Page 1

SEMICONDUCTOR TECHNICAL DATA

1

REV 0

Motorola, Inc. 1997

7/97

!

The MC100SX1451FI100 AutoBahn chip is a high–speed serial–

to–parallel, parallel–to–serial transceiver. The AutoBahn can be used to

implement a high–speed, half–duplex, bi–directional serial data link with

an effective data transfer rate of 100MByte/sec. A higher performance

AutoBahn chip, with user selectable serial data transfer rates of 100 or

200MByte/s, is planned (see the MC100SX1451FI200 datasheet).This

serial link can be used to establish multi–point or point–to–point

connections. A unique differential cutoff driver switches from a standard

PECL VOH level to cutoff. In the cutoff state the outputs present a high

impedance which is required to implement a true shared bus. The part

features a 32–bit wide parallel TTL compatible I/O interface that can

connect directly with standard memory or bus transceiver devices. The

control pins are all TTL compatible to simplify interfacing requirements.

The serial interface is PECL (Positive Emitter Coupled Logic) which

provides excellent transmission line drive capability. Because the serial

bus is implemented using differential ECL technology, the receiver

circuitry exhibits excellent common mode noise rejection.

• 100MByte/s Serial Data Transfer Capability

• TTL Compatible Parallel Interface

• Supports 16– or 32–Bit Data Bus Interfaces

• Bus Driving Differential ECL Serial Outputs

• On–Board Clock Recovery and Data Synchronization

• 64–Pin Surface Mount CQFP Packaging

• Parallel Data Bus Handshake Control

An innovative data synchronizing architecture allows data to be transmitted in bursts without preamble bits. This allows

instantaneous data acquisition without the inherent overhead of traditional PLL clock recovery. Thus, the data transfer is nearly

overhead free with only one synchronization bit for every byte of data transmitted. Insertion and removal of synchronization bits

are totally transparent to the user.

The AutoBahn supports variable data transfer rates. This is accomplished by combining the fixed burst transfer rates of 50 or

100MByte/s with a flexible method of allowing data to be written into the AutoBahn for transfer. If new data has not been written

into the parallel data register prior to the completion of a serial data burst, the AutoBahn will insert a gap in the serial data stream.

Therefore, the effective throughput of the serial bus is throttled by the speed of the parallel host interface which writes data to the

chip.

With its very high block data transfer capability and instantaneous start up ability, the AutoBahn is ideally suited for multimedia

graphics applications and parallel processing architectures requiring multi–processor communication links.

Motorola’s state–of–the–art MOSAIC V process allows for the realization of 1.8GHz internal clock rates at power levels

which are compatible with today’s low profile surface mount packages. Furthermore, the design is implemented with a

flow–through pinout architecture to simplify PCB layout and routing. The board space efficiency of the CQFP ensures that the

AutoBahn device will prove valuable in the most demanding space conscious applications.

The AutoBahn chip works from a single +5.0V supply. Separate internal VCC busses isolate the TTL outputs from the high

speed PECL circuitry.

AutoBahn and Spanceiver are trademarks of PEP Modular Computers.

‘Spanceiver’ has been formed as a contraction of Serial/Parallel Transceiver .

MOSAIC V is a trademark of Motorola, Inc.

AUTOBAHN

SPANCEIVER

FI SUFFIX

CERAMIC QFP PACKAGE

CASE 963–02

Page 2

MC100SX1451FI100

MOTOROLA ECLinPS and ECLinPS Lite

DL140 — Rev 3

2

CONTROL

REGISTER

ERROR

REGISTER

Figure 1. Simplified Block Diagram

TRANSMIT

REGISTER

PISO

SHIFT

REGISTER

SYNC

BIT

GENERATOR

RECEIVE

REGISTER

SIPO

SHIFT

REGISTER

SYNC

BIT

EXTRACT

PLL

CLOCK

GENERATOR

DIFFERENTIAL

DETECTOR

PISO

CONTROL

LOGIC

SIPO

CONTROL

LOGIC

SERIAL

BUS

TRANSCEIVER

FULL

BUSY

ERROR

FOSC

C1

D31–

D00

REGSEL

REGISTER

READ/

WRITE

LOGIC

RESET

LOGIC

R/W

STRB

RESET

SER

SER

Page 3

MC100SX1451FI100

ECLinPS and ECLinPS Lite

DL140 — Rev 3

3 MOTOROLA

PIN DESCRIPTIONS

Name I/O Description

TTL COMPATIBLE I/O

RESET I Asynchronous reset signal which places the AutoBahn into default state. In most applications, RESET should

only have to be asserted on system startup.

R/W I Read/Write control signal. Used to select between writing to or reading from the AutoBahn.

REGSEL I Control signal used to select between the Parallel Data Register and the Control and Error Register(s). A logic

‘H’ selects the data register while a logic ‘L’ selects the Control and Error Register(s).

D00 – D31 I/O Bi–directional data inputs/outputs. These pins comprise the data bus to be used to interface to the user host

interface. D00 is the least significant bit.

STRB I Data strobe signal. During a write, it indicates that data is valid on the parallel bus. While in a read, it indicates

that the AutoBahn can now place data on the parallel interface.

FULL O Signal which indicates that the transmitter or receiver presently contains data. In conjunction with the STRB

signal, it is used to implement a two signal handshake for parallel data transfers.

BUSY O Serial bus BUSY signal, used to indicate to the parallel interface that the AutoBahn bus is presently in use.

ERROR O Control output which is used to indicate that the AutoBahn has identified a fault condition. The error condition

can then be read out from the Error Register.

FOSC I 25.00MHz clock source from a crystal oscillator reference.

PECL COMPATIBLE I/O

SER/SER I/O Differential serial data inputs/outputs which operate at modified PECL levels.

POWER, GROUND AND FILTER PINS

Name Number Description

C1 1 PLL Filter Capacitor Pin

V

CCE

1 Positive Supply for Internal PECL Logic Circuitry

V

CCO

1 Positive Supply for PECL Outputs

V

EE

1 Ground for PECL

V

CCT

7 Positive Supply for TTL Compatible Signals

V

EET

8 Ground for TTL Compatible Signals

V

CCX

1 Positive Supply for VCO

V

EEX

1 Ground for VCO

BLOCK DIAGRAM FUNCTIONAL DESCRIPTION

Reset Logic

The Reset Logic generates the internal reset signal used

to set the device into a known state. The reset signal clears

the Control and Error Registers and resets the SIPO and

PISO Control Logic. The external reset signal is validated

with the FOSC input clock to assure that a valid reset pulse

has been applied to the chip. The external reset input pin

(RESET

) must be low for a minimum of 125 nsec after the

FOSC input is stable. STRB

assertion may occur no earlier

than 500 nsec after RESET

deassertion (reset recovery

time).

Control Register

The Control Register is used to configure the operation of

the AutoBahn. The register fields are described in detail in

the section containing the Control and Error Register Bit

Definition.

Register Read/Write Control Logic

This logic is utilized to access the Transmit Register, the

Receive Register, and the Control and Error Registers from

the parallel bus. The interface protocol utilizes two direction

control signals (R/W

and REGSEL). The actual handshake to

Page 4

MC100SX1451FI100

MOTOROLA ECLinPS and ECLinPS Lite

DL140 — Rev 3

4

read or write data from the chip is accomplished with the

input STRB

signal , combined with the output FULL signal.

Transmit Register

The transmit register is a 32–bit wide parallel–loadable

register. This register interfaces to the bi–directional TTL

compatible data bus. Access to this register is controlled via

the Register Read/Write Logic.

PISO Shift Register

The PISO (Parallel In/Serial Out) Register accepts data

from the Transmit Register and converts it into a serial bit

stream. This register is under control of the PISO Control

Logic. The shift register can be adjusted to handle 16–bit or

32–bit data traffic based on the state of the appropriate field

in the Control Register.

PISO Control Logic

The PISO (Parallel In/Serial Out) Control Logic is

responsible for controlling the transfer of data out from the

AutoBahn to the serial bus. This logic interfaces to the PISO

Shift Register and the SYNC Bit Generator. It is driven by the

PLL Clock Generator.

SYNC Bit Generator

This circuitry inserts one bit of timing information into the

data stream before every byte of data is sent to the Serial Bus

Transceiver and transmitted. This timing information is used

by the receiver to properly re–clock the incoming data

stream. T o support the maximum data rate of 100 MByte/sec,

the actual serial shift rate is 900 MBit/s NRZ, rather than

800 MBit/s NRZ. The insertion and removal of SYNC bits is

transparent to the end user.

Serial Bus Transceiver

The transceiver implements a two signal bi–directional

differential bus. The transceiver circuitry consists of a highly

sensitive differential receiver and a cutoff driver . The receiver

accepts a differential signal from the serial bus. This

differential signal is amplified and limited by the receiver

before being routed to the clock generation circuitry for clock

extraction and data re–timing.

The cutoff driver is used to transmit serial data on to the

bus. The outputs switch between a normal HIGH level (VOH)

and a cutoff LOW signal – when low the output emitter

follower is turned ’off’, thus presenting a high impedance to

the bus. If the cutoff driver is disabled, both outputs of the

differential pair go to the cutoff state so the bus resource is

available for use by other AutoBahn chips sharing the

same bus.

Differential Detector

The differential detector is used to recognize when the

serial bus goes out of the cutoff state and into a differential

steady state condition. The differential detector is only

utilized at the very start of a transmission. The detector

informs the SIPO Control Logic that the serial bus is no

longer in cutoff so that the bus BUSY

signal can be asserted

by the device.

PLL Clock Generator

The Clock Generator circuitry synthesizes a master timing

clock from the frequency reference signal (FOSC) input. The

clock generator provides timing signals used to support the

transfer rate of 900 MBit/s. The clock is generated by a

Phase Locked Loop (PLL) which requires a simple external

capacitor to set the loop filter bandwidth. The value for C1 is

2700 pF . This circuitry is used to provide the master timing for

the PISO and SIPO Control Logic blocks.

SYNC Bit Extractor

The SYNC Bit Extractor removes each SYNC bit from the

incoming data stream. It is controlled by the SIPO Control

Logic. If a SYNC bit is not detected at the proper bit time in

the extraction process, a field will be set in the Error Register

to indicate that a transmission error has occurred.

SIPO Shift Register

The SIPO (Serial In/Parallel Out) Register accepts data

from the SYNC Bit Extractor and converts it into a parallel

word that is then transferred to the Receive Register. The

operation of this shift register is controlled by the SIPO

Control Logic.

SIPO Control Logic

The SIPO (Serial In/Parallel Out) Control Logic is

responsible for controlling the transfer of data into the

AutoBahn. This circuitry performs all the critical control

functions to allow the AutoBahn to accept and process the

incoming serial data stream. The SIPO Control Logic has the

ability to detect certain transmission related errors and set

the appropriate field(s) in the Error Register.

Receive Register

The receive register is a 32–bit wide parallel load register.

It accepts data from the SIPO (Serial In/Parallel Out) Shift

Register. This register interfaces to the bi–directional TTL

compatible data bus. Access to this register is controlled via

the Register Read/Write Logic.

Error Register

The AutoBahn has the capability to detect certain

transmission related error conditions. These errors are

detected by the SIPO Control Logic which sets the

appropriate error field in the Error Register. The register fields

are described in detail in the section containing the Control

and Error Register Bit Definition. The Error Register has

additional logic that is used to generate the ERROR

signal.

Page 5

MC100SX1451FI100

ECLinPS and ECLinPS Lite

DL140 — Rev 3

5 MOTOROLA

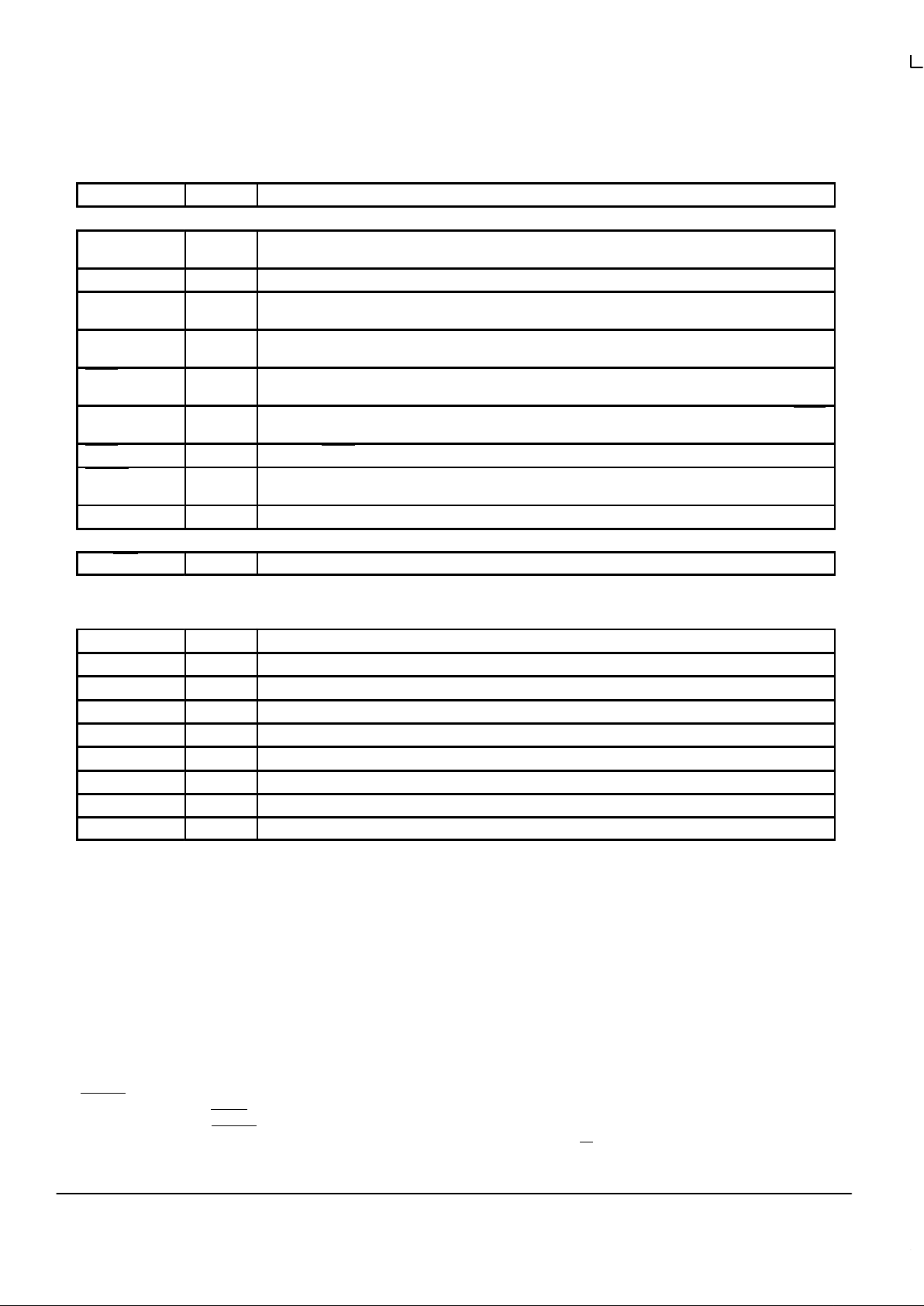

Differential SER detected

Figure 2. Transmit and Receive State Diagram

SER (Serial Data)

in CUTOFF

New data written into Transmit Register

SER differential,

Waiting for 15nS

15nS Timer Expired

NO new data written

into Transmit Register

New data written

into Transmit Register

New data written

into Transmit Register

Reset

4 longword

timer expired

AUTOBAHN

TRANSMIT State Diagram

Waiting for

differential SER

[Assert BUSY signal]

Waiting for Start bit

Start bit observed

Receiving serial

data words

NO new start bit observed

New start bit

observed

New start bit

observed

Reset

AUTOBAHN

RECEIVE State Diagram

Waiting four longword

periods since latest

start bit

4 longword timer expired

[Negate BUSY signal]

Waiting for 10nS

Transmitting

serial data words

Waiting four longword

periods since latest

start bit

10nS timer

expired

THEORY OF OPERATION AND TRANSMIT TIMING PRINCIPLE

The AutoBahn is a high speed data mover resource for

use in parallel bus systems, such as the VMEbus. It is also

suitable for proprietary bus architectures and point–to–point

links. All necessary logic, such as multiplexing/

de–multiplexing, control, and timing generation is

incorporated on chip. External control signals and a

frequency reference must be provided to the device.

Arbitration is off loaded to the parallel bus system; thus, no

collision detection or protocol overhead is required for the

chip. The AutoBahn has three primary operating modes:

– Idle

– Transmit

– Receive

Figure 2 has been included to aid in understanding the

operation of the device.

Idle Mode

After the device has been reset, the default operating

mode is Idle. In the default condition the serial bus is cut off

and the receiver is ’listening’ to detect activity on the serial

bus. The function of this mode is to detect serial bus activity

and assert a BUSY

signal. In a VME type application, this

signal is used by the local controller to determine when to

arbitrate for the serial bus resource.

Transmit Mode

To begin a transfer, data is written into the parallel data

register. This event starts an internal timeout timer. The

AutoBahn transfers the data to the serial transmit register,

inserts timing information, and shifts the data out the serial

bus. The timing information adds one additional bit into the

data stream for every byte of data. Because the data is NRZ,

a 900MBit/s data rate translates into a maximum frequency

of 450MHz.

If a new word has been loaded into the parallel data

register, the next transfer will begin. Otherwise, the

differential output driver will hold the serial bus at the state of

the last data bit transmitted. The bus will be held in this state

until new data is loaded into the parallel data register or the

timeout time expires.

The timeout timer runs for a period of four 32–bit transfer

times. The transfer rate is selected through control register

select bits. As an example, in 32–bit mode with a transfer rate

Page 6

MC100SX1451FI100

MOTOROLA ECLinPS and ECLinPS Lite

DL140 — Rev 3

6

of 100MByte/s, a new data word is transferred approximately

every 40ns (32 data bits + 4 synchronization bits = 36 bits *

1.1ns/bit). For this case, the timeout timer runs for

approximately 160ns. The timeout timer is re–started every

time a new serial word transmission begins.

The transmit timeout timer serves two functions. It allows

the termination of block data transfers without the need for

explicit external control. After the last word in a data block is

written into the device, the timeout timer will expire and the

device will return to the idle state. More importantly, it allows

the AutoBahn to support a broad range of data transfer rates.

If a hardware design application only needs capacity to

transfer data at 60MByte/s, the AutoBahn will automatically

burst the data out at 100MByte/sec and insert pauses in the

serial data stream to accommodate the slower parallel data

transfer rate. This means the user can tailor the design of the

parallel memory interface to meet the needs of the

application, while still taking advantage of the performance of

the AutoBahn.

Since the AutoBahn only has one level of elastic storage,

the receiver memory interface must be able to support the

same transfer rate as the transmitter.

Receive Mode

When the AutoBahn is operating in receive mode it strips

off the timing information and clocks the data into the serial

register. When the register is full, it transfers the data into the

parallel data register and asserts the FULL signal pin to

indicate the presence of data. The interface hardware

detects the presence of new data and reads out the content

of the data register. In receive mode, a timeout timer is also

employed to handle the end of data transfer termination. The

receive timeout timer operates in the same manner as the

transmit timeout timer. Every time new data is received, the

timeout timer is re–started. If no data is received, the timeout

timer will expire and the part will return to the idle state.

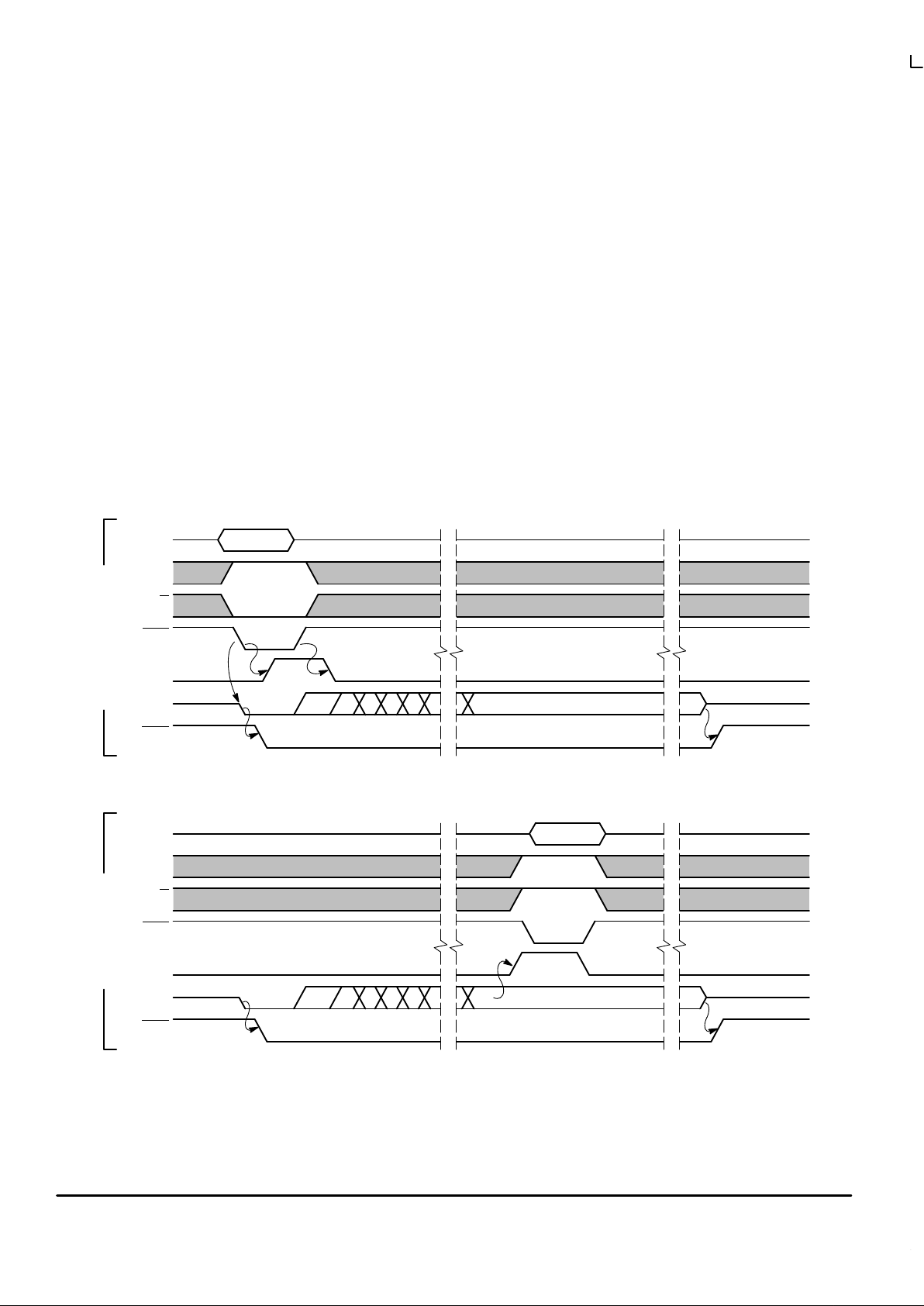

Typical data transmission waveforms are shown in Figure 3

and Figure 4.

Figure 3. Transmit and Receive Timing for a Single 32–Bit Longword Transmissions

REGSEL

D00:D31

R/W

STRB

FULL

SER

BUSY

WRITE DATA

TIMEOUT DELAY

D31SYNC D0 D1 D2 D3

CUTOFF CUTOFF

TRANSMITTING AUTOBAHN

REGSEL

D00:D31

R/W

STRB

FULL

SER

BUSY

READ DATA

TIMEOUT DELAY

D31

CUTOFF CUTOFF

RECEIVING AUTOBAHN

SYNC D0 D1 D2 D3

Page 7

MC100SX1451FI100

ECLinPS and ECLinPS Lite

DL140 — Rev 3

7 MOTOROLA

Figure 4. Transmit and Receive Timing for Burst Transmission

REGSEL

D00:D31

R/W

STRB

FULL

SER

BUSY

WRITE DATA

36–BIT SERIAL

CUTOFF

TRANSMITTING AUTOBAHN

REGSEL

D00:D31

R/W

STRB

FULL

SER

BUSY

RECEIVING AUTOBAHN

WRITE DATA WRITE DATA WRITE DATA WRITE DATA

36–BIT SERIAL 36–BIT SERIAL 36–BIT SERIAL

READ DATA

36–BIT SERIAL

CUTOFF

READ DATA READ DATA

36–BIT SERIAL 36–BIT SERIAL 36–BIT SERIAL

Figure 5. Simplified Application Circuit

AUTOBAHN

32–BIT DATA BUS

STRB

FULL

R/W

REGSEL

SER

SER

LOGIC

(PAL)

SERIAL BUS

OSCILLAT OR

FOSC

CONTROL SIGNALS

DATA BUS

AUTOBAHN

MC100SX1451

GND

Note 3

V

EEX

(20)

V

EE

(8)

V

EET

(3,11,18,30

36,43,51,59)

GND

Note 3

V

CCT

(7,14,33,39,

47,55,63)

GND

Note 1

V

CCT

(+5V)

V

CCO

(26)

GND

40pF

V

CCE

(+5V)

0.22

µ

F

0.22µF

1

µ

H

Note 2

V

CCX

(22)

GND

40pF

V

CCE

(+5V)

0.22µF

Note 1: Capaitor located close to every pin.

Note 2: If separate supply planes for ECL and TTL are available, the inductor is

not necessary.

Note 3: A common ground plane for TTL and ECL must be used.

Figure 6. Power Supply Filtering

APPLICATION CIRCUIT AND POWER SUPPLY

ADDRESS BUS

V

CCE

(41)

C1

V

CCx

C1

2700pF

V

CC

(56)

Page 8

MC100SX1451FI100

MOTOROLA ECLinPS and ECLinPS Lite

DL140 — Rev 3

8

PECL DESIGN CONSIDERA TIONS

The differential serial bus is realized using PECL (Positive

Emitter Coupled Logic). PECL is normal ECL with the V

CC

and VEE power supplies levels shifted from ground and –5.2V

to +5.0V and ground respectively. This change simplifies the

requirements of interfacing high speed ECL circuitry and TTL

circuitry on the same chip and improves the user system

architecture because only a single power supply is required.

The output driver circuitry is an open emitter, emitter

follower which generates PECL levels when terminated by a

pull down resistor to an appropriate reference voltage. The

output emitter follower circuitry is optimized to drive

transmission lines. To minimize line reflections, the

transmission line should be terminated with the line

characteristic impedance, in most cases 50Ω. The simplest

and most robust method of realizing this termination in PECL

is with a resistor divider network referenced to VCC. This

means the PECL output levels and the termination voltage

will then be referenced to the same VCC supply.

Figure 8 is the equivalent circuit for the serial bus.

Resistors R1 and R2 are used to implement a simple voltage

divider with the characteristic impedance of the transmission

line. The following equations are used to solve for these

values.

R1 = R2 ({VCC – VTT}/{VTT – VEE})

R2 = ZO ({VCC – VEE}/{VCC – VTT})

VTT = VCC (R2/{R1 + R2})

For the typical setup:

VCC = 5.0V; VEE = GND; VTT = 3.0V; and ZO = 50Ω

R2 = 50 ({5 – 0}/{5–3}) = 125Ω

R1 = 125 ({5–3}/{3–0}) = 83.3Ω

More detailed information about PECL and thevenin

equivalent termination schemes can be found in Motorola

Application Note AN1406/D – “Designing with PECL”.

Figure 7. Typical Bus Application

PARALLEL BUS

INTERFACE

AUTO

BAHN

CARD 1

PARALLEL BUS

INTERFACE

AUTO

BAHN

CARD 2

PARALLEL BUS

INTERFACE

AUTO

BAHN

CARD N

TRADITIONAL

PARALLEL BUS

DIFFERENTIAL BI–DIRECTIONAL SERIAL

BUS

RESISTOR DIVIDER

TERMINATION NETWORK

BACKPLANE

Figure 8. Equivalent Circuit for Serial Bus

R2

R1

V

CC

R2

R1

V

CC

R2

R1

V

CC

R2

R1

V

CC

AUTOBAHN 1 AUTOBAHN N

CONTROLLED IMPEDANCE

TRANSMISSION LINES

Page 9

MC100SX1451FI100

ECLinPS and ECLinPS Lite

DL140 — Rev 3

9 MOTOROLA

CONTROL AND ERROR REGISTER BIT DEFINITIONS

Figure 9. Control and Error Register Definitions

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

CLEAR

FACTORY TEST

FACTORY TEST

16–/32–BIT MODE

RESERVED

WRITE:

15

14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

CLEAR

FACTORY TEST

FACTORY TEST

16–/32–BIT MODE

RESERVED

READ:

FACTOR Y

TEST

FACTORY TEST

IGNORE TIMEOUT

SYNC BIT ERROR

WORD MISSING ERROR

ERROR CONTROL

FACTORY TEST

IGNORE TIMEOUT

OVERWRITE ERROR

FACTOR Y

TEST

Clear

Asserting this bit clears the internal control logic and

terminates any transmit or receive activity. To remove the

Clear condition, this bit must be set to a logic ‘H’ which sets

the chip into the Idle mode.

H Normal Operation

L Clear

16/32 Bit Mode

This bit defines the data width on the host interface. This

feature allows the AutoBahn chip to be used in systems with

either 16–bit or 32–bit data width without the need for

additional interface hardware. In 16–bit mode, the data bus

used is D00 – D15.

H 32–bit data width

L 16–bit data width

Factory Test

These bits are used by the manufacturer for testing the

product. It must be set to a logic ‘H’ state for proper operation.

H Normal Operation

Ignore Timeout

This bit is used to disable the timeout timer for the

transmitter. The purpose of this bit is to allow for the

establishment of permanent or temporary dedicated links.

When this bit is asserted, the timeout timer will be ignored by

the PISO Control Logic. This bit only needs to be set in the

transmitting AutoBahn chip. To exit this mode, the Control

Register must be accessed, and the field must be

de–asserted.

H Normal Operation

L Disable Timeout

Overwrite Error Flag

This bit will be set if the data in the parallel register is

overwritten. This can occur in Receive mode if data is not

read from the parallel register in a timely manner. The

overwrite error does not occur in idle mode.

H Overwrite

L No Overwrite

Word Missing Error

This bit will be asserted if the second half of a 32–bit

transfer is not completed before the time out timer expires.

This can occur if the transmitter fails to complete the transfer .

This field will be asserted only after the timeout timer expires.

H Word Missing Error

L No Error

SYNC Bit Missing Error

This bit will be asserted if the AutoBahn detects that a

SYNC bit has not been received at the proper time by the

PISO Control Logic. If this bit has been asserted then the

data has been corrupted.

H SYNC Bit Missing Error

L No Error

Page 10

MC100SX1451FI100

MOTOROLA ECLinPS and ECLinPS Lite

DL140 — Rev 3

10

Reserved Bits

All reserved bits are allocated for future enhancements.

The user must write logic ‘H’ values into these bits. Reserved

bits are read back as ‘do not care’.

CRYSTAL OSCILLATOR REQUIREMENTS

The AutoBahn requires a high quality frequency source

(FOSC) which is used as the reference for the PLL Clock

Generator. The performance requirements were targeted to

provide the AutoBahn chip appropriate design margin for the

serial data transfer operation as well as to allow the user

flexibility is selecting a commercially available low cost

crystal oscillator. Below is a list of the key performance

attributes of the crystal oscillator.

Parameter Rating

Frequency 25.000MHz

Stability ±100ppm

Output Levels TTL

Duty Cycle 45% / 55% at 1.5V

Rise/Fall Time ≤7nsec

Operating Range 0°C to 70°C

Startup Time 10msec

There are many suppliers of high quality crystal oscillator

frequency sources which meet or exceed the above

requirements. One such supplier is JVC. Their part numbers

for 25MHz oscillators are as follows: VX4321–2500 (Metal

Can) or SMC2500 (SMD).

THERMAL CONSIDERATIONS

As in any system, proper thermal management is

essential to establish the appropriate trade–off between

performance, density, reliability, and cost. In particular, the

designer should be aware of the reliability implications of

continuously operating semiconductor devices at high

junction temperatures.

The increasing use of surface mount devices (SMD) is

putting a greater emphasis on the need for better thermal

system management. SMD devices require less board space

than their through–hole equivalents; so, designs

incorporating SMD technologies have a higher thermal

density. To optimize the thermal management of the system,

it is imperative that the user understand all the variables

which contribute to the device junction temperature.

By proper package selection, the vendor can select the

proper package and die attach method to decrease the

thermal resistance and thus the junction temperature of the

device. The user has the greatest control of additional

variables which commonly impact the thermal performance

of the device. Ambient temperatures, air flow, and related

cooling techniques are obvious user–controlled variables;

however, PCB substrate material, layout density, size of the

air gap between the board and the package, amount of

exposed copper interconnect, use of thermally conductive

epoxies, and the number of boards in a chassis can all have

significant impacts on the thermal performance of the

system.

PCB substrates have different thermal characteristics

which should be explored when considering alternatives. The

user should also account for the different power dissipations

of various components in the system and space them on the

PCB accordingly. In this way the heat load is spread across a

larger area and “hot spots” do not appear in the layout.

Copper interconnect traces act as heat radiators; therefore,

improved thermal dissipation can be achieved through the

addition of interconnect traces on the top layer. Finally,

thermally conductive epoxies can accelerate the transfer of

heat from the device to the PCB where it can be more easily

transferred to the ambient.

The following equation can be used to estimate the

junction temperature of a device in a given environment:

TJ = TA + PD∗Θ

JA

TJJunction Temperature

TAAmbient Temperature

PDPower Dissipation

ΘJAAverage Package Thermal Resistance

(Junction – Ambient)

The power dissipation is comprised of two elements: the

internal gate power and the power associated with the output

signals. Essentially, the two contributors can be calculated

separately , then added to give the total power dissipation for

the device. The source of the output power distribution

depends on whether the device is transmitting or receiving. In

transmit mode, the PECL outputs are dissipating power,

while in receive mode, the parallel outputs are dissipating

dynamic power. The worst case condition, when the

AutoBahn is in receive mode, is described below.

PD = P

static

+ Po

(TTL)

where Pstatic = ICC * V

CC

V

CC

Operating voltage

I

CC

Static DC Current

and Po (TTL) = No* CL * FD * VS

^2

CL Capacitive load (in pF)

FD Parallel Data Rate (0.5 * # MBits/sec)

VS Output Swing

No Number of outputs (16 or 32)

Page 11

MC100SX1451FI100

ECLinPS and ECLinPS Lite

DL140 — Rev 3

11 MOTOROLA

For a typical application:

CL 20 pF

FD 0.5* 100 MBits/s

VS 3.8 V

No 32 outputs

V

CC

5V

I

CC

700 mA

PD = 470 * 5 + 32 * 20pF * 25 MHz*3.8

2

PD = 3.5 + 0.231W = 3.73W

The ceramic quad flat package selected is manufactured

from an Aluminum nitride (AlN) ceramic material for optimum

thermal performance. A table of the average ΘJA values for

this package under various air flow conditions is listed below:

Air Flow (m/sec) ΘJA (°C/W)

0 40

1 32

2 23

With this information, the user can estimate the junction

temperature of the device in their application.

MAXIMUM RATINGS*

Symbol Parameter Value Unit

V

CC

Power Supply (VEE = 0V) –0.5 to 6.5 V

V

IN

Input Voltage (VEE = 0V) –0.5 to 6.5 V

I

OUT

PECL Output Current Continuous

Surge

50

100

mA

I

OUT–TTL

TTL Output Current TBD

T

A

Operating Temperature Range 0 to 70 °C

T

STG

Storage Temperature Range –50 to +175 °C

T

J

Maximum Junction Temperature 175 °C

* Maximum Ratings are those values beyond which damage to the device may occur. Functional operation should be restricted to the

Recommended Operating Conditions.

TTL DC CHARACTERISTICS (V

CCT

= VCC = V

CCO

= 5.0V ±5%)

Symbol Parameter Min Typ Max Unit Condition

I

IH

Input HIGH Current 0.7 µA VIN = V

CC

I

IL

Input LOW Current –0.6 mA VIN = GND

V

OH

Output HIGH Voltage 2.5 V IOH = –2mA

V

OL

Output LOW Voltage 0.5 V IOL = 5.0mA

V

IH

Input HIGH Voltage 2.0 V

V

IL

Input LOW Voltage 0.8 V

I

OZ

Tri–State Current ±15 µA

I

CC

Device Current Drain 700 760 mA

100E PECL DC CHARACTERISTICS (V

CCT

= VCC = V

CCO

= 5.0V ±5%)

Symbol Parameter Min Max Unit Condition

I

IH

Input HIGH Current 200 µA

I

IL

Input LOW Current 0.500 µA

V

OH

Output HIGH Voltage 3.975 4.25 V

V

CUT

Output CUTOFF Voltage 3.000 3.07 V Note 1.

V

IH

Input HIGH Voltage 3.835 4.12 V

V

IL

Input LOW Voltage 3.000 3.07 V

VPP (DC) Input Sensitivity 150 mV Note 2.

NOTE: PECL levels are referenced to VCC and will vary 1:1 with power supply. The outputs are loaded with an equivalent 25Ω termination to +3.0V .

The values shown are for VCC = V

CCO

= V

CCT

= 5.0V .

1. Valid when the equivalent termination voltage is 3.0V to assure proper operation.

2. VPP is the minimum differential input voltage required to assure proper operation.

Page 12

MC100SX1451FI100

MOTOROLA ECLinPS and ECLinPS Lite

DL140 — Rev 3

12

AC CHARACTERISTICS (VCC = V

CCO

= V

CCT

= 5.0V ±5%; VEE = V

EEX

= V

EET

= GND)

Wave–

0°C 25°C 70°C

Symbol

Characteristic

N

ame

form

Min Typ* Max Min Typ* Max Min Typ* Max Unit

Condition

t

s

Setup Time

R/W

→STRB

REGSEL→STRB

Data→STRB

T2 2 1.0 1.0 1.0 ns

t

h

Hold Time

STRB

→R/W

STRB→REGSEL

T3 2 3.0 3.0 3.0 ns

t

pd

Propagation Delay

STRB

→FULL

T4 2 4.0 6.0 9.0 4.0 6.0 9.0 4.0 6.0 9.0 ns

t

h

Hold Time

STRB

→Data

T5 2 3.0 3.0 3.0 ns

t

pd

Propagation Delay

SER→BUSY

T6 3 6.0 8.0 10.0 6.0 8.0 10.0 6.0 8.0 10.0 ns

t

s

Setup Time

R/W

→STRB

REGSEL→STRB

T7 4 2.0 2.0 2.0 ns

t

h

Hold Time

STRB

→R/W

STRB→REGSEL

T8 4 1.0 1.0 1.0 ns

t

pd

Propagation Delay

STRB

→Data Valid

T9 4 7.0 8.5 18.0 7.0 8.5 18.0 7.0 8.5 18.0 ns

Note 1 on

page 13

t

pd

Propagation Delay

STRB

→FULL

T10 4 5.5 8.0 10.0 5.5 8.0 10.0 5.5 8.0 10.0 ns

Note 1 on

page 13

t

pd

Propagation Delay

STRB

→Data Invalid

T11 4 12.0 14.0 17.0 12.0 14.0 17.0 12.0 14.0 17.0 ns

Note 1 on

page 13

t

s

Setup Time

R/W

→STRB

REGSEL→STRB

Data→STRB

T12 5 1.0 1.0 1.0 ns

t

h

Hold Time

STRB

→R/W

STRB→REGSEL

T13 5 3.0 3.0 3.0 ns

t

h

Hold Time

STRB

→Data

T14 5 3.0 3.0 3.0 ns

t

pw

Pulse Width STRB T15 5 7.0 12.0 7.0 12.0 7.0 12.0 ns

t

s

Setup Time

R/W

→STRB

REGSEL→STRB

T16 6 2.0 2.0 2.0 ns

t

h

Hold Time

STRB

→R/W

STRB→REGSEL

T17 6 2.0 2.0 2.0 ns

t

pd

Propagation Delay

STRB

→Data Valid

T18 6 7.0 8.5 18.0 7.0 8.5 18.0 7.0 8.5 18.0 ns

t

pw

Pulse Width STRB T19 6 7.0 12.0 7.0 12.0 7.0 12.0 ns

t

pd

Propagation Delay

STRB

→Data Invalid

T20 6 14.0 17.0 14.0 17.0 14.0 17.0 ns

tr, t

f

TTL Rise/Fall Time — — 3.0

6.1

12.6

3.0 ns

10 – 90%

15pF Load

tr, t

f

PECL Rise/Fall Time — — 200

770

930

200 ps 20 – 80%

* Values for 0°C and 70°C are target values. Typicals for 25°C are taken from a small measurement database. Min and Max values are derived

from using 3 sigmas point of the data distribution and will be added when the data becomes available.

Page 13

MC100SX1451FI100

ECLinPS and ECLinPS Lite

DL140 — Rev 3

13 MOTOROLA

Note 1:

Propagation Delay T9

Becasue the typical use of the AutoBahn is in a shared bus

system, the propagartion delay T9 (STRB –> data valid) is

the time between the falling edge of STRB

and OUTPUT

ACTIVE of the receiver. The crosspoint of 1.5V is dependent

on the bus environment. See Figure 10.

Propagation Delay T10

This value is taken with the high impedance active probe.

With a higher load at the pin, this value will be higher up

to 5%.

Propagation Delay T11

The definition of the propagation delay T11 corresponds to

T9. In this case, T11 is the time between the rising edge of

STRB

and the HIGH IMPEDANCE of the receiver. That

means, other talker of the common bus have to wait for T11 to

send datas to the bus. See Figure 10.

T9 T11

OUTPUT ACTIVE HIGH ZHIGH Z

Figure 10. Definition of the Waveforms STRB → Data Valid

DATA

STRB

1.5V

0V

Load C=15pF

R=1k

Ω

TIMING WAVEFORMS

STRB (I)

SER (O)

SER (O)

T1

1.5V

50%

Waveform 1. Start of Transmit Timing

D00:D31 (I)

R/W (I) 1.5V1.5V

REGSEL (I) 1.5V1.5V

STRB (I) 1.5V

FULL (O) 1.5V

HIGH Z DATA VALID

1

1.5V HIGH Z

1

T4

T3

T2

T5

Waveform 2. Transmit Mode – Data Transfer Handshake

NOTE 2: T1 (STRB to SER differential) is indeterminate, varying from 3 to 9 bit clock cycles

due to synchronization circuitry to avoid metastability.

NOTE 3

NOTE 3: STRB deassertion to next FULL a minimum of 18 nsec.

Page 14

MC100SX1451FI100

MOTOROLA ECLinPS and ECLinPS Lite

DL140 — Rev 3

14

SER (I)

50%

SER (I)

BUSY (O)

T6

1.5V

Waveform 3. Timing for Detection of a Steady–State Differential Condition on the Serial Bus

R/W (I) 1.5V1.5V

REGSEL (I) 1.5V1.5V

D00:D31 (I)

DATA VALID

1

HIGH Z

1

STRB (I) 1.5V

FULL (O) 1.5V

T8

T7 T9

T10 T11

Waveform 4. Receive Mode – Data Transfer Handshake

D00:D31 (I)

R/W (I) 1.5V1.5V

REGSEL (I) 1.5V1.5V

STRB (I) 1.5V

HIGH Z DATA VALID

1

1.5V HIGH Z

1

T13

T15

Waveform 5. Write to Control Register

1.5V

T12

T14

R/W (I) 1.5V1.5V

REGSEL (I) 1.5V1.5V

D00:D31 (I)

DATA VALID

1

HIGH Z

1

STRB (I) 1.5V

T17

T16 T18

T19 T20

Waveform 6. Read from the Control and Error Registers

Page 15

MC100SX1451FI100

ECLinPS and ECLinPS Lite

DL140 — Rev 3

15 MOTOROLA

R/W

RESET

ERROR

D10

D11

VEET

D12

D13

D14

VCCT

VCC

D15

D16

VEET

D17

D18

D19

VCCT

D20

FULL

VEET

REGSEL

VCCO

SER

VCCX

FOSC

VEEX

C1

VEET

D09

VCCT

D08

D07

D06

VEET

D05

VCCE

D04

VCCT

D03

D02

VEET

D01

D00

VCCT

D21

D22

VEET

D23

D24

D25

VCCT

VEE

D26

D27

VEET

D28

D29

VCCT

D30

D31

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

12345678910111213141516

48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33

32

MC100SX1451

Figure 11. Pinout: 64–Lead CQFP (Top View)

SER

STRB

BUSY

Page 16

MC100SX1451FI100

MOTOROLA ECLinPS and ECLinPS Lite

DL140 — Rev 3

16

FI SUFFIX

CERAMIC QFP PACKAGE

CASE 963–02

ISSUE A

OUTLINE DIMENSIONS

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DATUM PLANE –H– IS LOCATED AT BOTTOM OF

LEAD AND IS COINCIDENT WITH THE LEAD

WHERE THE LEAD EXITS THE PLASTIC BODY AT

THE BOTTOM OF THE PARTING LINE.

4. DATUMS –A–, –B– AND –D– TO BE DETERMINED

AT DATUM PLANE –H–.

5. DIMENSIONS S AND V TO BE DETERMINED AT

SEATING PLANE –C–.

6. DIMENSIONS A AND B DEFINE MAXIMUM

CERAMIC BODY DIMENSION INCLUDING GLASS

PROTRUSION AND MISMATCH BETWEEN

CERAMIC BODY AND COVER.

DIMAMIN MAX MIN MAX

INCHES

13.90 14.10 0.547 0.555

MILLIMETERS

B 13.90 14.10 0.547 0.555

C 3.00 4.11 0.118 0.162

D 0.30 0.45 0.012 0.018

E 2.54 3.22 0.100 0.127

F 0.30 0.40 0.012 0.016

G 0.80 BSC 0.031 BSC

H 0.45 0.89 0.018 0.035

J 0.13 0.23 0.005 0.009

K 0.65 0.95 0.026 0.037

L 12.00 REF 0.472 REF

N 0.13 0.17 0.005 0.007

P 0.40 BSC 0.016 BSC

Q 0 7 0 7

R 0.13 0.30 0.005 0.012

S 16.95 17.45 0.667 0.687

T 0.13 ––– 0.005 –––

U 0 ––– 0 –––

V 16.95 17.45 0.667 0.687

W 0.35 0.45 0.014 0.018

X 1.60 REF 0.063 REF

____

__

L

L BV

A

S

G

H

EC

SEATING

PLANE

0.01 (0.004)

DETAIL C

DETAIL A

Q

U

X

T

R

W

K

DATUM

PLANE

DETAIL C

1

16

17

32

33

48

49

64

–A–

–B–

–H–

DATUM

PLANE

–C–

–D–

–H–

B

B

P

DETAIL A

D

F

J

N

VIEW ROTATED 90

CLOCKWISE

_

SECTION B–B

BASE METAL

–A–, –B–, –D–

S

A–B

M

0.02 (0.008) D

S

C

S

A–B

M

0.20 (0.008) D

S

C

A–B0.05 (0.002)

S

A–B

M

0.20 (0.008) D

S

H

S

A–B

M

0.20 (0.008) D

S

C

A–B0.05 (0.002)

S

A–B

M

0.20 (0.008) D

S

H

Page 17

MC100SX1451FI100

ECLinPS and ECLinPS Lite

DL140 — Rev 3

17 MOTOROLA

Motorola reserves the right to make changes without further notice to any products herein. Motorola makes no warranty , representation or guarantee regarding

the suitability of its products for any particular purpose, nor does Motorola assume any liability arising out of the application or use of any product or circuit, and

specifically disclaims any and all liability, including without limitation consequential or incidental damages. “T ypical” parameters which may be provided in Motorola

data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals”

must be validated for each customer application by customer’s technical experts. Motorola does not convey any license under its patent rights nor the rights of

others. Motorola products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other

applications intended to support or sustain life, or for any other application in which the failure of the Motorola product could create a situation where personal injury

or death may occur. Should Buyer purchase or use Motorola products for any such unintended or unauthorized application, Buyer shall indemnify and hold Motorola

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

Motorola was negligent regarding the design or manufacture of the part. Motorola and are registered trademarks of Motorola, Inc. Motorola, Inc. is an Equal

Opportunity/Affirmative Action Employer.

MC100SX1451FI100/D

◊

Mfax is a trademark of Motorola, Inc.

How to reach us:

USA/EUROPE /Locations Not Listed: Motorola Literature Distribution; JAPAN: Nippon Motorola Ltd.: SPD, Strategic Planning Office, 4–32–1,

P.O. Box 5405, Denver, Colorado 80217. 303–675–2140 or 1–800–441–2447 Nishi–Gotanda, Shinagawa–ku, Tokyo 141, Japan. 81–3–5487–8488

Mfax: RMFAX0@email.sps.mot.com – TOUCHT ONE 602–244–6609 ASIA/PACIFIC: Motorola Semiconductors H.K. Ltd.; 8B Tai Ping Industrial Park,

– US & Canada ONLY 1–800–774–1848 51 Ting Kok Road, Ta i Po, N.T., Hong Kong. 852–26629298

INTERNET: http://motorola.com/sps

Loading...

Loading...