Page 1

M39208

Single Chip 2 Mbit Flash and 64 Kbit Parallel EEPROM Memory

PRELIMINARY DATA

2.7V to 3.6V SUPPLY VOLTAGE for

PROGRAM, ERASE and READ OPARATIONS

100ns ACCESS TIME

(Flash and EEPROM blocks)

WRITE, PROGRAM and ERASE STATUS BITS

CONCURRENT MODE (Read Flash while

writing to EEPROM)

100,000 ERASE/WRITE CYCLES

10 YEARS DA TA RETE NT ION

LOW POWER CONSUMPTION

– Stand-by mode: 60µA

– Automatic Stand-by mode

– Deep Power Down mode

64 bytes ONE TIME PROGRAMMABLE

MEMORY

ST A NDA RD EPRO M /OTP MEMORY

P ACKAGE

EXTENDED TEMPERATURE RANGES

TSOP32 (NA)

8 x 20 mm

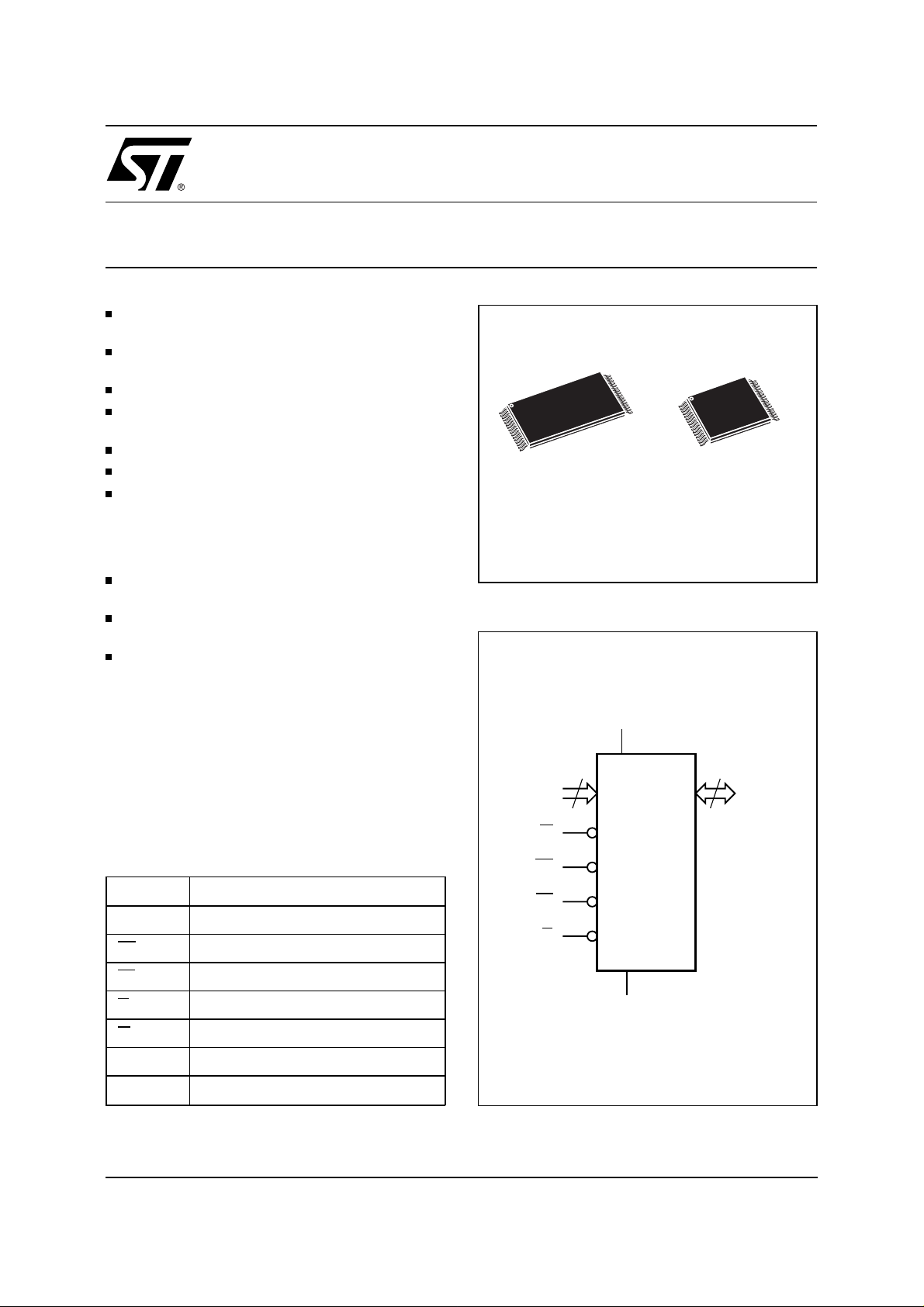

Figure 1. Logic Diagram

TSOP32 (NB)

8 x 14 mm

DESCRIPTION

The M39208 is a memory device combining Flash

and EEPROM into a single chip and using single

supply voltage. The memory is mapped in two

blocks: 2 Mbit of Flash memory and 64 Kbit of

EEPROM memory. Each space is independant for

writing, in concurrent mode the Flash Memory can

be read while the EEPROM is being written.

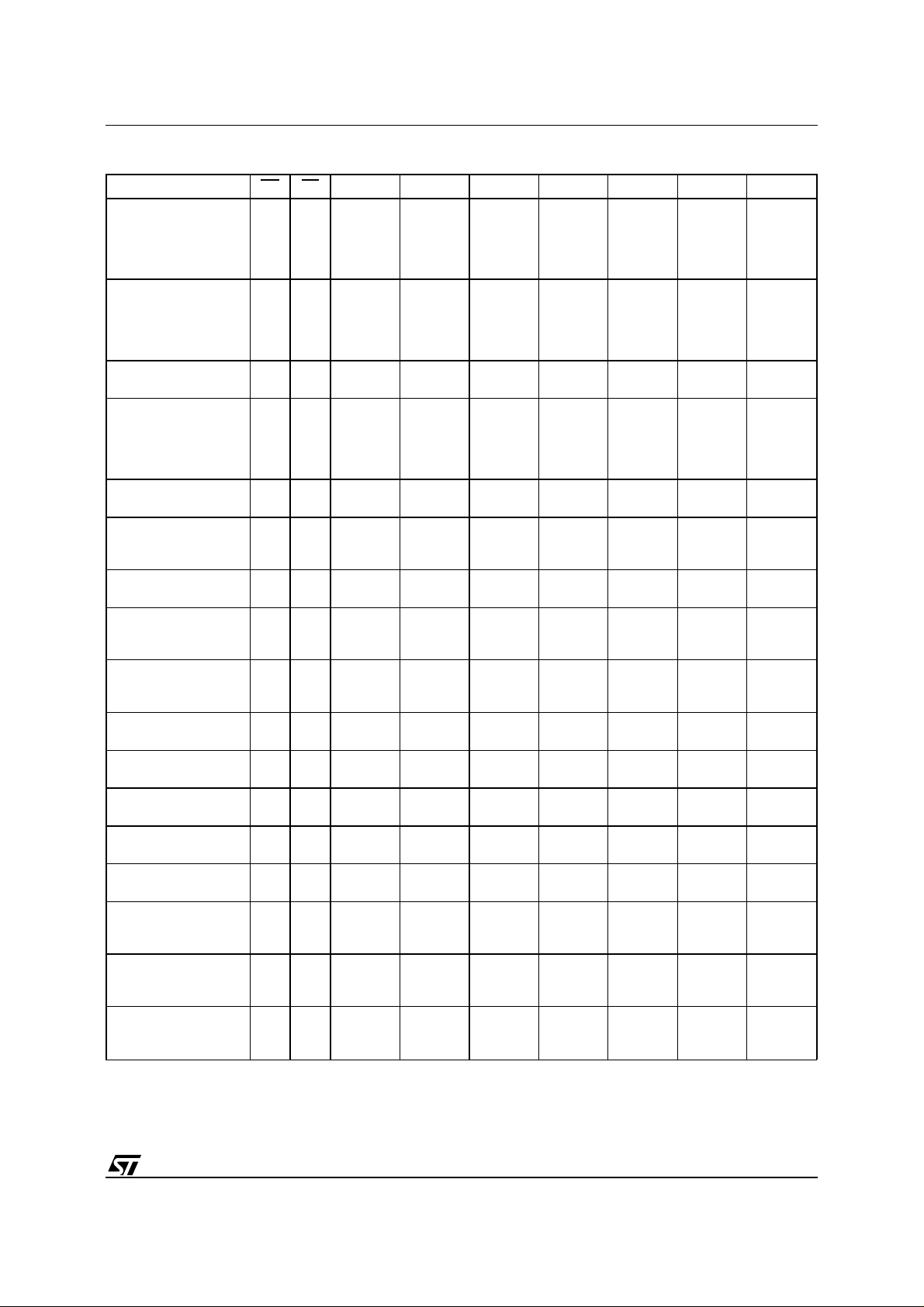

T ab le 1. Signal Names

A0-A17 Address Inputs

DQ0-DQ7 Data Input / Outputs

EE EEPROM Block Enable

EF Flash Block Enable

G Output Enable

W Write Enable

V

CC

V

SS

Supply Voltage

Ground

A0-A17

W

EE

EF

V

CC

18

M39208

G

V

SS

8

DQ0-DQ7

AI02589

February 1999 1/30

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to change with out not i ce.

Page 2

M39208

Table 2. Absolute Maximum Ratings

Symbol Parameter Value Unit

T

A

T

BIAS

T

STG

(2)

V

IO

V

CC

, VG, V

V

A9

Notes:

EF

1. Except for the rating "Operating Temperature Range", stresses above those listed in the Table "Absolute Maximum Ratings"

may cause permanent damage to the device. These are stress ratings only and operation of the device at these or any other

conditions above those indicated in the Operating sections of this specification is not implied. Exposure to Absolute Maximum

Rating conditions for extended periods may affect device reliability. Refer also to t he STMicroelectroni cs SURE Pro gr am and other

relevant quality documents.

2. Minimum Voltage may undershoot to –2V during transition and for less than 20ns.

Ambient Operating Temperature –40 to 85

Temperature Under Bias –50 to 125

Storage Temperature –65 to 150

Input or Output Voltages –0.6 to 5 V

Supply Voltage –0.6 to 5 V

(2)

A9, G, EF Voltage –0.6 to 13.5 V

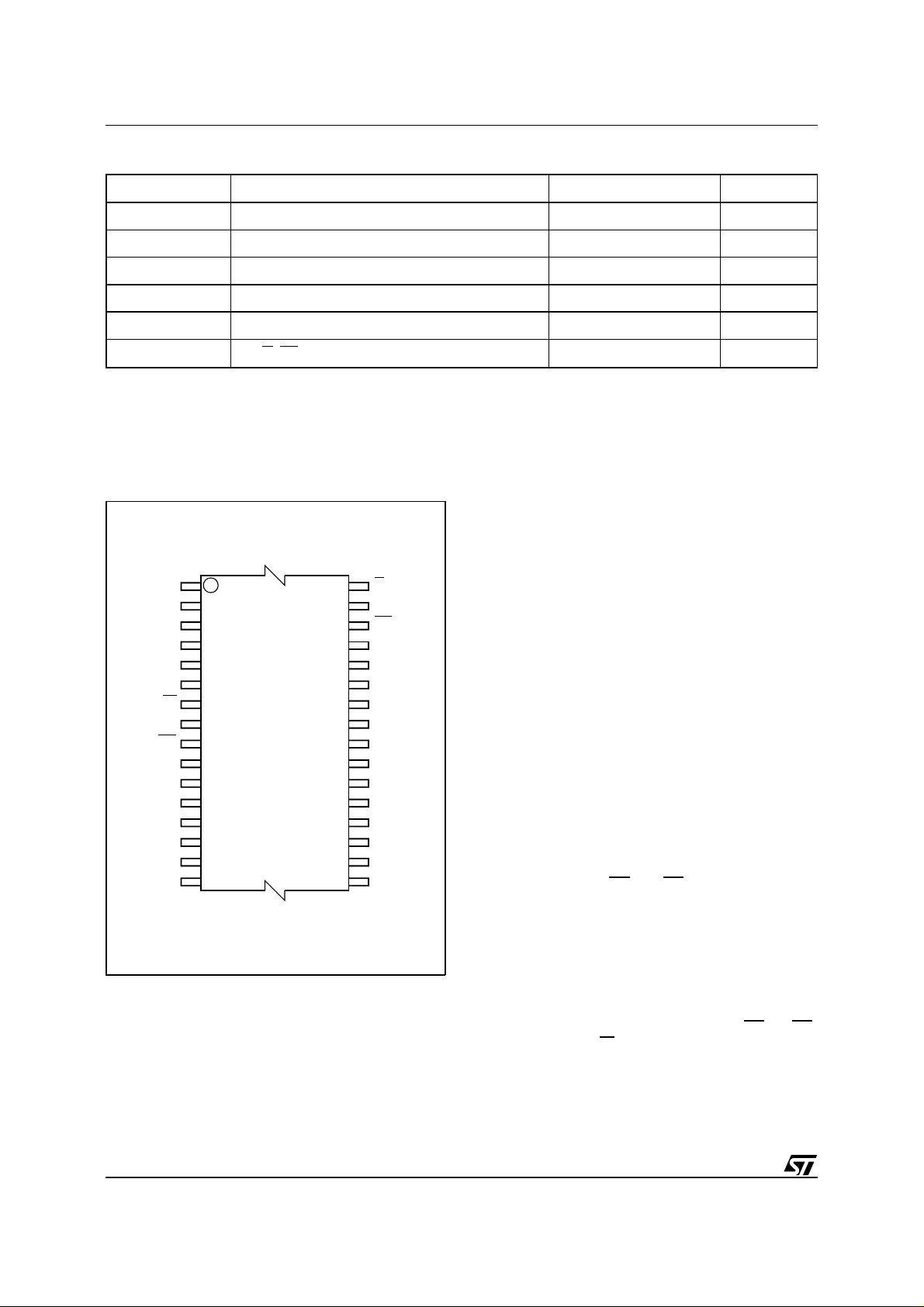

Figure 2. TSOP Pin Connections

(1)

of the data can be secured with the help of the

Software Data Protection (SDP).

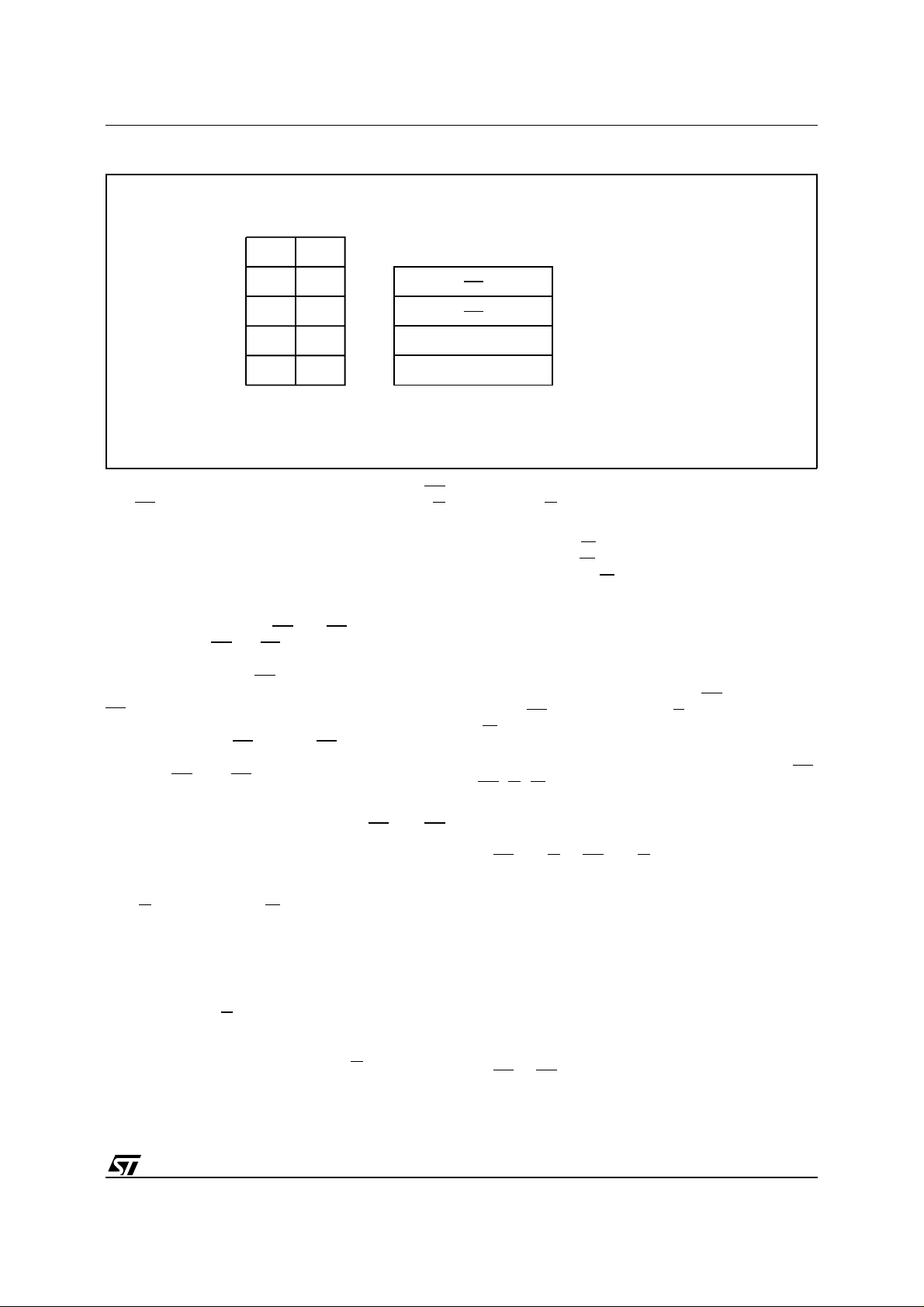

The M39208 Flash Memory block offers 4 sectors

of 64 Kbytes, each sector may be erased individually, and programmed Byte-by-Byte. Each sector

A11

A9 A10

A8 EF

A13

A14

A17

V

CC

EE

A16

A15

A12

A7

A6 A1

A5 A2

A4

1

W

8

9

16 17

M39208

32

25

24

AI02587

G

DQ7

DQ6

DQ5

DQ4

DQ3

V

SS

DQ2

DQ1

DQ0

A0

A3

can be separately protected and unprotected

against program and erase. Sector erasure may be

suspended, while data is read from other sectors

of the Flash memory block (or EEPROM memory

block), and then resumed.

During a Program or Erase cycle in the Flash

memory block or during a Write in the EEPROM

memory block, the status of the M39208 internal

logic can be read on the Data Outputs DQ7,DQ6,

DQ5 and DQ3.

PIN DESCRIPTION

Address Inputs (A0-A17).

The address inputs for

the memory array are latched during a write operation. A0-A12 access locations in the EEPROM

memory block A0-A17 access locations in the Flash

memory block. The memory block selected is given

by the state on the

When a specific voltage (V

EE and EF inputs r espectively.

) is applied on the A9

ID

address input, additional specific areas can be

accessed: Read the Manufacturer identifier, Read

the Flash block identifier, Read/Write the EEPROM

block identifier, Verify the Flash Sector Protection

Status.

DESCRIPTION

An additional 64 bytes of EPROM are One Time

Programmable.

The M39208 EEPROM memory block may be written by byte or by page of 64 bytes and the integrity

(Cont’d)

Data Input/Out put (DQ0-DQ7) .

inputs one byte which is latched when

and Write Enable

W are driven active.

Data read is valid when one Chip Enable (Chip

Enable Flash or Chip Enable EEPROM) and Output Enable are driven active. The out put is high

C

°

C

°

C

°

A write operation

EE (or EF)

2/30

Page 3

Figure 3. Flash Block Sectors

M39208

A17

AI02588

impedance when the chip is deselected (both

EF driven high) or the outputs are disabled (G

and

A16

1

1

0

0

1

0

1

0

64K Bytes Block

64K Bytes Block

EE

driven high).

Read operations are used to output the contents

from the memory, the Manufacturer identifier, the

Flash Sector protection Status, the Flash block

Identifier, the EEPROM identifier or the OTP row

content.

Memory Block Enable (

Block Enable (

EE or EF) activates the memory

EE and EF).

The Memo ry

control logic, input buffers, decoders and sense

amplifiers. When the

EE input is driven high, the

EEPROM memory block is not selected; when the

EF input is driven high, the Flash memory block is

not selected. Attempts to access both EEPROM

and Flash blocks (

EE low and EF low) are forbidden. Switching between the two memory block

enables (

same clock cycle, a delay of greater than t

EE and EF) must not be made on the

must

EHFL

be inserted.

The M39208 is in standby when both

EF and EE

are High (when no internal Erase or programming

is running). The power consumption is reduced to

the standby level and the outputs are in the high

impedance state, independent of the Output En-

G or Write Enable W inputs.

able

After 150ns of inactivity and when the addresses

are driven at CMOS levels, the chip automatically

enters a pseudo standby mode where consumption

is reduced to the CMOS standby value, while the

outputs continue to drive the bus.

The Output Enable gates the

Output Enable (

G).

outputs through the data buffers during a read

operation. The data outputs are in the high impedance state when the Output Enable

G is High.

TOP

ADDRESS

3FFFFh

2FFFFh

1FFFFh

0FFFFh

BOTTOM

ADDRESS

30000h

20000h

10000h

00000h

During Sector Protect and Sector Unprotect operations, the

G input must be forced to VID level (12V

+ 0.5V) (for Flash memory block only).

Addresses are latched on the

Write Enable (

falling edge of

the rising edge of

W).

W, and Data Inputs are latched on

W.

OPERATIONS

The M39208 memory is addressed through 18

inputs A0-A17 and provides data on eight Data

Inputs/Outputs DQ0-DQ7 with the help of four control lines: Chip Enable EEPROM (

Flash (

(

EF), Output Enable (E) and Write Enable

W) inputs.

EE), Chip Enable

An operation is defined as the basic decoding of

the logic level applied to the control input pins (

EF,

EE, G, W) and the specified voltages applied on

the relevant address pins. These operat ions are

detailed in Table 3.

Read.

is

Both Chip Enable and Output Enable (that

EF and G or EE and G) must be low in order to

read the output of the memory.

Read operations are used to output the contents

from the Flash or EEPROM block , the Manufacturer identifier, the Flash Sector protection Status,

the Flash block Identifier, the EEPROM identifier or

the OTP row content.

Notes:

– The Chip Enable input mainly provides power

control and should be used for device selection.

The Output Enable input should be used to gate

data onto the output in combination with active

EF or EE input signals.

– The data read depends on the previous instruc-

tion entered into the memory (see Table 4).

3/30

Page 4

M39208

Table 3. Basic Operations

Operation EF EE G W DQ0 - DQ7

V

Read

Write

Output Disable

Standby V

Note:

X = V

or VIH.

IL

A W rite operation can be used for two goals:

Write.

IL

V

IH

V

IL

V

IH

V

IL

V

IH

IH

V

IH

V

IL

V

IH

V

IL

V

IH

V

IL

V

IH

– either write data in the EEPROM memory block

– or enter a sequence of bytes composing an

instruction.

The reader should note that Programming a Flash

byte is an instruction (see Instructions paragraph).

Writing data requires:

– the Chip Enable (either

– the Write Enable (

EE or EF) to be Low

W) to be Low with Output

Enable (G) High.

Addresses in Flash block (or EEPROM block) are

latched on the falling edge of

W or EF (EE) whichever occurs last; the data to be written in Flash

block (EEPROM block) is latched on the rising edge

W or EF (EE) whichever occurs first.

of

Specific Read and Write Operations.

Device

specific data is accessed through operations decoding the V

level applied on A9 ( VID = 12V +

ID

0.5V) and the logic levels applied on address inputs

(A0, A1, A6). These specific operations are:

– Read the Manufacturer identifier

– Read the Device identifier

– Define the Flash Sector protection

– Read the EEPROM identifier

– Write the EEPROM identifier

Note: The OTP row (64 bytes) is acc es sed with a

specific software sequence detailed in the paragraph "Write in OTP row".

Instructions

An instruction is defined as a sequence of specific

Write operations. Each received byte is sequentially decoded (and not executed as standard Write

operations) and the instruction is executed when

V

IL

V

IL

V

IH

V

IH

V

IH

V

IH

XX Hi-Z

V

IH

V

IH

V

IL

V

IL

XHi-Z

XHi-Z

Read in Flash Block

Read in EEPROM Block

Write in Flash Block

Write in EEPROM Block

the correct number of bytes are properly received

and the time between two consecutive bytes is

shorter than the time-out value.

The sequencing of any instruction must be followed

exactly , any invalid combination of instruction bytes

or time-out between two consecutive bytes will

reset the device logic into a Read memory state

(when addressing the Flash block) or directly decoded as a single operation when addressing the

EEPROM block.

The M39208 set of instructions includes:

– Program a byte in the Flash block

– Read a Flash sector protection status

– Erase instructions: Flash Sector Erase, Flash

Block Erase, Flash Sector Erase Suspend, Flash

Sector Erase Resume

– EEPROM power down

– Deep power down

– Set/Reset the EEPROM software writ e protec-

tion (SDP)

– OTP row access

– Reset and Return

– Read identifiers: read the manufacturer identi-

fier, Read the Flash block identifier

These instructions are detailed in Table 4.

For efficient decoding of the instruction, the two first

bytes of an instruction are the coded cycles and are

followed by a command byte or a confirmation byte.

The coded cycles consist of writing the data AAh at

address 5555h during the first cycle and data 55h

at address 2AAAh during the second cycle.

In the specific case of the Erase instruction, the

instruction expects confirmation by two additional

coded cycles.

4/30

Page 5

M39208

T able 4. Instructions

(1)

Instruction EE EF Cycle 1 Cycle 2 Cycle 3 Cycle 4 Cycle 5 Cycle 6 Cycle 7

Read

Read Manufacturer

Identifier

(2)

10

AAh

@5555h

55h

@2AAAh

90h

@5555h

Identifier

with

(A0,A1,A6)

at (0,0,0)

Read

Read Flash

Identifier

(2)

10

AAh

@5555h

55h

@2AAAh

90h

@5555h

identifier

with

(A0,A1,A6)

at (1,0,0)

Read OTP Row 0 1

AAh

@5555h

55h

@2AAAh

90h

@5555h

Read

byte 1

Read

byte 2

Read

Read Block

Protection Status

(2)

10

AAh

@5555h

55h

@2AAAh

90h

@5555h

Identifier

with

(A0,A1,A6)

at (0,1,0)

Program a Flash Byte 1 0

Erase one Flash

Block

10

Erase the Whole Flash 1 0

AAh

@5555h

AAh

@5555h

AAh

@5555h

55h

@2AAAh

55h

@2AAAh

55h

@2AAAh

A0h

@5555h

80h

@5555h

80h

@5555h

Data

@address

AAh

@5555h

AAh

@5555h

55h

@2AAAh

55h

@2AAAh

30h

@Sector

address

10h

@5555h

B0h

Suspend Block Erase 1 0

@any

address

30h

Resume Block Erase 1 0

@any

address

EEPROM Power

Down

01

Deep Power Down 1 0

SDP Enable

(EEPROM)

SDP Disable

(EEPROM)

01

01

Write in OTP Row 0 1

Return (from OTP

Read or EEPROM

01

Power Down)

Reset 1 0

Reset (short

instruction)

Notes:

1. AAh @5555h means Write byte AAh at address 5555h.

2. This instruction can also be performed as a simple Read operation with A9=V

3. Additional blocks to be erased must be entered within 80µs.

10

AAh

@5555h

20h

@5555h

AAh

@5555h

AAh

@5555h

AAh

@5555h

F0h @

any

address

AAh

@5555h

F0h

@any

address

55h

@2AAAh

55h

@2AAAh

55h

@2AAAh

55h

@2AAAh

55h

@2AAAh

30h

@5555h

A0h

@5555h

80h

@5555h

B0h

@5555h

F0h

@any

Address

Write

byte 1

AAh

@5555h

Write

byte 1

(refer to READ chapter).

ID

Write

byte 2

55h

@2AAAh

Write

byte 2

20h

@5555h

Read

byte N

30h

@Sector

address

Write

byte N

Write

byte N

(3)

5/30

Page 6

M39208

T ab le 5. Device Identifiers

Identifier EF EE G WA0A1A6A9

Read the

Manufacturer

Identifier

Read the Flash

Block Identifier

Read the

EEPROM Block

Identifier

Note:

X = Don’t Care.

POWER SUPPLY and CURRENT CONSUMPTION

EEPROM Power Down.

with the EEPROM in power down with the help of

the EEPROM power down instruction (see Table

4). Once the EEPROM power down instruction is

decoded, the EEPROM block cannot be ac ces sed

unless a further Return instruction is decoded.

Deep Power Down.

lowest I

consumption mode with the help of the

CC

Deep Power Down instruction (see Table 4). Once

the instruction is d ecoded, the device is set in a

sleep mode until a Reset instruction is decoded.

Power Up.

The M39208 internal logic is reset upon

a power-up condition to Read memory status. Any

Write operation in EEPROM is inhibited during the

first 5 ms following the power-up.

Either

EF, EE or W must be tied to VIH during

Power-up for the maximum security of the data

contents and to remove the possibility of a byte

being written on the first rising edge of

W. Any write cycle initiation is locked when Vcc is

below V

LKO

.

READ

Read operations and instructions can be used to:

– read the contents of the Memory Array (Flash

block and EEPROM block)

– read the Memory Array (Flash block and

V

V

V

V

IL

V

IL

V

IH

V

IH

V

IH

V

IL

V

IL

IL

IL

IH

V

IH

V

IH

The M39208 can be set

The M39208 can be set in the

EF, EE o r

V

V

V

IL

V

IH

XXVILV

V

IL

IL

IL

V

IL

Read data (Flash a nd EEPR OM bloc ks)

Both Chip Enable

G) must be low in order to read the data from the

(

memory.

Read the Manufacturer Identifier

The manufacturer’s identifier can be read with two

methods: a Read operation or a Read instruction.

Read Operation.

be read with a Read operation with specific logic

levels applied on A0, A1, A6 and the V

= 12V + 0.5V) on A9 (see Table 5).

Read Instruction.

can also be read with a single instruction composed

of 4 operations: 3 specific Write operations (see

Table 4) and a Read which outputs the Manufacturer identifier, the Flash block identifier or the Flash

sector protection status.

Read the Flash Block Identifier

The Flash block identifier can be read with two

methods: a Read operation or a Read instruction.

Read Operation.

can be read with a single Read operation with

specific logic levels applied on A0, A1, A6 and the

level on A9 (see Table 5).

V

ID

Read Instruct ion.

also be read with an instruction composed of 4

operations: 3 specific Write operations and a Read

(see Table 4).

EEPROM block) status and identifiers.

Other

Addresses

V

ID

V

ID

ID

Don’t Care 20h

Don’t Care t.b.d.

Don’t Care

DQ0 - DQ7

64 bytes

user

defined

EF (or EE) and Output Enable

The manufacturer’s identifier can

level (V

ID

The manufacturer’s identifier

The Flash block identifier (t.b.d.)

The Flash block identifier can

ID

6/30

Page 7

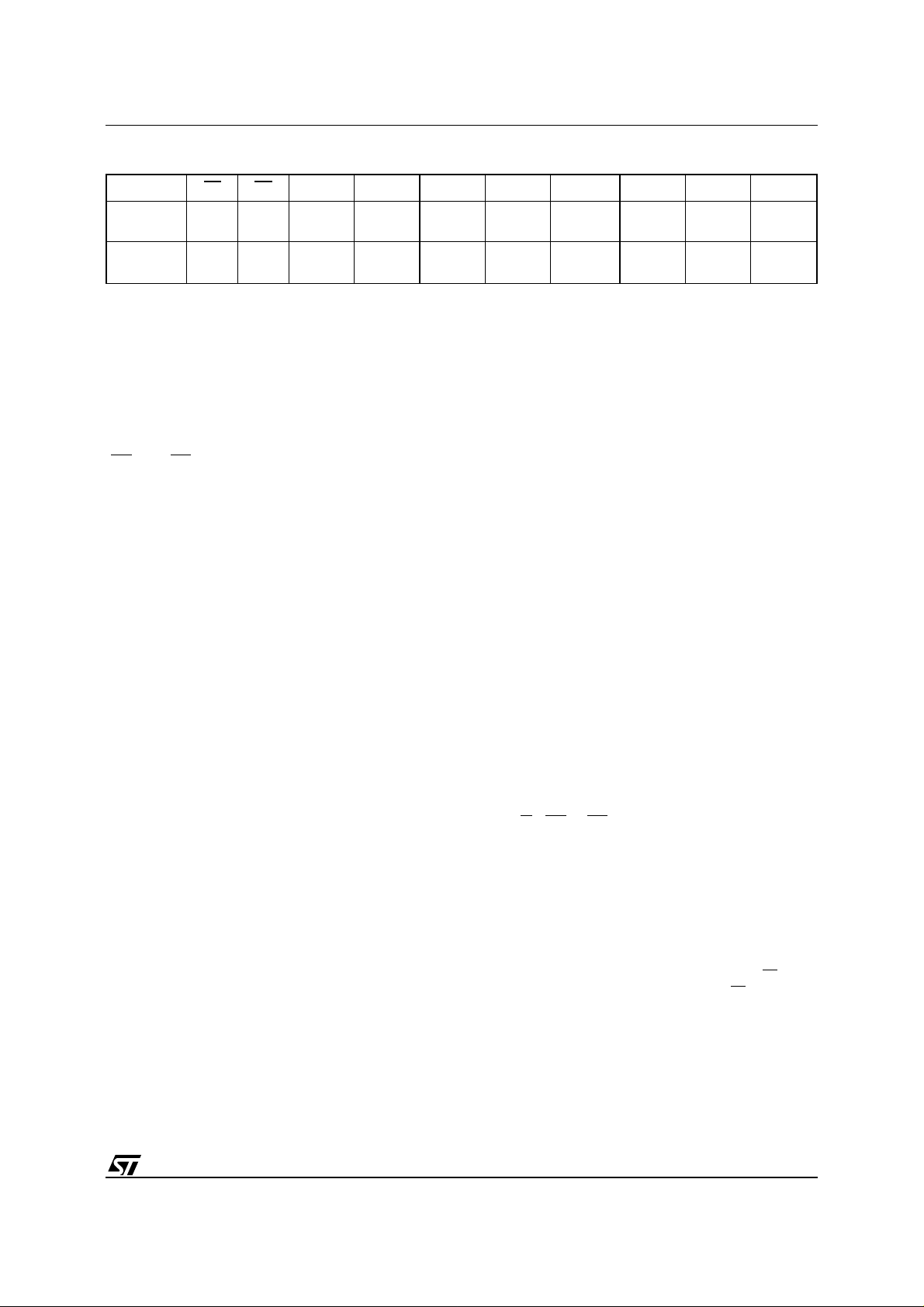

T able 6. Status Bit

EF EE DQ7 DQ6 DQ5 DQ4 DQ3 DQ2 DQ1 DQ0

M39208

Flash V

EEPROM V

Note:

X = Not guaranteed value, can be read either ’1’ or ’0’.

V

IL

V

IH

Data

IH

Polling

Data

IL

Polling

Toggle

Flag

Toggle

Flag

Read the EEPROM Block Identifier

The EEPROM block identifier (64 bytes, user defined) can be read with a single Read operation with

A6 = ’0’ and A9 = V

(see Table 5).

ID

Read the OTP Row

The OTP row is mapped in the EEPROM block

EE = ’0’, EF = ’1’). Read of the OTP row (64 bytes)

(

is by an instruction (see T able 4) composed of three

specific Write operations of data bytes at three

specific memory locations (each location in a different page) before reading the OTP row content.

When accessing the OTP row, only the LSB addresses (A6 to A0) are dec oded where A6 mus t be

’0’.

Each Read of the OTP row has to be followed by

the Return instruction (see Table 4).

Read the Flash Sector Protection Status

Reading the Flash sector protection status is by an

instruction similar to the Read Manufacturer identifier instruction, the only difference being the value

of the logic levels applied on A0, A1, A 6, while A16

and A17 define the Flash sector whose protection

has to be verified. Such a read instruction will

output a 01h if the Flash sector is protected and a

00h if the Flash sector is not protected.

The Flash sector protection status can also be

verified with a Read operation (see chapter: Flash

block specific features), with V

on A9.

ID

Read the Status Bits

The M39208 provides several Write operation

status flags which may be used to minimize the

application write (or erase or program) time. These

signals are available on the I/O port bits when

programming (or erasing) are in progress.

Data Polling flag, DQ7.

When Erasing or Programming into the Flash block (or when Writing into

the EEPROM block), bit DQ7 outputs the complement of the bit being entered for Programming/Writing on DQ7. Once the Program

instruction or the Write operation is per formed, the

Error

Flag

XXXXXX

X

Erase

Time-out

XXX

true logic value is read on DQ7 (in a Read operation).

Flash memory block specific features:

– Data Polling is effective after the fourth W pulse

(for programming) or after the sixth W pulse (for

Erase). It must be performed at the address

being programmed or at an address within the

Flash sector being erased.

– During an Erase instruction, DQ7 outputs a ’0’.

After completion of the instruction, DQ7 will output the last bit programmed (that is a ’1’ after

erasing).

– if the byte to be programmed is in a protected

Flash sector, the instruction is ignored.

– If all the Flash sectors to be erased are pro-

tected, DQ7 will be set to ’0’ for about 100µs, and

then return to t he previous addressed byte. No

erasure will be performed.

– if all sectors are protected, a Bulk Erase instruc-

tion is ignored.

T oggle flag, DQ6.

The M39208 also offers another

way for determining when the EEPROM write or

the Flash memory Program instruction is completed. During the internal Write operation, the DQ6

will toggle from ’0’ to ’1’ and ’1’ to ’0’ on subsequent

attempts to read any byte of the memory, when

G , EE or EF is low.

either

When the internal cycle is completed the toggling

will stop and the data read on DQ0-DQ7 is the

addressed memory byte. The device is now accessible for a new Read or Write operation. The operation is completed when two successive reads yield

the same output data.

Flash memory block specific features:

a. the T oggle bit is effective after the fourth

(for programming) or after the sixth

W pulse

W pulse (for

Erase).

b. If the byte to be programmed belongs to a pro-

tected Flash sector, the instruction is ignored and:

7/30

Page 8

M39208

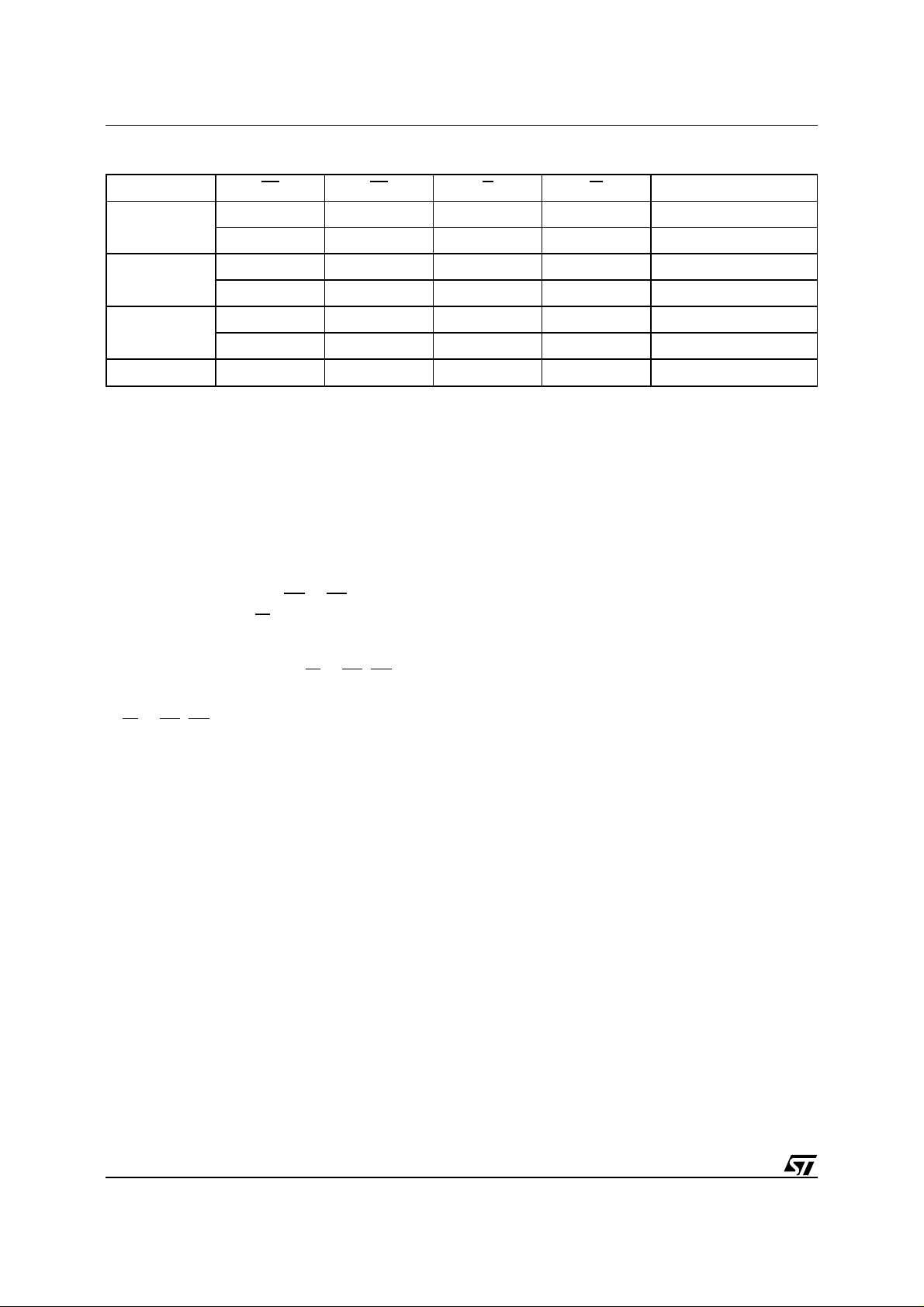

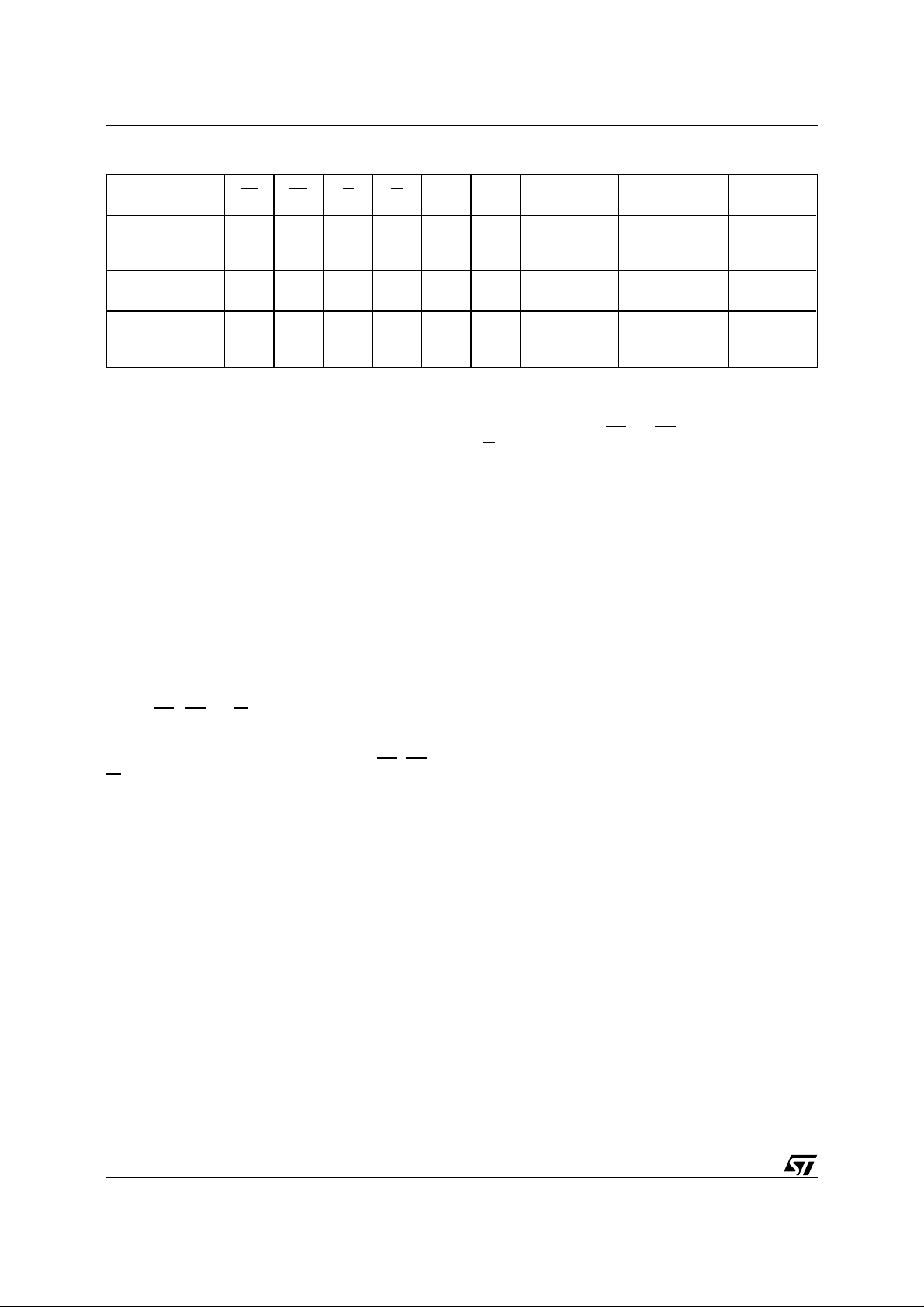

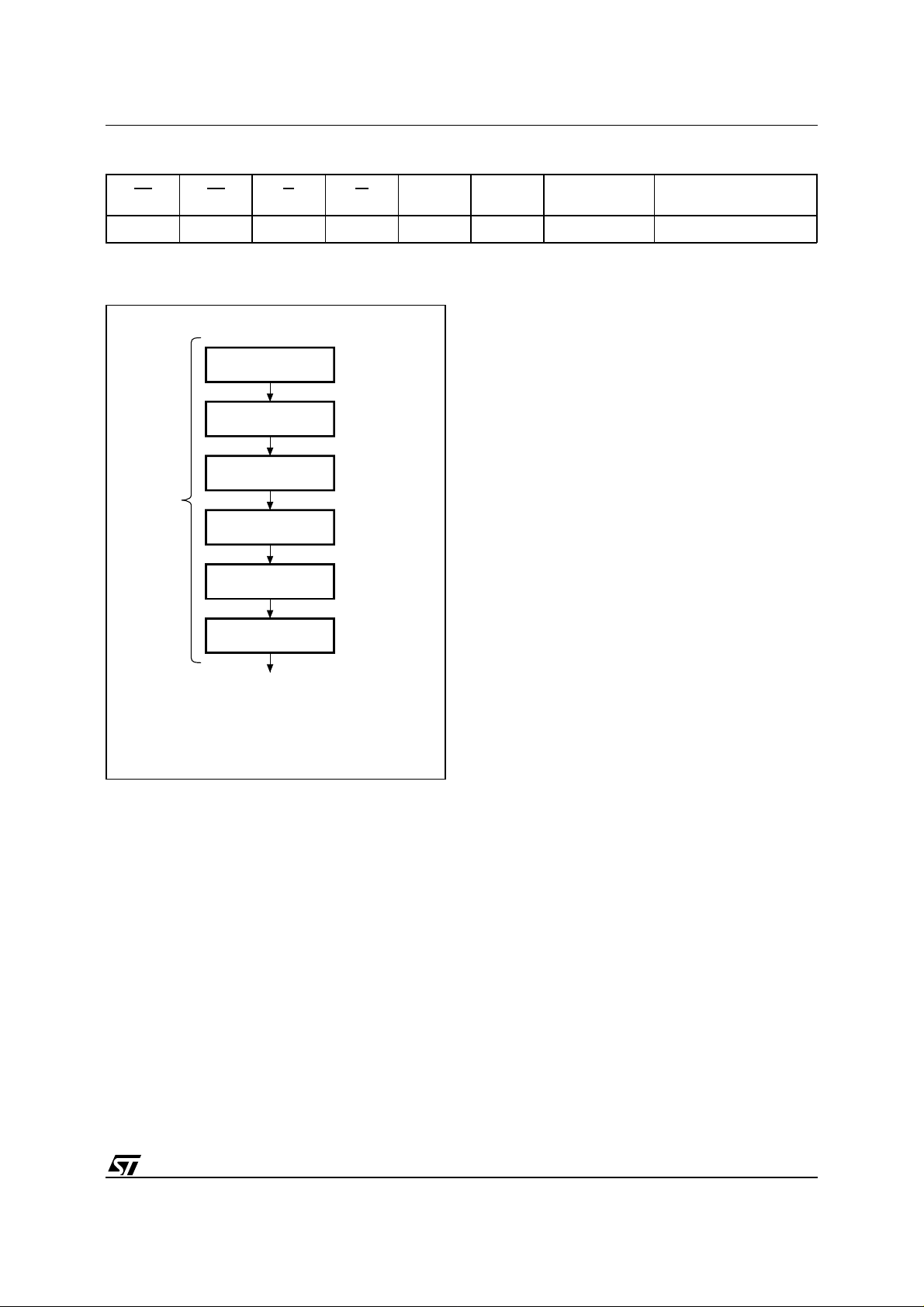

Figure 4. EEPROM SDP Enable Flowcharts

Page

Write

Instruction

WRITE AAh in

Address 5555h

WRITE 55h in

Address 2AAAh

WRITE A0h in

Address 5555h

SDP is set

SDP ENABLE ALGORITHM

Page

Write

Instruction

SDP

Set

WRITE AAh in

Address 5555h

WRITE 55h in

Address 2AAAh

WRITE A0h in

Address 5555h

WRITE Data to

be Written in

any Address

Write

in Memory

SDP

not Set

WRITE

is enabled

Write Data

+

SDP Set

after tWC

AI01698B

– if all the Flash sectors selected for erasure

are protected, DQ6 will toggle to ’0’ for about

100µs, and then return to the previous addressed byte.

– if all sectors are protected, the Bulk Erase in-

struction is ignored.

Error flag, DQ5 (F lash block only).

This bit is set

to ’1’ when there is a failure during either a Flash

byte programming or a Sector erase or the Bulk

Erase.

In case of error in Flash sector erase or byte

program, the Flash sector in which the error occurred or to which the programmed byte belongs,

must not be used any longer (other Flash sectors

may still be used). The Error bit resets after Reset

instruction.

During a correct Program or Erase, the Error bit will

set to ’0’.

Erase Time-out flag, DQ3 (Flash block only).

The Erase Timer bit reflects the time-out period

allowed between two consecutive Sector Erase

instructions. The Erase timer bit is set to ’0’ after a

Sector Erase instruction for a time period of 100µs

20% unless an additional Sector Erase instruction

±

is decoded. After this time period or when the

additional Sector Erase instruction is decoded,

DQ3 is set to ’1’.

WRITE a BYTE (or a P AGE ) in EEPROM

It should be noticed that writing in the EEPROM

block is an operation, it is not an instruction (as for

Programming a byte in the Flash block).

Write a Byte in EEPROM Block

A write operation is initiated w hen Chip Enable

is Low and Write Enable

Enable

edge of

G High. Addresses are latched on the falling

W, EE whichever occurs last.

W is Low with Output

EE

Once initiated, the write operation is internally

timed until completion, that is during a time t

.

W

The status of the write operation can be found by

reading the Data Polling and Toggle bits (as detailed in the READ chapter) or the Ready/Busy

output. This Ready/Busy output is driven low from

the write of the byte being written until the completion of the internal Write sequence.

8/30

Page 9

T ab le 7. Write the EEPROM Block Identifier

M39208

EF EE G WA6A9

V

IH

Figure 5. SDP disable Flowchart

V

IL

V

IH

V

IL

V

IL

V

period (between two consecutive Write operations)

that is smaller than the t

time exceeds the t

ming cycle will start.

WRITE AAh in

Address 5555h

EEPROM Block Software Data Protection

A protection instruction allows the user to inhibit all

WRITE 55h in

Address 2AAAh

write modes to the EEPROM block: the Software

Data Protection (referenced as SDP in the following). The SDP feature is useful for protecting the

EEPROM memory from inadvertent write cycles

Page

Write

Instruction

WRITE 80h in

Address 5555h

WRITE AAh in

Address 5555h

that may occur during uncontrolled bus conditions.

The M39208 is shipped as standard in the unpro-

tected state meaning that the EEPROM memory

contents can be changed by the user. After the SDP

enable instruction, the device enters the Protect

Mode where no further write oper ations have any

WRITE 55h in

Address 2AAAh

effect on the EEPROM memory contents.

The device remains in this mode until a valid SDP

disable instruction is received whereby t he device

WRITE 20h in

Address 5555h

Unprotected State

after

tWC (Write Cycle time)

AI01699B

reverts to the unprotected state.

T o enable the Software D ata Protection, the device

has to be written (with a Page Write) with three

specific data bytes at three specific memory locations (each location in a different page) as shown

in Figure 4. This sequence provides an unlock key

to enable the writ e action, and, at t he same time,

SDP continues to be set. Any further Write in

EEPROM when the SDP is set will use this same

sequence of three specific data bytes at three

Write a Page in EEPROM Block

The Page write allows up to 64 bytes within the

same EEPROM page to be consecutively latched

into the memory prior t o initiating a programming

cycle. All bytes must be located in a single pa ge

address, that is A6-A12 must be the same for all

bytes. Once initiated, the Page write operation is

internally timed until completion, that is during a

WC

.

time t

The status of the write operation can be seen by

reading the Data Polling and Toggle bits (as detailed in the READ chapter).

A Page write is composed of successive Write

instructions which must be sequenced within a time

specific memory locations followed by the bytes to

write. The first SDP enable sequence can be directly followed by the bytes to written.

Similarly, to disable the Software Data Protection

the user has to write specific data bytes into six

different locations with a Page Write addressing

different bytes in different pages, as shown in Figure 5.

The Software Data Protection state is non-volatile

and is not changed by power on/off sequences. The

SDP enable/disable instructions set/reset an internal non-volatile bit and therefore will require a write

time t

only on the Toggle bit (status bit DQ6).

Other

Addresses

ID

WC

Don’t Care 64 bytes User Defined

WLWL

value, the internal program-

WLWL

, This Write operation can be m onitored

DQ0 - DQ7

value. If this period of

9/30

Page 10

M39208

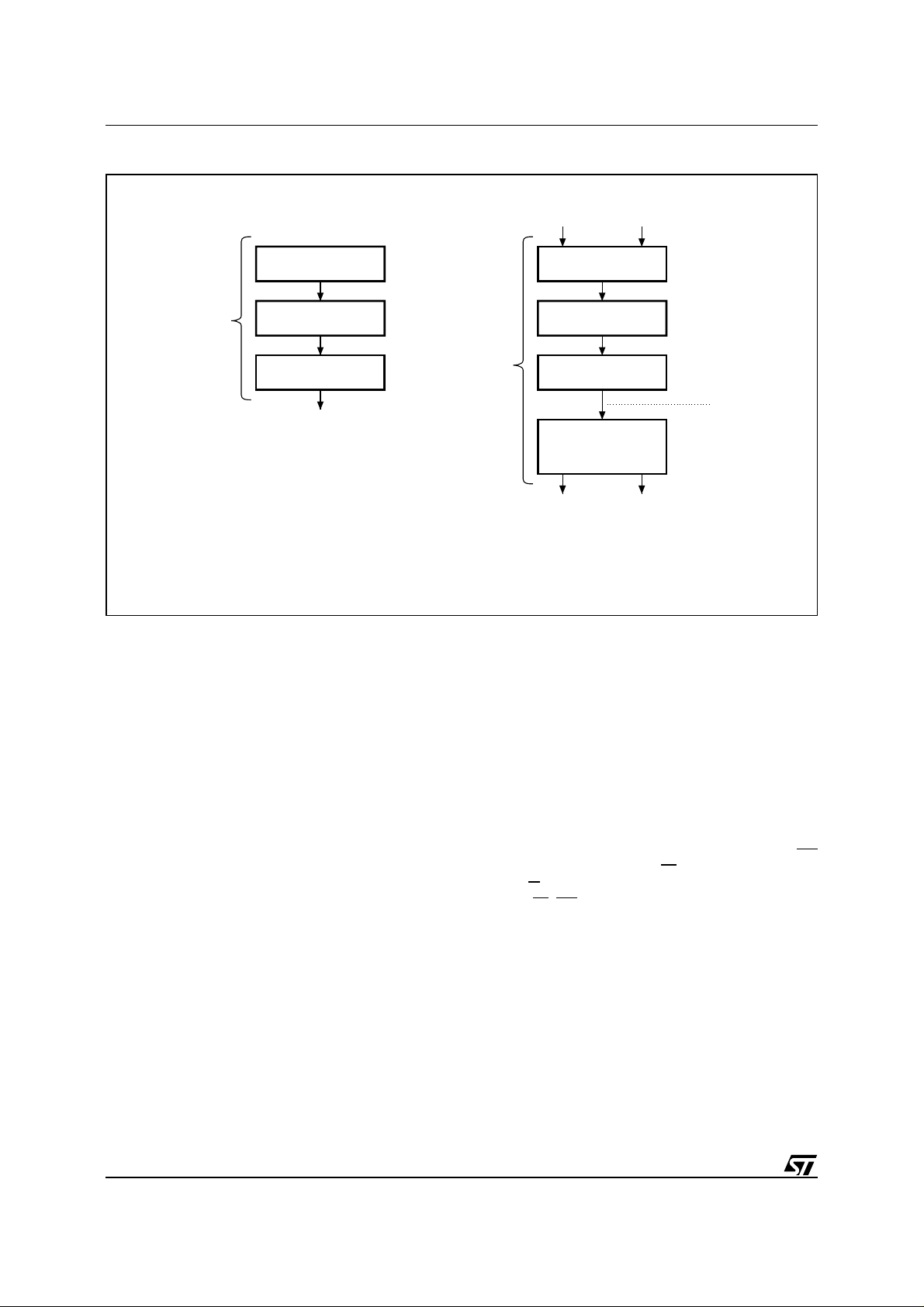

Figure 6. Data Polling Flowchart

START

READ DQ5 & DQ7

at VALID ADDRESS

DQ7

YES

=

DATA

NO

NO

DQ5

= 1

YES

READ DQ7

DQ7

YES

=

DATA

NO

FAIL PASS

Figure 7. Data Toggle Flowchart

START

READ

DQ5 & DQ6

DQ6

=

TOGGLE

NO

DQ5

= 1

READ DQ6

DQ6

=

TOGGLE

FAIL PASS

NO

YES

YES

NO

YES

AI01369

Write OTP Row

Writing (only one time) in the OTP row (64 bytes)

is enabled by an instruction. This instruction is

composed of three specific Write operations of data

bytes at three specific memory locations (each

location in a different page) followed by the the data

to store in the OTP row (refer to Table 4).

When accessing the OTP row, the only LSB addresses (A6 to A0) are decoded, with A6 = ’0’.

Write the EEPROM Block Identifier

The EEPROM block identifier can be written with a

single Write operation with specific logic levels

applied on A6 and the V

level on A9 (see Tab le

ID

7).

PROGRAM in the Flash BLOCK

It should be noted that writing data into the

EEPROM block and the Flash block is not per-

AI01370

formed in a similar way: the Flash memory requires

an instruction (see Instruction chapter) for Erasing

and another instruction for Programming one (or

more) byte(s), the EEPROM memory is directly

written with a simple operation (see Operation

chapter).

Program Instuction.

During the execution of the

Program instruction, the Flash block memory will

not accept any further instructions.

The Flash block memory can be program med byteby-byte. The program instruction is a sequence of

three specific Write operations followed by writing

the address and data byte to be programmed into

the Flash block memory (see T able 4). The M39208

automatically starts and performs the programming

after the fourth write operation.

During programming, the memory status may be

checked by reading the status bits DQ5, DQ6 and

DQ7, as detailed in the following sections.

10/30

Page 11

M39208

Data Polling.

Polling on DQ7 is a method of checking whether a Program or an Erase ins truction is in

progress or completed (see Figure 6). When a

Program instruction is in progress, data bit DQ7 is

the complement of the original data bit 7; when

DQ7 is identical to the old data and the Error bit

DQ5 is still ’0’, the instruction is complete. To determine if DQ7 is valid, each poll must store the

original data for comparison, and if t hey are the

same, it can be considered that the operation was

successful. The Error bit DQ5 is checked to ensure

timing limits have not exceeded.

When an Erase operation is in progress, DQ7 is

always ’0’, and will be ’1’ when finished, so long as

DQ5= ’0’.

In all cases, when DQ5 is ’1’, DQ7 should be

checked again, in case DQ7 changed simultaneously with DQ5. If DQ7 = true dat a (Program) or

DQ7 = ’1’ (Erase), the operation is successful and

execution should return to the caller. A suggested

second read will provide all true data (Program) or

all FFh (Erase). Otherwise, this should be flagged

as an error, and the device should be Reset.

Data Toggle.

Checking the Toggle bit DQ6 is an

alternative method of checking if Program or Erase

operations are in progress or com pleted (see Figure 7). When an operation is in progress, data bit

DQ6 constantly toggles for successive read operations. When DQ6 no longer toggles and t he Error

bit DQ5 is ’0’, the operation is com pleted. To determine if DQ6 has toggled, each polling action requires 2 consecutive read operations of the data,

and if the data read is the same, it can be considered that the operation was successful. The Error

bit DQ5 is checked to ensure timing limits hav e not

been exceeded. In all cases, when DQ5 is ’1’, DQ6

should be checked again, in case DQ6 has

changed simultaneously with DQ5. If DQ6 has

stopped toggling, the o peration is successful and

execution should return to the caller. A suggested

second read will provide all true data (Program) or

all FFh (Erase). Otherwise, this event should be

flagged as an error, and the device should be

Reset.

ERASE in the Flash BLOCK

It should be noted that:

a. Programming any byte of one Flash sector (or

bulk) requires that the Flash sector (or bulk) has

been previously erased (once for all bytes within

the sector or bulk) with the correct instruction (see

Instructions chapter).

b. Writing in the EEPROM memory is an operation

triggering an automatic sequencing of byte erase

followed by a byte write. Writing in EEPROM does

not require a specific erase operation before writing.

Bulk Erase Instruction.

The Bulk Erase instruction uses six write operations followed by Read

operations of the status register bits, as desc ribed

in Table 4. If any byte of the Bulk Erase instruction

is wrong, the Bulk Erase instruction aborts and the

device is reset to the Read Flash memory status.

During a Bulk Erase, the memory status may

checked by reading the status bits DQ5, DQ6 and

DQ7, as detailed in the "PROGRAM in t he Flash

BLOCK" chapter. The Error bit (DQ5) returns a ’1’

if there has been an Erase Failure (maximum number of erase cycles have been executed).

It is not necessary to program the array with 00h,

the M39208 will automatically do this before erasing to FFh.

During the execution of the Bulk Erase instruction,

the Flash block logic does not accept any instruction.

Sector Erase in Flash Block.

The Sector Erase

instruction uses six write operations, as described

in Table 4. Additional Flash Sector Erase confirm

commands and Flash sector addresses can written

subsequently to erase other Flash sectors in parallel, without further coded cycles, if the additional

instruction is transmited in a shorter time than the

timeout period to end of period. The input of a new

Sector Erase instruction will restart the time-out

period.

The status of the internal timer can be monitored

through the level of DQ3 (Erase time-out bit), if DQ3

is ’0’ the Sector Erase instruction has been received and the timeout is counting; if DQ3 is ’1’, the

timeout has expired and the M39208 is erasing the

Flash sector(s). Before and during Erase timeout,

any instruction different than Erase suspend and

Erase Resume will abort the instruction and reset

the device to read array mode.

It is not necessary to program the Flash sector with

00h as the M39208 will do this automatically before

erasing (byte = FFh).

During a Sector Erase, the memory status may be

checked by reading the status bits DQ5, DQ6 and

DQ7, as detailed in the "Program instruction" chapter. During the execution of the erase instruction,

the Flash block logic accepts only the Reset and

Erase Suspend instructions (erasure of one Flash

sector may be suspended, in order to read data

from another Flash sector, and then resumed).

11/30

Page 12

M39208

T ab le 8. Flash Sector Protection

EF EE G W A0 A1 A6 A9 A12 A16 A17 DQ0 - DQ7

V

V

Notes:

V

IL

V

IL

X = Don’t care.

SA = Software Address.

V

IH

IH

ID

V

IL

V

V

XXXVIDX SA SA Prot ection Activation

IL

V

IH

V

IL

V

IH

V

IL

XSASA

ID

Verify the protection status:

when DQ0= 1, the sector is

protected

T able 9. Flash Unprotection

EF EE G W A0 A1 A6 A9 A12 A15 A16 A17 DQ0 - DQ7

V

V

V

ID

IH

V

V

IL

IH

Notes:

X = Don’t care.

SA = Software Address.

V

ID

V

V

IL

Erase Suspend Instruction.

XXXVIDV

IL

V

V

IH

IL

V

IH

When a Flash Sector

V

IH

Erase operation is in progress, the Erase Suspend

instruction may suspend the operation by writing

V

IH

X X SA SA

ID

IH

XX

eration may be resumed by this instruction. The

Erase Resume instruction consists of writing 30h

at any address (see Table 4).

Activation of Unprotected

Mode

Verify the protection status:

when 00h, the sector is

unprotected

B0h at any address (see Table 4). This allows

reading of data from another Flash sector while

erase is in progress. Erase suspend is accepted

only during the Flash Sector Eras e instruction execution and defaults to read array mode. An Erase

Suspend instruction entered during an Erase

timeout will, in addition to suspending the erase,

terminates the timeout.

The Toggle bit DQ6 stops toggling when the

M39208 internal logic is suspended. The Toggle bit

status must be monitored at an address out of the

Flash sector being erased. Toggle bit will stop

toggling between 0.1µs and 15µs after the Erase

Suspend instruction has been written. The M39208

will then automatically be set into Read Flash Block

Memory Array mode.

When erase is suspended, Reading from Flash

sectors being erased will output invalid data, a

Read from Flash sector not being erased is valid.

During an Erase Suspend, the Flash memory will

respond only to Erase Resume and Reset instructions.

A Reset instruction will definitively abort erasure

and can leave invalid data in the Flash sectors

being erased.

Erase Resume Instruction.

If an Erase Suspend

instruction was previously executed, the erase op-

FLASH BLOCK SPECIFIC FEATURES

Flash Sector Pro tection.

Each Flash sector can

be separately protected against Program or Erase.

Flash Sector Protection provides additional data

security , as it disables all program or erase operations. This mode is activated when both A9 and

are set to V

(12V + 0.5V) and the Flash sector

ID

address is applied on A16 and A17, as shown in

Figure 8 and T able 8.

Flash sector protection is programmed with the

help of a specific sequence of levels applied on

EE, G, A0, A1, A6, A9, A16 and A17; this sequence

includes a verification of the Protection status on

DQ0 as shown in Table 8.

Any attempt to program or erase a pr otected Flash

sector will be ignored by the device.

Remarks:

– The Verify operation is a read with a simulated

worst case conditions. This allows a guarantee

of the retention of the Protection status

– During the application life, the Sector pr otection

status can be accessed with a regular Read

instruction without applying a "high voltage" V

on A9. This instruction is detailed in T able 4.

G

EF,

ID

12/30

Page 13

Figure 8. Sector Protection Flowchart

SECTOR ADDRESS

START

on A16, A17

EE = V

IH

n = 0

G, A9 = VID,

EF = V

IL

Wait 4µs

W = V

IL

Wait 100µs

M39208

W = V

IH

G = V

IH

Wait 4µs

READ DQ0 at PROTECTION

ADDRESS: A0, A6 = VIL, A1 = VIH and

A16, A17 DEFINING SECTOR

DQ0

A9 = V

PASS

NO

= 1

YES

IH

++n

= 25

A9 = V

FAIL

NO

YES

IH

AI02598

13/30

Page 14

M39208

Figure 9. Sector Unprotecting Flowchart

START

EE = EF = V

n = 0

A6, A12, A15 = V

G, A9 = V

EF, G, A9 = V

Wait 10ms

EF, G = V

Wait 4µs

Wait 4µs

W = V

W = V

Wait 4µs

IH

IL

IH

IH

IH

IH

ID

Note:

14/30

NO LAST

1. A6 is kept at V

reads, A6 must be kept at V

during unprotection algorithm in order to secure best unprotection verification. During all other protection status

IH

++n

= 1000

YES

FAIL

IL

READ at UNPROTECTION

ADDRESS: A1, A6 = VIH, A0 = V

A16, A17 DEFINING SECTOR

(see Note 1)

DATA

=

00h

and

IL

YESNO

INCREMENT

SECTOR

NO

SECT.

YES

PASS

AI02597

.

Page 15

M39208

T able 10. AC Measurement Conditions

Input Rise and Fall Times

Input Pulse Voltages 0.45V to 2.4V

Input Timing Ref. Voltages 0.8V and 2V

Output Timing Ref. Voltages 1.5V

10ns

≤

Figure 10. AC Testing Input Out put Waveform

2.4V

1.5V

0.45V

AI01950

(1)

T ab le 11. Capacitance

Symbol Parameter Test Condition Min Max Unit

C

IN

C

OUT

Note:

1. Sampled only, not 100% tested.

Input Capacitance VIN = 0V 6 pF

Output Capacitance V

(TA = 25 °C, f = 1 MHz )

Figure 11. Output AC Testing Load Circuit

V

CC

I

OL

DEVICE

UNDER

TEST

I

OH

CL includes JIG capacitance

V

= 1.5V when the DEVICE

OUT

UNDER TEST is in the

Hi-Z output state.

= 0V 12 pF

OUT

CL = 30pF

AI02596B

Flash Sector Unprotection.

Flash sectors can be

unprotected to allow updating of their contents.

Note that the Sector Unprotection unprotects all

sectors (sector 0 up to sector 7).

Flash Sector Unprotection is activated with a specific sequence of levels applied on

EF, EE, G, A 0,

A1, A6, A9, A12 and A15; this sequence includes a

verification of the Protection status on DQ0-DQ7

as shown in Figure 9 and Table 9.

This allows a guarantee of the retention of the

Protection status.

Remarks:

– The Verify operation is a read with a simulated

worst case conditions. This allows a guarantee

of the retention of the Protection status

– During the application life, the Sector pr otection

status can be accessed with a regular Read

instruction without "high voltage" V

on A9. This

ID

instruction is detailed in Table 4.

Reset Instruction.

The Reset instruction resets

the device internal logic in a f ew µs. Reset is an

instruction of either one write operation or three

write operations (refer to Table 4).

Supply Rails .

Normal precautions must be taken

for supply voltage decoupling, each device in a

system should have the V

0.1µF capacitor close to the V

rail decoupled with a

CC

and VSS pins. The

CC

printed circuit board trace width should be suff icient

to carry the V

program and erase currents re-

CC

quired.

15/30

Page 16

M39208

T ab le 12. DC Characteristics

(T

= 0 to 70°C or –20 to 85°C or –40 to 85°C; VCC = 2.7 V to 3.6V)

A

Symbol Parameter Test Condition Min Max Unit

I

Note:

I

I

CC1

I

CC2

I

CC3

I

CC4

I

CC5

I

CC6

V

V

V

V

V

I

V

LKO

LO

ID

Input Leakage Current 0V ≤ VIN ≤ V

LI

Output Leakage Current 0V ≤ V

(1)

Supply Current (Read Flash) TTL

Supply Current (Read EEPROM)

TTL

EE = VIH, EF = VIL, G =

V

, f = 6MHz

IH

EE = VIL, EF = VIH, G =

V

, f = 6MHz

IH

OUT

≤ V

CC

CC

Supply Current (Standby) CMOS EF = EE = VCC ± 0.2V 60

Supply Current (Flash Block

Program or Erase)

Supply Current (EEPROM Write) During t

Supply Current in Deep Power

Down Mode

Input Low Voltage –0.5 0.8 V

IL

Input High Voltage 0.7 V

IH

Output Low Voltage IOL = 1.8mA 0.45 V

OL

Output High Voltage IOH = –100µAV

OH

A9 High Voltage 11.5 12.5 V

ID

VID Current A9 = V

Byte program, Sector or

Chip Erase in progress

WC

After a Deep Power Down

instruction (see Table 4)

ID

VCC Minimum for Write, Erase and

Program

1. When reading the Flash block when an EEPROM byte(s) is under a write cycl e, the supply cur rent is I

1

±

1

±

15 mA

15 mA

20 mA

20 mA

2

CC

–0.4 V

CC

VCC + 0.3 V

100

2 2.3 V

+ I

CC5

.

CC1

A

µ

A

µ

A

µ

A

µ

A

µ

GLOSSARY

Block:

EEPROM block (64 Kbit) or Flash block (2

Mbit)

the whole Flash block (2 Mbit)

Bulk:

Sector:

Page:

Write and Program:

64 Kbyte of Flash memory

64 bytes of EEPROM

Writing (into the EEPROM

block) and programming (the Flash block) is not

performed in a similar way:

16/30

– the Flash memory requires an instruction (see

Instruction chapter) for Erasing and another instruction for Programming one (or more) byte(s)

– the EEPROM memory is directly written with a

simple operation (see Operation chapter).

Software Data Protection. Used for prot ect-

SDP:

ing the EEPROM block against false Write operations (as in noisy environments).

Page 17

Figure 12. Read Mode AC Waveforms

tEHFL

tEHQZ

tEHQX

tGHQZ

tGHQX

M39208

AI02595

VALID

tAVAV

VALID

A0-A17

tAVQV tAXQX

EE (EF)

tELQV

tEHFL

EF (EE)

tELQX

tGLQV

tGLQX

OUTPUT ENABLE DATA VALID

ADDRESS VALID

AND CHIP ENABLE

W) = High

G

DQ0-DQ7

Write Enable (

Note:

17/30

Page 18

M39208

Table 13. Read AC Characteristics

(T

= 0 to 70°C or –20 to 85°C or –40 to 85°C; VCC = 2.7 V to 3.6V)

A

Symbol Alt Parameter Test Condition

M39208

-100 -120 -150

Min Max Min Max Min Max

Unit

t

AVAV

t

AVQVtACC

t

ELQX

t

ELQV

t

GLQX

t

GLQV

t

EHQX

t

EHQZ

t

GHQX

t

GHQZ

t

AXQX

t

(1)

t

(2)

t

(1)

t

OLZ

(2)

t

t

(1)

t

t

(1)

t

t

Address Valid to Next

RC

Address Valid

Address Valid to

Output Valid

Chip Enable Low to

LZ

Output Transition

Chip Enable Low to

CE

Output Valid

Output Enable Low to

Output Transition

Output Enable Low to

OE

Output Valid

Chip Enable High to

OH

Output Transition

Chip Enable High to

HZ

Output Hi-Z

Output Enable High to

OH

Output Transition

Output Enable High to

DF

Output Hi-Z

Address Transition to

OH

Output Transition

(EE, EF) = (VIL, VIH) or

(EE, EF) = (VIH, VIL),

G = VIL

(EE, EF) = (VIL, VIH) or

(EE, EF) = (VIH, VIL),

G = VIL

G = V

IL

G = V

IL

(EE, EF) = (VIL, VIH) or

(EE, EF) = (VIH, VIL)

(EE, EF) = (VIL, VIH) or

(EE, EF) = (VIH, VIL)

G = V

IL

G = V

IL

(EE, EF) = (VIL, VIH) or

(EE, EF) = (VIH, VIL)

(EE, EF) = (VIL, VIH) or

(EE, EF) = (VIH, VIL)

(EE, EF) = (VIL, VIH) or

(EE, EF) = (VIH, VIL),

G = VIL

100 120 150 ns

100 120 150 ns

000ns

100 120 150 ns

000ns

40 55 55 ns

000ns

30 40 40 ns

000ns

30 40 40 ns

000ns

t

EHFLtCED

Notes:

1. Sampled only, not 100% tested.

G may be delayed by up to t

2.

EE (EF) Active to EF

EE)

(

18/30

ELQV

100 100 100 ns

- t

after the falling edge of EE (or EF) without increasing t

GLQV

ELQV

.

Page 19

Figure 13. Write AC Waveforms, W Controlled

M39208

WRITE CYCLE

A0-A17

(1)

E

G

W

DQ0-DQ7

V

CC

tVCHEL

tAVWL

tELWL

VALID

tWLWHtGHWL

tDVWH

tWLAX

tWHEH

tWHGL

tWHWL

tWHDX

VALID

AI02594

Notes:

Address are latched on the falling edge of

E is either EF when EE = VIH or EE when EF = VIH.

W, Data is latched on the rising edge of W.

19/30

Page 20

M39208

Figure 14. Write AC Waveforms, E Controlled

WRITE CYCLE

A0-A17

W

tWLEL

G

(1)

E

DQ0-DQ7

DQ0-DQ7

V

CC

tVCHWL

Notes:

Address are latched on the falling edge of

E is either EF when EE = VIH or EE when EF = VIH.

VALID

tAVEL

tELEHtGHEL

E, Data is latched on the rising edge of E.

tDVEH

tELAX

tEHWH

tEHGL

tEHEL

tEHDX

VALID

AI02593

20/30

Page 21

M39208

Table 14. Write AC Characteristics, Write Enable Contro lled

= 0 to 70°C or –20 to 85°C or –40 to 85°C; VCC = 2.7 V to 3.6V)

(T

A

Symbol Alt Parameter

t

AVAV

(2)

t

ELWL

t

WLWH

t

DVWH

t

WHDX

(2)

t

WHEH

t

WHWL

t

AVWL

t

WLAX

t

t

Address Valid to Next

WC

Address Valid

Chip Enable Low to Write

t

CS

Enable Low

Write Enable Low to Write

t

WP

Enable High

Input Valid to Write Enable

t

DS

High

Write Enable High to Input

t

DH

Transition

Write Enable High to Chip

t

CH

Enable High

Write Enable High to Write

WPH

Enable Low

Address Valid to Write

t

AS

Enable Low

Write Enable Low to Address

t

AH

Transition

-100 -120 -150

Min Max Min Max Min Max

100 120 150 ns

000ns

50 50 65 ns

50 50 65 ns

000ns

000ns

30 30 35 ns

000ns

50 50 65 ns

M39208

Unit

t

GHWL

t

VCHEL

t

WHQV1

t

WHQV2

t

WHWL0

t

WHGL

Notes:

1. Time is measured to Data Polling or Toggle Bit, t

2. Chip Enable means (EE, EF) = (VIL, VIH) or (EE, EF) = (VIH, VIL).

t

(1)

(1)

t

Output Enable High to Write

Enable Low

V

VCS

High to Chip Enable Low 50 50 50

CC

Write Enable High to Output

Valid (Program)

Write Enable High to Output

Valid (Sector Erase)

Time Out between 2

consecutive Section Erase

Write Enable High to Output

OEH

Enable Low

WHQV

000ns

s

µ

888

s

µ

0.5 30 0.5 30 0.5 30 sec

80 80 80

s

µ

000ns

= t

+ t

WHQ7V

Q7VQV

21/30

Page 22

M39208

T ab le 15. Write AC Characteristics, EE or EF Controlled

= 0 to 70°C or –20 to 85°C or –40 to 85°C; VCC = 2.7 V to 3.6V)

(T

A

Symbol Alt Parameter

t

WLWL

t

WC

t

AVAV

t

WLEL

t

ELEH

t

DVEH

t

EHDX

t

EHWH

t

EHEL

t

AVEL

t

t

Time-out after the Last Byte

BLC

Write

Write Cycle Time (EEPROM) 10 10 10 ms

Address Valid to Next Address

Valid

Write Enable Low to Memory

t

WS

Block Enable Low

Memory Block Enable Low to

t

CP

Memory Block Enable High

Input Valid to Memory Block

t

DS

Enable High

Memory Block Enable High to

t

DH

Input Transition

Memory Block Enable High to

t

WH

Write Enable High

Memory Block Enable High to

CPH

Memory Block Enable Low

Address Valid to Memory Block

t

AS

Enable Low

-100 -120 -150

Min Max Min Max Min Max

150 150 150

100 120 150 ns

000ns

50 50 65 ns

50 50 65 ns

000ns

000ns

30 30 35 ns

000ns

M39208

Unit

s

µ

t

ELAX

t

GHEL

t

VCHWL

t

EHQV1

t

EHQV2

t

EHGL

Notes:

1. Time is measured to Data Polling or Toggle Bit, t

t

(1)

(1)

t

Memory Block Enable Low to

t

AH

Address Transition

Output Enable High to Memory

Block Enable Low

VCC High to Write Enable Low 50 50 50

VCS

Memory Block Enable High to

Output Valid (Program)

Memory Block Enable High to

Output Valid (Sector Erase)

Memory Block Enable High to

OEH

Output Enable Low

WHQV

50 50 65 ns

000ns

s

µ

888

s

µ

0.5 30 0.5 30 0.5 30 sec

000ns

= t

+ t

WHQ7V

Q7VQV

.

22/30

Page 23

Figure 15. Data Polling DQ7 AC Waveforms

M39208

AI02592

READ CYCLE

DATA OUTPUT VALID

BYTE ADDRESS (WITHIN SECTORS)

tELQV

tAVQV

tEHQ7V

tGLQV

VALID

DQ7

tWHQ7V

VALID

tQ7VQV

IGNORE

DATA POLLING (LAST) CYCLE DATA VERIFY

READ CYCLES

DATA POLLING

.

IH

A0-A17

or E E when EF = V

IH

OR ERASE

LAST CYCLE

OF PROGRAM

is the Program or Erase time.

(5)

E

G

W

DQ7

DQ0-DQ6

WHQ7V

2. DQ7 and DQ0-DQ6 can transmi t to valid at any point during the data output valid period.

E is either EF when EE = V

3. t

4. During erasing operation Byte address must be within Sector being erased.

5.

1. All other timings are as a normal Read cyc le .

Notes:

23/30

Page 24

M39208

Ta ble 16. Data Polling and Toggle Bit AC Characteristics

= 0 to 70°C or –20 to 85°C or –40 to 85°C; VCC = 2.7 V to 3.6V)

(T

A

(1)

M39208

Symbol

Test

Conditions

Parameter

-100 -120 -150

Min Max Min Max Min Max

t

WHQ7V1

t

WHQ7V2

t

EHQ7V1

t

EHQ7V2

t

Q7VQV

Notes:

1. All other timings are defined in Read AC Characteristics table.

EF = 0

EE = 1

EF = 0

EE = 1

EF = 0

EE = 1

EF = 0

EE = 1

EF = 0

EE = 1

Write Enable High to DQ7 Valid

(Program, W Controlled)

Write Enable High to DQ7 Valid

(Sector Erase, W Controlled)

Flash Block Enable High to

DQ7 Valid (Program,

EF

Controlled)

Flash Block Enable High to

DQ7 Valid (Sector Erase,

EF

Controlled)

Q7 Valid to Output Valid (Data

Polling)

10 10 10

1.5 30 1.5 30 1.5 30 sec

10 10 10

1.5 30 1.5 30 1.5 30 sec

40 50 55 ns

Tabl e 17. Program, Erase Times and Program, Erase Endurance Cycl es (Flash Block)

(T

= 0 to 70°C or –20 to 85°C or –40 to 85°C; VCC = 2.7 V to 3.6V)

A

Parameter

Min Typ Max

Chip Program (Byte) 8 sec

M39208

Unit

Unit

s

µ

s

µ

Chip Erase (Preprogrammed) 3 30 sec

Chip Erase 10 sec

Sector Erase (Preprogrammed) 1 30 sec

Sector Erase 2 sec

Byte Program 10

s

µ

Program/Erase Cycles (per Sector) 100,000 cycles

24/30

Page 25

Figure 16. Data Toggle DQ6 AC Waveforms

M39208

AI02591

VALID

tEHQV

tAVQV

tELQV

tGLQV

VALID

tWHQV

DQ6 TOGGLE

VALID

IGNORE

READ CYCLE

READ CYCLE

DATA TOGGLE

.

IH

A0-A17

DATA

TOGGLE

READ CYCLE

OF ERASE

LAST CYCLE

OF PROGRAM

or E E when EF = V

IH

E is either EF when EE = V

1. All other timings are as a normal Read cyc le .

(2)

E

G

W

DQ6

DQ0-DQ5,

DQ7

2.

Notes:

25/30

Page 26

M39208

Figure 17. EEPROM Page Write Mode AC Waveforms, W Controlled

A0-A12

E

G

W

DQ0-DQ7

tWLWH

Addr 0

tWHWL

Byte 0 Byte 1 Byte 2 Byte n

Addr 1 Addr 2 Addr n

tWLWL

AI00600

26/30

Page 27

ORDERING INFORMATION SCHEME

Example: M39208 -15 W NA 1 T

M39208

Speed

-10 100ns

-12 120ns

-15 150ns

Operating Voltage

W 2.7V to 3.6V

Package

NA TSOP32

8 x 20mm

TSOP32

NB

8 x 14mm

Temp. Range

1 0 to 70 °C

5 –20 to 85 °C

6 –40 to 85 °C

Option

T Tape & Reel

Packing

Devices are shipped from the factory with the memory content set at all "1’s" (FFh).

For a list of available options (Speed, Package, etc...) or for further information on any aspect of this device,

please contact the STMicroelectronics Sales Office nearest to you.

27/30

Page 28

M39208

TSOP32 - 32 lead Plastic Thin Small Out l in e, 8 x 14mm

Symb

Typ Min Max Typ Min Max

A 1.20 0.047

A1 0.05 0.15 0.002 0.006

A2 0.95 1.05 0.037 0.041

B 0.17 0.27 0.007 0.011

C 0.10 0.21 0.004 0.008

D 13.80 14.20 0.543 0.559

D1 12.30 12.50 0.484 0.492

E 7.90 8.10 0.311 0.319

e 0.50 - - 0.020 - L 0.50 0.70 0.020 0.028

α

N32 32

CP 0.10 0.004

mm inches

0

°

5

°

0

°

5

°

Drawing is not to scale.

1 N

N/2

D1

DIE

TSOP-a

A2

e

E

B

A

D

CP

C

LA1 α

28/30

Page 29

TSOP32 - 32 lead Plastic Thin Small Out l in e, 8 x 20mm

M39208

Symb

Typ Min Max Typ Min Max

A 1.20 0.047

A1 0.05 0.15 0.002 0.007

A2 0.95 1.05 0.037 0.041

B 0.15 0.27 0.006 0.011

C 0.10 0.21 0.004 0.008

D 19.80 20.20 0.780 0.795

D1 18.30 18.50 0.720 0.728

E 7.90 8.10 0.311 0.319

e 0.50 - - 0.020 - L 0.50 0.70 0.020 0.028

α

N32 32

CP 0.10 0.004

mm inches

0

°

5

°

0

°

5

°

Drawing is not to scale.

1 N

N/2

D1

DIE

TSOP-a

A2

e

E

B

A

D

CP

C

LA1 α

29/30

Page 30

M39208

Information furnished is believ ed to be accura te and reliable. Ho wever, STMicroelectronics as sum es no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and repl aces all information previously supplied. STMicroelectron ics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelect roni cs

© 1999 STMicroelectronics - All Rights Reserved

Australia - Brazil - Canada - China - France - Germany - Italy - Japan - Korea - Malaysia - Malta - Mexico - Morocco - The Netherlands -

Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

STMicroelectronics GROUP OF COMPANIES

http://www.st.com

30/30

Loading...

Loading...