Page 1

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 1-800-835-8769.

General Description

The MAX3286/MAX3296 series of products are highspeed laser drivers for fiber optic LAN transmitters,

optimized for Gigabit Ethernet applications. Each

device contains a bias generator, laser modulator, and

comprehensive safety features. Automatic power control (APC) adjusts the laser bias current to maintain

average optical power at a constant level, regardless of

changes in temperature or laser properties. For lasers

without a monitor photodiode, these products offer a

constant-current mode. The circuit can be configured

for use with conventional shortwave (780nm to 850nm)

or longwave (1300nm) laser diodes, as well as verticalcavity surface-emitting lasers (VCSELs).

The MAX3286 series (MAX3286/MAX3287/MAX3288/

MAX3289) is optimized for operation at 1.25Gbps, and

the MAX3296 series (MAX3296/MAX3297/MAX3298/

MAX3299) is optimized for 2.5Gbps operation. Each

device can switch 30mA of laser modulation current at

the specified data rate. Adjustable temperature compensation is provided to keep the optical extinction

ratio within specifications over the operating temperature range. This series of devices is optimized to drive

lasers packaged in low-cost TO-46 headers. Deterministic jitter (DJ) for the MAX3286 is typically 22ps,

allowing a 72% margin to Gigabit Ethernet DJ specifications.

These laser drivers provide extensive safety features to

guarantee single-point fault tolerance. Safety features

include dual enable inputs, dual shutdown circuits, and

a laser-power monitor. The safety circuit detects faults

that could cause dangerous light output levels. A programmable power-on reset pulse initializes the laser

driver at start-up.

The MAX3286/MAX3296 are available in a compact,

5mm x 5mm, 32-pin TQFP package or in die form. The

MAX3287/MAX3288/MAX3289 and MAX3297/MAX3298/

MAX3299 are available in smaller 16-pin TSSOP-EP

packages, which are ideal for small form-factor optical

modules.

Applications

Gigabit Ethernet Optical Transmitter

Fibre Channel Optical Transmitter

ATM LAN Optical Transmitter

Features

♦ 7ps Deterministic Jitter (MAX3296)

22ps Deterministic Jitter (MAX3286)

♦ +3.0V to +5.5V Supply Voltage

♦ Selectable Laser Pinning (common cathode or

common anode) (MAX3286/MAX3296)

♦ 30mA Laser Modulation Current

♦ Temperature Compensation of Modulation

Current

♦ Automatic Laser Power Control or Constant Bias

Current

♦ Integrated Safety Circuits

♦ Power-On Reset Signal

♦ 16-Pin TSSOP-EP Package Available

MAX3286–MAX3289/MAX3296–MAX3299

3.0V

to

5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

________________________________________________________________ Maxim Integrated Products 1

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

GND TC

MODSET

V

CC

OUT-

OUT+

V

CC

BIASDRV

SHDNDRV

TOP VIEW

MAX3287

MAX3289

MAX3297

MAX3299

TSSOP-EP*

FLTDLY

V

CC

GND

IN+

IN-

REF

MD

19-1550; Rev 0; 12/99

PART

MAX3286CHJ

MAX3286C/D 0°C to +70°C

0°C to +70°C

TEMP. RANGE PIN-PACKAGE

32 TQFP (5mm x 5mm)

Dice*

Ordering Information continued at end of data sheet.

*Dice are designed to operate from T

J

= 0°C to +110°C, but are

tested and guaranteed only at TA= +25°C.

Pin Configurations

Ordering Information

Typical Application Circuits and Selector Guide appear at

end of data sheet.

*Exposed paddle is connected to GND.

Pin Configurations continued at end of data sheet.

Page 2

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

2 _______________________________________________________________________________________

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VCC= +3.0V to +5.5V, TA= 0°C to +70°C, unless otherwise noted. Typical values are at VCC= +3.3V and TA= +25°C, RTC= open;

see Figure 1a.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Supply Voltage at VCC..........................................-0.5V to +7.0V

Voltage at

EN, EN, PORDLY, FLTDLY, LV, IN+, IN-,

REF, POL, POL, MD, MON, BIASDRV,

MODSET, TC..........................................................-0.5V to (V

CC

+ 0.5V)

Voltage at OUT+, OUT-.........................(V

CC

- 2V) to (VCC+ 2V)

Current into FAULT, FAULT, POR, SHDNDRV....-1mA to +25mA

Current into OUT+, OUT- ....................................................60mA

Continuous Power Dissipation (T

A

= +70°C)

32-Pin TQFP (derate 14.3mW/°C) ...............................1100mW

16-Pin TSSOP (derate 27mW/°C)................................2162mW

Operating Temperature Range...............................0°C to +70°C

Operating Junction Temperature Range ..............0°C to +150°C

Processing Temperature (die) .........................................+400°C

Storage Temperature Range .............................-55°C to +150°C

Lead Temperature (soldering, 10s) .................................+300°C

0 ≤ V

PIN

≤ V

CC

Total differential signal, peak-peak, Figure 1a

LV = open

Figure 1a, R

MOD

= 1.82kΩ

LV = GND

V

MON

= V

CC

I

REF

≤ 2mA, MON = V

CC

FAULT = low, V

BIASDRV

≥ 0.6V

Normal operation (FAULT = low)

EN = GND

IOH= -100µA

Common-cathode configuration

IOL= 1mA

APC loop is closed

CONDITIONS

V

MD

+ 5% V

MD

+ 20%MD High Fault Threshold

V2.95REF Fault Threshold

mV150POR Hysteresis

2.65 3.0

V

3.9 4.5

POR Threshold

µA0.44 6MON Input Current

µA-2 0.16 2MD Input Current

V

0.4 1.2

V1.55 1.7 1.85V

MD

MD Nominal Voltage

µA-100 100TTL Input Current

mV200 1660V

ID

mA52 75I

CC

Supply Current

Data Input Voltage Swing

V2.45 2.65 2.85REF Voltage

mA

0.8BIASDRV Current Sink

µA-1 1BIASDRV Current, Shutdown

V2.0V

IH

TTL Input High Voltage

V0.8V

IL

TTL Input Low Voltage

V2.4V

OH

FAULT, FAULT Output High

Voltage

V0.4V

OL

FAULT, FAULT Output Low

Voltage

UNITSMIN TYP MAXSYMBOLPARAMETER

Common-anode configuration 2VCC- 0.8

MD Voltage During Fault

V

MD

- 20% V

MD

- 5%MD Low Fault Threshold

MAX3286/MAX3288/MAX3296/MAX3298

mV

VCC- V

CC -

600 480

MON Fault Threshold

V

0.8MODSET, TC Fault Threshold

FAULT = low, V

BIASDRV

≤ VCC- 1V 0.8BIASDRV Current Source

BIAS GENERATOR (Note 1)

POWER-ON RESET

FAULT DETECTION

Page 3

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

________________________________________________________________________________________ 3

ELECTRICAL CHARACTERISTICS (continued)

(VCC= +3.0V to +5.5V, TA= 0°C to +70°C, unless otherwise noted. Typical values are at VCC= +3.3V and TA= +25°C, RTC= open;

see Figure 1a.)

I

SHDNDRV

= 15mA, FAULT not asserted

I

SHDNDRV

= 10µA, FAULT asserted

MAX3296 series

MAX3286 series

I

SHDNDRV

= 1mA, FAULT not asserted

MAX3286 series

MAX3296 series

Tempco = max, R

MOD

= open; Figure 5

CONDITIONS

Ω620 800 980Differential Input Resistance

ppm/°C

4000

Modulation-Current

Temperature Coefficient

0V

CC

- 1.2

V

VCC- 0.4

Voltage at SHDNDRV

µA15 200Shutdown Modulation Current

24

ps

28

Random Jitter, RMS (Note 3)

0V

CC

- 2.4

Gbps

1.25

Data Rate

2.5

UNITS

MIN TYP MAXSYMBOL

PARAMETER

mA

2

Minimum Laser Modulation

Current

MAX3286 series

20% to 80% ps

130 220

Modulation-Current Edge

Speed

MAX3296 series 90 150

R

MOD

= 13kΩ

(i

MOD

= 5mA)

MAX3286 series

ps

46 65

Deterministic Jitter (Note 2)

R

MOD

= 4.1kΩ

(i

MOD

= 15mA)

29 45

R

MOD

= 1.9kΩ

(i

MOD

= 30mA)

22 35

R

MOD

= 13kΩ

(i

MOD

= 5mA)

MAX3296 series

14 35

R

MOD

= 4.1kΩ

(i

MOD

= 15mA)

822

R

MOD

= 1.9kΩ

(i

MOD

= 30mA)

720

C

PORDLY

= 0.01µF,

MAX3286/MAX3296 only

ms3 5.5

(Note 4)

µsGlitch Rejection at MD 10 20

µs22t

FAULT

Fault Time

SHUTDOWN

LASER MODULATOR

50Tempco = min, RTC= open; Figure 5

R

MOD

= 13kΩ (i

MOD

= 5mA) -15 15

Single ended Ω42 50 58Output Resistance

LASER SAFETY CIRCUIT

PORDLY = open 0.3 1.25 µs

t

PORDLY

POR Delay

V

V

CC

- 0.3

Input Bias Voltage

RL≤ 25Ω mA30

Maximum Laser Modulation

Current

R

MOD

= 1.9kΩ (i

MOD

= 30mA)

%

-10 10

Tolerance of Modulation Current

Page 4

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

4 _______________________________________________________________________________________

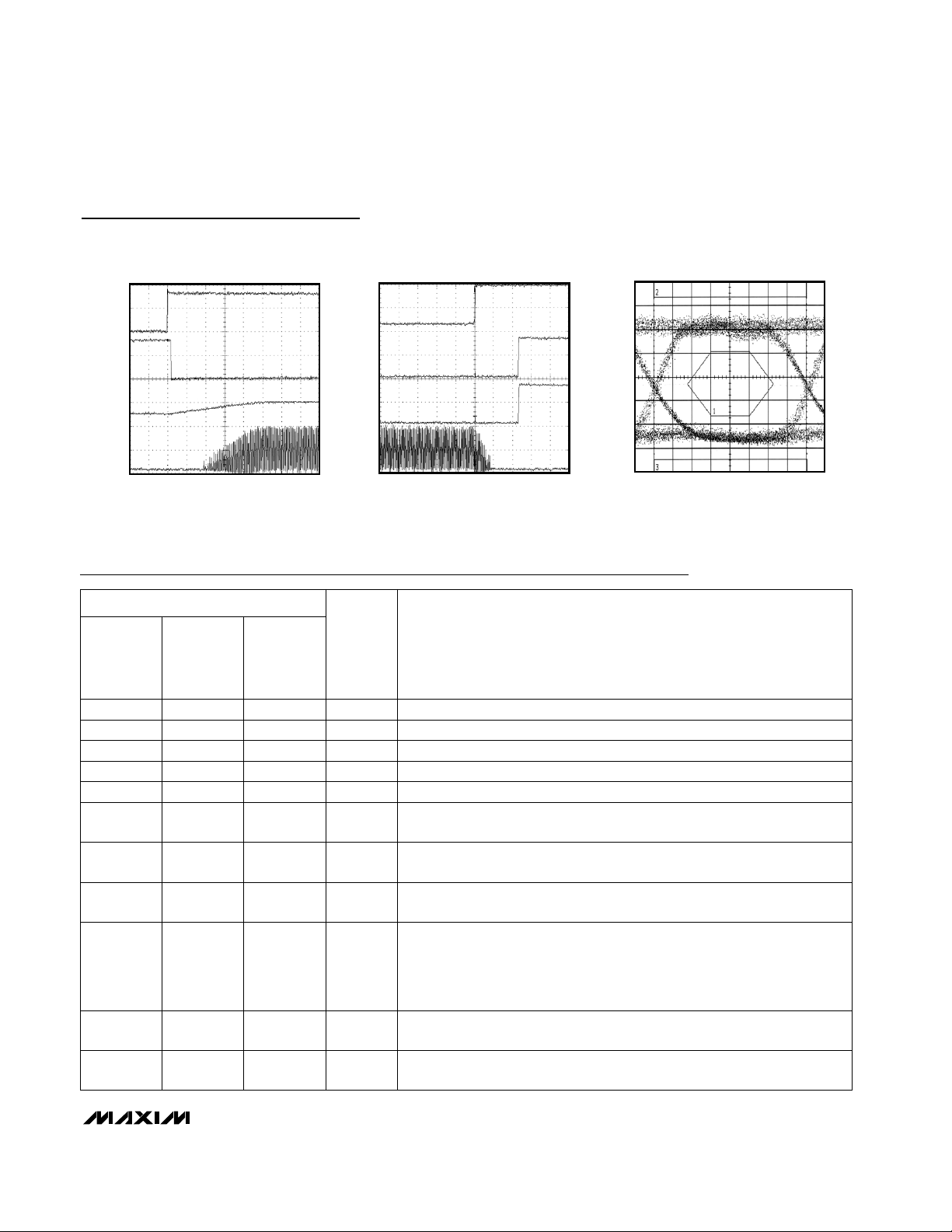

Typical Operating Characteristics

(TA = +25°C, unless otherwise noted.)

POR DELAY vs. C

PORDLY

MA3286 toc01

CAPACITANCE (pF)

DELAY (µs)

10k

100k

1

10

100

1k

100 1k 10k10 100k

FLTDLY DURATION vs. C

FLTDLY

MA3286 toc02

CAPACITANCE (pF)

DELAY (µs)

10k

1

10

100

1k

100 1k 10k101

Note 1: “Common-anode configuration” refers to a configuration where POL = GND, POL = VCC, and an NPN device is used to set

the laser bias current. “Common-cathode configuration” refers to a configuration where POL = V

CC

, POL = GND, and a PNP

device is used to set the laser bias current.

Note 2: Deterministic jitter measured with a repeating K28.5 bit pattern 00111110101100000101. Deterministic jitter is the peak-to-

peak deviation from the ideal time crossings per ANSI X3.230, Annex A.

Note 3: For Fibre Channel and Gigabit Ethernet applications, the peak-to-peak random jitter is 14.1 times the RMS jitter.

Note 4: Delay from a fault on MD until FAULT is asserted high.

ELECTRICAL CHARACTERISTICS (continued)

(VCC= +3.0V to +5.5V, TA= 0°C to +70°C, unless otherwise noted. Typical values are at VCC= +3.3V and TA= +25°C, RTC= open;

see Figure 1a.)

MAX3286/MAX3296 only,

Figure 1b

C

FLTDLY

= 270pF

C

FLTDLY

= 0

MAX3286/MAX3296 only,

Figure 1b

MAX3286/MAX3296 only,

Figure 1b

CONDITIONS

ns610t

EN_RESET

EN or EN Minimum Pulse Width

Required to Reset a Latched

Fault

100 140

µs

0.2 1

t

FLTDLY

FLTDLY Duration

µs3.5 5.5t

SHUTDN

SHDNDRV Asserted After EN =

low or EN = high

µs12t

RESET

FAULT Reset After EN, EN, or

POR Transition

UNITSMIN TYP MAXSYMBOLPARAMETER

2.5Gbps, 1310nm Laser, 27 - 1 PRBS, i

EYE DIAGRAM

50ps/div

MOD

MAX3286 toc03

= 15mA

Page 5

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

_______________________________________________________________________________________ 5

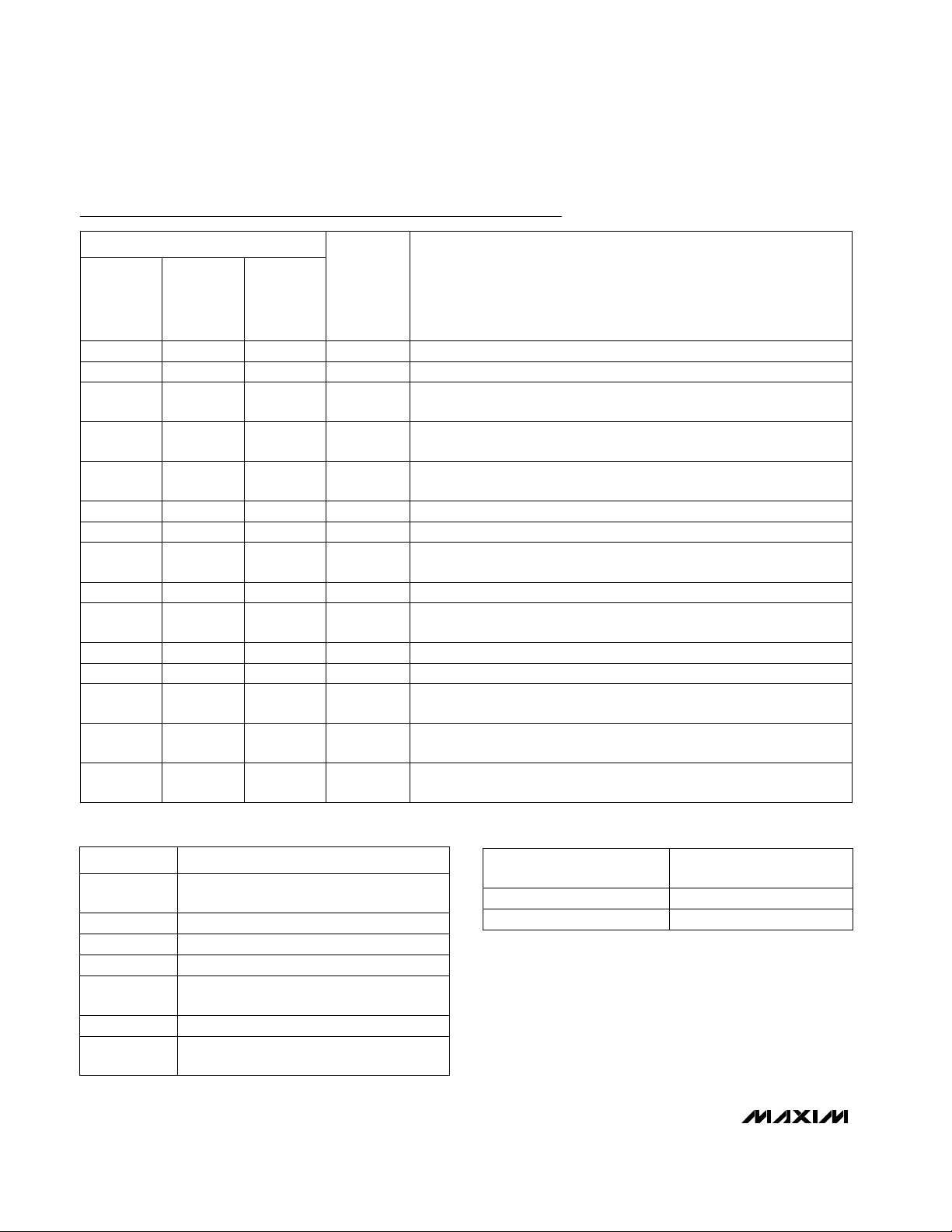

Pin Description

NAME FUNCTION

MAX3286

MAX3296

1

FAULT

Inverting Fault Indicator. See Table 1.

PIN

2, 16 N.C. No Connect

3 FAULT Noninverting Fault Indicator. See Table 1.

4 POR Power-On Reset. POR is a TTL-compatible output. See Figure 14.

5, 14, 22, 30 GND Ground

6 EN

Enable TTL Input. Laser output is enabled only when EN is high and EN is

low. If EN is left unconnected, the laser is disabled.

7

EN

Inverting Enable TTL Input. Laser output is enabled only when EN is low or

grounded and EN is high. If EN is left unconnected, the laser is disabled.

8 PORDLY

Power-On Reset Delay. To extend the delay for the power-on reset circuit,

connect a capacitor to PORDLY. See Design Procedure.

9 FLTDLY

Fault Delay Input. Determines the delay of the FAULT and FAULT outputs.

A capacitor attached to FLTDLY ensures proper start-up. (See Typical

Operating Characteristics.) FLTDLY = GND: holds FAULT low and FAULT

high. When FLTDLY = GND, EN = high, EN = low, and V

CC

is within the

operational range, the safety circuitry is inactive.

10 LV

Low-Voltage Operation. Connect to GND for 4.5V to 5.5V operation. Leave

open for 3.0V to 5.5V operation.

MAX3287

MAX3297

MAX3289

MAX3299

—

—

—

—

1, 6

—

—

—

2

—

MAX3288

MAX3298

—

—

—

—

1, 6

—

—

—

2

—

Typical Operating Characteristics (continued)

(TA = +25°C, unless otherwise noted.)

EN STARTUP

(COMMON-ANODE CONFIGURATION)

MA3286 toc04

EN

OPTICAL

OUTPUT

BIASDRV

FAULT

5µs/div

MD SHUTDOWN

MA3286 toc05

MD

OPTICAL

OUTPUT

SHDNDRV

FAULT

10µs/div

EYE DIAGRAM

MA3286 toc06

50ps/div

2.5Gbps, 1310nm LASER, 2

7

- 1 PRBS, i

mod

= 15mA

11, 25,

26, 29

V

CC

Supply Voltage3, 11, 14 3, 11, 14

Page 6

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

6 _______________________________________________________________________________________

Pin Description (continued)

MD

FAULT CONDITION

V

CC

VMD> 1.15 · V

MD(nom)

,

V

MD

< 0.85 · V

MD(nom)

LV = open and VCC< 3V;

LV = GND and VCC< 4.5V

REF

EN and EN

V

REF

> 2.95V

PIN

POL and POL

EN = low or open, EN = high or open

POL = POL

MON V

MON

< VCC- 540mV

Table 1. Typical Fault Conditions

>4.5Grounded

>3.0Open

OPERATING VOLTAGE

RANGE (V)

LV

Table 2. LV Operating Range

MAX3288

MAX3298

MAX3287

MAX3297

MAX3289

MAX3299

PIN

MAX3286

MAX3296

FUNCTIONNAME

EPEP

Ground. This must be soldered to the circuit board ground for proper

thermal performance. See Layout Considerations.

Exposed

Paddle

—

16

15

5

4

16

15

5

4

Temperature-Compensation Set. The resistor at TC programs the temperature-increasing component of the laser modulation current.

TC32

Modulation-Current Set. The resistor at MODSET programs the temperature-stable component of the laser modulation current.

MODSET31

Inverting Data InputIN-13

Noninverting Data InputIN+12

MODSET

and TC

V

MODSET

and VTC≤ 0.8V

13

12

13

12

Modulation-Current Output. See Typical Application Circuits.OUT-28

Modulation-Current Output. See Typical Application Circuits.OUT+27

—

7

—

7

Polarity Input. POL is used for programming the laser-pinning polarity.

(Table 4)

POL17

Reference Voltage. A resistor connected at REF to MD determines the

laser power when APC is used with common-cathode lasers.

REF15

9

8

—

8

Laser Bias Current Monitor. Used for programming laser bias current in

VCSEL applications.

MON21

Monitor Diode Connection. MD is used for automatic power control.MD20

—

—

—

—

Internally Connected. Do not connect.I.C.19

Inverting Polarity Input. POL is used for programming the laser-pinning

polarity (Table 4)

POL

18

10

—

10

9

Bias-Controlling Transistor Driver. Connects to the base of an external

PNP or NPN transistor.

BIASDRV24

Shutdown Driver Output. Provides a redundant laser shutdown.SHDN-DRV23

Page 7

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

_______________________________________________________________________________________ 7

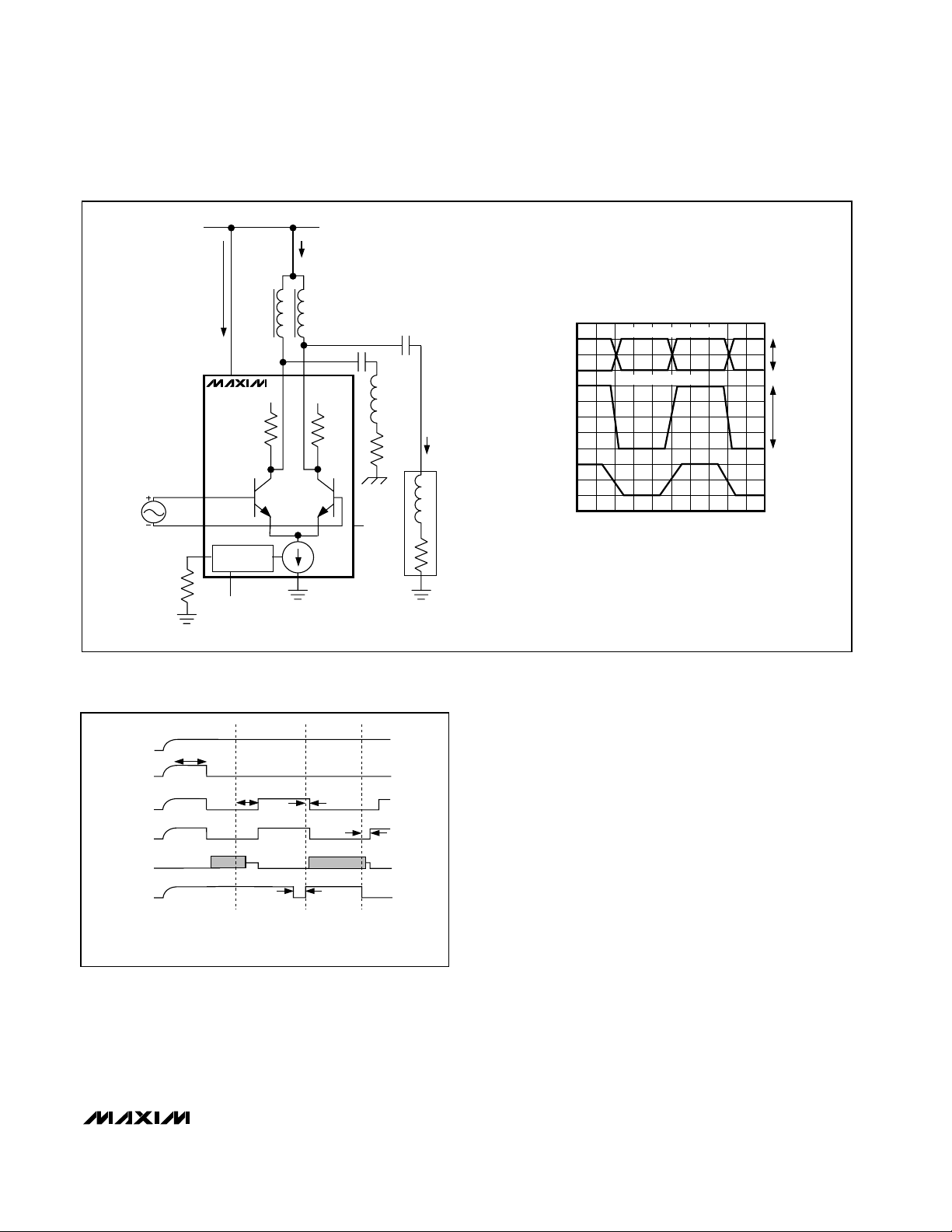

MODULATION

CONTROL

MODSET

TC

L = 3.9nH

L = 3.9nH

R

L

.= 25Ω

BIASDRV

LASER

EQUIVALENT

LOAD

(OPEN)

OUT- OUT+

FERRITE BEAD*

*MURATA

BLM11HA102

0.01µF

0.01µF

IN+

IN-

50Ω 50Ω

25Ω

R

L

R

MOD

V

CC

V

CC

V

CC

I

OUT

I

CC

V

CC

i

MOD

3/2

i

MOD

V

ID

VID = V

IN+ - VIN-

CURRENT

i

MOD

V

IN-

V

IN+

VOLTS

TIME

100mVp-p MIN

830mVp-p MAX

200mVp-p MIN

1660mVp-p MAX

DIFFERENTIAL INPUT

RESULTING SIGNAL

MAX3286

MAX3296

Figure 1a. Output Load for AC Specification

V

CC

POR

FAULT

FAULT ON MD RESET BY EN SHUTDOWN

BY EN

SHDNDRV

OPTICAL

OUT

EN

NOTE: TIMING IS

NOT TO SCALE.

t

PORDLY

t

FAULT

t

RESET

t

SHUTDN

t

EN_RESET

Figure 1b. Fault Timing

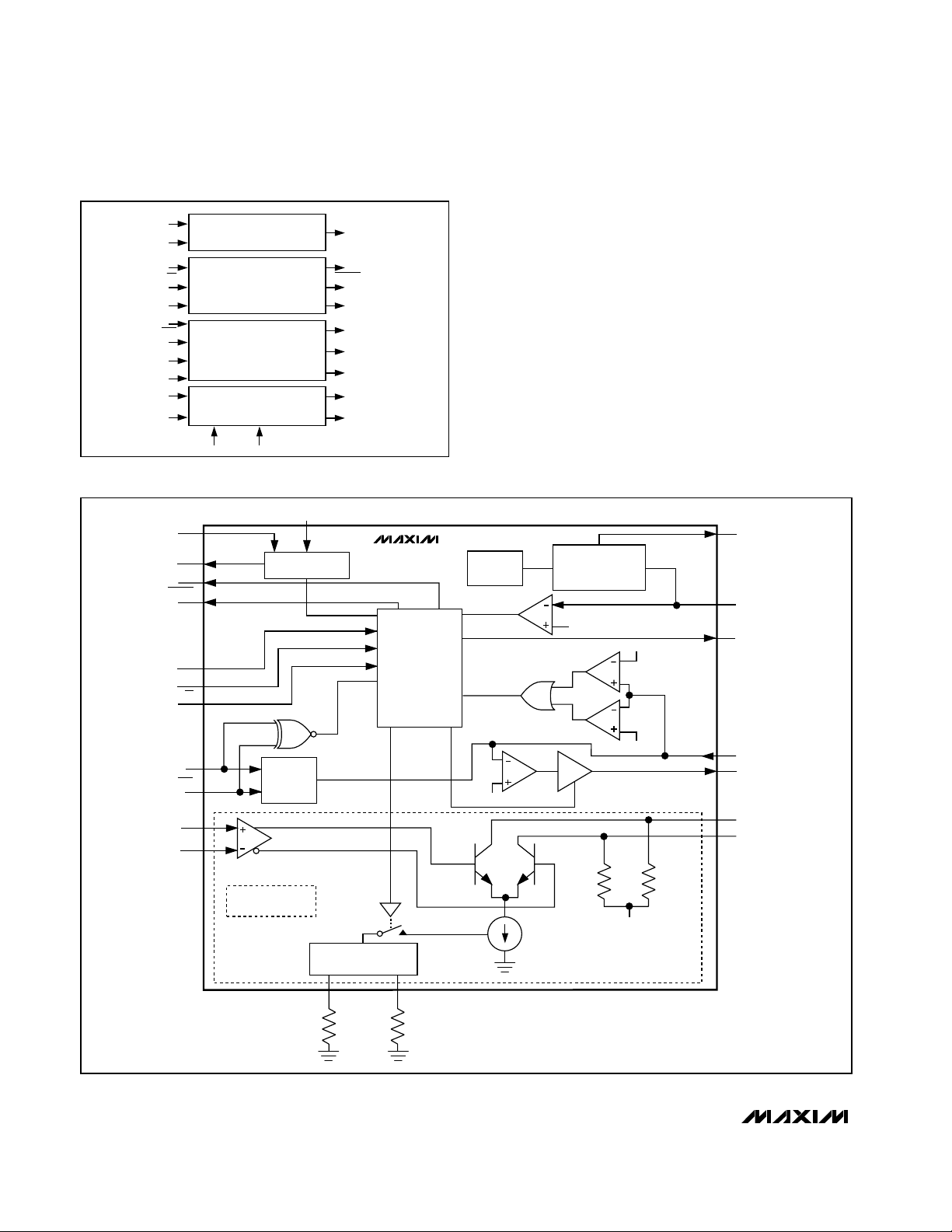

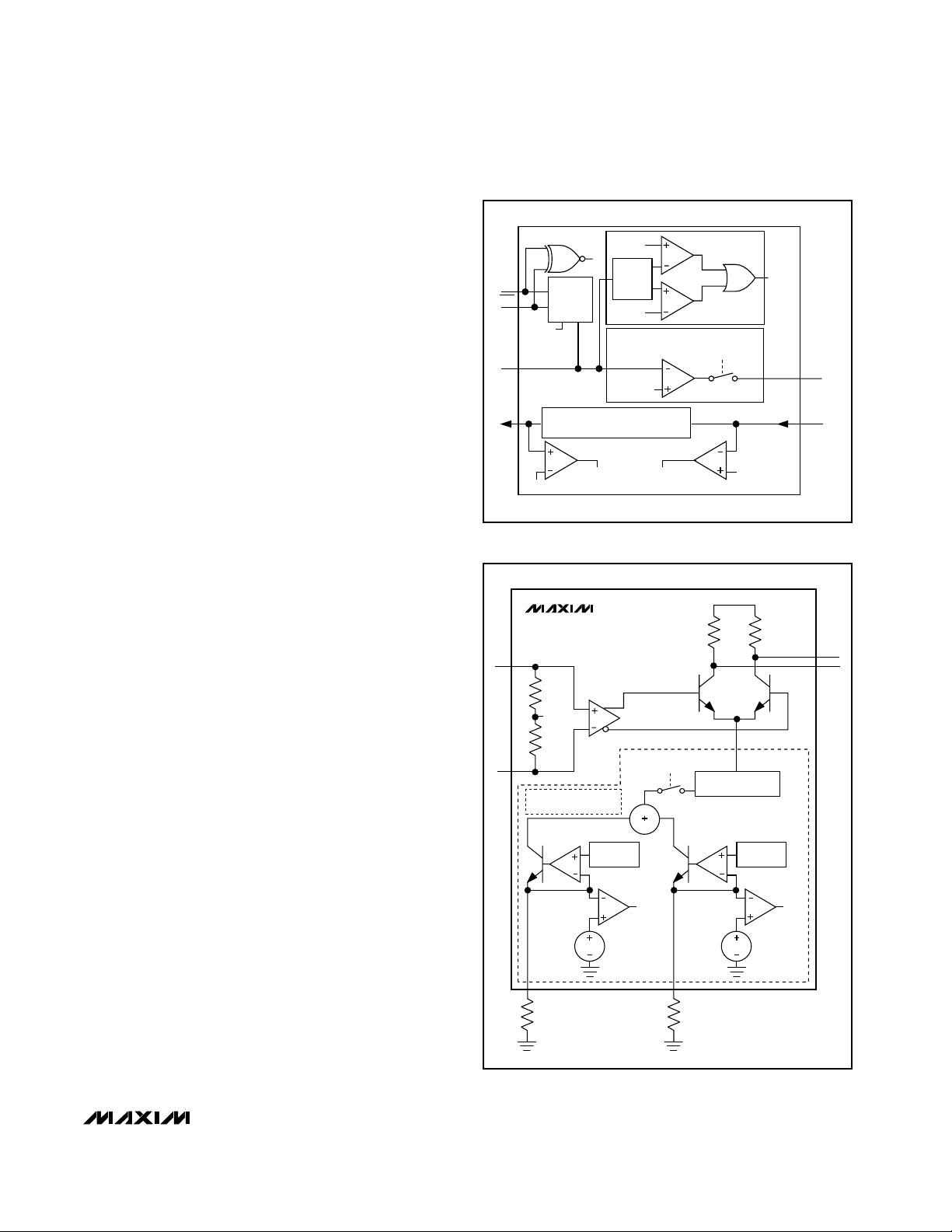

_______________Detailed Description

The MAX3286/MAX3296 series of laser drivers contain

a bias generator with automatic power control (APC),

laser modulator, power-on reset (POR) circuit, and

safety circuitry (Figures 2a and 2b).

Bias Generator

Figure 3 shows the bias generator circuitry containing a

power-control amplifier, controlled reference voltage,

smooth-start circuit, and window comparator. The bias

generator combined with an external PNP or NPN transistor provides DC laser current to bias the laser in a

light-emitting state. When there is a monitor diode (MD)

in the laser package, the APC circuitry adjusts the

laser-bias current to maintain average power over tem-

Page 8

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

8 _______________________________________________________________________________________

SMOOTH

START

IN+

IN-

TC MODSET

R

MOD

V

CC

R

TC

MON

SHDNDRV

REF

POR

PORDLY

POL

POL

FAULT

FAULT

FLTDLY

EN

EN

1.97V

LV

1.53V

+1.7V

50Ω 50Ω

CONTROLLED

REFERENCE

GENERATOR

LASER

MODULATOR

MODULATION CURRENT

GENERATOR

1.7V

REF

BIASDRV

MD

OUTOUT+

POR CIRCUIT

SAFETY

CIRCUITRY

INPUT BUFFER

VCC - 0.54V

MAX3286

MAX3296

BIAS GENERATOR

Figure 2b. Laser Driver Functional Diagram

LASER

MODULATOR

POR CIRCUIT

SAFETY

BIAS GENERATOR

MODSET

TC

BIASDRV

MD

SHDNDRV

FAULT

FAULT

POR

LV

PORDLY

EN

EN

FLTDLY

POL

POL

MON

MD

OUT-

OUT+

REF

IN+

IN-

Figure 2a. Simplified Laser Driver Functional Diagram

perature and changing laser properties. The MD input

is connected to the anode or cathode of a monitor photodiode or to a resistor-divider, depending on the specific

application circuit. Three application circuits are supported: common-cathode laser with photodiode, common-cathode laser without photodiode, and commonanode laser with photodiode (as shown in the Design

Procedure). The POL and POL inputs determine the laser

pinning (common cathode, common anode) (Table 4).

The smooth-start circuitry prevents current spikes to the

laser during power-up or enable; this ensures compliance

with safety requirements and extends the life of the laser.

The power-control amplifier drives an external transistor

to control the laser bias current. In a fault condition, the

power-control amplifier’s output is disabled (high

Page 9

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

_______________________________________________________________________________________ 9

impedance). This ensures that the PNP or NPN transistor

is turned off, removing the laser-bias current. (See

Applications Information.)

The REF pin provides a controlled reference voltage

dependent upon the voltage at MON. The voltage at

REF is V

REF

= 2.65 - 2.25(VCC- V

MON

). A resistor connected at REF determines the laser power when APC is

used with common-cathode lasers. See the Design

Procedure for setting the laser power.

Modulation Circuitry

The modulator circuitry consists of an input buffer, current

generator, and high-speed current switch (Figure 4). The

modulator drives up to 30mA of modulation current into

a 25Ω load.

Many of the modulator performance specifications

depend on the total modulator current (I

OUT

) (Figure 1a).

To ensure good driver performance, the voltage at

OUT+ and OUT- must not be less than VCC- 1V.

The amplitude of the modulation current is set with

resistors at the MODSET and TC (temperature coefficient)

pins. The resistor at MODSET (R

MOD

) programs the

temperature-stable portion of modulation current, while

the resistor at TC (RTC) programs the temperatureincreasing portion of the modulation current. Figure 5

shows modulation current as a function of temperature

for two extremes: RTCis open (the modulation current

has zero temperature coefficient) and R

MOD

is open

(the modulation temperature coefficient is 4000ppm).

Intermediate tempco values of modulation current can

be obtained as described in the Design Procedure.

Safety Circuitry

The laser driver can be used with two popular safety

systems. APC maintains laser safety using local feedback. Safety features monitor laser driver operation and

force a shutdown if a fault is detected. The shutdown

condition is latched until reset by a toggle of EN, EN, or

power.

Another safety system, Open Fiber Control (OFC), uses

safety interlocks to prevent eye hazards. To accommodate the OFC standard, the MAX3286/MAX3296 series

provide dual enable inputs and dual fault outputs.

The safety circuitry contains fault detection, dual enable

inputs, latched fault outputs, and a pulse generator

(Figure 6).

Safety circuitry monitors the APC circuit to detect unsafe

levels of laser emission during single-point failures. A

single-point failure can be a short to VCCor GND, or

between any two IC pins.

SMOOTH

START

POLARITY _FAULT

ENABLE

WINDOW

COMPARATOR

MD

FAULT

REF_FAULT MONITOR_FAULT

V

CC

- 540mV

BIASDRV

MON

POL

POL

MD

REF

POWER

CONTROL

AMPLIFIER

+1.7V

CONTROLLED REFERENCE VOLTAGE

V

REF

= 2.65 - 2.25 (VCC - V

MON

)

+1.97V

2.95V

+1.53V

GLITCH

REJECT

ENABLE

Figure 3. Bias Generator Circuitry

V

CC

CURRENT

SWITCH

INPUT

BUFFER

OUT+

OUT-

IN+

IN-

50Ω 50Ω

400Ω

400Ω

V

CC

- 0.3V

CURRENT AMPLIFIER

96X

4000ppm/°C

REFERENCE

ENABLE

0.8V

TC MODSET

R

TC

R

MOD

0.8V

TC_FAULT

MOD_FAULT

MODULATION CURRENT

GENERATOR

1.2V

REFERENCE

MAX3286

MAX3296

Figure 4. Laser Modulator Circuitry

Page 10

Pulse Generator

During start-up, the laser is not emitting light and the

APC loop is not closed, triggering a fault signal. To

allow start-up, an internal fault-delay pulse disables the

safety system for a programmable period of time, allowing

the driver to begin operation. The length of the pulse is

determined by the capacitor connected at FLTDLY and

should be set 5 to 10 times longer than the APC time

constant. The internal safety features can be disabled

by connecting FLTDLY to GND. Note that EN must be

high, EN must be low, and V

CC

must be in the opera-

tional range for laser operation.

Fault Detection

The MAX3286/MAX3296 series have extensive and

comprehensive fault-detection features. All critical

nodes are monitored for safety faults, and any node

voltage that differs significantly from its expected value

results in a fault (Table 1). When a fault condition is

detected, the laser is shut down. See Applications

Information for more information on laser safety.

Shutdown

The laser drivers offer dual redundant bias shutdown

mechanisms. The SHDNDRV output drives an optional

external MOSFET semiconductor. The bias and modulation drivers have separate, internal disable signals.

Latched Fault Output

Two complementary FAULT outputs are provided with

the MAX3286/MAX3296 series. In the event of a fault,

these outputs latch until one of three events occurs:

1) The power is switched off, then on.

2) EN is switched low, then high.

3) EN is switched to high, then low.

Power-On Reset (POR)

Figure 7 shows the power-on reset (POR) circuit for the

MAX3286/MAX3296 series devices. A POR signal

asserts low when VCCis in the operating range. The

voltage operating range is determined by the LV pin, as

shown in Table 2. POR contains an internal delay to

reject noise on VCCduring power-on or hot-plugging.

The delay can be extended by adding capacitance to

the PORDLY pin. The POR comparator includes hysteresis to improve noise rejection. The laser driver is

shut down while VCCis out of the operating range.

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

10 ______________________________________________________________________________________

V

CC

FLTDLY

FAULT

FAULT

SHDNDRV

(FROM POR CIRCUIT)

REF_FAULT

MONITOR_FAULT

MD_FAULT

POLARITY_FAULT

TC_FAULT

MOD_FAULT

EN

EN

ENABLE

QR

S

RESET

DOMINANT

FAULT

LATCH

FAULT

DETECTION

200ns

DELAY

t

FLTDLY

PULSE GENERATOR

MAX3286

MAX3296

Figure 6. Simplified Safety Circuit Schematic

0.6

0.8

0.7

1.0

0.9

1.2

1.1

1.3

0 20304010 50 60 70 80 90 100 110

JUNCTION TEMPERATURE (

°C)

i

MOD

/(i

MOD

AT+ 52°C)

RTC = OPEN

TEMPCO = 50ppm/°C

RTC ≥ 1.9kΩ

R

MOD

= OPEN

TEMPCO = 4000ppm/°C

Figure 5. Modulation Current vs. Temperature for Maximum

and Minimum Temperature Coefficient

Page 11

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

______________________________________________________________________________________ 11

Design Procedure

Select Laser

Select a communications-grade laser with a rise time of

260ps or better for 1.25Gbps, or 130ps or better for

2.5Gbps applications. To obtain the MAX3286/

MAX3296’s AC specifications, the instantaneous output

voltage at OUT+ must remain above VCC- 1V at all

times. Select a high-efficiency laser that requires low

modulation current and generates low-voltage swing at

OUT+. Laser package inductance can be reduced by

trimming the leads. Typical package leads have inductance of 25nH/in (1nH/mm), this inductance causes a

larger voltage swing across the laser. A compensation filter network can also be used to reduce ringing, edge

speed, and voltage swing.

Programming the Modulation Current

Resistors at the MODSET and TC pins set the amplitude of the modulation current. The resistor R

MOD

sets

the temperature-stable portion of the modulation current while the resistor RTCsets the temperatureincreasing portion of the modulation current.

To determine the appropriate temperature coefficient

from the slope efficiency (α) of the laser, use the following

equation:

where α is the slope of the laser output power to the

laser current.

For example, suppose a laser has a slope efficiency

α

25

of 0.021mW/mA at +25°C, which reduces to

0.018mW/mA at +70°C. Using the above equation will

produce a laser tempco of -3175ppm/°C.

To obtain the desired modulation current and tempco

for the device, the following two equations can be used

to determine the required values of R

MOD

and RTC:

where Tempco = -Laser Tempco.

Figure 8a shows a family of curves derived from these

equations. The straight diagonal lines depict constant

tempcos. The curved lines represent constant modulation currents. If no temperature compensation is

desired, Figure 8b displays a series of curves that

show laser modulation current with respect to R

MOD

for

different loads.

The following useful equations were used to derive

Figure 8a and the equations at the beginning of this

section. The first assumes R

L

= 25Ω.

Programming the Bias Current/APC

Three application circuits are described below: common-cathode laser with photodiode, common-cathode

laser without photodiode, and common-anode laser

with photodiode. The POL and POL inputs determine

the laser pinning (common cathode, common anode)

and affect the smooth-start circuits (Table 4).

Common Cathode with Photodiode

(Optical Feedback)

In the common-cathode with photodiode configuration,

a servo control loop is formed by external PNP Q1, the

laser diode, the monitor diode, R

SET

, and the powercontrol amplifier (Figure 9). The voltage at MD is stabilized to 1.7V. The monitor photodiode current (ID) is set

by (V

REF

- VMD) / R

SET

= 0.95 / R

SET

. Determine the

desired monitor current (ID), then select R

SET

= 0.95 / ID.

iii

TEMPCO C C A

MOD C MOD C MOD C() () ()

()(–)

70 25 25

70 25

°°°

=+

°°

[]

i

RR

TC

A

MOD

MOD TC

=

+Ω++Ω

+°

()

[]

⋅

⋅

⋅

−

51

115

250

106

250

14010 25

3

..

.–

R

R

MOD

TC

=

+Ω

−

−Ω

⋅

⋅

()

(. )

250 52

019 48

250

Tempco

Tempco

R

Tempco i

TC

MOD

=

()

−Ω

021

250

.

Laser Tempco =

−

°− °

°

[]

⋅

+

αα

α

70 25

25

6

70 25

10

()

/

CC

ppm C

V

CC

PORDLY

POR

1.2V

36k

25k

28k

LV

VARIABLE

DELAY

BANDGAP

= 0.7s/µF C

PORDLY

MAX3286

MAX3296

Figure 7. Power-On Reset Circuit

Page 12

The APC loop is compensated by C

BIASDRV

. A capacitor

must be placed from BIASDRV to VCCto ensure lownoise operation and to reject power-supply noise. The

time constant governs how quickly the laser bias current

reacts to a change in the average total laser current

(I

BIASDRV

+ i

MOD

). A capacitance of 0.1µF is sufficient

to obtain a loop time constant in excess of 1µs, provided that R

DEG

is chosen appropriately. Resistor R

DEG

may be necessary to ensure the APC loop’s stability

when low bias currents are desired.

The voltage across R

DEG should not be any larger than

250mV at maximum bias current.

The discrete components used with the common cath-

ode with photodiode configuration are as follows:

R

SET

= 0.88 / I

D

C

BIASDRV

= 0.1µF (typ)

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

12 ______________________________________________________________________________________

POL DESCRIPTION

MAX3286/MAX3296 V

CC

Common cathode with

photodiode

DEVICE

Table 4. POL Pin Setup for Each Laser Configuration Type

POL

GND

LASER PINNING

MAX3287/MAX3297 — —

MAX3286/MAX3296 V

CC

Common cathode without

photodiode

MAX3288/MAX3298 —

GND

—

MAX3286/MAX3296 GND

Common anode with

photodiode

MAX3289/MAX3299 —

V

CC

—

MAX3286/MAX3296 V

CC

V

CC

Not allowed; fault occurs —

MAX3286/MAX3296 GND GND Not allowed; fault occurs —

Figure 8a. RTCvs. R

MOD

for Various Conditions

0

10

5

20

15

35

30

25

40

042 6 8 101214

R

MOD

(kΩ)

LASER MODULATION CURRENT (i

MOD

) (mA)

NOTE: RTC = OPEN

10Ω

LOAD

25Ω

LOAD

50Ω

LOAD

Figure 8b. Laser-Modulation Current vs. R

MOD

53.61.69

R

MOD

(kΩ)

R

TC

(kΩ)

i

MOD

= 15mA

11.526.73500 162

R

MOD

(kΩ)

R

TC

(kΩ)

i

MOD

= 30mA

R

MOD

(kΩ)

i

MOD

= 5mA

3.65

R

TC

(kΩ)

TEMPCO

(ppm/°C)

8.063.16

11.32.49

18.72.0

20.04.122000 24.9

5.762500 16.2

9.533000

34.8

13.357.6

6.49

5.23

4.32

4.2213.3

5.116.49

6.194.32

80.62.26500 13.3

2.671000 40.2

3.241500

15.8

26.719.1

26.7

13.3

8.87

Table 3. RTCand R

MOD

Selection Table

1000

(kΩ)

10

TC

R

1

500ppm

1000ppm

1500ppm

RL = 25Ω

1 100 1000

2000ppm

10

R

MOD

2500ppm

3000ppm

3500ppm

5mA

10mA

15mA

20mA

25mA

30mA

(kΩ)

V

CC

Page 13

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

______________________________________________________________________________________ 13

R

DEG

= 0.25 / I

BIAS(MAX)

Q1 = general-purpose PNP, β >100, ft> 5MHz

B1 = ferrite bead (see Bias Filter section)

M1 = general-purpose PMOS device (optional)

Common Cathode with Current Feedback

In the common-cathode configuration with current feedback, a servo control loop is formed by an external PNP

transistor (Q1), R

MON

, the controlled-reference voltage

block, R

SET

, RMD, and the power-control amplifier

(Figure 10). The voltage at MD is stabilized to 1.7V. The

voltage at MON is set by the resistors R

SET

and RMD.

As in the short-wavelength configuration, a 0.1µF

C

BIASDRV

connected between BIASDRV and VCCis

sufficient to obtain approximately a 1µs APC loop time

constant. This improves power-supply noise rejection.

To select the external components:

1) Determine the required laser bias current:

I

BIAS

= ITH+ i

MOD/2

2) Select RMDand R

SET

.

Maxim recommends R

SET

= 1kΩ, RMD= 5kΩ, which

results in VCC- V

MON

≈ 250mV.

3) Select R

MON

where R

MON

= 250mV / I

BIAS

, assuming

R

SET

= 1kΩ and RMD= 5kΩ.

V

CC

V

CC

R

DEG

V

CC

CONTROLLED REFERENCE VOLTAGE

V

REF

= 2.65V

REF

ONLY

MAX3286/96

SHDNDRV

C

BIASDRV

BIASDRV

MON

M1

Q1

POL

MD

POWER CONTROL

AMPLIFIER

LASER

I

BIAS

PHOTO

DIODE

I

D

FERRITE

BEAD

B1

1.7V

SMOOTH

START

V

CC

R

SET

POL

MAX3286

MAX3287

MAX3296

MAX3297

Figure 9. Common-Cathode Laser with Photodiode

V

CC

R

MON

V

CC

CONTROLLED REFERENCE VOLTAGE

V

REF

= 2.65V - 2.25V (VCC - V

MON

)

REF

MAX3286/96

ONLY

SHDNDRV

C

BIASDRV

BIASDRV

MON

M1

Q1

POL

MD

POWER CONTROL

AMPLIFIER

I

BIAS

I

D

FERRITE

BEAD

B1

1.7V

SMOOTH

START

V

CC

R

SET

R

MD

POL

MAX3286

MAX3288

MAX3296

MAX3298

LASER

Figure 10. Common Cathode with Current Feedback (PNP Configuration)

Page 14

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

V

CC

V

CC

MAX3286/96

ONLY

SHDNDRV

C

BIASDRV

BIASDRV

MON

LASER

Q1

POL

MD

POWER CONTROL

AMPLIFIER

I

BIAS

I

D

FERRITE

BEAD

B1

MONITOR

DIODE

1.7V

SMOOTH

START

V

CC

V

CC

R

DEG

R

SET

POL

MAX3286

MAX3289

MAX3296

MAX3299

Figure 12. Common Anode With Photodiode

The relationship between laser bias current and R

MON

is shown in Figure 11. The remaining discrete components used with the common-cathode without photodiode configuration are as follows:

Q1 = general-purpose PNP, β >100, ft> 5MHz

B1 = ferrite bead (see Bias Filter section)

M1 = general-purpose PMOS device (optional)

C

BIASDRV

= 0.1µF (typ)

Common Anode with Photodiode

In the common-anode configuration with photodiode, a

servo control loop is formed by an external NPN transistor (Q1), the laser diode, the monitor diode, R

SET

, and

the power-control amplifier. The voltage at MD is stabilized to 1.7V. The monitor photodiode current is set by

ID= VMD/ R

SET

(Figure 12). Determine the desired mon-

itor current (ID), then select R

SET

= 1.7V / ID.

C

BIASDRV

and a degeneration resistor (R

DEG

) must be

connected to the bias transistor (in this case NPN) to

obtain the desired APC loop time constant. This

improves power-supply (and ground) noise rejection. A

capacitance of 0.1µF is sufficient to obtain time constants of up to 5µs in most cases. The voltage across

R

DEG

should not be larger than 250mV at maximum bias

current.

The discrete components used with the common-anode

with photodiode configuration are summarized as follows:

R

SET

= 1.7 / I

D

C

BIASDRV

= 0.1µF (typ)

R

DEG

= 0.25 / I

BIAS(MAX)

Q1 = general-purpose NPN, β > 100, ft> 5MHz

B1 = ferrite bead (see Bias Filter section)

M1 = general-purpose PMOS (optional)

Programming POR Delay

A capacitor may be added to PORDLY to increase the

delay for which POR will be asserted low (meaning that

VCCis within the operational range) when powering up

the part.

The delay will be approximately:

See Typical Operating Characteristics.

t

C

s

PORDLY

=

()

[]

−

1410

6

.

100

0.1

10 1k 10k

1

10

R

MON

(Ω)

LASER BIAS CURRENT (mA)

100

R

SET

= 1kΩ

R

MD

= 5kΩ

Figure 11. Common Cathode Without Photodiode Laser

14 ______________________________________________________________________________________

Page 15

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

______________________________________________________________________________________ 15

Designing the Bias Filter and

Output Pull-Up Beads

To reduce deterministic jitter, add a ferrite-bead inductor between the collector of the biasing transistor and

either the anode or cathode of the laser, depending on

type (see Typical Operating Characteristics). Use a ferrite-bead inductor with an impedance >100Ω between ƒ =

10MHz and ƒ = 2GHz, and a DC resistance < 3Ω.

Maxim recommends the Murata BLM11HA102SG.

These inductors are also desirable for tying the OUT+

and OUT- pins to VCC.

Designing the Laser-Compensation

Filter Network

Laser package inductance causes the laser impedance

to increase at high frequencies, leading to ringing, overshoot, and degradation of the output eye pattern. A lasercompensation filter network can be used to reduce the

output load seen by the laser driver at high frequencies,

thereby reducing output ringing and overshoot.

The compensation components (R

COMP

and C

COMP

)

are most easily determined by experimentation. Begin

with R

COMP

= 25Ω and C

COMP

= 2pF. Increase C

COMP

until the desired transmitter eye is obtained (Figure 13).

Quick Shutdown

To reduce laser shutdown time, a FET device can be

attached to SHDNDRV as shown in Figure 10. This will

provide a typical laser power shutdown time of less

than 10µs.

Applications Information

Laser Safety and IEC 825

The International Electrotechnical Commission (IEC)

determines standards for hazardous light emissions

from fiber optic transmitters. IEC 825 defines the maximum light output for various hazard levels. The MAX3286/

MAX3296 series provide features that facilitate compliance with IEC 825.

A common safety requirement is single-point fault tolerance, whereby one unplanned short, open, or resistive

connection does not cause excess light output. When

these laser drivers are used as shown in the Typical

Operating Circuits, the circuits respond to faults as

shown in Table 5.

Using these laser drivers alone does not ensure that a

transmitter design is compliant with IEC 825. The entire

transmitter circuit and component selections must be

considered. Customers must determine the level of fault

tolerance required by their applications, recognizing that

Maxim products are not designed or authorized for use

as components in systems intended for surgical implant

into the body, for applications intended to support or sustain life, or for any other application where the failure of

a Maxim product could create a situation where personal injury or death may occur.

Layout Considerations

The MAX3286/MAX3296 series are high-frequency

products. Their performance largely depends upon the

circuit board layout.

Use a multilayer circuit board with a dedicated ground

plane. Use short laser package leads placed close to

the modulator outputs. Power supplies must be capacitively bypassed to the ground plane with surface-mount

capacitors placed near the power-supply pins.

The dominant pole of the APC circuit is normally located at BIASDRV. To prevent a second pole in the APC

(that can lead to oscillations), ensure that parasitic

capacitance at MD is minimized.

Common Questions

Laser output is ringing or contains overshoot. This is often

caused by inductive laser packaging. Try reducing the

length of the laser leads. Modify the compensation components to reduce the driver’s output edge speed (see

Design Procedure). Extreme ringing can be caused by

low voltage at the OUT± pins. This may indicate that pullup beads or a lower modulation current are needed.

Low-frequency oscillation on the laser output. This is

more prevalent at low temperatures. The APC may be

oscillating. Try increasing the value of C

BIASDRV

or

increasing the value of R

DEG

. Ensure that the parasitic

capacitance at the MD node is kept very small (<10pF).

The APC is not needed. Connect FLTDLY to ground to

disable fault detection. Connect MD to REF and MON to

VCC. BIASDRV and SHDNDRV can be left open.

TIME

UNCOMPENSATED

CORRECTLY COMPENSATED

OVERCOMPENSATED

POWER

Figure 13. Laser Compensation

Page 16

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

16 ______________________________________________________________________________________

PIN NAME

CIRCUIT RESPONSE TO OVERVOLTAGE OR

SHORT TO V

CC

CIRCUIT RESPONSE TO UNDERVOLTAGE OR

SHORT TO GROUND

EN Normal condition for circuit operation. Fault state* occurs.

Does not affect laser power.FAULT Does not affect laser power.

Does not affect laser power.POR Does not affect laser power.

Normal condition for circuit operation.

EN

Fault state* occurs.

Fault state* occurs.PORDLY Does not affect laser power.

Fault state* occurs if VCCis less than +4.5V.LV Does not affect laser power.

If POL is a TTL LOW, a fault state* occurs; otherwise, the circuit is in normal operation.

POL

If POL is a TTL HIGH, a fault state* occurs; otherwise, the circuit is in normal operation.

MON

(Also MAX3288/98)

In common-cathode without photodiode configuration, a fault state* occurs; otherwise, does not affect

laser power.

A fault state* occurs.

If POL is a TTL LOW, a fault state* occurs; otherwise, the circuit is in normal operation.

POL

If POL is a TTL HIGH, a fault state* occurs; otherwise, the circuit is in normal operation.

Does not affect laser power.

SHDNDRV

(Also MAX3287/97/

89/99)

Does not affect laser power. If optional FET is used,

the laser output is shut off.

FLTDLY

Any fault that occurs cannot be reset. Does not

affect laser power.

Does not affect laser power.

Does not affect laser power.IN+, IN- Does not affect laser power.

In common cathode configurations, a fault state*

occurs; otherwise, does not affect laser power.

REF Fault state* occurs.

A fault state* occurs.MD Fault state* occurs.

OUT+, OUT- Does not affect laser power. Does not affect laser power.

Fault state* occurs.MODSET Does not affect laser power.

In common anode configurations, the laser bias

current is shut off. In common cathode, high laser

power triggers a fault state*. Shutdown occurs if a

shutdown FET (M1) is used (Figures 9,10).

BIASDRV

In common cathode configurations, the laser bias

current is shut off. In common anode, high laser

power triggers a fault state*. Shutdown occurs if a

shutdown FET (M1) is used. If shutdown FET is not

used, other means must be used to prevent high

laser power.

Fault state* occurs.TC Does not affect laser power.

Table 5. Circuit Response to Various Single-Point Faults

* A fault state will assert the FAULT pins, disable the modulator outputs, disable the bias output, and assert the SHDNDRV pin.

FAULT

Does not affect laser power. Does not affect laser power.

ALL DEVICES

MAX3286/MAX3296 ONLY

Page 17

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

______________________________________________________________________________________ 17

The modulator is not needed. Leave TC and MODSET

open. Connect IN+ to VCC. IN- to REF, and leave OUT+

and OUT– open.

Wirebonding Die

The MAX3286/MAX3296 series use bondpads with gold

metalization. Make connections to the die with gold wire

only, using ball-bonding techniques. Wedge bonding is

not recommended. Bondpad size is 4mil square. Die

thickness is typically 15mils (0.38mm).

Interface Models

Figures 14–18 show typical input/output models for the

MAX3286/MAX3296 series of laser drivers. If dice are

used, replace the package parasitic elements with

bondwire parasitic elements.

4k

2.5k

V

CC

FAULT, FAULT, POR

MAX3286

MAX3296

Figure 14. Logic Outputs

10k

550Ω

60Ω

V

CC

SHDNDRV

MAX3286

MAX3296

Figure 15. SHDNDRV Output

PACKAGE

V

CC

V

CC

1.5nH

OUT-

0.2pF

1.5nH

0.2pF

OUT+

50Ω

50Ω

PACKAGE

1pF 1pF

Figure 16. Modulator Outputs

Page 18

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

18 ______________________________________________________________________________________

40Ω

40Ω

V

CC

BIASDRV

MAX3286

MAX3296

Figure 18. BIASDRV Output

Q1

Q2

1.5nH

1.5nH

INPUT COMMON MODE VOLTAGE ≈ V

CC

- 0.3V

R

IN

Q1, Q2 > 100kΩ

PACKAGE

0.2pF

0.2pF

V

CC

V

CC

V

CC

400Ω

400Ω

1pF

1pF

IN+

IN-

MAX3286

MAX3296

Figure 17. Data Inputs

Page 19

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

______________________________________________________________________________________ 19

PART

MAX3287CUE

MAX3288CUE

0°C to +70°C

0°C to +70°C

TEMP. RANGE PIN-PACKAGE

16 TSSOP-EP**

16 TSSOP-EP**

*Dice are designed to operate from TJ= 0°C to +110°C, but are

tested and guaranteed only at TA= +25°C.

**Exposed paddle

MAX3289CUE

MAX3296CHJ

0°C to +70°C

0°C to +70°C 16 TSSOP-EP**

32 TQFP (5mm x 5mm)

MAX3296C/D

MAX3297CUE

MAX3298CUE

MAX3299CUE

0°C to +70°C

0°C to +70°C Dice*

16 TSSOP-EP**

0°C to +70°C

0°C to +70°C 16 TSSOP-EP**

16 TSSOP-EP**

Selector Guide

Ordering Information (continued)

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

GND TC

MODSET

V

CC

OUT-

OUT+

V

CC

BIASDRV

MON

MAX3288

MAX3298

TSSOP-EP*

FLTDLY

V

CC

GND

IN+

IN-

REF

MD

MAX3286

MAX3296

TQFP

TOP VIEW

32 28

293031

25

26

27

MODSET

GND

VCCOUT-TCOUT+

VCCV

CC

10

13

15

14

1611 12

9

FLTDLY

V

CC

LV

IN-

IN+

REF

GND

N.C.

17

18

19

20

21

22

23

SHDNDRV

24 BIASDRV

GND

MON

MD

I.C.

POL

POL

2

3

4

5

6

7

8PORDLY

EN

EN

GND

POR

FAULT

N.C.

1FAULT

Pin Configurations (continued)

1.25Gbps 2.5Gbps

COMMON

CATHODE

WITHOUT

PHOTODIODE

DATA RATE/DEVICE

VCSELLongwave

LASER CONFIGURATION

COMMON

ANODE WITH

PHOTODIODE

Shortwave or

VCSEL

COMMON

CATHODE

WITH

PHOTODIODE

✓

MAX3286 MAX3296

✓ ✓

32 TQFP/Dice

MAX3287 MAX3297

✓

16 TSSOP-EP

MAX3288 MAX3298

✓

16 TSSOP-EP

MAX3289 MAX3299

✓

16 TSSOP-EP

*Exposed paddle is connected to GND.

PACKAGE

Page 20

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

20 ______________________________________________________________________________________

Typical Application Circuits

POL

IN-

POL

FLTDLY

FAULT

FAULT

POR

EN

EN

IN+

OUT-

OUT+

MD

REF

MON

MODSET

TC

GND

SHDNDRV

BIASDRV

PORDLY

V

CC

115Ω

+3.0V TO +5.5V

FERRITE

BEAD

PMOSFET

(OPTIONAL)

PNP

TRANSISTOR

25Ω

0.01µF

R

TC

R

MOD

R

SET

0.01µF

0.01µF

C

COMP

DATA

INPUT

C

BIASDRV

0.1µF

LV

V

CC

R

COMP

0.01µF

V

CC

MAX3286

MAX3296

0.01µF

MAX3286/MAX3296

COMMON-CATHODE LASER

WITH PHOTODIODE

0.01µF

0.01µF

POL

IN-

POL

FLTDLY

FAULT

POR

EN

EN

IN+

OUT-

OUT+

MD

REF

MODSET

TC

GND

BIASDRV

PORDLY

V

CC

115Ω

+3.0V TO +5.5V

FERRITE

BEAD

PNP

TRANSISTOR

25Ω

0.01µF

R

TC

R

MOD

R

SET

1k

0.01µF

0.01µF

C

COMP

DATA

INPUT

C

BIASDRV

0.1µF

LV

V

CC

R

COMP

0.01µF

V

CC

MAX3286

MAX3296

0.01µF

MON

R

MON

SHDNDRV

R

MD

5k

FAULT

MAX3286/MAX3296

COMMON-CATHODE LASER

WITHOUT PHOTODIODE

0.01µF

0.01µF

Page 21

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

______________________________________________________________________________________ 21

Typical Application Circuits (continued)

POL

IN-

POL

FLTDLY

FAULT

FAULT

POR

EN

EN

IN+

OUT-

OUT+

MD

REF

MON

MODSET

TC

GND

SHDNDRV

BIASDRV

PORDLY

V

CC

115Ω

+3.0V TO +5.5V

FERRITE

BEAD

NPN

TRANSISTOR

25Ω

0.01µF

R

TC

R

MOD

R

SET

R

DEG

0.01µF

0.01µF

C

COMP

DATA

INPUT

LV

V

CC

R

COMP

0.01µF

V

CC

MAX3286

MAX3296

0.01µF

C

BIASDRV

0.1µF

MAX3286/MAX3296

COMMON-ANODE LASER

WITH PHOTODIODE

0.01µF

0.01µF

18Ω

IN-

FLTDLY

IN+

OUT-

OUT+

MD

REF

MODSET

TC

GND

SHDNDRV

BIASDRV

V

CC

115Ω

+3.0V TO +5.5V

FERRITE

BEAD

PNP

TRANSISTOR

25Ω

0.01µF

R

TC

R

MOD

R

SET

R

DEG

0.01µF

0.01µF

C

COMP

DATA

INPUT

C

BIASDRV

0.1µF

R

COMP

0.01µF

MAX3287

MAX3297

MAX3287/MAX3297

COMMON-CATHODE LASER

WITH PHOTODIODE

V

CC

V

CC

0.01µF

0.01µF

Page 22

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

22 ______________________________________________________________________________________

Typical Application Circuits (continued)

IN-

FLTDLY

IN+

OUT-

OUT+

MD

REF

MODSET

TC

GND

BIASDRV

V

CC

115Ω

+3.0V TO +5.5V

FERRITE

BEAD

PNP

TRANSISTOR

25Ω

0.01µF

R

TC

R

MOD

R

SET

1k

0.01µF

C

COMP

DATA

INPUT

C

BIASDRV

0.1µF

R

COMP

0.01µF

MAX3288

MAX3298

MON

R

MON

R

MD

5k

0.01µF

MAX3288/MAX3298

COMMON-CATHODE LASER

WITHOUT PHOTODIODE

V

CC

V

CC

0.01µF

0.01µF

IN-

FLTDLY

IN+

OUT-

OUT+

MD

REF

MODSET

TC

GND

SHDNDRV

BIASDRV

V

CC

115Ω

+3.0V TO +5.5V

FERRITE

BEAD

NPN

TRANSISTOR

25Ω

0.01µF

R

TC

R

MOD

R

SET

R

DEG

0.01µF

0.01µF

C

COMP

DATA

INPUT

V

CC

R

COMP

C

BIASDRV

0.1µF

0.01µF

V

CC

MAX3289

MAX3299

18Ω

MAX3289/MAX3299

COMMON-ANODE LASER

WITH PHOTODIODE

0.01µF

0.01µF

Page 23

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

______________________________________________________________________________________ 23

TC

V

CC

OUT-

OUT+

V

CC

V

CC

LV

V

CC

IN+

IN-

GND

REF

0.053"

(1.346mm)

MON

POL

GND

MD

POL

GNDENPOR

EN

I.C.

0.072"

(1.829mm)

SHDNDRV

BIASDRV

MODSET

FAULT

FAULT

PORDLY

FLTDLY

HF34Z-1Z

TC

V

CC

V

CC

V

CC

LV

V

CC

IN+

IN-

GND

REF

MON

POL

GND

MD

POL

GNDENPOR

EN

I.C.

0.072"

(1.829mm)

SHDNDRV

BIASDRV

MODSET

FAULT

FAULT

PORDLY

FLTDLY

HF34Z

0.053"

(1.346mm)

OUT-

OUT+

Chip Topographies

TRANSISTOR COUNT: 1154

SUBSTRATE CONNECTED TO GND

TRANSISTOR COUNT: 1154

SUBSTRATE CONNECTED TO GND

MAX3286 MAX3296

Page 24

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

24 ______________________________________________________________________________________

Package Information

32L,TQFP.EPS

Page 25

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

______________________________________________________________________________________ 25

Package Information (continued)

TSSOP.EPS

Page 26

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

26 ______________________________________________________________________________________

NOTES

Page 27

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

______________________________________________________________________________________ 27

NOTES

Page 28

Maxim makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does Maxim assume any liability arising out of the application or use of any product or circuit and specifically disclaims any and all liability, including without limitation consequential or

incidental damages. “Typical” parameters can and do vary in different applications. All operating parameters, including “typicals” must be validated for

each customer application by customer’s technical experts. Maxim products are not designed, intended or authorized for use as components in systems

intended for surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of the

Maxim product could create a situation where personal injury or death may occur.

28 ____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 1999 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

MAX3286–MAX3289/MAX3296–MAX3299

3.0V to 5.5V, 1.25Gbps/2.5Gbps

LAN Laser Drivers

NOTES

Loading...

Loading...