Page 1

MA17502

1/30

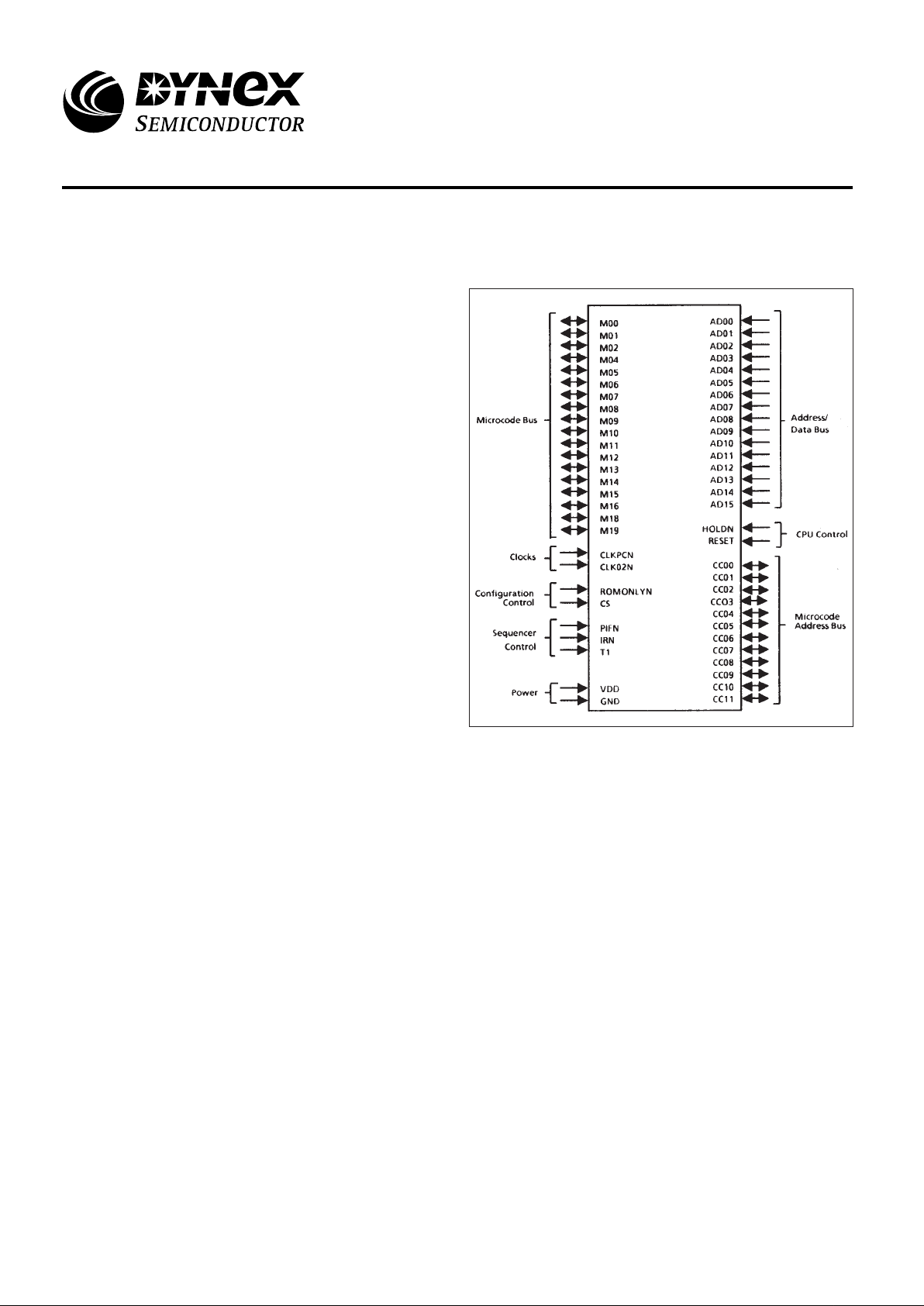

BLOCK DIAGRAM

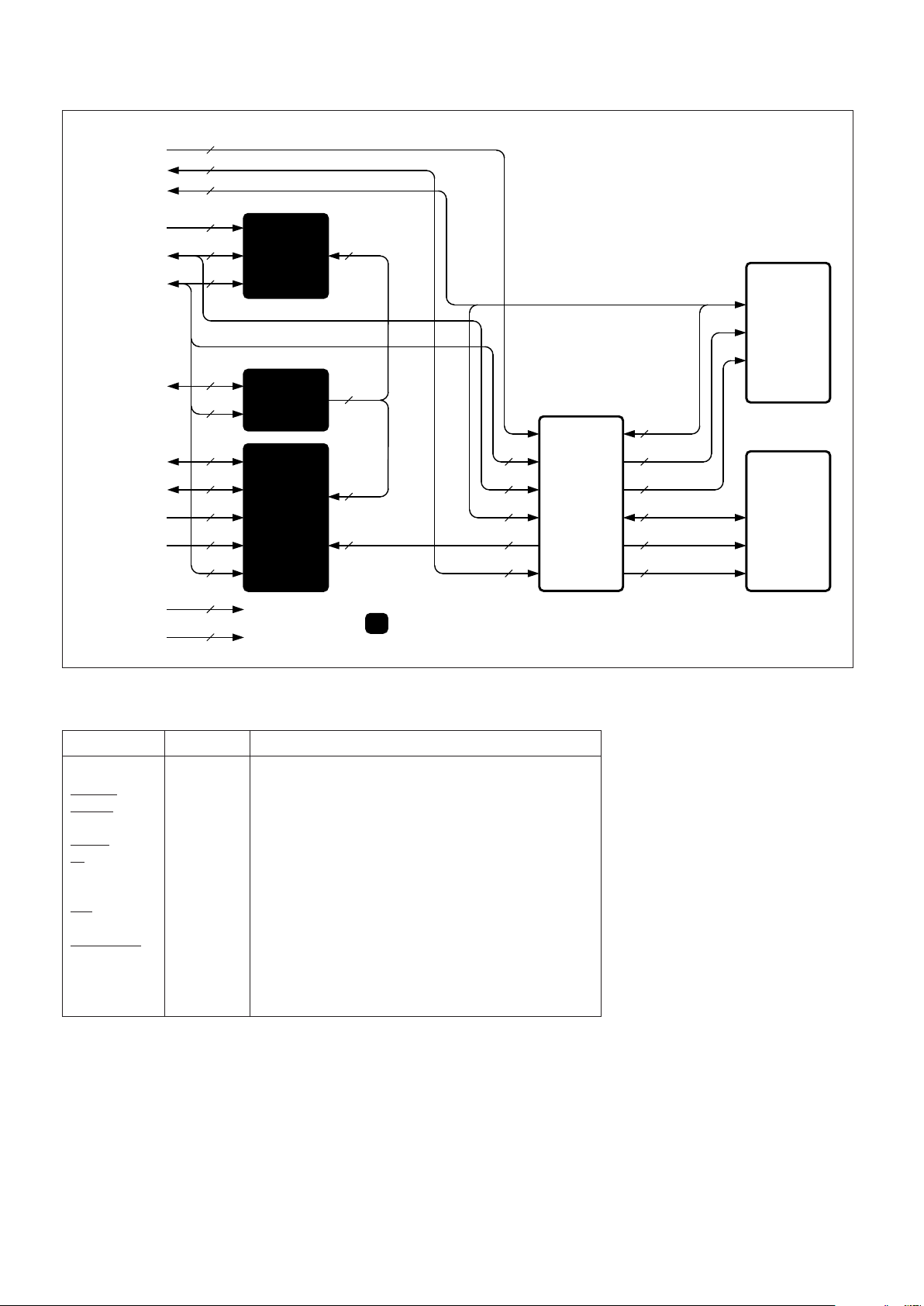

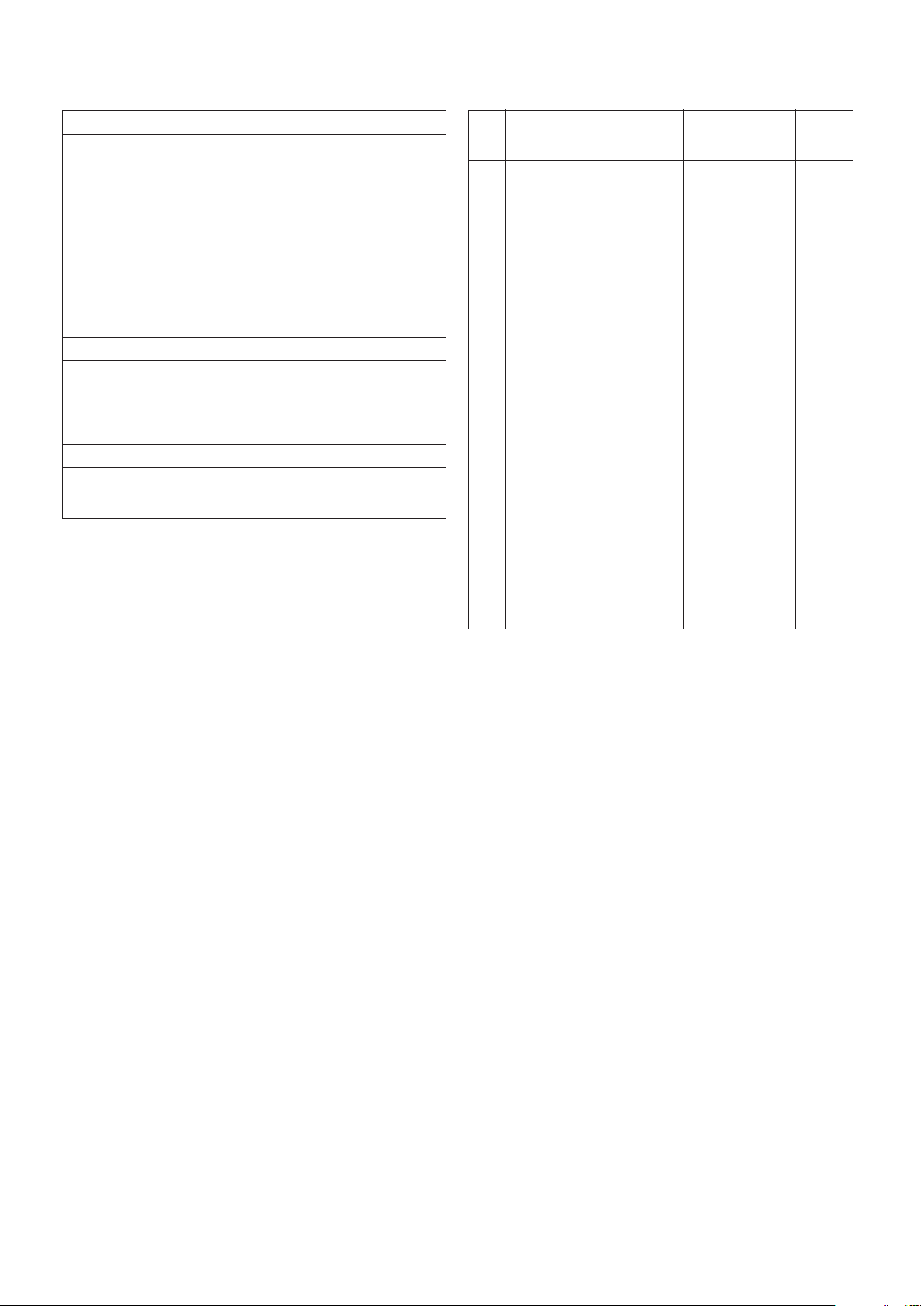

The MA17502 Control Unit is a component of the MAS281

chip set. Other chips in the set include the MA17501 Execution

Unit and the MA17503 Interrupt Unit. Also available is the

peripheral MA31751 Memory Management Unit/Block

Protection Unit. In conjunction these chips implement the full

MIL-STD-1750A Instruction Set Architecture.

The MA17502 consisting of a microsequencer, a microcode

storage ROM, and an instruction mapping ROM - controls all

chip set operations. Table 1 provides brief signal definitions.

The MA17502 is offered in several speed and screening

grades, and in dual in-line, flatpack or leadless chip carrier

packaging. Screening options are described in this document.

For availability of speed grades, please contact Dynex

Semiconductor.

FEATURES

■ MIL-STD-1750A Instruction Set Architecture

■ Full Performance Over Military Temperature Range

■ 12-Bit Microsequencer

- Instruction Prefetch

- Pipelined Operation

- Subroutine Capability

■ On-Chip ROM

- 2K x 40-Bit Microcode Store

- 512 x 8-Bit Instruction Map

■ MAS281 Integrated Built-In Self Test

■ TTL Compatible System Interface

■ Low Power CMOS/SOS Technology

1.0 SYSTEM CONSIDERATIONS

The MA17502 Control Unit (CU) is a component of the

Dynex Semiconductor MAS281 chip set. The other chips in the

set are the MA17501 Execution Unit (EU) and the MA17503

lnterrupt Unit (lU). Also available is the peripheral MA31751

Memory Management Unit/Block Protection Unit (MMU(BPU)).

The Control Unit, in conjunction with these chips, implements

the full MIL-STD-1750A lnstruction Set Architecture. Figure 1

depicts the relationship between the chip set components.

The CU provides the microprogram storage and

sequencing resources for the chip set. The EU provides the

MAS281’s system synchronizing and arithmetic/logic

computational resources. The lU provides interrupt and fault

handling resources, DMA interface control signals, and the

three MIL-STD-1750A timers. The MMU/BPU may be

configured to provide 1M-word memory management (MMU)

and/or 1K-word memory block write protection (BPU) functions.

MA17502

Radiation Hard MIL-STD-1750A Control Unit

Replaces June 1999 version, DS3565-4.0 DS3565-5.0 January 2000

Page 2

MA17502

2/30

Figure 1: MAS281 Chip Set With Optional MA17504 and Support RAMs

Signature l/O Definition

AD00 - AD15 I External 16-Bit Address/Data Bus

CC00 - CC11 I/O 12-Bit Microcode Address Bus

CLKPC I Precharge Clock

CLK02 I Phase 2 Clock

CS I Chip Select

HOLD I Hold Request Suspends lnternal Processor Functions

IR I Interrupt Request

M00 - M19 I/O/Z 20-Bit Microcode Bus

NC - No Connection

PIF I Privileged lnstruction Fault

RESET I Rest Indicates Device Initialization

ROMONLY I Indicates if Control Unit to be Used as ROM Only

T1 I Branch or Jump Control

VDD Power (External), 5 Volts

GND Ground

Table 1: Signal Definitions

MA17501

Execution

Unit

MA17502

Control

Unit

MA17503

Interrupt

Unit

MA31751

Block

Protection

& Memory

Management

Unit

Protection

RAM

128 x 16

Page

RAM

512 x 13

Address

7

Control

1

Data

16

Address

9

Control

1

Data

13

4

3

8

7

16

3

3

20

20

M Bus

16

4

4

7

9

10

1

16

1

16

10

1

8

4

8

Status

Control

Physical Page

Address

Clock

Control

Address/Data

Bus

Control

Control

Faults

Interrupts

Timer

Controls

Power

Reset

MAS281 Chip Set

Page 3

MA17502

3/30

As shown in Figure 1, the MAS281 is the minimum

processor configuration consisting of an Execution Unit, a

Control Unit, and an Interrupt Unit. This configuration is

capable of accessing a 64K-word address space. Addition of

an MMU configured MA31751 allows access to a 1M-word

address space. This can also be configured as a BPU to

provide hardware support for 1K-word memory block write

protection.

The CU, as with all components of the MAS281 chip set, is

fabricated with CMOS/SOS process technology. Input and

output buffers associated with signals external to the MAS281

are TTL compatible.

Detailed descriptions of the CU’s companion chips are

provided in separate data sheets. Additional discussions on

chip set system considerations, interconnection details, and the

Digital Avionics lnstruction Set (DAlS) mix benchmarking

analysis are provided in separate applications notes.

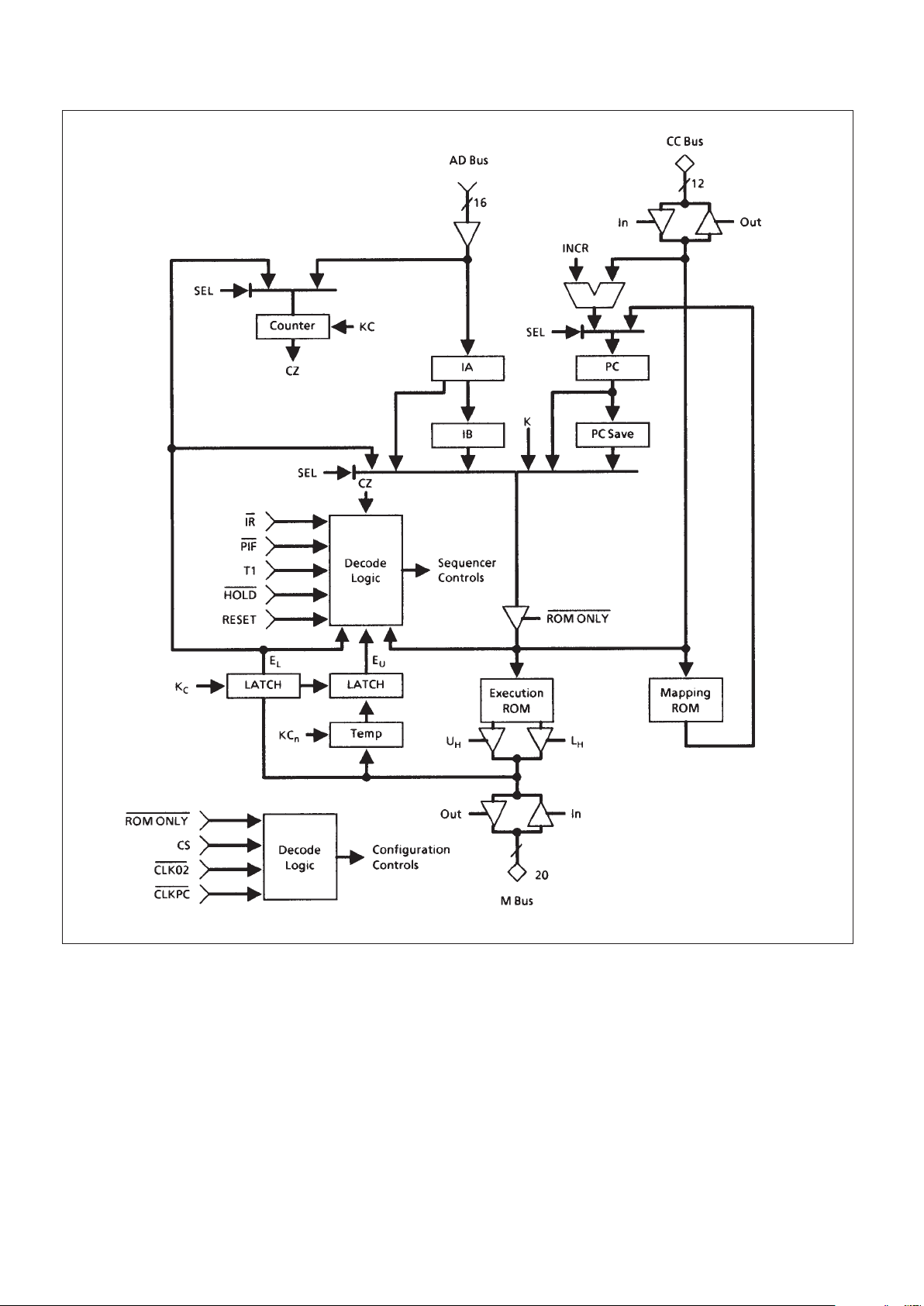

2.0 ARCHITECTURE

The Control Unit consists of a microsequencer, an

instruction mapping ROM, a microcode storage ROM, and

various buses. Details of these components are shown in

Figure 2 and are discussed below:

2.1 MICROSEQUENCER

The CU microsequencer is a 12-bit wide microcode address

generator. Major features of the microsequencer include a

microprogram counter (PC), a microprogram counter save

register (PC Save), microcode address increment logic,

instruction pipeline registers IA and IB, an iteration of loop

counter, a next microcode address source multiplexer, and

various pipelining latches. These features are represented in

Figure 2.

The 12-bit microcode address width allows the

microsequencer to access up to 4096 words of microcode. The

MIL-STD-1750A instructions are implemented as sequences of

microinstructions stored within the lower 2048 locations of this

address space. The address for each microinstruction in a

sequence is provided by the next microcode address source

multiplexer. This multiplexer, under control of the CU control

logic, select from one of six next address sources. Sequential,

direct jump, conditional jump, and subroutine address

generation modes are supported.

Sequential addressing is accomplished by providing a path

from the output of the next microcode address multiplexer to an

incrementer and back to the PC register input. Direct jumps are

supported by routing a portion of the microinstruction to one of

the next microcode address source multiplexer inputs.

Conditional jumps are determined in the ALU of the Execution

Unit which communicates the decision to the CU via the T1

signal. The T1 signal enables a portion of the microcode word

to create the new address. Subroutine jumps are accomplished

by loading the contents of the incremented PC register into the

PC Save register and then performing a direct jump. Upon

completion of the subroutine, the contents of the PC Save

register are used as the next microcode address.

A new microinstruction sequence begins when an opcode

residing in the lA or IB register is selected by the next

microcode address source multiplexer and used as an address

to simultaneously access both the CU’s Instruction Mapping

ROM and the Microcode Storage ROM. The instruction

Mapping ROM access provides a pointer which is then used to

update the microprogram counter (PC); the Microcode Storage

ROM access provides the first microinstruction of the

sequence. Remaining microinstructions in a sequence are

accessed through the use of the four address generation

modes discussed above.

Iterative microprogram operations are achieved through the

use of the loop counter. The loop counter may be selectively

loaded from either the AD bus or directly from microcode. This

counter tracks the number of iterations remaining and, when

appropriate, issues a completion signal (CZ). When an iterative

operation is called for, the loop counter is loaded and the CU

control logic repeats a particular microinstruction sequence,

using the four address generation modes discussed above,

until the CZ signal is received.

2.2 INSTRUCTION MAPPING ROM

The CU instruction mapping ROM provides 512 8-bit words

of microcode instruction vector storage. The address space of

this ROM is mapped into a portion of the microcode storage

ROM’s address space. Hence, both ROMs are accessed

whenever the microcode address falls within this range. The

eight bits from the instruction mapping ROM serve as-the lower

eight bits of a 12-bit microcode address; the upper four bits are

a hardwired constant. The 12-bit microcode address formed

from the 4-bit constant and the mapping ROM’s eight bits are

loaded into the PC register of the microsequencer and serve as

a means to access nonsequential microcode addresses within

the address space allocated to both the instruction mapping

and microcode storage ROMs.

2.3 MICROCODE ROM

The CU microcode ROM provides 2K (2048) 40-bit words of

storage capacity. All of the microcode required to implement

the full MIL-STD-1750A lnstruction Set Architecture (lSA) fits in

one such ROM.

2.4 BUSES

A 16-bit multiplexed Address/Data (AD) bus provides a

communications path between the CU, the other components

of the MAS281 chip set, the MA31751 MMU/BPU, and any

other devices mapped into the chip set’s address space. The

CU receives MIL-STD-1750A instructions, accessed from

system memory, over this bus and loads them into its

instruction pipeline registers.

A 20-bit multiplexed Microcode (M) bus provides a pathway

between the CU chip and the microcode decode logic on all

other chips which are under CU microcode control. The 40-bit

wide microinstructions from the CU’s microcode ROM are

multiplexed on chip as two 20-bit words and presented on the

interchip M bus during alternate phases of CLK02N. Microcode

bits 39 through 20 are placed on the M bus during the CLK02N

low phase and bits 19 through 0 during the high phase of

CLK02N. The M bus is bidirectional to permit microcode

memory expansion.

A 12-bit microcode address (CC) bus is used to route

microcode addresses from the next microcode address source

multiplexer to the microcode and instruction mapping ROMs as

shown in Figure 2.

Page 4

MA17502

4/30

3.0 INTERFACE SIGNALS

All signal definitions are shown in Table 1. In addition, each

of these functions is provided with Electrostatic Discharge

(ESD) protection diodes. All unused inputs must be held to their

inactive state via a connection to VDD or GND.

Throughout this data sheet, active low signals are denoted

by either a bar over the signal name or by following the name

with an “N” suffix. e.g. HOLDN. Referenced signals that are not

found on the MA17502 are preceded by the originating chip’s

functional acronym in parentheses, e.g. (IU)DMAKN.

A description of each pin function, grouped according to

functional interface, follows. The function acronym is presented

first, followed by its definition, its type, and its detailed

description. Function type is either input, output, high

impedance (Hi-Z), or a combination thereof. Timing

characteristics of each of the functions described are provided

in Section 6.0.

3.1 POWER INTERFACE

The power interface consists of a single 5V VDD connection

and two common GND connections.

3.2 CLOCKS

The clock interface, discussed below, is the means by

which the synchronous, microcoded operation of the MAS281

is driven.

3.2.1 Precharge Clock (CLKPCN)

Input. The MA17501 Execution Unit (EU), generates the

CLKPCN signal for the Control Unit. The Control Unit uses this

signal for most of its internal sequencing. During the low phase

of CLKPCN, the internal M Bus is precharged to the high state

to accelerate its response.

The normal CLKPCN period is defined by five OSC cycles

(two cycles low and three cycles high). When a microcode

branch is indicated by the EU, the low state of CLKPCN is

extended to three OSC cycles. During execution of Interrupt

Unit decoded XlO and microcode commands, the high state of

CLKPCN is extended to four OSC cycles. Also, during external

bus cycles, RDYN may be used to cause the EU to prolong the

high state of CLKPCN to greater than three OSC cycles; this

allows the MAS281 chip set to interface with slower external

memory or input/output devices.

During DMA ((IU)DMAKN is low) or Hold ((EU)HLDAKN is

low), CLKPCN will remain low until the CPU takes control

again.

3.2.2 Phase 2 Clock (CLK02N)

Input. The MA17501 generates the CLK02N signal for the

Control Unit. The CU then uses this signal, in conjunction with

CLKPCN, to control the distribution of microcode on the M Bus.

CLK02N is used to multiplex the 40-bit microcode instruction

into two 20-bit words (µW1 and µW2). The high-to-low edge of

CLK02N switches µW1 (bits 39 through 20) off the M Bus while

switching µW2 (bits 19 through 0) onto the M Bus.

The normal CLK02N period is defined by five OSC cycles

(one cycle low, three cycles high, one cycle low). When a

microcode branch is indicated by the EU, the high state of

CLK02N is extended to four cycles. During execution of

Interrupt Unit decoded XIO and microcode commands, the

trailing low state of CLK02N is extended to two OSC cycles.

Also, during external bus cycles, RDYN may be used to cause

the EU to prolong the CLK02N trailing low state to greater than

one OSC cycle; this allows the MAS281 chip set to interface

with slower external memory or inpuVoutput devices.

During DMA ((IU)DMAKN is low) or Hold ((EU)HLDAKN is

low), CLKPCN will remain low until the CPU takes control

again.

3.3 BUSES

The following is a discussion of the communication buses

connecting the three-chip set. The AD Bus and M Bus are

mainly operand transfer buses, while the CC Bus is strictly for

providing microcode addresses to auxiliary CUs.

3.3.1 Address/Data Bus (AD Bus)

Input. These signals comprise the multiplexed address and

data bus. During external bus operations, the AD bus

accommodates the transfer of instructions, from memory and

l/O ports, to the MA17502. During internal bus operations, the

AD bus provides additional data to the Control Unit from the

Execution Unit. AD00 is the most significant bit position and

AD15 is the least significant bit position of both the 16-bit data

and 16-bit address. A high on this bus corresponds to a logic 1

and a low corresponds to a logic 0. lnformation on the AD Bus is

clocked into the CU by the high-to-low transition of CLKPCN.

3.3.2 Microcode Bus (M Bus)

Input/Output/Hi-z. The M Bus is the 20-bit multiplexed

microcode bus. The 40-bit microcode instruction is multiplexed

onto the M Bus as two 20-bit words (µW1 and µW2). The first

half of the microcode word, µW1 (bits 39 through 20), is

assured valid on the high-to-low transition of CLK02N and µW2

(bits 19 through 0) is assured valid on the high-to-low transition

of CLKPCN. M00 corresponds to microcode bit 0 (µW1) or 20

(µW2) while M19 corresponds to microcode bit 19 (µW1) or 39

(µW2). A high level indicates a logic 1 and a low level indicates

a logic 0. A high level on CS allows the Control Unit to distribute

microcode over this bus, a low level places the bus in the high

impedance state.

During DMA or Hold states, CLKPCN is held low, thus

holding the internal M bus in the precharged state. Precharging

the internal M Bus forces the 20 bits of the external M Bus low.

3.3.3 Microcode Address Bus (CC Bus)

Input/Output/Hi-Z. The CC bus is provided for future

expansion and is left unconnected.

3.4 SEQUENCER CONTROL

The following is a discussion of the microsequencer control

input signals. These signals support chip set functions that

require microcode branching based on the results of operations

performed in the Execution or Interrupt Units.

3.4.1 Interrupt Request (IRN)

Input. A low on this input directs the CU to service pending

interrupt requests latched by the Interrupt Unit (IU). Upon

completion of the currently executing MIL-STD-1750A

instruction, the CU checks the IRN input. If IRN is low, then the

CU sequencer will branch to the microcoded interrupt service

routine; else the next MIL-STD-1750A instruction is mapped to

its microcode routine. The microcoded interrupt service routine

Page 5

MA17502

5/30

Figure 2: MA17502 Control Unit Architecture

Page 6

MA17502

6/30

stores the processor state, retrieves the highest priority

pending interrupt’s service routine processor state, and vectors

software execution to the user’s interrupt service routine. IRN

originates in the IU.

3.4.2 Privileged Instruction Fault (PIFN)

A low on this signal causes the CU to enable control of the

DMA interface (located in the Interrupt Unit), abort the currently

executing MIL-STD-1750A instruction and check the IRN input

for a pending level 1 interrupt caused by the IU latching a

memory protect (MPROEN), memory address (EXADEN), or

Bus Time-out fault. PIFN originates in the IU.

3.4.3 Branch or Jump Control (T1)

Input. A high on this input directs the CU microcode address

sequencer to branch execution to a nonsequential microcode

address. This signal is under the control of the Execution Unit’s

ALU and its level is dependent on the outcome of the presently

executing microcode instruction, e.g. conditional branch. T1

originates in the EU.

3.5 CONFIGURATION CONTROL

The following inputs are provided for control of multiple CU

systems. They allow for expansion of the microcode store to 4K

40-bit words.

3.5.1 ROM-Only (ROMONLYN)

Input. This signal is provided for future microcode

expansion and must be pulled up to VDD.

3.5.2 Chip Select (CS)

Input. A high on this signal enables the CU to drive the 20bit external M Bus. This signal is provided for future microcode

expansion and must be pulled up to VDD.

3.6 CPU CONTROL

Grouped under this heading are signals that have CPUwide control of normal operation. Each of these has the ability

to “freeze” the processor.

3.6.1 Hold Request (HOLDN)

Input. A low on this input will suspend internal processor

functions at the end of the currently executing MlL-STD1750A

instruction. When this signal becomes active, the CU

completes the currently executing MIL-STD-1750A instruction,

then branches to the Hold microcode routine and enters the

Hold state. The CU will resume normal operation by refilling the

instruction pipeline registers (IA and IB) upon release of

HOLDN.

3.6.2 System Reset (RESET)

Input. A high on this input for a duration of at least one

CLKPCN period will reset the MAS281 chip set by forcing the

Control Unit to microcode address zero. The high-to-low

transition of this input will cause the CU to begin executing the

MAS281 initialisation sequence starting with the first instruction

in microcode. Built-in Test (BIT) is performed as part of the

initialisation sequence. At the conclusion of initialisation and

successful execution of BIT, the MAS281 will be initialised as

shown in Table 3.

4.0 OPERATING MODES

The following discussions detail the MAS281 chip set

operating modes from the perspective of the Control Unit.

MAS281 operating modes involving the MA17502 include: (1)

Initialisation, (2) lnstruction Execution, (3) Interrupt Servicing,

(4) DMA Support, and (5) HOLD Support.

4.1 INITIALISATION

The MA17502 sequences the MAS281 chip set through the

microcoded initialisation routine in response to a high pulse on

the RESET input. This routine clears the chip set registers,

disables and masks interrupts’ reads the configuration register,

resets the output discrete register (if applicable), initialises the

MMU and BPU (if applicable), performs Built-in Test (BIT),

raises the StartUp ROM Enable discrete, clears and starts

timers A and B, resets the Trigger-Go counter, and loads the

instruction pipeline. The initialisation sequence is contained in

the first 33 locations of microcode ROM (an additional 14

locations contain the optional MMU and BPU initialisation

code). Because the initialisation sequence clears the Execution

Unit’s lnstruction Counter and Status Word (also the address

and processor state copies stored in the MMU(BPU), if

applicable), program execution begins with the instruction

located at address zero (page zero). Table 2 provides a

detailed breakdown of the initialisation sequence and Table 3

summarises the resulting initialised state.

BIT occupies 332 words of microcode storage ROM, and

consists of five subroutines that exercise the internal circuitry of

the MAS281, as outlined in Table 4. BIT begins by pulling the

Normal Power-UP ((IU)NPU) output low; this is the first time

after power-up that the state of NPU is guaranteed. If all five

BIT subroutines execute successfully, NPU is raised high.

If any part of BIT fails, an error code identifying the failed

subroutine is loaded into the Interrupt Unit Fault Register (via

the AD Bus), BlT is aborted, and NPU is left in the low state.

Table 4 defines the coding of the BIT results. (NPU is raised

high through microcode control of the lU in conjunction with the

(EU)lNTREN signal. The BIT error codes are loaded in the lU

Fault Register via the AD Bus under microcode control of the lU

in conjunction with the (EU)lNTREN signal.)

ln the event of such a failure, the resulting chip set reset

state is dependent on where in BIT the error occurred and may

not be the same as that shown in Table 3. A BIT failure

indication in the fault register sets the level 1 pending interrupt.

Since initialisation disables and masks interrupts, the IRN input

will remain high; thus the interrupt will not be serviced

immediately.

The last action performed by the initialisation routine is to

load the instruction pipeline. lnstruction fetches start at memory

location zero (page zero) from the Start-Up ROM (if

implemented). Whether BlT passes or not, the processor will

begin instruction execution at this point.

Note: To complete initialisation and pass BIT, interrupt and

fault inputs must be high for the duration of the initialisation

routine. Also, the Timers A and B must be clocked for BIT

success.

Page 7

MA17502

7/30

Label Cycle

MAIN B1 1. Enable Control of DMAE Output signal

P2.B1 3. Clear MAS281 Execution Unit Status Word (SW)

Clear Interrupt Mask (MK) (Internal l/O command, SKM, 2000H)

B1 4. Clear Pending lnterrupt Register (Pl) and Fault Register (FT) (lnternal l/O Command, CLlR, 2001H)

Clear Instruction Counter (IC)

P5.B1 6. Disable Interrupts (Internal l/O Command, DSBL, 2003H)

P7.B1 8. Clear MMU Status Word (lnternal l/O Command, WSW, 200EH) (Note 1)

P9.B1 10. Disable DMA Access (Internal l/O Command, DMAD, 4007H)

P 11. B1 12. Read Configuration Register (Internal l/O Command, RCW, 8400H, CONFWN Drops low per Figure

25, Section 5.0)

P 13. P 14. B2 15. - (If Output Discrete Register Present, then Continue; Else, Skip to 18)

P (16). I/O (17). Clear Output Discrete Register (External l/O Command)

B2 19. - (If BPU present, then Branch to BPU; else, continue)

P 20. B2 21. - (If MMU present, then Branch to MMU; Else, Continue)

P 22. - (Setup Temporary Register to indicate No MMU Present)

B2 23. - (Branch to MAS281 BIT)

P 24. B1 25. Enable Start-Up ROM (Internal l/O Command, ESUR, 4004H; SURE Raises High per Figure 25,

Section 5.0)

P 26. B1 27. Clear and Start Timer A (Internal l/O Command, OTA, 400AH)

B1 28. Reset the Trigger-Go timer (Internal l/O Command, GO, 400BH)

P 29. B1 30. Clear and Start Tlmer B (Internal l/O Command, OTB, 400EH)

B2 31. - (Branch to Load Instruction Pipeline Routine)

M 32. Load data-ln register (Dl) and instruction Register A (IA) from [IC], Increment IC

M 33. Load Data-ln Register (Dl) and lnstruction Register a (lA) from [lC] ([lA] Moves to lB), lncrement lC

Map Instruction Register B (IB) into Microcode Routine

BPU P (1). -

P (2). - (Set Loop to Clear Memory Protect RAM)

I/O (3). Clear a Location in MPRAM (Internal l/O Command, LMP, 50XXH), Increment Address; Do 128 Times

(4). - (Branch Back to 20.)

MMU P (1). -

P (2). P (3). - (Setup Loop to Load Instruction Page Registers (IPR) and Operand Page Registers (OPR) wlth

Sequential Values of 0 to 255)

P (4). P (5). I/O (6). Load a Location in the IPR with the value of the Locatron Address (Internal l/O Command, WIPR,

51XYH)

I/O (7). Load a Location in the OPR Increment Loaded Value with the Value of the Location Address (Internal

I/O Command, WOPR, 52XYH)

P (8). - (Increment IPR Address)

P (9). - (Increment OPR Address - Repeat Loop [4. - 9.] 256 Times)

B2 (10). - (Setup Temporary Register to Indicate MMU Present; Branch back to 23)

Notes: 1. This operation Is performed whether or not an MMU is present.

2. “-” indicates internal CPU operation.

3. Sequence numbers in “( )” are performed only under the stated conditions.

4. Each step enumerated above represents a single machine (SYNC) cycle of the type shown in the “Cycle” column.

“P” indicates a 5 OSC cycle, 60% duty cycle, machine cycle.

“I/O” and “M” indicate a 5 OSC cycle, 50% duty cycle, machine cycle.

“B1” indicates a 6 OSC cycle 50% duty cycle machine cycle.

“B2” indicates a 6 OSC cycle 66% duty cycle machlne cycle.

Table 2: MAS281 Initialisation Sequence

Page 8

MA17502

8/30

MAS281

Instruction Counter (IC) Zeroed

Status Word (EU and MMU) (SW) Zeroed

Fault (FT) Zeroed

Pending Interrupt (Pl) Zeroed

Mask (MK) Zeroed

General Register File (RO R15) Zeroed

Interrupts Disabled

DMA Access Disabled

TimerA Reset and Started

Timer B Reset and Started

Trigger-Go Timer Reset and Started

MMU

Page Registers Group Zero Enabled

AL, W, E, Fields Zeroed

PPA Field Logical to Physical

Map

BPU

Write Protect Zeroed

Global Memory Protect Enabled

BIT Test BIT Fail Codes Cycles

Coverage (FT

13, 14,15

)

Microcode Sequencer

1 IB Register Control 100 221

Barrel Shifter

Byte Operations and

Flags

Temporary Registers

(T0 - T7)

2 Microcode Flags 101 166

Multiply

Divide

Interrupt Unit

3 MK, Pl, FT 111 214

Enable/Disable

Interrupts

Status Word Control

4 User Flags 110 154

General Registers

(R0 - R15)

5 Timer A 111 763

Timer B

BIT Pass/Fail - 26

Overhead

Note: BIT pass is indicated by all zeros in FT bits 13, 14 and 15

Table 3: Initialisation State

Table 4: Built In Test (BIT) Summary

driven low during execution of this instruction). Interrupt, DMA,

and Hold support are explained in more detail in following

sections.

4.3 DIRECT MEMORY ACCESS

Direct Memory Access (DMA) is controlled by the Execution

Unit (EU) in concert with the Interrupt Unit DMA interface. The

CU supports DMA by suspending processor control upon

completion of the current machine cycle. If DMA is enabled

((UI)DMAE signal, high) a DMA request ((IU)DMARN input,

low) to the MAS281 causes the lU to acknowledge with

DMAKN, low. When the EU receives the DMAKN (DMA

Acknowledge) signal from the lU, the CU clocks are suspended

(CLKPCN, low; CLK02N, high) halting the MAS281’s

microcode sequencing. Microinstruction execution remains

suspended until DMARN is removed. When DMARN is

removed, microcode execution resumes where DMARN had

interrupted it.

4.4 INTERRUPT HANDLING

Interrupts are handled by the interrupt Unit (IU) and

communicated to the CU via the lRN input. The CU checks the

status of the lRN (lnterrupt Request) signal after the completion

of each MlL-STD-1750A microcode instruction sequence. lf the

lRN signal is low, the CU initiates interrupt handling, otherwise

the CU processes a new instruction.

4.2 INSTRUCTION EXECUTION

The MIL-STD-1750A microcoded instruction subroutines

are stored in 1255 locations of microcode storage ROM. The

Control Unit receives instructions from memory, via the AD

Bus, through the instruction pipeline registers lA and IB. When

the previous instruction or special process (Interrupts or Hold)

has been completed, the new instruction residing in register IB

is selected by the next microcode address source multiplexer.

A 4-bit hardwired constant, appended by the instruction

opcode, is then used as the first address of a microcode

sequence which distributes the required control to execute the

instruction. The microsequencer generates the remaining

microcode addresses necessary to complete the sequence as

described in Section 2.0 of this data sheet entitled,

“Architecture”.

Upon completion of the current instruction, the CU will

accept the next instruction in the program unless an interrupt,

DMA, or Hold request is received. The interrupt and Hold

request share a common branch point in microcode. If an

interrupt and Hold request are both pending at the conclusion of

the MIL-STD-1750A instruction microcode routine, the Hold

request has priority and is serviced first. Upon release of the

Hold state, the first instruction will execute even if the interrupt

is still pending; when this instruction is complete the interrupt

will be serviced (assuming the HOLDN input has not been

Page 9

MA17502

9/30

IU interrupt handling is controlled by the CU through three

microcode bits - M04, M05, and M06. Upon receipt of the IRN

signal and after completion of the currently executing

instruction, the CU branches to a microcoded interrupt handling

routine. The microprogram sequence supplies microcoded

control to the lU for reading the highest priority pending

interrupt vector code, which also clears this pending interrupt.

Due to the similarity of interrupt and hold request handling

by the CU, if a Hold and interrupt request are pending at the

end of an instruction sequence the Hold has priority and will be

serviced.

4.5 HOLD SUPPORT

The CU accepts a Hold request in much the same way as

an interrupt request. After the completion of each MlL-STD1750A microcode instruction sequence, the CU checks the

status of the HOLDN signal. If the HOLDN signal is low, a

microcoded sequence suspends further internal processing

functions; otherwise, the CU processes a new instruction or

services interrupt requests (Hold requests have priority over

interrupt requests).

The Control Unit responds to an active HOLDN signal, upon

completion of the currently executing instruction, but branching

to a microprogrammed sequence of instructions that suspends

all internal operations. This sequence of microinstructions

allows the processor to resume instruction execution at the

point HOLDN was accepted when the CU regains control of the

processor. The MAS281 remains in the Hold state until HOLDN

is pulled high (if the Hold state was reached through the

hardware interface, HOLDN) or HOLDN is pulsed low (if the

Hold state was reached through software, BPT instruction).

HOLDN should be synchronised to AS falling.

5.0 SOFTWARE CONSIDERATIONS

The MAS281 chip set implements the full MlL-STD-1750A

instruction set. Table 6a gives a brief listing of this instruction

set and provides performance data for each instruction. Table

6b provides a summary of the l/O commands implemented in

MAS281 and MA31751 MMU/BPU hardware. A complete

description of this instruction set is provided in MIL-STD-1705A

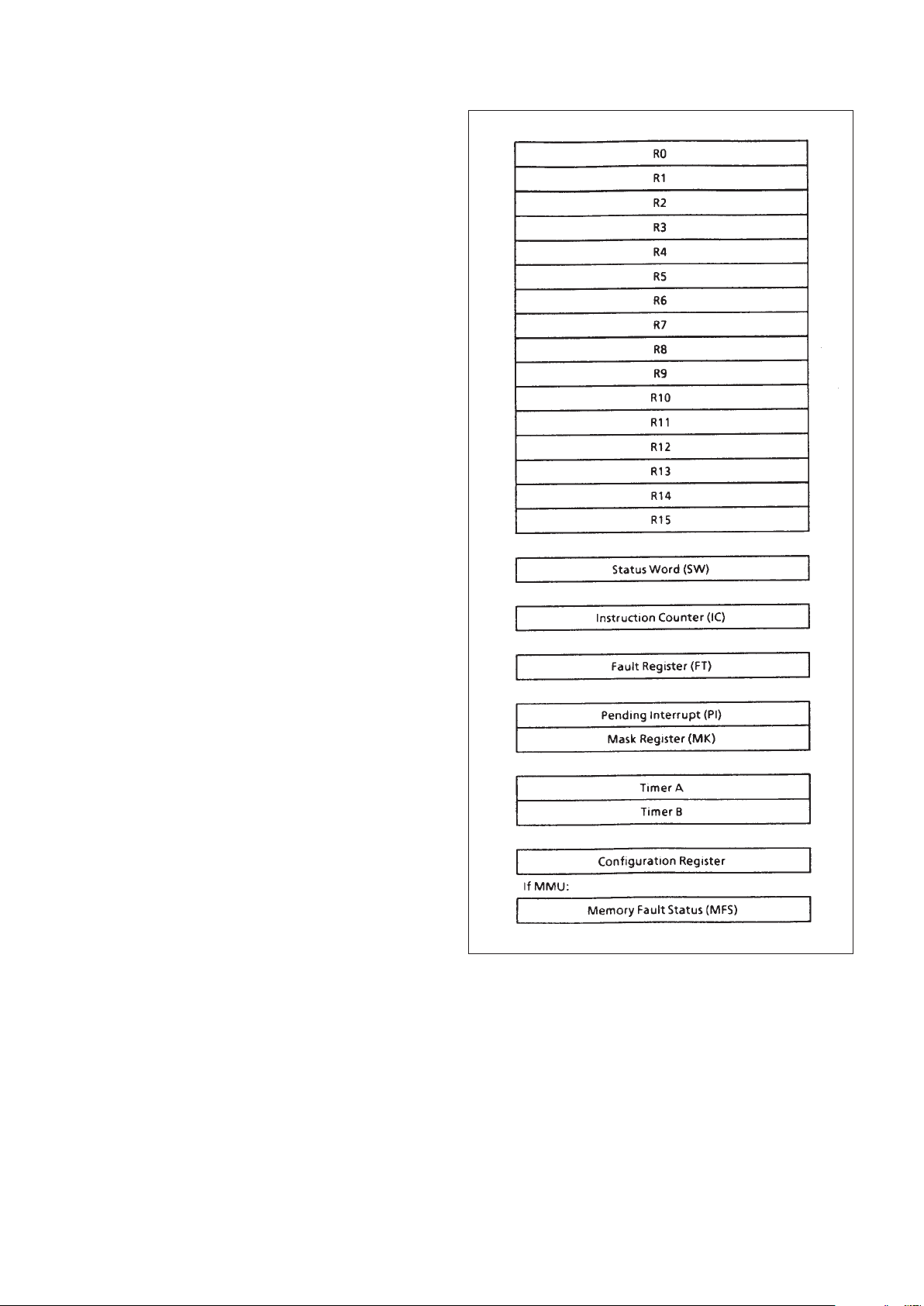

(Notice 1). The register set available to the software

programmer is depicted in Figure 3. A discussion of data types,

addressing modes, and benchmarking considerations fol lows.

5.1 DATA TYPES

The MAS281 chip set supports 16-bit fixed-point single

precision, 32-bit fixed-point double-precision, 32-bit floatingpoint, and 48-bit extended-precision floatingpoint data types.

Figure 4 depicts the formats of these data types.

All numerical data is represented in two’s complement form.

Floating-point numbers are represented by a fractional two’s

complement mantissa with an 8-bit two’s complement

exponent. The MAS281 expects all floating point operands to

be normalised. If they are not normalised, the results from an

instruction are not defined.

Figure 3: Register Set Model

Page 10

MA17502

10/30

5.2 ADDRESSING MODES

The MAS281 chip set supports the eight addressing

modes specified in MIL-STD-1750A. These addressing

modes are shown in Figure 5 and are defined below.

5.2.1 Register Direct (R)

The register specified by the instruction (RB) contains

the required operand.

5.2.2 Memory Direct (D,DX)

Memory Direct (without indexing) is an addressing

mode in which the instruction contains the memory address

(A) of the required operand. ln Memory Direct (indexed),

the memory address of the required operand is specified by

the sum of the contents of an index register (RX) and the

instruction address field (A). Registers R1 through R15

may be specified for indexing.

5.2.3 Memory Indirect (I,IX)

Memory Indirect (without indexing) is an addressing

mode in which the memory address (A) specified by the

instruction contains the address of the required operand. In

Memory Indirect (pre-indexed), the sum of the contents of a

specified index register (RX) and the instruction address

field (A) is the address of the address of the required

operand. Registers R1 through R15 may be specified for

indexing.

5.2.4 Immediate Long (IM)

There are two formats that implement Immediate Long

Addressing; one allows indexing and one does not. For the

indexable format, if the specified index register (RX) is not

equal to zero, the contents of RX are added to the

immediate field to form the required operand, otherwise,

the immediate field contains the required operand .

5.2.5 Immediate Short (IS)

In this mode the required 4-bit operand is contained

within the 16-bit instruction. The Immediate Short

addressing mode accommodates two formats; one which

interprets the contents of the immediate field as positive

data and the other which interprets the contents of the

immediate field as negative data.

5.2.6 Immediate Short Positive (ISP)

The immediate operand is treated as a positive integer

between 1 and 16.

5.2.7 Immediate Short Negative (ISN)

The immediate operand is treated as a negative integer

between 1 and 16. Its internal form is a two’s complement,

sign-extended 16-bit number.

5.2.8 Instruction Counter Relative (ICR)

This addressing mode is used for 16-bit branch

instructions. The contents of the instruction counter minus

two (the address of the current instruction) is added to the

sign-extended 8-bit displacement field (D) within the

instruction. This sum then points to the memory address to

which control may be transferred if a branch is to be taken.

Figure 4: Data Formats

5.2.9 Base Relative (B)

There are two formats which implement Base Relative

Addressing; one allows indexing and one does not. For the nonindexable form the contents of the instruction specified base

register (BR = BR' + 12) is added to the 8-bit displacement field

(DU) of the 16-bit instruction. For the indexable form, the sum of the

contents of a specified index register (RX) and a specified base

register (BR = BR' + 12) is the address of the required operand.

Registers R1 through R15 may be specified for indexing and the

base register may be R12 through R15.

Page 11

MA17502

11/30

Figure 5: Addressing Modes

Page 12

MA17502

12/30

5.2.10 Special (S)

This addressing mode is applicable to instructions that do

not follow the above formats.

5.3 BENCHMARKING

Table 6a defines the number and type of machine cycles

associated with each MIL-STD-1750A instruction. This

information may be used when benchmarking MAS281

performance. The Digital Avionics Instruction Set (DAIS) mix,

which defines a typical frequency of occurrence for MIL-STD1750A instructions, is used here for this purpose.

One problem with the DAlS mix, however, is that it does not

reflect the impact of data dependencies on system

performance. For example, a multiplication in which one

operand is zero may be performed much faster than one with

two non-zero operands. Also, the DAIS mix does not specify

such time consuming operations as normalization and

alignment.

Realistic benchmarks must therefore take both an

instruction mix and data dependencies into account. To this

end, machine cycle counts in Table 6a which have data

dependencies are annotated with either an “a” suffix to reflect

an average number of machine cycles (where each of several

possibilities is equally likely) or with a “wa” suffix to reflect a

weighted average number of machine cycles (where some data

possibilities are more likely than others). Weighted averages

are only applicable to floating-point operations.

Weighted averages provided in Table 6a, based on the

Sweeney (lBM Systems Journal, Vol. 4, No. 1, 1965)

guidelines, take a wide range of data dependencies into

consideration. Normalization and alignment operations are also

represented. Table 5 defines MAS281 throughput, at various

frequencies and wait states, for the DAIS mix using Sweeney

data dependencies.

It should be noted that using the Sweeney guidelines is a

conservative approach to benchmarking. If best case

assumptions are made and such operations as normalization

and alignment are not considered, MAS281 performance

figures are approximately 50% higher than those indicated in

Table 5.

Table 5: Throughput (KIPS)

Page 13

MA17502

13/30

5.4 INSTRUCTION SUMMARY

Cycles*

Operation Op Code/Ext Mnemonic Format M P B

LOAD/STORE

Single Precision Load 81 LR R 1 0 0

0X LB B 2 1 0

4X 0 LBX BX 2 1 0

82 LlSP lSP 1 0 0

83 LlSN ISN 1 0 0

80 L D,DX 3 0 0

85 Ll M IM,IMX 2 0 0

84 Ll I,IX 4 1 0

Double-Precision Load 87 DLR R 1 2 0

0X DLB B 3 1 0

4X 1 DLBX BX 3 2 0

86 D L D,DX 4 0 0

88 DLI I,IX 5 1 0

Single-Precision Store 0X STB B 2 2 0

4X 2 STBX BX 2 2 0

90 ST D,DX 3 1 0

94 STI I,IX 4 1 0

Store a Non-Negative 91 STC D,DX 3 1 0

Constant 92 STCI I,IX 4 1 0

Double-Precision Store 0X DSTB B 3 2 0

4X 3 DSTX BX 3 2 0

96 DST D,DX 4 0 0

98 DSTl I,IX 5 1 0

Load Multiple Registers 89 LM D,DX 3 + n 1 1

Store Multiple Registers 99 STM D,DX 3 + n 1 1

INTEGER ARITHMETIC

Single-Precision lntegerAdd A1 AR R 1 1 0

1X AB B 2 2 0

4X 4 ABX BX 2 2 0

A2 AISP ISP 1 1 0

A0 A D,DX 3 1 0

4A 1 AIM IM 2 1 0

Increment Memory by a A3 INCM D,DX 4 1 0

Positive Integer

Single-Precision Absolute A4 ABS R 1 1.5 1a

Value of Register

Double-Precision Absolute A5 DABS R 1 2.5 1a

Value of Register

* M = memory, P = processor (5 OSC cycles), B = processor (6 OSC cycles), a = average if more than one alternative exists.

Table 6a: Instruction Summary

Page 14

MA17502

14/30

Table 6a (continued): Instruction Summary

Cycles*

Operation Op Code/Ext Mnemonic Format M P B

Double-Precision Integer A7 DAR R 1 3 0

Add A6 DA D,DX 4 1 0

Single Precision Integer B1 SR R 1 1 0

Subtract 1X SBB B 2 2 0

4X 5 SBBX BX 2 2 0

B2 SISP ISP 1 1 0

B0 S D,DX 3 1 0

4A 2 SIM IM 2 1 0

Decrement Memory by a B3 DECM D,DX 4 1 0

Positive Integer

Single Precision Negate B4 NEG R 1 1 0

Register

Double-Precision Negate B5 DNEG R 1 3 0

Register

Double-Precision Integer B7 DSR R 1 3 0

Subtract B6 DS D,DX 4 1 0

Single Precision Integer C1 MSR R 1 6.5 4a

Multiply with 16-Bit Product C2 MISP ISP 1 7.5 4a

C3 MISN ISN 1 7.5 4a

C0 MS D,DX 3 6.5 4a

4A 4 MSIM IM 2 6.5 4a

Single Precision Integer C5 MR R 1 5 3

Multiply with 32-Bit Product 1X MB B 2 7 3

4X 6 MBX BX 2 7 3

C4 M D, DX 3 5 3

4A 3 MIM IM 2 5 3

Double-Precision Integer C7 DMR R 1 41 4.5a

Multiply C6 DM D,DX 4 40 4.5a

D1 DVR R 1 20.25 5.5a

Single Precision Integer D2 DISP ISP 1 20 5.5a

Divide with 16-Bit Dividend D3 DISN ISN 1 20.5 5.5a

D0 DV D,DX 3 20.25 5.5a

4A 6 DVIM IM 2 20.25 5.5a

Single Precision Integer D5 DR R 1 21.75 6.5a

Divide with 32-Bit Dividend 1 X DB R 2 22.75 6.5a

4X 7 DBX BX 2 22.75 6.5a

D4 D D,DX 3 21.75 6.5a

4A 5 DIM IM 2 22.75 6.5a

Double-Precision Integer D7 DDR R 1 79.5 5.5a

Divide D6 DD D,DX 4 77.5 5.5a

* M = memory, P = processor (5 OSC cycles), B = processor (6 OSC cycles), a = average if more than one alternative exists.

Page 15

MA17502

15/30

Table 6a (continued): Instruction Summary

Cycles*

Operation Op Code/Ext Mnemonic Format M P B

LOGICAL

Inclusive Logical OR E1 ORR R 1 0 0

3X ORB B 2 1 0

4X F ORBX BX 2 1 0

E0 OR D,DX 3 0 0

4A 8 ORIM IM 2 0 0

Logical AND E3 ANDR R 1 0 0

3X ANDB B 2 1 0

4X E ANDX BX 2 1 0

E2 AND D,DX 3 0 0

4A 7 ANDM IM 2 0 0

Exclusive Logical OR E5 XORR R 1 0 0

E4 XOR D,DX 3 0 0

4A 9 XORM IM 2 0 0

Logical NAND E7 NR R 1 1 0

E6 N D,DX 3 1 0

4A B NIM IM 2 1 0

Set Bit 51 SBR R 1 0 0

50 SB D,DX 4 1 0

52 SBI I,IX 5 2 0

Reset Bit 54 RBR R 1 1 0

53 RB D,DX 4 1 0

55 RBI I,IX 5 2 0

Test Bit 57 TBR R 1 0 0

56 TB D, DX 3 0 0

58 TBI I,IX 4 1 0

Test and Set Bit 59 TSB D,DX 4 0 2

Set Variable Bit in Register 5A SVBR R 1 0 1

Reset Variable Bit in Register 5C RVBR R 1 1 1

Test Variable Bit in Register 5E TVBR R 1 0 1

Store Register Through Mask 97 SRM D,DX 4 3 0

BYTE

Load From Upper Byte 8B LUB D,DX 3 0 0

8D LUBl I,IX 4 1 0

Load From Lower Byte 8C LLB D,DX 3 1 0

8E LLBI I,IX 4 2 0

Store Into Upper Byte 9B STUB D,DX 4 1 0

9D SUBI I, IX 5 3 0

Store Into Lower Byte 9C STLB D,DX 4 1 0

9E SLBI I,IX 5 2 0

Exchange Bytes in Register EC XBR S 1 0 1

* M = memory, P = processor (5 OSC cycles), B = processor (6 OSC cycles), a = average if more than one alternative exists.

Page 16

MA17502

16/30

Table 6a (continued): Instruction Summary

Cycles*

Operation Op Code/Ext Mnemonic Format M P B

COMPARE

Single-Precision Compare F1 CR R 1 0 0

3X CB B 210

4X C CBX BX 2 1 0

F2 CISP ISP 1 0 0

F3 CISN ISN 1 0 0

F0 C D,DX 3 0 0

4A A CIM IM 2 0 0

Compare Between Limits F4 CBL D,DX 4 2.75 1.75a

Double-Precision Compare F7 DCR R 1 2 0

F6 DC D,DX 4 0 0

JUMP/BRANCH

Jump on Condition 70 JC D,DX 2 0.5 1a

71 JCl I,IX 3 0.5 1a

Jump to Subroutine 72 JS D,DX 2 2 0

Subtract One and Jump 73 SOJ D,DX 2 2.5 1a

Branch Unconditionally 74 BR ICR 2 2 0

Branch if Equal to (zero) 75 BEz ICR 1.5 1 1a

Branch if Less than (zero) 76 BLT ICR 1.5 1 1a

Branch to Executive 77 BEX S 16 12 3a

Branch if Less than or Equal to (Zero) 78 BLE ICR 1.5 1 1a

Branch if Greater than (Zero) 79 BGT ICR 1.5 1 1a

Branch if Not Equal to (Zero) 7A BNZ ICR 1.5 1 1a

Branch if Greater than or Equal to (Zero) 7B BGE ICR 1.5 1 1a

SHIFT

Shift Left Logical 60 SLL R 1 1 0

Shift Right Logical 61 SRL R 1 1 0

Shift Right Arithmetic 62 SRA R 1 1 0

Shift Left Cyclic 63 SLC R 1 1 0

Double Shift Left Logical 65 DSLL R 1 3 0

Double Shift Right Logical 66 DSRL R 1 2 0

Double Shift Right Arithmetic 67 DSRA R 1 2 0

Double Shift Left Cyclic 68 DSLC R 1 3 0

Shift Logical, Count in Register 6A SLR R 1 1 3

Shift Arithmetic, Count in Register 6B SAR R 1 1.5 3.50a

Shift Cyclic, Count in Register 6C SCR R 1 1 3.25a

Double Shift Logical, Count in Register 6D DSLR R 1 2.25 4a

Double Shift Arithmetic, Count in Register 6E DSAR R 1 3.19 4.94a

Double Shift Cyclic, Count in Register 6F DSCR R 1 3.5 3a

* M = memory, P = processor (5 OSC cycles), B = processor (6 OSC cycles), a = average if more than one alternative exists.

Page 17

MA17502

17/30

Cycles*

Operation Op Code/Ext Mnemonic Format M P B

CONVERT

Convert Floating-Point to 16-Bit E8 FIX R 1 4.25 4.5a

Integer

Convert 16-Bit Integer to Floating- E9 FLT R 1 3 2a

Point

Convert Extended-Precision EA EFIX R 1 12.25 6.25a

Floating-Point to 32-Bit lnteger

Convert 32-Bit Integer to EB EFLT R 1 7.5 3.5a

Extended-Precision Floating-Point

STACK

Stack lC and Jump to Subroutine 7E SJS D,DX 4 3 0

Unstack lC and return from

Subroutine 7F URS S 3 1

Pop Multiple registers off the

Stack 8F POPM S 2.5 + n 2.25 + n 4.25a

(n=0-15) (n=0-15)

Push Multiple Registers onto the

Stack 9F PSHM S 1 + n 4.5 + n 2a

(n=0-15) (n=0-15)

I/O (See l/O Command Summary)

Execute l/O 48 XIO** IM,IMX 3 3.583 6.277a

Vectored l/O 49 VIO** D,DX - - -

SPECIAL

Built-ln Function Call 4F BIF S

Move Multiple Words, Memory-to- 93 MOV S 1 + 4n 1 + 3n 1 + 2na

Memory

Exchange Words in Registers ED XWR R 1 2 0

Load Status 7D LST** D,DX 8 2 3

7C LSTI** I,IX 9 2 4

No Operation FF NOP S 1 2 2

Break Point FF BPT S 3 4 4

* M = memory, P = processor (5 OSC cycles), B = processor (6 OSC cycles). ** Privileged instruction.

a = average if more than one alternative exists.

Table 6a (continued): Instruction Summary

Page 18

MA17502

18/30

Cycles*

Operation Op Code/Ext Mnemonic Format M P B

FLOATING-POINT

Extended-Precision Floating- 8A EFL D,DX 5 0 1

Point Load

Extended-Precision Floating- 9A EFST D,DX 5 0 1

Point Store

Floating-Point Absolute Value AC FABS R 1 1 .75 3.25a

of Register

Floating-Point Negate Register BC FNEG R 1 3.25 3.75a

Floating-Point Compare F9 FCR R 1 2.75 2.875wa

3X FCB B 2 2.75 2.875wa

4X D FCBX BX 2 2.75 2.875wa

F8 FC D,DX 3 1.75 2 875wa

Extended-Precision Floating- FB EFCR R 1 3.25 2.875wa

Point Compare FA EFC D,DX 4.25a 2.75 2.875wa

Floating-Point Add A9 FAR R 1 7.625 8.25wa

2X FAB B 3 6.625 8.25wa

4X 8 FABX BX 3 6.625 8.25wa

A8 FA D,DX 4 5.625 8.25wa

Extended-Precision Floating- AB EFAR R 1 21.3125 10.5625wa

Point Add AA EFA D,DX 5 19.3125 10.5625wa

Floating-Point Subtract B9 FSR R 1 8.625 8.625wa

2X FSB B 3 7.625 8.625wa

4X 9 FSBX BX 3 7.625 8.625wa

B8 FS D,DX 4 6.625 8.625wa

Extended-Precision Floating- BB EFSR R 1 23.0625 11.8125wa

Point Subtract BA EFS D,DX 5 21.0625 11.8125wa

Floating-Point Multiply C9 FMR R 1 12.75a 6.25wa

2X FMB B 3 12.75a 6.25wa

4X A FMBX BX 3 12.75a 6.25wa

C8 FM D,DX 4 11.75a 6.25wa

Extended-Precision Floating- CB EFMR R 1 59.75 6.25wa

point Multiply CA EFM D,DX 5 57.75 6.25wa

Floating-Point Divide D9 FDR R 1 31.5 32.75wa

2X FDB B 3 30. 5 32.75wa

4X B FDBX BX 3 30.5 32.75wa

D8 FD D,DX 4 29.5 32.75wa

Extended-Precision Floating- DB EFDR R 1 102.625 47.875wa

Point Divide DA EFD D,DX 5 100.625 47.875wa

* M = memory, P = processor (5 OSC cycles), B = processor (6 OSC cycles), a = average if more than one alternative exists,

wa = weighted average favouring one or more possible alternatives.

Table 6a (continued): Instruction Summary

Page 19

MA17502

19/30

Cycles*

Command

Operation Code (Hex) Mnemonic M P B

Implemented in MAS281

Set Fault Register 0401 SFR 2 3 9

Set Interrupt Mask 2000 SMK 2 3 9

Clear Interrupt request 2001 CLIR 2 3 9

Enable Interrupts 2002 ENBL 2 3 9

Disable Interrupts 2003 DSBL 2 3 9

Reset Pending Interrupt 2004 RPI 2 3 9

Set Pending Interrupt Register 2005 SPI 2 3 9

Reset Normal Power Up Discrete 200A RNS 2 3 9

Write Status Word 200E WSW 2 3a 8.5a

Enable Start-Up ROM 4004 ESUR 2 3 9

Disable Start-Up ROM 4005 DSUR 2 3 9

Direct Memory Access Enable 4006 DMAE 2 3 9

Direct MemoryAccess Disable 4007 DMAD 2 3 9

Ti mer A Start 4008 TAS 2 3 9

Ti mer A Halt 4009 TAH 2 3 9

Output Timer A 400A OTA 2 3 9

Reset Trigger-Go 400B GO 2 3 9

Timer B Start 400C TBS 2 3 9

Timer B Halt 400D TBH 2 3 9

Output Timer B 400E OTB 2 3 9

Read Configuration Word 8400 RCW 2 2 4

Read Fault Register Without Clear 8401 RFR 2 2 4

Read Interrupt Mask A000 RMK 2 2 4

Read Pending Interrupt Register A004 RPIR 2 2 4

Read Status Word A00E RSW 2 1 4

Read and Clear Fault Register A00F RCFR 2 2 4

Input Timer A C00A ITA 2 2 4

Input Timer B C00E ITB 2 2 4

Implemented in BPU

Memory Protect Enable 4003 MPEN 2 4 8

Load Memory Protect RAM 50XX LMP 2 4 8

Read Memory Protect RAM D0XX RMP 2 3 3

Implemented in MMU

Write Instruction Page Register 51XY WIPR 2 4 8

Write Operand Page Register 52XY WOPR 2 4 8

Read Memory Fault Status A00D RMFS 2 3 3

Read Instruction Page Register D1XY RIPR 2 3 3

Read Operand Page Register D2XY ROPR 2 3 3

* M = memory, P = processor (5 OSC cycles), B = processor (6 OSC cycles), a = average if more than one

alternative exists.

5.5 INTERNAL I/O COMMAND SUMMARY

Table 6b: Internal I/O Command Summary

Page 20

MA17502

20/30

6.0 TIMING CHARACTERISTICS

This section provides the detailed timing specifications for

the MA17502. Figure 6 depicts the test load used to obtain

timing data. Figures 7 through 9 depict the timing waveforms

associated with various MA17502 signals. Table 7 provides

values for parameters specified in the timing waveforms. All

timing values provided in Table 7 are valid over the full military

temperature range (-55°C to +125°C), and are measured from

50% point to 50% point (50% of VDD supply voltage, unless

otherwise specified). Crosshatching in Figure 7 indicates either

a “don’t care” or indeterminate state.

Figure 6: Test Load

Subgroup Definition

1 Static characteristics specified in Table 9 at +25°C

2 Static characteristics specified in Table 9 at +125°C

3 Static characteristics specified in Table 9 at -55°C

7 Functional tests at +25°C

8a Functional tests at +125°C

8b Functional tests at -55°C

9 Switching characteristics specified in Table 7b at +25°C

10 Switching characteristics specified in Table 7b at +125°C

11 Switching characteristics specified in Table 7b at -55°C

Table 7a: Definition of Subgroups

No. Parameter Test Condition

(1) (2)

Min Max Units

1 CLKPC ↑ to Microword 1 Valid Load 1 - 95 ns

2 CLK02 ↓ to Microword 2 Valid Load 1 - 41 ns

3 Microword 1 after CLK02 ↓ Load 1 5 - ns

4 Microword 2 after CLKPC ↓ Load 1 25 - ns

5 AD Bus to CLKPC ↓ -10 -ns

6 T1 to CLKPC ↑ -20 -ns

7 PIF to CLKPC ↑ -20 -ns

8 IR to CLKPC ↑ -20 -ns

9 HOLD to CLKPC ↓ -15 -ns

10 RESET to CLKPC ↓ -15 -ns

11 AD Bus after CLKPC ↓ -15 -ns

12 HOLD after CLKPC ↓ -15 -ns

13 RESET after CLKPC ↓ -15 -ns

14 T1, PlF, lR after CLKPC ↓ -0-ns

Mil-Std-883, Method 5005, Subgroup 9, 10, 11

Notes: 1. TA = +25°C, -55°C and +125°C tested at VDD = 4.5V and 5.5V.

2. Unless otherwise noted: VIL ≥ 0.0V, VIHTTL ≤ 4.0V; timing measured from 50% to 50% point.

Table 7b: Timing Parameter Values

Page 21

MA17502

21/30

Figure 7: Basic Timing

Figure 9:

HOLD

Timing

Figure 8: RESET Timing

Page 22

MA17502

22/30

Table 8: Absolute Maximum Ratings

7.0 ABSOLUTE MAXIMUM RATINGS

Parameter Min Max Units

Supply Voltage -0.5 7 V

Input Voltage -0.3 VDD+0.3 V

Current Through Any Pin -20 +20 mA

Operating Temperature -55 125 °C

Storage Temperature -65 150 °C

Note: Stresses above those listed may cause permanent

damage to the device. This is a stress rating only and

functional operation of the device at these conditions, or at

any other condition above those indicated in the operations

section of this specification, is not implied. Exposure to

absolute maximum rating conditions for extended periods

may affect device reliability.

Total Dose Radiation Not

Exceeding 3x105 Rad(Si)

Symbol Parameter Conditions Min Typ Max Units

V

DD

Supply Voltage VSS = 0 4.5 5.0 5.5 V

V

IHC

CMOS Input High Voltage (Note 1) - VDD-1 - - V

V

ILC

CMOS Input Low Voltage (Note 1) - - - VSS+1 V

V

IHT

TTL Input High Voltage (Note 2) - 2.0 - - V

V

ILT

TTL Input Low Voltage (Note 2) - - - 0.8 V

V

OHC

CMOS Output High Voltage (Note 1) IOH = -1.4mA, VDD = 4.5V 4.0 - - V

V

OLC

CMOS Output Low Voltage (Note 1) IOL = 2mA, VDD = 5.5V - - 0.5 V

I

IL

Input Leakage Current (Note 3) VDD = 5.5V, VIN = 0V or 5.5V - - ±10 µA

I

OZ

Output Leakage Current (Note 3) VDD = 5.5V, VO = 0V or 5.5V - - ±50 µA

I

IPU

CS or ROMONLYN Input Pull-up VDD = 5.5V, - - -300 µA

Current (Note 4) CS or ROMONLYN = 0V

I

DDOP

Operating Supply Current VDD = 5.5V, - 25 35 mA

CLKPCN = CLK02N = 4MHz

I

DDST

Static Supply Current VDD = 5.5V, - 5 10 mA

CLKPCN = CLK02N = 0MHz

VDD = 5V±10%, over full operating temperature range.

Mil-Std-883, Method 5005, Subgroup 1, 2, 3

Notes: 1. The following signals are CMOS compatible:

a) CMOS inputs: CS, ROMONLYN, T1, IRN, PIFN, CLK02N and CLKPCN

b) CMOS I/O signals: Microcode bus (M00-M19) and Microcode address bus (CC00-CC11)

2. The following signals are TTL compatible:

a) TTL inputs: Address/Data Bus (AD00-AD15), RESET and HOLDN

3. Worst case at TA = +125°C, guaranteed but not tested at TA = -55°C

4. CS and ROMONLYN inputs are provided for future microcode expansion and have internal pullup resistors. These

signals should be high for normal operation.

8.0 DC ELECTRICAL CHARACTERISTICS

Table 9: DC Electrical Characteristics

Page 23

MA17502

23/30

9.0 PACKAGING INFORMATION

Ref

Millimetres Inches

Min. Nom. Max. Min. Nom. Max.

A - - 5.715 - - 0.225

A1 0.38 - 1.53 0.015 - 0.060

b 0.35 - 0.508 0.014 - 0.020

c 0.229 - 0.36 0.009 - 0.014

D - - 82.04 - - 3.230

e - 2.54 Typ. - - 0.100 Typ. -

e1 - 22.86 Typ. - - 0.900 Typ. -

H 4.71 - 5.38 0.185 - 0.212

Me - - 23.4 - - 0.920

Z - - 1.27 - - 0.050

W - - 1.53 - - 0.060

XG413

D

W

A

e b Z

H

A

1

15°

M

E

C

e

1

Seating Plane

Figure 10a: 64-Pin Ceramic DIL - Package Style C

Page 24

MA17502

24/30

Figure 10b: Pin Assignments

1

IRN

2

VDD

3

PIFN

4

AD00

5

AD01

6

AD02

7

AD03

8

AD04

9

AD05

10

AD06

Top

View

11AD07

12

AD08

13

AD09

14

AD10

15

AD11

16

AD12

17

AD13

18

AD14

19

AD15

20

CLK02N

21

CLKPCN

22

M19

23

M18

24

M17

25

M16

26

M15

27

M14

28

M13

29

M12

30

M11

31

M10

32

M09

64

HOLDN

63

RESET

62

T1

61

NC

60

NC

59

GND

58

NC

57

ROMONLYN

56

CC11

55

CC10

54

CC09

53

CC08

52

CC07

51

CC06

50

CC05

49

CC04

48

CC03

47

CC02

46

CC01

45

CC00

44

M00

43

CS

42

GND

41

M01

40

M02

39

M03

38

M04

37

M05

36

M06

35

M07

34

NC

33

M08

Page 25

MA17502

25/30

Ref

Millimetres Inches

Min. Nom. Max. Min. Nom. Max.

A 1.905 - 2.21 0.075 - 0.087

b1 - 0.51 - - 0.020 -

D 18.08 - 18.62 0.712 - 0.733

E 18.08 - 18.62 0.712 - 0.733

e - 1.02 - - 0.040 Z 1.40 - 1.78 0.055 - 0.070

XG493

Bottom

View

Pad 1

Radius r

3 corners

E

Z

e b

1

D A

Figure 11a: 64-Pad Leadless Chip Carrier - Package Style L

Page 26

MA17502

26/30

Figure 11b: Pin Assignments

Bottom

View

6

5

4

3

2

1

64

63

62

61

60

59

25

26

27

28

29

30

31

32

33

34

35

36

M16

M15

M14

M13

M12

M11

M10

M09

M08

NC

M07

M06

AD02

AD01

AD00

PIFN

VDD

IRN

HOLDN

RESET

T1

NC

NC

GND

20191817161514131211109

AD05

AD06

AD07

AD08

AD09

AD10

AD11

AD12

AD13

AD14

AD15

CLK02N

414243444546474849505152

CC07

CC06

CC05

CC04

CC03

CC02

CC01

CC00

M00

CS

GND

M01

8

7

AD04

AD03

24232221

CLKPCN

M19

M18

M17

37

38

39

40

M05

M04

M03

M02

53545556

CC11

CC10

CC09

CC08

58

57

NC

ROMONLYN

Page 27

MA17502

27/30

Ref

Millimetres Inches

Min. Nom. Max. Min. Nom. Max.

A - - 2.72 - - 0.107

A1 1.83 - 2.24 0.072 - 0.088

b 0.41 - 0.51 0.016 - 0.020

c 0.20 - 0.30 0.008 - 0.012

D1, D2 23.88 - 24.51 0.940 - 0.960

e - 2.54 - - 0.050 j1 - 1.02 - - 0.040 j2 - 0.51 - - 0.020 L 10.16 - 10.54 0.400 - 0.415

Z 1.65 - 2.16 0.065 - 0.085

XG540

Figure 12a: 68-Lead Topbraze Flatpack - Package Style F

Top View

j1

D1L

Pin 1

j2

b

e

D2

Z

A1

A

c

Page 28

MA17502

28/30

Figure 12b: Pin Assignments

Top View

27

26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

9

8

7

6

5

4

3

2

1

68

67

66

65

64

63

62

61

44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

AD04

AD03

AD02

AD01

AD00

PIFN

VDD

NC

IRN

HOLDN

RESET

T1

NC

NC

NC

GND

NC

M15

M14

M13

M12

M11

M10

M09

M08

NC

NC

M07

M06

M05

M04

M03

M02

M01

M16

M17

M18

M19

CLKPCN

CLK02N

AD15

AD14

AD13

AD12

AD11

AD10

AD09

AD08

AD07

AD06

AD05

NC

GND

CS

M00

CC00

CC01

CC02

CC03

CC04

CC05

CC06

CC07

CC08

CC09

CC10

CC11

ROMONLYN

Page 29

MA17502

29/30

10.0 RADIATION TOLERANCE

Total Dose Radiation Testing

For product procured to guaranteed total dose radiation

levels, each wafer lot will be approved when all sample devices

from each lot pass the total dose radiation test.

The sample devices will be subjected to the total dose

radiation level (Cobalt-60 Source), defined by the ordering

code, and must continue to meet the electrical parameters

specified in the data sheet. Electrical tests, pre and post

irradiation, will be read and recorded.

Dynex Semiconductor can provide radiation testing

compliant with Mil-Std-883 method 1019 Ionizing Radiation

(total dose) test.

11.0 ORDERING INFORMATION

For details of reliability, QA/QC, test and assembly

options, see ‘Manufacturing Capability and Quality

Assurance Standards’ Section 9.

Unique Circuit Designator

S

R

Q

Radiation Hard Processing

100 kRads (Si) Guaranteed

300 kRads (Si) Guaranteed

Radiation Tolerance

C

F

L

Ceramic DIL (Solder Seal)

Flatpack (Solder Seal)

Leadless Chip Carrier

Package Type

QA/QCI Process

(See Section 9 Part 4)

Test Process

(See Section 9 Part 3)

Assembly Process

(See Section 9 Part 2)

L

C

D

E

B

S

Rel 0

Rel 1

Rel 2

Rel 3/4/5/STACK

Class B

Class S

Reliability Level

MAx17502xxxxx

Total Dose (Function to specification)* 3x105 Rad(Si)

Transient Upset (Stored data loss) 1x10

11

Rad(Si)/sec

Transient Upset (Survivability) >1x1012 Rad(Si)/sec

Neutron Hardness (Function to specification) >1x1015 n/cm

2

Single Event Upset** <1x10

-10

Errors/bit day

Latch Up Not possible

* Other total dose radiation levels available on request

** Worst case galactic cosmic ray upset - interplanetary/high altitude orbit

Table 10: Radiation Hardness Parameters

Page 30

MA17502

30/30

CUSTOMER SERVICE CENTRES

France, Benelux, Italy and Spain Tel: +33 (0)1 69 18 90 00. Fax: +33 (0)1 64 46 54 50

North America Tel: 011-800-5554-5554. Fax: 011-800-5444-5444

UK, Germany, Scandinavia & Rest Of World Tel: +44 (0)1522 500500. Fax: +44 (0)1522 500020

SALES OFFICES

France, Benelux, Italy and Spain Tel: +33 (0)1 69 18 90 00. Fax: +33 (0)1 64 46 54 50

Germany Tel: 07351 827723

North America Tel: (613) 723-7035. Fax: (613) 723-1518. Toll Free: 1.888.33.DYNEX (39639) /

Tel: (831) 440-1988. Fax: (831) 440-1989 / Tel: (949) 733-3005. Fax: (949) 733-2986.

UK, Germany, Scandinavia & Rest Of W orld Tel: +44 (0)1522 500500. Fax: +44 (0)1522 500020

These offices are supported by Representatives and Distributors in many countries world-wide.

© Dynex Semiconductor 2000 Publication No. DS3565-5 Issue No. 5.0 January 2000

TECHNICAL DOCUMENTATION – NOT FOR RESALE. PRINTED IN UNITED KINGDOM

HEADQUARTERS OPERATIONS

DYNEX SEMICONDUCTOR LTD

Doddington Road, Lincoln.

Lincolnshire. LN6 3LF. United Kingdom.

Tel: 00-44-(0)1522-500500

Fax: 00-44-(0)1522-500550

DYNEX POWER INC.

Unit 7 - 58 Antares Drive,

Nepean, Ontario, Canada K2E 7W6.

Tel: 613.723.7035

Fax: 613.723.1518

Toll Free: 1.888.33.DYNEX (39639)

This publication is issued to provide information only which (unless agreed by the Company in writing) may not be used, applied or reproduced for any purpose nor form part of any order or contract nor to be regarded

as a representation relating to the products or services concerned. No warranty or guarantee express or implied is made regarding the capability, performance or suitability of any product or service. The Company

reserves the right to alter without prior notice the specification, design or price of any product or service. Information concerning possible methods of use is provided as a guide only and does not constitute any guarantee

that such methods of use will be satisfactory in a specific piece of equipment. It is the user's responsibility to fully determine the performance and suitability of any equipment using such information and to ensure

that any publication or data used is up to date and has not been superseded. These products are not suitable for use in any medical products whose failure to perform may result in significant injury

or death to the user. All products and materials are sold and services provided subject to the Company's conditions of sale, which are available on request.

All brand names and product names used in this publication are trademarks, registered trademarks or trade names of their respective owners.

http://www.dynexsemi.com

e-mail: power_solutions@dynexsemi.com

Datasheet Annotations:

Dynex Semiconductor annotate datasheets in the top right hard corner of the front page, to indicate product status. The annotations are as follows:Target Information: This is the most tentative form of information and represents a very preliminary specification. No actual design work on the product has been

started.

Preliminary Information: The product is in design and development. The datasheet represents the product as it is understood but details may change.

Advance Information: The product design is complete and final characterisation for volume production is well in hand.

Loading...

Loading...