Page 1

8 Mbit (256Kb x32, Burst) Flash Memory

■ SUPPLY VOLTAGE

–VDD= 5V Supply Voltage

–V

– OptionalVPP=12Vforfast Program andErase

■ CONFIGURABLE OPTIONS

– Synchronous or Asynchronous write mode

– Burst Wrap/No-wrap default

– Critical Word X (3 or 4) and Burst Word

■ ACCESS TIME

– Synchronous X-Y-Y-Y Burst Read

– Asynchronous Read: 100ns

■ PROGRAMMING TIME: 10µs typical

■ MEMORY BLOCKS

– 32 equal Main blocks of 256 Kbit

– One Overlay block of 256 Kbit

■ ELECTRONIC SIGNATURE

– Manufacturer Code: 20h

– Device Code: F0h

– Version Code: 0-7h

DESCRIPTION

The M58BF008 is a family of 8 Mbit non-volatile

Flash memories that can be erased electrically at

the blocklevel and programmed in-system. Family

members are configured during product testingfor

a specific Synchronous or Asynchronous Write

mode, a Burst default of Wrap or No-wrap and for

Critical Word X = 3or 4 and Burst WordY = 1 or 2

latency times. The Main memory array matrix allows each of the 32 equal blocks of 256 Kbit to be

erased separately and re-programmed without affecting other blocks. The memory features a

256 Kbit Overlay block having the same address

space asthe firstMain memoryblock. TheOverlay

block provides a secure storage area that is controlled by special Instructions and an external input. A separate supply V

Output signals to be at 3.3Vlevels, while the main

supply VDDis 5V.

= 3.3V Input/Output Supply Voltage

DDQ

Y (1 or 2) latency times

up to 40MHz

allows the Input/

DDQ

BGA

LBGA80 (ZA)

10 x 8 solder balls

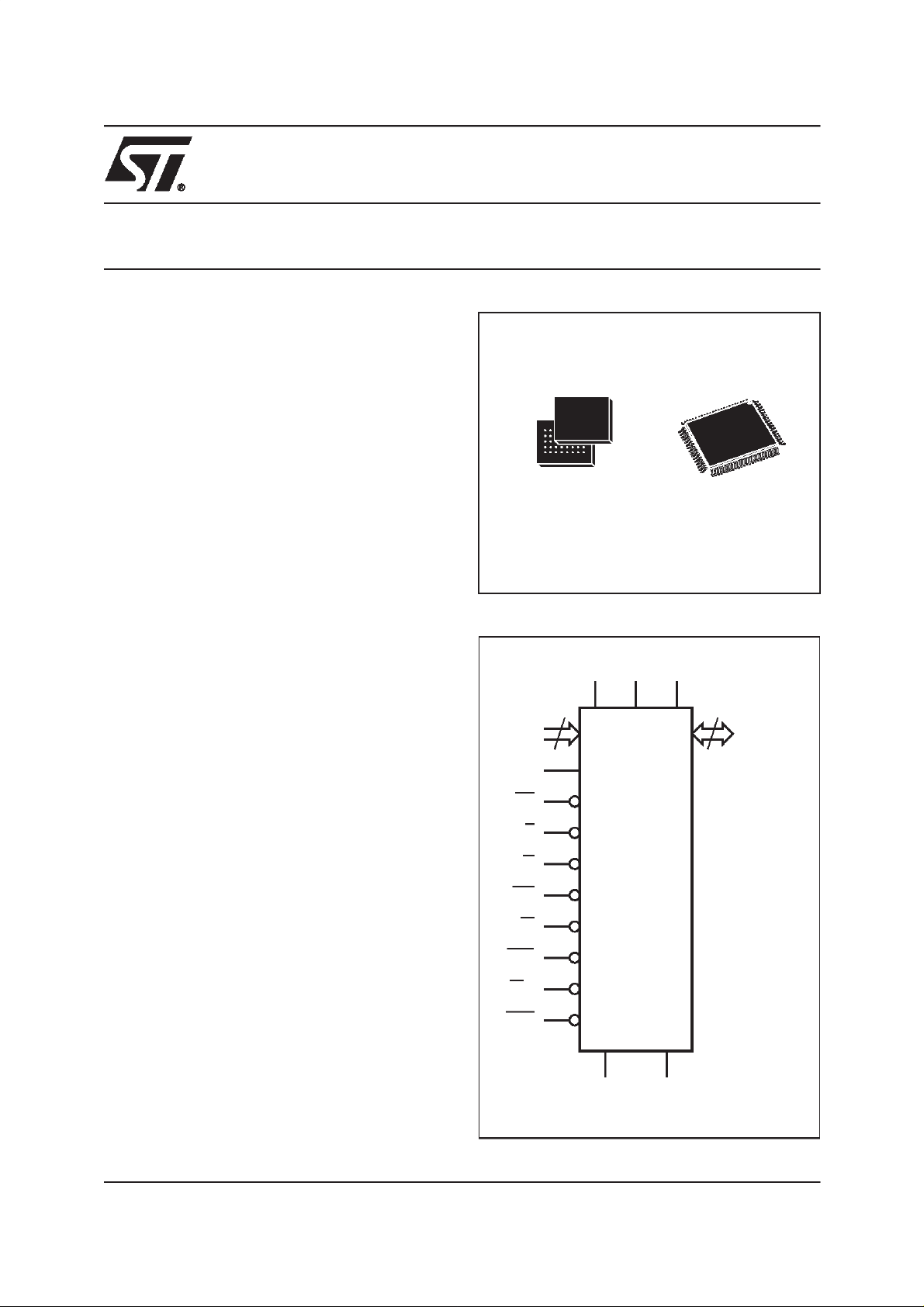

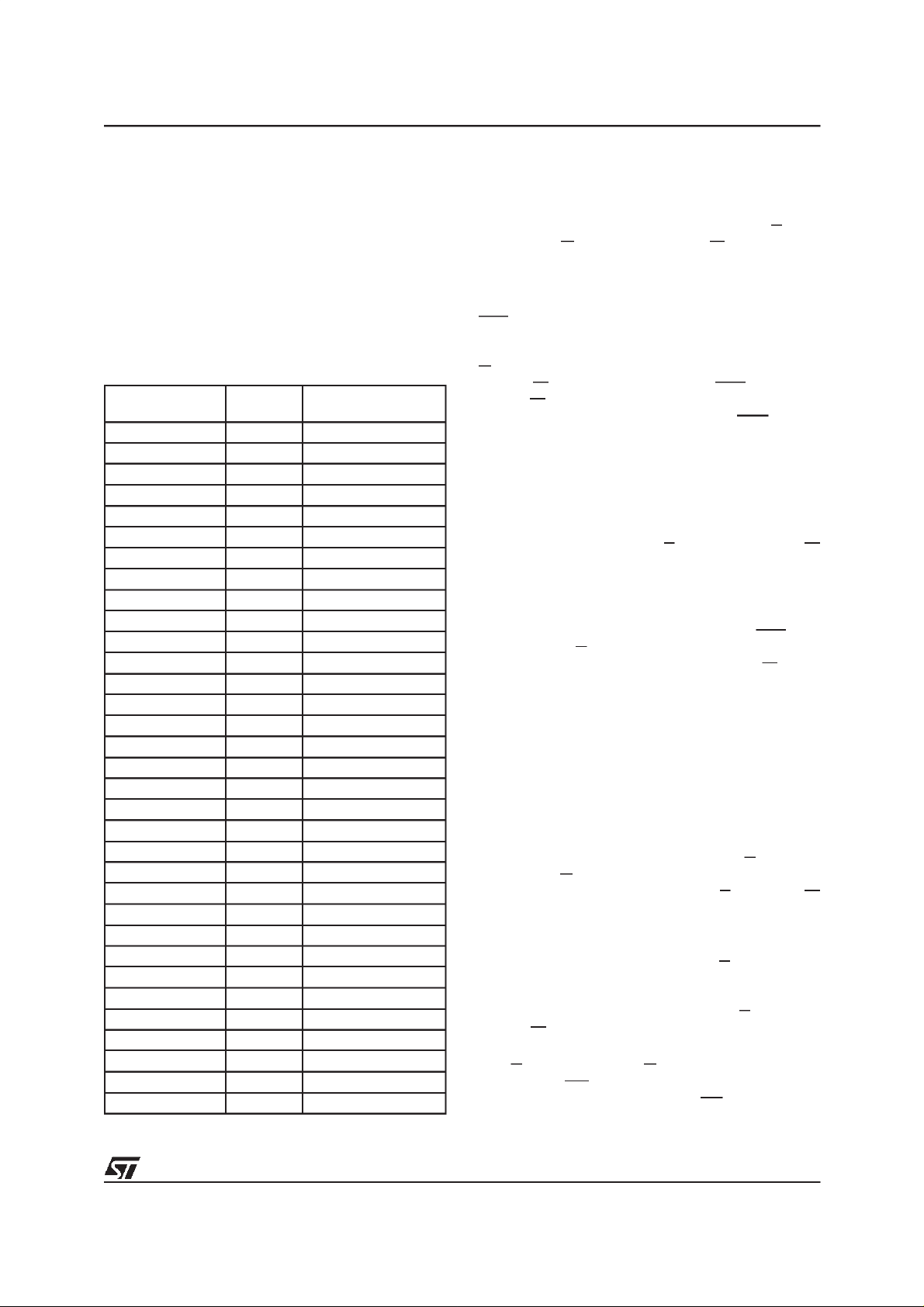

Figure 1. Logic Diagram

V

V

DD

DDQVPP

18

A17-A0

CLK

RP

E

G

GD

W

LBA

WR

BAA

M58BF008

V

SS

M58BF008

PRELIMINARY DATA

PQFP80 (D)

32

DQ31-DQ0

V

SSQ

AI02656B

February 2000

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to change without notice.

1/36

Page 2

M58BF008

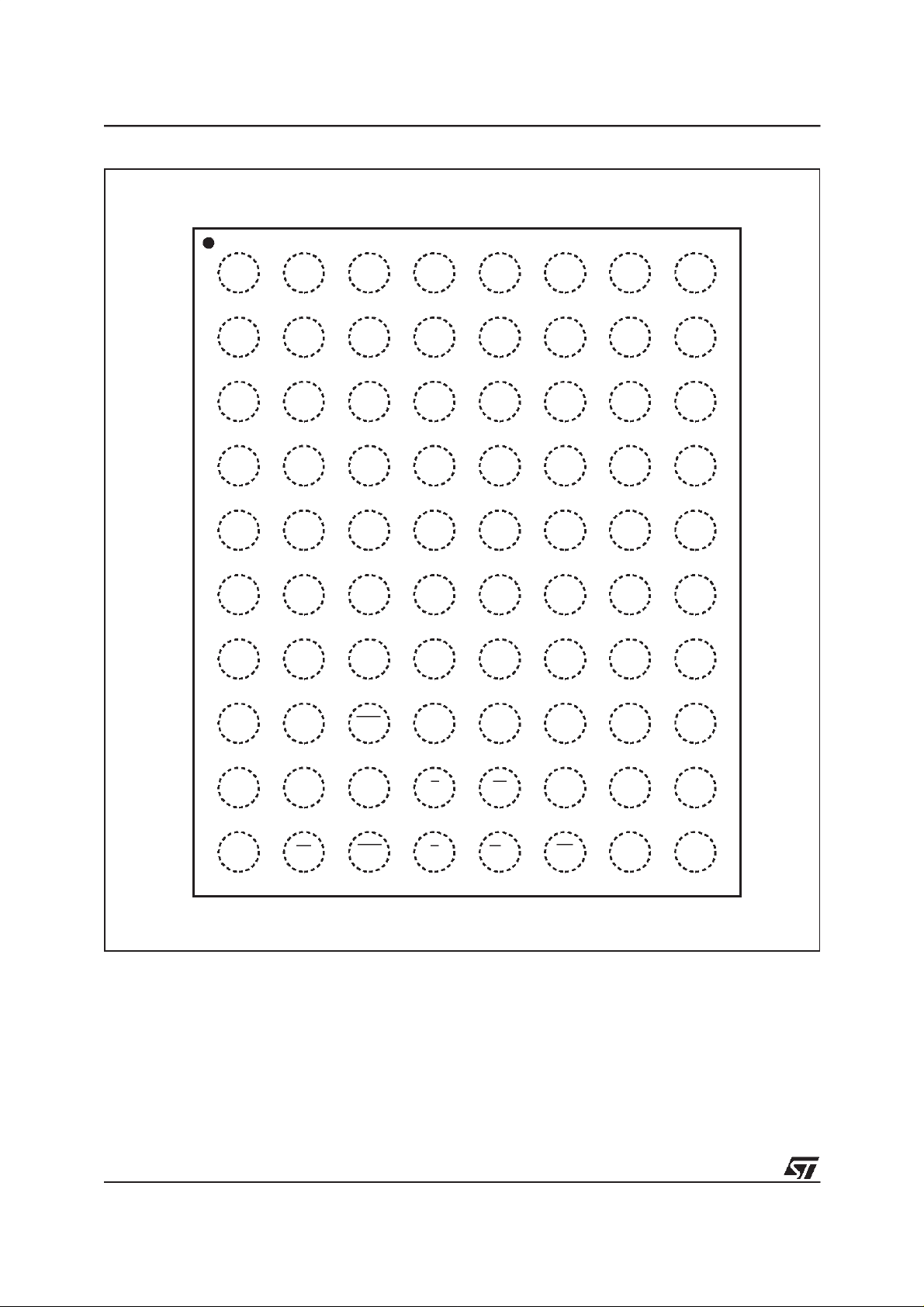

Figure 2. LBGA Connections (Top view through package)

87654321

A16 A9

A14A17B

DQ3DQ4D

G

A12 A10

V

DDQ

V

SSQ

V

DDQ

V

SSQ

A11A13A15A

V

DD

DU

DU DU

DU DU

V

DDQ

V

V

SS

PP

DU

V

V

V

V

DDQ

SSQ

SSQ

DDQ

DQ30

DQ26DQ6DQ8F

A3A4A8

A2A1A6A7

DQ31A5A0DQ0DQ2DQ1C

DQ28

DQ27DQ29DQ5DQ7E

DQ25

DQ24DQ23DQ9DQ10

2/36

H

J

K

RP

BAADQ12DQ11

LBA

V

SS

G

E

DD

W

WR

DQ19DQ201DQ22V

DQ17DQ21DQ18CLKDQ13DQ14

DQ16DUGDDQ15

AI02668

Page 3

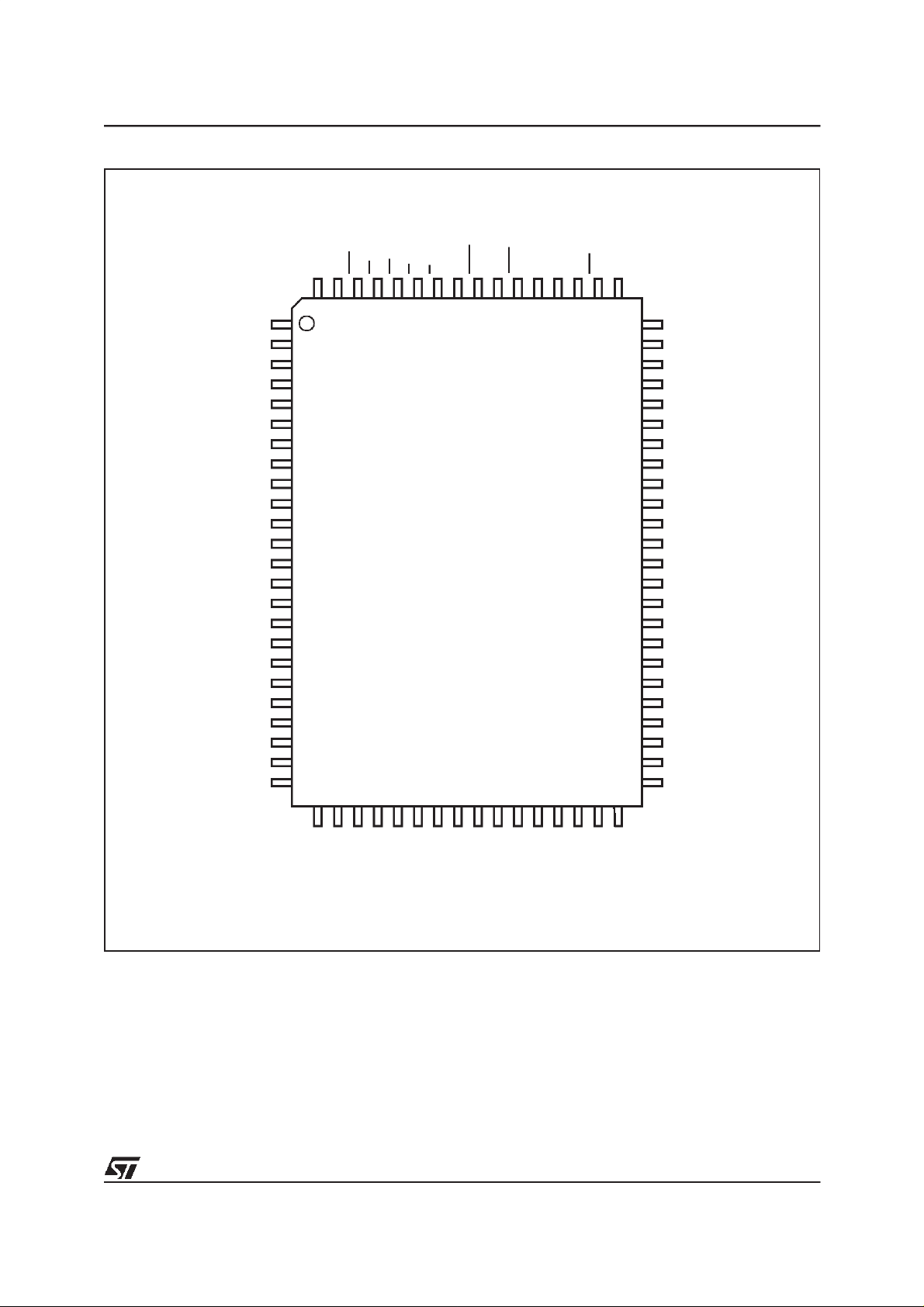

Figure 3. PQFP Connections

GDWRWNCG

NC

M58BF008

SS

DD

E

V

LBA

BAA

V

NC

NC

CLK

RP

DDQ

V

DQ16

DQ17

DQ18

DQ19

V

DDQ

V

SSQ

DQ20

DQ21

DQ22

DQ23

DQ24

DQ25

DQ26

DQ27

V

DDQ

V

SSQ

DQ28

DQ29

DQ30

DQ31

NC

A0

A1

A2

1

12

73

M58BF008 53

32

DQ15

DQ14

DQ13

DQ12

V

SSQ

V

DDQ

DQ11

DQ10

DQ9

DQ8

DQ7

DQ6

DQ5

DQ4

V

SSQ

V

DDQ

DQ3

DQ2

DQ1

DQ0

NC

NC

A17

A16

A3

A4

A5

A6

A7

A8

V

SS

V

PP

V

DD

A9

A10

A11

A12

A13

A14

AI02661

A15

3/36

Page 4

M58BF008

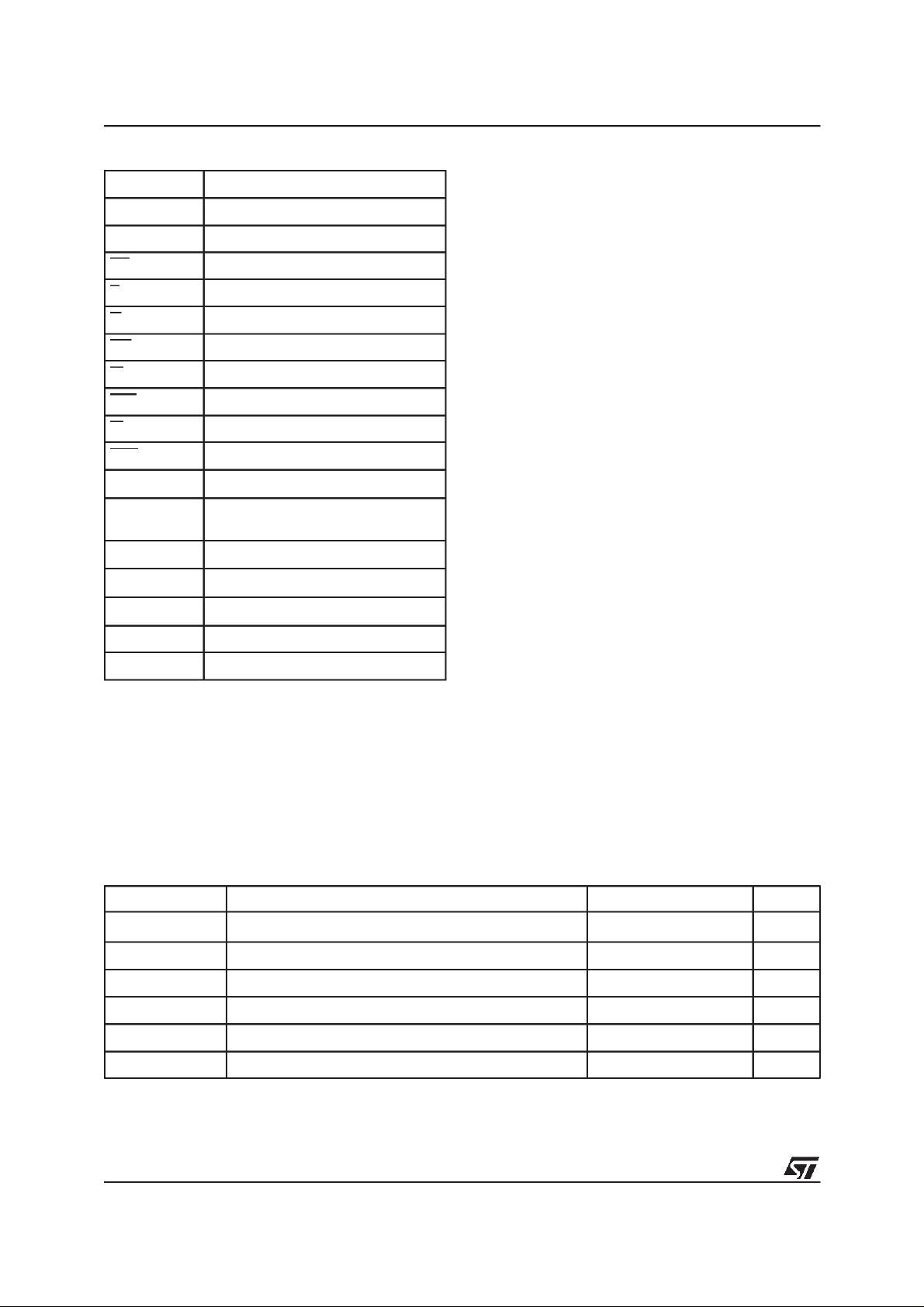

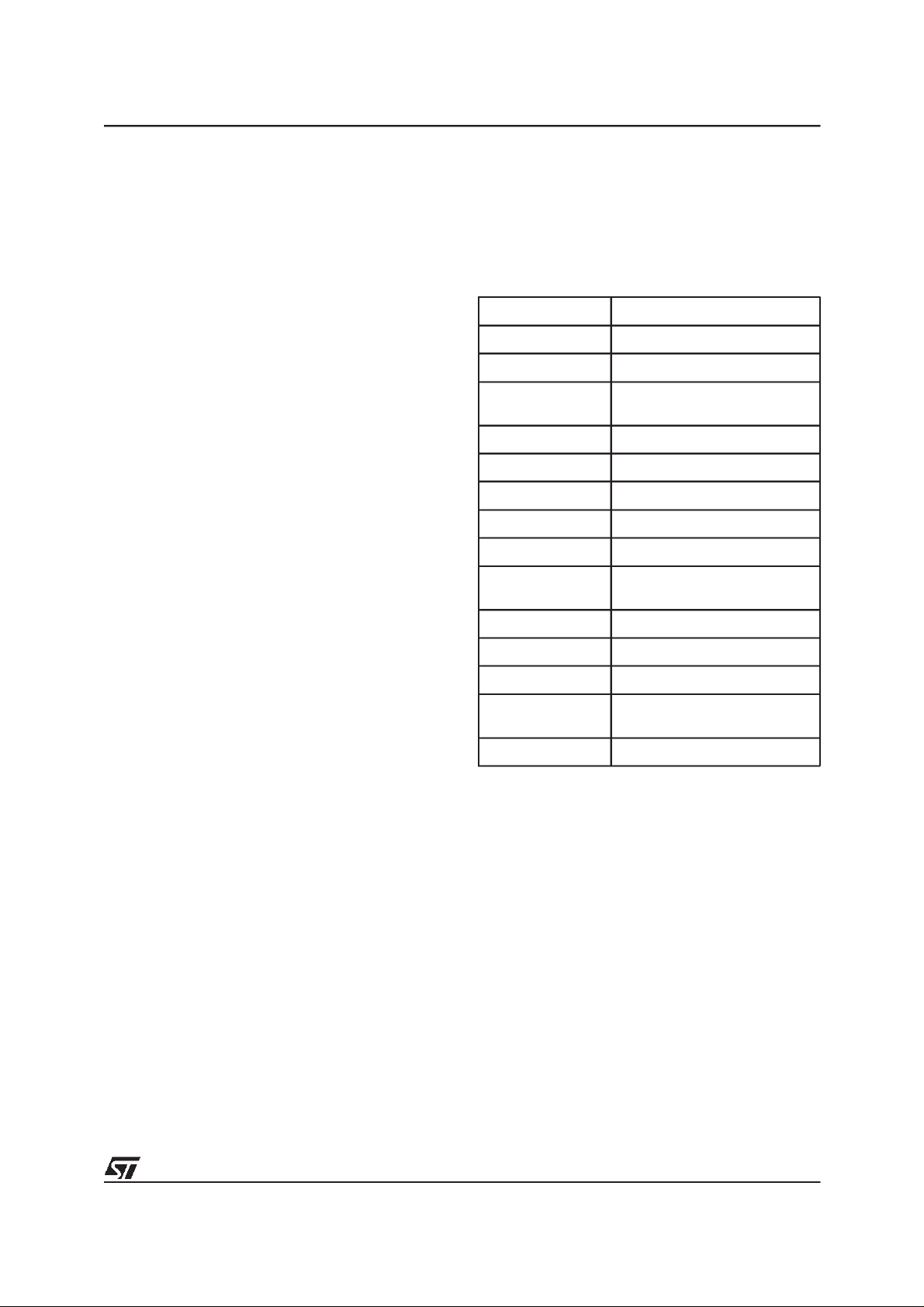

Table 1. Signal Names

A0-A17 Address Inputs

DQ0-DQ31 Data Input/Output

CLK System Clock

RP Reset/Power-down

E Chip Enable

G Output Enable

GD Output Disable

W Write Enable

LBA Load Burst Address

WR Write/Read

BAA Burst Address Advance

V

DD

V

DDQ

V

PP

V

SS

V

SSQ

NC Not Connected Internally

DU Don’t Use as Internally Connected

Supply Voltage

Supply Voltage for Input/Output

Buffers

Program Supply Voltage

Ground

Input/Output Ground

A Command Interface decodes the Instructions

written to the memory to access or modify the

memory content, to toggle the enable/disable of

read access to the Overlay block, to toggle the

burst Wrap/No-wrap or to toggle the Synchronous

or Asynchronous Read mode. A Program/Erase

Controller (P/E.C.) executes the algorithms taking

care of the timings necessary for program and

erase operations. The P/E.C. also takes care of

verification to unburden the system microprocessor, while a Status Register tracks the status of

each operation.

The following Instructions are executed by the

memory in either Asynchronous or Synchronous

mode.

Access or modify memory content:

- Read Array

- Read or Clear Status Register

- Read Electronic Signature

- Erase Main memory block or Overlay block

- Program Main memory or Overlay memory

- Program Erase Suspend or Resume

Toggle:

– Asynchronous/Synchronous Read

– Overlay Block Read Enable/Disable

– Burst Wrap/No-wrap

The M58BF008 devices are offered in PQFP80

and LBGA80 1.0mm ball pitch packages.

When the VPPsupply is at VSSthis prevents programming and erasure of the memory blocks and,

in addition, it prevents reading of the Overlay

block. When the VPPsupply is at 5V it enables

both in-system program/erase and read access to

the Overlay block. For a limited time and number

of program/erase cycles the VPPsupply may be

raised to 12V to provide fast program and erase

times.

Table 2. Absolute Maximum Ratings

Symbol Parameter Value Unit

T

A Ambient Operating Temperature

T

BIAS

T

STG

V

IO

V

DD,VDDQ

V

PP

Note: 1. Stresses above those listed in the Table”Absolute Maximum Ratings” may cause permanent damage to thedevice.

Temperature Under Bias –40 to 125 °C

Storage Temperature –55 to 150 °C

Input Output Voltage

Supply Voltage –0.6 to 7 V

Program Voltage –0.6 to 13.5 V

(1)

–40 to 125 °C

–0.6 to V

DDQ

+0.6

V

4/36

Page 5

M58BF008

ORGANISATION

The M58BF008 has a data path width of 32 bit

(Double-Word) and isorganised as a Main memory array of 32 blocks of 256 Kbit plus an Overlay

block of 256 Kbit having the same address space

as the first Main memory block. The memory map

is shown in Table 3.

The memory is addressed by A0-A17 which are

static for Asynchronous or latched for Synchronous operation. Data Input/Output is static or

latched on DQ0-DQ31, these signals output data,

Table 3. Block Addresses

#

31 256 3E000-3FFFF

30 256 3C000-3DFFF

29 256 3A000-3BFFF

28 256 38000-39FFF

27 256 36000-37FFF

26 256 34000-35FFF

25 256 32000-33FFF

24 256 30000-31FFF

23 256 2E000-2FFFF

22 256 2C000-2DFFF

21 256 2A000-2BFFF

20 256 28000-29FFF

19 256 26000-27FFF

18 256 24000-25FFF

17 256 22000-23FFF

16 256 20000-21FFF

15 256 1E000-1FFFF

14 256 1C000-1DFFF

13 256 1A000-1BFFF

12 256 18000-19FFF

11 256 16000-17FFF

10 256 14000-15FFF

9 256 12000-13FFF

8 256 10000-11FFF

7 256 0E000-0FFFF

6 256 0C000-0DFFF

5 256 0A000-0BFFF

4 256 08000-09FFF

3 256 06000-07FFF

2 256 04000-05FFF

1 256 02000-03FFF

0 256 00000-01FFF

Overlay Block 256 00000-01FFF

Size

(Kbit)

Address Range

status orsignatures read from thememory, or they

input data to be programmed or Instruction commands to the Command Interface.

Asynchronous mode

Memorycontrol isprovidedby ChipEnable E, Output Enable G and Write Enable W for read and

write operations.

Synchronous mode

Memorycontrol isprovided byLoad BurstAddress

LBA which loads a read or write address. A Synchronous Single Read or a Synchronous Burst

Read is performed under control of Output Enable

G. Synchronous Write is controlled by Write/Read

Enable WR, Load Burst Address LBA and Write

Enable W. Internal advance of theburst address is

controlled by Burst Address Advance BAA.

SIGNAL DESCRIPTIONS

See Figure 1 and Table 1.

Address Inputs (A0-A17). The address signal

A17 is the MSB and A0 the LSB.

In theAsynchronous mode the addresses must be

stable before Chip Enable E and Write Enable W

go to VIL. They mustremain stable during the read

or write cycle.

In the Synchronous modes, the addresses are

latched by the rising edge of the System Clock

CLK when both Latch Burst Address LBA and

Chip Enable E are at VIL. The addresses are

latched fora read operation if Write/ReadWR is at

VIHor for a write operation when it is at VIL.

Data Input/Output (DQ0-DQ31). The data signal

DQ31 is the MSB and DQ0 the LSB. Commands

are input on DQ0-DQ7.

Data input is a Double-Wordto beprogrammed in

the memory or an Instruction command to the

Command Interface.Data is read from theMain or

Overlay memory blocks, the Status Register orthe

Electronic Signature.

In the Asynchronous mode data is read when the

addresses are stable and Chip EnableE and Output Enable G are at VIL. Commands or address/

data are written when Chip Enable E and Write W

are at VIL.

In the Synchronous mode, after addresses are

latched, data is read on a rising edge of the System Clock CLK when Chip Enable E is at VILand

if Output Enable was at VILon the previous rising

clock edge. Data is written on a rising edge of the

System Clock CLK when Chip EnableE and Write

Enable W are at VIL.

The outputs are high impedance when Chip Enable E or OutputEnable G are atVIH, or whenOutput Disable GD is at VIL. Outputs are also high

impedance when System Reset RP is at VIL.

5/36

Page 6

M58BF008

System Clock (CLK). All synchronous signals

are input and output relative to the System Clock.

Synchronous input signals must respect the setup and hold times relative to theSystem Clock rising edge.

Reset/Power-down (RP). The Reset/Power-

down RP input provides a hardware reset for the

memory. When Reset/Power-down RP is at V

IL

the memoryis reset and in thePower-down mode.

In this mode the outputs are high impedance and

the current consumption is minimised. When Reset/Power-down RP is at VIHthe memory is in the

normal operating mode. When leaving the Powerdown mode the memory entersthe Asynchronous

Read Array mode.

Reset/Power-down has a weak pull-up resistor to

V

and will assume a high level if not connect-

DDQ

ed.

Chip Enable (E). When the Chip Enable E input

is at VILit activates the memory control logic, input

buffers, decoders and sense amplifiers. When

Chip Enable E is at VIHthe memory is deselected

and the power consumption is reduced to the

standby level.

Output Enable (G). Output EnableG controls the

data output buffers. In the Asynchronous mode

data is output when Output Enable G is at VIL.In

the Synchronous mode, Output Enable G is sampled on the rising edge of the System Clock CLK.

If OutputEnable E is at VILthen valid output data

on DQ0-DQ31 can be read at the next risingedge

of the System Clock CLK.

Output Disable (GD). In the Asynchronous

mode thedata outputsDQ0-DQ31 arehigh impedance when Output Disable GD is at VIL, irrespective of the state of Output Enable G. In

Synchronous mode Output Disable GD is sampled, together with Output Enable G, on the rising

edge of the System Clock CLK. If Output Disable

is at VILthenthe data outputsDQ0-DQ31 arehigh

impedance at the next rising edge of the System

Clock CLK, irrespective of the state of Output Enable G.

Output Disable has a weak pull-up resistor to

V

and willassume a high level if not externally

DDQ

connected.

Write Enable (W). The Write Enable W input

controls the writing of commands or input data. In

the Asynchronous mode commands or data are

written when Chip Enable E and Write Enable W

are at VIL. In the Synchronous mode with Chip Enable E at VIL, input data is sampledif Write Enable

WisatVILon the rising edge of the System Clock

CLK.

Load Burst Address (LBA). In the Asynchronous mode LoadBurst Address LBA isDon’t Care

(but if it falls during an asynchronous read then a

new read cycle is started). In the Synchronous

mode Load BurstAddress LBAenables latching of

the burst starting address forSynchronous read or

write. The address is latchedon the rising edge of

the System Clock CLK if Load Burst Address LBA

is at VIL.

Write/Read (WR). Write/Read WR is used in

Synchronous mode to control write or readoperations. If Load Burst Address LBA is at VILand

Write/Read is at VILthen the rising edge of the

System Clock CLK latches a write address. If

Write/Read is at VIHthen a read address is

latched.

Write/Read has a weak pull-up resistor to V

DDQ

and will assume a high level if not externally connected.

Burst Address Advance (BAA). When Burst

Address Advance BAA is at VIL, the rising edge of

the System Clock CLK advances the burst address. When BurstAddress AdvanceBAA isat V

IH

the advance is suspended.

VDDSupply Voltage. The supply VDDprovides

the power to the internal circuits of the memory.

The VDDsupply voltage is 4.5 to 5.5V.

V

Input/Output Supply Voltage. The Input/

DDQ

Output supply V

provides thepower for the in-

DDQ

put/outputs of the memory, independent from the

supply VDD. The Input/Output supply V

DDQ

may

be connected to the VDDsupply or it can use a

separate supply of 3.0 to 3.6V.

VPPProgram/Erase Supply Voltage. The Program/Erase supply VPPis used for programming

and erase operations. The memory normally executes program and erase operations at the supply

V

voltage levels.

PP1

In a manufacturing environment, programming

may be speeded upby applying ahigher V

PPH

level to the VPPProgram/EraseSupply. Thisis not intended forextended use. The V

supply may be

PPH

applied for atotal of 80 hours maximumand during

program anderase for a maximum of 1000 cycles.

Stressing the device beyond these limits could

damage the device.

When VPPProgram/Erase supply is at VSSall

blocks are protected from programming or erase.

Leaving VPPfloating is equivalent to connecting it

to VSSdue to an internal pull-down circuit.

Ground (VSSand V

). The Ground VSSis t he

SSQ

reference for the internal supply voltage VDD.The

Ground V

supply V

is the reference for the Input/Output

SSQ

.

DDQ

6/36

Page 7

M58BF008

DEVICE OPERATIONS

See Table 4 for Asynchronous or Synchronous

Bus Operations.

In theAsynchronous modethe memoryis selected

with Chip Enable E Low. The data outputs are enabled by Output Enable G Low or disabled by Output Disable GD Low. Datais input byWrite Enable

W Low.

In the Synchronous mode the memory latches addresses and data (input or output) on the rising

edge of the System Clock CLK. Burst address

latching is enabled by Load Burst Address LBA

Low with Write/Read WR Low for a write cycle or

High for a read cycle.

Data outputs are enabled for reading on the rising

edge of the System Clock CLK when Output Enable G is low. Data is input on the rising edge of

the System Clock CLK when Write Enable W is

Low.

power-down mode when Reset/Power-Down RP

is Low.

Read. Read operations are used to output the

contents of the memory, the Electronic Signature

or the Status Register. The data read depends on

the previous Instruction given to the memory.

Read operations can be Asynchronous or Synchronous, witha single or burst read.On power-up

the device is in Asynchronous read mode, the Instruction Asynchronous/Synchronous Read Toggle ART can be used to enter the Synchronous

read mode.

– Asynchronous Read. To read a data Double-

Wordin Asynchronousmode the address inputs

must be stable and Chip Enable E must be Low

during theread cycle. Output Enable Gmust be

Low and Output Disable GD High. The Load

Burst Address LBA is Don’t Care, but its falling

edge will start a new read cycle.

The memory is deselected and in standby mode

when Chip Enable E is High, and it is reset or in

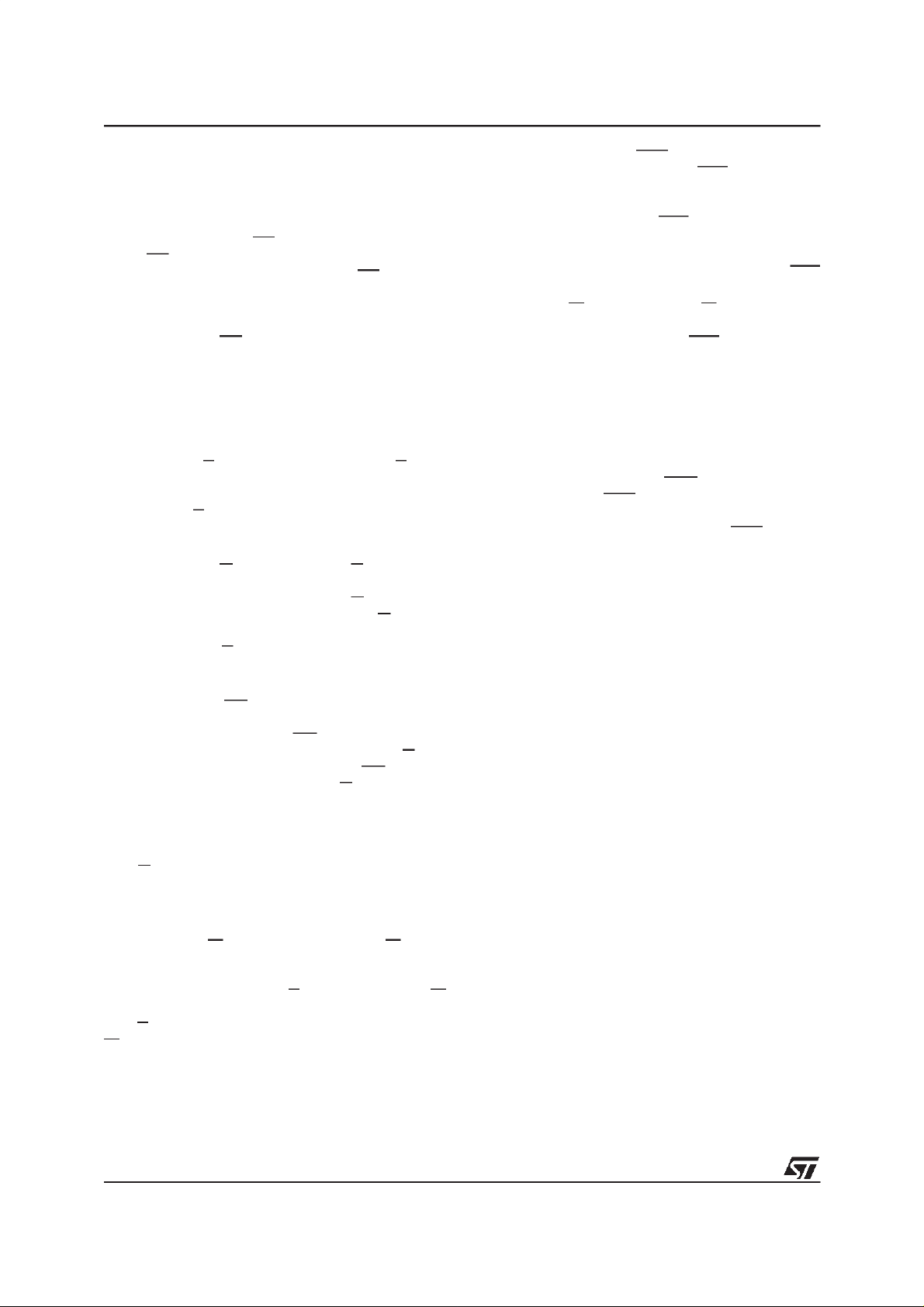

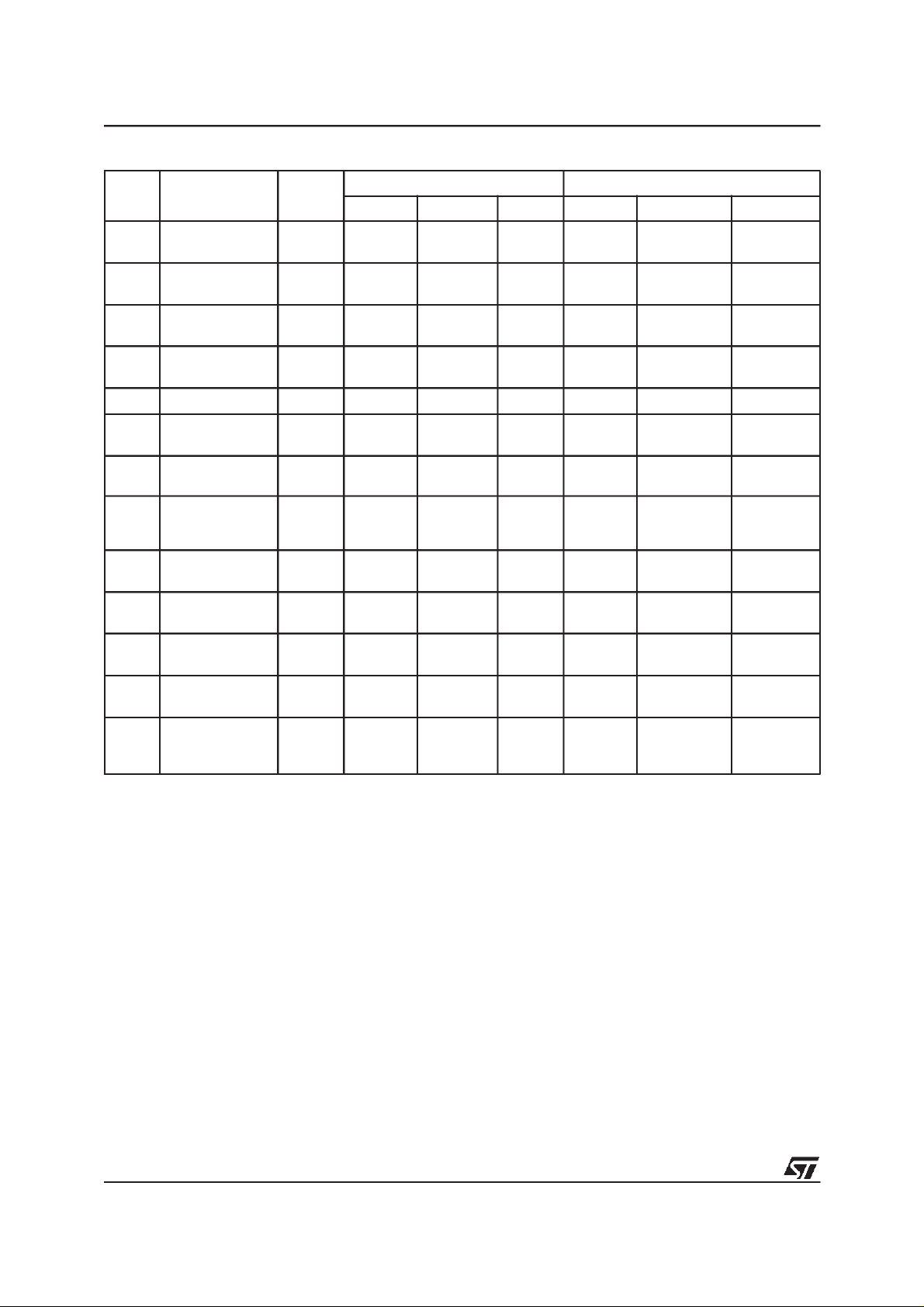

Table 4. Bus Operations

Operation RP CLK E LBA WR W GD G DQ0-DQ31

Asynchronous Read

Asynchronous Write

Synchronous Read

Synchronous Write Address for

Read

Synchronous Write Address for

Command

Synchronous Data Write

Output Disabled by G

Output Disabled by GD

Standby

Reset / Power-down

Note: 1. See Device Operations, Instructions and Commands, sections for more details.

2. X=V

or V

IL

IH.

(1,2)

V

IH

V

IH

V

IH

V

IH

V

IH

V

IH

V

IH

V

IH

V

IH

V

IL

V

X

V

X

V

V

V

V

V

X

V

X

V

X

XX

IL

XX

IL

V

IL

V

IL

V

IL

V

IL

IL

IL

IH

V

IH

IL

IL

IH

IH

V

IH

V

IL

V

IH

XXX

XXX

XXXXX Hi-Z

XXXXXXX Hi-Z

V

V

V

IH

IL

X

X

IH

V

IH

V

IH

V

IH

XVIHV

V

V

IL

IH

V

IH

V

IL

V

V

V

V

V

V

IL

IH

IL

IH

IH

IH

IH

Data Output

Data Input

Data Output

Data Input

Hi-Z

X Hi-Z

X

X

Table 5. Read Electronic Signature

Code RP E G W A0 A1 A2-A17 DQ0-DQ31

Manufacturer

Device

Version

Note: ”x” = version level. The first version is ”0” and it can have a value up to ”7”.

V

IH

V

IH

V

IH

V

IL

V

IL

V

IL

V

IL

V

IL

V

IL

V

IH

V

IH

V

IH

V

IL

V

IH

V

IL

V

IL

V

IL

V

IH

Don’t Care 00000020h

Don’t Care 000000F0h

Don’t Care 0000000xh

7/36

Page 8

M58BF008

– Synchronous Single Read. To read a single

data Double-Word in Synchronous mode Chip

Enable E must be Low. Load Burst Address

LBA must be Low for one System ClockCLK rising edgewith Write/Read WRHigh. This latches

the read address, after which the address bus

inputs are Don’t Care. The Output Enable G is

Low for a single System Clock CLK cycle. The

Double-Word of valid data is output on the next

System Clock CLK rising edge.

– Synchronous Burst Read. To read a burst of

four Double-Words in Synchronous mode Chip

Enable /E must be Low. Load Burst Address

LBA must be Low for one System ClockCLK rising edgewith Write/Read WRHigh. This latches

the first address of the burst sequence, after

which the address bus inputs are Don’t Care.

The Output Enable G is driven Low before the

burst output sequence. Four Double-Words of

data are output on the subsequent System

Clock CLK rising edges if Burst Address Advance BAA is maintainedLow. The address advance for synchronous burst read is suspended

if Burst Address Advance BAA goes High and

the output data remains constant. The data bus

will go high impedanceon the rising edge ofthe

System Clock CLK after Output Enable G goes

High.

The burst timing depends on the device configuration for theCritical Word X and BurstWord Y

latency times and the choiceof wrap orno-wrap

for burst addresses. The operation burst wrap is

shown in Table 13. The wrap sequence uses

only the address bits A0 and A1 and does not

repeat after the last Double-Wordhas been output.

Read Overlay Block. The Overlay block can be

read, as for a Main block, after it has been enabled. To enable the Overlay block the Overlay

Block Enable bit OBEB and the OverlayBlock Status bit OBS in the Status Register must be set to

’1’- see Table 9.

The Overlay Block Enable bit OBEB can be set to

’1’in three ways - see Table 10:

– By Toggling the Reset/Power-Down signal RP

with the VPPProgram/Erase supply in the range

V

PP1

or V

PPH.VPP

out of range will reset the

OBEB bit to ’0’.

– By a leaving power-on reset with VPPProgram/

Erase supplyin the rangeV

PP1

orV

PPH.VPP

out

of range will reset the OBEB bit to ’0’.

– By giving the Overlay Block Enable/Disable for

Read Instruction OBT.

The Overlay Block Status bit OBS monitors the

VPPProgram/Erase supply and will be set to ’1’

when in the range V

PP1

or V

. The Overlay

PPH

block is enabled with OBEB at ’1’ but will not be

read unless OBS status bit is also at ’1’. If it is not

then a read operation will read the contents of the

Main block at the same address.

When the Overlay block is enabled for reading,

only this one block of 256 Kbit is accesible and

none of the other Main blocks may be accessed,

the address signals A13-A17 are Don’tCare.

Read Electronic Signature. The memory contains three Electronic Signature codes identifying

the manufacturer, device and version, which can

be read after giving the Instruction RSIG. The

manufacturer code 00000020h is read when the

address inputs A0 and A1 are at VIL. The device

code 000000F0his read when A0 isat VIHand A1

is at VIL. The version code 0000000xh is read

when A0 is at VILand A1 is at VIH. The codes are

read on DQ0-DQ31,all other address signalinputs

are Don’t Care. See Table 5.

Write. Write operations are used to give commands tothe memory that latch input data and addresses to program or block addresses to erase.

– Asynchronous Write. To write data in the

Asynchronous mode the address inputs must

be stable and Chip Enable E must be Low during thewrite cycle. WriteW mustbe Low andinput data valid on the rising edge is Write W.

– Synchronous Write. To write input data in

Synchronous mode Chip Enable E must be

Low. Load Burst Address LBA must be Low for

one System Clock CLK rising edge with Write/

Read WR Low. This latches the write address,

after which the address bus inputs are Don’t

Care. WhenWrite EnableW isLow input datais

latched on the next System Clock CLK rising

edge.

Output Disable. The data outputs are high impedance when the Output Enable G is High or

when the Output Disable GD is Low, independent

of the level on Output Enable G.

Standby. The memory is in standby when the P/

E.C. is not running, the memory is in read mode

and Chip Enable E is High. The power consumption is reducedto the standby level and the outputs

are high impedance, independent of the Output

Enable G or Write Enable W inputs.

If Chip Enable goes High during a program or

erase operation the device enters the standby

mode when the internal algorithm has finished.

Reset/Power-down. During power-down all internal circuits are switched off, the memory is deselected and the outputs arehigh impedance. The

memoryis inPower-down mode whenReset/Power-down RP isLow. The power consumption is reduced to thepower-down level,independent of the

Chip Enable E, Load Burst Address LBA, Output

Enable G or Write Enable W inputs.

If Reset/Power-down RP is pulled Low during a

program or erase operation thisis aborted and the

memory content is no longer valid.

8/36

Page 9

M58BF008

INSTRUCTIONS AND COMMANDS

The Instructions are listed in Tables 6 and 7. They

may be broadly divided into two types, those that

access or modify the memory content and those

that toggle a mode or function.

The Instructionsthat access ormodify the memory

content include:

– Read Memory Array (RD)

– Read Status Register (RSR) and Clear Status

Register (CLRS)

– Read Electronic Signature (RSIG)

– Erase (EE) and OverlayBlock Erase (OBEE)

– Program (PG) and Overlay Block Program (OB-

PG)

– Program or Erase Suspend (PES) and Program

or Erase Resume (PER)

The Instructions that toggle a mode or function in-

clude:

– Asynchronous/Synchronous Read mode Tog-

gle (ART)

– Wrap/No-wrap Burst mode Toggle (WBT)

– Overlay Block Enable/Disable function Toggle

(OBT)

Instructions are written, in one or more write cy-

cles, to the memory Command Interface (C.I.) for

decoding. The Command Interface is reset to

Read Memory Array at power-up, when exiting

from power-down. Any invalid sequence of commands will also reset the Command Interface to

Read Memory Array.

A Program/Erase Controller (P/E.C.) handles all

the timing and verifies the correct execution of the

Program or Erase instructions. The P/E.C. has a

Status Register which monitors the operations and

which may be read at any time during program or

erase. The Status Register bits indicate the operation and exit status of the internal algorithms.

The VPPProgram and Erase Supply Voltage must

be withinthe range V

PP1

orV

for programming

PPH

or erasure. If VPPout of range, the program or

erase algorithms do not start and Status Register

bit VPPStatus V

will be set to ’1’.

PPS

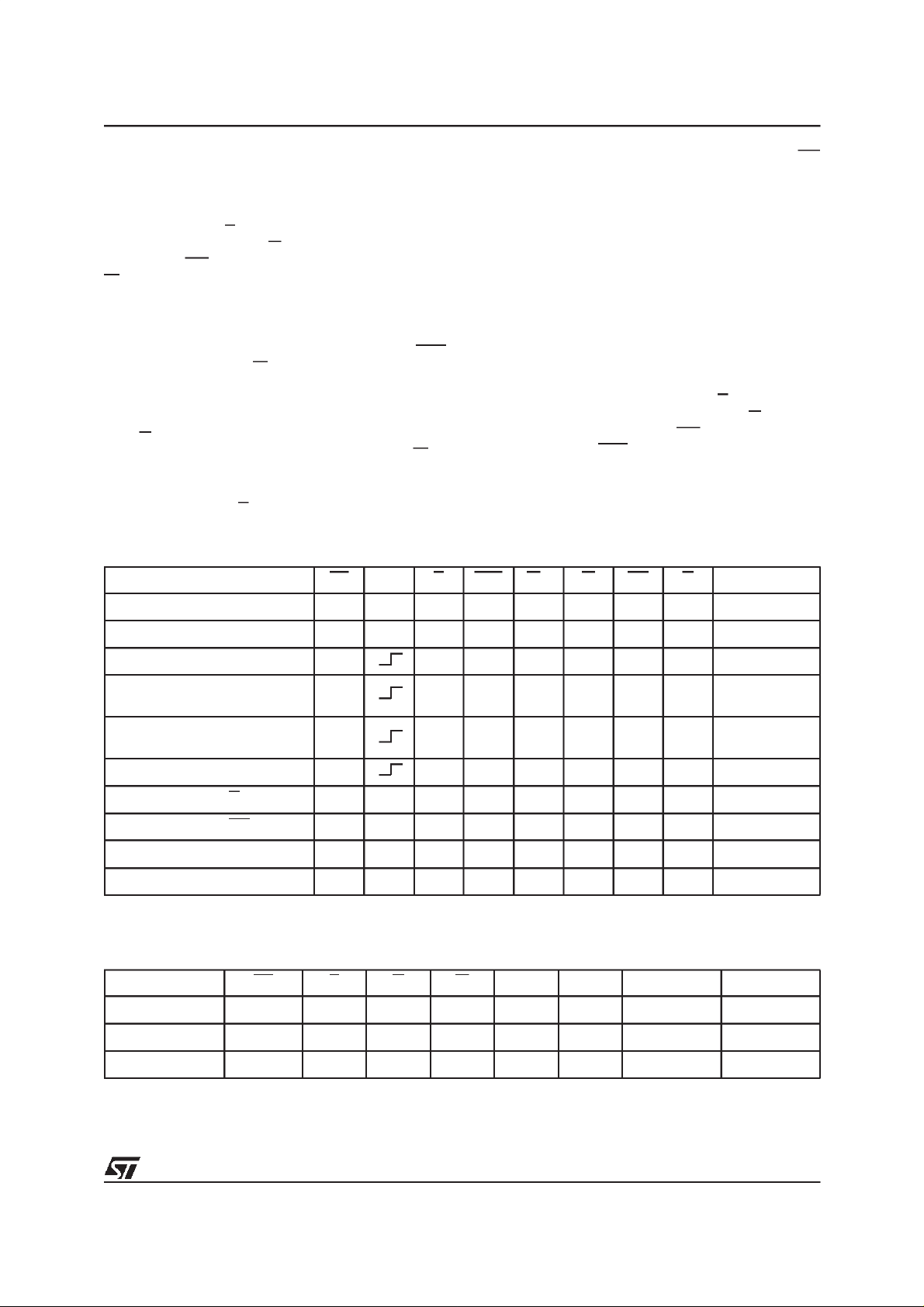

Table 6. Commands

Code Command

02h Overlay Block Erase Set-up

04h Overlay Block Program Set-up

06h

0Dh Overlay Block Erase Confirm

20h Erase Set-up

30h Wrap/No-wrap Burst Toggle

40h Program Set-up

50h Clear Status Register

60h

70h Read Status Register

90h Read Electronic Signature

B0h Program/Erase Suspend

D0h

FFh Read Memory Array

Overlay Block Read Enable/

Disable

Asynchronous/Synchronous

Read Toggle

Program/Erase Resume or

Erase Confirm

9/36

Page 10

M58BF008

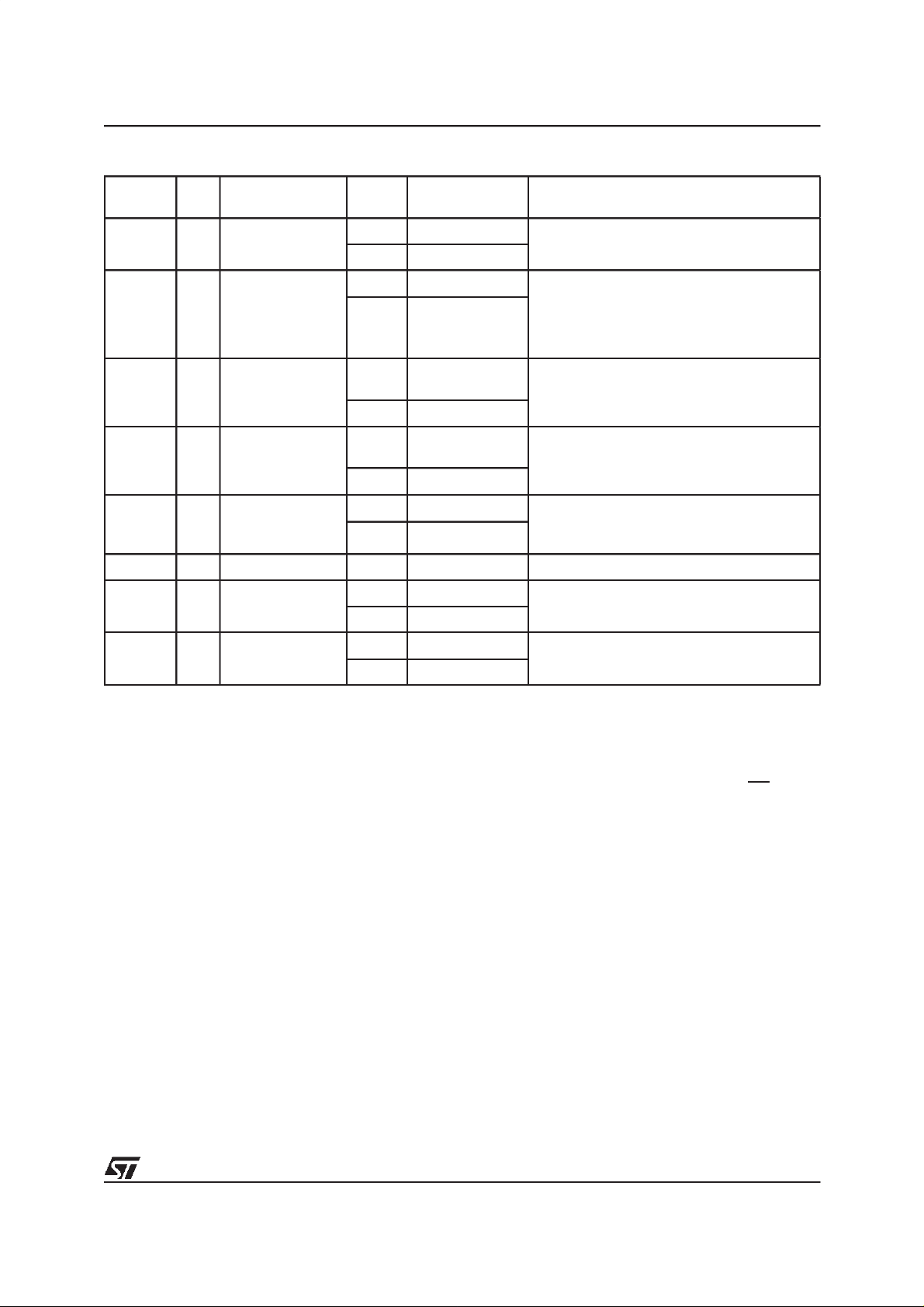

Table 7. Instructions

Mne-

monic

RD

RSR

CLRS

RSIG

EE Erase 2 Write 00000h 20h Write Block Address D0h

Instruction Cycles

Read Memory

Array

Read Status

Register

Clear Status

Register

Read Electronic

Signature

Operation Address Data Operation Address. Data

1+ Write 00000h FFh

1+ Write 00000h 70h Read X

1 Write 00000h 50h

1+++ Write 00000h 90h Read

1st Cycle 2nd Cycle

Read

Read Address Data Output

Signature

Address

Status

Register

Electronic

Signature

OBEE

PG Program 2 Write 00000h 40h Write

OBPG

PES

PER

ART

WBT

OBT

Read Memory Array (RD). The Read Memory

Array instruction consists of one write cycle giving

the command FFh atthe address 00000h. Subsequent read operations will read the addressed location and output the memory data. The data can

be read from the Main memory Array or the Overlay memory block if it is enabled.

Read Status Register (RSR). The Read Status

Register instructionconsists ofone write cycle giving thecommand 70h attheaddress 00000h.Subsequent read operations will output the Status

Register contents. See Table 8 for an explanation

of the Status Register bits. TheStatus Register indicates when a program or Erase operation is

complete and its success or failure. The Status

Register also indicates if the Overlay block is accessible for reading. The Read Status Register instruction may be given at anytime, including while

Overlay Block

Erase

Overlay Block

Program

Program/Erase

Suspend

Program/Erase

Resume

Asynch/Synch

Read Toggle

Wrap//No-wrap

Burst Toggle

Overlay Block

Read En/Dis

Toggle

2 Write 00000h 02h Write

2 Write 00000h 04h Write

1 Write 00000h B0h

1 Write 00000h D0h

1 Write 00000h 60h

1 Write 00000h 30h

1+ Write 00000h 06h Read Read Address Data Output

Clear Status Register (CLRS). The Clear Status

Register instructionconsists of onewrite cycle giving the command 50h at the address 00000h.The

Clear Status Register command clears the bits 3,

4 and 5 of the Status Registerif theyhavebeen set

to ’1’ by the P/E.C. operation. The Clear Status

Register command should be given after an error

has been detected and before any new operation

is attempted. A Read Memory Array command

should also be given beforedata can beread from

the memory array.

Read Electronic Signature (RSIG). The Read

Electronic Signature instruction consists of a first

write cycle giving the command90h atthe address

00000h. This is followed by three read operations

at addresses xxxx0h, xxxx1h and xxxx2h which

output the manufacturer, device and version

codes respectively.

a program or erase operation in progress.

Overlay Block

Address

Program

Address

Overlay Block

Program

Address

0Dh

Data Input

Data Input

10/36

Page 11

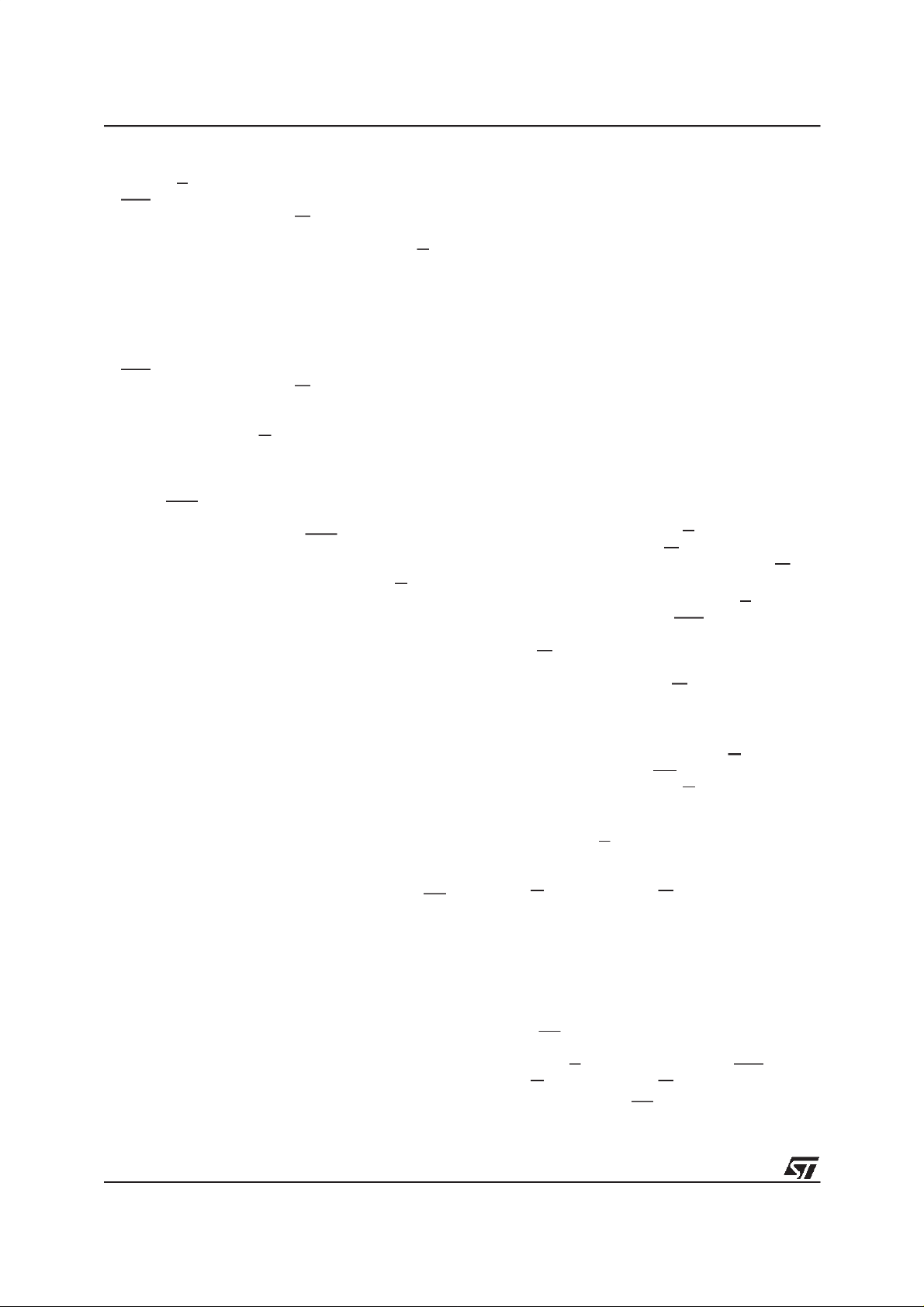

Table 8. Status Register Bits

Mne-

monic

P/ECS 7 P/E.C. Status

PESS 6

ES 5 Erase Status

Bit Name

Program/Erase

Suspend Status

M58BF008

Logic

Level

’1’ Ready

’0’ Busy

‘1’ Suspend On Program/Erase Suspend instruction both

‘0’

’1’ Erase Error or

’0’ Erase Success

Definition Note

Indicates the P/E.C. status, check during

Program or Erase

P/ECS and PESS bits are set to ‘1’.

In Progress or

Completed

Erase Suspend

Either ES bit or PS bit is set to ‘1’.

PESS and either ES or PS bits remain at ‘1’

until Erase Resume instruction is given.

ES bit is set to ‘1’ if either PESS instruction is

given or Erase operation fails. If ES bit is ‘1’,

check PESS bit.

’1’ Program Error or

PS 4 Program Status

V

VPPS 3

Reserved 2

OBEB 1

OBS 0

Status

PP

Overlay Block

Enable Bit

Overlay Block

Status

Program Suspend

’0’ Program Success

V

’1’

’0’

’1’ Enabled

’0’ Disabled

’1’ Activated

’0’ Not Activated

PP

V

PP

Erase (EE). The Erase instruction consists oftwo

write cycles, the first is the eraseset-up command

20h at theaddress 00000h. Thisis followed by the

Erase Confirm command D0h written to an address within the block to be erased. If the second

is not the Erase Confirm command the Status

Register bits 4 and 5 are set to ’1’and the instruction aborts. While erasing is in progress only the

Read Status Registerand Erase Suspend instructions are valid.

Blocks are erased one at a time. An erase operation sets all bits in a block to ’1’. The erase algorithm automatically programs all bits to ’0’ before

erasing the block to all ’1’s.

Read operations output the Status Register after

the erase operation has started. The Status Register bit 7 is ’0’ whilethe erase is in progress andis

set to’1’when it is completed.After completionthe

Status Register bit 5 is set to ’1’ if there has been

an erase failure.

Erasure should not be attempted when the V

PP

Program/Erase Supply Voltage is out of the range

V

PP1

or V

as the results will be uncertain. The

PPH

PS bit is set to ‘1’ if either PESS instruction is

given or Program operation fails.If PSbit is ‘1’,

check PESS bit.

Invalid VPPS bit is set to ‘1’ if initially VPPis not V

OK

nor V

are executed.

OBEB bit is set to ‘1’ when OverlayBlock is

Enabled.

OBS bit is set to ‘1’ when OBEB is ‘1’ and V

is in the range V

, when Program or Erase Instruction

PP1

PP1

or V

PPH

.

Status Register bit 3 is set to’1’ if VPPis not within

the allowedranges whenerasing is attempted or if

it falls out of the ranges during erase execution.

The erase operation aborts if VPPdrops out of the

allowed range or if Reset/Power-down RP falls to

VIL. As data integrity cannot be guaranteed when

the erase operation is aborted, the erase must be

repeated.

A Clear Status Register instruction must be given

to clear the Status Register bits.

Overlay Block Erase (OBEE). The Overlay

Block Erase instruction consists of two write cycles, the first is the Overlay block erase set-up

command 02h at the address 00000h. This is followed by the Overlay Block Erase Confirm command 0Dh written to an address withinthe Overlay

block. If the secondis not the Overlay Block Erase

Confirm command the Status Register bit 5 is set

to ’1’ and theinstruction aborts. While erasing is in

progress only theRead Status Register instruction

is valid.

The operation is executed as described for the

Erase (EE) instruction of the Main memory array.

A Clear Status Register instruction must be given

to clear the Status Register bits.

PPH

PP

11/36

Page 12

M58BF008

Program (PG). The Program instruction consists

of two write cycles, the first is the program set-up

command 40h at the address 00000h. This is followed by asecond write cycle tolatch the address

and data to be programmed. This second command starts the P/E.C. A program operation can

be aborted by writing FFFFFFFFh to any address

after the program set-up command has been given. While programming is in progress only the

Read Status Register and Program Suspend instructions are valid.

Read operations output the Status Register after

the program operation has started. The Status

Register bit 7 is ’0’ while programming is in

progress and is set to ’1’ when it is completed. After completion the Status Register bit 4 is set to ’1’

if there has been a programming failure.

Programming should not be attempted when the

VPPProgram/Erase Supply Voltage is out of the

range V

PP1

or V

as the results will be uncer-

PPH

tain. The Status Register bit 3 is set to ’1’if VPPis

not within the allowed ranges when programming

is attempted or if it falls out of the ranges during

program execution.

The program operation aborts if VPPdrops out of

the allowed ranges or if Reset/Power-Down RP

falls to VIL. As data integrity cannot beguaranteed

when the program operation is aborted, the memory block must be erased and programming repeated.

A Clear Status Register instruction must be given

to clear the Status Register bits.

Overlay Block Program (OBPG). The Overlay

Block Program instruction consists of twowrite cycles, the first is the program set-up command 04h

at the address 00000h. This is followed by a second write cycle to latch theaddress and data to be

programmed. This second command starts the P/

E.C.

The operation is executed as described for the

Program (PG) instruction of the Main memory array.

While programming of the Overlay block in

progress onlythe ReadStatus Registerinstruction

is valid.

Program/Erase Suspend (PES). As memory

erasure takes of the order of seconds to complete

and programming a few microseconds, a Program/Erase Suspend instruction is implemented.

Program/Erase Suspend interrupts the operations

to allow reading or programming in a block other

than one in whichprogram or erase is suspended.

A Program/Erase Suspend instruction is accepted

only during a Program or Erase instruction. When

the Program/Erase Suspend command is written

to the Command Interface, the P/E.C. freezes the

program or erase operation. The suspended program orerase operation maybe restartedby using

the Program/Erase Resume instruction. Program/

Erase Suspend is not allowed during the Overlay

block program/erase operation and the command

is ignored.

The Program/Erase Suspend instruction consists

of one write cycle giving the command B0h at the

address 00000h.

If a program operation is in progress when the instruction is given, the Status Register bits 4 and 6

are set to ’1’ after it has been suspended. If an

erase operation is in progress when theinstruction

is given, the Status Register bits 5 and 6 are set to

’1’after it has been suspended.

The valid instructions that may be given to the

memory while programing is suspended are

– Read Memory Array (RD)

– Read Status Register (RSR)

– Read Electronic Signature (RSIG)

– Program/Erase Resume (PER)

In addition, while erasure is suspended, the Pro-

gram (PG) instruction may be given.

In Program/Erase Suspendmode the memory can

be placed in a pseudo-standby mode by taking

Chip Enable /E to VIH to reduce power consumption.

Program/Erase Resume (PER). If a Program/

Erase Suspend instruction has previously been

executed, then the operation may be resumed by

giving the command D0h at the address 00000h.

The Status Register bits 4, 5 and 6 are cleared

when programor erase resumes.A Read Memory

Array instructionwill output theStatus Register after program or erase is resumed.

Suggested flow charts for software that uses programming, erasure and program/erase suspend/

resume operations are shown in Figures 11, 12,

13 and 14.

Asynchronous/Synchronous Rea d Toggle (ART).

Asynchronous Read Memory Array is thememory

default atpower-up or whenreturning from PowerDown. To read data in Synchronous mode, either

single or burst, the Asynchronous/Synchronous

Read Toggle instruction must be used.

The Asynchronous/Synchronous Read Toggle instruction consists of one write cycle giving the

command 60h at the address 00000h. Two consecutive instructions are not recognised and another Instruction, for example the Read Memory

Array, must be given before another Asynchronous/Synchronous Read Toggle will be recognised.

12/36

Page 13

M58BF008

Wrap/No-wrap Burst Toggle (WBT). The de-

fault for burst read is set by the device configuration. The Wrap/No-wrap Burst Togglecan be used

to toggle the burst wrap operation.

The Wrap/No-wrap Burst Toggle instruction consists of onewrite cycle giving the command 30h at

the address 00000h. Two consecutiveinstructions

are not recognised and another Instruction, for example the Read Memory Array, must be given be-

Overlay Block Read Enable/Disable Toggle

(OBT). Read operations in the Overlay block can

be enabled or disabled using the Overlay Block

Read Enable/Disable Toggle instruction. This toggle instruction consists of one write cycle giving

the command 06h at the address 00000h. Two

consecutive instructions are not recognised.

The Status Register bit 1 is set to ’1’ when the

Overlay block is enabled.

fore another Wrap/No-wrap Burst Toggle will be

recognised.

Table 9. Read Access to Overlay Block or Main Block

OBEB Status Bit

1

1

0 X 0 Main Block

1 Unknown Not guaranteed Unknown

In the range V

V

PP

or V

PP1

Out of the range

V

or V

PP1

PPH

PPH

Table 10. Overlay Block Enable/Disable Bit (OBEB)

Method

In the range

V

ToggleRP

Power-on-reset

Overlay Block Read Enable/Disable instruction OBT

Note: 1. Toggle H-L-H for t

(1)

PLPH

minimum.

PP1

Out of the range

V

PP1

In the range

V

PP1

Out of the range

V

PP1

OBS Status Bit Read Access

1 Overlay Block

0 Main Block

OBEB Status Bit

V

PP

or V

PPH

or V

PPH

or V

PPH

or V

PPH

–01

–10

Prior state of

OBEB

X1

X0

X1

X0

Next state of

OBEB

13/36

Page 14

M58BF008

CONFIGURATION

The M58BF008 is configured during testing which

sets the default for the write and burst interface.

The settings are:

Write Interface. The write interface can be set

permanently to either Asynchronous or Synchronous. Note that the read interface is not affected

by thisconfiguration and defaults to Asynchronous

read at power-up, it can be toggled to Synchronous read and back using the Asynchronous/Synchronous Read Toggle Instruction.

Wrap/No-Wrap. The burst function can be set to

default to wrap or no-wrap. The behaviour is

shown in Table 13. Wrap/No-wrap can be toggled

using the Wrap/No-wrap Burst Toggle Instruction.

Critical Word and Burst Word Latency Times.

The Critical Word and Burst Word latency times

can be set permanently to

– Critical Word Latency Time X = 3 or 4

– Burst Word Latency Time Y = 1 or 2

A burst sequence is described as X-Y-Y-Y.

Table 11. Configuration

Name Option 1 Option 2

Write Interface Synchronous Asynchronous

Wrap/No-wrap Burst Wrap No-wrap

Critical Word Latency Time (X)

Burst Word Latency Time(Y)

43

12

Table 12. Wrap/No-wrap Burst Sequence

First Burst Address A1-A0 Data Wrap Data No-wrap

00 Double-Word 0 ⇒ 1 ⇒ 2 ⇒ 3 Double-Word 0 ⇒ 1 ⇒ 2 ⇒ 3

01 Double-Word 1 ⇒ 2 ⇒ 3 ⇒ 0 Double-Word 1 ⇒ 2 ⇒ 3

10 Double-Word 2 ⇒ 3 ⇒ 0 ⇒ 1 Double-Word 2 ⇒ 3

11 Double-Word 3 ⇒ 0 ⇒ 1 ⇒ 2 Double-Word 3

POWER SUPPLY

The M58BF008 places itself in one of three different modes depending on the status of the control

signals which define decreasing levels of current

consumption. This minimises the memory power

consumption, allowing an overall decrease in the

system power consumption without affecting performance. A different recovery time is, however,

linked to the different modes - see the AC timing

tables.

Active Power mode. When Chip Enable E is at

VILand Reset/Power-DownRP is atVIHthe memory is in Active Power mode. The DC characteristics tables show the current consumption figures.

Standby mode. Refer to the Device Operating

section

Power-Down mode. Refer to the Device Operating section.

14/36

Power Up. The VDDSupply Voltage, V

DDQ

Input/

Output Supply Voltage and the VPPProgram/

Erase Supply Voltage can beapplied in anyorder.

The memory Command Interface is reset on power-up to Read Memory Array, but a negative transition on Chip Enable E or a change of the

addresses is required to ensure valid data is output.

Care must be taken toavoid writes to the memory

when the VDDSupply Voltage is above V

LKO

and

VPPProgram/Erase Supply Voltage powers-up

first. Writes can be inhibited by driving either Write

Enable W or Write/Read WR to VIH.

The memory is disabled until Reset/Power-Down

RP is up to VIH.

SUPPLY RAILS

Normal precautions must be taken for supply rail

decoupling. Each device in a system should have

the VDD,V

and VPPrails decoupled with a

DDQ

0.1µF capacitor close to the package pins. PCB

track widths should be sufficient to carry the required program and erase currents on the V

PP

supply.

Page 15

M58BF008

Table 13. AC Measurement Conditions

Input Rise and Fall Times ≤ 10ns

Input Pulse Voltages

Input and Output Timing Ref. Voltages V

0toV

DDQ

DDQ

/2

Figure 5. AC Testing Load Circuit

V

/2

DDQ

1N914

3.3kΩ

Figure 4. AC Testing Input Output Waveform

DEVICE

UNDER

V

DDQ

V

/2

DDQ

0V

AI00610

Table 14. Capacitance

(1)

(TA=25°C, f = 1MHz)

Symbol Parameter Test Condition Min Max Unit

C

IN

C

OUT

Note: 1. Sampled only, not 100% tested.

Input Capacitance

Output Capacitance V

V

OUT

IN

TEST

CL= 80pF

CLincludes JIG capacitance

=0V

6pF

=0V 12 pF

OUT

AI02657

15/36

Page 16

M58BF008

Table 15. DC Characteristics

(TA= –40 to 125°C; VDD=5V±10% and V

Symbol Parameter Test Condition Min Max Unit

I

I

I

LT1

I

LIVPP

I

CC

I

CCB

I

CC1

I

CC2

I

CC3

I

CC4

I

I

PP1

I

PP2

I

PP3

Input Leakage Current

LI

Output Leakage Current

LO

Input Leakage Current pull-up

Input Leakage Current pull-down

Supply Current (Async. Read) E = VIL,G=VIL, f = 5MHz 25 mA

Supply Current (Burst Read)

Supply Current (Standby) E = VIH,RP=V

Supply Current (Power-down)

Supply Current (Program)

Program in Progress

Supply Current (Erase)

Erase in Progress

Program Current (Read or Standby)

PP

Program Current (Read or Standby)

Program Current (Power-down)

Program Current (Program)

Program in Progress

=3.3V ± 0.3V)

DDQ

E=V

0V≤ V

0V

0V≤ V

IL

≤ V

IN

DDQ

≤ V

OUT≤VDDQ

≤ V

IN

DDQ

0≤ V

≤ 12.6

PP

,G=VIL, f = 40MHz

IH

RP = V

IL

V

PP=VPP1

V

PP=VPPH

V

PP=VPP1

V

PP=VPPH

V

≥ V

PP

PP1

V

≤ V

PP

PP1

RP = V

IL

VPP=V

V

PP1

PP=VPPH

±1 µA

±10 µA

–20 –600 µA

200 µA

25 mA

10 µA

10 µA

25 mA

25 mA

25 mA

25 mA

200 µA

±15 µA

5 µA

15 mA

25 mA

I

V

V

V

V

V

V

PP4

V

IL

V

IH

OL

OH

PP1

PPH

LKO

PPLK

V

Program Current (Erase)

Erase in Progress

PP=VPP1

V

PP=VPPH

Input Low Voltage –0.3

Input High Voltage

Output Low Voltage

Output High Voltage

Program Voltage

(Program or Erase operations)

Program Voltage

(Program or Erase operations)

I

= 100µA,

OL

V

DD=VDD

V

DDQ=VDDQ

I

= –100µA,

OL

V

DD=VDD

V

DDQ=VDDQ

min,

min

min,

min

0.9V

V

DDQ

4.5 5.5 V

11.4 12.6 V

VDDSupply Voltage Lock-out

DDQ

–0.2

15 mA

25 mA

0.1V

DDQ

V

DDQ

+0.3

0.2 V

1.5 V

Program Voltage Lock-out 1.5 V

V

V

V

16/36

Page 17

M58BF008

Table 16. Asynchronous Read AC Characteristics

(TA= –40 to 125°C; VDD=5V±10% and V

DDQ

(1)

=3.3V ± 0.3V)

Symbol Alt Parameter Min Max Unit

t

AVAV

t

AVQV

(2)

t

AXQX

(2)

t

EHQX

(2, 3)

t

ELQV

(2)

t

ELQX

(2)

t

EXQZ

(2)

t

GHQX

(2)

t

GHQZ

(2)

t

GLQV

t

GLQX

Note: 1. See AC Testing Measurements Conditions for timing measurements.

2. Sampled only, not 100% tested.

3. G may be delayed up to t

t

t

ACC

t

t

t

t

t

t

t

t

t

OLZ

Address Valid to Next Address Valid 100 ns

RC

Address Valid to Output Valid 100 ns

Address Transition to Output Transition 0 ns

OH

Chip Enable High to Output Transition 0 ns

OH

Chip Enable Low to Output Valid 100 ns

CE

Chip Enable Low to Output Transition 0 ns

LZ

Chip Enable High to Output Hi-Z 25 ns

HZ

Output Enable High to Output Transition 0 ns

OH

Output Enable High to Output Hi-Z 25 ns

DF

Output Enable Low to Output Valid 30 ns

OE

Output Enable Low to Output Transition 0 ns

ELQV-tGLQV

after falling edge of E without increasing t

ELQV

.

Figure 6. Asynchronous Read AC Waveforms

A12-A29

tAVQV

E, LBA

tELQV

tELQX

G

tGLQX

tGLQV tGHQZ

DQ0-DQ31

tPHQV

RP

tAVAV

VALID

tEHQX

tEHQZ

tGHQX

VALID

AI03571

17/36

Page 18

M58BF008

Table 17. Synchronous Read AC Characteristics

(TA= –40 to 125°C; VDD=5V±10% and V

DDQ

(1)

=3.3V ± 0.3V)

Symbol Parameter Min Max Unit

DC

CLK

(2)

t

AVCH

t

BALCH

(2)

t

BLCH

(2)

t

CHAX

(2)

t

CHBH

t

CHCL

t

CHGDH

(2)

t

CHGH

(2)

t

CHQV

(2)

t

CHQX1

(2)

t

CHQX2

(2)

t

CHQZ

t

CLCH

t

CLCL

t

ELCH

(2)

t

GDLCH

(2)

t

GLCH

t

PHBL

t

WRHCH

Note: 1. See AC Testing Measurement Conditions for timing measurements.

2. Sampled only, not 100% tested.

System Clock Duty Cycle 45 55 %

Address Valid toSystem Clock High 10 ns

Burst Address Advance Low to System Clock High 10 ns

Load Burst Address Low to System Clock High 10 ns

System Clock High to Address Transition 5 ns

System Clock High to Load Burst Address High 5 ns

System Clock FallTime 3 ns

(2)

System Clock High to Output Disable High 5 ns

System Clock High to Output Enable High 5 ns

System Clock High to Data Valid 20 ns

System Clock High to Data Transition 0 ns

System Clock High to Data Transition 5 ns

System Clock High to Data Hi-Z 20 ns

System Clock Rise Time 3 ns

System Clock Period 25 ns

Chip Enable Low to System Clock High 20 ns

Output Disable Low to System Clock High 10 ns

Output Enable Low to System Clock High 10 ns

Reset/Power-down High to Load Burst Address Low 20 ns

Write/Read High to System Clock High 10 ns

18/36

Page 19

Figure 7. Synchronous Single Read AC Waveforms

CLK

tCHAXtAVCH

A0-A17

LBA

VALID

M58BF008

G

E

DQ0-DQ31

RP

WR

tBLCH

tELCH tCHQZtCHQV

tPHBL

tWRHCH

tCHBH

tGLCH tCHGH

tCHQX1

tCHQX2

VALID

AI02658

19/36

Page 20

M58BF008

Figure 8. Synchronous Burst Read AC Waveforms

CLK

tCHAXtAVCH

A0-A17

LBA

VALID

G

E

DQ0-DQ31

RP

WR

BAA

tBLCH

tELCH tCHQVtCHQV

tPHBL

tWRHCH

tCHBH

tGLCH

tCHQX1

tBALCH

VALID

tCHQX2

VALID

tCHQX2

AI03583

20/36

Page 21

M58BF008

Table 18. Asynchronous Write AC Characteristics

(TA= –40 to 125°C; VDD=5V±10% and V

DDQ

(1)

=3.3V ± 0.3V)

Symbol Alt Parameter Min Max Unit

t

AVAV

t

AVWH

t

DVWH

t

ELWL

t

PHWL

t

QVVPL

t

VPHWH

t

WHAX

t

WHDX

t

WHEH

t

WHQV1

t

WHQV2

t

WHWL

t

WLWH

Note: 1. See AC Testing Measurement conditions for timing measurements.

2. Sampled only, not 100% tested.

3. Time ismeasured to Status Register Read giving bit b7 = ’1’.

(2)

(2)

(3)

(3)

t

WC

t

t

t

t

t

VPS

t

t

t

t

WPH

t

WP

Write Cycle Time 70 ns

Address Valid to Write Enable High 70 ns

AS

Data Valid to Write Enable High 70 ns

DS

Chip Enable Low to Write Enable Low 0 ns

CS

Reset/Power-down High to Write Enable Low 70 ns

PS

Output Valid to VPPout of the range V

VPPHigh to Write Enable High

Write Enable High to Address Transition 0 ns

AH

Write Enable High to Data Transition 0 ns

DH

Write Enable High to Chip Enable High 0 ns

CH

PP1

or V

PPH

0ns

200 ns

Write Enable High to Output Valid, Program 10 µs

Write Enable High to Output Valid, Erase 2.1 sec

Write Enable High to Write Enable Low 30 ns

Write Enable Low to Write Enable High 70 ns

21/36

Page 22

M58BF008

Figure 9. Asynchronous Write AC Waveforms

A0-A17

00000h

tAVAV

VALID

G

E

W

DQ0-DQ31

V

PP

RP

WR

tELWL

tWLWH

tDVWH tWHDX

COMMAND

tPHWL

tWHAX

tWHEH

tWHWL

tVPHWH

COMMAND

or DATA

tAVWH

tWHQV1,2

STATUS

REGISTER

tQVVPL

22/36

WRITE WRITE READ

AI02660

Page 23

M58BF008

Table 19. Synchronous Write AC Characteristics

(TA= –40 to 125°C; VDD=5V±10% and V

DDQ

(1)

=3.3V ± 0.3V)

Symbol Parameter Min Max Unit

DC

CLK

(2)

t

AVCH

(2)

t

BLCH

(2)

t

CHAX

(2)

t

CHBH

t

CHCL

(3)

t

CHQV1

(3)

t

CHQV2

(2)

t

CHQX

(2)

t

CHWH

t

CHWRH

t

CLCH

t

CLCL

t

ELCH

t

PHCH

(2)

t

QVCH

(2)

t

QVVPL

(2)

t

VPHCH

(2)

t

WLCH

t

WRLCH

Note: 1. See AC Testing Measurement conditions for timing measurements.

2. Sampled only, not 100% tested.

3. Time ismeasured to Status Register Read giving bit b7 = ’1’.

System Clock Duty Cycle 45 55 %

Address Valid toSystem Clock High 10 ns

Load Burst Address Low to System Clock High 10 ns

System Clock High to Address Transition 5 ns

System Clock High to Load Burst Address High 5 ns

System Clock FallTime 3 ns

System Clock High to Output Valid,Program 10 µs

System Clock High to Output Valid,Erase 2.1 sec

System Clock High to Data Transition 5 ns

System Clock High to Write/Read High 5 ns

(2)

System Clock High to Write Enable High 5 ns

System Clock Rise Time 3 ns

System Clock Period 25 ns

Chip Enable Low to System Clock High 20 ns

Reset/Power-down High to System Clock High 200 ns

Data Valid to System Clock High 10 ns

Output Validto VPPout of range V

VPPHigh to System Clock High

PP1

or V

PPH

0ns

200 ns

Write Enable Low to System Clock High 10 ns

(2)

Write/Read Low to System Clock High 10 ns

23/36

Page 24

M58BF008

Figure 10. Synchronous Write AC Waveforms

CLK

tCHAXtAVCH

A17-A0

LBA

00000h

VALID

WR

W

DQ31-DQ0

RP

V

PP

E

tBLCH

tCHBH

tWRLCH tCHWRH

tWLCH tCHWH

tQVCH tCHQX

tPHCB

tELCH

WRITE WRITE READ

COMMAND

tVPHCH

COMMAND

or DATA

tWHQV1,2

AI02659

STATUS

REGISTER

24/36

Page 25

M58BF008

Table 20. Reset/Power-down AC Characteristics

(TA= –40 to 125°C; VDD=5V±10% and V

Mode Symbol Parameter Min Max Unit

t

PHEL

t

PHQV

t

Async

Sync

Note: 1. The device Reset is possible but notguaranteed ift

A Reset will complete within 100ns if RP is Low while not in Program or Erase.

PHWL

t

PLPH

t

PLRH

t

PHBL1

t

PHBL2

(1)

Reset/Power-down High to Chip Enable Low 70 ns

Reset/Power-down High to Output Valid 100 ns

Reset/Power-down High to Write Enable Low 70 ns

Reset/Power-down Pulse Width 100 ns

Reset/Power-down Low to Program Erase Abort 22 µs

Reset/Power-down High to Load Burst Address Low 20 ns

Reset/Power-down High to Load Burst Address Low 22 µs

Figure 11. Reset/Power-down AC Waveforms

=3.3V ± 0.3V)

DDQ

< 100ns.

PLPH

Reset during Read Mode

tPLPH

RP

RP

RP

Reset during Program with t

tPLRH

tPLPH

Reset during Program/Erase with t

Abort

Complete

tPLRH

tPLPH

PLPHtPLRH

Abort

Complete

Power

Down

tPHQV

tPHBL1

≤

tPHWL

tPHEL

tPHBL1

PLPH>tPLRH

tPHWL

tPHEL

tPHBL2

AI00624

25/36

Page 26

M58BF008

Table 21. Program, Erase Times and Program/Erase Endurance Cycles

(TA= –40 to 125°C; VDD=5V±10% and V

Parameter Test Conditions Min

Main/Overlay Block Program Time

Main/Overlay Block Erase Time

Program/Erase Cycles (per Block)

Figure 12. Program Flowchart and Pseudo Code

Start

Write

40h/04h

Command

Write

Address

& Data

=3.3V ± 0.3V)

DDQ

V

PP=VPPH

V

PP=VPP1

V

PP=VPPH

V

PP=VPP1

V

PP=VPPH

V

PP=VPP1

1,000 cycles

10,000 cycles

PG/OBPG

– write 40h/04h

– write Address &

(memory enters read status

state after the PG instruction)

instructions:

Typ

Max Unit

0.14 1.4 sec

0.18 1.8 sec

0.21 2.1 sec

0.33 3.3 sec

command

Data

Read Status

Register

YES

YES

YES

NO

NO

NO

VPPInvalid

Error (1)

Program

Error (1)

b7=1

b3=0

b4=0

End

Note: 1. If an error is found, the Status Register must be cleared (CLRS instruction) before further P/E.C. operations.

do:

– read status

(E orG must be toggled)

while b7 = 1

If b3 = 1, VPPinvalid

– error handler

If b4 = 1, Program

– error handler

register

error:

error:

AI02663

26/36

Page 27

Figure 13. Program Suspend & Resume Flowchart and Pseudo Code

Start

Write

B0h

Command

Write

70h

Command

Read Status

Register

PES instruction (note

– write B0h

(memory enters read register

state after the PES instruction)

do:

– read status

(E orG must be toggled)

M58BF008

1):

command

register

b7 = 1

YES

b6 = 1

YES

b4 = 1

YES

Write FFh

Command

Read data

another block

Program Continues

Write

D0h

Command

from

NO

NO

NO

Program Complete

Write FFh

Command

Read Data

while b7 = 1

If b4 = 0, Program

(at this point the memory will

accept only theRD or PER instruction)

RD

instruction:

– write FFh

– one or more data

from another block

PER

instruction:

– write D0h

to resume

– if the program operation completed

then this is not necessary. The device

returns to Read Array as normal

(as ifthe Program/Erase suspend

was notissued).

completed

command

reads

command

erasure

Note: 1. PES instruction is not allowed during OBPG operation.

AI02664

27/36

Page 28

M58BF008

Figure 14. Erase Flowchart and Pseudo Code

Start

Write

20h/02h

Command

Write Block

& D0h Command

Address

EE/OBEE

– write20h/02h

– writeBlock

(memory entersread status

state after the EE instruction)

instructions:

command

Address

(A12-A17) & command

D0h/0Dh

Read Status

Register

b7 = 1

YES

b3 = 0

YES

b4, b5 = 0

YES

b5 = 0

YES

YES

End

NO

NO

NO

NO

VPPInvalid

Error (1)

Command

Sequence Error

Erase

Error (1)

do:

– readstatus

(E or G must be toggled)

while b7 = 1

If b3 = 1, VPPinvalid

– errorhandler

If b4, b5 = 1, Command Sequence

– errorhandler

If b5 = 1, Erase

– errorhandler

register

error:

error:

error:

AI02680

Note: 1. If an error is found, the Status Register must be cleared (CLRS instruction) before further P/E.C. operations.

28/36

Page 29

Figure 15. Erase Suspend & Resume Flowchart and Pseudo Code

Start

Write

B0h

Command

Write

70h

Command

Read Status

Register

PES instruction(note

– writeB0h

(memory entersread register

state after the PES instruction)

do:

– readstatus

(E or G must be toggled)

M58BF008

1):

command

register

b7 = 1

YES

b6 = 1

YES

b5 = 1

YES

Write FFh

Command

Read data

another

Program Continues

block

or Program

Write

D0h

Command

from

NO

NO

NO

Erase Complete

Write FFh

Command

Read Data

while b7 = 1

If b6 = 0, Erase

(at this point the memory

accept only the RD or PER instruction)

RD

instruction:

– writeFFh

– oneo more data

from another block

PG

instruction:

– write40h

– writeAddress & Data

PER

instruction:

– writeD0h

to resume

– ifthe program operation completed

then this is not necessary. The device

returns to Read Array as normal

(as if the Program/Erase suspend

was not issued).

completed

wich

command

reads

command

command

erasure

Note: 1. PES instruction is not allowed during OBEE operation.

AI02681

29/36

Page 30

M58BF008

Figure 16. Command Interface and Program Erase Controller Flowchart (a)

WAIT FOR

COMMAND

WRITE (1)

NO

90h

YES

READ

ARRAY

READ

SIGNATURE

06h

YES

OBEB

TOGGLE

NO

STATUS

70h

YES

READ

NO

30h

WRAPPING

TOGGLE

YES

YES

NO

CLEAR

STATUS

NO

READY

50h

YES

NO

PROGRAM

OB SET-UP

PROGRAM

04h

OB

YES

NO

ERASE

OB SET-UP

02h

0Dh

NO

YES

A

NO

READ

STATUS

YES

B

Note: 1. If no command is written, the Command Interface remains in its previous valid state. Upon power-up, on exit from power-down or

2. P/E.C. status (Ready or Busy) is read on StatusRegister bit 7.

if V

DD

falls belowV

, theCommand Interface defaults to Read Array mode.

LKO

NO

READY

ERASE

OB

ERASE

COMMAND

ERROR

D

AI02682

30/36

Page 31

Figure 17. Command Interface and Program Erase Controller Flowchart (b)

M58BF008

B

YES

A

40h

YES

PROGRAM

SET UP

PROGRAM

READY

(2)

NO

B0h

YES

PROGRAM

SUSPEND

NO

(READ STATUS)

NO

READ

STATUS

C

NO

PROGRAM

SUSPENDED

YES

READ

STATUS

READ

SIGNATURE

READ

ARRAY

Note: 2. P/E.C.status (Ready or Busy) is read on StatusRegister bit 7.

YES

YES

NO

70h

90h

D0h

NO

NO

NO

YES

YES

READ

STATUS

READY

(2)

NO

READ

STATUS

(PROGRAM RESUME)

AI02684

31/36

Page 32

M58BF008

Figure 18. Command Interface and Program Erase Controller Flowchart (c)

B

YES

C

20h

ERASE

SET-UP

D0h

YES

ERASE

READY

(2)

NO

B0h

YES

ERASE

SUSPEND

YES

NO

ERASE

COMMAND

ERROR

(READ STATUS)

NO

STATUS

FFh

READ

D

NO

ERASE

NO

SUSPENDED

YES

READ

STATUS

READ

SIGNATURE

PROGRAM

SET-UP

c

READ

ARRAY

Note: 2. P/E.C.status (Ready or Busy) is read on StatusRegister bit 7.

YES

YES

YES

NO

70h

90h

40h

10h

D0h

NO

NO

or

NO

YES

32/36

YES

READ

STATUS

READY

(2)

NO

READ

STATUS

(ERASE RESUME)

AI02683

Page 33

Table 22. Ordering Information Scheme

Example: M58BF008B 100 ZA 6 T

Device Type

M58

Architecture

B = Burst Mode

Operating Voltage

F=V

Device Function

008 = 8 Mbit (256Kb x 32), Burst

Configuration

B = Synchronous Write, Burst Wrap,

Speed

100 = 100ns

=5V±10%; V

DD

Critical Word Latency = 4

Burst Word Latency = 1

DDQ

= 3.0V or 3.6V

M58BF008

Package

D = PQFP80

ZA = LBGA80: 1.0 mm pitch

Temperature Range

3 = –40 to 125 °C

Option

T = Tape & Reel Packing

Devices are shipped from the factory with the memory content bits erased to ’1’.

For a list of available options (Configuration, Package, etc...) or for further information on any aspect of

this device, please contact the STMicroelectronics Sales Office nearest to you.

33/36

Page 34

M58BF008

Table 23. PQFP80 - 80 lead Plastic Quad Flat Pack, Package Mechanical Data

Symbol

Typ Min Max Typ Min Max

A 3.40 0.1339

A1 0.25 0.0098

A2 2.80 2.55 3.05 0.1102 0.1004 0.1201

b 0.30 0.45 0.0118 0.0177

c 0.11 0.23 0.0043 0.0091

D 23.90 – – 0.9409 – –

D1 20.00 – – 0.7874 – –

e 0.80 – – 0.0315 – –

E 17.90 – – 0.7047 – –

E1 14.00 – – 0.5512 – –

L 0.88 0.73 1.03 0.0346 0.0287 0.0406

α 3.5 ° 0 ° 7 ° 3.5 ° 0 ° 7 °

N80 80

Nd 24 24

Ne 16 16

CP 0.250 0.0098

mm inches

Figure 19. PQFP80 - 80 lead Plastic Quad Flat Pack, Package Outline

D

D1

D2

E1

ENe

Drawing is not to scale.

N

TQFP

E2

1

Nd

A2

e

b

A

CP

c

LA1 α

34/36

Page 35

Table 24. LBGA80 - 10 x 8 balls, 1mm pitch, Package Mechanical Data

mm inch

Symbol

Typ Min Max Typ Min Max

A 1.700 0.0669

A1 0.400 0.350 0.450 0.0157 0.0138 0.0177

A2 1.100 0.0433

b 0.500 – – 0.0197 – –

D 12.000 – – 0.4724 – –

D1 9.000 – – 0.3543 – –

ddd 0.150 0.0059

e 1.000 – – 0.0394 – –

E 10.000 – – 0.3937 – –

E1 7.000 – – 0.2756 – –

FD 1.500 – – 0.0591 – –

FE 1.500 – – 0.0591 – –

SD 0.500 – – 0.0197 – –

SE 0.500 – – 0.0197 – –

M58BF008

Figure 20. LBGA80 - 10 x 8 balls, 1mm pitch, Bottom View Package Outline

E

FE

FD

D1D

eb

A

E1

SE

SD

e

A2

A1

ddd

Drawing is not to scale.

BGA-Z05

35/36

Page 36

M58BF008

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of useofsuch information nor for any infringement ofpatents orother rights of third partieswhich may result from itsuse. Nolicense is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces allinformation previously supplied. STMicroelectronics products are not

authorized for use as critical components in lifesupport devices or systems without express written approval of STMicroelectronics.

The ST logo is registered trademark of STMicroelectronics

2000 STMicroelectronics - All Rights Reserved

All othernames are the property of their respective owners.

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia -Malta - Morocco -

Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

STMicroelectronics GROUP OF COMPANIES

http://www.st.com

36/36

Loading...

Loading...