Page 1

General Description

The MAX1660 digitally controlled fuel-gauge interface

executes two essential functions for rechargeable battery-pack management: fuel gauging and pack overcurrent protection. It accurately monitors a battery pack’s

charge and discharge current flow, and records each

using two independent, on-board Coulomb counters.

Each counter’s contents are externally accessible via a

System Management Bus (SMBus™)-compatible 2-wire

serial interface. An optional third wire interrupts the

microcontroller (µC) when the charge or discharge

counters reach a preset value, or when an overcurrent

condition (charge or discharge) occurs. In the event of

an overcurrent or short-circuit condition, the MAX1660

disconnects the load and alerts its host. The MAX1660’s

flexibility allows accurate fuel gauging for any battery

chemistry, using any desired control algorithm.

The MAX1660 operates with battery voltages from +4V

to +28V and provides two micropower shutdown

modes, increasing battery lifetime. To minimize total

parts count, the device integrates a precision 2.00V

system-reference output, a 3.3V linear-regulator output

that can supply up to 5mA to power external circuitry,

and a power-on reset output for the system µC. The

MAX1660 is available in a 16-pin QSOP package.

________________________Applications

Smart-Battery Packs Battery-Pack Fuel Gauging

Battery-Pack Overcurrent Digital Current-Sense

Protection Instrumentation

Industrial-Control System Analog-to-Digital

Interfaces Conversion

____________________________Features

♦ 1% Accuracy over a 600µA to 4A Current Range

(R

SENSE

= 30mΩ)

♦ 5µV Input Offset Voltage (28µV max)

♦ SMBus 2-Wire (plus optional interrupt)

Serial Interface

♦ 2.00V Precision System Reference Output

♦ 3.3V Linear-Regulator Output Powers External

Circuitry

♦ Two Micropower Shutdown Modes

♦ Independent 32-Bit Charge and Discharge

Coulomb Counters

♦ Battery-Overcharge/Overdischarge Protection

♦ Battery Short-Circuit/Overcurrent Protection

♦ On-Board Power MOSFET Drivers

♦ 80µA Quiescent Current

♦ <1µA Shutdown Current

♦ Small 16-Pin QSOP Package

(same board area as 8-pin SO)

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

________________________________________________________________

Maxim Integrated Products

1

19-1308; Rev 1; 10/98

EVALUATION KIT MANUAL

FOLLOWS DATA SHEET

SMBus is a trademark of Intel Corp.

*

Patent pending

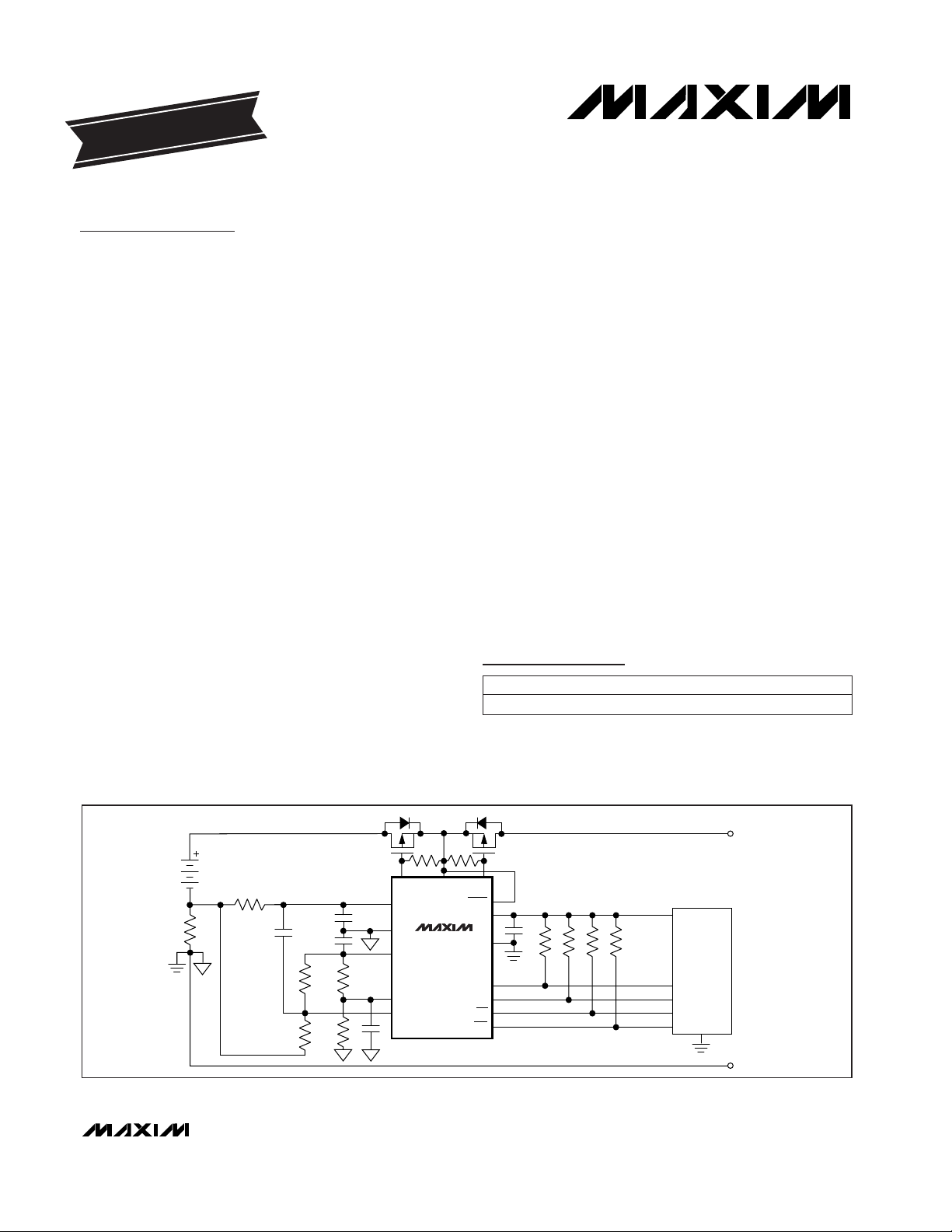

MAX1660

BATT

CS

AGND

REF

OCI

ODI

GND

SCL

SDA

SHDN

OCO

VL

V

CC

GND

PACK-

PACK+

µC

RST

INT

ODO

R

CS

___________________________________________________Typical Operating Circuit

For free samples & the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 1-800-835-8769.

PART

MAX1660EEE -40°C to +85°C

TEMP. RANGE PIN-PACKAGE

16 QSOP

Ordering Information

Pin Configuration appears at end of data sheet.

Page 2

*

Patent pending

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

2 _______________________________________________________________________________________

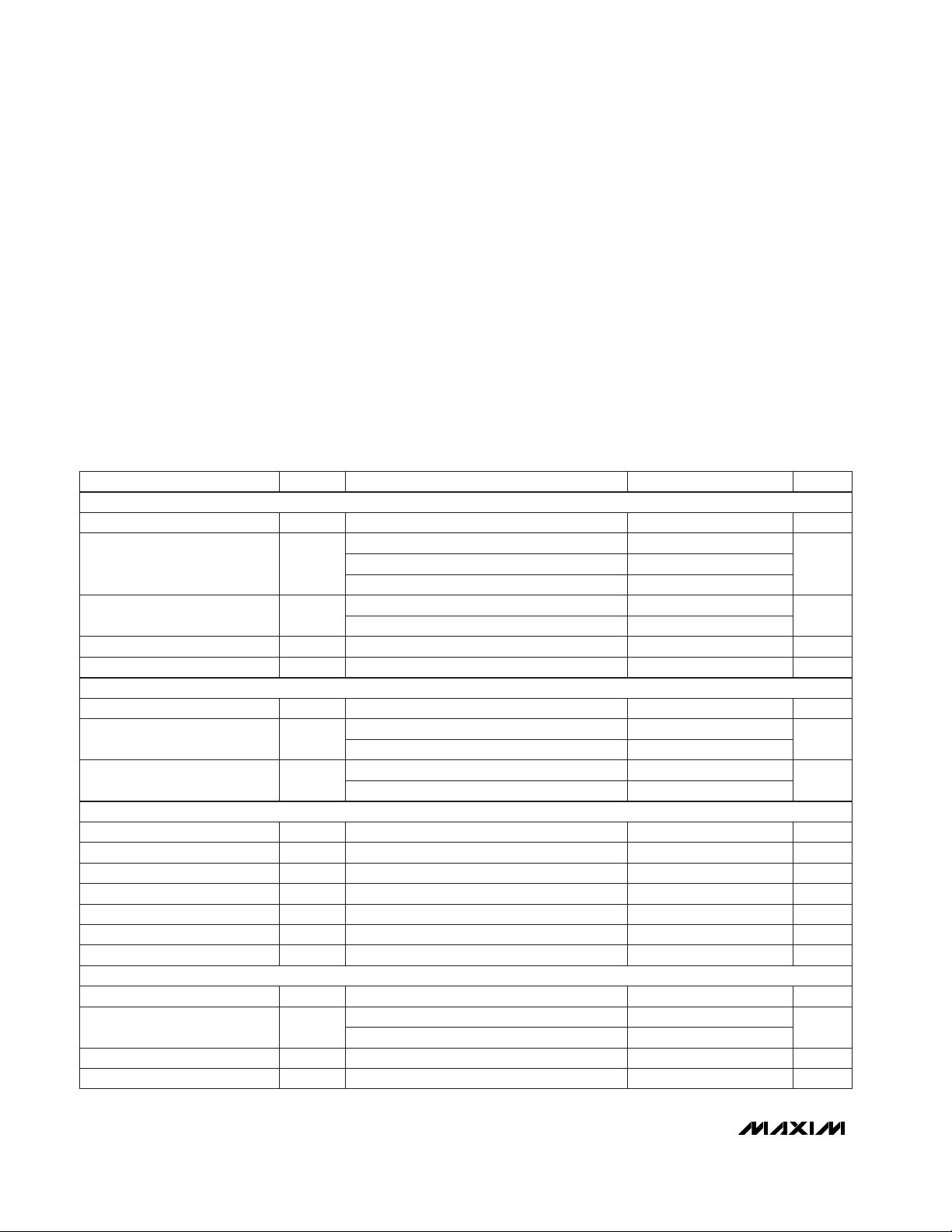

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(V

SHDN

= V

BATT

= 12V, V

SCL

= V

SDA

= 3.6V, C

REF

= 10nF, CVL= 0.1µF, TA= 0°C to +85°C, unless otherwise noted. Typical values

are at T

A

= +25°C.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

BATT, ODO, OCO, SHDN to GND .........................-0.3V to +30V

SCL, SDA, INT, RST to GND ....................................-0.3V to +6V

REF, ODI, OCI to GND..................................-0.3V to (VL + 0.3V)

VL to GND ................................................................-0.3V to +6V

CS to GND...................................................................-2V to +6V

AGND to GND.............................................................-1V to +1V

Continuous Power Dissipation (T

A

= +70°C)

16-Pin QSOP (derate 8.3mW/°C above +70°C).............667mW

Operating Temperature Range ...........................-40°C to +85°C

Storage Temperature Range.............................-65°C to +165°C

Lead Temperature (soldering, 10sec).............................+300°C

V

OCO

= 0.4V

V

ODO

= 28V

V

SHDN

= 3.3V, SOFTSHDN = 0, IVL= 0

V

ODO

= 0.4V

(Note 1)

VCS= 120mV

VCS= 0

0 ≤ I

REF

≤ 200µA

I

REF

= 0

V

SHDN

= 3.3V, SOFTSHDN = 1, IVL= 0

V

SHDN

≤ 0.4V

SOFTSHDN = 0, 0 ≤ IVL≤ 5mA

VCS= -120mV

SOFTSHDN = 1, 0 ≤ IVL≤ 5mA

VCS= 0

CONDITIONS

mA1 2.5OCO Sink Current

µA0.01 1ODO Off-Leakage Current

mA1 2.5ODO Sink Current

µs1Propagation Delay

µA-1 0.01 1OCI, ODI Input Offset Current

mV-7 0 7OCI, ODI Input Offset Voltage

49,500 50,000 50,500

counts/

sec

0212

Charge Coulomb-Counter

Accumulation Rate

49,500 50,000 50,500

counts/

sec

0212

Discharge Coulomb-Counter

Accumulation Rate

µA

80 135

I

BATT

BATT Supply Current

V428V

BATT

BATT Input Voltage Range

kΩ100CS to AGND Input Resistance

µV/µA10 50REF Load Regulation

V1.96 2.00 2.04V

REF

REF Output Voltage

15 30

0.02 1

V

3.1 3.25 3.4

V

VL

VL Output Voltage

3.1 3.25 3.6

UNITSMIN TYP MAXSYMBOLPARAMETER

V

INT

= 0.4V

V

SDA

= 0.6V

SHDN

SCL, SDA

SHDN, SCL, SDA

V

OCO

= 28V

mA2V

OL

INT Output Low Sink Current

mA6V

OL

SDA Output Low Sink Current

0.6

V

0.8

V

IL

Input Low Voltage

V2.2V

IH

Input High Voltage

µA0.01 1OCO Off-Leakage Current

SUPPLY AND REFERENCES

FUEL GAUGE

OVERCURRENT COMPARATOR

INTERFACE-LOGIC LEVELS

Page 3

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

_______________________________________________________________________________________ 3

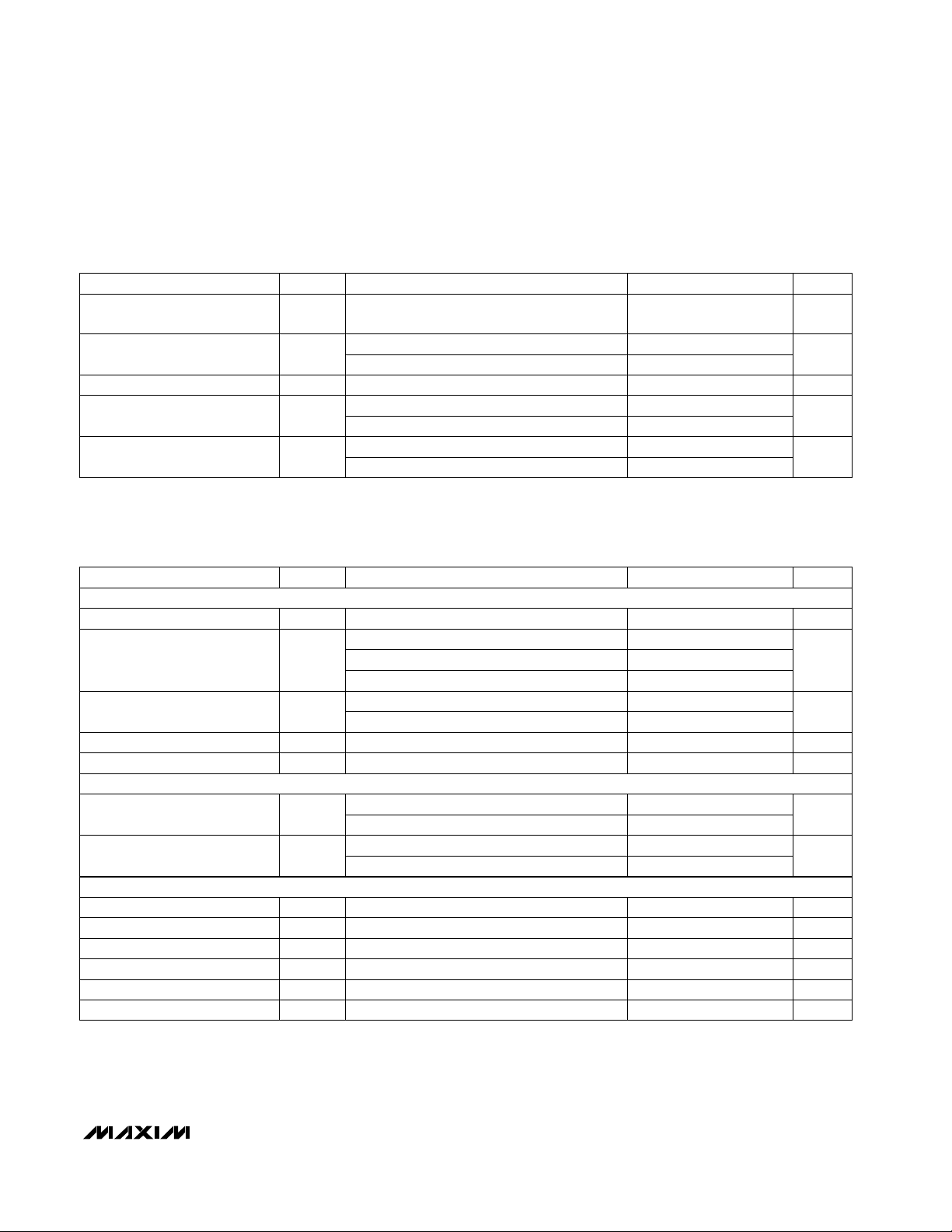

ELECTRICAL CHARACTERISTICS (continued)

(V

SHDN

= V

BATT

= 12V, V

SCL

= V

SDA

= 3.6V, C

REF

= 10nF, CVL= 0.1µF, TA= 0°C to +85°C, unless otherwise noted. Typical values

are at T

A

= +25°C.)

V

TH1

, VL rising

VVL= 3V, I

SINK

= 1.2mA

CONDITIONS

VVL= 1V, I

SINK

= 50µA

V

TH2

, VL falling

2.75 2.90 3.05

V

1.0 1.7 2.2

0.3

V

0.3

V

RST

RST Output Voltage

V

TH1

,

V

TH2

RST Threshold Voltage

UNITSMIN TYP MAXSYMBOLPARAMETER

SHDN forced to 28V

SHDN forced to 3.6V

Output forced to 5V

ms25

RST Active Timeout Period

20 100

µA

0.7 3.0

I

SHDN

SHDN Input Bias Current

µA0.01 1

SCL, SDA, INT, RST Leakage

Current

V

ODO

= 0.4V

V

ODO

= 28V

V

SHDN

= 3.3V, SOFTSHDN = 0, IVL= 0

V

ODO

= 0.4V

(Note 1)

VCS= 120mV

VCS= 0

0 ≤ I

REF

≤ 200µA

I

REF

= 0

V

SHDN

= 3.3V, SOFTSHDN = 1, IVL= 0

V

SHDN

≤ 0.4V

SOFTSHDN = 0, 0 ≤ IVL≤ 5mA

VCS= -120mV

SOFTSHDN = 1, 0 ≤ IVL≤ 5mA

VCS= 0

CONDITIONS

mA1OCO Sink Current

µA1ODO Off-Leakage Current

mA1ODO Sink Current

µA-1 1OCI, ODI Input Offset Current

mV-10 10OCI, ODI Input Offset Voltage

49,250 50,750

counts/

sec

012

Charge Coulomb-Counter

Accumulation Rate

counts/

sec

012

Discharge Coulomb-Counter

Accumulation Rate

µA

135

I

BATT

BATT Supply Current

V428V

BATT

BATT Input Voltage Range

µV/µA50REF Load Regulation

V1.96 2.04V

REF

REF Output Voltage

30

1

V

3.1 3.4

V

VL

VL Output Voltage

3.1 3.6

UNITSMIN TYP MAXSYMBOLPARAMETER

V

ODO

= 28V µA1OCO Off-Leakage Current

ELECTRICAL CHARACTERISTICS

(V

SHDN

= V

BATT

= 12V, V

SCL

= V

SDA

= 3.6V, C

REF

= 10nF, CVL= 0.1µF, TA= -40°C to +85°C, unless otherwise noted.) (Note 2)

SUPPLY AND REFERENCES

FUEL GAUGE

OVERCURRENT COMPARATOR

*

Patent pending

Page 4

*

Patent pending

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

4 _______________________________________________________________________________________

V

TH1

, VL rising

VVL= 3V, I

SINK

= 1.2mA

CONDITIONS

VVL= 1V, I

SINK

= 50µA

V

TH2

, VL falling

2.75 3.05

V

1.0 2.2

0.3

V

0.3

V

RST

RST Output Voltage

V

TH1

,

V

TH2

RST Threshold Voltage

UNITSMIN TYP MAXSYMBOLPARAMETER

SHDN forced to 28V

SHDN forced to 3.6V

Output forced to 5V

V

INT

= 0.4V

V

SDA

= 0.6V

SHDN

SCL, SDA

SHDN, SCL, SDA

120

µA

3.0

I

SHDN

SHDN Input Bias Current

µA1

SCL, SDA, INT, RST Leakage

Current

mA2V

OL

INT, RST Output Low Sink Current

mA6V

OL

SDA Output Low Sink Current

0.6

V

0.8

V

IL

Input Low Voltage

V2.2V

IH

Input High Voltage

ELECTRICAL CHARACTERISTICS (continued)

(V

SHDN

= V

BATT

= 12V, V

SCL

= V

SDA

= 3.6V, C

REF

= 10nF, CVL= 0.1µF, TA= -40°C to +85°C, unless otherwise noted.) (Note 2)

TIMING CHARACTERISTICS

(TA= 0°C to +85°C, unless otherwise noted.)

CONDITIONS

µs4.7t

SU:STA

Start-Condition Setup Time

µs4.7t

LOW

µs4t

HIGH

SCL Serial-Clock High Period

SCL Serial-Clock Low Period

µs4t

HD:STA

Start-Condition Hold Time

ns800t

SU:DAT

SDA Valid to SCL Rising-Edge Setup

Time, Slave Clocking in Data

ns0t

HD:DAT

SCL Falling Edge to SDA Transition

µs1t

DV

SCL Falling Edge to SDA Valid, Master

Clocking in Data

UNITSMIN TYP MAXSYMBOLPARAMETER

INTERFACE-LOGIC LEVELS

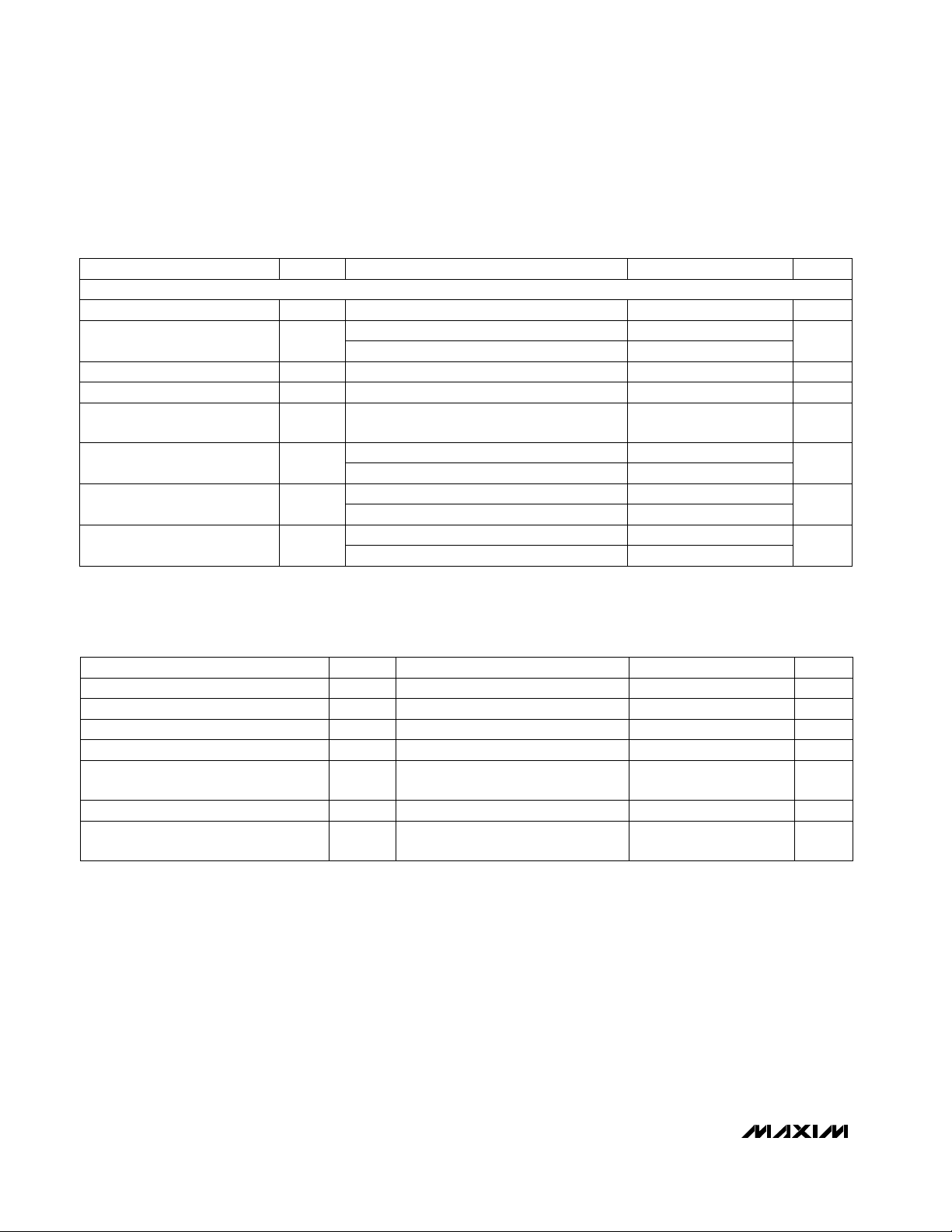

Page 5

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

_______________________________________________________________________________________ 5

SCL

START

CONDITION

t

HIGH

SDA

t

LOW

t

HD:STA

t

SU:STA

t

SU:DAT

t

HD:DAT

t

SU:DAT

t

HD:DAT

MOST SIGNIFICANT ADDRESS BIT

(A6) CLOCKED INTO SLAVE

A5 CLOCKED

INTO SLAVE

A4 CLOCKED

INTO SLAVE

A3 CLOCKED

INTO SLAVE

Note 1: OCI and ODI are MOSFET inputs. Minimum and maximum limits are for production screening only. Actual performance is

indicated in typical value.

Note 2: Specifications to -40°C are guaranteed by design, not production tested.

CONDITIONS

µs1t

DV

SCL Falling Edge to SDA Valid, Master

Clocking in Data

ns0t

HD:DAT

SCL Falling Edge to SDA Transition

ns800t

SU:DAT

SDA Valid to SCL Rising-Edge Setup

Time, Slave Clocking in Data

µs4t

HD:STA

Start-Condition Hold Time

µs4.7t

SU:STA

Start-Condition Setup Time

µs4.7t

LOW

SCL Serial-Clock Low Period

µs4t

HIGH

SCL Serial-Clock High Period

UNITSMIN TYP MAXSYMBOLPARAMETER

TIMING CHARACTERISTICS

(TA= -40°C to +85°C, unless otherwise noted.) (Note 2)

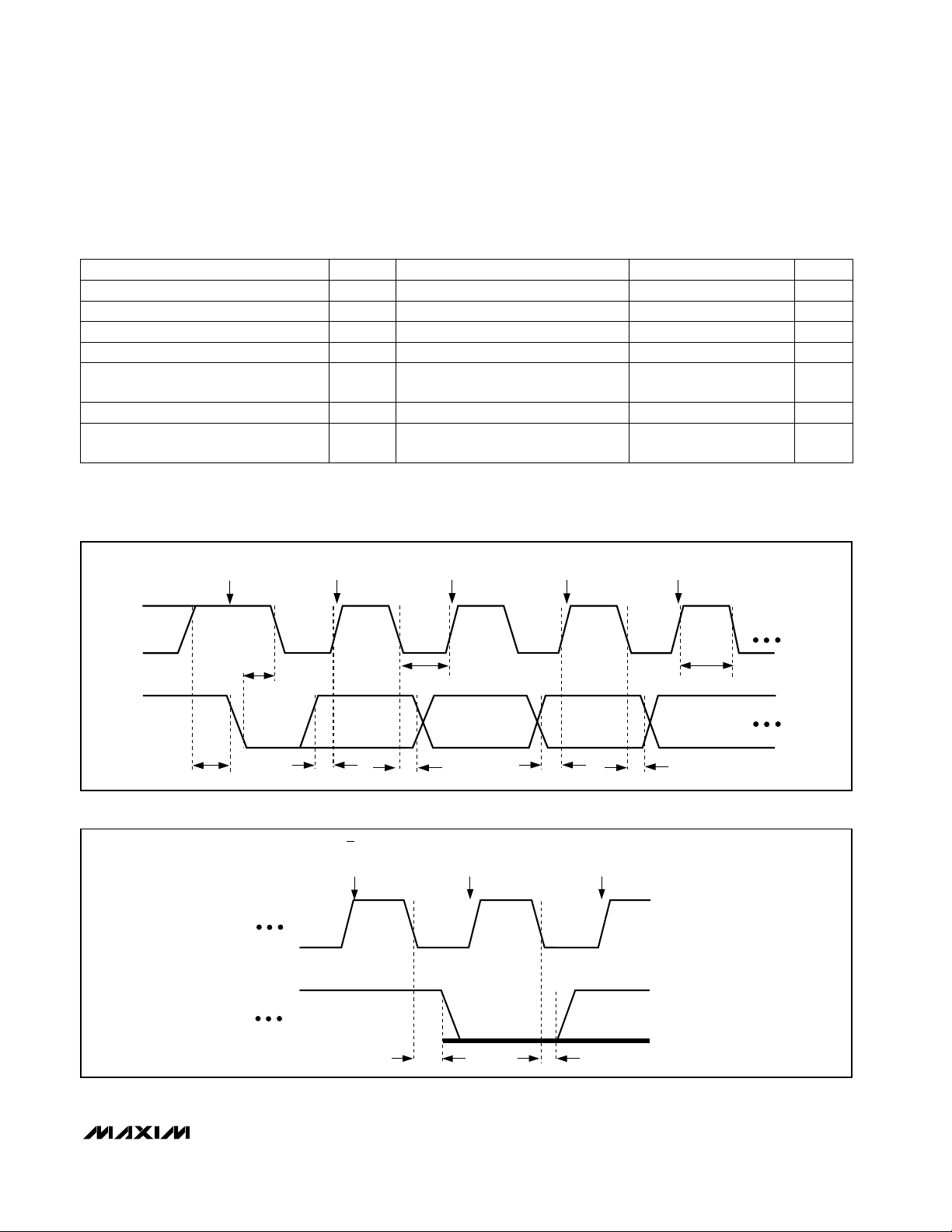

Figure 1. SMBus Serial-Interface Timing—Address

SCL

RW BIT

CLOCKED

INTO SLAVE

SDA

t

DV

t

DV

ACKNOWLEDGE

BIT CLOCKED

INTO MASTER

SLAVE PULLING

SDA LOW

MOST SIGNIFICANT BIT

OF DATA CLOCKED

INTO MASTER

Figure 2. SMBus Serial-Interface Timing—Acknowledge

*

Patent pending

Page 6

*

Patent pending

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

6 _______________________________________________________________________________________

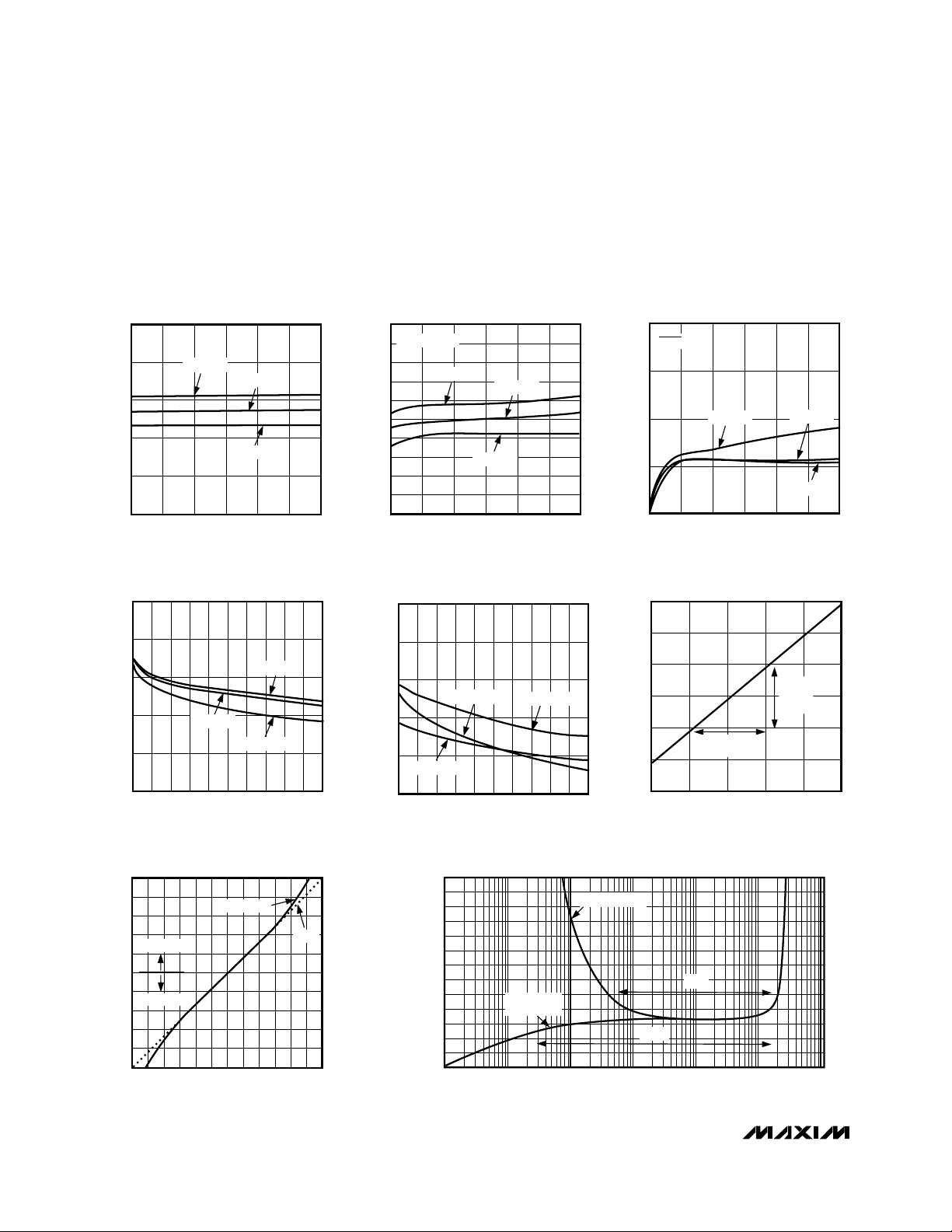

__________________________________________Typical Operating Characteristics

(V

BATT

= V

SHDN

= 12V, C

REF

= 10nF, CVL= 0.1µF, TA= +25°C, unless otherwise noted.)

50

60

70

80

90

100

412816202428

SUPPLY CURRENT vs. V

BATT

MAX1660-01

V

BATT

(V)

SUPPLY CURRENT (µA)

TA = +85°C

TA = +25°C

TA = -40°C

10

12

11

14

13

16

15

18

19

17

20

412816202428

SHUTDOWN SUPPLY CURRENT

vs. V

BATT

MAX1660-02

V

BATT

(V)

SUPPLY CURRENT (µA)

SOFTSHDN = 1

TA = -40°C

TA = +25°C

TA = +85°C

0.01

0.02

0.03

0.04

0.05

412816202428

SHUTDOWN SUPPLY CURRENT

vs. V

BATT

MAX1660-03

V

BATT

(V)

SUPPLY CURRENT (µA)

TA = +25°C

TA = +85°C

SHDN = GND

T

A

= -40°C

3.15

3.18

3.21

3.24

3.27

3.30

0 1.5 2.00.5 1.0 2.5 3.0 3.5 4.0 4.5 5.0

VL VOLTAGE vs. VL LOAD CURRENT

MAX1660-04

LOAD CURRENT (mA)

VL VOLTAGE (V)

TA = +25°C

TA = +85°C

TA = -40°C

1.994

1.996

1.998

2.000

2.002

2.004

0608020 40 100 120 140 160 180 200

REFERENCE VOLTAGE

vs. REFERENCE LOAD CURRENT

MAX1660 05

LOAD CURRENT (µA)

VOLTAGE (V)

TA = +25°C

TA = +85°C

TA = -40°C

-4

-2

0

2

6

4

8

-15 -5-10 0 5 10

FREQUENCY vs. INPUT VOLTAGE

MAX1660-06

INPUT VOLTAGE (µV)

FREQUENCY (Hz)

INPUT

OFFSET

FREQUENCY

INPUT OFFSET

VOLTAGE

150

90

120

60

0

30

120

90

60

30

150

-360

-120

0

-240

120 240 360

FREQUENCY vs. INPUT VOLTAGE

MAX1660-07

INPUT VOLTAGE (mV)

FREQUENCY (kHz)

IDEAL

MEASURED

CHGCOUNT

DISCOUNT

456

404

0.001 0.01 0.1 1 10 100 1000

CONVERSION GAIN vs. INPUT VOLTAGE

416

412

408

MAX1660-08

INPUT VOLTAGE (mV)

CONVERSION GAIN (Hz/mV)

424

420

436

432

428

448

444

440

452

*SEE INTERNAL OFFSET MEASUREMENT SECTION

OFFSET

CORRECTED*

275:1

6000:1

UNCORRECTED*

Page 7

_______________Detailed Description

The MAX1660 measures the cumulative charge into

(charging) and out of (discharging) the system battery

pack and stores the information in one of two internal,

independent charge and discharge counters. It

achieves battery-pack overcharge and overdischarge

protection through a powerful digital compare function

that interrupts the host CPU when the charge or discharge counter reaches a host-programmed value. The

device also informs the host of changes in the direction

of current flow and protects the battery pack from

short-circuit and overcurrent conditions.

The MAX1660 incorporates a 2-wire System Management Bus (SMBus™)-compliant serial interface,

allowing access to charge/discharge counters and

internal registers. An optional third wire provides an

SMBALERT#-compliant interrupt signal, or it may be used

as a simple, stand-alone host interrupt.

Coulomb-Counting Interface

The MAX1660’s Coulomb-counting interface monitors

the charge flowing in either the charging or discharging

direction, and counts the Coulombs of charge by incrementing either the charge counter (CHGCOUNT) or the

discharge counter (DISCOUNT) accordingly. The number of counter increments generated per Coulomb of

charge sensed (conversion gain) is given by the following equation:

where RCSis the current-sense resistor (see the

Typical

Operating Circuit

). The gain factor is the constant of

proportionality that relates the counter values stored in

CHGCOUNT and DISCOUNT to the amount of charge

flow into or out of the battery pack. A higher conversion

gain (larger RCS) increases resolution at low currents,

A = 416.7 10 R

Counts

Coulomb

CCS

3

⋅

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

_______________________________________________________________________________________________________ 7

______________________________________________________________Pin Description

NAME FUNCTION

1

INT

Open-Drain Host-Interrupt Output. INT sinks current when active, otherwise high-impedance (see

INT

Output

section). INT is compatible with the SMBus SMBALERT# (the “#” indicates asserted low) signal.

Connect a 100kΩ pull-up resistor between INT and VL. Leave INT unconnected if host interrupt is not used.

2

SHDN

Active-Low Shutdown Input (see

Shutdown Modes

section)

PIN

3 N.C. No Connection. Not internally connected.

4 CS Current-Sense Resistor Input

8 OCI Charge Overcurrent-Detection Input (see

Overcurrent Detection

section)

7 ODI Discharge Overcurrent-Detection Input (see

Overcurrent Detection

section)

6 REF

2.00V Reference Output. Bypass REF to AGND with a 10nF capacitor (see

Internal Regulator and Reference

section).

5 AGND Analog Ground

13 OCO

High-Voltage, Open-Drain MOSFET Gate-Driver Output. OCO controls activation of the battery-charge path

(see

OCO and ODO Gate Drivers

section).

12 ODO

High-Voltage, Open-Drain MOSFET Gate-Driver Output. ODO controls activation of the battery-discharge

path (see

OCO and ODO Gate Drivers

section).

11 BATT Supply Input

10 VL

3.3V Linear-Regulator Output. Bypass VL with a 0.33µF capacitor to GND (see

Internal Regulator and

Reference

section).

9 GND Ground

16 SCL Serial-Clock Input. Connect a 10kΩ resistor between SDA and VL (see

SMBus Interface

section).

15 SDA Serial-Data Input/Output. Connect a 10kΩ resistor between SDA and VL (see

SMBus Interface

section).

14

RST

Active-Low Reset Output. Connect a 100kΩ pull-up resistor between RST and VL. Leave RST unconnected

if the power-on reset function is not used (see

RST Output

section).

*

Patent pending

Page 8

MAX1660

*

but limits the maximum measurable current. Likewise, a

smaller conversion gain (smaller RCS) decreases resolution at low currents, but increases the maximum measurable current. A 30mΩ current-sense resistor (AC=

12.5 x 103counts per Coulomb) provides a good balance between resolution and input current range for

many applications. With this current-sense resistance,

the MAX1660 typically measures currents from 600µA to

4A with better than 1% accuracy (see the section

Choosing R

CS

).

Charge and Discharge Counters

Figure 3 shows the functional diagram of the MAX1660’s

Coulomb-counter section. The Coulomb counter’s output increments (but never decrements) one of two independent 32-bit counters: CHGCOUNT for charging

currents, and DISCOUNT for discharging currents. By

independently counting the charge and discharge currents, the MAX1660 can accommodate any algorithm to

account for a battery pack’s energy-conversion efficiency. A 2x1 multiplexer, gated by the configuration word’s

SETCOUNT bit, determines which counter’s contents

are passed to the COUNT register when COUNT

updates. The 32-bit COUNT register is divided into

4 bytes: COUNT0 (the least significant) through

COUNT3 (the most significant). See Table 1 for a

description of the different registers.

CHGCOUNT and DISCOUNT reset to zero whenever a

power-on reset executes, or when the configuration

word’s CLRCOUNTER bit is set. Each counter also

resets any time an overflow condition occurs. The counters’ 32-bit capacity allows them to continually monitor

4A for almost 24 hours before overflowing (with RCS=

30mΩ). When a counter overflows, it simply clears and

begins counting from 0; no interrupts are generated.

Execute the ReadCount01 and ReadCount23 commands to read the active counter’s contents at any time

(Table 2). Since the Read-Word protocol supports only

16-bit data transfers, issue these commands sequentially to read the entire 32-bit COUNT register. First

issue ReadCount01 to read COUNT0 and COUNT1,

and then issue ReadCount23 to read COUNT2 and

COUNT3. Executing ReadCount01 enables updating of

the COUNT register; the COUNT register updates on

SCL’s falling edge after the command-byte ACK bit

Digitally Controlled

Fuel-Gauge Interface

8 _______________________________________________________________________________________

*

Patent pending

2 x 1 MUX

CHGCOUNT DISCOUNT

DIRINTENABLE

SETCOUNT

COUNTSTATUS

LATCH

LOGIC

ReadCount01

ReadCount23

CLRCOUNTER

DIRCHANGE

OFFSETMEAS CHARGESTATUS

8888

888

32

MUXOUT

32

32

8

SMB INTERFACE

COUNT0COUNT1COUNT2COUNT3

COULOMB

COUNTER

Figure 3. Coulomb Counter Functional Diagram

REGISTER NAME DESCRIPTION

CHGCOUNT

The 32-bit counter that accumulates the number of units of charge that have passed through RCSin the charging direction since CHGCOUNT was last cleared. CHGCOUNT clears on a power-on reset, or when the configuration word’s CLEARCOUNTER bit is set. CHGCOUNT is unaffected by discharging currents.

DISCOUNT

The 32-bit counter that accumulates the number of units of charge that have passed through RCSin the discharging direction since DISCOUNT was last cleared. DISCOUNT clears on a power-on reset, or when the

configuration word’s CLEARCOUNTER bit is set. DISCOUNT is unaffected by charging currents.

COUNT

The 32-bit register that stores the value held in the counter selected by the configuration word’s SETCOUNT bit

when updating has been enabled by the ReadCount01 command. Data transfers to COUNT from the selected

CHGCOUNT or DISCOUNT register whenever the MAX1660’s SMBus interface detects a new command. See

the

Charge and Discharge Counters

section.

COMP

The 32-bit register that stores the host-defined COUNT threshold. The contents of COMP are continuously compared with the contents of either CHGCOUNT or DISCOUNT (whichever is selected by the SETCOUNT bit) for

equality. When an equality occurs, the configuration word’s COMPSTATUS bit is set, and an interrupt is generated (INT goes low).

Table 1. Register Descriptions

Page 9

clocks in (Figure 4). COUNT0 returns in the least significant byte (LSB), and COUNT1 returns in the most significant byte (MSB) of the Read-Word protocol. After

the ReadCount01 command is executed (updating is

enabled), any command executed by the MAX1660

prior to execution of the ReadCount23 command

updates the COUNT contents, potentially corrupting the

data read by ReadCount23 (if a 16th-bit carry occurs).

ReadCount23 disables COUNT updating and then

returns COUNT2 and COUNT3 in the Read-Word protocol’s LSB and MSB. To ensure proper execution, issue

these commands in the correct order, with no commands executed between them (ReadCount01 first, followed by ReadCount23).

Digital Compare Function

The MAX1660’s digital compare function simplifies

implementation of end-of-charge and end-of-discharge

detection, relieving the host from having to constantly

monitor the counters. The host simply programs a value

into the COMP register, and the MAX1660 generates an

interrupt (INT goes low) when this condition is met.

Figure 5 shows the MAX1660’s digital compare section

functional diagram. When the digital compare function

is enabled, the MAX1660 continuously compares the

contents of the counter selected by the configuration

word’s SETCOUNT bit with the 32-bit word stored in the

COMP register (Table 1). The 32-bit COMP register is

divided into 4 bytes: COMP0 (the least significant)

through COMP3 (the most significant). When COMP is

equal to MUXOUT, the configuration word’s COMPSTATUS bit is set, and the MAX1660 generates an interrupt

(INT goes low). The host defines any action taken as a

result of this interrupt. The COMP register contents

remain valid until either the host redefines the value

stored in COMP, or a power-on reset is executed.

Executing a power-on reset disables the digital compare function. Enable the digital compare function by

setting the configuration word’s COMPENABLE bit.

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

_______________________________________________________________________________________ 9

*

Patent pending

COUNT

REGISTER

UPDATED

SCL

SDA

ANY

COMMAND

BYTE

MAX1660

PULLING

SDA LOW

ACKNOWLEDGE

BIT CLOCKED

INTO MASTER

Figure 4. COUNT Register Updating

COMMAND

NAME

DESCRIPTION

ReadCount01

Enables updating of the COUNT register; returns COUNT0 in the LSB and COUNT1 in the MSB of

the Read-Word protocol. COUNT updating remains enabled until the ReadCount23 command is

executed. See the

Charge and Discharge Counters

section.

ReadCount23

Disables COUNT register updating; returns COUNT2 in the LSB and COUNT3 in the MSB of the

Read-Word protocol. See the

Charge and Discharge Counters

section.

ReadStatus()

Returns the status word’s contents in the Read-Word protocol’s LSB. The MSB’s contents are all 1s.

See Table 5 for a description of the status bits.

COMMAND

CODE

0x82

0x83

0x84

Table 2. Read Word Commands

Q

32 32

D

DIGITAL

COMPARE

CLR

OCSTATUS

ODSTATUS

CLRINT

POWER-ON RESET

COMPSTATUS

DIRCHANGE

INT

COULOMB

COUNTER

MUXOUT

COMP0COMP1

DIRINTENABLE

COMP2COMP3

CHG

DIS

8888

SMB INTERFACE

Figure 5. Digital Compare Section Functional Diagram

Page 10

MAX1660

*

Use the WriteComp01 and WriteComp23 commands to

define the COMP register contents (Table 3). Since the

Write-Word protocol supports only 16-bit data transfers,

sequentially execute these commands to write the

entire 32-bit COMP word. First execute WriteComp01

to write COMP0 and COMP1, and then execute

WriteComp23 to write COMP2 and COMP3. Executing

WriteComp01 internally disables the COMPINT interrupt

and writes the Write-Word protocol’s LSB into COMP0

and its MSB into COMP1. The COMPINT interrupt disables on SCL’s 18th rising edge during WriteComp01

execution (Figure 6). Executing WriteComp23 writes the

Write-Word protocol’s LSB and MSB into COMP2 and

COMP3, and enables the COMPINT interrupt. The

COMPINT interrupt reenables on the falling edge following SCL’s 36th rising edge during WriteComp23

execution. Disabling the COMPINT interrupt with the

WriteComp01 command prevents an erroneous interrupt, due to incomplete data in the COMP register. To

ensure proper execution, issue these commands in the

correct sequence.

Direction-Change Detection Function

The MAX1660’s direction-change detection function

informs the host whenever the current flow changes

direction. When it is used in conjunction with the

MAX1660’s digital compare function and CHARGESTATUS bit in end-of-charge and end-of-discharge

detection routines, the host can ensure that the digital

compare function continues to monitor the proper

counter when the current flow changes direction.

The direction-change function is simple: the status

word’s DIRCHANGE bit sets any time the current flow

changes direction. Once DIRCHANGE is set, it remains

set until it is cleared; additional changes in the currentflow direction do not affect the bit. To clear the DIRCHANGE bit, write a 1 to the configuration word’s

CLRINT bit. DIRCHANGE also clears when the

MAX1660 enters soft-shutdown mode and after a

power-on reset. In end-of-charge and end-of-discharge

routines, in which the host must be informed immediately of a change in current-flow direction, set the configuration word’s DIRINTENABLE bit to generate an interrupt

whenever the status word’s DIRCHANGE bit is set.

Digitally Controlled

Fuel-Gauge Interface

10 ______________________________________________________________________________________

COMMAND

NAME

DESCRIPTION

WriteComp01

Disables the COMPINT interrupt; writes the Write-Word protocol’s LSB into COMP0 and its MSB into

COMP1.

WriteComp23

Writes the Write-Word protocol’s LSB into COMP2 and its MSB into COMP3, and enables the

COMPINT interrupt.

WriteConfig()

Writes the Write-Word protocol’s data bytes into the configuration word. See Table 6 for a description of the configuration bits.

COMMAND

CODE

0x00

0x01

0x04

Table 3. Write-Word Commands

SCL

SDA

BOLD LINE INDICATES MAX1660

PULLING SDA LOW

STOP

CONDITION

ACK BIT CLOCKED

INTO HOST

18TH RISING EDGE OF

SCL DURING WriteComp01

WRITE-WORD PROTOCOL

STOP

CONDITION

INTERRUPT

ENABLES ON

SCL’s FALLING

EDGE

ACK BIT CLOCKED

INTO HOST

36TH RISING EDGE OF

SCL DURING WriteComp23

WRITE-WORD PROTOCOL

INTERRUPT

DISABLES ON

SCL’s RISING

EDGE

Figure 6. Automatic Interrupt Enable/Disable During COMP Update

*

Patent pending

Page 11

Overcurrent Detection

The MAX1660’s precision analog interface continuously

monitors the input current to detect an overcurrent condition. Figure 7 shows the functional diagram of the

overcurrent comparator section.

An overcurrent condition occurs whenever the voltage

on CS exceeds the voltage on OCI (for charging currents), or when ODI falls below ground (for discharging

currents). When an overcurrent condition occurs, the

overcurrent comparators generate an interrupt (INT

goes low) and set the OD (discharging) or OC (charging) latch, which remains set until either the configuration word’s CLRINT bit is set, the MAX1660 enters softshutdown mode, or the MAX1660 initiates a power-on

reset. The host defines any action taken upon receipt of

this interrupt. A logic block follows the latch, which sets

the gate-driver output’s appropriate state, as defined in

Table 4, and drives the N-channel MOSFET open-drain

gate drivers.

Although the host has complete control over the

MAX1660’s response to an overcurrent condition, take

care to ensure adequate overcurrent protection. In general, the configuration word’s OCLO and ODLO bits

should

always

remain cleared. This ensures that either

the MAX1660 will be in overcurrent auto-detect mode

(the power-on-reset state), or the external FETs are

forced off (the load is disconnected). Regardless of the

OCLO and ODLO bit settings, the MAX1660 interrupts

the host (INT goes low) if the current flow exceeds the

overcurrent threshold.

When OCHI = OCLO = 1 or ODHI = ODLO = 1, the corresponding overcurrent comparator operates in freerunning mode, driving OCO and ODO directly. When

the current exceeds the overcurrent threshold, the

appropriate MOSFET turns off, and when the current

is below the overcurrent threshold, it turns on. Forcing

the MOSFET off prevents current from flowing, which in

turn decreases the current flow to below the overcurrent threshold. A persistent overcurrent condition,

therefore, produces a pulsed output as the current flow

repeatedly crosses the overcurrent threshold. In freerunning mode, INT pulls low when the first overcurrent

condition occurs, and stays low until the interrupt is

cleared, as described in the

INT Output

section.

Operation in this mode requires that OCO and ODO

be buffered to ensure fast MOSFET turn-off and slow

MOSFET turn-on times. The relatively slow turn-off

response of the OCO and ODO open-drain outputs

alone is unsuitable for driving MOSFETs directly in this

mode.

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

______________________________________________________________________________________ 11

+

-

ODI

S

R

Q

ODO LOGIC

ODO

ODSTATUS

ODICMP

POWER-ON

RESET

ODLO

CLRINT

ODHI

+

-

OCI

CS

S

R

Q

OCO LOGIC

OD

OC

OCO

OCSTATUS

OCICMP

a) DISCHARGING DIRECTION

b) CHARGING DIRECTION

POWER-ON

RESET

OCLO

CLRINT

OCHI

Figure 7. Overcurrent Comparator Section Functional Diagram

*

Patent pending

Page 12

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

12 ______________________________________________________________________________________

MAX1660

BATT

CS

AGND

REF

OCI

ODI

GND

SCL

SDA

SHDN

OCO

VL

GPIO

GPIO

GPIO

R9

R7

R8

M1M2

R10

R2

+

R

CS

C3

C2

C5

R5 R3

R6 R4

C4

R11

C1

D1

R14R13 R15 R16

SDA

SCL

SERIAL

EEPROM

V

CC

V

CC

RST

GND

GND

PACK-

PACK+

µC

INT

RST

INT

ODO

Figure 8. Typical Application Circuit

Table 4a. OCO Logic Truth Table

Table 4b. ODO Logic Truth Table

OCHI BIT OCLO BIT OCSTATUS BIT OCO OUTPUT STATE

0 0 0 GND Automatic overcurrent protection (default)

0 0 1 HI-Z Overcurrent detected

0 1 X GND Force-charge path on

1 0 X HI-Z Force-charge path off

1 1 X OCICMP Free running

1 1 X ODICMP Free running

ODHI BIT ODLO BIT ODSTATUS BIT ODO OUTPUT STATE

0 0 0 GND Automatic overcurrent protection (default)

0 0 1 HI-Z Overcurrent detected

0 1 X GND Force-discharge path on

1 0 X HI-Z Force-discharge path off

*

Patent pending

Page 13

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

______________________________________________________________________________________ 13

OCO and ODO Gate Drivers

OCO and ODO are open-drain N-channel MOSFET outputs that drive the external P-channel MOSFET gates.

Connect pull-up resistors in the 500kΩ to 1MΩ range

from OCO and ODO to BATT to reduce current draw

when OCO and ODO are driven low. For additional protection of OCO and ODO from voltage spikes coupled

through the MOSFET gate capacitance, place 10kΩ

resistors (R9 and R10) from OCO and ODO to the

respective MOSFET gates (Figure 8). To protect the

battery pack and load during power-up, OCO and

ODO are forced into a high-Z state during the poweron-reset timeout period. Table 4 shows the truth tables

defining the OCO and ODO output states with respect

to the overcurrent comparators and the MAX1660’s

configuration bits.

INT

Output

The MAX1660’s INT output drives an optional third wire

that interrupts the host whenever an alert condition

occurs. The MAX1660’s host-interrupt procedure is

compatible with the SMBus SMBALERT# signal, but it is

equally useful as a simple host-interrupt output.

By default, an interrupt is triggered (INT is pulled low) any

time an overcurrent condition occurs (see the

Overcurrent

Detection

section). The MAX1660 may also be configured

to generate an interrupt whenever a digital compare

equality occurs and/or when a change in the current-flow

direction is detected (see the

Digital Compare Function

and

Direction-Change Detection Function

sections).

Once triggered, INT stays low until the interrupt is

cleared. An interrupt is cleared when one of three conditions is true: a 1 is written into the configuration

word’s CLRINT bit, the MAX1660 acknowledges the

SMBus Alert Response Address (ARA), or a power-on

reset occurs. The MAX1660 acknowledges the ARA

with the 0 x 8F byte.

INT is an open-drain output; connect a 100kΩ pull-up

resistor between INT and VL.

Alert Response Address (0001100)

The Alert Response address provides quick fault identification for single slave devices that lack the complex,

expensive logic needed to be a BusMaster.

When a slave device generates an interrupt, the host

(BusMaster) interrogates the bus slave devices via a

special receive-byte operation that includes the Alert

Response address. The data returned by this read-byte

operation is the address of the interrupting slave

device. The MAX1660 when interrupted, will respond

with 0x8F.

RST

Output

RST is an open-drain, active-low power-on reset output

provided for the MAX1660’s host controller and other

external circuitry. RST drives low on power-up whenever the MAX1660 enters hard-shutdown mode, or whenever the VL regulator output is below V

TH1

(typically

1.7V). In hard-shutdown mode, RST goes low and

remains low as long as the VL regulator provides sufficient gate drive to the RST output switch (typically until

VL falls to 1V), after which RST drifts slightly upward.

On power-up or when exiting hard-shutdown mode,

RST drives low until 25ms (typ) after VL exceeds V

TH2

(typically 2.9V). Although RST offers a reliable poweron reset function, it does not detect brownout conditions (V

TH1

< VL < V

TH2

). For applications that require

brownout detection, refer to Maxim’s complete line of

precision microprocessor supervisory products.

Connect a 100kΩ pull-up resistor between RST and VL.

Leave RST unconnected if the power-on reset function

is not used.

Internal Regulator and Reference

The 3.3V VL internal linear regulator powers the

MAX1660 control circuitry, logic, and reference, and

can supply up to 5mA to power external loads, such as

a microcontroller or other circuitry. Bypass VL to GND

with a 0.33µF capacitor.

The 2.00V precision reference (REF) is accurate to

±2%, making it useful as a system reference. REF can

supply up to 200µA to external circuitry. Bypass REF to

GND with a 10nF capacitor.

Shutdown Modes

Hard Shutdown

Driving SHDN low puts the MAX1660 into hard-shutdown mode and forces the power-on reset state. In

hard-shutdown mode, the VL regulator and the reference turn off, reducing supply current to 1µA (max). To

protect the battery pack and load during the power-onreset timeout period, the OCO and ODO outputs are

forced into their high-Z states. SHDN is a logic-level

input, but can be safely driven by voltages up to V

BATT

.

Soft Shutdown

Drive the MAX1660 into soft-shutdown mode by setting

the configuration word’s SHDNSTATUS bit. All interrupts

clear in soft-shutdown mode. In this mode, only the VL

regulator and the SMBus interface remain active, reducing the supply current to just 15µA.

To prevent current from flowing undetected while the

MAX1660 remains in soft-shutdown mode, ensure that

the command to enter soft-shutdown mode contains a

*

Patent pending

Page 14

low byte of 0xA (ODHI = OCHI = 1, ODLO = OCLO

= 0) to force the FETs off and disconnect the load. The

MAX1660 does not perform a power-on reset when

exiting soft-shutdown mode.

SMBus Interface

The MAX1660’s 2-wire serial interface is compatible

with Intel’s SMBus interface. An interrupt output (INT)

allows the MAX1660 to immediately interrupt its host in

the event of an overcurrent condition. This interrupt

complies with the SMBALERT# signal of the SMBus

specification. Although each of the MAX1660’s pins are

designed to protect against ±2kV ESD strikes, SDA and

SCL pins have extended ESD-protection structures

designed to provide protection for ±4kV ESD.

The MAX1660 operates as an SMBus slave only, never

as a master. It does not initiate communication on the

bus; it only receives commands and responds to

queries for status information. Although the MAX1660

offers the host an array of configuration commands,

providing complete control over many of its functions, it

performs its functions automatically. The host needs to

communicate with the MAX1660 only to retrieve data

and change configurations as necessary.

Each communication with the MAX1660 begins with a

start condition, defined as a falling edge on SDA with

SCL high. The device address follows the start condition. The MAX1660 device address is fixed at

0b1000111 (where 0b indicates a binary number),

which may also be denoted as 0x8E (where 0x indicates a hexadecimal number) for Read-Word commands, or 0x8F for Write-Word commands. Figure 9

shows examples of SMBus Write-Word and Read-Word

protocols.

ReadStatus() Command

The host determines the MAX1660’s status by executing the ReadStatus() command. This command returns

the MAX1660’s status, including the state of its interrupts, as well as the present direction of current flow.

Table 5 describes each of the status word’s bits.

Status information is retrieved from the MAX1660 using

the Read-Word protocol; however, the device’s flexible

implementation of the SMBus standard also allows the

Receive-Byte protocol to be substituted when status is

being read. When the MAX1660 receives a command,

its command code is latched, remaining valid until it is

overwritten by a new command code. When status

information is repeatedly being read, polling time can

be significantly decreased by using the Receive-Byte

protocol to read the status word’s LSB after the initial

ReadStatus() command.

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

14 ______________________________________________________________________________________

SLAVE ADDRESS

WRITE-WORD PROTOCOL

SCL

SDA

SCL

SDA

READ-WORD PROTOCOL

BOLD LINE INDICATES THAT

MAX1660 PULLS SDA LOW

COMMAND CODEWr A A

SLAVE ADDRESS COMMAND CODEWr A A

LEAST SIGNIFICANT BYTE A MOST SIGNIFICANT BYTE A

SLAVE ADDRESS Rd A

LEAST SIGNIFICANT BYTE A MOST SIGNIFICANT BYTE A

STOP

REPEATED

START

STOP

ACK

START START

ACK

D8

D9

D10

D11

D12

D13

D14

D15

ACK

D0

D1

D2

D3

D4

D5

D6

D7

ACK

CMD0

CMD1

CMD2

CMD3

CMD4

CMD5

CMD6

CMD7

W

1

1

1

0

0

0

1

ACK

ACK

CMD0

CMD1

CMD2

CMD3

CMD4

CMD5

CMD6

CMD7

W

1

1

1

0

0

0

1

ACK

ACK

D8

D9

D10

D11

D12

D13

D14

D15

ACK

D0

D1

D2

D3

D4

D5

D6

D7

R

1

1

1

0

0

0

1

Figure 9. Write-Word and Read-Word Examples

*

Patent pending

Page 15

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

______________________________________________________________________________________ 15

WriteConfig() Command

The host configures the MAX1660 using the

WriteConfig() command. Table 6 describes each of the

configuration word’s bits.

Applications Information

Choosing R

CS

For greatest accuracy, choose RCSto ensure that the

product of the maximum current to be measured (I

MAX

)

and RCSdoes not exceed 120mV. Calculate the proper

sense-resistor value as follows:

where I

MAX

is the maximum current to be accurately

measured. Use only surface-mount metal-film resistors;

wire-wound resistors are too inductive to provide ac-

ceptable results. Be sure to consider power dissipation

when choosing the current-sense resistor to avoid

resistor self-heating.

Setting the Overcurrent Threshold

Set the current at which the voltage on CS exceeds the

voltage on OCI with a voltage divider placed between

REF and GND (Figure 10a). To set the overcharge

threshold, choose R5 in the 1MΩ range and calculate

R6 from:

where V

REF

= 2.00V, I

CHG,MAX

is the maximum allowable charging current, and RCSis the current-sense

resistor value.

R6 =

R5

V

IR

- 1

REF

CHG,MAX CS

R =

120mV

I

CS

MAX

Table 5. ReadStatus() Bit Functions

Unused. Always returns 1.—0—

The bit sets when the current flow changes direction. This bit clears when the

configuration word’s CLRINT or SOFTSHDN bit is set, or following a power-on

reset. See

Direction-Change Detection Function

section.

01DIRCHANGE

Charge-Status Indicator. This bit sets upon detection of charging current. The

bit clears upon detection of discharging current.

02CHARGESTATUS

Soft-Shutdown Status Indicator. Returns 1 when the device is in soft-shutdown

mode; returns 0 when it is not in soft-shutdown mode.

03SHDNSTATUS

SETCOUNT Status Indicator. This bit sets when the configuration word’s

SETCOUNT bit is set. This bit clears when SETCOUNT clears.

—4COUNTSTATUS

COMPINT-Interrupt Status. This bit sets upon generation of the COMPINT

interrupt. This bit clears in soft shutdown, on a power-on reset, or when the

configuration word’s CLRINT bit is set.

05COMPSTATUS

Overcurrent-Interrupt Status. This bit sets when an overcurrent condition

occurs in the charging direction. This bit clears in soft shutdown, following a

power-on reset, or when the configuration word’s CLRINT bit is set.

06OCSTATUS

Overcurrent-Interrupt Status. This bit sets when an overcurrent condition

occurs in the discharging direction. This bit clears in soft shutdown, following a

power-on reset, or when the configuration word’s CLRINT bit is set.

07ODSTATUS

Unused. Always returns 1.18—

Unused. Always returns 1.19—

Unused. Always returns 1.110—

Unused. Always returns 1.111—

Unused. Always returns 1.112—

Unused. Always returns 1.113—

Unused. Always returns 1.114—

Unused. Always returns 1.115—

DESCRIPTION

POWER-ON

RESET STATE

BIT

POSITION

BIT NAME

*

Patent pending

Page 16

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

16 ______________________________________________________________________________________

MAX1660

REF

OCI

CS

C5

R6

R5

AGND

MAX1660

REF

ODI

AGND

C4

R3

R4

R

CS

a) CHARGING CURRENTS

b) DISCHARGING CURRENTS

TO BATT-

GND

Figure 10. Overcurrent-Detection Networks

Table 6. WriteConfig() Bit Functions

Second of two bits controlling OCO output state. To ensure proper overcurrent

protection, OCLO should always remain cleared. See the

Overcurrent

Detection

section.

00OCLO

First of two bits controlling OCO output state. See the

Overcurrent Detection

section.01OCHI

Second of two bits controlling the ODO output state. To ensure proper overcurrent protection, ODLO should always remain cleared. See the

Overcurrent

Detection

section.

02ODLO

First of two bits controlling the ODO output state. See the

Overcurrent Detection

section.

03ODHI

the Compare-Interrupt Enable. Set this bit to enable the digital compare function.

Clear this bit to disable this function. See the

Digital Compare Function

section.

04COMPENABLE

Offset-Measurement Enable. Set this bit to disconnect CS from the external

circuitry and internally short it to AGND. Clear this bit to reconnect CS to the

external circuitry and resume normal operation. See the

Internal Offset

Measurement

section.

05OFFSETMEAS

Counter Selection. Selects which counter is multiplexed to COUNT. Set this bit

to select the charge counter. Clear this bit to select the discharge counter. See

the

Charge and Discharge Counters

section.

06SETCOUNT

Clear Interrupts. Write 1 to clear ODSTATUS, OCSTATUS, COMPSTATUS, and

DIRCHANGE.

—7CLRINT

Clear Counter. Write 1 to clear both CHGCOUNT and DISCOUNT.—8CLRCOUNTER

Soft-Shutdown Enable. Set this bit to enable soft shutdown. Clear this bit to

resume normal operation. See the

Shutdown Modes

section.

09SOFTSHDN

Direction-Change Interrupt Enable. Set this bit to enable direction-change

interrupt generation. Clear this bit to disable this function. See the

Direction-

Change Detection Function

section.

010DIRINTENABLE

Unused—11—

Unused—12—

Unused—13—

Unused—14—

Unused —15—

DESCRIPTION

POWER-ON

RESET STATE

BIT

POSITION

BIT NAME

*

Patent pending

Page 17

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

______________________________________________________________________________________ 17

Set the current at which the ODI voltage falls below

AGND with a voltage divider placed between REF and

CS (Figure 10b). To set the overdischarge threshold,

choose R3 in the 1MΩ range, then calculate R4 from:

where V

REF

= 2.00V, I

DISCHG,MAX

is the maximum

allowable discharging current, and RCSis the currentsense resistor value.

Lowpass filter the ODI and OCI inputs with C4 and C5

(Figure 10) to prevent short current pulses from tripping

the overcurrent thresholds. Use the smallest capacitances that provide the desired filtering; large capacitances slow the MAX1660’s response to overcurrent

conditions.

Internal Offset Measurement

Although the MAX1660 has extremely low input offset

error, some low-current, high-precision applications

may require accounting for this offset. Set the configuration word’s OFFSETMEAS bit to disconnect the

Coulomb-counter input from the external circuitry and

internally short it to AGND. Subtract the resulting offset

current from succeeding measurements to correct for

the internal offset.

Clear OFFSETMEAS to resume normal operation. Note

that since the Coulomb-counting circuitry is disconnected from the current-sense resistor during this measurement, currents that flow through the sense resistor when

OFFSETMEAS is set do not increment the counters.

Ensure that the command to measure the internal offset

contains a low byte of 0xA (ODHI = OCHI = 1, ODLO =

OCLO = 0) to force the FETs off and disconnect the

load. Although the MAX1660 cannot perform its

Coulomb-counting function while in offset-measurement

mode, the overcurrent comparators are still active.

Improving Measurement Accuracy

Filtering the Input

Place a 100Ω resistor (R2) between RCSand the CS pin,

and bypass CS to AGND with a 0.1µF capacitor (C3), as

shown in Figure 11. To minimize leakage errors due to

finite trace-to-trace resistance, place both filter components, as well as C5, as close to the CS pin as possible.

Minimizing SMBus Activity

Although proper layout minimizes coupling from the

digital data lines to the high-resolution analog interface,

the MAX1660’s analog interface may still detect switching noise in low-current, high-precision applications. In

such applications, it may be advantageous to use the

MAX1660’s digital compare function to limit activity on

the digital data lines during the measurement. By

removing the requirement that the host poll the

MAX1660 to determine when a counter has reached

the desired value, the MAX1660 requires no digital

switching while it accumulates sensitive data. See

Digital Compare Function

section.

Exiting Hard-Shutdown Mode

In most applications, hard-shutdown mode is used only

when the battery pack has become fully discharged, at

which point the pack’s load current must be minimized

to prevent cell overdischarge. When the MAX1660’s

host is powered from VL, which turns off in hardshutdown mode, the host is unable to signal the

MAX1660 to exit hard-shutdown mode. Figure 8’s circuit demonstrates a simple topology that handles this

situation.

During normal operation, the external MOSFETs M1

and M2 conduct so that V

SHDN

is pulled up to V

BATT

. If

M1 is forced off, however, the voltage at SHDN falls

toward ground. To ensure that the signal at SHDN is a

logic high, one of the host’s GPIO lines is programmed

high at all times and is connected to SHDN through

diode D1. This diode protects the GPIO pin from voltages at PACK+ that exceed the VL voltage. To command the MAX1660 to enter hard-shutdown mode, the

host simply turns MOSFET M1 off and drives the GPIO

line low, allowing the MAX1660’s SHDN to fall. Once in

hard-shutdown mode, the MAX1660 cannot wake up

until a valid supply voltage is applied to PACK+ (i.e.,

when the battery is connected to a charger), pulling

SHDN high through R11.

Layout Considerations

Use care during board layout to obtain the MAX1660’s

full precision over a wide range of input currents.

Proper board layout minimizes the noise coupled to the

analog sections from both high-current traces and digital switching. Use a star ground configuration and route

the SCL and SDA lines away from CS and AGND.

Lowpass filter the Coulomb-counter input by placing a

100Ω resistor between RCSand CS, and bypass CS to

AGND with a 0.1µF ceramic capacitor. To reduce leakage errors due to finite trace-to-trace resistance, place

both filter components as close to the IC as possible.

Use a Kelvin connection to obtain accurate measurements when large currents are flowing (Figure 11).

Bypass REF to AGND with a 10nF ceramic capacitor

placed as close to the IC as possible. Bypass VL to

GND with a 0.33µF capacitor, also placed as close to

the IC as possible. Refer to the MAX1660 evaluation kit

layout for an example of proper board layout.

R4 = R3

IR

V

DISCHG,MAX CS

REF

*

Patent pending

Page 18

___________________Chip Information

TRANSISTOR COUNT: 9078

SUBSTRATE CONNECTED TO GND

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

18 ______________________________________________________________________________________

KELVIN CONNECTION

REDUCES ERROR

DUE TO TRACE RESISTANCE

SHORT, COMPACT PLACEMENT OF

LOWPASS FILTER COMPONENTS

REDUCES HIGH-FREQUENCY NOISE AND

TRACE-TO-TRACE LEAKAGE ERROR.

CS

CURRENT-SENSE

RESISTOR (R

CS

)

WIDE, HIGH CURRENT TRACE

WIDE, HIGH CURRENT TRACE

THIN, LOW CURRENT TRACES

AGND

GND

MAIN CURRENT PATH

MAX1660

R2

100Ω

70nF

C3

0.1µF

C5

Figure 11. Proper Layout for Current-Sense Input

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

INT SCL

SDA

RST

OCO

ODO

BATT

VL

GND

TOP VIEW

MAX1660

QSOP

SHDN

N.C.

REF

CS

AGND

ODI

OCI

Pin Configuration

*

Patent pending

Page 19

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

______________________________________________________________________________________ 19

*

Patent pending

Digitally Controlled

Fuel-Gauge Interface

________________________________________________________Package Information

QSOP.EPS

Page 20

MAX1660

*

Digitally Controlled

Fuel-Gauge Interface

20 ______________________________________________________________________________________

*

Patent pending

NOTES

Loading...

Loading...