MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING HYBRID GATE DRIVERS AND GATE DRIVE POWER SUPPLIES

5.0 Using Hybrid Gate Drivers

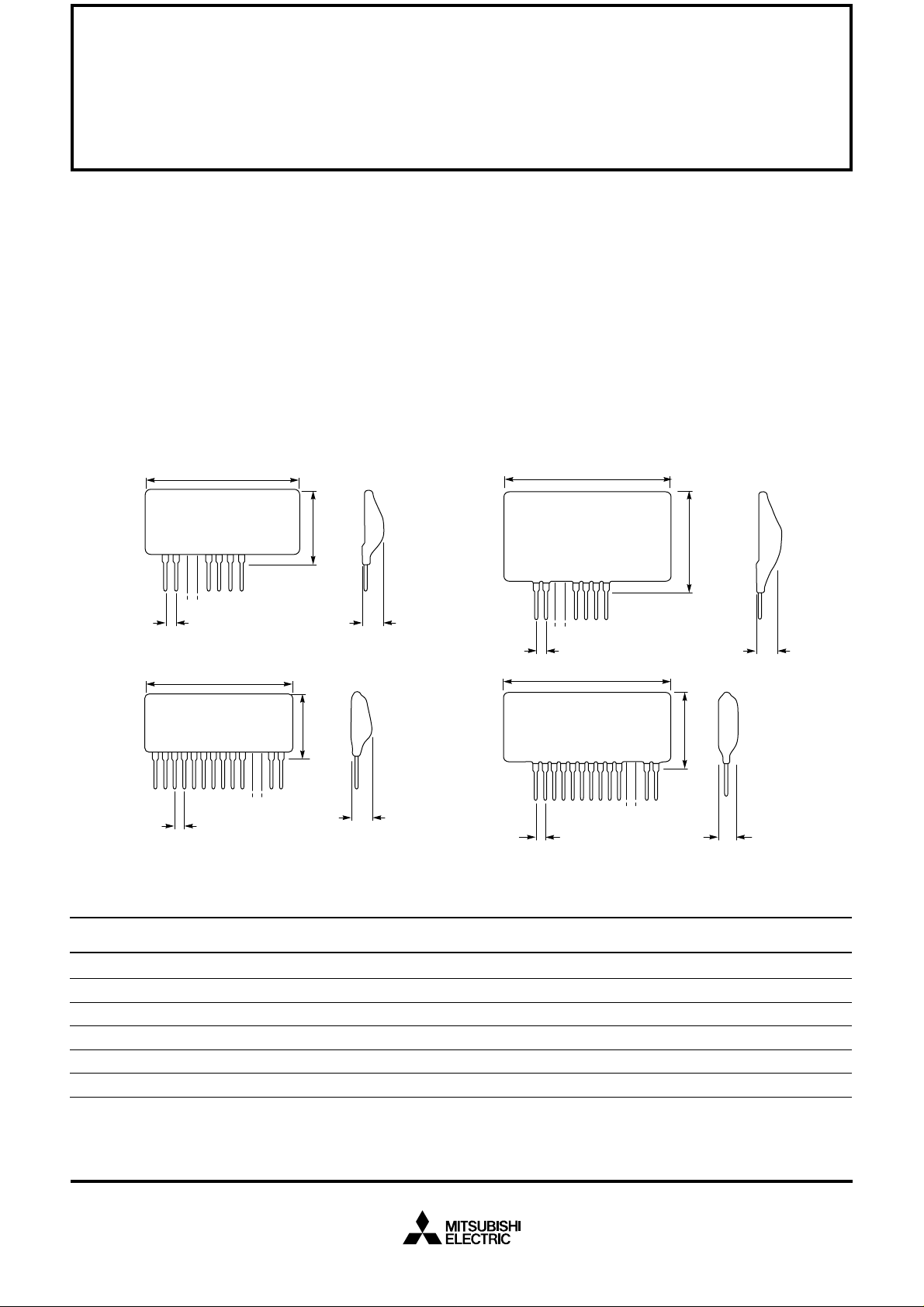

Mitsubishi offers four single in-line

hybrid ICs for driving IGBT

modules. All four drivers are high

speed devices designed to convert

logic level control signals into

optimal IGBT gate drive. Input

signals are isolated from the IGBT

drive using high speed

optocouplers with 15,000V/ms

Figure 5.1 Hybrid IGBT Gate Drivers

35 MAX

M57957L

2.54

23 MAX

10 MAX

common mode noise immunity.

This feature allows convenient

common referencing of high and

low side control signals. Mitsubishi

IGBT drivers are designed to

provide the pulse currents

necessary for high performance

switching applications and to

maintain sufficient off bias to

guarantee ruggedness. Hybrid

IGBT drivers simplify gate drive

M57958L

design by minimizing the number

of components required. In

addition to high performance gate

drive, the M57959L and the

M57962L provide short-circuit

protection. The basic package

outlines of the four Mitsubishi

drivers are shown in Figure 5.1.

Table 5.1 lists the key electrical

characteristics of each hybrid

driver.

51 MAX

29

MAX

10 MAX2.54

43 MAX

M57959L

2.54

All Dimensions in mm.

22 MAX

11 MAX

51 MAX

M57962L

2.54

25

MAX

12 MAX

Table 5.1 Recommended Gate Driver Applications

Optimum Application Range*

Gate Drive Circuit Peak Output Current Short Circuit Protection For 600V IGBT Modules For 1200V/1400V IGBT Modules

M57957L 2 Amps No Up to 100A Up to 50A

M57958L 5 Amps No Up to 400A Up to 200A

M57959L 2 Amps Yes Up to 100A Up to 50A

M57962L 5 Amps Yes Up to 400A Up to 200A

M57958L with Booster** 20 Amps No Up to 600A Up to 1000A

M57962L with Booster** 20 Amps Yes Up to 600A Up to 1000A

*Use RG specified in the switching time section of the IGBT module data sheet.

**See Section 5.10

Sep.1998

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING HYBRID GATE DRIVERS AND GATE DRIVE POWER SUPPLIES

5.1 Output Current Limit

When using hybrid gate drivers

RG must be selected such that the

output current rating (IOP) is not

exceeded. If RG is computed using

Equation 5.1 then IOP will not be

exceeded under any condition.

Equation 5.1

Conservative equation for minimum R

R

G

= (VCC + VEE)/I

G(MIN)

OP

Example:

With VCC = 15V and

-VEE = 10V R

G(MIN)

for

M57958L will be:

RG = (15V + 10V)/5A = 5 ohms

In most applications this limit is

unnecessarily conservative.

Considerably lower values of R

G

can usually be used. The

expression for R

G(MIN)

should be

modified to include the effects of

parasitic inductance in the drive

circuit, IGBT module internal

impedance and the finite switching

speed of the hybrid drivers output

stage. Equation 5.2 is an improved

version of Equation 5.1 for

R

G(MIN)

.

Equation 5.2

Improved equation for R

R

IOP - (RG)

= (VCC + VEE)/

G(MIN)

INT

- φ

G(MIN)

Large IGBT modules that contain

parallel chips have internal gate

resistors that balance the gate

drive and prevent internal

oscillations. The parallel

combination of these internal

resistors is R

G(INT)

. R

G(INT)

ranges from 0.75 ohm in large

IGBT modules like CM600HA-24H

to 3.0 ohms in smaller modules like

CM150DY-12H with two parallel

chips. The value of f depends on

the parasitic inductance of the gate

drive circuit and the switching

speed of the hybrid driver. The

exact value of f is difficult to

determine. It is often desirable to

estimate the minimum value of R

G

that can be used with a given

hybrid driver circuit and IGBT

module by monitoring the peak

gate current while reducing R

G

until the rated IOP is reached. The

minimum restriction on RG often

limits the switching performance

and maximum usable operating frequency when large modules

outside of the drivers optimum

application range are being

driven.Further steps to address

this issue are provided in

Section 5.10.

5.2 Power Supply Requirements

Power is usually supplied to hybrid

IGBT gate drivers from low

voltage DC power supplies that

are isolated from the main DC bus

voltage. Isolated power supplies

are required for high side gate

drivers because the emitter

potential of high side IGBTs is

constantly changing. Isolated

power supplies are often desired

for low side IGBT gate drivers in order to eliminate ground loop noise

problems. The gate drive supplies

should have an isolation voltage

rating of at least two times the

IGBTs V

V

= 2400V for 1200V IGBT).

ISO

rating (i.e.

CES

In systems with several isolated

supplies intersupply capacitances

must be minimized in order to

avoid coupling of common mode

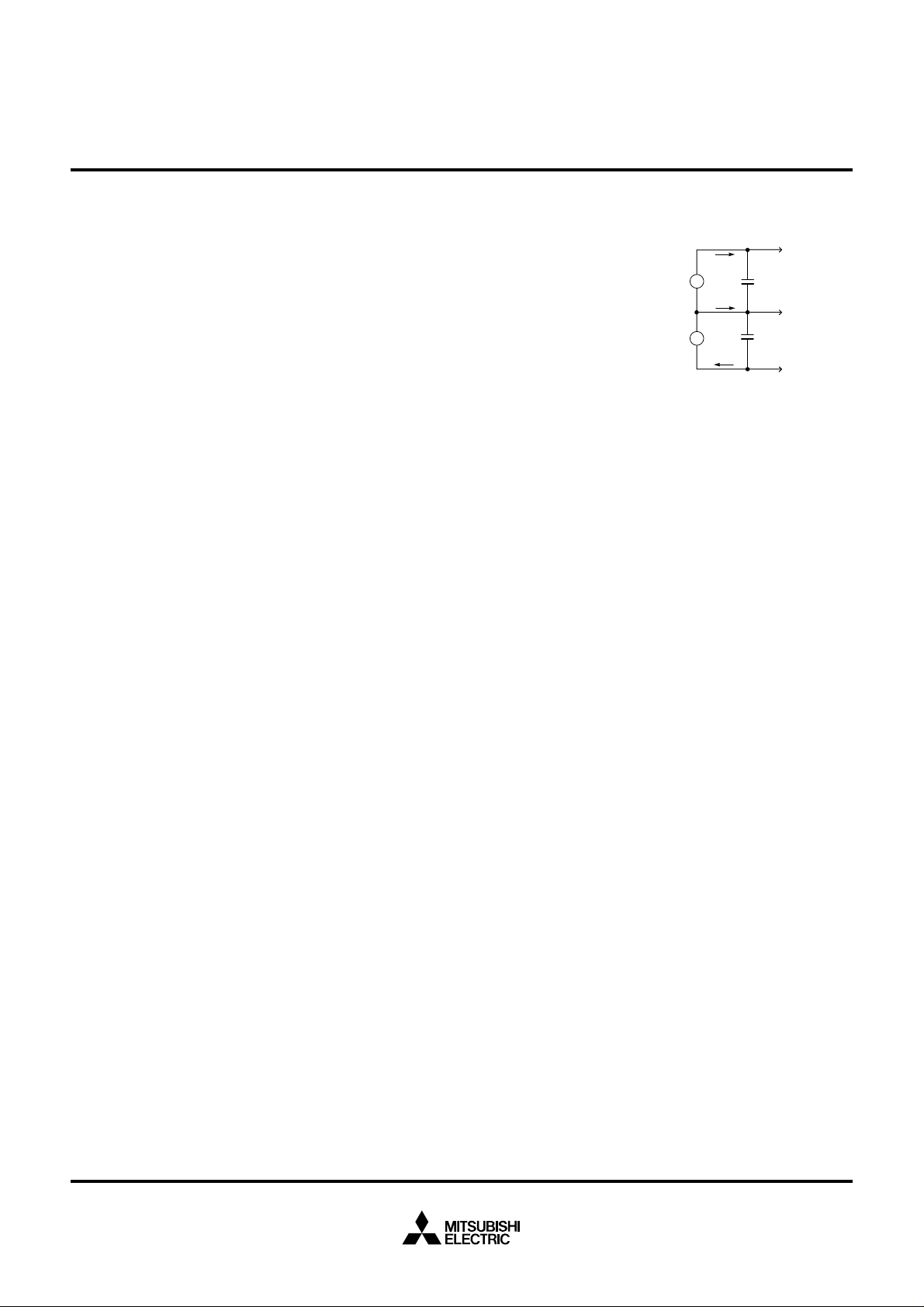

Figure 5.2 Hybrid Driver Power

Supply

I

D

V

(15V)

V

(10V)

+

CC

+

EE

I

COM

+

47µF

+

47µF

I

D

TO HYBRID DRIVER

noise. The recommended power

supply configuration for Mitsubishi

hybrid IGBT gate drivers is shown

in Figure 5.2. Two supplies are

used in order to provide the onand off-bias for the IGBT. The recommended on bias supply (VCC)

voltage is +15V and the recommended off-bias supply voltage

(VEE) is -10V.

Normally these supplies should be

regulated to ±10% however

operation within the range

indicated on the individual driver

data sheets is acceptable.

Electrolytic or tantalum decoupling

capacitors should be connected at

the power supply input pins of the

hybrid driver. These capacitors

supply the high pulse currents

required to drive the IGBT gate.

The amount of capacitance

required depends on the size of the

IGBT module being driven. A 47µF

capacitor is sufficient for most applications.

5.2.1 Supply Current

The current that must be supplied

to the IGBT driver is the sum of two

components. One component is

the quiescent current required to

bias the drivers internal circuits.

The current is constant for fixed

values of VCC and VEE. The second component is the current re-

Sep.1998

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING HYBRID GATE DRIVERS AND GATE DRIVE POWER SUPPLIES

quired to drive the IGBT gate. This

current is directly proportional to

the operating frequency and the total gate charge (QG) of the IGBT

being driven. With small IGBT

modules and at low operating frequencies the quiescent current will

be the dominant component. The

amount of current that must be

supplied to the hybrid driver when

VCC = 15V and VEE = -10V can

be determined from Equations 5.3

and 5.4.

Equation 5.3

Required supply current for

M57957L and M57958L

ID = QG x f

PWM

+ 13mA

Equation 5.4

Required supply current for

M57959L and M57962L

ID = QG x f

PWM

+ 18mA

Where:

ID = Required supply current

QG = Gate charge (See

Section 4.6.3)

f

= Operating frequency

PWM

5.2.2 Single Supply Operation

The current drawn from VCC (ID+)

is nearly equal to the current drawn

from VEE (ID-). Only a small

amount of current flows in the common connection (I

COM

). In many

applications it is desirable to operate the hybrid driver from a single

isolated supply. An easy method of

accomplishing this is to create the

common potential using a resistor

and a zener diode. In order to size

the resistor for minimum loss we

must first determine the current

flowing in the common connection

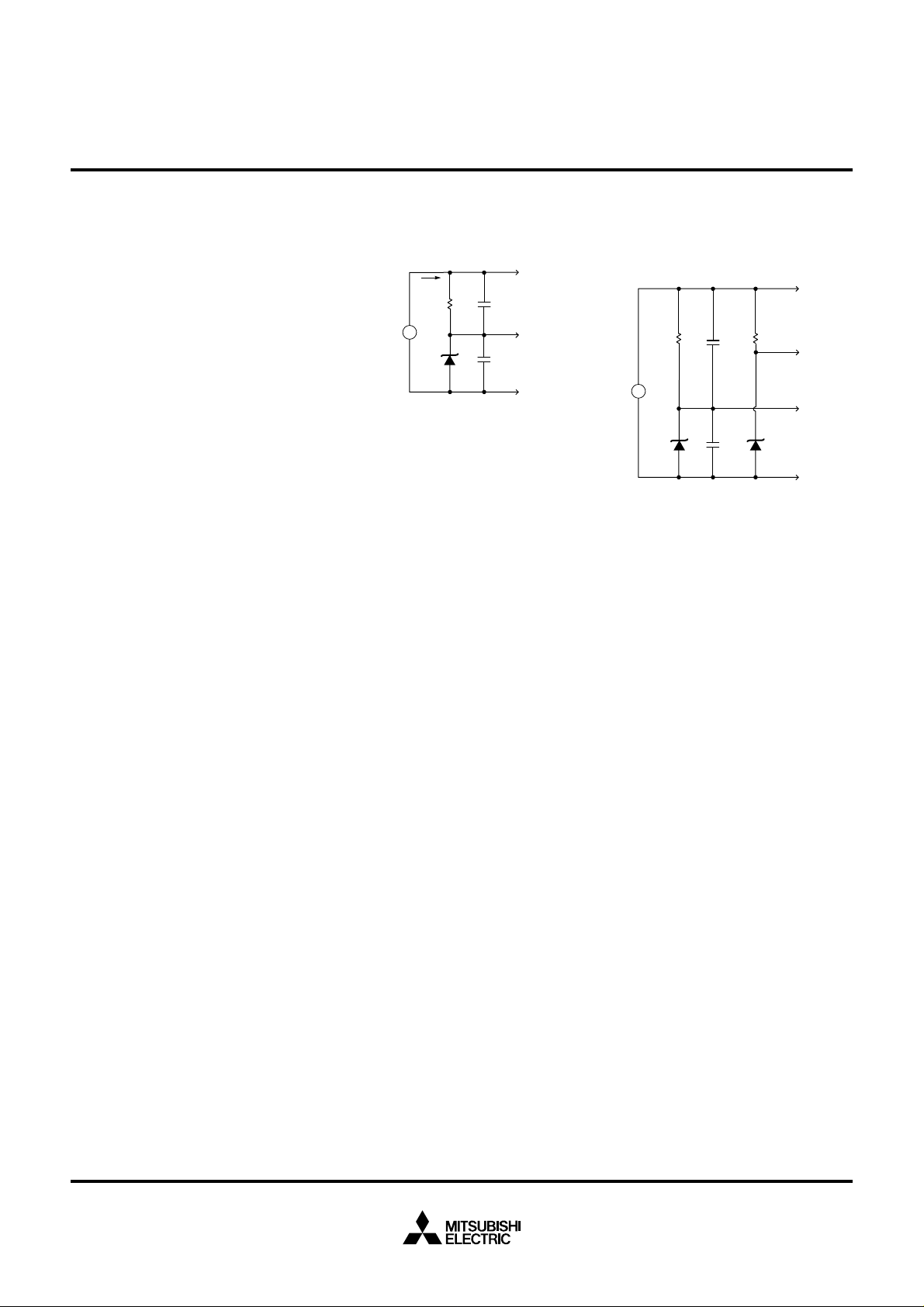

Figure 5.3 Single Supply

Operation of Hybrid

IGBT Drivers

I

D

2.7kΩ

+

V

D

(25V)

(I

). In M57957L and M57958L

COM

10V

+

47µF

+

47µF

TO HYBRID DRIVER

a common connection current of

about 2.5mA is required to bias internal circuits. In M57959L and

M57962L about 3.5mA flows from

the detect pin through the IGBT to

the common connection. The circuit in Figure 5.3 uses a zener supply designed for about 5mA to supply the common current. This circuit allows operation of Mitsubishi

hybrid drivers from a single isolated

25 volt DC supply.

When the power supply circuit

shown in Figure 5.3 is used with

M57957L and M57958L the

required bias voltage at pin 5 of the

hybrid driver appears after a delay

caused by the 2.7kΩ resistor and

the 47µF capacitor. This delay may

cause these drivers to generate an

ON output pulse during power up.

In applications where the main

DC bus voltage is applied before

the gate drive power supplies are

on and stabilized the circuit in Figure 5.4 should be used.

The voltage of the single supply

and the zener diode can be varied

to allow use of standard supplies.

For example, if a 24V DC-to-DC

Figure 5.4 Improved Power

Supply Circuit for

M57957L and

M57958L

TO

HYBRID

DRIVER

2.7kΩ

10V

PIN 6

TO

HYBRID

DRIVER

PIN 5

TO

EMITTER

OF IGBT

TO

HYBRID

DRIVER

PIN 8

V

(25V)

10V

+

47µF

+

47µF

2.7kΩ

+

D

converter is to be used then a 9V

zener diode would give +15/-9

which is acceptable for all of the

hybrid gate drivers. The two

limiting factors that need to be

observed if changes are made are:

(1) Voltages must be within the al-

lowable range specified on the

gate driver data sheet and

(2) The turn on supply should be

15V+/-10% for proper IGBT

performance.

5.3 Total Power Dissipation

The hybrid IGBT driver has a

maximum allowable power

dissipation that is a function of the

ambient temperature. With

VCC = 15V and VEE = -10V the

power dissipated in the driver can

be estimated using Equation 5.5.

Sep.1998

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING HYBRID GATE DRIVERS AND GATE DRIVE POWER SUPPLIES

Equation 5.5

Total power Dissipation

PD = ID x (VCC + VEE)

The power computed using

Equation 5.5 can then be

compared to the derating curves

shown in Figures 5.5 through

5.8 to determine the maximum

allowable ambient temperature.

The power computed using

Equation 5.5 includes the

dissipation in the external gate

resistor (RG). This loss is outside

the hybrid driver and can be

subtracted from the result of

Equation 5.5. The dissipation in

RG is difficult to estimate because

it depends on drive circuit parasitic

inductance, IGBT module type

and the hybrid driver’s switching

speed. In most applications the

loss in RG can be ignored. Direct

use of Equation 5 will result in a

conservative design with the

included loss of RG acting as a

safety margin. When operating

large modules at high frequencies

the limitations on ambient

temperature may be significant.

5.4 Application Circuit for

M57957L and M57958L

An internal schematic and example

application circuit for the M57957L

and M57958L are shown in

Figures 5.9 and 5.10. For

optimum performance parasitic

inductance in the gate drive loop

must be minimized. This is

accomplished by connecting the

47µF decoupling capacitors as

close as possible to the pins of the

hybrid driver and by minimizing the

lead length between the drive

circuit and the IGBT. The zeners

shown should be rated at about 18

volts and be connected as close to

the IGBT’s gate as possible. These

zeners protect the gate during

switching and short circuit

operation.

The gate driver has a built in

185 ohm input resistor that is

designed to provide proper drive

for the internal opto isolator when

V

= 5V. If other input voltages are

IN

desired an external resistor should

be added to maintain the proper

opto drive current of 16ma. The

value of the required external resistor can be computed by assuming

the forward voltage drop of the

opto diode is 2V. For example:

5.5 Short-Circuit Protection

Using Desaturation

Techniques

The M57959L and M57962L have

built in circuits that will protect the

IGBT from short circuits by

detecting desaturation. When a

short circuit occurs a high current

will flow in the IGBT causing its collector to emitter voltage to increase

to a level much higher than normal.

The hybrid driver detects this condition and quickly turns the IGBT

off, saving it from certain destruction.

If 15V drive is required then

R

16ma - 185Ω = 630Ω.

= (15V - 2V) ÷

ext

Sep.1998

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING HYBRID GATE DRIVERS AND GATE DRIVE POWER SUPPLIES

Figure 5.5 Derating Curve for

M57957L

5

4

3

2

1

ALLOWABLE POWER DISSIPATION (W)

0

0 100

20 40 60 80

AMBIENT TEMPERATURE (oC)

Figure 5.7 Derating Curve for

M57959L

5

4

3

2

1

ALLOWABLE POWER DISSIPATION (W)

0

0 100

20 40 60 80

AMBIENT TEMPERATURE (oC)

Figure 5.6 Derating Curve for

M57958L

5

4

3

2

1

ALLOWABLE POWER DISSIPATION (W)

0

0 100

20 40 60 80

AMBIENT TEMPERATURE (oC)

Figure 5.8 Derating Curve for

M57962L

5

4

3

2

1

ALLOWABLE POWER DISSIPATION (W)

0

0 100

20 40 60 80

AMBIENT TEMPERATURE (oC)

5.6 Operation of M57959L

and M57962L

Figure 5.11 is a flow diagram showing the operation of the short protection in M57959L and M57962L.

The hybrid driver monitors the collector emitter voltage (VCE) of the

IGBT. Normally, when an on signal

is applied to the input of the driver

the IGBT will turn on and VCE will

quickly attain its low on-state value

of VCE(SAT). If a short circuit is

present when the on signal is applied a large current will flow in the

IGBT and VCE will remain high. A

short circuit is detected by the hybrid driver when VCE remains

greater than the desaturation trip

level (VSC) for longer than t

TRIP

after the input on signal is applied.

The t

delay is used to avoid

TRIP

false tripping by allowing enough

time for normal turn on of the IGBT.

The hybrid driver initiates a controlled slow turn off and generates

a fault output signal when a short

circuit is detected. The slow turn off

helps to control dangerous transient voltages that can occur when

high short circuit currents are interrupted. The output of the driver will

remain disabled and the fault signal

will remain active for t

RESET

after a

short circuit is detected. The input

signal of the driver must be in its off

state in order for the fault signal to

be reset.

Sep.1998

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING HYBRID GATE DRIVERS AND GATE DRIVE POWER SUPPLIES

Figure 5.9 Internal Schematic Diagram of M57957L and M57958L

5

2

1

6

7

8

Figure 5.10 Application Circuit for M57957L and M57958L

V

LOGIC

SIGNAL

INPUT

BUFFER

IN

2

M57957L

M57958L

1

7

6

+

47µF

5

+

47µF

8

R

G

+

V

CC

+

V

EE

18V

Figure 5.11 Protection Circuit

Operation

START

IS V

CE

GREATER THAN

V

SC

IS

INPUT SIGNAL

ON?

DELAY

t

TRIP

IS VCE

GREATER THAN

V

SC

NO

YES

NO

YES

NO

YES

SLOW SHUTDOWN

DISABLE OUTPUT

SET FAULT SIGNAL

WAIT t

RESET

IS

INPUT SIGNAL

OFF?

YES

CLEAR FAULT

SIGNAL

ENABLE OUTPUT

NO

Sep.1998

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING HYBRID GATE DRIVERS AND GATE DRIVE POWER SUPPLIES

5.7 Application Circuit for

M57959L and M57962L

Figure 5.12 is a block diagram of

the M57959L and M57962L drivers

showing the logical implementation

of the flow diagram in Figure 5.11.

Figure 5.13 is an example application circuit for M57959L and

M57962L. Parasitic inductance in

the drive circuit should be minimized using the techniques described for the M57957L and

M57958L in Section 5.4. Pins

(3,7,9,10) are used for factory testing and should not be connected to

any external circuit. The detect diode (D1) must be fast recovery

(approximately 100ns) and should

be rated at a voltage equal to or

higher than the IGBT module being

driven. The 20V zener DZ1 is recommended in order to protect the

hybrid IC’s detect input from transient voltages that can occur during

recovery of the detect diode. This

zener can be eliminated if the detect diode’s recovery remains fast

and soft over its entire temperature

range and pin 1 of the hybrid IC remains free of high voltage transients and ringing.

tor can be computed by assuming

5.8 Adjusting the Desaturation

the forward voltage drop of the

opto diode is 2V. For example:

The hybrid drivers built in t

If 15V drive is required then

delay will work for most

applications. However when large

R

= (15V - 2V) ÷

ext

16ma - 185Ω = 630Ω.

modules are being driven with near

maximum gate resistance the

driver may incorrectly detect a

Figure 5.12 Block Diagram for M57959L

DETECT

V

CC

COMPARE

V

ISOLATION

TRIP

FAULT

LATCH

QSQS

R

DISABLE OUTPUT

FAULT

INPUT

V

CC

V

EE

Trip Time (t

DELAY

t

TRIP

ONE

SHOT

t

RESET

AND

TRIP

AND

GATE DRIVE

)

SHORT

DETECTED

SLOW

SHUTDOWN

TRIP

GATE

The gate driver has a built in

185 ohm input resistor that is

designed to provide proper drive

for the internal opto isolator when

V

= 5V. If other input voltages are

IN

desired an external resistor should

be added to maintain the proper

opto drive current of 16mA. The

value of the required external resis-

Figure 5.13 Block Diagram for M57959L

FAULT

LOGIC

SIGNAL

INPUT

OUTPUT

Buffer

V

IN

14

M57959L

M57962L

13

4.7 kΩ

8

1

5

4

6

Sources for D1: EDI (Electronic Devices Inc.) P/N RF160A

VMI (Voltage Multipliers Inc.) P/N 1N6528

+

47µF

+

47µF

DZ1 30V

D1

R

G

+

V

CC

+

V

EE

18V

Sep.1998

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING HYBRID GATE DRIVERS AND GATE DRIVE POWER SUPPLIES

short circuit. The false trip occurs

because it takes longer than

t

for the module to reach its

TRIP

low on-state voltage. In these

applications the t

TRIP

delay can

be extended by connecting a

capacitor from pin 2 to VCC.

Figure 5.14 shows the typical

increase in t

as a function of

TRIP

the external capacitor value for

M57959L and M57962L.

5.9 Operational Waveforms

Figure 5.15 is a typical waveform

showing the gate to emitter

voltage during a slow shutdown for

M57962L. Approximately 2.4ms

after the detect input (pin 1)

voltage exceeds VSC the gate to

emitter voltage is slowly brought to

zero in about 2ms. Figure 5.16

shows the collector-emitter voltage

(VCE) and collector current (IC) for

an IGBT module during a short

circuit. This waveform shows the

effectiveness of the slow shutdown

in controlling transient voltage.

5.10 Driving Large IGBT

Modules

In order to achieve efficient and

reliable operation of high current,

high voltage IGBT modules, a

gate driver with high pulse

current capability and low output

impedance is required. Mitsubishi

hybrid gate drivers are designed to

perform this function as stand

alone units in most applications.

However, for optimum performance

with large modules, it may be

necessary to add an output booster

stage to the hybrid gate driver.

When using the hybrid gate drivers

as stand alone units with IGBT

modules outside the range

specified in Table 5.1, three things

must be considered. First, the

maximum peak output current

rating of the hybrid gate driver

places a restriction on the

minimum value of RG that can be

used. For example, the minimum

allowable RG for M57962L is about

5 ohms (for additional information

refer to Section 5.1). This value is

higher than the recommended

value for many large IGBTs. Using

RG larger than the data sheet

value will cause an increase in

t

, t

d(on)

, tr and turn-on

d(off)

switching losses. In high frequency

(more than 5kHz) applications

these additional losses are usually

unacceptable. Second, even if the

additional losses and slower

switching times are acceptable, the

drivers allowable power dissipation

must be considered. At an ambient

temperature of 60°C, the M57962L

is permitted to dissipate a

maximum of about 1.5Ω (for more

information refer to Section 5.3). If

a CM600HA-24H is being used, the

driver will dissipate 1.5W at a

switching frequency of 14kHz. In

this case, operation at a higher frequency than 14kHz will cause the

driver to overheat. Lastly, the

driver’s slow shutdown becomes

less effective when it is used with

large devices. This occurs because

current that flows to the gate

through the relatively high reverse

transfer capacitance (C

res

) of

large devices can not be absorbed

by the driver. Its output impedance

is not low enough. The slow

shutdown may become less

slow and a larger turn-off snubber

capacitor may be required. This

third limitation is perhaps the most

serious. In some cases, the hybrid

driver may completely lose control

of the gate voltage and allow it to

Figure 5.14 Adding

Capacitance to

Extend t

7

6

, (µs)

5

TRIP

4

3

2

DESATURATION TRIP TIME t

1

0

0 15000

CONDITIONS:

V

CC

5000

CAPACITANCE (pF)

Figure 5.15 VGE and V

TRIP

M57962L

M57959L

= 15V, VEE,= -10V, TC= 25°C

10000

DETECT

Waveform

V

GE

V

DETECT

0

CONDITIONS:

VCC= 15V, VEE= -10V, TC= 25

VGE: 5v/div, V

DETECT

: 5v/div, 1µs/div

Figure 5.16 Short-Circuit

Shutdown

Waveform

CONDITIONS:

= 300V, Tj= 25°C

V

BUS

0

: 50v/div, IC: 100A/

V

CE

V

CE

, 0.5µs/div

div

I

C

°C

Sep.1998

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING HYBRID GATE DRIVERS AND GATE DRIVE POWER SUPPLIES

climb above 15V. If this happens,

the short circuit durability of the

IGBT module may be compromised.

All of the limitations outlined

above can be overcome by adding

a discrete npn/pnp complimentary

output stage to the hybrid driver.

One possible implementation is

shown in Figure 5.18.

The NPN and PNP booster

transistors should be fast switching

(tf < 200nS) and have sufficient

current gain to deliver the desired

peak output current. Table 5.2

lists some combinations of booster

transistors that can be used in

the circuit shown in figure 5.18.

Normally, either M57958L or

M57962L is used to drive the

booster stage. However, if the

gain of the booster transistors is

sufficiently high the lower current

M57957L and M57959L can be

used. If very high gain or

Darlington type transistors are

used in the booster stage care

must be exercised to avoid

oscillations in the output stage. It

may become necessary to add

resistance from base to emitter on

the booster transistors as shown in

Figure 5.19. In addition, when

darlingtons are used the turn-on

supply may need to be increased in

order to compensate for the

additional voltage drop across the

booster stage.

Figure 5.17 shows an example

output waveform with a

booster constructed using

D44VH10/D45VH10. For this

example, an output impedance

of 1ohm was used to drive a

capacitive load of 300nF. The

circuit shown in Figure 5.18 shows

the output booster being used with

M57962L. This output booster

stage can be used with M57958L

if short circuit protection is not

needed.

Figure 5.17 Output Waveform,

I

= 5A/div,

OUT

V

= 5V /div,

OUT

T = 1µs/div

V

OUT

I

OUT

M2

M 1.00µs ch3 -5.4V

Figure 5.18 Example Circuit for Driving Large IGBT Modules

FAULT

OUTPUT

VIN=5V

LOGIC

SIGNAL

INPUT

BUFFER

4.7 kΩ

8

V

IN

14

M57962L

13

1

5

4

6

DZ1

30V

+

47µF

+

47µF

VCC=15V VEE=10V

D1

+

V

CC

+

V

EE

EDI: RF160A

VMI: 1N6528

R

G

IGBT

MODULE

Sep.1998

MITSUBISHI SEMICONDUCTORS POWER MODULES MOS

USING HYBRID GATE DRIVERS AND GATE DRIVE POWER SUPPLIES

Table 5.2 Booster Stage Transistors

npn Transistor pnp Transistor Peak Current V

MJD44H11 MJD45H11 15A 80V Motorola Surface Mount

D44VH10 D45VH10 20A 80V Motorola TO-220

MJE15030 MJE15031 15A 150V Motorola TO-220

MJE243 MJE253 8A 100V Motorola TO-255

2SC4151 2SA1601 30A 40V Shindengen Isolated TO-220

Figure 5.19 Alternate Booster Stage Configuration

PIN 5 OF M57962L OR

PIN 7 OF M57958L

R

G

TO IGBT

GATE

CEO

Manufacturer Package

Sep.1998

Loading...

Loading...