Page 1

SO8N (MN)

150 mil width

TSSOP8 (DW)

169 mil width

WLCSP (2.809 × 1.863 mm)

Product status link

M95M04-DR

M95M04-DR

Datasheet

4-Mbit serial SPI bus EEPROM

Features

• Compatible with the serial peripheral interface (SPI) bus

• Memory array

– 4 Mbit (512 Kbytes) of EEPROM

– Page size: 512 bytes

– Additional write lockable page (identification page)

• Write time

– Byte write within 5 ms

– Page write within 5 ms

• Write protect

– quarter array

– half array

– whole memory array

• Max clock frequency:

– 10 MHz for VCC ≥ 2.5 V

– 5 MHz for VCC ≥ 1.8 V

• Single supply voltage: 1.8 V to 5.5 V

• Operating temperature range: from -40 °C up to +85 °C

• Enhanced ESD protection (up to 4 kV in human body model)

• More than 4 million write cycles

• More than 40-year data retention

• Packages

– SO8N (ECOPACK2)

– TSSOP8 (ECOPACK2)

– WLCSP (ECOPACK2)

DS12179 - Rev 2 - February 2021

For further information contact your local STMicroelectronics sales office.

www.st.com

Page 2

1 Description

The M95M04-DR device is electrically erasable programmable memory (EEPROM) organized as 524288 x 8 bits,

accessed through the SPI bus.

The M95M04-DR can operate with a supply range from 1.8 to 5.5 V, and is guaranteed over the -40 °C/+85 °C

temperature range.

The M95M04-DR offer an additional page, named the identification page (512 bytes). The identification page can

be used to store sensitive application parameters that can be (later) permanently locked in read-only mode.

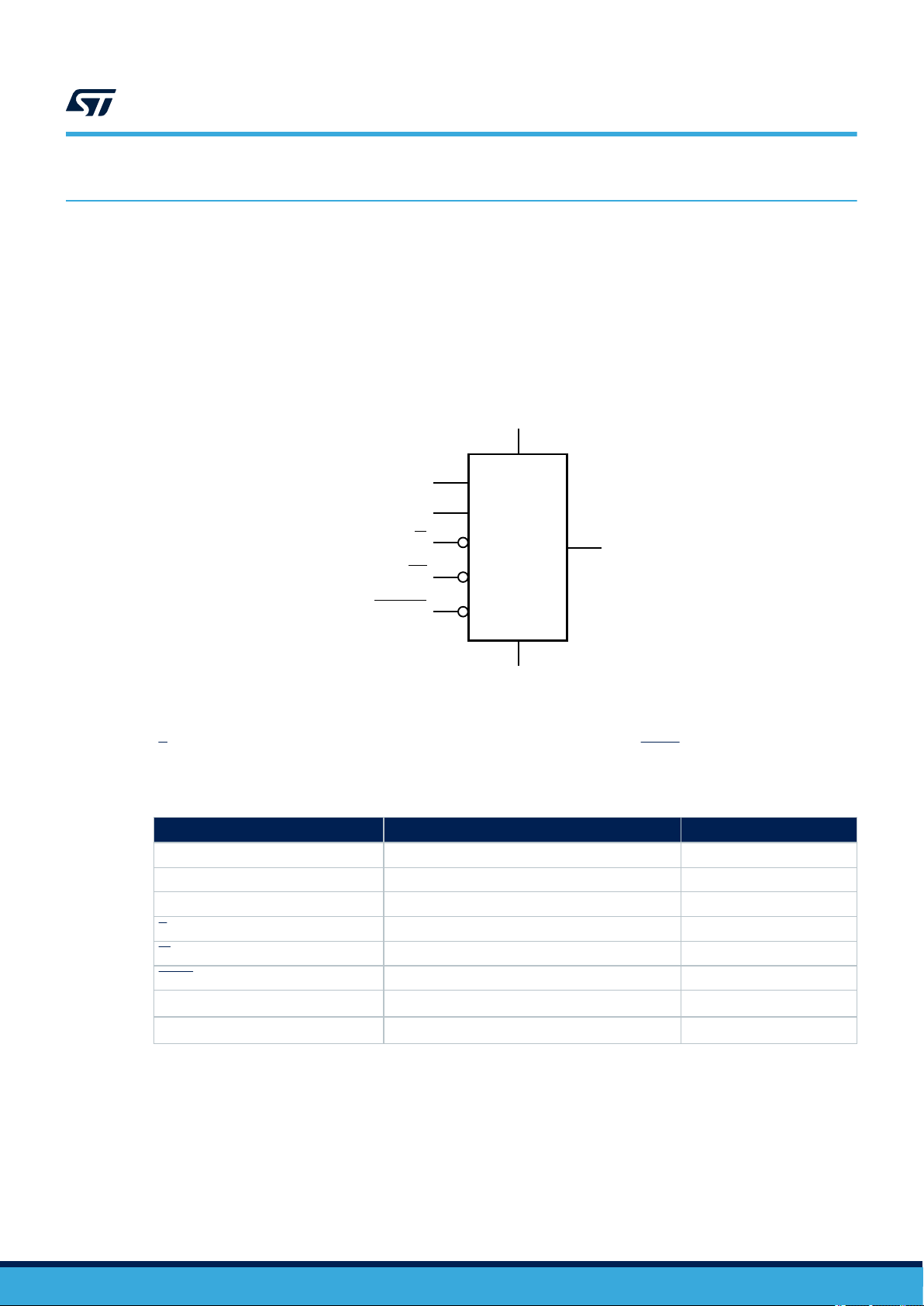

Figure 1. Logic diagram

V

CC

D

C

M95M04-DR

Description

S

M95xxx

Q

W

HOLD

V

SS

The SPI bus signals are C, D and Q, as shown in Figure 1 and Table 1. The device is selected when Chip select

(S) is driven low. Communications with the device can be interrupted when the HOLD is driven low.

Table 1. Signal names

Signal name

C Serial clock Input

D Serial data input Input

Q Serial data output Output

S Chip select Input

W Write protect Input

HOLD Hold Input

V

CC

V

SS

Supply voltage -

Ground -

Function Direction

MS45413V1

DS12179 - Rev 2

page 2/44

Page 3

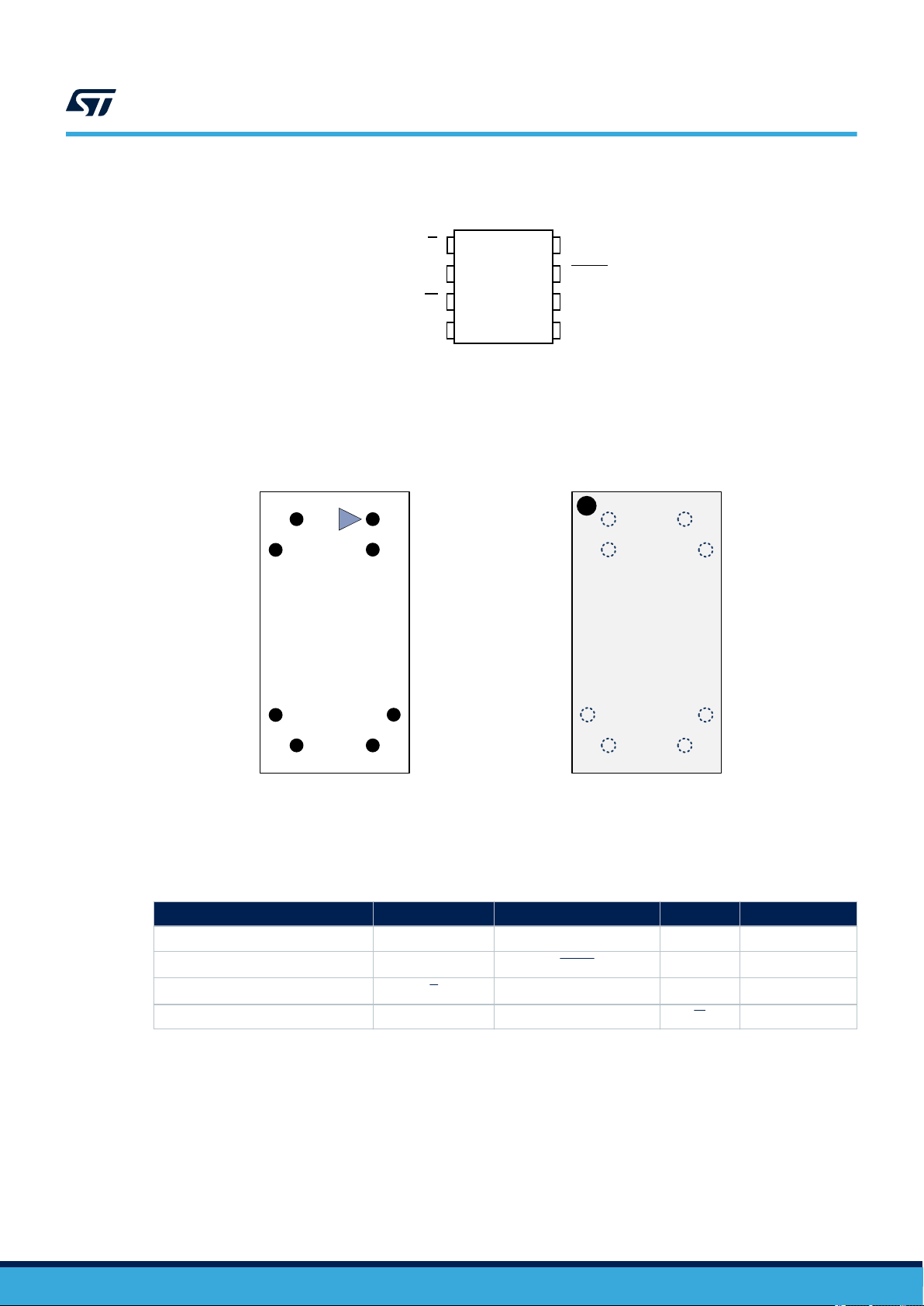

Figure 2. 8-pin package connections (top view)

M95xxx

S V

1

8

CC

M95M04-DR

Description

2

W

3

4

SS

1. See Section 10 Package information for package dimensions, and how to identify pin 1.

Figure 3. WLCSP connections

4 3 2 1

A

B

C

HOLDQ

7

C

6

DV

5

MS51579V1

1 2 3 4

A

B

C

D

Bump side view

Table 2. Signals vs. bump position

Position

1 - - C -

2

3 S - -

4 - Q W -

A B C D

V

CC

D

Top view (bumps underneath)

HOLD - D

MS38243V1

V

SS

DS12179 - Rev 2

page 3/44

Page 4

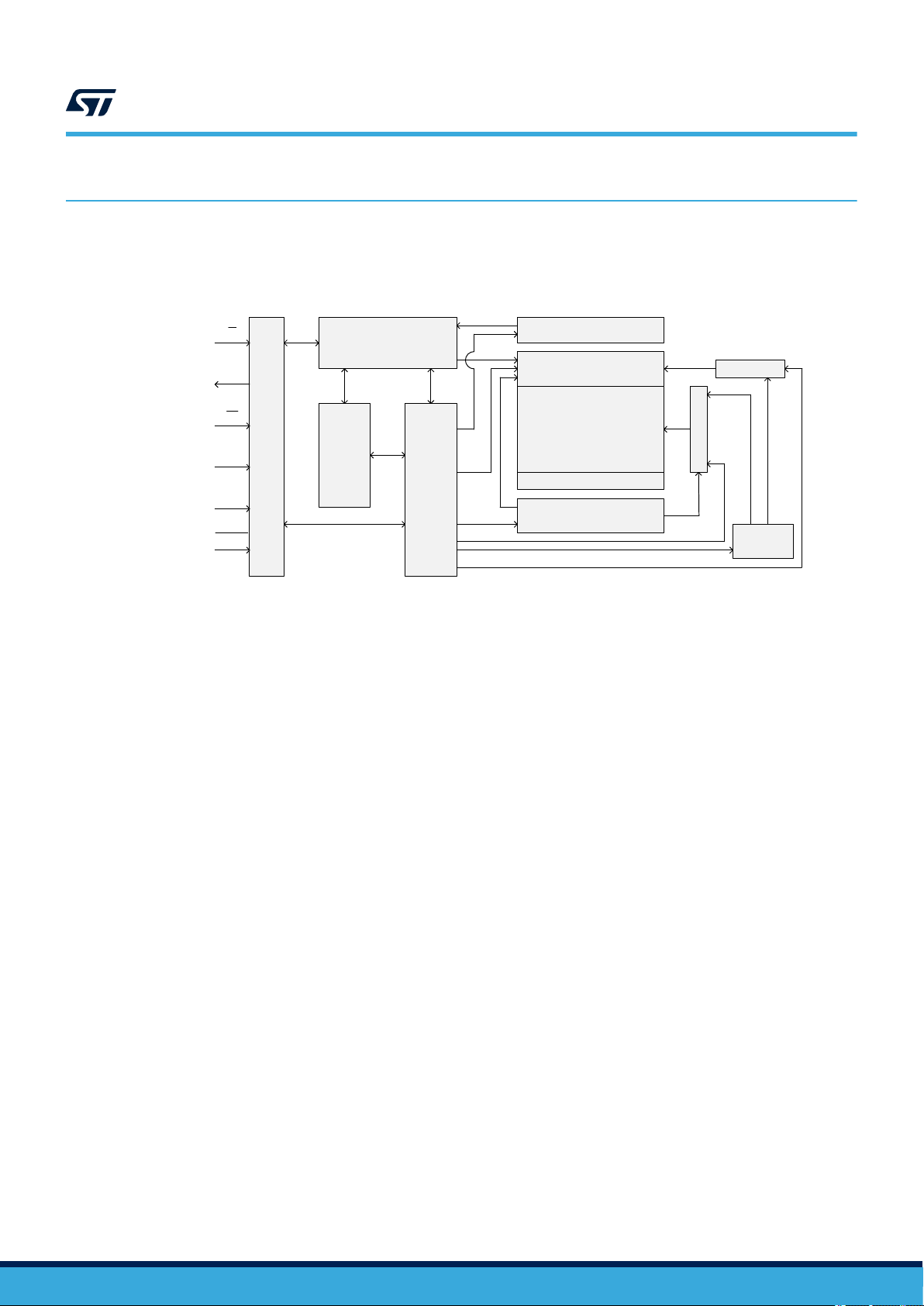

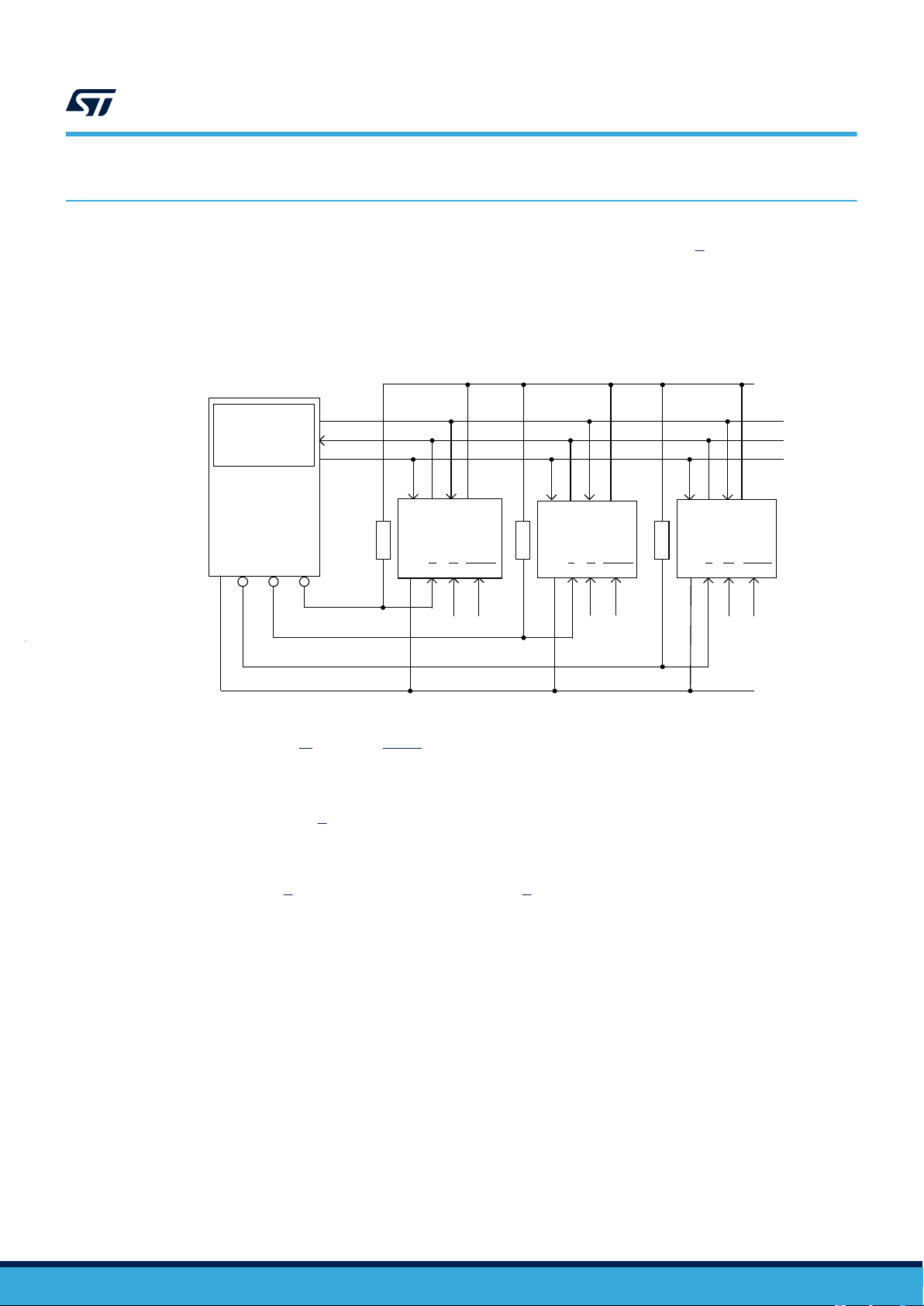

2 Memory organization

The memory is organized as shown in the following figure.

M95M04-DR

Memory organization

Figure 4. Block diagram

S

Q

W

D

C

HOLD

I/Os

Data register and ECC

Status

register

Control

logic

Sense amplifiers

Page latches

Array

Custom area

HV generator

and sequencer

X decoder

Y decoder

Address

register

MS52059V1

DS12179 - Rev 2

page 4/44

Page 5

3 Signal description

During all operations, VCC must be held stable and within the specified valid range: VCC(min) to VCC(max).

All of the input and output signals must be held high or low (according to voltages of VIH, VOH, VIL or VOL, as

specified in Section 9 DC and AC parameters). These signals are described next.

M95M04-DR

Signal description

3.1

Serial data output (Q)

This output signal is used to transfer data serially out of the device. Data is shifted out on the falling edge of serial

clock (C).

3.2 Serial data input (D)

This input signal is used to transfer data serially into the device. It receives instructions, addresses, and the data

to be written. Values are latched on the rising edge of serial clock (C).

3.3 Serial clock (C)

This input signal provides the timing of the serial interface. Instructions, addresses, or data present at serial data

input (D) are latched on the rising edge of serial clock (C). Data on serial data output (Q) change from the falling

edge of serial clock (C).

3.4 Chip select (S)

When this input signal is high, the device is deselected and serial data output (Q) is at high impedance. The

device is in the standby power mode, unless an internal write cycle is in progress. Driving chip select (S) low

selects the device, placing it in the active power mode.

After power-up, a falling edge on chip select (S) is required prior to the start of any instruction.

3.5 Hold (HOLD)

The hold (HOLD) signal is used to pause any serial communications with the device without deselecting the

device.

During the hold condition, the serial data output (Q) is high impedance, and serial data input (D) and serial clock

(C) are "Don’t care".

To start the hold condition, the device must be selected, with chip select (

S) driven low.

3.6 Write protect (W)

The main purpose of this input signal is to freeze the size of the area of memory that is protected against Write

instructions (as specified by the values in the BP1 and BP0 bits of the Status register).

This pin must be driven either high or low, and must be stable during all Write instructions.

3.7 V

supply voltage

CC

VCC is the supply voltage.

3.8 VSS ground

VSS is the reference for all signals, including the VCC supply voltage.

DS12179 - Rev 2

page 5/44

Page 6

4 Connecting to the SPI bus

All instructions, addresses and input data bytes are shifted in to the device, most significant bit first. The serial

data input (D) is sampled on the first rising edge of the serial clock (C) after chip select (S) goes low.

All output data bytes are shifted out of the device, most significant bit first. The serial data output (Q) is latched

on the first falling edge of the serial clock (C) after the instruction (such as the read from memory array and read

status register instructions) have been clocked into the device.

Figure 5. Bus master and memory devices on the SPI bus

M95M04-DR

Connecting to the SPI bus

V

CC

SPI interface with

(CPOL, CPHA) =

(0, 0) or 1, 1)

SPI bus master

CS3 CS2 CS1

SDO

SDI

SCK

V

CC

SPI memory

R R R

device

S

W

HOLD

(1) (1) (1) (1) (1) (1)

SPI memory

device

S

W

V

CC

HOLD

C Q DC Q DC Q D

SPI memory

device

S

W

V

CC

HOLD

V

MS19755V3

SS

1. The write protect (W) and hold (HOLD) signals should be driven, high or low as appropriate.

Figure 5 shows an example of three memory devices connected to an SPI bus master. Only one memory device

is selected at a given time, so only one memory device drives the serial data output (Q) line at that time. The

other memory devices are in high impedance state. The pull-up resistor R ensures that a device is not selected if

the bus master leaves the

S line in the high impedance state.

In applications where the bus master may leave all SPI bus lines in high impedance at the same time (for

example, if the Bus master is reset during the transmission of an instruction), it is recommended to connect the

clock line (C) to an external pull-down resistor so that, if all inputs/outputs become high impedance, the C line is

pulled low (while the

so, that the t

SHCH

S line is pulled high): this ensures that S and C do not become high at the same time, and

requirement is met. The typical value of R is 100 kΩ.

DS12179 - Rev 2

page 6/44

Page 7

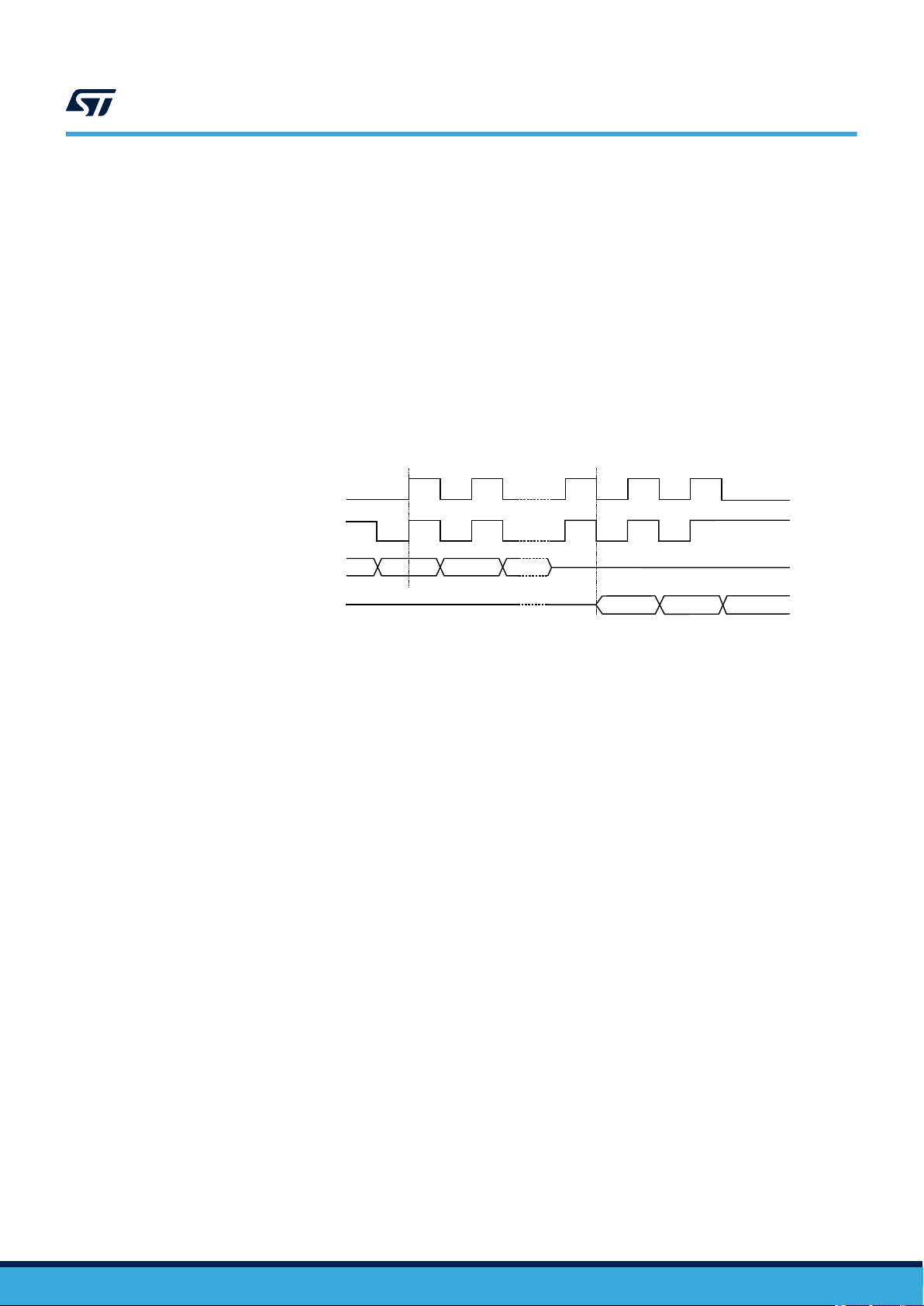

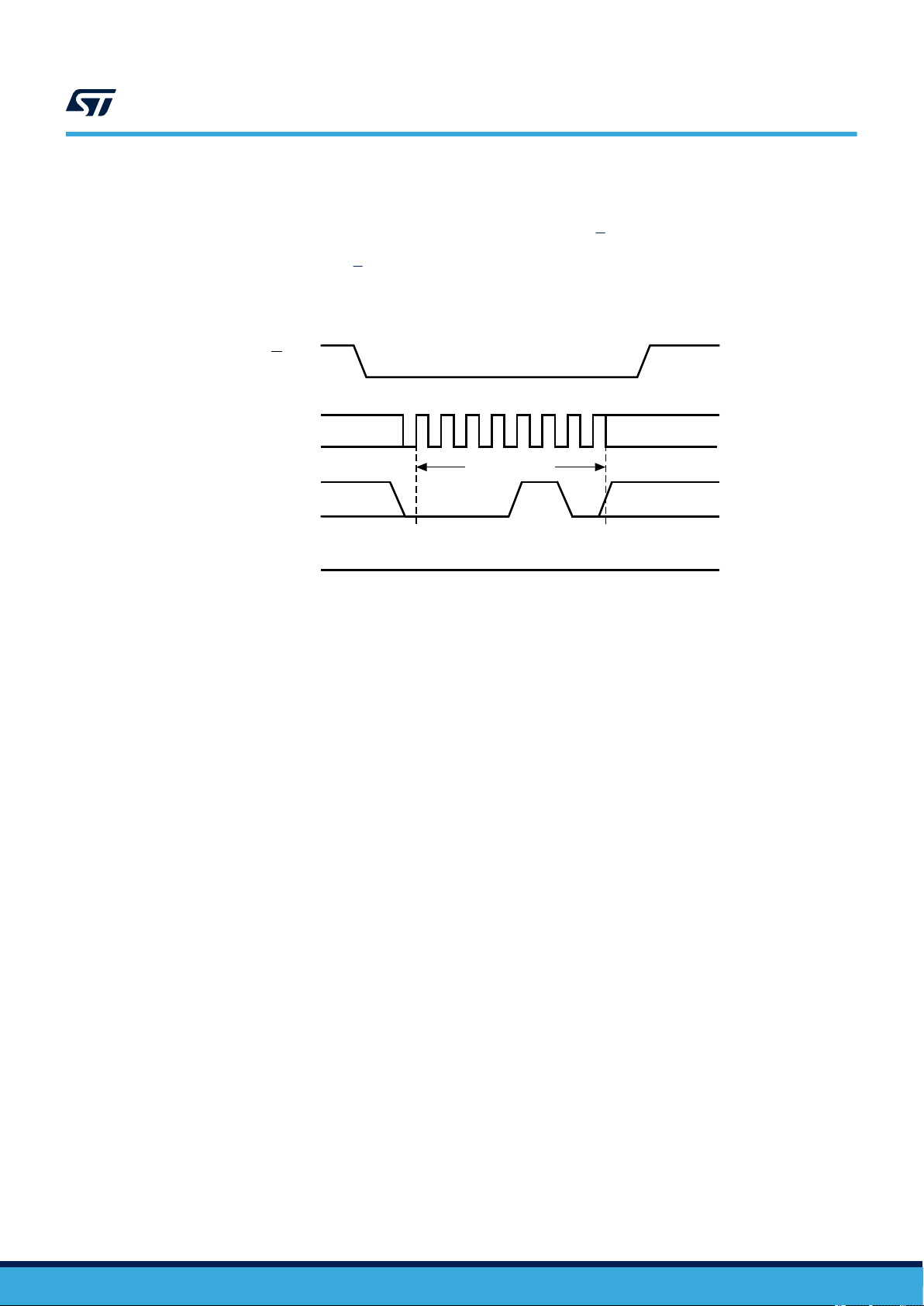

4.1 SPI modes

These devices can be driven by a microcontroller with its SPI peripheral running in either of the following two

modes:

• CPOL = 0, CPHA = 0

• CPOL = 1, CPHA = 1

For these two modes, input data is latched in on the rising edge of serial clock (C), and output data is available

from the falling edge of serial clock (C).

The difference between the two modes, as shown in Figure 6, is the clock polarity when the bus master is in

stand-by mode and not transferring data:

• C remains at 0 for (CPOL = 0, CPHA = 0)

• C remains at 1 for (CPOL = 1, CPHA = 1)

M95M04-DR

SPI modes

Figure 6. SPI modes supported

CPOL

0

1

CPHA

0

1

C

C

D

Q

MSB

MSB

MS42674V2

DS12179 - Rev 2

page 7/44

Page 8

5 Operating features

5.1 Supply voltage (VCC)

5.1.1 Operating supply voltage (VCC)

Prior to selecting the memory and issuing instructions to it, a valid and stable VCC voltage within the specified

[VCC(min), VCC(max)] range must be applied (see operating conditions in Section 9 DC and AC parameters).

This voltage must remain stable and valid until the end of the transmission of the instruction and, for a Write

instruction, until the completion of the internal write cycle (tW). In order to secure a stable DC supply voltage, it is

recommended to decouple the VCC line with a suitable capacitor (usually in the range between 10 and 100 nF)

close to the VCC / VSS device pins.

5.1.2 Device reset

In order to prevent erroneous instruction decoding and inadvertent write operations during power-up, a power-onreset (POR) circuit is included. At power-up, the device does not respond to any instruction until VCC reaches the

POR threshold voltage. This threshold is lower than the minimum VCC operating voltage (see operating conditions

in Section 9 DC and AC parameters).

At power-up, when VCC passes over the POR threshold, the device is reset and is in the following state:

• in Standby power mode,

• deselected,

• Status register values:

– the write enable latch (WEL) bit is reset to 0

– the write in progress (WIP) bit is reset to 0

– the SRWD, BP1 and BP0 bits remain unchanged (non-volatile bits).

It is important to note that the device must not be accessed until VCC reaches a valid and stable level within

the specified [VCC(min), VCC(max)] range, as defined under Operating conditions in Section 9 DC and AC

parameters.

M95M04-DR

Operating features

5.1.3 Power-up conditions

When the power supply is turned on, VCC rises continuously from VSS to VCC. During this time, the chip select (S)

line is not allowed to float but should follow the VCC voltage. It is therefore recommended to connect the

VCC via a suitable pull-up resistor (see Figure 5).

In addition, the chip select (S) input offers a built-in safety feature, as the S input is edge-sensitive as well as

level-sensitive: after power-up, the device does not become selected until a falling edge has first been detected

on chip select (

operation.

The VCC voltage has to rise continuously from 0 V up to the minimum VCC operating voltage defined in

Section 9 DC and AC parameters.

S). This ensures that chip select (S) must have been high, prior to going low to start the first

S line to

DS12179 - Rev 2

page 8/44

Page 9

M95M04-DR

Active power and standby power modes

5.1.4 Power-down

During power-down (continuous decrease of the VCC supply voltage below the minimum VCC operating voltage

defined in Section 9 DC and AC parameters), the device must be:

• deselected (chip select

• in standby power mode (there must not be any internal write cycle in progress).

S must be allowed to follow the voltage applied on VCC)

5.2 Active power and standby power modes

When chip select (S) is low, the device is selected, and in the active power mode. The device consumes ICC.

When chip select (S) is high, the device is deselected. If a write cycle is not currently in progress, the device then

goes into the standby power mode, and the device consumption drops to I

(see Section 9 DC and AC parameters).

, as specified in DC characteristics

CC1

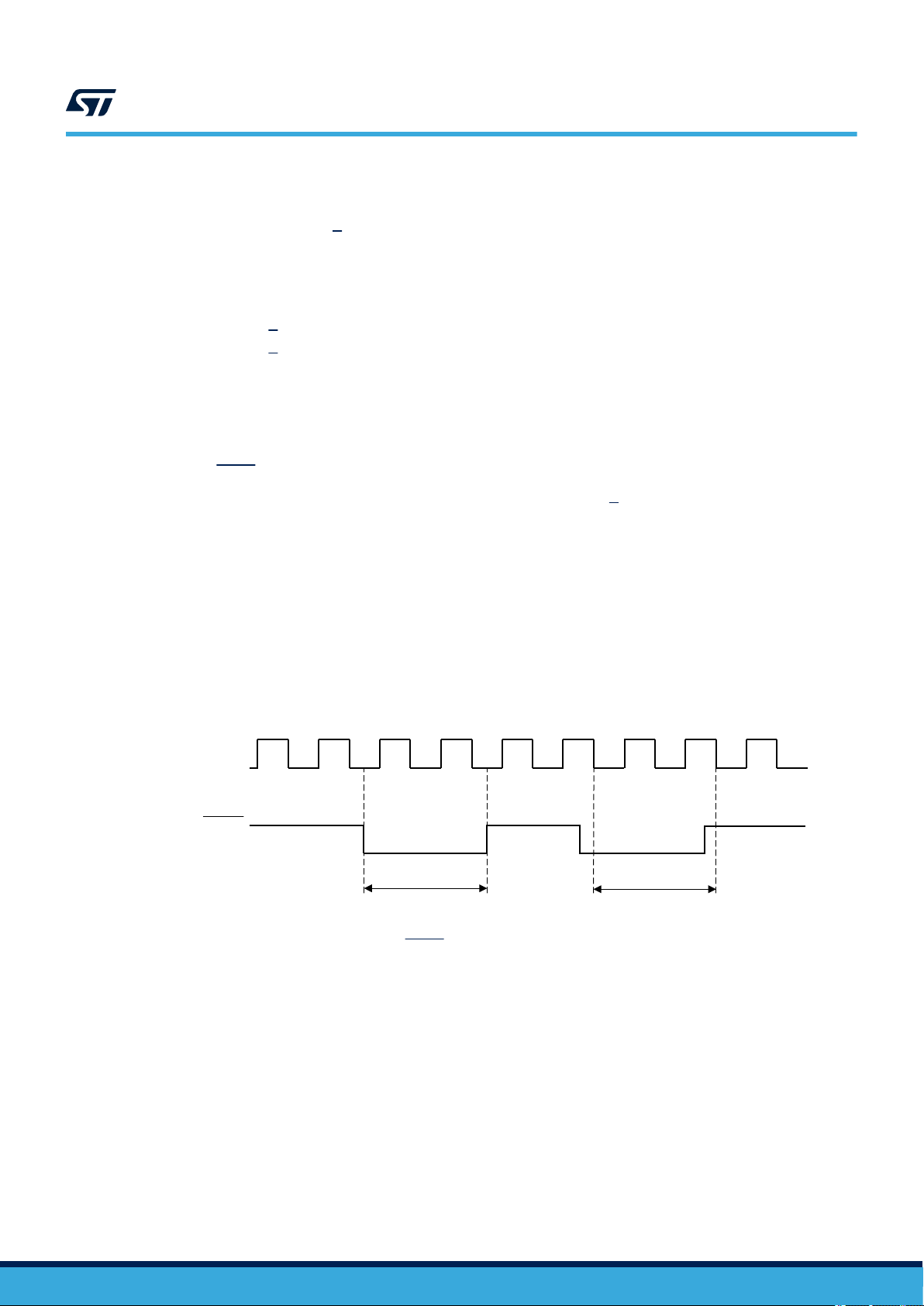

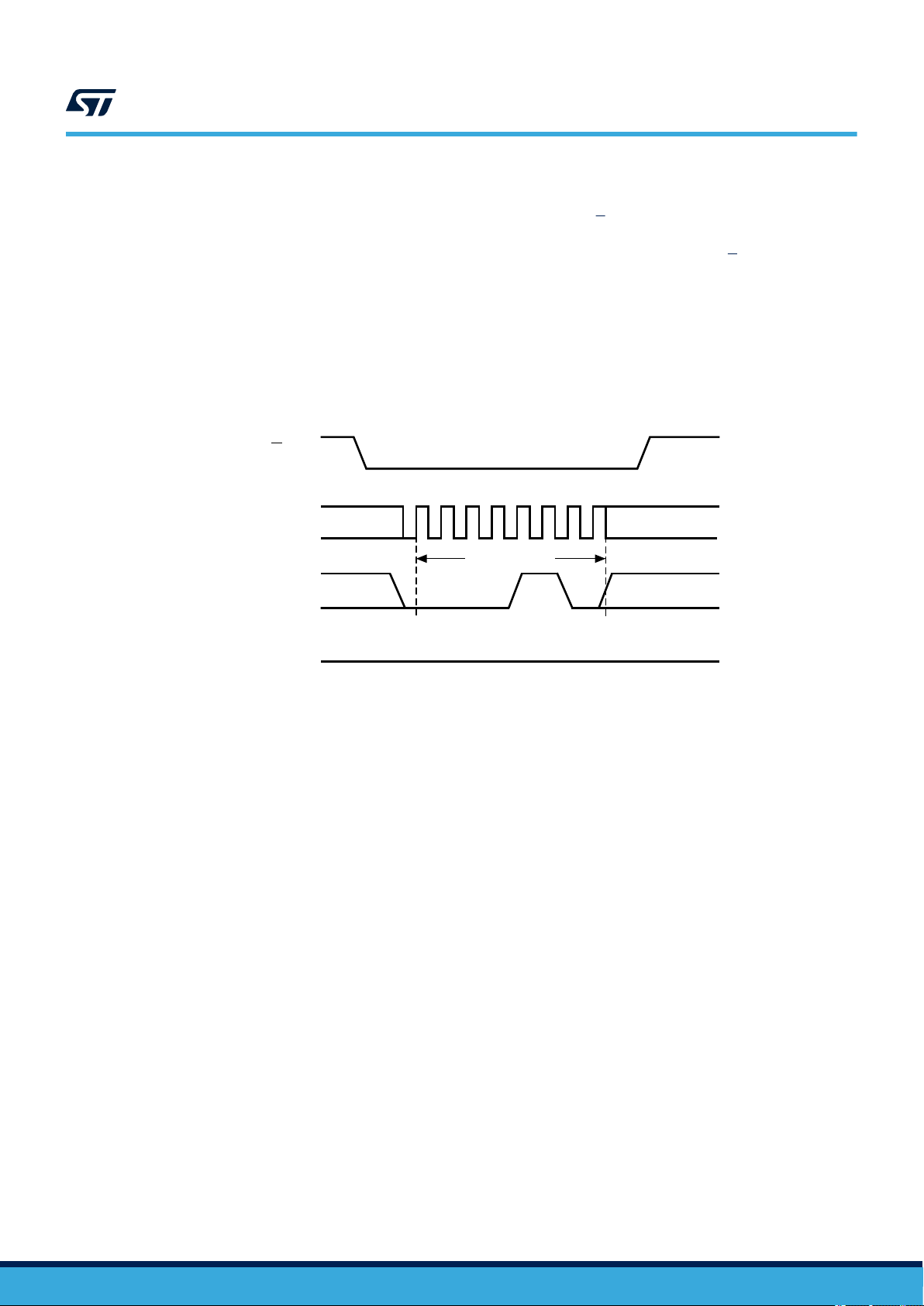

5.3 Hold condition

The hold (HOLD) signal is used to pause any serial communications with the device without resetting the clocking

sequence.

To enter the hold condition, the device must be selected, with chip select (S) low.

During the hold condition, the serial data output (Q) is high impedance, and the serial data input (D) and the serial

clock (C) are "Don’t care".

Normally, the device is kept selected for the whole duration of the Hold condition. Deselecting the device while it is

in the hold condition has the effect of resetting the state of the device: this mechanism can be used, if required, to

reset the ongoing processes.

Note: This resets the internal logic, except the WEL and WIP bits of the status register.

Note: In the specific case where the device has moved in a write command (Inst + Address + data bytes, each data

byte being exactly 8 bits), deselecting the device also triggers the write cycle of this decoded command.

Figure 7. Hold condition activation

C

HOLD

Hold

condition

The hold condition starts when the hold (HOLD) signal is driven low when serial clock (C) is already low (as

shown in Figure 7).

Figure 7 also shows what happens if the rising and falling edges are not timed to coincide with serial clock (C)

being low.

Hold

condition

MS47281V1

DS12179 - Rev 2

page 9/44

Page 10

5.4 Status register

The status register contains a number of status and control bits that can be read or set (as appropriate) by

specific instructions. See Section 6.3 Read status register (RDSR) for a detailed description of the status register

bits.

5.5 Data protection and protocol control

The device features the following data protection mechanisms:

• Before accepting the execution of the write and write status register instructions, the device checks whether

the number of clock pulses comprised in the instructions is a multiple of eight.

• All instructions that modify data must be preceded by a write enable (WREN) instruction to set the write

enable latch (WEL) bit.

• The block protect (BP1, BP0) bits in the status register are used to configure part of the memory as

read-only.

• The write protect (

For any instruction to be accepted, and executed, chip select (

serial clock (C) for the last bit of the instruction, and before the next rising edge of serial clock (C).

Two points to note in the previous sentence:

• The “last bit of the instruction” can be the eighth bit of the instruction code, or the eighth bit of a data byte,

depending on the instruction (except for read status register (RDSR) and read (READ) instructions).

• The “next rising edge of serial clock (C)” might (or might not) be the next bus transaction for some other

device on the SPI bus.

W) signal is used to protect the block protect (BP1, BP0) bits in the status register.

M95M04-DR

Status register

S) must be driven high after the rising edge of

Table 3. Write-protected block size

Status register bits

BP1 BP0

0 0

0 1 Upper quarter 60000h - 7FFFFh

1 0 Upper half 40000h - 7FFFFh

1 1 Whole memory 00000h - 7FFFFh

Protected block Protected array addresses

None None

DS12179 - Rev 2

page 10/44

Page 11

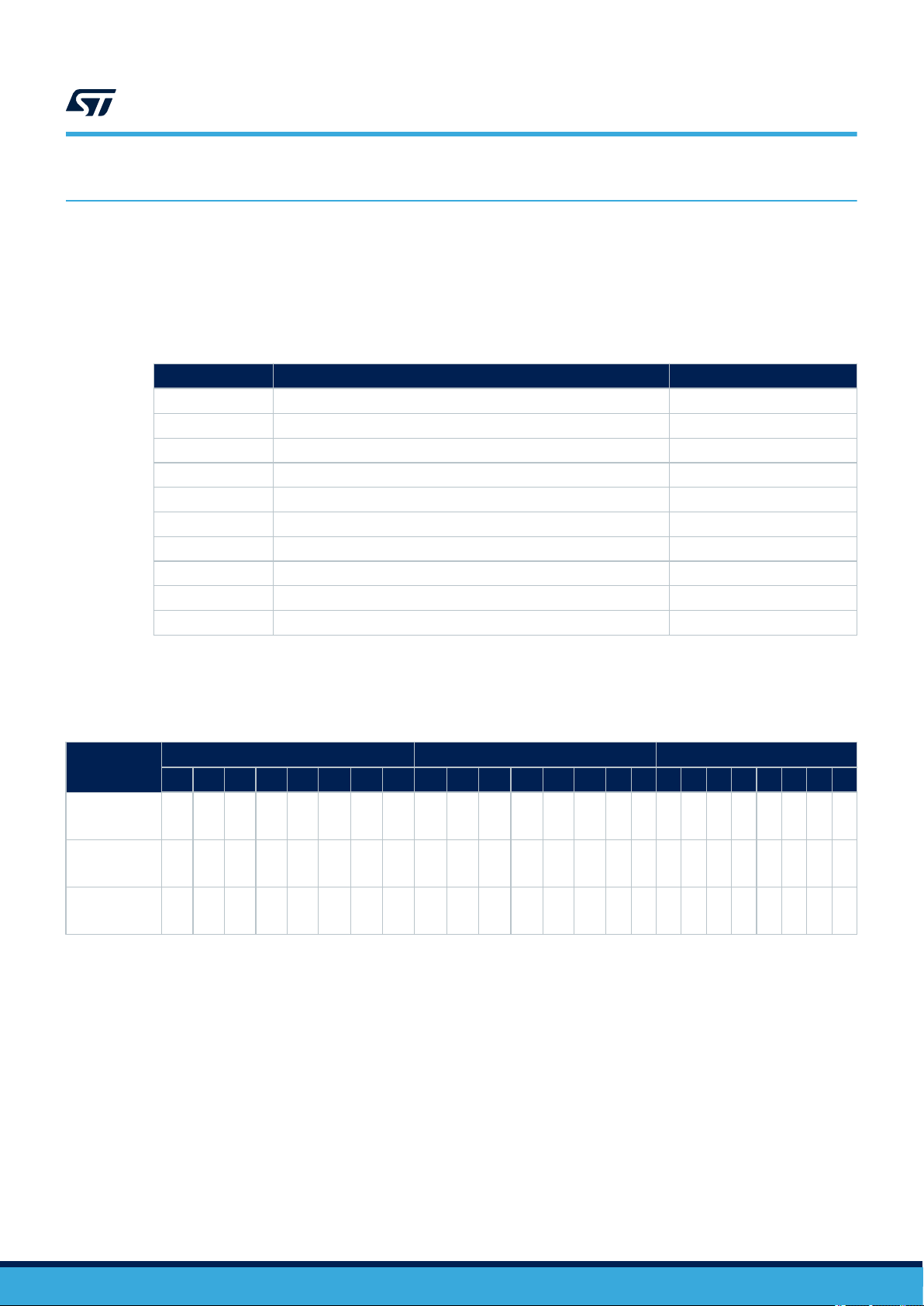

6 Instructions

Each command is composed of bytes (MSB bit transmitted first), initiated with the instruction byte, as summarized

in Table 4.

If an invalid instruction is sent (one not contained in Table 4), the device automatically enters in a wait state until

deselected.

Instruction Description Instruction format

WREN Write enable 0000 0110

WRDI Write disable 0000 0100

RDSR Read status register 0000 0101

WRSR Write status register 0000 0001

READ Read from memory array 0000 0011

WRITE Write to memory array 0000 0010

RDID Read identification page 1000 0011

WRID Write identification page 1000 0010

RDLS Read identification page lock status 1000 0011

LID Lock identification page in react-only mode 1000 0010

M95M04-DR

Instructions

Table 4. Instruction set

For read and write commands to memory array and identification page the address is defined by three bytes as

explained in Table 5.

Instruction

READ

or WRITE

RDID

or WRID

RDLS

or LID

1. A: Significant address bit

2. X: Don't Care bit

(1)(2)

b23 b22 b21 b20 b19 b18 b17 b16 b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

X X X X X A18 A17 A16 A15 A14 A13 A12 A11 A10 A9 A8 A7 A6 A5 A4 A3 A2 A1 A0

X X X X X X X X X X X X X 0 X A8 A7 A6 A5 A4 A3 A2 A1 A0

X X X X X X X X X X X X X 1 X X X X X X X X X X

Table 5. Significant bits within the address bytes

Upper address byte Middle address byte Lower address byte

DS12179 - Rev 2

page 11/44

Page 12

6.1 Write enable (WREN)

The write enable latch (WEL) bit must be set prior to each WRITE and WRSR instruction. The only way to do this

is to send a write enable instruction to the device.

As shown in Figure 8, to send this instruction to the device, chip select (S) is driven low, and the bits of the

instruction byte are shifted in, on serial data input (D). The device then enters a wait state. It waits for the device

to be deselected by chip select (S) being driven high.

S

M95M04-DR

Write enable (WREN)

Figure 8. Write enable (WREN) sequence

C

D

Q

0

21 3 4 5 6 7

Instruction

High impedance

MS41478V1

DS12179 - Rev 2

page 12/44

Page 13

6.2 Write disable (WRDI)

One way of resetting the write enable latch (WEL) bit is to send a write disable instruction to the device.

As shown in Figure 9, to send this instruction to the device, chip select (S) is driven low, and the bits of the

instruction byte are shifted in, on serial data input (D).

The device then enters a wait state. It waits for a the device to be deselected, by chip select (S) being driven high.

The write enable latch (WEL) bit, in fact, becomes reset by any of the following events:

• Power-up

• WRDI instruction execution

• WRSR instruction completion

• WRITE instruction completion.

S

M95M04-DR

Write disable (WRDI)

Figure 9. Write disable (WRDI) sequence

C

D

Q

0

21 3 4 5 6 7

Instruction

High impedance

MS41478V1

DS12179 - Rev 2

page 13/44

Page 14

6.3 Read status register (RDSR)

The read status register (RDSR) instruction is used to read the status register. The status register may be read at

any time, even while a write or write status register cycle is in progress. When one of these cycles is in progress,

it is recommended to check the write in progress (WIP) bit before sending a new instruction to the device. It is

also possible to read the Status register continuously, as shown in Figure 10.

Figure 10. Read Status register (RDSR) sequence

S

21 3 4 5 6 7 8 9 10 11 12 13 14 15

0

C

Instruction

D

M95M04-DR

Read status register (RDSR)

The status and control bits of the status register are detailed in the following subsections.

6.3.1 WIP bit

The WIP bit (write in progress) is a read-only flag that indicates the ready/busy state of the device. When a write

command (WRITE, WRSR, WRID, LID) has been decoded and a write cycle (tW) is in progress, the device is

busy and the WIP bit is set to 1. When WIP = 0 the device is ready to decode a new command.

During a write cycle, reading continuously the WIP bit allows to detect when the device becomes ready (WIP = 0)

to decode a new command.

6.3.2 WEL bit

The WEL bit (write enable latch) bit is a flag that indicates the status of the internal write enable latch. When WEL

is set to 1, the write instructions (WRITE, WRSR, WRID, LID) are executed; when WEL is set to 0, any decoded

write instruction is not executed.

The WEL bit is set to 1 with the WREN instruction. The WEL bit is reset to 0 after the following events:

• Write disable (WRDI) instruction completion

• Write instructions (WRITE, WRSR, WRID, LID) completion including the write cycle time t

• Power-up

High impedance

Status Register Out

Q

MSB MSB

Status Register Out

77 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0

MS47548V1

W

6.3.3 BP1, BP0 bits

The block protect (BP1, BP0) bits are non volatile. They define the size of the area to be software-protected

against Write instructions. These bits are written with the write status register (WRSR) instruction. When one or

both of the block protect (BP1, BP0) bits is set to 1, the relevant memory area (as defined in Table 3) becomes

protected against write (WRITE) instructions. The block protect (BP1, BP0) bits can be written provided that the

hardware protected mode has not been set.

DS12179 - Rev 2

page 14/44

Page 15

6.3.4 SRWD bit

The status register write disable (SRWD) bit is operated in conjunction with the write protect (W) signal. The

status register write disable (SRWD) bit and write protect (W) signal enable the device to be put in the hardware

protected mode (when the status register write disable (SRWD) bit is set to 1, and write protect (W) is driven low).

In this mode, the non-volatile bits of the status register (SRWD, BP1, BP0) become read-only bits and the write

status register (WRSR) instruction is no longer accepted for execution.

M95M04-DR

Read status register (RDSR)

Table 6. Status register format

DS12179 - Rev 2

page 15/44

Page 16

6.4 Write status register (WRSR)

The write dtatus register (WRSR) instruction is used to write new values to the status register. Before it can be

accepted, a write enable (WREN) instruction must have been previously executed.

The write Status register (WRSR) instruction is entered by driving chip select (S) low, followed by the instruction

code, the data byte on serial data input (D) and chip select (S) driven high. Chip select (S) must be driven high

after the rising edge of serial clock (C) that latches in the eighth bit of the data byte, and before the next rising

edge of serial clock (C). Otherwise, the write status register (WRSR) instruction is not executed.

The instruction sequence is shown in Figure 11.

Figure 11. Write status register (WRSR) sequence

S

M95M04-DR

Write status register (WRSR)

0

21 3 4 5 6 7 8 9 10 11 12 13 14 15

C

Instruction

D

MSB

High impedance

Status Register In

7 6 5 4 3 2 1 0

Q

MS47556V1

Driving the chip select (S) signal high at a byte boundary of the input data triggers the self-timed write cycle that

takes tW to complete (as specified in AC tables in Section 9 DC and AC parameters).

While the write status register cycle is in progress, the status register may still be read to check the value of the

write in progress (WIP) bit: the WIP bit is 1 during the self-timed write cycle tW, and 0 when the write cycle is

complete. The WEL bit (Write enable latch) is also reset at the end of the write cycle tW.

The write status register (WRSR) instruction enables the user to change the values of the BP1, BP0 and SRWD

bits:

• The block protect (BP1, BP0) bits define the size of the area that is to be treated as read-only, as defined in

Table 3.

• The SRWD (status register write disable) bit, in accordance with the signal read on the write protect pin (

enables the user to set or reset the write protection mode of the status register itself, as defined in Table 7.

When in write-protected mode, the write status register (WRSR) instruction is not executed.

The contents of the SRWD and BP1, BP0 bits are updated after the completion of the WRSR instruction, including

the tW write cycle.

The write status register (WRSR) instruction has no effect on the b6, b5, b4, b1, b0 bits in the status register. Bits

b6, b5, b4 are always read as 0.

W),

DS12179 - Rev 2

page 16/44

Page 17

Table 7. Protection modes

M95M04-DR

Write status register (WRSR)

W signal

1. As defined by the values in the Block protect (BP1, BP0) bits of the Status register. See Table 3.

SRWD

1 0

0 0

1 1

0 1

bit

Mode Write protection of the Status register

Software-

protected

(SPM)

Hardware-

protected

(HPM)

Status register is writable (if the WREN

instruction has set the WEL bit).

The values in the BP1 and BP0 bits can be

changed.

Status register is hardware write-protected.

The values in the BP1 and BP0 bits cannot be

changed.

Writeprotected

Writeprotected

Protected

(1)

area

Memory content

Unprotected area

Ready to accept

write instructions

Ready to accept

write instructions

The protection features of the device are summarized in Table 7.

When the status register write disable (SRWD) bit in the status register is 0 (its initial delivery state), it is possible

to write to the status register (provided that the WEL bit has previously been set by a WREN instruction),

regardless of the logic level applied on the write protect (

W) input pin.

When the status register write disable (SRWD) bit in the Status register is set to 1, two cases should be

considered, depending on the state of the write protect (

W) input pin:

• If write protect (W) is driven high, it is possible to write to the status register (provided that the WEL bit has

previously been set by a WREN instruction).

• If write protect (

W) is driven low, it is not possible to write to the status register even if the WEL bit has

previously been set by a WREN instruction. (attempts to write to the status register are rejected, and are

not accepted for execution). As a consequence, all the data bytes in the memory area, which are softwareprotected (SPM) by the block protect (BP1, BP0) bits in the status register, are also hardware-protected

against data modification.

Regardless of the order of the two events, the hardware-protected mode (HPM) can be entered by:

• either setting the SRWD bit after driving the write protect (

W) input pin low,

• or driving the write protect (W) input pin low after setting the SRWD bit.

Once the hardware-protected mode (HPM) has been entered, the only way of exiting it is to pull high the write

protect (

W) input pin.

If the write protect (W) input pin is permanently tied high, the hardware-protected mode (HPM) can never be

activated, and only the software-protected mode (SPM), using the block protect (BP1, BP0) bits in the status

register, can be used.

(1)

DS12179 - Rev 2

page 17/44

Page 18

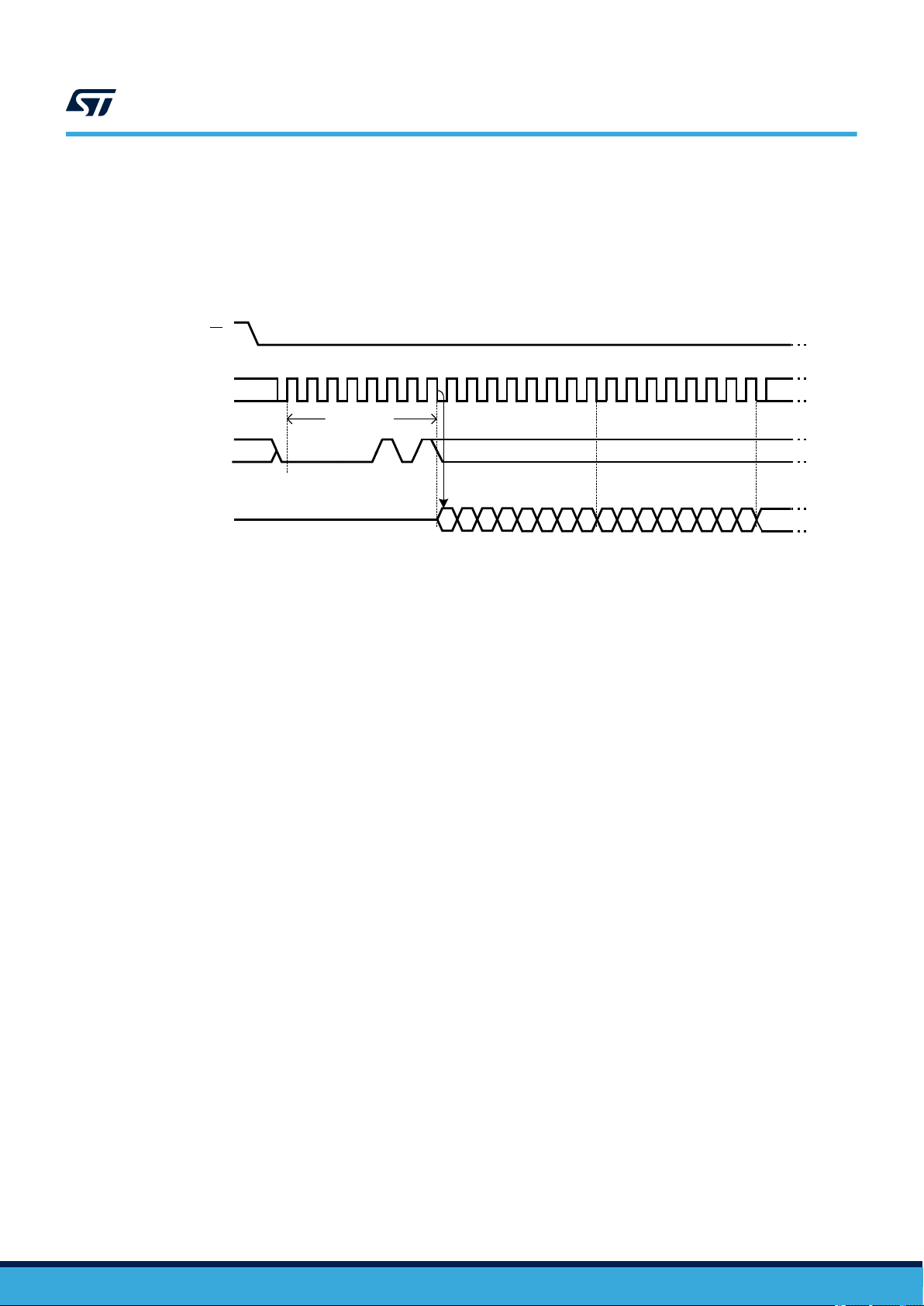

6.5 Read from memory array (READ)

As shown in Figure 12, to send this instruction to the device, chip select (S) is first driven low. The bits of the

instruction byte and address bytes are then shifted in, on serial data input (D). The address is loaded into an

internal address register, and the byte of data at that address is shifted out, on serial data output (Q).

Figure 12. Read from memory array (READ) sequence

M95M04-DR

Read from memory array (READ)

If chip select (S) continues to be driven low, the internal address register is incremented automatically, and the

byte of data at the new address is shifted out.

When the highest address is reached, the address counter rolls over to zero, allowing the read cycle to be

continued indefinitely. The whole memory can, therefore, be read with a single READ instruction.

The read cycle is terminated by driving chip select (

at any time during the cycle.

The instruction is not accepted, and is not executed, if a write cycle is currently in progress.

S) high. The rising edge of the chip select (S) signal can occur

DS12179 - Rev 2

page 18/44

Page 19

6.6 Write to memory array (WRITE)

As shown in Figure 13, to send this instruction to the device, chip select (S) is first driven low. The bits of the

instruction byte, address byte, and at least one data byte are then shifted in, on serial data input (D).

The instruction is terminated by driving chip select (S) high at a byte boundary of the input data. The selftimed write cycle, triggered by the chip select (S) rising edge, continues for a period tW (as specified in AC

characteristics in Section 9 DC and AC parameters), at the end of which the write in progress (WIP) bit is reset

to 0.

Figure 13. Byte write (WRITE) sequence

S

M95M04-DR

Write to memory array (WRITE)

21 3 4 5 6 7 8 9 10 28 29 30 31 32 33 34 35

0

36 37 38

39

C

Instruction 24-bit address

22 21

D

Q

High impedance

23

3 2 1 0

7 6 5 4 3 2 0

In the case of Figure 13, chip select (S) is driven high after the eighth bit of the data byte has been latched in,

indicating that the instruction is being used to write a single byte. However, if chip select (S) continues to be

driven low (as shown in Figure 14), the next byte of input data is shifted in, so that more than a single byte,

starting from the given address towards the end of the same page, can be written in a single internal write cycle.

Each time a new data byte is shifted in, the least significant bits of the internal address counter are incremented.

If more bytes are sent than will fit up to the end of the page, a condition known as “roll-over” occurs. In case of

roll-over, the bytes exceeding the page size are overwritten from location 0 of the same page.

The instruction is not accepted, and is not executed, under the following conditions:

• if the write enable latch (WEL) bit has not been set to 1 (by executing a write enable instruction just before),

• if a write cycle is already in progress,

• if the device has not been deselected, by driving high chip select (

S), at a byte boundary (after the eighth bit,

b0, of the last data byte that has been latched in),

• if the addressed page is in the region protected by the block protect (BP1 and BP0) bits.

Note: The self-timed write cycle tW is internally executed as a sequence of two consecutive events: [Erase addressed

byte(s)], followed by [Program addressed byte(s)]. An erased bit is read as “0” and a programmed bit is read as

“1”.

Data byte

1

MS30905V2

DS12179 - Rev 2

page 19/44

Page 20

M95M04-DR

Write to memory array (WRITE)

Figure 14. Page write (WRITE) sequence

S

21 3 4 5 6 7 8 9 10 28 29 30 31 32 33 34 35

0

36 37 38

39

C

Instruction 24-bit address

23

D

22 21

3 2 1 0

7 6 5 4 3 2 0

Data byte 1

1

S

C

Data byte 2

D

7 6 5 4 3 2 0

7 6 5 4 3 2 0

1

Data byte 3

Data byte N

1

6 5 4 3 2 0

1

MS30906V2

DS12179 - Rev 2

page 20/44

Page 21

6.7 Read identification page

The identification page (512 bytes) is an additional page that can be written and (later) permanently locked in

Read-only mode.

This page is read with the read identification page instruction (see Table 4). The chip select signal (S) is first

driven low, the bits of the instruction byte and address bytes are then shifted in, on serial data input (D). Address

bit A10 must be 0, upper address bits are "Don't care", and the data byte pointed to by the lower address bits

[A8:A0] is shifted out on serial data output (Q). If chip select (S) continues to be low, the internal address register

is automatically incremented, and the byte of data at the new address is shifted out.

The number of bytes to read in the ID page must not exceed the page boundary, otherwise unexpected data are

read (e.g. when reading the ID page from location 200d, the number of bytes must be lower than or equal to

312d, as the ID page boundary is 512 bytes).

The read cycle is terminated by driving chip select (

at any time during the cycle. The first byte addressed can be any byte within any page.

The instruction is not accepted, and is not executed, if a write cycle is currently in progress.

Figure 15. Read identification page sequence

S

M95M04-DR

Read identification page

S) high. The rising edge of the chip select (S) signal can occur

21 3 4 5 6 7 8 9 10 28 29 30 31 32 33 34 35

0

36 37 38

39

C

Instruction 24-bit address

23

D

Q

High impedance

22 21 3 2 1 0

MSB

Data Out 1

7 6 5 4 3 1 7

MSB

2

Data Out 2

0

MS30907V2

DS12179 - Rev 2

page 21/44

Page 22

6.8 Write identification page

The identification page (512 bytes) is an additional page that can be written and (later) permanently locked in

Read-only mode.

Writing this page is achieved with the write identification page instruction (see Table 4). The chip select signal (S)

is first driven low. The bits of the instruction byte, address bytes, and at least one data byte are then shifted in

on serial data input (D). Address bit A10 must be 0, upper address bits are "Don't care", the lower address bits

[A8:A0] define the byte address within the identification page. The instruction sequence is shown in Figure 16.

Figure 16. Write identification page sequence

S

M95M04-DR

Write identification page

21 3 4 5 6 7 8 9 10 28 29 30 31 32 33 34 35

0

C

Instruction 24-bit address

D

High impedance

Q

23

22 21 3 2 1 0

7 6 5 4 3 2 0

36 37 38

Data byte

39

1

MS30909V1

DS12179 - Rev 2

page 22/44

Page 23

6.9 Read lock status

The read lock status instruction (see Table 4) is used to check whether the identification page is locked or not in

Read-only mode. The read lock status sequence is defined with the chip select (S) first driven low. The bits of the

instruction byte and address bytes are then shifted in on serial data input (D). Address bit A10 must be 1, all other

address bits are "Don't Care". The lock bit is the LSB (least significant bit) of the byte read on serial data output

(Q). It is at “1” when the lock is active and at “0” when the lock is not active. If chip select (S) continues to be

driven low, the same data byte is shifted out. The read cycle is terminated by driving chip select (S) high.

The instruction sequence is shown in Figure 17.

S

0

C

Figure 17. Read lock status sequence

21 3 4 5 6 7 8 9 10 28 29 30 31 32 33 34 35

Instruction 24-bit address

36 37 38

M95M04-DR

Read lock status

39

D

High impedance

Q

23 22 21

MSB

3 2 1 0

Data Out 1

7 6 5 4 3 1 7

MSB

2

0

Data Out 2

MS30910V1

DS12179 - Rev 2

page 23/44

Page 24

6.10 Lock ID

The lock ID instruction permanently locks the identification page in read-only mode. Before this instruction can be

accepted, a write enable (WREN) instruction must have been executed.

The lock ID instruction is issued by driving chip select (S) low, sending the instruction code, the address and a

data byte on serial data input (D), and driving chip select (S) high. In the address sent, A10 must be equal to 1,

all other address bits are "Don't Care". The data byte sent must have the b0 bit equal to 1 (b0=1) and the others

value of the bits b7 to b1 are "Don't Care". The data byte has the following format: xxxx xxx1 (where x = Don't

Care)".

Chip select (S) must be driven high after the rising edge of serial clock (C) that latches in the eighth bit of the data

byte, and before the next rising edge of serial clock (C). Otherwise, the lock ID instruction is not executed.

Driving chip select (

is tW (as specified in AC characteristics in Section 9 DC and AC parameters). The instruction sequence is shown

in Figure 18.

The instruction is discarded, and is not executed, under the following conditions:

• If a write cycle is already in progress

• If block protect bits (BP1,BP0) = (1,1)

• If a rising edge on chip select (S) happens outside of a byte boundary

• If the identification is already locked.

M95M04-DR

Lock ID

S) high at a byte boundary of the input data triggers the self-timed write cycle whose duration

Figure 18. Lock ID sequence

S

21 3 4 5 6 7 8 9 10 28 29 30 31 32 33 34 35

C

D

Q

0

Instruction 24-bit address

23

High impedance

22 21 3 2 1 0

6.11 Error correction code (ECC x 4) and write cycling

M95M04-DR devices offer an error correction code (ECC), an internal logic function transparent for the SPI

communication protocol.

The ECC logic is implemented on each group of four EEPROM bytes (A group of four bytes is located at

addresses [4*N, 4*N+1, 4*N+2, 4*N+3], where N is an integer). Even if the ECC function is performed on groups

of four bytes, a single byte can be written/cycled independently. In this case, the ECC function also writes/cycles

the three other bytes located in the same group. As a consequence, the maximum cycling budget is defined at

group level and the cycling can be distributed over the four bytes of the group: the sum of the cycles seen by

byte0, byte1, byte2 and byte3 of the same group must remain below the maximum value defined in Section 9 .

36 37 38

Data byte

7 6 5 4 3 2 0

1

39

DS12179 - Rev 2

page 24/44

Page 25

7 Power-up and delivery state

7.1 Power-up state

After power-up, the device is in the following state:

• standby power mode

• deselected (after power-up, a falling edge is required on chip select (S) before any instructions can be

started)

• not in the hold condition

• the write enable latch (WEL) is reset to 0

• write in progress (WIP) is reset to 0.

The SRWD, BP1 and BP0 bits of the status register are unchanged from the previous power-down (they are

non-volatile bits).

7.2 Initial delivery state

The device is delivered with the memory array and identification page bits set to all 1s (each byte = FFh). The

status register write disable (SRWD) and block protect (BP1 and BP0) bits are initialized to 0.

M95M04-DR

Power-up and delivery state

DS12179 - Rev 2

page 25/44

Page 26

8 Maximum ratings

Stressing the device outside the ratings listed in Table 8 may cause permanent damage to the device. These

are stress ratings only, and operation of the device at these, or any other conditions outside those indicated in

the operating sections of this specification, is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability.

Symbol Parameter Min. Max. Unit

T

AMB

T

STG

T

LEAD

V

V

V

I

OL

I

OH

V

ESD

1. Compliant with JEDEC standard J-STD-020 (for small-body, Sn-Pb or Pb free assembly), the ST ECOPACK 7191395

specification, and the European directive on Restrictions on Hazardous Substances (RoHS directive 2011/65/EU of July

2011).

2. Positive and negative pulses applied on different combinations of pin connections, according to AEC-Q100-002 (compliant

with ANSI/ESDA/JEDEC JS-001, C1 = 100 pF, R1 = 1500 Ω, R2 = 500 Ω).

Ambient operating temperature –40 130

Storage temperature –65 150

Lead temperature during soldering

Output voltage –0.50

O

Input voltage –0.50 6.5

I

Supply voltage –0.50 6.5

CC

DC output current (Q = 0) - 5

DC output current (Q = 1) - 5

Electrostatic discharge voltage (human body model)

Table 8. Absolute maximum ratings

(2)

M95M04-DR

Maximum ratings

See note

- 4000 V

(1)

V

+ 0.6

CC

mA

°C

V

DS12179 - Rev 2

page 26/44

Page 27

9 DC and AC parameters

This section summarizes the operating conditions and the DC/AC characteristics.

Table 9. Operating conditions (range R)

Symbol Parameter Min. Max. Unit

V

CC

T

A

Symbol Parameter Min. Max. Unit

C

L

-

-

-

Supply voltage 1.8 5.5 V

Ambient operating temperature –40 85 °C

Load capacitance - 30 pF

Input rise and fall times - 25 ns

Input pulse voltages

Input and output timing reference voltages

Table 10. AC measurement conditions

DC and AC parameters

0.2 VCC to 0.8 V

0.3 VCC to 0.7 V

M95M04-DR

CC

CC

V

V

Input Levels

0.8 ₓ V

0.2 ₓ V

Figure 19. AC measurement I/O waveform

CC

CC

Input and Output

Timing Reference Levels

0.7 ₓ V

CC

0.3 ₓ V

CC

DS12179 - Rev 2

page 27/44

Page 28

Table 11. Cycling performance by groups of four bytes

M95M04-DR

DC and AC parameters

Symb

ol

Ncycle

Parameter Test condition Min. Max. Unit

Write cycle

endurance

TA ≤ 25 °C, VCC(min) < VCC < VCC(max)

(1)

TA = 85 °C, VCC(min) < VCC < VCC(max)

- 4,000,000

- 1,200,000

Write cycle

(2)

1. The write cycle endurance is defined for groups of four data bytes located at addresses [4*N, 4*N+1, 4*N+2, 4*N+3], where

N is an integer. The write cycle endurance is defined by characterization and qualification.

2. A write cycle is executed when either a page write, a byte write, a WRSR, a WRID or an LID instruction is decoded. When

using the byte write, the page write or the WRID instruction, refer also to Section 6.11 Error correction code (ECC x 4) and

write cycling.

Table 12. Memory cell data retention

Parameter Test conditions Min. Unit

Data retention

(1)

TA = 55 °C

40 Year

1. The data retention behaviour is checked in production, while the 40-year limit is defined from characterization and

qualification results.

Table 13. Capacitance

= 0 V

(1)

Min. Max. Unit

- 8 pF

- 8 pF

- 6 pF

Symbol

C

OUT

C

IN

1. Sampled only, not 100% tested, at TA = 25 °C and at a frequency of 5 MHz.

Output capacitance (Q)

Input capacitance (D)

Input capacitance (other pins)

Parameter

Test conditions

V

VIN = 0 V

VIN = 0 V

OUT

DS12179 - Rev 2

page 28/44

Page 29

M95M04-DR

DC and AC parameters

Table 14. DC characteristics

Symbol Parameter Test conditions Min Max Unit

I

CC0

I

I

I

CC1

V

V

V

I

Input leakage current

LI

Output leakage current

LO

Supply current (Read)

CC

(4)

Supply current (Write)

Supply current

(Standby power mode)

Input low voltage

IL

Input high voltage

IH

Output low voltage

OL

V

= VSS or V

IN

S= VCC, V

CC

= VSS or V

OUT

CC

C = 0.1 VCC / 0.9 VCC at 5 MHz, VCC = 1.8 V, Q = open

C = 0.1 VCC / 0.9 VCC at 10 MHz, VCC = 3.3 V, Q = open

C = 0.1 VCC / 0.9 VCC at 10 MHz, VCC = 5.5 V, Q = open

During tW,S = VCC,

S= VCC, V

S= VCC, V

S= VCC, V

= VSS or VCC, V

IN

= VSS or VCC, V

IN

= VSS or VCC, V

IN

CC

CC

CC

= 1.8 V

= 3.3 V

= 5.5 V

1.8 V ≤ VCC < 2.5 V

2.5 V ≤ VCC < 5.5 V

- ±2

- ±2

-

-

-

-

- 2

- 3

- 5

- 0.45

- 0.45

1.8 V ≤ VCC < 2.5 V 0.75 V

2.5 V ≤ VCC < 5.5 V 0.70 V

IOL = 0.15 mA, VCC = 1.8 V

- 0.3

VCC = 2.5 V, IOL = 1.5 mA, or

VCC = 5.0 V, IOL = 2.0 mA

- 0.4

CC

CC

(1)

1

(2)

2

(3)

3

(5)

2

0.25 V

0.30 V

VCC + 1

VCC + 1

µA

mA

µA

CC

CC

V

IOH = –0.1 mA, VCC = 1.8 V

V

Output high voltage

OH

VCC = 2.5 V, IOH = -0.4 mA, or

VCC = 5.0 V, IOH = -2.0 mA

1. 2 mA before year 2021 - week 07, DC107 on marking

2. 3 mA before year 2021 - week 07, DC107 on marking

3. 5 mA before year 2021 - week 07, DC107 on marking

4. Value guaranteed by characterization. Not tested in production.

5. 3 mA before year 2021 - week 07, DC107 on marking

0.80 V

CC

-

DS12179 - Rev 2

page 29/44

Page 30

Table 15. AC characteristics

Test conditions specified in Table 9 and Table 10

Symbol Alt. Parameter

f

C

t

SLCH

t

SHCH

t

SHSL

t

CHSH

t

CHSL

t

CH

(1)

t

CL

t

CLCH

t

CHCL

t

DVCH

t

CHDX

t

HHCH

t

HLCH

t

CLHL

t

CLHH

t

SHQZ

t

CLQV

t

CLQX

t

QLQH

t

QHQL

t

HHQV

t

HLQZ

t

W

1. tCH + tCL must never be less than the shortest possible clock period, 1 / fC(max)

2. Value guaranteed by characterization, not 100% tested in production.

3. t

CLQV

equal to or greater than t

4. Write time for LID instruction is 10 ms.

f

Clock frequency

SCK

t

S active setup time 60 - 30 - ns

CSS1

t

S not active setup time 60 - 30 - ns

CSS2

t

S Deselect time 60 - 40 - ns

CS

t

S active hold time 60 - 30 - ns

CSH

- S not active hold time 60 - 30 - ns

(1)

t

Clock high time 90 - 40 - ns

CLH

t

Clock low time 90 - 40 - ns

CLL

(2)

t

Clock rise time - 2 - 2 µs

RC

(2)

t

Clock fall time - 2 - 2 µs

FC

t

Data in setup time 20 - 10 - ns

DSU

t

Data in hold time 20 - 10 - ns

DH

- Clock low hold time after HOLD not active 60 - 30 - ns

- Clock low hold time after HOLD active 60 - 30 - ns

- Clock low set-up time before HOLD active 0 - 0 - ns

- Clock low set-up time before HOLD not active 0 - 0 - ns

(2)

t

Output disable time - 80 - 40 ns

DIS

(3)

t

Clock low to output valid - 80 - 40 ns

V

t

Output hold time 0 - 0 - ns

HO

(2)

t

Output rise time - 80 - 40 ns

RO

(2)

t

Output fall time - 80 - 40 ns

FO

t

HOLD high to output valid - 80 - 40 ns

LZ

(2)

t

HOLD low to output high-Z - 80 - 40 ns

HZ

t

Write time -

WC

must be compatible with tCL (clock low time): if tSU is the Read setup time of the SPI bus master, then tCL must be

+ tSU.

CLQV

M95M04-DR

DC and AC parameters

V

≥ 1.8 V V

CC

Min. Max. Min. Max.

DC 5 DC 10

(4)

5

CC

-

≥ 2.5 V

5

(4)

Unit

MHz

ms

DS12179 - Rev 2

page 30/44

Page 31

M95M04-DR

DC and AC parameters

Figure 20. Serial input timing

t

SHSL

S

C

D

Q

t

CHSL

S

C

Q

HOLD

t

DVCH

t

SLCH

MSB IN

High impedance

t

CH

t

CHCL

t

CHDX

Figure 21. Hold timing

t

CLHL

t

HLQZ

t

CHSH

t

CL

t

CLCH

t

SHCH

LSB IN

t

HLCH

t

HHCH

t

CLHH

t

HHQV

Figure 22. Serial output timing

S

t

CH

C

t

CL

t

CLQX

t

CLQV

t

CLCH

t

CHCL

Q

t

QLQH

t

QHQL

ADDR

D

LSB IN

t

SHSL

t

SHQZ

DS12179 - Rev 2

page 31/44

Page 32

10 Package information

In order to meet environmental requirements, ST offers these devices in different grades of ECOPACK packages,

depending on their level of environmental compliance. ECOPACK specifications, grade definitions and product

status are available at: www.st.com. ECOPACK is an ST trademark.

10.1 SO8N package information

SO8N is an 8-lead, 4.9 x 6 mm, plastic small outline, 150 mils body width, package.

M95M04-DR

Package information

Figure 23. SO8N – Outline

h x 45˚

A2

b

e

8

1

A

ccc

D

E1

E

A1

L

L1

1. Drawing is not to scale.

Table 16. SO8N – Mechanical data

Symbol

Min. Typ. Max. Min. Typ. Max.

A

- - 1.750 - - 0.0689

A1 0.100 - 0.250 0.0039 - 0.0098

A2 1.250 - - 0.0492 - -

b 0.280 - 0.480 0.0110 - 0.0189

c 0.170 - 0.230 0.0067 - 0.0091

D 4.800 4.900 5.000 0.1890 0.1929 0.1969

E 5.800 6.000 6.200 0.2283 0.2362 0.2441

E1 3.800 3.900 4.000 0.1496 0.1535 0.1575

e - 1.270 - - 0.0500 -

h 0.250 - 0.500 0.0098 - 0.0197

k 0° - 8° 0° - 8°

L 0.400 - 1.270 0.0157 - 0.0500

L1 - 1.040 - - 0.0409 -

1. Values in inches are converted from mm and rounded to four decimal digits.

ccc - - 0.100 - - 0.0039

millimeters

c

0.25 mm

GAUGE PLANE

k

inches

(1)

DS12179 - Rev 2

page 32/44

Page 33

Figure 24. SO8N - Recommended footprint

0.6 (x8)

3.9

6.7

1.27

M95M04-DR

SO8N package information

1. Dimensions are expressed in millimeters.

DS12179 - Rev 2

page 33/44

Page 34

10.2 WLCSP8 package information

This WLCSP is a 8-ball, 2,809 x 1,863 mm, wafer level chip scale package.

Figure 25. WLCSP8 - Outline with BSC

Orientation

reference

E

(2X)

aaa

X

Y

M95M04-DR

WLCSP8 package information

e3

H

e4

Orientation

reference

e2

Z

bbb

DETAIL A

D

aaa

(2X)

TOP VIEW BOTTOM VIEW SIDE VIEW

F

G

e1

e

A1

eee

Z

ccc

ddd

b

ZZX Y

DETAIL A

Z

SEATING PLANE

E1_WLCSP8_4MF9V_ME_V1

1. Drawing is not to scale.

2. Dimension is measured at the maximum bump diameter parallel to primary datum Z.

3. Primary datum Z and seating plane are defined by the spherical crowns of the bump.

4. Bump position designation per JESD 95-1, SPP-010.

b

BACKSIDE PROTECTION

A3

A1

A

A2

DS12179 - Rev 2

page 34/44

Page 35

Table 17. WLCSP8 - Mechanical data

Symbol

Min Typ Max Min Typ Max

A

0.500 0.540 0.580 0.0197 0.0213 0.0228

A1 - 0.190 - - 0.0075 -

A2 - 0.325 - - 0.0128 -

A3 - 0.025 - - 0.0010 -

(2)

b

- 0.270 - - 0.0106 -

D - 2.809 2.829 - 0.1106 0.1114

E - 1.863 1.883 - 0.0733 0.0741

e - 1.100 - - 0.0433 -

e1 - 2.100 - - 0.0827 -

e2 - 0.500 - - 0.0197 -

e3 - 1.000 - - 0.0394 -

e4 - 1.400 - - 0.0551 -

F - 0.232 - - 0.0091 -

G - 0.355 - - 0.0140 -

H - 0.200 - - 0.0079 -

aaa - 0.110 - - 0.0043 -

bbb - 0.110 - - 0.0043 -

ccc - 0.110 - - 0.0043 -

ddd - 0.060 - - 0.0024 -

eee - 0.060 - - 0.0024 -

1. Values in inches are converted from mm and rounded to 4 decimal digits.

2. Dimension is measured at the maximum bump diameter parallel to primary datum Z.

millimeters

M95M04-DR

WLCSP8 package information

(1)

inches

Figure 26. WLCSP8 - Recommended footprint

0.200

0.270

1. Dimensions are expressed in millimeters.

1.000

1.400

0.500

2.100

1.100

E1_WLCSP8_4MF9V_FP_V1

DS12179 - Rev 2

page 35/44

Page 36

10.3 TSSOP8 package information

TSSOP8 is an 8-lead thin shrink small outline, 3 x 6.4 mm, 0.65 mm pitch, package.

D

8 5

Figure 27. TSSOP8 – Outline

E

E1

M95M04-DR

TSSOP8 package information

c

1

A

CP

4

A2

b

e

1. Drawing is not to scale.

Table 18. TSSOP8 – Mechanical data

Symbol

Min. Typ. Max. Min. Typ. Max.

A

- - 1.200 - - 0.0472

A1 0.050 - 0.150 0.0020 - 0.0059

A2 0.800 1.000 1.050 0.0315 0.0394 0.0413

b 0.190 - 0.300 0.0075 - 0.0118

c 0.090 - 0.200 0.0035 - 0.0079

CP - - 0.100 - - 0.0039

D 2.900 3.000 3.100 0.1142 0.1181 0.1220

e - 0.650 - - 0.0256 -

E 6.200 6.400 6.600 0.2441 0.2520 0.2598

E1 4.300 4.400 4.500 0.1693 0.1732 0.1772

L 0.450 0.600 0.750 0.0177 0.0236 0.0295

L1 - 1.000 - - 0.0394 -

1. Values in inches are converted from mm and rounded to four decimal digits.

α 0° - 8° 0° - 8°

millimeters

α

A1

L

L1

inches

(1)

DS12179 - Rev 2

page 36/44

Page 37

Figure 28. TSSOP8 – Recommended footprint

2.3

1.0

7.0

0.65

M95M04-DR

TSSOP8 package information

1. Dimensions are expressed in millimeters.

0.35

DS12179 - Rev 2

page 37/44

Page 38

11 Ordering information

Example: M95 M04- D R MN 6 T P /V

Device type

M95 = SPI serial access EEPROM

Device function

M04‑- = 4096 Kbit

Device family

D = with additional identification page

Operating voltage

R = VCC = 1.8 V to 5.5 V

Package

MN = SO8N (150 mil width)

DW = TSSOP8 (169 mil width)

CS = WLCSP

Device grade

6 = Industrial: device tested with standard test flow over -40 to 85 °C

Option

T = Tape and reel packing

blank = tube packing

Planting technology

P = RoHS compliant and halogen-free (ECOPACK2)

Process

/V = Manufacturing technology code

1. All packages are ECOPACK2 (RoHS-compliant and free of brominated, chlorinated and antimony-oxide flame retardants).

(1)

M95M04-DR

Ordering information

Table 19. Ordering information scheme

Note: Parts marked as “ES”, “E” or accompanied by an Engineering Sample notification letter, are not yet qualified and

therefore not approved for use in production. ST is not responsible for any consequences resulting from such

use. In no event will ST be liable for the customer using any of these engineering samples in production. ST

Quality has to be contacted prior to any decision to use these Engineering samples to run qualification activity.

DS12179 - Rev 2

page 38/44

Page 39

Revision history

Table 20. Document revision history

Date Revision Changes

24-Oct-2019 1 Initial release.

Updated:

• Features, Section 6.10 Lock ID

• Titles in Figure 25. WLCSP8 - Outline with BSC, Table 17. WLCSP8 - Mechanical data and

22-Feb-2021 2

Figure 26. WLCSP8 - Recommended footprint

• Table 14. DC characteristics, Table 15. AC characteristics

added sentence at the top of Section 10.2 WLCSP8 package information, note 2,3 and 5 in Table 14. DC

characteristics

M95M04-DR

DS12179 - Rev 2

page 39/44

Page 40

M95M04-DR

Contents

Contents

1 Description ........................................................................2

2 Memory organization ..............................................................4

3 Signal description .................................................................5

3.1 Serial data output (Q) ...........................................................5

3.2 Serial data input (D) ............................................................5

3.3 Serial clock (C) ................................................................5

3.4 Chip select (S) .................................................................5

3.5 Hold (HOLD) ..................................................................5

3.6 Write protect (W) ...............................................................5

3.7 VCC supply voltage ............................................................5

3.8 VSS ground ...................................................................5

4 Connecting to the SPI bus .........................................................6

4.1 SPI modes ....................................................................7

5 Operating features.................................................................8

5.1 Supply voltage (VCC) ...........................................................8

5.1.1 Operating supply voltage (VCC) .............................................8

5.1.2 Device reset ............................................................8

5.1.3 Power-up conditions ......................................................8

5.1.4 Power-down ............................................................9

5.2 Active power and Standby power modes ...........................................9

5.3 Hold condition .................................................................9

5.4 Status register ................................................................10

5.5 Data protection and protocol control ..............................................10

6 Instructions ......................................................................11

6.1 Write enable (WREN) ..........................................................12

6.2 Write disable (WRDI) ..........................................................13

6.3 Read Status register (RDSR) ...................................................14

6.3.1 WIP bit ...............................................................14

6.3.2 WEL bit ...............................................................14

6.3.3 BP1, BP0 bits ..........................................................14

DS12179 - Rev 2

page 40/44

Page 41

M95M04-DR

Contents

6.3.4 SRWD bit .............................................................15

6.4 Write Status register (WRSR) ...................................................16

6.5 Read from Memory array (READ) ................................................18

6.6 Write to Memory array (WRITE) .................................................19

6.7 Read Identification page........................................................21

6.8 Write Identification page........................................................22

6.9 Read Lock status..............................................................23

6.10 Lock ID ......................................................................24

6.11 Error correction code (ECC x 4) and write cycling ..................................24

7 Power-up and delivery state ......................................................25

7.1 Power-up state ...............................................................25

7.2 Initial delivery state ............................................................25

8 Maximum ratings .................................................................26

9 DC and AC parameters ...........................................................27

10 Package information..............................................................32

10.1 SO8N package information .....................................................32

10.2 WLCSP8 package information...................................................34

10.3 TSSOP8 package information ...................................................36

11 Ordering information .............................................................38

Revision history .......................................................................39

DS12179 - Rev 2

page 41/44

Page 42

M95M04-DR

List of figures

List of figures

Figure 1. Logic diagram.....................................................................2

Figure 2. 8-pin package connections (top view) ....................................................3

Figure 3. WLCSP connections ................................................................3

Figure 4. Block diagram ....................................................................4

Figure 5. Bus master and memory devices on the SPI bus.............................................6

Figure 6. SPI modes supported ...............................................................7

Figure 7. Hold condition activation .............................................................9

Figure 8. Write enable (WREN) sequence ....................................................... 12

Figure 9. Write disable (WRDI) sequence ....................................................... 13

Figure 10. Read Status register (RDSR) sequence .................................................. 14

Figure 11. Write status register (WRSR) sequence .................................................. 16

Figure 12. Read from memory array (READ) sequence .............................................. 18

Figure 13. Byte write (WRITE) sequence ........................................................ 19

Figure 14. Page write (WRITE) sequence ........................................................ 20

Figure 15. Read identification page sequence ..................................................... 21

Figure 16. Write identification page sequence .....................................................22

Figure 17. Read lock status sequence .......................................................... 23

Figure 18. Lock ID sequence ................................................................ 24

Figure 19. AC measurement I/O waveform ....................................................... 27

Figure 20. Serial input timing ................................................................. 31

Figure 21. Hold timing...................................................................... 31

Figure 22. Serial output timing ................................................................ 31

Figure 23. SO8N – Outline .................................................................. 32

Figure 24. SO8N - Recommended footprint .......................................................33

Figure 25. WLCSP8 - Outline with BSC.......................................................... 34

Figure 26. WLCSP8 - Recommended footprint..................................................... 35

Figure 27. TSSOP8 – Outline ................................................................ 36

Figure 28. TSSOP8 – Recommended footprint..................................................... 37

DS12179 - Rev 2

page 42/44

Page 43

M95M04-DR

List of tables

List of tables

Table 1. Signal names ......................................................................2

Table 2. Signals vs. bump position ..............................................................3

Table 3. Write-protected block size ............................................................. 10

Table 4. Instruction set ..................................................................... 11

Table 5. Significant bits within the address bytes ................................................... 11

Table 6. Status register format ................................................................ 15

Table 7. Protection modes................................................................... 17

Table 8. Absolute maximum ratings ............................................................ 26

Table 9. Operating conditions (range R) ......................................................... 27

Table 10. AC measurement conditions ........................................................... 27

Table 11. Cycling performance by groups of four bytes ................................................ 28

Table 12. Memory cell data retention ............................................................ 28

Table 13. Capacitance ...................................................................... 28

Table 14. DC characteristics .................................................................. 29

Table 15. AC characteristics .................................................................. 30

Table 16. SO8N – Mechanical data ............................................................. 32

Table 17. WLCSP8 - Mechanical data............................................................ 35

Table 18. TSSOP8 – Mechanical data ........................................................... 36

Table 19. Ordering information scheme........................................................... 38

Table 20. Document revision history ............................................................. 39

DS12179 - Rev 2

page 43/44

Page 44

M95M04-DR

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and improvements to ST

products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST products before placing orders. ST

products are sold pursuant to ST’s terms and conditions of sale in place at the time of order acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the design of

Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. For additional information about ST trademarks, please refer to www.st.com/trademarks. All other product or service

names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2021 STMicroelectronics – All rights reserved

DS12179 - Rev 2

page 44/44

Loading...

Loading...