Page 1

MNS Microwave Chip Capacitors MA4M Series

p

MA4M Series

MNS Microwave

Chi

Capacitors

Features

•

Excellent Repeatability

(Wafer-to-Wafer and Lot-to-Lot)

•

Small Size

•

Low Loss, High Q

•

Available with Round or Square Bonding Pads

Description

M/A-COM’s MA4M series of MNS (metal-nitride-silicon) silicon chip capacitors is designed specifically for high reliability and

repeatable performance in microwave circuit ap plications . These

capacitors are made using a low press ure chemical vapor depos ition (LPCVD) that results in dense, uniform nitride layers. These

capacitors exhibit higher capacitance per unit area (resulting in

smaller chip size) than similar MOS, MIS and ceramic capacitors.

Evaporated gold contacts are used t o provide an easily bondable

metal pad on the capacitor chip. M/A-COM MNS capacitors have

shown no measurable capacitance change when subjected to the

rated standoff voltage of 150ºC.

The MA4M series of chip capacitors is an excellent choice for use

in hybrid microwave circuits up through Ku-band, where low

loss, high reliability, small size and temperature stability are

prime concerns.

Case Style

350

These chip capacitors are suited for applications requiring DC

blocks, coupling capacitors, bypass capacitors, capacitive loads

and tuning elements in oscillators, multipliers and filters.

Comparison of M/A-COM MNS Capacitors to Ceramic Chip Capacitors

Characteristics Compared MNS Ceramic

Operating Temperature Range -55 to +200°C -55 to +125°C

Temperature Coefficient 180 PPM 1000 PPM

Insertion Loss of a 20 pF Capacitor in a 50 Ω line at 15 GHz

Chip Size

200 pF, 100V 40 x 40 mils 70 x 70 mils

20 pF, 100V 22 x 22 mils 50 x 50 mils

M/A-COM Division of AMP Incorporated ■ North America: Tel. (800) 366-2266, Fax (800) 618-8883 ■ Asia/Pacific: Tel.+85 2 2111 8088, Fax +85 2 2111 8087

■

Europe: Tel. +44 (1344) 869 595, Fax+44 (1344) 300 020

www.macom.com

AMP and Connecting at a Higher Level are trademarks.

Specifications subject to change without notice.

0.1 dB 0.2 dB

V3.00

Page 2

MNS Microwave Chip Capacitors MA4M Series

Specifications

Chip Capacitor s with Round Bonding Pads

Chip Capacitor s with Square Bonding Pads

Model

Number

Capactance

1,2,3,4

(pF)

±

10 %

Maximum

Standoff

Voltage

2,5

Rating

(Volts)

Chip

Style

Nominal

Top

Contact

Diameter

(mils)

MA4M2002 2 200 132 3.5

MA4M2005 5 200 132 6.0

MA4M1010 10 100 132 6.0

MA4M1020 20 100 132 9.0

MA4M2020 20 200 132 11.5

MA4M1030 30 100 132 11.0

MA4M1050 50 100 132 14.0

MA4M1080 80 100 199 18.0

MA4M1100 100 100 199 20.0

MA4M2100 100 200 200 26.0

MA4M1200 200 100 200 28.0

MA4M1250 250 100 200 32.0

MA4M1300 300 100 201 35.0

Maximum

Standoff

Voltage

Rating

(Volts)

2,5

Chip

Style

Model

Number

Capactance

1,2,3,4

(pF)

±

10 %

MA4M3010 10 200 350

MA4M3020 20 200 351

MA4M3030 30 200 352

MA4M3050 50 200 354

MA4M3100 100 50 358

MA4M3150 150 50 359

Notes:

1 5% capacitance tolerance is available on request.

2 Other capacitance and standoff voltage values are av ai la ble o n re ques t.

3 Capacitance is mea s u r ed a t 1 MHz.

4 Temperature coeffic i ent o f capacitance is nominally 180 PPM/°C.

5 Device failure may occur if standoff voltage ratio is exceeded.

MA4M2300 300 200 263 45.0

MA4M1600 600 100 263 48.0

Maximum Ratings

Applied Voltage

Operating Temperature

Storage Temperature

Specified standoff voltage

-55°C to +200°C

-55°C to +200°C

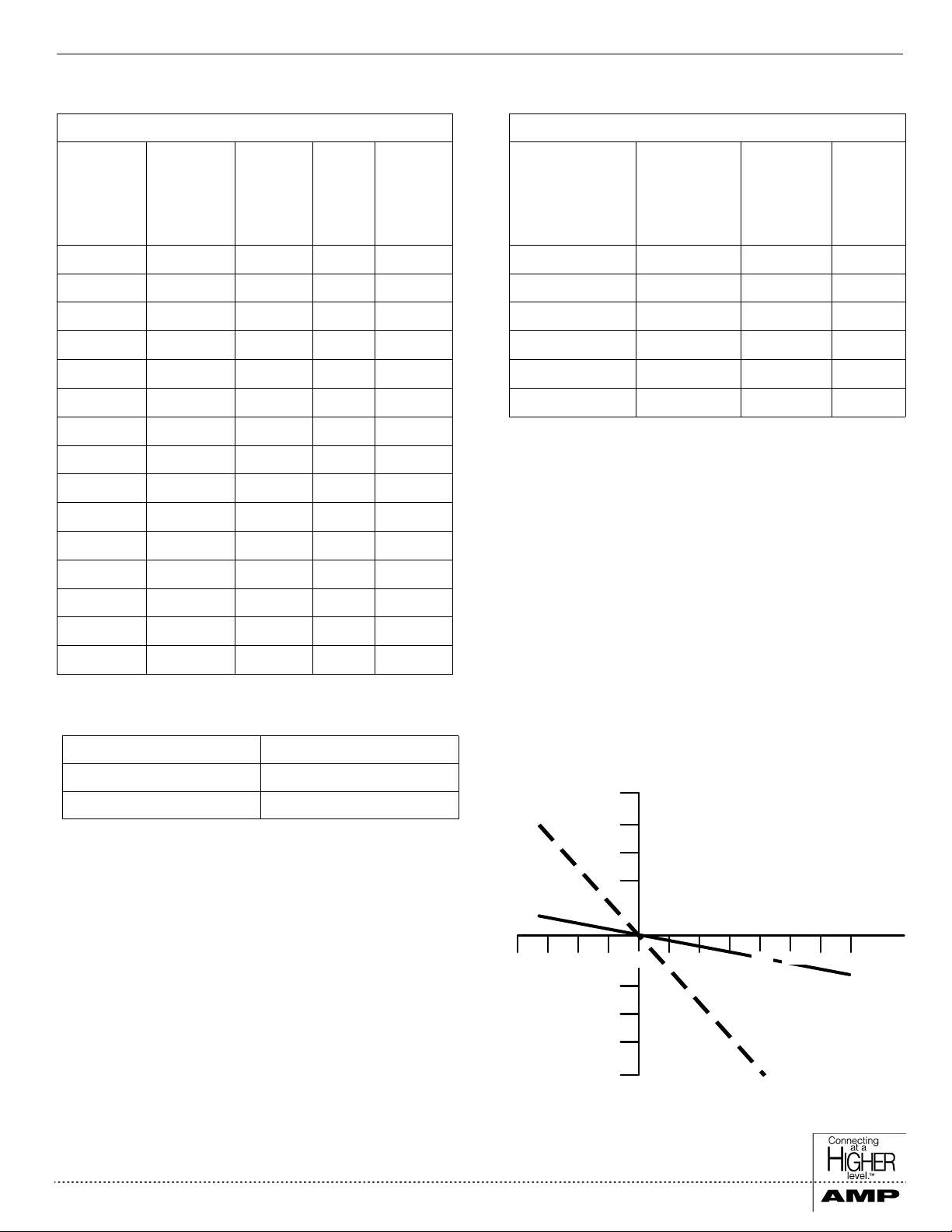

TYPICAL CAPACITANCE CHANGE FOR MNS and

CERAMIC CAPACITOR vs TEMPERATURE

(200 pF CAPACITOR)

+10

%

+8

+6

+4

-75 -25 0 50

25 125 150 200

-4

-6

-8

-10

CAPACITANCE

CHANGE

TEMPERATURE qC

M/A-COM M A4M1200

CAPACITOR

CERAMIC

CAPACITOR

M/A-COM Division of AMP Incorporated ■ North America: Tel. (800) 366-2266, Fax (800) 618-8883 ■ Asia/Pacific: Tel.+85 2 2111 8088, Fax +85 2 2111 8087

■

Europe: Tel. +44 (1344) 869 595, Fax+44 (1344) 300 020

www.macom.com

AMP and Connecting at a Higher Level are trademarks.

Specifications subject to change without notice.

V3.00

Page 3

MNS Microwave Chip Capacitors MA4M Series

Case Style

C A

B

Chip INCHES MILLIMETERS

Style DIM. MIN. MAX. MIN. MAX.

132 A 0.020 0.024 0.51 0.61

B 0.003 0.008 0.08 0.203

199 A 0.027 0.031 0.69 0.79

B 0.004 0.008 0.10 0.203

200 A 0.037 0.041 0.94 1.04

B 0.004 0.008 0.10 0.203

201 A 0.047 0.051 1.19 1.30

B 0.004 0.008 0.10 0.203

263 A — 0.060 — 1.52

B 0.004 0.008 0.10 0.203

Note:

For “C” dimension on above case styles, see spec i f i c a t io ns.

Chip INCHES MILLIMETERS

C A

B

Style DIM. MIN. MAX. MIN. MAX.

350 A 0.018 0.021 0.46 0.53

B — 0.008 — 0.203

C — 0.009 — 0.23

351 A 0.018 0.021 0.46 0.53

B — 0.008 — 0.203

C — 0.012 — 0.30

352 A 0.018 0.021 0.46 0.53

B — 0.008 — 0.203

C — 0.015 — 0.38

354 A 0.020 0.023 0.51 0.58

B — 0.008 — 0.203

C — 0.018 — 0.46

358 A 0.018 0.021 0.46 0.53

B — 0.008 — 0.203

C — 0.013 — 0.33

359 A 0.018 0.021 0.46 0.53

B — 0.008 — 0.203

C — 0.016 — 0.41

M/A-COM Division of AMP Incorporated ■ North America: Tel. (800) 366-2266, Fax (800) 618-8883 ■ Asia/Pacific: Tel.+85 2 2111 8088, Fax +85 2 2111 8087

■

Europe: Tel. +44 (1344) 869 595, Fax+44 (1344) 300 020

www.macom.com

AMP and Connecting at a Higher Level are trademarks.

Specifications subject to change without notice.

V3.00

Page 4

MNS Microwave Chip Capacitors MA4M Series

p

Bonding and Handling Considerations for

MNS Chi

Capacitors

Handling

Normal precautions that are common to the handling of hybrid

semiconductors also apply to MNS chip capacitors. Removal of

chips from waffle packs and subsequent handling should be

done with a vacuum pencil. Pencils equipped with either metallic or nonmetallic tips are acceptable.

Surface Preparation

Each MNS chip and substrate should be free of oils and other

surface contamination. Such contaminants may result in poor

solder wetting. Cleansing can be done with acetone, alcohol,

freon, TMS or other common microelectronic solvents. Burnishing of MNS capacitor chips is not necessary or recommended.

Solder

Soldering temperatures up to 300ºC are acceptable for a duration

not greater than 5 seconds for MNS chip capacitors. Any of the

common tin-lead-silver, lead-indium, or higher temperature gold

alloy solders are acceptable provided that the 300ºC temperature

is not exceeded. Pure tin or tin-antimony solders are not

recommended. Cleaning of residual flux is required and can be

accomplished with a fluorinated or chlorinated solvent.

Conductive Epoxy

Any of the conductive epoxies that are available for semiconductor die attachment are acceptable for MNS chip capacitor

attachment. Follow the manufacturer’s recommendations for

mixing and application carefully. Take care to seat the capacitor

on the substrate using a soft implement.

Lead Bonding

Ball, ultrasonic, TC or pulse bonding of the wire or ribbon leads

are all acceptable methods . Temperature for the pulse bon der

should not exceed 300ºC. Maximum pressure applied to the

MNS capacitor chips should not exceed 25 grams for any of the

methods used. Proper procedure will result in bond strength that

exceeds MIL-STD-883B Method 2011.2 for gold wire or gold

ribbon.

M/A-COM Division of AMP Incorporated ■ North America: Tel. (800) 366-2266, Fax (800) 618-8883 ■ Asia/Pacific: Tel.+85 2 2111 8088, Fax +85 2 2111 8087

■

Europe: Tel. +44 (1344) 869 595, Fax+44 (1344) 300 020

www.macom.com

AMP and Connecting at a Higher Level are trademarks.

Specifications subject to change without notice.

V3.00

Loading...

Loading...