Page 1

SEMICONDUCTOR TECHNICAL DATA

Order this data sheet

by MC10SX1130/D

The MC10SX1 130 is high speed LED Driver/current switch specifically

targeted for use in FDDI PMD and ANSI X3T9.3 FibreChannel 266

Mbits/s optical transmitters. The integrated circuit contains several

unique functional blocks which makes it easily configurable for use with a

variety of high performance LED devices. The part is fabricated using

Motorola’s proven MOSAIC III advanced bipolar process. The logic is

designed so that a data HIGH input results in the modulation current

flowing through the I

• Differential Data Inputs

• 300MHz Operation

• 100mA Peak Drive Current

• Extremely Low Jitter

• Duty Cycle Distortion Compensation

• Adjustable Output Current Tracking With Temperature

• Thermally Enhanced 16-Lead SOIC Package

• 75kΩ Data Input Pulldown Resistors

• +5V or –5.2V Operation

• V

Reference Available

BB

The device incorporates open collector outputs with a capability of

driving peak currents of 100mA. Since the output current switching

circuitry simply switches current between the complementary outputs, the

dynamic switching demands on the system power supply are greatly reduced. In addition, because the design is pure bipolar, the

device current drain is insensitive to the data pattern and frequency of operation.

The LED drive current is adjustable through the selection of an external set resistor, RSET. In addition, to allow for open loop

compensation for the LED’s negative optical output power tracking over temperature, a circuit is included to provide an

adjustable positive temperature tracking coefficient to the LED drive current. This is controlled through the selection of an

external resistor, RTCO.

The MC10SX1 130 incorporates novel pulse stretching circuitry which is intended to compensate for the turn-on delay and rise

and fall time asymmetry inherent in LED devices. The stretch circuitry can be used to pre-distort the input signal pulse width to

minimize the duty cycle distortion of the transmitted optical eye pattern. The stretch circuitry supports three different selections of

pre-distortion. This choice is accomplished through a unique ‘tri-state’ input which can be left open, tied to VCC, or tied to VEE to

determine the pre-distortion amount.

The device provides a VBB output for either single-ended use or as a DC bias for AC coupling the signal into the device. The

VBB pin should only be used as a bias for the MC10SX1 130 as its current sink/source capability is limited. Whenever used, the

VBB pin should be bypassed to ground via a 0.01µF capacitor.

pin to turn on the LED.

OUT

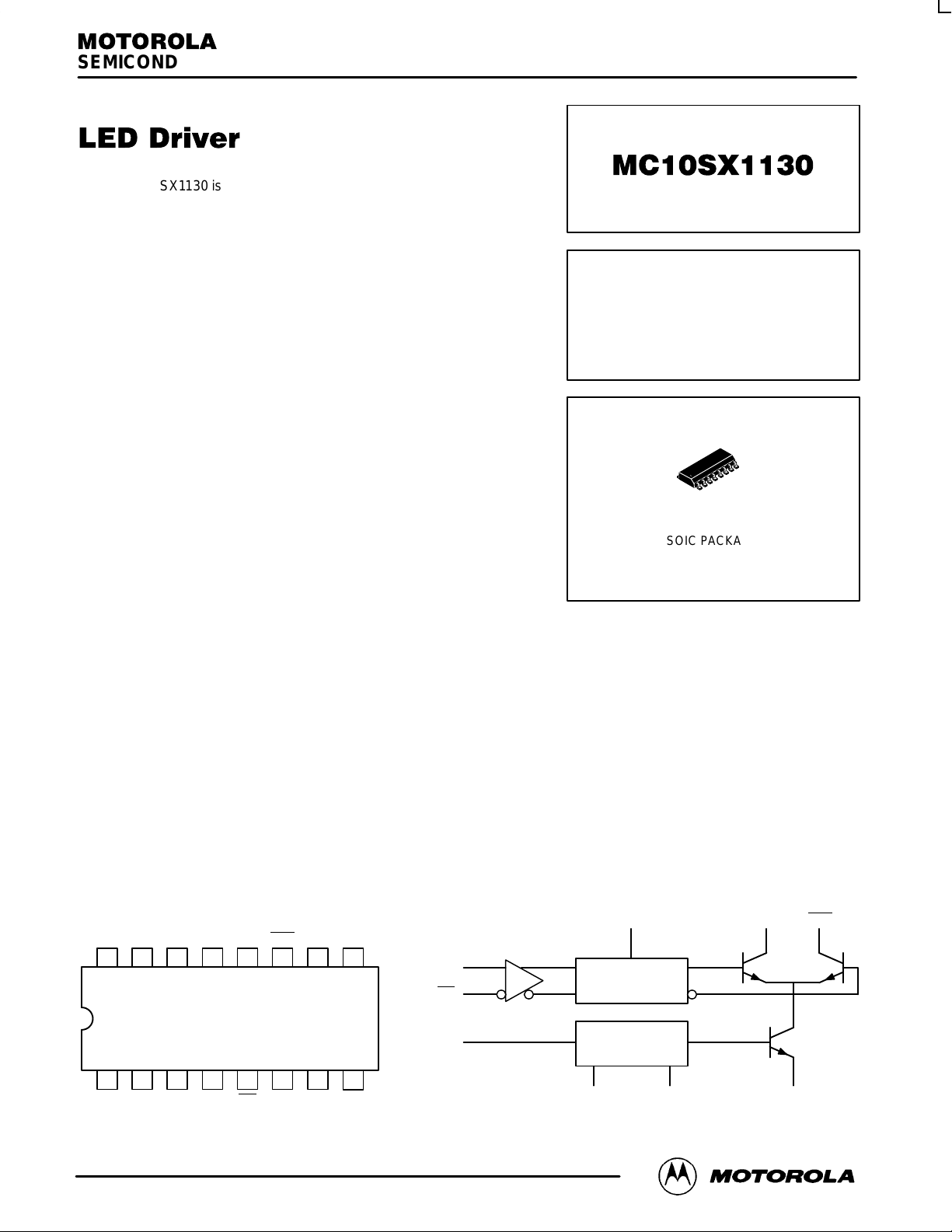

LED DRIVER

16

1

D SUFFIX

SOIC PACKAGE

CASE 751B-05

Pinout: 16-Lead Plastic Package (Top View)

Stretch VEEI

V

EE

1516 14 13 12 11 10

21 34567

VEEVCCVBBDIND

MOSAIC III is a trademark of Motorola.

3/94

OUT

RSET I

OUTVCCVEE

RTCO1RTCO2V

IN

Motorola, Inc. 1994

9

8

EE

BLOCK DIAGRAM

ECL

BUFFER

D

IN

D

IN

V

BB

Stretch

PULSE WIDTH

ADJUST CIRCUIT

BIAS

CONTROL

1

REV 1

RTCO

2

I

OUTIOUT

RSETRTCO

Page 2

PIN FUNCTION TABLE

Pin

D

IN

I

OUT

STRETCH Control input to select the amount of duty cycle pre-distortion. When the pin is left open, no pre-distortion is introduced.

RSET Resistor to set LED drive current. This resistor sets the tail current of the output current switch and should be connected

RTCO1, RTCO

V

CC

V

EE

V

BB

Differential data inputs.

Differential open collector outputs.

If the pin is connected to VCC, the output LOW state current pulse width is increased by 155ps. When it is connected to

VEE, the current pulse width is increased by 310ps.

to the VEE plane. Since the RSET voltage compensation circuit is referenced to VEE, the RSET voltage will track 1:1 with

VEE changes, thus the voltage across the RSET resistor will remain constant.

Terminals for positive temperature tracking resistor. This resistor controls the temperature tracking rate of the voltage at

2

the RSET pin, which in turn sets the LED drive current tracking. If the two pins are shorted together, the nominal tracking

rate is 1.4mV/°C and when a 2kΩ resistor is connected across the pins, the nominal tracking rate is 4.9mV/°C.

Most positive power supply input. +5V for PECL operation or ground for standard ECL operation.

Most negative power supply input. Ground for PECL operation or –5.2V for standard ECL operation.

Reference voltage for use in single ended applications or when the input signal is AC coupled into the device.

Function

V

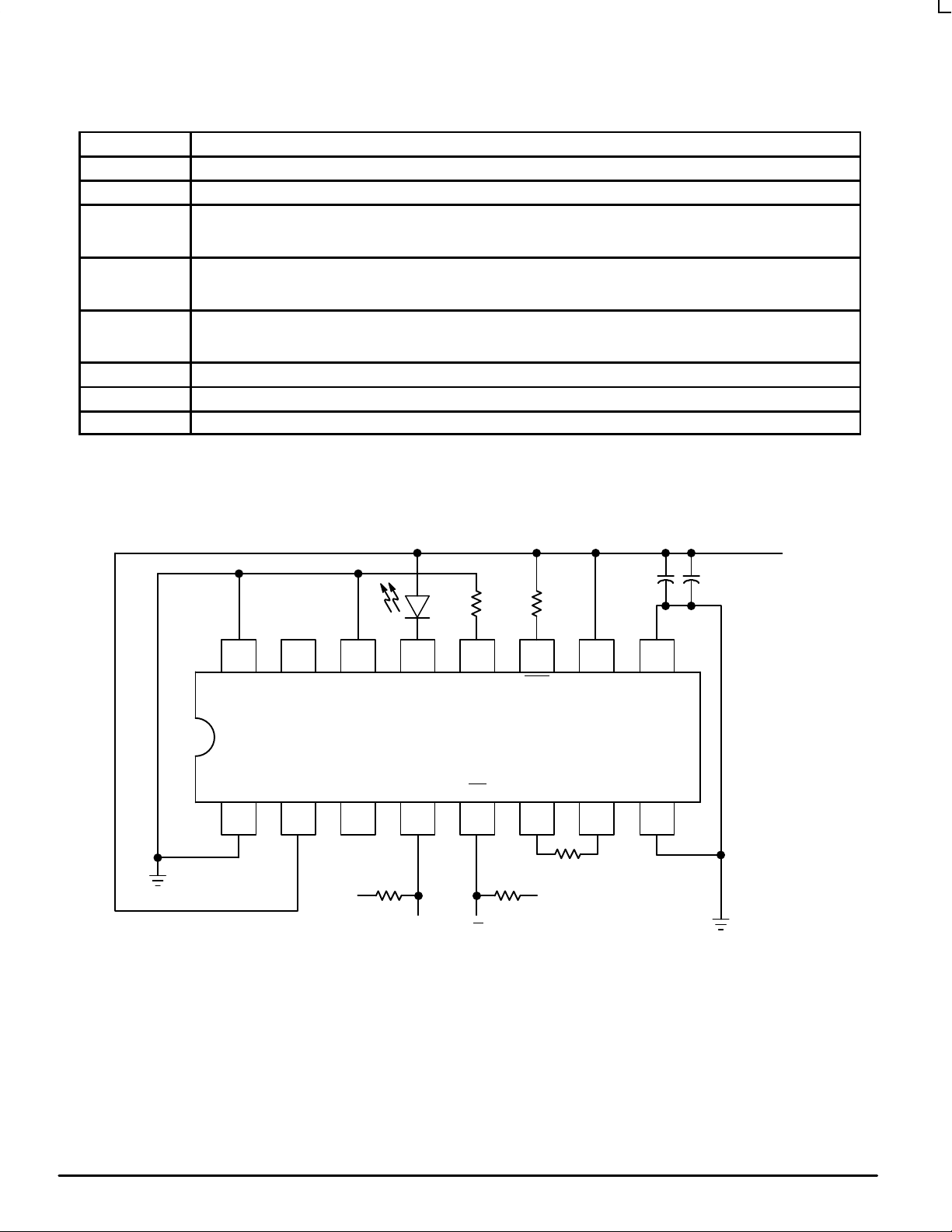

EE

V

EE

Stretch V

V

10

Ω

1516 14 13 12 11 10

50

I

OUT

D

IN

Ω

IN

EE

PECL

BIAS

V

BB

CC

21 34567

RSET I

D

IN

50

IN

10

Ω

OUT

RTCO1RTCO

1k

Ω

PECL

BIAS

Ω

9

V

CC

V

EE

V

2

EE

8

Figure 1. T ypical +5V Applications Circuit

SUPPLY

+5.0V

DECOUPLING

CAPACITORS

MOTOROLA High Performance Frequency

2

Control Products — BR1334

Page 3

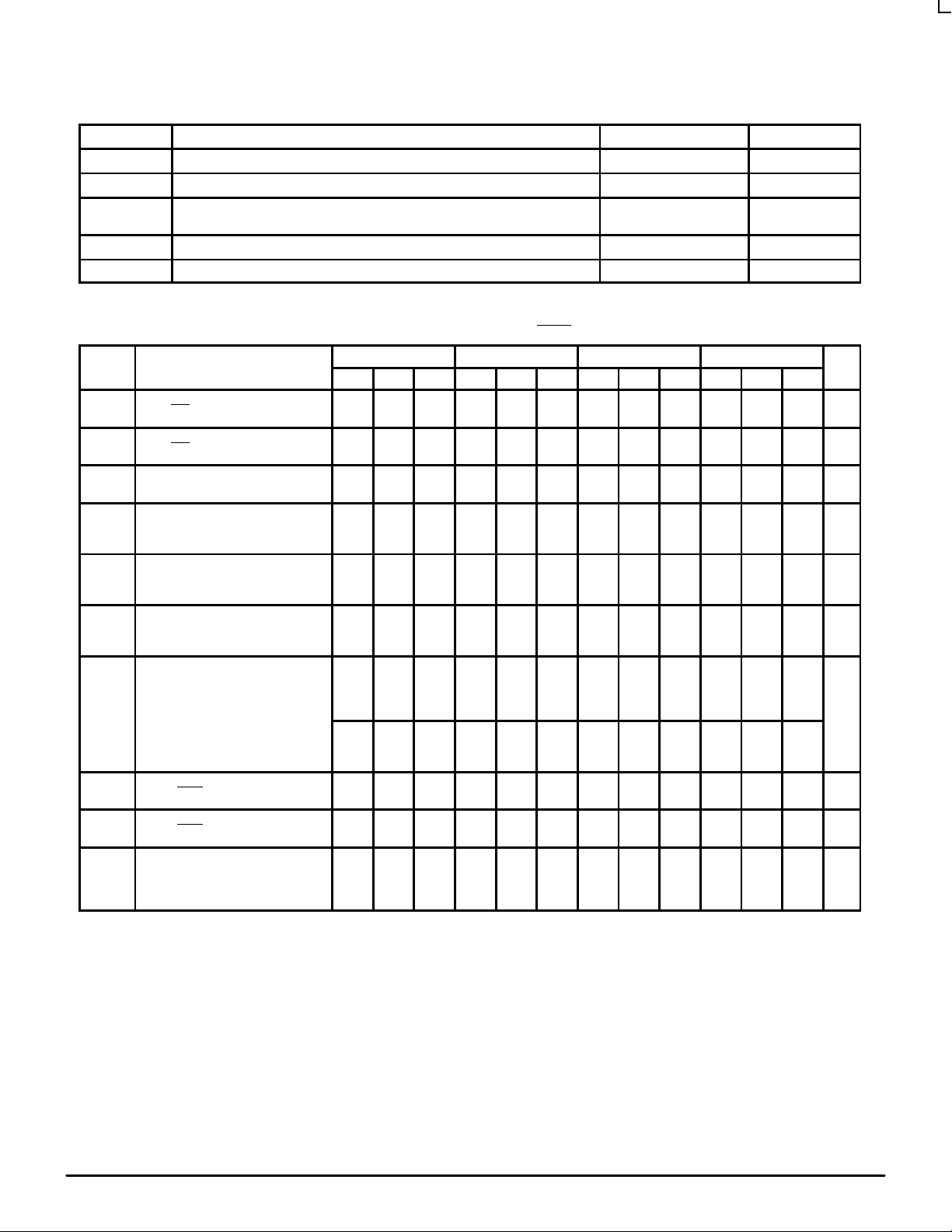

ABSOLUTE MAXIMUM RATINGS

Symbol

V

V

I

out

T

V

EE

I

A

EE

Power Supply (VCC = 0V) –7.0 to 0 VDC

Input Voltage (VCC = 0V) 0 to –6.0 VDC

Output Current Continuous

Operating Temperature Range –40 to +85 °C

Operating Range (VCC = 0) –5.5 to –4.5 VDC

*

Parameter Value Unit

Surge

* Absolute maximum rating, beyond which, device life may be impaired.

100

110

mA

DC CHARACTERISTICS1 (RTCO = 1kΩ ±5%, R

Symbol Characteristic Min Typ Max Min Typ Max Min Typ Max Min Typ Max Unit

I

IH

I

IL

I

CC

V

IH

V

IL

V

BB

V

SET

IO

IO

V

TR

1. 10SX circuits are designed to meet the DC specifications shown in the table after thermal equilibrium has been established. The circuit is mounted in a test socket

or mounted on a printed circuit board and transverse air greater than 500lfm is maintained.

2. Note that in PECL applications, VIH, VIL, VBB will vary 1:1 with the VCC supply.

3. V

4. VTR tracking measures the rate of change of the V

Input HIGH Current

(DIN, DIN

Input LOW Current

(DIN, DIN

Quiescent Supply Current

(No Load on RSET Pin)

Input HIGH Voltage

Input LOW Voltage

Output Reference Voltage

Output Voltage at RSET Pin

VCC = 5.0V, RTCO = Short

VEE = GND RTCO = 1kΩ

VCC = GND

VEE = –5.2V RTCO = 1kΩ

Output ‘ON’ Current

on

(IOUT, IOUT

Output ‘OFF’ Current

off

(IOUT, IOUT

VSET Tracking

tracks 1:1 with the VEE supply to maintain the same voltage across the RSET resistor.

SET

Pins)

Pins)

2

VCC = 5.0V, VEE = GND

VCC = GND, VEE = -4.5 to -5.5V

2

VCC = 5.0V, VEE = GND

VCC = GND, VEE = -4.5 to -5.5V

2

VCC = 5.0V, VEE = GND

VCC = GND, VEE = -4.5 to -5.5V

RTCO = 2kΩ

3

Pins)

Pins)

Short Between RTCO1 and RTCO2

1kΩ Between RTCO1 and RTCO2

2kΩ Between RTCO1 and RTCO2

RTCO = Short

RTCO = 2kΩ

4

0.5 0.5 0.5 0.5

12 17 24 12 17 24 12 18 24 12 19 24

3770

-1230

3050

-1950

3570

-1430

30 75 30 75 30 75 30 100

voltage over temperature.

SET

= R at I

SET

-40°C 0°C 25°C 85°C

200 200 200 200

4110

-890

3500

-1500

3700

-1300

600

430

230

-4400

-4570

-4770

50 50 50 50

1.4

3.4

4.9

OUT

3830

-1170

3050

-1950

3620

-1380

= R at I

635

515

355

-4365

-4485

-4645

1.4

3.4

4.9

= 10Ω ±1%, Unless Otherwise Noted)

OUT

4160

-840

3520

-1480

3730

-1270

3870

-1130

3050

-1950

3650

-1350

610

570

470

-4390

-4430

-4530

690

650

550

-4310

-4350

-4450

1.4

3.4

4.9

4190

-810

3520

-1480

3750

-1250

770

730

630

-4230

-4270

-4370

3940

-1060

3050

-1950

3690

-1310

775

855

845

-4225

-4145

-4155

1.4

3.4

4.9

µA

µA

mA

mV

4280

-720

mV

3555

-1445

mV

3810

-1190

mV

mA

µA

mV/

°C

Control Products — BR1334

MOTOROLAHigh Performance Frequency

3

Page 4

AC CHARACTERISTICS1 (RTCO = 1kΩ ±5%, R

SET

= R at I

OUT

= R at I

= 10Ω ±1%, Unless Otherwise Noted)

OUT

–40°C 0 to 85°C

Symbol Characteristic Min Typ Max Min Typ Max Unit Condition

t

,

PLH

t

PHL

t

Stretch

tr 10–90

tf 90–10

tr 20–80

tf 80–20

Jitter Jitter Square Wave Input

Propagation Delay (Differential)

to Output (Single-Ended)

Propagation Delay Stretch = OPEN

Stretch = V

Stretch = V

CC

EE

Rise Time

Fall Time

Rise Time

Fall Time

Pseudo Random Input

1300

1300

0

145

300

600

375

490

260

9

10

1000

950

120

250

510

330

360

220

1400

1400

0

155

310

880

550

600

500

6

15

1800

1850

200

380

1260

860

850

750

ns

ps Note 2

ps 10% to 90%

90% to 10%

ps 20% to 80%

80% to 20%

ps Note 3

Note 4

BW Bandwidth 300 400 300 400 MHz

t

SKEW

V

PP

V

CMR

1. 10SX circuits are designed to meet the AC specifications shown in the table after thermal equilibrium has been established. The circuit is mounted in a test socket

or mounted on a printed circuit board and transverse air greater than 500lfm is maintained.

2. When the Stretch function is used, the output low pulse width is increased by the specified amount.

3. Test condition uses a 133 MHz 50% duty cycle signal.

4. T est condition uses a 266 Mbit/s input psuedo-random data stream (n=23).

5. Duty cycle skew is the difference between t

6. Minimum input swing for which AC parameters are guaranteed.

7. The CMR range is referenced to the most positive side of the differential input signal. Normal operation is obtained if the HIGH level falls within the specified range

and the peak-to-peak voltage lies between VPP

Duty Cycle Skew (Differential) ±30 ±30 ps Note 5

Minimum Input Swing 150 150 mV Note 6

Common Mode Range –0.400 See 7 –0.400 See 7 V Note 7

PLH

and t

propagation delay through a device, Stretch input is left open.

PHL

and 1.0V. The lower end of the CMR range is dependent on VEE and is equal to VEE + 3.5V.

Min

MOTOROLA High Performance Frequency

4

Control Products — BR1334

Page 5

APPLICATIONS INFORMATION

Introduction

The MC10SX1130 is intended to be integrated into high

performance fiber optic modules or used stand-alone to drive

a packaged optical LED device. The wide frequency

response of the device allows it to be used to support a

variety of digital communication applications ranging from:

• OC1/3 SONET/SDH Links

• 100 MBit/s FDDI

• 155 MBit/s A TM

• 133/266 MBit/s FibreChannel

To support such wide ranging application areas, the LED

Driver incorporates a variety of unique features. These offer

designers added flexibility that could not previously be

realized in less integrated designs.

LED Characteristics

LED devices emit light when forward biased. The optical

power emitted by an LED is determined by the amount of

current flowing through the device. This relationship is a

relatively linear function of the current, until the device

saturates. In some ways, an LED device behaves much like a

traditional small signal silicon diode, although the forward

“ON” voltage of an LED is much larger and ranges from 1.0V

to 2.0V. In addition, for a fixed amount of current, the optical

power from the LED will decrease if the device junction

temperature increases. Another behavior of most LED

devices is that they have unequal turn-on and turn-off times.

In developing an LED transmitter, the designer must wrestle

with all these behaviors to develop a product that meets the

design targets.

LED Driver

The MC10SX1130 LED Driver accepts a digital binary

data stream which is processed by the driver circuitry to

create a current waveform to modulate the LED device. The

LED Driver contains circuitry to program the modulation

current, pre-distort the input waveform to partially

compensate for the LED turn-on/turn-off delay, and

compensate for the negative optical output power tracking

co-efficient. The LED Driver operates from a +5V supply for

PECL applications or a –5.2V supply for traditional ECL

systems. For further information on PECL, please consult

“Designing with PECL Application Note”, AN1406/D available

from a Motorola representative.

Circuit Blocks

Some of the key sub-circuits in the LED Driver are listed

below:

• Input Line Receiver

• Pulse Stretcher

• Bias Control Circuitry

• Output Current Switch

The data input circuitry has been realized as a traditional

differential ECL line receiver. It can accept either differential

100K or 10KH style ECL or PECL depending on the supply

voltage used. In addition, a VBB reference is provided for use

in single ended applications. This reference is useful if the

input signal must be AC coupled into the device.

The pulse stretcher provides two choices of duty cycle

pre-distortion. It is controlled by the input STRETCH signal.

When the pin is left open, no pre-distortion is applied to the

input waveform. If the pin is strapped to the upper or lower

rail, then the output waveform low pulse width will be

increased. In a +5V application, when the STRETCH pin is

tied to +5V, the nominal pulse width increase is 155 ps and

when it is connected to 0V, the nominal pulse width is

increased by 310 ps.

The bias control circuitry regulates the voltage supplied at

the RSET pin of the output current switch. In addition, it

implements a positive tracking circuit which provides open

loop temperature compensation for the LED’s negative

tracking coefficient. An external resistor connected between

the RTCO1 and RTCO2 is used to select the rate of voltage

change at the RSET pin.

The output current switch is the final stage in modulating

the LED. The emitter of the current source is pinned out so

that an external resistor can be used to set the modulation

current. This circuit is implemented using a fully differential

gate where both collectors are brought out. As the LED is

modulated on and off, the current switches from one collector

to another. This architecture minimizes the switching noise

inherent in some LED driver design topologies where the

modulation current is actually turned on and off.

Design Considerations

Once the user has selected an LED, the driver circuitry

should be optimized to match the characteristics of the LED.

The three circuit blocks previously described allow the user

to control the pulse width adjustment, LED drive current and

temperature tracking rate. A very simple example may best

illustrate the design process steps.

An LED has been selected which has the desired optical

output power when modulated with a waveform of 65mA. In

addition, the LED has an output power tracking coefficient of

–0.5%/°C. Thus for every 1°C rise in the case temperature of

the LED, the output power will decrease by 0.5% of the

nominal value. In addition, the LED forward voltage is 1.5V.

First, the RSET resistor must be chosen to set the desired

nominal modulation current based on the following equation:

RSET = V

The voltage at VSET is a function of the RTCO tracking

resistor, so the desired tracking rate (VTR) must also be

chosen. To determine this, the equation must be normalized

to correspond to how the LED has been specified.

Temp Co = VTR/V

The data sheet has three temperature tracking rates for

different values of the RTCO resistor. By using the V

values at 25°C and substituting those numbers into Equation

2, normalized tracking rates can be calculated.

SET/IMOD

SET

(Equation 1)

(Equation 2)

SET

Control Products — BR1334

MOTOROLAHigh Performance Frequency

5

Page 6

Normalized Tracking at 25°C

RTCO Tracking %/°C

Short +0.20

1 KΩ +0.52

A specially designed thermally enhanced leadframe has

been used to house the LED Driver. Below is a graph of the

average ΘJA plotted against air flow.

110

2 KΩ +0.89

To match the LED chosen, a 1KΩ resistor can be used.

Now that this is known, the value of the voltage at the V

SET

can be substituted into Equation 1 to determine the value of

RSET resistor which, for this example is 10Ω.

The Stretch circuit can be used to compensate for the

turn-on/turn-off delay of the LED. The circuit has been

designed for ease of use so the pin is designed to be

strapped to one of the two power plane levels to select the

pre-distortion value. If no pre-distortion is desired, the pin can

be left open. In this +5V example, the maximum amount of

pre-distortion is desired, so the STRETCH pin is connected

to ground.

In addition a resistor must be placed between I

OUT

and

VCC. In selecting this resistor, just as in the case of the

RSET, the resistor type should be chosen to dissipate the

worst case power and derated for the worst case

temperature. As a rule of thumb, the voltage drop across the

resistor should match the forward voltage across the diode.

The voltage can be larger to minimize the power dissipated

on chip when the LED is not ’ON’. Although, the voltage drop

across this resistor should not be greater than 2V. For this

example:

I

MOD(max)

R @ I

+

R @ I

= VF/I

OUT

V

SET

°

@85 C

RSET

= 1.5V/86mA = 17Ω

OUT

MOD

855mV

+

10

+

86mA

W

Because of the positive tracking circuitry in the LED driver,

the modulation current will increase over temperature. It is

important to now go back and re-calculate the numbers

under the worst case environmental conditions to ensure that

operating conditions have not been exceeded.

100

°Θ

90

( C/W)

JA

80

70

0 100 200 300 400 500

AIRFLOW (LFPM)

Figure 2. T ypical ΘJA versus Airflow

The power dissipation of the device has two components;

the quiescent power drain related to the pre-drive circuitry,

and the power dissipated in the current switch when driving

the LED.

Pd = Pstatic + Pswitching (Equation 4)

The power dissipated in the current switch is a function of

the IMOD current, the LED forward voltage, and the value of

RSET. For example in a +5V application, the following

equations can be used:

Pstatic = VCC * ICC (Equation 5)

Pswitching = (VCC-VF-V

SET

)* I

(Equation 6)

MOD

Now to calculate the dissipated power on the chip for a

nominal application.

V

= 5V

CC

V

= 1.5V

F

V

= 0.7V

SET

I

= 60mA

MOD

I

= 18mA

CC

so:

Pd = 5 * 18 + (5 - 1.5 - 0.7) * 60

Pd = 258mW

Thermal Management

LED devices tend to require large amounts of current for

most efficent operation. This requirement is then translated

into the design of the LED Driver. When large modulation

currents are required, power dissipation becomes a critical

issue and the user must be concerned about the junction

temperature of the device. The following equation can be

used to estimate the junction temperature of a device in a

given environment:

TJ = TA + PD * Θ

T

Junction Temperature

J

T

Ambient Temperature

A

P

Power Dissipation

D

Θ

Average Thermal Resistance

JA

JA

(Equation 3)

(Junction-Ambient)

MOTOROLA High Performance Frequency

6

This number can be entered into Equation 3 along with the

environmental information to calculate the nominal operating

junction temperature.

Because of the open loop feedback control in the bias

control circuitry, the revised I

value must be determined

MOD

given the tracking rate chosen so that the power dissipation

can be re-calculated. For assessing product reliability, worst

case values should be entered to calculate the maximum

junction temperature.

Reliability of Plastic Packages

Although today’s plastic packages are as reliable as

ceramic packages under most environmental conditions, as

the junction temperature increases a failure mode unique to

plastic packages becomes a significant factor in the long

term reliability of the device.

Control Products — BR1334

Page 7

Modern plastic package assembly utilizes gold wire

bonded to aluminum bonding pads throughout the

electronics industry. As the temperature of the silicon

(junction temperature) increases, an intermetallic compound

forms between the gold and aluminum interface. This

intermetallic formation results in a significant increase in the

impedance of the wire bond and can lead to performance

failure of the affected pin. With this relationship between

intermetallic formation and junction temperature established,

it is incumbent on the designer to ensure that the junction

temperature for which a device will operate is consistent with

the long term reliability goals of the system.

Reliability studies were performed at elevated ambient

temperatures (125°C) from which an arrhenius equation,

relating junction temperature to bond failure, was

established. The application of this equation yields the table

of Figure 3. This table relates the junction temperature of a

device in a plastic package to the continuous operating time

before 0.1% bond failure (1 failure per 1000 bonds)

The MC10SX1130 device is designed with chip power

levels that permit acceptable reliability levels, in most

systems, under the conventional 500 lfpm (2.5m/s) airflow.

T = 6.376 × 10–9 e

11554.267

273.15 + T

J

Where:

T = Time to 0.1% bond failure

Junction

Temp. (°C)

80 1,032,200 117.8

90 419,300 47.9

100 178,700 20.4

110 79,600 9.1

120 37,000 4.2

130 17,800 2.0

140 8,900 1.0

Time (Hrs.) Time (yrs.)

Figure 3. Tj vs Time to 0.1% Bond Failure

Control Products — BR1334

MOTOROLAHigh Performance Frequency

7

Page 8

-T-

SEATING

PLANE

OUTLINE DIMENSIONS

D SUFFIX

PLASTIC SOIC PACKAGE

-A-

CASE 751B-05

916

-B-

8 PL

P

1

8

0.25 (0.010) B

M M

G

K

R X 45°

F

C

J

D

16 PL

0.25 (0.010) T B A

M

M

S S

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A AND B DO NOT INCLUDE MOLD

PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

MILLIMETERS INCHES

MIN MINMAX MAX

DIM

A

9.80

B

3.80

C

1.35

D

0.35

F

0.40

1.27 BSC 0.050 BSC

G

J

0.19

K

0.10

M

°

0

P

5.80

R

0.25

10.00

4.00

1.75

0.49

1.25

0.25

0.25

7

6.20

0.50

0.386

0.393

0.150

0.157

0.054

0.068

0.014

0.019

0.016

0.049

0.008

0.009

0.004

0.009

°

°

0

0.229

0.010

7

0.244

0.019

°

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit,

and specifically disclaims any and all liability, including without limitation consequential or incidental damages. “Typical” parameters can and do vary in different

applications. All operating parameters, including “T ypicals” must be validated for each customer application by customer’s technical experts. Motorola does

not convey any license under its patent rights nor the rights of others. Motorola products are not designed, intended, or authorized for use as components in

systems intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of

the Motorola product could create a situation where personal injury or death may occur. Should Buyer purchase or use Motorola products for any such

unintended or unauthorized application, Buyer shall indemnify and hold Motorola and its officers, employees, subsidiaries, affiliates, and distributors harmless

against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that Motorola was negligent regarding the design or manufacture of the part.

Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal Opportunity/Affirmative Action Employer.

Literature Distribution Centers:

USA: Motorola Literature Distribution; P.O. Box 20912; Phoenix, Arizona 85036.

EUROPE: Motorola Ltd.; European Literature Centre; 88 T anners Drive, Blakelands, Milton Keynes, MK14 5BP, England.

JAPAN: Nippon Motorola Ltd.; 4-32-1, Nishi-Gotanda, Shinagawa-ku, Tokyo 141 Japan.

ASIA-PACIFIC: Motorola Semiconductors H.K. Ltd.; Silicon Harbour Center, No. 2 Dai King Street, Tai Po Industrial Estate, Tai Po, N.T., Hong Kong.

3PHX32168-1 PRINTED IN USA 3/94 IMPERIAL LITHO XXXXX 7,500 LOGIC YDAAAA

MOTOROLA High Performance Frequency

8

◊

*MC10SX1130/D*

Control Products — BR1334

MC10SX1130/D

Loading...

Loading...