Page 1

Low Noise, Matched

a

FEATURES

Dual Matched PNP Transistor

Low Offset Voltage: 100 V Max

Low Noise: 1 nV/√Hz @ 1 kHz Max

High Gain: 100 Min

High Gain Bandwidth: 190 MHz Typ

Tight Gain Matching: 3% Max

Excellent Logarithmic Conformance: r

GENERAL DESCRIPTION

The MAT03 dual monolithic PNP transistor offers excellent

parametric matching and high frequency performance. Low

√

noise characteristics (1 nV/

(190 MHz typical), and low offset voltage (100 µV max), makes

the MAT03 an excellent choice for demanding preamplifier applications. Tight current gain matching (3% max mismatch) and

high current gain (100 min), over a wide range of collector current, makes the MAT03 an excellent choice for current mirrors.

A low value of bulk resistance (typically 0.3 Ω) also makes the

MAT03 an ideal component for applications requiring accurate

logarithmic conformance.

Hz max @ 1 kHz), high bandwidth

⯝ 0.3 ⍀ typ

BE

Dual PNP Transistor

MAT03

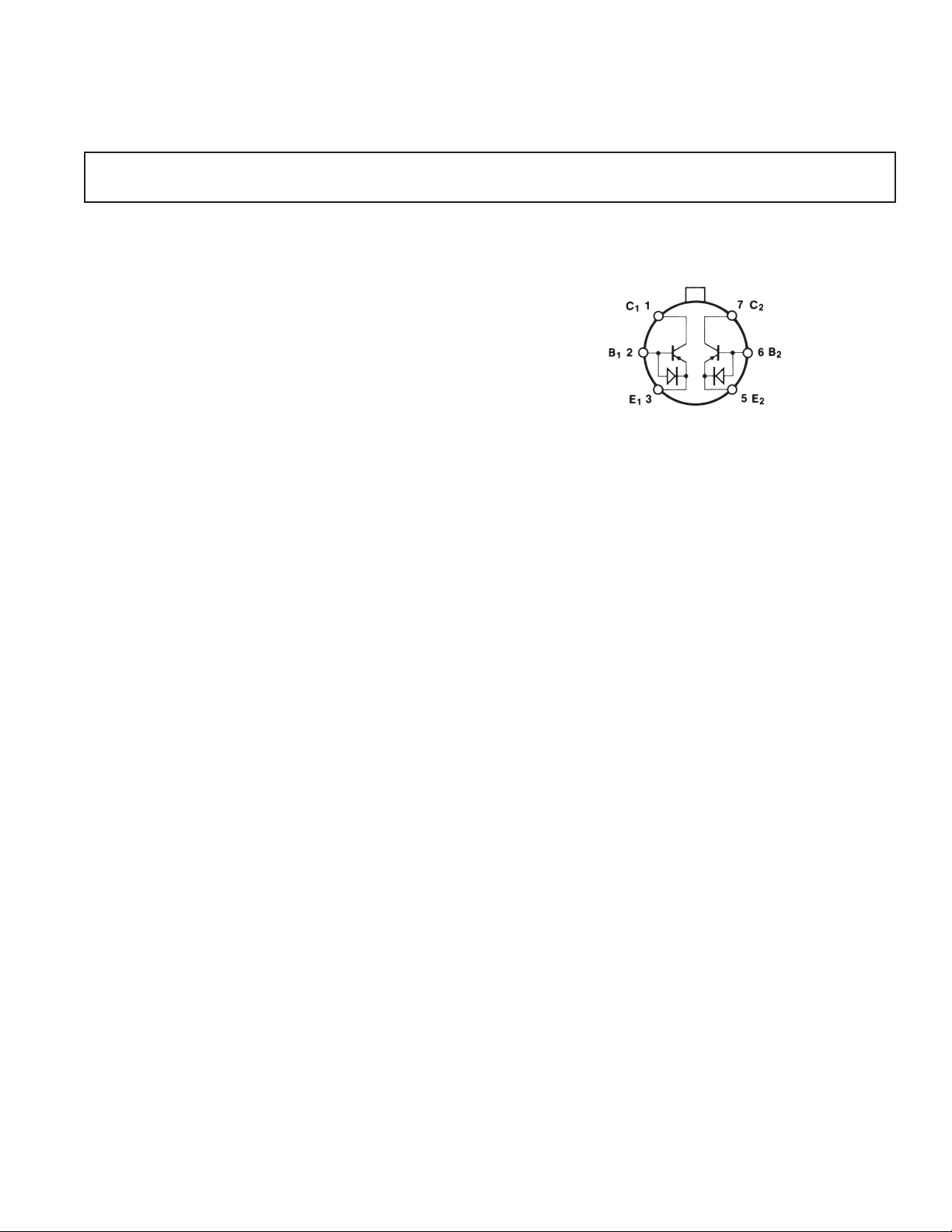

PIN CONNECTION

TO-78

(H Suffix)

Each transistor is individually tested to data sheet specifications.

Device performance is guaranteed at 25°C and over the extended

industrial and military temperature ranges. To ensure the longterm stability of the matching parameters, internal protection

diodes across the base-emitter junction clamp any reverse baseemitter junction potential. This prevents a base-emitter breakdown

condition that can result in degradation of gain and matching

performance due to excessive breakdown current.

REV. C

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

Page 2

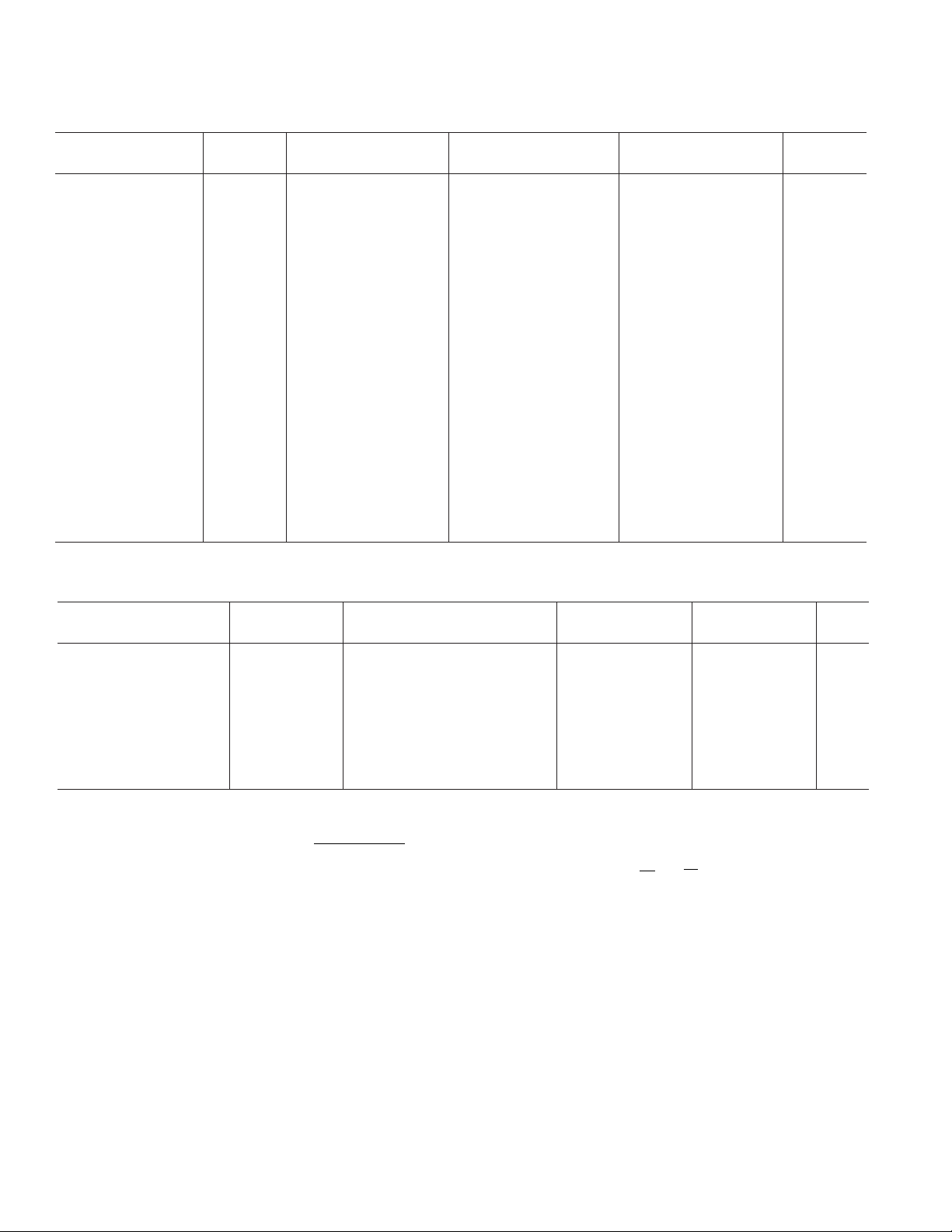

MAT03–SPECIFICATIONS

ELECTRICAL CHARACTERISTICS

(@ TA = 25ⴗC, unless otherwise noted.)

MAT03E MAT03F

Parameter Symbol Conditions Min Typ Max Min Typ Max Unit

Current Gain

Current Gain Matching

Offset Voltage

Offset Voltage Change ∆V

vs. Collector Voltage V

Offset Voltage Change ∆V

vs. Collector Current I

Bulk Resistance r

Offset Current I

1

3

h

FE

2

Dh

FE

V

OS

/∆V

OS

/∆I

OS

BE

OS

VCB = 0 V, –36 V

= 1 mA 100 165 80 165

I

C

= 100 µA 90 150 70 150

I

C

= 10 µA 80 120 60 120

I

C

IC = 100 µA,VCB = 0 V 0.5 3 0.5 6 %

VCB = 0 V, IC = 100 µA 40 100 40 200 µV

= 100 µA

CBIC

C

= 0 V 11 150 11 200 µV

CB1

= –36 V 11 150 11 200 µV

V

CB2

VCB = 0 V 12 50 12 75 µV

= 10 µA, IC2 = 1 mA 12 50 12 75 µV

C1

VCB = 0 V 0.3 0.75 0.3 0.75 Ω

10 µA ≤ I

≤ 1 mA 0.3 0.75 0.3 0.75 Ω

C

IC = 100 µA, VCB = 0 V 6 35 6 45 nA

Collector-Base

Leakage Current I

Noise Voltage Density4e

CB0

N

VCB = –36 V = V

MAX

IC = 1 mA, VCB = 0

= 10 Hz 0.8 0.8 nV/÷Hz

f

O

= 100 Hz 0.7 0.7 nV/÷Hz

f

O

50 200 50 400 pA

fO = 1 kHz 0.7 0.7 nV/÷ Hz

= 10 kHz 0.7 0.7 nV/÷ Hz

f

O

Collector Saturation

Voltage V

CE(SAT)

IC = 1 mA, IB = 100 µA 0.025 0.1 0.025 0.1 V

ELECTRICAL CHARACTERISTICS

(@ –40ⴗC ≤ TA ≤ 85ⴗC, unless otherwise noted.)

MAT03E MAT03F

Parameter Symbol Conditions Min Typ Max Min Typ Max Unit

Current Gain h

Offset Voltage V

Offset Voltage Drift

5

Offset Current I

Breakdown Voltage BV

NOTES

1

Current gain is measured at collector-base voltages (VCB) swept from 0 to V

2

Current gain matching (∆hFE) is defined as: ∆h

3

Offset voltage is defined as: VOS = V

4

Sample tested. Noise tested and specified as equivalent input voltage for each transistor.

5

Guaranteed by VOS test (TCVOS = VOS/T for VOS VBE) where T = 298°K for TA = 25°C.

Specifications subject to change without notice.

TCV

OS

BE1

FE

OS

OS

CEO

FE =

– V

, where VOS is the differential voltage for IC1 = IC2: VOS = V

BE2

VCB = 0 V, –36 V

= 1 mA 70 120 60 120

I

C

I

= 100 µA 60 105 50 105

C

I

= 10 µA 5090 4090

C

IC = 100 µA, VCB = 0 V 30 135 30 265 µV

IC = 100 µA, VCB = 0 V 0.3 0.5 0.3 1.0 µV/°C

IC = 100 µA, VCB = 0 V 1085 10200 nA

36 36 V

at indicated collector current. Typicals are measured at VCB = 0 V.

100 (∆IB) hFE(min )

I

C

MAX

.

I

BE1

– V

BE2

=

KT

C1

In

q

.

I

C2

–2–

REV. C

Page 3

MAT03

WARNING!

ESD SENSITIVE DEVICE

ORDERING GUIDE

VOS max Temperature Package

Model (TA = +25ⴗC) Range Option

MAT03EH 100 µV –40°C to +85°C TO-78

MAT03FH 200 µV –40°C to +85°C TO-78

ABSOLUTE MAXIMUM RATINGS

Collector-Base Voltage (BV

CBO

Collector-Emitter Voltage (BV

Collector-Collector Voltage (BV

Emitter-Emitter Voltage (BV

Collector Current (I

Emitter Current (I

C

) . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 mA

E

EE

) . . . . . . . . . . . . . . . . . . . . . . . . . . 20 mA

Total Power Dissipation

Ambient Temperature ≤ 70°C

Operating Temperature Range

MAT03E/F . . . . . . . . . . . . . . . . . . . . . . . . –40°C to +85°C

Operating Junction Temperature . . . . . . . . . –55°C to +150°C

Storage Temperature . . . . . . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (Soldering, 60 sec) . . . . . . . . . . . . . 300°C

Junction Temperature . . . . . . . . . . . . . . . . . –65°C to +150°C

NOTES

1

Absolute maximum ratings apply to both DICE and packaged devices.

2

Rating applies to TO-78 not using a heat sink and LCC; devices in free air only. For

TO-78, derate linearly at 6.3 mW/°C above 70°C ambient temperature; for LCC,

derate at 7.8 mW/°C.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the MAT03 features propriety ESD protection circuitry, permanent damage may occur

on devices subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions

are recommended to avoid performance degradation or loss of functionality.

1

) . . . . . . . . . . . . . . . . . . . 36 V

) . . . . . . . . . . . . . . . . . 36 V

CEO

) . . . . . . . . . . . . . . . . . 36 V

CC

) . . . . . . . . . . . . . . . . . . . 36 V

2

. . . . . . . . . . . . . . . 500 mW

REV. C

–3–

Page 4

MAT03

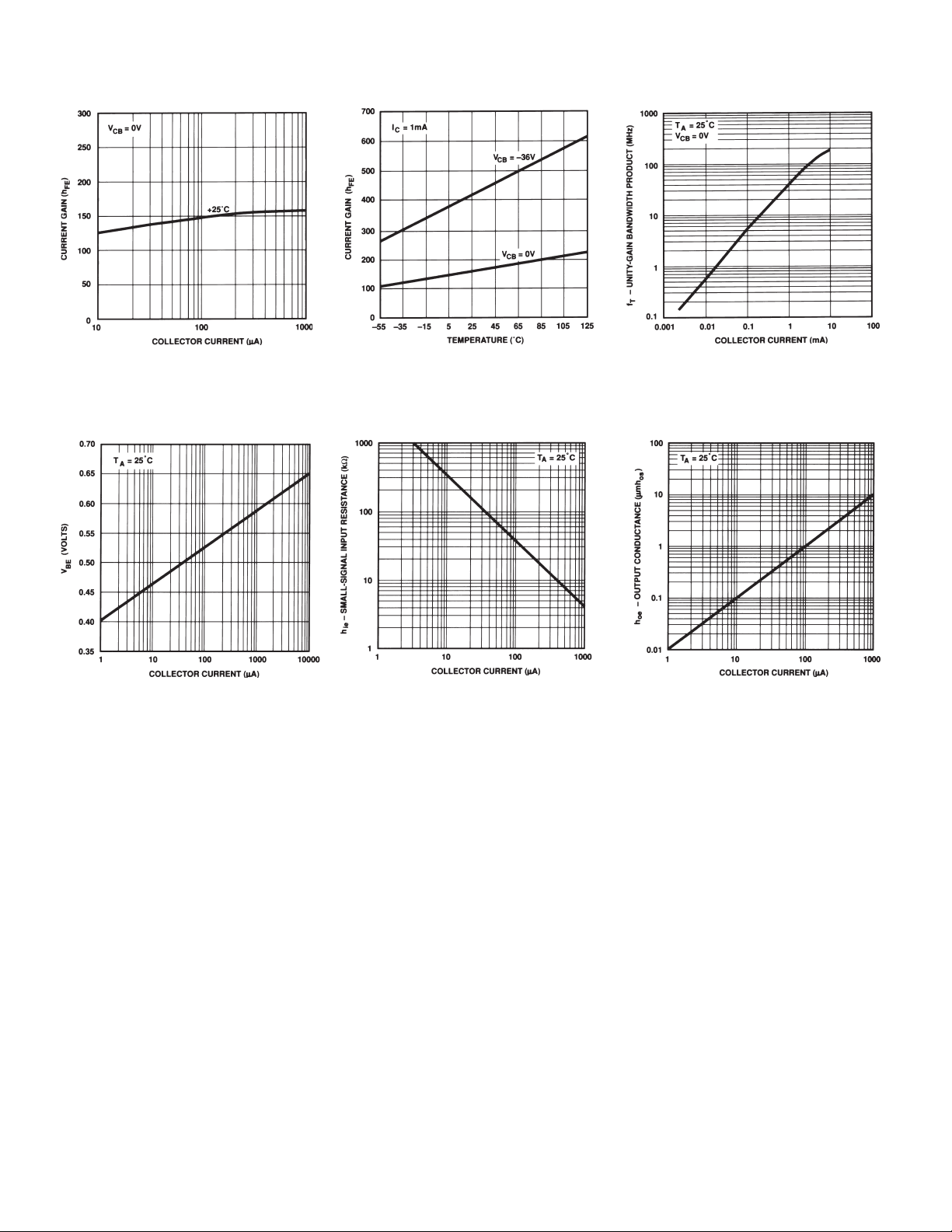

–Typical Performance Characteristics

TPC 1. Current Gain vs.

Collector Current

TPC 4. Base-Emitter Voltage

vs. Collector Current

TPC 2. Current Gain

vs. Temperature

TPC 5. Small-Signal Input Resistance

) vs. Collector Current

(h

ie

TPC 3. Gain Bandwidth vs.

Collector Current

TPC 6. Small Signal Output Conductance (h

) vs. Collector Current

oe

–4–

REV. C

Page 5

MAT03

TPC 7. Saturation Voltage

vs. Collector Current

TPC 10. Total Noise vs. Collector Current

TPC 8. Noise Voltage Density

vs. Frequency

TPC 11. Collector-Base Capacitance vs. V

TPC 9. Noise Voltage Density

CB

REV. C

–5–

Page 6

MAT03

Figure 1. SPICE or SABER Model

APPLICATIONS INFORMATION

MAT03 MODELS

The MAT03 model (Figure 1) includes parasitic diodes D

3

through D6. D1 and D2 are internal protection diodes that prevent

zenering of the base-emitter junctions.

The analysis programs, SPICE and SABER, are primarily used

in evaluating the functional performance of systems. The models

are provided only as an aid in using these simulation programs.

MAT03 NOISE MEASUREMENT

All resistive components (Johnson noise, e

= 0.13√R nV/√Hz, where R is in kΩ) and semiconductor

e

n

2

= 4kTBR, or

n

junctions (shot noise, caused by current flowing through a

junction, produces voltage noise in series impedances such as

transistor-collector load resistors, I

= 0.566 √I pA/√Hz where

n

I is in µA) contribute to the system input noise.

Figure 2 illustrates a technique for measuring the equivalent input noise voltage of the MAT03. 1 mA of stage current is used

Figure 2. MAT03 Voltage Noise Measurement Circuit

–6–

REV. C

Page 7

MAT03

to bias each side of the differential pair. The 5 kΩ collector

resistors noise contribution is insignificant compared to the voltage noise of the MAT03. Since noise in the signal path is referred

back to the input, this voltage noise is attenuated by the gain of

the circuit. Consequently, the noise contribution of the collector load resistors is only 0.048 nV/√Hz. This is considerably

less than the typical 0.8 nV/√Hz input noise voltage of the

MAT03 transistor.

The noise contribution of the OP27 gain stages is also negligible due to the gain in the signal path. The op amp stages

amplify the input referred noise of the transistors to increase the

signal strength to allow the noise spectral density (e

to be measured with a spectrum analyzer. Since we assume

equal noise contributions from each transistor in the MAT03,

the output is divided by √2 to determine a single transistor’s

input noise.

Air currents cause small temperature changes that can appear

as

low frequency noise. To eliminate this noise source, the mea-

× 10000)

in

surement circuit must be thermally isolated. Effects of extraneous

noise sources must also be eliminated by totally shielding the circuit.

SUPER LOW NOISE AMPLIFIER

The circuit in Figure 3a is a super low noise amplifier with

equivalent input voltage noise of 0.32 nV/√Hz. By paralleling

three MAT03 matched pairs, a further reduction of amplifier

noise is attained by a reduction of the base spreading resistance

by a factor of 3, and consequently the noise by √3. Additionally,

the shot noise contribution is reduced by maintaining a high

collector current (2 mA/device) which reduces the dynamic

emitter resistance and decreases voltage noise. The voltage noise

is inversely proportional to the square root of the stage current,

and current noise increases proportionally to the square root of

the stage current. Accordingly, this amplifier capitalizes on

voltage noise reduction techniques at the expense of increasing

the current noise. However, high current noise is not usually

important when dealing with low impedance sources.

REV. C

Figure 3a. Super Low Noise Amplifier

–7–

Page 8

MAT03

This amplifier exhibits excellent full power ac performance,

0.08% THD into a 600 Ω load, making it suitable for exacting

audio applications (see Figure 3b).

Figure 3b. Super Low Noise Amplifier—Total

Harmonic Distortion

LOW NOISE MICROPHONE PREAMPLIFIER

Figure 4 shows a microphone preamplifier that consists of a

MAT03 and a low noise op amp. The input stage operates at a

relatively high quiescent current of 2 mA per side, which reduces

the MAT03 transistor’s voltage noise. The 1/ƒ corner is less than

1 Hz. Total harmonic distortion is under 0.005% for a 10 V p-p

signal from 20 Hz to 20 kHz. The preamp gain is 100, but can be

modified by varying R

or R6 (V

5

OUT/VIN

A total input stage emitter current of 4 mA is provided by Q

The constant current in Q

is set by using the forward voltage of

2

= R5/R6 + 1).

.

2

a GaAsP LED as a reference. The difference between this voltage

and the V

of a silicon transistor is predictable and constant (to

BE

a few percent) over a wide temperature range. The voltage difference, approximately 1 V, is dropped across the 250 Ω resistor

which produces a temperature stabilized emitter current.

CURRENT SOURCES

A fundamental requirement for accurate current mirrors and

active load stages is matched transistor components. Due to the

excellent V

matching (the voltage difference between VBEs

BE

required to equalize collector current) and gain matching, the

MAT03 can be used to implement a variety of standard current

mirrors that can source current into a load such as an amplifier

stage. The advantages of current loads in amplifiers versus

resistors is an increase of voltage gain due to higher impedances, larger signal range, and in many applications a wider

signal bandwidth.

Figure 5 illustrates a cascode current mirror consisting of two

MAT03 transistor pairs.

The cascode current source has a common base transistor in series with the output which causes an increase in output impedance of the current source since V

stays relatively constant.

CE

High frequency characteristics are improved due to a reduction

of Miller capacitance. The small-signal output impedance can

be determined by consulting “h

vs. Collector Current” typical

OF

graph. Typical output impedance levels approach the performance of a perfect current source.

Considering a typical collector current of 100 µA, we have:

ro

=

Q3

1

MHOS

= 1 MΩ

1. 0

µ

Figure 4. Low Noise Microphone Preamplifier

–8–

REV. C

Page 9

MAT03

Q2 and Q3 are in series and operate at the same current levels so

the total output impedance is:

RO = hFE roQ3 @ (160)(1 MΩ) = 160 MΩ.

Figure 5. Cascode Current Source

CURRENT MATCHING

The objective of current source or mirror design is generation of

currents that are either matched or must maintain a constant ratio. However, mismatch of base emitter voltages cause output

current errors. Consider the example of Figure 5. If the resistors

and transistors are equal and the collector voltages are the same,

the collector currents will match precisely. Investigating the current matching errors resulting from a nonzero V

as the current error between the two transistors.

∆I

C

, we define

OS

Graph 6b describes the relationship of current matching errors

versus offset voltage for a specified average current I

. Note that

C

since the relative error between the currents is exponentially

proportional to the offset voltage, tight matching is required to

design high accuracy current sources. For example, if the offset

voltage is 5 mV at 100 µA collector current, the current match-

ing error would be 20%. Additionally, temperature effects such

as offset drift (3 µV/°C per mV of V

if Q

and Q2 are not well matched.

1

DIGITALLY PROGRAMMABLE BIPOLAR CURRENT PUMP

) will degrade performance

OS

The circuit of Figure 7 is a digitally programmable current

pump. The current pump incorporates a DAC08, and a fast

Wilson current source using the MAT03. Examining Figure 7,

the DAC08 is set for 2 mA full-scale range so that bipolar current operation of ±2 mA is achieved. The Wilson current mirror

maintains linearity within the LSB range of the 8-bit DAC08

(±2 mA/256 = 15.6 µA resolution) as seen in Figure 8. A negative feedback path established by Q

regulates the collector cur-

2

rent so that it matches the reference current programmed by the

DAC08.

Collector-emitter voltages across both Q

by D

, with Q3’s collector-emitter voltage remaining constant,

1

and Q3 are matched

1

independent of the voltage across the current source output.

Since Q

maintain the same collector current. D

clamp which prevents Q

buffers Q3, both transistors in the MAT03, Q1 and Q3,

2

from turning off, thereby improving

2

and D3 form a Baker

2

the switching speed of the current mirror. The feedback serves

to increase the output impedance and improves accuracy by reducing the base-width modulation which occurs with varying

collector-emitter voltages. Accuracy and linearity performance

of the current pump is summarized in Figure 8.

Figure 6a. Current Matching Circuit

Figure 6b. Current Matching Accuracy %

vs. Offset Voltage

REV. C

Figure 7. Digitally Programmable Bipolar Current Pump

–9–

Page 10

MAT03

Figure 8. Digitally Programmable Current

Pump—INL Error as Digital Code

The full-scale output of the DAC08, I

of I

REF

256

IFR =

The current mirror output is I

I

REF

I = 2 I

= 2

× I

256

= 2 mA:

– 1.992 mA

OUT

Input Code

256

REF

, and I

OUT

OUT

+

–

(2 mA) – 1.992 mA.

, is a linear function

OUT

= I

I

OUT

I

OUT

REF

= 1, so that if

256

256

DIGITAL CURRENT PUMP CODING

Digital Input

B1 . . . B8 Output Current

FULL RANGE 1111 1111 I = 1.992 mA

HALF RANGE 1000 0000 I = 0.008 mA

ZERO SCALE 0000 0000 I = –1.992 mA

–10–

REV. C

Page 11

0.185 (4.70)

0.165 (4.19)

0.370 (9.40)

0.335 (8.51)

0.335 (8.51)

0.305 (7.75)

0.040 (1.02) MAX

0.045 (1.14)

0.010 (0.25)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

TO-78 Metal Can

REFERENCE PLANE

0.750 (19.05)

0.500 (12.70)

0.250 (6.35) MIN

0.050 (1.27) MAX

0.019 (0.48)

0.016 (0.41)

0.021 (0.53)

0.016 (0.41)

BASE & SEATING PLANE

0.200

(5.08)

BSC

0.100

(2.54)

BSC

0.100 (2.54) BSC

4

3

2

1

0.034 (0.86)

0.027 (0.69)

0.160 (4.06)

0.110 (2.79)

5

6

45° BSC

0.045 (1.14)

0.027 (0.69)

MAT03

Revision History

Location Page

Data Sheet changed from REV. B to REV. C.

Edits to ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Deleted WAFER TEST LIMITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Deleted DICE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Edits to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Edits to ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

REV. C

–11–

Page 12

C00284-0-2/02(C)

–12–

PRINTED IN U.S.A.

Loading...

Loading...