Page 1

MAX1617

SMBus Temperature Sensor

with Internal and External

Diode Input

The MAX1617 is a serially programmable temperature sensor

optimized for monitoring modern high performance CPUs with

on–board, integrated temperature sensing diodes. Temperature data is

converted from the CPU’s diode outputs and made available as an

8–bit digital word.

Communication with the MAX1617 is accomplished via the

standard System Management Bus (SMBus) commonly used in

modern computer systems. This permits reading the current

internal/external temperature, programming the threshold setpoints,

and configuring the device. Additionally, an interrupt is generated on

the ALERT pin when temperature moves outside the preset threshold

windows in either direction.

A Standby command may be sent via the SMBus by signaling the

STBY input to activate the low–power Standby mode. Registers can

be accessed while in Standby mode. Address selection inputs allow up

to nine MAX1617s to share the same 2–wire SMBus for multi–zone

monitoring.

All registers can be read by the host, and both polled and interrupt

driven systems are easily accommodated. Small size, low installed

cost, and ease of use make the MAX1617 an ideal choice for

implementing sophisticated system management schemes, such as

ACPI.

Features

• Includes Internal and External Sensing Capability

• Outputs T emperature As 8–Bit Digital Word

• Solid State T emperature Sensing; 1°C Resolution

• 3.0 — 5.5V Operating Range

• Independent Internal and External Threshold Set–Points With

ALERT Interrupt Output

• SMBus 2–Wire Serial Interface

• Up T o 9 MAX1617s May Share the Same Bus

• Low Standby Power Mode

• Low Power: 70 µA (max) Operating, 10 µA (max) Standby Mode

• 16–Pin Plastic QSOP Package

• Operating T emperature Range: –55°C to +125°C

http://onsemi.com

16–Pin QSOP

DB SUFFIX

PRELIMINARY INFORMATION

ADD1

ORDERING INFORMATION

Device Package Shipping

MAX1617DBR2 16–Pin QSOP 2500 Tape/Reel

CASE TBD

PIN CONFIGURATION

(Top View)

NC

V

DD

D

D

NC

GND

GND

+

–

1

2

3

4

MAX1617

5

6

7

8

16

15

14

13

12

11

10

9

NC

STBY

SCL

NC

SDA

ALERT

ADD0

NC

Typical Applications

• Thermal Protection For Intel “Deschutes” Pentium II and Other

High Performance CPUs with Integrated On–Board Diode - No

Sensor Mounting Problems!

• Accurate T emperature Sensing From Any Silicon Junction Diode

• Thermal Management in Electronic Systems: Computers, Network

Equipment, Power Supplies

Semiconductor Components Industries, LLC, 1999

February , 2000 – Rev. 0

1 Publication Order Number:

MAX1617/D

Page 2

MAX1617

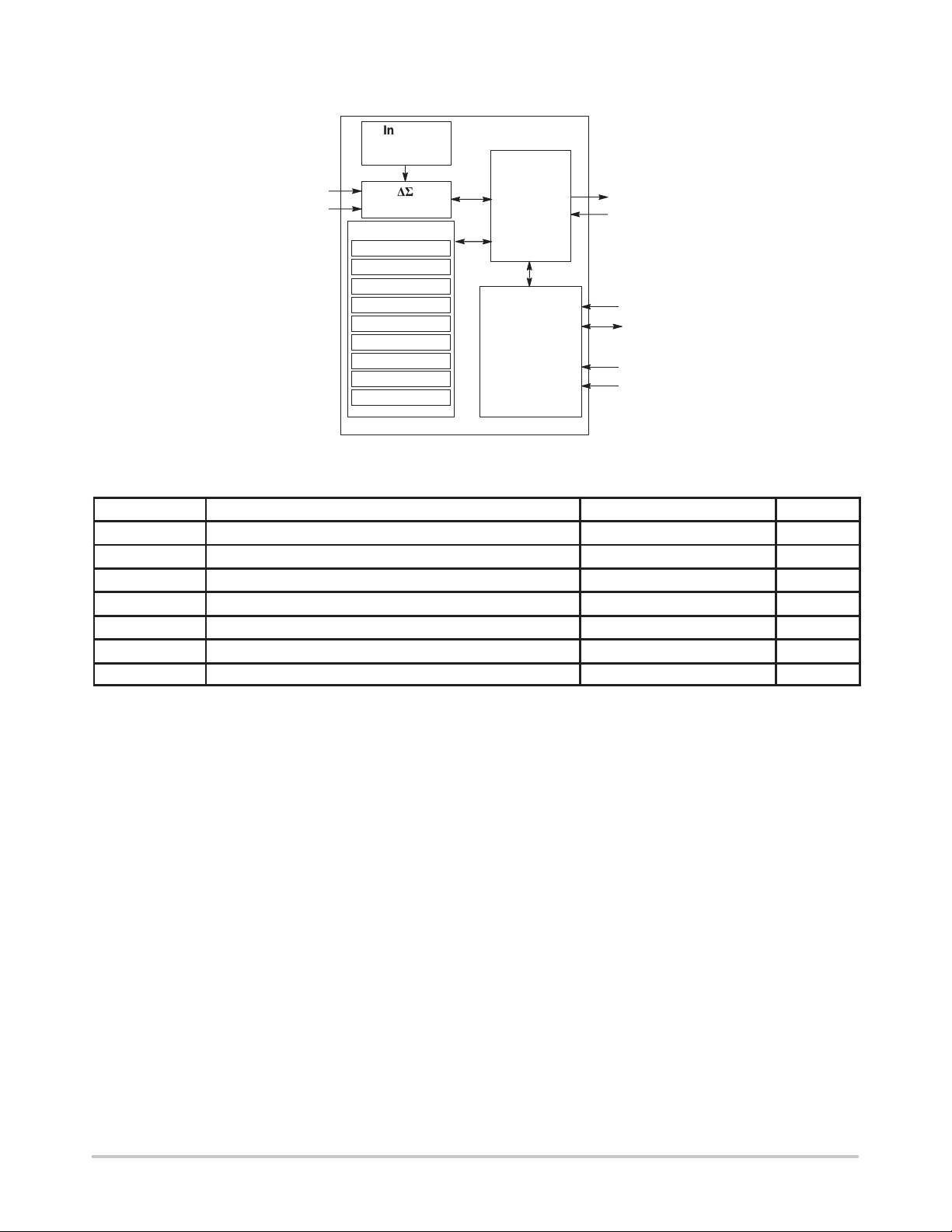

FUNCTIONAL BLOCK DIAGRAM

Internal

Sensor

(Diode)

+

D

–

D

ABSOLUTE MAXIMUM RATINGS*

Symbol Parameter Value Unit

V

DD

T

A

T

stg

P

D

* Maximum Ratings are those values beyond which damage to the device may occur.

Power Supply Voltage 6.0 V

Voltage on Any Pin (GND – 0.3 V) to (VDD + 0.3 V) V

Operating Temperature Range –55 to +125 °C

Storage Temperature Range –65 to +150 °C

SMBus Input/Output Current –1 to +50 mA

D– Input Current ±1 mA

Maximum Power Dissipation 330 mW

DS

Modulator

Register Set

Int. Temp

Ext.Temp

Status Byte

Config. Byte

Conv. Rate

Ext. Hi Limit

Ext. Lo Limit

Int. Hi Limit

Int. Lo Limit

Control

Logic

SMBus

Interface

ALERT

STBY

SCL

SDA

ADD 0

ADD 1

http://onsemi.com

2

Page 3

MAX1617

PIN DESCRIPTION

Pin No. Symbol Type Description

2

3

4

6, 10

7, 8

11

12

14

15

1, 5, 9, 13, 16

SCL

Input. SMBus serial clock. Clocks data into and out of the

MAX1617.

SDA

Bi–directional. Serial data is transferred on the SMBus in

both directions using this pin.

ADD1, ADD0

Inputs. Sets the 7–bit SMBus address. These pins are

“tri–state,” and the SMBus addresses are specified in the

Address Decode Table below.

(NOTE: The tri–state scheme allows up to nine

MAX1617s on a single bus. A match between the

MAX1617’s address and the address specified in the serial

bit stream must be made to initiate communication. Many

SMBus–compatible devices with other addresses may share

the same 2–wire bus. These pins are only active at power–on

reset, and will latch into the appropriate states.

ALERT

Output, Open Collector, Active Low. The ALERT output

corresponds to the general SMBALER T signal and indicates

an interrupt event. The MAX1617 will respond to the

standard SMBus Alert Response Address when ALERT is

asserted. Normally , the ALERT output will be asserted when

any of the following occurs:

INT_TEMP equal to or exceeds INT_HLIM

INT_TEMP falls below INT_LLIM

EXT_TEMP equal to or exceeds EXT_HLIM

EXT_TEMP falls below EXT_LLIM

External Diode “Open”

The operation of the ALERT output is controlled by the

MASK1 bit in the CONFIG register . If the MASK1 bit is set

to “1,” no interrupts will be generated on ALERT. The

ALERT output is cleared and re–armed by the Alert

Response Address (ARA). This output may be

WIRE–ORed with similar outputs from other SMBus

devices. If the alarm condition persists after the ARA, the

ALERT output will be immediately re–asserted.

V

DD

+

D

–

D

ADD[1:0]

GND

ALERT

SDA

SCL

STBY

NC

Power

Bi–Directional

Bi–Directional

Input

Power

Output

Bi–Directional

Input

Input

—

Power Supply Input

Current Source and A/D Positive Input

Current Sink and A/D Negative Input

Address Select Pins (See Address Decode Table)

System Ground

SMBus Interrupt (SMBALERT) or Comparator Output

SMBus Serial Data

SMBus Serial Clock

Standby Enable

Not Connected

PIN DESCRIPTION

(NOTE: A pull–up resistor is necessary on ALERT since

it is an open–drain output. Current sourced from the pull–up

resistor causes power dissipation and may cause internal

heating of the MAX1617. T o avoid affecting the accuracy of

internal temperature readings, the pull–up resistors should

be made as large as possible.)

STBY

Input. The activation of Standby mode may be achieved

using either the STBY pin or the CHIP STOP bit (CONFIG

register). If STBY is pulled low, the MAX1617

unconditionally enters its low–power Standby mode. The

temperature–to–digital conversion process is halted, but

ALERT remains functional. The MAX1617’s bus interface

remains active, and all registers may be read from and

written to normally. The INT_TEMP and EXT_TEMP

registers will contain whatever data was valid at the time of

Standby. (Transitions on SDA or SCL due to external bus

activity may increase the Standby power consumption.)

+

D

Bi–directional. this pin connects to the anode of the

external diode and is the positive A/D input. Current is

injected into the external diode from the MAX1617, and the

temperature proportional V

digital temperature data.

—

D

Bi–directional. This pin connects to the cathode of the

external diode. Current is sunk from the external diode into

the MAX1617 through this pin. It also is the negative input

terminal to the MAX1617’s A/D converter . This node is kept

at approximately 0.7V above GROUND.

V

DD

Input. Power supply input. See electrical specifications.

GND

Input. Ground return for all MAX1617 functions.

is measured and converted to

BE

http://onsemi.com

3

Page 4

MAX1617

DC ELECTRICAL CHARACTERISTICS (VDD = 3.3 V, –55°C ≤ TA ≤ 125°C, unless otherwise noted.)

Symbol

Power Supply

V

DD

V

UV–LOCK

V

POR

I

DD

I

DD

I

DD–STANDBY

I

DD–STANDBY

I

ADD–BIAS

ALERT Output

V

OL

ADD[1:0] Inputs

V

IL

V

IH

STBY Input

V

IL

V

IH

Temp–to–Bits Converter

T

RES

T

IERR

T

EERR

I

DIODE–HIGH

I

DIODE–LOW

V

D–SOURCE

t

CONV

D

CR

2–Wire SMBus Interface

V

IH

V

IL

V

OL

C

IN

I

LEAK

1. Operating current is an average value (including external diode injection pulse current) integrated over multiple conversion cycles. Transient

current may exceed this specification.

2. For true recurring conversion time see Conversion Rate register description.

3. Output current should be minimized for best temperature accuracy. Power dissipation within the MAX1617 will cause self–heating and

temperature drift error.

Power Supply Voltage 3.0 — 5.5 V

VDD Undervoltage Lockout Threshold 2.4 2.80 2.95 V

Power–On Reset Threshold (VDD Falling Edge) 1.0 1.7 2.3 V

Operating Current

0.25 Conv./Sec Rate SMBus Inactive

Operating Current

2 Conv./Sec Rate SMBus Inactive

Standby Supply Current (SMBus Active) — — 100

Standby Supply Current (SMBus Inactive) — — 10

ADD[1:0] Bias Current (Power–Up Only) — 160 —

Output Low Voltage (IOL = 1.0 mA)

Logic Input Low — — VDD x 0.3 V

Logic Input High VDD x 0.7 — — V

Logic Input Low — — VDD x 0.3 V

Logic Input High VDD x 0.7 — — V

Basic Temperature Resolution — 1.0 — °C

Internal Diode Temperature

+60°C ≤ TA ≤ +100°C

0°C ≤ TA ≤ +125°C

–55°C ≤ TA ≤ 0°C

External Diode Temperature

+60°C ≤ TA ≤ +100°C

0°C ≤ TA ≤ +125°C

–55°C ≤ TA ≤ 0°C

External Diode High Source Current

(D+) – (D–) ~ 0.65 V

External Diode Low Source Current

(D+) – (D–) ~ 0.65 V

Source Voltage — 0.7 — V

Conversion Time

From CHIP STOP to Conv. Complete

Conversion Rate Accuracy

(See Conversion Rate Register Desc.)

Logic Input High 2.2 — — V

Logic Input Low — — 0.8 V

SDA Output Low

IOL = 2 mA

IOL = 4 mA

Input Capacitance SDA, SCL — 5.0 — pF

I/O Leakage –1.0 0.1 1.0

(3)

(3)

Characteristic Min Typ Max Unit

m

m

m

m

m

°C

°C

m

m

m

A

A

A

A

A

A

A

V

A

(3)

(1)

(1)

(2)

— — 70

— — 180

— — 0.4 V

–2

–3

—

–3

–5

—

— 100 —

— 10 —

54 83 112 msec

–35 — +35 %

—

—

—

—

±3

—

—

±5

—

—

+2

+3

—

+3

+5

—

0.4

0.6

http://onsemi.com

4

Page 5

MAX1617

SMBus PORT AC TIMING (VDD = 3.3 V, –55°C ≤ (TA = TJ) ≤ 125°C; CL = 80 pF, unless otherwise noted.)

Symbol

f

SMB

t

LOW

t

HIGH

t

R

t

F

t

SU(START)

t

H(START)

t

SU–DATA

t

H–DATA

t

SU(STOP)

t

IDLE

SMBus Clock Frequency 10 — 100 kHz

Low Clock Period (10% to 10%) 4.7 — —

High Clock Period (90% to 90%) 4 — —

SMBus Rise Time (10% to 90%) — — 1,000 nsec

SMBus Fall Time (90% to 10%) — — 300 nsec

Start Condition Setup Time (90% SCL to 10% SDA)

(for Repeated Start Condition)

Start Condition Hold Time 4 — —

Data in Setup Time 1,000 — — nsec

Data in Hold Time 1,250 — — nsec

Stop Condition Setup Time 4 — —

Bus Free Time Prior to New Transition 4.7 — —

SMBUS Write Timing Diagram

AB C DEF G HIJKLM

I

LOWIHIGH

Characteristic Min Typ Max Unit

4 — —

m

m

m

m

m

m

sec

sec

sec

sec

sec

sec

SCL

SDA

t

SU(START)tH(START)

t

A = Start Condition

B = MSB of Address Clocked into Slave

C= LSB of Address Clocked into Slave

D= R/W

Bit Clocked into Slave

E = Slave Pulls SDA Line Low

SMBUS Read Timing Diagram

AB C DEF G HI JK

I

LOWIHIGH

SCL

SDA

t

SU(START)tH(START)

t

SU–DATA

F = Acknowledge Bit Clocked into Master

G= MSB of Data Clocked into Slave

H= LSB of Data Clocked into Slave

I = Slave Pulls SDA Line Low

SU–DATA

t

H–DATA

t

SU(STOP)tIDLE

J = Acknowledge Clocked into Master

K = Acknowledge Clock Pulse

L = Stop Condition, Data Executed by Slave

M= New Start Condition

t

SU(STOP)tIDLE

A = Start Condition

B = MSB of Address Clocked into Slave

C= LSB of Address Clocked into Slave

Bit Clocked into Slave

D= R/W

E = Slave Pulls SDA Line Low

F = Acknowledge Bit Clocked into Master

G= MSB of Data Clocked into Master

H= LSB of Data Clocked into Master

http://onsemi.com

5

I = Acknowledge Clock Pulse

J = Stop Condition

K = New Start Condition

Page 6

MAX1617

DET AILED OPERATING DESCRIPTION

The MAX1617 acquires and converts temperature

information from two separate sources, both silicon junction

diodes, with a basic accuracy of ±1°C. One is located on the

MAX1617 die; the other is connected externally. The

external diode may be located on another IC die. The

analog–to–digital converter on the MAX1617 alternately

converts temperature data from the two sensors and stores

them separately in internal registers.

The system interface is a slave SMBus port with an

ALERT (SMBALERT) interrupt output. The interrupt is

triggered when one or more of four preset temperature

thresholds are tripped (see Figure 1). These four thresholds

are user–programmable via the SMBus port. Additionally,

the temperature data can be read at any time through the

SMBus port. Nine SMBus addresses are programmable for

the MAX1617, which allows for a multi–sensor

configuration. Also, there is low–power Standby mode

where temperature acquisition is suspended.

STANDBY MODE

The MAX1617 allows the host to put it into a low power

(I

= 10 µA, max) Standby mode. In this mode, the A/D

DD

converter is halted, and the temperature data registers are

frozen. The SMBus port operates normally. Standby mode

can be enabled with either the STBY input pin or the CHIP

STOP bit in the CONFIG register. The following table

summarizes this operation.

Standby Mode Operation

STBY Chip Stop Bit One Shot? Operating

Mode

0 Don’t Care Don’t Care Standby

1 0 Don’t Care Normal

1 1 No Standby

1 1 Yes Normal (1

Conversion

Only, then

Standby)

EXT_TEMP

INT_TEMP

ASSERT

ALERT

ASSERT

ASSERT

ASSERT

TEMPERATURE

ALERT

Note: This diagram implies that the appropriate setpoint is moved,

temporarily, after each ALERT event to suppress re–assertion

of ALERT immediately after the ARA/de–assertion.

ALERT

ALERT

TIME

ALERT

EXT_HLIM

INT_HLIM

EXT_LLIM

INT_LLIM

SETPOINTS

Figure 1. T emperature vs. Setpoint Event Generation

SMBus SLAVE ADDRESS

The two pins ADD1 and ADD0 are tri–state input pins

which determine the 7–bit SMBus slave address of the

MAX1617. The address is latched during POR.

Address Decode T able

ADD0 ADD1 SMBus Address

0 0 001 1 000

0 open (3–state) 0011 001

0 1 001 1 010

open (3–state) 0 0101 001

open (3–state) open (3–state) 0101 010

open (3–state) 1 0101 011

1 0 1001 100

1 open (3–state) 1001 101

1 1 1001 1 10

http://onsemi.com

6

Page 7

POR*, initialize

all registers

STBY mode

active?

NO

Start internal

conversion

STATUS [D7]

YES

STBY

active?

NO

NO

EOC*?

YES

YES

YES

released?

STATUS D[7]

NO

STBY

Update

INT_TEMP

MAX1617

Stop conv.,

reset

One

shot?

NO

Perform one

conversion

cycle

YES

Monitor SMBus

for STAR T

condition

READ

NO

NO

YES

STATUS

read?

NO

WRITE

Read/

Write?

YES

Valid

command?

Execute

Status read

and clear

STATUS

Execute

SMBus

read

Execute

SMBus

write

YES

Rest

period

over?

NO

YES

One Shot?

NO

Rest Period

according to

CONV_RATE

register

Start external

conversion

STBY

active?

Ext. diode

open?

NO

EOC*?

Update

EXT_TEMP

Thermal

Reset

STATUS

bit D[7]

YES

Trip?

NO

NO

NO

NO

Thermal

YES

YES

YES

Set appropriate

STATUS bit

D[6:2]

Trip?

NO

YES

CONFIG

[D7] active?

Enable

ALERT#

YES

Address

match?

YES

NO

ARA*?

YES

ALERT

active ?

YES

ARA* bus

arbitration?

Win

arbitration?

NO

YES

Disable and re–arm

ALERT, send

local address to host

* POR = Power On Reset; ARA = Alert Response Address; EOC = End Of Conversion

Figure 2. MAX1617 Functional Description Flowchart

http://onsemi.com

7

Page 8

MAX1617

Serial Port Operation

The Serial Clock input (SCL) and bi–directional data port

(SDA) form a 2–wire bi–directional serial port for

programming and interrogating the MAX1617. The

following conventions are used in this bus architecture. (See

SMBus Write/Read Timing Diagram.)

All transfers take place under control of a host, usually a

CPU or microcontroller, acting as the Master, which

provides the clock signal for all transfers. The MAX1617

always operates as a slave. The serial protocol is illustrated

in Figure 3. All data transfers have two phases; all bytes are

transferred MSB first. Accesses are initiated by a start

condition (START), followed by a device address byte and

one or more data bytes. The device address byte includes a

Read/Write selection bit. Each access must be terminated by

a Stop Condition (STOP). A convention called

Acknowledge (ACK) confirms receipt of each byte. Note

that SDA can change only during periods when SCL is LOW

(SDA changes while SCL is High are reserved for Start and

Stop conditions.)

MAX1617 Serial Bus Conventions

T erm

Transmitter The device sending data to the bus.

Receiver The device receiving data from the bus.

Master The device which controls the bus: initiating

Slave The device addressed by the master.

Start A unique condition signaling the beginning

Stop A unique condition signaling the end of a

ACK A receiver acknowledges the receipt of

Busy Communication is not possible because

NOT Busy When the bus is idle, both SDA and SCL

Data V alid The state of SDA must remain stable dur-

Explanation

transfers (START), generating the clock, and

terminating transfers (STOP).

of a transfer indicated by SDA falling (High

— Low) while SCL is high.

transfer indicated by SDA rising (Low —

High) while SCL is high.

each byte with this unique condition. The

receiver drives SDA low during SCL high

of the ACK clock–pulse. The Master provides the clock pulse for the ACK cycle.

the bus is in use.

will remain high.

ing the High period of SCL in order for a

data bit to be considered valid. SDA only

changes state while SCL is low during normal data transfers (see Start and Stop

conditions).

Start Condition (START)

The MAX1617 continuously monitors the SDA and SCL

lines for a start condition (a High to Low transition of SDA

while SCL is High), and will not respond until this condition

is met. (See SMBus Write/Read Timing Diagram.)

Address Byte

Immediately following the Start Condition, the host must

transmit the address byte to the MAX1617. The states of

ADD1 and ADD0 during power–up determine the 7–bit

SMBus address for the MAX1617. The 7–bit address

transmitted in the serial bit stream must match for the

MAX1617 to respond with an Acknowledge (indicating the

MAX1617 is on the bus and ready to accept data). The eighth

bit in the Address Byte is a Read–Write Bit. This bit is 1 for

a read operation or 0 for a write operation.

Acknowledge (ACK)

Acknowledge (ACK) provides a positive handshake

between the host and the MAX1617. The host releases SDA

after transmitting eight bits, then generates a ninth clock

cycle to allow the MAX1617 to pull the SDA line Low to

acknowledge that it successfully received the previous eight

bits of data or address.

Data Byte

After a successful ACK of the address byte, the host must

transmit the data byte to be written or clock out the data to

be read. (See the appropriate timing diagrams.) ACK will be

generated after a successful write of a data byte into the

MAX1617.

Stop Condition (STOP)

Communications must be terminated by a stop condition

(a Low to High transition of SDA while SCL is High). The

Stop Condition must be communicated by the transmitter to

the MAX1617. (See SMBus Write/Read T iming Diagram.)

http://onsemi.com

8

Page 9

MAX1617

Write Byte Format

S ADDRESS WR ACK

7 Bits

Slave Address Command Byte: selects Data Byte: data goes

Read Byte Format

S ADDRESS WR ACK

7 Bits

Slave Address Command Byte: selects

Send Byte Format Receive Byte Format

S ADDRESS WR ACK

7 Bits

S = Start Condition

P = Stop Condition

Shaded = Slave Transmission

COMMAND RD NACK

8 Bits

which register you

reading from.

COMMAND

8 Bits

Command Byte: sends

command with no data,

usually used for one–shot

command.

Figure 3. SMBus Protocols

REGISTER SET AND PROGRAMMER’S MODEL

MAX1617 Command Set

The MAX1617 supports four SMBus command

protocols. These are READ_BYTE, WRITE_BYTE,

SEND_BYTE, and RECEIVE_BYTE. See System

Management Bus Specification Rev. 1.0 for details.

Command Byte Description

Command Code Function

RIT 00h Read Internal Temp (INT_TEMP)

RET 01h Read External Temp (EXT_TEMP)

RS 02h Read Status Byte (STATUS)

RC 03h Read Configuration Byte (CONFIG)

RCR 04h Read Conversion Rate Byte

RIHL 05h Read Internal High Limit (INT_HLIM)

RILL 06h Read Internal Low Limit (INT_LLIM)

REHL 07h Read External High Limit (EXT_HLIM)

RELL 08h Read External Low Limit (EXT_LLIM)

WC 09h Write Configuration Byte (CONFIG)

WCR 0Ah Write Conversion Rate Byt3

WIHL 0Bh Write Internal High Limit (INT_HLIM)

WILL 0Ch Write Internal Low Limit (INT_LLIM)

WEHL 0Dh Write External High Limit (EXT_HLIM)

WELL 0Eh Write External Low Limit (EXT_LLIM)

OSHT 0Fh One Shot Temp Measurement

RMID FEh Read Manufacturer ID (MFR_ID)

RMREV FFh Read Manufacturer Revision Number

NOTE: Proper device operation is NOT guaranteed if undefined

locations (10h to FDh) are addressed. In case of erroneous SMBus

operation (RECEIVE_BYTE command issued immediately after

WRITE_BYTE command) the MAX1617 will ACKnowledge the

address and return 1111 1111b to signify an error. Under no condition

will it implement an SMBus “timeout.”

(CONV_RATE)

(CONV_RATE)

(MFR_REV)

COMMAND DATA P

8 Bits

which register you

writing to.

ACK ACK

S ADDRESS

7 Bits

Slave Address: repeated

due to change in data–

flow direction.

PACK

ACK ACK

8 Bits

into the register set

by the command byte.

DATA

8 Bits

Data Byte: reads from

the register set by the

command byte.

ACK

7 Bits

P

DATARD NACKS ADDRESS

8 Bits

Data Byte: reads data from

the register commanded by

the last Read Byte.

P

http://onsemi.com

9

Page 10

MAX1617

Configuration Register (Config), 8–Bits,

Read/Write

Configuration Register (Config)

D[7] D[6] D[5] D[4] D[3] D[2] D[1] D[0]

Mask1 Chip Stop Reserved

Bit POR State Function Operation

D[7] 0 Interrupt Mask

(see text)

D[6] 0 Standby switch 1 = standby,

D[5]—D[0] 0 Reserved —

Always returns

zero when read.

1 = mask ALERT

0 = don’t mask

ALERT

0 = normal

N/A

A/D Conversion Rate Register (CONV_RATE),

8–Bits, Read/Write

A/D Conversion Rate Register (CONV_RATE)

D[7] D[6] D[5] D[4] D[3] D[2] D[1] D[0]

Reserved MSB X LSB

Bit POR State Function Operation

D[7:3] 0 Reserved — Always

D[2:0] 010b Conversion rate bits. See below.

returns zero when

read.

A/D Conversion Rate Selection

D2 D1 D0 Conversion Rate Samples/sec

0 0 0 0.0625

0 0 1 0.125

0 1 0 0.25

0 1 1 0.5

1 0 0 1.0

1 0 1 2.0

1 1 0 4.0

1 1 1 8.0

NOTE: Conversion rate denotes actual sampling of both internal

and

external sensors.

N/A

The value is in 2’s–complement binary format such that a

reading of 00000000b corresponds to 0°C. Examples of this

temperature–to–binary value relationship are shown in the

following table.

T emperature–to–Digital Value Conversion (INT_TEMP,

EXT_TEMP, INT_HLIM, INT_LLIM,EXT_HLIM,

EXT_LLIM)

Actual

Temperature

+130.00°C +127°C 01111111 7F

+127.00°C +127°C 01111111 7F

+126.50°C +127°C 01111111 7F

+25.25°C +25°C 00011001 19

+0.50°C +1°C 00000001 01

+0.25°C 0°C 00000000 00

0.00°C 0°C 00000000 00

—0.25°C 0°C 00000000 00

—0.50°C 0°C 00000000 00

—0.75°C —1°C 11111111 FF

—1.00°C —1°C 11111111 FF

—25.00°C —25°C 11100111 E7

—25.25°C —25°C 11100110 E7

—54.75°C —55°C 11001001 C9

—55.00°C —55°C 11001001 C9

—65.00°C —65°C 10111111 BF

Rounded

Temperature

Binary

Value

Hex

Value

Temperature Threshold Setpoint Registers,

8–Bits, Read–Write (INT_HLIM, INT_LLIM,

EXT_HLIM, EXT_LLIM)

These registers store the values of the upper and lower

temperature setpoints for event detection. The value is in

2’s–complement binary. INT_HLIM and INT_LLIM are

compared with the INT_TEMP value, and EXT_HLIM and

EXT_LLIM are compared with EXT_TEMP. These

registers may be written at any time.

Internal High Limit Setpoint Register (INT_HLIM)

D[7] D[6] D[5] D[4] D[3] D[2] D[1] D[0]

MSB x x x x x x LSB

Temperature Registers, 8–Bits, Read–Only

(INT_TEMP, EXT_TEMP)

The binary value (2’s complement format) in these two

registers represents temperature of the internal and external

sensors following a conversion cycle. The registers are

automatically updated in an alternating manner .

Internal T emperature Register (INT_TEMP)

D[7] D[6] D[5] D[4] D[3] D[2] D[1] D[0]

MSB x x x x x x LSB

External T emperature Register (EXT_TEMP)

D[7] D[6] D[5] D[4] D[3] D[2] D[1] D[0]

MSB x x x x x x LSB

In the two temperature data and four threshold setpoint

registers, each unit value represents one degree (Celsius).

http://onsemi.com

Internal Low Limit Setpoint Register (INT_LLIM)

D[7] D[6] D[5] D[4] D[3] D[2] D[1] D[0]

MSB x x x x x x LS

External High Limit Setpoint Register (EXT_HLIM)

D[7] D[6] D[5] D[4] D[3] D[2] D[1] D[0]

MSB x x x x x x LSB

External Low Limit Setpoint Register (EXT_LLIM)

D[7] D[6] D[5] D[4] D[3] D[2] D[1] D[0]

MSB x x x x x x LSB

NOTE: POR states:

INT_HLIM 01111111b +127°C

INT_LLIM 11001001b —55°C

EXT_HLIM 01111111b +127°C

EXT_LLIM 11001001b —55°C

10

Page 11

MAX1617

Status Register (Status)

D[7] D[6] D[5] D[4] D[3] D[2] D[1] D[0]

Busy Flag1 Flag2 Flag3 Flag4 Flag5 Flag6 Re-

Bit(s) POR

State

D[7] 0 Signal A/D

D[6] 0 Interrupt flag for

D[5] 0 Interrupt flag for

D[4] 0 Interrupt flag for

D[3] 0 Interrupt flag for

D[2] 0 External diode

D[1:0] 0 Reserved —

NOTE: All status bits are cleared after a read operation is

performed on STATUS. The EXT_TEMP register will read +127°C

if an external diode “open” is detected.

Function Operation*

converter is busy.

INT_HLIM event

INT_LLIM event

EXT_HLIM event

EXT_LLIM event

“fault” flag

Always returns

zero.

1 = A/D busy,

0 = A/D idle

1 = interrupt occurred,

0 = none

1 = interrupt occurred,

0 = none

1 = interrupt occurred,

0 = none

1 = interrupt occurred,

0 = none

1 = external diode fault

0 = external diode OK

N/A

served

Manufacturer’s Identification Register (MFR_ID),

8–Bits, Read Only:

Manufacturer’s Identification Register (MFR_ID)

D[7] D[6] D[5] D[4] D[3] D[2] D[1] D[0]

MSB X X X X X X LSB

Manufacturer’s Revision Register (MFR_REV),

8–Bits, Read Only:

Manufacturer’s Revision Register (MFR_REV)

D[7] D[6] D[5] D[4] D[3] D[2] D[1] D[0]

MSB X X X X X X LSB

Register Set Summary:

The MAX1617’s register set is summarized in the following table. All registers are 8–bits wide.

Name Description POR State Read Write

INT_TEMP Internal sensor temperature (2’s complement) 0000 0000b* √

EXT_TEMP External sensor temperature (2’s complement) 0000 0000b* √

STATUS STATUS register 0000 0000b √

CONFIG CONFIG register 0000 0000b √ √

CONV_RATE A/D conversion rate register 0000 0010b √ √

INT_HLIM Internal high limit (2’s complement) 0111 1111b √ √

INT_LLIM Internal low limit (2’s complement) 1100 1001b √ √

EXT_HLIM External high limit (2’s complement) 0111 1111b √ √

EXT_LLIM External low limit (2’s complement) 1100 1001b √ √

MFR_ID ASCII for letter “T” 0101 0100b √

MFR_REV Serial device revision # ** √

CRITICAL CRITICAL limit (2’s complement) N/A √***

*NOTE: The INT_TEMP and EXT_TEMP register immediately will be updated by the A/D converter after POR. If STBY is low at power–up,

INT_TEMP and EXT_TEMP will remain in POR state (0000 0000b).

**MFR_REV will sequence 01h, 02h, 03h, etc. by mask changes.

***CRITICAL only can be written via the CRIT[1:0] pins. It cannot be accessed through the SMBus port.

http://onsemi.com

11

Page 12

MAX1617

P ACKAGE DIMENSIONS

16–Pin QSOP

PLASTIC PACKAGE

CASE TBD

ISSUE TBD

PIN 1

.244 (6.20)

.228 (5.80)

.010 (0.25)

.004 (0.10)

.069 (1.75)

.053 (1.35)

8°

MAX.

.050 (1.27)

.016 (0.41)

.010 (0.25)

.007 (0.19)

.025

(0.635)

TYP.

.197 (4.98)

.189 (4.80)

.012 (0.31)

.008 (0.21)

.157 (3.99)

.150 (3.81)

Dimensions: inches (mm)

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty , representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability ,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly , any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer .

PUBLICATION ORDERING INFORMATION

NORTH AMERICA Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 Toll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line: 303–675–2167 or 800–344–3810 T oll Free USA/Canada

N. American Technical Support: 800–282–9855 Toll Free USA/Canada

EUROPE: LDC for ON Semiconductor – European Support

German Phone: (+1) 303–308–7140 (M–F 1:00pm to 5:00pm Munich Time)

Email: ONlit–german@hibbertco.com

French Phone: (+1) 303–308–7141 (M–F 1:00pm to 5:00pm Toulouse T ime)

Email: ONlit–french@hibbertco.com

English Phone: (+1) 303–308–7142 (M–F 12:00pm to 5:00pm UK Time)

Email: ONlit@hibbertco.com

EUROPEAN TOLL–FREE ACCESS*: 00–800–4422–3781

*Available from Germany, France, Italy, England, Ireland

http://onsemi.com

CENTRAL/SOUTH AMERICA:

Spanish Phone: 303–308–7143 (Mon–Fri 8:00am to 5:00pm MST)

Email: ONlit–spanish@hibbertco.com

ASIA/PACIFIC : LDC for ON Semiconductor – Asia Support

Phone: 303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong Time)

T oll Free from Hong Kong & Singapore:

001–800–4422–3781

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, T okyo, Japan 141–8549

Phone: 81–3–5740–2745

Email: r14525@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

MAX1617/D

12

Loading...

Loading...