Page 1

The MC12181 is a monolithic bipolar synthesizer integrating a high

performance prescaler, programmable divider, phase/frequency detector,

charge pump, and reference oscillator/buffer functions. The device is

capable of synthesizing a signal which is 25 to 40 times the input reference

signal. The device has a 4–bit parallel interface to set the proper total

multiplication which can range from 25 to 40. When combined with an

external passive loop filter and VCO, the MC12181 serves as a complete

PLL subsystem.

• 2.7 to 5.5 V Operation

• Low power supply current of 4.25 mA typical

• On chip reference oscillator/buffer supporting wide frequency operating

range from 5 to 25 MHz

• 4–bit parallel interface for programming divider (N = 25 .... 40)

• Wide 125 – 1000 MHz frequency of operation

• Digital phase/frequency detector with linear transfer function

• Balanced Charge Pump Output

• Space efficient 16 lead SOIC package

• Operating Temperature Range of –40 to 85°C

• > 1000 V ESD Protection (I/O to Ground, I/O to V

The device is suitable for applications where a fixed local oscillator (LO)

needs to be synthesized or where a limited number of LO frequencies need

to be generated. The device also has auxiliary open emitter outputs (Pout

and Rout) for observing the inputs to the phase detector for verification

purposes. In normal use the pins should be left open. The Reset input is

normally LOW. When this input is placed in the HIGH state the reference

prescaler is reset and the charge pump output (Do) is placed in the OFF

state.

The 4–bit programming interface maps into divider states ranging from 25

to 40. A is the LSB and D is the MSB. The data inputs (A,B,C, and D) are

CMOS compatible and have pull–up resistors. The inputs can be tied directly

to Vcc or Ground for programming or can be interfaced to an external data

latch/register. Table 1 below has a mapping of the programming states.

T able 1. Programming States

D C B A Divider

L L L L 25

L L L H 26

L L H L 27

L L H H 28

L H L L 29

L H L H 30

L H H L 31

L H H H 32

H L L L 33

H L L H 34

H L H L 35

H L H H 36

H H L L 37

H H L H 38

H H H L 39

H H H H 40

CC

)

Order this document by MC12181/D

125 – 1000 MHZ

FREQUENCY SYNTHESIZER

SEMICONDUCTOR

TECHNICAL DATA

16

1

D SUFFIX

PLASTIC PACKAGE

CASE 751B

(SO–16)

PIN CONNECTIONS

AOSCin

161

BOSCout

152

CV

P

CC

(Top View)

ORDERING INFORMATION

Operating

Device

MC12181D TA = –40° to +85°C SO–16

Temperature Range

143

134

125

116

107

98

DV

PoutDo

ResetGND

RoutFin

GNDFin

Package

Motorola, Inc. 1997 Rev 2

Page 2

MC12181

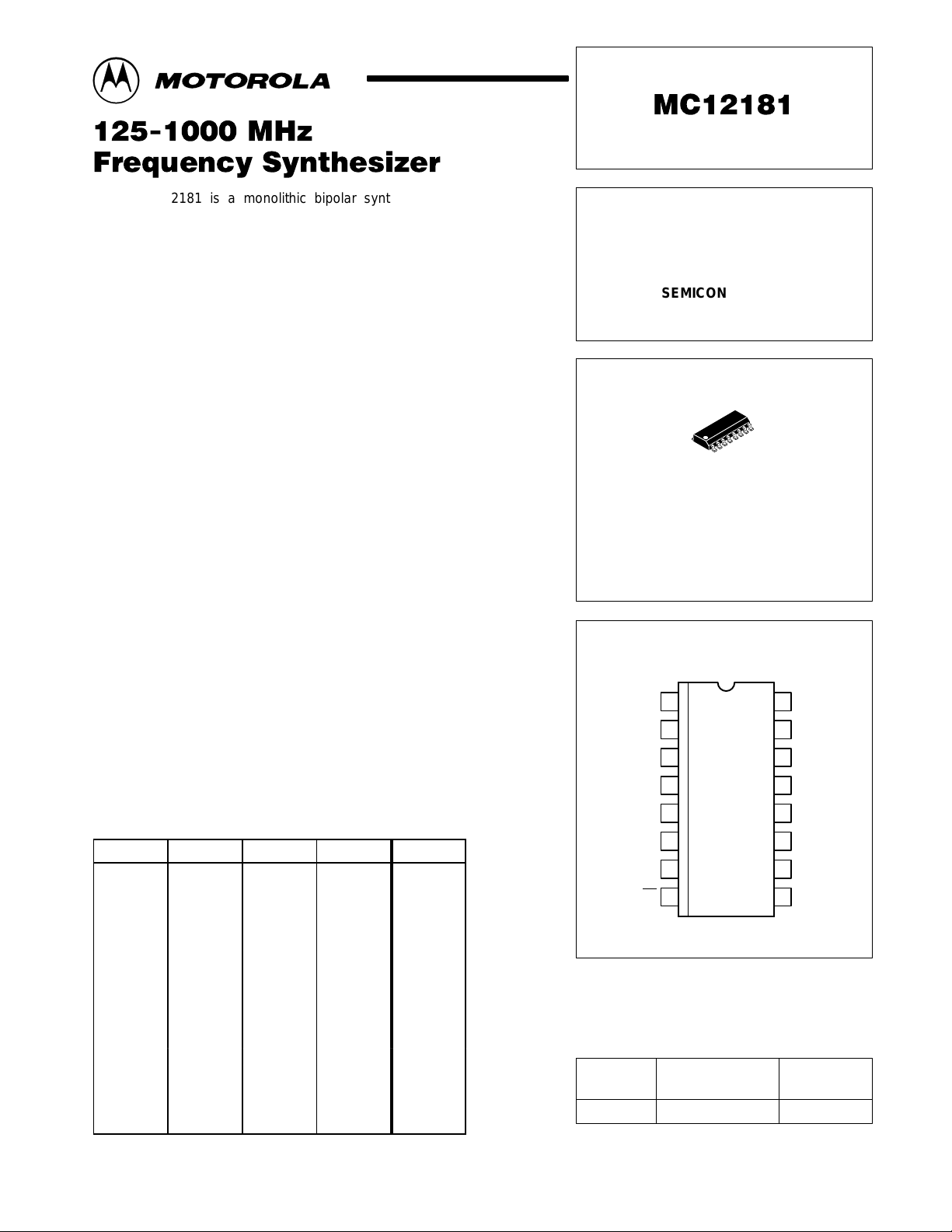

Figure 1. MC12181 Programmable Synthesizer

ABCD

DECODE

LOGIC

Fin

Fin

Reset

OSCin

OSCout

DIVIDE BY 8

PRESCALER

CRYSTAL

OSCILLA T OR/BUFFER

PROGRAMMABLE

DIVIDER (25 – 40)

DIVIDE BY 8

PRESCALER

PHASE/FREQ

DETECTOR

DIVIDE

BY 2

CHARGE

PUMP

Pout

Do

Rout

PIN NAMES

Pin No. Pin Function

1 OSCin An external parallel resonant, fundamental crystal is connected between OSCin and OSCout to form an internal

2 OSCout Oscillator output, for use with an external crystal as shown in Figure 2.

3 V

4 V

5 Do Single ended phase/frequency detector output. Three–state current sink/source output for use as a loop error

6 GND Ground. This pin should be directly tied to the ground plane.

7 Fin Prescaler input – The VCO signal is ac–coupled into the Fin Pin.

8 Fin Complementary prescaler input – This pin should be capacitively coupled to ground.

9 GND Ground. This pin should be directly tied to the ground plane.

10 Rout Open emitter test point used to verify proper operation of the reference divider chain. In normal operation this pin

11 Reset Test pin used to clear the prescalers (Reset = H). When the Reset is in the HIGH state, the charge pump output

12 Pout Open emitter test point used to verify proper operation of the programmable divider chain. The output is a

13

14

15

16

CC

D

C

B

A

reference crystal oscillator. External capacitors C1 and C2 are required to set the proper crystal load capacitance

and oscillator frequency (Figure 2). For an external reference oscillator, a signal is ac–coupled into the OSCin pin.

In either mode a 50 kΩ resistor MUST be connected between OSCin and OSCout.

Positive power supply for charge pump. VP MUST be greater than or equal to VCC. Bypassing should be placed

P

as close as possible to this pin and be connected directly to the ground plane.

Positive power supply. Bypassing should be placed as close as possible to this pin and be connected directly to

the ground plane.

signal when combined with an external low pass filter. The phase/frequency detector is characterized by a linear

transfer function.

should be left OPEN.

is disabled. The Reset input has an internal pulldown. In normal operation it can be left open or tied to ground.

divide–by–2 version of the programmable input to the phase/frequency detector. In normal operation this pin

should be left OPEN.

Digital control inputs for setting the value of the programmable divider. A is the LSB and D is the MSB. In normal

operation these pins can be tied to VCC and/or ground to program a fixed divide or they can be driven by a CMOS

logic level when used in a programmable mode. There is an internal pull–up resistor to VCC on each input.

2

MOTOROLA RF/IF DEVICE DATA

Page 3

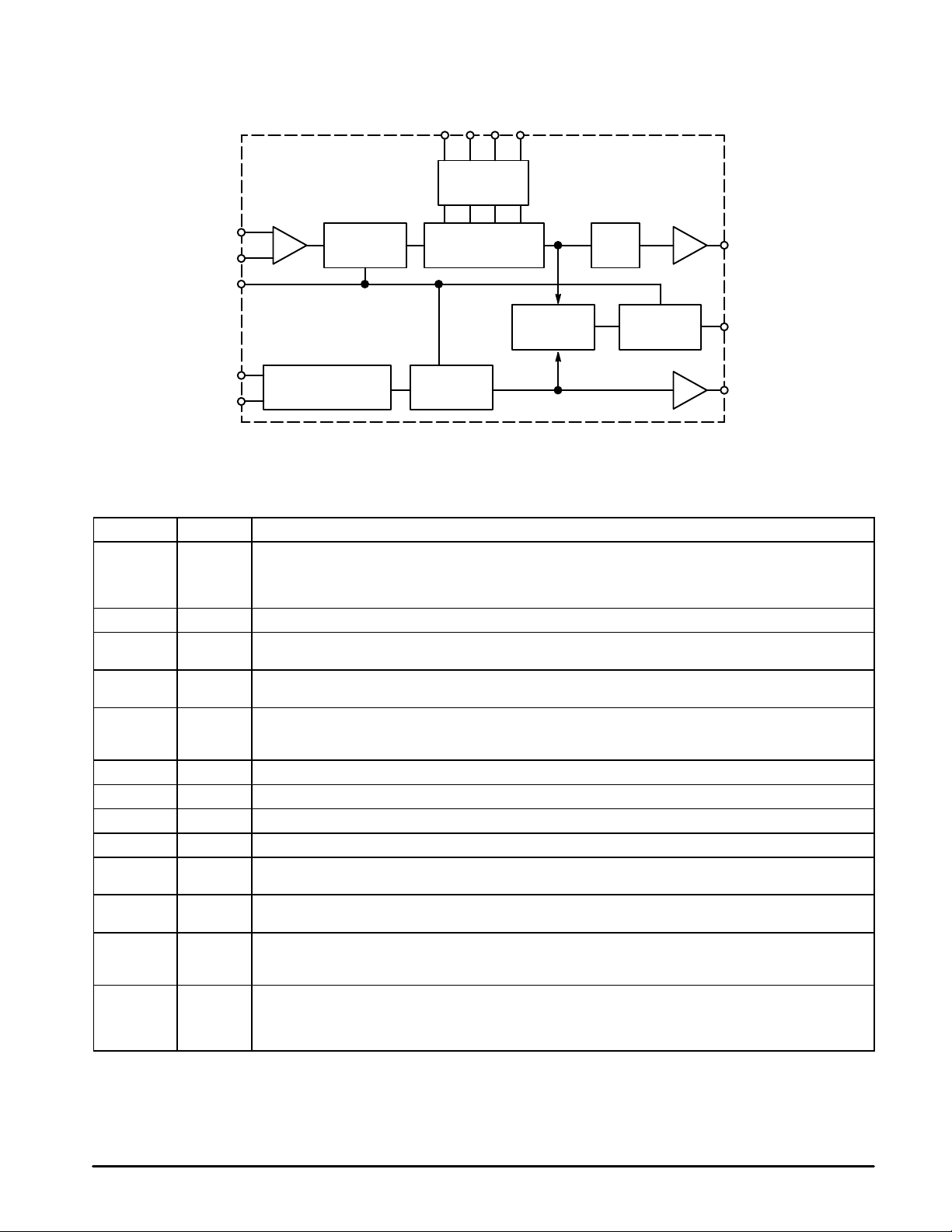

R1 is 50 k

Ω

C1/C2 depend on crystal selected

(Nominal)

Passive

Filter

V

P

0.1 µF 100 pF

V

CC

0.1 µF 100 pF

C1

C2

MC12181

Figure 2. T ypical Applications Example

OSCin

R1

OSCout B

V

P

V

CC

Do

Pout

A

161

152

C

143

D

134

125

CMOS Logic

Levels or V

and/or GND

NC

CC

VCO

GND Reset

1000 pF

Fin Rout

1000 pF

Fin

GND

116

NC

107

98

Figure 3. T ypical Passive Loop Filter Topology

R

Do

X

R

O

C

O

C

A

C

VCO Input

X

RECOMMENDED OPERATING CONDITIONS

Parameter Symbol Min Max Unit

Supply Range V

Maximum Supply Range VCCmax – –6.0 VDC

Maximum Charge Pump Voltage VPmax – VCC to +6.0 VDC

T emperature Ambient T

Storage Temperature T

Maximum Input Signal (Any Pin) Vinmax – VCC+0.5 V VDC

CC

A

STG

2.7 5.5 VDC

–40 85 °C

–65 150 °C

MOTOROLA RF/IF DEVICE DATA

3

Page 4

MC12181

ELECTRICAL CHARACTERISTICS (V

Characteristic

Supply Current for V

Supply Current for V

Input Frequency Range OSCin 5 – 25 MHz Note 2

RF Input Frequency Range Fin 125 – 1000 MHz Note 3

Fin Input Sensitivity Vin 100 – 1000 mVpp Note 4

OSCin Input Sensitivity V

Output Source Current (Do) I

Output Sink Current (Do) I

Output Leakage Current (Do) I

Charge Pump Operating Volt VDo 0.5 – VP–0.5 V

Input HIGH Voltage Reset, A, B, C, D V

Input LOW Voltage Reset, A, B, C, D V

Input HIGH Current A, B, C, D I

Input LOW Current A, B, C, D I

Output Amplitude (Pout, Rout) Vout 250 400 – mVpp Note 7

NOTES: 1. VCC and VP = 5.5 V; Fin = 1.0 GHz; OSCin = 25 MHz; Do open.

2.Assumes C1 and C2 (Figure 2) limited to ≤30 pF each including stray capacitance in crystal mode, ac coupled input for external reference mode.

3.AC coupling, Fin measured with a 1000pF capacitor.

4.Signal ac coupling in input.

5.VCC = 5.5 V; VP = 6.0 V; VDO = 3.0 V.

6.VP = VCC = 3.0 V; VDO = 1.5 V.

7.Minimum resistor value of 25 kΩ to ground.

CC

P

Reset – – +100

Reset –1 – +1

= 2.7 to 5.5 V; VP = VCC to 6.0 V; TA = –40 to +85°C, unless otherwise noted.)

CC

Symbol Min Typ Max Unit Condition

I

CC

I

P

OSC

OH

OL

OZ

IH

IL

IH

IL

– 4.0 5.5 mA Note 1

– 0.25 0.5 mA Note 1

500 – 2200 mVpp Note 4

–2.8 –2.2 –2.0 mA Note 5

–2.4 –2.0 –1.6 Note 6

2.0 2.4 2.8 mA Note 5

1.6 2.0 2.4 Note 6

– 0.5 10 nA VCC=5.5; VP = 6.0 V;

0.7 V

CC

– – 0.3 V

– – +1 µA

–100 – – µA

– – V

CC

VDo=0.5 to 5.5 V

V

4

MOTOROLA RF/IF DEVICE DATA

Page 5

MC12181

APPLICATIONS INFORMATION

The MC12181 is intended for applications where a fixed

LO, or a limited number of local oscillator frequencies is

required to be synthesized. The device acts as a x25 – 40

PLL. The 4–bit parallel interface allows 1 of 16 divide ratios to

be selected. Internally there are fixed divide by 8 prescalers

in the reference and programmable paths of the PLL. The

MC12181 operates from 125 MHz to 1000 MHz which makes

the part ideal for FCC Title 47; Part 15 applications in the 260

MHz to 470 MHz band and the 902 to 928 MHz Band.

Figure 4 shows a typical block diagram of the application.

Figure 4. T ypical Block Diagram of Complete PLL

External

Ref

10.0MHz

MC12181 PLL

φ

÷

8

/Freq

Det

÷

N

25–40

Charge

Pump

÷

8

Loop

Filter

VCO

250–400

MHz

As can be seen from the block diagram, with the addition

of a VCO, a loop filter, and either an external oscillator or

crystal, a complete PLL sub–system can be realized. Since

most of the PLL functions are integrated into the 12181, the

users focus is on the loop filter design and the crystal

reference oscillator circuit.

Crystal Oscillator Design

The PLL is used to transfer the high stability characteristic

of a low frequency reference source to the high frequency

VCO within the PLL loop. To facilitate this, the device

contains an input circuit which can be configured as a crystal

oscillator or a buffer for accepting an external signal source.

In the external reference mode, the reference source is

ac–coupling into the OSCin input pin. The level of this signal

should be between 500 – 2200 mVp–p. An external low noise

reference should be used when it is desired to obtain the best

close–in phase noise performance for the PLL. In addition the

input reference amplitude should be close to the upper

amplitude specification. This maximizes the slew rate of the

input signal as it switches against the internal voltage

reference.

In the crystal mode, an external parallel–resonant

fundamental mode crystal should be connected between the

OSCin and OSCout pins. This crystal must be between 5 and

25 MHz. External capacitors C1 and C2, as shown in

Figure 2, are required to set the proper crystal load

capacitance and oscillator frequency. The values of the

capacitors are dependent on the crystal choosen and the

input capacitance of the device as well as stray board

capacitance.

Since the MC12181 is realized with an all–bipolar ECL

style design, the internal oscillator circuitry is different from

more traditional CMOS oscillator designs which realize the

crystal oscillator with a modified inverter topology. These

CMOS designs typically excite the crystal with a rail–to–rail

signal which may overdrive the crystal resulting in damage or

unstable operation. The MC12181 design does not exhibit

this phenomena because the swing out of the OSCout pin is

less than 600 mVp–p. This has the added advantage of

minimizing EMI and switching noise which can be generated

by rail–to–rail CMOS outputs. The OSCout output should not

be used to drive other circuitry.

The oscillator buffer in the MC12181 is a single stage, high

speed, differential input/output amplifier; it may be

considered to be a form of the Pierce oscillator. A simplified

circuit diagram is seen in Figure 5.

Figure 5. Simplified Crystal Oscillator/Buffer Circuit

V

CC

OSC

out

Bias

Source

OSC

in

To Phase/

Frequency

Detector

OSCin drives the base of one input of an NPN transistor

differential pair . The non–inverting input of the differential pair

is internally biased. OSC

is the inverted input signal and is

out

buffered by an emitter follower with a 70 µA pull–down

current and has a voltage swing of about 600mVp–p. Open

loop output impedance is approximately 425 Ω. The opposite

side of the differential amplifier output is used internally to

drive another buffer stage which drives the phase/frequency

detector. With the 50 kΩ feedback resistor in place, OSC

and OSC

are biased to approximately 1.1 V below VCC.

out

The amplifier has a voltage gain of about 15dB and a

bandwidth in excess of 150 MHz. Adherence to good RF

design and layout techniques, including power supply pin

decoupling, is strongly recommended.

A typical crystal oscillator application is shown in Figure 2.

The crystal and the feedback resistor are connected directly

between OSCin and OSC

, while the loading capacitors, C1

out

and C2, are connected between OSCin and ground, and

OSC

and ground respectively . It is important to understand

out

that as far as the crystal is concerned, the two loading

capacitors are in series (albeit through ground). So when the

crystal specification defines a specific loading capacitance,

this refers to the total external (to the crystal) capacitance

seen across its two pins.

This capacitance consists of the capacitance contributed

by the amplifier (IC and packaging), layout capacitance, and

the series combination of the two loading capacitors. This is

illustrated in the equation below:

CI+

C

AMP

)

C

STRAY

C1 C2

)

C1)C2

Provided the crystal and associated components are

located immediately next to the IC, thus minimizing the stray

capacitance, the combined value of C

AMP

and C

STRAY

is

approximately 5pF. Note that the location of the OSCin and

OSC

pins at the end of the package, facilitates placing the

out

crystal, resistor and the C1 and C2 capacitors very close to

the device. Usually , one of the capacitors is in parallel with an

adjustable capacitor used to trim the frequency of oscillation.

in

MOTOROLA RF/IF DEVICE DATA

5

Page 6

MC12181

It is important that the total external (to the IC) capacitance

seen by either OSCin or OSC

In operation, the crystal oscillator will start up with the

application of power. If the crystal is in a can that is not

grounded it is often possible to monitor the frequency of

oscillation by connecting an oscilloscope probe to the can;

this technique minimizes any disturbance to the circuit. If this

is not possible, a high impedance, low capacitance, FET

probe can be connected to either OSCin or OSC

typically seen at those points will be very nearly sinusoidal

with amplitudes of roughly 300–600mVp–p. Some distortion

is inevitable and has little bearing on the accuracy of the

signal going to the phase detector.

Loop Filter Design

Because the device is designed for a non–frequency agile

synthesizer (i.e., how fast it tunes is not critical) the loop filter

design is very straight forward. The current output of the

charge pump allows the loop filter to be realized without the

need of any active components. The preferred topology for

the filter is illustrated in Figure 6.

Figure 6. Loop Filter

Xtl

Osc

MC12181

Ph/Frq

÷

8

÷

25–40

Det

÷

Chrg

Pump

K

N

8

The Ro/Co components realize the primary loop filter. Ca is

added to the loop filter to provide for reference sideband

suppression. If additional suppression is needed, the Rx/C

realizes an additional filter. In most applications, this will not

be necessary. If all components are used, this results in a 4th

order PLL, which makes analysis difficult. To simplify this, the

loop design will be treated as a 2nd order loop (Ro/Co) and

additional guidelines are provided to minimize the influence

of the other components. If more rigorous analysis is needed,

mathematical/system simulation tools should be used.

Component Guideline

C

a

R

x

C

x

The focus of the design effort is to determine what the

loop’s natural frequency , ωo, should be. This is determined by

Ro, Co, Kp, Kv, and Nt. Because Kp, Kv, and Nt are given, it is

only necessary to calculate values for Ro and Co. There are

3 considerations in selecting the loop bandwidth:

1) Maximum loop bandwidth for minimum tuning speed

, be no greater than 30pF.

out

R

p

o

C

o

<0.1 × C

>10 × R

<0.1 × C

o

o

o

. Signals

out

R

C

a

VCO

x

K

v

C

x

2) Optimum loop bandwidth for best phase noise

performance

3) Minimum loop bandwidth for greatest reference sideband

suppression

Usually a compromise is struck between these 3 cases,

however, for a fixed frequency application, minimizing the

tuning speed is not a critical parameter.

To specify the loop bandwidth for optimal phase noise

performance, an understanding of the sources of phase

noise in the system and the effect of the loop filter on them is

required. There are 3 major sources of phase noise in the

phase–locked loop – the crystal reference, the VCO, and the

loop contribution. The loop filter acts as a low–pass filter to

the crystal reference and the loop contribution. The loop filter

acts as a high–pass filter to the VCO with an in–band gain

equal to unity. The loop contribution includes the PLL IC, as

well as noise in the system; supply noise, switching noise,

etc. For this example, a loop contribution of 15dB has been

selected, which corresponds to data in Figure NO TAG.

The crystal reference and the VCO are characterized as

high–order 1/f noise sources. Graphical analysis is used to

determine the optimum loop bandwidth. It is necessary to

have noise plots from the manufacturers of both devices.

This method provides a straightforward approximation

suitable for quickly estimating the optimal bandwidth. The

loop contribution is characterized as white–noise or

low–order 1/f noise given in the form of a noise factor which

combines all the noise effects into a single value. The phase

noise of the Crystal Reference is increased by the noise

factor of the PLL IC and related circuitry. It is further

increased by the total divide–by–N ratio of the loop. This is

illustrated in Figure 7.

The point at which the VCO phase noise crosses the

amplified phase noise of the Crystal Reference is the point of

the optimum loop bandwidth. In the example of Figure 7, the

x

optimum bandwidth is approximately 15 KHz.

Figure 7. Graphical Analysis of Optimum Bandwidth

Closed Loop Response

–60

–70

–80

–90

–100

dB

–110

–120

–130

–140

–150

Crystal Reference

10 100 1k 10k 100k 1M

20*log(Nt)

Hz

Optimum Bandwidth

15dB NF of the Noise

Contribution from Loop

VCO

6

MOTOROLA RF/IF DEVICE DATA

Page 7

MC12181

Figure 8. Closed Loop Frequency Response for ζ = 1

Natural Frequency

10

0

–10

–20

dB

–30

–40

–50

–60

0.1 1.0 k

To simplify analysis further a damping factor of 1 will be

selected. The normalized closed loop response is illustrated

in Figure 8 where the loop bandwidth is 2.5 times the loop

natural frequency (the loop natural frequency is the

frequency at which the loop would oscillate if it were

unstable). Therefore the optimum loop bandwidth is

15 kHz/2.5 or 6.0 kHz (37.7 krads) with a damping coefficient,

ζ ≈ 1. T(s) is the transfer function of the loop filter.

T(s)

+

ǒ

KpK

NC

o

ǒ

KpK

RoCo+

where Nt = T otal PLL Divide Ratio — 8×N where (N = 25...40)

ǒ

Ǔ

+

v

Kv = VCO Gain — Hz/V

Kp = Phase Detector/Charge Pump Gain — A

= ( |IOH| + |IOL| ) / 2

1.0 10 100

RoCos)1

NC

o

Ǔ

s2)

RoCos)1

v

1

Ǔ

³

wo+

2

w

o

2

z

ǒ

Ǔ

³z+

w

o

Ǹ

woRoC

ǒ

KpK

2

3dB Bandwidth

Hz

ǒ

+

1

ǒ

Ǔ

s2)

2

w

o

v

³

NC

Co+

o

o

Ǔ

³

Ro+

2

w

z

Ǔ

o

s)1

2

z

ǒ

w

o

KpK

ǒ

N

ǒ

Ǔ

s)1

w

2

woC

v

Ǔ

2

o

z

Ǔ

o

Technically, Kv and Kp should be expressed in Radian

units [Kv (RAD/V), Kp (A/RAD)]. Since the component

design equation contains the Kv × Kp term. the 2π

cancels and the values can be epressed as above.

Figure 9. Design Equations for the 2nd Order System

In summary, follow the steps given below:

Step 1: Plot the phase noise of crystal reference and the

VCO on the same graph.

Step 2: Increase the phase noise of the crystal reference by

the noise contribution of the loop.

Step 3: Convert the divide–by–N to dB (20log 8 × N) and

increase the phase noise of the crystal reference by

that amount.

Step 4: The point at which the VCO phase noise crosses the

amplified phase noise of the Crystal Reference is the

point of the optimum loop bandwidth. This is

approximately 15 kHz in Figure 7.

Step 5: Correlate this loop bandwidth to the loop natural

frequency per Figure 8. In this case the 3.0 dB

bandwidth for a damping coefficient of 1 is 2.5 times

the loop’s natural frequency. The relationship

between the 3.0 dB loop bandwidth and the loop’s

“natural” frequency will vary for different values of ζ.

Making use of the equations defined in Figure 9, a

math tool or spread sheet is useful to select the

values for Ro and Co.

Appendix: Derivation of Loop Filter Transfer Function

The purpose of the loop filter is to convert the current from

the phase detector to a tuning voltage for the VCO. The total

transfer function is derived in two steps. Step 1 is to find the

voltage generated by the impedance of the loop filter. Step 2

is to find the transfer function from the input of the loop filter to

its output. The “voltage” times the “transfer function” is the

overall transfer function of the loop filter. To use these

equations in determining the overall transfer function of a PLL

multiply the filter’s impedance by the gain constant of the

phase detector then multiply that by the filter’s transfer

function (Figure 10 contains the transfer function equations

for 2nd, 3rd and 4th order PLL filters.)

MOTOROLA RF/IF DEVICE DATA

7

Page 8

MC12181

Figure 10. Overall Transfer Function of the PLL

For the 2nd Order PLL:

For the 3rd Order PLL:

For the 4th Order PLL:

V

p

R

o

C

o

V

p

R

C

o

C

o

V

p

R

o

C

o

ZLF(s)

TLF(s)

a

C

a

+

CoRoCaRxCxs3)[(Co)

Vt(s)

+

Vp(s)

ZLF(s)

TLF(s)

ZLF(s)

TLF(s)

R

x

+

V

t

RoCos)1

+

Vt(s)

+

Vp(s)

V

t

+

CoRoCas2)

Vt(s)

+

Vp(s)

V

C

x

1

(RxCxs)1)

Cos

+

1,Vp(s)+Kp(s)ZLF(s)

RoCos)1

(Co)

Ca)s

+

1,Vp(s)+Kp(s)ZLF(s)

t

(RoCos)1) (RxCxs)1)

Ca)RxCx)

,Vp(s)+Kp(s)ZLF(s)

CoRo(Cx)

Ca)]s2)

(Co)

Ca)

Cx)s

Figure 11. Typical Charge Pump Current versus Temperature

(VCC = 5.5 V; VP = 6.0 V)

FIGURES 11 THRU 17 COULD NOT BE PROCESSED

FOR PDF FORMAT. FOR COMPLETE DOCUMENT

WITH ALL IMAGES, PLEASE ORDER FROM MFAX OR

LITERATURE DISTRIBUTION CENTER.

8

MOTOROLA RF/IF DEVICE DATA

Page 9

–T–

MC12181

OUTLINE DIMENSIONS

D SUFFIX

PLASTIC PACKAGE

CASE 751B-05

–A–

16 9

–B–

18

G

K

SEATING

PLANE

D

16 PL

0.25 (0.010) A

M

S

B

T

8 PLP

0.25 (0.010) B

C

M

S

(SO–16)

ISSUE J

M

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

S

R

X 45

_

F

J

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

DIM MIN MAX MIN MAX

A 9.80 10.00 0.386 0.393

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.054 0.068

D 0.35 0.49 0.014 0.019

F 0.40 1.25 0.016 0.049

G 1.27 BSC 0.050 BSC

J 0.19 0.25 0.008 0.009

K 0.10 0.25 0.004 0.009

M 0 7 0 7

____

P 5.80 6.20 0.229 0.244

R 0.25 0.50 0.010 0.019

INCHESMILLIMETERS

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

How to reach us:

USA/EUROPE/Locations Not Listed: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.: SPD, Strategic Planning Office, 141,

P.O. Box 5405, Denver, Colorado 80217. 1–303–675–2140 or 1–800–441–2447 4–32–1 Nishi–Gotanda, Shagawa–ku, Tokyo, Japan. 03–5487–8488

Customer Focus Center: 1–800–521–6274

Mfax: RMFAX0@email.sps.mot.com – TOUCHTONE 1–602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

Moto rola Fa x Back Syst em – US & Canada ONL Y 1–800–774–1848 51 Ting Kok Road, Tai Po, N.T., Hong Kong. 852–26629298

HOME PAGE: http://motorola.com/sps/

MOTOROLA RF/IF DEVICE DATA

– http://sps.motorola.com/mfax/

◊

Mfax is a trademark of Motorola, Inc.

MC12181/D

9

Loading...

Loading...