Page 1

General Description

The MAX7321 2-wire serial-interfaced peripheral features eight open-drain I/O ports with selectable internal

pullups and transition detection. Any port may be used

as a logic input or an open-drain output. Ports are overvoltage protected to +6V independent of supply voltage.

All I/O ports configured as inputs are continuously

monitored for state changes (transition detection).

State changes are indicated by the open-drain INT

output. The interrupt is latched, allowing detection of

transient changes. When the MAX7321 is subsequently accessed through the serial interface, any pending

interrupt is cleared.

The open-drain outputs are rated to sink 20mA and are

capable of driving LEDs.

The RST input clears the serial interface, terminating

any I2C communication to or from the MAX7321.

The MAX7321 uses two address inputs with four-level

logic to allow 16 I

2

C slave addresses. The slave

address also determines the power-up logic state for

the I/O ports, and enables or disables internal 40kΩ

pullups in groups of four ports.

The MAX7321 is one device in a family of pin-compatible

port expanders with a choice of input ports, open-drain

I/O ports, and push-pull output ports (see Table 1).

The MAX7321 is available in 16-pin QSOP and TQFN

packages, and is specified over the automotive temperature range (-40°C to +125°C).

Features

♦ 400kHz I2C Serial Interface

♦ +1.71V to +5.5V Operating Voltage

♦ 8 Open-Drain I/O Ports Rated to 20mA Sink Current

♦ I/O Ports Are Overvoltage Protected to +6V

♦ Any Port Can Be a Logic Input or an Open-Drain

Output

♦ Selectable I/O Port Power-Up Default Logic States

♦ Transient Changes Are Latched, Allowing Detection

Between Read Operations

♦ INT Output Alerts Change on Inputs

♦ AD0 and AD2 Inputs Select from 16 Slave

Addresses

♦ Low 0.6µA (typ) Standby Current

♦ -40°C to +125°C Operating Temperature

MAX7321

I2C Port Expander with 8 Open-Drain I/Os

________________________________________________________________ Maxim Integrated Products 1

19-3738; Rev 1; 4/06

For pricing, delivery, and ordering information, please contact Maxim/Dallas Direct! at

1-888-629-4642, or visit Maxim’s website at www.maxim-ic.com.

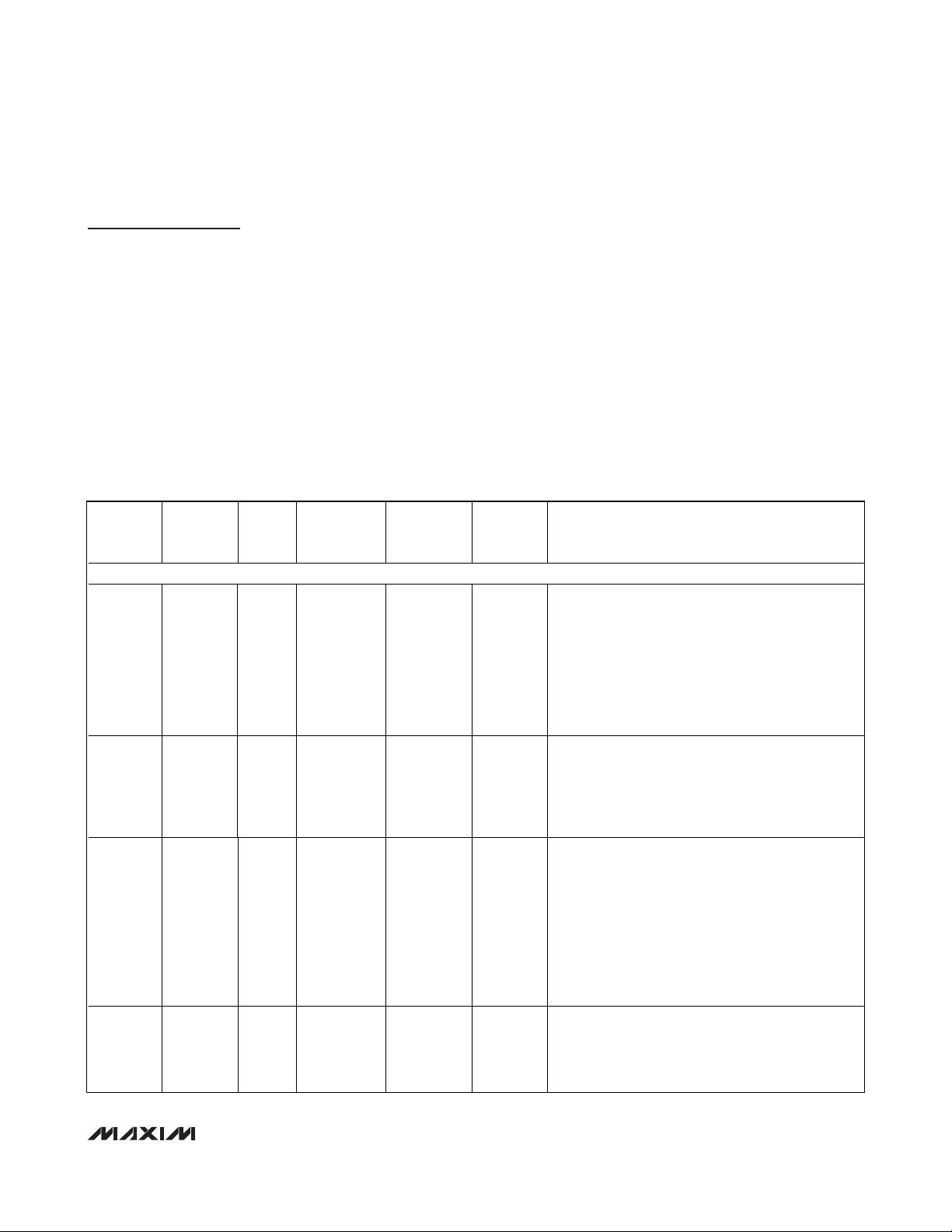

Ordering Information

PART

TEMP

PINPACKAGE

TOP

PKG

CODE

MAX7321AEE+

-40°C to

16 QSOP —

E16-4

MAX7321ATE+

-40°C to

T1633-4

Pin Configurations are continued at end of data sheet.

Typical Application Circuit and Functional Diagram appear

at end of data sheet.

Selector Guide

PART

INPUTS

INTERRUPT

MASK

OPENDRAIN

PUSH-PULL

OUTPUTS

MAX7319

8 Yes — —

MAX7320

—— — 8

MAX7321

—

—

MAX7322

4 Yes — 4

MAX7323

—

4

MAX7328

—

—

MAX7329

—

—

**EP = Exposed paddle.

+Denotes lead-free package.

Cell Phones

SAN/NAS

Servers

Notebooks

Satellite Radio

Automotive

Applications

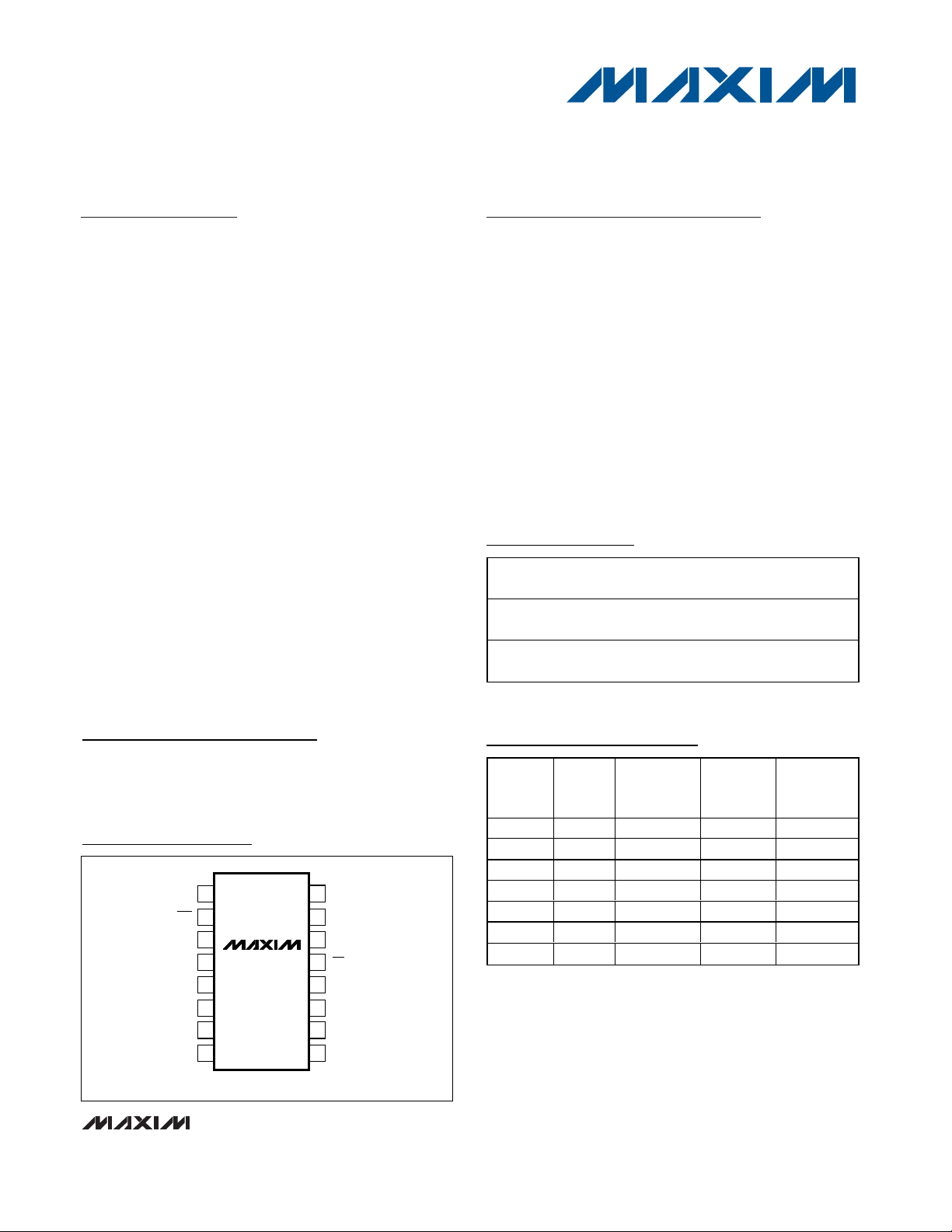

Pin Configurations

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

AD0

V+

SDA

SCL

INT

P7

P6

P5

P4

MAX7321

QSOP

RST

AD2

P2

P0

P1

P3

GND

+

+

RANGE

+125°C

+125°C

16 TQFN-EP** ADC

MARK

OUTPUTS

Up to 8

Up to 4

Up to 8

Up to 8

Up to 8

Up to 4

Up to 8

Up to 8

Page 2

MAX7321

I2C Port Expander with 8 Open-Drain I/Os

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

(All voltages referenced to GND.)

Supply Voltage V+....................................................-0.3V to +6V

SCL, SDA, AD0, AD2, RST, INT, P0–P7 ...................-0.3V to +6V

P0–P7 Sink Current ............................................................ 25mA

SDA Sink Current ............................................................... 10mA

INT Sink Current..................................................................10mA

Total V+ Current..................................................................50mA

Total GND Current ...........................................................100mA

Continuous Power Dissipation (T

A

= +70°C)

16-Pin QSOP (derate 8.3mW/°C above +70°C)...........667mW

16-Pin TQFN (derate 15.6mW/°C above +70°C) .......1250mW

Operating Temperature Range .........................-40°C to +125°C

Junction Temperature......................................................+150°C

Storage Temperature Range .............................-65°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

ELECTRICAL CHARACTERISTICS

(V+ = +1.71V to +5.5V, TA= -40°C to +125°C, unless otherwise noted. Typical values are at V+ = +3.3V, TA= +25°C.) (Note 1)

Operating Supply Voltage V+ 1.71 5.50 V

Power-On Reset Voltage V

Standby Current

(Interface Idle)

Supply Current

(Interface Running)

Input High Voltage

SDA, SCL, AD0, AD2, RST, P0–P7

Input Low Voltage

SDA, SCL, AD0, AD2, RST, P0–P7

Input Leakage Current

SDA, SCL, AD0, AD2, RST, P0–P7

Input Capacitance

SDA, SCL, AD0, AD2, RST, P0–P7

Output Low Voltage

P0–P7

Output Low Voltage

SDA

Output Low Voltage

INT

Port Input Pullup Resistor R

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

POR

I

STB

I

V

V

I

IH

V

V

OLSDAISINK

V

OLINTISINK

V+ falling 1.6 V

SCL and SDA and other digital inputs at V+ 0.6 1.5 µA

f

+

IH

, I

OL

PU

IL

IL

= 400kHz; other digital inputs at V+ 23 55 µA

SCL

V+ < 1.8V 0.8 x V+

V+ ≥ 1.8 0.7 x V+

V+ < 1.8V 0.2 x V+

V+ ≥ 1.8V 0.3 x V+

SDA, SCL, AD0, AD2, RST, P0–P7 at V+ or

GND, internal pullup disabled

V+ = +1.71V, I

V+ = +2.5V, I

V+ = +3.3V, I

V+ = +5V, I

= 6mA 250 mV

= 5mA 130 250 mV

= 5mA 90 180

SINK

= 10mA 110 210

SINK

= 15mA 130 230

SINK

= 20mA 140 250

SINK

-0.2 +0.2 µA

10 pF

25 40 55 kΩ

V

V

mV

Page 3

MAX7321

I2C Port Expander with 8 Open-Drain I/Os

_______________________________________________________________________________________ 3

PORT AND INTERRUPT INT TIMING CHARACTERISTICS

(V+ = +1.71V to +5.5V, TA= -40°C to +125°C, unless otherwise noted. Typical values are at V+ = +3.3V, TA= +25°C.) (Note 1)

TIMING CHARACTERISTICS

(V+ = +1.71V to +5.5V, TA= -40°C to +125°C, unless otherwise noted. Typical values are at V+ = +3.3V, TA= +25°C.) (Note 1)

Note 1: All parameters tested at TA= +25°C. Specifications over temperature are guaranteed by design.

Note 2: A master device must provide a hold time of at least 300ns for the SDA signal (referred to V

IL

of the SCL signal) in order to

bridge the undefined region of SCL’s falling edge.

Note 3: Guaranteed by design.

Note 4: C

b

= total capacitance of one bus line in pF. I

SINK

≤ 6mA. tRand tFmeasured between 0.3 x V+ and 0.7 x V+.

Note 5: Input filters on the SDA and SCL inputs suppress noise spikes less than 50ns.

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Port Output Data Valid t

Port Input Setup Time t

Port Input Hold Time t

INT Input Data Valid Time t

INT Reset Delay Time from STOP t

INT Reset Delay Time from

Acknowledge

PPV

PSU

PH

t

CL ≤ 100pF 4 µs

CL ≤ 100pF 0 µs

CL ≤ 100pF 4 µs

CL ≤ 100pF 4 µs

IV

CL ≤ 100pF 4 µs

IP

CL ≤ 100pF 4 µs

IR

PARAMETER SYMBOL CONDITIONS MIN TYP MAX UNITS

Serial-Clock Frequency f

Bus Free Time Between a STOP

and a START Condition

Hold Time (Repeated) START

Condition

Repeated START Condition

Setup Time

t

t

STOP Condition Setup Time t

Data Hold Time t

Data Setup Time t

SCL Clock Low Period t

SCL Clock High Period t

Rise Time of Both SDA and SCL

Signals, Receiving

Fall Time of Both SDA and SCL

Signals, Receiving

Fall Time of SDA, Transmitting t

SCL

t

BUF

HD, STA

SU, STA

SU, STO

HD, DAT

SU, DAT

LOW

HIGH

t

R

t

F

F,TX

1.3 µs

0.6 µs

0.6 µs

0.6 µs

(Note 2) 0.9 µs

100 ns

1.3 µs

0.7 µs

(Notes 3, 4)

(Notes 3, 4)

(Notes 3, 4)

20 +

0.1C

20 +

0.1C

20 +

0.1C

400 kHz

300 ns

b

300 ns

b

250 ns

b

Pulse Width of Spike Suppressed t

Capacitive Load for Each Bus

Line

RST Pulse Width t

RST Rising to START Condition

Setup Time

C

t

RST

SP

W

(Note 5) 50 ns

(Note 3) 400 pF

b

500 ns

1µs

Page 4

MAX7321

I2C Port Expander with 8 Open-Drain I/Os

4 _______________________________________________________________________________________

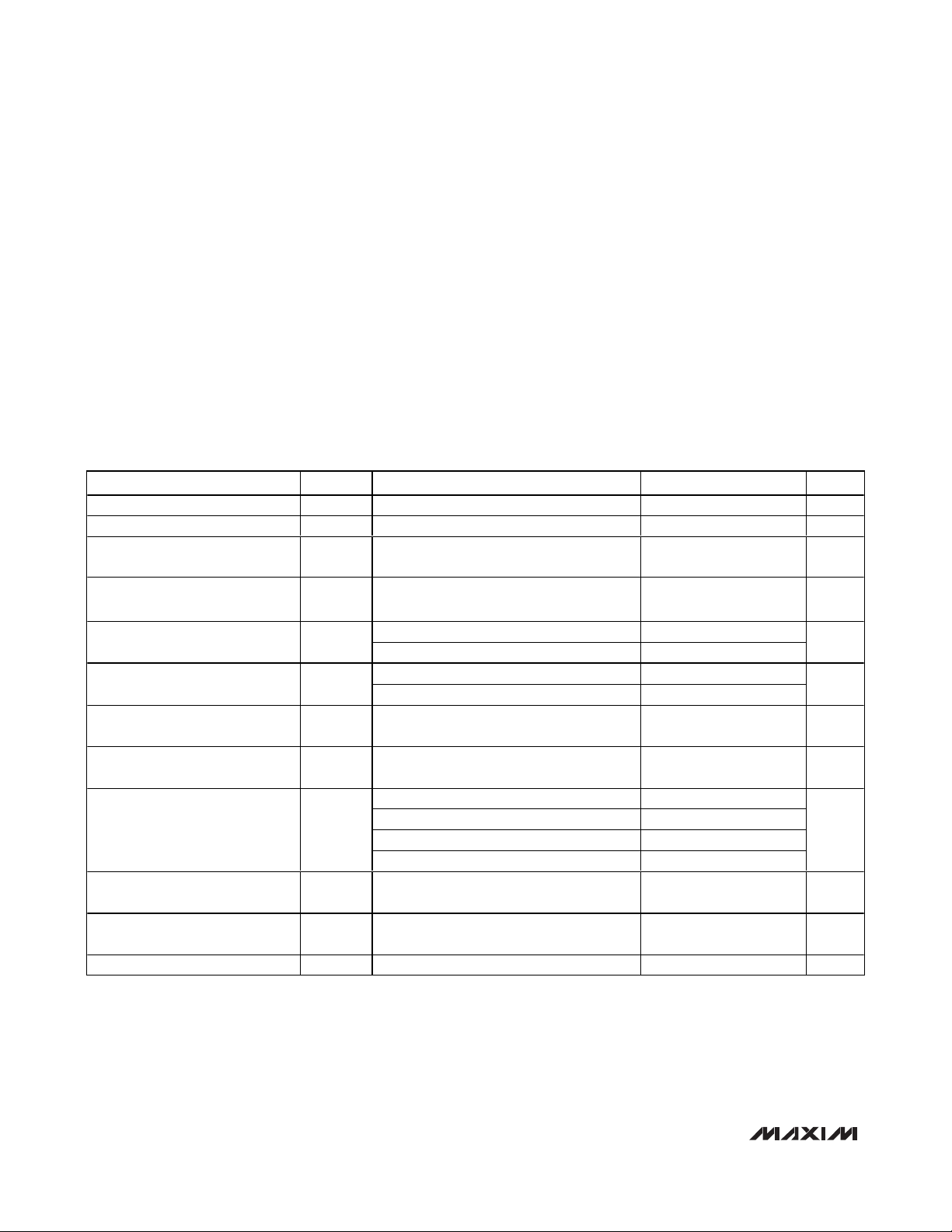

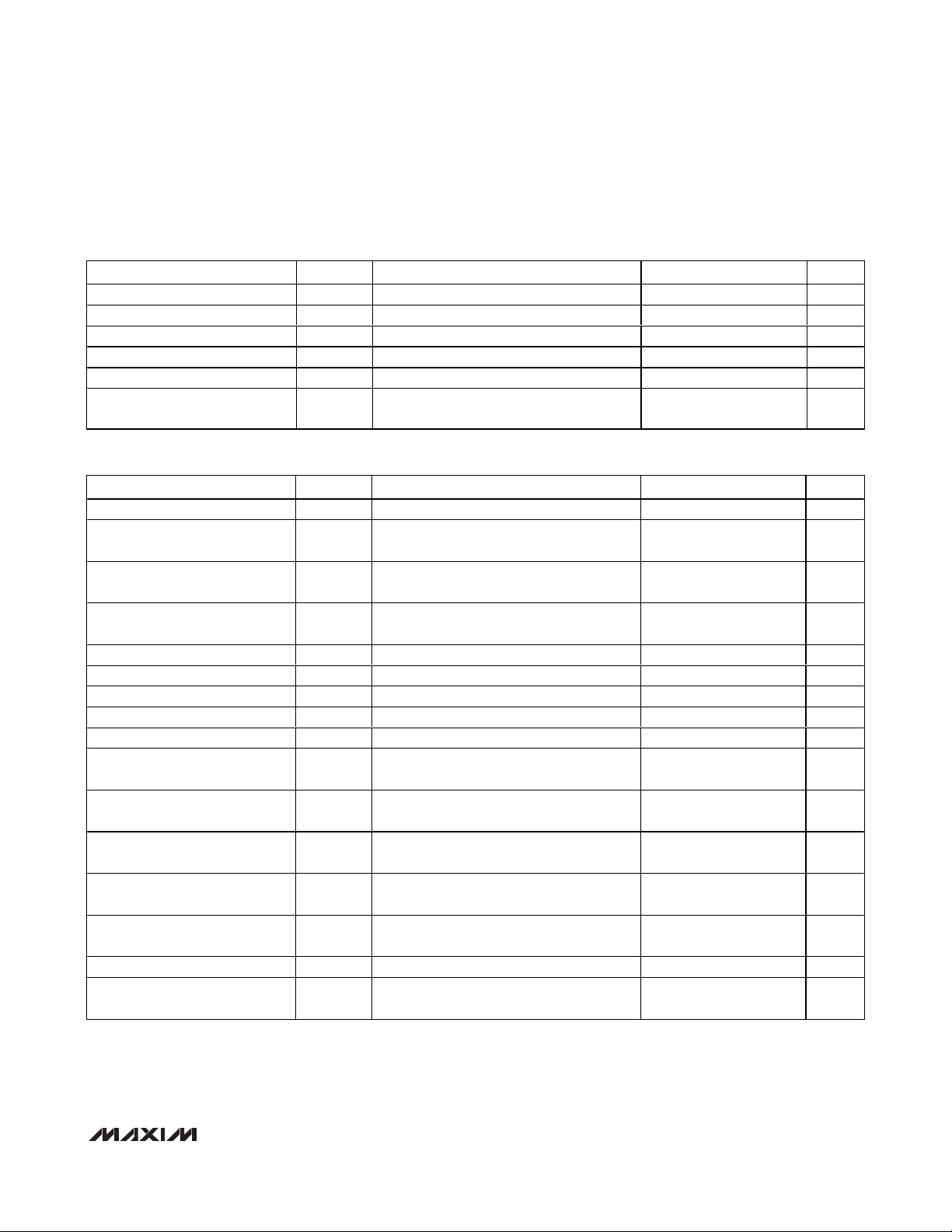

Typical Operating Characteristics

(TA = +25°C, unless otherwise noted.)

0

0.4

0.2

1.0

0.8

0.6

1.2

1.4

1.8

1.6

2.0

-40 -10 5-25 203550658095110125

STANDBY CURRENT vs. TEMPERATURE

MAX7321 toc01

TEMPERATURE (°C)

STANDBY CURRENT (μA)

V+ = +3.3V

V+ = +2.5V

V+ = +5.0V

V+ = +1.71V

f

SCL

= 0kHz

0

20

10

40

30

50

60

-40 -10 5 20-25 3550658095110125

SUPPLY CURRENT vs. TEMPERATURE

MAX7321 toc02

TEMPERATURE (°C)

SUPPLY CURRENT (μA)

V+ = +3.3V

V+ = +5.0V

V+ = +1.71V

V+ = +2.5V

f

SCL

= 400kHz

OUTPUT VOLTAGE LOW

vs. TEMPERATURE

TEMPERATURE (°C)

OUTPUT VOLTAGE LOW (V)

MAX7321 toc03

-40 -25 -10 5 20 35 50 65 80 95 110 125

0

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

V+ = +5.0V

I

SINK

= 20mA

V+ = +2.5V

I

SINK

= 10mA

V+ = +1.71V

I

SINK

= 5mA

V+ = +3.3V

I

SINK

= 15mA

Pin Description

PIN

QSOP TQFN

1, 3 15, 1

216RST Reset Input, Active Low. Drive RST low to clear the 2-wire interface.

4–7, 9–12 2–5, 7–10 P0–P7 Input/Output Ports. P0 to P7 are open-drain I/Os.

8 6 GND Ground

13 11 INT Interrupt Output. INT is an open-drain output.

14 12 SCL I2C-Compatible Serial Clock Input

15 13 SDA I2C-Compatible Serial Data I/O

16 14 V+

— EP EP Exposed Pad. Connect exposed pad to GND.

NAME FUNCTION

AD0,

AD2

Address Inputs. Select device slave address with AD0 and AD2. Connect AD0 and

AD2 to either GND, V+, SCL, or SDA to give four logic combinations (see Table 3).

Positive Supply Voltage. Bypass V+ to GND with a ceramic capacitor of at least

0.047µF as close to the device as possible.

Page 5

Detailed Description

MAX7319–MAX7329 Family Comparison

The MAX7319–MAX7323 family consists of five pincompatible, eight-port expanders. Each version is optimized for different applications. The MAX7328 and

MAX7329 are industry standard parts.

The MAX7324–MAX7327 family consists of four pincompatible, 16-port expanders that integrate the functions of the MAX7320 and one of either the MAX7319,

MAX7321, MAX7322, or MAX7323.

Functional Overview

The MAX7321 is a general-purpose port expander

operating from a +1.71V to +5.5V supply that provides

eight open-drain I/O ports. Each open-drain output is

rated to sink 20mA, and the entire device is rated to

sink 100mA into all ports combined. The outputs drive

loads connected to supplies up to +5.5V, independent

of the MAX7321’s supply voltage.

The MAX7321 is set to one of 16 I

2

C slave addresses

(0x60 to 0x6F) using the address select inputs AD0 and

AD2, and is accessed over an I

2

C serial interface up to

400kHz. The RST input clears the serial interface in

MAX7321

I2C Port Expander with 8 Open-Drain I/Os

_______________________________________________________________________________________ 5

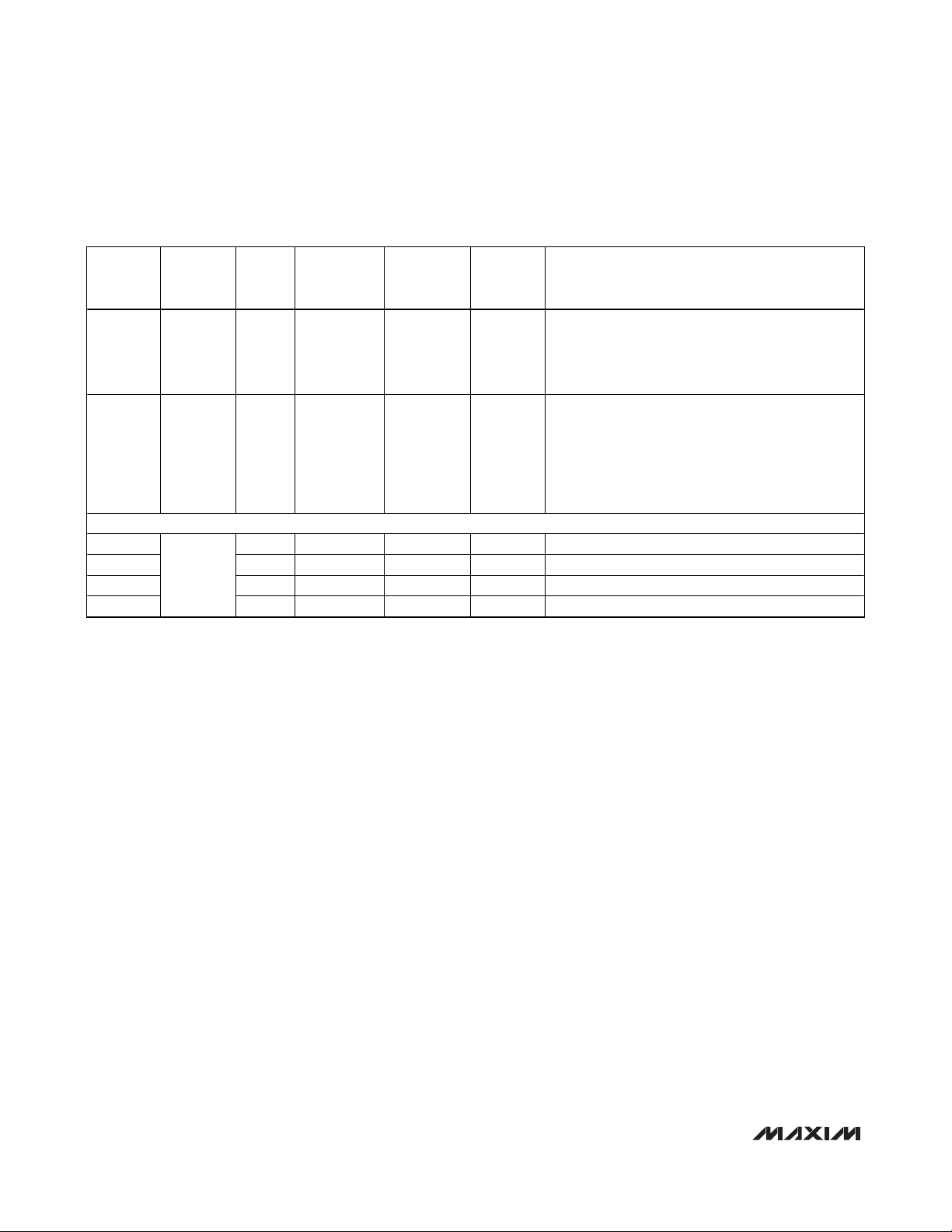

Table 1. MAX7319–MAX7329 Family Comparison

2

C

I

PART

8-PORT EXPANDERS

MAX7319 110xxxx 8 Yes — —

MAX7320 101xxxx — — — 8

SLAVE

ADDRESS

INPUTS

INPUT

INTERRUPT

MASK

OPENDRAIN

OUTPUTS

PUSH-

PULL

OUTPUTS

APPLICATION

Input-only versions:

8 input ports with programmable latching transition

detection interrupt and selectable pullups.

Offers maximum versatility for automatic input

monitoring. An interrupt mask selects which inputs

cause an interrupt on transitions, and transition flags

identify which inputs have changed (even

momentarily) since the ports were last read.

Output-only versions:

8 push-pull outputs with selectable power-up default

levels.

Push-pull outputs offer faster rise time than opendrain outputs, and require no pullup resistors.

I/O versions:

8 open-drain I/O ports with latching transition

detection interrupt and selectable pullups.

MAX7321 110xxxx Up to 8 — Up to 8 —

MAX7322 110xxxx 4 Yes — 4

Open-drain outputs can level shift the logic-high

state to a higher or lower voltage than V+ using

external pullup resistors. Any port can be used as an

input by setting the open-drain output to logic-high.

Transition flags identify which inputs have changed

(even momentarily) since the ports were last read.

4 input-only, 4 output-only versions:

4 input ports with programmable latching transition

detection interrupt and selectable pullups;

4 push-pull outputs with selectable power-up default

levels.

Page 6

MAX7321

case of a bus lockup, terminating any serial transaction

to or from the MAX7321.

Any port can be configured as a logic input by setting

the port output logic-high (logic-high for an open-drain

output is high impedance). When the MAX7321 is read

through the serial interface, the actual logic levels at

the ports are read back.

The open-drain ports offer latching transition detection

when used as inputs. All input ports are continuously

monitored for changes. An input change sets 1 of 8 flag

bits that identify changed input(s). All flags are cleared

upon a subsequent read or write transaction to the

MAX7321.

A latching interrupt output, INT, is programmed to flag

logic changes on ports used as inputs. Data changes

on any input port forces INT to a logic-low. Changing

the I/O port level through the serial interface does not

cause an interrupt. The interrupt output INT is deasserted when the MAX7321 is next accessed through the

serial interface.

Internal pullup resistors to V+ are selected by the

address select inputs, AD0 and AD2. Pullups are

enabled on the input ports in groups of four (see Table 3).

Use the slave address selection to ensure that I/O ports

used as inputs are logic-high on power-up. I/O ports with

internal pullups enabled default to a logic-high output

state. Ports with internal pullups disabled default to a

logic-low output state. Output port power-up logic

states are selected by the address select inputs AD0

and AD2. Ports default to logic-high or logic-low on

power-up in groups of four (see Table 3).

Initial Power-Up

On power-up, the transition detection logic is reset, and

INT is deasserted. The transition flags are cleared to

indicate no data changes. The power-up default states

of the eight I/O ports are set according to the I2C slave

address selection inputs, AD0 and AD2 (Table 3). For

I/O ports used as inputs, ensure that the default

states are logic-high so that the I/O ports power up

in the high-impedance state. All I/O ports configured

with pullups enabled also have a logic-high powerup state.

Power-On Reset

The MAX7321 contains an integral power-on reset

(POR) circuit that ensures all registers are reset to a

known state on power-up. When V+ rises above V

POR

(1.6V max), the POR circuit releases the registers and

2-wire interface for normal operation. When V+ drops to

less than V

POR

, the MAX7321 resets all register con-

tents to the POR defaults (Table 3).

I2C Port Expander with 8 Open-Drain I/Os

6 _______________________________________________________________________________________

Table 1. MAX7319–MAX7329 Family Comparison (continued)

2

C

I

PART

MAX7323 110xxxx Up to 4 — Up to 4 4

SLAVE

ADDRESS

INPUTS

MAX7328

MAX7329

16-PORT EXPANDERS

MAX7324 8 Yes — 8 Software equivalent to a MAX7320 plus a MAX7319.

MAX7325 Up to 8 — Up to 8 8 Software equivalent to a MAX7320 plus a MAX7321.

MAX7326 4 Yes — 12 Software equivalent to a MAX7320 plus a MAX7322.

MAX7327

0100xxx

0111xxx

101xxxx

and

110xxxx

Up to 8 — Up to 8 —

Up to 4 — Up to 4 12 Software equivalent to a MAX7320 plus a MAX7323.

INPUT

INTERRUPT

MASK

OPENDRAIN

OUTPUTS

PUSH-

PULL

OUTPUTS

APPLICATION

4 I/O, 4 output-only versions:

4 open-drain I/O ports with latching transition

detection interrupt and selectable pullups.

4 push-pull outputs with selectable power-up default

levels.

8 open-drain I/O ports with nonlatching transition

detection interrupt and pullups on all ports.

All ports power up as inputs (or logic-high outputs).

Any port can be used as an input by setting the

open-drain output to logic-high.

Page 7

RST

Input

The RST input voids any I2C transaction involving the

MAX7321, forcing the MAX7321 into the I2C STOP condition. A reset does not affect the interrupt output (INT).

Standby Mode

When the serial interface is idle, the MAX7321 automatically enters standby mode, drawing minimal supply

current.

Slave Address, Power-Up Default Logic

Levels, and Input Pullup Selection

Address inputs AD0 and AD2 determine the MAX7321

slave address, set the power-up I/O state for the ports,

and select which inputs have pullup resistors. Internal

pullups and power-up default states are set in groups

of four (Table 3). The MAX7319, MAX7321, MAX7322,

and MAX7323 use a different range of slave addresses

(110xxxx) than the MAX7320 (101xxxx) (Table 2).

The MAX7321 slave address is determined on each I2C

transmission, regardless of whether the transmission is

actually addressing the MAX7321. The MAX7321 distinguishes whether address inputs AD2 and AD0 are connected to SDA or SCL instead of fixed logic levels V+ or

GND during this transmission. This means that the

MAX7321 slave address can be configured dynamically in the application without cycling the device supply.

On initial power-up, the MAX7321 cannot decode

address inputs AD0 and AD2 fully until the first I

2

C

transmission. AD0 and AD2 initially appear to be connected to V+ or GND. This is important because the

address selection is used to determine the power-up

logic state and whether pullups are enabled. However,

at power-up, the I2C SDA and SCL bus interface lines

are high impedance at the pins of every device (master

or slave) connected to the bus, including the MAX7321.

This is guaranteed as part of the I2C specification.

Therefore, address inputs AD2 and AD0 that are connected to SDA or SCL normally appear at power-up to

be connected to V+. The power-up logic uses AD0 to

select the power-up state and whether pullups are

enabled for ports P3–P0, and AD2 for ports P7–P4. The

rule is that a logic-high, SDA, or SCL connection

selects the pullups and sets the default logic state to

high. A logic-low deselects the pullups and sets the

default logic state to low (Table 3). The port configuration is correct on power-up for a standard I2C configuration, where SDA or SCL are pulled up to V+ by the

external I2C pullup resistors.

MAX7321

I2C Port Expander with 8 Open-Drain I/Os

_______________________________________________________________________________________ 7

Table 2. Read and Write Access to Eight-Port Expander Family

2

I

PART

MAX7319 110xxxx 8 Yes — —

MAX7320 101xxxx — — — 8

MAX7321 110xxxx Up to 8 — Up to 8 —

MAX7322 110xxxx 4 Yes — 4

MAX7323 110xxxx Up to 4 — Up to 4 4 <port outputs>

MAX7328 0100xxx Up to 8 — Up to 8 —

MAX7329 0111xxx Up to 8 — Up to 8 —

C SLAVE

ADDRESS

INPUTS

INTERRUPT

MASK

OPENDRAIN

OUTPUTS

PUSH-

PULL

OUTPUTS

2

C DATA WRITE I2C DATA READ

I

<I7–I0 interrupt

mask>

<O7–O0 port

outputs>

<P7–P0 port

outputs>

<O7, O6 outputs,

I5–I2 interrupt

mask, O1, O0

outputs>

<P7–P0 port

outputs>

<P7–P0 port

outputs>

<I7–I0 port inputs>

<I7–I0 transition flags>

<O7-O0 port inputs>

<P7–P0 port inputs>

<P7–P0 transition flags>

<O7, O6, I5–I2, O1, O0 port

inputs>

<0, 0, I5–I2 transition flags,

0, 0>

<O7, O6, P5–P2, O1, O0 port

inputs>

<0, 0, P5–P2 transition flags,

0, 0>

<P7–P0 port inputs>

<P7–P0 port inputs>

Page 8

MAX7321

There are circumstances where the assumption that

SDA = SCL = V+ on power-up is not true—for example,

in applications in which there is legitimate bus activity

during power-up. Also, if SDA and SCL are terminated

with pullup resistors to a different supply voltage than

the MAX7321’s supply voltage, and if that pullup supply

rises later than the MAX7321’s supply, then SDA or

SCL may appear at power-up to be connected to GND.

In such applications, use the four address combinations that are selected by connecting address inputs

AD2 and AD0 to V+ or GND (shown in bold in Table 3).

These selections are guaranteed to be correct at

power-up, independent of SDA and SCL behavior. If

one of the other 12 address combinations is used, an

unexpected combination of pullups might be asserted

until the first I2C transmission (to any device, not necessarily the MAX7321) is put on the bus, and an unexpected combination of ports may initialize as logic-low

outputs instead of inputs or logic-high outputs.

Port Inputs

I/O port inputs switch at the CMOS-logic levels as

determined by the expander’s supply voltage, and are

overvoltage tolerant to +6V, independent of the

expander’s supply voltage.

I/O Port Input Transition Detection

All I/O ports configured as inputs are monitored for

changes since the expander was last accessed

through the serial interface. The state of the input ports

is stored in an internal “snapshot” register for transition

monitoring. The snapshot is continuously compared

with the actual input conditions, and if a change is

detected for any port, INT is asserted to signal a state

change. An internal transition flag is set for that port.

The input is sampled (internally latched into the snapshot register) and the old transition flags cleared during

the I2C acknowledge of every MAX7321 read and write

access. The previous port transition flags are read

through the serial interface as the second byte of a

2-byte read sequence.

I2C Port Expander with 8 Open-Drain I/Os

8 _______________________________________________________________________________________

Table 3. MAX7321 Address Map

PIN CONNECTION DEVICE ADDRESS 40kΩ INPUT PULLUP ENABLES

AD2 AD0 A6 A5 A4 A3 A2 A1 A0 I7 I6 I5 I4 I3 I2 I1 I0

SCL GND 1100000YYYY————

SCL V+ 1100001YYYYYYYY

SCL SCL 1 1 0 0 0 1 0 Y Y Y Y Y Y Y Y

SCL SDA 1 1 0 0 0 1 1 Y Y Y Y Y Y Y Y

SDA GND 1100100YYYY————

SDA V+ 1100101YYYYYYYY

SDA SCL 1 1 0 0 1 1 0 Y Y Y Y Y Y Y Y

SDA SDA 1 1 0 0 1 1 1 Y Y Y Y Y Y Y Y

GND GND 1101000————————

GND V+ 1101001————YYYY

GND SCL 1101010————YYYY

GND SDA 1101011————YYYY

V+ GND 1101100YYYY————

V+ V+ 1101101YYYYYYYY

V+ SCL 1101110YYYYYYYY

V+ SDA 1101111YYYYYYYY

Page 9

Serial Interface

Serial Addressing

The MAX7321 operates as a slave that sends and

receives data through an I2C interface. The interface

uses a serial data line (SDA) and a serial clock line (SCL)

to achieve bidirectional communication between master(s) and slave(s). The master initiates all data transfers

to and from the MAX7321 and generates the SCL clock

that synchronizes the data transfer (Figure 1).

SDA operates as both an input and an open-drain output. A pullup resistor, typically 4.7kΩ, is required on

SDA. SCL operates only as an input. A pullup resistor,

typically 4.7kΩ, is required on SCL if there are multiple

masters on the 2-wire interface, or if the master in a single-master system has an open-drain SCL output.

Each transmission consists of a START condition sent

by a master, followed by the MAX7321’s 7-bit slave

address plus R/W bit, 1 or more data bytes, and finally

a STOP condition (Figure 2).

START and STOP Conditions

Both SCL and SDA remain high when the interface is

not busy. A master signals the beginning of a transmission with a START (S) condition by transitioning SDA

from high to low while SCL is high. When the master

has finished communicating with the slave, the master

issues a STOP (P) condition by transitioning SDA from

low to high while SCL is high. The bus is then free for

another transmission (Figure 2).

Bit Transfer

One data bit is transferred during each clock pulse.

The data on SDA must remain stable while SCL is high

(Figure 3).

Acknowledge

The acknowledge bit is a clocked 9th bit the recipient

uses to acknowledge receipt of each byte of data

(Figure 4). Each byte transferred effectively requires 9

bits. The master generates the 9th clock pulse, and the

recipient pulls down SDA during the acknowledge

clock pulse, such that the SDA line is stable low during

the high period of the clock pulse. When the master is

transmitting to the MAX7321, the MAX7321 generates

the acknowledge bit because the device is the recipient. When the MAX7321 is transmitting to the master,

the master generates the acknowledge bit because the

master is the recipient.

Slave Address

The MAX7321 has a 7-bit-long slave address (Figure

5). The eighth bit following the 7-bit slave address is

the R/W bit. It is low for a write command, and high for

a read command.

The first (A6), second (A5), and third (A4) bits of the

MAX7321 slave address are always 1, 1, and 0.

Connect AD2 and AD0 to GND, V+

,

SDA, or SCL to

select slave address bits A3, A2, A1, and A0. The

MAX7321 has 16 possible slave addresses (Table 3),

allowing up to 16 MAX7321 devices on an I2C bus.

MAX7321

I2C Port Expander with 8 Open-Drain I/Os

_______________________________________________________________________________________ 9

SDA

Figure 1. 2-Wire Serial Interface Timing Details

Figure 2. START and STOP Conditions

t

BUF

t

LOW

t

SU,DAT

t

t

HD,DAT

SU,STA

t

HD,STA

t

SU,STO

SCL

t

HD,STA

START CONDITION

t

HIGH

t

t

R

F

REPEATED START CONDITION

SDA

SCL

SP

START

CONDITION

STOP

CONDITION

CONDITION

START

STOP

CONDITION

Page 10

MAX7321

Accessing the MAX7321

The MAX7321 is accessed through an I

2

C interface. The

transition flags are cleared, and INT is deasserted each

time the device acknowledges the I2C slave address.

A single-byte read from the MAX7321 returns the status of the eight I/O ports.

A 2-byte read returns first the status of the eight I/O

ports (as for a single-byte read), followed by the transition flags.

A multibyte read (more than 2 bytes before the I

2

C

STOP bit) repeatedly returns the port data, alternating

with the transition flags. As the port data is resampled

for each transmission, and the transition flags are reset

each time, a multibyte read continuously returns the

current data and identifies any changing ports.

If a port data change occurs during the read sequence,

INT is reasserted after the I2C STOP bit. The MAX7321

does not generate another interrupt during a singlebyte or multibyte read.

Port data is sampled during the preceding I2C

acknowledge bit (the acknowledge bit for the I

2

C slave

address in the case of a single-byte or 2-byte read).

A single-byte write to the MAX7321 sets the logic state

of all eight I/O ports.

A multibyte write to the MAX7321 repeatedly sets the

logic state of all eight I/O ports.

Reading from the MAX7321

A read from the MAX7321 starts with the master transmitting the MAX7321’s slave address with the R/W bit

set high. The MAX7321 acknowledges the slave

address, and samples the ports during the acknowledge bit. INT deasserts during the slave address

acknowledge.

Typically, the master reads 1 or 2 bytes from the

MAX7321, each byte being acknowledged by the master upon reception with the exception of the last byte.

When the master reads 1 byte from the MAX7321 and

subsequently issues a STOP condition (Figure 6), the

MAX7321 transmits the current port data, clears the

change flags, and resets the transition detection. INT

deasserts during the slave acknowledge. The new

snapshot data is the current port data transmitted to the

master; therefore, port changes ocurring during the

transmission are detected. INT remains high until the

STOP condition.

The master can read 2 bytes from the MAX7321 and

then issue a STOP condition (Figure 7). In this case, the

MAX7321 transmits the current port data, followed by the

change flags. The change flags are then cleared, and

transition detection resets. INT goes high (high impedance if an external pullup resistor is not fitted) during the

slave acknowledge. The new snapshot data is the current port data transmitted to the master; therefore, port

changes occurring during the transmission are detected.

INT remains high until the STOP condition.

I2C Port Expander with 8 Open-Drain I/Os

10 ______________________________________________________________________________________

Figure 3. Bit Transfer

Figure 4. Acknowledge

SDA

SCL

DATA LINE STABLE;

DATA VALID

START

CONDITION

SCL

SDA BY

TRANSMITTER

SDA BY

RECEIVER

S

CHANGE OF DATA

ALLOWED

CLOCK PULSE

FOR ACKNOWLEDGMENT

12 89

Page 11

MAX7321

I2C Port Expander with 8 Open-Drain I/Os

______________________________________________________________________________________ 11

Figure 5. Slave Address

Figure 6. Reading the MAX7321 (1 Data Byte)

Figure 7. Reading the MAX7321 (2 Data Bytes)

.

SDA

SCL

11

MSB

S1 1 0 A

SCL

PORT I/O

t

IV

INT OUTPUT

0

MAX7321 SLAVE ADDRESS

A3

R/W

A2 A1 A0

P6

P7

1

PORT SNAPSHOT

t

PH

t

IR

INT REMAINS HIGH UNTIL STOP CONDITION

PORT I/O

DATA

LSB

P1

P2P3P4P5

PORT SNAPSHOT

R/W

P0

ACK

P

N

D0D1D2D3D4D5D6D7

t

PSU

t

IP

MAX7321 SLAVE ADDRESSS110

R/W

SCL

PORTS

t

IV

INT OUTPUT

1

PORT I/O INTERRUPT FLAGS

I6

I7

A

PORT SNAPSHOT

t

PH

t

IR

INT REMAINS HIGH UNTIL STOP CONDITION

I1

I2I3I4I5

PORT SNAPSHOT

I0

t

PSU

F6

F7

AD0D1D2D3D4D5D6D7

D7 D6 D5 D4 D3 D2 D1 D0 N

S = START CONDITION

P = STOP CONDITION

SHADED = SLAVE TRANSMISSION

N = NOT ACKNOWLEDGE

F1

F2F3F4F5

PORT SNAPSHOT

F0

P

t

IP

Page 12

MAX7321

Writing to the MAX7321

A write to the MAX7321 starts with the master transmitting the MAX7321’s slave address with the R/W bit set

low. The MAX7321 acknowledges the slave address,

and samples the ports (takes a snapshot) during

acknowledge. INT goes high (high impedance if an

external pullup resistor is not fitted) during the slave

acknowledge. Typically, the master proceeds to transmit 1 or more bytes of data. The MAX7321 acknowledges these subsequent bytes of data and updates the

I/O ports with each new byte until the master issues a

STOP condition (Figure 8).

Applications Information

Port Input and I2C Interface Level

Translation from Higher or Lower

Logic Voltages

The MAX7321’s SDA, SCL, AD0, AD2, RST, INT, and I/O

ports P0–P7 are overvoltage protected to +6V independent of V+. This allows the MAX7321 to operate from a

lower supply voltage, such as +3.3V, while the I2C interface and/or any of the eight I/O ports are driven as inputs

driven from a higher logic level, such as +5V.

The MAX7321 can operate from a higher supply voltage, such as +3V, while the I2C interface and/or some

of the I/O ports P0–P7 are driven from a lower logic

level, such as +2.5V. Apply a minimum voltage of 0.7 x

V+ to assert a logic-high on any I/O port. For example,

a MAX7321 operating from a +5V supply may not recognize a +3.3V nominal logic-high. One solution for

input-level translation is to drive MAX7321 I/Os from

open-drain outputs. Use a pullup resistor to V+ or a

higher supply to ensure a high logic voltage greater

than 0.7 x V+.

Port-Output Port-Level Translation

The open-drain output architecture allows for level

translation to higher or lower voltages than the

MAX7321’s supply. Use an external pullup resistor on

any output to convert the high-impedance logic-high

condition to a positive voltage level. The resistor can be

connected to any voltage up to +6V, and the resistor

value chosen to ensure no more than 20mA is sunk in

the logic-low condition. For interfacing CMOS inputs, a

pullup resistor value of 220kΩ is a good starting point.

Use a lower resistance to improve noise immunity, in

applications where power consumption is less critical,

or where a faster rise time is needed for a given capacitive load.

Each of the I/O ports P0–P7 has a protection diode to

GND (Figure 9). When a port is driven to a voltage

lower than GND, the protection diode clamps the voltage to a diode drop below GND.

Each of the I/O ports P0–P7 also has a 40kΩ (typ) pullup

resistor that can be enabled or disabled. When a port is

driven to a voltage higher than V+,the body diode of the

pullup enable switch conducts and the 40kΩ pullup

resistor is enabled. When the MAX7321 is powered

down (V+ = 0), each I/O port appears as a 40kΩ resistor

in series with a diode connected to zero. I/O ports are

protected to +6V under any of these circumstances

(Figure 9).

I2C Port Expander with 8 Open-Drain I/Os

12 ______________________________________________________________________________________

Figure 8. Writing to the MAX7321

SCL

SDA

INTERNAL WRITE

TO PORT

DATA OUT

FROM PORT

12345678

SLAVE ADDRESS

S0

START CONDITION R/W

S = START CONDITION SHADED = SLAVE TRANSMISSION

P = STOP CONDITION N = NOT ACKNOWLEDGE

AAA

DATA TO PORT DATA TO PORT

DATA 1 DATA 2

t

PV

t

PV

t

PV

DATA 2 VALIDDATA 1 VALID

t

PV

Page 13

Driving LED Loads

When driving LEDs, a resistor must be fitted in series

with the LED to limit the LED current to no more than

20mA. Connect the LED cathode to the MAX7321 port,

and the LED anode to V+ through the series currentlimiting resistor, R

LED

. Set the port output low to illuminate the LED. Choose the resistor value according to

the following formula:

R

LED

= (V

SUPPLY

- V

LED

- VOL) / I

LED

where:

R

LED

is the resistance of the resistor in series with the

LED (Ω).

V

SUPPLY

is the supply voltage used to drive the LED (V).

V

LED

is the forward voltage of the LED (V).

VOLis the output-low voltage of the MAX7321 when

sinking I

LED

(V).

I

LED

is the desired operating current of the LED (A).

For example, to operate a 2.2V red LED at 10mA from a

+5V supply:

R

LED

= (5 - 2.2 - 0.07) / 0.010 = 270Ω.

MAX7321

I2C Port Expander with 8 Open-Drain I/Os

______________________________________________________________________________________ 13

Figure 9. MAX7321 I/O Structure

Functional Diagram

AD0

AD2

SCL

SDA

RST

INPUT

FILTER

POWER-

ON RESET

CONTROL

MAX7321

PULLUP

ENABLE

INPUT

OUTPUT

I/O

PORTS

I2C

P7

P6

P5

P4

P3

P2

P1

P0

INT

V+

V+

MAX7321

40kΩ

P0–P7

Page 14

MAX7321

Driving Load Currents Higher than 20mA

The MAX7321 can be used to drive loads, such as

relays, that draw more than 20mA by paralleling outputs. Use at least one output per 20mA of load current;

for example, a 5V, 330mW relay draws 66mA, and

therefore, requires four paralleled outputs. Any combination of outputs can be used as part of a load-sharing

design because any combination of ports can be set or

cleared at the same time by writing the MAX7321. Do

not exceed a total sink current of 100mA for the device.

The MAX7321 must be protected from the negative

voltage transient generated when switching off inductive loads (such as relays), by connecting a reversebiased diode across the inductive load. Choose the

peak current for the diode to be greater than the inductive load’s operating current.

Power-Supply Considerations

The MAX7321 operates with a supply voltage of +1.71V

to +5.5V over the -40°C to +125°C temperature range.

Bypass the supply to GND with a ceramic capacitor of

at least 0.047µF as close to the device as possible. For

the TQFN version, additionally connect the exposed

pad to GND.

I2C Port Expander with 8 Open-Drain I/Os

14 ______________________________________________________________________________________

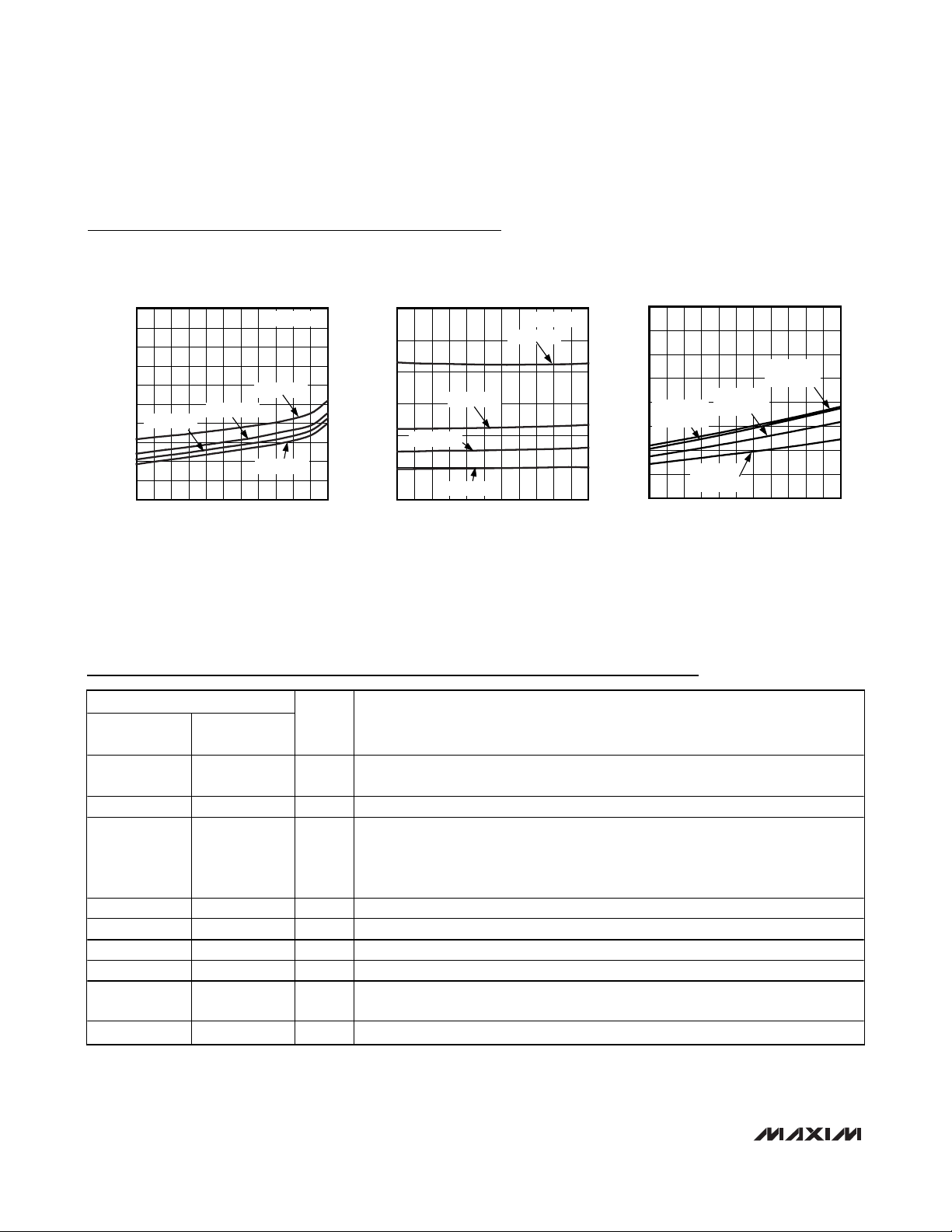

Pin Configurations (continued)

Typical Application Circuit

+

+5V

μC

SCL

SDA

RST

INT INT

SCL

SDA

RST

AD0

AD2

+3.3V

V+

MAX7321

GND

0.047μF

P7

P6

P5

P4

P3

P2

P1

P0

I/O

I/O

I/O

I/O

TOP VIEW

P7

P6

P5

8

P4

7

GND

6

P3

5

4

P1

P2

SDA

AD0

RST

SCL

12 10 9

11

13

14

V+

15

16

MAX7321

*EP

13

2

P0 INT

AD2

TQFN

*EXPOSED PADDLE, CONNECTED TO GND

Page 15

MAX7321

I2C Port Expander with 8 Open-Drain I/Os

______________________________________________________________________________________ 15

Package Information

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

QSOP.EPS

Page 16

MAX7321

I2C Port Expander with 8 Open-Drain I/Os

16 ______________________________________________________________________________________

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

MARKING

E/2

D/2

D

AAAA

0.10 C 0.08 C

L

(NE - 1) X e

E2/2

E2

D2/2

D2

b

0.10 M C A B

C

L

L

e

12x16L QFN THIN.EPS

E

(ND - 1) X e

C

L

C

L

A

A2

A1

L

e

k

C

L

e

PACKAGE OUTLINE

8, 12, 16L THIN QFN, 3x3x0.8mm

21-0136

1

I

2

Page 17

MAX7321

I2C Port Expander with 8 Open-Drain I/Os

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

17 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 2006 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products, Inc.

Package Information (continued)

(The package drawing(s) in this data sheet may not reflect the most current specifications. For the latest package outline information,

go to www.maxim-ic.com/packages

.)

PKG

8L 3x3

REF. MIN.

MIN.

NOM. MAX.

0.70 0.75 0.80

A

b

0.25 0.30 0.35

D

2.90

3.00 3.10

E

2.90 3.00 3.10

e

0.65 BSC.

L

0.35

0.55 0.75

ND

NE

0

A1

A2

0.02

0.20 REF

k

0.25

NOTES:

1. DIMENSIONING & TOLERANCING CONFORM TO ASME Y14.5M-1994.

2. ALL DIMENSIONS ARE IN MILLIMETERS. ANGLES ARE IN DEGREES.

3. N IS THE TOTAL NUMBER OF TERMINALS.

4. THE TERMINAL #1 IDENTIFIER AND TERMINAL NUMBERING CONVENTION SHALL CONFORM TO

JESD 95-1 SPP-012. DETAILS OF TERMINAL #1 IDENTIFIER ARE OPTIONAL, BUT MUST BE LOCATED

WITHIN THE ZONE INDICATED. THE TERMINAL #1 IDENTIFIER MAY BE EITHER A MOLD OR

MARKED FEATURE.

5. DIMENSION b APPLIES TO METALLIZED TERMINAL AND IS MEASURED BETWEEN 0.20 mm AND 0.25 mm

FROM TERMINAL TIP.

6. ND AND NE REFER TO THE NUMBER OF TERMINALS ON EACH D AND E SIDE RESPECTIVELY.

7. DEPOPULATION IS POSSIBLE IN A SYMMETRICAL FASHION.

8. COPLANARITY APPLIES TO THE EXPOSED HEAT SINK SLUG AS WELL AS THE TERMINALS .

9. DRAWING CONFORMS TO JEDEC MO220 REVISION C.

10. MARKING IS FOR PACKAGE ORIENTATION REFERENCE ONLY.

11. NUMBER OF LEADS SHOWN ARE FOR REFERENCE ONLY.

12. WARPAGE NOT TO EXCEED 0.10mm.

0.70

0.20

2.90

2.90

0.45

8

2

2

0.05

-

-

0.25

12L 3x3

NOM. MAX. NOM.

0.75

0.80

0.25

0.30

3.00

3.10

3.10

3.00

0.50 BSC.

0.65

0.55

12N

3

0.0230.05

0

0.20 REF

-

-

16L 3x3

MIN. MAX.

0.70

0.75

0.25

3.00

3.00

0.50 BSC.

0.40

040.02

0.20 REF

0.80

0.30

3.10

3.10

0.50

16

4

0.05

-

0.20

2.90

2.90

0.30

0.25

EXPOSED PAD VARIATIONS

PKG.

CODES

TQ833-1 1.250.25 0.70 0.35 x 45° WEEC1.250.700.25

T1233-1

T1233-3

T1233-4

T1633-2 0.95

T1633F-3

T1633FH-3 0.65 0.80 0.95

T1633-4 0.95

-

T1633-5 0.95

D2

MIN.

NOM.

MAX.

0.95

0.95

0.65

1.25

1.10

1.25

1.10

1.251.10

1.25

1.10

0.95

0.80

1.10 1.25 0.95 1.10

1.25

1.10

NOM.

MIN.

1.10

0.95

0.95 1.10 0.35 x 45°1.25 WEED-10.95

1.100.95

1.10

0.95

0.80

0.65

0.65 0.80

1.10 1.25

0.95

E2

PIN ID

MAX.

0.35 x 45°

1.25

0.35 x 45°

1.25

0.35 x 45°

0.95

0.225 x 45°

0.95

0.225 x 45°

1.25

0.35 x 45°

0.35 x 45° WEED-2

PACKAGE OUTLINE

8, 12, 16L THIN QFN, 3x3x0.8mm

JEDEC

WEED-1

WEED-11.25

WEED-2

WEED-2

WEED-2

WEED-2

21-0136

2

I

2

Loading...

Loading...