Page 1

MITSUBISHI SEMICONDUCTOR (LSI)

GND

GND

LOIN

MU

LO

RSL

SL

V

RSP

HW

HV

HU

GND

GNDHBFG

TOIN

LOIN

OSC

FO

RTO

OPIN-SPIN

V

VM

M63015FP

SPINDLE MOTOR AND 4CH ACTUATOR DRIVER

DESCRIPTION

This M63015FP is 1 chip driver IC for spindle motor and 4 channel

actuators. All of the motor and actuator of optical disk drive system

(CD-ROM etc.) can be drived by only this IC.

This IC has current control drive system for Focus,Tracking,

Spindle and Slide channel drive, also has a direct PWM control

system for Spindle and Slide channels drive due to reducing IC

power dissipation.

This IC has three voltage supply terminals (for Spindle,

Slide/Loading and Focus/Tracking) , and these voltage supply can

be set separately.

Further more this IC has an operational amplifier for Slide input,

FG amplifier, thermal shut down circuit, standby circuit, channel

select function, reverse rotation detect circuit and Short braking

select.

APPLICATION

CD-ROM, DVD, DVD-ROM, DVD-RAM ,Optical disc related

system, etc.

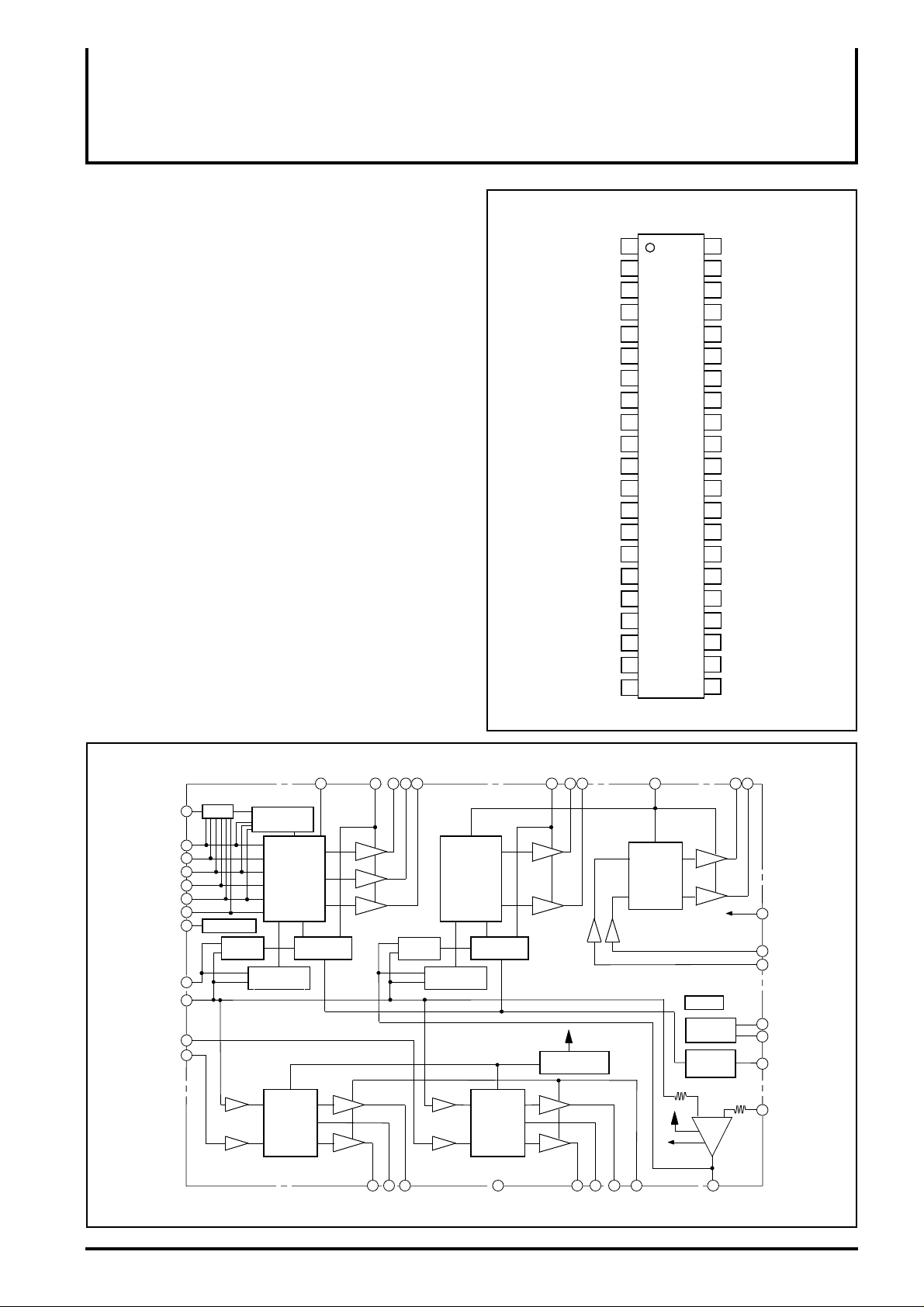

PIN CONFIGURATION (TOP VIEW)

+

1

MU1

2

2

3

VM23

4

+

LO-

7

8

SL+

-

W

13

14

U

15 28

HW-

16

+

17

18

HV-

+

19

HU-

20

21

+

Outline 42P9R-K/B

42

RFO

41

40

5

39

VM4

385

376

TO+

TO-

36

FO-

35

349

M63015FP

3310

SLIN

3211

3112

30

29

FOIN

27

26

REF

25

24

23

22

-

CC

+

1

BLOCK DIAGRAM

FG

HU+

HU-

HV+

HVHW+

HW-

HB

SPIN

REF

TOIN

FOIN

FG

Hall Bias

VM1

s

s

Reverse

Detect

Spindle Slide

Direction

comp.

Focus

Current

comp.

ss

TO+

CTL

amp.

RSPUV

RTO

CTL

amp.

TO-

W

Direction

comp.

Current

comp.

Reg

Tracking

GND

SL+

RSL

VM1

Regulator

FO+

SL-

RFO

FO-

VM23

ss

Loading

VM4

10K

Reg

5VCC

5V power

supply

TSD

BIAS

Frequency

generator

+ -

SLIN

2 K

LO+

LO-

5VCC

LOIN+

LOIN-

MU1

MU2

OSC

OPIN-

Page 2

C

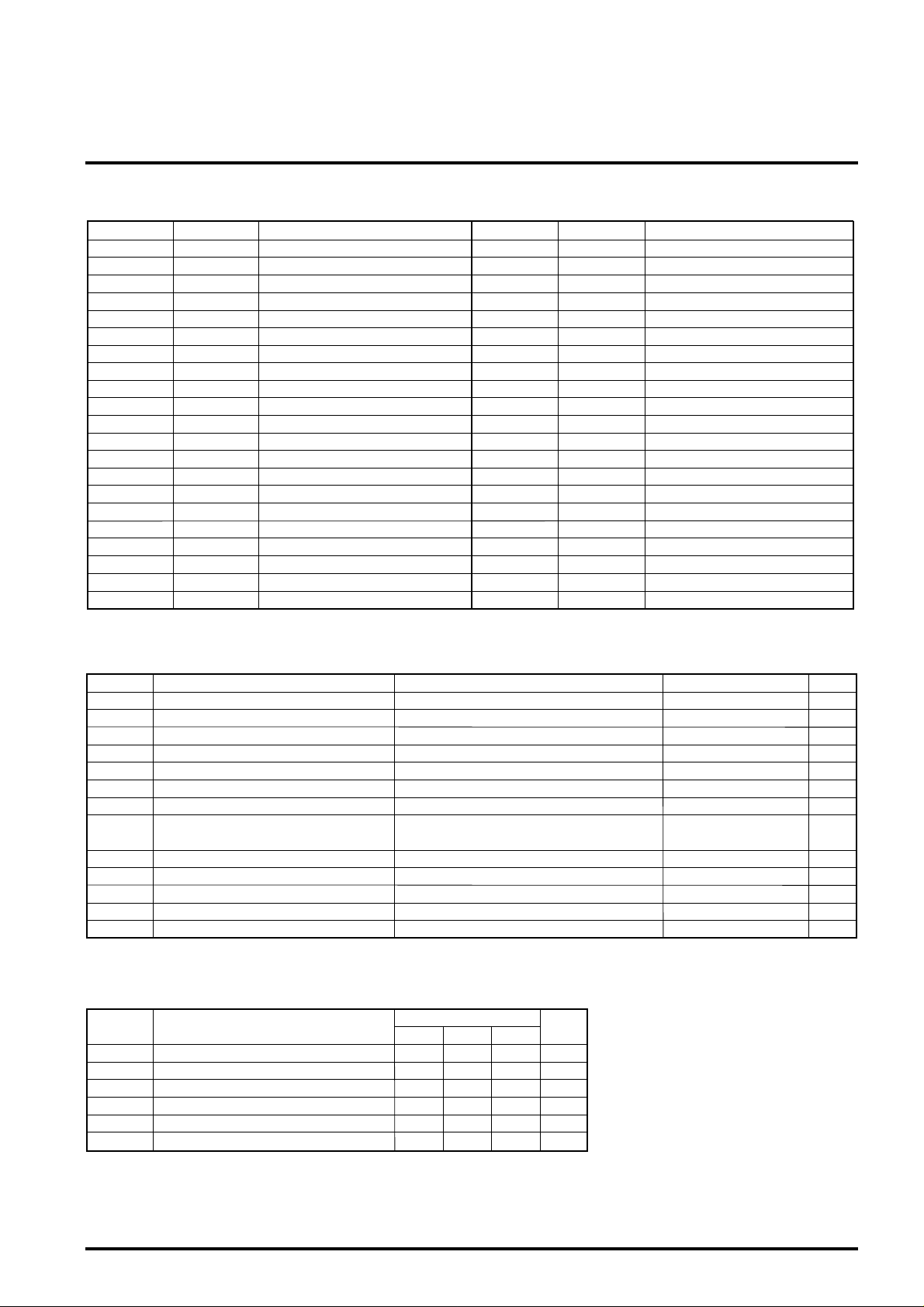

DESCRIPTIN OF PIN

O

lifi

M

Slide/Loading)

M

TS)

C

N

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Symbol

LOIN+

MU1

MU2

VM23

LO+

LOGND

RSL

SL+

SLGND

W

V

U

RSP

HW-

HW+

HV-

HV+

HUHU+

SPINDLE MOTOR AND 4CH ACTUATOR DRIVER

Function

Loading control input(+)

mute 1

mute 2

otor Power Suppry 3(for

Loading non-inverted output

Loading inverted output

GND

Slide current sense

Slide non-inverted output 34

Slide inverted output

GND 32

Motor drive output W

Motor drive output V 30

Motor drive output U

Spindle current sensie

HW- sensor amp. input

HW+ sensor amp. input

HV- sensor amp. input

HV+ sensor amp. input

HU- sensor amp. input

HU+ sensor amp. input

Pin No. Symbol Function

42

41

40

39

38

37

36

35

33

31

29

28

27

26

25

24

23

22

MITSUBISHI SEMICONDUCTOR (LSI)

M63015FP

LOINRFO

RTO

5VCC 5V Power Suppry

VM4

TO+

TOFOFO+

GND

SLIN

OPINOSC

GND

FOIN

TOIN

SPIN

REF

FG

HB

VM1

Loading control input(-)

urrent feedback terminal for Focus

urrent feedback terminal for Tracking

otor Power Suppry 4(for FS and

Tracking non-inverted output

Tracking inverted output

Focus inverted output

Focus non-inverted output

GND

Slide control input

perational amp

er imverted input

PWM carrier oscilation set

GND

Focus control voltage input

Tracking control voltage input

Spindle control voltage input

Reference voltage input

Frequency generator output

Bias for Hall Sensor

Motor Power Suppry 1(for Spindle)

ABSOLUTE MAXIMUM RATINGS (Ta=25˚C, unless otherwise noted)

Symbol

5VCC

VM1

VM23

VM4

IoA

IoB

IoC

5V power supply

Motor power supply 1

Motor power supply 23

Motor power supply 4

Motor output current A 1.5

Motor output current B

Motor output current C 1.0

Maximum input voltage of terminals

Pt

Kq

T

j

opr

T

Tstg

ote 1 : The ICs must be operated within the Pt (power dissipation) or the area of safety operation.

Power dissipation 2.6

Thermal derating 20.8

Junction temperature 150

Operating temperature -20~+75

Storage temperature -40~+150

Parameter

Conditions

Spindle power supply

Slide and loading power supply

Focus and tracking power supply

Spindle output current Note1

Slide output current Note1

Focus,Tracking and Loading output current Note1

MU1,MU2,Hw-,Hw+,Hv-,Hv+,Hu-,Hu+,REF,SPIN,

TOIN, FOIN, OSC,OPIN-,LOIN-,LOIN+

Free air and on the grass epoxy board 70mmX70mmX1.6mm

Free air and on the grass epoxy board 70mmX70mmX1.6mm

RECOMMENDED OPERATING CONDITIONS (Ta=25˚C, unless otherwise noted)

Symbol UnitParameter

VM1

VM23

VM4

IoA

IoB

Fosc

VM1 power supply (forspindle)

VM23 power supply (for slide and loading)

VM4 power supply (for focus and tracking)

Spindle and slide output current Note 2

Focus, tracking and loading output current

Focus, tracking and loading output current

Limits

min. typ. max.

6 13.2

12

4.5 13.2 V12

4.5

–

–

30

0.5

–

5

13.2

1.0

0.8

120 kHz

V

V

A

A0.5

Ratings

7

15

15

15

1.0

CC

0~5V

Unit

V

V

V

V

A

A

A

VVin

W

mW/˚C

˚C

˚C

˚C

Page 3

TYPICAL CHARACTERISTICS

This IC'

POWER-SSOP

6.0

5.0

4.0

3.0

2.0

1.0

POWER DISSIPATION (Pdp)W

Using N-type board:3.6W

Using P-type,O-type

board:2.6W

MITSUBISHI SEMICONDUCTOR (LSI)

M63015FP

SPINDLE MOTOR AND 4CH ACTUATOR DRIVER

s package is

improving the board on which the IC is

mounted enables a large power dissipation

without a heat sink.

For example, using an 1 layer glass epoxy

resin board, the IC's power dissipation is

2.6W at least. And it comes to 3.6W by

using an improved 2 layer board.

The information of the N, P, O type board is

shown in attached.

, so

0

0

25

50 100

75

125 150

AMBIENT TEMPERATURE Ta (˚C)

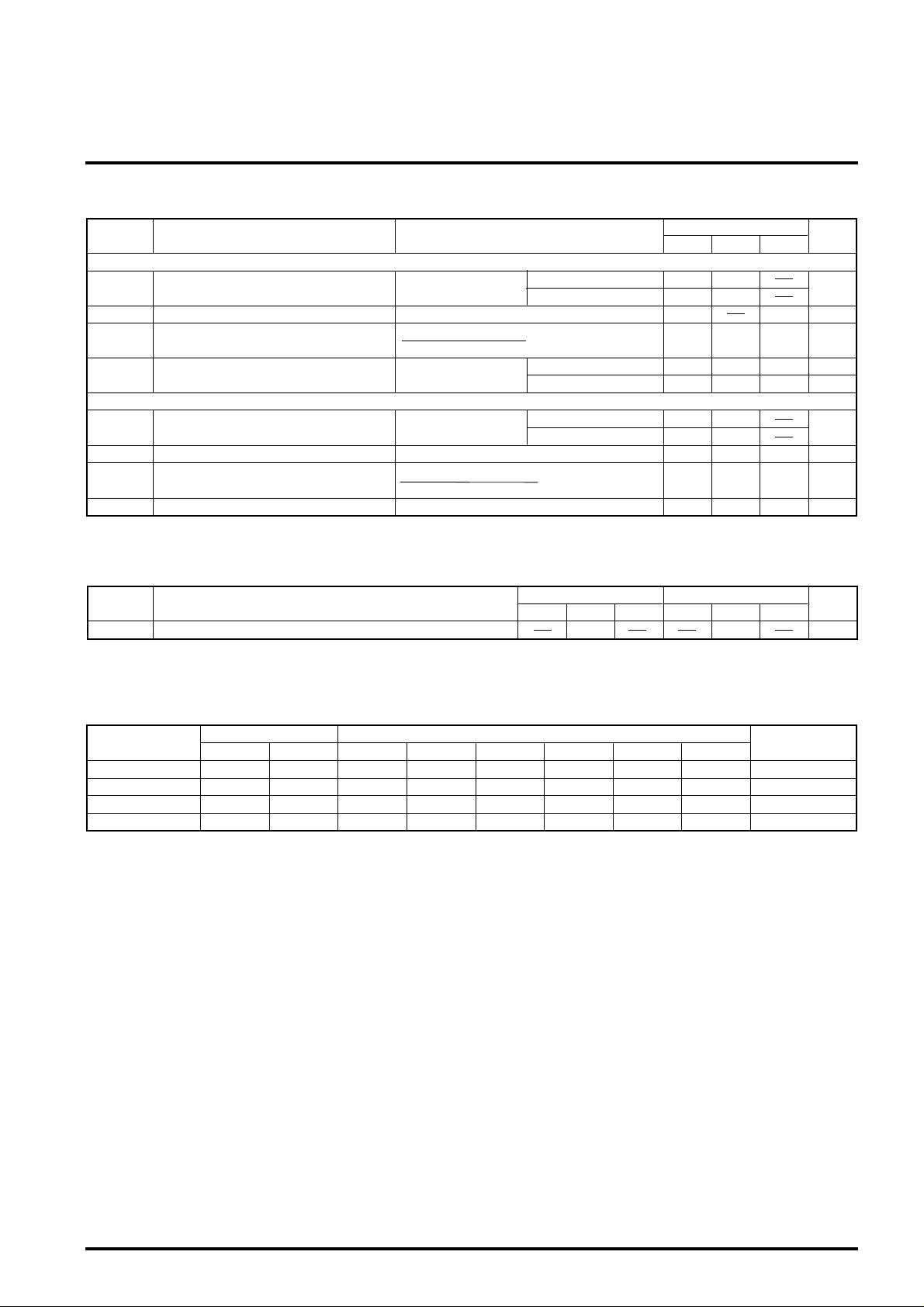

ELECTRICAL CHARACTERISTICS (Ta=25˚C, 5VCC=VM4=5V,VM1=VM23=12V unless otherwise noted.)

Parameter Test conditionsSymbol

Common

Icc1

Icc2

Fosc

VinOP

IinOP

VofOP

VoutOP

VinREF

IinREF

VMULO

VMUHI

IMU

Spindle

Vdyc1

Vdead1Vdead1+

Vin1

Gvo1

Vlim1F

Vlim1R

VHcom

VHmin

VHB

IHB

FGD

Slide

Vdyc2

Vdead2-

Vdead2+

Vin2

Gvo2

Vlim2

Tdon

Tdoff

Tdsw

Ileak

Supply current

Sleep current

PWM carrier frequency

OPamp input voltage range

OPamp input current

OPamp input offset voltage

OPamp output voltage range

REF input voltage range

REF input voltage range

MUTE terminal low voltage 0.8 V

MUTE terminal high voltage V

Mute terminal input current

Dynamic range of output V

Control voltage dead zone1

Control voltage input range 1 5V

Control gain 1 1.15

Control limit 1F

Control limit 1R 0.41 V

Hall sensor amp.common mode input range

Hall sensor amp.input signal level

HB output voltage 1.2 V

HB terminal sink current 30 mV

FG duty 30 mV

Dynamic range of output

Control voltage dead zone 2

Control voltage input range 2

Control gain 2

Control limit 2 0.58 V

Output turn-on delay 2.0

Output turn-off delay

Output switching delay 10.0 µsec

Output leak current 100

5VCC,VM1, VM23, VM4 current

5VCC,VM1, VM23, VM4 current under Sleep (MU1 = MU2 =0V).

OSC : with 180pF

OPINOPIN-=1.65V

REF=1.65V(OPIN-=OPOUT ;buffer)

Io=-2.0~+2.0mA

VREF=1.65V

MU1,MU2

MU1,MU2

MU1,MU2 at 5V input voltage

Io=0.5 [A]

SPIN<REF [REVERSE]

REF<SPIN [FORWARD]

SPIN

Ilim1F=Vlim1F/ Rs [A] [FORWARD]

Ilim1R=Vlim1R/ Rs [A] [REVERSE]

Hu+,Hu-,Hv+,Hv-,Hw+ ,Hwat Load current (IHB)=10mA

MU1=MU2=0V or MU1=MU2=5V orMU1=5V/MU2=0V

at FG frequency=3kHz,hall input signal level 80mVp-p

Io=0.5 [A]

at VM23=5[V]

at VM23=12[V]

SLIN < REF

REF < SLIN

SLIN

Gio2=Gvo2/ Rs [A/V]

Ilim2=Vlim2/ Rs [A]

The time taken to turn on the output after the Rs voltage goes above the

command value.

The time taken to turn off the output after the Rs voltage goes down the

command value.

The time when all the output Tr.s are turned off during the switching of the

output Tr.

-0

-1.0

-10

0.5

1.0

-10

3.0

10.3

-80

0

0

0.85

0.4

0.27

1.3

60

0.6

3.3

10.3

-80

0

0

0.85

0.43

-100

Limits

Typ. Max.Min.

60

110

-0.15

10.8

-40

+40

1.0

0.5

0.34

0.85

3.8

10.8

-40

+40

1.0

0.5

1.0

3.5

5.0

Unit

78

mA

30

µA

KHz

5

V

0

µA

+10

4.5

mV

V

3.3 V

+10 µA

500 µA

0mV

+80 mV

V/VGio1=Gvo1/ Rs [A/V]

0.6 V

3.7

VHu+,Hu-,Hv+,Hv-,Hw+ ,Hw-

mVp-p

V

0mV

+80 mV

5V

1.15 V/V

µsec

7.0 µsec

µAMU1=MU2=5v,MU1=MU2=0v

Page 4

MITSUBISHI SEMICONDUCTOR (LSI)

r

M63015FP

SPINDLE MOTOR AND 4CH ACTUATOR DRIVER

ELECTRICAL CHARACTERISTICS (Ta=25˚C, 5VCC=VM4=5V,VM1=VM23=12V unless otherwise noted.)(cont.)

3.3

10.3

16.6

-100

-50

3.8

6.8

-6.7

Limits

Typ. Max.Min.

3.8

10.8

0

18

0

0

4.2

7.6

0

-8.0

0-5

Loading

Vdyc3

Vin3

Gvo3

Voff1

Focus/Tracking

Vdyc4

Vin4

Gvo4

Voff 2

Dynamic range of output V

Control voltage input range3

Control gain 3

Output offset voltage

Dynamic range of output

Control voltage input range 4

Control gain 4

Output offset voltage

Parameter Test conditionsSymbol

Io=0.5[A]

LOIN+,LOIN-

(LO+) - (LO-)

(LOIN+) - (LOIN-)

(LO+) - (LO-)

Io=0.5[A]

VM1=12[V]

FOIN,TOIN

RFO (RTO)-FO-(TO-)

FOIN(TOIN)-REF

RFO (RTO)-FO-(TO-) at REF=FOIN(TOIN)=1.65V

VM23=5[V]

VM23=12[V]

LOIN+=LOIN-=5V

LOIN+=LOIN-=1.65V

VM4=5[V]

VM4=12[V]

5

19.3

+100

+50

5

-9.4 dB

+5

Unit

V

dB

mV

mV

V

V

mV

THERMAL CHARACTERISTICS

ParameterSymbol

Thermal shut downTSD

● Channel select function

Logic control Drive channel Brake select

MU1 MU2

SELECT4

SELECT3

SELECT2

SELECT1

This IC has two MUTE terminal (MU1 and MU2).

It is possible to control ON / OFF of each channel by external logic

inputs.

It has four kinds of function for select.In case of SELECT1, the bias

of all circuit becomes OFF.

Therefore, this mode is available in order to reduce the powe

dissipation when the waiting mode.

In case of SELECT2,it is possible to select the PWM reverse

braking to take the brake of Spindle motor.

H

L

H

L

H

H

L

L

Loading Slide Focus Tracking Spindle Opamp

On

On

On

Off

On

Off

On

Off

Function starttemperatureofic

Typ. Max.Min.

On

On

On

Off

Also,in case of SELECT4,it is possible to select the short braking

when in the same.

In case of SELECT3,it is possible to do OFF the slide channel.

Regard with making OFF the loading channel in case of

SELECT2,SELECT3 and SELECT4,please refer to

[Loading channel].

On

On

On

Off

Function stop temperature of ic

Typ. Max.Min.

130160 ˚C

On

On

On

Off

On

On

On

Off

Unit

(SPIN<REF)

Short

Short

PWM

-

Page 5

● Loading channel

The loading channel is the circuit of BTL voltage drive. This circuit

has the referential input. Output swing is determined with ∆Vin X 8.

Also,it is possible for this channel to use for the slide motor , the

focus coil and the tracking coil.

The input terminal is high impedance. It is possible to do variable a

gain by external resistor.

The output becomes high impedance in case of both input voltage

becomes under 0.5 volts. It is possible for the input terminal to

operate from 0 volts.The following table and diagram show an

application in case of two MCU port and one MCU port for the

loading motor.In case of one MCU port, if use three state port, it is

possible for this channel to have the stop function.

MITSUBISHI SEMICONDUCTOR (LSI)

M63015FP

SPINDLE MOTOR AND 4CH ACTUATOR DRIVER

VM23

Forward

M

Reverse

LOIN+

LOIN-

LOADING

Channel

LO+

+

Vo

-

LO-

LO-

VM23

2

Coil

-

+

LO+

Application.1 (Two port H/L control)

Logic control

P1 P2

5V 5V

05V

5V 0

00

Situation of loading channel Output voltage swing

Short brake --> Stop Vo= 0 [V]

Reverse rotation Vo= - 8X5XR1/(R1+2XR2)

Forward rotation Vo= 8X5XR1/(R1+2XR2)

Off [ High impedance output] Off

Vo

Output

voltage [V]

Gvo = 8 [v/v]

Vo=[LO+]-[LO-]

=8 X([LOIN+]-[LOIN-])

LO+

+

Coil

-

[LOIN+]-[LOIN-] (V)

LO-

Application.2 (One port H/L control)

Logic control

P1

5V

Z

(Hi impedance)

0

Situation of loading channel

Forward rotation

Short brake --> Stop

Reverse rotation

Output voltage swing

Vo=2.5[V] X8X R2

(R1/2)+R2+R3

Vo= 0 [V]

Vo=- 2.5[V] X8X R2

(R1/2)+R2+R3

Page 6

MITSUBISHI SEMICONDUCTOR (LSI)

REF

SPIN

RSP

R

R

CTL

VM1R

M

Rh5V

F

R

M63015FP

SPINDLE MOTOR AND 4CH ACTUATOR DRIVER

P1

5v

P1

0v

P2

application.1

( Two port H/L control)

5v

0v

P2

R2

R1

R2

LOIN+

LOIN-

● Spindle channel

The relationship between the differential voltage between SPIN

and REF and the torque is shown in right Figure. The voltage

gain[Gvo] is 1.0 [V/V].

The current gain[Gio] is 2.0A/V (at sensing resistor : 0.5 ohm,and

R1=∞,R2=0ohm) in forward torque directions, and the dead zone is

from 0mV to 80mV (at R1=∞,R2=0ohm) .

The coil current gain under the reverse torque is the same with in

forward torque directions.And the limitation function gets on when

the differential voltage of VM1(12V)~RSP is 0.5V at forward and

0.3V at reverse.

Therefore current-gain-control and current-limit of this IC is

determined with sensing resister value, and more detail control

can be determined with setting a gain-resister outer this IC as

below.

5v

Z

P1

0v

application.2

(One port H/Z/L control)

Current limit

Dead zone

Gio

P1

lim1F

IL(A)

R2R3

orward Torque

Dead zone

lim1R

Current limit

5V

R1

LOIN+

LOIN-

R1

Gio

CTL -REF (V)

The example of current-gain and current-limit of spindle

Gio* [A/V]

[A]

1.00

0.66

0.50

Ilim1R

[A]

R1=∞

R2=0 ohm

R1=R2

1.00

1.33

0.66

0.50

Gio*= R1 / [(R1+R2)•Rs] [A/V]

R1=2•R2

0.66

0.44

0.33

2

1.65v

Rs [Ω]

Ilim1F

0.50 0.68 2.00

0.75 0.45

1.00 0.34 1.00

everse torque

s

HB

HU+

HU-

HV+

GND

HV-

HW+

HW-

U

V

W

1

Page 7

MITSUBISHI SEMICONDUCTOR (LSI)

CTL

CTL

REF

SLIN

RSL

VM

R

K

K

OPIN

R

R

SLIN

OPIN

R1R2SLIN

OPIN

C1SL+SL

M

R

M63015FP

SPINDLE MOTOR AND 4CH ACTUATOR DRIVER

● Slide channel

The relationship between the differential voltage between SLIN and

REF and the torque is shown in right Figure. The voltage gain[Gvo]

is 1.0 [V/V]. The current gain is 2.0A/V (at sensing resistor : 0.5

ohm and R1=R2) in forward torque directions, and the dead zone

is from 0mV to 60mV (at R1=R2=16kohm).

The coil current gain under the reverse torque is the same with in

forward torque directions.And the limitation function gets on when

the differential voltage of VM23(12V)~RSL is 0.5V.

Therefore current-gain-control and current-limit of this IC is

determined with sensing resister value.In the input part,built-in an

inverted amplifier. It is possible to control more detail by setting

external circuit.

Forward

everse Torque

Gio

Dead zone

Current limit

s

IL (A)

Current limit

23

Dead zone

CTL -REF (V)

Gio

Reverse

1

2

-

-

2

10

-

+

The example of current-gain and current-limit of slide.

Rs [Ω]

Ilim [A]

0.50

0.75 0.66

1.00

1.00

0.50 1.00

Gio* [A/V]

R1=R2

2.00

1.33

2•R1=R2

1.00

0.66

0.50

Gio*= R1 / [(R1+R2)•Rs] [A/V]

Forward

-

GND

The input resisters, the 10kΩ resister to the non-inverted input and,

the 2kΩ resister to the inverted input, are built-in the operational amplifier.

Therefore the composition value of the external input resisters(R1 R2)

should be set 8kΩ because of the compensation for the input offset voltage.

Reverse

Page 8

MITSUBISHI SEMICONDUCTOR (LSI)

M63015FP

SPINDLE MOTOR AND 4CH ACTUATOR DRIVER

● Focus/tracking channel

The focus and tracking channel is the current feedback control

drive of MITSUBISHI original.The focus and tracking is the same

composition.

The relationship between the differential voltage between FOIN

and REF and the output current is shown in right Figure.

The voltage gain is 0.4 [V/V].Therefore, the current gain is 0.8[A/V]

in case of the sensing resistor is 0.5 ohm.

The maximum range of output swing is limited around 7.5 volts,in

case of VM4 is above 10 volts.

Coil

current [A]

FOIN

REF

2.5R

2.5R

VM4

R

R

+

R

FO-

R

R

RFO

R

FO+

Rs

Coil

VM4

2

Rs

Coil

IL=Vrs/Rs

FO-

RFO

-

+

FO+

IL

Gio=1.0A/V

at Rs=0.33 ohm

Vcoil

Vrs

0

-

Output

voltage [V]

Vrs=(RFO - [FO-])

=0.4 X (FOIN - REF)

FOIN - REF (V)

FO+

+

Coil

-

FOIN - REF (V)

RFO

Rs

FO-

Page 9

● Direct PWM operation

M

M

The spindle and the slide channel is controlled by the direct PWM

control.

Also,built-in the current limit circuit. This IC controls the motor

current directly.

MITSUBISHI SEMICONDUCTOR (LSI)

M63015FP

SPINDLE MOTOR AND 4CH ACTUATOR DRIVER

FORWARD Current path timing 1.

Rs

Current path 1

SL+

Current

path 1

SL-

VM23

RSL

GND

Current

path 2

FORWARD Current path timing 2.

SL+

Current path 2

Control value

VM23

Rs

RSL

SL-

GND

Control value

Io=Vrs / Rs

Motor current

carrier period

Time

Page 10

MITSUBISHI SEMICONDUCTOR (LSI)

M63015FP

SPINDLE MOTOR AND 4CH ACTUATOR DRIVER

● PWM carrier frequency setting

PWM carrier frequency is decided by charging and discharging the

capacitor that is connected to OSC terminal outer IC. Examination

of the relationship the capacitor connected to OSC terminal and

PWM carrier frequency is given in following table.

Capacitor [pF]

Carrier Frequency [kHz]

330 220

65 90

Note : This PWM carrier frequency is typ value.

180

110

130

140

110

160

● Recommendation of short brake mode at spindle drive

This IC has two brake mode, PWM-BRAKE-MODE and SHORTBRAKE-MODE. In this IC recommendation, SHORT-BRAKEMODE is superior to PWM-BRAKE-MODE to reducing the power

dissipation and to avoid breaking down of this IC.

(By excessive reverse torque current in braking a motor with

PWM-BRAKE from high-speed-rotation with being excessive BackEMF, this IC could be broken.)

● The relationship between hall-amplifier-input and

output-current-commutation/FG output at spindle

drive

The relationship between the hall elements, the motor output

current and FG output(18pulse/rotation)

are shown in bellow Figure.

Hw+ Hv+ Hu+

Hall

input

● FG function duty at spindle drive

The FG terminal outputs the square pulse signal synchronizing

with the hall inputs (Hu+,Hu-,Hv+, Hv-,Hw+,Hw-) timing. and, the

FG terminal is open-collector output. (cf. FG timing chart on the

previous page)

● FG function duty at spindle drive

FG function DUTY is shown in a below equation at rihgt Figure.

FG DUTY [%] =

Hall

input

FG

output

Ton

Ton + Toff

Hw+ Hv+ Hu+

Ton

Toff

FG pull-up R:10kΩ

FG output voltage:5V

FG output frequency:3kHz

(SPM motor rev 10000rpm)

Hall input signal level : 80mVp-p

5V

FG High voltage threshold:3.2V

FG Low voltage threshold:0.8V

0V

● Phase delay circuit at slide

Phase delay circuit is built in the IC to detect an output spike

current, when the motor current direction is switching.

In switching the motor current direction, Phase delay circuit switchoff all output trangister of H-bridge for 3µsec.

Output

current

FG

output

Hall elements

VUW

+

0

W

U

W

V

U

Forward

SPIN > REF

V

W

U

V

V

U

V

W

W

Outer roter

U

Reverse

SPIN < REF

In this IC, since output tranjister is NPN-type tranjister, motor coil

current (Io) is larger than sensing resistance current about 20mA

(TYP.) according to base current of output tranjister.

Therefore please design output current with consisting these base

current.

● Output current setting at slide

Page 11

I/O circuit

VM

RSP

UVW

GND

MITSUBISHI SEMICONDUCTOR (LSI)

M63015FP

SPINDLE MOTOR AND 4CH ACTUATOR DRIVER

● FOIN,TOIN,SPIN

LOIN+, LOINOPIN-,REF

5VCC

2K

● HB

5VCC

● VM4,FO+,FO-,TO+,TO-

● Hu+,Hu-

Hv+,HvHw+,Hw-

5VCC

2K

● MU1,MU2

5VCC

2K

8K

30K

● FG ● VM1,RSP,U,V,W

5VCC

5VCC

1

10K

● OSC

5VCC

2K

2K

2K

VM1

VM4

FO+

GND

● VM23,RSL,SL+,SL-,LO+,LO-

VM23

RSL

SL+

GND

FO-

SL-

TO+

TO-

LO+ LO-

9Vmax

REG

Page 12

THE BOARDS FOR THERMAL DERATIN

G

EVALUATION

Board material

Glass-epoxy FR-4

Size

70X70mm

thickness

t=1.6mm

1 and 2 layers

material : copper

thickness : t=18µm

N-type

board

[2 layer]

MITSUBISHI SEMICONDUCTOR (LSI)

M63015FP

SPINDLE MOTOR AND 4CH ACTUATOR DRIVER

1st layer [TOP view] 2nd layer [BACK view]

POWER-SSOP

O-type

board

[2 layer]

P-type

board

[1 layer]

42P9R-K/B

Heat sink

Lead

mounted IC

Chip

Evaluation board

Page 13

MITSUBISHI SEMICONDUCTOR (LSI)

M63015FP

SPINDLE MOTOR AND 4CH ACTUATOR DRIVER

The notes on designing the layout of the board

This IC has direct PWM controls for the Spindle channel and the

Slide channel drive, therefore the circuits of the IC are influenced

more easily by the PWM switching noise than those have linear

controls. Please refer to the following notes on the ocasion of

designing the layout pattern of the board on which the IC is

mounted.

The bad influence of the PWM noise differs in each board,

therefore please consider the following notes as the reference

materials for designing the board.

Note 1

It is necessary for some application in order to reduce the PWM

noise that pass condensers are connected between power supply

pins(VM23:4pin, VM1:22pin, VM4:38 pin, 5VCC:39pin) and GND

pin, even if the power supplies of the application already have pass

condensers. The closer the connection points of the condensers

are to the pins, the more effective it is to reduce the noise.

Please refer to the values of the condensers on the page of [An

example of the values of the external parts.

(The value of the condensors is only a reference value. It differs in

each application because the bad influence of PWM noise relates

to the layout pattern of the board.)

Note 5

The closer the GND side of the capacitor connected with OSC pin

(30 pin) is to the GND pin(33pin), which is the nearest GND to the

GND of the small signal circuit inside the IC, the less the bad

influence of the PWM noise on the GND line comes to be.

cf. [application circuit]

Note 2

The feedback point of the Spindle channel [the Slide channel] is

the connected point to the VM1(22pin) [the VM23(4pin)] line from

the RSP(15pin) [RSL(8pin)] pin through the sensing resistor

RSP[RSL]. Therefore the closer the feedback point is to the power

supply pin, the more stable the circuits are for the PWM noise.

cf. [application circuit]

Note 3

The farther the large current output lines(especially PWM output

lines of the Spindle CH. and the Slide CH.) which are indicated as

wide lines in the Fig. [application circuit] are to the small signal

input lines, the less the bad influence of the PWM noise comes to

be without the cross-talk between a large current output line and a

small input signal line.

Note 4

In case the PWM switching noise influences the REF input, it is

necessary for some application that a condenser is connected

between REF pin(25pin) and GND pin. The closer the connection

points of the condensers are to the pins, the more effective it is to

reduce the noise. (This is the same as note1.)

cf.[application circuit], [An example of the values of the external

parts]

Page 14

APPLICATION EXAMPLE

MITSUBISHI SEMICONDUCTOR (LSI)

M63015FP

SPINDLE MOTOR AND 4CH ACTUATOR DRIVER

5 ~12v

Slide, Loading

M

M

Loading

SLIDE

M

note2

RSP

RSL

R6

R2

R7

MCU

5V

5V

TS

FS

C1

DSP

6v~12v

C3

note5

RTO

C3

C3

10K

*Pull-up

Resistance

R9

R9

RFO

C3

R8

LOIN+

1

MU1

2

MU2

3

VM23

4

LO+

5

6

LOGND

7

RSL

8

SL+

9

+

C5

C4

+

SL-

10

GND

11

12

W

13

V

14

U

RSP

15

16

HW-

17

HW+

18

HVHV+

19

20

HU-

21

HU+

M63015FP

LOIN-

RFO

RTO

5VCC

VM4

TO+

TOFO-

FO+

GND

SLIN

OPIN-

OSC

GND

FOIN

TOIN

SPIN

REF

FG

HB

VM1

R10

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

+

C2

1.65v

+

C7

C6

C8

C9

R5

R3 R4

R1

note2

Rh

An example of the values of the external parts

These values are only examples, not the guaranteed values. And the values differ in each application.

External parts name

RSP

RSL

RFO, RTO

Rh

R1,R2,R3,R4,R5,R6

R7, R8

R9, R10

C1

C2

C3

C4,C5,C6,C7

C8

Typ.value

0.33

0.5

0.33

200

10

10

10

330

180

0.1-0.01

10-33

0.1

C9 470 pF

Unit

Ω

Ω

Ω

Ω

kΩ

kΩ

kΩ

pF

pF

µF

µF

µF

Note

Ilim1F=1.5[A], Ilim1R=1.0[A], Gain=3.0[A/V]

Ilim=1.0[A], Gain=2.0[A/V]

Gain=1.2[A/V]

Fosc=110kHz

Capacitors against output oscillation in a cold atomosphere.

(The capacitors are not necessary in some application)

Pass condenser for power supply Note 1

REF input noise filter condenser

(The capacitors are not necessary in some application) Note 4

FG output noise filter condenser

(The capacitors are not necessary in some application)

Page 15

PACKAGE OUTLINE

MITSUBISHI SEMICONDUCTOR (LSI)

M63015FP

SPINDLE MOTOR AND 4CH ACTUATOR DRIVER

42P9R-B

HSSOP42-P-450-0.8

E

HE

G

Z1

Lead MaterialWeight(g)JEDEC CodeEIAJ Package Code

Cu Alloy

42

1

D

e

y

z

Detail G

22

F

21

b

A

A2

A1

M

X

L1

Detail F

L

C

e1

Recommended Mount Pad

Symbol

A

1

A

A2

b

c

D

E

e

HE

L

1

L

z

Z1

x

y

b2

e1

l2

e

b2

l2

Dimension in Millimeters

Min Nom Max

—

—

0.27

0.23

17.3

8.2

—

11.63

0.3

—

—

—

—

——

0

—

——

1.27

—

0.10

2.0

0.32

0.25

17.5

8.4

0.8

11.93

0.5

1.765

0.75

—

—

—

¡

0.5

11.43

——

2.2

0.2

—

0.37

0.3

17.7

8.6

—

12.23

0.7

—

—

0.9

0.16

0.1

10

—

¡

Plastic 42pin 450mil HSSOP

Loading...

Loading...