Page 1

MITSUBISHI <CONTROL / DRIVER IC>

)

t

7

6

y

M51971L/FP

MOTOR SPEED CONTROL

DESCRIPTION

The M51971 is a semiconductor integrated circuit designed to

control the motor rotating speed.

The built-in FG amplifier with high gain enables to use a wide

range of rotating speed detector (FG detector).

Use of less external parts enables DC motors to be controlled with

high precision.

FEATURES

●Wide range of supply voltage • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 4 – 17.5V

● V ariation coefficient of supply voltage •••••±0.005%/V (standard)

●Load variation coefficient•••••±0.01% (standard, full load range)

●Temperature coefficient of rotating speed • • • • 7ppm/˚C (standard)

●Built-in high performance FG amplifier

APPLICATION

Motor rotating speed control i n floppy disk driver, player, tape

recorder, car stereo, etc.

RECOMMENDED OPERATING CONDITIONS

Supply voltage range ••••••••••••••••••••••••••••••••••••4–17.5V

Rated supply voltage ••••••••••••••••••••••••••••••••••••••••••••9V

Input voltage range at pin ••••••••••••••••• -0.4 – Vcc Note 1

Input voltage range at pin •••••••••••••••••••••••••• -0.4 – Vcc

Highest setup tacho-generator frequency •••••••••••••••• 2.5kHz

Minimum trigger pulse width (input pulse at pin )

Note 1: The linear operation range is -0.4 to +0.4V.

Note 2: This condition applies to both periods: from pulse rising to

pulse falling and pulse falling to pulse rising.

1

4

4

• • • • • • • • • • 40µs Note 2

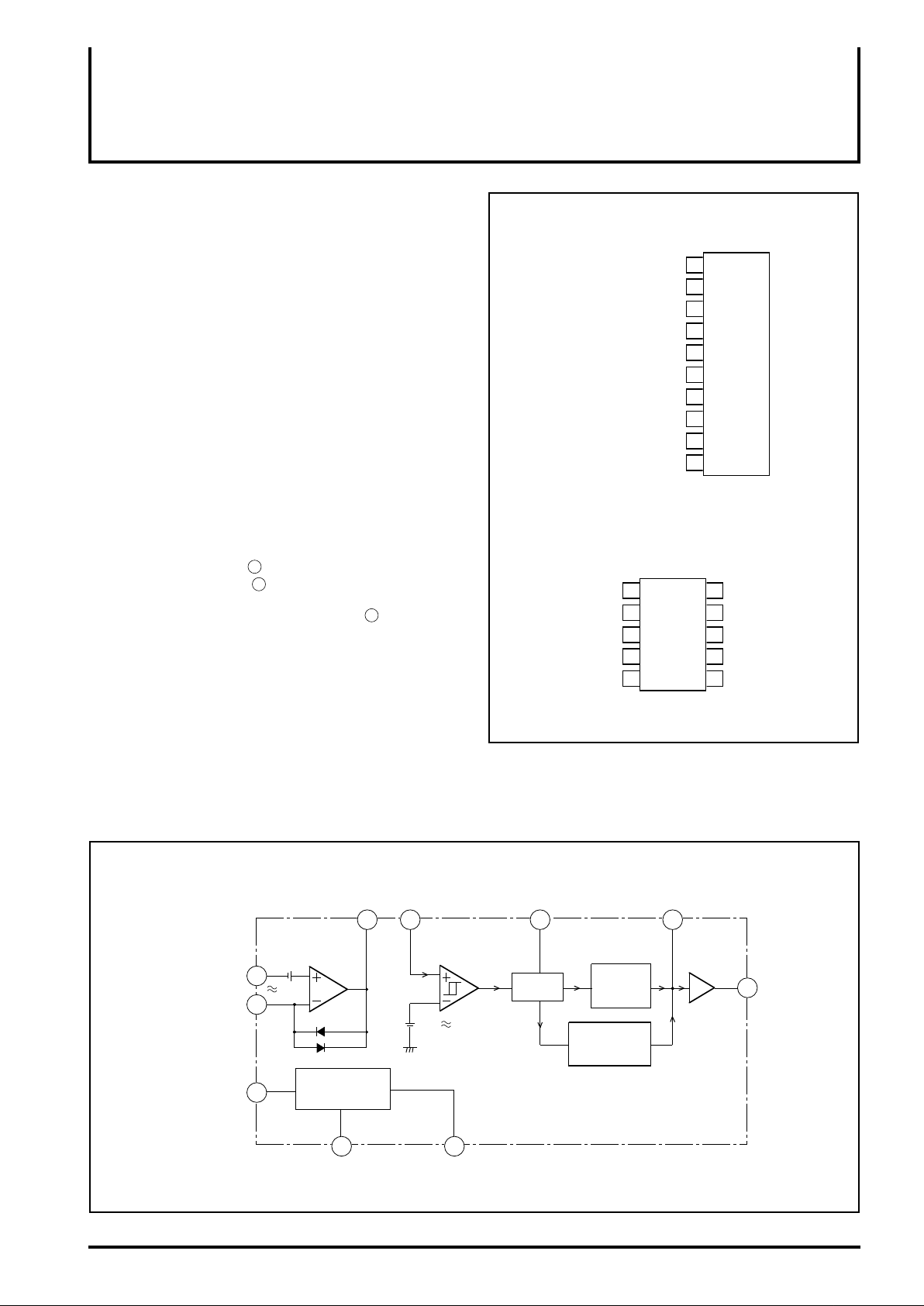

PIN CONFIGURATION(TOP VIEW

GND

Output

1

2

3

4

5

6

7

8

9

10

Outline 10P5

M51971FP

M51971L

Power supply

10

Output

9

Integration capacitance

8

GND

7

Stabilized voltage

65

Non-inverted input

Amplifier output

Stabilized voltage

Integration capacitance

Non-inverted input

Inverted input

Amplifier outpu

Schmitt input

Time constant

Inverted input

Schmitt input

Time constant

Power supply

1

2

3

4

BLOCK DIAGRAM

Non-inverted input

Inverted input

Power suppl

Outline 10P2-C

Amplifier

output

Operational

amplifier

V

LS

1

1.9V

2

10

Stabilized supply

voltage

Schmitt

intput

3

4

Schmitt

comparator

VLS 1.9V

Time constant

5

Timer

Over-shoot

prevention

circuit

Constant

current

control

Integration

capacitance

8

Buffer

amplifier

9

Output

GND

Stabilized

voltage

Page 2

ABSOLUTE MAXIMUM RATINGS(Ta=25°C unless otherwise noted

)

)

MITSUBISHI <CONTROL / DRIVER IC>

M51971L/FP

MOTOR SPEED CONTROL

Symbol

Vcc

V

1

I

3

I 6

V4

I

9

Pd

F

K

θF

Topr

Tstg

Supply voltage

Apply voltage at pin

Source current at pin

Source current at pin

Apply voltage at pin

Source current at pin

Power dissipation

Thermal derating

Operating temperature

Storage temperature

Parameter Conditions

1

3

6

4

9

Ta≥25˚C

ELECTRICAL CHARACTERISTICS(Ta=25°C, Vcc=9V unless otherwise noted

Symbol Test conditions UnitParameter

CC Supply voltage range

V

I

CC

VS

I

1

I 2

1

V LS

AV

4

I

4

V TH

4

V HY

5

V S

Tτ

8

I C

rCD

9

R

9

V max

9

V min

V

BO

Circuit current

Stabilized supply voltage

Input current at pin

Input current at pin

Level shift voltage at pin

1

2

1

FG amplifier voltage gain

Input current at pin

4

Threshold voltage at pin 4

Hysteresis width at pin

Saturation voltage at pin

4

5

One-shot pulse width

Charging current at pin

8

Ratio of charging to discharging current at pin

Output protection resistance at pin

Maximum voltage at pin

Minimum voltage at pin

9

9

9

Buffer amplifier offset voltage

Voltage at pin

1

V = 0V

1

V = 0V

1

V = 0V

1

V =0.2mVrms,f=500Hz,

4

V = 2.5V

Useslevel shift voltageatpin as thereference.

6

External set gain=60dB

1

Rτ = 75kΩ

Rτ= 75kΩ, Cτ = 4700pF

8

V = 1V

8

8

V = 1V

9

I = -20mA

8 8 9

V = 1V, V - V

Ratings

18

-3

– Vcc

-5

-5

0 – Vcc

-20

880 (M51971L)

450 (M51971FP)

8.8 (M51971L)

4.5 (M51971FP)

-20 – +75

-40 – +125

Limits

Min. Typ. Max.

3.2

-30

59

0.4

16

37

3

395

100

3.2

50

100

17.5

6.0

2.98

2.27

64

2.0

40

55

20

415

-140

-9.0

150

200

200

4.0

2.44

-3.0

-180

1.51

54

0

20

375

-260

-14.5

65

2.9

0

2.71

-0.5

1.89

-190

-11.6

Unit

V

V

mA

mA

V

mA

mW

mW / °C

°C

°C

V

mA

V

µA

nA

V

dB

µA

mV

mV

mV

µsec

µA

–

Ω

V

mV

mV

Page 3

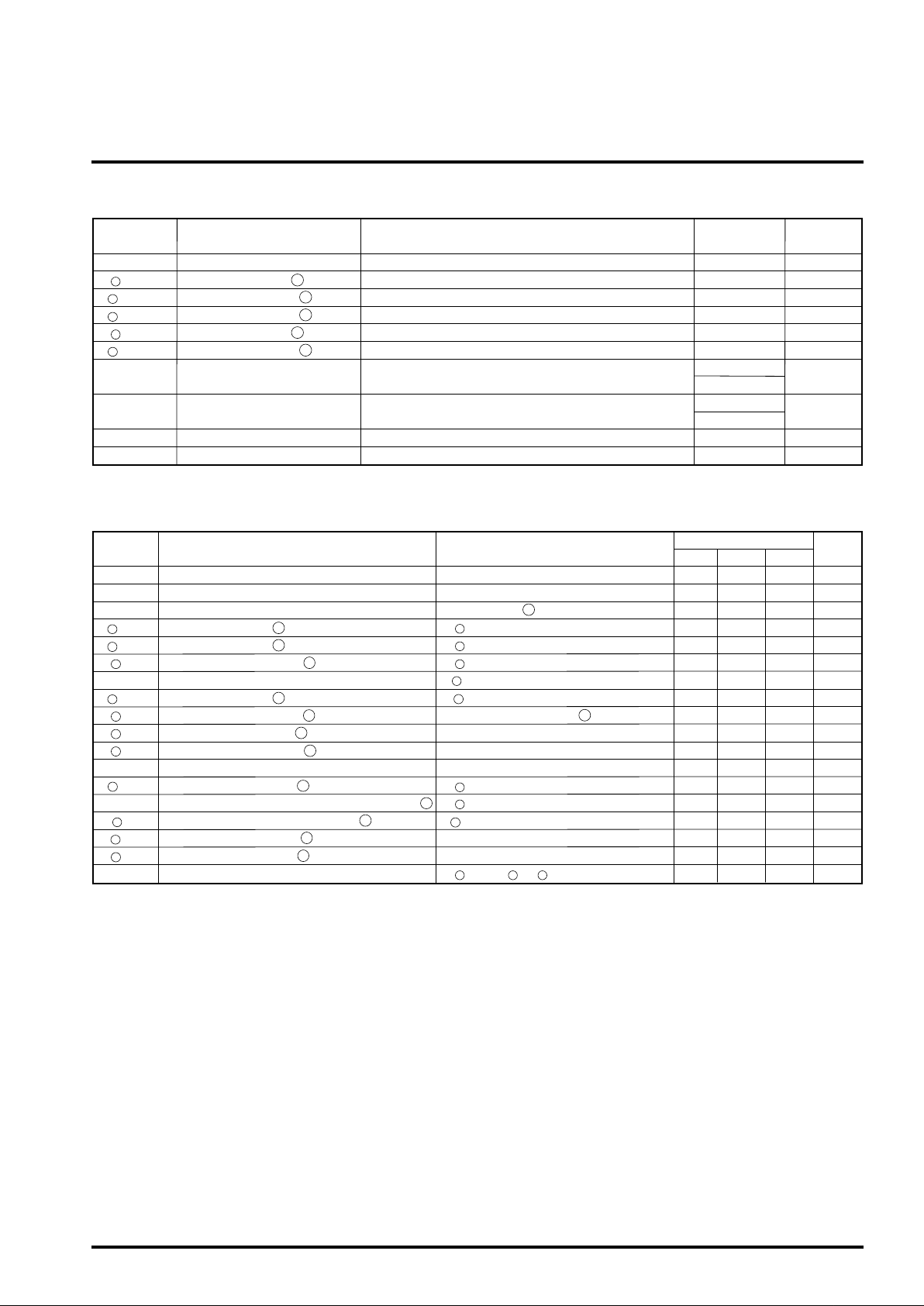

TYPICAL CHARACTERISTICS

0

)

MITSUBISHI <CONTROL / DRIVER IC>

M51971L/FP

MOTOR SPEED CONTROL

Thermal Derating (Maximum Rating)

1000

M51971L

800

600

M51971FP

400

Power Dissipation Pd (mW)

200

0

25 50 75 100 125

Ambient temperature Ta (°C)

Rotating speed–Motor torque characteristics

3005

VCC=9V

Rotating speed–Supply voltage characteristics

3005

No load

3000

Rotating speed N (rpm)

2995

048121620

Supply voltage VCC (V)

Rotating speed–Ambient temperature

characteristics

3005

VCC=9V

No load

Rτ, Cτ

Outside constant

temperature bath

3000

Rotating speed N (rpm)

2995

0 50 100

Torque T (g-cm)

Circuit current–Supply voltage characteristics

5

4

3

2

Circuit current ICC (mA)

1

0

0 4 8 121620

Supply voltage VCC (V)

3000

Rotating speed N (rpm)

2995

-50

0255075

-25

Ambient temperature Ta(°C

Circuit current–Ambient temperature

characteristics

5

4

3

2

Circuit current ICC (mA)

1

0

-50 100

-25 0 25 50 75

Ambient temperature Ta (˚C)

100

Page 4

MITSUBISHI <CONTROL / DRIVER IC>

)

)

M51971L/FP

MOTOR SPEED CONTROL

FG amplifier open loop voltage gain,

phase transition characteristics

100

80

60

40

20

Voltage gain AV (dB)

0

-20

10 100 1k 10k 100k 1M

Voltage gain

Phase

Frequency FIN (Hz)

Level shift voltage at pin – Ambient

temperature characteristics

3.0

2.5

1

1

2.0

1.5

VCC=9V

1

-90

-120

-150

Phase φ (degree)

Revel shift voltage at pin –

Input voltage characteristics at pin

2.5

VCC=9V

1

1

2.0

Level shift voltage at pin V LS (V)

1.5

-0.6 -0.4 -0.2 0 0.2 0.4 0.6 0.8 1.0 1.2 1.4

Input voltage at pin V (V)

Voltage at pin – Output current

characteristics of pin

4

3

3

3

2

1 1

3

3

1

CC=9V

V

1 =0V

V

1

1.0

0.5

Level shift voltage at pin V LS (V)

0

-25 0 50 75

-50 25 100

Ambient temperature Ta(°C

Threshold voltage at pin – Ambient

4

temperature characteristics

50

40

30

4

Threshold voltage at pin (mV)

20

10

0

-10

-20

-30

-40

-50

-50 -25

Ambient temperature T

ON level

OFF level

25 50 75

0

a (°C)

100

Voltage at pin V (V)

1

0

-15 15

-10

Output current at pin I (mA)

0510

-5

3

Saturetion voltage at pin –Sink

current characteristics at pin

40

30

5 5

20

10

Saturation voltage at pin V S (mV)

0

0 1.20.2 0.4 0.6 0.8 1.0

Sink current at pin I(mA

5

3

5

5

VCC=9V

5

Page 5

MITSUBISHI <CONTROL / DRIVER IC>

)

)

0

)

M51971L/FP

MOTOR SPEED CONTROL

Stabilized voltage–Supply voltage

characteristics

3.0

2.8

2.6

2.4

Stabilized voltage VS (V)

2.2

2.0

048121620

Supply voltage VCC (V)

Stabilized voltage–Source current

characteristics of pin

2.8

6

VCC=9V

Stabilized voltage–ambient

temperature characteristics

5

VCC=9V

4

3

2

Stabilized voltage VS (V)

2

24

1

-50 -25 0 25 50 100

Ambient temperature Ta(°C

Voltage at pin – Input signal

8

75

frequency characteristics

4

CC=9V

V

3

2.7

Stabilized voltage VS (V)

2.6

0

12

Source current at pin I (mA

6 6

Charging current at pin – Ambient

temperature characteristics

-300

-250

8

-200

8

-150

-100

-50

Charging current at pin I c (µA)

0

-25-50

Ambient temperature Ta(°C

25 50 75

8

VCC=9V

8 8

2

Voltage at pin V (V)

1

0

5

43

401.5

Discharging current at pin – Ambient

402.0 402.5 403.0

8

Pin – input signal frequency fIN (Hz)

8

temperature characteristics

30

VCC=9V

a (°C)

100

25

8 8

20

15

10

5

Discharging current at pin I d (µA)

0

-25 0 25 50 75

-50 100

Ambient temperature T

Page 6

MITSUBISHI <CONTROL / DRIVER IC>

M51971L/FP

MOTOR SPEED CONTROL

Output voltage range at pin – Supply

voltage characteristics

4

9

3

9

2

Ta =25°C

Ta =75°C

1

Output voltage range at pin V (V)

0

4 8 12 16

Supply voltage V

9

Ta = -20°C

CC (V)

Buffer amplifier offset voltage –

Voltage characteristics at pin

160

120

80

40

0

Buffer amplifier offset voltage VBO (mV)

–40

01234

Voltage at pin V (V)

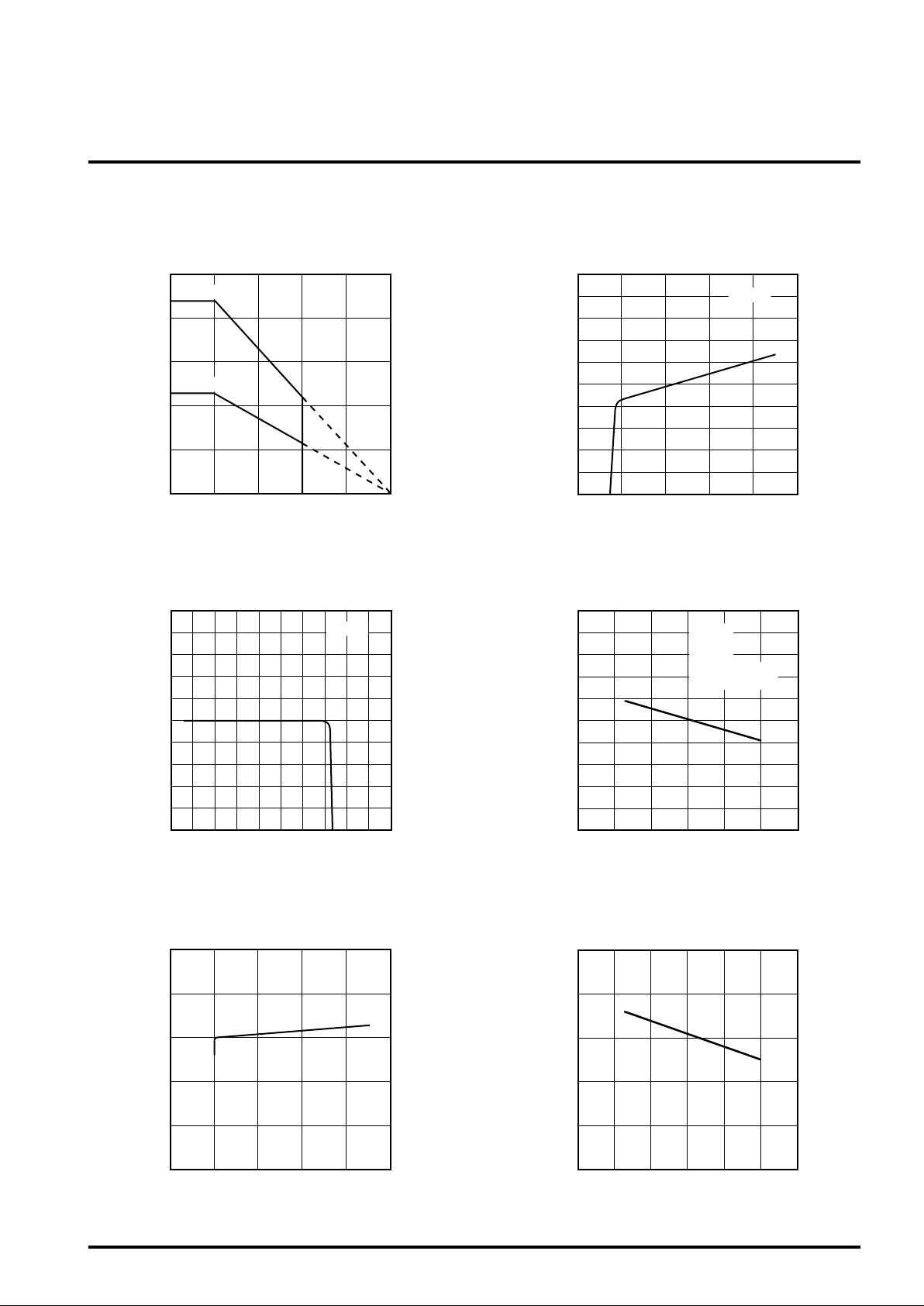

Application Characteristics Example How to determine Rτ and Cτ

These constants determine the motor rotating speed. If the motor

rotating speed and the number of poles of tacho-generator are

assumed to be N and P, respectively, the following relational

expression is generally established. According to the required

rotating speed, select the constant in such a way that Rτ can be

100

90

put in the range of 10kΩ – 500kΩ. When using a high resistance,

take care for leak current that may flow on the surface of the

printed circuit board.

NP

≈

1

1.20 • Rτ • Cτ

8

VCC=9V

8

8

10

0%

Upper side : Motor speed (FV conversion waveform of tacho-

generator frequency)

Lower side : Supply voltage

Horizontal axis : 20 ms/div

Time constant of motor ≈ 100 ms

Tacho-generator output frequency –

Connection resistance characteristics at pin

10000

7000

5000

3000

2000

1000

700

500

300

200

Tacho-generator output frequency NP (Hz)

10 20 30 50 70 100 200 300 500

Connection resistance Rτ (kΩ) at pin Rτ (kΩ)

0.1

0.047µ

µF

0.022µ

F

C

τ= 4700pF

0.01

µF

F

1

1

1000

Page 7

Brief Description on M51971 Operation

6M9

8

y

Block Description

Amplifier

output

3

1

D

D2

Non-inverted input

Inverted input

1

2

FG amplifier

VLS

1.9V

Operational

amplifier

Schmitt

input

4

A

Schmitt

circuit

VLS 1.9V

A’

Timer

Logic for timer

MITSUBISHI <CONTROL / DRIVER IC>

M51971L/FP

MOTOR SPEED CONTROL

6

To pin

7.5k

Rτ

C

B

E

5

Q

1

comparator

Cτ

15k

D

Over-shoot

prevention signal

Over-shoot prevention circuit

G

Logic for over-shoot

prevention

H

C

F1

I

100Ω

Buffer

OP

Q

3

FG amplifier

The FG amplifier consists of an operational amplifier, revel shift

circuit and diode for waveform clip.

When a DC block capacitor is connected to pin , output DC

voltage at pin becomes higher than DC voltage at pin by VLS

3

(≈1.9V≈3VBE).

AC signals centering around the GND can be therefore amplified

easily. The clipper diode limits the output signal amplitude to

±0.7V (VBE) max. and rapidly charges DC block capacitor with

power supply turned ON.

2

1

Timer output

Power

10

7

supply

GND

RF

CF2

Q2

Constant current

control

206µA

I1

16µA

I2

Stabilized

power

suppl

Stabilized voltage

(≈190µA) for the period without one-shot pulse and generates sink

current of I2 (≈16µA) for the period with one-shot pulse.

The ratio of I1 to I2 is characteristic to the IC. The frequency of the

tacho-generator to be set is determined by the one-short pulse

width and this current ratio (I1/ I2 ≈12.6).

T

G = Tτ x ≈ 1.09 x Tτ

1–I2

I

I1

Where:

TG: Tacho-generator signal frequency (set value)

Tτ : One-short pulse width

Schmitt circuit

The Schmitt circuit is a comparator with histeresis, and has ON

level of VLS + 20mV and OFF level of VLS - 20mV.

Timer

The timer generates basic time necessary for controlling the

speed.

This timer is a one-shot circuit triggered with input signals and

Over-shoot prevention circuit

The over-shoot prevention circuit operates when over-shoot is

large in particular, e.g. the motor is suddenly released from lock

status.

Q3 is set to ON for the period of one-short pulse width (Tτ) when

the signal period of the tacho-generator in a motor is shorter than

the one-shot pulse. Generally, electric charge of CF1 is discharged

for this period due to RF • CF2 >>Tτ.

generates pulse of 1.1 Cτ Rτ in pulse width.

Buffer amplifier

Consta nt currentcontrolcircuit

The constant current control circuit is controlled with output of timer

circuit. The circuit generates, at pin , source current of I1 –I2

8

The buffer circuit is a voltage follower circuit using an operational

amplifier. The input current is very small (10nA max.) and the

circuit can drive the output current of 20mA.

Page 8

Input/Output Circuit Drawing

2

318

495

6

To pin 10

MITSUBISHI <CONTROL / DRIVER IC>

M51971L/FP

MOTOR SPEED CONTROL

10

To pin

1k

To pin 6

To pin 10

I

Control signal

100

200

To pin 6

Control signal

2k

10

To pin

1k

I

2k

To the

next stage

I

100Ω

3k

To pin 10

To pin 6

I

To pin 10

7.5k

15k

Timing Chart

I. In normal operation II. Normal operation to rapid discharging operation

A, A’

A, A’

B

Approx

S

10µ

H, I

B

Approx

S

10µ

C

D

E

F

G

Tτ

G

T

TG 1.09Tτ

C

D

E

F

G

H, I

Page 9

Application Circuit Examples

MITSUBISHI <CONTROL / DRIVER IC>

M51971L/FP

MOTOR SPEED CONTROL

I. When the ou tput im pedance of the tacho-

generator is lo w ;

RS Rf RNF

CS

G

2 3 4 5 6

CNF

M51971L

M51971FP

CS : Coupling capacitor for AC amplification

RS, Rf : FG amplifier gain set resistance

RNF, CNF : Filter for noise removal

Rτ, Cτ : Time constant for motor speed setup

CF1, CF2, RF : Phase compensation capacitance and resistance to

stabilize integration and speed control systems

Notes:

1. The signal amplitude of the tacho-generator for set motor

rotating speed must be set to 1 mVP-P or more.

2. FG amplifier gain ≈

1+ω

ωG: Angle frequency of tacho-generator signal

3. The CS, RS, RNF and CNF values are desirable to be selected as

follows:

(Values omitted)

CS≤4.7µF

2

≥ CSRS ≥

ωG

RNF • CNF ≤

1

ω

1

ω

G

Rτ VCC

Cτ

10

71

1+ω

G

2

GCS

2

GCS

8

CF1

M : Motor

G : Tacho-generator

2

(RS+Rf)

2RS2

2

RF

CF2

M

9

III. When the signal amplitude of the tacho-

generator is large;

R

1

2

RNF

G

3 4 5 6 10

CNF

M51971L

M51971FP

71

Rτ

Cτ

CF1

VCC

M

9

8

F

R

CF2

In the above three examples, the portion over Vf (0.7V) of the

output waveform at pin is clipped in the built-in waveform clip

3

diode.

IV. When the input waveform is pulse shape

Input pulse signal

4 5 6 10

M51971L

M51971FP

3 2

Note: The threshold voltage at pin to GND is approx. 1.9V.

Rτ VCC

Cτ

9

CF1

4

8

RF

CF2

71

M

II.When the output impedance of the ta cho-

generator is high and the signal amplitude is

small;

CS

RS Rf RNF

2 3 4 5 6 10

1G

CNF

M51971L

M51971FP

7

Rτ VCC

CF1

Cτ

9

8

RF

CF2

M

V. When turning the m ot or ON/OFF with control

signals;

Rτ

5 6 10

M51971L

M51971FP

7

When Q1 is set to ON

When Q

8

CF1

1 is set to OFF

Cτ

9

R

F

CF2

Control signal

Q1

1

R

: Stops the motor.

: Controls the motor rotating speed.

VCC

M

Page 10

MITSUBISHI <CONTROL / DRIVER IC>

(

)

4

y

M51971L/FP

MOTOR SPEED CONTROL

VI.To switch the set rotating speed in stages with

control signals

Control

signal 1

6

Rτ1

M51971L

M51971FP

5

7

Rτ2

VII. Limiting output current at pin to prevent the

Control

signal 2

Rτ3

Cτ

9

IC from heating

Rτ

Cτ

5 6 10

M51971L

M51971FP

CF1

V max

9

R +RSC

9

8

RF

CF2

: V max9

~

~

7

I max =

9

(See the Electrical Characteristics and Typical Characteristics.)

9

3.2V, R

RSC

9

~

~

100Ω

VCC

M

Q1

VIII. To limit drive current to the motor

1)

Rτ

Cτ

5 6 10

~

~

R1 200Ω

9

0.7V

RSC

M51971L

M51971FP

7 8

CF1

IMmax =

RF

CF2

V

RSC

BE2

2) To reduce power loss due to a current limiting resistance

Rτ

τ

C

5 6 10

x

• RSC

R1 200Ω

9

R3

R2 +R3

Q2

M51971L

M51971FP

7

8

~

~

RF

CF2

0.7V x R2

R2 +R3

CF1

IMmax = (VBE2 – VBE1 )/RSC

M

Q1

Q2

RSC

M

R2

R3

Q1

IM

RSC

V

CC

V

CC

IM

IX. Frequency comparator

Frequency input

VCC

10 6

M51971L

M51971FP

7

Note: The selected Hysteresis of the Schmitt circuit must be more than or

equal to the ripple current at pin (to prevent chattering).

Rτ

8

C

F

R’τ

Cτ

5

9

8

R’τ> 2Rτ

Output

Schmitt circuit

Input/output transmission characteristics

Output voltage

fTH2 fTH1

Input frequenc

~

f

TH1

~

~

TH2

f

~

1

1.20 x Rτ • Cτ

1

1.09 x Rτ // R’τ x Cτ x In

3(Rτ + R’τ)

R’τ – 2Rτ

Page 11

Hint for designing a stabilized speed control

ω

(S)

(S)

system

(Method for determining the filter constants (CF1, CF2 and RF) at

8

pin )

The filter constants at pin must be determined to satisfy the

system stability.

8

MITSUBISHI <CONTROL / DRIVER IC>

M51971L/FP

MOTOR SPEED CONTROL

1. Transfer Function of the Motor Speed Control

System

Control circuit

C

- G

Motor speed control system

The motor speed control system is a negative feedback system

including a control circuit and a motor.

As the condition necessary for stable negative feedback, the phase

must be generally 180˚ or less in the frequency area where the

gain of open-loop transfer function (GC(S) • GM(S)) is 1 or more.

Motor

M

G

2. Transfer Function of Motor

If the motor armature current and angular velocity are assumed to

be la and ωv, respectively, the following equation is established.

∆

Tg = KT • ∆la = (SJ+D) • ∆ωv • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • (1)

Where:T g : Torque generated in the motor

KT : Proportional constant between the torque genera-

ted in the motor and the armature current

J : Inertia moment of Motor and load

D : Coefficient of viscosity friction

If the number of poles in the tacho-generator is assumed to be P,

the relation of ω= P • ωv exists between tacho-generator angular

frequency ωand motor angular velocity ωv and, therefore, the

motor transfer function (transfer function including motor and

tacho-generator) GM(S) takes a single-pole transfer function as

follows:

GM(S) = • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • (2)

∆

∆

la

=

D

• (1+S • )

=

1 +

• KT

P

J

D

M

K

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • (3)

S

ω

M

log GM (jω)

M

ω

log ω

Approximate motor transfer function

3. Transfer Function of Control Circuit Using the

M51971

If input information is assumed to be given continuously (the tachogenerator frequency is assumed to be infinitely high), the transfer

function from the input at pin to the output at pin is as follows:

∆

GC(M51971)(S)

≡

∆

Tτ( I C + I d )

=

Where : Tτ: Timer pulse width 1.10 x Rτx C

8

l C : Charging current at pin

8

l d : Discharging current at pin

1

≡

ω

F1

RF • CF2

F2

≡

RF • CF1 • CF2

CF1 +CF2

ω

If the gain of the circuit connected to the back of pin of the

M51971 is assumed to be KCP, transfer function GC(S) for the

entire circuit is as follows:

Tτ( I C + I d )

GC(S) = KCP

x

C

4 9

(output voltage at pin )

(input frequency at pin )

~

~

x

x

S(1 + S/

1 + S/

S(1 + S/

8

8

1 + S/

8 8

F1 + CF2

C

8 8

F1 + CF2

9

4

ω

F1

ω

τ

ω

F1

ω

F2)

• • • • • • • • • • • (6)

F2)

9

• • • • • • • • • • • • • (7)

Where:

KM =

ω

M =

P• KT

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • (4)

D

D

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • (5)

J

log GC (jω)

F1

ω

log ω

Approximate transfer function of control circuit

ω

F2

Page 12

MITSUBISHI <CONTROL / DRIVER IC>

M51971L/FP

MOTOR SPEED CONTROL

4. Necessity for stable control

Stable control requires the gain of GC(S) • GM(S) to be the phase

characteristics of 180˚ or less in a frequency area of 1 or more.

The relation of the phase and the gain is determined according to

the Baud’s theorem when all poles and zero points of the transfer

function are placed at the left side of the complex sphere.

If GC(jω) • GM(jω) follows the Baud’s theorem, in a frequency area

of | GC(jω) • GM(jω) | ≥ 1 the inclination of gain of GC(jω) • GM(jω)

must be -12dB/oct or more for stable control.

For the reason above, when the circuit constant is selected to

achieve ωF1 ≈ωM, and the inclination of the gain of each of GC(jω)

and GM(jω) is -6dB/oct, that is, the following formula must be

established with respect to the frequency of ωF2 where the

inclination of the gain of GC(jω) • GM(jω) begins to be -12dB/oct.

| GC

(jωF2)

• GM

(jωF2)

| < 1 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • (8)

To make a precise control, the gain of open-loop transfer function

must be large in the entire area of frequency.

The variation of the motor rotating speed attenuates due to

disturbance at an inclination of -6dB/oct with the frequency of ωM

or more.

The capability of rotating speed control in the frequency area from

ωF1 to ωF2 is determined by the gain of open-loop transfer function

at ωF1(≈ωM). The following formula is established with

| GC

(jωF2)

• GM

(jωF2)

| < 1 and when the inclination of the gain of

GC

(jω)

• GM

(jω)

is almost equal to -6dB/oct with the frequency of

ωF2or less.

ω

F2

ω

C

(jωM)

• GM

(jωM)

| G

| <

ω

Improvement of control precision in the frequency area from

F2

≈

F1

• • • • • • • • • • • • • • • • • • • • • • (9)

ω

M

ωF1to

ωF2requires the following conditions.

ωF1≈ω

M

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • (10)

ω

F2

>> • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • (11)

1

ω

F1

The KCP or CF1 +CF2 value must be set to satisfy formulae (4) and

(5).

5. Influence on the S tability of Tacho-generator

Frequency

The control system that is controlled with tacho-generator frequency, i.e. period, is a kind of sample hold system controlled with

discrete information in the time axis.

Addition of extra phase delay to sample hold operation makes the

system more unstable.

More precise transfer function H*(jω) (GC*(jω) • GM*(jω)) taking the

above operation into account is as follows, when H(jω)(GC(jω) •

GM(jω)) is assumed to be the transfer function where this operation is not taken into account:

2

πω

–j

∞

H*(

sinπ(ω/

jω

)=

π(ω/ωG)

ωG)

ωG

ΣH(jω

e

n=–

+ jn

∞

• • • • • • • • • • • • • • (12)

ωG)

Where:

ωG: Set value of tacho-generator frequency

That is, extra phase delay of 2πω/

ωG(radian) must be taken into

account.

That is, if the angular frequency satisfying | GC*(

jω)

• GM*(

jω)

| = 1

is assumed to be ωodB, the following relation must be established.

ωG> 4• ωod

When this determines

function with

| G

B

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • (13)

ωG, the possible gain of open-loop transfer

ωMcan be obtained.

C

(

jωM) • GM(

jωM)

| < 0.357 x

ω

G

• • • • • • • • • • • • • • • • • • • • (14)

ω

M

This formula (14) must be satisfied in the control system using the

frequency of the tacho-generator regardless of the control system

and indicates that the upper limit value of the control gain with

ω

is inevitably determined when the motor and tacho-generator are

determined.

Improvement of the control precision in the rotating speed requires

| Gc(

jωM) • GM(

jωM)

| >> 1. The following formula must be there-

fore established.

ω

G

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • (15)

>> 1

•

0.357

ω

M

6. Conclusion

According to the theoretical consideration above, the design of

speed control system making the best use of the characteristics of

the motor is described as follows:

(1)

ωF1≡

If

ωMsharply changes with motor load changed, a circuit constant

1

R

F

• CF2

is desirable to be set around minimum

(2)

ωF2≡

CF1 +CF2

R

F

• CF1 • CF2

As CF1is smaller, influence by

peak-to-peak value of the output pin waveform becomes larger and

the drive waveform becomes closer to pulse shape.

In most of design cases, both sides are therefore desirable to be

equal.

(3) Selection of gain constant

Keeping the relation satisfying formulae (16) and (17) above,

obtain a value for stable control by changing the KCPor CF1+C

value.

If the motor set speed is divided into several stages, stage of lower

speed is less stable. In this case, experiment must be made at

lower speeds.

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • (16)

ω

M

≈

ωM.

1

≥

• • • • • • • • • • • • • • • • • • • • • • (17)

ω

G

4

ωF2becomes smaller, but the

F2

M

Page 13

MITSUBISHI <CONTROL / DRIVER IC>

M51971L/FP

MOTOR SPEED CONTROL

How to find rough value of motor transfer

function

(1) Finding KM

∆ω

∆I

a ∆Ia

2π ∆f

KM = =

Tacho-generator frequency ω

Motor drive current Ia

Plot the relation between the motor drive current and tachogenerator frequency to obtain the inclination.

(2) Finding ω

M

Though ωM is found by measuring the motor frequency response,

this method generally takes a lot of time and labor. Measurement

of step response can find rough values easily.

63%

Motor speed

M

Motor drive current

t

τ

Supply step-shape current to the motor in static status, measure

τMuntil the motor speed reaches 63% of the final speed and

time

then find

ωMby the following formula.

1

ωM=

• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • (18)

τ

M

Loading...

Loading...