Datasheet M38504M6-XXXSP, M38504M6-XXXFP, M38504E6SS, M38504E6SP, M38504E6FP Datasheet (Mitsubishi)

...Page 1

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

DESCRIPTION

The 3850 group is the 8-bit microcomputer based on the 740 family core technology.

The 3850 group is designed for the household products and office

automation equipment and includes serial I/O functions, 8-bit

timer, and A-D converter.

FEATURES

●Basic machine-language instructions ...................................... 71

●Minimum instruction execution time .................................. 0.5 µs

(at 8 MHz oscillation frequency)

●Memory size

ROM ................................................................... 8K to 24K bytes

RAM.....................................................................512 to 640 byte

●Programmable input/output ports ............................................ 34

●Interrupts ................................................. 14 sources, 14 vectors

●Timers ............................................................................. 8-bit ✕ 4

●Serial I/O ....................... 8-bit ✕ 1(UART or Clock-synchronized)

●PWM ............................................................................... 8-bit ✕ 1

●A-D converter ............................................... 10-bit ✕ 5 channels

●Watchdog timer ............................................................ 16-bit ✕ 1

●Clock generating circuit..................................... Built-in 2 circuits

(connect to external ceramic resonator or quartz-crystal oscillator)

●Power source voltage

In high-speed mode .................................................. 4.0 to 5.5 V

(at 8 MHz oscillation frequency)

In high-speed mode .................................................. 2.7 to 5.5 V

(at 4 MHz oscillation frequency)

In middle-speed mode............................................... 2.7 to 5.5 V

(at 8 MHz oscillation frequency)

In low-speed mode.................................................... 2.7 to 5.5 V

(at 32 kHz oscillation frequency)

●Power dissipation

In high-speed mode .......................................................... 34 mW

(at 8 MHz oscillation frequency, at 5 V power source voltage)

In low-speed mode............................................................ 60 µW

(at 32 kHz oscillation frequency, at 3 V power source voltage)

●Operating temperature range.................................... –20 to 85°C

APPLICATION

Office automation equipment, FA equipment, Household products,

Consumer electronics, etc.

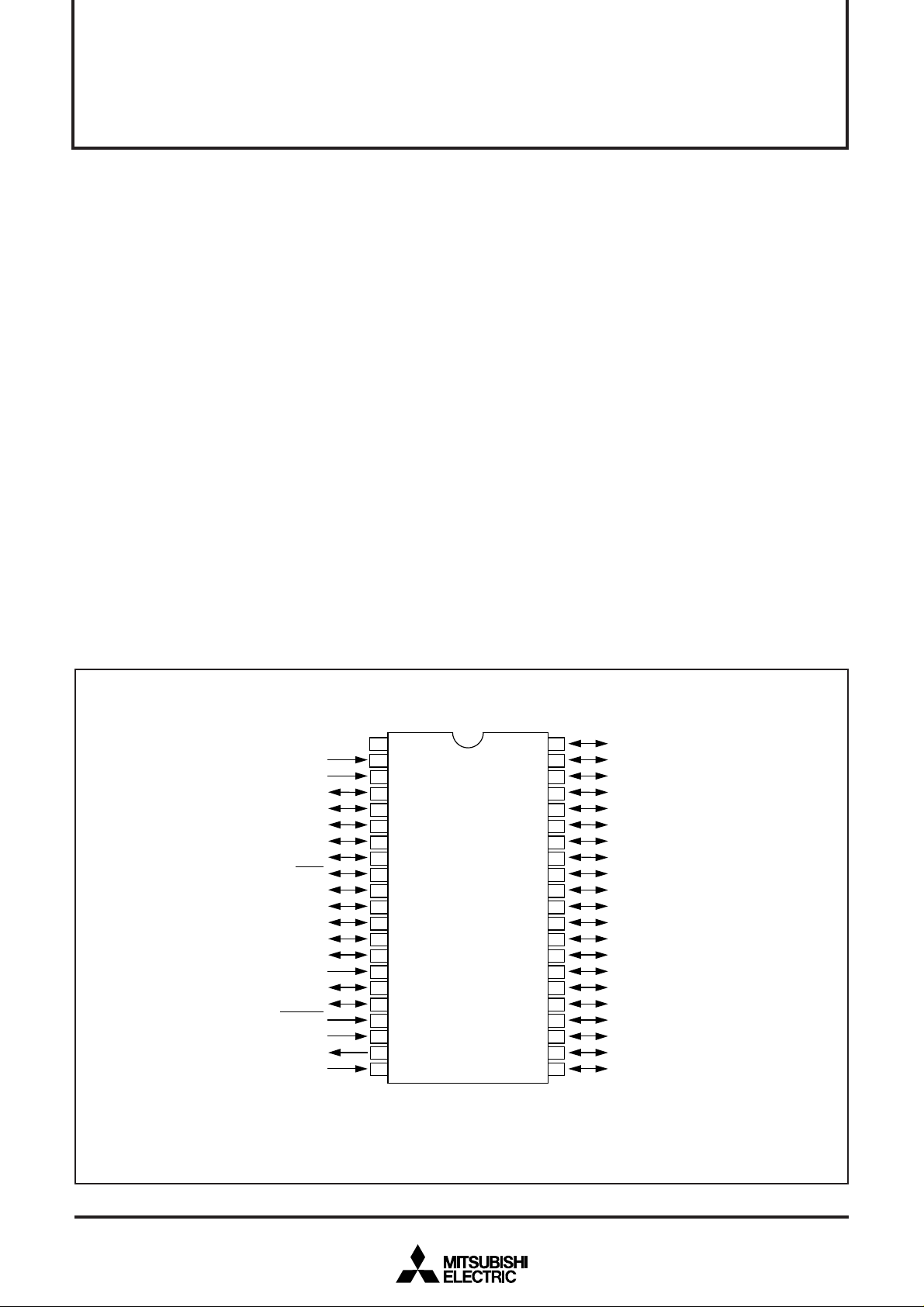

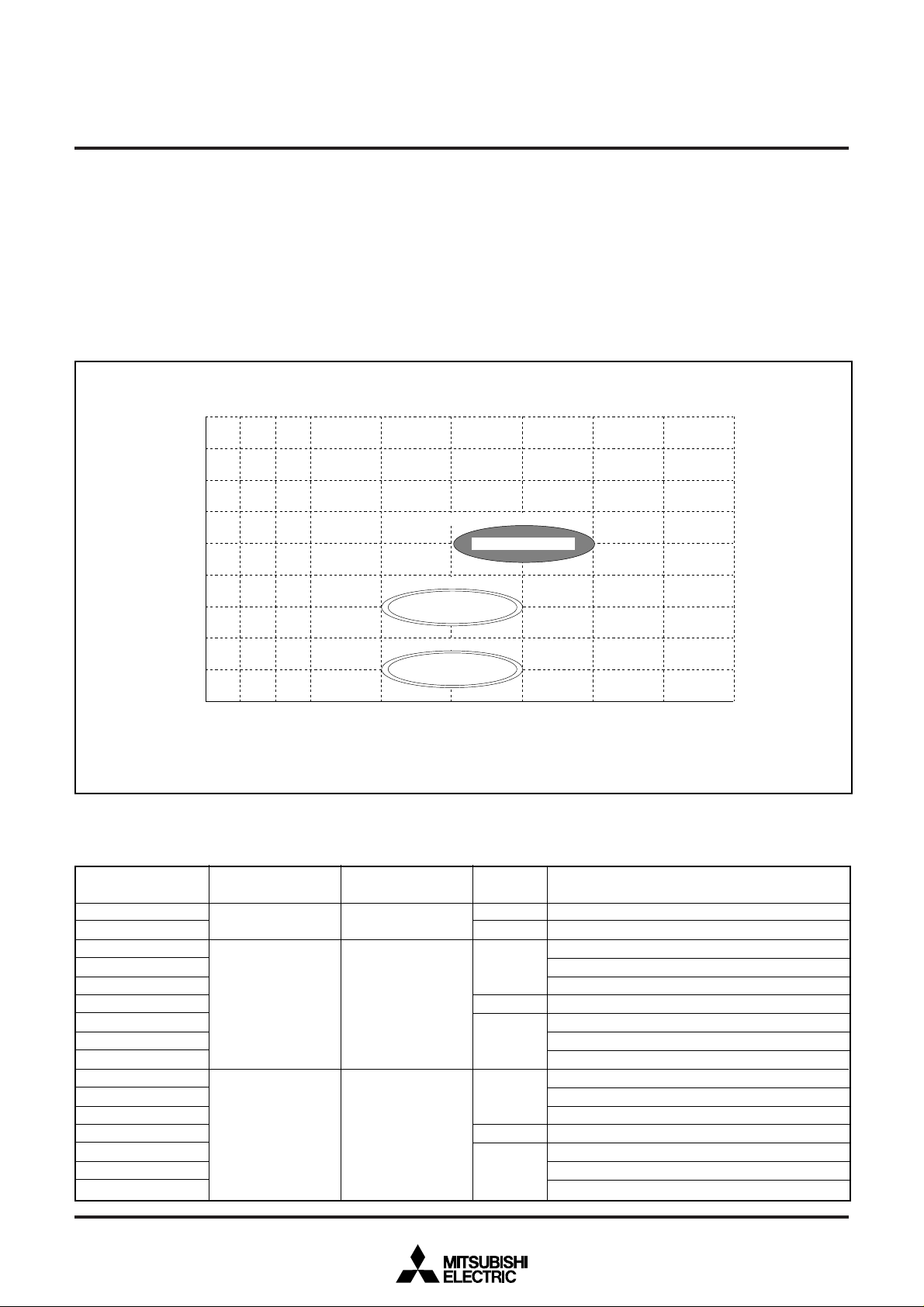

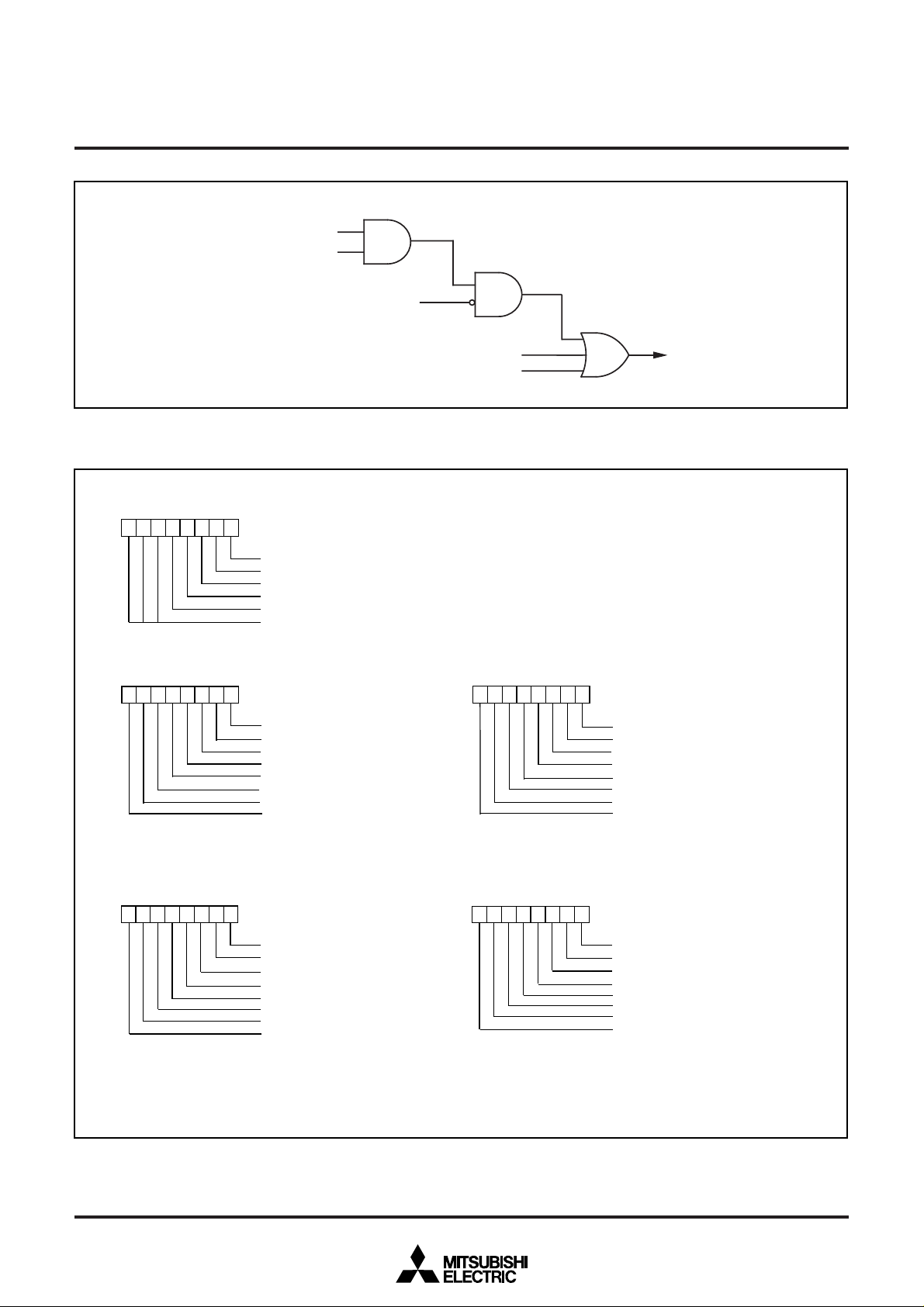

PIN CONFIGURATION (TOP VIEW)

V

CC

REF

V

SS

AV

P44/INT3/PWM

P43/INT

2

P42/INT

1

P41/INT

0

P40/CNTR

7

/CNTR0/S

P2

P26/S

P20/X

Package type : FP ........................... 42P2R-A (42-pin plastic-molded SSOP)

Package type : SP ........................... 42P4B (42-pin shrink plastic-molded DIP)

RDY

CLK

P25/TxD

4

/RxD

P2

P2

P2

CNV

P21/X

CIN

COUT

RESET

X

X

OUT

V

1

3

2

SS

IN

SS

P30/AN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

M38503M4-XXXSP

M38503M4-XXXFP

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

0

P31/AN

1

P32/AN

2

P33/AN

3

P34/AN

4

P0

0

P0

1

P0

2

P0

3

P0

4

P0

5

P0

6

P0

7

P1

0

P1

1

P1

2

P13/(LED0)

4

/(LED1)

P1

5

/(LED2)

P1

P16/(LED3)

P1

7

/(LED4)

Fig. 1 M38503M4-XXXFP/SP pin configuration

Page 2

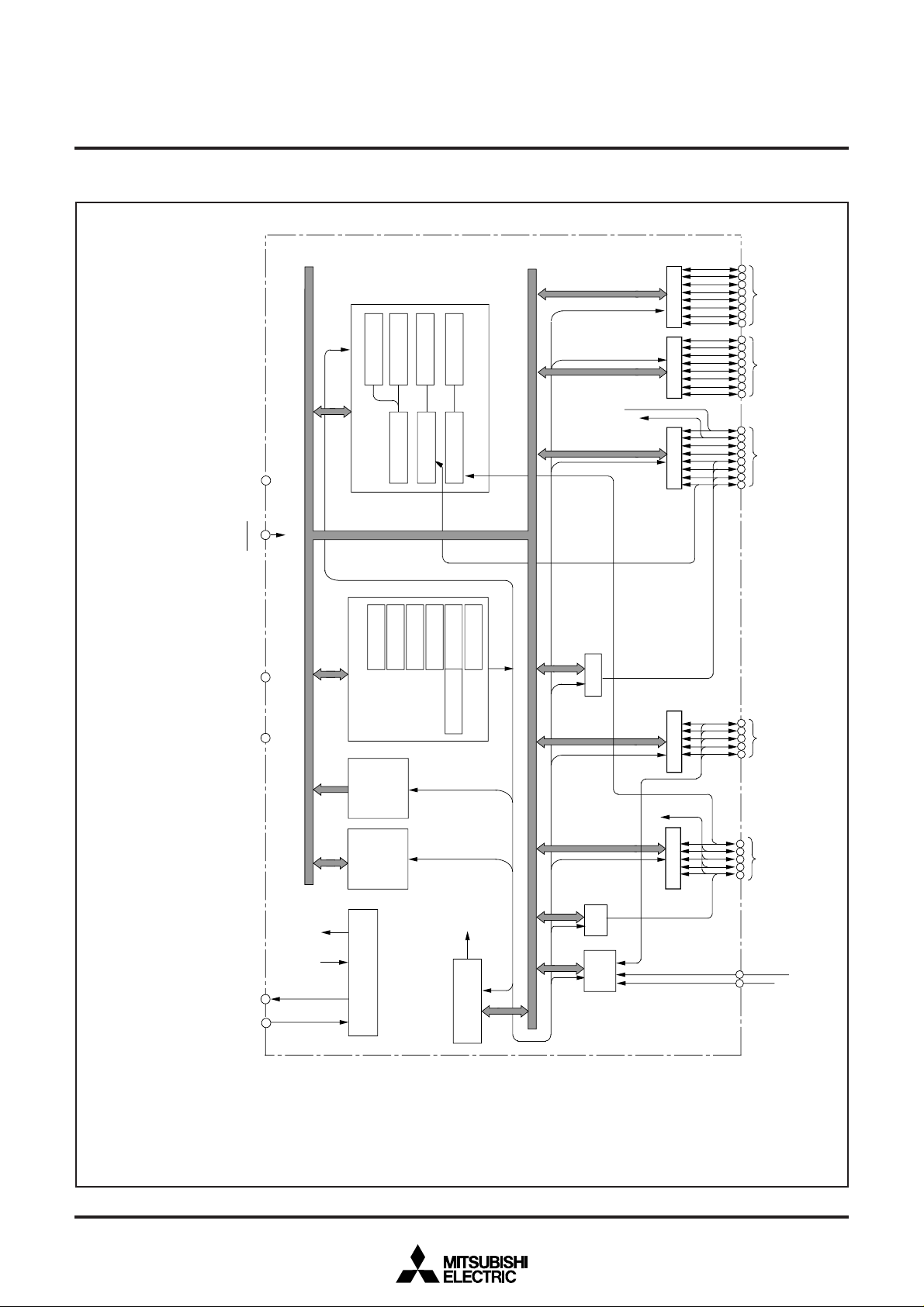

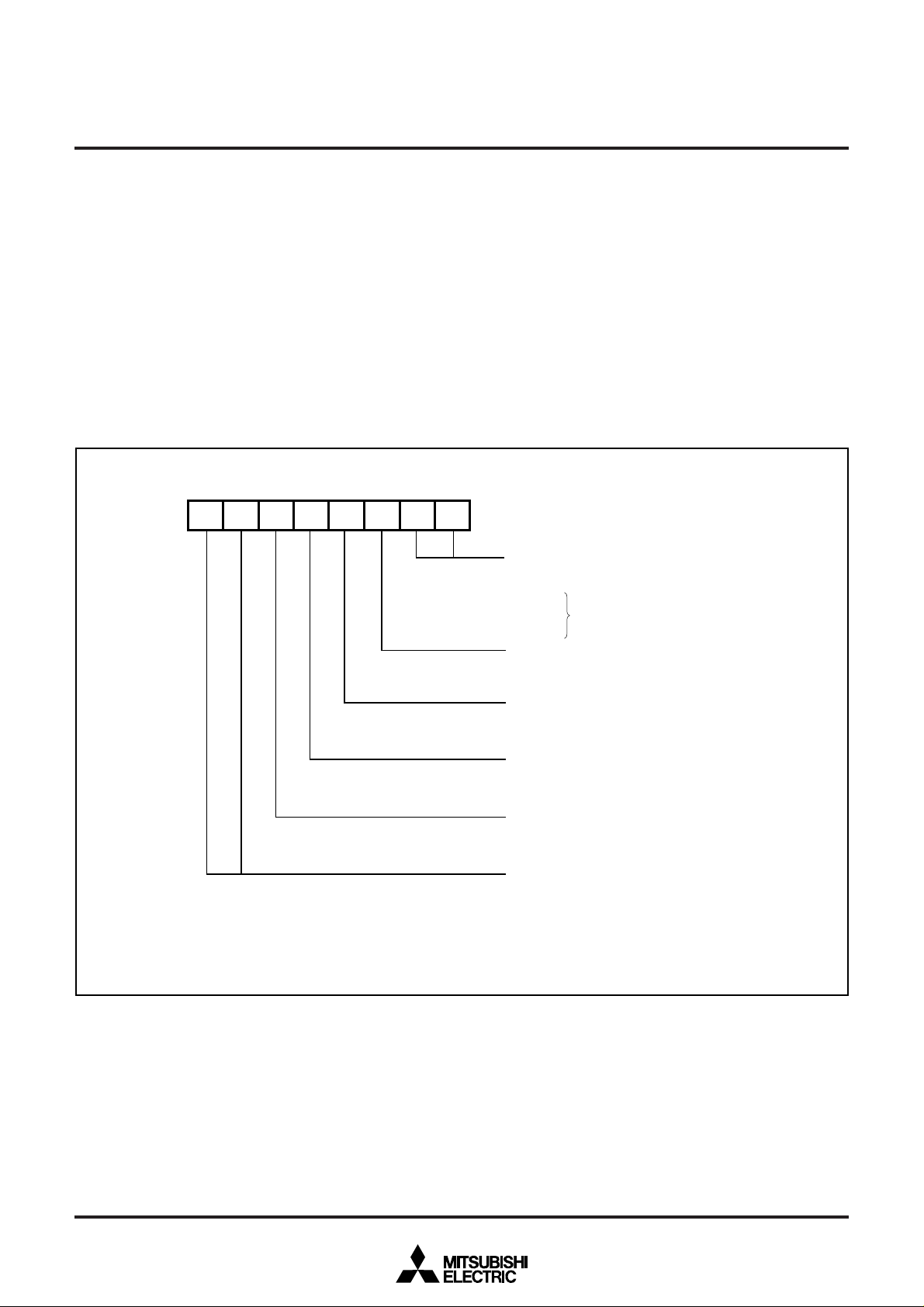

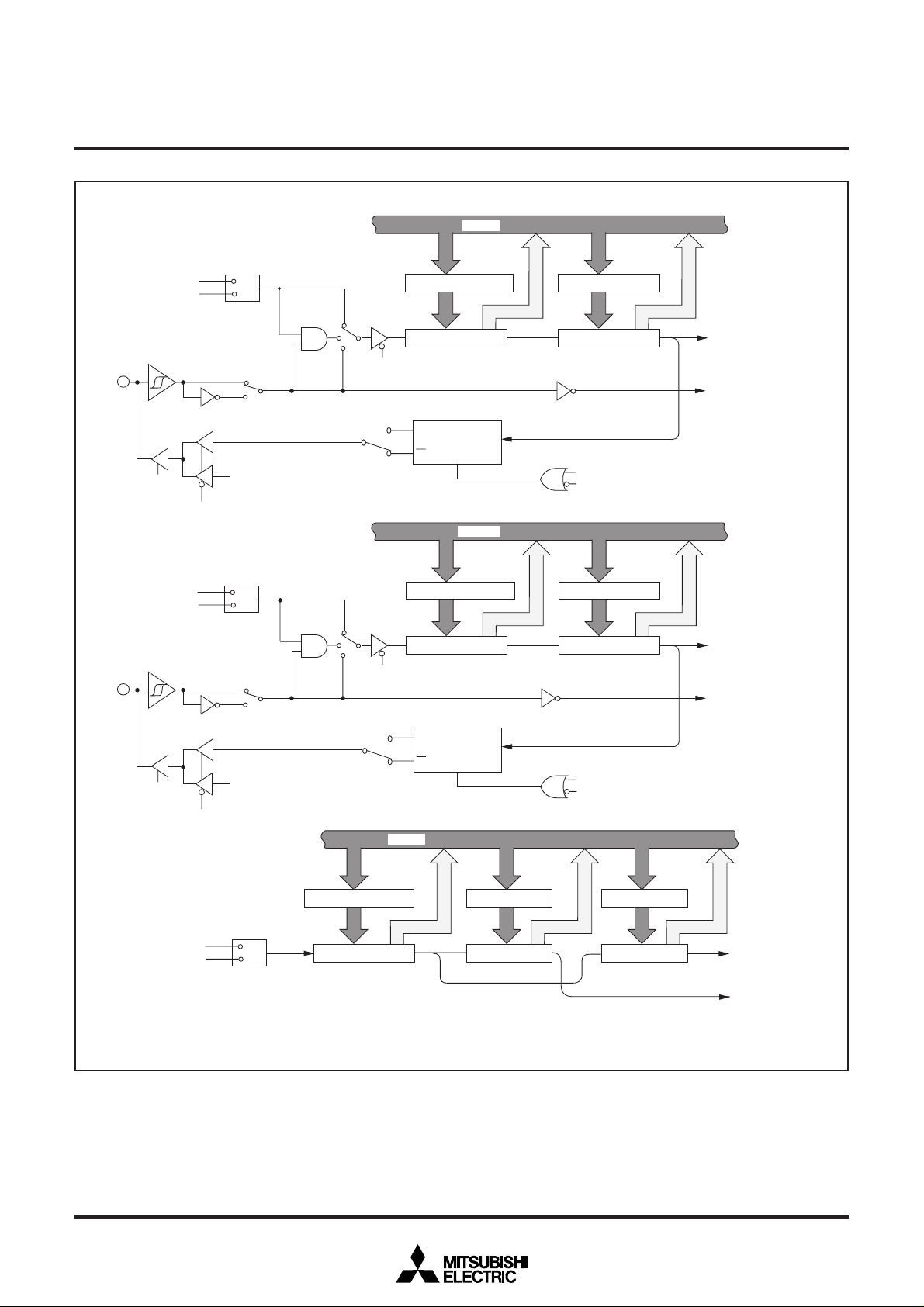

FUNCTIONAL BLOCK

INT

0

–

CNTR

0

CNTR

1

V

REF

AV

SS

R A M

R O M

C P U

A

X

Y

S

PC

H

PCLPS

V

SS

21

RESET

18

V

CC

1 15

CNV

SS

23

X

IN

19

20

SI/O(8)

Reset input

Clock generating circuit

Main-clock

input

Main-clock

output

A-D

converter

(10)

Timer Y( 8 )

Timer X( 8 )

Prescaler 12(8)

Prescaler X(8)

Prescaler Y(8)

Timer 1( 8 )

Timer 2( 8 )

Sub-clock

input

X

OUT

X

CIN

X

COUT

Sub-clock

output

Watchdog

timer

Reset

P2(8)

P3(5)

I/O port P2

I/O port P3

P4(5)

I/O port P4

INT

3

4

68

5

7

39

4138 40

42

9

11

13

17

10

12

14

16

P1(8)

I/O port P1

22 24 26 2823 25 27 29

P0(8)

I/O port P0

30 3132 3334 35 36

37

PWM

(8)

X

CIN

X

COUT

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

FUNCTIONAL BLOCK DIAGRAM

Fig. 2 Functional block diagram

2

Page 3

PIN DESCRIPTION

Table 1 Pin description

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

VCC, VSS

RESET

IN

X

XOUT

P00–P07

P10–P17

P20/XCOUT

P21/XCIN

P22

P23

P24/RxD

P25/TxD

P26/SCLK

P27/CNTR0/

SRDY

P30/AN0–

P34/AN4

P4

0/CNTR1

P41/INT0–

P43/INT2

P44/INT3/PWM

NamePin

Power source

SS inputCNVSS

CNV

Reset input

Clock input

Clock output

I/O port P0

I/O port P1

I/O port P2

I/O port P3

I/O port P4

Functions

•Apply voltage of 2.7 V – 5.5 V to Vcc, and 0 V to Vss.

•This pin controls the operation mode of the chip.

•Normally connected to V

•Reset input pin for active “L.”

•Input and output pins for the clock generating circuit.

•Connect a ceramic resonator or quartz-crystal oscillator between the X

the oscillation frequency.

•When an external clock is used, connect the clock source to the XIN pin and leave the XOUT

pin open.

•8-bit CMOS I/O port.

•I/O direction register allows each pin to be individually programmed as either input or output.

•CMOS compatible input level.

•CMOS 3-state output structure.

•P1

3 to P17 (5 bits) are enabled to output large current for LED drive.

•8-bit CMOS I/O port.

•I/O direction register allows each pin to be individually

programmed as either input or output.

•CMOS compatible input level.

•P20, P21, P24 to P27 : CMOS3-state output structure.

•P22, P23: N-channel open-drain structure.

•8-bit CMOS I/O port with the same function as port P0.

•CMOS compatible input level.

•CMOS 3-state output structure.

•8-bit CMOS I/O port with the same function as port P0.

•CMOS compatible input level.

•CMOS 3-state output structure.

SS.

Function except a port function

IN and XOUT pins to set

• Sub-clock generating circuit I/O

pins (connect a resonator)

• Serial I/O function pin

• Serial I/O function pin/

Timer X function pin

• A-D converter input pin

• Timer Y function pin

• Interrupt input pins

• Interrupt input pin

• PWM output pin

3

Page 4

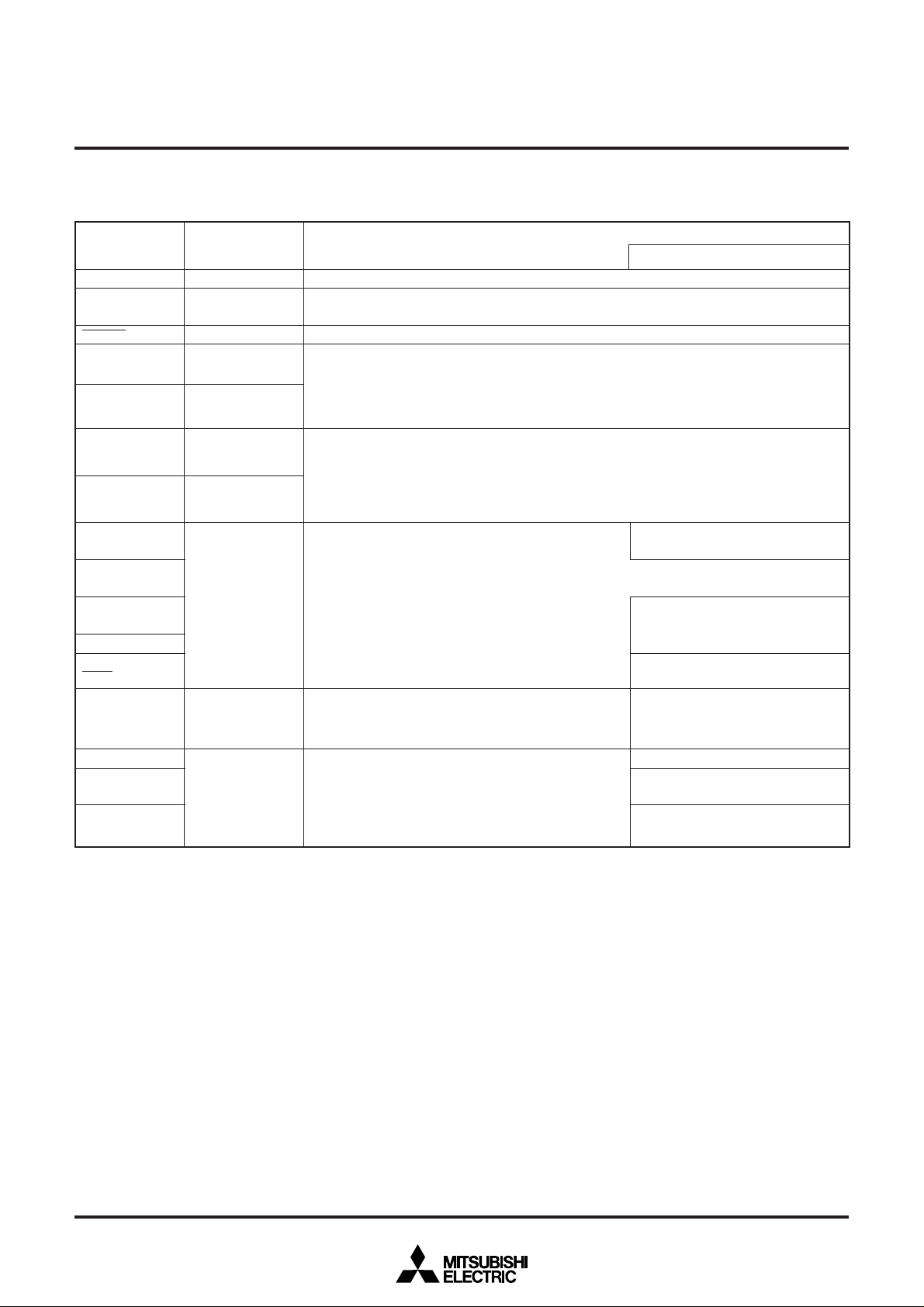

PART NUMBERING

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

Product

M3850 3 M 4 XXX FP

Package type

: 42P2R-A package

FP

SP

: 42P4B package

SS

: 42S1B-A package

ROM number

Omitted in some types.

ROM/PROM size

: 4096 bytes

1

: 8192 bytes

2

: 12288 bytes

3

: 16384 bytes

4

: 20480 bytes

5

: 24576 bytes

6

: 28672 bytes

7

: 32768 bytes

8

: 36864 bytes

9

A

: 40960 bytes

B

: 45056 bytes

C

: 49152 bytes

D

: 53248 bytes

E

: 57344 bytes

: 61440 bytes

F

Fig. 3 Part numbering

The first 128 bytes and the last 2 bytes of ROM

are reserved areas ; they cannot be used.

Memory type

ME : Mask ROM version

: EPROM or One Time PROM version

RAM size

: 192 bytes

0

: 256 bytes

1

: 384 bytes

2

: 512 bytes

3

: 640 bytes

4

: 768 bytes

5

: 896 bytes

6

: 1024 bytes

7

: 1536 bytes

8

: 2048 bytes

9

4

Page 5

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

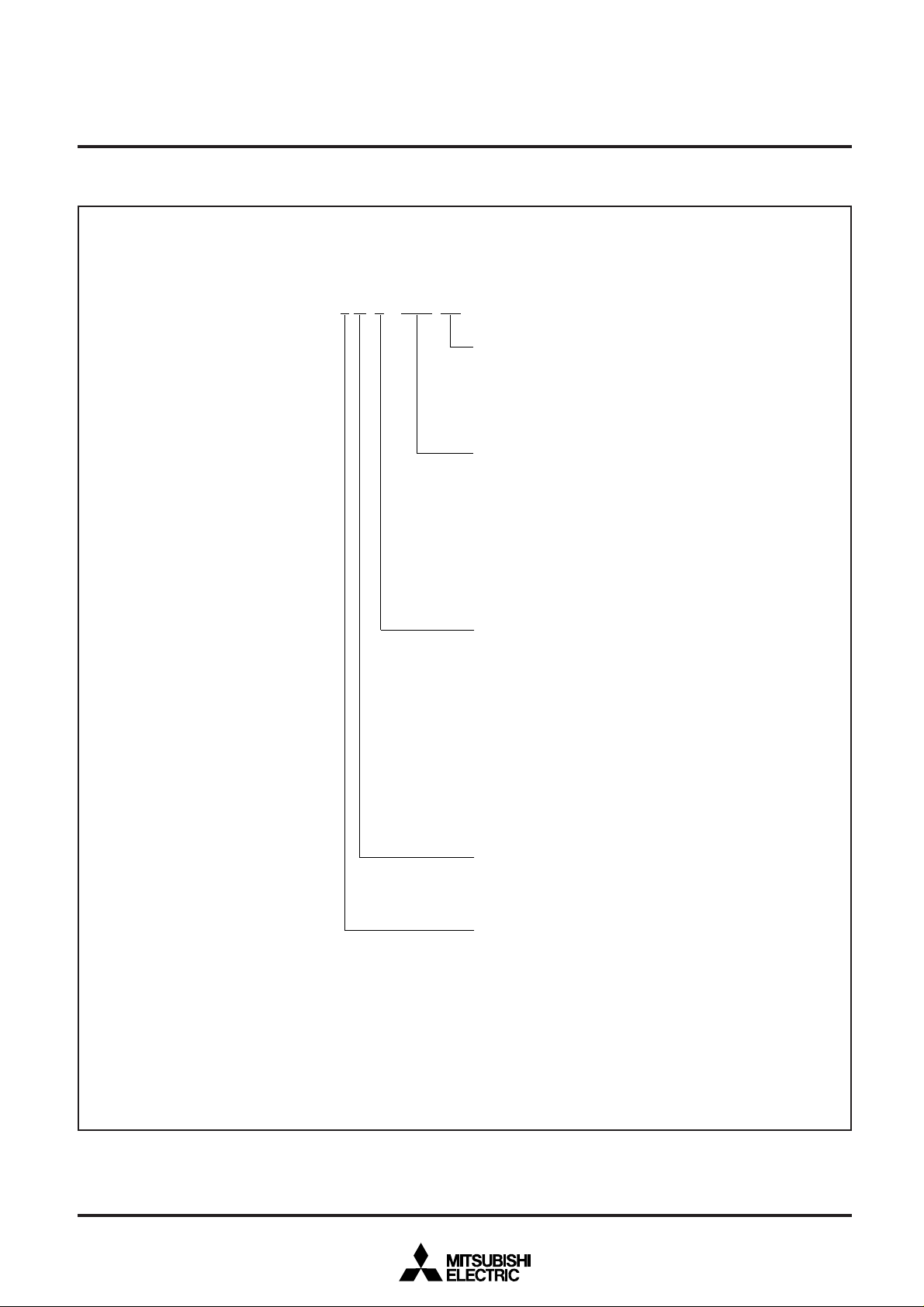

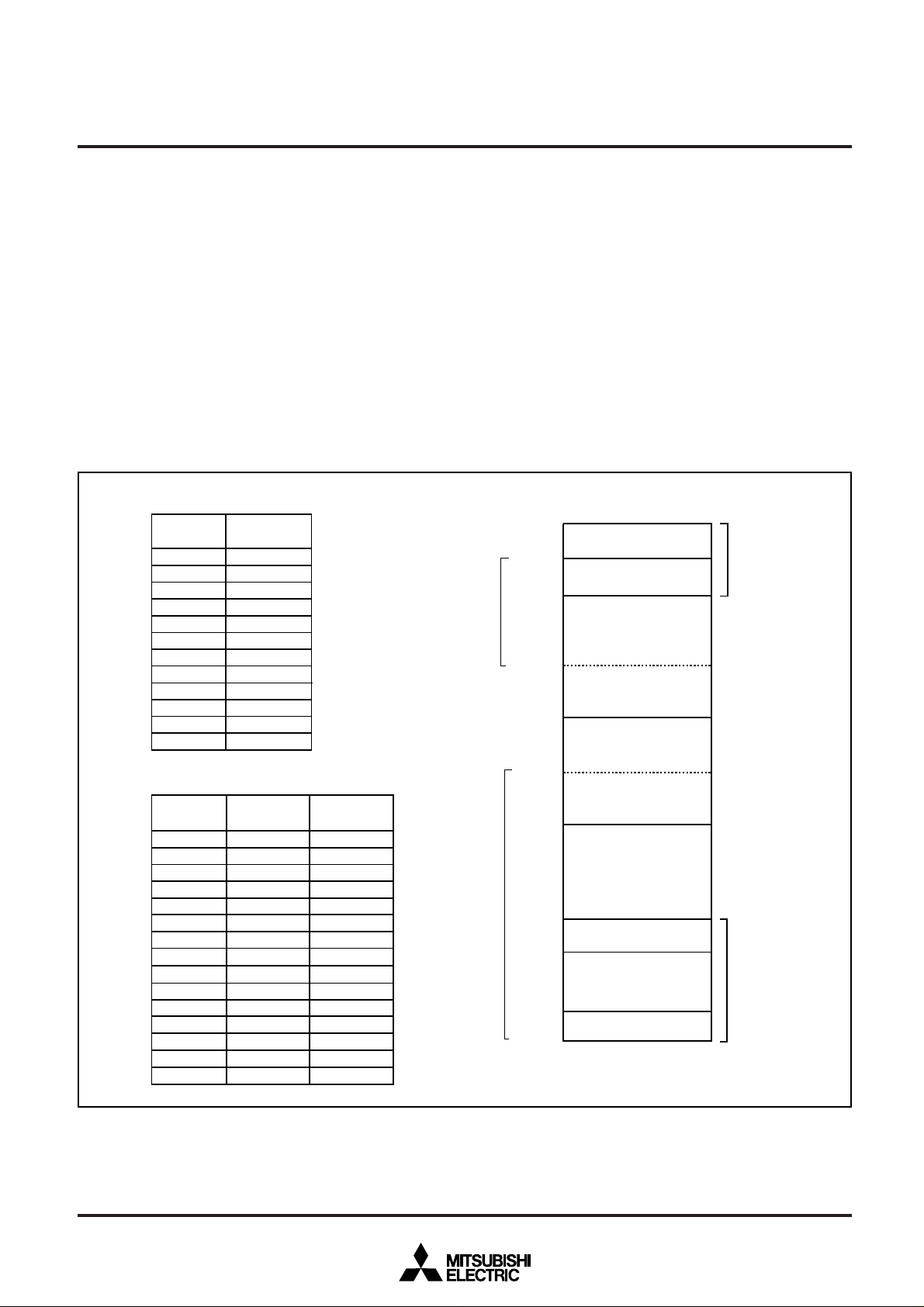

GROUP EXPANSION

Mitsubishi plans to expand the 3850 group as follows:

Memory T ype

Support for mask ROM, One Time PROM, and EPROM versions.

Memory Size

ROM/PROM size................................................... 8K to 24K bytes

RAM size .............................................................. 512 to 640 bytes

Memory Expansion Plan

ROM size (bytes)

48K

32K

28K

24K

20K

16K

12K

8K

Mass production

M38503M4/E4

Mass production

M38503M2

Packages

42P4B..........................................42-pin shrink plastic molded DIP

42P2R-A ............................................ 42-pin plastic molded SSOP

42S1B-A ................... 42-pin shrink ceramic DIP(EPROM version)

Under development

M38504M6/E6

128 192 256

Products under development or planning : the development schedule and specification may be revised without notice.

Planning products may be stopped the development.

Fig. 4 Memory expansion plan

Currently planning products are listed below.

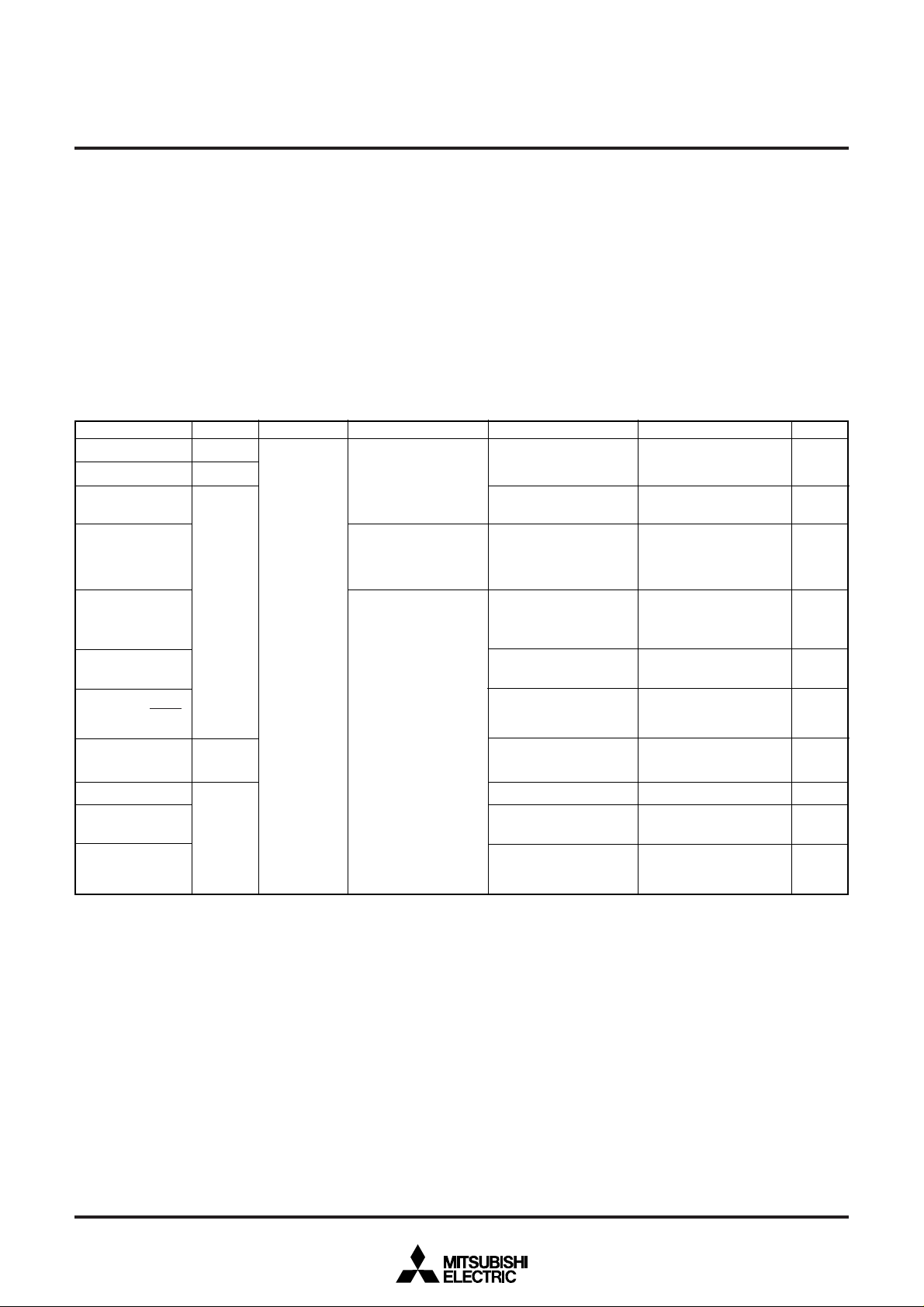

Table 2 Support products

Product name

M38503M2-XXXSP

M38503M2-XXXFP

(P) ROM size (bytes)

ROM size for User in ( )

8192

(8062)

M38503M4-XXXSP

M38503E4-XXXSP

M38503E4SP

M38503E4SS

16384

(16254)

M38503M4-XXXFP

M38503E4-XXXFP

M38503E4FP

M38504M6-XXXSP

M38504E6-XXXSP

M38504E6SP

M38504E6SS

32768

(32638)

M38504M6-XXXFP

M38504E6-XXXFP

M38504E6FP

384 512 640 768 896 1024

RAM size (bytes)

RAM size (bytes)

512

Package

42P4B

42P2R-A

Remarks

Mask ROM version

Mask ROM version

Mask ROM version

42P4B

One Time PROM version

One Time PROM version (blank)

512

42S1B-A

EPROM version (stock only replaced by M38504E6SS)

Mask ROM version

42P2R-A

One Time PROM version

One Time PROM version (blank)

Mask ROM version

42P4B

One Time PROM version

One Time PROM version (blank)

640

42S1B-A

EPROM version

Mask ROM version

42P2R-A

One Time PROM version

One Time PROM version (blank)

As of August 1998

5

Page 6

FUNCTIONAL DESCRIPTION

CENTRAL PROCESSING UNIT (CPU)

The 3850 group uses the standard 740 Family instruction set. Refer to the table of 740 Family addressing modes and machine

instructions or the 740 Family Software Manual for details on the

instruction set.

Machine-resident 740 Family instructions are as follows:

The FST and SLW instructions cannot be used.

The STP, WIT, MUL, and DIV instructions can be used.

[CPU Mode Register (CPUM)] 003B16

The CPU mode register contains the stack page selection bit, etc.

The CPU mode register is allocated at address 003B

16.

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

b7

b0

CPU mode register

(

CPUM : address

003B16)

Processor mode bits

b1 b0

0 0 : Single-chip mode

0 1 :

1 0 : Not available

1 1 :

Stack page selection bit

0 : 0 page

1 : 1 page

Not used (return “1” when read)

(Do not write “0” to this bit.)

C

switch bit

Port X

0 : I/O port function (stop oscillating)

CIN–XCOUT

1 : X

Main clock (X

0 : Oscillating

1 : Stopped

Main clock division ratio selection bits

b7 b6

0 0 : φ = f(X

0 1 : φ = f(X

1 0 : φ = f(X

1 1 : Not available

IN–XOUT

oscillating function

) stop bit

IN

)/2 (high-speed mode)

IN

)/8 (middle-speed mode)

CIN

)/2 (low-speed mode)

Fig. 5 Structure of CPU mode register

6

Page 7

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

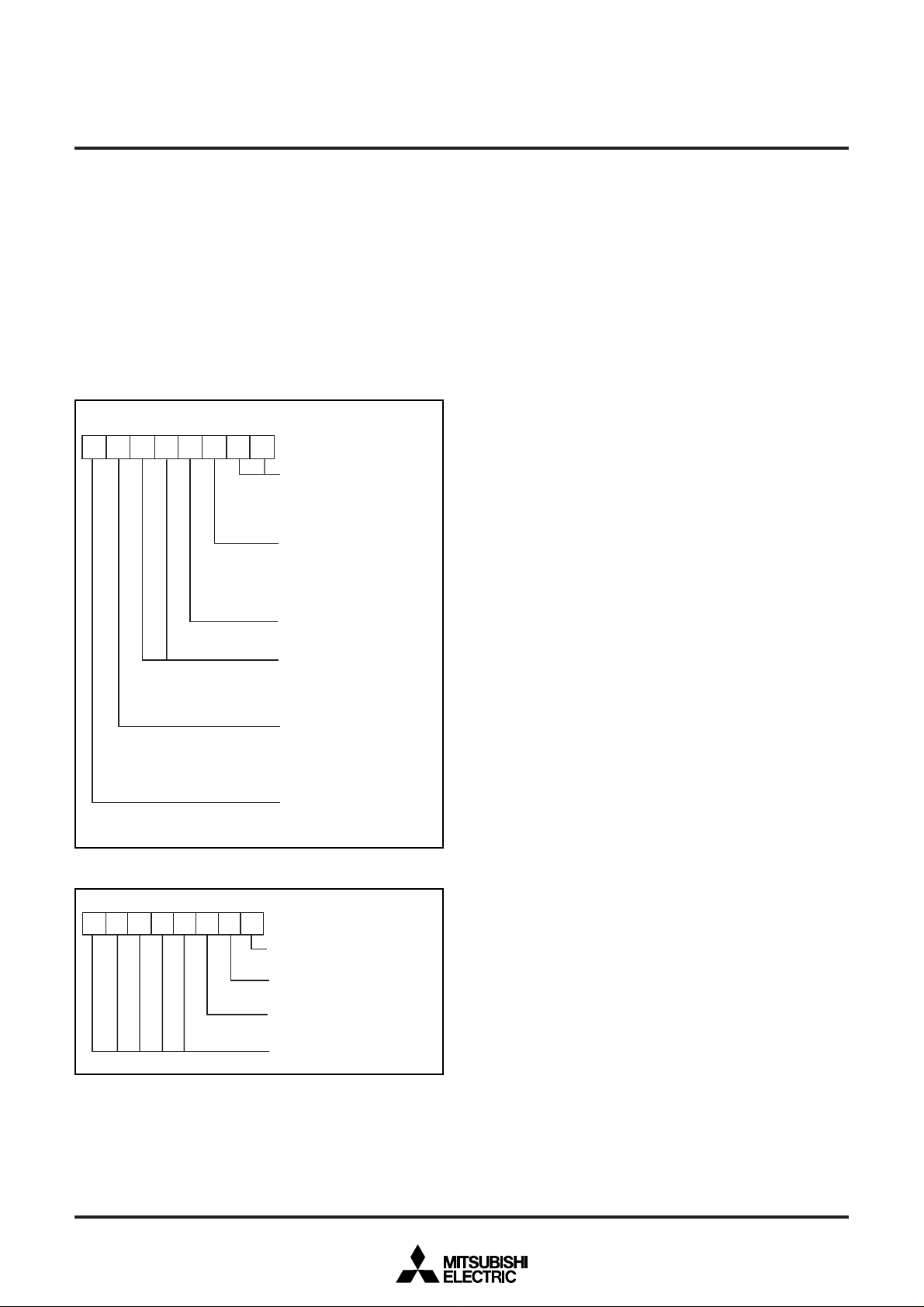

MEMORY

Special Function Register (SFR) Area

The Special Function Register area in the zero page contains control registers such as I/O ports and timers.

RAM

RAM is used for data storage and for stack area of subroutine

calls and interrupts.

ROM

The first 128 bytes and the last 2 bytes of ROM are reser ved for

device testing and the rest is user area for storing programs.

Interrupt Vector Area

The interrupt vector area contains reset and interrupt vectors.

RAM area

RAM size

(bytes)

192

256

384

512

640

768

896

1024

1536

2048

3072

4032

Address

XXXX

00FF

013F

01BF

023F

02BF

033F

03BF

043F

063F

083F

0C3F

0FFF

16

16

16

16

16

16

16

16

16

16

16

16

16

Zero Page

Access to this area with only 2 bytes is possible in the zero page

addressing mode.

Special Page

Access to this area with only 2 bytes is possible in the special

page addressing mode.

0000

RAM

0040

0100

XXXX

0440

16

16

16

16

16

SFR area

Zero page

Reserved area

Not used

ROM area

ROM size

(bytes)

4096

8192

12288

16384

20480

24576

28672

32768

36864

40960

45056

49152

53248

57344

61440

Fig. 6 Memory map diagram

Address

YYYY

F000

E000

D000

C000

B000

A000

9000

8000

7000

6000

5000

4000

3000

2000

1000

YYYY

16

Reserved ROM area

Address

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

ZZZZ

F080

E080

D080

C080

B080

A080

9080

8080

7080

6080

5080

4080

3080

2080

1080

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

ROM

ZZZZ

FF00

FFDC

FFFE

FFFF

16

16

16

16

16

(128 bytes)

Interrupt vector area

Reserved ROM area

Special page

7

Page 8

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

0000

0001

0002

0003

0004

0005

0006

0007

0008

0009

000A

000B

000C

000D

000E

000F

0010

0011

0012

0013

0014

0015

0016

0017

0018

0019

001A

001B

001C

001D

001E

001F

Port P0 (P0)

16

Port P0 direction register (P0D)

16

Port P1 (P1)

16

Port P1 direction register (P1D)

16

Port P2 (P2)

16

Port P2 direction register (P2D)

16

Port P3 (P3)

16

Port P3 direction register (P3D)

16

Port P4 (P4)

16

Port P4 direction register (P4D)

16

16

16

16

16

16

16

16

16

16

16

16

16

Reserved ✽

16

Reserved ✽

16

Reserved ✽

Transmit/Receive buffer register (TB/RB)

16

Serial I/O status register (SIOSTS)

16

Serial I/O control register (SIOCON)

16

UART control register (UARTCON)

16

Baud rate generator (BRG)

16

PWM control register (PWMCON)

16

PWM prescaler (PREPWM)

16

PWM register (PWM)

16

✽ Reserved : Do not write “1” to this address.

0020

0021

0022

0023

0024

0025

0026

0027

0028

0029

002A

002B

002C

002D

002E

002F

0030

0031

0032

0033

0034

0035

0036

0037

0038

0039

003A

003B

003C

003D

003E

003F

Prescaler 12 (PRE12)

16

Timer 1 (T1)

16

Timer 2 (T2)

16

Timer XY mode register (TM)

16

Prescaler X (PREX)

16

Timer X (TX)

16

Prescaler Y (PREY)

16

Timer Y (TY)

16

Timer count source selection register (TCSS)

16

16

16

16

Reserved ✽

Reserved ✽

16

16

Reserved ✽

16

Reserved ✽

16

Reserved ✽

16

Reserved ✽

16

16

16

A-D control register (ADCON)

16

A-D conversion low-order register (ADL)

16

A-D conversion high-order register (ADH)

16

16

MISRG

16

Watchdog timer control register (WDTCON)

16

Interrupt edge selection register (INTEDGE)

16

CPU mode register (CPUM)

16

Interrupt request register 1 (IREQ1)

16

Interrupt request register 2 (IREQ2)

16

Interrupt control register 1 (ICON1)

16

Interrupt control register 2 (ICON2)

16

Fig. 7 Memory map of special function register (SFR)

8

Page 9

I/O PORTS

The I/O ports have direction registers which determine the input/

output direction of each individual pin. Each bit in a direction register corresponds to one pin, and each pin can be set to be input

port or output port.

When “0” is written to the bit corresponding to a pin, that pin becomes an input pin. When “1” is written to that bit, that pin

becomes an output pin.

If data is read from a pin which is set to output, the value of the

port output latch is read, not the value of the pin itself. Pins set to

input are floating. If a pin set to input is written to, only the port

output latch is written to and the pin remains floating.

Table 3 I/O port function

Pin

P00–P07

P10–P17

P20/XCOUT

P21/XCIN

P22

P23

Name

Port P0

Port P1

Input/Output

I/O Structure Non-Port Function

CMOS compatible

input level

CMOS 3-state output Sub-clock generating

CMOS compatible

input level

N-channel open-drain

output

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

Related SFRs

circuit

CPU mode register

Ref.No .

(1)

(2)

(3)

(4)

P24/RxD

P25/TxD

6/SCLK

P2

P27/CNTR0/SRDY

P30/AN0–

P34/AN4

P40/CNTR1

P41/INT0–

P43/INT2

P44/INT3/PWM

Port P2

Port P3

Port P4

Input/output,

individual

bits

CMOS compatible

input level

CMOS 3-state output

Serial I/O function I/O

Serial I/O function I/O

Serial I/O function I/O

Timer X function I/O

A-D conversion input

Timer Y function I/O

External interrupt input

External interrupt input

PWM output

Serial I/O control

register

Serial I/O control

register

Serial I/O control

register

Timer XY mode register

A-D control register

Timer XY mode register

Interrupt edge selection

register

Interrupt edge selection

register

PWM control register

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

9

Page 10

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

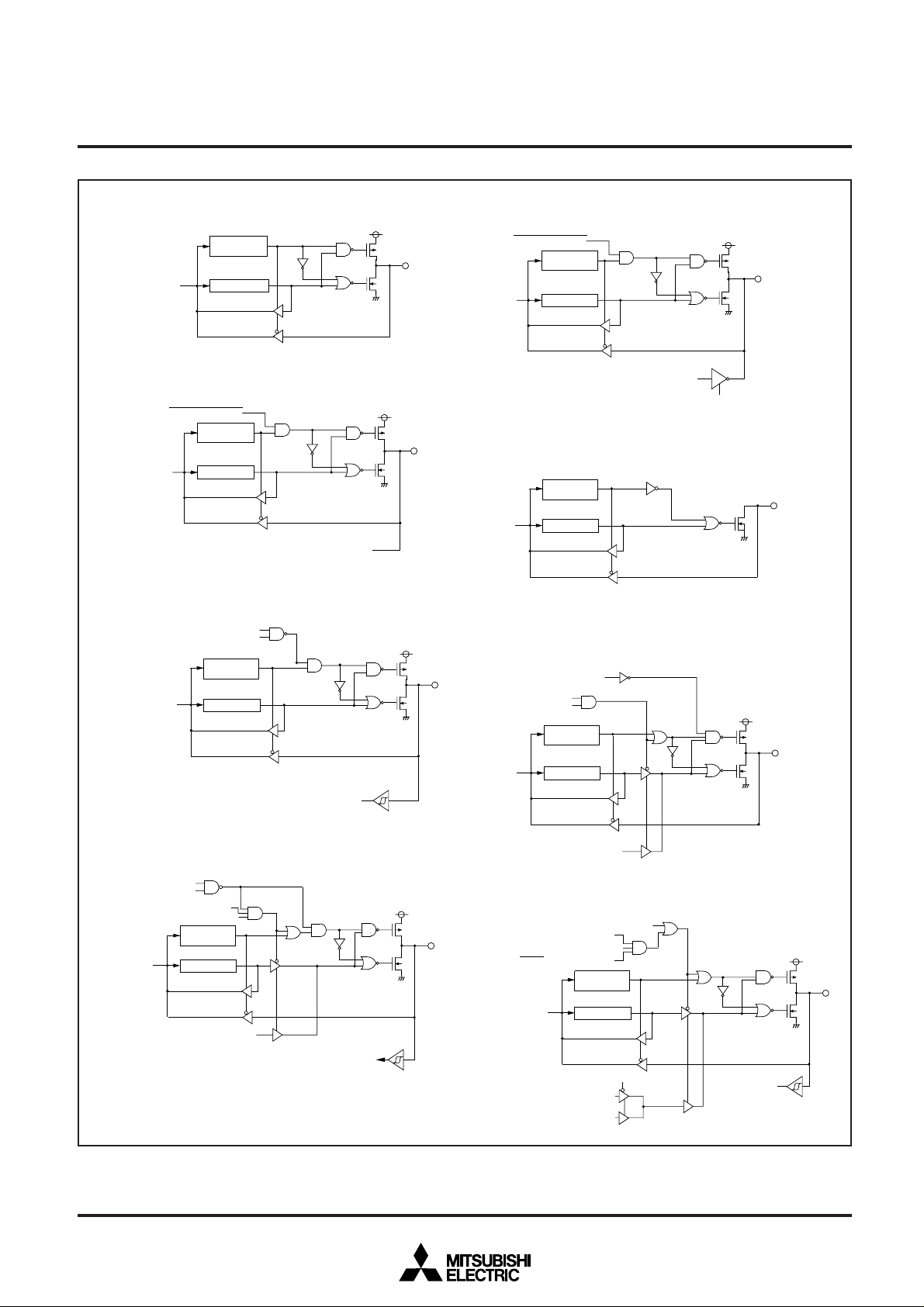

(1) Port P0, P1

Data bus

(3) Port P2

Data bus

1

Port XC switch bit

(5) Port P2

Serial I/O enable bit

Receive enable bit

Data bus

Direction

register

Port latch

Direction

register

Port latch

Sub-clock generating circuit input

4

Direction

register

Port latch

(2) Port P2

Data bus

(4) Port P2

Data bus

(6) Port P2

0

Port XC switch bit

Direction

register

Port latch

2, P23

Port latch

5

P-channel output disable bit

Serial I/O enable bit

Transmit enable bit

Direction

register

Direction

register

Port P2

Port X

Oscillator

1

C

switch bit

(7) Port P2

Serial I/O clock

Serial I/O enable bit

Serial I/O mode selection bit

Data bus

6

selection bit

Serial I/O enable bit

Direction

register

Port latch

Serial clock output

Fig. 8 Port block diagram (1)

Serial I/O input

External clock input

Data bus

(8) Port P2

Serial I/O mode selection bit

7

Serial I/O enable bit

RDY

output enable bit

S

Data bus

Serial ready output

Port latch

Serial I/O output

Pulse output mode

Pulse output mode

Direction

register

Port latch

Timer output

CNTR

0

interrupt

input

10

Page 11

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

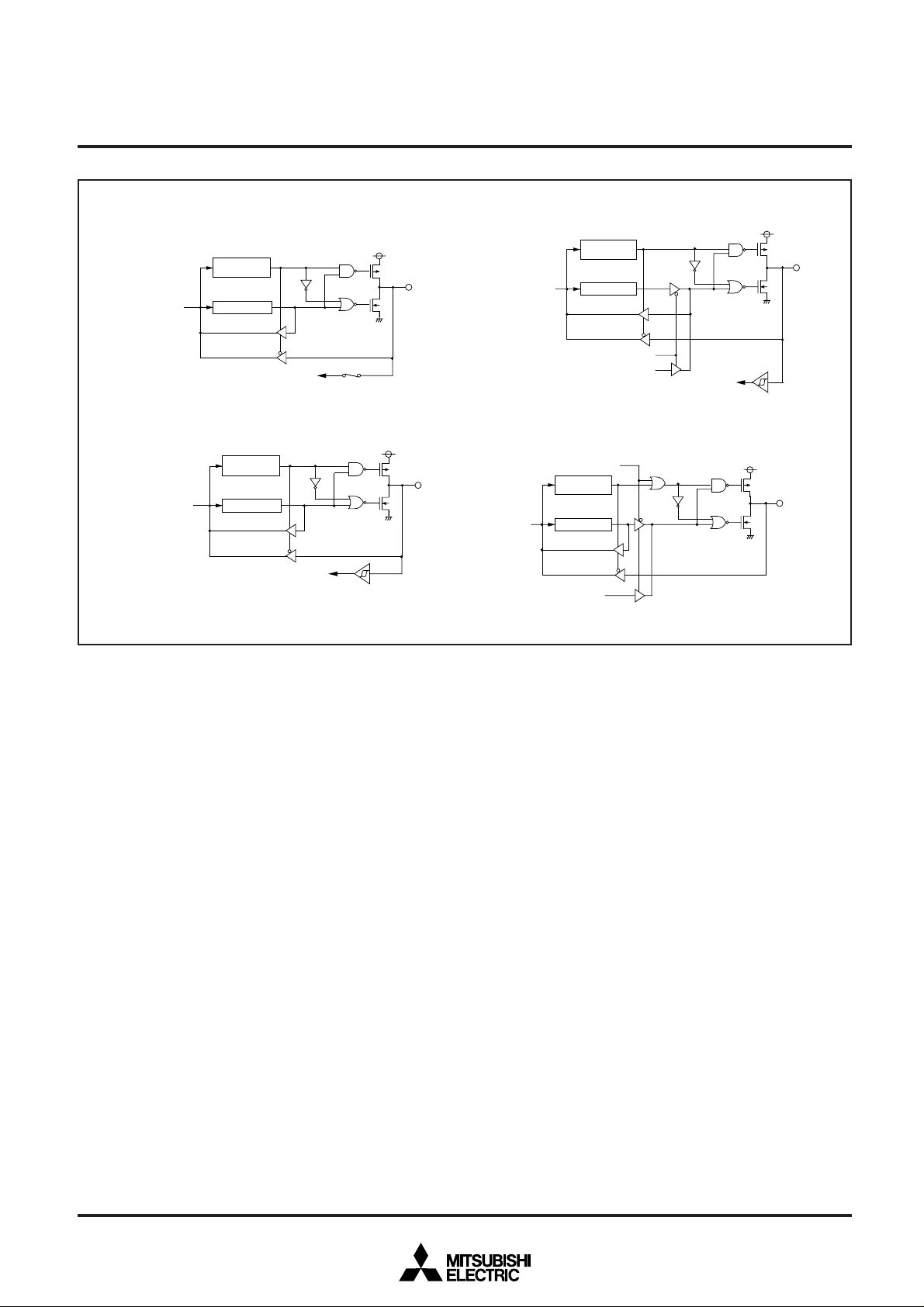

(9) Port P30–P3

Data bus

(11) Port P41–P4

Data bus

4

Direction

register

Port latch

A-D converter input

3

Direction

register

Port latch

Fig. 9 Port block diagram (2)

Analog input pin selection bit

Interrupt input

(10) Port P4

(12) Port P4

Data bus Port latch

0

Data bus

4

PWM output enable bit

Direction

register

PWM output

Direction

register

Port latch

Pulse output mode

Timer output

CNTR1 interrupt input

11

Page 12

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

INTERRUPTS

Interrupts occur by 14 sources among 14 sources: six external,

seven internal, and one software.

Interrupt Control

Each interrupt is controlled by an interrupt request bit, an interrupt

enable bit, and the interrupt disable flag except for the software interrupt set by the BRK instruction. An interrupt occurs if the

corresponding interrupt request and enable bits are “1” and the interrupt disable flag is “0”.

Interrupt enable bits can be set or cleared by software.

Interrupt request bits can be cleared by software, but cannot be

set by software.

The BRK instruction cannot be disabled with any flag or bit. The I

(interrupt disable) flag disables all interrupts except the BRK instruction interrupt.

When several interrupts occur at the same time, the interrupts are

received according to priority.

Interrupt Operation

By acceptance of an interrupt, the following operations are automatically performed:

1. The contents of the program counter and the processor status

register are automatically pushed onto the stack.

2. The interrupt disable flag is set and the corresponding interrupt

request bit is cleared.

3. The interrupt jump destination address is read from the vector

table into the program counter.

■Notes

When the active edge of an external interrupt (INT0–INT3, CNTR0,

CNTR

1) is set, the corresponding interrupt request bit may also be

set. Therefore, take the following sequence:

1. Disable the interrupt

2. Change the interrupt edge selection register

(the timer XY mode register for CNTR

3. Clear the interrupt request bit to “0”

4. Accept the interrupt.

0 and CNTR1)

12

Page 13

Table 4 Interrupt vector addresses and priority

Interrupt Source

Reset (Note 2)

INT0

Reserved

INT1

INT2

INT3

Reserved

Timer X

Timer Y

Timer 1

Timer 2

Serial I/O

reception

Serial I/O

Transmission

CNTR

0

CNTR1

A-D converter

BRK instruction

Notes 1: Vector addresses contain interrupt jump destination addresses.

2: Reset function in the same way as an interrupt with the highest priority.

Priority

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17 Non-maskable software interrupt

Vector Addresses (Note 1)

High

FFFD16

FFFB16

FFF916

FFF716

FFF516

FFF316

FFF116

FFEF16

FFED16

FFEB16

FFE916

FFE716

FFE516

FFE316

FFE116

FFDF16

FFDD16

Low

FFFC

FFFA

FFF816

FFF616

FFF416

FFF216

FFF016

FFEE16

FFEC16

FFEA16

FFE816

FFE616

FFE416

FFE216

FFE016

FFDE16

FFDC16

16

16

MITSUBISHI MICROCOMPUTERS

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

Interrupt Request

Generating Conditions

At reset

At detection of either rising or

falling edge of INT

Reserved

At detection of either rising or

falling edge of INT

At detection of either rising or

falling edge of INT2 input

At detection of either rising or

falling edge of INT

Reserved

At timer X underflow

At timer Y underflow

At timer 1 underflow

At timer 2 underflow

At completion of serial I/O data

reception

At completion of serial I/O trans-

fer shift or when transmission

buffer is empty

At detection of either rising or

falling edge of CNTR

At detection of either rising or

falling edge of CNTR1 input

At completion of A-D conversion

At BRK instruction execution

0 input

1 input

3 input

0 input

3850 Group

Remarks

Non-maskable

External interrupt

(active edge selectable)

External interrupt

(active edge selectable)

External interrupt

(active edge selectable)

External interrupt

(active edge selectable)

STP release timer underflow

Valid when serial I/O is selected

Valid when serial I/O is selected

External interrupt

(active edge selectable)

External interrupt

(active edge selectable)

13

Page 14

Interrupt request bit

Interrupt enable bit

Interrupt disable flag (I)

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

Fig. 10 Interrupt control

b7 b0

b7 b0

Interrupt edge selection register

(INTEDGE : address 003A

16

)

INT0 active edge selection bit

INT

1

active edge selection bit

INT

2

active edge selection bit

INT

3

active edge selection bit

Reserved(Do not write “1” to this bit)

Not used (returns “0” when read)

Interrupt request register 1

(IREQ1 : address 003C

16

)

INT0 interrupt request bit

Reserved

INT

1

interrupt request bit

INT

2

interrupt request bit

3

interrupt request bit

INT

Reserved

Timer X interrupt request bit

Timer Y interrupt request bit

0 : No interrupt request issued

1 : Interrupt request issued

BRK instruction

Reset

0 : Falling edge active

1 : Rising edge active

b7 b0

Interrupt request

Interrupt request register 2

(IREQ2 : address 003D

Timer 1 interrupt request bit

Timer 2 interrupt request bit

Serial I/O reception interrupt request bit

Serial I/O transmit interrupt request bit

CNTR

0

interrupt request bit

CNTR

1

interrupt request bit

AD converter interrupt request bit

Not used (returns “0” when read)

0 : No interrupt request issued

1 : Interrupt request issued

16

)

b7 b0

Interrupt control register 1

(ICON1 : address 003E

INT0 interrupt enable bit

Reserved(Do not write "1" to this bit)

1

interrupt enable bit

INT

INT

2

interrupt enable bit

INT

3

interrupt enable bit

Reserved(Do not write "1" to this bit)

Timer X interrupt enable bit

Timer Y interrupt enable bit

0 : Interrupts disabled

1 : Interrupts enabled

Fig. 11 Structure of interrupt-related registers (1)

14

b7 b0

16

)

Interrupt control register 2

(ICON2 : address 003F

16

)

Timer 1 interrupt enable bit

Timer 2 interrupt enable bit

Serial I/O reception interrupt enable bit

Serial I/O transmit interrupt enable bit

CNTR

0

interrupt enable bit

CNTR

1

interrupt enable bit

AD converter interrupt enable bit

Not used (returns “0” when read)

(Do not write “1” to this bit)

0 : Interrupts disabled

1 : Interrupts enabled

Page 15

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

TIMERS

The 3850 group has four timers: timer X, timer Y, timer 1, and

timer 2.

The division ratio of each timer or prescaler is given by 1/(n + 1),

where n is the value in the corresponding timer or prescaler latch.

All timers are count down. When the timer reaches “00

derflow occurs at the next count pulse and the corresponding

timer latch is reloaded into the timer and the count is continued.

When a timer underflows, the interrupt request bit corresponding

to that timer is set to “1”.

b7

b0

Timer XY mode register

(TM : address 0023

Timer X operating mode bit

b1b0

0 0: Timer mode

0 1: Pulse output mode

1 0: Event counter mode

1 1: Pulse width measurement mode

CNTR0 active edge selection bit

0: Interrupt at falling edge

Count at rising edge in event

counter mode

1: Interrupt at rising edge

Count at falling edge in event

counter mode

Timer X count stop bit

0: Count start

1: Count stop

Timer Y operating mode bit

b5b4

0 0: Timer mode

0 1: Pulse output mode

1 0: Event counter mode

1 1: Pulse width measurement mode

1 active edge selection bit

CNTR

0: Interrupt at falling edge

Count at rising edge in event

counter mode

1: Interrupt at rising edge

Count at falling edge in event

counter mode

Timer Y count stop bit

0: Count start

1: Count stop

Fig. 12 Structure of timer XY mode register

16”, an un-

16)

Timer 1 and Timer 2

The count source of prescaler 12 is the oscillation frequency

which is selected by timer 12 count source selection bit. The output of prescaler 12 is counted by timer 1 and timer 2, and a timer

underflow sets the interrupt request bit.

Timer X and Timer Y

Timer X and Timer Y can each select in one of four operating

modes by setting the timer XY mode register.

(1) Timer Mode

The timer counts the count source selected by Timer count source

selection bit.

(2) Pulse Output Mode

The timer counts the count source selected by Timer count source

selection bit. Whenever the contents of the timer reach “00

signal output from the CNTR

CNTR

0 (or CNTR1) active edge selection bit is “0”, output begins

0 (or CNTR1) pin is inverted. If the

16”, the

at “ H”.

If it is “1”, output starts at “L”. When using a timer in this mode, set

the corresponding port P2

7 ( or port P40) direction register to out-

put mode.

(3) Event Counter Mode

Operation in event counter mode is the same as in timer mode, except that the timer counts signals input through the CNTR

CNTR

1 pin.

When the CNTR

rising edge of the CNTR

When the CNTR

falling edge of the CNTR

0 (or CNTR1) active edge selection bit is “0”, the

0 (or CNTR1) pin is counted.

0 (or CNTR1) active edge selection bit is “1”, the

0 (or CNTR1) pin is counted.

0 or

(4) Pulse Width Measurement Mode

If the CNTR0 (or CNTR1) active edge selection bit is “0”, the timer

counts the selected signals by the count source selection bit while

the CNTR

tive edge selection bit is “1”, the timer counts it while the CNTR

(or CNTR1) pin is at “L”.

0 (or CNTR1) pin is at “H”. If the CNTR0 (or CNTR1) ac-

0

b7

b0

Timer count source selection register

(TCSS : address 0028

Timer X count source selection bit

IN

)/16 (f(X

CIN

)/16 (f(X

)/16 (f(X

)

CIN

CIN

CIN

CIN

)/16 at low-speed mode)

)/2 at low-speed mode)

)/16 at low-speed mode)

)/2 at low-speed mode)

)/16 at low-speed mode)

0 : f(X

1 : f(XIN)/2 (f(X

Timer Y count source selection bit

0 : f(X

IN

1 : f(XIN)/2 (f(X

Timer 12 count source selection bit

0 : f(X

IN

1 : f(X

CIN

Not used (returns “0” when read)

16

)

Fig. 13 Structure of timer count source selection register

The count can be stopped by setting “1” to the timer X (or timer Y)

count stop bit in any mode. The corresponding interrupt request

bit is set each time a timer underflows.

■Note

When switching the count source by the timer 12, X and Y count

source bit, the value of timer count is altered in unconsiderable

amount owing to generating of a thin pulses in the count input

signals.

Therefore, select the timer count source before set the value to

the prescaler and the timer.

15

Page 16

Data bus

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

f(XIN)/16

f(XIN)/2

Timer X count source selection bit

7/CNTR0

P2

7

Port P2

direction register

f(XIN)/16

f(XIN)/2

Timer Y count source selection bit

P40/CNTR1

Port P4

direction register

CNTR

edge selection

“0”

“1”

Port P2

latch

Pulse output mode

CNTR

edge selection

“0”

“1”

Port P4

0

Pulse output mode

latch

0 active

bit

7

1 active

bit

0

Pulse width

measurement

mode

Event

counter

mode

CNTR

edge selection

bit

Pulse width

measurement mode

Event

counter

mode

CNTR1 active

edge selection

bit

Timer mode

Pulse output mode

Timer X count stop bit

0 active

“1”

“0”

Timer mode

Pulse output mode

Timer Y count stop bit

“1”

“0”

Data bus

Prescaler X latch (8)

Prescaler X (8)

Q

Toggle flip-flop

Q

R

Data bus

Prescaler Y latch (8)

Prescaler Y (8)

Q

Toggle flip-flop

Q

R

Timer X latch (8)

Timer X (8)

T

Timer X latch write pulse

Pulse output mode

Timer Y latch (8)

Timer Y (8)

T

Timer Y latch write pulse

Pulse output mode

To timer X interrupt

request bit

To CNTR

0 interrupt

request bit

To timer Y interrupt

request bit

To CNTR

1 interrupt

request bit

Prescaler 12 latch (8)

f(XIN)/16

f(XCIN)

Timer 12 count source selection bit

Prescaler 12 (8)

Fig. 14 Block diagram of timer X, timer Y, timer 1, and timer 2

16

Timer 1 latch (8)

Timer 1 (8)

Timer 2 latch (8)

Timer 2 (8)

To timer 2 interrupt

request bit

To timer 1 interrupt

request bit

Page 17

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

SERIAL I/O

Serial I/O can be used as either clock synchronous or asynchronous (UART) serial I/O. A dedicated timer is also provided for baud

rate generation.

Data bus

Address 0018

Transmit shift register

Transmit buffer register

Data bus

P24/RXD

P26/SCLK

P2

7/SRDY

P2

5/TXD

XIN

Receive buffer register

Receive shift register

BRG count source selection bit

1/4

F/F

Falling-edge detector

(1) Clock Synchronous Serial I/O Mode

Clock synchronous serial I/O mode can be selected by setting the

serial I/O mode selection bit of the serial I/O control register (bit 6

of address 001A

For clock synchronous serial I/O, the transmitter and the receiver

must use the same clock. If an internal clock is used, transfer is

started by a write signal to the TB/RB.

16

Shift clock

Serial I/O synchronous

clock selection bit

Frequency division ratio 1/(n+1)

Baud rate generator

Address 001C

Shift clock

Address 0018

Clock control circuit

16

Clock control circuit

16

16) to “1”.

Serial I/O control register

Receive buffer full flag (RBF)

Receive interrupt request (RI)

1/4

Transmit interrupt source selection bit

Serial I/O status register

Address 001A16

Transmit shift completion flag (TSC)

Transmit interrupt request (TI)

Transmit buffer empty flag (TBE)

Address 0019

16

Fig. 15 Block diagram of clock synchronous serial I/O

Transfer shift clock

(1/2 to 1/2048 of the internal

clock, or an external clock)

Serial output TxD

Serial input RxD

Receive enable signal S

RDY

D

0

D

0

Write pulse to receive/transmit

buffer register (address 0018

16

)

TBE = 0

TBE = 1

TSC = 0

1: As the transmit interrupt (TI), either when the transmit buffer has emptied (TBE=1) or after the transmit shift operation has

Notes

ended (TSC=1), by setting the transmit interrupt source selection bit (TIC) of the serial I/O control register.

2: If data is written to the transmit buffer register when TSC=0, the transmit clock is generated continuously and serial data

is output continuously from the TxD pin.

3: The receive interrupt (RI) is set when the receive buffer full flag (RBF) becomes “1” .

Fig. 16 Operation of clock synchronous serial I/O function

D

D

1

D

2

D

1

D

2

D

3

D

3

D

4

D

4

D

5

D

5

D

6

D

6

7

D

7

RBF = 1

TSC = 1

Overrun error (OE)

detection

17

Page 18

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

(2) Asynchronous Serial I/O (UART) Mode

Clock asynchronous serial I/O mode (UART) can be selected by

clearing the serial I/O mode selection bit (b6) of the serial I/O control register to “0”.

Eight serial data transfer formats can be selected, and the transfer

formats used by a transmitter and receiver must be identical.

The transmit and receive shift registers each have a buffer, but the

Data bus

Address 001816

Receive buffer register

Receive shift register

PE FE

SP detector

Frequency division ratio 1/(n+1)

Baud rate generator

Address 001C

ST/SP/PA generator

Transmit shift register

Transmit buffer register

Data bus

P2

P2

P2

4/RXD

6/SCLK1

XIN

5/TXD

OE

Character length selection bit

ST detector

BRG count source selection bit

1/4

7 bits

8 bits

Serial I/O synchronous clock selection bit

Character length selection bit

two buffers have the same address in memory. Since the shift register cannot be written to or read from directly, transmit data is

written to the transmit buffer register, and receive data is read from

the receive buffer register.

The transmit buffer register can also hold the next data to be

transmitted, and the receive buffer register can hold a character

while the next character is being received.

Serial I/O control register

Receive buffer full flag (RBF)

Receive interrupt request (RI)

Clock control circuit

16

1/16

Transmit interrupt source selection bit

Address

001816

Serial I/O status register

Address 001A

1/16

16

UART control register

Address 001B

Transmit shift completion flag (TSC)

Transmit interrupt request (TI)

Transmit buffer empty flag (TBE)

Address

16

001916

Fig.17 Block diagram of UART serial I/O

18

Page 19

Transmit or receive clock

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

Transmit buffer write

Receive buffer read

signal

TBE=0 TBE=0

TSC=0

TBE=1

Serial output TXD

signal

Serial input R

Notes

X

D

1: Error flag detection occurs at the same time that the RBF flag becomes “1” (at 1st stop bit, during reception).

2: As the transmit interrupt (TI), when either the TBE or TSC flag becomes “1,” can be selected to occur depending on the setting of the transmit

interrupt source selection bit (TIC) of the serial I/O control register.

3: The receive interrupt (RI) is set when the RBF flag becomes “1.”

4: After data is written to the transmit buffer when TSC=1, 0.5 to 1.5 cycles of the data shift cycle is necessary until changing to TSC=0.

ST

0

D

1

1 start bit

7 or 8 data bit

1 or 0 parity bit

1 or 2 stop bit (s)

ST

0

D

1

Fig. 18 Operation of UART serial I/O function

[Transmit Buffer Register/Receive Buffer

Register (TB/RB)] 0018

The transmit buffer register and the receive buffer register are located at the same address. The transmit buffer is write-only and

the receive buffer is read-only. If a character bit length is 7 bits, the

MSB of data stored in the receive buffer is “0”.

16

[Serial I/O Status Register (SIOSTS)] 001916

The read-only serial I/O status register consists of seven flags

(bits 0 to 6) which indicate the operating status of the serial I/O

function and various errors.

Three of the flags (bits 4 to 6) are valid only in UART mode.

The receive buffer full flag (bit 1) is cleared to “0” when the receive

buffer register is read.

If there is an error, it is detected at the same time that data is

transferred from the receive shift register to the receive buffer register, and the receive buffer full flag is set. A write to the ser ial I/O

status register clears all the error flags OE, PE, FE, and SE (bit 3

to bit 6, respectively). Writing “0” to the serial I/O enable bit SIOE

(bit 7 of the serial I/O control register) also clears all the status

flags, including the error flags.

Bits 0 to 6 of the serial I/O status register are initialized to “0” at reset, but if the transmit enable bit (bit 4) of the serial I/O control

register has been set to “1”, the transmit shift completion flag (bit

2) and the transmit buffer empty flag (bit 0) become “1”.

TBE=1

STD

SP

RBF=1

STD

SP D

D

0

D

1

Generated at 2nd bit in 2-stop-bit mode

RBF=0

0

D

1

TSC=1

SP

RBF=1

SP

Serial I/O Control Register (SIOCON)] 001A16

The serial I/O control register consists of eight control bits for the

serial I/O function.

[UART Control Register (UARTCON)] 001B16

The UART control register consists of four control bits (bits 0 to 3)

which are valid when asynchronous serial I/O is selected and set

the data format of an data transfer and one bit (bit 4) which is always valid and sets the output structure of the P2

5/TXD pin.

[Baud Rate Generator (BRG)] 001C16

The baud rate generator determines the baud rate for serial transfer.

The baud rate generator divides the frequency of the count source

by 1/(n + 1), where n is the value written to the baud rate generator.

19

Page 20

MITSUBISHI MICROCOMPUTERS

b7

b7

Transmit buffer empty flag (TBE)

0: Buffer full

1: Buffer empty

Receive buffer full flag (RBF)

0: Buffer empty

1: Buffer full

Transmit shift completion flag (TSC)

0: Transmit shift in progress

1: Transmit shift completed

Overrun error flag (OE)

0: No error

1: Overrun error

Parity error flag (PE)

0: No error

1: Parity error

Framing error flag (FE)

0: No error

1: Framing error

Summing error flag (SE)

0: (OE) U (PE) U (FE)=0

1: (OE) U (PE) U (FE)=1

Not used (returns “1” when read)

Serial I/O status register

Serial I/O control register

b0

b0

BRG count source selection bit (CSS)

0: f(X

IN

)

1: f(X

IN

)/4

Serial I/O synchronous clock selection bit (SCS)

0: BRG output divided by 4 when clock synchronous

serial I/O is selected, BRG output divided by 16

when UART is selected.

1: External clock input when clock synchronous serial

I/O is selected, external clock input divided by 16

when UART is selected.

S

RDY

output enable bit (SRDY)

0: P2

7

pin operates as ordinary I/O pin

1: P2

7

pin operates as S

RDY

output pin

Transmit interrupt source selection bit (TIC)

0: Interrupt when transmit buffer has emptied

1: Interrupt when transmit shift operation is completed

Transmit enable bit (TE)

0: Transmit disabled

1: Transmit enabled

Receive enable bit (RE)

0: Receive disabled

1: Receive enabled

Serial I/O mode selection bit (SIOM)

0: Clock asynchronous (UART) serial I/O

1: Clock synchronous serial I/O

Serial I/O enable bit (SIOE)

0: Serial I/O disabled

(pins P2

4

to P27 operate as ordinary I/O pins)

1: Serial I/O enabled

(pins P2

4

to P27 operate as serial I/O pins)

b7

UART control register

Character length selection bit (CHAS)

0: 8 bits

1: 7 bits

Parity enable bit (PARE)

0: Parity checking disabled

1: Parity checking enabled

Parity selection bit (PARS)

0: Even parity

1: Odd parity

Stop bit length selection bit (STPS)

0: 1 stop bit

1: 2 stop bits

P2

5/TX

D P-channel output disable bit (POFF)

0: CMOS output (in output mode)

1: N-channel open drain output (in output mode)

Not used (return “1” when read)

b0

(SIOSTS : address 001916)

(SIOCON : address 001A

16

)

(UARTCON : address 001B

16

)

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

Fig. 19 Structure of serial I/O control registers

20

Page 21

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

PULSE WIDTH MODULATION (PWM)

The 3850 group has a PWM function with an 8-bit resolution,

based on a signal that is the clock input X

vided by 2.

IN or that clock input di-

Data Setting

The PWM output pin also functions as port P44. Set the PWM period by the PWM prescaler, and set the “H” term of output pulse by

the PWM register.

If the value in the PWM prescaler is n and the value in the PWM

register is m (where n = 0 to 255 and m = 0 to 255) :

PWM period = 255 ✕ (n+1) / f(X

= 31.875 ✕ (n+1) µs (when f(X

Output pulse “H” term = PWM period ✕ m / 255

= 0.125 ✕ (n+1) ✕ m µs

(when f(X

IN) = 8 MHz)

IN)

IN) = 8 MHz)

PWM Operation

When bit 0 (PWM enable bit) of the PWM control register is set to

“1”, operation starts by initializing the PWM output circuit, and

pulses are output starting at an “H”.

If the PWM register or PWM prescaler is updated during PWM

output, the pulses will change in the cycle after the one in which

the change was made.

31.875 ✕ m ✕ (n+1)

255

PWM output

T = [31.875 ✕ (n+1)] µs

m: Contents of PWM register

n : Contents of PWM prescaler

T : PWM period (when f(X

Fig. 20 Timing of PWM period

µs

IN) = 8 MHz)

Data bus

prescaler pre-latch

prescaler latch

Count source

selection bit

1/2

“0”

PWM prescaler

“1”

XIN

Fig. 21 Block diagram of PWM function

PWM

Transfer control circuit

PWM

PWM

register pre-latch

PWM

register latch

PWM register

Port P44 latch

PWM enable bit

Port P4

4

21

Page 22

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

b7

Fig. 22 Structure of PWM control register

b0

PWM control register

(PWMCON : address 001D

PWM function enable bit

0: PWM disabled

1: PWM enabled

Count source selection bit

IN)

0: f(X

IN)/2

1: f(X

Not used (return “0” when read)

ABC

PWM output

PWM register

write signal

16)

T

T

(Changes “H” term from “A” to “B”.)

T2

C

B

=

T2

T

PWM prescaler

write signal

(Changes PWM period from “T” to “T2”.)

When the contents of the PWM register or PWM prescaler have changed, the PWM

output will change from the next period after the change.

Fig. 23 PWM output timing when PWM register or PWM prescaler is changed

■Note

The PWM starts after the PWM enable bit is set to enable and "L" level is output from the PWM pin.

The length of this "L" level output is as follows:

n+1

2 • f(X

n+1

f(X

sec (Count source selection bit = 0, where n is the value set in the prescaler)

IN)

sec (Count source selection bit = 1, where n is the value set in the prescaler)

IN)

22

Page 23

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

A-D CONVERTER

[A-D Conversion Registers (ADL, ADH)]

0035

16, 003616

The A-D conversion registers are read-only registers that store the

result of an A-D conversion. Do not read these registers during an

A-D conversion

[AD Control Register (ADCON)] 003416

The AD control register controls the A-D conversion process. Bits

0 to 2 select a specific analog input pin. Bit 4 indicates the

completion of an A-D conversion. The value of this bit remains at

“0” during an A-D conversion and changes to “1” when an A-D

conversion ends. Writing “0” to this bit starts the A-D conversion.

Comparison V oltage Generator

The comparison voltage generator divides the voltage between

AV

SS and VREF into 1024 and outputs the divided voltages.

Channel Selector

The channel selector selects one of ports P30/AN0 to P34/AN4 and

inputs the voltage to the comparator.

Comparator and Control Circuit

The comparator and control circuit compare an analog input voltage with the comparison voltage, and the result is stored in the

A-D conversion registers. When an A-D conversion is completed,

the control circuit sets the A-D conversion completion bit and the

A-D interrupt request bit to “1”.

Note that because the comparator consists of a capacitor coupling, set f(X

IN) to 500 kHz or more during an A-D conversion.

b7

Fig. 24 Structure of AD control register

b0

AD control register

(ADCON : address 0034

Analog input pin selection bits

b2 b1 b0

0 0 0: P3

0 0 1: P31/AN1

0 1 0: P32/AN2

0 1 1: P33/AN3

1 0 0: P34/AN4

Not used (returns “0” when read)

A-D conversion completion bit

0: Conversion in progress

1: Conversion completed

Not used (returns “0” when read)

0/AN0

10-bit reading

16

(Read address 0036

before 003516)

b7 b0

16

(Address 0036

)

b7

16

(Address 0035

Note : The high-order 6 bits of address 003616 become “0”

at reading.

)

b7 b6 b5 b4 b3 b2 b1 b0

8-bit reading (Read only address 0035

b7

16

(Address 0035

)

b9 b8 b7 b6 b5 b4 b3 b2

b9

16

16)

b8

b0

)

b0

AD control register

(Address 0034

P30/AN

P31/AN

P32/AN

P33/AN

P34/AN

Fig. 26 Block diagram of A-D converter

16

0

1

2

3

4

b7 b0

)

3

Comparator

Channel selector

Fig. 25 Structure of A-D conversion registers

Data bus

A-D control circuit

A-D conversion high-order register

A-D conversion low-order register

10

Resistor ladder

REF

AV

V

SS

A-D interrupt request

(Address 0036

(Address 0035

16

)

16

)

23

Page 24

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

WA TCHDOG TIMER

The watchdog timer gives a mean of returning to the reset status

when a program cannot run on a normal loop (for example, because of a software run-away). The watchdog timer consists of an

8-bit watchdog timer L and an 8-bit watchdog timer H.

Standard Operation of Watchdog Timer

When any data is not written into the watchdog timer control register (address 0039

stop state. The watchdog timer starts to count down by writing an

optional value into the watchdog timer control register (address

0039

16) and an internal reset occurs at an underflow of the watch-

dog timer H.

Accordingly, programming is usually performed so that writing to

the watchdog timer control register (address 0039

started before an underflow. When the watchdog timer control register (address 0039

of the watchdog timer H, STP instruction disable bit, and watchdog timer H count source selection bit are read.

●Initial value of watchdog timer

At reset or writing to the watchdog timer control register (address

0039

16), each watchdog timer H and L is set to “FF16.”

16) after resetting, the watchdog timer is in the

16) may be

16) is read, the values of the high-order 6 bits

●Watchdog timer H count source selection bit operation

Bit 7 of the watchdog timer control register (address 0039

16) per-

mits selecting a watchdog timer H count source. When this bit is

set to “0”, the count source becomes the underflow signal of

watchdog timer L. The detection time is set to 131.072 ms at f(X

= 8 MHz frequency and 32.768 s at f(X

CIN) = 32 kHz frequency.

IN)

When this bit is set to “1”, the count source becomes the signal

divided by 16 for f(X

is set to 512 µs at f(X

IN) (or f(XCIN)). The detection time in this case

IN) = 8 MHz frequency and 128 ms at f(XCIN)

= 32 kHz frequency. This bit is cleared to “0” after resetting.

●Operation of STP instruction disable bit

Bit 6 of the watchdog timer control register (address 0039

16) per-

mits disabling the STP instruction when the watchdog timer is in

operation.

When this bit is “0”, the STP instruction is enabled.

When this bit is “1”, the STP instruction is disabled, once the STP

instruction is executed, an internal reset occurs. When this bit is

set to “1”, it cannot be rewritten to “0” by program. This bit is

cleared to “0” after resetting.

“FF

16” is set when

XCIN

Main clock division

ratio selection bits

(Note)

XIN

STP instruction disable bit

RESET

Note: Any one of high-speed, middle-speed or low-speed mode is selected by bits 7 and 6 of the CPU mode register.

watchdog timer

control register is

written to.

“10”

1/16

“00”

“01”

STP instruction

Fig. 27 Block diagram of Watchdog timer

b7

Watchdog timer L (8)

“0”

“1”

Watchdog timer H count

source selection bit

b0

Watchdog timer control register

(WDTCON : address 0039

Watchdog timer H (for read-out of high-order 6 bit)

STP instruction disable bit

0: STP instruction enabled

1: STP instruction disabled

Watchdog timer H (8)

Reset

circuit

Data bus

“FF16” is set when

watchdog timer

control register is

written to.

Internal reset

16)

Fig. 28 Structure of Watchdog timer control register

24

Watchdog timer H count source selection bit

0: Watchdog timer L underflow

IN)/16 or f(XCIN)/16

1: f(X

Page 25

RESET CIRCUIT

To reset the microcomputer, RESET pin must be held at an "L"

level for 2 µs or more. Then the RESET pin is returned to an "H"

level (the power source voltage must be between 2.7 V and 5.5 V,

and the oscillation must be stable), reset is released. After the reset is completed, the program starts from the address contained in

address FFFD

byte). Make sure that the reset input voltage is less than 0.54 V for

V

CC of 2.7 V.

16 (high-order byte) and address FFFC16 (low-order

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

Poweron

(Note)

0.2V

CC

RESET

V

CC

Power source

voltage

0V

Reset input

voltage

0V

Note : Reset release voltage ; Vcc=2.7 V

X

IN

φ

RESET

RESETOUT

RESET

V

CC

Fig. 29 Reset circuit example

Power source

voltage detection

circuit

Address

Data

SYNC

XIN: 8 to 13 clock cycles

Fig. 30 Reset sequence

AD

?

?

?

Notes

??

??

1: The frequency relation of f(XIN) and f(φ) is f(XIN) = 2 • f(φ).

2: The question marks (?) indicate an undefined state that depends on the previous state.

3: All signals except X

?

?

FFFC FFFD

?

IN and RESET are internals.

AD

L

H,L

Reset address from the vector table.

ADH

25

Page 26

(1)

Port P0 direction register (P0D)

(2)

Port P1 direction register (P1D)

(3)

Port P2 direction register (P2D)

(4)

Port P3 direction register (P3D)

(5)

Port P4 direction register (P4D)

(6)

Serial I/O status register (SIOSTS)

(7)

Serial I/O control register (SIOCON)

(8)

UART control register (UARTCON)

(9)

PWM control register (PWMCON)

(10)

Prescaler 12 (PRE12)

(11)

Timer 1 (T1)

(12)

Timer 2 (T2)

(13)

Timer XY mode register (TM)

(14)

Prescaler X (PREX)

(15)

Timer X (TX)

(16)

Prescaler Y (PREY)

(17)

Timer Y (TY)

(18)

Timer count source select register

(19)

Reserved

(20)

Reserved

(21)

Reserved

(22)

Reserved

(23)

Reserved

(24)

AD control register (ADCON)

(25)

MISRG

(26)

Watchdog timer control register (WDTCON)

(27)

Interrupt edge selection register (INTEDGE)

(28)

CPU mode register (CPUM)

(29)

Interrupt request register 1 (IREQ1)

(30)

Interrupt request register 2 (IREQ2)

(31)

Interrupt control register 1 (ICON1)

(32)

Interrupt control register 2 (ICON2)

(33)

Processor status register

(34)

Program counter

Note : X indicates Not fixed .

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

Address Register contents

0001

000316

000516

000716

000916

001916

001A16

001B16

001D16

002016

002116

002216

002316

002416

002516

002616

002716

002816

002C16

002D16

002E16

002F16

003016

003416

003816

003916

003A16

003B16

003C16

003D16

003E16

003F16

(PS)

(PC

(PC

16

H)

L)

0016

0016

0016

0016

0016

10000000

0016

11100000

0016

FF16

0116

0016

0016

FF16

FF16

FF16

FF16

0016

Not fixed

Not fixed

Not fixed

Not fixed

Not fixed

00010000

00

16

00111111

0016

010010 0

0

00

16

0016

0016

0016

1

XXXXXXX

FFFD16 contents

FFFC16 contents

Fig. 31 Internal status at reset

26

Page 27

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

CLOCK GENERATING CIRCUIT

The 3850 group has two built-in oscillation circuits. An oscillation

circuit can be formed by connecting a resonator between X

X

OUT (XCIN and XCOUT). Use the circuit constants in accordance

with the resonator manufacturer’s recommended values. No external resistor is needed between X

resistor exists on-chip. However, an external feed-back resistor is

needed between X

Immediately after power on, only the X

oscillating, and X

CIN and XCOUT.

CIN and XCOUT pins function as I/O ports.

IN and XOUT since a feed-back

IN oscillation circuit starts

IN and

Frequency Control

(1) Middle-speed mode

The internal clock φ is the frequency of XIN divided by 8. After reset, this mode is selected.

(2) High-speed mode

The internal clock φ is half the frequency of XIN.

(3) Low-speed mode

The internal clock φ is half the frequency of XCIN.

■Note

If you switch the mode between middle/high-speed and lowspeed, stabilize both X

is required for the sub-clock to stabilize, especially immediately after power on and at returning from the stop mode. When switching

the mode between middle/high-speed and low-speed, set the frequency on condition that f(X

IN and XCIN oscillations. The sufficient time

IN) > 3•f(XCIN).

(4) Low power dissipation mode

The low power consumption operation can be realized by stopping

the main clock X

bit 5 of the CPU mode register to “1.” When the main clock X

restarted (by setting the main clock stop bit to “0”), set sufficient

time for oscillation to stabilize.

The sub-clock X

clocks that are generated externally. Accordingly, make sure to

cause an external resonator to oscillate.

IN in low-speed mode. To stop the main clock, set

IN is

CIN-XCOUT oscillating circuit can not directly input

be generated.

(2) Wait mode

If the WIT instruction is executed, the internal clock φ stops at an

“H” level, but the oscillator does not stop. The internal clock φ restarts at reset or when an interrupt is received. Since the oscillator

does not stop, normal operation can be started immediately after

the clock is restarted.

To ensure that the interrupts will be received to release the STP or

WIT state, their interrupt enable bits must be set to “1” before executing of the STP or WIT instruction.

When releasing the STP state, the prescaler 12 and timer 1 will

start counting the clock XIN divided by 16. Accordingly, set the

timer 1 interrupt enable bit to “0” before executing the STP instruction.

■Note

When using the oscillation stabilizing time set after STP instruction

released bit set to “1”, evaluate time to stabilize oscillation of the

used oscillator and set the value to the timer 1 and prescaler 12.

XCIN XCOUT XIN XOUT

Rf

Rd

COUT

CCOUT

CCIN

Fig. 32 Ceramic resonator circuit

CIN

Oscillation Control

(1) Stop mode

If the STP instruction is executed, the internal clock φ stops at an

“H” level, and X

stabilizing time set after STP instruction released bit is “0,” the

prescaler 12 is set to “FF

oscillation stabilizing time set after STP instruction released bit is

“1,” set the sufficient time for oscillation of used oscillator to stabilize since nothing is set to the prescaler 12 and timer 1.

Either X

count source. Oscillator restarts when an external interrupt is received, but the internal clock φ is not supplied to the CPU (remains

at “H”) until timer 1 underflows. The internal clock φ is supplied for

the first time, when timer 1 underflows. This ensures time for the

clock oscillation using the ceramic resonators to be stabilized.

When the oscillator is restarted by reset, apply “L” level to the

RESET pin until the oscillation is stable since a wait time will not

IN and XCIN oscillation stops. When the oscillation

16” and timer 1 is set to “0116.” When the

IN or XCIN divided by 16 is input to the prescaler 12 as

XCIN XCOUT XIN XOUT

Rf

Rd

External oscillation

circuit

CCOUT

CCIN

Fig. 33 External clock input circuit

Vcc

Vss

Open

27

Page 28

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

b7

b0

MISRG

(MISRG : address 0038

Oscillation stabilizing time set after STP instruction

released bit

Middle-speed mode automatic switch set bit

Middle-speed mode automatic switch wait time set bit

Middle-speed mode automatic switch start bit

(Depending on program)

Not used (return “0” when read)

Fig. 34 Structure of MISRG

X

CIN

16

)

0: Automatically set “0116” to Timer 1,

“FF

16

” to Prescaler 12

1: Automatically set nothing

0: Not set automatically

1: Automatic switching enable

0: 4.5 to 5.5 machine cycles

1: 6.5 to 7.5 machine cycles

0: Invalid

1: Automatic switch start

X

COUT

“0”

“1”

Port X

C

switch bit

Middle-speed mode automatic switch set bit

By setting the middle-speed mode automatic switch set bit to “1”

while operating in the low-speed mode, X

cally starts and the mode is automatically switched to the

middle-speed mode when defecting a rising/falling edge of the

S

CL or SDA pin. The middle-speed automatic switch wait time set

bit can select the switch timing from the low-speed to the middlespeed mode; either 4.5 to 5.5 machine cycles or 6.5 to 7.5

machine cycles in the low-speed mode. Select it according to oscillation start characteristics of used X

The middle-speed mode automatic switch start bit is used to automatically make to X

IN oscillation start and switch to the

middle-speed mode by setting this bit to “1” while operating in the

low-speed mode.

IN oscillation automati-

IN oscillator.

X

IN

SRQ

Interrupt disable flag l

Interrupt request

X

Reset

OUT

Main clock division ratio

selection bits (Note)

Low-speed mode

High-speed or

middle-speed

mode

Main clock stop bit

STP instruction

1/2 1/4

low-speed mode

WIT instruction

1/2

Main clock division ratio

selection bits (Note)

Middle-speed mode

High-speed or

SRQ

Prescaler 12 Timer 1

FF

16

Timing φ (internal clock)

SRQ

STP instruction

01

16

Reset or

STP instruction

Note: Any one of high-speed, middle-speed or low-speed mode is selected by bits 7 and 6 of the CPU mode register.

When low-speed mode is selected, set port Xc switch bit (b1) to “1”.

Fig. 35 System clock generating circuit block diagram (Single-chip mode)

28

Page 29

Reset

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

Middle-speed mode

(f(φ)=1 MHz)

CM7=0

6=1

CM

5=0(8 MHz oscillating)

CM

CM

4=0(32 kHz stopped)

CM4

“1”←→“0”

Middle-speed mode

(f(φ)=1 MHz)

CM

7=0

6=1

CM

CM

5=0(8 MHz oscillating)

4=1(32 kHz oscillating)

CM

4

CM

“1”←→“0”

CM

6

“1”←→“0”

CM6

“1”←→“0”

CM6

“1”←→“0”

“0”←→“1”

CM

“1”←→“0”

CM

“1”←→“0”

CM

7

6

CM

“0”←→“1”

4

6

High-speed mode

(f(φ)=4 MHz)

7=0

CM

6=0

CM

5=0(8 MHz oscillating)

CM

CM

4=0(32 kHz stopped)

CM4

“1”←→“0”

High-speed mode

(f(φ)=4 MHz)

7=0

CM

CM

6=0

5=0(8 MHz oscillating)

CM

4=1(32 kHz oscillating)

CM

CM7

“1”←→“0”

Low-speed mode

(f(φ)=16 kHz)

CM

7=1

CM

6=0

5=0(8 MHz oscillating)

CM

4=1(32 kHz oscillating)

CM

b7 b4

CPU mode register

(CPUM : address 003B16)

Notes

1 : Switch the mode by the allows shown between the mode blocks. (Do not switch between the modes directly without an allow.)

2 : The all modes can be switched to the stop mode or the wait mode and return to the source mode when the stop mode or the wait mode is

ended.

3 : Timer operates in the wait mode.

4 : When the stop mode is ended, a delay of approximately 1 ms occurs by connecting prescaler 12 in middle/high-speed mode.

5 : When the stop mode is ended, a delay of approximately 16 ms occurs by Timer 1 and Timer 2 in low-speed mode.

6 : Wait until oscillation stabilizes after oscillating the main clock X

mode.

7 : The example assumes that 8 MHz is being applied to the X

Fig. 36 State transitions of system clock

CM5

“1”←→“0”

Low-speed mode

(f(φ)=16 kHz)

CM

7=1

6=0

CM

5=1(8 MHz stopped)

CM

CM

4=1(32 kHz oscillating)

IN pin and 32 kHz to the XCIN pin. φ indicates the internal clock.

CM4 : Port Xc switch bit

0 : I/O port function (stop oscillating)

1 : X

CM

0 : Operating

1 : Stopped

CM

b7 b6

0 0 : φ = f(X

0 1 : φ = f(X

1 0 : φ = f(X

1 1 : Not available

IN before the switching from the low-speed mode to middle/high-speed

CIN-XCOUT oscillating function

5 : Main clock (XIN- XOUT) stop bit

7, CM6: Main clock division ratio selection bit

IN)/2 ( High-speed mode)

IN)/8 (Middle-speed mode)

CIN)/2 (Low-speed mode)

29

Page 30

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

NOTES ON PROGRAMMING

Processor Status Register

The contents of the processor status register (PS) after a reset are

undefined, except for the interrupt disable flag (I) which is “1.” After

a reset, initialize flags which affect program execution. In particular, it is essential to initialize the index X mode (T) and the decimal

mode (D) flags because of their effect on calculations.

Interrupts

The contents of the interrupt request bits do not change immediately after they have been written. After writing to an interrupt

request register, execute at least one instruction before performing

a BBC or BBS instruction.

Decimal Calculations

• To calculate in decimal notation, set the decimal mode flag (D)

to “1”, then execute an ADC or SBC instruction. After executing

an ADC or SBC instruction, execute at least one instruction before executing a SEC, CLC, or CLD instruction.

• In decimal mode, the values of the negative (N), overflow (V),

and zero (Z) flags are invalid.

Timers

If a value n (between 0 and 255) is written to a timer latch, the frequency division ratio is 1/(n+1).

A-D Converter

The comparator uses capacitive coupling amplifier whose charge

will be lost if the clock frequency is too low.

Therefore, make sure that f(X

A-D conversion.

Do not execute the STP or WIT instruction during an A-D conversion.

IN) is at least on 500 kHz during an

Instruction Execution Time

The instruction execution time is obtained by multiplying the frequency of the internal clock φ by the number of cycles needed to

execute an instruction.

The number of cycles required to execute an instruction is shown

in the list of machine instructions.

The frequency of the internal clock φ is half of the X

high-speed mode.

IN frequency in

Multiplication and Division Instructions

• The index X mode (T) and the decimal mode (D) flags do not affect the MUL and DIV instruction.

• The execution of these instructions does not change the contents of the processor status register.

Ports

The contents of the port direction registers cannot be read. The

following cannot be used:

• The data transfer instruction (LDA, etc.)

• The operation instruction when the index X mode flag (T) is “1”

• The addressing mode which uses the value of a direction register as an index

• The bit-test instruction (BBC or BBS, etc.) to a direction register

• The read-modify-write instructions (ROR, CLB, or SEB, etc.) to a

direction register.

Use instructions such as LDM and STA, etc., to set the port direction registers.

Serial I/O

In clock synchronous serial I/O, if the receive side is using an external clock and it is to output the S

enable bit, the receive enable bit, and the S

to “1.”

Serial I/O continues to output the final bit from the T

transmission is completed.

When an external clock is used as synchronous clock in serial I/O,

write transmission data to the transmit buffer register while the

transfer clock is “H.”

RDY signal, set the transmit

RDY output enable bit

XD pin after

30

Page 31

MITSUBISHI MICROCOMPUTERS

3850 Group

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

DATA REQUIRED FOR MASK ORDERS

The following are necessary when ordering a mask ROM production: