Page 1

MA28151

1/22

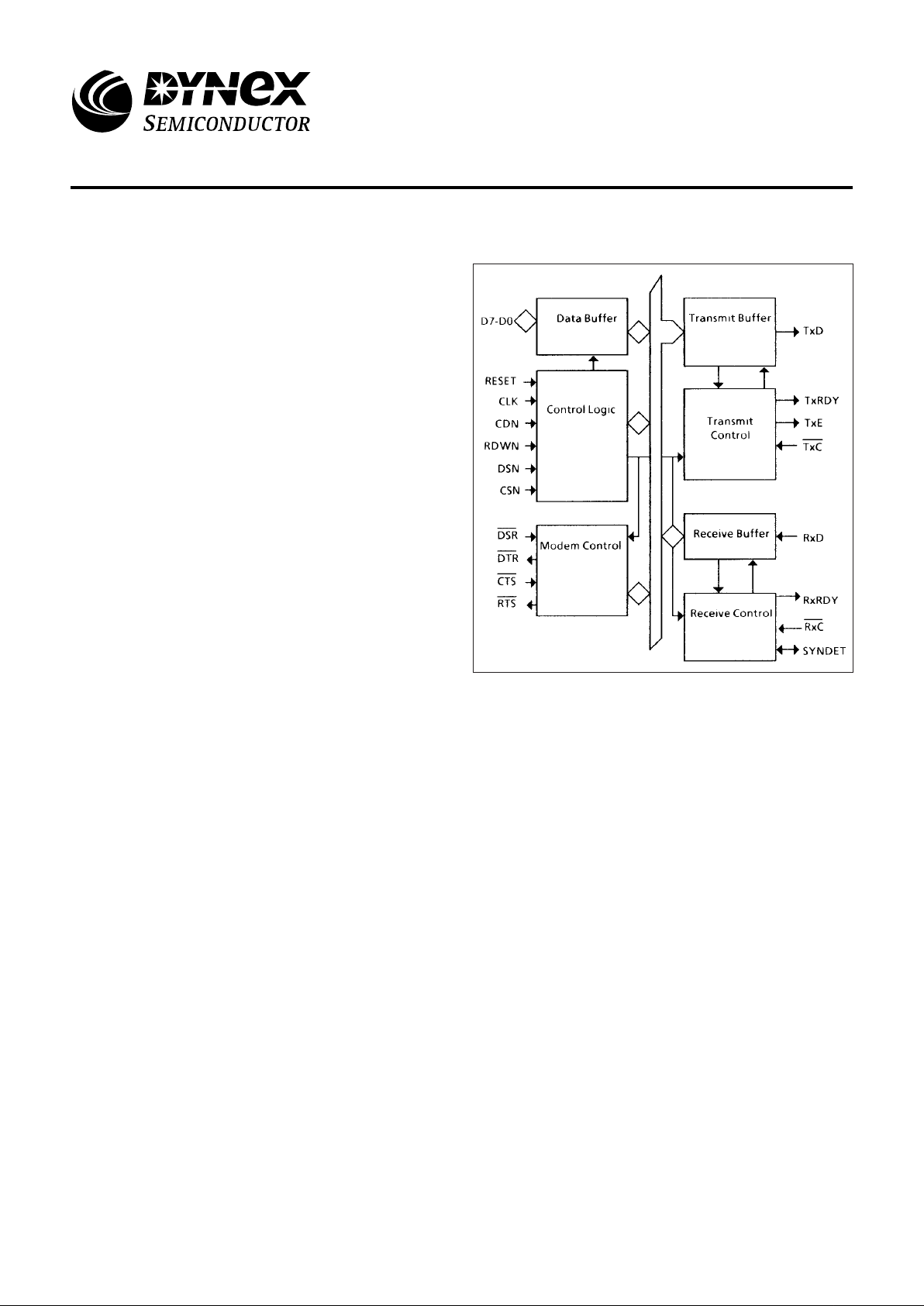

Figure 1: MA28151 Block Diagram

The MA28151 is based on the industry standard 8251A

Universal Synchronous Asynchronous Receiver/Transmitter

(USART), modified for data communications with the MAS281

microprocessor.

The MA28151 is used as a peripheral device and is

programmed by the CPU to operate using virtually any serial

data transmission technique presently in use (including IBM

“bi-sync”). The USART accepts data characters from the CPU

in parallel format and then converts them into a continuous

serial data stream for transmission.

Simultaneously, it can receive serial data streams and

convert them into parallel data characters for the CPU. The

USART signals the CPU whenever it receives a character for

transmission or whenever it receives a character for the CPU.

The CPU can read the complete status of the USART at any

time, including data transmission errors and control signals

such as SYNDET and TxEMPTY.

FEATURES

■ Radiation Hard to 1MRad(Si)

■ Latch Up Free, High SEU Immunity

■ Silicon-on-Sapphire Technology

■ Synchronous 5 - 8 Bit Characters; Internal or External

Character Synchronisation; Automatic Sync Insertion

■ Asynchronous 5 - 8 Bit Characters; Clock Rate - 1, 16 or

64 Times Baud Rate; Break Character Generation, 1

1

⁄2 or

2 Stop Bits

■ All Inputs and Outputs are TTL Compatible

■ Compatible with the MAS281 (MIL-STD-1750A)

Microprocessor

The MA28151 is based on the industry standard 8251A

USART, modified for use with the MAS281 processor,

incorporating the following features:

1. MA28151 has double-buffered data paths with separate l/O

registers for control status, data in and data out, which

considerably simplifies control programming and minimizes

CPU overhead.

2. In synchronous operations, the Receiver detects and

handles “break” automatically, relieving the CPU of this task.

3. A refined Rx initialisation prevents the Receiver from

starting when in the “break” state, preventing unwanted

interrupts from the disconnected USART.

4. At the conclusion of a transmission, the TxD line will always

return to the marking state unless SBRK is programmed.

5. Tx Enable logic enhancement prevents a Tx Disable

command from prematurely halting transmission of the

previously written data before completion. The logic also

prevents the transmitter from turning off in the middle of a

word.

6. When external Sync Detect is programmed, Internal Sync

Detect is disabled and an External Sync Detect status is

provided via a flip-flop, which clears itself upon a status read.

7. The possibility of a false sync detect is minimized in two

ways: by ensuring that if double character sync is

programmed, the characters will be continuously detected and

by clearing the Rx register to all 1’s whenever Enter-Hunt

command is issued in Sync mode.

8. When the MA28151 is not selected, the RDWN and DSN

lines do not affect the internal operation of the device.

9. The MA28151 Status can be read at any time but the status

update will be inhibited during status read.

10. The MA28151 is free from extraneous glitches, providing

higher speed and better operating margins.

11. Synchronous Baud rate is from DC to 64K.

12. Asynchronous Baud rate is from DC to 19.2K.

MA28151

Radiation hard Programmable

Communication Interface

Replaces Jone 1999 version, DS3574-4.0 DS3574-5.0 January 2000

Page 2

MA28151

2/22

1. FUNCTIONAL DESCRIPTION

1.1 GENERAL

The MA28151 is a Universal Synchronous/Asynchronous

Receiver/Transmitter designed for use with the MAS281

microprocessor. Like other l/O devices in a microcomputer

system, its functional configuration is programmed by the

system’s software for maximum flexibility. The MA28151 can

support most serial data techniques in use, including IBM bisync.

In a communication environment, an interface device must

convert parallel format system data into serial format for

transmission, and convert incoming serial data into parallel

system data for reception. The interface device must also

delete or insert bits or characters that are functionally unique to

the communication technique. In essence, the interface should

appear transparent to the CPU for the simple input or output of

byte-oriented system data.

1.2 DATA BUS BUFFER

This 3-state, bidirectional, 8-bit buffer is used to interface

the MA28151 to the system data bus. Data is transmitted or

received by the buffer upon execution of OUTput or INput

instructions from the CPU.

Control word, Command words and Status information are

also transferred through the Data Bus Buffer. The Command

Status, Data-in and Data-out registers are separate 8-bit

registers, communicating with the system bus through the

Data Bus Buffer.

This functional block accepts inputs from the system

control bus and generates control signals for overall device

operation. It contains the Control Word Register and

Command Word Register, which store the various control

formats for the device’s functional definition.

1.3 RESET

A high on this input forces the MA28151 into idle mode.

The MA28151 will remain at idle until its functional definition is

programmed with a new set of control words. Minimum RESET

pulse width is 6 tcy (clock must be running).

The device can also be put into the idle state by a

command reset operation .

1.4 CLOCK (CLK)

The CLK input is used to generate internal device timing

and is normally connected to the clock generator (OSC) of the

system.

Please note: None of the external inputs or outputs are

referenced to CLK but the frequency of CLK must be greater

than 30 times the Receiver or Transmitter data bit rates.

1.5 DATA STROBE (DSN)

This input indicates that a data transfer is taking place.

During a CPU write operation the MA28151 reads data from

the bus on the rising edge of DSN. During a read operation the

MA28151 can output data while DSN is low. Data is valid on

the rising edge of DSN.

1.6 READ/WRITE SELECT (RDWN)

A high on the RDWN input indicates a read of data or

status information from the MA28151. A low on this input

indicates a transfer of data or control words into the MA28151.

The RDWN line is valid only when DSN is low. Figure 2

summarises the MAS28151 read/write operati ons.

1.7 CONTROL/DATA (CDN)

This input, in conjunction with the DSN and RDWN inputs,

informs the MA28151 that the word on the Data Bus is either a

data character, control word or status information.

1 = CONTROL/STATUS; 0= DATA

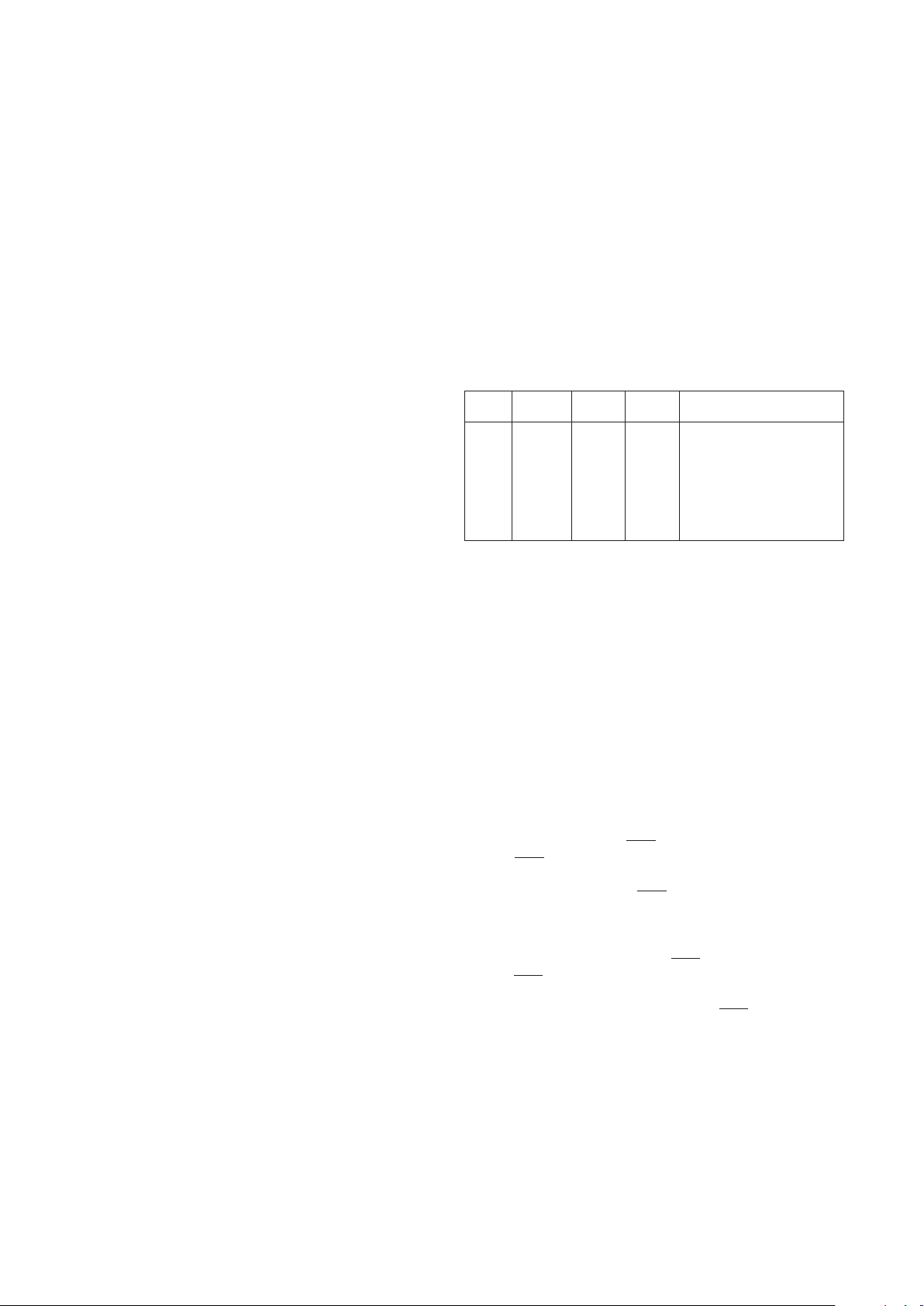

CDN RDWN DSN CSN ACTION

0 1 0 0 28151 TO CPU

0 0 0 0 CPU TO 28151

1 1 0 0 STATUS TO CPU

1 0 0 0 CPU TO CONTROL

x x 1 0 BUS TRISTATE

x x x 1 BUS TRISTATE

Figure 2: Read/Write Control

1.8 CHIP SELECT (CSN)

A low on this input selects the MA28151. No reading or

writing will occur unless the device is selected. When CSN is

high, the Data Bus is in the float state and the DSN and RDWN

lines have no effect on the chip.

1.9 MODEM CONTROL

The MA28151 has a set of control inputs and outputs which

can be used to simplify the interface to almost any modem.

The modem control signals are general purpose in nature and

can be used for functions other than modem control, if

necessary.

1.10 DATA SET READY (

DSR)

The DSR input signal is a general-purpose, 1-bit inverting

input port. Its condition can be tested by the CPU using a

Status Read operation. The DSR input is normally used to test

modem conditions such as Data Set Ready.

1.11 DATA TERMINAL READY (

DTR)

The DTR output signal is a general purpose, 1-bit inverting

output port. It can be set low by programming the appropriate

bit in the Command instruction word. The DTR output signal is

normally used for modem control such as Data Terminal

Ready.

Page 3

MA28151

3/22

1.12 REQUEST TO SEND (

RTS)

The RTS output signal is a general purpose, 1-bit inverting

output port. It can be set low by programming the appropriate

bit in the Command instruction word. The RTS output signal is

normally used for modem control such as Request To Send.

1.13 CLEAR TO SEND (

CTS)

A low on this input enables the MA28151 to transmit serial

data if the Tx Enable bit in the Command byte is set to a high.

If either a Tx Enable off or

CTS off condition occurs while the

Tx is in operation, the Tx will transmit all the data in the

USART, written prior to Tx disable command, before shutting

down.

1.14 TRANSMITTER BUFFER

The Transmitter Buffer accepts parallel data from the Data

Bus Buffer, converts it to a serial bit stream, inserts the

appropriate characters or bits (based on the communication

technique) and outputs a composite serial stream of data on

the TxD output pin on the falling edge of

TxC. The transmitter

will begin transmission upon being enabled if CTS = 0. The

TxD line will be held in the marking state immediately upon a

master Reset, or when Tx Enable or CTS = 1, or the

transmitter is empty.

1.15 TRANSMITTER CONTROL

The Transmitter Control manages all activities associated

with the transmission of serial data. It accepts and issues

signals both externally and internally to accomplish this

function.

1.16 TRANSMITTER READY (TxRDY)

This output signals the CPU that the transmitter is ready to

accept a data character. The TxRDY output pin can be used as

an interrupt to the system since it is masked by TxEnable; or,

for Polled operation, the CPU can check TxRDY using a Status

Read operation. TxRDY is automatically reset by the falling

edge of DSN (with RDWN low) when a data character is

loaded from the CPU.

Note that when using the polled operation, the TxRDY

status bit is not masked by TxEnable, but will only indicate the

Empty/Full Status of the Tx Data input Register.

1.17 TRANSMITTER EMPTY (TxE)

When the MA28151 has no characters to send, the

TxEMPTY output will go high. It resets upon receiving a

character from CPU if the transmitter is enabled. TxEMPTY

remains high when the transmitter is disabled. TxEMPTY can

be used to indicate the end of transmission mode, so that the

CPU can turn the line around in the half-duplex operational

mode.

In the Synchronous mode, a high on the TxEMPTY output

indicates that a character has not been loaded and the SYNC

character or characters are about to be or are being

automatically transmitted as fillers. TxEMPTY does not go low

when the SYNC characters are being shifted out.

1.18 TRANSMITTER CLOCK

(TxC)

The Transmitter Clock controls the rate at which the

character is to be transmitted. In the Synchronous

transmission mode, the Baud Rate (1x) is equal to the TxC

frequency. In Asynchronous transmission mode, the baud rate

is a fraction of the actual TxC frequency. A portion of the mode

instruction selects this factor; it can be 1,1/16 or 1/64 the TxC.

For Example:

If Baud Rate equals 110 Baud

TxC equals 110Hz in the 1x mode

TxC equals 1 72KHz in the 16x mode

TxC equals 7.04KHz in the 64x mode

The falling edge of TxC shifts the serial data out of the

MA28151.

1.19 RECEIVER BUFFER

The Receiver accepts serial data, converts the data to

parallel format, checks for bits or characters that are unique to

the communications techniques and sends an assembled

character to the CPU. Serial data is input to the RxD pin and is

clocked in on the rising edge of RxC.

1.20 RECEIVER CONTROL

This functional block manages all receiver-related activities

which consist of the following features:

The RxD initialisation circuit prevents the MA28151 from

mistaking an unused input line for an active low data line in the

break condition. Before starting to receive serial characters on

the RxD line, a valid 1 must first be detected after a chip master

Reset. Once this has been determined, a search for a valid low

(start bit) is enabled. This feature is only active in the

asynchronous mode and is only done once for each master

Reset.

The False Start bit detection circuit prevents false starts as

the result of a transient noise spike by first detecting the falling

edge and then strobing the nominal center of the Start bit (RxD

= low).

Parity error detection sets the corresponding status bit.

The Framing Error status bit is set if the Stop bit is absent

at the end of the data byte (asynchronous mode).

1.21 RxRDY (RECEIVER READY)

This output indicates that the MA28151 contains a

character that is ready to be input to the CPU. RxRDY can be

connected to the interrupt structure of the CPU or, for polled

operation, the CPU can check the condition of RxRDY using a

Status Read operation. RxEnable, when off holds RxRDY in

the Reset Condition. For Asynchronous mode, to set RxRDY,

the Receiver must be enabled to sense a Start Bit and a

complete character must be assembled and transferred to the

Data Output Register. For Synchronous mode, to set RxRDY,

Page 4

MA28151

4/22

the Receiver must be enabled and a character must finish

assembly and be transferred to the Data Output Register

Failure to read the received character from the Rx Data

Output Register prior to the assembly of the next Rx Data

character will set overrun condition error and the previous

character will be written over and lost. If the Rx Data is being

read by the CPU when the internal transfer is occurring, the

overrun error will be set and the old character will be Iost.

1.22

RxC (RECEIVER CLOCK)

The Receiver Clock controls the rate at which the character

is to be received. In Synchronous Mode the Baud Rate (1x) is

equal to the actual frequency of

RxC. In Asynchronous Mode,

the Baud Rate is a fraction of the actual RxC frequency. A

portion of the mode instruction selects this factor: 1,1⁄16 or 1⁄64 of

the Receiver Clock.

For example:

Baud Rate equals 300 Baud, if

RxC equals 300 Hz in the 1 x mode:

RxC equals 4800 Hz in the 16x mode

RxC equals 19.2 KHz in the 64x mode.

Baud Rate equals 2400 Baud if

RxC equals 2400Hz in the 1x mode

RxC equals 38.4 KHz in the 16x mode;

RxC equals 153.6 KHz in the 64x mode.

Data is sampled into the MA28151 on the rising edge of RxC.

Note: In most communications systems, the MA28151 will

be handling both the transmission and reception operations of

a single link. Consequently the Receive and Transmit Baud

Rates will be the same. Both

TxC and RxC will require identical

frequencies for this operation and can be tied together and

connected to a single frequency source (Baud Rate

Generator) to simplify the interface.

1.23 SYNC/BREAK DETECT (SYNDET/BRKDET)

This pin is used in Synchronous Mode for SYNDET and

may be used as either input or output, programmable through

the Control Word. It is reset to output mode, low upon RESET.

When used as an output (internal Sync mode), the SYNDET

pin will go high to indicate that the MA28151 has located the

SYNC character in the Receive mode. If the MA28151 is

programmed to use double Sync characters (bi-sync), the

SYNDET will go high in the middle of the last bit of the second

Sync character.

SYNDET is automatically reset upon a Status Read

operation.

When used as an input (external SYNC detect mode), a

positive going signal will cause the MA28151 to start

assembling data characters on the rising edge of the next

RxC.

Once in SYNC, the high input signal can be removed. When

External SYNC Detect is programmed, Internal SYNC Detect

is disabled.

1.24 BREAK (ASYNC MODE ONLY)

This output will go high whenever the receiver remains low

through two consecutive stop bit sequences including the start

bits, data bits, and parity bits. Break Detect may also be read

as a Status bit. It is reset only upon a master chip Reset or Rx

Data returning to a “one” state.

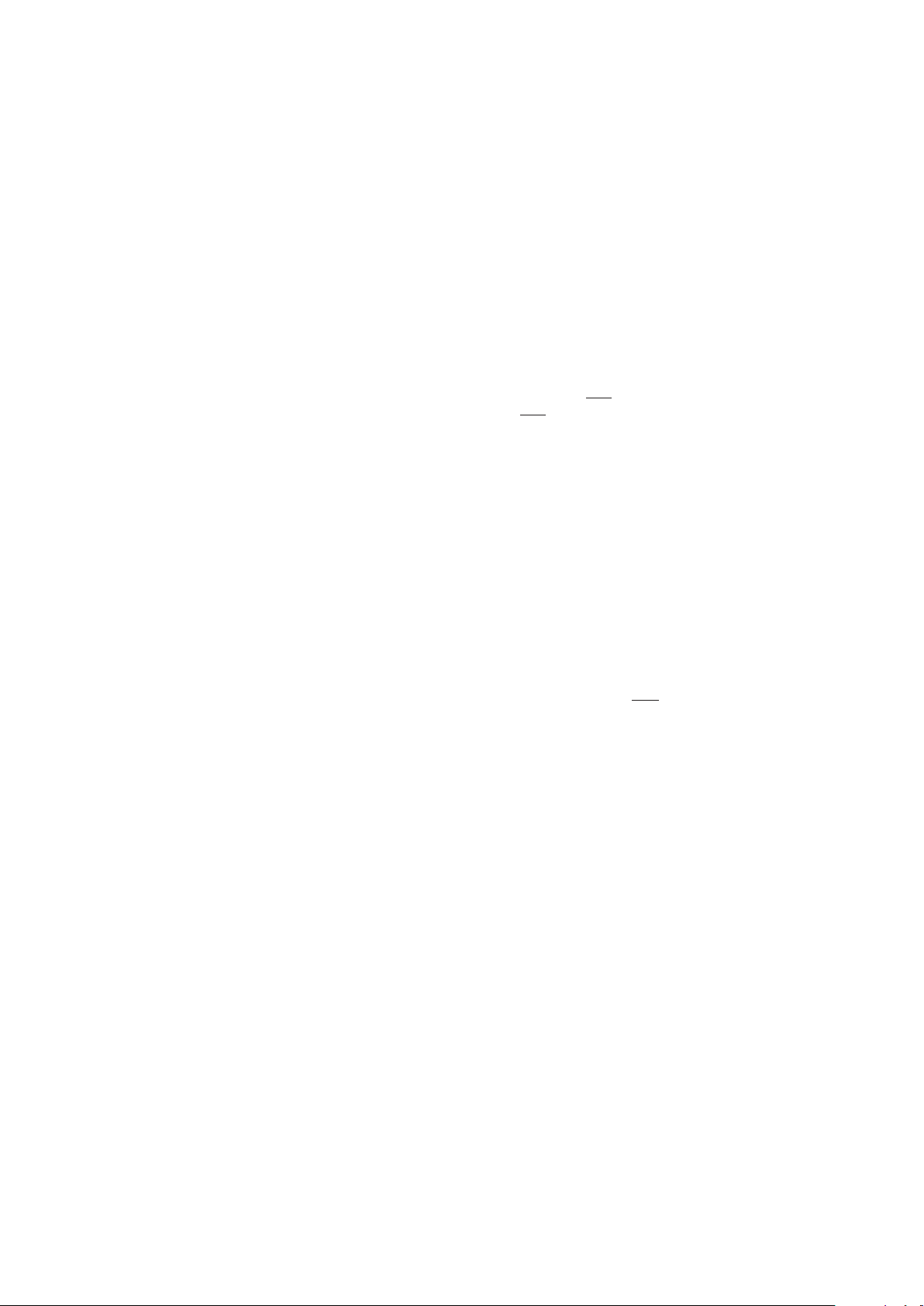

C/D ACTION

1 MODE INSTRUCTION

1 SYNC CHARACTER 1 (SYNC ONLY) *

1 SYNC CHARACTER 2 (SYNC ONLY) *

1 COMMAND INSTRUCTION

0 DATA

1 COMMAND INSTRUCTION

0 DATA

1 COMMAND INSTRUCTION

Note: The second sync character is skipped if mode instruction

has programmed the MA28151 to single character mode. Both

sync characters are skipped if mode instruction has

programmed the MA28151 to async mode

Figure 3: Typical data block

2. OPERATION DESCRIPTION

2.1 GENERAL

The complete functional definition of the MA28151 is

programmed by the system’s software. A set of control words

must be sent out by the CPU to initialize the MA28151 to

support the desired communications format. These control

words will program the: Baud Rate, Character Length, Number

of Stop Bits, Synchronous or Asynchronous Operation, Even/

Odd/Off Parity, etc. In the Synchronous Mode, options are also

provided to select either internal or external character

synchronization.

Once programmed, the MA28151 is ready to perform its

communication functions. The TxRDY output is raised high to

signal the CPU that the MA28151 is ready to receive a data

character from the CPU. This output (TxRDY) is reset

automatically when the CPU writes a character into the

MA28151. Alternatively, the MA28151 receives serial data

from the MODEM or l/O device. Upon receiving an entire

character, the RxRDY output is raised high to signal the CPU

that the MA28151 has a complete character ready for the CPU

to fetch. RxRDY is reset automatically upon the CPU data read

operation.

The MA28151 cannot begin transmission until the

TxEnable (Transmitter Enable) bit is set in the Command

instruction and it has received a Clear To Send (

CTS) input.

The TxD output will be held in the marking state upon Reset.

Page 5

MA28151

5/22

3. PROGRAMMING THE MA28151

3.1 MODE AND COMMAND INSTRUCTIONS

Prior to starting data transmission or reception, the

MA28151 must be loaded with a set of control words

generated by the CPU. These control signals define the

complete functional definition of the MA28151 and must

immediately follow a Reset operation (internal or external).

The control words are split into two formats:

1. Mode Instruction

2. Command Instruction

3.1.1 Mode Instruction

This instruction defines the general operational

characteristics of the MA28151. It must follow a Reset

operation (internal or external). Once the Mode instruction has

been written into the MA28151 by the CPU, SYNC characters

or Command Instructions may be written.

3.1.2 Command Instruction

This instruction defines a word that is used to control the

actual operation of the MA28151.

Both the Mode and Command Instruction must conform to

a specified sequence for proper device operation. The Mode

instruction must be written immediately following a Reset

operation, prior to using the MA28151 for data

communications.

All control words written into the MA28151 after the Mode

Instruction will load the Command Instruction. Command

Instructions can be written into the MA28151 at any time in the

data block during the operation of the MA28151. To return to

the Mode Instruction format, the master Reset bit in the

Command Instruction word can be set to initiate an internal

Reset operation. This automatically places the MA28151 back

into the Mode Instruction format. Command Instructions must

follow the Mode Instructions or Sync characters.

3.2 MODE INSTRUCTION DEFINITION

The MA28151 can be used for either Asynchronous or

Synchronous data communications. To understand how the

Mode Instruction defines the functional operation of the

MA28151, the designer can best view the device as two

separate components, one Asynchronous and the other

Synchronous, sharing the same package. The format

definition can be changed only after a master chip Reset. For

explanation purposes the two formats will be isolated.

NOTE: When parity is enabled it is not considered as one

of the data bits for the purpose of programming the word

length. The actual parity bit received on the Rx Data line

cannot be read on the Data Bus. In the case of a programmed

character length of less than 8 bits, the least significant data

bus bits will hold the data; unused bits are ‘don’t care’ when

writing data to the MA28151, and will be zeros when reading

the data from the MA28151.

3.3 TEST MODE

The Mode Instruction can be used to select a scan path

test facility. In this mode a test vector is read in through RxD

and read out in TxD. For further information of test mode

please contact GEC Plessey Semiconductors.

3.4 ASYNCHRONOUS MODE (TRANSMISSION)

Whenever a data character is sent by the CPU the

MA28151 automatically adds a Start bit (low level), followed by

the data bits (least significant bit first,) and the programmed

number of Stop bits to each character. Also, an even or odd

Parity bit is inserted prior to the Stop bit(s), as defined by the

Mode Instruction. The Character is then transmitted as a serial

data stream on the TxD output. The serial data is shifted out on

the falling edge of

TxC at a rate equal to 1, 1⁄16 or 1⁄64 times that

of the TxC, as defined by the Mode Instruction. BREAK

characters can be continuously sent to the TxD if commanded

to do so.

When no data characters have been loaded into the

MA28151 the TxD output remains high (marking) unless a

Break (continuously low) has been programmed.

3.5 ASYNCHRONOUS MODE (RECEIVE)

The RxD line is normally high. A falling edge on this line

triggers the beginning of a START bit. The validity of this

START bit is checked by again strobing this bit at its nominal

center (16x or 64X mode only). If a low is detected again, it is a

valid START bit, and the bit counter will start counting. The bit

counter thus locates the center of the data bits, the parity bit (if

it exists) and the stop bits. If a parity error occurs, the parity

error flag is set. Data and parity bits are sampled on the RxD

pin with the rising edge of

RxC. If a low level is detected as the

STOP bit, the Framing Error flag will be set. The STOP bit

signals the end of a character. Note that the receiver requires

only one stop bit, regardless of the number of stop bits

programmed. This character is then loaded into the parallel l/O

buffer of the MA28151. The RxRDY pin is raised to signal the

CPU that a character is ready to be fetched.

If a previous character has not been fetched by the CPU,

the present character replaces it in the l/O buffer, and the

OVERRUN Error flag is raised (thus the previous character is

lost). All of the error flags can be reset by an Error Reset

Instruction. The occurrence of any of these errors will not affect

the operation of the MA28151.

Page 6

MA28151

6/22

D7D6D5D4D3D2D1D

0

S2S

1 EP PEN L2 L1 B2 B1

BAUD RATE FA

CTO

R

SYNC

MODE

(1x) (16x) (64x)

0011

0011

C

HARACTER LENGTH

5

BITS6BITS7BITS8BITS

0011

0101

PARITY ENABLE AND SENSE

1 = ENABLE 0 = DISABLE

1 = EVEN 0 = ODD

NUMBER OF STOP BIT

S

NOT

VALID1BIT

1 1/2

BITS2BITS

0011

0101

Figure 4: Mode Instruction Format, Asynchronous Mode

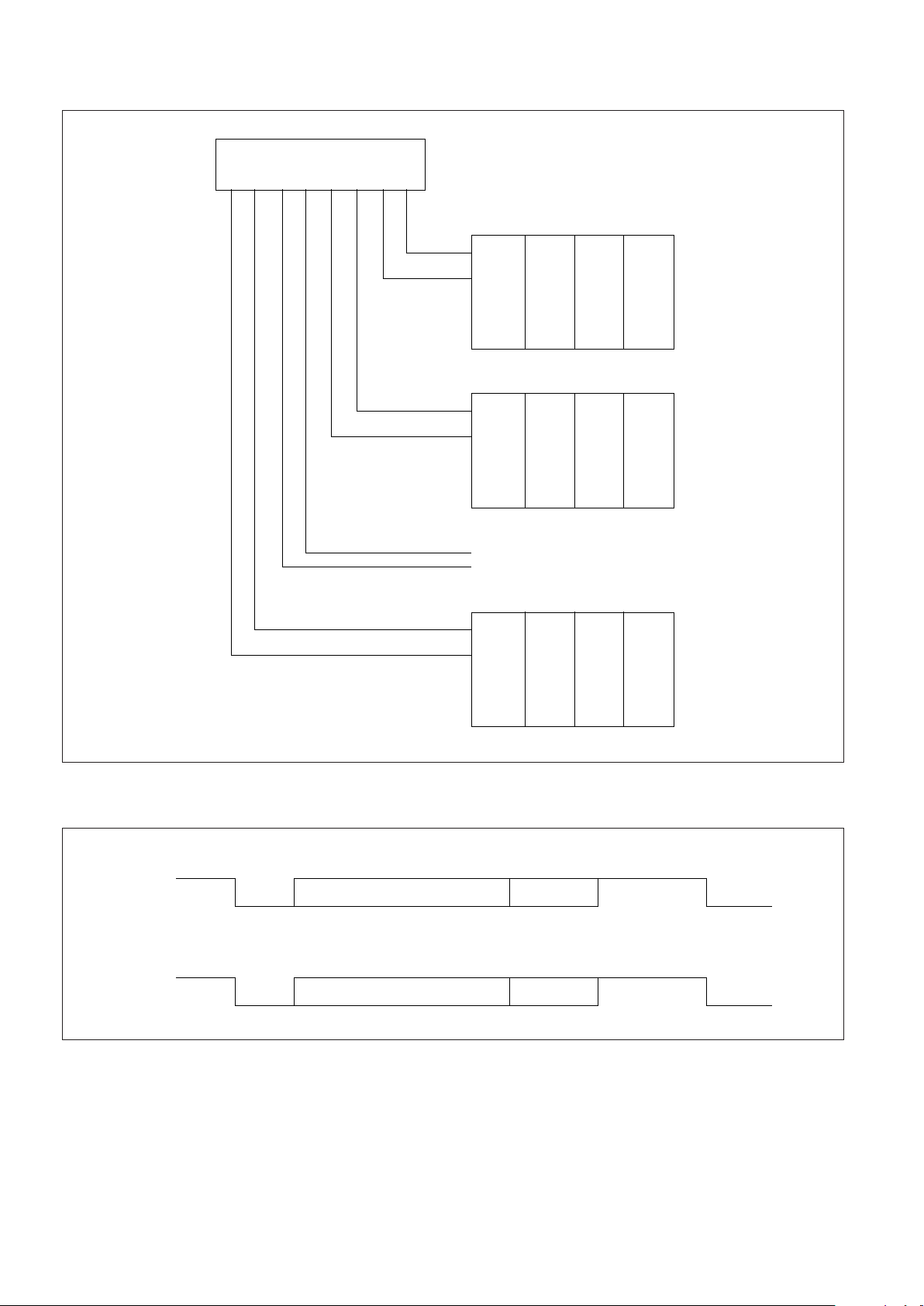

TxD MARKING

DATA BITS D0-Dx GENERATED BY MA28151

PARITY BIT

STOP

BITS

RxD

DATA BITS D0-Dx DOES NOT APPEAR ON DBUS

PARITY BIT

STOP

BITS

PROGRAMMED CHAR. LENGTH

Figure 5: Asynchronous Mode

Page 7

MA28151

7/22

Figure 6: Transmission Format

Figure 7: Receive Format

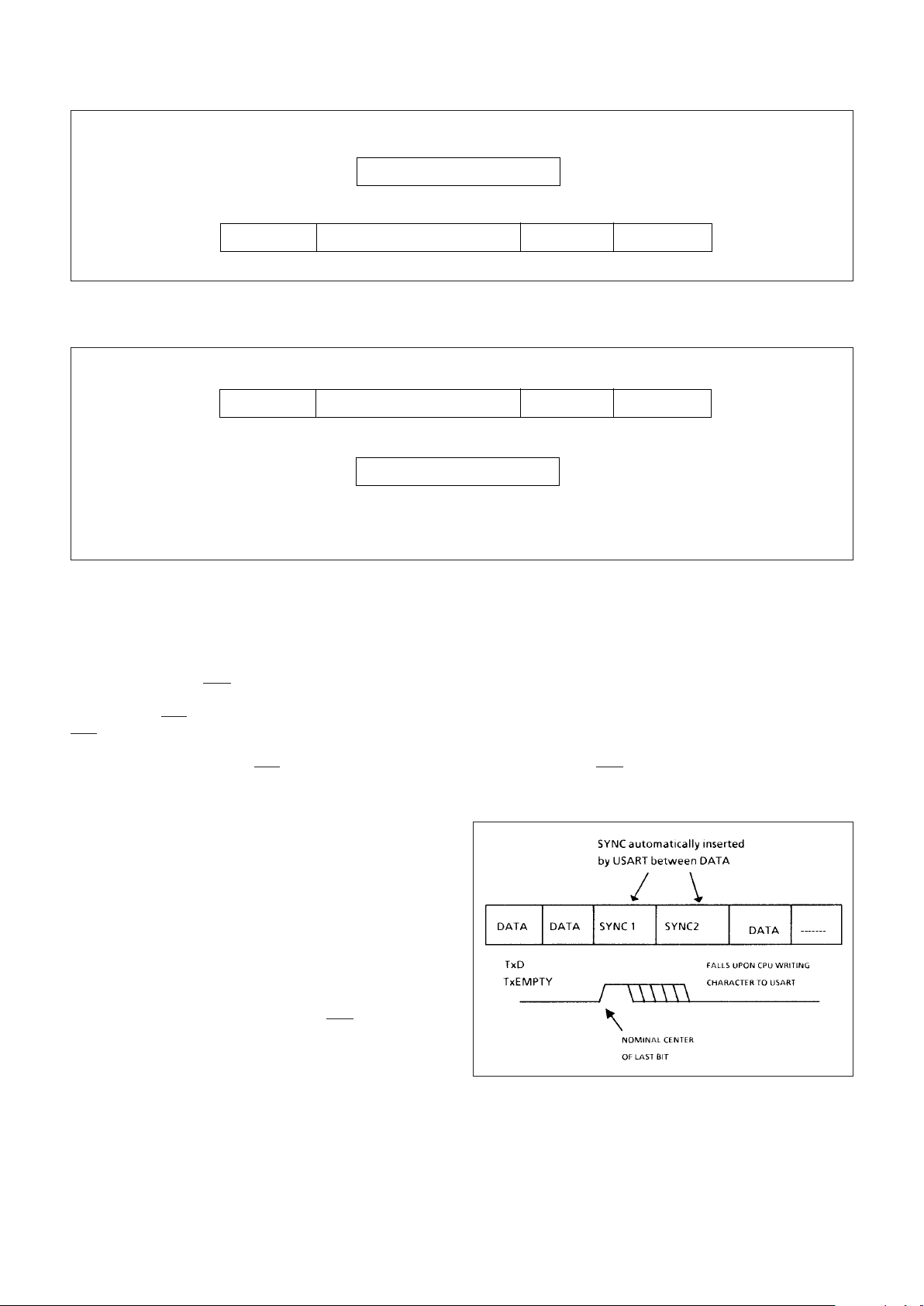

3.6 SYNCHRONOUS MODE (TRANSMISSION)

The TxD output is continuously high until the CPU sends its

first character to the MA28151 which usually is a SYNC

character. When the

CTS line goes low, the first character is

serially transmitted out. All characters are shifted out on the

falling edge of TxC. Data is shifted out at the same rate as the

TxC.

Once transmission has started, the data stream at the TxD

output must continue at the TxC rate. If the CPU does not

provide the MA28151 with a data character before the

MA28151 Transmitter Buffers become empty, the SYNC

characters (or character if in single SYNC character mode) will

be automatically inserted in the TxD data stream. In this case,

the TxEMPTY does not go low when the SYNC is being shifted

out (see figure 8). The TxEMPTY pin is internally reset by a

data character being written into the MA28151.

3.7 SYNCHRONOUS MODE (RECEIVER)

In this mode character synchronisation can be internally or

externally achieved. If the SYNC mode has been

programmed, ENTER-HUNT command should be included in

the first command instruction word written. Data on the RxD

pin is then sampled on the rising edge of

RxC. The content of

the Rx buffer is compared to every bit boundary with the first

SYNC character until a match occurs.

If the MA28151 has been programmed for two SYNC

characters, the subsequent received character is also

compared; when both SYNC characters have been detected,

the USART ends the HUNT mode and is in character

synchronization. The SYNDET pin is then set high, and is reset

automatically by a STATUS READ. If parity is programmed,

SYNDET will not be set until the middle of the parity bit, instead

of the middle of the last data bit.

In the external SYNC mode, synchronization is achieved

by applying a high level on the SYNDET pin, thus forcing the

MA28151 out of the HUNT mode. The high level can be

removed after one

RxC cycle. An ENTER HUNT command

has no effect in the asynchronous mode of operation.

Figure 8: Sync Character Insertion

PARITY BITDATA CHARACTER STOP BITSSTART BIT

DATA CHARACTER

ASSEMBLED SERIAL DATA OUTPUT (TxD)

CPU BYTE (5-8 BITS/CHARACTER)

PARITY BITDATA CHARACTER STOP BITSSTART BIT

DATA CHARACTER

SERIAL DATA INPUT (RxD)

CPU BYTE (5-8 BITS/CHARACTER) (See Note Below)

NOTE: If character length is defined as 5, 6 or 7 bits the unused bits are set to zero.

Page 8

MA28151

8/22

Parity error and overrun error are both checked in the same

way as in the Asynchronous Receive mode. Parity is checked

when not in HUNT, regardless of whether the Receiver is

enabled or not.

The CPU can command the receiver to enter the HUNT

mode if synchronisation is lost. This will also set all the used

character bits in the buffer to a one thus preventing a possible

false SYNDET caused by data that happens to be in the Rx

buffer at ENTER HUNT time.

Note: the SYNDET flip-flop is reset at each Status Read,

regardless of whether internal or external SYNC has been

programmed. This does not cause the MA28151 to return to

the HUNT mode. When in SYNC mode, but not in HUNT, Sync

Detection is still functional, but only occurs at the known word

boundaries. Thus, if one Status Read indicates SYNDET and a

second Status Read also indicates SYNDET, then the

programmed SYNDET characters have been received since

the previous Status Read. (If double character sync has been

contiguously received to gate a SYNDET indication). When

external SYNDET mode is selected, internal Sync Detect is

disabled, and the SYNDET flip-flop may be set at any bit

boundary.

3.9 DATA FORMAT, SYNCHRONOUS MODE

DATA CHARACTERS

ASSEMBLED SERIAL DATA OUTPUT (TxD)

SYNC CHAR 1 SYNC CHAR 2 DATA CHARACTERS

Figure 9: Receive Format, Synchronous Mode

Figure 10: Data Format, Synchronous Mode

DATA CHARACTERS

CPU BYTES (5-8 BITS/CHARACTER)

SYNC CHAR 1 SYNC CHAR 2 DATA CHARACTERS

3.8 MODE INSTRUCTION FORMAT, SYNCHRONOUS MODE

D7D6D5D4D3D2D1D

0

SSES

EP PEN L2 L1 0 0

C

HARACTER LENGTH

5

BITS6BITS7BITS8BITS

0011

0101

PARITY ENABLE AND SENSE

1 = ENABLE 0 = DISABLE

1 = EVEN 0 = ODD

EXTERNAL SYNC DETECT

1 = SYNCDET IS AN INPUT

0 = SYNCDET IS AN OUTPUT

SING

LE CHARACTER SYN

C

1 = SINGLE SYNC CHAR.

0 = DOUBLE SYNC CHAR.

Figure 11: Mode Instruction Format, Synchronous Mode

Page 9

MA28151

9/22

3.10 COMMAND INSTRUCTION DEFINITION

Once the functional definition of the MA28151 has been

programmed by the Mode Instruction and the sync characters

are loaded (if in Sync Mode) then the device is ready to be

used for data communications. The Command Instruction

controls the actual operation of the selected format. Functions

such as: Enable Transmit/Receive, Error Reset and Modem

Controls are provided by the Command Instruction.

Once the Mode Instruction has been written into the

MA28151 and Sync characters inserted, if necessary, then all

further “control writes” (CDN=1) will load a Command

Instruction. A Reset Operation (internal or external) will return

the MA28151 to the Mode instruction format.

Note: Internal Reset on Power-up. When power is first

applied, the MA28151 may come up in the Mode, Sync

character or Command format. To guarantee that the device is

in the Command instruction format before the Reset command

is issued, it is safest to execute the worst-case initialization

sequence (sync mode with two sync characters). Loading

three 00Hs consecutively into the device with CDN=1

configures sync operation and writes two dummy 00H sync

characters. An internal reset command (40H) may then be

issued to return the device to the idle state.

3.11 COMMAND INSTRUCTION FORMAT

D

7

TRANSMIT ENABLE

1 = ENABLE

0 = DISABLE

EH

D

6

IR

D

5

RTS

D

4

ER

D

3

SBRK

D

2

RxE

D

1

DTR

D

0

TxEN

DATA TERMINAL READY

HIGH WILL FORCE DTR

OUTPUT TO ZERO

RECEIVE ENABLE

1 = ENABLE

0 = DISABLE

S

END BREAK CHARACTER

1 = FORCES TxD LOW

0 = NORMAL OPERATION

ERROR RESET

1 = RESET ERROR FLAGS

PE, OE, FE

REQUEST TO SEND

HIGH WILL FORCE RTS

OUTPUT TO ZERO

INTERNAL RESET

HIGH RETURNS THE MA28151 TO

MODE INSTRUCTION FORMAT

ENTER HUNT MODE*

HIGH ENABLES SEARCH FOR SYNC

CHARACTERS (HAS NO EFFECT IN ASYNC MODE)

*NOTE: ERROR RESET must be performed whenever RxENABLE and ENTER-HUNT

are programmed.

Figure 12: Command Instruction Format

Page 10

MA28151

10/22

3.12 STATUS READ DEFINITION

In data communication systems it is often necessary to

examine the status of the active device to ascertain if errors

have occurred or other conditions that require the processor’s

attention. The MA28151 has facilities that allow the

programmer to read the status of the device at any time during

the functional operation. (Status update is inhibited during

status read).

A normal read command is issued by the CPU with CDN

high to accomplish this function.

Some of the bits in the Status Read Format have identical

meanings to external output pins so that the MA28151 can be

used in a completely polled or interrupt-driven environment.

TxRDY is an exception.

Note that status update can have a maximum delay of 28

clock periods from the actual event affecting the status.

3.13 STATUS READ FORMAT

D

7

DSR

D

6

S

YNDET

BRKDET

D

5

FE

D

4

O

E

D

3

PE

D

2

Tx

EMPTY

D

1

RxRDY

D

0

TxRDY

PARITY ERROR

The PE flag is set when the

parity error is detected. It is

reset by the ER bit of the

Command Instruction. PE does

not inhibit the operation of the

MA28151.

Note 1: TxRDY status bit has different meanings from the TxRDY output pin. The former

is not conditioned by CTS and TxEN, the latter is conditioned by both CTS and TxEN.

ie. TxRDY status bit 0 DB buffer empty

TxRDY pin out = DB buffer empty OR (CTSN = 0) OR (TxEN = 1)

Note 1

Same as I/O pins

O

VERRUN ERROR

The OE flag is set when the

CPU does not read a character

before the next one becomes

available. It is reset by the ER

bit of the Command Instruction

OE does not inhibit operation

of the MA28151, however the

previously overrun character is

lost.

FRAMING ERROR (ASYNC

ONLY)

The FE flag is set when a valid

Stop bit is not detected at the

end of every character. It is

reset by the ER bit of the

Command Instruction. FE does

not inhibit the operation of the

MA28151.

DATA SET READY

Indicates that the DSR is at a

zero level.

Figure 13: Status Read Format

Page 11

MA28151

11/22

4. TIMING WAVEFORMS

Figure 14: System Clock Input

Figure 15: Transmitter Clock and Data

Figure 16: Receive Clock and Data

Page 12

MA28151

12/22

Figure 17: Write Data Cycle (CPU to USART)

Figure 19: Write Control or Output Port Cycle (CPU to USART)

Note: tWC includes the response timing of a control byte.

Figure 18: Read Data Cycle (USART to CPU)

Page 13

MA28151

13/22

Figure 20: Read Control or Output Port Cycle (USART to CPU)

Note: tCR includes the effect of CTS on the TxENABLE circuitary.

Figure 21: Transmitter Control and Flag Timing (ASYNC Mode)

Example Format = 7 bit character with parity and 2 stop bits.

Page 14

MA28151

14/22

Figure 22: Receiver Control and Flag Timing (ASYNC Mode)

Example Format = 7 bit character with parity and 2 stop bits.

Page 15

MA28151

15/22

5. AC ELECTRICAL CHARACTERISTICS

Symbol Parameter Min. Max. Units Condition

t

CY

Internal clock cycle time 200 1000 nS Notes 1, 5, 6

t

0

External Clock high pulse width 25 - nS -

t

0

External Clock low pulse width 25 - nS -

tR, t

F

Clock rise and fall time - 10 nS -

t

DTX

TxD delay from falling edge of TxD - 1 µS-

t

TPW

Transmitter input clock pulse width 12xt

CY

- - 1 x baud rate

1xt

CY

- - 16 x and 64 x baud rate

t

TPD

Transmitter input clock pulse delay 15xt

CY

- - 1 x baud rate

3xt

CY

- - 16 x and 64 x baud rate

t

RPW

Receive input clock pulse width 12xt

CY

- - 1 x baud rate

1xt

CY

- - 16 x and 64 x baud rate

t

RPD

Receive input clock pulse delay 15xt

CY

- - 1 x baud rate

3xt

CY

- - 16 x and 64 x baud rate

t

TxRDY

TxRDY pin delay from CENTER of last bit - 8xt

CY

- Note 7

t

TxRDY CLEAR

TxRDY fall from falling DSN (WRITE) - 45 - Note 7

t

RxRDY

RxRDY pin delay from center of last bit - 26xt

CY

- Note 7

t

RxRDY CLEAR

RxRDY fall from falling DSN (READ) - 45 - Note 7

t

TxEMPTY

TxEMPTY from centre of last bit 20xt

CY

- - Note 7

t

WC

Control delay from rising edge of WRITE 8xt

CY

- - Note 7

t

CR

Control to READ set-up time (DSR, CTS) 20xt

CY

- - Note 7

t

AR

Address stable before DSN (CSN, CDN) 0 - ns Note 2

t

RA

Address hold time before DSN (CSN, CDN) 0 - ns Note 2

t

RR

DSN pulse width 20 - ns -

t

RD

Data delay from DSN falling (READ) - 30 ns Note 3

t

DF

DSN rising to data floating (READ) 10 45 ns Note 8

t

DW

Data set-up time to DSN rising (WRITE) 15 - ns -

t

WD

Data hold time to DSN rising (WRITE) 5 - ns -

t

RV

Recovery time between writes (not shown) 6xt

CY

- - Note 4

Notes: 1. AC Timings measured VOH = 1.5 VOL = 1.5.

2. CSN and Command/Data are considered as addresses.

3. Assumes that address is valid before DSN goes low.

4. This recovery time is for Mode Initialisation only. Write data is allowed when TxRDY = 1. Recovery time between

writes for Asynchronous Mode is 8xt

CY

and for Synchronous Mode is 16xtCY.

5. The TxC and RxC frequencies have the following limitation with respect to clock: For 1 x baudrate, fTX or fRX≤1/

(30t

CY

): For 16 x and 64 x baud rate, fTX or fRX ≤1/(4.5tCY).

6. Reset Pulse Width = 6tCY minimum; System clock must be running during Reset.

7. Status update can have a maximum delay of 28 clock periods from the event affecting the status.

8. Data Bus connected to V

DD

via loads of 680Ω (minimum).

Mil-Std-883, method 5005, subgroups 9, 10, 11

Figure 23: AC Electrical Characteristics

Symbol Parameter Min. Max. Units Condition

- Clock Frequency (osc) - 20 MHz -

f

Tx

Transmitter input clock frequency DC 64 kHz 1 x baud rate

DC 310 kHz 16 x baud rate

DC 615 kHz 64 x baud rate

f

Rx

Receiver input clock frequency DC 64 kHz 1x baud rate

DC 310 kHz 16 x baud rate

DC 615 kHz 64 x baud rate

Mil-Std-883, method 5005, subgroups 7, 8A, 8B

Figure 24: Operating AC Electrical Characteristics

Page 16

MA28151

16/22

6. DC CHARACTERISTICS AND RATINGS

Parameter Min Max Units

Supply Voltage -0.5 7 V

Input Voltage -0.3 V

DD

+0.3 V

Current Through Any Pin -20 +20 mA

Operating Temperature -55 125 °C

Storage Temperature -65 150 °C

Note: Stresses above those listed may cause permanent

damage to the device. This is a stress rating only and

functional operation of the device at these conditions, or at

any other condition above those indicated in the operations

section of this specification, is not implied. Exposure to

absolute maximum rating conditions for extended periods

may affect device reliability.

Figure 25: Absolute Maximum Ratings

Total dose radiation not

exceeding 3x105 Rad(SI)

Symbol Parameter Conditions Min Typ Max Units

V

DD

Supply Voltage - 4.5 5.0 5.5 V

V

IH

Input High Voltage - 2.2 - - V

V

IL

Input Low Voltage - - - 0.8 V

V

OH

Output High Voltage IOH = -2mA VDD-0.5 - - V

V

OL

Output Low Voltage IOL = 5mA - - VSS+0.4 V

I

IN

Input Leakage Current (Note 1) VDD = 5.5V, - - ±10 µA

VIN = VSS or V

DD

I

OZ

Tristate Leakage Current (Note 1) VDD = 5.5V, - - ±50 µA

V

IN

= VSS or V

DD

I

DD

Power Supply Current Static, VDD = 5.5V - 0.1 10 mA

VDD = 5V±10%, over full operating temperature range.

Mil-Std-883, method 5005, subgroups 1, 2, 3

Note 1: Guaranteed but not tested at -55°C

Figure 26: Electrical Characteristics

Subgroup Definition

1 Static characteristics specified in Figure 26 at +25°C

2 Static characteristics specified in Figure 26 at +125°C

3 Static characteristics specified in Figure 26 at -55°C

7 Functional characteristics specified in Figure 24 at +25°C

8A Functional characteristics specified in Figure 24 at +125°C

8B Functional characteristics specified in Figure 24 at -55°C

9 Switching characteristics specified in Figure 23 at +25°C

10 Switching characteristics specified in Figure 23 at +125°C

11 Switching characteristics specified in Figure 23 at -55°C

Figure 27: Definition of Mil-Std-883, Method 5005 Subgroups

Page 17

MA28151

17/22

7. OUTLINES AND PIN ASSIGNMENTS

D

W

A

e b Z

H

A

1

15°

M

E

C

e

1

Seating Plane

114

2815

Ref

Millimetres Inches

Min. Nom. Max. Min. Nom. Max.

A - - 5.715 - - 0.225

A1 0.38 - 1.53 0.015 - 0.060

b 0.35 - 0.59 0.014 - 0.023

c 0.20 - 0.36 0.008 - 0.014

D - - 36.02 - - 1.418

e - 2.54 Typ. - - 0.100 Typ. -

e1 - 15.24 Typ. - - 0.600 Typ. -

H 4.71 - 5.38 0.185 - 0.212

Me - - 15.90 - - 0.626

Z - - 1.27 - - 0.050

W - - 1.53 - - 0.060

XG404

28

D1

27

D0

26

Vdd

25

RxC

24

DTR

23

RTS

22

DSR

21

RESET

20

CLK

19

TxD

18

TxE

17

CTS

16

SYNDET

15

TxRDY

1

D2

2

D3

3

RxD

4

GND

5

D4

6

D5

7

D6

8

D7

9

TxC

10

RDWN

11

CSN

12

CDN

13

DSN

14

RxRD

Y

Top

View

Figure 28: 28-Lead Ceramic DIL (Solder Seal) - Package Style C

Page 18

MA28151

18/22

Figure 29: 48-Pad Leadless Chip Carrier - Package Style L

Bottom

View

Pad 1

Radius r

3 corners

E

Z

e b

1

D A

Ref

Millimetres Inches

Min. Nom. Max. Min. Nom. Max.

A - - 2.29 - - 0.090

b1 - 0.51 - - 0.020 -

D - - 14.60 - - 0.575

E - - 14.60 - - 0.575

e - 1.02 - - 0.040 Z - 1.52 Typ. - - 0.060 Typ. -

XG431

Bottom

View

19

181716151413121110987

20

21

22

23

24

25

26

27

28

29

30

313233343536373839404142

6

5

4

3

2

1

48

47

46

45

44

43

N

C

C

DN

D

S

N

RxRDY

N

CNC

TxRDY

S

YNDET

N

C

CTS

TxEMPTY

N

CNC

G

ND

RxD

D3

N

C

D2

N

CNC

D1

D0

N

C

Vdd

NCD4D5

NC

D6

NC

D7

NC

TxC

RDW

N

CSN

NC

NC

RxC

NC

DTR

RTS

NC

DSR

NC

RESET

CLK

TxD

NC

Page 19

MA28151

19/22

Top View

j1

D1L

Pin 1

j2

b

e

D2

Z

A1

A

c

Ref

Millimetres Inches

Min. Nom. Max. Min. Nom. Max.

A - - 2.72 - - 0.107

A1 1.83 - 2.24 0.072 - 0.088

b 0.41 - 0.51 0.016 - 0.020

c 0.20 - 0.30 0.008 - 0.012

D1, D2 23.88 - 24.51 0.940 - 0.960

e - 2.54 - - 0.050 j1 - 1.02 - - 0.040 j2 - 0.51 - - 0.020 L 10.16 - 10.54 0.400 - 0.415

Z 1.65 - 2.16 0.065 - 0.085

XG540

Figure 30a: 68-Lead Topbraze Flatpack - Package Style F

Page 20

MA28151

20/22

Figure 30b: 68-Lead Topbraze Flatpack - Package Style F

Top View

27

26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59

NC

NC

CDN

NC

DSN

NC

RXRDY

NC

TXRD

Y

NC

SYNDET

NC

CTS

NC

TXE

NC

NC

NC

NC

CSNNCRDWN

NC

TXC

NC

D7

NC

D6

NC

D5

NCD4NC

NC

NC

TXD

NC

CLK

NC

ESET

NC

DSR

NC

RTS

NC

DTR

NC

RXC

NC

Page 21

MA28151

21/22

8. RADIATION TOLERANCE

Total Dose Radiation Testing

For product procured to guaranteed total dose radiation

levels, each wafer lot will be approved when all sample

devices from each lot pass the total dose radiation test.

The sample devices will be subjected to the total dose

radiation level (Cobalt-60 Source), defined by the ordering

code, and must continue to meet the electrical parameters

specified in the data sheet. Electrical tests, pre and post

irradiation, will be read and recorded.

Dynex Semiconductor can provide radiation testing

compliant with MIL-STD-883 Ionizing Radiation (Total Dose)

test 1019.

9. ORDERING INFORMATION

For details of reliability, QA/QC, test and assembly

options, see ‘Manufacturing Capability and Quality

Assurance Standards’ Section 9.

Unique Circuit Designator

S

R

Q

H

Radiation Hard Processing

100 kRads (Si) Guaranteed

300 kRads (Si) Guaranteed

1000 kRads (Si) Guaranteed

Radiation Tolerance

C

F

L

Ceramic DIL (Solder Seal)

Flatpack (Solder Seal)

Leadless Chip Carrier

Package Type

QA/QCI Process

(See Section 9 Part 4)

Test Process

(See Section 9 Part 3)

Assembly Process

(See Section 9 Part 2)

L

C

D

E

B

S

Rel 0

Rel 1

Rel 2

Rel 3/4/5/STACK

Class B

Class S

Reliability Level

MAx28151xxxxx

Total Dose (Function to specification)* 3x105 Rad(Si)

Transient Upset (Stored data loss) 5x10

10

Rad(Si)/sec

Transient Upset (Survivability) >1x1012 Rad(Si)/sec

Neutron Hardness (Function to specification) >1x1015 n/cm

2

Single Event Upset** <1x10

-10

Errors/bit day

Latch Up Not possible

* Other total dose radiation levels available on request

** Worst case galactic cosmic ray upset - interplanetary/high altitude orbit

Figure 31: Radiation Hardness Parameters

Page 22

MA28151

22/22

CUSTOMER SERVICE CENTRES

France, Benelux, Italy and Spain Tel: +33 (0)1 69 18 90 00. Fax: +33 (0)1 64 46 54 50

North America Tel: 011-800-5554-5554. Fax: 011-800-5444-5444

UK, Germany, Scandinavia & Rest Of World Tel: +44 (0)1522 500500. Fax: +44 (0)1522 500020

SALES OFFICES

France, Benelux, Italy and Spain Tel: +33 (0)1 69 18 90 00. Fax: +33 (0)1 64 46 54 50

Germany Tel: 07351 827723

North America Tel: (613) 723-7035. Fax: (613) 723-1518. Toll Free: 1.888.33.DYNEX (39639) /

Tel: (831) 440-1988. Fax: (831) 440-1989 / Tel: (949) 733-3005. Fax: (949) 733-2986.

UK, Germany, Scandinavia & Rest Of World Tel: +44 (0)1522 500500. Fax: +44 (0)1522 500020

These offices are supported by Representatives and Distributors in many countries world-wide.

© Dynex Semiconductor 2000 Publication No. DS3574-5 Issue No. 5.0 January 2000

TECHNICAL DOCUMENTATION – NOT FOR RESALE. PRINTED IN UNITED KINGDOM

HEADQUARTERS OPERATIONS

DYNEX SEMICONDUCTOR LTD

Doddington Road, Lincoln.

Lincolnshire. LN6 3LF. United Kingdom.

Tel: 00-44-(0)1522-500500

Fax: 00-44-(0)1522-500550

DYNEX POWER INC.

Unit 7 - 58 Antares Drive,

Nepean, Ontario, Canada K2E 7W6.

Tel: 613.723.7035

Fax: 613.723.1518

Toll Free: 1.888.33.DYNEX (39639)

This publication is issued to provide information only which (unless agreed by the Company in writing) may not be used, applied or reproduced for any purpose nor form part of any order or contract nor to be regarded

as a representation relating to the products or services concerned. No warranty or guarantee express or implied is made regarding the capability, performance or suitability of any product or service. The Company

reserves the right to alter without prior notice the specification, design or price of any product or service. Information concerning possible methods of use is provided as a guide only and does not constitute any

guarantee that such methods of use will be satisfactory in a specific piece of equipment. It is the user's responsibility to fully determine the performance and suitability of any equipment using such information and

to ensure that any publication or data used is up to date and has not been superseded. These products are not suitable for use in any medical products whose failure to perform may result in significant injury

or death to the user. All products and materials are sold and services provided subject to the Company's conditions of sale, which are available on request.

All brand names and product names used in this publication are trademarks, registered trademarks or trade names of their respective owners.

http://www.dynexsemi.com

e-mail: power_solutions@dynexsemi.com

Datasheet Annotations:

Dynex Semiconductor annotate datasheets in the top right hard corner of the front page, to indicate product status. The annotations are as follows:-

Target Information: This is the most tentative form of information and represents a very preliminary specification. No actual design work on the product has been started.

Preliminary Information: The product is in design and development. The datasheet represents the product as it is understood but details may change.

Advance Information: The product design is complete and final characterisation for volume production is well in hand.

No Annotation: The product parameters are fixed and the product is available to datasheet specification.

Loading...

Loading...