Page 1

MOTOROLA

SEMICONDUCTOR TECHNICAL DATA

68030/040

PECL-TTL Clock Driver

The MC10H/100H640 generates the necessary clocks for the 68030,

68040 and similar microprocessors. It is guaranteed to meet the clock

specifications required by the 68030 and 68040 in terms of part–to–part

skew, within–part skew and also duty cycle skew.

The user has a choice of using either TTL or PECL (ECL referenced to

+5.0V) for the input clock. TTL clocks are typically used in present MPU

systems. However, as clock speeds increase to 50MHz and beyond, the

inherent superiority of ECL (particularly differential ECL) as a means of

clock signal distribution becomes increasingly evident. The H640 also

uses differential PECL internally to achieve its superior skew

characteristic.

The H640 includes divide–by–two and divide–by–four stages, both to

achieve the necessary duty cycle skew and to generate MPU clocks as

required. A typical 50MHz processor application would use an input clock

running at 100MHz, thus obtaining output clocks at 50MHz and 25MHz

(see Logic Symbol).

The 10H version is compatible with MECL 10H ECL logic levels,

while the 100H version is compatible with 100K levels (referenced

to +5.0V).

• Generates Clocks for 68030/040

• Meets 030/040 Skew Requirements

• TTL or PECL Input Clock

• Extra TTL and PECL Power/Ground Pins

• Asynchronous Reset

• Single +5.0V Supply

MC10H640

MC100H640

68030/040

PECL–TTL CLOCK

DRIVER

FN SUFFIX

PLASTIC PACKAGE

CASE 776–02

Function

Reset (R):

Power–Up:

Select (SEL):

The H640 also contains circuitry to force a stable state of the ECL input differential pair, should both sides be left open. In this

case, the DE side of the input is pulled LOW, and DE

LOW on RESET forces all Q outputs LOW and all Q outputs HIGH.

The device is designed to have the POS edges of the ÷2 and ÷4 outputs synchronized at power up.

LOW selects the ECL input source (DE/DE). HIGH selects the TTL input source (DT).

goes HIGH.

VT VT Q1 GT GT Q0 VT

25 24 23 22 21 20 19

18

Q2

GT

GT

VT

VT

Q3

26

27

28

1

2

3

4

Pinout: 28–Lead PLCC

(Top View)

567891011

Q1

GT GT Q4 Q5 VT SEL

V

BB

17

DE

16

DE

VE

15

R

14

GE

13

12

DTQ0

11/93

Motorola, Inc. 1996

2–1

REV 3

Page 2

MC10H640 MC100H640

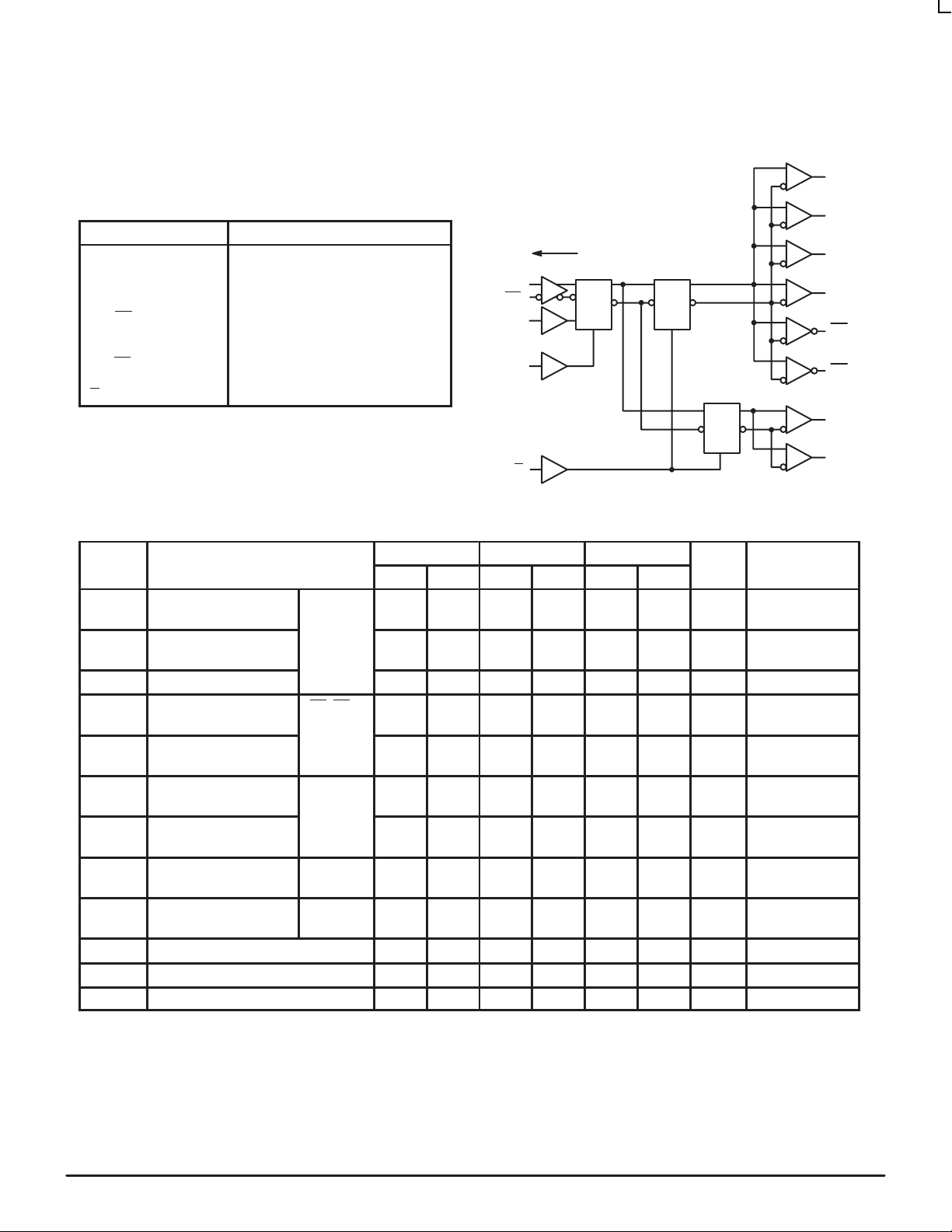

LOGIC DIAGRAM

TTL Outputs

Q0

PIN NAMES

TTL/ECL Clock Inputs

V

BB

DE

DE

DT

SEL

MUX

÷ 2

÷ 4

GT

VT

VE

GE

DE, DE

V

BB

DT

Qn, Qn

SEL

R

PIN FUNCTION

TTL Ground (0 V)

TTL VCC (+5.0 V)

ECL VCC (+5.0 V)

ECL Ground (0 V)

ECL Signal Input (positive ECL)

VBB Reference Output

TTL Signal Input

Signal Outputs (TTL)

Input Select (TTL)

Reset (TTL)

TTL Control Inputs

R

AC CHARACTERISTICS (VT = VE = 5.0V ±5%)

0°C 25°C 85°C

Symbol Characteristic Min Max Min Max Min Max Unit Condition

t

PLH

t

PLH

tskwd* Within–Device Skew 0.5 0.5 0.5 ns CL = 25pF

t

PLH

t

PLH

t

PLH

t

PLH

t

PD

t

R

t

F

f

max

t

pw

t

rr

* Within–Device Skew defined as identical transitions on similar paths through a device.

Propagation Delay ECL

D to Output

Propagation Delay TTL

D to Output

Propagation Delay ECL

D to Output

Propagation Delay TTL

D to Output

Propagation Delay ECL

D to Output

Propagation Delay TTL

D to Output

Propagation Delay

R to Output

Output Rise/Fall Time

0.8 V – 2.0 V

Maximum Input Frequency 135 135 135 MHz CL = 25pF

Minimum Pulse Width 1.50 1.50 1.50 ns

Reset Recovery Time 1.25 1.25 1.25 ns

Q0–Q3 4.9 5.9 4.9 5.9 5.2 6.2 ns CL = 25pF

5.0 6.0 5.0 6.0 5.3 6.3 ns CL = 25pF

Q0, Q1 4.9 5.9 4.9 5.9 5.2 6.2 ns CL = 25pF

5.0 6.0 5.0 6.0 5.3 6.3 ns CL = 25pF

Q4, Q5 4.9 5.9 4.9 5.9 5.2 6.2 ns CL = 25pF

5.0 6.0 5.0 6.0 5.3 6.3 ns CL = 25pF

All

Outputs

All

Outputs

4.3 6.3 4.3 6.3 5.0 7.0 ns CL = 25pF

2.5

2.5

2.5

2.5

2.5

2.5

ns CL = 25pF

Q1

Q2

Q3

Q0

Q1

Q4

Q5

MOTOROLA MECL Data

2–2

DL122 — Rev 6

Page 3

MC10H640 MC100H640

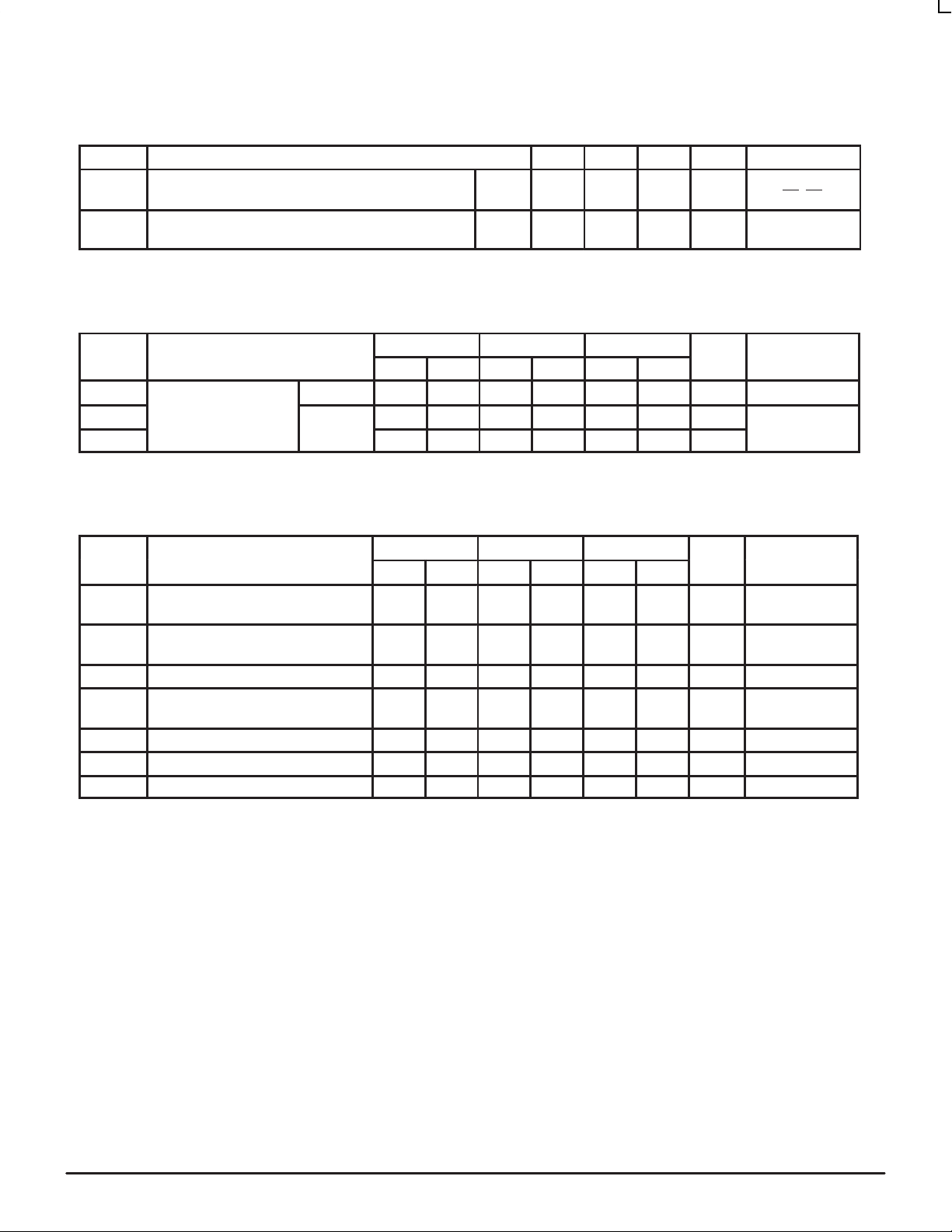

VCC and CLOAD RANGES TO MEET DUTY CYCLE REQUIREMENTS (0°C ≤ TA ≤ 85°C Output Duty Cycle Measured

Relative to 1.5V)

Symbol Characteristic Min Nom Max Unit Condition

Range of VCC and CL to meet minimum pulse width

(HIGH or LOW) = 11.5 ns at f

Range of VCC and CL to meet minimum pulse width

(HIGH or LOW) = 9.5 ns at 40 < f

≤ 40 MHz

out

out

≤ 50 MHz

DC CHARACTERISTICS (VT = VE = 5.0 V ±5%)

0°C 25°C 85°C

Symbol Characteristic Min Max Min Max Min Max Unit Condition

I

EE

I

CCH

I

CCL

Power Supply Current ECL 57 57 57 mA VE Pin

TTL 30 30 30 mA Total all VT pins

V

CC

CL

V

CC

CL

30 30 30 mA

4.75

10

4.875155.0 5.125

5.0 5.25

50

27

V

pF

V

pF

Q0–Q3

–Q1

Q0

Q0–Q3

TTL DC CHARACTERISTICS (VT = VE = 5.0 V ±5%)

0°C 25°C 85°C

Symbol Characteristic Min Max Min Max Min Max Unit Condition

V

V

I

I

V

V

V

I

IH

IL

IH

IL

OH

OL

IK

OS

Input HIGH Voltage

Input LOW Voltage

Input HIGH Current 20

Input LOW Current –0.6 –0.6 –0.6 mA VIN = 0.5V

Output HIGH Voltage 2.5

Output LOW Voltage 0.5 0.5 0.5 V IOL = 24mA

Input Clamp Voltage –1.2 –1.2 –1.2 V IIN = –18mA

Output Short Circuit Current –100 –225 –100 –225 –100 –225 mA V

2.0

2.0

0.8

100

2.0

2.5

2.0

0.8

20

100

2.0

2.5

2.0

0.8

20

100

V

µA VIN = 2.7V

VIN = 7.0V

V IOH = –3.0mA

IOH = –15mA

= 0V

OUT

DL122 — Rev 6

2–3 MOTOROLAMECL Data

Page 4

MC10H640 MC100H640

10H PECL DC CHARACTERISTICS (VT = VE = 5.0 V ±5%)

0°C 25°C 85°C

Symbol Characteristic Min Max Min Max Min Max Unit Condition

I

IH

I

IL

VIH*

VIL*

VBB* Output Reference Voltage 3.62 3.73 3.65 3.75 3.69 3.81 V

*NOTE: PECL levels are referenced to VCC and will vary 1:1 with the power supply. The values shown are for VCC = 5.0V.

100H PECL DC CHARACTERISTICS (VT = VE = 5.0 V ±5%)

Symbol Characteristic Min Max Min Max Min Max Unit Condition

I

IH

I

IL

VIH*

VIL*

VBB* Output Reference Voltage 3.62 3.74 3.62 3.74 3.62 3.74 V

*NOTE: PECL levels are referenced to VCC and will vary 1:1 with the power supply. The values shown are for VCC = 5.0V.

Input HIGH Current

Input LOW Current

Input HIGH Voltage

Input LOW Voltage

Input HIGH Current

Input LOW Current

Input HIGH Voltage

Input LOW Voltage

0.5

3.83

3.05

0.5

3.835

3.19

225

4.16

3.52

0°C 25°C 85°C

225

4.12

3.525

0.5

3.87

3.05

0.5

3.835

3.19

175

4.19

3.52

175

4.12

3.525

0.5

3.94

3.05

0.5

3.835

3.19

175 µA

4.28

3.555

175 µA

4.12

3.525

V VE = 5.0V

V VE = 5.0V

10/100H640

DUTY CYCLE CONTROL

T o maintain a duty cycle of ±5% at 50MHz, limit the load capacitance and/or power supply variation as shown in Figures 1 and 2.

For a ±2.5% duty cycle limit, see Figures 3 and 4. Figures 5 and 6 show duty cycle variation with temperature. Figure 7 shows typical

TPD versus load. Figure 8 shows reset recovery time. Figure 9 shows output states after power up.

Best duty cycle control is obtained with a single µP load and minimum line length.

MOTOROLA MECL Data

2–4

DL122 — Rev 6

Page 5

MC10H640 MC100H640

11

11

OS

T

VE

LSE

DT

OS

T

VE

LSE

DT

5.25 V

CC

5 V

CC

4.75 V

CC

10

PW (ns)

9

10

9

NEGATIVE PULSE WIDTH (ns)

4.75 V

5 V

CC

5.25 V

CC

CC

0 25507585

LOAD (pF)

Figure 1. Positive Pulse Width at

25°C Ambient and 50 MHz Out

11

5.125 V

CC

5 V

CC

4.875 V

H (ns)

10

WI

PU

I

I

P

9

025507585

LOAD (pF)

CC

Figure 3. Positive Pulse Width at

25°C Ambient at 50 MHz Out

025507585

LOAD (pF)

Figure 2. Negative Pulse Width @ 50 MHz

Out and 25°C Ambient

11

10

4.875 V

CC

5 V

CC

5.125 V

9

NEGATIVE PULSE WIDTH (ns)

025507585

LOAD (pF)

CC

Figure 4. Negative Pulse Width @ 50 MHz

Out and 25°C Ambient

11

50 pF

H (ns)

10

WI

PU

I

I

P

9

0° 25° 50° 75° 85°

TEMPERATURE (°C)

25 pF

10 pF

Figure 5. T emperature versus Positive Pulse W idth

for 100H640 at 50 MHz and +5.0 V V

DL122 — Rev 6

CC

11

10 pF

10

9

NEGATIVE PULSE WIDTH (ns)

0°

25°

TEMPERATURE (°C)

25 pF

50° 75° 85°

Figure 6. T emperature versus Negative Pulse W idth

for MC100H640 @ 50 MHz and +5.0 V V

2–5 MOTOROLAMECL Data

CC

Page 6

MC10H640 MC100H640

6.2

TP (ns)

D++

6.0

5.8

5.6

5.4

4.75 V

5 V

5.25 V

DT

RESET, R

Q0, Q1, Q2, Q3

Q0

, Q1

Q4, Q5

5.2

0

25

50 75 85

C

(pF)

LOAD

Figure 7. TP versus Load T ypical at TA = 25°C

R

R

tpw

trec

Figure 8. MC10H/100H640 Clock Phase and Reset Recovery Time After Reset Pulse

D

in

Q0 Q

3

Q

Q

1

2

Q4 & Q

5

AFTER POWER UP

OUTPUTS Q4 & Q5 WILL SYN WITH POSITIVE EDGES OF Din & Q0 Q3 & NEGATIVE EDGES OF Q

0

& Q

1

Figure 9. Output Timing Diagram

MOTOROLA MECL Data

2–6

DL122 — Rev 6

Page 7

OUTLINE DIMENSIONS

FN SUFFIX

PLASTIC PLCC PACKAGE

CASE 776–02

ISSUE D

MC10H640 MC100H640

–L–

–N–

28 1

Z

C

G

G1

S

0.010 (0.250) N

L–M

T

S

L–M

T

M

S

S

L–M

T

S

Y BRK

0.007 (0.180) N

B

0.007 (0.180) N

U

M

D

Z

–M–

W

D

V

0.010 (0.250) N

G1X

S

S

L–M

T

S

VIEW D–D

A

0.007 (0.180) N

0.007 (0.180) N

R

E

M

M

S

L–M

T

L–M

T

S

S

S

H

0.007 (0.180) N

M

S

L–M

T

S

K1

0.004 (0.100)

SEATING

J

–T–

PLANE

VIEW S

S

S

K

VIEW S

0.007 (0.180) N

F

M

S

L–M

T

S

NOTES:

1. DATUMS –L–, –M–, AND –N– DETERMINED

WHERE TOP OF LEAD SHOULDER EXITS

PLASTIC BODY AT MOLD PARTING LINE.

2. DIMENSION G1, TRUE POSITION TO BE

MEASURED AT DATUM –T–, SEATING PLANE.

3. DIMENSIONS R AND U DO NOT INCLUDE

MOLD FLASH. ALLOWABLE MOLD FLASH IS

0.010 (0.250) PER SIDE.

4. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

5. CONTROLLING DIMENSION: INCH.

6. THE PACKAGE TOP MAY BE SMALLER THAN

THE PACKAGE BOTTOM BY UP TO 0.012

(0.300). DIMENSIONS R AND U ARE

DETERMINED AT THE OUTERMOST

EXTREMES OF THE PLASTIC BODY

EXCLUSIVE OF MOLD FLASH, TIE BAR

BURRS, GATE BURRS AND INTERLEAD

FLASH, BUT INCLUDING ANY MISMATCH

BETWEEN THE TOP AND BOTTOM OF THE

PLASTIC BODY.

7. DIMENSION H DOES NOT INCLUDE DAMBAR

PROTRUSION OR INTRUSION. THE DAMBAR

PROTRUSION(S) SHALL NOT CAUSE THE H

DIMENSION TO BE GREATER THAN 0.037

(0.940). THE DAMBAR INTRUSION(S) SHALL

NOT CAUSE THE H DIMENSION TO BE

SMALLER THAN 0.025 (0.635).

DIM MIN MAX MIN MAX

A 0.485 0.495 12.32 12.57

B 0.485 0.495 12.32 12.57

C 0.165 0.180 4.20 4.57

E 0.090 0.110 2.29 2.79

F 0.013 0.019 0.33 0.48

G 0.050 BSC 1.27 BSC

H 0.026 0.032 0.66 0.81

J 0.020 ––– 0.51 –––

K 0.025 ––– 0.64 –––

R 0.450 0.456 11.43 11.58

U 0.450 0.456 11.43 11.58

V 0.042 0.048 1.07 1.21

W 0.042 0.048 1.07 1.21

X 0.042 0.056 1.07 1.42

Y ––– 0.020 ––– 0.50

Z 2 10 2 10

____

G1 0.410 0.430 10.42 10.92

K1 0.040 ––– 1.02 –––

MILLIMETERSINCHES

DL122 — Rev 6

2–7 MOTOROLAMECL Data

Page 8

MC10H640 MC100H640

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

How to reach us:

USA/EUROPE/ Locations Not Listed: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.; Tatsumi–SPD–JLDC, 6F Seibu–Butsuryu–Center,

P.O. Box 20912; Phoenix, Arizona 85036. 1–800–441–2447 or 602–303–5454 3–14–2 Tatsumi Koto–Ku, Tokyo 135, Japan. 03–81–3521–8315

MFAX: RMF AX0@email.sps.mot.com – T OUCHTONE 602–244–6609 ASIA/ PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

INTERNET: http://Design–NET .com 51 Ting Kok Road, Tai Po, N.T., Hong Kong. 852–26629298

MOTOROLA MECL Data

2–8

*MC10H640/D*

◊

MC10H640/D

DL122 — Rev 6

Loading...

Loading...