Page 1

General Description

The MAX8655 synchronous-PWM buck regulator operates from a 4.5V to 25V input and generates an output

voltage adjustable from 0.7V to 5.5V at loads up to 25A.

Integrated power MOSFETs provide a small footprint,

ease of layout, and reduced EMI. Removing the board

trace inductances ensures the highest efficiency at

high frequency.

The MAX8655 uses peak current-mode control architecture with an adjustable (200kHz to 1MHz), constantswitching frequency, which is externally synchronizable.

The MAX8655’s adjustable current limit uses the inductor’s DC resistance to improve efficiency or an external

sense resistor for higher accuracy. Foldback type current limit is available to reduce the power dissipation

under severe-overload or short-circuit conditions. A reference input is provided for use with a high-accuracy

external reference or for DDR and tracking applications.

Monotonic startup provides safe starting into a prebiased output, where traditional step-down regulators

discharge the output capacitor during soft-start, creating a negative voltage at the output and possibly damaging the load.

A 180° out-of-phase synchronization output is available

for synchronizing with another MAX8655.

An enable input is provided for on/off control and to

facilitate output sequencing. Output-voltage sensing for

programmable overvoltage protection is provided and

is independent of the feedback network to further

enhance the output overvoltage protection.

Overall, the MAX8655 provides enough flexibility for the

experienced user, as well as simplicity and ease of use

for non-power-supply engineers.

Applications

Point-of-Load Power Supplies

Telecom Power

Networking

Nonisolated DC-DC Power Modules

Servers and Workstations

Notebook Computers

IBA Power Supplies

Features

♦ 25A Output Current

♦ Integrated Power MOSFETs

♦ Operates from 4.5V to 25V Supply

♦ 1% FB Voltage Accuracy Over Temperature

♦ Adjustable Output Voltage Down to 0.7V

♦ Adjustable Switching Frequency and External

Synchronization from 200kHz to 1MHz

♦ Multiphase Operation with Accurate Current

Sharing

♦ 180° Phase-Shifted Synchronization

♦ Adjustable Overcurrent Limit

♦ Adjustable Slope Compensation

♦ Selectable Current-Limit Mode: Latch-Off or

Automatic Recovery

♦ Monotonic Output Voltage Rise at Startup into

Prebias Output

♦ Output Sources and Sinks Current for DDR

Applications

♦ Enable Input

♦ Power-OK (POK) Output

♦ Adjustable Soft-Start

♦ Independently Adjustable Overvoltage Protection

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

________________________________________________________________ Maxim Integrated Products 1

Ordering Information

19-3982; Rev 0; 10/07

For pricing, delivery, and ordering information, please contact Maxim Direct at 1-888-629-4642,

or visit Maxim’s website at www.maxim-ic.com.

PART

TEMP

RANGE

PIN-

PACKAGE

PKG

CODE

MAX8655ETN+

-40°C to +85°C

56 TQFN - E P *

( 8mm x 8m m )

T5688M-4

Pin Configuration appears at end of data sheet.

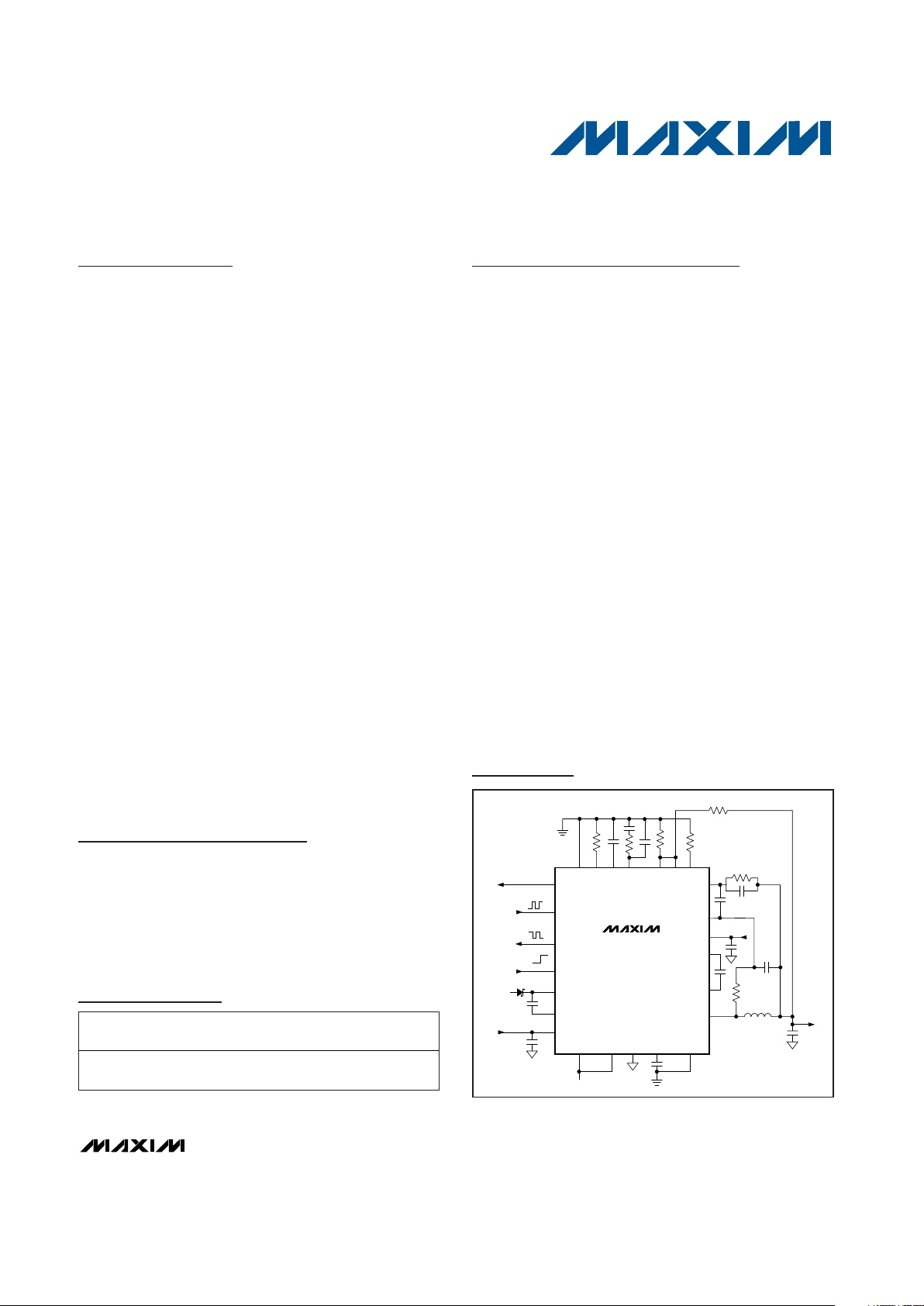

MAX8655

REFIN

MODE

PGND

AVL

GND

OFF

ON

PVIN

INPUT 7V

TO 28V

SYNC OUTPUT

ENABLE INPUT

POWER-OK OUTPUT

FSYNC INPUT

OUTPUT

0.7V TO 12V

UP TO 25A

LX

VL

AVL

VLGND

VL

IN

CS+

CS-

SCOMP

ILIM2

SS

COMP

FB

OVP

ILIM1

PVIN

LXB

SYNCO

FSYNC

POK

EN

BST

Typical Operating Circuit

+Denotes a lead-free package.

*EP = Exposed pad.

Page 2

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VIN= 12V, V

BST

- VLX= 6.5V, TA= -40°C to +85°C, circuit of Figure 4, typical values are at TA= +25°C, unless otherwise noted.) (Note 2)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

PVIN, IN, EN to GND ..............................................-0.3V to +30V

BST to LXB ............................................................-0.3V to +7.5V

LX, LXB to GND............ (-2.5V for < 50ns transient) -1V to +30V

ILIM2, ILIM1, SYNCO, FSYNC, OVP,

SCOMP to GND .....................................-0.3V to (V

AVL

+ 0.3V)

VL to PGND ...........................................................-0.3V to +7.5V

AVL, FB, POK, COMP, SS, MODE, REFIN to GND ..-0.3V to +6V

CS+, CS- to GND ....................................................-0.3V to +6V

PGND to GND to VLGND ......................................-0.3V to +0.3V

Operating Junction Temperature Range.......... -40°C to +125°C

Junction Temperature......................................................+150°C

θJC(thermal resistance from

junction to exposed pad) (Note 1) ...............................3.5°C/W

θ

JT

(thermal resistance from junction to the top) ............3.9°C/W

I

LX (RMS)

.................................................................................27A

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

PARAMETER CONDITIONS

MIN TYP MAX UNITS

PVIN Operating Voltage Range 3 25 V

IN Operating Voltage Range VL = IN for V

IN

< 7V 4.5

25.0

V

IN Quiescent Supply Current V

FB

= 0.75V, no switching 2 3 mA

EN = GND, V

IN

≤ 28V 10

Shutdown Supply Current

I

IN

+ IVL + I

AVL

, EN = GND, V

AVL

= VVL = VIN = 5V 32

µA

PVIN Shutdown Supply Current V

PVIN

= VLX = V

BST

1 µA

AVL Undervoltage-Lockout

Threshold

V

AVL

rising, 3% typical hysteresis

3.90 4.15 4.40

V

Output-Voltage Adjust Range

Minimum output voltage is limited by minimum duty cycle

and external components

0.7 5.5 V

VL Regulation Voltage 7V < V

IN

< 28V 6.0 6.5 7.0 V

AVL Regulation Voltage 5.5V < V

VL

< 7V, 1mA < I

LOAD

< 10mA

4.900 4.975 5.050

V

AVL Output Current 10 mA

SOFT-START

SS Shutdown Resistance From SS to GND, V

EN

= 0V 20 100 Ω

SS Soft-Start Current V

REF

= 0.625V 18 23 28 µA

REFIN INPUT

REFIN Dual Mode™ Threshold

V

AVL

-

1.0V

V

AVL

V

REFIN Input Bias Current V

REFIN

= 0.7V to 1.5V

-250

+250

nA

REFIN Input Voltage Range 0 1.5 V

Dual Mode is a trademark of Maxim Integrated Products, Inc.

Note 1: Package thermal resistances were obtained using the method described in JEDEC specification JESD51-7, using a 4-layer

board. For detailed information on package thermal considerations, see www.maxim-ic.com/thermal-tutorial

.

Page 3

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

_______________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 12V, V

BST

- VLX= 6.5V, TA= -40°C to +85°C, circuit of Figure 4, typical values are at TA= +25°C, unless otherwise noted.) (Note 2)

PARAMETER CONDITIONS MIN

TYP

MAX

UNITS

ERROR AMPLIFIER

REFIN = AVL

0.693

0.7

0.707

FB Regulation Voltage

V

REFIN

= 0.7V to 1.5V

V

RE F IN

-

0.00375

V

REFIN

V

RE FIN

+

0.00375

V

Transconductance 70 110 160 µS

COMP Shutdown Resistance From COMP to GND, V

EN

= 0V 20 100 Ω

FB Input Leakage Current V

FB

= 0.7V 5 50 nA

FB Input Common-Mode Range -0.1

+1.5

V

CURRENT-SENSE AMPLIFIER

V

OUT

= 0 to 5.5V 12

V/V

Voltage Gain

V

C S +

- V

C S -

= 30m V

Part to part variation at T

A

= +85°C

-4 +4 %

CURRENT LIMIT

R

ILIM1

= 24kΩ

27.2

32

36.8

Peak Current-Limit

Threshold (V

CS+

- V

CS-

)

ILIM1 = AVL 60 80 92

mV

Negative Current Limit % of valley current limit -90

-120 -150

%

CS+, CS- Input Bias Current V

CS+

= V

CS-

= 0 or 5.5V -25 +25 µA

CS+, CS- Input Common-Mode

Range

0 5.5 V

SLOPE COMPENSATION

V

SCOMP

= 2.5V

231.25 250.00 268.75

V

SCOMP

= 1.25V

113.77 123.00 132.23

SCOMP = AVL

231.25 250.00 268.75

T

A

= 0°C to +85°C

113.77 123.00 132.23

Slope Compensation at Maximum

Duty Cycle

SCOMP = GND

T

A

= -40°C to +85°C

110.70 123.00 132.23

mV

SCOMP High Threshold

V

AVL

-

0.5

V

SCOMP Low Threshold 0.5 V

SCOMP Adjustment Range

1.25

2.50

V

SCOMP Input Leakage Current V

SCOMP

= 1.25V to 2.5V 5 200 nA

Page 4

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

4 _______________________________________________________________________________________

ELECTRICAL CHARACTERISTICS (continued)

(VIN= 12V, V

BST

- VLX= 6.5V, TA= -40°C to +85°C, circuit of Figure 4, typical values are at TA= +25°C, unless otherwise noted.) (Note 2)

PARAMETER CONDITIONS

MIN TYP MAX

UNITS

OSCILLATOR

R

FSYNC

= 21.0kΩ

800 1000 1200

Switching Frequency

R

FSYNC

= 143kΩ

160 200

240

kHz

Minimum Off-Time Measured at LX

235

ns

Minimum On-Time Measured at LX 75 100 ns

FSYNC Synchronization Range

160

1200

kHz

FSYNC Input High Pulse Width

100

ns

FSYNC Input Low Pulse Width

100

ns

FSYNC Rise/Fall Time 100 ns

SYNCO Phase Shift

180

D eg r ees

SYNCO Output Low Level I

SYNCO

= 5mA 0.4 V

SYNCO Output High Level I

SYNCO

= -5mA V

AV L

- 1V V

FSYNC Input Low 0.4 V

FSYNC Input High 2.5 V

THERMAL PROTECTION

Thermal Shutdown Rising temperature

+160

°C

Thermal-Shutdown Hysteresis 15 °C

POK

REFIN = AVL, V

FB

rising, typical hysteresis is 3%

629 650

671 mV

POK Threshold

V R E F IN = 0.75V to 1.5V , V F B r i si ng , typ i cal hyster esi s i s 3% 88.7 91.7 94.7

%

POK Output Voltage, Low V

FB

= 0.6V, I

POK

= 2mA

25 200 mV

POK Leakage Current, High V

POK

= 5.5V 1 µA

OVP

REFIN = AVL

770 800

840 mV

OVP Threshold Voltage

V

REFIN

= 0.7V to 1.5V

110 115

120 %

OVP, Leakage Current, High V

OVP

= 0.8V 500 nA

MODE CONTROL

MODE Logic-Level Low 4.5V ≤ V

AVL

≤ 5.5V 0.4 V

MODE Logic-Level High 4.5V ≤ V

AVL

≤ 5.5V 1.8 V

MODE Input Current V

MODE

= 0 to V

AVL

-1

+1

µA

SHUTDOWN CONTROL

EN Logic-Level Low 4.5V ≤ V

AVL

≤ 5.5V

0.45

V

EN Logic-Level High 4.5V ≤ V

AVL

≤ 5.5V 2 V

V

EN

= 0V -1

+1

EN Input Current

V

EN

= 28V 1.5 6.0

µA

Note 2: Specifications are 100% production tested at TA= +85°C. Limits over the operating temperature range are guaranteed by

design.

Page 5

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

_______________________________________________________________________________________ 5

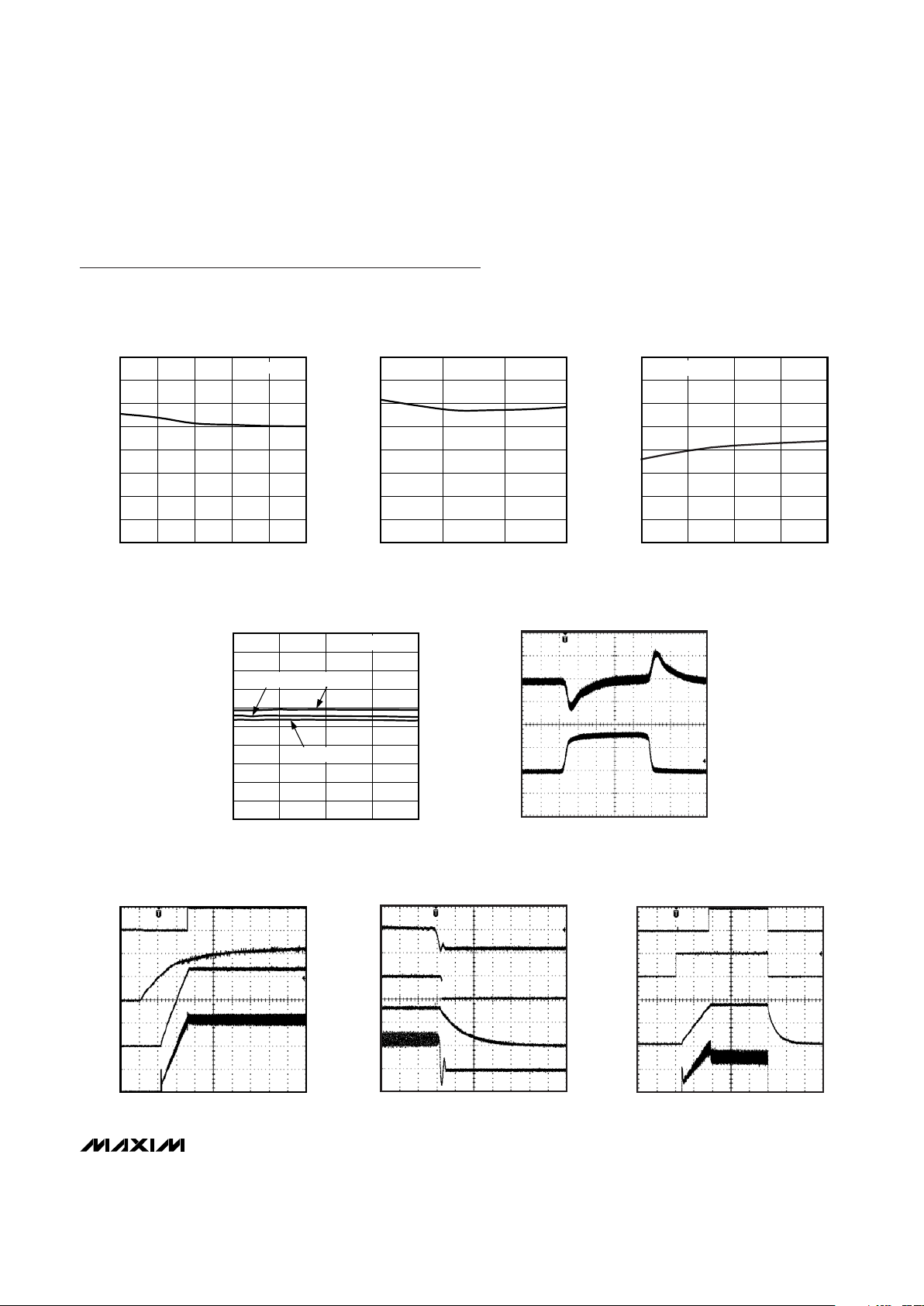

Typical Operating Characteristics

(TA = +25°C, unless otherwise noted.)

Typical Operating Characteristics

(TA = +25°C, unless otherwise noted.)

LOAD REGULATION

(CIRCUIT OF FIGURE 4)

LOAD CURRENT (A)

OUTPUT VOLTAGE (V)

MAX8655 toc01

0 5 10 15 20 25

3.26

3.27

3.28

3.29

3.30

3.31

3.32

3.33

3.34

VIN = 12V

LINE REGULATION

(CIRCUIT OF FIGURE 4)

INPUT VOLTAGE (V)

OUTPUT VOLTAGE (V)

MAX8655 toc02

5 101520

3.26

3.27

3.28

3.29

3.30

3.31

3.32

3.33

3.34

12A LOAD

FB VOLTAGE vs. EXPOSED PAD TEMPERATURE

(CIRCUIT OF FIGURE 4)

EXPOSED PAD TEMPERATURE (°C)

FB VOLTAGE (V)

MAX8655 toc03

-40 0 40 80 120

0.680

0.685

0.690

0.695

0.700

0.705

0.710

0.715

0.720

7.5A LOAD

OSCILLATOR FREQUENCY vs. INPUT VOLTAGE

(CIRCUIT OF FIGURE 4)

INPUT VOLTAGE (V)

OSCILLATOR FREQUENCY (kHz)

MAX8655 toc04

8 13182328

300

310

320

330

340

350

360

370

380

390

400

TA = -40°C

TA = +25°C

TA = +85°C

R

FSYNC

= 76.8kΩ

I

OUT

5A/div

0A

V

OUT

50mV/div

(AC-COUPLED)

40

μ

s/div

STEP-LOAD RESPONSE

(CIRCUIT OF FIGURE 3)

MAX8655 toc05

V

OUT

= 1.2V

V

IN

I

LX

10V/div

1V/div

5A/div

2ms/div

POWER-UP WAVEFORMS

(CIRCUIT OF FIGURE 4)

MAX8655 toc06

V

POK

V

OUT

5V/div

V

POK

I

LX

10V/div

2V/div

10A/div

200μs/div

POWER-DOWN WAVEFORMS

(CIRCUIT OF FIGURE 4)

MAX8655 toc07

V

IN

V

OUT

5V/div

V

EN

I

LX

5V/div

2V/div

10A/div

2ms/div

ENABLE WAVEFORMS

(CIRCUIT OF FIGURE 4)

MAX8655 toc08

V

POK

V

OUT

5V/div

Page 6

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

6 _______________________________________________________________________________________

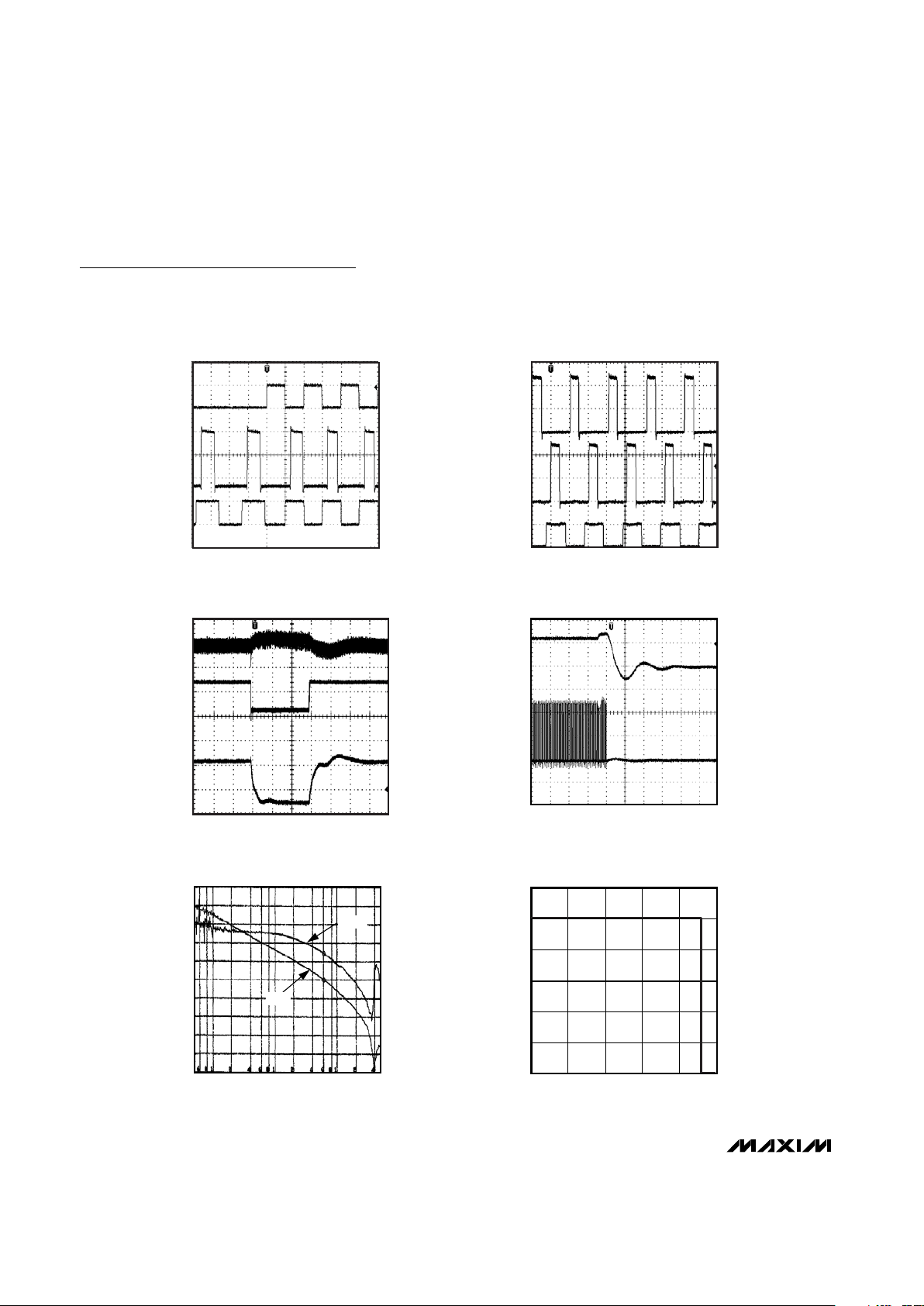

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

V

SYNCO

V

FSYNC

V

LX

5V/div

5V/div

5V/div

1

μ

s/div

FSYNC AND SYNCO

(CIRCUIT OF FIGURE 4)

MAX8655 toc09

INTERNAL 350kHz

OPERATION

SYNCHRONIZED TO

EXTERNAL 500kHz CLOCK

V

SYNCO

(MASTER)

V

LX

(SLAVE)

V

LX

(MASTER)

5V/div

5V/div

5V/div

1

μ

s/div

DUAL-PHASE SWITCHING

(CIRCUIT OF FIGURE 5)

MAX8655 toc10

I

IN

V

IN

V

OUT

500mV/div

(AC-COUPLED)

1V/div

1A/div

1ms/div

SHORT CIRCUIT AND RECOVERY

MAX8655 toc11

V

OUT

V

LX

2V/div

5V/div

40μs/div

OVERVOLTAGE PROTECTION

(CIRCUIT OF FIGURE 3)

MAX8655 toc12

CLOSED-LOOP BODE PLOT

(CIRCUIT OF FIGURE 3)

MAX8655toc13

50

500 1k 2k 4k 10k 20k

FREQUENCY (Hz)

GAIN (dB)

PHASE MARGIN (DEGREES)

40k 100k 200k400k

40

30

20

10

0

180

144

108

72

36

0

-10

-20

-30

-40

GAIN

PHASE

SAFE OPERATING AREA

INPUT VOLTAGE (V)

OUTPUT CURRENT (A)

MAX8655 toc14

5 1015202530

0

5

10

15

20

25

30

Page 7

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

_______________________________________________________________________________________ 7

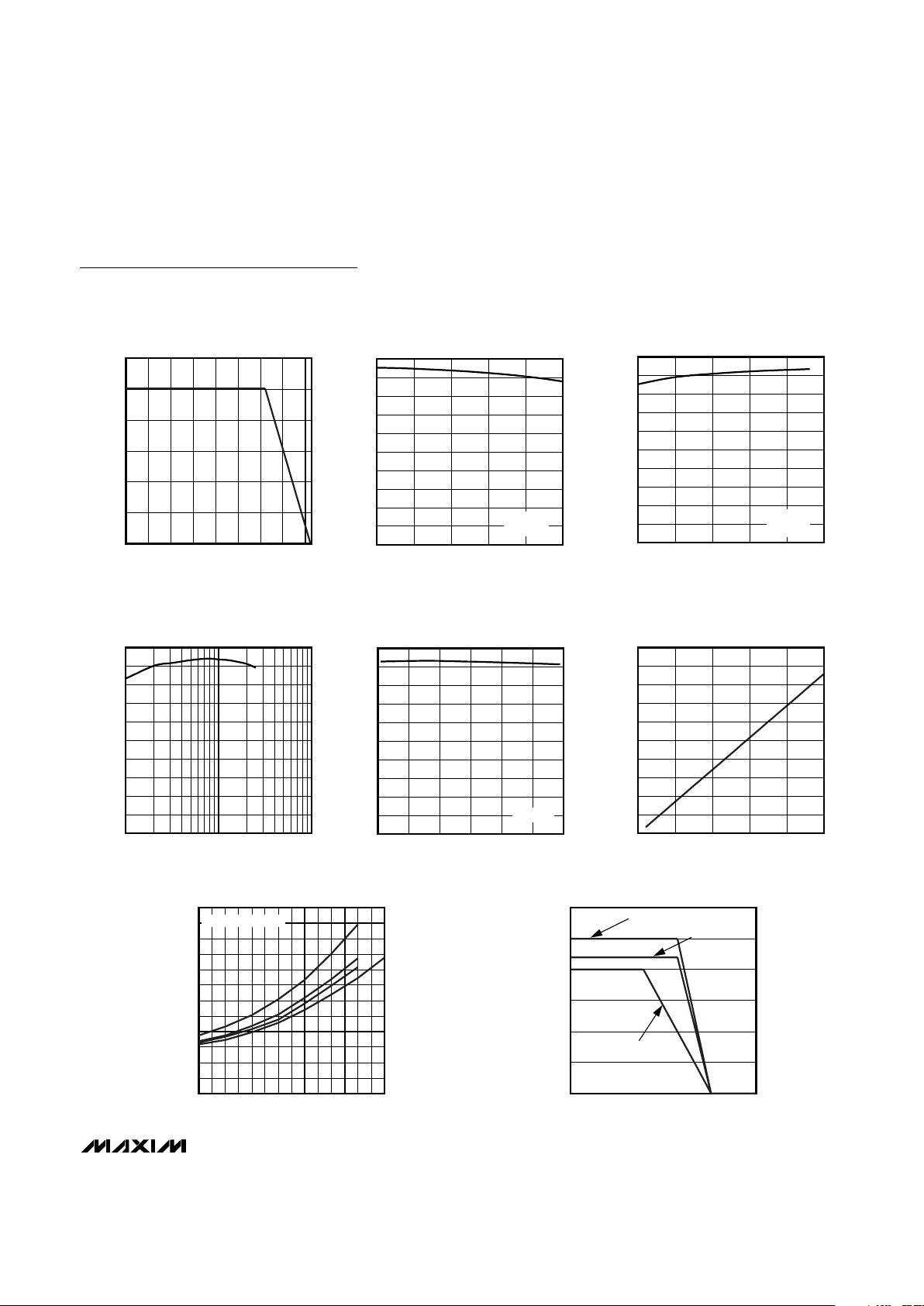

Typical Operating Characteristics (continued)

(TA= +25°C, unless otherwise noted.)

MAXIMUM OUTPUT CURRENT

vs. EXPOSED PAD TEMPERATURE

(CIRCUIT OF FIGURE 4)

EXPOSED PAD TEMPERATURE (°C)

OUTPUT CURRENT (A)

MAX8655 toc15

-40 80 10040020-20 60 120

0

5

10

15

20

25

30

EFFICIENCY vs. INPUT VOLTAGE

(CIRCUIT OF FIGURE 4)

INPUT VOLTAGE (V)

EFFICIENCY (%)

MAX8655 toc16

5 8 11 14 17 20

0

10

20

30

40

50

60

70

80

90

100

VO = 3.3V

10A LOAD

EFFICIENCY vs. OUTPUT VOLTAGE

(CIRCUIT OF FIGURE 4)

OUTPUT VOLTAGE (V)

EFFICIENCY (%)

MAX8655 toc17

1.0 1.5 2.0 2.5 3.0 3.5

0

10

20

30

40

50

60

70

80

90

100

12V INPUT

10A LOAD

EFFICIENCY vs. LOAD CURRENT

12V INPUT, 3.3V OUTPUT

(CIRCUIT OF FIGURE 4)

LOAD CURRENT (A)

EFFICIENCY (%)

MAX8655 toc18

0

10

20

30

40

50

60

70

80

90

100

1 10 100

EFFICIENCY vs. FREQUENCY

12.0V INPUT 3.3V OUTPUT

(CIRCUIT OF FIGURE 4)

FREQUENCY (kHz)

EFFICIENCY (%)

MAX8655 toc19

200 300 400 500 600 700 800

0

10

20

30

40

50

60

70

80

90

100

10A LOAD

R

VALLEY

vs. VALLEY CURRENT LIMIT

VALLEY CURRENT LIMIT (A)

R

VALLEY

(kΩ)

MAX8655 toc20

0 5 10 15 20 25

0

20

40

60

80

100

120

140

160

180

200

BOTTOM LAYER PCB TEMPERATURE vs.

OUTPUT CURRENT

I

OUT

(A)

BOTTOM PCB TEMPERATURE (°C)

MAX8655 toc21

0 5 10 15 20 25

0

120

80

20

100

40

60

VIN = 12V, VCC = 1.2V

OUTPUT-CURRENT CAPABILITY

vs. AMBIENT TEMPERATURE

AMBIENT TEMPERATURE (°C)

OUTPUT-CURRENT CAPABILITY (A)

MAX8655 toc22

-40 -25 -10 5 20 35 50 65 80 95 110 125

0

30

20

5

25

10

15

300 LFM

100 LFM

NO AIRFLOW

Page 8

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

8 _______________________________________________________________________________________

Pin Description

PIN NAME FUNCTION

1–5, 51–56

PVIN

Power-Input Supply. PVIN connects to the drain of the internal high-side MOSFET. Connect inputdecoupling capacitors as close as possible between PVIN and PGND.

6, 16–21 LX

External Inductor Connection. Connect to the external power inductor. Leave pin 6 unconnected for

best routing.

7–15 PGND

Power Ground Connection from Source of Internal Low-Side MOSFET. Connect input-decoupling

capacitors as close as possible between PVIN and PGND.

22 VLGND Return for Low-Side MOSFET Gate-Driver Current

23, 28, 39,

48

GND

Analog Ground. Connect all pins to the analog ground plane, and connect the analog and power

ground planes together at the negative terminal of the output capacitor. Low-current signals return to

GND. Pin 28 must be connected externally to GND-EP, the analog ground plane.

24 VL

Internal 6.5V Linear-Regulator Output. Connect a 2.2µF to 10µF ceramic capacitor from VL to VLGND.

For V

IN

< 7V, connect VL directly to IN. VL supplies power for the internal gate drivers. VL is the input

to the AVL internal linear regulator.

25 IN

Input Supply Voltage. IN is the input to the VL linear regulator. Connect VL to IN for V

IN

< 7V.

Decouple to PGND with a 0.22µF ceramic capacitor.

26 EN

Enable. Apply logic-high to EN to enable the output, or logic-low to place the regulator in low-power

shutdown mode. Connect EN to IN for always-on operation.

27 AVL

Internal 5V Linear-Regulator Output. AVL powers the MAX8655’s internal circuits. Connect a 1µF

ceramic capacitor from AVL to GND.

29, 30, 42, 49

N.C. No Connection. Not internally connected.

31 CS+ Positive Differential Current-Sense Input

32 CS- Negative Differential Current-Sense Input

33 ILIM1

Analog Programmable Current-Limit Input for Inductor Current. Connect a resistor from ILIM1 to GND

to set the overcurrent threshold. ILIM1 sources 10µA through the resistor, and the voltage at ILIM1 is

attenuated 7.5:1 to set the final current limit. For example, a 60kΩ resistor results in 600mV at ILIM1.

This results in a current-limit threshold (V

CS+

- V

CS-

) of 80mV. The ILIM1 resistor range is 24kΩ to

60kΩ. Connect ILIM1 to AVL to set the default threshold of 80mV.

34 OVP

Output-Voltage Sensing for Overvoltage Protection. Connect OVP to the center of a resistor-divider

connected between the output of the regulator and GND to set the FB independent output

overvoltage trip point. Connect OVP to FB if this independence is not desired. The OVP threshold is

1.15 times the nominal feedback regulation voltage.

35 FB

Feedback Input. Connect FB to the center of a resistor voltage-divider connected between the output

and GND to set the output voltage. FB regulates to 0.7V or V

REFIN

.

36 COMP

Loop Compensation. Connect COMP to an external RC network to compensate the loop. COMP is

internally pulled to GND through 20Ω during shutdown.

37 SS

Soft-Start. Connect a 0.01µF to 1µF ceramic capacitor from SS to GND. This capacitor sets the softstart period during startup. See the Startup and Soft-Start section for more details. SS is internally

pulled to GND through 20Ω during shutdown.

38 REFIN

External Reference Input. Connect REFIN to AVL to use the internal 0.7V reference for the feedback

threshold.

Page 9

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

_______________________________________________________________________________________ 9

Pin Description (continued)

PIN NAME FUNCTION

40 ILIM2

Programmable Current-Limit Input. Connect a resistor from ILIM2 to GND to set the valley current

limit. See the Setting the Current Limit section.

41 SCOMP

Programmable Slope-Compensation Input. Internal slope-compensation voltage rate is the voltage at

SCOMP times 0.1 divided by the oscillator period (T). Connect SCOMP to AVL or GND to set to the

default of 250mV/T or 125mV/T, respectively.

43 POK

Open-Drain Power-OK Output. POK goes high impedance when the output voltage rises above 91%

of the nominal regulation voltage. POK pulls low during shutdown or when the output drops below

88% of the nominal regulation voltage.

44 FSYNC

Frequency Set and Synchronization Input. Connect a resistor from FSYNC to GND to set the switching

frequency, or drive with a clock signal to synchronize between 160kHz and 1.2MHz. See the

Switching Frequency and Synchronization section.

45 MODE

Current-Limit Operating Mode Selection. Connect MODE to AVL for latch-off current limit or connect

MODE to GND for automatic recovery current limit.

46 SYNCO

Synchronization Output. Provides a clock output for synchronizing another MAX8655 with 180°

out-of-phase operation.

47 BST Boost Capacitor Connection. Connect a 0.22µF ceramic capacitor from BST to LXB.

50 LXB LX Boost Capacitor Connection. Connect a 0.22µF ceramic capacitor between LXB and BST.

— GND-EP Exposed Pad. Connect to GND externally. See the Pin Configuration.

— PVIN-EP Exposed Pad. Internally connected to PVIN. See the Pin Configuration.

— LX-EP Exposed Pad. Internally connected to LX. See the Pin Configuration.

Page 10

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

10 ______________________________________________________________________________________

Figure 1. Functional Diagram

IN

6.5V LDO

REGULATOR

5V AVL

LDO

EN

PWM

CONTROL

LOGIC

SHOOT-THROUGH

PROTECTION

LEVEL

SHIFT

BST

SYNCO

FSYNC

MODE

CS+

CS-

ILIM1

GND

ILIM2

POK

CURRENT-LIMIT

CONTROL LOGIC

UVLO

VL

LX

÷7.5

10μA

VL

OVP

SCOMP

THERMAL

SHDN

COMP

PWM

COMPARATOR

REF

SELECT

LOGIC

SS

REFIN

SOFT-START

CIRCUITRY

FB

AVL

VL

VOLTAGE

REFERENCE

V

REF

V

SUM

VLGND

PGND

PVIN

MAX8655

COMP

CLAMP

OSCILLATOR

SLOPE

COMP

GM

ERROR

AMPLIFIER

OVP

1.15V REF

CURRENT-SENSE

AMPLIFIER

12

CURRENT-LIMIT

COMPARATOR

X1

LEVEL

SHIFT

FB

0.9V REF

Page 11

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

______________________________________________________________________________________ 11

Detailed Description

DC-DC Converter Control Architecture

The MAX8655 step-down regulator uses a PWM, peak

current-mode control scheme. An internal transconductance amplifier establishes an integrated error voltage.

The heart of the PWM controller is a PWM comparator

that compares the integrated voltage-feedback signal

against the amplified current-sense signal plus an

adjustable slope-compensation ramp, which is

summed with the current signal to ensure stability. At

each rising edge of the internal clock, the internal highside MOSFET turns on until the PWM comparator trips

or the maximum duty cycle is reached. During this ontime, current ramps up through the inductor, storing

energy in the output inductor while sourcing current to

the output. The current-mode feedback system regulates the peak inductor current as a function of the output-voltage error signal. The circuit acts as a

switch-mode transconductance amplifier and pushes

the output LC filter pole normally found in a voltagemode PWM to a higher frequency. Figure 1 is the functional diagram.

During the second half of the cycle, the internal highside MOSFET turns off and the internal low-side MOSFET turns on. The output inductor releases the stored

energy as the current ramps down, providing current to

the load. The output capacitor stores charge when the

inductor current exceeds the required load current and

discharges when the inductor current is lower, smoothing the voltage across the load. Under soft-overload

conditions, when the peak inductor current exceeds the

selected current limit (see the Current-Limit Circuit section), the high-side MOSFET is turned off immediately

and the low-side MOSFET is turned on and remains on

to let the inductor current ramp down until the next

clock cycle. Under severe-overload or short-circuit conditions, the valley foldback current limit is enabled to

reduce power dissipation of external components.

The MAX8655 operates in a forced-PWM mode. As a

result, the regulator maintains a constant switching frequency, regardless of load, to allow for easier filtering

of the switching noise.

Internal Linear Regulators

The MAX8655 contains two internal LDO regulators.

The AVL regulator provides 5V for the IC’s internal circuitry, and the VL regulator provides 6.5V for the MOSFET gate drivers. Connect a 2.2µF ceramic capacitor

from VL to VLGND, and connect a 1µF ceramic capacitor from AVL to GND. The AVL regulator input is internally connected to the VL regulator output. For 5V input

applications, connect VL directly to IN and connect a

10Ω resistor from VL to AVL.

Undervoltage Lockout

When V

AVL

drops below 4.03V, the MAX8655 assumes

that the supply voltage is too low to make valid decisions, so the undervoltage-lockout (UVLO) circuitry

inhibits switching and turns off both internal power

MOSFETs. When V

AVL

rises above 4.15V, the regulator

enters the startup sequence and then resumes normal

operation.

Startup and Soft-Start

The internal soft-start circuitry gradually ramps up the

reference voltage to control the rate of rise of the output

voltage and reduce input surge currents during startup.

The soft-start period is determined by the value of the

capacitor from SS to GND. The soft-start time is

approximately (30.4ms/µF) x CSS. The MAX8655 also

features monotonic output-voltage rise; therefore, both

power MOSFETs are kept off if the voltage at FB is

higher than the voltage at SS. This allows the MAX8655

to start up into a prebiased output without pulling the

output voltage down.

Before the MAX8655 begins the soft-start and powerup sequence, the following conditions must be met:

•V

AVL

exceeds the 4.15V UVLO threshold.

• EN is at logic-high.

• The thermal limit is not exceeded.

Enable

The MAX8655 features a low-power shutdown mode. A

logic-low at EN shuts down the regulator. During shutdown, the output is high impedance. Shutdown

reduces the IN current to less than 10µA. A logic-high

at EN enables the regulator.

Page 12

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

12 ______________________________________________________________________________________

High-Side Gate-Drive Supply (BST)

A flying capacitor boost circuit (Figure 2) generates the

gate-drive voltage for the internal high-side n-channel

MOSFET. The capacitor between BST and LXB is

charged from VL to 6.5V minus the diode forward-voltage drop while the low-side MOSFET is on. When the

low-side MOSFET is switched off, the stored voltage of

the capacitor is stacked above LXB to provide the necessary turn-on voltage (VGS) for the high-side MOSFET.

An internal switch between BST and the internal highside MOSFET’s gate closes to turn the MOSFET on.

Current-Sense Amplifier

The current-sense circuit amplifies the differential current-sense voltage (V

CS+

- V

CS-

). This amplified current-sense signal and the internal-slope-compensation

signal are summed (V

SUM

) together and fed into the

PWM comparator’s inverting input. The PWM comparator shuts off the high-side MOSFET when V

SUM

exceeds the integrated feedback voltage (V

COMP

).

The differential current sense is also used to provide

peak inductor current limiting. This current limit is more

accurate than the valley current limit, which is measured

across the internal low-side MOSFET.

Current-Limit Circuit

The MAX8655 uses both foldback and peak current limiting. The valley foldback current limit is used to reduce

power dissipation of external components—mainly the

inductor, internal power MOSFETs, and the upstream

power source, when the output is severely overloaded

or short circuited and when POK is low. Thus, the circuit

can withstand short-circuit conditions continuously without causing overheating of any component. The peak

constant current limit sets the current-limit point more

accurately since it does not have to suffer the wide variation of the low-side power MOSFET’s on-resistance

due to tolerance and temperature.

The valley current is sensed across the on-resistance of

the low-side MOSFET. The valley current limit trips when

the sensed current exceeds the valley current limit.

Set the minimum valley current limit when the output

voltage is at its nominal regulated value, higher than

the maximum peak current-limit setting. With this

method, the current-limit point accuracy is controlled

by the peak current limit and is not interfered with by

the wide variation of the MOSFET’s on-resistance. See

the Setting the Current Limit section for how to set

these limits.

The MAX8655 can be configured for either an

adjustable valley current-limit threshold with adjustable

foldback ratio or a fixed valley current limit that latches

the regulator off. To use foldback current limit with

autorecovery, connect MODE to GND. When the latch-off

mode is used, connect MODE to AVL and set the current-limit threshold with one resistor from ILIM2 to GND.

Cycle EN or input power to reset the current-limit latch.

The peak current limit is used to sense the inductor current, and is more accurate than the valley current limit

because it does not depend upon the on-resistance of

the low-side MOSFET. The peak current can be measured across the resistance of the inductor for the highest efficiency, or alternatively, a current-sense resistor

can be used for more accurate current sensing. A

resistor connected from ILIM1 to GND sets the peak

current-limit threshold.

For more information on the current limit, see the

Setting the Current Limit section.

Switching Frequency and Synchronization

The MAX8655 has an adjustable internal oscillator that

can be set to any frequency from 200kHz to 1MHz. To

set the switching frequency, connect a resistor from

FSYNC to GND.

The MAX8655 can also be synchronized to an external

clock by connecting the clock signal to FSYNC. A synchronization output (SYNCO) is provided to synchronize

a second MAX8655 180° out-of-phase with the first by

connecting SYNCO of the first MAX8655 to FSYNC of the

second. When the first MAX8655 is synchronized to an

external clock, the external clock is inverted to generate

SYNCO. Therefore, to get 180° out-of-phase operation

with an external clock, the clock input to the first

MAX8655 should have a 50% duty cycle. Figure 3 is the

single-phase, 600kHz switching, 10.8V to 13.2V input

and 1.2V/20A output. Figure 4 shows single-phase,

350kHz switching, 6V to 20V input, and 3.3V/20A output.

VL

BST

LXB

MAX8655

Figure 2. High-Side Gate Boost Circuit

Page 13

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

______________________________________________________________________________________ 13

REFIN

The MAX8655 has a reference input (REFIN). When an

external reference up to 1.5V is connected to REFIN,

the feedback regulation voltage is equal to the voltage

applied to REFIN.

Connect REFIN to AVL to use the internal 0.7V reference.

Overvoltage Protection

The MAX8655 provides output overvoltage protection

(OVP). The OVP threshold is set independent of the

output regulation voltage with a resistor voltage-divider.

When the voltage at OVP exceeds the OVP threshold,

the regulator stops switching and latches on the lowside power MOSFET. Cycle EN or the power applied to

AVL to clear the latch.

Power-Good Signal (POK)

POK is an open-drain output on the MAX8655 that monitors the output voltage. When the output is above 92%

of its nominal regulation voltage, POK is high impedance. When the output drops below 89% of its nominal

regulation voltage, POK is internally pulled low. POK is

also internally pulled low when the MAX8655 is shut

down or in a fault condition.

Thermal-Overload Protection

Thermal-overload protection limits total power dissipation in the MAX8655. When the junction temperature

exceeds +160°C, an internal thermal sensor shuts

down the device, allowing the IC to cool. The thermal

sensor turns the IC on again after the junction temperature cools by 15°C, resulting in a pulsed output during

continuous thermal-overload conditions.

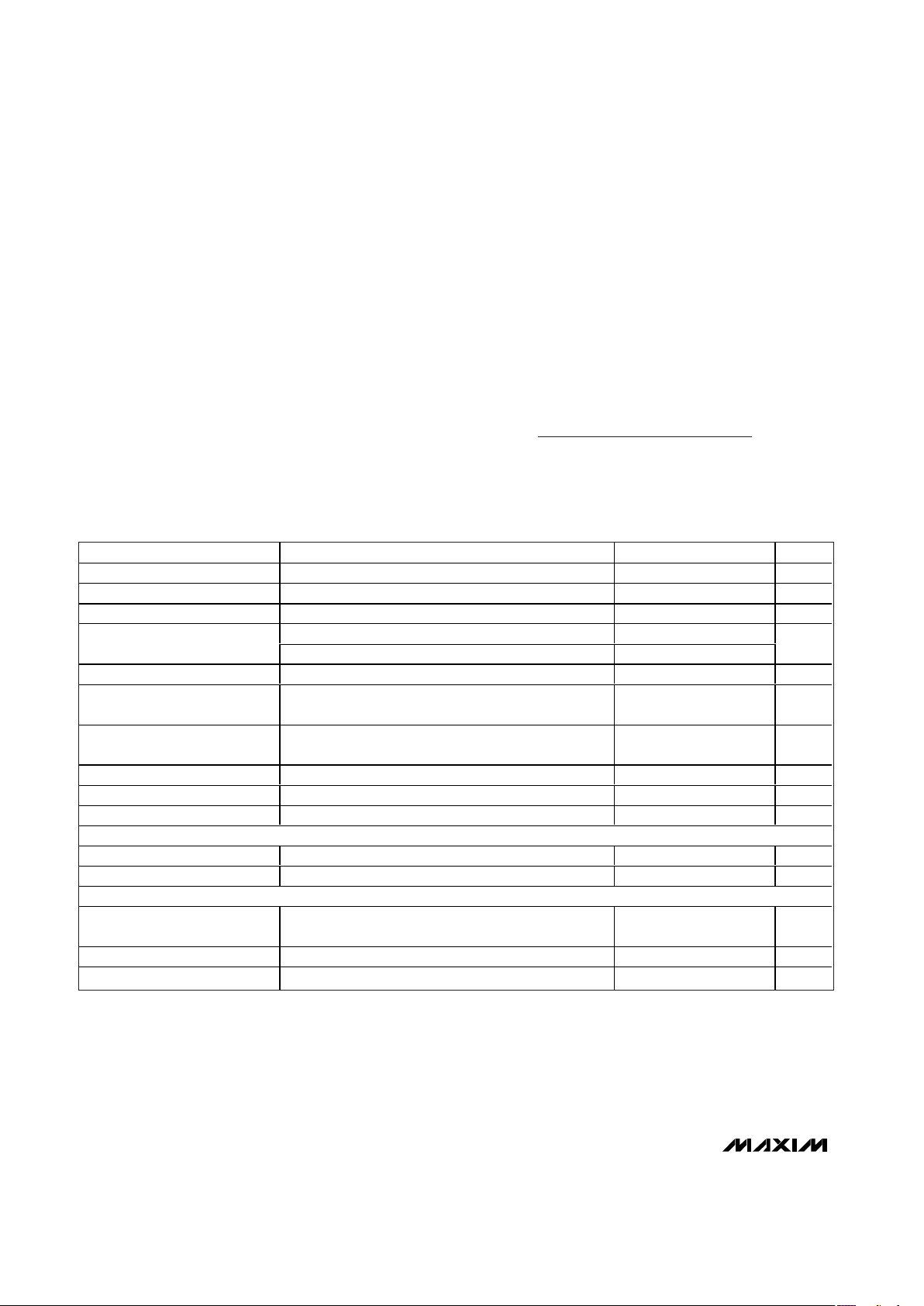

MAX8655

PVIN

PVIN

PVIN

PVIN

PVIN

LX

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

LX

LX

LX

LX

LX

OFF

ON

PVIN

C14

1μF

C8

0.47μF

C10

100pF

C12

470pF

C13

0.022μF

C15

0.22μF

C1–C3

3 x 10μF

CERAMIC

C16

0.22μF

R1

681Ω

R3

2.87kΩ

R12

80.6kΩ

R2

357Ω

R9

56.2kΩ

R7

40.2kΩ

L1

0.56μH

1.8mΩ

C18

2.2μF

R8

41.2kΩ

R13

100kΩ

R10

51.1kΩ

C9

0.47μF

C6–C20

4 x 100μF

CERAMIC

ENABLE

INPUT

INPUT

11.8V TO 13.2V

FOR INTERNAL

OSCILLATOR

OPERATION ONLY

POWER-OK OUTPUT

FSYNC INPUT

SYNC OUTPUT

OUTPUT 1.2V

UP TO 20A

AVL

D1

VL

AVL

LX

VLGND

GND

VL

IN

EN

AVL

GND

SCOMP

ILIM2

GND

REFIN

SS

COMP

FB

OVP

ILIM1

CS-

CS+

N.C.

N.C.

PVIN

PVIN

PVIN

PVIN

PVIN

PVIN

LXB

N.C.

GND

BST

SYNCO

MODE

FSYNC

POK

R5

4.02kΩ

Figure 3. Single-Phase, 600kHz Switching, 10.8V to 13.2V Input, and 1.2V/20A Output

Page 14

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

14 ______________________________________________________________________________________

Design Procedure

Setting the Output Voltage

To set the output voltage for the MAX8655, connect FB

to the center of an external resistor-divider from the output to GND (R3 and R5 of Figure 5). Select R5 between

5kΩ and 24kΩ, and then calculate R3 with the following

equation:

where V

FB

= 0.7V or V

REFIN

. R3 and R5 should be

placed as close as possible to the IC.

RR

V

V

OUT

FB

35 1=× −

⎛

⎝

⎜

⎞

⎠

⎟

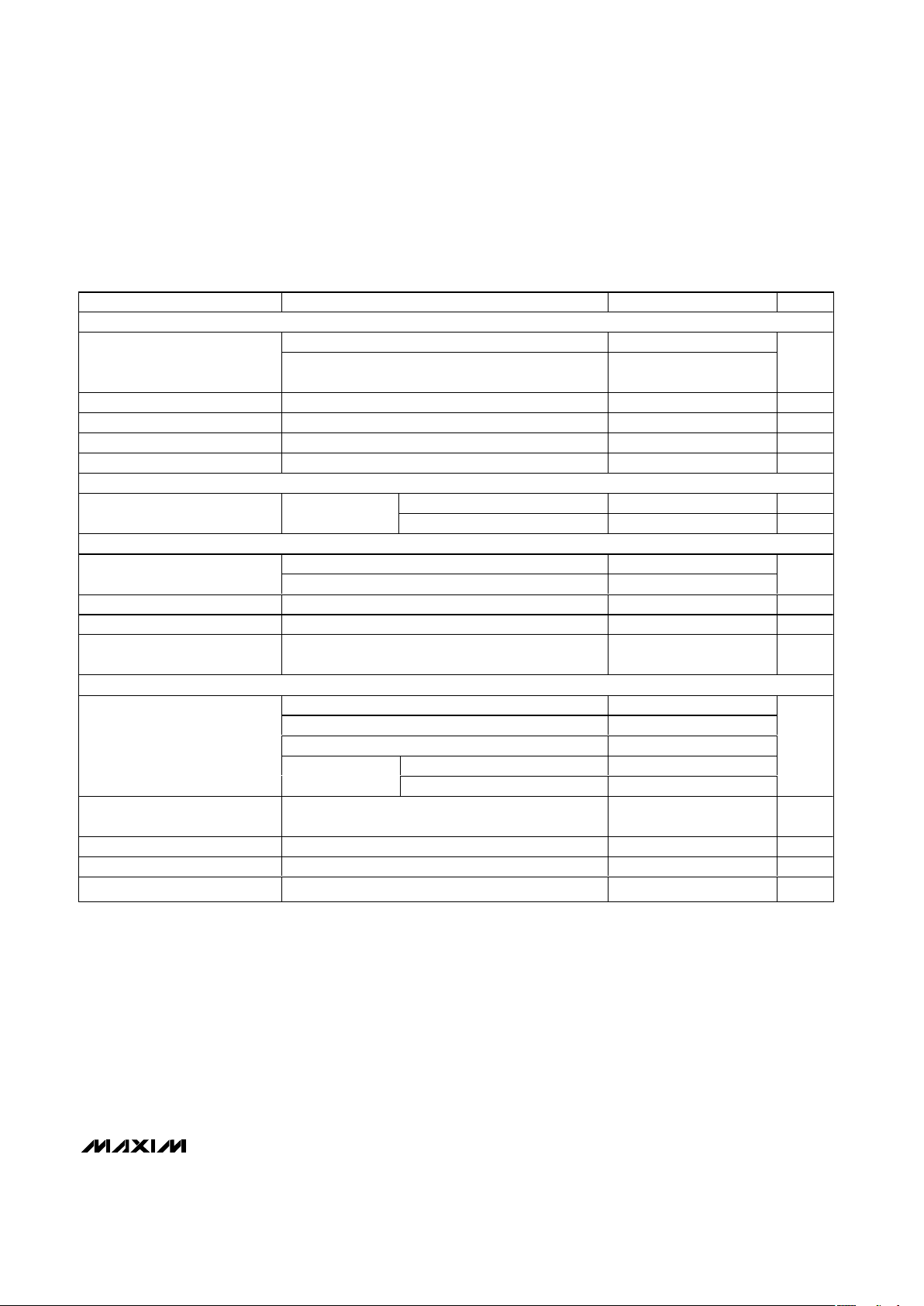

MAX8655

PVIN

PVIN

PVIN

PVIN

PVIN

LX

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

LX

LX

LX

LX

LX

OFF

ON

PVIN

C14

1μF

C8

0.22μF

C10

100pF

C12

560pF

C13

0.022μF

C15

0.22μF

C1–C5

5 x 10μF

CERAMIC

C16

0.22μF

R1

1.74kΩ

R4

11.5kΩ

R3

11.5kΩ

R2

3.57kΩ

R9

71.5kΩ

R7

243kΩ

R6

3.09kΩ

L1

1μH

1.6mΩ

C18

2.2μF

R8

76.8kΩ

R13

100kΩ

R14

13kΩ

R11

140kΩ

C9

0.22μF

ENABLE

INPUT

INPUT 6V TO 20V

FOR INTERNAL

OSCILLATOR

OPERATION ONLY

POWER-OK OUTPUT

FSYNC INPUT

SYNC OUTPUT

OUTPUT 3.3V

UP TO 20A

AVL

AVL

D1

VL

AVL

LX

VLGND

GND

VL

IN

EN

AVL

GND

SCOMP

ILIM2

REFIN

SS

COMP

FB

OVP

ILIM1

CS-

CS+

N.C.

N.C.

PVIN

PVIN

PVIN

PVIN

PVIN

PVIN

LXB

N.C.

GND

BST

SYNCO

MODE

FSYNC

POK

GND

R12

10kΩ

C6–C19

3 x 220μF

15μΩ ESR

R5

3.09kΩ

Figure 4. Single-Phase, 350kHz Switching, 6V to 20V Input, and 3.3V/20A Output

MAX8655

LX

R5

R3

FB

Figure 5. Setting the Output Voltage with a Resistor VoltageDivider

Page 15

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

______________________________________________________________________________________ 15

Setting the Output Overvoltage Protection

To set the overvoltage threshold voltage for the

MAX8655, connect OVP to the center of an external

resistor-divider connected between the output and GND

(R4 and R6 of Figure 3). Select R6 between 5kΩ and

24kΩ, then calculate R4 with the following equation:

where V

OVP

= 1.15 x VFB.

Inductor Selection

There are several parameters that must be examined

when determining which inductor is to be used. Input

voltage, output voltage, load current, switching frequency, and LIR. LIR is the ratio of the inductor current

ripple to the maximum DC load current. A higher LIR

value allows for a smaller inductor, but results in higher

losses and higher output ripple. A good compromise

between size and efficiency is an LIR of 0.3. Once all

the parameters are chosen, the inductor value is determined as follows:

where fS is the switching frequency. Choose a standard-value inductor close to the calculated value. The

exact inductor value is not critical and can be adjusted

to make trade-offs among size, cost, and efficiency.

Lower inductor values minimize size and cost, but they

also increase the output ripple and reduce the efficiency due to higher peak currents. On the other hand,

higher inductor values increase efficiency, but eventually resistive losses due to extra turns of wire exceed

the benefit gained from lower AC current levels. This is

especially true if the inductance is increased without

also increasing the physical size of the inductor. Find a

low-loss inductor having the lowest possible DC resistance that fits the allotted dimensions. The chosen

inductor’s saturation current rating must exceed the

peak inductor current determined as:

Setting the Switching Frequency

To set the switching frequency, connect a resistor from

FSYNC to GND. Calculate the resistor value in kΩ from

the following equation:

where fSis the desired switching frequency in kHz.

Setting the Slope Compensation

For most applications where the duty cycle is less than

40%, connect SCOMP to GND to set the internal slope

compensation to the default of 125mV/T, where T is the

oscillator period (T = 1 / fS).

For a slope compensation of 250mV/T, connect

SCOMP to AVL.

For applications with a duty cycle greater than 40%, set

the SCOMP voltage with a resistor voltage-divider from

AVL to GND (R11 and R12 in Figure 6). First, use the

following equation to find the SCOMP voltage:

where RLis the DC resistance of the inductor, V

IN_MIN

is the minimum operating input voltage, and fSis the

switching frequency.

Next, select a value for R11, typically 10kΩ, and solve

for R12 as follows:

This sets the internal slope-compensation voltage rate

to V

SCOMP

/ (10 x T).

R

VV R

V

SCOMP

SCOMP

12

511

=

−

()

×

V

R

fL

VV

SCOMP

L

S

OINMIN

=

×

×

×− ×

120

0 182(. )

_

R

f

FSYNC

S

=−

30600

9 914.

II

LIR

I

PEAK LOAD MAX LOAD MAX

=+×

() ()

2

L

VVV

V f I LIR

OUT IN OUT

IN S LOAD MAX

=

×−

×× ×

()

()

RR

V

V

OUT

OVP

46 1=× −

⎛

⎝

⎜

⎞

⎠

⎟

MAX8655

AVL

R11

R12

SCOMP

Figure 6. Resistor-Divider for Setting the Slope Compensation

Page 16

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

16 ______________________________________________________________________________________

Setting the Current Limit

Valley Current Limit

The MAX8655 has an adjustable valley current limit, configurable for foldback with automatic recovery, or constant-current limit with latch-up. To set the constantcurrent limit for the latch-up mode, connect a single

resistor R

ILIM2

from ILIM2 to GND. For latch-up current-

limit mode, set R

ILIM2

equal to R

VALLEY

obtained from

the R

VALLEY

vs. Valley Current Limit graph in the Typical

Operating Characteristics section for the required valley

current I

VALLEY

. I

VALLEY

is the value of the inductor val-

ley current at maximum load (I

LOAD(MAX)

- 1/2 I

P-P

)

To set the current limit for foldback mode, connect a

resistor from ILIM2 to the output (R

FOBK

), and another

resistor from ILIM2 to GND (R

ILIM2

). See Figure 7. The

values of R

FOBK

and R

ILIM2

are calculated as follows.

First, select the percentage of foldback (PFB). This percentage corresponds to the current limit when V

OUT

equals zero divided by the current limit when V

OUT

equals its nominal voltage. A typical value of PFBis in

the 15% to 40% range. A lower value of PFByields

lower short-circuit current. The following equations are

used to calculate R

FOBK

and R

ILIM2

:

where I

ILIM2

is 5µA.

If the resulting value of R

ILIM2

is negative, increase PFB.

Peak Current Limit

The peak current-limit threshold (VTH) is set by a resistor

connected from ILIM1 to GND (R

ILIM1

). VTHcorresponds

to the peak voltage across the sensing element (inductor

or current-sense resistor). R

ILIM1

is calculated as follows:

This allows a maximum DC output current of:

where R

L

is the DC resistance of the inductor.

To ensure maximum output current, use the minimum

value of VTHfrom each setting, and the maximum R

L

values at the highest expected operating temperature.

The DC resistance of the inductor’s copper wire has a

+0.38%/°C temperature coefficient.

An RC circuit is connected across the inductor (see

Figure 8). The RC time constant is set to be 1.1 to 1.2

times the inductor (L/R

L

) time constant. Pick the value

of C9 in the 0.1µF to 0.47µF range, and then calculate

R1 from:

R1 = 1.2L / (R

L

x C9)

Add a resistor (R2 in Figure 8) to the CS- connection to

minimize input offset error. Calculate the value of R2 as

follows:

• When V

OUT

≥ 2.4V:

• When V

OUT

< 2.4V:

R

AxR

A

RxA

k

ILIM

2

15 1

15

10

32

1

=

μ

μ+

μ

Ω

⎛

⎝

⎜

⎞

⎠

⎟

R

A

RA

k

R

A

ILIM

2

20

10

32

1

20

1

=

+

×

⎛

⎝

⎜

⎞

⎠

⎟

×μ

μ

μ

Ω

I

V

R

I

LIM

THLPP

=−

−

2

R

V

A

ILIMTH1

75

10

=

×.

μ

R

IR R

VI R R

ILIM

ILIM VALLEY FOBK

OUT ILIM FOBK VALLEY

2

2

2

=

××

+× −

()

()

R

PV

IP

FOBK

FB OUT

ILIM FB

=

×

×−

()

2

1

MAX8655

LX

R

ILIM2

R

FOBK

ILIM2

OUT

Figure 7. ILIM2 Resistor Connections

MAX8655

LX

R2

R1

L1

C9

C10

CS+

CS-

V

OUT

C11

Figure 8. Current Sense Using the Inductor’s DC Resistance

Page 17

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

______________________________________________________________________________________ 17

Capacitor C11 is connected in parallel with R2 and is

equal in value with C9.

Add a 100pF (C10) capacitor across the CS+ and CSinputs close to the IC.

Input Capacitor

The input filter capacitor reduces peak currents drawn

from the power source and reduces noise and voltage

ripple on the input caused by the circuit’s switching.

The input capacitors must meet the ripple-current

requirement (I

RMS

) imposed by the switching currents

defined by the following equation:

I

RMS

has a maximum value when the input voltage

equals twice the output voltage (VIN= 2 x V

OUT

), so

I

RMS(MAX)

= I

LOAD

/ 2. Ceramic capacitors are recommended due to the low ESR and ESL at high frequency

with relatively low cost. Choose a capacitor that

exhibits less than 10°C temperature rise at the maximum operating RMS current for optimum long-term reliability. Ceramic capacitors with an X5R or better

temperature characteristic are recommended.

Output Capacitor

The key selection parameters for the output capacitor

are the actual capacitance value, the equivalent series

resistance (ESR), the equivalent series inductance

(ESL), and the voltage-rating requirements. These

parameters affect the overall stability, output-voltage

ripple, and transient response. The output ripple has

three components: variations in the charge stored in

the output capacitor, the voltage drop across the

capacitor’s ESR, and ESL caused by the current into

and out of the capacitor. The maximum output-voltage

ripple is estimated as follows:

V

RIPPLE

= V

RIPPLE(ESR)

+ V

RIPPLE(C)

+ V

RIPPLE(ESL)

The output-voltage ripple as a consequence of the

ESR, ESL, and output capacitance is:

where I

P-P

is the peak-to-peak inductor current.

These equations are suitable for initial capacitor selection, but final values should be chosen based on a prototype or evaluation circuit. As a general rule, a smaller

current ripple results in less output-voltage ripple.

Since the inductor ripple current is a factor of the

inductor value and input voltage, the output-voltage ripple decreases with larger inductance, and increases

with higher input voltages. The MAX8655 is designed to

work with polymer, tantalum, aluminum electrolytic, or

ceramic output capacitors. The aluminum electrolytic

capacitor is the least expensive; however, it has higher

ESR. To compensate for this, use a ceramic capacitor

in parallel to reduce the switching ripple and noise.

Ceramic capacitors are recommended for high-frequency (500kHz to 1MHz) designs. For reliable and

safe operation, ensure that the capacitor’s voltage and

ripple-current ratings exceed the calculated values.

The response to a load transient depends on the

selected output capacitors. During a load transient, the

output voltage instantly changes by ESR x ΔI

LOAD

.

Before the regulator can respond, the output voltage

deviates further, depending on the inductor and outputcapacitor values. After a short time (see the Typical

Operating Characteristics section), the regulator

responds by regulating the output voltage back to its

nominal state. The regulator response time depends on

its closed-loop bandwidth. With a higher bandwidth,

the response time is faster, thus preventing the output

voltage from further deviation from its regulating value.

Compensation Design

The MAX8655 uses an internal transconductance error

amplifier whose output compensates the control loop.

The external inductor, output capacitor, compensation

resistor, and compensation capacitors determine the

loop stability. The inductor and output capacitor are chosen based on performance, size, and cost. Additionally,

the compensation resistor and capacitors are selected to

optimize control-loop stability. The component values,

shown in Figures 3 and 4, yield stable operation over the

given range of input-to-output voltages.

The regulator uses a current-mode control scheme that

regulates the output voltage by forcing the required current through the external inductor. The voltage drop

across the DC resistance of the inductor or the alternate

series current-sense resistor is used to measure the

inductor current. Current-mode control eliminates the

double pole in the feedback loop caused by the

I

VV

fLVV

PP

IN OUTSOUT

IN

−

=

−

×

×

V

I

Cf

RIPPLE C

PP

OUT S

()

=

××

−

8

V

V

L ESL

ESL

RIPPLE ESLIN()

=

+

×

V I ESR

RIPPLE ESR P P()

=×

−

I

IVVV

V

RMS

LOAD OUT IN OUT

IN

=

×−

()

Page 18

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

18 ______________________________________________________________________________________

inductor and output capacitor resulting in a smaller

phase shift and requiring a less elaborate error-amplifier

compensation than voltage-mode control. A simple

series RCand CCis all that is needed to have a stable,

high-bandwidth loop in applications where ceramic

capacitors are used for output filtering. For other types

of capacitors, due to the higher capacitance and ESR,

the frequency of the zero created by the capacitance

and ESR is lower than the desired closed-loop crossover

frequency. To stabilize a nonceramic output-capacitor

loop, add another compensation capacitor from COMP

to GND to cancel this ESR zero. See Figure 9.

The basic regulator loop is modeled as a power modulator, an output feedback divider, and an error amplifier. The power modulator has DC gain G

MOD(dc)

, set by

gmcx R

LOAD

, with a pole and zero pair set by R

LOAD

,

the output capacitor (C

OUT

), and its equivalent series

resistance (ESR). Below are equations that define the

power modulator:

where R

LOAD

= V

OUT

/ I

OUT(MAX)

, fSis the switching

frequency, L is the output inductance, gmc= 1 / (A

VCS

x

R

L

), where A

VCS

is the gain of the current-sense amplifi-

er (12 typ), R

L

is the DC resistance of the inductor, the

duty cycle D = V

OUT

/ V

IN. KS

is a slope compensation

factor calculated from the following equation:

When SCOMP is connected to GND, use V

SCOMP

= 1.25V;

when SCOMP is connected to AVL, use V

SCOMP

= 2.5V.

Find the pole and zero frequencies created by the

power modulator as follows:

When C

OUT

comprises “n” identical capacitors in paral-

lel, the resulting C

OUT

= n x C

OUT(EACH)

, and ESR =

ESR

(EACH)

/ n. Note that the capacitor zero for a parallel combination of like capacitors is the same as for an

individual capacitor. Figure 10 is the simplified gain

plot for the f

zMOD

> fCcase.

The feedback voltage-divider has a gain of GFB= VFB/

V

OUT

, where VFBis equal to 0.7V.

The transconductance error amplifier has a DC gain,

G

EA(DC)

= g

mEA

x RO, where g

mEA

is the error-amplifi-

er transconductance, which is equal to 110µS, and R

O

is the output resistance of the error amplifier, which is

30MΩ. A dominant pole (f

pdEA

) is set by the compensation capacitor (CC), the amplifier output resistance

(RO), and the compensation resistor (RC); a zero (f

zEA

)

is set by the compensation resistor (RC) and the compensation capacitor (CC). There is an optional pole

(f

pEA

) set by CFand RCto cancel the output capacitor

ESR zero if it occurs near the crossover frequency (fC).

Thus:

f

CR

pEA

FC

=

××

1

2π

f

CR

zEA

CC

=

××

1

2π

f

CRR

pdEA

COC

=

×× +

1

2π ()

f

C ESR

zMOD

OUT

=

××

1

2π

f

RC

Lf C

KD

pMOD

LOAD OUT

S OUT

S

=

××

+

×× ×

××−−

[]

⎡

⎣

⎢

⎤

⎦

⎥

1

2

1

2

105

π

π

().

K

VLf

VVR

S

SCOMP S

IN O L

=+

××

×−×

1

120 ( )

Gg

R

R

Lf

KD

MOD dc mc

LOAD

LOAD

S

()

.

=×

+

×

××−

()

()

−

[]

⎡

⎢

1105

MAX8655

C

C

C

F

R

C

COMP

Figure 9. Compensation Components

GAIN

(dB)

FREQUENCY

fp

MOD

fz

MOD

fc

CLOSED LOOP

ERROR

AMPLIFIER

0dB

FB

DIVIDER

POWER

MODULATOR

Figure 10. Simplified Gain Plot for the f

zMOD

> fCCase

Page 19

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

______________________________________________________________________________________ 19

The crossover frequency, fC, should be much higher

than the power-modulator pole f

PMOD

. Also, fCshould

be less than or equal to 1/5 the switching frequency.

Select a value for fCin the range:

At the crossover frequency, the total loop gain must

equal 1, and is expressed as:

For the case where f

zMOD

is greater than fC:

Then RCcan be calculated as:

where g

mEA

= 110µS.

The error-amplifier compensation zero formed by R

C

and CCshould be set at the modulator pole f

PMOD

.

Calculate the value of C

C

as follows:

If f

zMOD

is less than 5 x fC, add a second capacitor C

F

from COMP to GND. The value of CFis:

As the load current decreases, the modulator pole

also decreases; however, the modulator gain increases

accordingly and the crossover frequency remains

the same.

For the case where f

zMOD

is less than fC:

The power modulator gain at fCis:

The error-amplifier gain at fCis:

Figure 11 is the simplified gain plot for the f

zMOD

< f

C

case.

R

C

is calculated as:

where g

mEA

= 110µS.

C

C

is calculated from:

C

F

is calculated from:

The current-mode control model on which the above

design procedure is based requires an additional highfrequency term, GS(s), to account for the effect of sampling the peak inductor current. The term GS(s)

produces additional phase lag at crossover and should

be modeled to estimate the phase margin obtainable

by the selected compensation components. As a final

step, it is useful to plot the dB gain and phase of the

following loop-gain transfer function and check the

C

Rf

F

C zMOD

=

××

1

2π

C

fR

C

p

MOD

C

=

××

1

2π

R

V

V

f

gG f

C

OUT

FB

C

mEA MOD fc zMOD

=×

××

()

GgR

f

f

EA fc mEA C

zMOD

C

()

=××

GG

f

f

MOD fc MOD dc

pMOD

zMOD

() ( )

=×

C

Rf

F

C zMOD

=

××

1

2π

C

fR

C

p

MOD

C

=

××

1

2π

R

V

gVG

C

OUT

mEA FB MOD fc

=

××

()

GG

f

f

MOD fc MOD dc

pMOD

C

() ( )

=×

GgR

EA fc mEA C()

=×

GG

V

V

EA fc MOD fc

FB

OUT

() ()

××=1

ff

f

pMOD C

S

<< ≤

5

GAIN

(dB)

FREQUENCY

fp

MOD

fz

MOD

fc

CLOSED LOOP

ERROR

AMPLIFIER

0dB

FB

DIVIDER

POWER

MODULATOR

Figure 11. Simplified Gain Plot for the f

zMOD

< fCCase

Page 20

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

20 ______________________________________________________________________________________

obtained phase margin. A phase margin of at least 45°

is recommended:

where the sampling effect quality factor:

,

Below is a numerical example to calculate R

C

and C

C

values of the typical operating circuit of Figure 3:

A

VCS

= 12

L = 0.56µH

R

L

= 1.8mΩ

f

S

= 600kHz

gmc= 1 / (A

VCS

x RL) = 1 / (12 x 0.0018) = 46.29S

V

OUT

= 1.2V

I

OUT(MAX)

= 20A

R

LOAD

= V

OUT

/ I

OUT(MAX)

= 1.2 / 20 = 0.06Ω

C

OUT

= 4 x 100µF = 400µF

ESR = 2mΩ/4 = 0.5mΩ

D = V

OUT

/ VIN= 1.2/12 = 0.1:

8.18kHz << fC≤ 120kHz, select fC= 60kHz.

Since f

zMOD

> fC:

RC = 44.7kΩ

Select the nearest standard value: RC= 40.2kΩ:

Select the nearest standard value: CC= 470pF:

R7 = RC = 40.2kΩ

C12 = CC= 470pF

C11 = CF= 5pF (not used)

C

Rf

x

pF

F

C zMOD

=

××

=

×××

=

1

2

1

2 40 2 10 884 2 10

5

33

π

π (. )( . )

C

fR

x

pF

C

p

MOD

C

=

××

=

××

=

1

2

1

2 8181 40 2 10

483 9

3

π

π (. )

.

R

V

Vg G

x

C

OUT

FB mEA MOD fc

=×

×

=×

−

1

12

07

1

110 10 0 307

6

()

.

.

()(.)

GG

f

f

MOD fc MOD dc

pMOD

c

() ( )

..=×=×=253

8118

60000

0 345

f

C ESR

kHz

zMOD

OUT

=

×× ×

=

×× × ×

=

−

1

209

1

2 0 9 400 10 0 0005

884 2

6

ππ.

.( ).

.

ff

f

pMOD C

S

<< ≤

5

f

RC

Lf C

KD

x

xx

pMOD

LOAD OUT

S OUT

S

=

×××

+

×× × ×

××−−

[]

⎡

⎣

⎢

⎤

⎦

⎥

=

×

+

×

−−

()

⎡

⎣

⎢

−

−−

1

209

1

208

105

1

2 400 10 0 06 0 9

1

2 0 56 10 600000 400 10 0 8

1181 01 05

6

66

π

π

π

π

.

.

().

()(.).

( . )( )( ) .

.( .) .

⎢⎢

⎤

⎦

⎥

⎥

= 818. kHz

Gg

R

R

Lfs

KD

x

MOD dc mc

LOAD

LOAD

S

()

.

.

.

.

( . )( )

.( .) .

.

=×

+

×

××−

()

()

−

[]

⎡

⎣

⎢

⎤

⎦

⎥

=

×

+×−−

[]

=

−

1105

46 29

006

1

006

0 56 10 600000

1181 01 05

253

6

K

VLf

VVR

x

S

SCOMP S

IN O L

=+

××

×−×

=+

−

=

−

1

120

1

1 25 0 56 10 600000

120 12 1 2 0 0018

118

6

()

.(. )( )

(.)(.)

.

Q

KD

C

S

=

−−

[]

1

105π.( .( ) . )

Gs

s

Qf

s

f

S

cS

S

()

..

.

=

++

()

⎛

⎝

⎜

⎜

⎞

⎠

⎟

⎟

1

1

2

2

π

π

Gs

gR

R

Lf

KD

sf

sf

sf

sf sf

gRoV

V

Gs

LOOP

mc LOAD

LOAD

S

S

zMOD

pMOD

zEA

pEA pdEA

mEA FB

O

S

()

().

(/ )

(/ )

(/ )

(/ )(/ )

()

=

×

+

×

××−

()

−

[]

⎡

⎣

⎢

⎤

⎦

⎥

×

+×

+×

×

+×

+× ×+×

×

××

1105

12

12

12

12 12

π

π

π

ππ

Page 21

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

______________________________________________________________________________________ 21

Applications Information

PCB Layout Guidelines

Careful PCB layout is critical to achieve low losses and

clean, stable operation. Refer to the MAX8655

Evaluation Kit for an example layout. If it is necessary to

deviate from this layout, follow the procedure below.

Follow these guidelines for good PCB layout:

1) Place IC decoupling capacitors as close as possible to the IC pins. Separate the power and analog

ground planes. Place the input ceramic decoupling

capacitor directly across and as close as possible

to PVIN and PGND. This is to help contain the high

switching current within this small loop.

2) For output current greater than 10A, a four-layer

PCB is recommended. Pour an analog ground

plane in the second layer underneath the IC to minimize noise coupling.

3) Connect input, output, and VL capacitors to the

power ground plane; connect all other capacitors to

the signal ground plane. Connect analog and

power ground planes at the output capacitor.

4) Place the inductor current-sense resistor and

capacitor as close as possible to the inductor.

Make a Kelvin connection to minimize the effect of

PCB trace resistance. Place the input bias balance

resistor (R2 in Figure 8) near CS-. Run two closely

parallel traces from across capacitor C9 to CS+

and the input bias balance resistor R2.

5) Connect the exposed pad sections to the corresponding IC pins and allow sufficient copper area

to help cooling the device.

6) Place the feedback and compensation components

as close as possible to the IC pins. Connect the

feedback resistor-divider from FB to V

OUT

as close

as possible to the farthest output capacitor.

Chip Information

PROCESS: BiCMOS

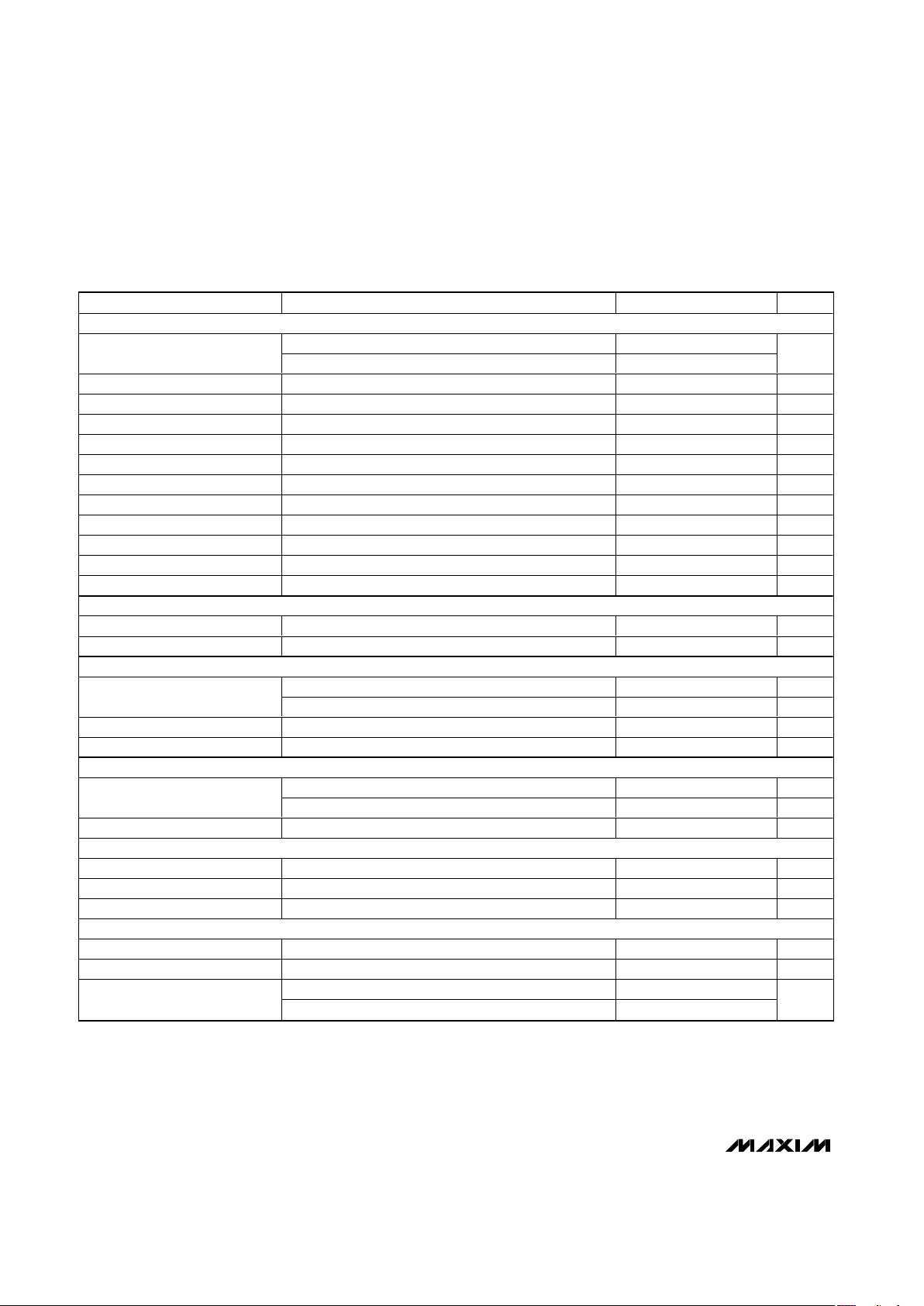

Page 22

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

22 ______________________________________________________________________________________

TOP VIEW

MAX8655ETN

THIN QFN

(8mm x 8mm)

15

17

16

18

19

20

21

22

23

24

25

26

27

28

48

47

46

45

44

43

54

53

56

55

52

51

50

49

1 2 3 4 5 6 7 8 910 11121314

42 41 40 39 38 37 36 35 34 33 32 31 30 29

PVIN

PVIN

PVIN

PVIN

PVIN

LX

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

LX

LX

LX

LX

LX

LX

VLGND

GND-EP

LX-EPPVIN-EP

GND

VL

IN

EN

AVL

GND

N.C.

SCOMP

ILIM2

GND

REFINSSCOMPFBOVP

ILIM1

CS-

CS+

N.C.

N.C.

PVIN

PVIN

PVIN

PVIN

PVIN

PVIN

LXB

N.C.

GND

BST

SYNCO

MODE

FSYNC

POK

+

Pin Configuration

Page 23

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

______________________________________________________________________________________ 23

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

56L THIN QFN.EPS

Page 24

MAX8655

Highly Integrated, 25A, Wide-Input,

Internal MOSFET, Step-Down Regulator

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

24 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2007 Maxim Integrated Products is a registered trademark of Maxim Integrated Products, Inc.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information

go to www.maxim-ic.com/packages

.)

Loading...

Loading...