Page 1

For the latest literature: http://www.maxim-ic.com, or phone 1-800-998-8800.

For small orders, phone 408-737-7600 ext. 3468.

General Description

The MAX1458 highly integrated analog-sensor signal

processor is optimized for piezoresistive sensor calibration and compensation without any external components. It includes a programmable current source for

sensor excitation, a 3-bit programmable-gain amplifier

(PGA), a 128-bit internal EEPROM, and four 12-bit

DACs. Achieving a total error factor within 1% of the

sensor’s repeatability errors, the MAX1458 compensates offset, offset temperature coefficient, full-span

output (FSO), FSO temperature coefficient (FSOTC),

and FSO nonlinearity of silicon piezoresistive sensors.

The MAX1458 calibrates and compensates first-order

temperature errors by adjusting the offset and span of

the input signal via digital-to-analog converters (DACs),

thereby eliminating quantization noise. Built-in testability features on the MAX1458 result in the integration of

three traditional sensor-manufacturing operations into

one automated process:

•

Pretest:

Data acquisition of sensor performance

under the control of a host test computer.

•

Calibration and compensation:

Computation and

storage (in an internal EEPROM) of calibration and

compensation coefficients computed by the test

computer and downloaded to the MAX1458.

•

Final test operation:

Verification of transducer calibration and compensation without removal from the

pretest socket.

Although optimized for use with piezoresistive sensors,

the MAX1458 may also be used with other resistive

sensors (i.e., accelerometers and strain gauges) with

some additional external components.

______________________Customization

Maxim can customize the MAX1458 for unique requirements. With a dedicated cell library consisting of more

than 90 sensor-specific functional blocks, Maxim can

quickly provide customized MAX1458 solutions. Please

contact Maxim for further information.

________________________Applications

Piezoresistive Pressure and Acceleration

Transducers and Transmitters

MAP (Manifold Absolute Pressure) Sensors

Automotive Systems

Hydraulic Systems

Industrial Pressure Sensors

Features

♦ Medium Accuracy (±1%), Single-Chip Sensor

Signal Conditioning

♦ Sensor Errors Trimmed Using Correction

Coefficients Stored in Internal EEPROM—

Eliminates the Need for Laser Trimming and

Potentiometers

♦ Compensates Offset, Offset-TC, FSO, FSOTC,

FSO Linearity

♦ Programmable Current Source (0.1mA to 2.0mA)

for Sensor Excitation

♦ Fast Signal-Path Settling Time (<1ms)

♦ Accepts Sensor Outputs from 10mV/V to 40mV/V

♦ Fully Analog Signal Path

MAX1458

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

________________________________________________________________

Maxim Integrated Products

1

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

SCLK LIMIT

V

DD

INP

BDRIVE

INM

I.C.

OUT

ISRC

TOP VIEW

MAX1458

SSOP

CS

I.C.

DIO

TEMP

FSOTC

WE

V

SS

19-1373; Rev 0; 5/98

PART

MAX1458CAE

MAX1458C/D

MAX1458AAE -40°C to +125°C

0°C to +70°C

0°C to +70°C

TEMP. RANGE PIN-PACKAGE

16 SSOP

Dice*

16 SSOP

*

Dice are tested at TA= +25°C, DC parameters only.

Functional Diagram appears at end of data sheet.

Pin Configuration

Ordering Information

Page 2

MAX1458

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

2 _______________________________________________________________________________________

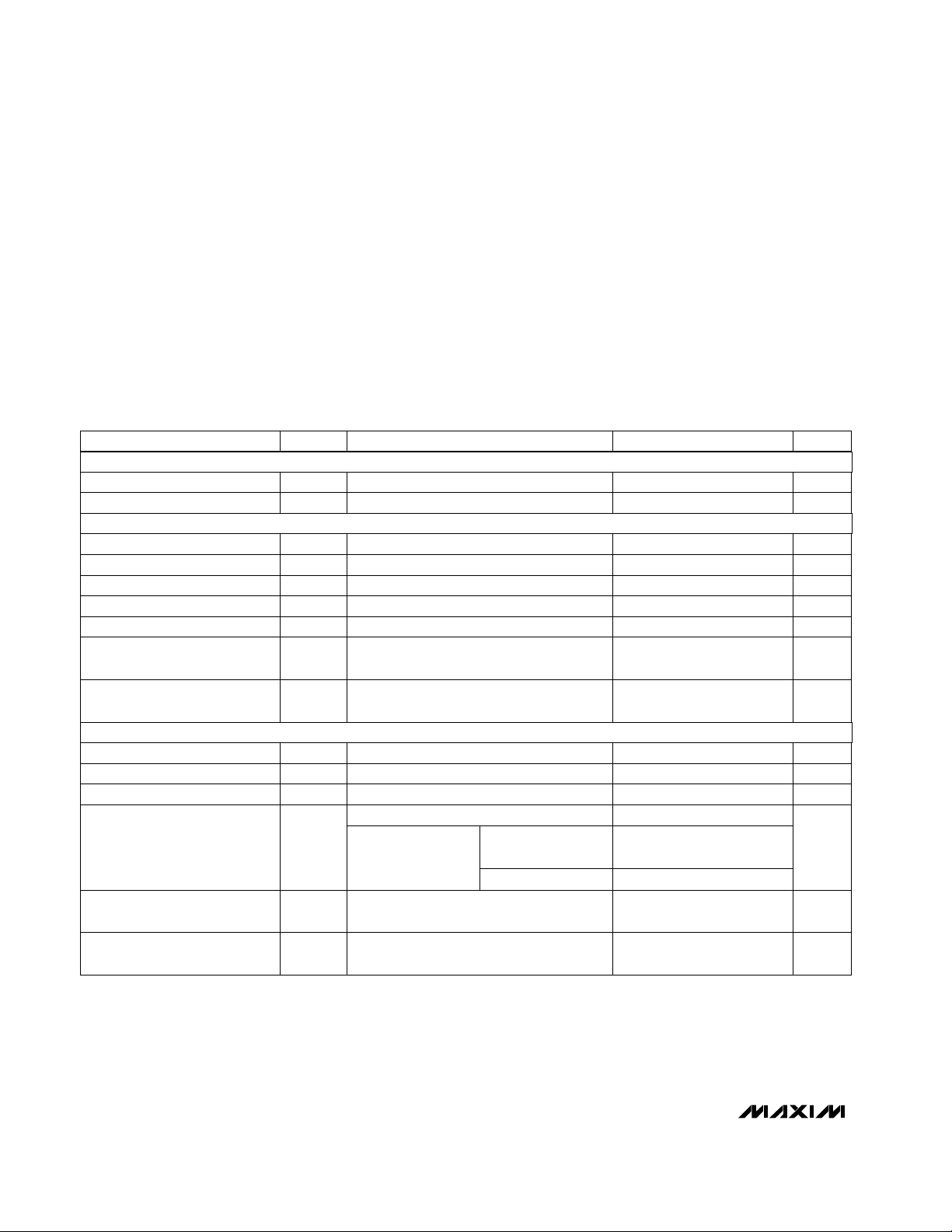

ABSOLUTE MAXIMUM RATINGS

ELECTRICAL CHARACTERISTICS

(VDD= +5V, VSS= 0, TA= +25°C, unless otherwise noted.)

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to

absolute maximum rating conditions for extended periods may affect device reliability.

Supply Voltage, VDDto VSS......................................-0.3V to +6V

All Other Pins ...................................(V

SS

- 0.3V) to (VDD+ 0.3V)

Short-Circuit Duration, FSOTC, OUT, BDRIVE...........Continuous

Continuous Power Dissipation (T

A

= +70°C)

SSOP (derate 8.00mW/°C above +70°C) .....................640mW

Operating Temperature Ranges

MAX1458CAE ......................................................0°C to +70°C

MAX1458AAE .................................................-40°C to +125°C

Storage Temperature Range.............................-65°C to +160°C

Lead Temperature (soldering, 10sec).............................+300°C

(Note 1)

DC to 10Hz (gain = 41,

source impedance = 5kΩ)

V

LIMIT

= 4.6V,

V

OUT

= (VSS+ 0.25V) to (V

LIMIT

- 0.3V)

At minimum gain (Note 4)

From VSSto V

DD

TA= T

MIN

to T

MAX

Selectable in eight steps

63% of final value

(Notes 2, 3)

(Note 5)

CONDITIONS

µV

RMS

500Output Noise

mA

-0.45 0.45

(sink) (source)

Output Current Range

V

SS

+ 0.15 VDD- 0.25

ppm/°C±50Differential Signal-Gain Tempco

V/V36 41 45Minimum Differential Signal Gain

V/V41 to 230Differential Signal-Gain Range

mV/V10 to 40

Input-Referred Adjustable FSO

Range

mA3 6I

DD

Supply Current

V4.5 5.0 5.5V

DD

Supply Voltage

mV±150

Input-Referred Adjustable Offset

Range

dB90CMRRCommon-Mode Rejection Ratio

ms1Output Step Response

MΩ1R

IN

Input Impedance

µV/°C±0.5Input-Referred Offset Tempco

%V

DD

0.01Amplifier Gain Nonlinearity

UNITSMIN TYP MAXSYMBOLPARAMETER

10kΩ load to V

SS

or V

DD

V

LIMIT

= 4.6V

VOutput Voltage Swing V

SS

+ 0.25 V

LIMIT

± 0.3

V

SS

+ 0.1 V

LIMIT

± 0.2No load

GENERAL CHARACTERISTICS

ANALOG INPUT (PGA)

ANALOG OUTPUT (PGA)

V

LIMIT

= 5.0V, no load

Page 3

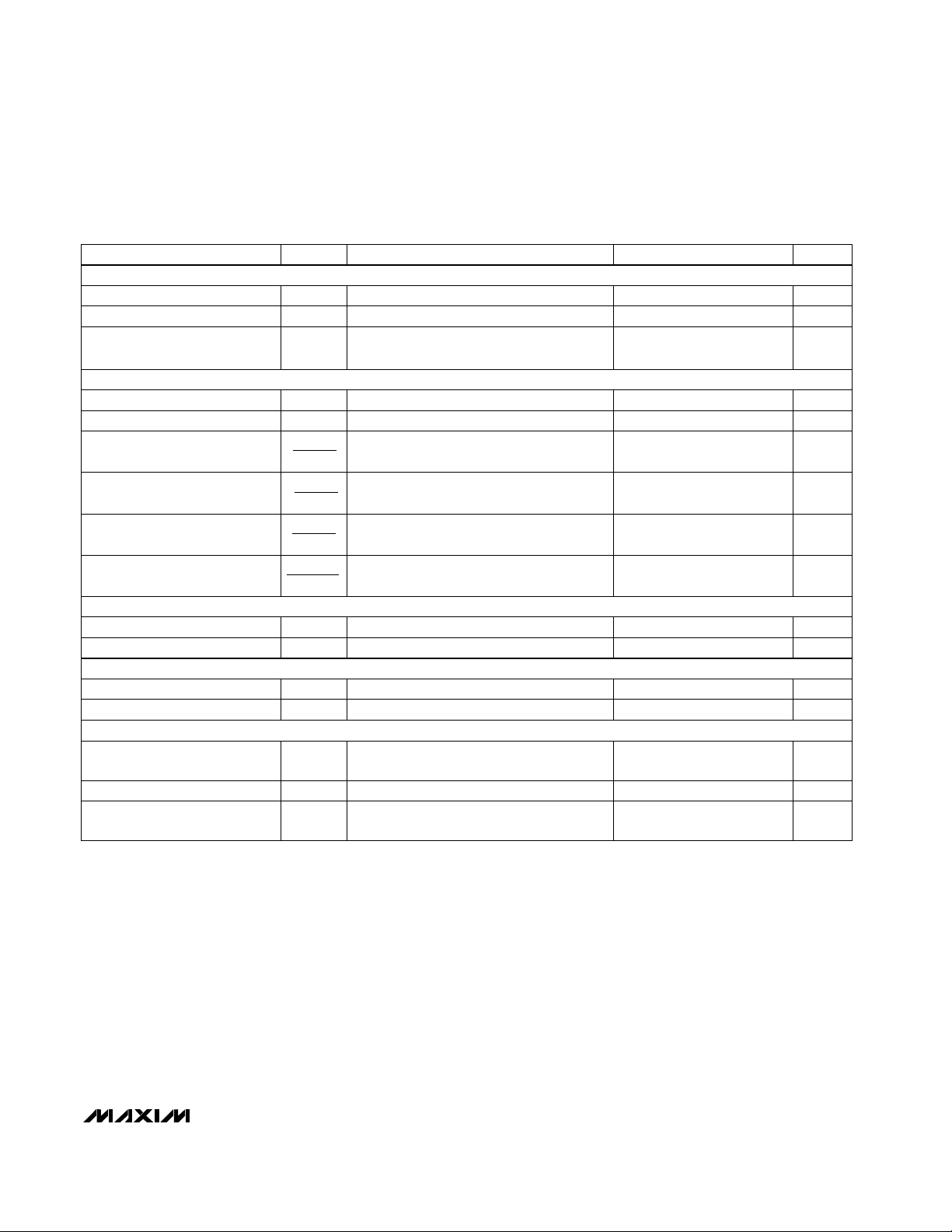

ELECTRICAL CHARACTERISTICS (continued)

(VDD= +5V, VSS= 0, TA= +25°C, unless otherwise noted.)

Note 1: Excludes the sensor or load current.

Note 2: All electronics temperature errors are compensated together with sensor errors.

Note 3: The sensor and the MAX1458 must always be at the same temperature during calibration and use.

Note 4: This is the maximum allowable sensor offset.

Note 5: This is the sensor’s sensitivity normalized to its drive voltage, assuming a desired full-span output of 4V and a bridge

voltage of 2.5V.

Note 6: Bit weight is ratiometric to V

DD

.

MAX1458

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

_______________________________________________________________________________________ 3

Typically 4600ppm/°C tempco

V

FSOTC

= 2.5V

No load

Input referred, VDD= 5V (Note 6)

CONDITIONS

kΩ100R

TEMP

Temperature-Dependent

Resistor

kΩ75R

FTC

FSO Trim Resistor

kΩ75R

ISRC

Current-Source Reference

Resistor

VV

SS

+ 1.3 VDD- 1.3V

BDRIVE

Bridge Voltage Swing

mA0.1 0.5 2.0I

BDRIVE

Bridge Current Range

µA-20 20Current Drive

VV

SS

+ 0.3 VDD- 1.3Output Voltage Swing

Bits3DAC Resolution

mV/bit9DAC Bit Weight

UNITSMIN TYP MAXSYMBOLPARAMETER

LSB±1.5DNLDifferential Nonlinearity

Bits12DAC Resolution

VV

SS

+ 1.3 VDD- 1.3V

ISRC

Reference Input Voltage Range

(ISRC)

DAC reference = V

BDRIVE

= 2.5V

DAC reference = VDD= 5.0V

mV/bit1.4

∆V

OUT

∆Code

Offset TC DAC Bit Weight

mV/bit2.8

∆V

OUT

∆Code

Offset DAC Bit Weight

DAC reference = V

BDRIVE

= 2.5V

DAC reference = VDD= 5.0V

mV/bit0.6

∆V

FSOTC

∆Code

FSO TC DAC Bit Weight

mV/bit1.22

∆V

ISRC

∆Code

FSO DAC Bit Weight

CURRENT SOURCE

DIGITAL-TO-ANALOG CONVERTERS

IRO DAC

FSOTC BUFFER

INTERNAL RESISTORS

Page 4

_______________Detailed Description

The MAX1458 provides an analog amplification path for

the sensor signal. Calibration and temperature compensation are achieved by varying the offset and gain

of a programmable-gain amplifier (PGA) and by varying

the sensor bridge current. The PGA uses a switchedcapacitor CMOS technology, with an input-referred

coarse offset trimming range of approximately ±63mV

(9mV steps). An additional output-referred fine offset

trim is provided by the Offset DAC (approximately

2.8mV steps). The PGA provides eight gain values from

+41V/V to +230V/V. The bridge current source is programmable from 0.1mA to 2mA.

The MAX1458 uses four 12-bit DACs and one 3-bit

DAC, with calibration coefficients stored by the user in

an internal 128-bit EEPROM. This memory contains the

following information as 12-bit-wide words:

• Configuration register

• Offset calibration coefficient

• Offset temperature error compensation coefficient

• FSO (full-span output) calibration coefficient

• FSO temperature error compensation coefficient

• 24 user-defined bits for customer programming of

manufacturing data (e.g., serial number and date)

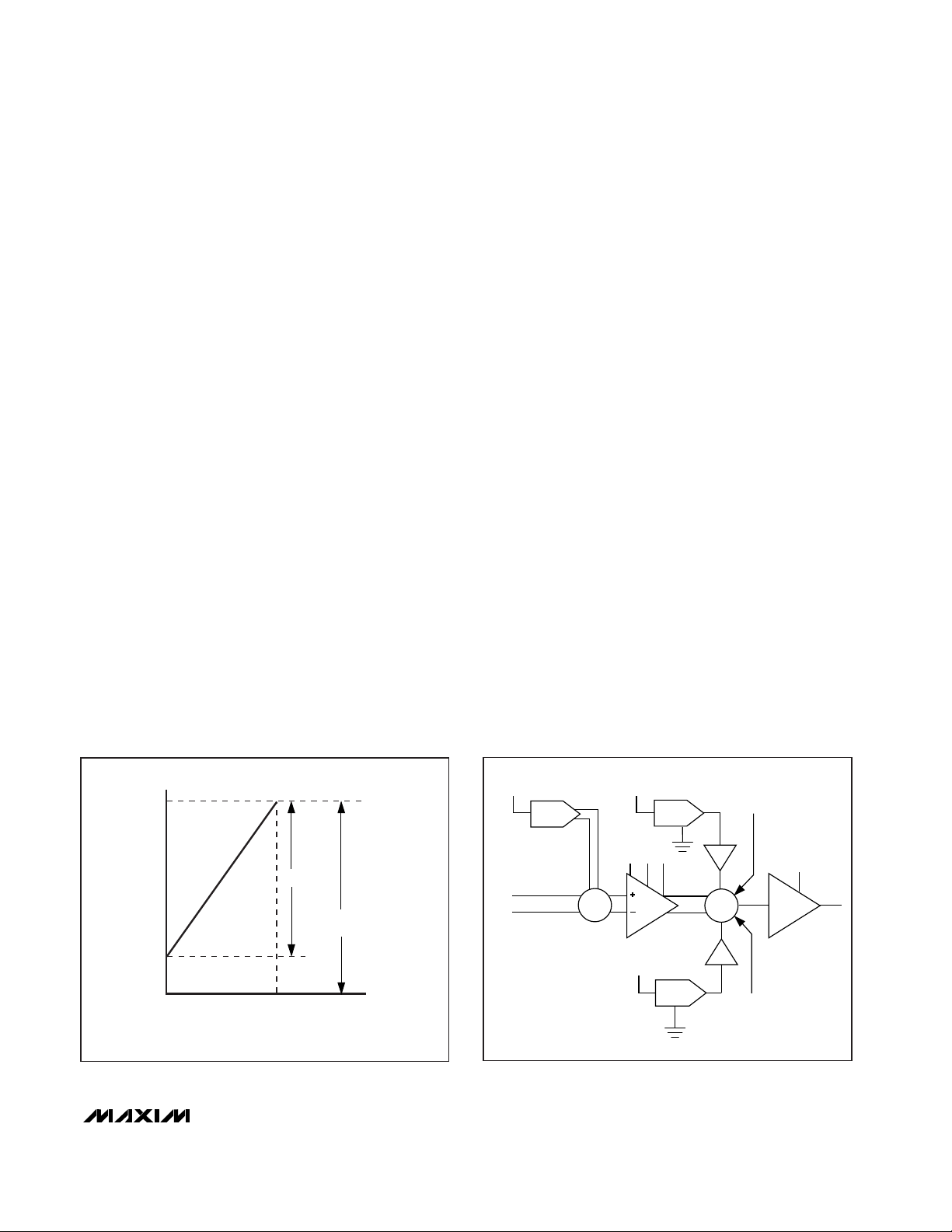

Figure 1 shows a typical pressure-sensor output and

defines the offset, full-scale, and full-span output values

as a function of voltage.

MAX1458

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

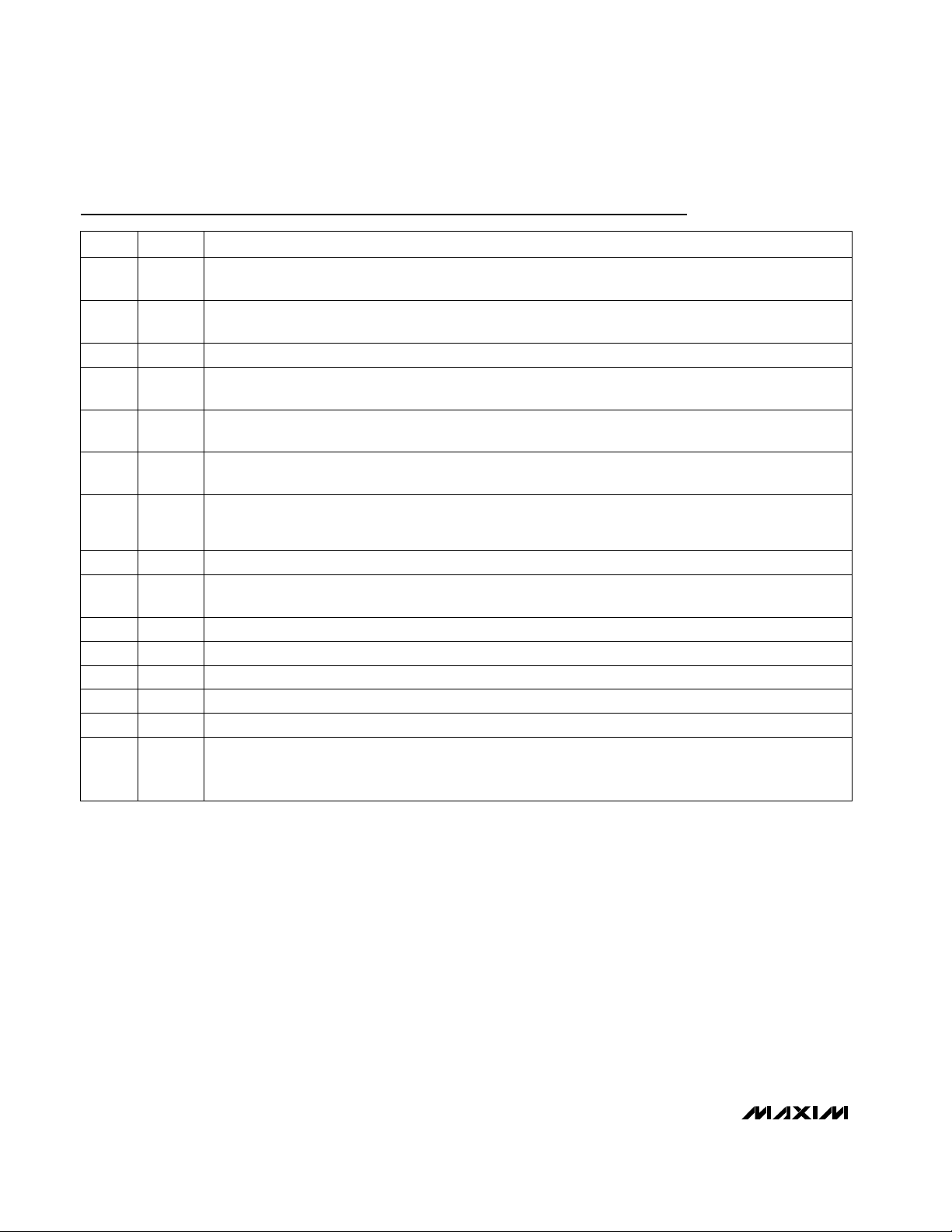

4 _______________________________________________________________________________________

NAME FUNCTION

1 SCLK

Data Clock Input. Used only during programming/testing. Internally pulled to VSSwith a 1MΩ (typical) resistor. Data is clocked in on the rising edge of the clock. The maximum SCLK frequency is 10kHz.

2 CS

Chip-Select Input. The MAX1458 is selected when this pin is high. When low, OUT and DIO become high

impedance. Internally pulled to VDDwith a 1MΩ (typical) resistor. Leave unconnected for normal operation.

PIN

3, 11 I.C. Internally Connected. Leave unconnected.

4 TEMP

Temperature Sensor Output. An internal temperature sensor (a 100kΩ, 4600ppm/°C TC resistor) which can

provide a temperature-dependent voltage.

8 V

SS

Negative Power-Supply Input

7 WE

Dual-Function Input Pin. Used to enable EEPROM erase/write operations. Also used to set the DAC refreshrate mode. Internally pulled to V

DD

with a 1MΩ (typical) resistor. Refer to the

Chip-Select (CS) and Write-

Enable (WE)

section.

6 DIO

Data Input/Output. Used only during programming/testing. Internally pulled to VSSwith a 1MΩ (typical)

resistor. High impedance when CS is low.

5 FSOTC

Buffered FSOTC DAC Output. An internal 75kΩ resistor (R

FTC

) connects FSOTC to ISRC (see

Functional

Diagram

). Optionally, external resistors can be used in place of or in parallel with R

FTC

and R

ISRC

.

14 INP Positive Sensor Input. Input impedance >1MΩ. Rail-to-rail input range.

13 BDRIVE Sensor Excitation Current Output. This current source drives the bridge.

12 INM Negative Sensor Input. Input impedance >1MΩ. Rail-to-rail input range.

10 OUT PGA Output Voltage

9 ISRC

Current-Source Reference. An internal 75kΩ resistor (R

ISRC

) connects ISRC to VSS(see

Functional

Diagram

). Optionally, external resistors can be used in place of or in parallel with R

FTC

and R

ISRC

.

Pin Description

16 LIMIT

Voltage Limit Input. This pin sets the maximum voltage at OUT. If left unconnected, the output voltage will be

limited to 4.6V (VDD= 5V). Connect to VDDfor maximum output swing. The acceptable range is 4.5V ≤

V

LIMIT

≤ VDD.

15 V

DD

Positive Power-Supply Input. Connect a 0.1µF capacitor from VDDto V

SS.

Page 5

FSOTC Compensation

Silicon piezoresistive transducers (PRTs) exhibit a large

positive input resistance tempco (TCR) so that, while

under constant current excitation, the bridge voltage

(V

BDRIVE

) increases with temperature. This depen-

dence of V

BDRIVE

on the sensor temperature can be

used to compensate the sensor temperature errors.

PRTs also have a large negative full-span output sensitivity tempco (TCS) so that, with constant voltage excitation, full-span output (FSO) will decrease with

temperature, causing a full-span output temperature

coefficient (FSOTC) error. However, if the bridge voltage can be made to increase with temperature at the

same rate that TCS decreases with temperature, the

FSO will remain constant.

FSOTC compensation is accomplished by resistor

R

FTC

and the FSOTC DAC, which modulate the excitation reference current at ISRC as a function of temperature (Figure 3). FSO DAC sets V

ISRC

and remains

constant with temperature while the voltage at FSOTC

varies with temperature. FSOTC is the buffered output

of the FSOTC DAC. The reference DAC voltage is

V

BDRIVE

, which is temperature dependent. The FSOTC

DAC alters the tempco of the current source. When the

tempco of the bridge voltage is equal in magnitude and

opposite in polarity to the TCS, the FSOTC errors are

compensated and FSO will be constant with temperature.

OFFSET TC Compensation

Compensating offset TC errors involves first measuring

the uncompensated offset TC error, then determining

the percentage of the temperature-dependent voltage

V

BDRIVE

that must be added to the output summing

junction to correct the error. Use the Offset TC DAC to

adjust the amount of BDRIVE voltage that is added to

the output summing junction (Figure 2).

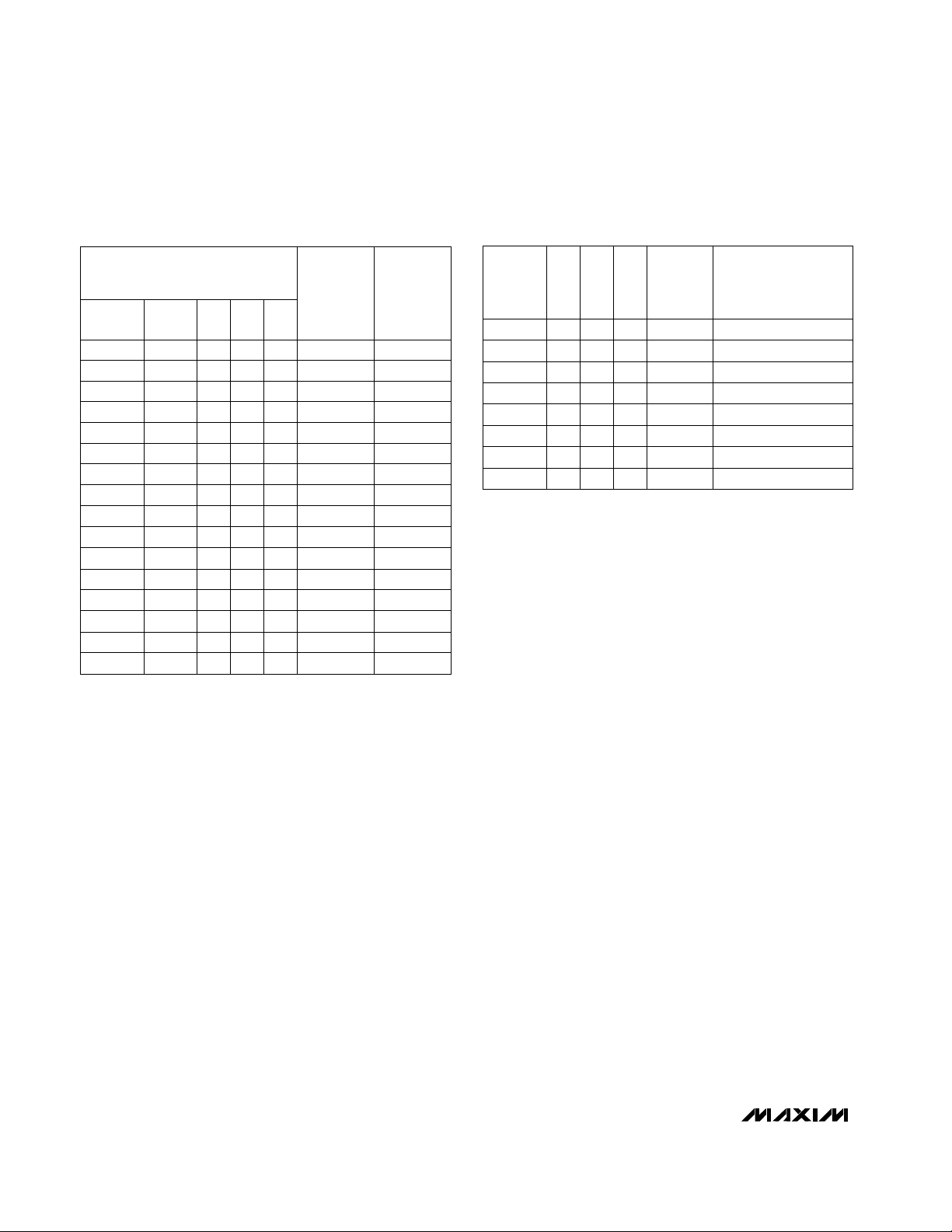

Analog Signal Path

The fully differential analog signal path consists of four

stages:

• Front-end summing junction for coarse offset correction

• 3-bit PGA with eight selectable gains ranging from

41 through 230

• Three-input-channel summing junction

• Differential to single-ended output buffer (Figure 2)

Coarse Offset Correction

The sensor output is first fed into a differential summing

junction (INM (negative input) and INP (positive input))

with a CMRR > 90dB, an input impedance of approximately 1MΩ, and a common-mode input voltage range

from VSSto VDD. At this summing junction, a coarse offset-correction voltage is added, and the resultant voltage is fed into the PGA. The 3-bit (plus sign)

input-referred Offset DAC (IRO DAC) generates the

coarse offset-correction voltage. The DAC voltage reference is 1.25% of VDD; thus, a VDDof 5V results in a

front-end offset-correction voltage ranging from -63mV

to +63mV, in 9mV steps (Table 1). To add an offset to

the input signal, set the IRO sign bit high; to subtract an

offset from the input signal, set the IRO sign bit low.

The IRO DAC bits (C2, C1, C0, and IRO sign bit) are

programmed in the configuration register (see

Internal

EEPROM

section).

MAX1458

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

_______________________________________________________________________________________ 5

VOLTAGE (V)

PRESSURE

P

MIN

P

MAX

FULL-SCALE (FS)

4.5

0.5

FULL-SPAN OUTPUT (FSO)

OFFSET

Figure 1. Typical Pressure-Sensor Output

SOTC

BDRIVE

1.25% V

DD

SOFF

±

±

A2

INP

INM

A1 A0

PGA

ΣΣ

A = 1

OUT

LIMIT

A = 2.3

A = 2.3

OFFTC

DAC

IRO

DAC

V

DD

Offset

DAC

Figure 2. Signal-Path Block Diagram

Page 6

MAX1458

Table 1. Input-Referred Offset DAC

Correction Values

Programmable-Gain Amplifier

The programmable-gain amplifier (PGA), which is used

to set the coarse FSO, uses a switched-capacitor

CMOS technology and contains eight selectable gain

levels from 41 to 230, in increments of 27 (Table 2). The

output of the PGA is fed to the output summing junction. The three PGA gain bits A2, A1, and A0 are stored

in the configuration register.

Output Summing Junction

The third stage in the analog signal path consists of a

summing junction for the PGA output, offset correction,

and the offset TC correction. Both the offset and the offset TC correction voltages are gained by a factor of 2.3

before being fed into the summing junction, increasing

the offset and offset TC correction range. The offset

sign bit and offset TC sign bit are stored in the configuration register. The offset sign bit determines if the offset correction voltage is added to (sign bit is high) or

subtracted from (sign bit is low) the PGA output.

Negative offset TC errors require a logic high for the

offset TC sign bit. Alternately, positive offset TC errors

dictate a logic low for the offset TC sign bit. The output

of the summing junction is fed to the output buffer.

Output Buffer

OUT can drive 0.1µF of capacitance. If CS is brought

low, OUT becomes high impedance (resulting in typical

output impedance of 1MΩ). The output is current limited and can be shorted to either VDDor VSSindefinitely.

The maximum output voltage can be limited using the

LIMIT pin. Output limiting can be performed for sensor

diagnostic purposes. Connect LIMIT to VDDto disable

the voltage-limiting feature.

Bridge Drive

Fine FSO correction is accomplished by varying the

sensor excitation current with the 12-bit FSO DAC

(Figure 3). Sensor bridge excitation is performed by a

programmable current source capable of delivering up

to 2mA. The reference current at ISRC is established by

resistor R

ISRC

and by the voltage at node ISRC (controlled by the FSO DAC). The reference current flowing

through this pin is multiplied by a current mirror (AA ≅

14) and then made available at BDRIVE for sensor excitation. Modulation of this current with respect to temperature can be used to correct FSOTC errors, while

modulation with respect to the output voltage (V

OUT

)

can be used to correct FSO linearity errors.

Digital-to-Analog Converters

The four 12-bit, sigma-delta DACs typically settle in

less than 100ms. The four DACs have a corresponding

memory register in EEPROM for storage of correction

coefficients.

Use the FSO DAC for fine FSO adjustments. The FSO

DAC takes its reference from VDDand controls V

ISRC

which, in conjunction with R

ISRC

, sets the baseline sensor excitation current. The Offset DAC also takes its reference from VDDand provides a 1.22mV resolution with

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

6 _______________________________________________________________________________________

+7 1 1 1

IRO DAC

1

OFFSET

CORREC-

TION

% of V

DD

(%)

+1.25

OFFSET

CORREC-

TION AT

V

DD

= 5V

(mV)

+63

SIGN C1C2 C0VALUE

+6 1 1 1 0 +1.08 +54

+5 1 1 0 1 +0.90 +45

+4 1 1 0 0 +0.72 +36

+3 1 0 1 1 +0.54 +27

+2 1 0 1 0 +0.36 +18

+1 1 0 0 1 +0.18 +9

+0 1 0 0 0

0

0

-0 0 0 0 0

-1 0 0 0 1 -0.18 -9

-2 0 0 1 0 -0.36 -18

-3 0 0 1 1 -0.54 -27

-4 0 1 0 0 -0.72 -36

-5 0 1 0 1 -0.90 -45

-6 0 1 1 0 -1.08 -54

-7 0 1 1 1 -1.25 -63

A1

0 0 0

A2 A0

PGA

VALUE

0

PGA

GAIN

(V/V)

41

OUTPUTREFERRED IRO

DAC STEP SIZE

(VDD= 5V) (V)

0.369

1 0 0 1 68 0.612

2 0 1 0 95 0.855

3 0 1 1 122 1.098

4 1 0 0 149 1.341

5 1 0 1 176 1.584

6 1 1 0 203 1.827

7 1 1 1 230 2.070

Table 2. PGA Gain Settings and IRO DAC

Step Size

0

0

Page 7

a VDDof 5V. The output of the Offset DAC is fed into

the output summing junction where it is gained by

approximately 2.3, which increases the resulting output-referred offset correction resolution to 2.8mV.

Both the Offset TC and FSOTC DACs take their reference from BDRIVE, a temperature-dependent voltage. A

nominal V

BDRIVE

of 2.5V results in a step size of 0.6mV.

The Offset TC DAC output is fed into the output summing junction where it is gained by approximately 2.3,

thereby increasing the Offset TC correction range. The

buffered FSOTC DAC output is available at FSOTC and

is connected to ISRC via R

FTC

to correct FSOTC errors.

Internal Resistors

The MAX1458 contains three internal resistors (R

ISRC

,

R

FTC

, and R

TEMP

) optimized for common silicon PRTs.

R

ISRC

(in conjunction with the FSO DAC) programs the

nominal sensor excitation current. R

FTC

(in conjunction

with the FSOTC DAC) compensates the FSOTC errors.

Both R

ISRC

and R

FTC

have a nominal value of 75kΩ. If

external resistors are used, R

ISRC

and R

FTC

can be disabled by resetting the appropriate bit (address 07h

reset to zero) in the configuration register (Table 3).

R

TEMP

is a high-tempco resistor with a TC of

+4600ppm/°C and a nominal resistance of 100kΩ at

+25°C. This resistor can be used with certain sensor

types that require an external temperature sensor.

Internal EEPROM

The MAX1458 has a 128-bit internal EEPROM arranged

as eight 16-bit words. The four uppermost bits for each

register are reserved. The internal EEPROM is used to

store the following (also shown in the memory map in

Table 4):

MAX1458

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

_______________________________________________________________________________________ 7

Figure 3. Bridge Excitation Circuit

V

DD

AA ≈ 14I

ISRC

= I

BDRIVE

I = I

ISRC

I

SRC

FSOTC

R

ISRC

BDRIVE

V

DD

R

FTC

EXTERNAL

SENSOR

FSO

DAC

FSOTC

DAC

01h Offset Sign Bit, SOFF

00h

03h

Offset TC Sign Bit, SOTC

PGA Gain, A1

DESCRIPTION

02h

EEPROM

ADDRESS (hex)

PGA Gain (MSB), A2

05h Reserved “0”

04h

07h

PGA Gain (LSB), A0

Internal Resistor (R

FTC

and R

ISRC

)

Selection

06h Reserved “0”

09h Input-Referred Offset (MSB)

08h

0Bh

Input-Referred Offset (IRO) Sign Bit

Input-Referred Offset (LSB)

0Ah Input-Referred Offset

Table 3. Configuration Register

Page 8

MAX1458

• Configuration register (Table 3)

• 12-bit calibration coefficients for the Offset and FSO

DACs

• 12-bit compensation coefficients for the Offset TC

and FSOTC DACs

• Two general-purpose registers available to the user

for storing process information such as serial number, batch date, and check sums

Program the EEPROM one bit at a time. The bits have

addresses from 0 to 127 (7F hex).

Configuration Register

The configuration register (Table 3) determines the

PGA gain, the polarity of the offset and offset TC coefficients, and the coarse offset correction (IRO DAC). It

also enables/disables internal resistors (R

FTC

and

R

ISRC

).

DAC Registers

The Offset, Offset TC, FSO, and FSOTC registers store

the coefficients used by their respective calibration/

compensation DACs.

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

8 _______________________________________________________________________________________

Table 4. EEPROM Memory Map

EE Address

Contents

EE Address

Contents

EE Address

Contents

EE Address

Contents

EE Address

Contents

Reserved*

EE Address

Contents

EE Address

Contents

0E

0

0C

0

0F 0D

0

0A 080B 09 06 0407 05 02

1

00

Configuration

03 01

1E

0

1C

1

1F 1D

0

1A 181B 19 16 1417 15 12

1

10

MSB Offset LSB

13 11

2E

0

2C

0

2F 2D

1

2A 282B 29 26 2427 25 22

1

20

MSB Offset TC LSB

23 21

3E

0

3C

1

3F 3D

1

3A 383B 39 36 3437 35 32

1

30

MSB FSO LSB

33 31

4E

1

4C

0

4F 4D

0

4A 484B 49 46 4447 45 42

1

40

MSB FSOTC LSB

43 41

5E

0

5C

0

5F 5D

0

5A 585B 59 56 5457 55 52

0

50

0

53 51

6E

0

6C

0

6F 6D

0

6A 686B 69 66 6467 65 62

0

60

User defined bits

63 61

7E

0

7C

0

7F 7D

0

7A 787B 79 76 7477 75 72

0

70

User defined bits

73 71

Note: The MAX1458 processes the Reserved Bits in the EEPROM. If these bits are not properly programmed, the configuration

and DAC registers will not be updated correctly.

* The contents of the Reserved EE Address 50–5F must all be reset to zero.

= Reserved Bits

00000000000

Page 9

Detailed Description of the Digital Lines

Chip-Select (CS) and Write-Enable (WE)

CS is used to enable OUT, control serial communication, and force an update of the configuration and DAC

registers.

• A low on CS disables serial communication and

places OUT in a high-impedance state.

• A transition from low to high on CS forces an update

of the configuration and DAC registers from the

EEPROM when the “U” bit is zero.

• A transition from high to low on CS terminates programming mode.

• A logic high on CS enables OUT and serial communication (see

Communication Protocol

section).

WE controls the refresh rate for the internal configuration and DAC registers from the EEPROM and enables

the erase/write operations. If communication has been

initiated (see

Communication Protocol

section), internal

register refresh is disabled.

• A low on WE disables the erase/write operations and

also disables register refreshing from the EEPROM.

• A high on WE selects a refresh rate of approximately

400 times per second and enables EEPROM

erase/write operations.

• It is recommended that WE be connected to V

SS

after the MAX1458 EEPROM has been programmed.

SCLK (Serial Clock)

SCLK must be driven externally and is used to input

commands to the MAX1458 and read EEPROM contents. Input data on DIO is latched on the rising edge of

SCLK. Noise on SCLK may disrupt communication. In

noisy environments, place a capacitor (0.01µF)

between SCLK and VSS.

Data Input/Output (DIO)

The DIO line is an input/output pin used to issue commands to the MAX1458 (input mode) or read the

EEPROM contents (output mode).

In input mode (the default mode), data on DIO is

latched on each rising edge of SCLK. Therefore, data

on DIO must be stable at the rising edge of SCLK and

should transition on the falling edge of SCLK.

DIO will switch to output mode after receiving a “READ

EEPROM” command, and will return the data bit

addressed by the digital value in the “READ EEPROM”

command. After a low-to-high transition or CS, DIO

returns to input mode and is ready to accept more

commands.

Communication Protocol

To initiate communication, the first six bits on DIO after

CS transitions from low to high must be 1010U0

(defined as the INIT SEQUENCE). The MAX1458 will

then begin accepting 16-bit control words (Figure 4).

If the INIT SEQUENCE is not detected, all subsequent

data on DIO is ignored until CS again transitions from

low to high and the correct INIT SEQUENCE is received.

The “U” bit of the INIT SEQUENCE controls the updating of the DACs and configuration register from the

internal EEPROM. If this bit is low (U = 0), all four internal DACs and the configuration register will be updated

from the EEPROM on the next rising edge of CS (this is

also the default on power-up). If the “U” bit is high, the

DACs and configuration register will not be updated

from the internal EEPROM; they will retain their current

value on any subsequent CS rising edge. The

MAX1458 continues to accept control words until CS is

brought low.

MAX1458

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

_______________________________________________________________________________________ 9

Figure 4. Communication Sequence

CS

SCLK

DIO

t

MIN

= 200µs

16 CLK

CYCLES

BEGIN

PROGRAMMING

SEQUENCE

CONTROL

WORD

CONTROL

WORD

CONTROL

WORDS

16 CLK

CYCLES

n x 16 CLK

CYCLES

X

1

0

1 D0D0D1D1CM3

CM3

0 U 0

Page 10

MAX1458

Control Words

After receiving the INIT SEQUENCE on DIO, the MAX1458

begins latching in 16-bit control words, LSB first (Figure 5).

The first 12 bits (D0–D11) represent the data field. The

last four bits of the control word (the MSBs, CM0–CM3)

are the command field. The MAX1458 supports the

commands listed in Table 5.

ERASE EEPROM Command

When an ERASE EEPROM command is issued, all of

the memory locations in the EEPROM are reset to a

logic “0.” The data field of the 16-bit word is ignored.

Important: An internal charge pump develops voltages

greater than 20V for EEPROM programming operations.

The EEPROM control logic requires 50ms to erase the

EEPROM. After sending a WRITE or ERASE command,

failure to wait 50ms before issuing another command

may result in data being accidentally written to the

EEPROM. The maximum number of ERASE EEPROM

cycles should not exceed 100.

BEGIN EEPROM WRITE Command

The BEGIN EEPROM WRITE command stores a logic

high at the memory location specified by the lower

seven bits of the data field (A0–A6). The higher bits of

the data field (A7–A11) are ignored (Figure 6). Note that

to write to the internal EEPROM, WE and CS must be

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

10 ______________________________________________________________________________________

Figure 5. Control-Word Timing Diagram

SCLK

DIO

DATA

LSB MSB MSBLSB

LSB MSB MSBLSB

COMMAND

16-BIT CONFIGURATION WORD

D6D9D7

D10D8D11

CM0 CM2 CM2 CM3

D0D3D1D4D2

D5

Figure 6. Timing Diagram for WRITE EEPROM Operation

WE

CS

SCLK

DIO

t

MIN

= 200µs

16 CLK

CYCLES

INIT SEQUENCE

BEGIN

EEPROM

WRITE

END

EEPROM

WRITE

t

WAIT

T

WRITE

n

COMMAND

WORDS

16 CLK

CYCLES

n x 16 CLK

CYCLES

X

1

0

1

A0 D0A0A1 D1A1CM3 CM3 CM30 U 0

Table 5. MAX1458 Commands

FUNCTION

ERASE EEPROM

CM20CM1

01h

HEX

CODE

CM3

0

CM0

1

BEGIN EEPROM WRITE at

Address

0 12h 0 0

READ EEPROM at Address

0 13h 0 1

Maxim Reserved

1 04h 0 0

END EEPROM WRITE at

Address

1 05h 0 1

WRITE Data to

Configuration Register

0 08h 1 0

WRITE Offset DAC

0 09h 1 1

WRITE Offset TC DAC

0 1Ah 1 0

WRITE FSO DAC

0 1Bh 1 1

WRITE FSOTC DAC

1 0Ch 1 0

No Operation

0 00h 0 0

Load Register

1

1

1

1

1

1

1

0

1

1

6h,

7h,

Dh,

Eh,

Fh

0

0

1

1

1

0

1

1

0

1

Page 11

high. In addition, the EEPROM should only be written to

at TA= +25°C and VDD= 5V.

Writing to the internal EEPROM is a time-consuming

process and should only be required once. All calibration/compensation coefficients are determined by writing directly to the DAC and configuration registers. Use

the following procedure to write these calibration/compensation coefficients to the EEPROM:

1) Issue an ERASE EEPROM command.

2) Wait 50ms (t

WRITE

).

3) Issue on END EEPROM WRITE command at

address 00h.

4) Wait 1ms (t

WAIT

).

5) Issue a BEGIN EEPROM WRITE command

(Figure 7) at the address of the bit to be set.

6) Wait 50ms.

7) Issue an END EEPROM WRITE command (Figure 7)

using the same address as in Step 5.

8) Wait 1ms.

9) Return to Step 5 until all necessary bits have been

set.

10) Read EEPROM to verify that the correct calibration/compensation coefficients have been stored.

READ EEPROM Command

The READ EEPROM command returns the bit stored at

the memory location addressed by the lower seven bits

of the data field (A0–A6). The higher bits of the data

field (A7–A11) are ignored. Note that after a read command has been issued, the DIO lines become an output and the state of the addressed EEPROM location

will be available on DIO 200µs (t

READ

) after the falling

edge of the 16th SCLK cycle (Figure 8). After issuing

the READ EEPROM command, DIO returns to input

mode on the falling edge of CS. Reading the entire

EEPROM requires the READ EEPROM command be

issued 128 times.

MAX1458

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

______________________________________________________________________________________ 11

Figure 7. Begin WRITE EEPROM and End WRITE EEPROM Timing Diagrams

SCLK

SCLK

DIO

DATA

LSB MSB MSB

LSB MSB

LSB

COMMAND

DATA

LSB MSB MSBLSB

COMMAND

16-BIT COMMAND WORD – BEGIN EEPROM WRITE AT ADDRESS COMMAND

LSB MSB

16-BIT COMMAND WORD – END EEPROM WRITE AT ADDRESS COMMAND

A0 A1 A2 A3 A4 A5 A6 0 0 0 0 0

0

0

0

1

DIO

A0 A1 A2 A3 A4 A5 A6 0 0 0 0 0

1

1

00

Figure 8. READ EEPROM Timing Diagram

SCLK

t

MIN

= 200µs

CS

DIO

16 CLOCK CYCLES

INIT SEQUENCE

A0X 1 0 1 0 U 0 A1

A2

A3 A4 A5 A6 0 0 0 0 0 0 0 X XEE DATA

DIO IS AN

OUTPUT PIN

1 1

t

READ

READ EEPROM AT ADDRESS COMMAND

DIO IS AN INPUT PIN

Page 12

MAX1458

Writing to the Configuration and DAC Registers

When writing to the configuration register or directly to

the internal 12-bit DACs, the data field (D0–D11) contains the data to be written to the respective register.

Note that all four DACs and the configuration register

can be updated without toggling the CS line. Every

register write command must be followed by a LOAD

REGISTER command.

__________Applications Information

Power-Up

At power up, the following occurs:

1) The DAC and configuration registers are reset to

zero.

2) CS transitions from low to high after power-up (an

internal pull-up resistor ensures that this happens if

CS is left unconnected), and the EEPROM contents

are read and processed.

3) The DAC and configuration registers are updated

either once or approximately 400 times per second

(as determined by the state of WE).

4) The MAX1458 begins accepting commands in a serial format on DIO immediately after receiving the INIT

SEQUENCE.

The MAX1458 is shipped with all memory locations in

the internal EEPROM uninitialized. Therefore, the

MAX1458 must be programmed for proper operation.

Compensation Procedure

The following compensation procedure was used to

obtain the results shown in Figure 9 and Table 8. It

assumes a pressure transducer with a +5V supply and

an output voltage that is ratiometric to the supply voltage. The desired offset voltage (V

OUT

at P

MIN

) is 0.5V,

and the desired FSO voltage (V

OUT(P

MAX

)

- V

OUT(P

MIN

)

)

is 4V; thus the full-scale output voltage (V

OUT

at P

MAX

)

will be 4.5V (refer to Figure 1). The procedure requires

a minimum of two test pressures (e.g., zero and full

scale) at two arbitrary test temperatures, T1and T2.

Ideally, T1and T2are the two points where we wish to

perform best linear fit compensation. The following outlines a typical compensation procedure:

1) Perform Coefficient Initialization

2) Perform FSO Calibration

3) Perform FSOTC Compensation

4) Perform Offset TC Compensation

5) Perform Offset Calibration

Coefficient Initialization

Select the resistor values and the PGA gain to prevent

overload of the PGA and bridge current source. These

values depend on sensor behavior and require some

sensor characterization data, which may be available

from the sensor manufacturer. If not, the data can be

generated by performing a two-temperature, two-pressure sensor evaluation. The required sensor information

is shown in Table 6 and can be used to obtain the values for the parameters listed in Table 7.

Table 6. Sensor Information for Typical

PRT

Selecting R

ISRC

When using an external resistor, use the equation

below to determine the value of R

ISRC

, and place the

resistor between ISRC and VSS. Since the 12-bit FSO

DAC provides considerable dynamic range, the R

ISRC

value need not be exact. Generally any resistor value

within ±50% of the calculated value is acceptable. If

both the internal resistors R

ISRC

and R

FTC

are used, set

the IRS bit at EEPROM address bit 7 high. Otherwise,

set IRS low and connect external resistors as shown in

Figure 10.

where Rb(T) is the sensor input impedance at temperature T1 (+25°C in this example).

R Rb(T

k k

ISRC

≈

≈ =

)

14 1

14 5 70

x

x

Ω Ω

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

12 ______________________________________________________________________________________

5kΩ at +25°C

TYPICAL

VALUES

Rb(T)

2600ppm/°C

Bridge Impedance

TCR

SENSOR

DESCRIPTION

Bridge Impedance

Tempco

PARAMETER

1.5mV/V per

PSI at +25°C

S(T)

-2100ppm/°C

Sensitivity

TCS Sensitivity Tempco

12mV/V at

+25°C

O(T)

-1000ppm/°C

of FSO

Offset

OTC Offset Tempco

0.1% FSO,

BSLF

S(p)

0 PSI

Sensitivity Linearity Error

as % FSO, BSLF

(Best Straight-Line Fit)

P

MIN

Minimum Input Pressure

10 PSIP

MAX

Maximum Input Pressure

Page 13

Selecting R

FTC

When using an external resistor, use the equation

below to determine the value for R

FTC

, and place the

resistor between ISRC and FSOTC. Since the 12-bit

FSOTC DAC provides considerable dynamic range, the

R

FTC

value need not be exact. Generally, any resistor

value within ±50% of the calculated value is acceptable.

This approximation works best for bulk, micromachined,

silicon PRTs. Negative values for R

FTC

indicate unconventional sensor behavior that cannot be compensated

by the MAX1458 without additional external circuitry.

Selecting the PGA Gain Setting

To select the PGA gain setting, first calculate

SensorFSO, the sensor full-span output voltage at T1:

SensorFSO = S x V

BDRIVE

x ∆P

= 1.5mV/V per PSI x 2.5V x 10 PSI

= 0.0375V

where S is the sensor sensitivity at T1, V

BDRIVE

is the

sensor excitation voltage (initially 2.5V), and ∆P is the

maximum pressure differential.

Then calculate the ideal gain using the following formula,

and select the nearest gain setting from Table 2:

where OUTFSO is the desired calibrated transducer

full-span output voltage, and SensorFSO is the sensor

full-span output voltage at T1.

In this example, a PGA value of 2 (gain of +95V/V) is

the best selection.

Determining Input-Referred OFFSET (IRO)

The input-referred offset register is used to null any

front-end sensor offset errors prior to amplification by

the PGA. This reduces the possibility of saturating the

PGA and maximizes the useful dynamic range of the

PGA (particularly at the higher gain values.)

First, calculate the ideal IRO correction voltage using

the following formula, and select the nearest setting

from Table 1:

where IROideal is the exact voltage required to perfectly null the sensor, O(T1) is the sensor offset voltage in

V/V at +25°C, and V

BDRIVE

(T1) is the nominal sensor

excitation voltage at +25°C. In this example, 30mV

must be subtracted from the amplifier front end to null

the sensor perfectly. From Table 1, select an IRO value

of 3 to set the IRO DAC to 27mV, which is nearest the

ideal value. To subtract this value, set the IRO sign bit

to 0. The residual output-referred offset error will be

corrected later with the Offset DAC.

Determining OFFTC COEF Initial Value

Generally, OFFTC COEF can initially be set to 0, since

the offset TC error will be compensated in a later step.

However, sensors with large offset TC errors may

require an initial coarse offset TC adjustment to prevent

the PGA from saturating during the compensation procedure as temperature is increased. An initial coarse

offset TC adjustment is required for sensors with an offset TC greater than about 10% of the FSO. If an initial

IROideal - O T1 x V T1

- 0.012V/V x 2.5V

-30mV

BDRIVE

=

( ) ( )

[ ]

=

( )

=

A

OUTFSO

SensorFSO

4V

0.0375V

106V/V

PGA

=

= =

R

R x 500ppm/ C

70k x 500ppm/ C

70k

FTC

ISRC

≅

°

≅

°

° °

= Ω

TCR - TCS

2600ppm/ C - -2100ppm/ C

| |

| |

Ω

MAX1458

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

______________________________________________________________________________________ 13

A

PGA

Programmable-gain amplifier gain

R

ISRC

IRO

Internal (approximately 75kΩ) or usersupplied resistor that programs the nominal sensor excitation current.

Input-referred offset correction DAC

value

DESCRIPTION

IRO Sign

PARAMETER

Input-referred offset sign bit

IRS Internal resistor selection bit

OFF COEF Offset correction DAC coefficient

OFF Sign Offset sign bit

OFFTC COEF Offset TC compensation DAC coefficient

OFFTC Sign Offset TC sign bit

FSO COEF FSO trim DAC coefficient

FSOTC COEF FSO TC compensation DAC coefficient

R

FTC

Internal (approximately 75kΩ) or usersupplied resistor that compensates

FSO TC errors.

Table 7. Compensation Components and

Values

Page 14

MAX1458

coarse offset TC adjustment is required, use the following equation:

where OTC is the sensor offset TC error as a ppm/°C of

OUTFSO (Table 6), ∆T is the operating temperature

range in °C, and OFFTC COEF is the numerical decimal

value to be loaded into the DAC. For positive values,

set the OFFTC sign bit high; for negative values, set the

OFFTC sign bit low. If the absolute value of the OFFTC

COEF is larger than 4096, the sensor has a very large

offset TC error, which the MAX1458 is unable to completely correct.

FSO Calibration

Perform FSO calibration at room temperature with a fullscale sensor excitation.

1) Set FSOTC COEF to 1000.

2) At T1, adjust FSO DAC until V

BDRIVE

is about 2.5V.

3) Adjust Offset DAC (and OFFSET sign bit, if needed)

until the T1 offset voltage is 0.5V (see

OFFSET

Calibration

section).

4) Measure the full-span output (measuredV

FSO

).

5) Calculate the ideal bridge voltage, V

BIDEAL

(T1),

using the following equation:

Note: If V

BIDEAL

(T1) is outside the allowable bridge

voltage swing of (VSS+ 1.3V) to (VDD- 1.3V), readjust

the PGA gain setting. If V

BIDEAL

(T1) is too low,

decrease the PGA gain setting by one step and return

to Step 2. If V

BIDEAL

(T1) is too high, increase the PGA

gain setting by one step and return to Step 2.

6) Set V

BIDEAL

(T1) by adjusting the FSO DAC.

7) Readjust Offset DAC until the offset voltage is 0.5V

(see

OFFSET Calibration

section).

Three-Step FSOTC Compensation

Step 1

Use the following procedure to determine FSOTC

COEF. Four variables, A–D, will be used.

1) Name the existing FSO DAC coefficient “A”.

2) Change FSOTC DAC to 3000.

3) Adjust FSO DAC until V

BDRIVE

(T1) is equal to

V

BIDEAL

(T1).

4) Name the existing FSO DAC coefficient “B”.

5) Readjust the offset voltage (by adjusting the Offset

DAC), if required, to 0.5V.

At this point, it is important that no other changes be

made to the Offset or Offset TC DACs until the Offset

TC Compensation step has been completed.

Step 2

To complete linear FSOTC compensation, take data

measurements at a second temperature, T2 (T2 > T1).

Perform the following steps:

1) Measure the full-span output (measuredV

FSO

(T2).

2) Calculate V

BIDEAL

(T2) using the following equation:

3) Set V

BIDEAL

(T2) by adjusting the FSO DAC.

4) Name the current FSO DAC coefficient “D”.

5) Change FSOTC DAC to 1000.

6) Adjust FSO DAC until V

BDRIVE

is equal to

V

BIDEAL

(T2).

7) Name the FSO DAC coefficient “C”.

Step 3

Insert the data previously obtained from Steps 1 and 2

into the following equation to compute FSOTC COEF:

1) Load this FSOTC COEF value into the FSOTC DAC.

2) Adjust the FSO DAC until V

BDRIVE

(T2) is equal to

V

BIDEAL

(T2).

This completes both FSO calibration and FSO TC compensation.

FSOTC COEF

1000 B-D 3000 C- A

B-D C- A

=

( )

+

( )

( )

+

( )

V T2 V x

1

desiredV - measuredV T2

measuredV T2

BIDEAL BDRIVE

FSO FSO

FSO

( )

=

+

( )

( )

V T V x

1

desiredV - measuredV T

measuredV T

BIDEAL BDRIVE

FSO FSO

FSO

1

1

1

( )

=

+

( )

( )

OFFTC COEF

4096 x V T

V T x 2.3

4096 x OTC x FSO

TCS x V x 2.3 x

4096 x -1000ppm/ C x 4V

-2100ppm/ C x 2.5V x 2.3

OUT

BDRIVE

BDRIVE

=

( )

( )

≅

( )

=

°

( )

°

=

∆

∆

∆

∆

x T

T

1357

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

14 ______________________________________________________________________________________

Page 15

Offset TC Compensation

The offset voltage at T1 was previously set to 0.5V;

therefore, any variation from this voltage at T2 is an

offset TC error. Perform the following steps:

1) Measure the offset voltage at T2.

2) Use the following equation to compute the correction required:

Note: CurrentOFFTC COEF is the current value

stored in the Offset TC DAC. If the Offset TC sign bit

(SOTC) is low, this number is negative.

3) Load this value into the Offset TC DAC.

4) If NewOFFTC COEF is negative, set the SOTC bit

low; otherwise, set it high.

Offset TC Compensation is now complete.

OFFSET Calibration

At this point the sensor should still be at temperature

T2. The final offset adjustment can be made at T2 or T1

by adjusting the Offset DAC (and optionally the offset

sign bit, SOFF) until the output (V

OUT(P

MIN

)

) reads 0.5V

at zero input pressure. Use the following procedure:

1) Set Offset DAC to zero (Offset COEF = 0).

2) Measure the voltage at OUT.

3) If V

OUT

is greater than the desired offset voltage

(0.5V in this example), set SOFF low; otherwise set it

high.

4) Increase Offset COEF until V

OUT

equals the desired

offset voltage.

Offset calibration is now complete. Table 8 and Figure 9

compare an uncompensated input to a typical compensated transducer output.

NewOFFTC COEF CurrentOFFTC COEF +

4096 V T - V T2

2.3 V T - V T2

OFFSET OFFSET

BDRIVE BDRIVE

=

( ) ( )

[ ]

( ) ( )

[ ]

1

1

MAX1458

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

______________________________________________________________________________________ 15

Typical Uncompensated Input (Sensor) Typical Compensated Transducer Output

Offset ..........................................................................±80% FSO

FSO..................................................................................15mV/V

Offset TC......................................................................-17% FSO

Offset TC Nonlinearity..................................................0.7% FSO

FSO TC.........................................................................-35% FSO

FSO TC Nonlinearity.....................................................0.5% FSO

Temperature Range...........................................-40°C to +125°C

V

OUT

...................................................Ratiometric to VDDat 5.0V

Offset at +25°C ......................................................0.500V ±5mV

FSO at +25°C .........................................................4.000V ±5mV

Offset Accuracy Over Temp. Range ..........±28mV (±0.7% FSO)

FSO Accuracy Over Temp. Range.............±20mV (±0.5% FSO)

Table 8. MAX1458 Calibration and Compensation

-20

-10

10

0

20

30

-50 0 50 100 150

UNCOMPENSATED SENSOR ERROR

TEMPERATURE (°C)

ERROR (% FSO)

OFFSET

FSO

-0.8

-0.6

0.4

-0.2

-0.4

0

0.2

0.6

0.8

-50 0 50 100 150

COMPENSATION TRANSDUCER ERROR

TEMPERATURE °(C)

ERROR (% SPAN)

OFFSET

FSO

Figure 9. Comparison of an Uncalibrated Sensor and a Temperature-Compensated Transducer

Page 16

MAX1458

Ratiometric Output Configuration

Ratiometric output configuration provides an output that

is proportional to the power-supply voltage. When used

with ratiometric A/D converters, this output provides

digital pressure values independent of supply voltage.

Most automotive and some industrial applications

require ratiometric outputs.

The MAX1458 provides a high-performance ratiometric

output with a minimum number of external components

(Figure 10). These external components include the following:

• One power-supply bypass capacitor (C1)

• Two optional resistors, one from FSOTC to ISRC, and

another from ISRC to VSS, depending on the sensor

type

• One optional capacitor C2 from BDRIVE to V

SS

Test System Configuration

The MAX1458 is designed to support an automated

production pressure-temperature test system with integrated calibration and temperature compensation.

Figure 11 shows the implementation concept for a lowcost test system capable of testing up to 12 transducer

modules connected in parallel. Three-state outputs on

the MAX1458 allow for parallel connection of transducers. The test system shown in Figure 11 includes a

dedicated test bus consisting of five wires:

• Two power-supply lines

• One analog output voltage line from the transducers

to a system digital voltmeter

• Two serial-interface lines: DIO (input/output) and

SCLK (clock)

For simultaneous testing of more than 12 sensor modules, use buffers to prevent overloading the data bus. A

digital multiplexer controls the chip-select signal for

each transducer.

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

16 ______________________________________________________________________________________

MAX1458

12-BIT D/A - OFFSET TC

12-BIT D/A - OFFSET

CONFIGURATION REGISTER

12-BIT D/A - FSO

OFFSET

(IRODAC)

12-BIT D/A - FSOTC

FSOTC

LIMIT

TEMP

A = 1

V

SS

+5V

OUT

V

DD

DIGITAL

INTERFACE

PGA

CS

TEMP

WE

SCLK

DIO

BDRIVE

INM

ISRC

INP

C2

0.1µF

C1

0.1µF

V

SS

R

ISRC

R

FTC

R

ISRC

R

FTC

128-BIT

EEPROM

V

DD

Σ

SENSOR

Figure 10. Basic Ratiometric Output Configuration

Page 17

MAX1458 Evaluation

____________________________________ Development Kit

To expedite the development of MAX1458 based transducers and test systems, Maxim has produced the

MAX1458 evaluation kit (EV kit).

First-time users of the

MAX1458 are strongly encouraged to use this kit.

The

MAX1458 EV kit is designed to facilitate manual programming of the MAX1458 and includes the following:

1) Evaluation Board with a silicon pressure sensor.

2) Design/Applications Manual, which describes in

detail the architecture and functionality of the

MAX1458. This manual was developed for test engineers familiar with data acquisition of sensor data

and provides sensor compensation algorithms and

test procedures.

3) MAX1458 Communication Software, which enables

programming of the MAX1458 from a computer (IBM

compatible), one module at a time.

4) Interface Adapter and Cable, which allow the con-

nection of the evaluation board to a PC parallel port.

MAX1458

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

______________________________________________________________________________________ 17

MAX1458

DIO

OUT

V

DD

CS

MODULE 1

SCLK

V

SS

V

SS

V

DD

V

DD

V

SS

TEST

OVEN

MAX1458

DIO

OUT

CS

MODULE 2

SCLK

DIO

VOUT

DIGITAL

MULTIPLEXER

+5V

CS[1:N]

CS1

BDRIVE

INP

INM

BDRIVE

INP

INM

BDRIVE

INP

INM

CS2

CSN

SCLK

MAX1458

DIO

OUT

CS

MODULE N

SCLK

DVM

Figure 11. Automated Test System Concept

Page 18

MAX1458

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

18 ______________________________________________________________________________________

Functional Diagram

MAX1458

12-BIT D/A - OFFSET TC

12-BIT D/A - OFFSET

CONFIGURATION REGISTER

12-BIT D/A - FSO

OFFSET

(IRODAC)

12-BIT D/A - FSOTC

FSOTC

LIMIT

TEMP

A = 1

V

SS

OUT

V

DD

DIGITAL

INTERFACE

PGA

CS

TEMP

WE

SCLK

DIO

BDRIVE

INM

ISRC

INP

V

SS

R

ISRC

R

FTC

128-BIT

EEPROM

V

DD

Σ

Chip Information

TRANSISTOR COUNT: 7772

SUBSTRATE CONNECTED TO V

SS

Page 19

MAX1458

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

______________________________________________________________________________________ 19

Package Information

SSOP.EPS

Page 20

MAX1458

1%-Accurate, Digitally Trimmed

Sensor Signal Conditioner

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

20

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 1998 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

Maxim cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Maxim product. No circuit patent licenses are

implied. Maxim reserves the right to change the circuitry and specifications without notice at any time.

20

____________________Maxim Integrated Products, 120 San Gabriel Drive, Sunnyvale, CA 94086 408-737-7600

© 1998 Maxim Integrated Products Printed USA is a registered trademark of Maxim Integrated Products.

NOTES

Loading...

Loading...