Page 1

19-0302; Rev 0; 9/94

Low-Cost, High-Resolution, 200MHz

Video CRT Driver

_______________General Description

The MAX445 is a high-performance, monolithic, variablegain transconductance amplifier with a high-voltage

open-collector output capable of directly driving a video

display (CRT cathode). A 2.5ns rise time is achieved

using a peaking network with a 200Ω load resistor and

an 8pF total load (CRT and parasitic capacitance).

Differential inputs and a linear adjustable gain stage

with an output offset adjustment make the versatile

MAX445 well suited for many video display applications. A buffered bandgap reference voltage is available for the gain (contrast) and offset adjustments

along with a TTL BLANK input to turn off the output current, independent of signal input.

The MAX445 is available in a 24-pin power-tab DIP

package. A suitable heatsink must be attached to

maintain the junction temperature within the recommended operating range.

________________________Applications

CRT Driver for High-Resolution Monochrome and

Color Displays

High-Voltage, Variable-Gain Transconductance

Amplifier

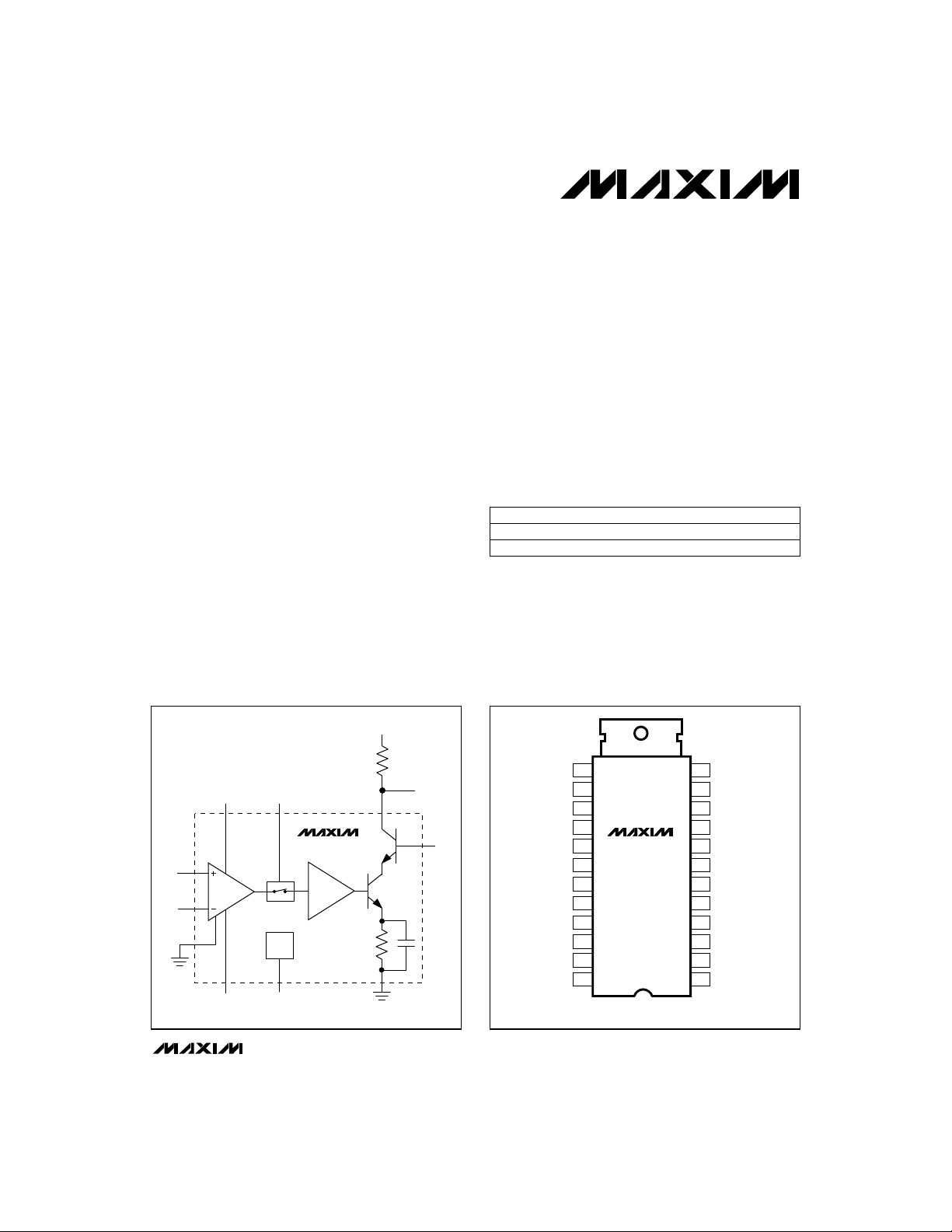

________________Functional Diagram

V

AA

____________________________Features

♦ 2.5ns Rise/Fall Time into an 8pF Load

♦ 200MHz Small-Signal Bandwidth

♦ 50Vp-p Output

♦ Ground Referenced Differential Inputs

♦ Linear Variable Gain for Contrast Control

♦ Offset Adjustment for Black Level

♦ 5.5V Bandgap Reference

♦ Drives 1280 x 1024 and 1530 x 1280 Displays

______________Ordering Information

PART

MAX445CPG

MAX445C/D 0°C to +70°C**

* Case temperature range, T

Maximum Ratings and Applications Information for thermal/heat

sink considerations.

**Dice are specified at TJ= +25°C, DC parameters only.

TEMP. RANGE PIN-PACKAGE

0°C to +70°C*

CASE

24 Power-Tab DIP

Dice

= 0°C to +90°C. See Absolute

__________________Pin Configuration

TOP VIEW

MAX445

R

VIN+

VIN-

GNDA

L

V

CONTRAST

BLANK

IOUT

MAX445

BAND

GAP

VREF

CURRENT

AMP

GND

PRE-AMP

OFFSET

________________________________________________________________

OUT

VCB

GND

VREF

OFFSET

CONTRAST

GNDA

VINVIN+

V

BLANK

GND

1

2

3

4

MAX445

5

6

7

V

EE

8

V

EE

9

CC

10

11

12

Power-Tab DIP

Maxim Integrated Products

Call toll free 1-800-998-8800 for free samples or literature.

GND

24

GND

23

GND

22

V

EEO

21

N.C.

20

IOUT

19

N.C.

18

VCB

17

VCB

16

GND

15

GND

14

GND

13

1

Page 2

Low-Cost, High-Resolution, 200MHz

Video CRT Driver

ABSOLUTE MAXIMUM RATINGS

VAAOutput Supply.................................................................80V

Output Supply with Respect to VCB...............................70V

V

AA

VCB Common-Base Supply...................................................20V

Positive Supply............................................................12.5V

V

CC

Negative Supply..........................................................-12.5V

V

EE

Differential Input Voltage..........................................................2V

Common-Mode Input Voltage................................................±2V

MAX445

Contrast Input Voltage.................................................-1V to +6V

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

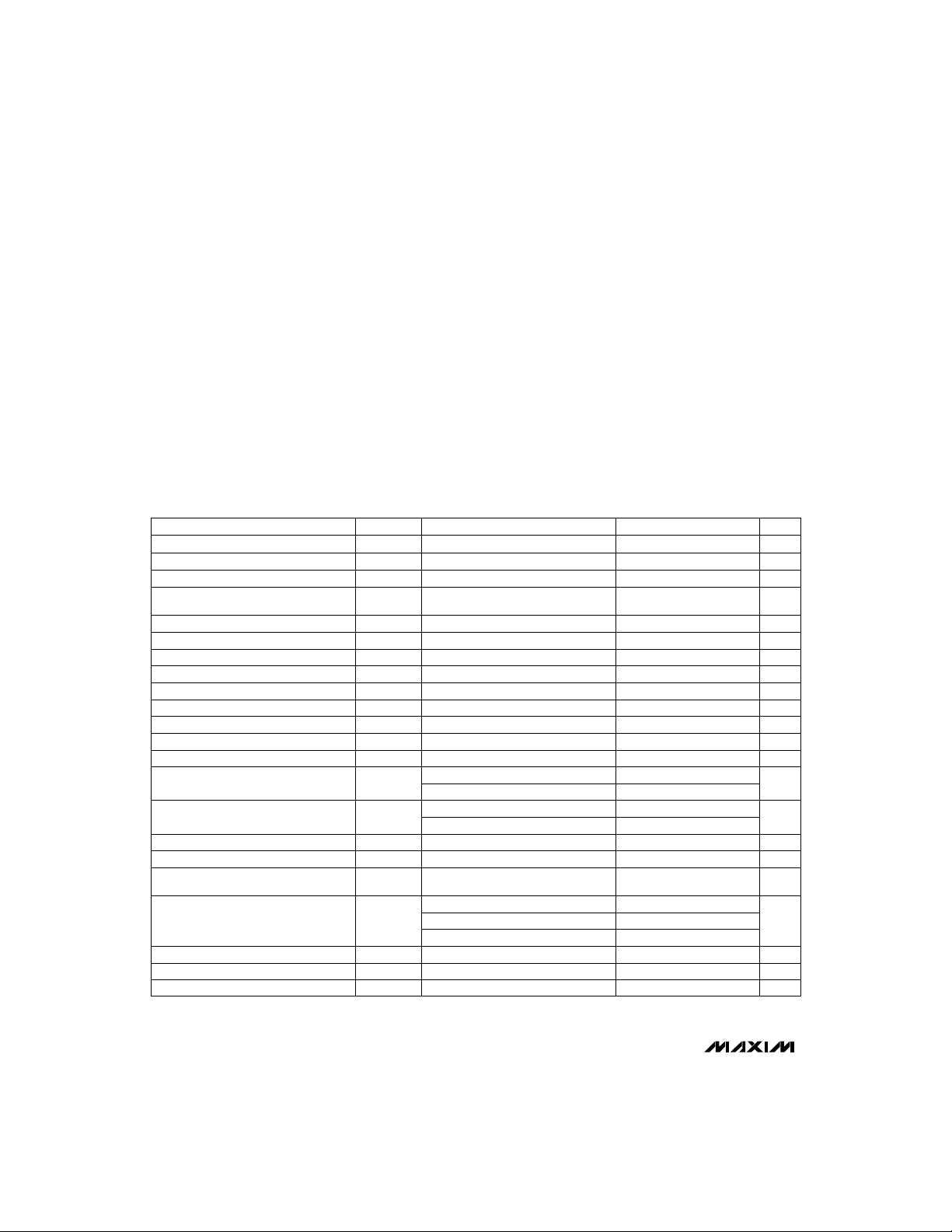

ELECTRICAL CHARACTERISTICS

(VAA= 20V, VCB = 10V ±0.5V, VCC= 10V ±0.5V, VEE= -10.5V ±0.5V, VIN = (VIN+) - (VIN-) = 0V, CONTRAST = 1.0V,

OFFSET = 1.0V, R

Output-Common-Base Supply Current

Positive Supply Current

Negative Supply Current

Low Blank Input Bias Current

High Blank Input Bias Current

Contrast Input Bias Current

Offset Input Bias Current

VIN+ or VIN- Signal Input Current

VIN+ or VIN- DC Input Impedance

VIN+ or VIN- Input Capacitance

Reference Output Voltage

Output Current (Blanked)

Output Current

Output Current Change vs. Temperature

Output Current Change vs. Contrast ADJ

Output Current Change vs. VIN, Blanked

Amplifier Linearity Error (∆Gm/∆VIN)

Contrast Linearity Error (∆Gm/∆Contrast)

= 0Ω, BLANK = 0.4V, T

L

to VIN

OUT

= +25°C, unless otherwise noted.)

CASE

CB

CC

I

VEE

VCC, VEE= ±5%, VIN = +250mV,

CONTRAST = 5.0V, referred to input

BLANK = 0.4V

IL

BLANK = 2.4V

CONTRAST = 5.0V

OFFSET = 1.0V

VCM= ±0.5V, CONTRAST = 5.0V

IN

I

LOAD

BLANK = 2.4V, OFFSET = 1V, VAA= 75V

BLANK = 2.4V, OFFSET = 3V

OFFSET = 0V, CONTRAST = 4.0V

OFFSET = 5.0V, CONTRAST = 1V

TC= +25°C to +90°C

CONTRAST = 0V to 5V

BLANK = 2.4V, CONTRAST = 5.0V,

∆VIN- = 0.3V

CONTRAST = 5.0V

CONTRAST = 1.0V

CONTRAST = 0V

CONTRAST = 4.0V, OFFSET = 1.0V

VIN = 0.2V, OFFSET = 0V

OFFSET = 0V, R

∆I

∆I

∆I

I

OUT

I

OUT

GmTransconductance, I

EE

IH

IC

IB

IS

VIN

REF

OUT

OUT

OUT

Offset Input Voltage.....................................................-1V to +6V

Blank Input Voltage.....................................................-1V to +6V

Bandgap-Reference Output Current...................................-5mA

Continuous Power Dissipation

derate at 170mW/°C above T

Operating Junction Temperature ......................-55°C to +150°C

Storage Temperature.........................................-55°C to +150°C

Lead Temperature (soldering, 10sec).............................+300°C

CONDITIONS

+ I

VEEO

= 2mA

= 100Ω

LOAD

= +90°C.......................10W

CASE

-0.1 25

80 140

400 600

70 120

-25 25

±1

±1

UNITSMIN TYP MAXSYMBOLPARAMETER

mA40I

mA70I

mA-100I

dB25PSRRPower-Supply Rejection Ratio

mA-0.6 0I

mA-0.4 0I

µA010I

µA010I

µA-50 50I

dB36CMRRInput Common-Mode Rejection Ratio

kΩ10R

pF2C

V5.25 5.75V

mA

mA

mA±3

mA±10

mA±1

mA/V

%±2

%±3

MHz200BWBandwidth, 3dB

2 _______________________________________________________________________________________

Page 3

Low-Cost, High-Resolution, 200MHz

Video CRT Driver

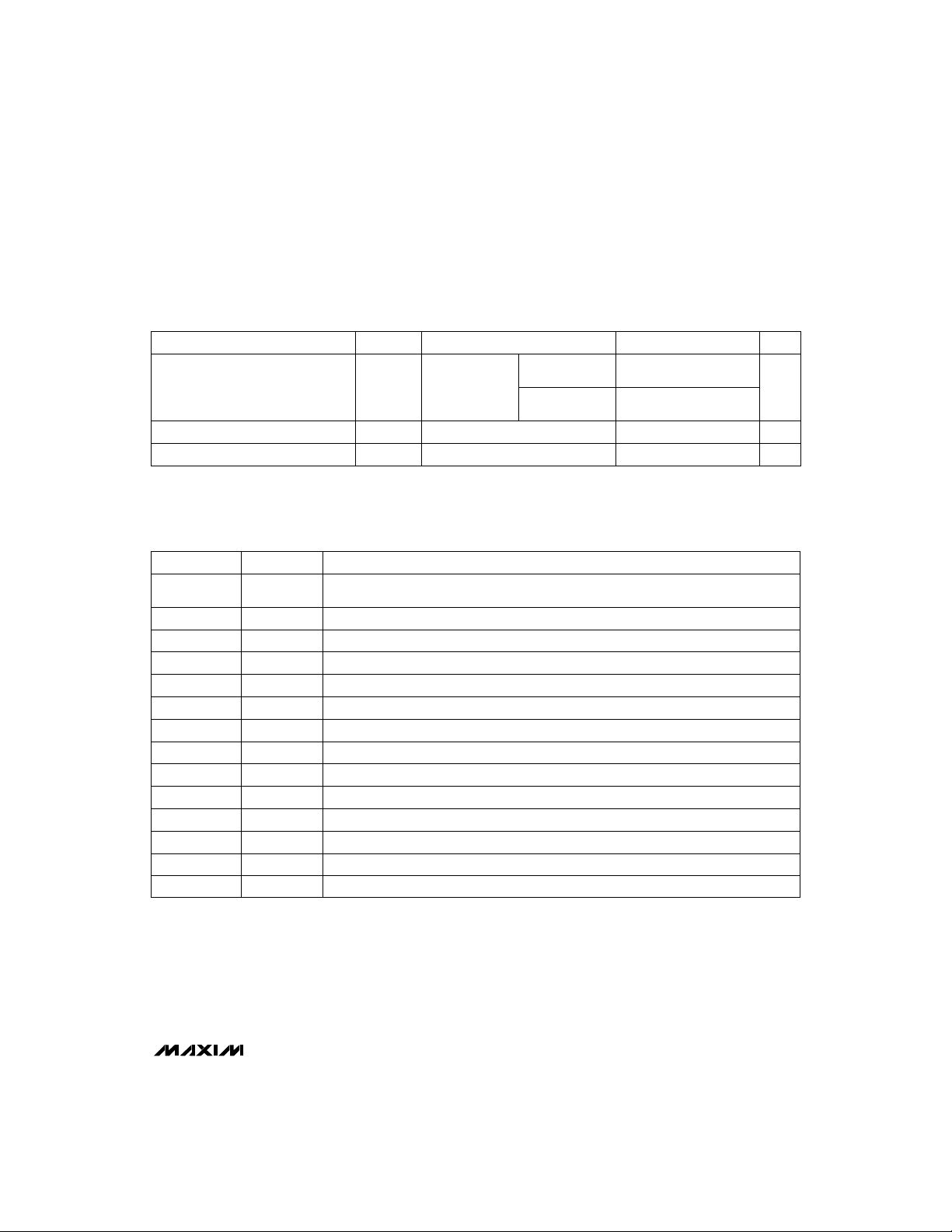

ELECTRICAL CHARACTERISTICS (continued)

(VAA= 20V, VCB = 10V ±0.5V, VCC= 10V ±0.5V, VEE= -10.5V ±0.5V, VIN = (VIN+) - (VIN-) = 0V, CONTRAST = 1.0V,

OFFSET = 1.0V, R

Rise/Fall Time (10% to 90%)

Settling Time (90% to 100% ±2%)

= 0Ω, BLANK = 0.4V, T

L

= +25°C, unless otherwise noted.)

CASE

CONDITIONS

RL= 200Ω,

tr, t

CL= 8pF,

f

VAA= 75V,

tr(VIN) < 1ns,

CL= 8pF, no peaking

s

No peaking,

OUTp-p = 50V

With peaking,

OUTp-p = 45V

UNITSMIN TYP MAXSYMBOLPARAMETER

3.6

ns

2.5

ns8t

%±2Thermal Distortion

______________________________________________________________Pin Description

PIN

1, 12, 13, 14,

15, 22, 23, 24

2 VREF Reference Output (+5.5V)

3 OFFSET Output Voltage Offset-Adjustment Input

4 CONTRAST Output Gain-Adjustment Input

5 GNDA Pre-Amp Ground

6 VIN- Inverting Signal Input

7 VIN+ Noninverting Signal Input

8, 9 V

10 V

11 BLANK Blanking Input, TTL

16, 17 VCB Output Common-Base Supply (+10V)

18, 20 N.C. No Connection—leave open

19 IOUT Open-Collector Current Output

21 V

NAME FUNCTION

GND High-Current Ground. Connect all pins to ground plane.

EE

CC

EEO

Negative Supply (-10.5V)

Positive Supply (+10V)

Negative Supply for Output Stage (-10.5V)

MAX445

_______________________________________________________________________________________ 3

Page 4

Low-Cost, High-Resolution, 200MHz

Video CRT Driver

__________Applications Information

VIN+ and VIN- are differential video input pins designed

to allow DC coupling of a 0V to +1V signal into VIN+, with

respect to VIN-. For correct operation, it is recommended that the signals applied to these inputs be kept within

±1V, with respect to ground. Although large signals and

MAX445

offsets can be handled safely without damage, exceeding these limits may cause output linearity to suffer.

The contrast control is the overall DC-gain control that

will vary the voltage gain from 0V/V to -90V/V (with a

200Ω load resistor). An internal reference supply pin,

VREF, provides the nominal 5.5V needed to drive the

contrast input. Normally, a 5kΩ potentiometer between

VREF and ground is used to vary the contrast, but an

external source can be used instead of VREF, with some

degradation of gain stability with temperature.

The contrast control is a linear relationship. Vary the

input from 0V to 5V to achieve a voltage-gain range of

0V/V to -90V/V. This yields the following relationship for

overall voltage gain of this device (for IOUT < 250mA):

V

(-10.5V)

ANALOG

INPUT

BLANK

* STACK POLE 57-0180 OR

INDIANA GENERAL F-1650-H

Figure 1. Typical Connection Diagram

D1

EE

1N4152

50V

0.1µF

0.1µF

5k

0.1µF

5k

25Ω

50Ω

Differential Inputs

Contrast Control

+10V

D2

1N4152

BEAD*

50V

10 1716

V

CC

2

VREF

3

OFFSET

4

CONTRAST

6

VIN-

7

VIN+

11

BLANK

GNDA GND

5 24*

MAX445

0.1µF

24Ω

VCB

V

V

EE

EE

89

-10.5V

D3

1N486A

100V

BEAD*

VCB

21

VEEO

VAA- VO= [VIN(Gm) + V

VAA- VO= [VIN(V

CONTRAST

OFFSET

) (0.09) + V

The MAX445’s overall gain can vary by ±20% due to

normal process variations of internal components. Also,

if multiple devices are used in a system, all devices

must track thermally (i.e., a common heatsink).

The offset control is used to set the output quiescent

current from 5mA to 110mA (typ) when the control input

is adjusted from 0V to 5V. Normally, offset is adjusted

using a 5kΩ potentiometer between VREF and ground.

When asserted (BLANK = TTL high), this input will disable the video signal and allow the output to rise to the

VAAsupply independent of offset control.

Bandgap Reference

VREF is a bandgap bias reference for easy adjustment

of the offset and contrast inputs. This reference has a

nominal output voltage of 5.5V ±5% that can source up

to 4mA.

V

AA

(+75V)

R

L

200Ω

10W

CB

L2

L1

L1, L2, L3, AND CB ARE

ELEMENTS OF THE PEAKING COIL.

IS THE TOTAL INDUCTANCE

L

S

TO THE CATHODE. R

ARC PROTECTION ELEMENT.

C

R

100Ω

1

W (CARBON)

2

L

S

SECTION.

IOUT

10pF

22µF

100V

D4

19

L3

NOTES:

COMBINES CRT CATHODE, AND PARASITIC C.

C

L

D4 (PHILIPS BAV20 OR HITACHI 1SS91) IS ARC PROTECTION DIODE.

APPLICATIONS INFORMATION

SEE

0.1µF

(0.02)] (RL)

(0.02)] (RL)

OFFSET

Offset Control

Blank Control

IS A SERIES

S

R

S

C

L

4 _______________________________________________________________________________________

Page 5

Low-Cost, High-Resolution, 200MHz

Video CRT Driver

The MAX445’s output is an open collector of a cascode

amplifier. This output is designed to work with nominal

output supplies of VAA= +75V. The high-voltage supply

must be greater than any applied VCB voltage for proper

operation. The MAX445 sinks up to 250mA. Optimum

performance into a capacitive load can be achieved

when an impedance-matching network is used.

VCB

IOUT

The output stage consists of a common-base, high-voltage

stage and a high-speed, low-voltage current amplifier in a

cascode arrangement. The VCB input is the base connection to the common-base device of this stage. Be sure to

provide a stable DC voltage at this pin of nominally +10V.

High-frequency compensation at this input is required to

avoid output oscillations. Use a series 24Ω resistor to sup-

ply, shunted with a 10pF capacitor to ground (Figure 1).

Smaller values of this RC combination will improve output

rise/fall times, but can cause output oscillations.

Power Supplies

+10V and -10.5V supplies are required for proper operation. These supplies can be set to ±12V for convenience, however this will add additional component

power dissipation. The high-voltage supply, VAA, can be

any voltage between VCB + 10V and VCB + 65V.

V

(pin 21) is the negative supply to the output stage

EEO

and must be DC connected to VEE(pins 8 and 9), the

most negative voltage applied to the device. However,

V

must be decoupled from VEEto prevent output

EEO

oscillations. A ferrite bead and separate 0.1µF decoupling capacitors, as shown in Figure 1, will provide

appropriate decoupling.

Power-Supply Sequencing

Power-supply sequencing is important to avoid internal

device latchup. To avoid sequencing problems, external

diodes should be placed from VEEto ground, from

ground to VCC, and from VCCto the output supply (VAA),

as shown in Figure 1. With diodes used as shown, special power-supply sequencing is not required.

CRT Arc Protection

The MAX445 must be protected from electrostatic discharge (“arcs”) from the CRT. It is recommended that the

output be clamped with a low-capacitance (less than

2pF) diode to the VAAsupply. The peak current-handling

capability required of the diode is a function of the CRT

arc characteristics, but typically should be 1A or more,

such as Philips BAV20 or Hitachi 1SS91. For additional

information regarding arc protection, contact Maxim’s

applications department.

For maximum speed from the MAX445, be sure to

Impedance Matching Network

“match” the output to the CRT. Figure 1’s typical connection diagram shows a network (including parasitic reactances) associated with arc protection devices, CRT

wiring and grid structure, and load resistors. These parasitic reactances are all detrimental to good transient

response and should be minimized as much as possible.

CLis the grid-to-cathode capacitance of the CRT, plus

any parasitic capacitance to ground associated with the

cathode structure. This capacitance varies from tubetype to tube-type over the 4pF to 12pF range.

In Figure 1, LSis the inductance of the lead from the

amplifier board to the CRT cathode and the return path

from the grid to circuit ground. A wire in free space has

an inductance of 20nH/inch to 25nH/inch. With care, the

total path through the CRT gun can be kept at 1.5 to 2

inches, such that LSranges from 30nH to 50nH.

Excessive lead length will cause undesirable overshoot

and ringing in the transient response.

The peaking networks assume that 2pF of parasitic

capacitance is associated with the CRT arc protection

diode connected at the junction of L3 and L1.

Lr is the parasitic inductance of the load resistor, RL. In

some cases, CRmay be needed to improve step

response.

RSis a damping resistor in series with the CRT grid.

It also provides current limiting in the event of CRT

arcing.

The equations for determining optimum peaking network values are as follows:

L1 = (RL)2(CL) / 4

L2 = 3(RL)2(CL) / 4

CB= CL/ 5

RS= RL/ 2

L3 = k3(RL)2[2.5 x 10

CR(optional) = Lr / (2R

k3is an empirically determined factor increasing with

CLand varying from 0 for CL~ 2pF to 1 for CL~ 12pF.

However, L3 >100nH will compromise large-signal performance.

Table 1 shows peaking networks for the nominal load,

RL= 200Ω (and RS= 100Ω).

Optimum peaking depends on board layout and CRT

construction. The values given by these equations

should be used as starting points for empirically determining optimum values.

-12

L

]

2

)

MAX445

_______________________________________________________________________________________ 5

Page 6

Low-Cost, High-Resolution, 200MHz

Video CRT Driver

Table 1. Peaking Networks

(RL= 200Ω, RS= 100Ω)

CL(pF) L3 (nH) L1 (nH) L2 (nH) CB(pF) tR(ns)

2 0 20 60 0.4 1.7

4 0 40 120 0.8 1.9

6 20 60 180 1.1 2.1

MAX445

8 50 80 240 1.5 2.3

10 75 100 300 2.0 2.7

12 100 120 360 2.2 3.0

Inductors L1, L2, and L3 should be air or ferrite-core

coils with self-resonant frequencies higher than

500MHz.

The MAX445 can dissipate a large amount of power

depending on speed and load-driving requirements. The

power-tab package provides a low thermal resistance

path from the chip to an external heatsink. Be sure the

board design provides sufficient heatsinking capacity for

the intended operating range. When mounting to a chassis, it should be noted that the device tab is attached to

VEE(-10.5V). This tab should be electrically isolated from

ground through a thermally conductive insulator.

It is highly recommended that the external heatsink be

connected to ground, since an arc or electrostatic discharge entering the heatsink may break down or

bypass the tab insulator and damage the device. Also,

the grounded heatsink to package tab capacitance will

help to bypass the VEEsupply. Another option would

be to bypass the heatsink to ground with a 0.01µF

capacitor with no tab insulator. Inadvertently shorting

the package tab to ground for less than 10 seconds will

Thermal Environment

not cause component damage. Junction-to-case thermal resistance is rated at 6°C/W for the power-tab DIP

package. Table 2 shows the relationship of output voltage and duty cycle to total power.

Table 2. Power Dissipation at VAA= 70V

and Load Resistor = 200Ω

Output Level

Relative to

Black (V)

0 0 1.6 0 1.6

35 100 7.8 6.1 13.9

35 80 6.5 4.9 11.4

50 80 5.6 10.0 15.6

Due to the extremely high-speed performance of the

MAX445, layout design precautions are required to

realize the display driver’s full high-speed capability.

The precautions are as follows:

1) A printed circuit board with a good, unbroken, lowinductance ground plane is required.

2) Place a decoupling capacitor (0.01µF ceramic) as

close to VCCas possible.

3) Pay close attention to the decoupling capacitors’

resonant frequency and keep leads short.

4) On the inputs and outputs, keep lead lengths short

to avoid unwanted parasitic feedback around the

display driver.

5) Solder the MAX445 directly to the printed circuit

board. Do not use sockets.

Duty Cycle

(%)

IC Power

(W)

Load Power

(W)

Circuit Layout and Bypassing

Total

(W)

200

MAX445 FG2

175

150

BANDWIDTH (MHz)

125

100

24681012

LOAD CAPACITANCE (pF)

Figure 2. Typical Rise/Fall Time vs. Loading, with Peaking Network Optimized for Load Capacitance

6 _______________________________________________________________________________________

3.0

2.5

2.0

RISE OR FALL TIME (ns)

1.5

1.0

24681012

LOAD CAPACITANCE (pF)

MAX445 FG2

Page 7

Low-Cost, High-Resolution, 200MHz

70V

V

OUT

(10V/div)

0V

TIME (10ns/div)

Figure 3. Step Response Showing Typical Rise/Fall Times from

MAX445 EV Kit Using a Tektronix 11401 Oscilloscope

Video CRT Driver

MAX445

_______________________________________________________________________________________ 7

Page 8

Low-Cost, High-Resolution, 200MHz

Video CRT Driver

___________________Chip Topography

C

IOUT V

0.118"

(2.997mm)

B1

V

EEO

EEO

GNDA

GNDA

D2

HEAT SPREADER

e1

S

B

GND*

GND*

GND*

GND*

0.133"

(3.378mm)

VREF

OFFSET

CONTRAST

* All high-current ground pads must be bonded and connected

to a low-inductance ground plane.

**Connect both VCB pads.

DIM

D

D1

Ø.140±.005

SEATING PLANE

K1

K2

A1

A2

A

0.170

A1

0.048

A2

0.145

B

0.016

B1

0.145

C

D1

D2

E1

K1

K2

0.009

D

1.590

1.330

0.135

E

0.545

e1

L

0.120

S

0.110

K

0.398

0.195

0.098

α

K

A

L

24-PIN POWER-TAB

PLASTIC DUAL-IN-LINE

PACKAGE WITHOUT HEAT SINK

INCHES MILLIMETERS

MAX

MIN

0.600 BSC

0.100 BSC

0˚

0.200

0.052

0.155

0.020

0.155

0.011

1.610

1.345

0.145

0.555

0.130

0.120

0.402

0.205

0.102

15˚

MIN

4.318

1.219

3.683

0.406

3.683

0.229

40.386

33.782

3.429

15.240 BSC

13.843

2.540 BSC

3.048

2.794

10.109

4.953

2.489

0˚

VCB** VCB**

GND*

GND*

GND*

MAX445

GND*

BLANK

V

CC

VEEVEEVIN+ VIN-

________________________________________________________Package Information

E

E1

α

MAX

5.080

1.321

3.937

0.508

3.937

0.279

40.894

33.163

3.683

14.097

3.302

3.048

10.211

5.207

2.591

15˚

21-7000A

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

8

___________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 (408) 737-7600

8

___________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 (408) 737-7600

© 1994 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

© 1994 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Loading...

Loading...