3V to 5.0V ±5%)

Symbol Characteristic Min Max Unit Condition

F

MAXI

Maximum Input Frequency S_CLOCK

Xtal Oscillator

FREF_EXT

10

10

10

20

Note 3.

MHz Note 2.

F

MAXO

Maximum Output Frequency VCO (Internal)

FOUT

400

50

800

800

MHz

t

LOCK

Maximum PLL Lock Time 10 ms

t

jitter

Cycle–to–Cycle Jitter (Peak–to–Peak) Note 4. ±25

±65

ps N = 2, 4, 8; Note 5.

N = 1; Note 5.

t

s

Setup Time S_DATA to S_CLOCK

S_CLOCK to S_LOAD

M, N to P_LOAD

20

20

20

ns

t

h

Hold Time S_DATA to S_CLOCK

M, N to P_LOAD

20

20

ns

tpw

MIN

Minimum Pulse Width S_LOAD

P_LOAD

50

50

ns

tr, t

f

Output Rise/Fall FOUT 300 800 ps 20%–80%

2. 10MHz is the maximum frequency to load the feedback devide registers. S_CLOCK can be switched at higher frequencies when used as a

test clock in TEST_MODE 6.

3. Maximum frequency on FREF_EXT is a function of the internal M counter limitations. The phase detector can handle up to 100MHz on the input,

but the M counter must remain in the valid range of 200 ≤ M ≤ 400. See the programming section on page 3 of this data sheet fore more details.

4. See Applications Information below for additional information.

5. 50Ω to VCC – 2.0V pull–down.

APPLICATIONS INFORMATION

Using the On–Board Crystal Oscillator

The MC12430 features a fully integrated on–board crystal

oscillator to minimize system implementation costs. The

oscillator is a series resonant, multivibrator type design as

opposed to the more common parallel resonant oscillator

design. The series resonant design provides better stability

and eliminates the need for large on chip capacitors. The

oscillator is totally self contained so that the only external

component required is the crystal. As the oscillator is

somewhat sensitive to loading on its inputs the user is

advised to mount the crystal as close to the MC12430 as

possible to avoid any board level parasitics. To facilitate

co–location surface mount crystals are recommended, but

not required.

The oscillator circuit is a series resonant circuit and thus

for optimum performance a series resonant crystal should be

used. Unfortunately most crystals are characterized in a

parallel resonant mode. Fortunately there is no physical

difference between a series resonant and a parallel resonant

crystal. The difference is purely in the way the devices are

characterized. As a result a parallel resonant crystal can be

used with the MC12430 with only a minor error in the desired

frequency. A parallel resonant mode crystal used in a series

resonant circuit will exhibit a frequency of oscillation a few

hundred ppm lower than specified, a few hundred ppm

translates to kHz inaccuracies. In a general computer

application this level of inaccuracy is immaterial. Table 1

below specifies the performance requirements of the crystals

to be used with the MC12430.

Table 1. Crystal Specifications

Parameter Value

Crystal Cut Fundamental AT Cut

Resonance Series Resonance*

Frequency Tolerance ±75ppm at 25°C

Frequency/Temperature Stability ±150pm 0 to 70°C

Operating Range 0 to 70°C

Shunt Capacitance 5–7pF

Equivalent Series Resistance (ESR) 50 to 80Ω

Correlation Drive Level 100µW

Aging 5ppm/Yr (First 3 Y ears)

* See accompanying text for series versus parallel resonant

discussion.

Page 7

MC12430

TIMING SOLUTIONS

BR1333 — Rev 6

7 MOTOROLA

Power Supply Filtering

The MC12430 is a mixed analog/digital product and as

such it exhibits some sensitivities that would not necessarily

be seen on a fully digital product. Analog circuitry is naturally

susceptible to random noise, especially if this noise is seen

on the power supply pins. The MC12430 provides separate

power supplies for the digital ciruitry (VCC) and the internal

PLL (PLL_VCC) of the device. The purpose of this design

technique is to try and isolate the high switching noise digital

outputs from the relatively sensitive internal analog

phase–locked loop. In a controlled environment such as an

evaluation board this level of isolation is sufficient. However,

in a digital system environment where it is more difficult to

minimize noise on the power supplies a second level of

isolation may be required. The simplest form of isolation is a

power supply filter on the PLL_VCC pin for the MC12430.

NO TAG illustrates a typical power supply filter scheme.

The MC12430 is most susceptible to noise with spectral

content in the 1KHz to 1MHz range. Therefore the filter

should be designed to target this range. The key parameter

that needs to be met in the final filter design is the DC voltage

drop that will be seen between the VCC supply and the

PLL_VCC pin of the MC12430. From the data sheet the

I

PLL_VCC

current (the current sourced through the PLL_VCC

pin) is typically 15mA (20mA maximum), assuming that a

minimum of 3.0V must be maintained on the PLL_VCC pin

very little DC voltage drop can be tolerated when a 3.3V V

CC

supply is used. The resistor shown in NO TAG must have a

resistance of 10–15Ω to meet the voltage drop criteria. The

RC filter pictured will provide a broadband filter with

approximately 100:1 attenuation for noise whose spectral

content is above 20KHz. As the noise frequency crosses the

series resonant point of an individual capacitor it’s overall

impedance begins to look inductive and thus increases with

increasing frequency. The parallel capacitor combination

shown ensures that a low impedance path to ground exists

for frequencies well above the bandwidth of the PLL.

Figure 3. Power Supply Filter

PLL_VCC

VCC

MC12430

0.01µF

22

µ

F

0.01

µ

F

3.3V or

5.0V

RS=10–15

Ω

A higher level of attenuation can be acheived by replacing

the resistor with an appropriate valued inductor. A 1000µH

choke will show a significant impedance at 10KHz

frequencies and above. Because of the current draw and the

voltage that must be maintained on the PLL_VCC pin a low

DC resistance inductor is required (less than 15Ω). Generally

the resistor/capacitor filter will be cheaper, easier to

implement and provide an adequate level of supply filtering.

The MC12430 provides sub–nanosecond output edge

rates and thus a good power supply bypassing scheme is a

must. NO TAG shows a representaive board layout for the

MC12430. There exists many different potential board

layouts and the one pictured is but one. The important aspect

of the layout in NO TAG is the low impedance connections

between VCC and GND for the bypass capacitors.

Combining good quality general purpose chip capacitors with

good PCB layout techniques will produce effective capacitor

resonances at frequencies adequate to supply the

instantaneous switching current for the 12430 outputs. It is

imperative that low inductance chip capacitors are used; it is

equally important that the board layout does not introduce

back all of the inductance saved by using the leadless

capacitors. Thin interconnect traces between the capacitor

and the power plane should be avoided and multiple large

vias should be used to tie the capacitors to the buried power

planes. Fat interconnect and large vias will help to minimize

layout induced inductance and thus maximize the series

resonant point of the bypass capacitors.

Figure 4. PCB Board Layout for MC12430

C2

1

C3

R1

Xtal

C1 C1

R1 = 10–15

Ω

C1 = 0.01µF

C2 = 22

µ

F

C3 = 0.1

µ

F

= V

CC

= GND

= Via

Note the dotted lines circling the crystal oscillator

connection to the device. The oscillator is a series resonant

circuit and the voltage amplitude across the crystal is

relatively small. It is imperative that no actively switching

signals cross under the crystal as crosstalk energy coupled

to these lines could significantly impact the jitter of the device.

Special attention should be paid to the layout of the crystal to

ensure a stable, jitter free interface between the crystal and

the on–board oscillator.

Although the MC12430 has several design features to

minimize the susceptibility to power supply noise (isolated

power and grounds and fully differential PLL) there still may

be applications in which overall performance is being

degraded due to system power supply noise. The power

supply filter and bypass schemes discussed in this section

Page 8

MC12430

MOTOROLA TIMING SOLUTIONS

BR1333 — Rev 6

8

should be adequate to eliminate power supply noise related

problems in most designs.

Jitter Performance of the MC12430

The MC12430 exhibits long term and cycle–to–cycle jitter

which rivals that of SAW based oscillators. This jitter

performance comes with the added flexibility one gets with a

synthesizer over a fixed frequency oscillator.

Figure 5. RMS PLL Jitter versus VCO Frequency

0

5

10

15

20

25

400 500 600 700 800

N=2

N=4

N=8

VCO Frequency (MHz)

RMS Jitter (ps)

Figure 5 illustrates the RMS jitter performance of the

MC12430 across its specified VCO frequency range. Note

that the jitter is a function of both the output frequency as well

as the VCO frequency, however the VCO frequency shows a

much stronger dependence. The data presented has not

been compensated for trigger jitter, this fact provides a

measure of guardband to the reported data. In addition the

data represents long term period jitter, the cycle–to–cycle

jitter could not be measured to the level of accuracy required

with available test equipment but certainly will be smaller

than the long term period jitter.

The most commonly specified jitter parameter is

cycle–to–cycle jitter. Unfortunately with today’s high

performance measurement equipment there is no way to

measure this parameter for jitter performance in the class

demonstrated by the MC12430. As a result different methods

are used which approximate cycle–to–cycle jitter. The typical

method of measuring the jitter is to accumulate a large

number of cycles, create a histogram of the edge placements

and record peak–to–peak as well as standard deviations of

the jitter. Care must be taken that the measured edge is the

edge immediately following the trigger edge. The

oscilloscope cannot collect adjacent pulses, rather it collects

pulses from a very large sample of pulses. It is safe to

assume that collecting pulse information in this mode will

produce period jitter values somewhat larger than if

consecutive cycles (cycle–to–cycle jitter) were measured. All

of the jitter data reported on the MC12430 was collected in

this manner.

Figure 6. RMS Jitter versus Output Frequency

0

5

10

15

20

25

25 50 75 100 125 150 175 200 225 250 275 300 325 350 375 400

Output Frequency (MHz)

RMS Jitter (ps)

6.25ps Reference

Figure 6 shows the jitter as a function of the output

frequency. For the 12430 this information is probably of more

importance. The flat line represents an RMS jitter value that

corresponds to an 8 sigma ±25ps peak–to–peak long term

period jitter. The graph shows that for output frequencies

from 87.5 to 400MHz the jitter falls within the ±25ps

peak–to–peak specification. The general trend is that as the

output frequency is decreased the output edge jitter will

increase.

The jitter data from Figure 5 and Figure 6 do not include

the performance of the 12430 when the output is in the divide

by 1 mode. In divide by one mode the output signal is a

digitally doubled version of the VCO output. The period of the

outputs of the digital doubler is dependent on the duty cycle

of the VCO output. Since the VCO output duty cycle cannot

be guaranteed to be always 50% the resulting 12430 output

in divide by one mode will be bimodal at times. Since a

bimodal distribution cannot be acurately represented with an

rms value, peak–to–peak values of jitter for the divide by one

mode are presented.

NO TAG shows the peak–to–peak jitter of the 12430

output in divide by one mode as a function of output

frequency. Notice that as with the other modes the jitter

improves with increasing frequency. The ± 65ps shown in the

data sheet table represents a conservative value of jitter,

especially for the higher vco, and thus output frequencies.

Figure 7. Peak–to–Peak Jitter versus

Output Frequency

40

60

80

100

120

140

400 500 600 700 800

Spec Limit

N=1

Output Frequency (MHz)

Peak–to–Peak Jitter (ps)

The jitter data presented should provide users with

enough information to determine the effect on their overall

Page 9

MC12430

TIMING SOLUTIONS

BR1333 — Rev 6

9 MOTOROLA

timing budget. The jitter performance meets the needs of

most system designs while adding the flexibility of frequency

margining and field upgrades. These features are not

available with a fixed frequency SAW oscillator.

Output Voltage Swing vs Frequency

In the divide by one mode the output rise and fall times will

limit the peak to peak output voltage swing. For a 400MHz

output the peak to peak swing of the 12430 output will be

approximately 700mV. This swing will gradually degrade as

the output frequency increases, at 800MHz the output swing

will be reduced to approximately 400mV. For a worst case

analysis it would be safe to assume that the 12430 output will

always generate at least a 400mV output swing. Note that

most high speed ECL receivers require only a few hundred

millivolt input swings for reliable operation. As a result the

output generated by the 12430 will, under all conditions, be

sufficient for clocking standard ECL devices. Note that if a

larger swing is desired the 12430 could drive a single gate

ECLinPS Lite amplifier like the MC100LVEL16. The LVEL16

will speed up the output edge rates and produce a full swing

ECL output at 800MHz.

Page 10

MC12430

MOTOROLA TIMING SOLUTIONS

BR1333 — Rev 6

10

OUTLINE DIMENSIONS

FN SUFFIX

PLASTIC PLCC PACKAGE

CASE 776–02

ISSUE D

0.007 (0.180) T L

–M

SNSM

0.007 (0.180) T L

–M

SNSM

0.007 (0.180) T L

–M

SNSM

0.010 (0.250) T L

–M

SNSS

0.007 (0.180) T L

–M

SNSM

0.010 (0.250) T L

–M

SNSS

0.007 (0.180) T L

–M

SNSM

0.007 (0.180) T L

–M

SNSM

0.004 (0.100)

SEATING

PLANE

–T

–

12.32

12.32

4.20

2.29

0.33

0.66

0.51

0.64

11.43

11.43

1.07

1.07

1.07

—

2

°

10.42

1.02

12.57

12.57

4.57

2.79

0.48

0.81

—

—

11.58

11.58

1.21

1.21

1.42

0.50

10

°

10.92

—

1.27 BSC

A

B

C

E

F

G

H

J

K

R

U

V

W

X

Y

Z

G1

K1

MIN MINMAX MAX

INCHES MILLIMETERS

DIM

NOTES:

1. DATUMS –L–, –M–, AND –N– DETERMINED

WHERE TOP OF LEAD SHOULDER EXITS

PLASTIC BODY AT MOLD PARTING LINE.

2. DIM G1, TRUE POSITION TO BE MEASURED

AT DATUM –T–, SEATING PLANE.

3. DIM R AND U DO NOT INCLUDE MOLD FLASH.

ALLOWABLE MOLD FLASH IS 0.010 (0.250)

PER SIDE.

4. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

5. CONTROLLING DIMENSION: INCH.

6. THE PACKAGE TOP MAY BE SMALLER THAN

THE PACKAGE BOTTOM BY UP TO 0.012

(0.300). DIMENSIONS R AND U ARE

DETERMINED AT THE OUTERMOST

EXTREMES OF THE PLASTIC BODY

EXCLUSIVE OF MOLD FLASH, TIE BAR

BURRS, GATE BURRS AND INTERLEAD

FLASH, BUT INCLUDING ANY MISMATCH

BETWEEN THE TOP AND BOTTOM OF THE

PLASTIC BODY.

7. DIMENSION H DOES NOT INCLUDE DAMBAR

PROTRUSION OR INTRUSION. THE DAMBAR

PROTRUSION(S) SHALL NOT CAUSE THE H

DIMENSION TO BE GREATER THAN 0.037

(0.940). THE DAMBAR INTRUSION(S) SHALL

NOT CAUSE THE H DIMENSION TO BE

SMALLER THAN 0.025 (0.635).

VIEW S

B

U

Z

G1

X

VIEW D–D

H

K

F

VIEW S

G

C

Z

A

R

E

J

0.485

0.485

0.165

0.090

0.013

0.026

0.020

0.025

0.450

0.450

0.042

0.042

0.042

—

2

°

0.410

0.040

0.495

0.495

0.180

0.110

0.019

0.032

—

—

0.456

0.456

0.048

0.048

0.056

0.020

10

°

0.430

—

0.050 BSC

–N

–

Y BRK

D

D

W

–M

–

–L

–

28 1

V

G1

K1

Page 11

MC12430

TIMING SOLUTIONS

BR1333 — Rev 6

11 MOTOROLA

OUTLINE DIMENSIONS

FA SUFFIX

TQFP PACKAGE

CASE 873A–02

ISSUE A

DETAIL Y

A

S1

VB

1

8

9

17

25

32

AE

AE

P

DETAIL Y

BASE

N

J

DF

METAL

SECTION AE–AE

G

SEATING

PLANE

R

Q

_

W

K

X

0.250 (0.010)

GAUGE PLANE

E

C

H

DETAIL AD

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DATUM PLANE –AB– IS LOCATED AT BOTTOM OF

LEAD AND IS COINCIDENT WITH THE LEAD

WHERE THE LEAD EXITS THE PLASTIC BODY AT

THE BOTTOM OF THE PARTING LINE.

4. DATUMS –T–, –U–, AND –Z– TO BE DETERMINED

AT DATUM PLANE –AB–.

5. DIMENSIONS S AND V TO BE DETERMINED AT

SEATING PLANE –AC–.

6. DIMENSIONS A AND B DO NOT INCLUDE MOLD

PROTRUSION. ALLOWABLE PROTRUSION IS

0.250 (0.010) PER SIDE. DIMENSIONS A AND B

DO INCLUDE MOLD MISMATCH AND ARE

DETERMINED AT DATUM PLANE –AB–.

7. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. DAMBAR PROTRUSION SHALL

NOT CAUSE THE D DIMENSION TO EXCEED

0.520 (0.020).

8. MINIMUM SOLDER PLATE THICKNESS SHALL BE

0.0076 (0.0003).

9. EXACT SHAPE OF EACH CORNER MAY VARY

FROM DEPICTION.

DIMAMIN MAX MIN MAX

INCHES

7.000 BSC 0.276 BSC

MILLIMETERS

B 7.000 BSC 0.276 BSC

C 1.400 1.600 0.055 0.063

D 0.300 0.450 0.012 0.018

E 1.350 1.450 0.053 0.057

F 0.300 0.400 0.012 0.016

G 0.800 BSC 0.031 BSC

H 0.050 0.150 0.002 0.006

J 0.090 0.200 0.004 0.008

K 0.500 0.700 0.020 0.028

M 12 REF 12 REF

N 0.090 0.160 0.004 0.006

P 0.400 BSC 0.016 BSC

Q 1 5 1 5

R 0.150 0.250 0.006 0.010

V 9.000 BSC 0.354 BSC

V1 4.500 BSC 0.177 BSC

__

____

DETAIL AD

A1

B1

V1

4X

S

4X

B1 3.500 BSC 0.138 BSC

A1 3.500 BSC 0.138 BSC

S 9.000 BSC 0.354 BSC

S1 4.500 BSC 0.177 BSC

W 0.200 REF 0.008 REF

X 1.000 REF 0.039 REF

9

–T–

–Z–

–U–

T–U0.20 (0.008) ZAC

T–U0.20 (0.008) ZAB

0.10 (0.004) AC

–AC–

–AB–

M

_

8X

–T–, –U–, –Z–

T–U

M

0.20 (0.008) ZAC

Page 12

MC12430

MOTOROLA TIMING SOLUTIONS

BR1333 — Rev 6

12

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

How to reach us:

USA/EUROPE /Locations Not Listed: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, 6F Seibu–Butsuryu–Center,

P.O. Box 5405; Denver, Colorado 80217. 303–675–2140 or 1–800–441–2447 3–14–2 Tatsumi Koto–Ku, T okyo 135, Japan. 81–3–3521–8315

Mfax: RMFAX0@email.sps.mot.com – TOUCHTONE 602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://www.mot.com/sps/ 51 Ting Ko k Road, Tai Po, N.T., Hong Kong. 852–26629298

MC12430/D

◊

Loading...

Loading...