Page 1

1/62

PRELIMINARY DATA

November 2002

This is preliminary information on a new product now in development or undergoing evaluation. Details are subject to change without notice.

M36W216TI

M36W216BI

16 Mbit (1Mb x16, Boot Block) Flash Memory

and 2 Mbit (128Kb x16) SRAM, Multiple Memory Product

FEATURES SUMMARY

■ MULTIPLE MEMORY PRODUCT

– 16 Mbit (1Mb x 16) Boot Block Flash Memory

– 2 Mbit (128Kb x 16) SRAM

■ SUPPLY VOLTAGE

–V

DDF

= V

DDS

= 2.7V to 3.3V

–V

DDQF

= V

DDS

= 2.7V to 3.3V

–V

PPF

= 12V for Fast Program (optional)

■ ACCESS TIME: 70ns, 85ns

■ LOW POWER CONSUMPTION

■ ELECTRONIC SIGNATURE

– Manufacturer Code: 20h

– Top Device Code, M36W216TI: 88CEh

– Bottom Device Code, M36W216BI: 88CFh

FLASH MEMORY

■ MEMORY BLOCKS

– Parameter Blocks (Top or Bottom location)

– Main Blocks

■ PROGRAMMING TIME

– 10µs typical

– Double Word Programming Option

■ BLOCK LOCKING

– All blocks locked at Power up

– Any combination of blocks can be locked

–WP

F

for Block Lock-Down

■ AUTOMATIC STAND-BY MODE

■ PROGRAM and ERASE SUSPEND

■ 100,000 PROGRAM/ERASE CYCLES per

BLOCK

■ COMMON FLASH INTERFACE

– 64 bit Security Code

■ SECURITY

– 64 bit user programmable OTP cells

– 64 bit unique device identifier

– One parameter block permanently lockable

SRAM

■ 2 Mbit (128K x 16 bit)

■ ACCESS TIME: 70ns

■ LOW V

DDS

DATA RETENTION: 1.5V

■ POWER DOWN FEATURES USING TWO

CHIP ENABLE INPUTS

Figure 1. Packages

FBGA

Stacked LFBGA66 (ZA)

12 x 8mm

Page 2

M36W216TI, M36W216BI

2/62

TABLE OF CONTENTS

SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

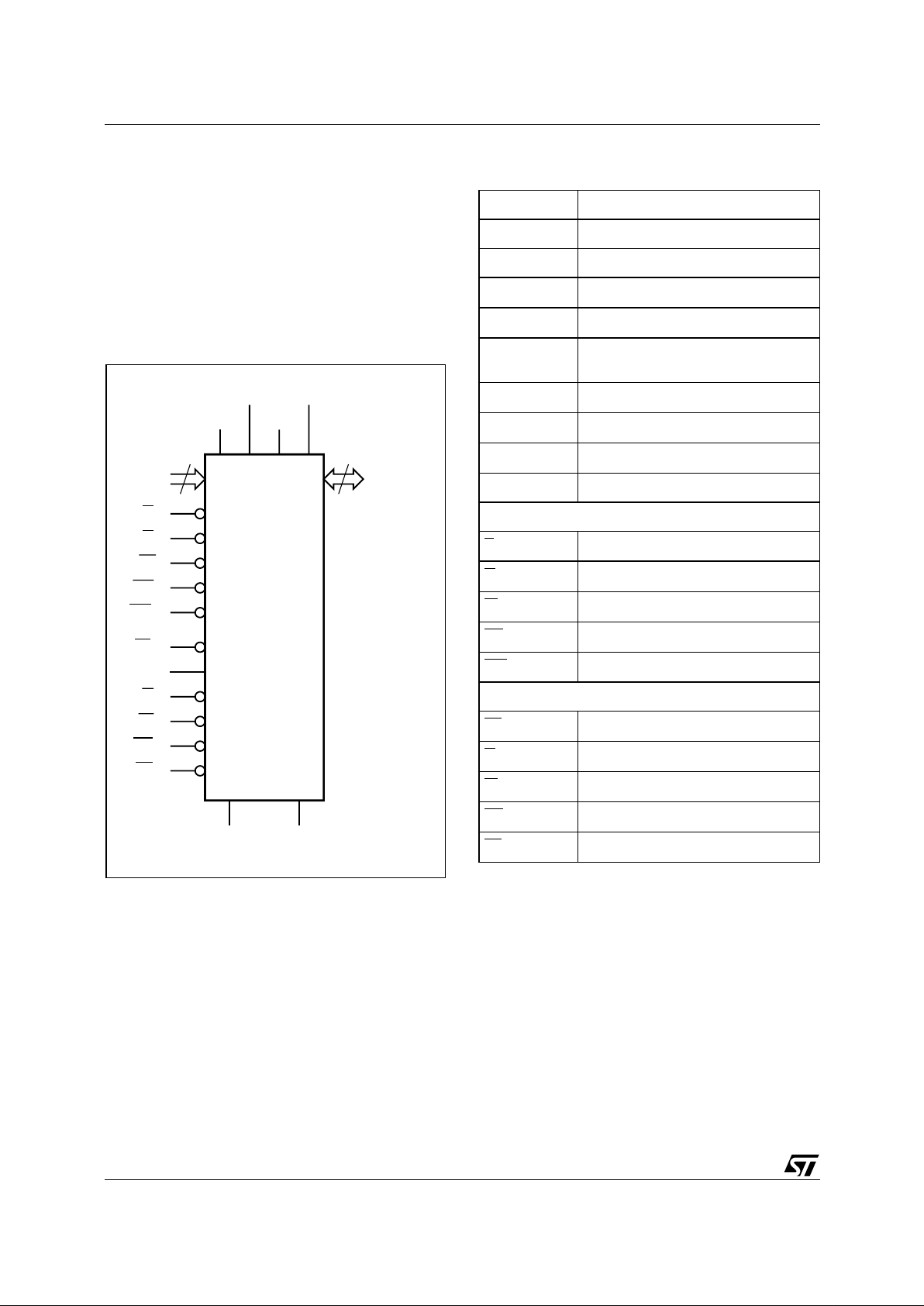

Figure 2. Logic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 1. Signal Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

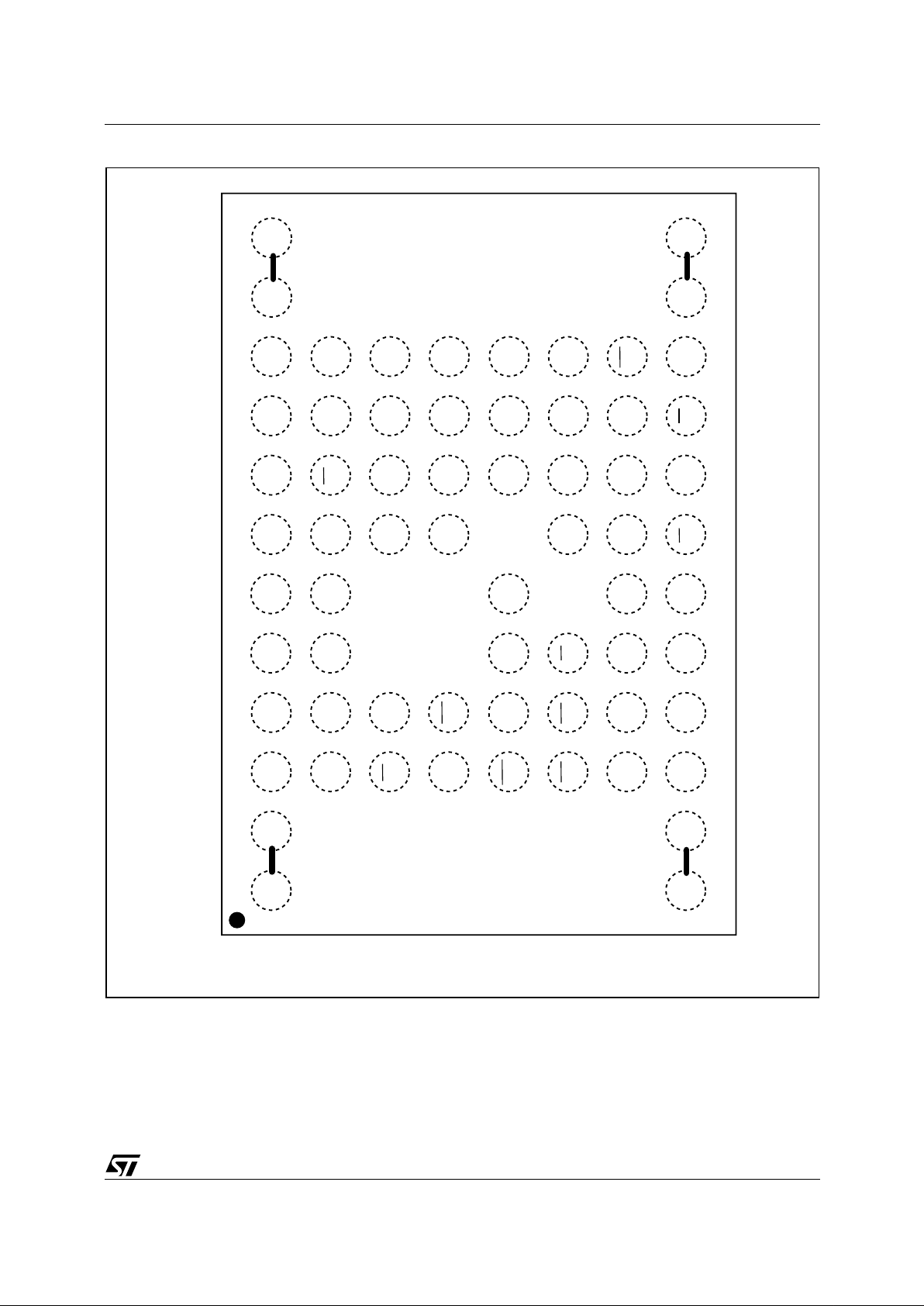

Figure 3. LFBGA Connections (Top view through package). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SIGNAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Address Inputs (A0-A16). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Address Inputs (A17-A19). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Data Inputs/Outputs (DQ0-DQ15). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flash Chip Enable (EF). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flash Output Enable (GF). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flash Write Enable (WF). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flash Write Protect (WPF). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flash Reset (RPF). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SRAM Chip Enable (E1S, E2S). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SRAM Write Enable (WS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SRAM Output Enable (GS).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SRAM Upper Byte Enable (UBS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

SRAM Lower Byte Enable (LBS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

V

DDF

and VDDS Supply Voltages.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

V

DDQF

and V

DDS

Supply Voltage (2.7V to 3.3V). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

V

PPF

Program Supply Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

V

SSF

and V

SSS

Ground.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

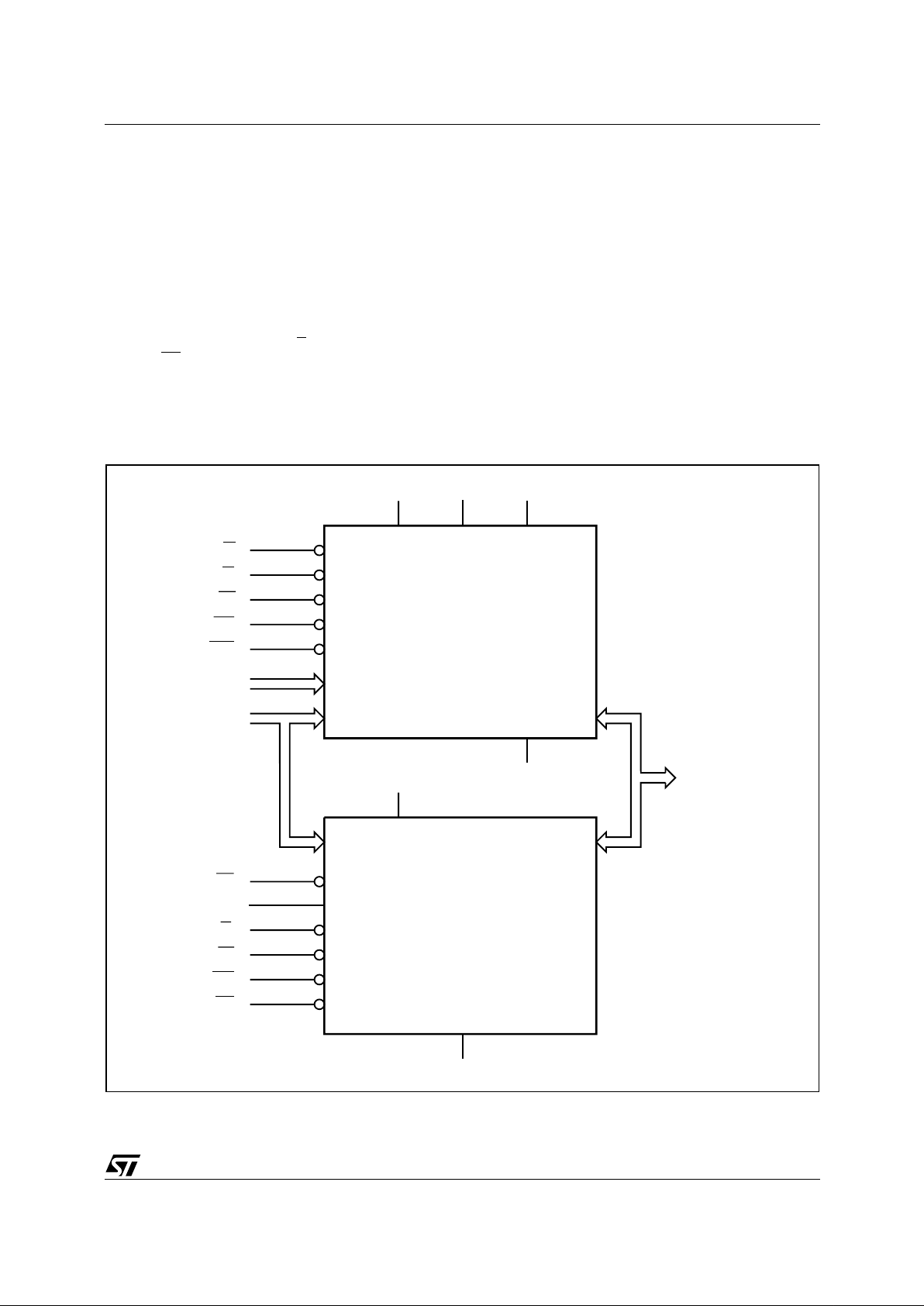

Figure 4. Functional Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

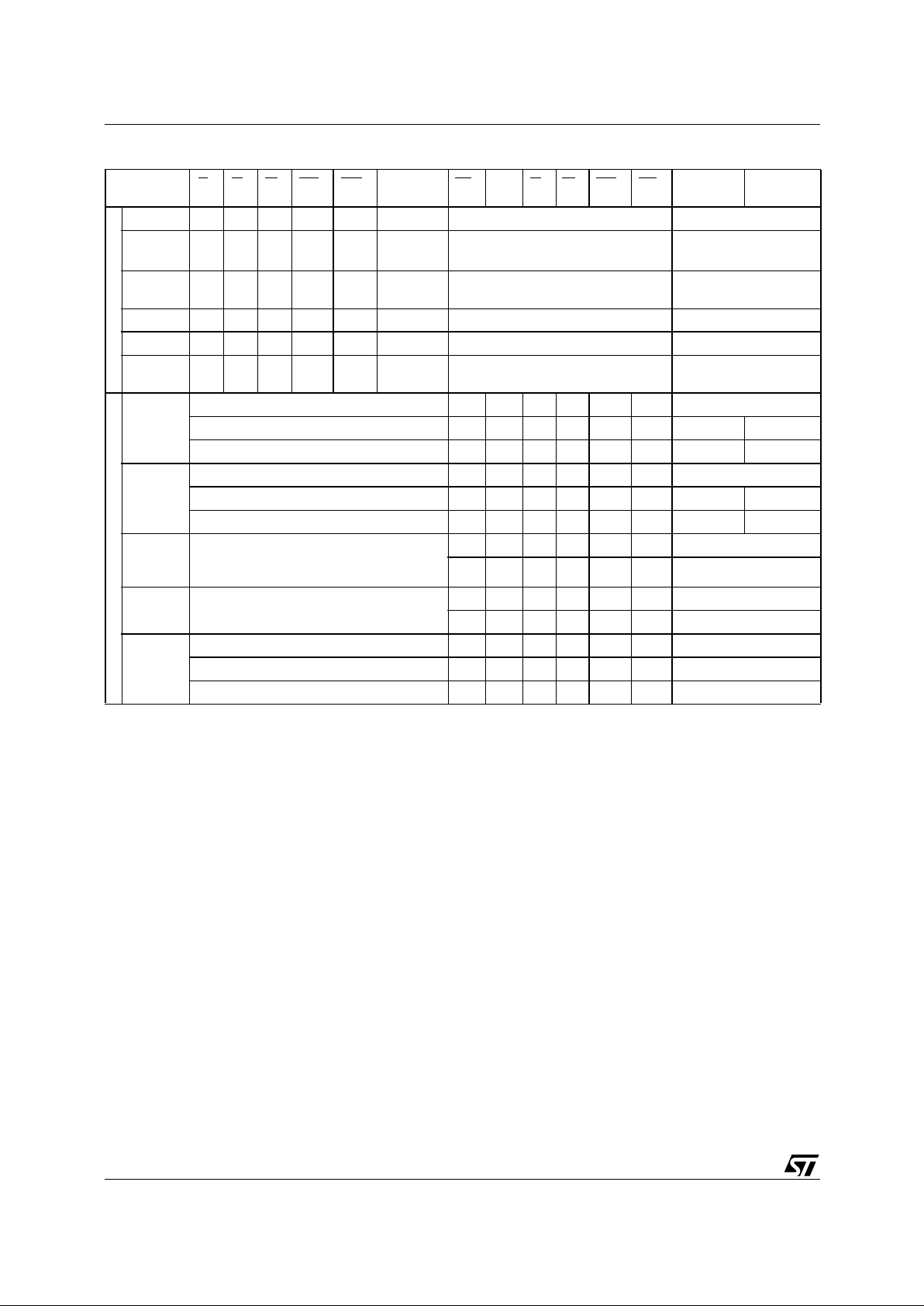

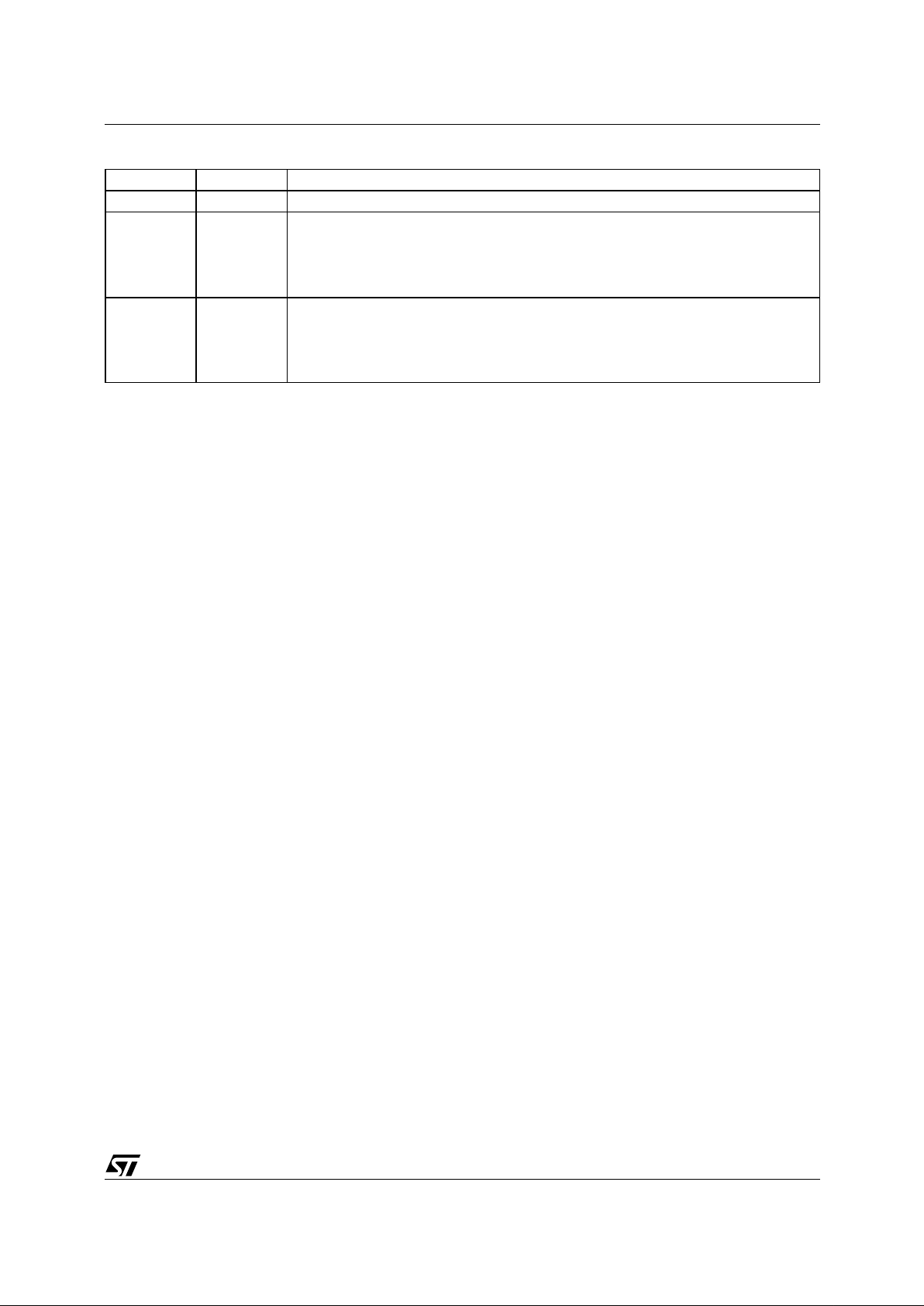

Table 2. Main Operation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 3. Absolute Maximum Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

DC AND AC PARAMETERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 2

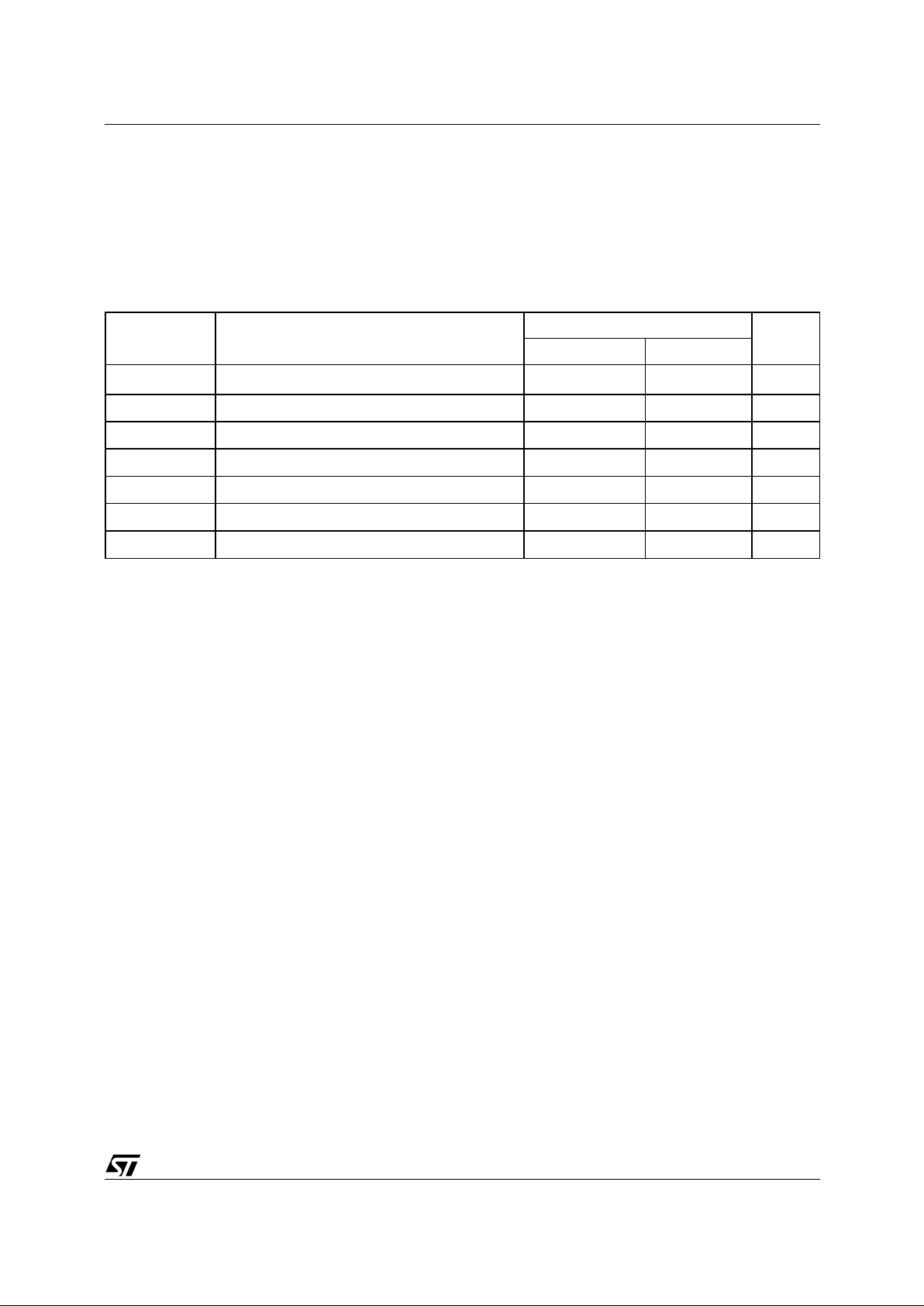

Table 4. Operating and AC Measurement Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 5. AC Measurement I/O Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Figure 6. AC Measurement Load Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 5. Device Capaci ta n ce. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 6. DC Character i stics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

PACKAGE MECHANICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

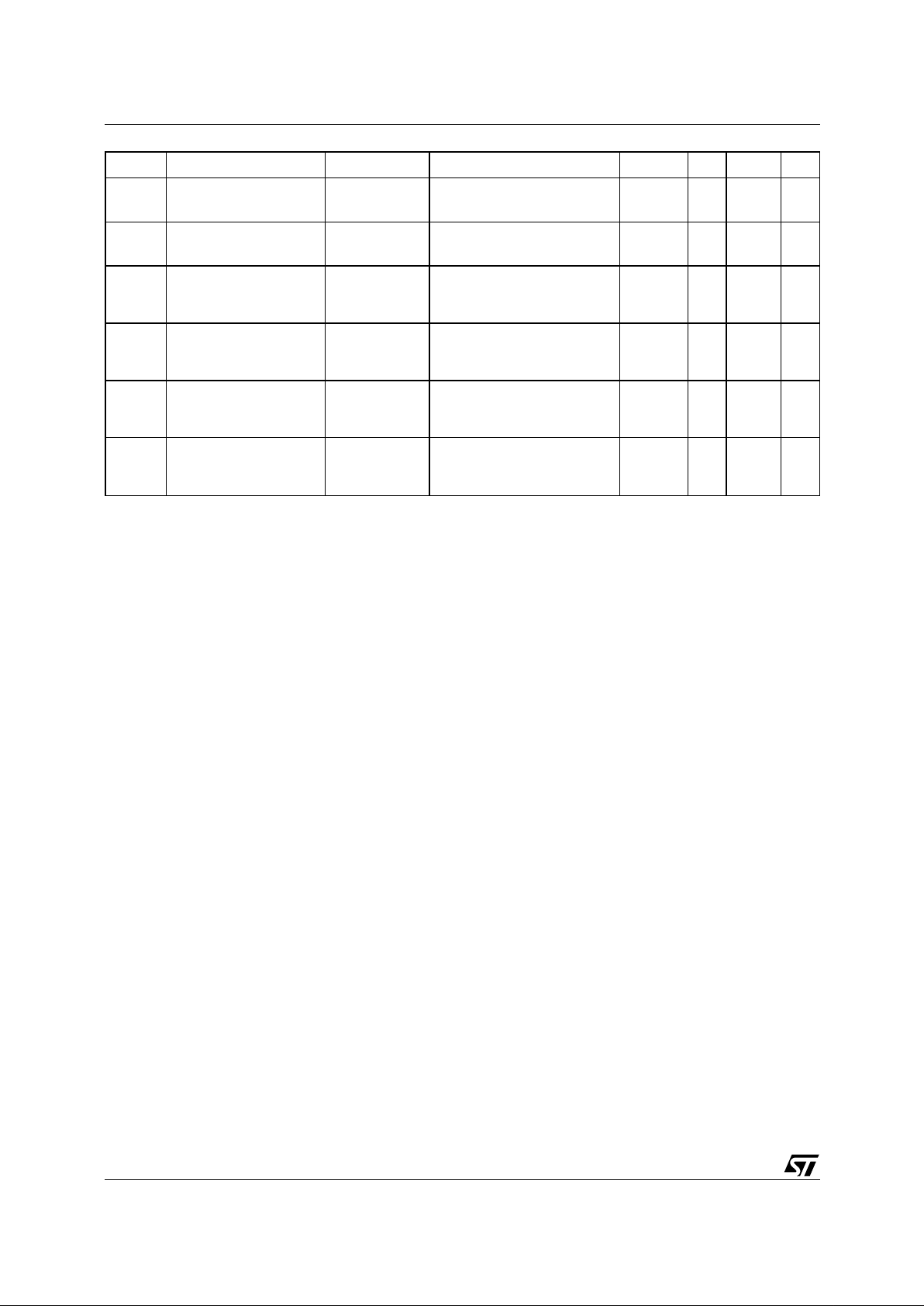

Figure 7. Stacked LFBGA66-12x8mm , 8x8 ball array, 0.8mm pitch, Bottom Vi ew Package Ou tline15

Table 7. Stacked LFBGA66 - 12x8mm, 8x8 ball array, 0.8 mm pitch, Package Mechanical Data . 15

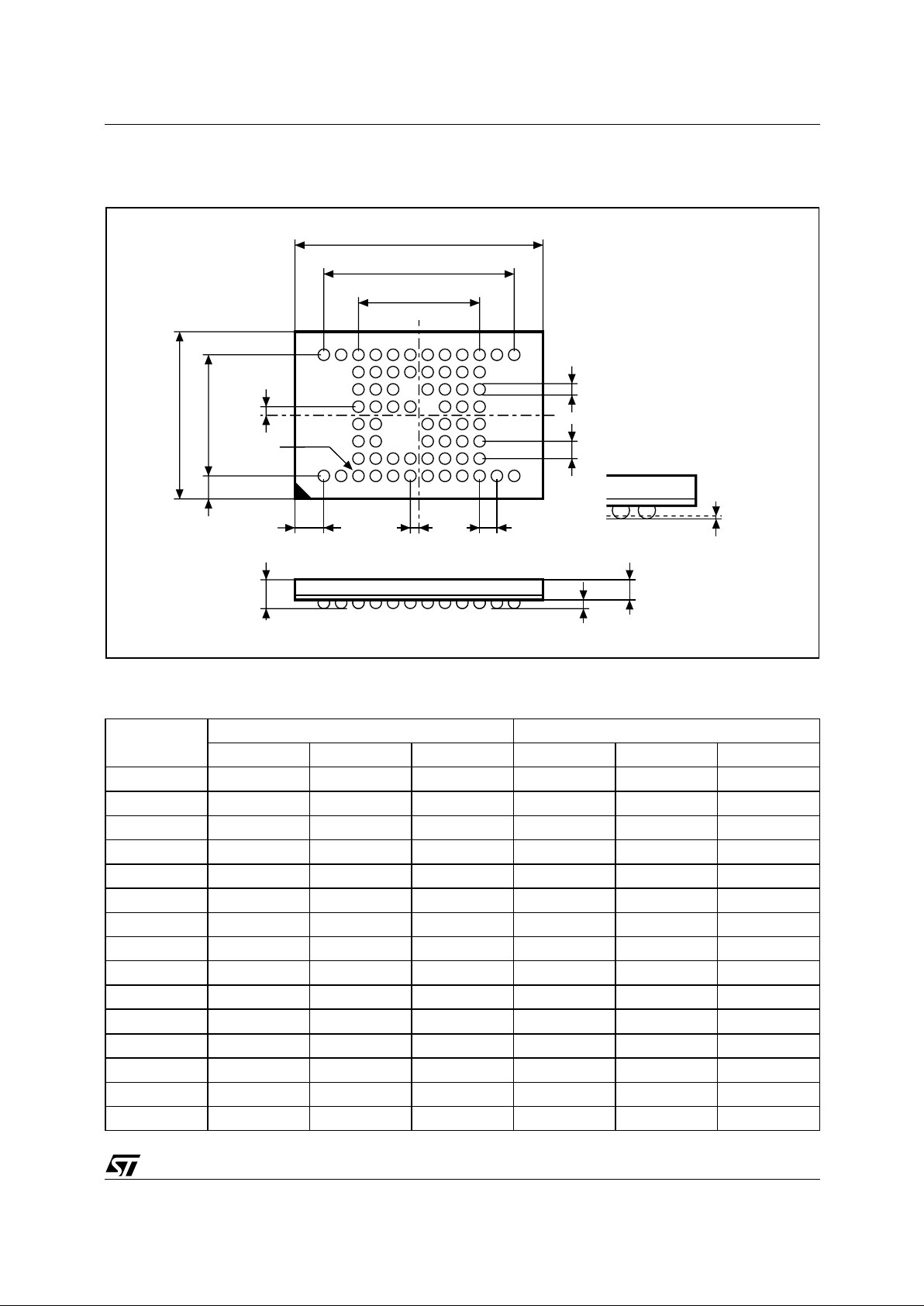

Figure 8. Stacked LFBGA66 Daisy Chain - Package Connections (Top view through package) . . 16

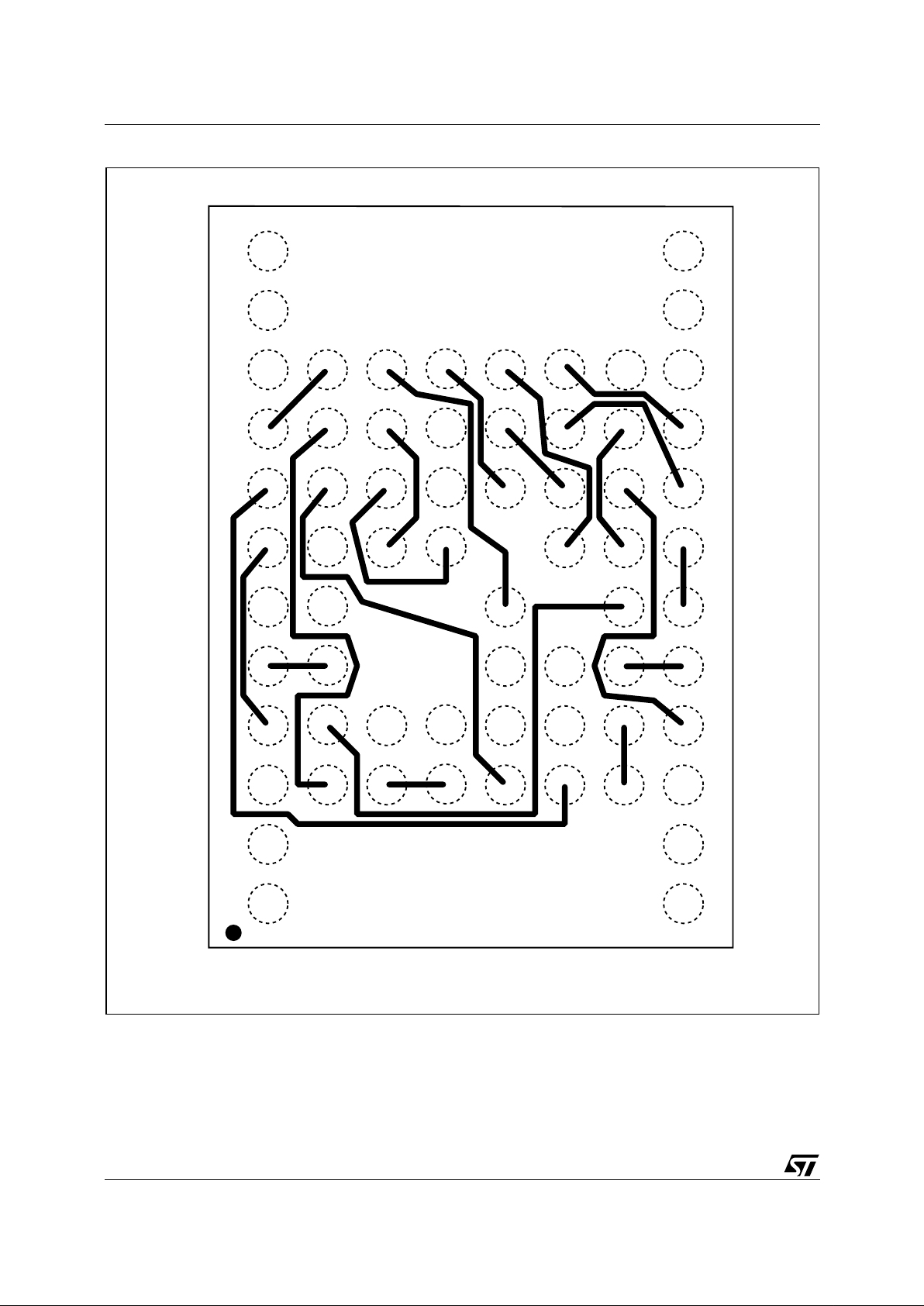

Figure 9. Stac k ed LFBGA6 6 Daisy C hain - PC B Connect ions proposal (Top view through package).17

Page 3

3/62

M36W216TI, M36W216BI

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 8. Ordering Information Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 9. Daisy Chain Orde r ing Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

FLASH DEVICE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

FLASH SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 10. Flash Block Ad d re sse s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 11. Flash Security Block and Protection Register Memory Map . . . . . . . . . . . . . . . . . . 20

FLASH BUS OPERATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Read.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 1

Write.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Output Disable.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Standby. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Automatic Standby.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

FLASH COMMAND INTERFACE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Read Memory Array Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Read Status Register Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Read Electronic Signature Comma nd . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Read CFI Query Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 2

Block Erase Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Program Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Double Word Program Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Clear Status Regist e r Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Program/Erase Suspend Comm and . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Program/Eras e Resume Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Protection Regi ste r Pr o g ra m Comman d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Block Lock Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Block Unlock Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 4

Block Lock-Down Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 10. Flash Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 11. Read Electronic Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 12. Read Block Lock Signature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 13. Read Protection Register and Lock Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 14. Program, Erase Times and Program/E rase Endu ranc e Cycles . . . . . . . . . . . . . . . . 26

FLASH BLOCK LOCKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Reading a Block’s Lock Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Locked State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Unlocked State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Lock-Down State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Locking Operatio n s Durin g Erase Su sp e nd . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 15. Block Lock Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Table 16. Protection Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Page 4

M36W216TI, M36W216BI

4/62

FLASH STATUS REGISTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Program/Erase Controller Status (Bit 7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Erase Suspend Status (Bit 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Erase Status (Bit 5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Program Status (Bit 4). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

V

PP

Status (Bit 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Program Suspend Status (Bit 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Block Protection Status (Bit 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Reserved (Bit 0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 0

Table 17. Status Register Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Figure 12. Flash Read Mode AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 18. Flash Read AC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 13. Flash Write AC Wavefo r ms, Write Enable Control l e d . . . . . . . . . . . . . . . . . . . . . . . 32

Table 19. Flash Write AC Chara cte ristics, Write En a ble Controlled. . . . . . . . . . . . . . . . . . . . . 33

Figure 14. Flash Write AC Waveforms, Chip Enable Controlled . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 20. Flash Write AC Characteristics, Chip Enable Controlled . . . . . . . . . . . . . . . . . . . . . 35

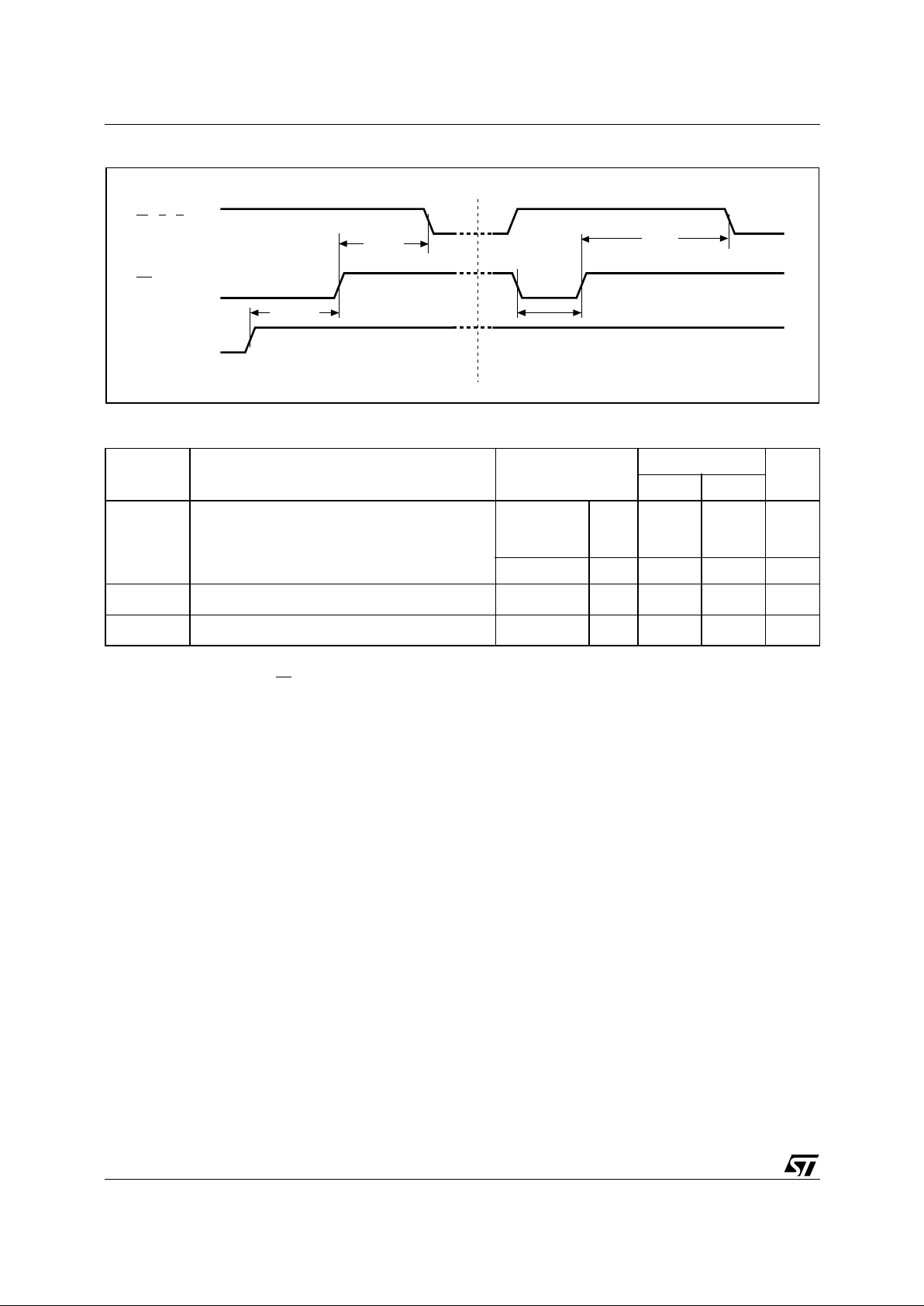

Figu r e 1 5 . Flash Power -Up an d R e set AC W a veforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 21. Flash Power-Up and Reset AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

SRAM DEVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 7

SRAM SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 16. SRAM Logic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

SRAM OPERATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 8

Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Standby/Power-Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Data Retention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Output Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 8

Figure 17. SRAM Read Mode AC Waveforms, Address Controlled with UBS = LBS = V

IL

. . . 39

Figure 18. SRAM Read AC Waveforms, GS Controlled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 19. SRAM Standby AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 22. SRAM Read AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Figure 20. SRAM Write AC Waveforms, WS Controlled. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figu r e 2 1 . SRAM Write A C Wav e forms, E1S Con trolle d . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 22. SRAM Write AC Waveforms, WS Controlled with GS Low . . . . . . . . . . . . . . . . . . . 43

Figure 23. SRAM Write Cycle Waveform, UBS and LBS Controlled, GS Low . . . . . . . . . . . . . 43

Table 23. SRAM Write AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 24. SRAM Low V

DDS

Data Retention AC Waveforms, E1S or UBS / LBS Controlled . . 45

Table 24. SRAM Low V

DDS

Data Retention Characte r i stic. . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

APPENDIX A. BLOCK ADDRESS TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 25. Top Boot Block Addresses, M36W216TI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 26. Botto m Boo t Bl oc k Addre sse s, M36W216BI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Page 5

5/62

M36W216TI, M36W216BI

APPENDIX B. COMMON FLASH INTERFACE (CFI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 27. Query Stru cture Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Table 28. CFI Query Identification String . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Table 29. CFI Query System Interface Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 30. Device Geome try Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Table 31. Primary Algorithm-Specific Extended Query Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 32. Security Code Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

APPENDIX C. FLOWCHARTS AND PSEUDO CODES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 25. Program Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 26. Double Word Program Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 27. Program Suspend & Resume Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . . 54

Figure 28. Erase Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 29. Erase Suspend & Resume Flowchart and Pseudo Code. . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 30. Locking Operations Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

APPENDIX D. COMMAND INTERFACE AND PROGRAM/ERASE CONTROLLER STATE . . . . . . . 59

Table 33. Write State Machine Current/Next, sheet 1 of 2.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 34. Write State Machine Current/Next, sheet 2 of 2.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

REVISION HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 35. Document Revision History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Page 6

M36W216TI, M36W216BI

6/62

SUMMARY DESCRIPTION

The M36W216TI is a low voltage Multiple Memory

Product which combines two memory devices; a

16 Mbit boot block Flash memory and a 2 Mbit

SRAM. Recommended operating conditions do

not allow both the F lash memory and the S RAM

memory to be active at the same time.

The memory is offered in a Stacked LFBGA66

(12x8mm, 8 x 8 active ball, 0.8 mm pitch) package

and is supplied with all the bits erased (set to ‘1’).

Figure 2. Logic Diagram

Table 1. Signal Names

AI07903

20

A0-A19

E

F

DQ0-DQ15

V

DDF

M36W216TI

M36W216BI

G

F

V

SSF

16

W

F

RP

F

WP

F

V

DDQF

E1

S

G

S

W

S

UB

S

LB

S

V

SSS

V

PPF

V

DDS

E2

S

A0-A16 Flash and SRAM Address Inputs

A17-A19 Address Inputs for Flash Chip only

DQ0-DQ15 Data Input/Output

V

DDF

Flash Power Supply

V

DDQF

Flash Power Supply for I/O Buffers

V

PPF

Flash Optional Supply V oltage for Fast

Program & Erase

V

SSF

Flash Ground

V

DDS

SRAM Power Supply

V

SSS

SRAM Ground

NC Not Connected Internally

Flash control functions

E

F

Chip Enable input

G

F

Output Enable input

W

F

Write Enable input

RP

F

Reset input

WP

F

Write Protect input

SRAM control functions

E1

S

, E2

S

Chip Enable inputs

G

S

Output Enable input

W

S

Write Enable input

UB

S

Upper Byte Enable input

LB

S

Lower Byte Enable input

Page 7

7/62

M36W216TI, M36W216BI

Figure 3. LFBGA Connections (Top view through package)

AI90254

A

654321#2#1

E

B

F

A12

A13A11NCNC

NC

E2SDQ12V

SSS

A2A3A6A7A18

EFA0A4NCNC

DQ4

WS

DQ15A9A16

DQ6DQ13NCWF

A8 A10

A5

NC V

SSF

A17

RPF

A15 A14

NCNC

V

DDF

E1SA1

NCNCGF

V

DDS

DQ7

DQ5

DQ14

NC

V

SSF

V

DDQF

#4#387

C

DQ10

DQ11A19WPF

V

PPF

DQ3DQ2

D

DQ8DQ9GSLBS

UBS

DQ1DQ0

G

H

Page 8

M36W216TI, M36W216BI

8/62

SIGNAL DESCRIPTION

See Figure 2 Logic Diagram and Table 1, Sign al

Names, for a brief overview of the signals connected to this de vice.

Address Inputs (A0-A16). Addresses A0-A16

are common inputs for the Flash an d the SRAM

components. The Address Inputs select the cells

in the memory array to access during Bu s Read

operations. During Bus Write operations they control the commands sent to the Command Interface

of the internal state machine. The Flash memory is

accessed through the Chip Enable (

E

F

) and Write

Enable (W

F

) signals, while the SRAM i s acce sse d

through two Chip Enable ( ES

) and Write Enable

(W

S

) signals.

Address Inputs (A17-A19). Addresses A17-A19

are inputs for the Flash component only. The

Flash memory is acc essed through the Chip E nable (

E

F

) and Write Enable (WF) signals

Data Inputs/Outputs (DQ0-DQ15). The Data I/

O output the d ata stored at the selected addres s

during a Bus Read operation or in put a c om m and

or the data to be programmed durin g a Write Bus

operation.

Flash Chip Enable (

E

F

). The Chip Enable input

activates the Flash memory control logic, input

buffers, decoders and sense amplifiers. When

Chip Enable is at V

IL

and Reset is at VIH the device

is in active mode. When Chip Enable is at V

IH

the

memory is deselected, the outputs are high impedance and the power consumption is reduced to the

standby level.

Flash Output Enable (G

F

). The Output Enable

controls the data outputs during the Bus Read operation of the Flash memory.

Flash Write Enable (

W

F

). The Write Enable con-

trols the Bus Write operation of the Flash m emory’s Command Interface. The data and address

inputs are latched on the rising e dge of Chip Enable,

E

F

, or Write Enable, WF, whichever occurs

first .

Flash Write Protect (WP

F

). Write Protect is an

input that gives an additional hardware protection

for each block. When Write Protect is at V

IL

, the

Lock-Down is enabled and the protection status of

the block cannot be changed. When Write Protect

is at V

IH

, the Lock-Down is disabled and the block

can be locked or unlocked. (refer to T able 6, Read

Protection Register and Protection Register Lock).

Flash Reset (RP

F

). The Reset input provides a

hardware reset of the Flash memory. When Reset

is at V

IL

, the memory is in reset mode: the outputs

are high impedance and the current c onsumption

is minimized. After Reset all blocks are in the

Locked state. When Reset is at V

IH

, the device is

in normal operation. Exiting reset mode the device

enters read array mode, but a negative t ransition

of Chip Enable or a change of the address is required to ensure valid data outputs.

SRAM Chip Enable (E1

S

, E2S). The Chip En-

able inputs activate the SRAM memory control

logic, input buffers and decoders. E1

S

at VIH or

E2

S

at VIL deselects the memory and reduces the

power consumption to the standby level. E1

S

or

E2

S

can also be used to control writing to the

SRAM memory array, while W

S

rema in s at V

IL.

It

is not allowed to set

E

F

at VIL and, E1S at VIL or

E2

S

at VIL at the same time.

SRAM Write Enable (W

S

). The Write Enable in-

put controls writing to the SRA M memory array.

W

S

is active low .

SRAM Output E nable (G

S

). The Output Enable

gates the outputs through the data buffers during

a read operation of the SRAM m emory. G

S

is ac-

tive low.

SRAM Upper Byte Enable (UB

S

). The Upper

Byte Enable enables the upper bytes for SRAM

(DQ8-DQ15). UB

S

is acti v e low.

SRAM Lower Byte Enable (LB

S

). The Lower

Byte Enable enables the lower bytes for SRAM

(DQ0-DQ7). LB

S

is active low.

V

DDF

and V

DDS

Supply Voltages. V

DDF

provides the power supply to the internal core of the

Flash Memory device. It is the main power s upply

for all operations (Read, Program and Erase).

V

DDQF

and V

DDS

Supply Voltage (2.7V to 3.3V).

V

DDQF

provides the power supply for the Flash

memory I/O pins and V

DDS

provides the power

supply for t he SRAM control pins. This a llows all

Outputs to be powered independently of the Flash

core power supply, V

DDF

. V

DDQF

can be tied to

V

DDS.

V

PPF

Program Supp ly Vol tage. V

PPF

is both a

control input and a power suppl y pin for t he F lash

memory. The two functions are selected by the

voltage range applied to the pin. The Supply Voltage V

DDF

and the Program Supply Vol tage V

PPF

can be applied in any order.

If V

PPF

is kept in a low voltage range (0V t o 3.6V)

V

PPF

is seen as a control input. In this case a volt-

age lower than V

PPLK

gives an absolute protection

against program or erase, while V

PPF

> V

PP1

enables these functions (see Table 6, DC Characteristics for the relevant values). V

PPF

is only

sampled at the beginning of a program or erase; a

change in its value after the operation has started

does not have any effect and program or erase operations continue.

If V

PPF

is in the range 11.4V to 12.6V it acts as a

power supply pin. In this condition V

PPF

must be

stable until the Program/Erase algorithm i s completed (see Table 19 and 20).

Page 9

9/62

M36W216TI, M36W216BI

V

SSF

and V

SSS

Ground. V

SSF

and V

SSS

are the

ground reference for all voltage measurements in

the Flash and SRAM chips, respectively.

Note: Each device in a system should have V

D-

DF

, V

DDQF

and V

PPF

decoupled with a 0.1µF ca-

pacitor close to the pin. See Figure 9, AC

Measurement Load Circuit. The PCB trace

widths should be sufficient to carry the required V

PPF

program and erase currents.

FUNCTIONAL DESCRIPTION

The Flash and SRAM components have separate

power supplies and grounds and are distinguished

by three chip enable inputs:

E

F

for the Flash mem-

ory and E1

S

and E2S for the SRAM.

Recommended operating conditions do not allow

both the Flash and the SRAM to be in active mode

at the same time. The most common example is

simultaneous read operations on the Flash and

the SRAM which would resul t in a data bus contention. Therefore it is recommended to put the

SRAM in the h igh impedance state whe n reading

the Flash and vice versa (see Table 2 Main Operation Modes for details).

Figure 4. Func ti onal Block Di a gram

AI07904

Flash Memory

16 Mbit (x16)

V

SSF

E

F

G

F

W

F

RP

F

WP

F

E1

S

G

S

W

S

UB

S

LB

S

DQ0-DQ15

V

DDF

V

PPF

A17-A19

A0-A16

SRAM

2 Mbit (x16)

V

SSS

V

DDS

V

DDQF

E2

S

Page 10

M36W216TI, M36W216BI

10/62

Table 2. Main Operation Modes

Note: X = Don’t care = VIL or VIH, V

PPFH

= 12V ± 5%.

Operation

Mode

E

FGFWF

RPFWP

F

V

PPF

E1SE2SGSWSUBSLB

S

DQ7-DQ0 DQ15-DQ8

Flash Memory

Read

V

ILVILVIHVIH

X Don’t care SRAM must be disabled Data Output

Write

V

ILVIHVILVIH

X

V

DDF

or

V

PPFH

SRAM must be disabled Data Input

Block

Locking

V

IL

XX

V

IH

V

IL

Don’t care SRAM must be disabled X

Standby

V

IH

XX

V

IH

X Don’t care Any SRAM mode is allowed Hi-Z

Reset X X X

V

IL

X Don’t care Any SRAM mode is allowed Hi-Z

Output

Disable

V

ILVIHVIHVIH

X Don’t care Any SRAM mode is allowed Hi-Z

SRAM

Read

Flash must be disabled

V

ILVIHVILVIHVIL

V

IL

Data out Word Read

Flash must be disabled

V

ILVIHVILVIHVIHVIL

Data out Hi-Z

Flash must be disabled

V

ILVIHVILVIHVIL

V

IH

Hi-Z Data out

Write

Flash must be disabled

V

ILVIH

XVILV

IL

V

IL

Data in Word Write

Flash must be disabled

V

ILVIH

XVILV

IHVIL

Data in Hi-Z

Flash must be disabled

V

ILVIH

XVILV

IL

V

IH

Hi-Z Data in

Standby/

Power

Down

Any Flash mode is allowable

V

IHVIL

X X X X Hi-Z

XXXX

V

IHVIH

Hi-Z

Data

Retention

Any Flash mode is allowable

V

IHVIL

X X X X Hi-Z

XXXX

V

IHVIH

Hi-Z

Output

Disable

Any Flash mode is allowable

V

ILVIHVIHVIHVIL

V

IL

Hi-Z

Any Flash mode is allowable

V

ILVIHVIHVIHVIHVIL

Hi-Z

Any Flash mode is allowable

V

ILVIHVIHVIHVIL

V

IH

Hi-Z

Page 11

11/62

M36W216TI, M36W216BI

MAXIMUM RATIN G

Stressing the device above the rating l isted in the

Absolute Maximum Ratings table m ay cause permanent damage to the device. These are stress

ratings only and operation of the device at t hese or

any other conditions ab ove those i ndicated in t he

Operating sections of this specificat ion is not im-

plied. Exposure to Absolute Maximum Rating conditions for extended periods may affect device

reliability. Refer also to the STMicroelectronics

SURE Program and other relevant quality documents.

Table 3. Absolute Maximum Ratings

Note: 1. Depends on range.

Symbol Parameter

Value

Unit

Min Max

T

A

Ambient Operating Temperature

(1)

–40 85 °C

T

BIAS

Temperature Under Bias –40 125 °C

T

STG

Storage Temperature –55 150 °C

V

IO

Input or Output Voltage –0.5

V

DDQF

+0.5

V

V

DDF

, V

DDQF

Flash Supply Voltage –0.5 3.8 V

V

PPF

Program Voltage –0.6 13 V

V

DDS

SRAM Supply Voltage –0.5 3.8 V

Page 12

M36W216TI, M36W216BI

12/62

DC AND AC PARAMETERS

This section summarizes the operat ing and measurement conditions, and the DC and AC characteristics of the device. The parameters in the DC

and AC characteristics Tables that follow, are derived from tests performed under the Measure-

ment Conditions summarized in Table 4,

Operating and AC Measurem ent Conditions. Designers should check that the operating conditions

in their circuit match the measurement conditions

when relying on the quoted parameters.

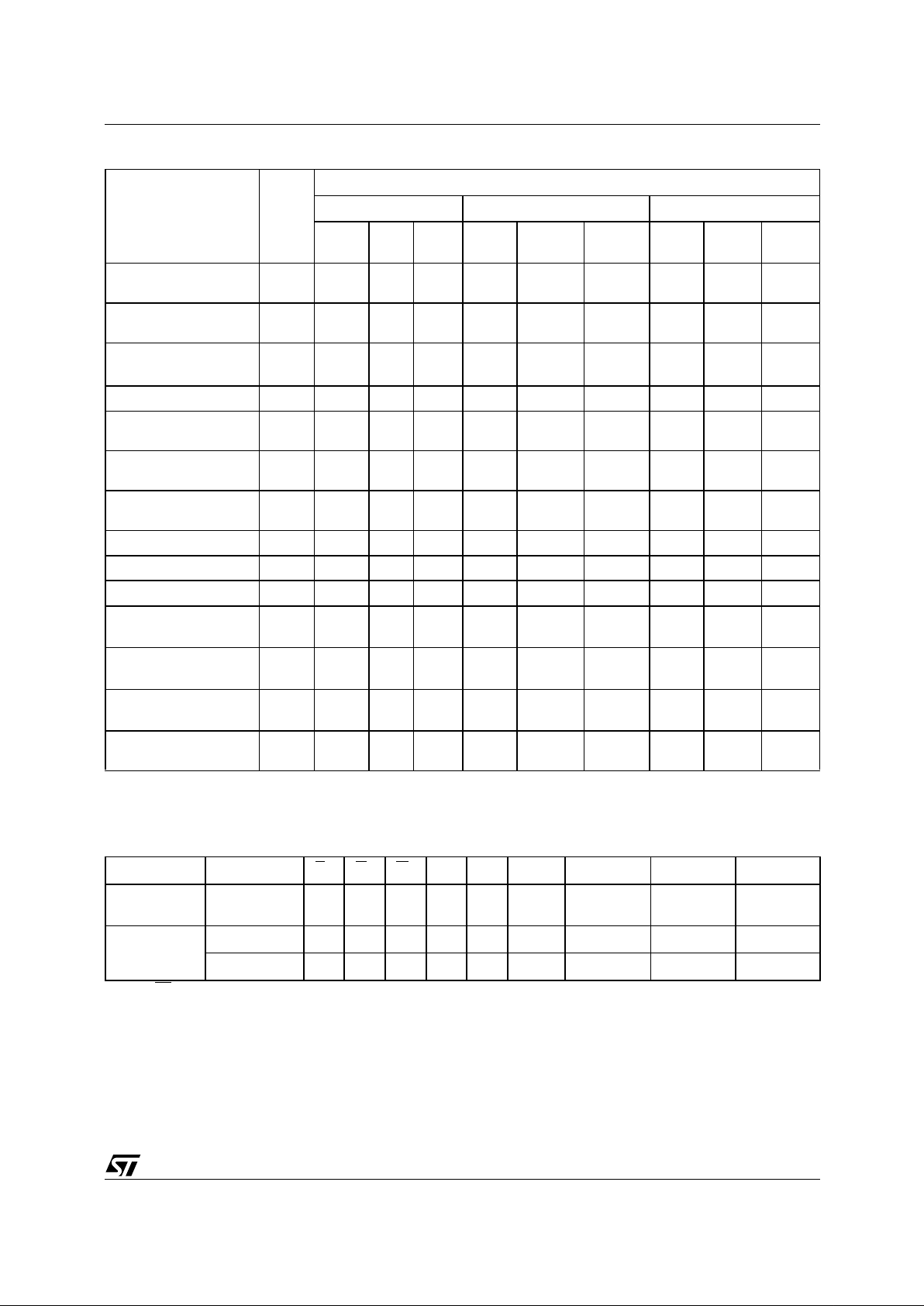

Table 4. Operating and AC Measurement Conditions

Figure 5. AC Measurement I/O Waveform

Note: V

DDQ

means V

DDQF

= V

DDS

Figure 6. AC Me asureme nt Load Circuit

Table 5. Device Capacitance

Note: Sampled o nl y, not 100% test ed.

Parameter

SRAM Flash Memory

Units70 70/85

Min Max Min Max

V

DDF

Supply Voltage

– – 2.7 3.3 V

V

DDQF

Supply Voltage

– – 2.7 3.3 V

V

DDS

Supply Voltage

2.7 3.3 – – V

Ambient Operating Temperature – 40 85 – 40 85 °C

Load Capacitance (C

L

)

30 50 pF

Input Rise and Fall Times 1V/ns 5ns

Input Pulse Voltages

0 to V

DDQF

0 to V

DDQF

V

Input and Output Timing Ref. Voltages

V

DDQF

/2 V

DDQF

/2

V

AI90258

V

DDQ

0V

V

DDQ

/2

AI90259

V

DDQF

C

L

CL includes JIG capacitance

25kΩ

DEVICE

UNDER

TEST

0.1µF

V

DDF

0.1µF

V

DDQF

25kΩ

Symbol Parameter Test Condition Typ Max Unit

C

IN

Input Capacitance

V

IN

= 0V, f=1 MHz

12 pF

C

OUT

Output Capacitance

V

OUT

= 0V, f=1 MHz

15 pF

Page 13

13/62

M36W216TI, M36W216BI

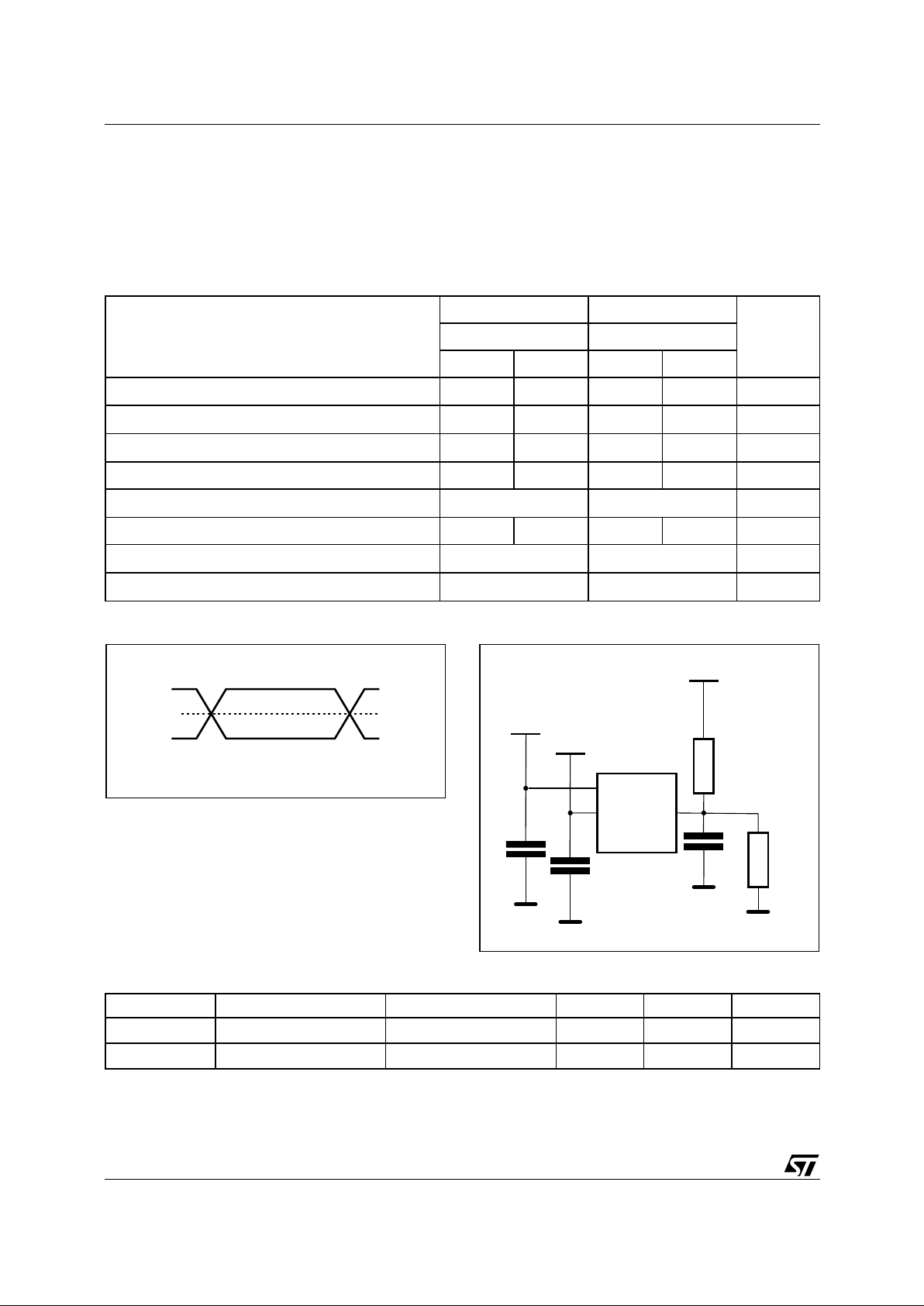

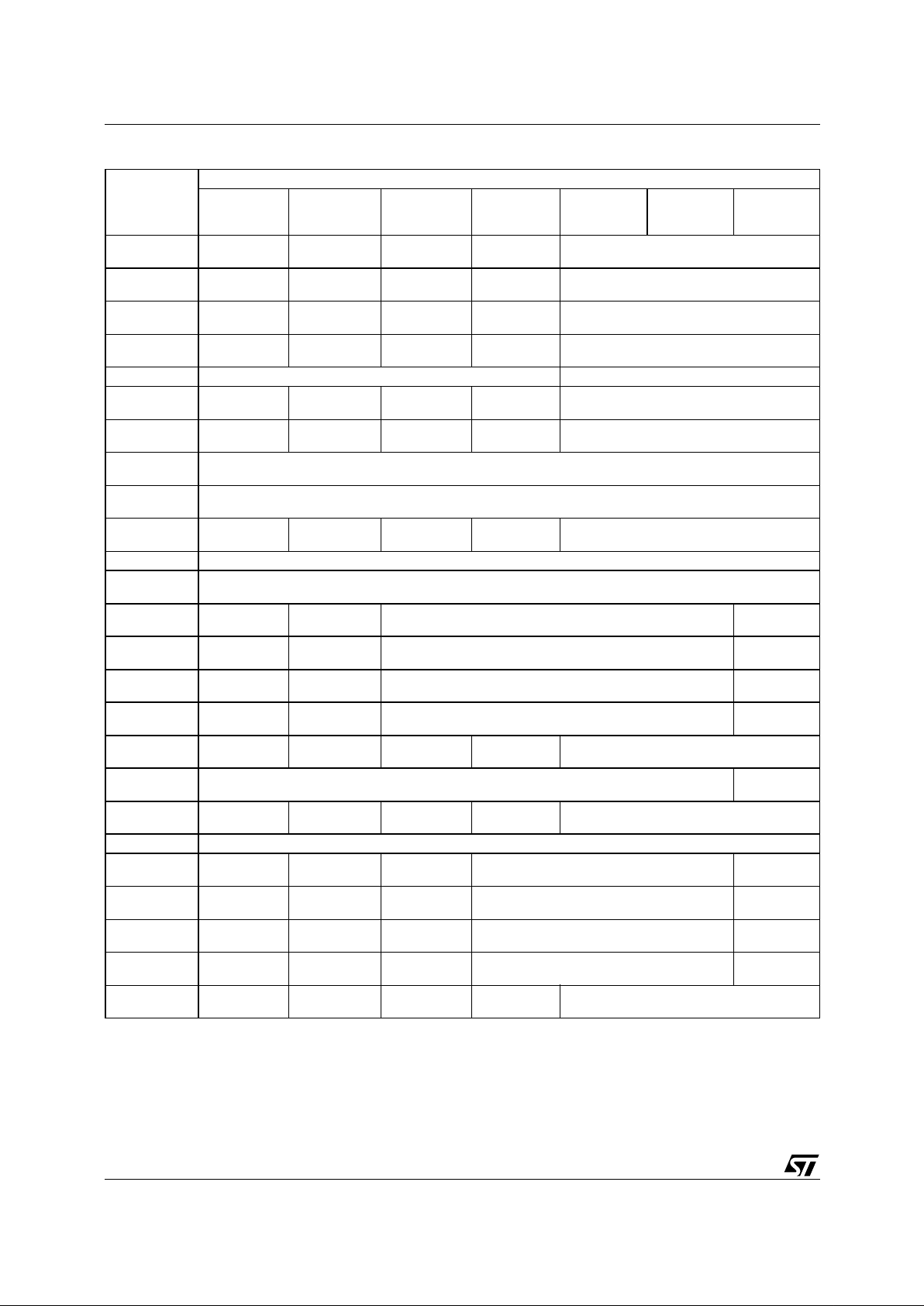

Table 6. DC Characteristics

Symbol Parameter Device Test Condition Min Typ Max Unit

I

LI

Input Leakage Current Flash & SRAM

0V≤ V

IN

≤

V

DDQF

±1 µA

I

LO

Output Leakage Current

Flash

0V ≤V

OUT

≤

V

DDQF

±10 µA

SRAM

0V ≤V

OUT

≤

V

DDQF,

SRAM Outputs Hi-Z

±1 µA

I

DDSVDD

Standby Current

Flash

E

F

= V

DDQF

± 0.2V

RP

F

= V

DDQ

± 0.2V

15 50 µA

SRAM

E1

S

≥

V

DDS

– 0.2V

V

IN

≥

V

DDS

−

0.2V or V

IN

≤

0.2V

515µA

I

DDD

Supply Current (Reset) Flash

RP

F

= V

SSF

± 0.2V

15 50 µA

I

DD

Supply Current SRAM

V

DDS

= 3.3V

,

I

OUT

= 0 mA, f = 1MHz

1.5 3 mA

V

DDS

= 3.3V

,

I

OUT

= 0 mA, f = f

MAX

= 1/t

AVAV

715mA

I

DDR

Supply Current (Read) Flash

E

F

= VIL, G

F

=

V

IH,

f = 5 MHz

10 20 mA

I

DDW

Supply Current

(Program)

Flash

Program in progress

V

PPF

= 12V ± 5%

10 20 mA

Program in progress

V

PPF

= V

DDF

10 20 mA

I

DDE

Supply Current (Erase) Flash

Erase in progress

V

PPF

= 12V ± 5%

520mA

Erase in progress

V

PPF

= V

DDF

520mA

I

DDES

Supply Current

(Program/Erase

Suspend)

Flash

E

F

= V

DDQF

± 0.2V,

Erase suspended

50 µA

I

PP1

Program Current

(Read or Standby)

Flash

V

PPF

> V

DDF

400 µA

I

PP2

Program Current

(Read or Standby)

Flash

V

PPF

≤

V

DDF

5µA

I

PPR

Program Current (Reset) Flash

RP

F

= V

SSF

± 0.2V

5µA

I

PPW

Program Current

(Program)

Flash

V

PPF

= 12V ± 0.5V

Program in progress

10 mA

V

PPF

= V

DDF

Program in progress

5mA

I

PPE

Program Current (Erase) Flash

V

PPF

= 12V ± 0.5V

Erase in progress

10 mA

V

PPF

= V

DDF

Erase in progress

5µA

V

IL

Input Low Voltage Flash & SRAM

V

DDQF

= V

DDS

≥

2.7V

–0.3 0.6 V

V

IH

Input High Voltage Flash & SRAM

V

DDQF

= V

DDS

≥

2.7V 0.7V

DDQF

V

DDQF

+0.3

V

Page 14

M36W216TI, M36W216BI

14/62

V

OL

Output Low Voltage Flash & SRAM

V

DDQF

= V

DDS

= VDDmin

I

OL

= 100µA

0.1 V

V

OH

Output High Voltage Flash & SRAM

V

DDQF

= V

DDS

= VDDmin

I

OH

= –100µA

V

DDQ

–0.1

V

V

PP1

Program Voltage

(Program or Erase

operations)

Flash 1.65 3.6 V

V

PPFH

Program Voltage

(Program or Erase

operations)

Flash 11.4 12.6 V

V

PPLK

Program Voltage

(Program and Erase

lock-out)

Flash 1 V

V

LKO

V

DDF

Supply Voltage

(Program and Erase

lock-out)

Flash 2 V

Symbol Parameter Device Test Condition Min Typ Max Unit

Page 15

15/62

M36W216TI, M36W216BI

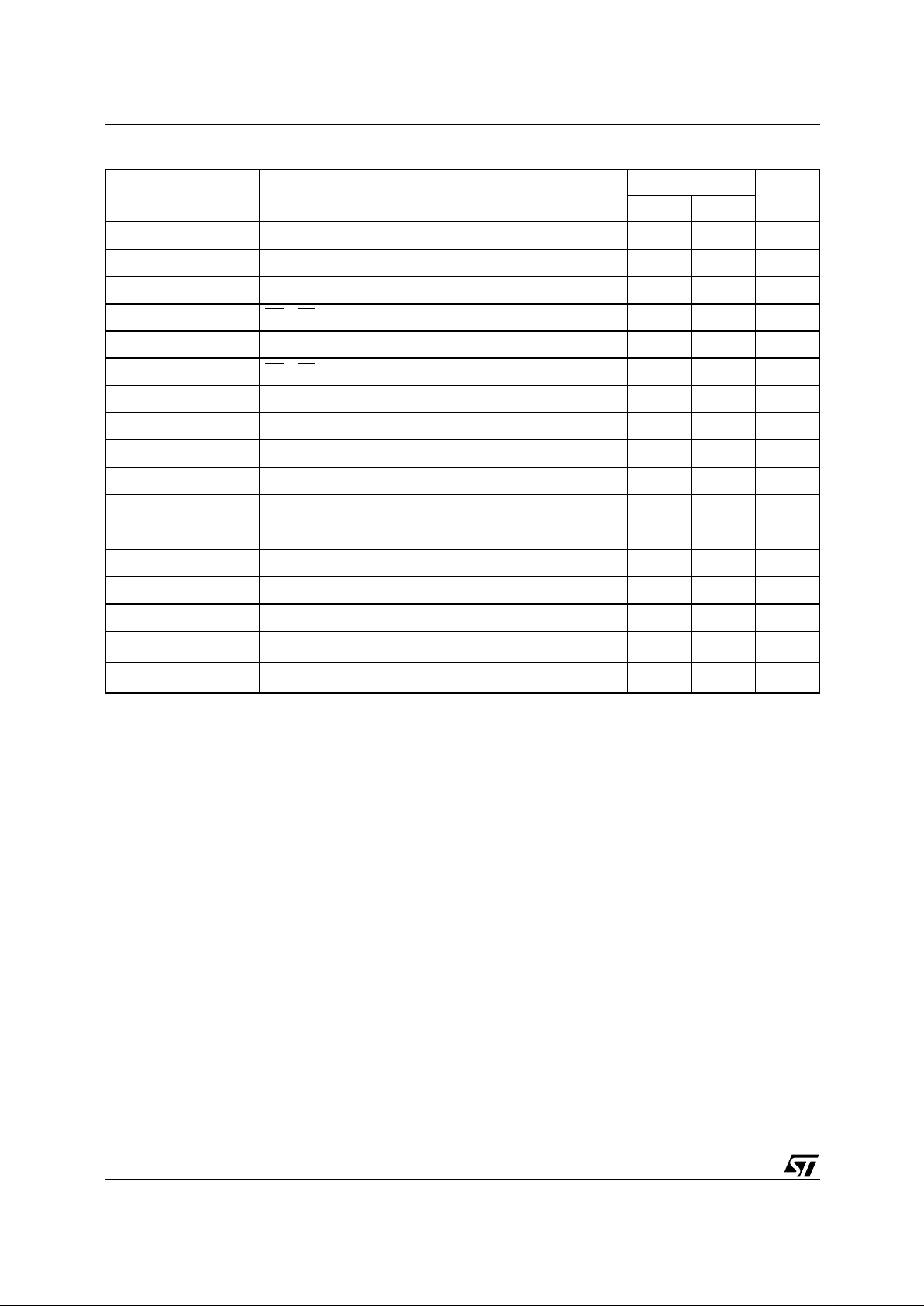

PACKAGE MECHANICAL

Figure 7. Stacked LFBGA66-12x8mm, 8x8 ball arra y, 0.8mm pitch, Bottom View Package Outline

Note: Drawing is not to scale.

Table 7. Stacked LFBGA66 - 12x8mm, 8x8 ball array, 0.8 mm pitch, Pack age Mechanical Data

Symbol

millimeters inches

Typ Min Max Typ Min Max

A 1.400 0.0551

A1 0.300 0.0118

A2 1.100 0.0433

b 0.400 0.300 0.500 0.0157 0.0118 0.0197

D 12.000 – – 0.47 24 – –

D1 5.600 – – 0.22 05 – –

D2 8.800 – – 0.34 65 – –

ddd 0.100 0.0039

E 8.000 – – 0.31 50 – –

E1 5.600 – – 0.2205 – –

e 0.800 – – 0.03 15 – –

FD 1.600 – – 0.0630 – –

FE 1.200 – – 0.04 72 – –

SD 0 .400 – – 0.0157 – –

SE 0.400 – – 0.0157 – –

A2

A1

A

BGA-Z12

ddd

D

E

e

b

SE

FDFE

E1

e

D1

SD

D2

BALL "A1"

Page 16

M36W216TI, M36W216BI

16/62

Figure 8. Stacked LFBGA66 Daisy Chain - Package Connections (Top view through package)

AI90273

D

C

#4#3

8761

E

F

A

B

H

G

5

4

32#1 #2

Page 17

17/62

M36W216TI, M36W216BI

Figure 9. Stacked LFBGA66 Daisy Chain - PCB Connections proposal (Top view through package)

#1

AI90274

D

C

E

F

A

B

H

G

START

POINT

END

POINT

#4#3

87615

4

32#2

Page 18

M36W216TI, M36W216BI

18/62

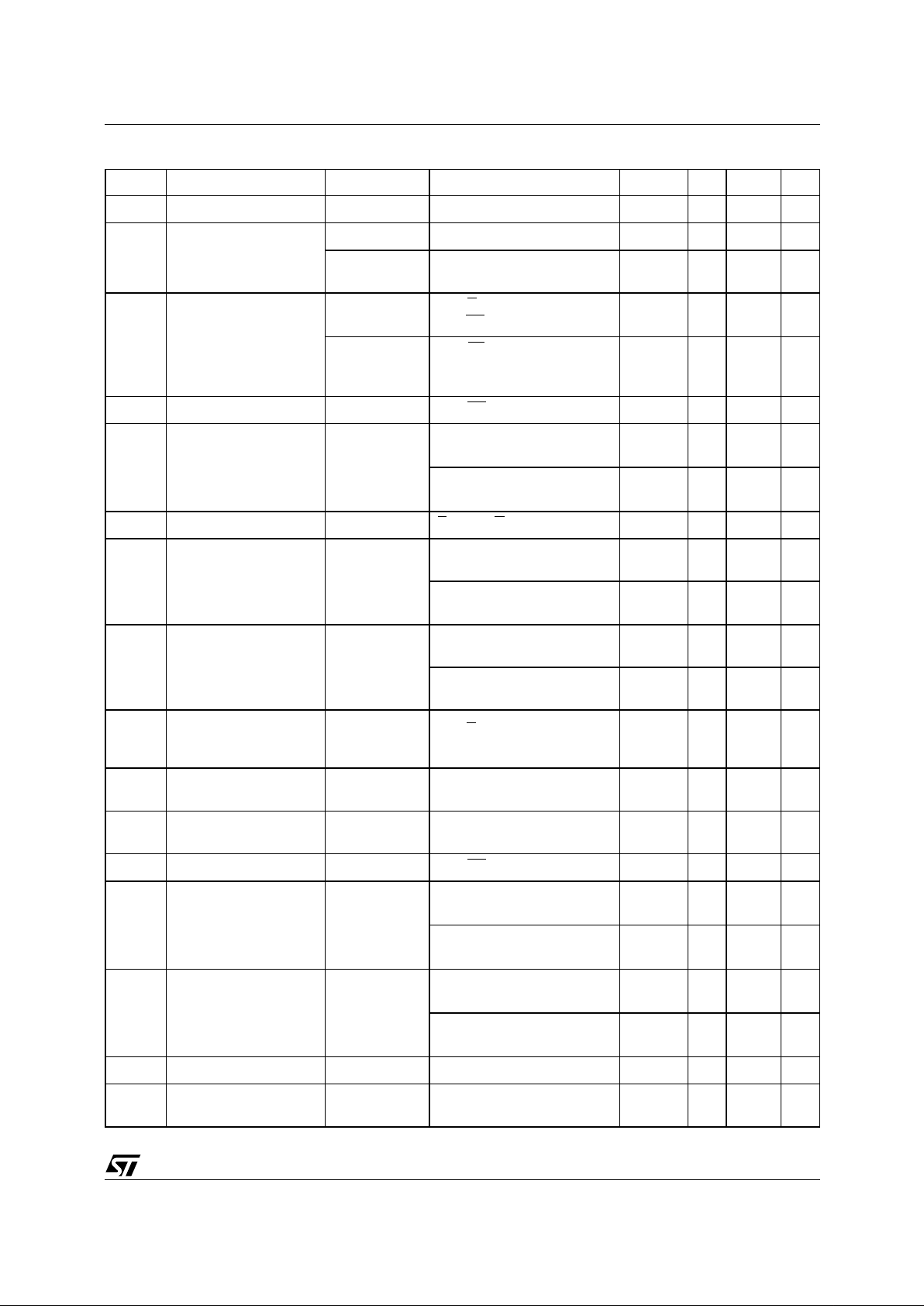

PART NUMBERING

Table 8. Ordering Information Scheme

Devices are shipped from the factory with the memory content bits erased to ’1’.

Table 9. Daisy Chain Ordering Scheme

For a list of available options (Speed, Package, etc.) or for further information on any aspect of this device,

please contact the STMicroelectronics Sales Office nearest to you.

Example: M36W216 T I 85 ZA 6 T

Device Type

M36 = MMP (Flash + SRAM)

Operating Voltage

W = V

DDF

= 2.7V to 3.3V, V

DDS

= V

DDQF

= 2.7V to 3.3V

SRAM Chip Size & Organization

2 = 2 Mbit (128K x 16 bit)

Device Function

16 = 16 Mbit (x16), Boot Block

Array Matrix

T = Top Boot

B = Bottom Boot

SRAM Component

I = 2Mb, 0.16µm, 70ns, 3V

Speed

70 = 70ns

85 = 85ns

Package

ZA = LFBGA66: 12x8mm, 0.8mm pitch

Temperature Range

1 = 0 to 70°C

6 = –40 to 85°C

Option

T = Tape & Reel packing

Example: M36W216TI -ZA T

Device Type

M36W216TI

Daisy Chain

-ZA = LFBGA66: 0.8mm pitch

Option

T = Tape & Reel Packing

Page 19

19/62

M36W216TI, M36W216BI

FLASH DEVICE

The M36W216TI contains one 16 Mbit Flash

memory. This section describes how to use the

Flash device and all signals refer to the Flash device .

FLASH SUMMARY DESCRIPTION

The Flash Memory is a 16 Mb it (1 Mb it x 16) nonvolatile device that can be erased electrically at

the block level and prog rammed in-system on a

Word-by-Word basis. These operations can be

performed using a single low voltage (2.7 to 3.6V)

supply. V

DDQF

is used to drive the I/O pin down to

1.65V. An optional 12V V

PPF

power supply is pro-

vided to speed up customer programming.

The device features an asymmetrical blocked ar-

chitecture with an array of 39 blocks: 8 Parameter

Blocks of 4 KWords and 31 Main Blocks of 32

KWords. The M36W216TI has the Parameter

Blocks at the top of the memory address space

while the M36W216BI locates the Parameter

Blocks starting from the bottom. The memory

maps are shown in Figure 10, Block Addresses.

The Flash Memory features an instant, individual

block locking scheme that allows any block to be

locked or unlocked with no latency, enabling instant code and data protection. All blocks have

three levels of protection. They can be locked and

locked-down individually preventing any accidental programming or erasure. There is an additional

hardware protection against program and erase.

When V

PPF

≤ V

PPLK

all blocks are protected

against program or erase. All blocks are locked at

Power Up.

Each block can be erased separately. Erase can

be suspended in order to perform either read or

program in any other block and then resumed.

Program can be suspended to read data in any

other block and then resumed. Each block can be

programmed and erased over 100,000 cycles.

The device includes a 128 b it Protection Register

and a Security Block to increase the protection of

a system design. The Protection Register is divided into two 64 bit segments, the first one contains

a unique device number written by ST, while the

second one is one-time-programmable by the user. The user programmable segm ent can be permanently protected. The Security Block,

parameter block 0, can be permanentl y protected

by the user. Figure 11, shows the Flash Security

Block Memory Map.

Program and Erase command s are written to the

Command Interface of the memory. An on-chip

Program/Erase Controller takes care of the timings necessary for program and erase operations.

The end of a program or erase operation can be

detected and any error conditions identified. The

command set required to control the memory is

consistent with JEDEC standards.

Page 20

M36W216TI, M36W216BI

20/62

Figure 10. Flash Block Addresses

Note: Also see Appendix A, Tables 25 and 26 f or a full listing of the Flash Bl ock Addresses.

Figure 11. Flash Security Block and Protection Register Memory Map

AI90256

4 KWords

FFFFF

FF000

32 KWords

0FFFF

08000

32 KWords

07FFF

00000

Top Boot Block Addresses

4 KWords

F8FFF

F8000

32 KWords

F0000

F7FFF

Total of 8

4 KWord Blocks

Total of 31

32 KWord Blocks

4 KWords

FFFFF

F8000

32 KWords

32 KWords

00FFF

00000

Bottom Boot Block Addresses

4 KWords

F7FFF

0FFFF

32 KWords

F0000

08000

Total of 31

32 KWord Blocks

Total of 8

4 KWord Blocks

07FFF

07000

AI07905

Parameter Block # 0

User Programmable OTP

Unique device number

Protection Register Lock 2 1 0

88h

85h

84h

81h

80h

SECURITY BLOCK

PROTECTION REGISTER

Page 21

21/62

M36W216TI, M36W216BI

FLASH BUS OPERATIONS

There are six standard bus operations that control

the device. These are Bus Read, Bus Wri te, Output Disable, Standby, Automatic Standby and Reset. See Table 2, Main Operation Modes, for a

summary.

Typically glitches of less than 5ns on Chip Enable

or Write Enable are ignored by the memory and do

not affect bus operations.

Read. Read Bus operations are used to output

the contents of the Memory Array, the Electronic

Signature, the Status Register and the Common

Flash Interface. Both Chip Enable and Output Enable must be at V

IL

in order to perform a read operation. The Chip Enable input should be used t o

enable the device. Out put E nable shoul d be used

to gate data onto th e output. The data read depends on the previous command written to the

memory (see Command Interface section). See

Figure 12, Flash Read Mode AC W av eforms , and

Table 18, Flash Read AC Chara cteristics, for details of when the output becomes valid.

Read mode is the default state of the device when

exiting Reset or after power-up.

Write. Bus Write operations write Comm ands to

the memory or latch Input Data to be programmed.

A write operation is initiated when Chip Enable

and Write Enable are at V

IL

with Output Enable at

V

IH

. Commands, Input Data and Addresses are

latched on the rising edge of Write Enable or Chip

Enable, whichever occurs first.

See Figures 13 and 14, Flash Write AC Waveforms, and Tables 19 and 20, Flash Write AC

Characteristics, for details of the timing requirements.

Output Disa bl e . The data outputs are high impedance when the Output Enable is at V

IH

.

Standby. Stan dby disables most of the inte rnal

circuitry allowing a substantial reduction of the current consumption. The memory is in stand-by

when Chip Enable is at V

IH

and the device is in

read mode. The power consumption is reduced to

the stand-by level and the o utputs are set to high

impedance, independently from the Output Enable

or Write Enable inputs. If Chip Enable switches to

V

IH

during a program or erase operation, t he de-

vice enters Standby mode when finished.

Automatic Standby. Automatic Standby pro-

vides a low power consumption state during Read

mode. Following a read operation, the device enters Automatic Standby after 150ns of bus inactivity even if Chip Enable is Low, V

IL

, and the supply

current is reduced to I

DD1

. The data I nputs/Outputs will still output data if a bus Read operation is

in progress.

Reset. During Reset mode when Output Enable

is Low, V

IL

, the memory is deselected and the outputs are high impedance. The memory is in Reset

mode when Reset is at V

IL

. The power consumption is reduced to the Standby level, independently

from the Chip Enable, Output Enable or Write Enable inputs. If Reset is pulled to V

SS

during a Program or Erase, this operation is aborted and the

memory content is no longer valid.

Page 22

M36W216TI, M36W216BI

22/62

FLASH COMMAND INTERFACE

All Bus Write operations t o the me mory are in terpreted by the Command Interface. Commands

consist of one or more sequential Bus Write operations. An internal Program/Erase Controller handles all timings and verifies the correct execution

of the Program and Erase commands. The Program/Erase Controller provides a Status Regi ster

whose output may be read at any time during, to

monitor the progress of the operat ion, or the Program/Erase states. See Appendix 29, Table 33,

Write State Machine Current/Next, for a summary

of the Command Interface.

The Command Interface is reset to Read mode

when power is first applied, when exiting from Reset or whenever V

DD

is lower than V

LKO

. Command sequences must be followed exactly. Any

invalid combination of commands will reset the device to Read mode. Refer to Table 10, Commands, in conjunction with the text descriptions

below.

Read Memory Array Command

The Read command returns the memory to its

Read mode. One Bus Write cycle is required to issue the Read Memory Array command and return

the memory to Read mode. Subsequ ent read operations will read the addressed location and output the data. When a device Reset occurs, the

memory defaults to Read mode.

Read Status Register Command

The Status Register indicates when a program or

erase operation is complete and the success or

failure of the operation itself. Issue a Read Status

Register command to rea d the Status Register’s

contents. Subsequent Bus Read op erations read

the Status Register at any address, u ntil another

command is issued. See Table 17, Status Register

Bits, for details on the definitions of the bits.

The Read Status Register command m ay be issued at any time, even during a Program/Erase

operation. Any Read attempt during a Program/

Erase operation will automatically output the content of the Status Register.

Read Electronic Signature Command

The Read Electronic Signature command reads

the Manufacturer and Device Codes and the Block

Locking Status, or the Protection Register.

The Read Electronic Signature command consists

of one write cycle, a subsequent read will ou tput

the Manufacturer Code, the Device Code, the

Block Lock and Lock-Down Status, or the Protection and Lock Register. See Tables 11, 12 and 13

for the valid address.

Read CFI Query Command

The Read Query Command is used to read dat a

from the Common Flash Interface (CFI) Memory

Area, allowing programming equi pment or applications to automatically match their interface to

the characteristics of the device. One Bus Write

cycle is required to issue the Read Query Command. Once the command is issued subsequent

Bus Read operations read from the Common

Flash Interface Memory Area. See Appendix B,

Common Flash Inte rface, Tables 27, 28, 29, 30,

31 and 32 for details on the information contained

in the Common Flash Interface memory area.

Block Erase Command

The Block Erase com mand can be used to erase

a block. It sets all the bits within the selected block

to ’1’. A ll previous data in t he block is lost. If the

block is protected then the Erase operation will

abort, the data in the block will not be changed and

the Status Register will output the error.

Two Bus Write cycles are required to issue the

command.

■ The first bus cycle sets up the Erase command.

■ The second latches the block address in the

internal state machine and starts the Program/

Erase Controller.

If the second bus cycle is not Write Erase Confirm

(D0h), Status Register bits b4 and b5 are set and

the command aborts.

Erase aborts if Reset turns to V

IL

. As data integrity

cannot be guaranteed when the Erase operation is

aborted, the block must be erased again.

During Erase operations the memory will accept

the Read Status Re gister com mand and the P rogram/Erase Suspend command, all other commands will be ignored. Typical Erase times are

given in Table 14, Program, Erase Times and Program/Erase Endurance Cycles.

See Appendix C, Figure 28 , Erase Flowchart and

Pseudo Code, for a suggested flowchart for us ing

the Erase command.

Program Command

The memory array can be programmed word-byword. Two bus write cycles are required to issue

the Program Command.

■ The first bus cycle sets up the Program

command.

■ The second latches the Address and the Data to

be written and starts the Program/Erase

Controller.

During Program operations the memory will accept the Read Status Register command and the

Program/Erase Suspend command. Typical Program times are given in Table 14, Program, Erase

Times and Program/Erase Endurance Cycles.

Programming aborts if Reset goe s to V

IL

. As data

integrity cannot be guaranteed when the program

Page 23

23/62

M36W216TI, M36W216BI

operation is aborted, the block containing the

memory location must be erased and reprogrammed.

See Appendix C, Figure 25, Program Flowchart

and Pseudo Code, for the f lowchart for using the

Program command.

Double Word Program Command

This feature is offered to improve the programming

throughput, writing a page of two adjacent words

in parallel.The two words m ust differ only for the

address A0. Programm ing s hould not b e at t emp ted when V

PP

is not at V

PPFH

. The command can

be executed if V

PP

is below V

PPFH

but the result is

not guaranteed.

Three bus write cycles are necessary to issue the

Double Word Program command.

■ The first bus cycle sets up the Double Word

Program Command.

■ The second bus cycle latches the Address and

the Data of the first word to be written.

■ The third bus cycle latches the Address and the

Data of the second word to be written and starts

the Program/Erase Controller.

Read operations output the Status Register content after the programming has s tarted. Programming aborts if Res et goes to V

IL

. As data integrity

cannot be guaranteed when the program operation is aborted, the block containing the memory

location must be erased and reprogrammed.

See Appendix C, Figure 26, Double Word Program Flowchart and Pseudo Code, for the flowchart for using the Double Word Program

command.

Clear Status Register Command

The Clear Status Register comm and can be used

to reset bits 1, 3, 4 and 5 in the Status Register to

‘0’. One bus write cycle is required to issue the

Clear Status Register command.

The bits in the Status Register do not automatically return to ‘0’ when a new Program or Erase command is issued. The error bits in the Status

Register should be cleared before attempting a

new Program or Erase command.

Program/Erase Suspend Command

The Program/Erase Suspend command is used to

pause a Program or Erase operation. One bus

write cycle is required to issue the Program/Erase

command and pau se the Prog ram/Erase controller.

During Program/Erase Suspend the Command Interface will accept the Program/Erase Resume,

Read Array, Read Status Register, Read Electronic Signature and Read CFI Query commands. Additionally, if the suspend operation was Erase then

the Program, Block Lock, Block Lock-Down or

Protection Program commands will also be accepted. The block being erased may be protected

by issuing the Block Protect, Block Lock or Protection Program commands. When the Program/

Erase Resume comm and is issued the operation

will complete. Only the blocks not being erased

may be read or programmed correctly.

During a Program/Erase Suspend, the device can

be placed in a pseudo-standby mode by taking

Chip Ena ble to V

IH

. Program/Erase is aborted if

Reset turns to V

IL

.

See Appendix C, Figure 27 , Program Suspend &

Resume Flowchart and Pseudo Code, and Figure

29, Erase Suspend & Resume Flowchart and

Pseudo Code for flowcharts for using the Program/

Erase Suspend command.

Program/Er ase Resume Command

The Program/Erase Resume command can be

used to restart the Program/Erase Controller after

a Program/Erase Suspend operation has paused

it. One Bus Write cycle is required to issue the

command. Once the command is issued subsequent Bus Read operations read the Status Register.

See Appendix C, Figure 27 , Program Suspend &

Resume Flowchart and Pseudo Code, and Figure

29, Erase Suspend & Resume Flowchart and

Pseudo Code for flowcharts for using the Program/

Erase Resume command.

Prot e ction R e gister P rogram C om m and

The Protection Register Program command is

used to Program the 64 bit user One-Time-Programmable (OTP) segment of the Protection Register. The segment is programmed 16 bits at a

time. When shipped all bits in the segment are set

to ‘1’. The user can only program the bits to ‘0’.

Two write cycles are required to issue the Protection Register Program command.

■ The first bus cycle sets up the Protection

Register Program command.

■ The second latches the Address and the Data to

be written to the Protection Register and starts

the Program/Erase Controller.

Read operations output the Status Register content after the programming has started.

The segment can be protected by programming bit

1 of the Protection Lock Register. Bit 1 of the Protection Lock Register prote cts bit 2 of the P rotection Lock Register. Programming bit 2 of the

Protection Lock Register will result in a permanent

protection of the Security Block (see Figure 11,

Flash Security Block and Protection Register

Memory Map). Attempting to program a previously

protected Protection Register will result in a Status

Register error. The protection of the Protection

Page 24

M36W216TI, M36W216BI

24/62

Register and/or the Security Block is not reversible.

The Protection Register Program cannot be suspended. See Appendix C, Figure 31, Protection

Register Program Flowchart and Pseudo Code,

for the flowchart for using the P rotection Register

Program command.

Block Lock Command

The Block Lock command is used to lock a block

and prevent Program or Erase operations from

changing the data in it. All blocks are locked at

power-up or reset.

Two Bus Write cycles are required to issue the

Block Lock command.

■ The first bus cycle sets up the Block Lock

command.

■ The second Bus Write cycle latc hes the blo ck

address.

The lock status can be monitored for each block

using the Read Electronic Signature command.

Table. 16 shows the protection status after issuing

a Block Lock command.

The Block Lock bits are volatile, once set they remain set until a hardware reset or power-down/

power-up. They are cleared by a Blocks Unlock

command. Refer to the section, Block Locking, for

a detailed explanation.

Block Unlock Command

The Blocks Unlock command i s used to unlock a

block, allowing the block to be programmed or

erased. Two Bus Write cycles are requ ired to issue the Blocks Unlock command.

■ The first bus cycle sets up the Block Unlock

command.

■ The second Bus Write cycle latc hes the blo ck

address.

The lock status can be monitored for each block

using the Read Electronic Signature command.

Table. 16 shows the protection status after issuing

a Block Unlock command. Refer to the section,

Block Locking, for a detailed explanation.

Block Lock-Down Command

A locked block cannot be Programmed or Erased,

or have its protection status changed when WP

F

is

low, V

IL

. Whe n WPF is high, V

IH,

the Lock-Down

function is disabled and the lock ed blocks can be

individually unlocked by the Block Unlock command.

Two Bus Write cycles are required to issue the

Block Lock-Down command.

■ The first bus cycle sets up the Block Lock

command.

■ The second Bus Write cycle latc hes the blo ck

address.

The lock status can be monitored for each block

using the Read Electronic Signature command.

Locked-Down blocks revert to the locked (and not

locked-down) state when the device is reset on

power-down. Table. 16 sho ws the protection status after issuing a Block Lock-Down command.

Refer to the section, Block Locking, for a detailed

explanation.

Page 25

25/62

M36W216TI, M36W216BI

Table 10. Flash Commands

Note: 1. X = Don’t Care.

2. The s i gnature addresses are li st e d in Tables 11, 12 and 13.

3. Addr 1 and Addr 2 must be consecutive Addresses differing only for A0.

Table 11. Read Electronic Signature

Note: RPF = VIH.

Commands

No. of

Cycles

Bus Write Operations

1st Cycle 2nd Cycle 3nd Cycle

Bus

Op.

Addr Data

Bus

Op.

Addr Data

Bus

Op.

Addr Data

Read Memory Array 1+ Write X FFh

Read

Read

Addr

Data

Read Status Regist er 1+ Write X 70h

Read

X

Status

Register

Read Electro nic Signature 1+ Write X 90h

Read

Signature

Addr

(2)

Signature

Read CFI Query 1+ Write X 98h Read CFI Addr Query

Erase 2 Write X 20h Write

Block

Addr

D0h

Program 2 Write X

40h or

10h

Write Addr

Data

Input

Double Word Program

(3)

3 Write X 30h Write Addr 1

Data

Input

Write Addr 2

Data

Input

Clear Status Register 1 Write X 50h

Program/Erase Suspend 1 Write X B0h

Program/Erase Resume 1 Write X D0h

Block Loc k 2 Write X 60h Write

Block

Address

01h

Block Unlock 2 Write X 60h Write

Block

Address

D0h

Block Loc k-Down 2 Write X 60h Write

Block

Address

2Fh

Protection Register

Program

2 Write X C0h Write

Address

Data

Input

Code Device

E

F

GFW

F

A0 A1 A2-A7 A8-A19 DQ0-DQ7 DQ8-DQ15

Manufacture.

Code

V

IL

VILV

IH

V

ILVIL

0 Don’t Care 20h 00h

Device Code

M36W216TI

V

IL

VILV

IHVIHVIL

0 Don’t Care CEh 88h

M36W216BI

V

IL

VILV

IHVIHVIL

0 Don’t Care CFh 88h

Page 26

M36W216TI, M36W216BI

26/62

Table 12. Read Block Lock Signature

Note: 1. A Locked-Down Blo ck can be locked "D Q0 = 1" or unlocked "DQ0 = 0"; see Block Locking sec tion.

Table 13. Read Protection Register and Lock Register

Table 14. Program, Erase Times and Program /Eras e Endur ance Cycles

Block Status

E

F

GFW

F

A0 A1 A2-A7 A8-A11 A12-A19 DQ0 DQ1 DQ2-DQ15

Locked Block

V

ILVILVIHVILVIH

0 Don’t Care Block Address 1 0 00h

Unlocked Block

V

ILVILVIHVILVIH

0 Don’t Care Block Address 0 0 00h

Locked-Down

Block

V

ILVILVIHVILVIH

0 Don’t Care Block Address

X

(1)

1 00h

Word

E

F

GFW

F

A0-A7 A8-A19 DQ0 DQ1 DQ2 DQ3-DQ7 DQ8-DQ15

Lock

V

ILVILVIH

80h Don’t Care 0

OTP Prot.

data

Security

prot. data

00h 00h

Unique ID 0

V

ILVILVIH

81h Don’t Care ID data ID data ID data ID data ID data

Unique ID 1

V

ILVILVIH

82h Don’t Care ID data ID data ID data ID data ID data

Unique ID 2

V

ILVILVIH

83h Don’t Care ID data ID data ID data ID data ID data

Unique ID 3

V

ILVILVIH

84h Don’t Care ID data ID data ID data ID data ID data

OTP 0

V

ILVILVIH

85h Don’t Care OTP data OTP data OTP data OTP data OTP data

OTP 1

V

ILVILVIH

86h Don’t Care OTP data OTP data OTP data OTP data OTP data

OTP 2

V

ILVILVIH

87h Don’t Care OTP data OTP data OTP data OTP data OTP data

OTP 3

V

ILVILVIH

88h Don’t Care OTP data OTP data OTP data OTP data OTP data

Parameter Test Conditions

M36W216TI

Unit

Min Typ Max

Word Program

V

PP

= V

DD

10 200 µs

Double Word Program

V

PP

= 12V ±5%

10 200 µs

Main Block Program

V

PP

= 12V ±5%

0.16 5 s

V

PP

= V

DD

0.32 5 s

Parameter Block Program

V

PP

= 12V ±5%

0.02 4 s

V

PP

= V

DD

0.04 4 s

Main Block Erase

V

PP

= 12V ±5%

110 s

V

PP

= V

DD

110 s

Parameter Block Erase

V

PP

= 12V ±5%

0.8 10 s

V

PP

= V

DD

0.8 10 s

Program/Erase Cycles (per Block) 100,000 cycles

Page 27

27/62

M36W216TI, M36W216BI

FLASH BLOCK LOCKING

The Flash memory features an instant, individual

block locking scheme that allows any block to be

locked or unlocked with no latency. This locking

scheme has three levels of protection.

■ Lock/Unlock - this first level allows software-

only control of block locking.

■ Lock-Down - this second level requires

hardware interaction before locking can be

changed.

■ V

PP

≤ V

PPLK

- the third level offers a complete

hardware protection against program and erase

on all blocks.

The lock status of each block can be set to

Locked, Unlocked, and Lock-Down. Table 16, defines all of the possible protection states (WP

F

,

DQ1, DQ0), and Appendi x C, Figure 30, shows a

flowchart for the locking operations.

Reading a Block’s Lock Status

The lock status of every block can be read in the

Read Electronic Signature mode of the device. To

enter this mode write 90h t o the device. Subsequent reads at the a ddress s pecified in Table 12,

will output the lock status of that block. The lock

status is represented by DQ0 and DQ1. DQ0 indicates the Block Lock/Unlock status and is se t by

the Lock command and cleared by the Unlock

command. It is also automatically set when entering Lock-Down. DQ1 indicates the Lock-Down status and is set by the Lock-Down command. It

cannot be cleared by software, only by a hardware

reset or power-down.

The following sections explain the operation of the

locking system.

Locked State

The default status of all blocks on power-up or after a hardware reset is Locked (states (0,0,1) or

(1,0,1)). Locked blocks are fully protected from

any program or erase. Any program or erase operations attempted on a locked block will return an

error in the Status Register. The Status of a

Locked block can be changed to Unlocked or

Lock-Down using the appropriate software commands. An Unlocked block can be Locked by issuing the Lock command.

Unlocked State

Unlocked blocks (states (0,0,0), (1,0,0) (1,1,0)),

can be programmed or erased. All unlocked

blocks return to the Locked state a ft er a hardware

reset or when the device is powered-down. The

status of an unlocked block can be changed to

Locked or Locked-Down using the appropriate

software commands. A locked block can be unlocked by issuing the Unlock command.

Lock-Down State

Blocks that are Locked-Down (state (0,1,x))are

protected from program and erase operations (as

for Locked blocks) but their lock status cannot be

changed using software commands alone. A

Locked or Unlocked block can be Locked-Down by

issuing the Lock-Down com mand. Locked-Down

blocks revert to the Locked state when the device

is reset or powered-down.

The Lock-Down function is dependent on the WP

F

input pin. When WPF=0 (VIL), the blocks in the

Lock-Down state (0,1,x) are protected from program, erase and protection status changes. When

WP

F

=1 (VIH) the Lock-Down function is disabled

(1,1,1) and Locked-Down blocks can be ind ividually unlocked to the (1,1,0) state by issuing the

software command, where they can be erased and

programmed. These blocks can then be relocked

(1,1,1) and unlocked (1,1,0) as desired while WP

F

remains high. When WPF is low , blocks that were

previously Locked-Down return to the Lock-Down

state (0,1,x) regardless of any changes made

while WP

F

was high. Device reset or power-down

resets all blocks , including those in Lock-Down, to

the Locked state.

Locking Operations During Erase Suspend

Changes to block lock status can be performed

during an erase suspend by using the standard

locking command sequences to unlock, lock or

lock-down a block. This is useful in the case when

another block needs to be updated while an erase

operation is in progress.

To change block locking during an erase operation, first write the Erase Suspend command, then

check the status register until it indicates that the

erase operation has been suspended. Next write

the desired Lock com mand sequence to a block

and the protection status will be changed. After

completing any desired lock, read, or program operations, resume the erase operation with the

Erase Resume command.

If a block is locked or locked-down during an erase

suspend of the same block, the locking status bits

will be changed immediately , but when the eras e

is resumed, the erase operation will complete.

Locking operations cannot be performed du ring a

program suspend. Refer to Appendix D, Command Interface and Program/Erase Controller

State, for detailed information on which commands are valid during erase suspend.

Page 28

M36W216TI, M36W216BI

28/62

Table 15. Block Lock Status

Table 16. Protection Status

Note: 1. The p rotection st atus is de fined by th e write prot ect pin and by DQ1 (‘1’ for a l ocked-dow n block) and DQ0 (‘1’ for a locked block)

as read in the Read Electroni c Signatu re command with A1 = V

IH

and A0 = VIL.

2. All blocks are loc ked at power-up, so the default config uration is 00 1 or 101 accor di ng to WP

F

status.

3. A WP

F

transition to VIH on a locked block will restore the previous DQ0 value, giving a 111 or 110.

Item Address Data

Block Lock Configuration

xx002

LOCK

Block is Unlocked DQ0=0

Block is Locked DQ0=1

Block is Locked-Down DQ1=1

Current

Protection Status

(1)

(WPF, DQ1, DQ0)

Next Protection Status

(1)

(WPF, DQ1, DQ0)

Current State

Program/Erase

Allowed

After

Block Lock

Command

After

Block Unlock

Command

After Block

Lock-Down

Command

After

WP

F

transition

1,0,0 yes 1,0,1 1,0,0 1,1,1 0,0,0

1,0,1

(2)

no 1,0,1 1,0,0 1,1,1 0,0,1

1,1,0 yes 1,1,1 1,1,0 1,1,1 0,1,1

1,1,1 no 1,1,1 1,1,0 1,1,1 0,1,1

0,0,0 yes 0,0,1 0,0,0 0,1,1 1,0,0

0,0,1

(2)

no 0,0,1 0,0,0 0,1,1 1,0,1

0,1,1 no 0,1,1 0,1,1 0,1,1

1,1,1 or 1,1,0

(3)

Page 29

29/62

M36W216TI, M36W216BI

FLASH STATUS REGISTER

The Status Register provides information on t he

current or previous Program or Erase operation.

The various bits convey information and errors on

the operation. To read the Status register the

Read Status Register command can be issued, refer to Read Status Register Command section. To

output the contents, the Status Register is latched

on the falling edge of the Chip Enable or Output

Enable signals, and can be read until Chip Enable

or Output Enable returns to V

IH

. Either Chip Enable or Output Enable must be toggled to update

the latched data.

Bus Read operations from any address always

read the Status Register during Program and

Erase operations.

The bits in the Status Register are summarized in

Table 17, Status Register Bits. Refer to Table 17

in conjunction with the following text descriptions.

Program/Erase Controller Status (Bit 7). The Progra m/Erase Controller Status bit indicates whether

the Program/Erase Controller is active or inactive.

When the Program/Erase Controller Status bit is

Low (set to ‘0’), the Program/Erase Controller is

active; when the bit is High (set to ‘1’), the Program/Erase Controller is inactive, and the device

is ready to process a new command.

The Program/Erase Controller Status is Low immediately after a Program/Erase Suspend command is issued until the Program/Erase Controller

pauses. After the Program/Erase Controller pauses the bit is High .

During Program, Erase, operations the Program/

Erase Controller Status bit can be polled to find the

end of the operation. Other bits in the Status Register should not be tested until the Program/Erase

Controller completes the operation and the bit is

High.

After the Program/Erase Cont roller completes its

operation the Erase Status, Prog ram Status, V

PP

Status and Block Lock Status bits should be tested

for errors.

Erase Suspend Status (Bit 6). The Erase Suspend Status bit indicates that an Erase o peration

has been suspended or is going to be suspended.

When the Erase Suspend Status bit is High (set to

‘1’), a Program/Erase Suspend command has

been issued and the memory is waiting for a Program/Erase Resume command.

The Erase Suspend Status should only be considered valid when the Program/Erase Controller Status bit is High (Program/Erase Controller inactive).

Bit 7 is set within 30µs of the Program/Erase Suspend command being issued therefore the memory may still complete the operation rather than

entering the Suspend mode.

When a Program/Erase Re sume command is issued the Erase Suspend Status bit returns Low.