Datasheet M29F080A90N6, M29F080A90N1, M29F080A90M6, M29F080A Datasheet (SGS Thomson Microelectronics)

Page 1

1/21April 2000

M29F080A

8 Mbit (1Mb x8, Uniform Block) Single Supply Flash Memory

■ SINGLE 5V±10% SUPPLY VOLTAGE for

PROGRAM, ERASE and READ OPERATIONS

■ ACCESS TIME: 70ns

■ PROGRAMMING TIME

–8µs by Byte typical

■ 16 UNIFORM 64 Kbyte MEMORY BLOCKS

■ PROGRAM/ERASE CONTROLLER

– Embedded Byte Program algorithm

– Embedded Multi-Block/Chip Erase algorithm

– Status Register Polling and Toggle Bits

– Ready/Busy Output Pin

■ ERASE SUSPEND and RESUME MODES

– Read and Program another Block during

Erase Suspend

■ TEMPORARY BLOCK UNPROTECTION

MODE

■ LOW POWER CONSUMPTION

– Standby and Automatic Standby

■ 100,000 PROGRAM/ERASE CYCLES per

BLOCK

■ 20 YEARS DATA RETENTION

– Defectivity below 1 ppm/year

■ ELECTRONIC SIGNATURE

– Manufacturer Code: 20h

– Device Code: F1h

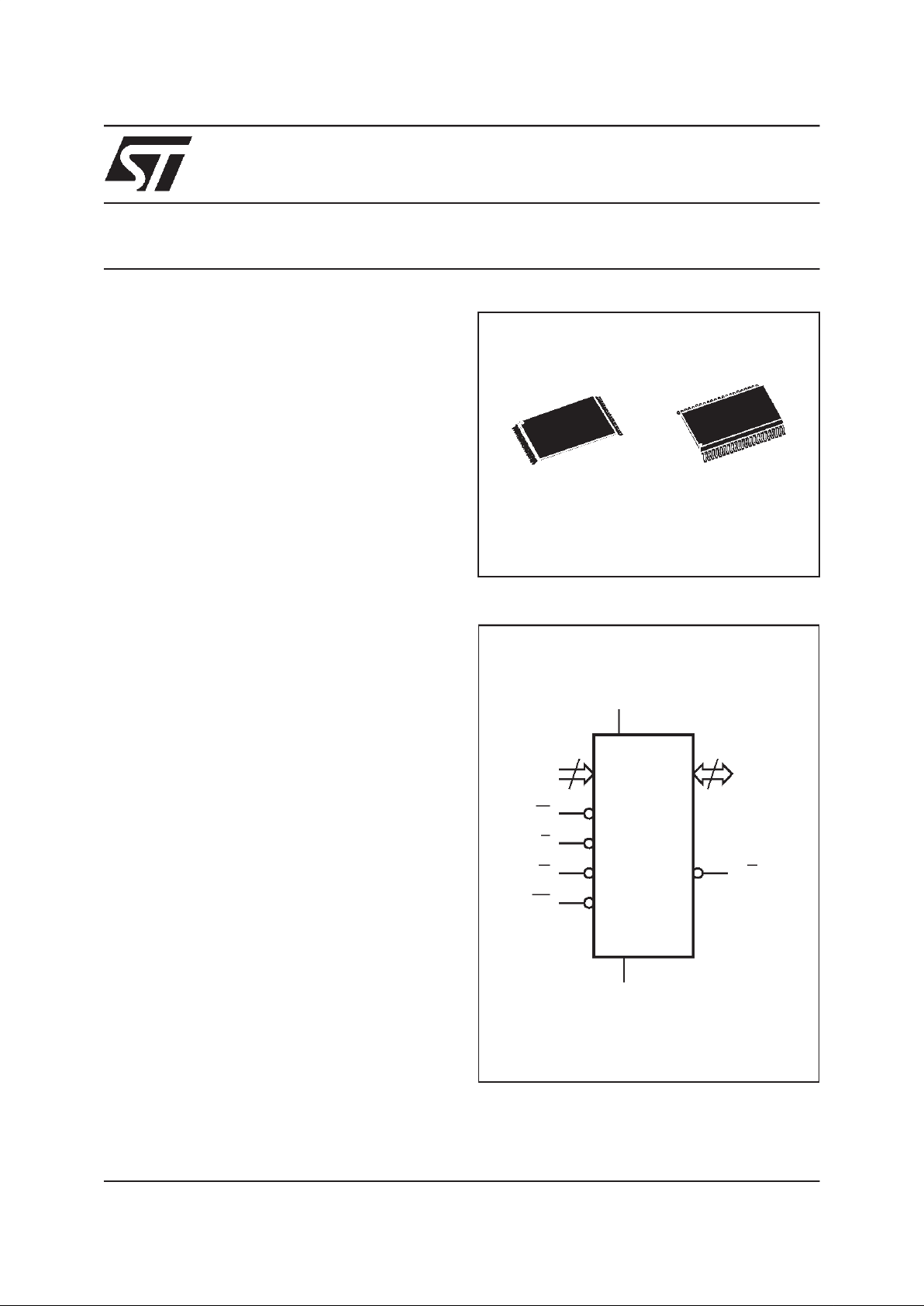

TSOP40 (N)

10 x 20mm

SO44 (M)

44

1

Figure 1. Logic Diagram

AI00501C

20

A0-A19

W

DQ0-DQ7

V

CC

M29F080A

E

V

SS

8

G

RP

RB

Page 2

M29F080A

2/21

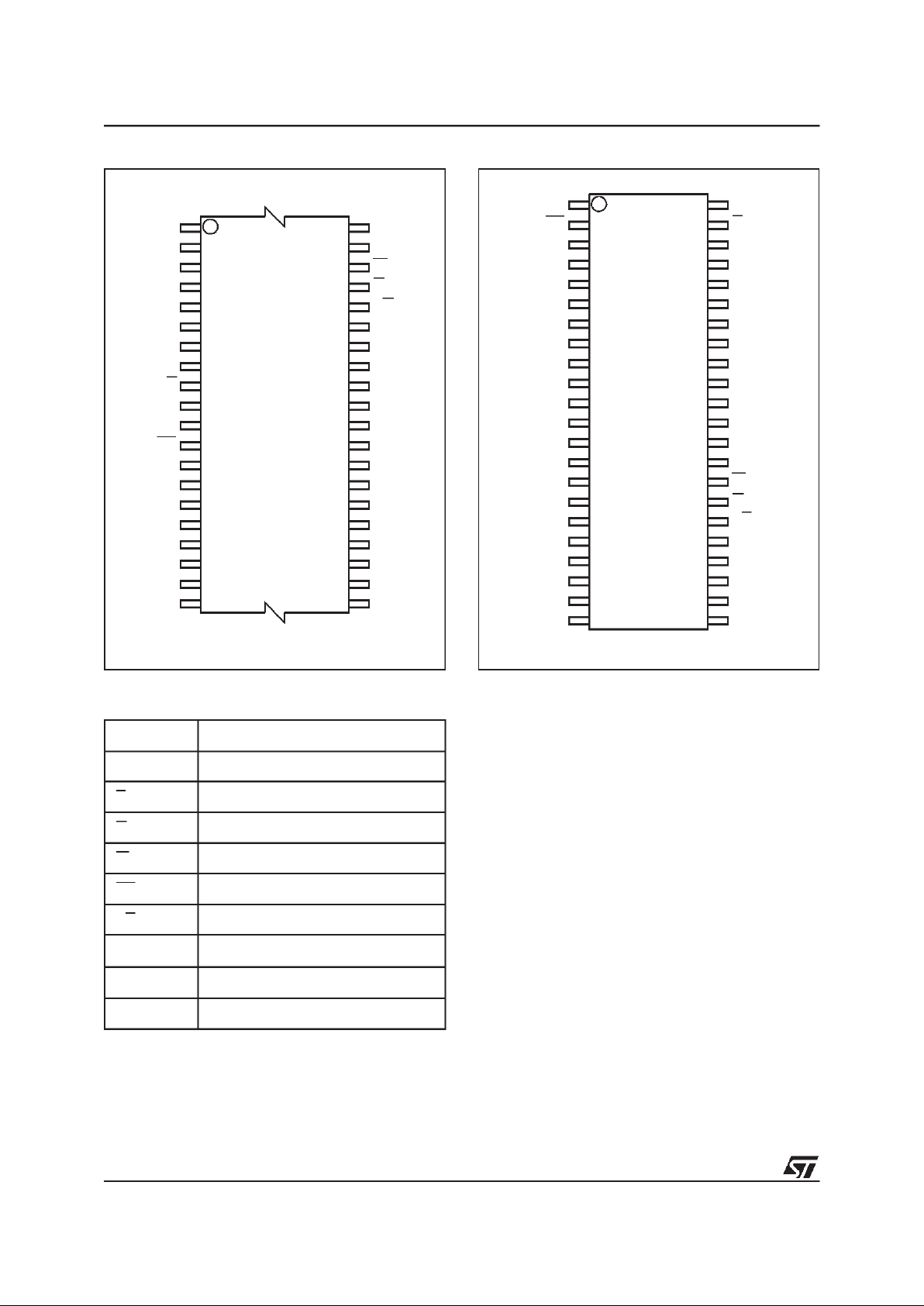

Figure 2. TSOP Connections

A1

DQ1

DQ2A10

A4

A2

A7

A6

A14

NC

A17

A18

DQ7

A13

A19

A0

W

DQ5

DQ3

V

SS

V

CC

DQ4

DQ6

A12

E

RP

A11

NC

V

CC

AI00520B

M29F080A

10

1

11

20 21

30

31

40

A3

A15

A16 G

RB

A8

A9

V

SS

DQ0

NC

A5

Figure 3. SO Connections

A2

A1

A0

A6

NC

NC

A3

A5

A4

A17

NC

A18

A19

W

A16

NC

NC

NC

DQ6DQ2

V

SS

V

CC

V

SS

DQ4

G

A13

E

NC

A7

RP

V

CC

A10

AI00521B

M29F080A

8

2

3

4

5

6

7

9

10

11

12

13

14

15

16

32

31

30

29

28

27

26

25

24

2322

20

19

18

17DQ0

DQ1

A9

A8

RB

DQ7

44

39

38

37

36

35

34

33

A15

A14

DQ3

21

DQ5

40

43

1

42

41

A11 A12

Table 1. Signal Names

A0-A19 Address Inputs

DQ0-DQ7 Data Inputs/Outputs

E Chip Enable

G Output Enable

W Write Enable

RP Reset/Block Temporary Unprotect

RB Ready/Busy Output

V

CC

Supply Voltage

V

SS

Ground

NC Not Connected Internally

SUMMARY DESCRIPTION

The M29F080A is an 8 Mbit (1Mb x8) non-volatile

memory that can be read, erased and reprogrammed. These operations can be performedus-

ing a single 5V supply. On power-up the memory

defaults to its Read mode where it can be read in

the same way as a ROM or EPROM.

The memory is divided into blocks that can be

erased independently so it is possible to preserve

valid data while old data is erased. Blocks can be

protected in groups to prevent accidental Program

or Erase commands from modifying the memory.

Program and Erase commands are written to the

Command Interface of the memory. An on-chip

Program/Erase Controllersimplifiestheprocessof

programming or erasing the memory by taking

care of all of the special operations that are required to update the memory contents. The end of

a program or eraseoperation can be detected and

any error conditions identified. The command set

required to control the memory is consistent with

JEDEC standards.

Chip Enable, Output Enableand Write Enable signals control the bus operation of the memory.

They allow simple connection to most microprocessors, often without additional logic.

The memory is offered in a TSOP40 (10 x 20mm)

and SO44 packages and it is supplied with all the

bits erased (set to ’1’).

Page 3

3/21

M29F080A

SIGNAL DESCRIPTIONS

See Figure 1, Logic Diagram, and Table 1, Signal

Names, forabrief overview of the signals connected to this device.

Address Inputs (A0-A19). The Address Inputs

select the cells in the memory array to access during Bus Read operations. During BusWrite operations they control the commands sent to the

Command Interface of the internal state machine.

Data Inputs/Outputs (DQ0-DQ7). The Data Inputs/Outputs output thedatastoredatthe selected

address during a Bus Read operation. During Bus

Write operations they represent the commands

sentto theCommandInterfaceof the internal state

machine.

Chip Enable (E). The Chip Enable, E, activates

the memory, allowing Bus Read and Bus Write operations to be performed. When Chip Enable is

High, VIH, all other pins are ignored.

Output Enable (G). The Output Enable, G, controls the Bus Read operation of the memory.

Write Enable (W). The Write Enable, W, controls

the Bus Write operation of the memory’s Command Interface.

Reset/Block TemporaryUnprotect (RP). The Reset/Block Temporary Unprotect pin can be usedto

apply a Hardware Reset to the memory or to temporarily unprotect all blocks that have been protected.

Table 2. Absolute Maximum Ratings

(1)

Note: 1. Except for the rating ”Operating Temperature Range”, stresses above those listed in the Table ”Absolute Maximum Ratings” may

cause permanent damage to the device. These are stress ratings only and operation of the device at these or any other conditions

above those indicated in the Operating sections of this specification is not implied. Exposure to Absolute Maximum Rating conditions for extended periods may affect device reliability. Refer also to the STMicroelectronics SUREProgram andotherrelevant quality documents.

2. Minimum Voltage may undershoot to –2V during transition and for less than 20ns during transitions.

Symbol Parameter Value Unit

T

A

Ambient Operating Temperature (Temperature Range Option 1) 0 to 70 °C

Ambient Operating Temperature (Temperature Range Option 6) –40 to 85 °C

Ambient Operating Temperature (Temperature Range Option 3) –40 to 125 °C

T

BIAS

Temperature Under Bias –50 to 125 °C

T

STG

Storage Temperature –65 to 150 °C

V

IO

(2)

Input or Output Voltage –0.6 to 6 V

V

CC

Supply Voltage –0.6 to 6 V

V

ID

Identification Voltage –0.6 to 13.5 V

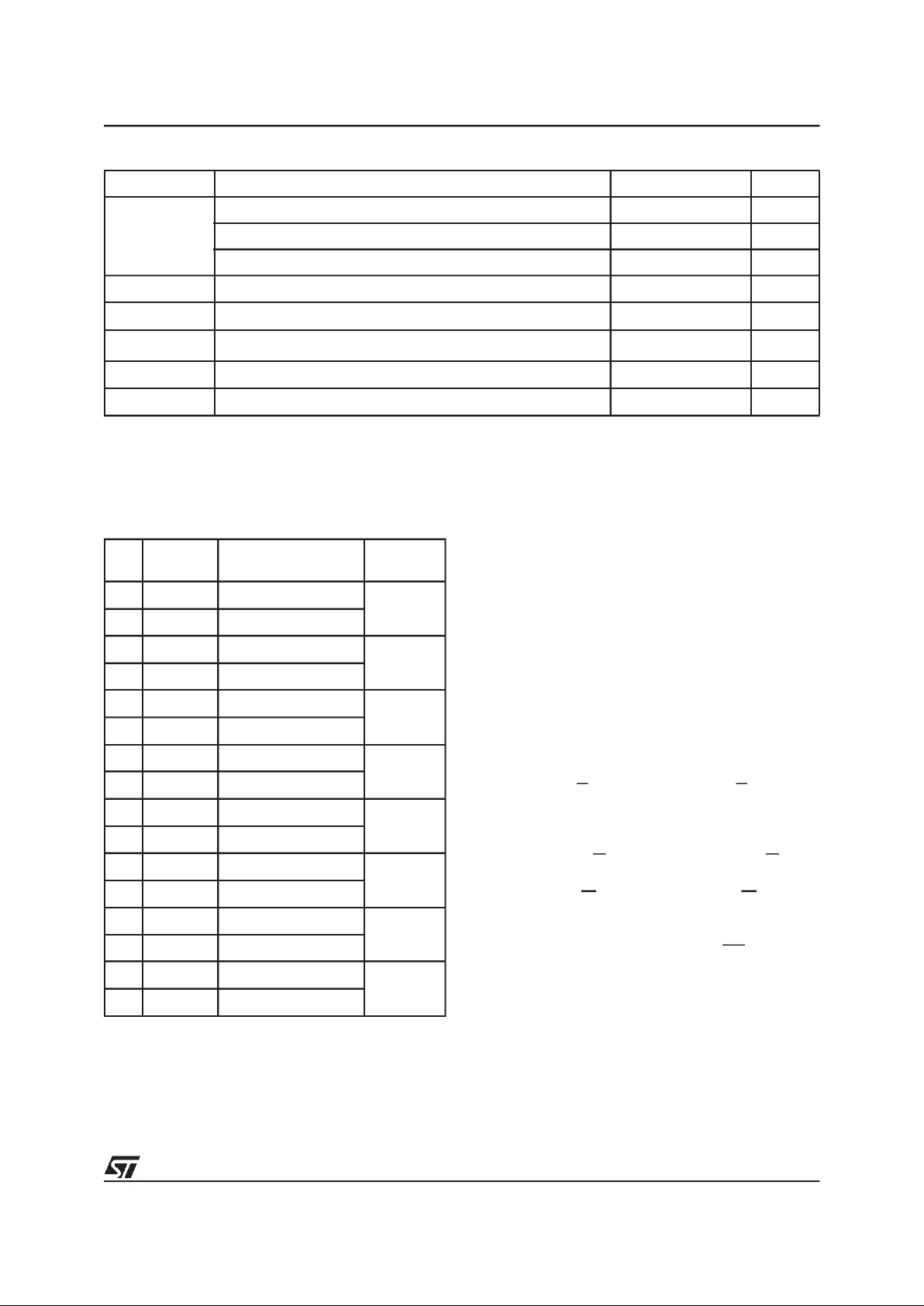

Table 3. Uniform Block Addresses, M29F080A

#

Size

(Kbytes)

Address Range

Protection

Group

15 64 F0000h-FFFFFh

7

14 64 E0000h-EFFFFh

13 64 D0000h-DFFFFh

6

12 64 C0000h-CFFFFh

11 64 B0000h-BFFFFh

5

10 64 A0000h-AFFFFh

9 64 90000h-9FFFFh

4

8 64 80000h-8FFFFh

7 64 70000h-7FFFFh

3

6 64 60000h-6FFFFh

5 64 50000h-5FFFFh

2

4 64 40000h-4FFFFh

3 64 30000h-3FFFFh

1

2 64 20000h-2FFFFh

1 64 10000h-1FFFFh

0

0 64 00000h-0FFFFh

Page 4

M29F080A

4/21

A 0.1µF capacitor should be connected between

the VCCSupply Voltage pin and the VSSGround

pin to decouple the current surges from the power

supply. The PCB track widths must be sufficient to

carry the currents required during program and

erase operations, I

CC4

.

VSSGround. The VSSGroundis the reference for

all voltage measurements.

BUS OPERATIONS

There arefive standard busoperations that control

the device. These are Bus Read, Bus Write, Output Disable, Standby and Automatic Standby. See

Table 4, Bus Operations, for asummary. Typically

glitches of less than 5ns on Chip Enable or Write

Enable are ignored by the memory and do not affect bus operations.

Bus Read. Bus Read operations read from the

memory cells, or specific registers in the Command Interface. A valid Bus Read operation involves setting the desired address on the Address

Inputs, applying a Low signal, VIL, to Chip Enable

and Output Enable and keeping Write Enable

High, VIH. The Data Inputs/Outputs will output the

value, see Figure 8, Read Mode AC Waveforms,

and Table 11, Read AC Characteristics, for details

of when the output becomes valid.

Bus Write. Bus Write operations write to the

Command Interface. A valid Bus Write operation

begins by setting the desired address on the Address Inputs. The Address Inputs are latched by

the Command Interface on the falling edge of Chip

Enable or Write Enable, whichever occurs last.

The Data Inputs/Outputs are latched by the Command Interface on the rising edge of Chip Enable

or WriteEnable, whichever occurs first. OutputEnable must remain High, VIH, during the whole Bus

Write operation. See Figures 9 and 10, Write AC

Waveforms, and Tables 12 and 13, Write AC

Characteristics, for details of the timing requirements.

A Hardware Reset is achieved by holding Reset/

Block Temporary Unprotect Low, VIL, for at least

t

PLPX

. After Reset/Block Temporary Unprotect

goes High, VIH, the memory will be ready for Bus

Read and Bus Write operations after t

PHEL

or

t

RHEL

, whicheveroccurs last.See the Ready/Busy

Output section, Table 14 and Figure 11, Reset/

Temporary Unprotect AC Characteristics for more

details.

Holding RP at VIDwill temporarily unprotect the

protected blocks in the memory. Program and

Erase operations on all blocks will be possible.

The transition from VIHtoVIDmust be slower than

t

PHPHH

.

Ready/Busy Output (RB). The Ready/Busy pin

is anopen-drain outputthat can be used toidentify

when the memory array can be read. Ready/Busy

is high-impedanceduring Read mode, Auto Select

mode and Erase Suspend mode.

After a Hardware Reset, Bus Read and Bus Write

operations cannot begin until Ready/Busy becomes high-impedance. See Table 14 and Figure

11, Reset/Temporary Unprotect AC Characteristics.

During Program or Erase operations Ready/Busy

is Low, VOL. Ready/Busy will remain Low during

Read/Reset commands or Hardware Resets until

the memory is ready to enter Read mode.

The use of an open-drain output allows the Ready/

Busy pins from several memories to be connected

to a single pull-up resistor. A Low will then indicate

that one, or more, of the memories is busy.

VCCSupply Voltage. The VCCSupply Voltage

supplies the power for all operations (Read, Program, Erase etc.).

The CommandInterface is disabled when the V

CC

Supply Voltage is less than the Lockout Voltage,

V

LKO

. This prevents Bus Write operations from accidentally damaging the data during power up,

power down and power surges. If the Program/

Erase Controller is programming or erasing during

this time then the operation aborts and the memory contents being altered will be invalid.

Page 5

5/21

M29F080A

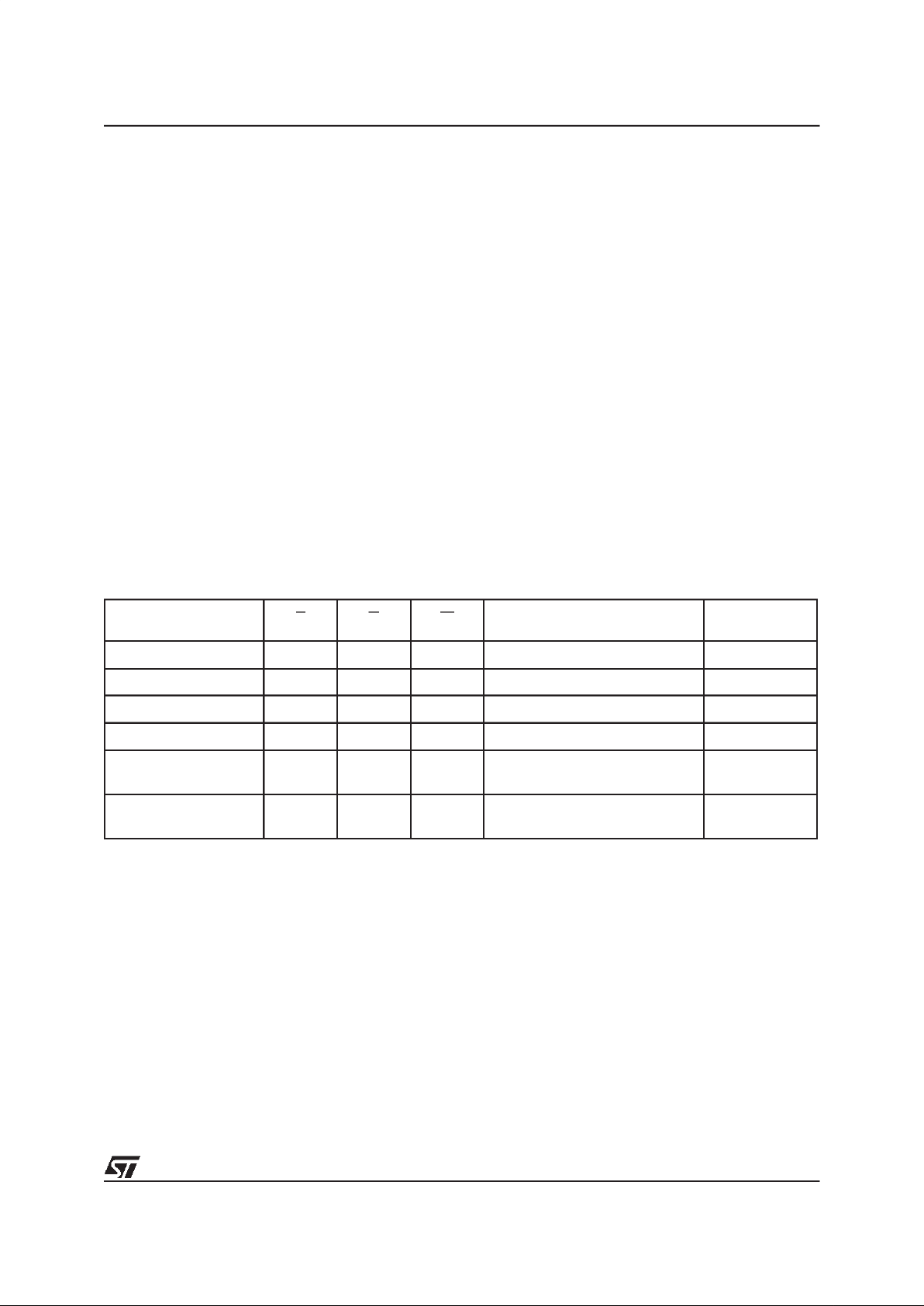

Table 4. Bus Operations

Note: X = VILor VIH.

Operation E G W Address Inputs

Data

Inputs/Outpu ts

Bus Read

V

IL

V

IL

V

IH

Cell Address Data Output

Bus Write

V

IL

V

IH

V

IL

Command Address Data Input

Output Disable

XV

IH

V

IH

XHi-Z

Standby

V

IH

XXX Hi-Z

Read Manufacturer

Code

V

IL

V

IL

V

IH

A0 = VIL,A1=VIL,A9=VID,

Others V

IL

or V

IH

20h

Read Device Code

V

IL

V

IL

V

IH

A0 = VIH,A1=VIL,A9=VID,

Others V

IL

or V

IH

F1h

Output Disable. The Data Inputs/Outputs are in

the high impedance state when Output Enable is

High, VIH.

Standby. When Chip Enable is High, VIH, the

Data Inputs/Outputs pins are placed in the highimpedance state and the Supply Current is reduced to the Standby level.

When Chip Enable is at VIHthe Supply Current is

reduced to the TTL Standby Supply Current, I

CC2

.

To further reduce the Supply Current to the CMOS

Standby Supply Current, I

CC3

, ChipEnable should

be held within VCC± 0.2V. For Standby current

levels see Table 10, DC Characteristics.

During program or erase operations the memory

will continue to use the Program/Erase Supply

Current, I

CC4

, for Program or Eraseoperations un-

til the operation completes.

AutomaticStandby. If CMOS levels (VCC± 0.2V)

are usedto drive the bus and the bus is inactive for

150ns or more the memory enters Automatic

Standby where the internal Supply Current is reduced to the Standby Supply Current, I

CC3

. The

Data Inputs/Outputs will still output data if a Bus

Read operation is in progress.

Special Bus Operations

Additional bus operations can be performed to

read the Electronic Signature and also to apply

and remove Block Protection. These bus operations are intended for use by programming equipment and are not usually used in applications.

They require VIDto be applied to some pins.

Electronic Signature. The memory has two

codes, the manufacturer code and the device

code, that can be read to identify the memory.

These codes can be read by applying the signals

listed in Table 4, Bus Operations.

Block Protection and BlocksUnprotection. Blocks

can be protected in groups against accidental Program or Erase. See Table 3, Block Addresses, for

details of which blocks must be protected together

as a group. Protected blocks can be unprotected

to allow data to be changed. Block Protection and

Block Unprotection operations must only be performed on programming equipment.

For further information refer to Application Note

AN1122, Applying Protection and Unprotection to

M29 Series Flash.

Page 6

M29F080A

6/21

COMMAND INTERFACE

All Bus Write operations to the memory are interpreted by the Command Interface. Commands

consist of one or more sequential Bus Write operations. Failure to observe a validsequence of Bus

Write operations will result in the memory returning toRead mode. In this case, after at least 50ns,

an address transition or Chip Enable going Low is

required before reading correct data. The long

command sequences are imposed to maximize

data security.

The commands are summarized in Table 5, Commands. Refer to Table 5 in conjunction with the

text descriptions below.

Read/Reset Command. The Read/Reset command returnsthe memory to its Read mode where

it behaves like a ROM or EPROM. It also resets

the errors in the Status Register. Either one or

three Bus Write operations can be used to issue

the Read/Reset command.

If the Read/Reset command is issued during a

Block Eraseoperation or following a Programming

or Eraseerror thenthe memory will takeup to10µs

to abort. During the abort period no valid data can

be read from the memory. Issuing a Read/Reset

command during a Block Erase operation will

leave invalid data in the memory.

Auto Select Command. The Auto Select command is used to read the Manufacturer Code, the

Device Code and the Block Protection Status.

Three consecutive Bus Write operations are required to issue the Auto Select command. Once

the Auto Select command is issued the memory

remains in Auto Select mode until another command is issued.

From the Auto Select mode the Manufacturer

Code can be read using a Bus Read operation

with A0 = VILand A1 = VIL. The otheraddress bits

may be set to either VILor VIH. The Manufacturer

Code for STMicroelectronics is 20h.

The Device Code can be read using a Bus Read

operation with A0 = VIHand A1 = VIL. The other

address bits may be set to either VILor VIH. The

Device Code for the M29F080A is F1h.

The Block Protection Status of each block can be

read using a Bus Read operation with A0 = VIL,

A1 = VIH, and A16-A19 specifying the address of

the block. The other address bits may be set toeither VILor VIH. If the addressed block is protected

then 01his outputon the DataInputs/Outputs, otherwise 00h is output.

Program Command. The Program command

can be used to program a value to one address in

the memory array at a time. The command requires fourBus Writeoperations, the finalwrite operation latches the address and datain the internal

state machine and starts the Program/Erase Controller.

If the address falls in a protected block then the

Program command is ignored, the data remains

unchanged. The Status Register is never read and

no error condition is given.

During the program operation the memory will ignore all commands. It is not possible to issue any

command to abort or pause the operation. Typical

program times are given in Table 6. Bus Read operations during the program operation will output

the Status Register on the Data Inputs/Outputs.

See the section on the Status Register for more

details.

After the program operation has completed the

memory will return to the Read mode, unless an

error has occurred. When an error occurs the

memory will continue to output the Status Register. A Read/Reset command must be issued to reset the error condition and return to Read mode.

Note that the Program command cannot change a

bit set at ’0’ back to ’1’. One of the Erase Commands must be used to set all the bits in a block or

in the whole memory from ’0’ to ’1’.

Page 7

7/21

M29F080A

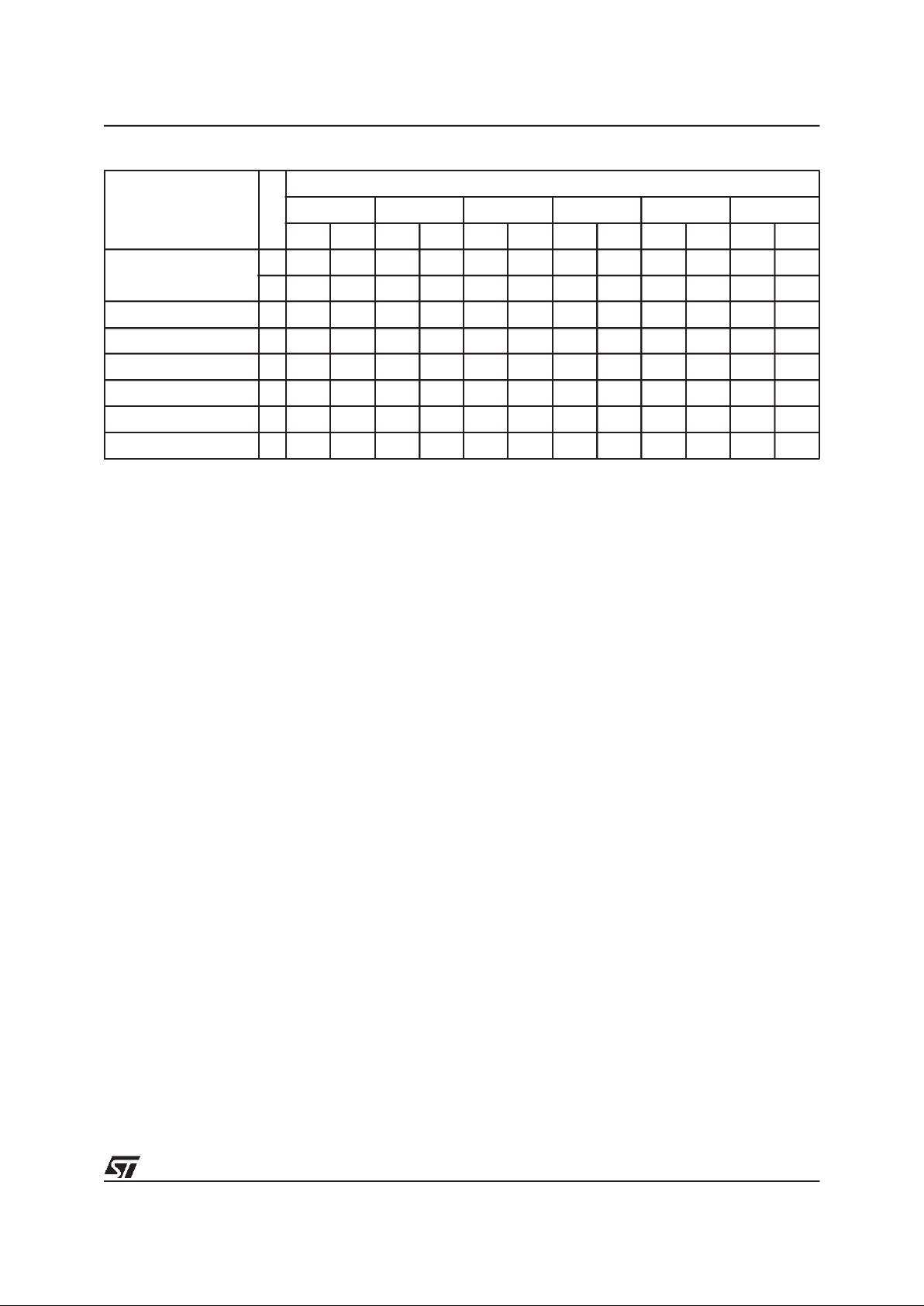

Table 5. Commands

Note: X Don’t Care, PA Program Address, PD Program Data, BA Any address in the Block.

All values in the table are in hexadecimal.

The Command Interface only uses address bits A0-A10 to verify the commands, the upper address bits are Don’t Care.

Read/Reset. After a Read/Reset command, read the memory as normal until another command is issued.

Auto Select. After an Auto Select command, read Manufacturer ID, Device ID or Block Protection Status.

Program, Chip Erase, Block Erase. After these commands read the Status Register until the Program/Erase Controller completes and the

memory returns to Read Mode. Add additional Blocks during Block Erase Command with additional Bus WriteOperations until the Timeout

Bit is set.

Erase Suspend. After the Erase Suspend command read non-erasing memory blocks as normal, issue AutoSelect and Program commands

on non-erasing blocks as normal.

Erase Resume. After the Erase Resume command the suspended Erase operation resumes, read the Status Register until the Program/

Erase Controller completes and the memory returns to Read Mode.

Command

Length

Bus Write Operations

1st 2nd 3rd 4th 5th 6th

Addr Data Addr Data Addr Data Addr Data Addr Data Addr Data

Read/Reset

1X F0

3 555 AA 2AA 55 X F0

Auto Select 3 555 AA 2AA 55 555 90

Program 4 555 AA 2AA 55 555 A0 PA PD

Chip Erase 6 555 AA 2AA 55 555 80 555 AA 2AA 55 555 10

Block Erase 6+ 555 AA 2AA 55 555 80 555 AA 2AA 55 BA 30

Erase Suspend 1 X B0

Erase Resume 1 X 30

Chip Erase Command. The Chip Erase command can beused to erasethe entire chip. Six Bus

Write operations are required to issue the Chip

Erase Command and start the Program/Erase

Controller.

If any blocks are protected then these are ignored

and all the other blocks are erased. If all of the

blocks are protected the ChipErase operation appears tostart but willterminate within about 100µs,

leaving the data unchanged. No error condition is

given when protected blocks are ignored.

During the erase operation the memory will ignore

all commands. It is not possible to issue any command to abort the operation. Typical chip erase

times are given in Table 6. All Bus Read operations during the Chip Erase operation will output

the Status Register on the Data Inputs/Outputs.

See the section on the Status Register for more

details.

After the Chip Erase operation has completed the

memory will return to the Read Mode, unless an

error has occurred. When an error occurs the

memory will continue to output the Status Register. A Read/Reset command must be issued to reset the error condition and return to Read Mode.

TheChip Erase Command sets allof the bits inunprotected blocks of the memory to ’1’. All previous

data is lost.

Page 8

M29F080A

8/21

Block Erase Command. The Block Erase command can be used to erase a list of one or more

blocks. Six Bus Write operations are required to

select the first block in the list. Each additional

block in the list can be selected by repeating the

sixth Bus Write operation using the address of the

additional block. The Block Erase operation starts

the Program/Erase Controller about 50µs after the

last Bus Write operation. Once the Program/Erase

Controller starts it is not possible to select any

more blocks. Each additional block must therefore

be selectedwithin 50µs of the last block.The 50µs

timer restartswhen an additional block isselected.

The Status Register can be read after the sixth

Bus Write operation. See the Status Register for

details on how to identify if the Program/Erase

Controller has started the Block Erase operation.

If any selected blocks areprotected thenthese are

ignored and all the other selected blocks are

erased. If all of the selected blocks are protected

the Block Erase operation appears to start but will

terminate within about 100µs, leaving the data unchanged. No error condition is given when protected blocks are ignored.

During the Block Erase operation the memory will

ignore all commands except the Erase Suspend

and Read/Reset commands. Typical block erase

times are given in Table 6. All Bus Read operations during the Block Erase operation will output

the Status Register on the Data Inputs/Outputs.

See the section on the Status Register for more

details.

After theBlock Erase operation has completed the

memory will return to the Read Mode, unless an

error has occurred. When an error occurs the

memory will continue to output the Status Regis-

ter. A Read/Reset command must be issued to reset the error condition and return to Read mode.

The Block Erase Command sets all of the bits in

the unprotected selected blocks to ’1’. All previous

data in the selected blocks is lost.

Erase Suspend Command. The Erase Suspend

Command may be used to temporarily suspend a

Block Erase operation and return the memory to

Read mode. The command requires one Bus

Write operation.

The Program/Erase Controller will suspend within

15µs of the Erase Suspend Command being issued. Once the Program/Erase Controller has

stopped the memory will be set toRead mode and

the Erase will be suspended. If the Erase Suspend

command is issued during the period when the

memory is waiting for an additional block (before

the Program/Erase Controller starts) then the

Erase is suspended immediately and will start immediately when the Erase Resume Command is

issued. It will not be possible to select any further

blocks for erasure after the Erase Resume.

During Erase Suspend it is possible to Read and

Program cells in blocks that are not being erased;

both Read and Program operations behave as

normal on these blocks. Reading from blocks that

are being erased will output the Status Register.It

is also possible to enter theAuto Select mode: the

memorywill behaveas in the Auto Select mode on

all blocks until a Read/Reset command returns the

memory to Erase Suspend mode.

Erase Resume Command. The Erase Resume

command must be used to restart the Program/

Erase Controller from Erase Suspend. An erase

can be suspended and resumed more than once.

Table 6. Program, Erase Times and Program, Erase Endurance Cycles

(TA= 0 to 70 °C, –40 to 85 °C or –40 to 125 °C)

Note: 1. TA=25°C, VCC=5V.

Parameter Min

Typ

(1)

Typical after

100k W/E Cycles

(1)

Max Unit

Chip Erase (All bits in the memory set to ‘0’) 3 3 sec

Chip Erase 8 8 30 sec

Block Erase (64 Kbytes) 0.6 0.6 4 sec

Program 8 8 150 µs

Chip Program 9 9 35 sec

Program/Erase Cycles (per Block) 100,000 cycles

Page 9

9/21

M29F080A

STATUS REGISTER

Bus Read operations from any address always

read the Status Register during Program and

Erase operations. It isalso read during Erase Suspend when anaddress within ablock beingerased

is accessed.

The bits in the Status Register are summarized in

Table 7, Status Register Bits.

Data Polling Bit (DQ7). The Data Polling Bit can

be used to identify whether the Program/Erase

Controller has successfully completed its operation or if it has responded to an Erase Suspend.

The Data Polling Bit is output on DQ7 when the

Status Register is read.

During Program operations the Data Polling Bit

outputs the complement of the bit being programmed to DQ7. After successful completion of

the Program operation the memory returns to

Read mode and Bus Read operationsfrom the address just programmed output DQ7, not its complement.

During Erase operations the Data Polling Bit outputs ’0’, the complement of the erased state of

DQ7. After successful completion of the Erase operation the memory returns to Read mode.

In Erase Suspend mode the Data Polling Bit will

output a ’1’ during a Bus Read operation within a

block being erased. The Data Polling Bit will

change from a ’0’ to a ’1’ when the Program/Erase

Controller has suspended the Erase operation.

Figure 4, Data Polling Flowchart, gives an example of how to use the Data Polling Bit. A Valid Ad-

dress is the address being programmed or an

address within the block being erased.

Toggle Bit (DQ6). The Toggle Bit can be used to

identify whether the Program/Erase Controller has

successfully completed its operation or if it has responded to an Erase Suspend. The Toggle Bit is

output on DQ6 when the Status Register is read.

During Program and Erase operations the Toggle

Bit changes from ’0’ to ’1’ to ’0’, etc., with successive Bus Read operations at any address. After

successful completion of the operation the memory returns to Read mode.

During Erase Suspend mode the Toggle Bit will

output when addressing a cell within a block being

erased. The Toggle Bit will stop toggling when the

Program/Erase Controller has suspended the

Erase operation.

Figure 5, Data Toggle Flowchart, gives an example of how to use the Data Toggle Bit.

Error Bit (DQ5). The Error Bit can be used to

identify errors detected by the Program/Erase

Controller. The Error Bit is set to ’1’ when a Program, Block Erase or Chip Erase operation fails to

write the correct data to the memory. If the Error

Bit is set a Read/Reset command must be issued

before other commands are issued. The Error bit

is output onDQ5 whenthe Status Registeris read.

Note that the Program command cannot change a

bit setat ’0’ back to ’1’ and attempting to do so may

or may not set DQ5 at ’1’. In both cases, a successive Bus Read operation will show the bit is still ’0’.

One of the Erase commands must be used to set

all the bits in a block or in the whole memory from

’0’ to ’1’.

Table 7. Status Register Bits

Note: Unspecified data bits should be ignored.

Operation Address DQ7 DQ6 DQ5 DQ3 DQ2 RB

Program Any Address DQ7 Toggle 0 – – 0

Program During Erase

Suspend

Any Address DQ7 Toggle 0 – – 0

Program Error Any Address DQ7 Toggle 1 – – 0

Chip Erase Any Address 0 Toggle 0 1 Toggle 0

Block Erase before

timeout

Erasing Block 0 Toggle 0 0 Toggle 0

Non-Erasing Block 0 Toggle 0 0 No Toggle 0

Block Erase

Erasing Block 0 Toggle 0 1 Toggle 0

Non-Erasing Block 0 Toggle 0 1 No Toggle 0

Erase Suspend

Erasing Block 1 No Toggle 0 – Toggle 1

Non-Erasing Block Data read as normal 1

Erase Error

Good Block Address 0 Toggle 1 1 No Toggle 0

Faulty Block Address 0 Toggle 1 1 Toggle 0

Page 10

M29F080A

10/21

Figure 4. Data Polling Flowchart

READ DQ5 &

DQ7

at VALID ADDRESS

START

READ

DQ7

at VALID ADDRESS

FAIL PASS

AI03598

DQ7

=

DATA

YES

NO

YES

NO

DQ5

=1

DQ7

=

DATA

YES

NO

Figure 5. Data Toggle Flowchart

READ DQ6

START

READ

DQ6

TWICE

FAIL PASS

AI01370B

DQ6

=

TOGGLE

NO

NO

YES

YES

DQ5

=1

NO

YES

DQ6

=

TOGGLE

READ

DQ5 & DQ6

Erase Timer Bit (DQ3). The Erase Timer Bit can

be used to identify the start of Program/Erase

Controller operation during a Block Erase command.

Once the Program/Erase Controller starts erasing

the Erase Timer Bit is set to ’1’. Before the Program/Erase Controller starts theErase Timer Bit is

set to ’0’ and additional blocks to be erased may

be written to the Command Interface. The Erase

Timer Bit is output on DQ3 when the Status Register is read.

Alternative Toggle Bit (DQ2). The Alternative

Toggle Bit can be used to monitor the Program/

Erase controller during Erase operations. The Alternative Toggle Bit is output on DQ2 when the

Status Register is read.

During ChipErase and Block Erase operations the

Toggle Bit changes from ’0’ to ’1’ to ’0’, etc., with

successive Bus Read operations from addresses

within the blocks being erased. Once the operation

completes the memory returns to Read mode.

During Erase Suspend the Alternative Toggle Bit

changes from ’0’ to ’1’ to ’0’, etc. with successive

Bus Read operations from addresses within the

blocks being erased. Bus Read operations to addresses within blocks not being erased will output

the memory cell data as if in Read mode.

After an Erase operation that causes the Error Bit

to be set the Alternative Toggle Bit can be used to

identify whichblock or blocks have caused the error. The Alternative Toggle Bit changes from ’0’ to

’1’ to ’0’, etc. with successive Bus Read Operations from addresses within blocks that have not

erased correctly. The Alternative Toggle Bit does

not change if the addressed block has erased correctly.

Page 11

11/21

M29F080A

Figure 6. AC Testing Input Output Waveform

AI01275B

3V

High Speed

0V

1.5V

2.4V

Standard

0.45V

2.0V

0.8V

Figure 7. AC Testing Load Circuit

AI03027

1.3V

OUT

CL= 30pF or100pF

CLincludes JIG capacitance

3.3kΩ

1N914

DEVICE

UNDER

TEST

Table 9. Capacitance

(TA=25°C, f = 1 MHz)

Note: Sampled only, not 100% tested.

Symbol Parameter Test Condition Min Max Unit

C

IN

Input Capacitance

V

IN

=0V

6pF

C

OUT

Output Capacitance

V

OUT

=0V

12 pF

Table 8. AC Measurement Conditions

Parameter

M29F080A

70 90 / 120

ACTest Conditions High Speed Standard

Load Capacitance (C

L

) 30pF 100pF

Input Rise and Fall Times ≤ 10ns ≤ 10ns

Input Pulse Voltages 0 to 3V 0.45 to 2.4V

Input and Output Timing Ref. Voltages 1.5V 0.8V and 2.0V

Page 12

M29F080A

12/21

Table 10. DC Characteristics

(TA= 0 to 70°C, –40 to 85°C or –40 to 125°C)

Note: 1. Sampled only, not 100% tested.

2. T

A

=25°C, VCC=5V.

Symbol Parameter Test Condition Min

Typ.

(2)

Max Unit

I

LI

Input Leakage Current

0V ≤ V

IN

≤ V

CC

±1 µA

I

LO

Output Leakage Current 0V ≤ V

OUT

≤ V

CC

±1 µA

I

CC1

Supply Current (Read)

E=V

IL

,G=VIH, f = 6MHz

10 20 mA

I

CC2

Supply Current (Standby) TTL

E=V

IH

1mA

I

CC3

Supply Current (Standby) CMOS

E=V

CC

± 0.2V,

RP = V

CC

± 0.2V

35 150 µA

I

CC4

(1)

Supply Current (Program/Erase)

Program/Erase

Controller active

20 mA

V

IL

Input Low Voltage –0.5 0.8 V

V

IH

Input High Voltage 2

V

CC

+ 0.5

V

V

OL

Output Low Voltage

I

OL

= 5.8mA

0.45 V

V

OH

Output High Voltage TTL

I

OH

= –2.5mA

2.4 V

Output High Voltage CMOS

I

OH

= –100µAV

CC

–0.4

V

V

ID

Identification Voltage 11.5 12.5 V

I

ID

Identification Current

A9 = V

ID

100 µA

V

LKO

(1)

Program/Erase Lockout Supply

Voltage

3.2 4.2 V

Page 13

13/21

M29F080A

Figure 8. Read Mode AC Waveforms

AI02925

tAVAV

tAVQV tAXQX

tELQX tEHQZ

tGLQV

tGLQX tGHQX

VALID

A0-A19

G

DQ0-DQ7

E

tELQV tEHQX

tGHQZ

VALID

Table 11. Read AC Characteristics

(TA= 0 to 70°C, –40 to 85°C or –40 to 125°C)

Note: 1. Sampled only, not 100% tested.

Symbol Alt Parameter Test Condition

M29F080A

Unit

70 90 / 120

t

AVAV

t

RC

Address Valid to Next Address Valid

E=V

IL

,

G=V

IL

Min 70 90 ns

t

AVQV

t

ACC

Address Valid to Output Valid

E=V

IL

,

G=V

IL

Max 70 90 ns

t

ELQX

(1)

t

LZ

Chip Enable Low to Output Transition G = V

IL

Min 0 0 ns

t

ELQV

t

CE

Chip Enable Low to Output Valid

G=V

IL

Max 70 90 ns

t

GLQX

(1)

t

OLZ

Output Enable Low to Output

Transition

E=V

IL

Min 0 0 ns

t

GLQV

t

OE

Output Enable Low to Output Valid

E=V

IL

Max 30 35 ns

t

EHQZ

(1)

t

HZ

Chip Enable High to Output Hi-Z G = V

IL

Max 20 20 ns

t

GHQZ

(1)

t

DF

Output Enable High to Output Hi-Z

E=V

IL

Max 20 20 ns

t

EHQX

t

GHQX

t

AXQX

t

OH

Chip Enable, Output Enable or

Address Transition to Output Transition

Min 0 0 ns

Page 14

M29F080A

14/21

Figure 9. Write AC Waveforms, Write Enable Controlled

AI00524

E

G

W

A0-A19

DQ0-DQ7

VALID

VALID

V

CC

tVCHEL

tWHEH

tWHWL

tELWL

tAVWL

tWHGL

tWLAX

tWHDX

tAVAV

tDVWH

tWLWHtGHWL

RB

tWHRL

Table 12. Write AC Characteristics, Write Enable Controlled

(TA= 0 to 70 °C, –40 to 85 °C or –40 to 125 °C)

Note: 1. Sampled only, not 100% tested.

Symbol Alt Parameter

M29F080A

Unit

70 90 / 120

t

AVAV

t

WC

Address Valid to Next Address Valid Min 70 90 ns

t

ELWL

t

CS

Chip Enable Low to Write Enable Low Min 0 0 ns

t

WLWH

t

WP

Write Enable Low to Write Enable High Min 45 45 ns

t

DVWH

t

DS

Input Valid to Write Enable High Min 30 45 ns

t

WHDX

t

DH

Write Enable High to Input Transition Min 0 0 ns

t

WHEH

t

CH

Write Enable High to Chip Enable High Min 0 0 ns

t

WHWL

t

WPH

Write Enable High to Write Enable Low Min 20 20 ns

t

AVWL

t

AS

Address Valid to Write Enable Low Min 0 0 ns

t

WLAX

t

AH

Write Enable Low to Address Transition Min 45 45 ns

t

GHWL

Output Enable High to Write Enable Low Min 0 0 ns

t

WHGL

t

OEH

Write Enable High to Output Enable Low Min 0 0 ns

t

WHRL

(1)

t

BUSY

Program/Erase Valid to RB Low Max 30 35 ns

t

VCHEL

t

VCS

VCCHigh to Chip Enable Low

Min 50 50 µs

Page 15

15/21

M29F080A

Table 13. Write AC Characteristics, Chip Enable Controlled

(TA= 0 to 70 °C, –40 to 85 °C or –40 to 125 °C)

Note: 1. Sampled only, not 100% tested.

Symbol Alt Parameter

M29F080A

Unit

70 90 / 120

t

AVAV

t

WC

Address Valid to Next Address Valid Min 70 90 ns

t

WLEL

t

WS

Write Enable Low to Chip Enable Low Min 0 0 ns

t

ELEH

t

CP

Chip Enable Low to Chip Enable High Min 45 45 ns

t

DVEH

t

DS

Input Valid to Chip Enable High Min 30 45 ns

t

EHDX

t

DH

Chip Enable High to Input Transition Min 0 0 ns

t

EHWH

t

WH

Chip Enable High to Write Enable High Min 0 0 ns

t

EHEL

t

CPH

Chip Enable High to Chip Enable Low Min 20 20 ns

t

AVEL

t

AS

Address Valid to Chip Enable Low Min 0 0 ns

t

ELAX

t

AH

Chip Enable Low to Address Transition Min 45 45 ns

t

GHEL

Output Enable High Chip Enable Low Min 0 0 ns

t

EHGL

t

OEH

Chip Enable High to Output Enable Low Min 0 0 ns

t

EHRL

(1)

t

BUSY

Program/Erase Valid to RB Low Max 30 35 ns

t

VCHWL

t

VCS

VCCHigh to Write Enable Low

Min 50 50 µs

Figure 10. Write AC Waveforms, Chip Enable Controlled

AI00525

E

G

W

A0-A19

DQ0-DQ7

VALID

VALID

V

CC

tVCHWL

tEHWH

tEHEL

tWLEL

tAVEL

tEHGL

tELAX

tEHDX

tAVAV

tDVEH

tELEHtGHEL

RB

tEHRL

Page 16

M29F080A

16/21

Table 14. Reset/Block Temporary Unprotect AC Characteristics

(TA= 0 to 70 °C, –40 to 85 °C or –40 to 125 °C)

Note: 1. Sampled only, not 100% tested.

Symbol Alt Parameter

M29F080A

Unit

70 90 / 120

t

PHWL

(1)

t

PHEL

t

PHGL

(1)

t

RH

RP High to Write Enable Low, Chip Enable Low,

Output Enable Low

Min 50 50 ns

t

RHWL

(1)

t

RHEL

(1)

t

RHGL

(1)

t

RB

RB High to Write Enable Low, Chip Enable Low,

Output Enable Low

Min 0 0 ns

t

PLPX

t

RP

RP Pulse Width Min 500 500 ns

t

PLYH

(1)

t

READY

RP Low to Read Mode Max 10 10 µs

t

PHPHH

(1)

t

VIDR

RP Rise Time to V

ID

Min 500 500 ns

Figure 11. Reset/Block Temporary Unprotect AC Waveforms

AI02931

RB

W,

RP

tPLPX

tPHWL, tPHEL, tPHGL

tPLYH

tPHPHH

E, G

tRHWL, tRHEL, tRHGL

Page 17

17/21

M29F080A

Table 15. OrderingInformation Scheme

Note: The last two characters of the ordering code may be replaced by a letter code for preprogrammed

parts, otherwise devices are shipped from the factory with the memory content bits erased to ’1’.

For a list of available options (Speed, Package, etc...) or for further information on any aspect of this device, please contact the ST Sales Office nearest to you.

Example: M29F080A 70 N 1 T

Device Type

M29

Operating Voltage

F=V

CC

=5V±10%

Device Function

080A = 8 Mbit (1Mb x8), Uniform Block

Speed

70 = 70 ns

90 = 90 ns

120 = 120ns

Package

N = TSOP40: 10 x 20 mm

M = SO44

Temperature Range

1=0to70°C

3 = –40 to 125 °C

6=–40to85°C

Option

T = Tape& Reel Packing

Page 18

M29F080A

18/21

Table 16. Revision History

Date Revision Details

July 1999 First Issue

09/21/99

Removed 55ns speed option

Chip Erase Max. specification added (Table6)

Block Erase Max. specification added (Table6)

Program Max. specification added (Table 6)

Chip Program Max. specification added (Table6)

I

CC1

Typ.specification added (Table 10)

I

CC3

Typ.specification added (Table 10)

10/04/99

I

CC3

TestCondition change (Table10)

11/12/99 Block Protection and Unprotection paragraph change

01/14/00 Command Interface paragraph change

03/30/00

New document template

Document type: from Preliminary Data to Data Sheet

Status Register bit DQ5 clarification

Data Polling Flowchart diagram change (Figure 4)

Data Toggle Flowchart diagram change (Figure 5)

Restrictive Read AC Characteristics removed

TSOP40 Package mechanical data change (Table17)

SO44 Package mechanical data change (Table18)

Page 19

19/21

M29F080A

Table 17. TSOP40 - 40 lead Plastic Thin Small Outline, 10 x 20mm, Package Mechanical Data

Symbol

mm inches

Typ Min Max Typ Min Max

A 1.20 0.0472

A1 0.05 0.15 0.0020 0.0059

A2 0.95 1.05 0.0374 0.0413

B 0.17 0.27 0.0067 0.0106

C 0.10 0.21 0.0039 0.0083

D 19.80 20.20 0.7795 0.7953

D1 18.30 18.50 0.7205 0.7283

E 9.90 10.10 0.3898 0.3976

e 0.50 – – 0.0197 – –

L 0.50 0.70 0.0197 0.0276

α 0° 5° 0° 5°

N40 40

CP 0.10 0.0039

Figure 12. TSOP40 - 40 lead Plastic Thin Small Outline, 10 x 20 mm, Package Outline

Drawing is not to scale.

TSOP-a

D1

E

1N

CP

B

e

A2

A

N/2

D

DIE

C

LA1 α

Page 20

M29F080A

20/21

Figure 13. SO44 - 44 lead Plastic Small Outline, 525 mils body width, Package Outline

Drawing is not to scale.

SO-b

E

N

CP

B

e

A2

D

C

LA1 α

H

A

1

Table 18. SO44 - 44 lead Plastic Small Outline, 525 mils body width, Package Mechanical Data

Symbol

mm inches

Typ Min Max Typ Min Max

A 2.42 2.62 0.0953 0.1031

A1 0.22 0.23 0.0087 0.0091

A2 2.25 2.35 0.0886 0.0925

B 0.50 0.0197

C 0.10 0.25 0.0039 0.0098

D 28.10 28.30 1.1063 1.1142

E 13.20 13.40 0.5197 0.5276

e 1.27 – – 0.0500 – –

H 15.90 16.10 0.6260 0.6339

L 0.80 – – 0.0315 – –

α 3° ––3°––

N44 44

CP 0.10 0.0039

Page 21

21/21

M29F080A

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use ofsuch information nor for any infringement of patents or other rights of third parties which may result from itsuse. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is registered trademark of STMicroelectronics

2000 STMicroelectronics - All Rights Reserved

All other names are the property of their respective owners.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco -

Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

Loading...

Loading...