Datasheet M28F101-120N1, M28F101-100P1, M28F101-150P6, M28F101-150P1, M28F101-150K1 Datasheet (SGS Thomson Microelectronics)

Page 1

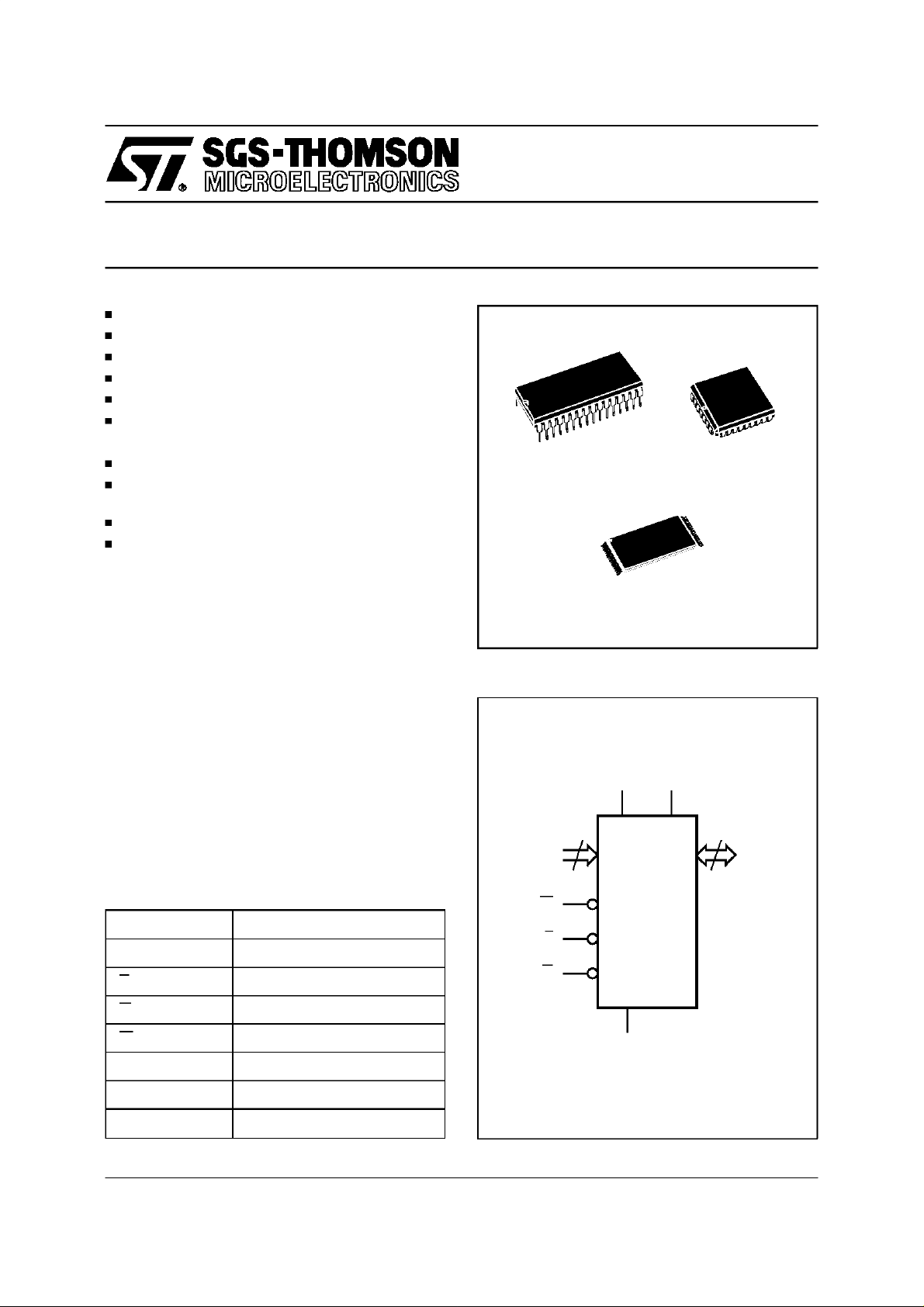

1 Mb (128K x 8, Chip Erase) FLASH MEMORY

5V ±10% SUPPLY VOLTAGE

12V PROGRAMMINGVOLTAGE

FASTACCESSTIME: 70ns

BYTEPROGRAMINGTIME: 10µs typical

ELECTRICALCHIP ERASE in 1s RANGE

LOW POWERCONSUMPTION

– Stand-byCurrent: 100µAmax

10,000ERASE/PROGRAM CYCLES

INTEGRATED ERASE/PROGRAM-STOP

TIMER

OTPCOMPATIBLE PACKAGESand PINOUTS

ELECTRONIC SIGNATURE

– ManufacturerCode: 20h

– DeviceCode: 07h

DESCRIPTION

The M28F101 FLASH Memory is a non-volatile

memory which may be erased electrically at the

chip level and programmed byte-by-byte. It is organisedas128K bytesof8 bits.It usesacommand

registerarchitectureto select the operating modes

and thus provides a simple microprocessor interface.The M28F101 FLASHMemory is suitablefor

applications where the memory has to be reprogrammed in the equipment. The access time of

70ns makes the device suitable for use in high

speedmicroprocessor systems.

32

1

PDIP32 (P)

TSOP32 (N)

8 x 20 mm

Figure 1. Logic Diagram

V

CC

17

A0-A16

M28F101

PLCC32 (K)

V

PP

8

DQ0-DQ7

Table 1. Signal Names

A0-A16 Address Inputs

DQ0-DQ7 Data Inputs / Outputs

E Chip Enable

G Output Enable

W Write Enable

V

PP

V

CC

V

SS

April 1997 1/23

Program Supply

SupplyVoltage

Ground

W

M28F101

E

G

V

SS

AI00666B

Page 2

M28F101

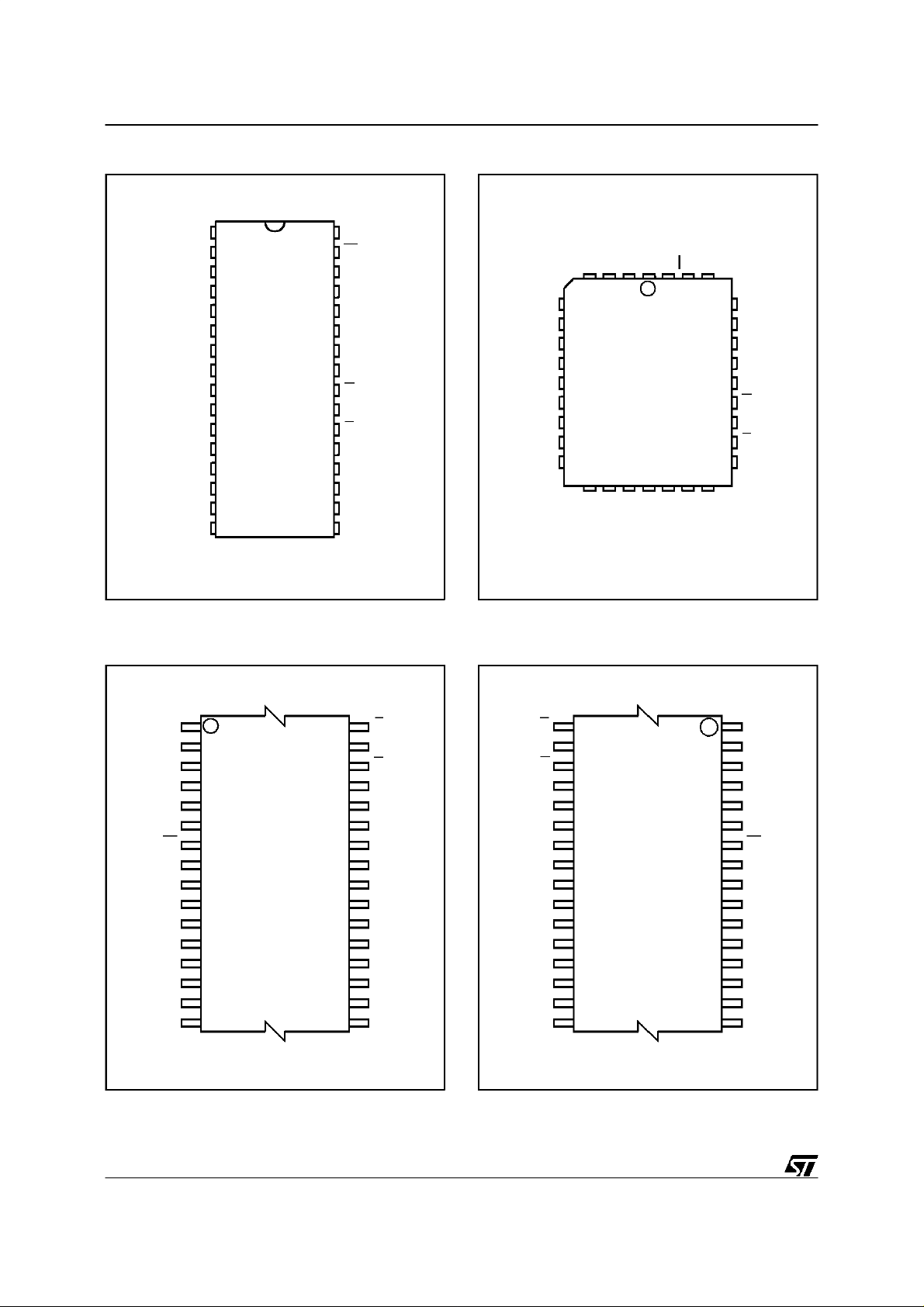

Figure2A. DIP Pin Connections

V

1

PP

2

A15

3

A12

4

A7

5

A6

6

A5

7

A4

8

9

10

11

12

13

M28F101

A3

A2

A1

A0

DQ0

14

DQ2

15

16

SS

Warning: NC = Not Connected. Warning: NC = Not Connected.

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

AI00667

V

CC

WA16

NC

A14

A13

A8

A9

A11

G

A10

E

DQ7

DQ6

DQ5DQ1

DQ4

DQ3V

Figure2B. LCC Pin Connections

A16

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

A12

9

DQ1

VPPV

A15

1

M28F101

17

SS

V

DQ2

DQ3

32

CC

DQ4

W

DQ5

NC

25

DQ6

A14

A13

A8

A9

A11

G

A10

E

DQ7

AI00668

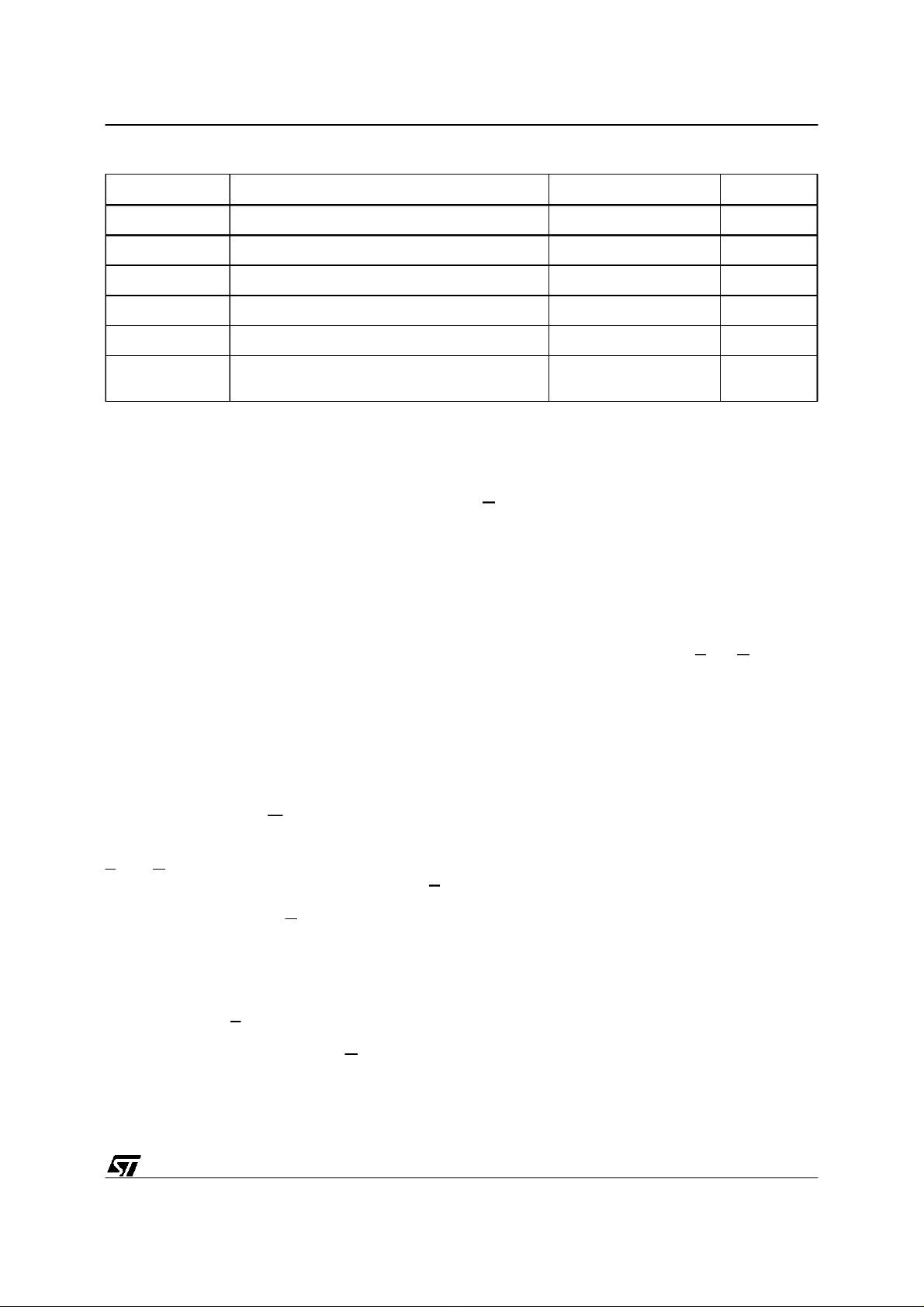

Figure2C. TSOP Pin Connections

A11 G

A9

A8

A13

A14

NC

V

CC

V

PP

A16

A15

A12

A7

A6

A5

A4 A3

Warning: NC = Not Connected.

1

W

8

9

16 17

M28F101

(Normal)

32

25

24

AI00669B

A10

E

DQ7

DQ6

DQ5

DQ4

DQ3

V

SS

DQ2

DQ1

DQ0

A0

A1

A2

Figure2D. TSOP Reverse Pin Connections

1

A10

E

DQ7

DQ6

DQ5

DQ4

DQ3

V

SS

8

9

M28F101

(Reverse)

DQ2

DQ1

DQ0

A0

A1

A2

16 17

Warning: NC = Not Connected.

AI00670C

32

25

24

A11G

A9

A8

A13

A14

NC

W

V

CC

V

PP

A16

A15

A12

A7

A6

A5

A4A3

2/23

Page 3

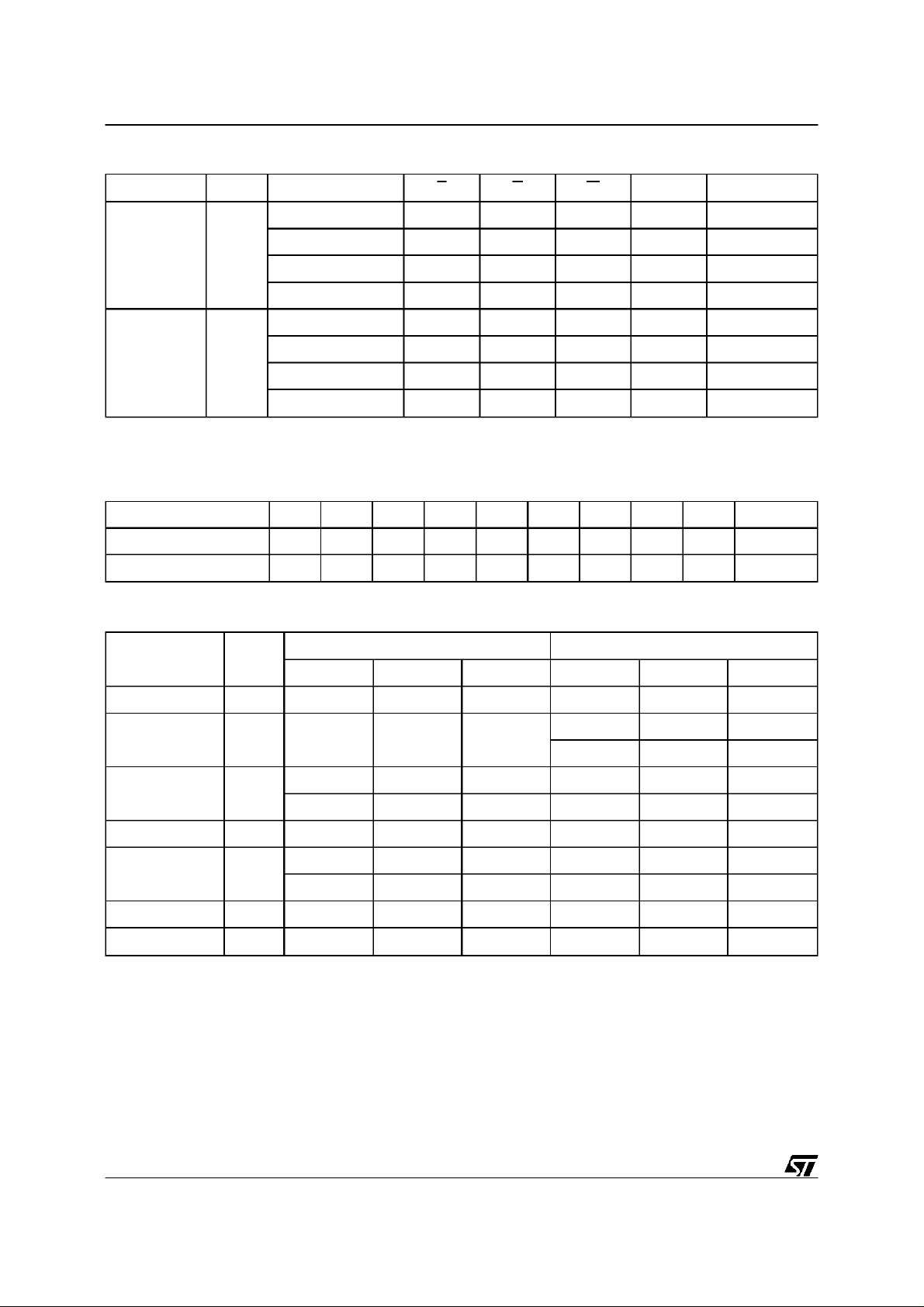

Table 2. AbsoluteMaximumRatings

Symbol Parameter Value Unit

M28F101

T

A

T

STG

V

IO

V

CC

V

A9

V

PP

Note: Except for therating ”Operating Temperature Range”, stressesabove those listed in the Table”Absolute Maximum Ratings” may

cause permanent damage to the device. These are stress ratings only and operation ofthe device at these or any otherconditions above

those indicated in the Operating sections of this specification is not implied. Exposure to Absolute Maximum Rating conditions for extended

periods may affect device reliability.Refer also to the SGS-THOMSON SURE Program and other relevant quality documents.

DEVICE OPERATION

The M28F101FLASHMemoryemploys a technologysimilar to a 1 MegabitEPROMbut adds to the

devicefunctionalityby providingelectrical erasure

and programming. These functions are managed

by a command register. The functions that are

addressed via the command register depend on

the voltage applied to the V

input. When V

commandregisteris disabled and M28F101functions as a read only memory providing operating

modes similar to an EPROM (Read, Output Disable, Electronic Signature Read and Standby).

When V

is raised to 12V the command regsiter

PP

isenabledand this provides,inaddition,Eraseand

Programoperations.

Ambient Operating Temperature –40 to 125 °C

Storage Temperature –65 to150 °C

Input or Output Voltages –0.6 to 7 V

Supply Voltage –0.6 to 7 V

A9 Voltage –0.6 to 13.5 V

Program Supply Voltage, during Erase

or Programming

–0.6 to 14 V

Output Disable Mode. When the Output Enable

(G) is High the outputs are in a high impedance

state.

ElectronicSignatureMode.Thismodeallowsthe

read outof two binarycodesfrom thedevice which

identify the manufacturer and device type. This

mode is intended for use by programming equip-

, program voltage,

is less than or equal to 6.5V,the

PP

PP

mentto automaticallyselect the correct erase and

programmingalgorithms.TheElectronicSignature

Modeis activewhen a high voltage (11.5Vto 13V)

isappliedto addresslineA9with EandG Low.With

A0 Low the output data is the manufacturercode,

whenA0 isHigh the outputis the devicetype code.

All other address lines should be maintained Low

while reading the codes. The electronicsignature

may also be accessedin Read/Write modes.

READONLYMODES, V

PP

≤ 6.5V

For all Read Only Modes, except Standby Mode,

the Write Enable input W should be High. In the

StandbyMode this input is don’t care.

ReadMode. TheM28F101has two enable inputs,

E and G, both of which must be Low in order to

output data from the memory. TheChipEnable (E)

is the powercontrol and shouldbe used for device

selection. Output Enable (G) is the output control

and should be used to gate data on to the output,

independantof the deviceselection.

Standby Mode. In the Standby Mode the maximum supply current is reduced. The device is

placedin the StandbyMode by applyinga High to

the Chip Enable (E) input. When in the Standby

Mode the outputs are in a high impedance state,

independantof the OutputEnable (G) input.

READ/WRITEMODES, 11.4V ≤ V

When V

is High both read and write operations

PP

≤ 12.6V

PP

may be performed. These are defined by the contents of an internal commandregister.Commands

may be written to this register to set-up and execute,Erase,EraseVerify,Program,ProgramVerify

and Reset modes. Each of these modes needs 2

cycles. Eah mode starts with a write operation to

set-upthe command,this is followedbyeither read

or write operations. The device expects the first

cycle to be a writeoperation and does not corrupt

data at any location in the memory.Read mode is

set-upwith one cycleonly and may be followed by

any number of read operations to output data.

ElectronicSignatureRead modeis set-up with one

cycle and followed by a read cycle to output the

manufactureror devicecodes.

3/23

Page 4

M28F101

Table 3. Operations

ReadOnly V

(1)

V

PP

PPL

Operation E G W A9 DQ0 - DQ7

Output Disable V

Electronic Signature V

(2)

Read/Write

V

PPH

Output Disable V

Notes: 1. X = VILor VIH.

2. Refer also tothe Command table.

Table4. Electronic Signature

Identifier A0 DQ7 DQ6 DQ5 DQ4 DQ3 DQ2 DQ1 DQ0 Hex Data

Manufacturer’s Code V

Device Code V

IL

IH

Read V

Standby V

Read V

Write V

Standby V

IL

IL

IH

IL

IL

IL

IL

IH

V

IL

V

IH

V

IH

V

IH

A9 Data Output

X Hi-Z

X X X Hi-Z

V

IL

V

IL

V

IH

V

IH

V

IH

V

IH

V

ID

Codes

A9 Data Output

VILPulse A9 Data Input

V

IH

X Hi-Z

X X X Hi-Z

00100000 20h

00000111 07h

Table 5. Commands

Command Cycles

(1)

1st Cycle 2nd Cycle

Operation A0-A16 DQ0-DQ7 Operation A0-A16 DQ0-DQ7

Read 1 Write X 00h

Electronic

Signature

(2)

Setup Erase/

2 Write X 90h

2

Write X 20h

Read 00000h 20h

Read 00001h 07h

Erase Write X 20h

Erase Verify 2 Write A0-A16 A0h Read X Data Output

Setup Program/

2

Write X 40h

Program Write A0-A16 Data Input

Program Verify 2 Write X C0h Read X Data Output

Reset 2 Write X FFh Write X FFh

Notes: 1. X= VILor VIH.

2. Refer also to the Electronic Signature table.

4/23

Page 5

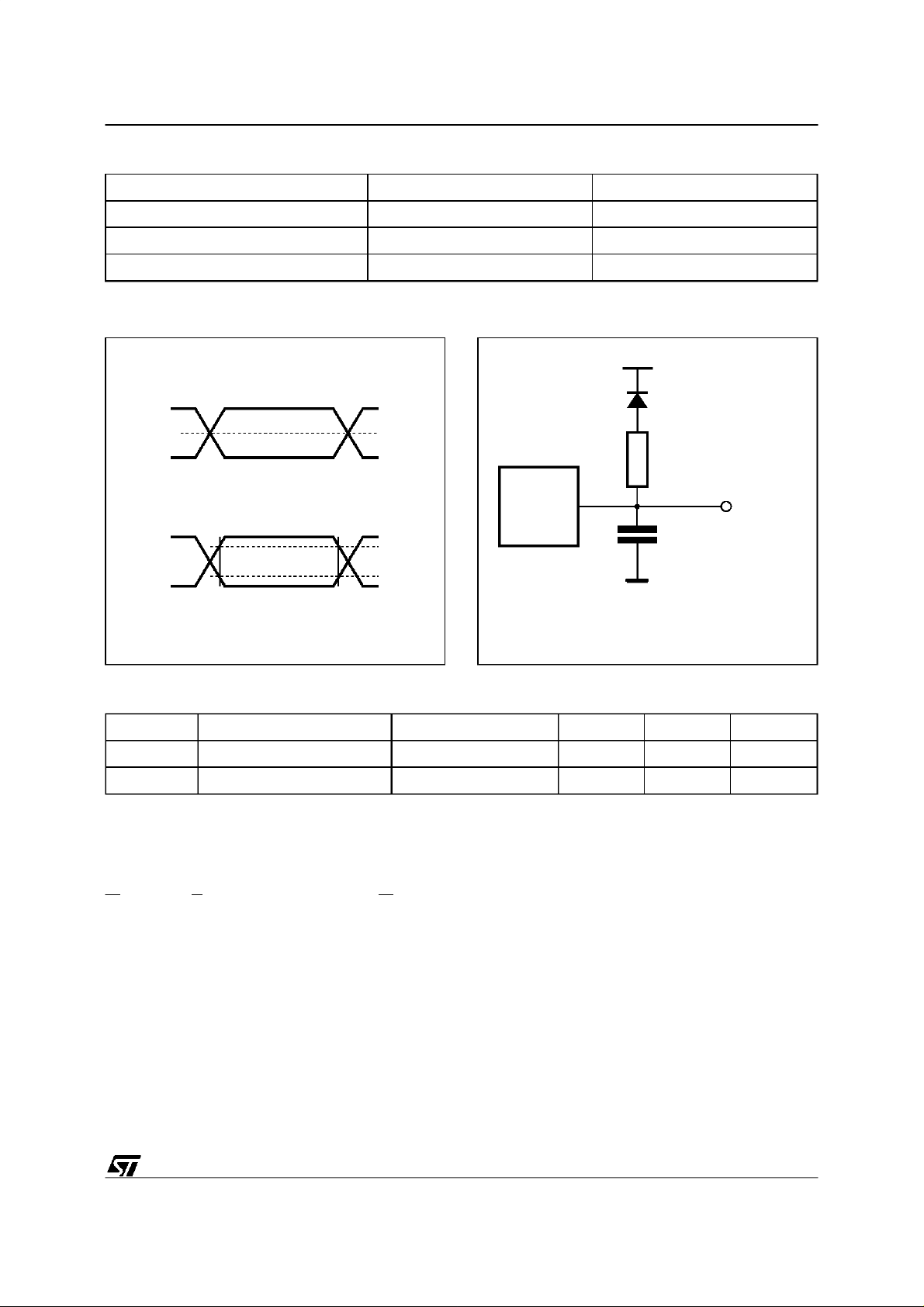

Table6. AC MeasurementConditions

SRAM Interface Levels EPROM Interface Levels

Input Rise and Fall Times ≤ 10ns ≤ 10ns

Input Pulse Voltages 0 to 3V 0.45V to 2.4V

Input and Output Timing Ref. Voltages 1.5V 0.8V and 2V

M28F101

Figure 3. AC TestingInput Output Waveform

SRAM Interface

3V

1.5V

0V

EPROM Interface

2.4V

0.45V

Table 7. Capacitance

Symbol Parameter Test Condition Min Max Unit

C

IN

C

OUT

Note: 1. Sampled only, not 100% test.ed

Input Capacitance VIN=0V 6 pF

Output Capacitance V

(1)

(TA=25°C, f = 1 MHz )

2.0V

0.8V

AI01275

Figure 4. ACTesting Load Circuit

1.3V

1N914

3.3kΩ

DEVICE

UNDER

TEST

CL= 30pF or 100pF

CL= 30pF for SRAM Interface

CL= 100pF for EPROM Interface

CLincludes JIG capacitance

=0V 12 pF

OUT

OUT

AI01276

READ/WRITE MODES (cont’d)

Awritetothecommandregisterismadebybringing

WLowwhileEisLow.ThefallingedgeofW latches

Addresses, while the rising edge latches Data,

which are used for those commands that require

address inputs, command input or provide data

output.

The supply voltage V

canbe applied in any order. When the device

V

PP

is powered up or when V

and the program voltage

CC

is ≤ 6.5V the contents

PP

of the command register defaults to 00h, thus

automaticallysetting-up Read operations. In addition a specific command may be used to set the

commandregister to 00h for reading the memory.

Thesystem designer may chose to provide a constanthigh V

all operations,or toswitchthe V

and use the register commands for

PP

fromlow to high

PP

only when needing to eraseor program the memory. Allcommandregisteraccess isinhibited when

falls below the Erase/Write Lockout Voltage

V

CC

) of 2.5V.

(V

LKO

If the device is deselected during Erasure, Programmingor Verification it will draw active supply

currentsuntil the operations are terminated.

The device is protected against stress caused by

long erase or program times. If the end of Erase or

Programming operations are not terminated by a

Verifycycle within a maximum time permitted, an

internal stop timer automatically stops the operation.The deviceremainsin an inactivestate, ready

to start a Verifyor ResetMode operation.

5/23

Page 6

M28F101

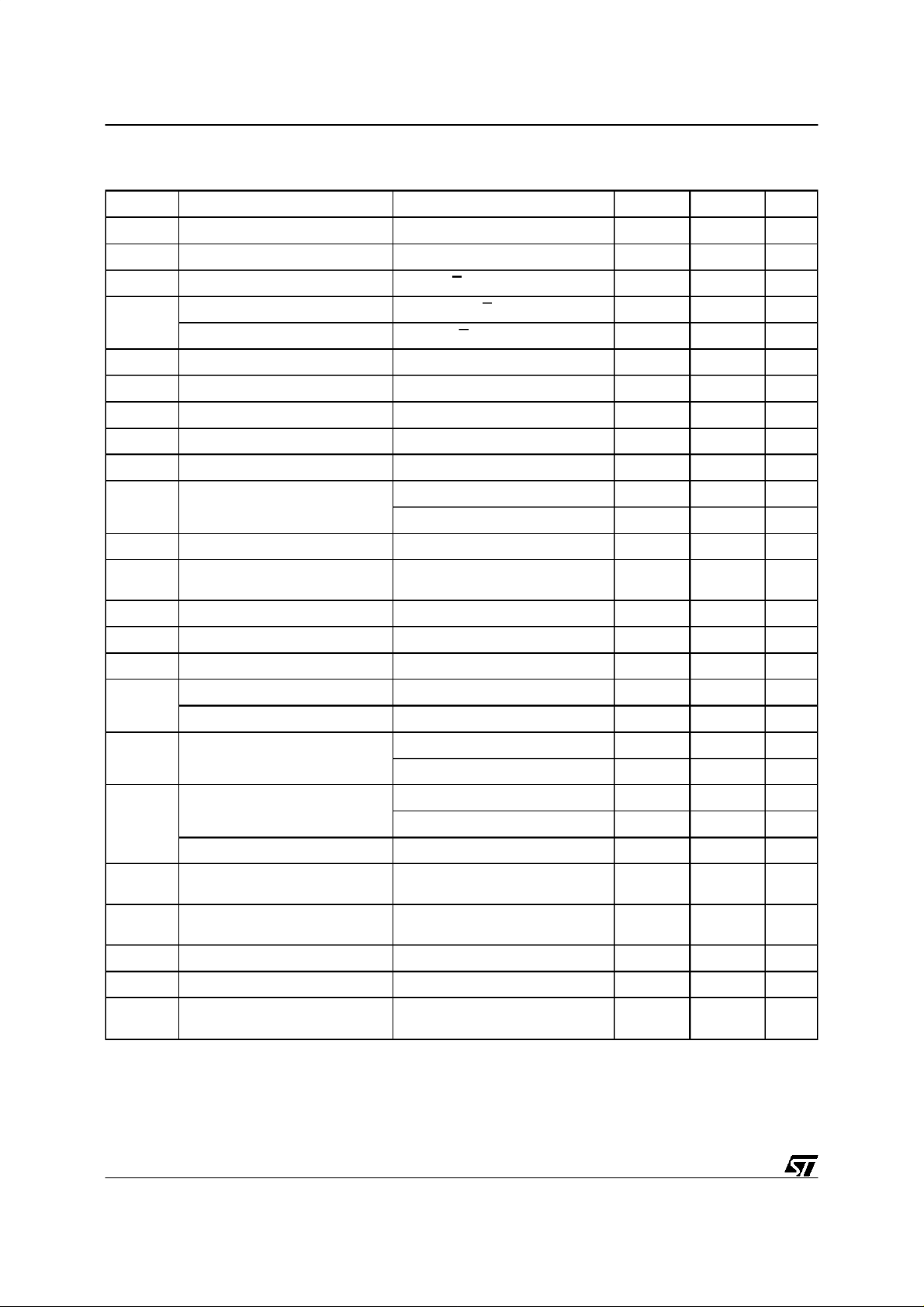

Table8. DC Characteristics

= 0 to 70°C, –40to 85 °C or–40 to 125 °C;VCC=5V±10%)

(T

A

Symbol Parameter TestCondition Min Max Unit

I

I

LO

I

CC

I

CC1

I

CC2

I

CC3

I

CC4

I

CC5

I

LPP

I

PP

I

PP1

I

PP2

I

PP3

I

PP4

V

V

V

V

OH

V

PPL

V

PPH

V

I

ID

V

LKO

Note: 1. Not 100% tested.Characterisation Data available.

Input Leakage Current 0V ≤ VIN≤ V

LI

Output Leakage Current 0V ≤ V

OUT

≤ V

CC

CC

Supply Current (Read) E = VIL, f = 6MHz 30 mA

Supply Current (Standby) TTL E = V

Supply Current (Standby) CMOS E = V

(1)

Supply Current (Programming) DuringProgramming 10 mA

(1)

Supply Current (Program Verify) During Verify 15 mA

(1)

Supply Current (Erase) During Erasure 15 mA

(1)

Supply Current (Erase Verify) During Erase Verify 15 mA

Program Leakage Current VPP≤ V

Program Current (Read or

Standby)

(1)

Program Current (Programming) VPP=V

(1)

Program Current (Program

Verify)

(1)

Program Current (Erase) VPP=V

(1)

Program Current (Erase Verify) VPP=V

Input Low Voltage –0.5 0.8 V

IL

Input High VoltageTTL 2 VCC+ 0.5 V

IH

PPH

V

PP=VPPH

PPH

Input High Voltage CMOS 0.7 V

= 5.8mA (grade 1) 0.45 V

I

Output Low Voltage

OL

Output High Voltage CMOS

Output High Voltage TTL I

OL

I

= 2.1mA (grade 6) 0.45 V

OL

I

OH

I

OH

OH

Program Voltage (Read

Operations)

Program Voltage (Read/Write

Operations)

A9 Voltage (Electronic Signature) 11.5 13 V

ID

(1)

A9 Current (Electronic Signature) A9 = V

Supply Voltage, Erase/Program

Lock-out

IH

± 0.2V 50 µA

CC

CC

V

PP>VCC

V

≤ V

PP

CC

, During Programming 30 mA

, During Verify 5 mA

, During Erase 30 mA

PPH

, During Erase Verify 5 mA

CC

= –100µA 4.1 V

= –2.5mA 0.85 V

CC

= –2.5mA 2.4 V

0 6.5 V

11.4 12.6 V

ID

2.5 V

±1 µA

±10 µA

1mA

±10 µA

120 µA

±10 µA

VCC+ 0.5 V

200 µA

V

6/23

Page 7

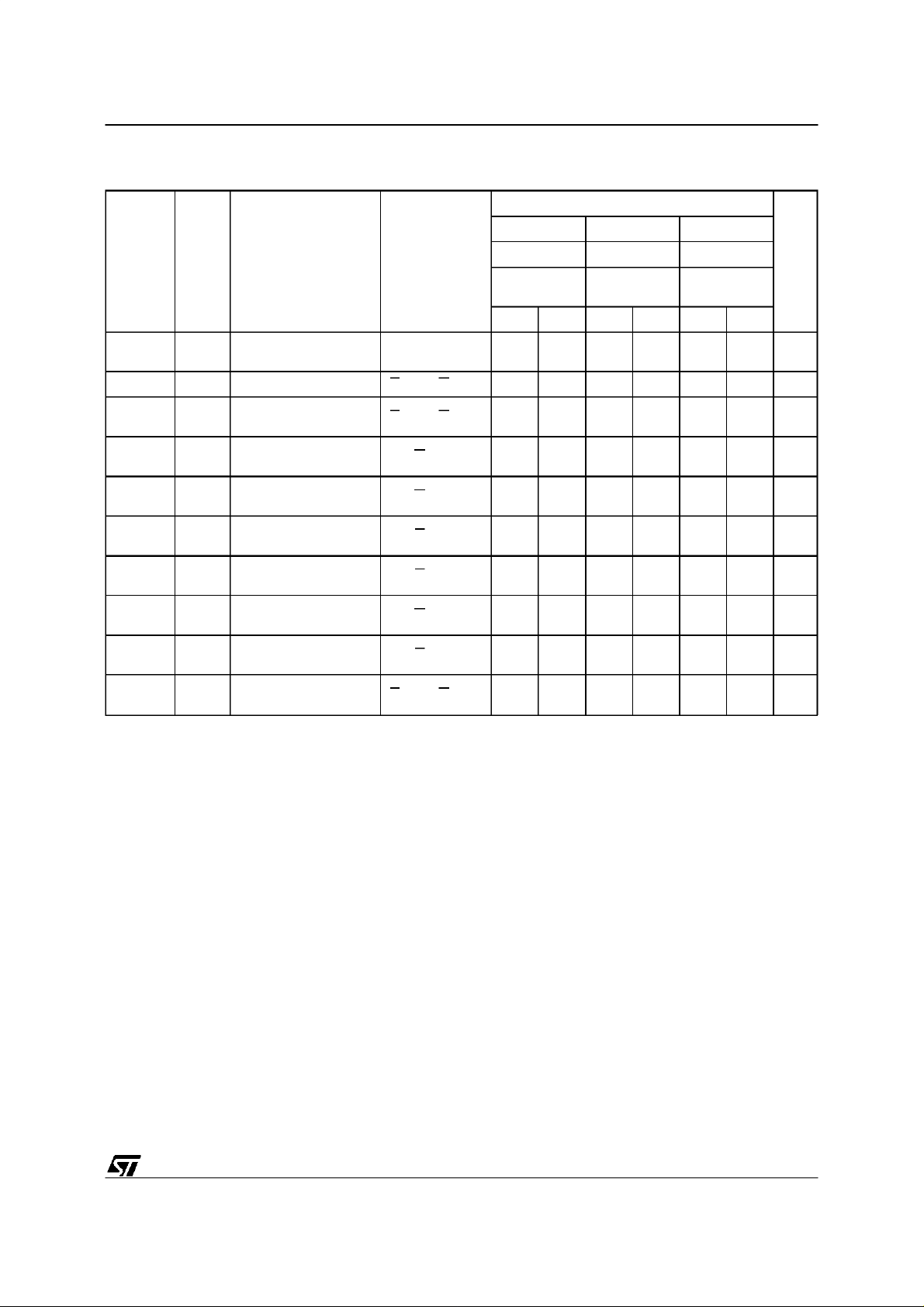

Table 9A. Read Only Mode AC Characteristics

= 0 to70 °C, –40 to 85 °C or –40 to125 °C; 0V ≤ VPP≤ 6.5V)

(T

A

Symbol Alt Parameter TestCondition

t

WHGL

t

AVAV

t

AVQV

(1)

t

ELQX

t

ELQV

(1)

t

GLQX

t

GLQV

(1)

t

EHQZ

(1)

t

GHQZ

t

AXQX

Note: 1. Sampled only, not 100% tested

Write Enable High to

Output Enable Low

t

Read Cycle Time E = VIL,G=VIL70 90 100 ns

RC

Address Validto

t

ACC

Output Valid

Chip Enable Low to

t

LZ

Output Transition

Chip Enable Low to

t

CE

Output Valid

Output Enable Low to

t

OLZ

Output Transition

Output Enable Low to

t

OE

Output Valid

Chip Enable High to

Output Hi-Z

Output Enable High to

t

DF

Output Hi-Z

Address Transitionto

t

OH

Output Transition

E=V

G=V

G=V

G=V

E=V

,G=V

IL

E=V

E=V

E=V

,G=V

IL

IL

IL

IL

IL

IL

IL

IL

IL

M28F101

M28F101

-70 -90 -100

=5V±5% VCC=5V±10% VCC=5V±10%

V

CC

SRAM

Interface

EPROM

Interface

EPROM

Interface

Min Max Min Max Min Max

666µs

70 90 100 ns

000ns

70 90 100 ns

000ns

40 40 45 ns

0 30 0 45 0 45 ns

0 30 0 30 0 30 ns

000ns

Unit

Read Mode. The Read Mode is the default at

power up or may be set-up by writing 00h to the

command register. Subsequent read operations

outputdatafromthememory.Thememoryremains

in the Read Mode until a new commandis written

to the command register.

ElectronicSignatureMode. In order to select the

correct erase and programming algorithms for onboard programming, the manufacturerand device

codesmay beread directly. It isnot neccessaryto

apply a high voltage to A9 when using the command register. The Electronic Signature Mode is

set-upby writing 90htothe commandregister.The

following read cycles,with address inputs00000h

or 00001h, output the manufactureror devicetype

codes.The command is terminated by writinganothervalid command to the commandregister(for

exampleReset).

7/23

Page 8

M28F101

Table 9B. Read Only Mode AC Characteristics

=0 to 70 °C, –40 to 85 °C or –40 to 125 °C; 0V ≤ VPP≤ 6.5V)

((T

A

Symbol Alt Parameter Test Condition

t

WHGL

t

AVAV

t

AVQV

(1)

t

ELQX

t

ELQV

(1)

t

GLQX

t

GLQV

(1)

t

EHQZ

(1)

t

GHQZ

t

AXQX

Note: 1. Sampled only, not 100% tested

Write Enable High to

Output Enable Low

t

Read Cycle Time E = VIL,G=VIL120 150 200 ns

RC

Address Validto

t

ACC

Output Valid

Chip Enable Low to

t

LZ

Output Transition

Chip Enable Low to

t

CE

Output Valid

Output Enable Low to

t

OLZ

Output Transition

Output Enable Low to

t

OE

Output Valid

Chip Enable High to

Output Hi-Z

Output Enable High to

t

DF

Output Hi-Z

Address Transitionto

t

OH

Output Transition

E=V

G=V

G=V

G=V

E=V

,G=V

IL

E=V

E=V

E=V

,G=V

IL

IL

IL

IL

IL

IL

IL

IL

IL

M28F101

-120 -150 -200

=5V±10% VCC=5V±10% VCC=5V±10%

V

CC

EPROM

Interface

EPROM

Interface

EPROM

Interface

Unit

Min Max Min Max Min Max

666µs

120 150 200 ns

000ns

120 150 200 ns

000ns

50 55 60 ns

055055060ns

030035040ns

000ns

Erase and Erase Verify Modes. The memory is

erased by first Programming all bytes to 00h, the

Erase command then erases them to FFh. The

Erase Verify command is then used to read the

memory byte-by-byte for a content of FFh. The

Erase Mode is set-up by writing 20h to the command register. The write cycle is then repeated to

start the erase operation. Erasure starts on the

rising edge of W during this secondcycle.Eraseis

followed by an Erase Verify which reads an addressedbyte.

8/23

Erase Verify Mode is set-up by writing A0h to the

commandregisterand at the same time supplying

the address of the byte to be verified. The rising

edgeof W duringthe set-up of the first EraseVerify

Mode stops the Erase operation. The following

read cycle is made with an internally generated

marginvoltageapplied; readingFFh indicatesthat

all bits of the addressed byte are fullyerased.The

whole contentsof the memory are verified by repeating theErase VerifyOperation,first writingthe

set-upcode A0h with the address of the byte to be

verified and then reading the byte contents in a

secondread cycle.

Page 9

Figure5. Read Mode ACWaveforms

A0-A16

E

G

tGLQV

tGLQX

tAVAV

tAVQV tAXQX

tELQV

tELQX

tEHQZ

tGHQZ

M28F101

DQ0-DQ7

Figure6. Read Command Waveforms

V

PP

tVPHEL

A0-A16

E

tELWL tWHEH

G

tGHWL

W

tWLWH

DATA OUT

AI00671

VALID

tAVQV

tELQV tEHQZ

tWHGL

tGLQV

tAXQX

tGHQZ

DQ0-DQ7 DATA OUTCOMMAND

tWHDXtDVWH

READREAD SET-UP

AI00672

9/23

Page 10

M28F101

Figure7. ElectronicSignatureCommand Waveforms

V

PP

tVPHEL

A0-A16

E

tELWL tWHEH

G

tGHWL

W

tWLWH

tWHDXtDVWH

DQ0-DQ7 DATA OUTCOMMAND

READ

ELECTRONIC

SIGNATURE SET-UP

READ/WRITE MODES (cont’d)

As the Erase algorithmflow chartshows,whenthe

data read during Erase Verify is not FFh, another

Eraseoperationis performedand verification continuesfromthe addressofthelastverifiedbyte. The

command is terminated by writing another valid

command to the command register (for example

Programor Reset).

Program and Program Verify Modes. The ProgramModeis set-upbywriting40htothecommand

register. This is followed by a second write cycle

which latches the address and data of the byte to

be programmed.The rising edge of W during this

secind cycle starts the programming operation.

Programmingisfollowedby aProgramVerify ofthe

datawritten.

00000h-00001h

tAVQV

tELQV tEHQZ

tWHGL

tGLQV

READ

MANUFACTURER

OR DEVICE

tAXQX

tGHQZ

AI00673

ProgramVerify Modeisset-upbywritingC0hto the

commandregister. The rising edgeof W duringthe

set-up of the ProgramVerify Mode stops the Programming operation. The following read cycle, of

the address already latched during programming,

is made with an internallygenerated margin voltageapplied,readingvaliddataindicatesthatallbits

havebeen programmed.

ResetMode.Thiscommandis usedto safelyabort

Erase or Program Modes. The Reset Mode is

set-up and performed by writing FFh two times to

the command register. The command should be

followed by writing a valid command to the the

commandregister (for exampleRead).

10/23

Page 11

Table 10A. Read/Write Mode AC Characteristics, W and E Controlled

= 0 to70 °C, –40 to 85 °C or –40 to125 °C)

(T

A

M28F101

-70 -90 -100

Symbol Alt Parameter

t

VPHEL

t

VPHWL

t

WHWH3

t

AVWL

t

AVEL

t

WLAX

t

ELAX

t

ELWL

t

WLEL

t

GHWL

t

GHEL

t

DVWH

t

DVEH

t

WLWH

t

ELEH

t

WHDX

t

EHDX

t

WHWH1

t

EHEH1

t

WHWH2

t

WHEH

t

EHWH

t

WHWLtWPH

t

EHEL

t

WHGL

t

EHGL

t

AVQV

(1)

t

ELQX

t

ELQV

(1)

t

GLQX

t

GLQV

(1)

t

EHQZ

(1)

t

GHQZ

t

AXQX

Note: 1. Sampled only, not 100% tested.

VPPHigh to Chip Enable Low 1 1 1 µs

VPPHigh to Write Enable Low 1 1 1 µs

t

Write Cycle Time 70 90 100 ns

WC

t

Address Validto Write Enable Low 0 0 0 ns

AS

Address Validto Chip Enable Low 0 0 0 ns

t

Write Enable Low to Address Transition 40 40 40 ns

AH

Chip Enable Low to Address Transition 50 60 60 ns

t

Chip Enable Low to Write Enable Low 10 15 15 ns

CS

Write Enable Low to Chip Enable Low 0 0 0 ns

Output Enable High to Write Enable

Low

Output Enable High to ChipEnable Low 0 0 0 µs

t

Input Validto Write Enable High 30 40 40 ns

DS

Input Validto Chip Enable High 30 35 40 ns

Write Enable Low to Write Enable High

t

WP

(Write Pulse)

Chip Enable Low to Chip Enable High

(Write Pulse)

t

Write Enable High to InputTransition 10 10 10 ns

DH

Chip Enable High to Input Transition 10 10 10 ns

Duration of Program Operation 9.5 9.5 9.5 µs

Duration of Program Operation 9.5 9.5 9.5 µs

Duration of Erase Operation 9.5 9.5 9.5 ms

t

Write Enable High to Chip Enable High 0 0 0 ns

CH

Chip Enable High to WriteEnable High 0 0 0 ns

Write Enable High to Write Enable Low 20 20 20 ns

Chip Enable High to Chip Enable Low 20 20 20 ns

Write Enable High to Output Enable

Low

Chip Enable High to Output Enable Low 6 6 6 µs

t

Addess Validto data Output 70 90 100 ns

ACC

t

Chip Enable Low to Output Transition 0 0 0 ns

LZ

t

Chip Enable Low to Output Valid 70 90 100 ns

CE

t

Output Enable Low to OutputTransition 0 0 0 ns

OLZ

t

Output Enable Low to Output Valid 40 40 45 ns

OE

Chip Enable High to Output Hi-Z 30 40 40 ns

t

Output Enable High to Output Hi-Z 30 30 30 ns

DF

t

Address Transitionto Output Transition 0 0 0 ns

OH

=5V±5% VCC=5V±10% VCC=5V±10%

V

CC

SRAM

Interface

EPROM

Interface

Min Max Min Max Min Max

000µs

35 40 40 ns

35 45 45 ns

666µs

M28F101

Unit

EPROM

Interface

11/23

Page 12

M28F101

Table10B. Read/WriteMode AC Characteristics,W and E Controlled

= 0 to 70°C, –40to 85 °C or–40 to 125 °C)

(T

A

M28F101

-120 -150 -200

Symbol Alt Parameter

t

VPHEL

t

VPHWL

t

WHWH3

t

AVWL

t

AVEL

t

WLAX

t

ELAX

t

ELWL

t

WLEL

t

GHWL

t

GHEL

t

DVWH

t

DVEH

t

WLWH

t

ELEH

t

WHDX

t

EHDX

t

WHWH1

t

EHEH1

t

WHWH2

t

WHEH

t

EHWH

t

WHWLtWPH

t

EHEL

t

WHGL

t

EHGL

t

AVQV

(1)

t

ELQX

t

ELQV

(1)

t

GLQX

t

GLQV

(1)

t

EHQZ

(1)

t

GHQZ

t

AXQX

Note: 1. Sampled only,not100% tested.

VPPHigh to Chip Enable Low 1 1 1 µs

VPPHigh to Write Enable Low 1 1 1 µs

t

Write Cycle Time 120 150 200 ns

WC

t

Address Validto Write Enable Low 0 0 0 ns

AS

Address Validto Chip Enable Low 0 0 0 ns

t

Write Enable Low toAddress Transition 60 60 75 ns

AH

Chip Enable Low to Address Transition 80 80 80 ns

t

Chip EnableLow to Write Enable Low 20 20 20 ns

CS

Write Enable Low to Chip Enable Low 0 0 0 ns

Output Enable High to Write Enable

Low

Output Enable High to Chip Enable Low 0 0 0 µs

t

Input Validto Write Enable High 50 50 50 ns

DS

Input Validto Chip Enable High 50 50 50 ns

Write Enable Low to Write Enable High

t

WP

(Write Pulse)

Chip EnableLow to Chip Enable High

(Write Pulse)

t

Write Enable High to Input Transition 10 10 10 ns

DH

Chip Enable High to Input Transition 10 10 10 ns

Duration of Program Operation 9.5 9.5 9.5 µs

Duration of Program Operation 9.5 9.5 9.5 µs

Duration of Erase Operation 9.5 9.5 9.5 ms

t

Write Enable High to Chip Enable High 0 0 0 ns

CH

Chip Enable High to Write Enable High 0 0 0 ns

Write Enable High to Write Enable Low 20 20 20 ns

Chip Enable High to Chip Enable Low 20 20 20 ns

Write Enable High to Output Enable

Low

Chip Enable High to Output Enable Low 6 6 6 µs

t

Addess Validto data Output 120 150 200 ns

ACC

t

Chip EnableLow to Output Transition 0 0 0 ns

LZ

t

Chip EnableLow to Output Valid 120 150 200 ns

CE

t

Output Enable Low to Output Transition 0 0 0 ns

OLZ

t

Output Enable Low to Output Valid 50 55 60 ns

OE

Chip Enable High to Output Hi-Z 50 55 60 ns

t

Output Enable High to Output Hi-Z 30 35 40 ns

DF

t

Address Transitionto Output Transition 0 0 0 ns

OH

=5V±10% VCC=5V±10% VCC=5V±10%

V

CC

EPROM

Interface

Interface

Min Max Min Max Min Max

000µs

60 60 60 ns

70 70 70 ns

666µs

EPROM

Unit

EPROM

Interface

12/23

Page 13

Figure8. Erase Set-up and Erase VerifyCommandsWaveforms, W Controlled

M28F101

ERASE OPERATION

VALID

tWLAX

tAVWL

tELQV tEHQZ

tWHEH

tELWL

tGHQZtWHWH2

tWHGLtWHWL

tWLWH tGLQV

tWHDXtDVWH

DATA OUT

VERIFY

COMMAND

ERASE VERIFY

AI00674

READ

SET-UP

COMMAND

ERASE SET-UP

tWHWH3

tVPHEL

G

tGHWL

W

tELWL tWHEH

PP

V

A0-A16

E

tWHDXtDVWH

tWLWH

DQ0-DQ7 COMMAND

(REPEAT OF 1st CYCLE)

ERASE SET-UP

13/23

Page 14

M28F101

Figure9. Erase Set-up and Erase VerifyCommandsWaveforms, E Controlled

ERASE OPERATION

VALID

tELAX

tAVEL

tGLQV

tEHWH

tWLEL

tGHQZtEHEH2

tEHGLtEHEL

tEHQZ

tELEH tELQV

tEHDXtDVEH

DATA OUT

VERIFY

COMMAND

ERASE VERIFY

AI01313

READ

SET-UP

14/23

V

PP

tVPHWL

A0-A16

tWHWH3

W

tWLEL tEHWH

COMMAND

ERASE SET-UP

tEHDXtDVEH

tELEH

tGHEL

G

E

DQ0-DQ7 COMMAND

(REPEAT OF 1st CYCLE)

ERASE SET-UP

Page 15

Figure10. ProgramSet-up and ProgramVerify Commands Waveforms,W Controlled

M28F101

PROGRAM OPERATION

tELQV tEHQZ

tWHEH

tGHQZ

tWHGLtWHWL

tWHWH1

tELWL

tWLWH tGLQV

tWHDXtDVWH

tWHDX

DATA OUT

VERIFY

COMMAND

PROGRAM

AI00675

READ

VERIFY SET-UP

V

PP

tVPHEL

VALID

A0-A16

tWLAX

tWHWH3

tAVWL

E

tWHEH

tELWL tWHEH

G

tELWL

tGHWL

W

tWLWH

tWHDX

tWLWH

tDVWH

tDVWH

DATA IN

ADDRESS AND

PROGRAM SET-UP

DQ0-DQ7 COMMAND

DATA LATCH

15/23

Page 16

M28F101

Figure11. ProgramSet-up and Program Verify Commands Waveforms, E Controlled

PROGRAM OPERATION

tELAX

tGLQV

tEHWH

tGHQZ

tEHGLtEHEL

tEHEH1

tWLEL

tELQV tEHQZ

tELEH

tELEH

tEHDXtDVEH

tEHDX

DATA OUT

VERIFY

COMMAND

PROGRAM

DATA IN

AI00676

READ

VERIFY SET-UP

16/23

V

PP

tVPHEL

VALID

A0-A16

tWHWH3

tAVEL

W

tEHWH

tWLEL tEHWH

DATA LATCH

tDVEH

tEHDX

tWLEL

tDVEH

tELEH

tGHEL

G

E

ADDRESS AND

PROGRAM SET-UP

DQ0-DQ7 COMMAND

Page 17

M28F101

Figure12. Erasing Flowchart

VPP= 12V

PROGRAM

BYTES TO 00h

n=0, Addr=00000h

ERASE SET-UP

Wait 10ms

ERASE VERIFY

Latch Addr.

Wait 6µs

READ DATA OUTPUT

Data

NO

OK

YES

Last

Addr

YES

READ COMMAND

VPP< 6.5V, PASS

VPP<

FAIL

YES

NO

++n

LIMIT

6.5V

ALL

NO

Addr++

AI00678

Figure13. ProgrammingFlowchart

VPP= 12V

n=0

PROGRAM SET-UP

Latch Addr, Data

Wait 10µs

PROGRAM VERIFY

++n

READ DATA OUTPUT

NO

READ COMMAND

VPP< 6.5V, PASS

Wait 6µs

Data

OK

YES

Last

Addr

YES

NO

VPP<

FAIL

NO

YES

=25

6.5V

Addr++

AI00677

Limit: 1000 at grade 1; 6000 at grades 3 &6.

PRESTOF ERASE ALGORITHM

The PRESTO F Erase Algorithm guarantees that

the device will be erased in a reliable way. The

algorithmfirst programmsall bytes to 00h in order

to ensure uniform erasure. The programming follows the PRESTO F Programming Algorithm.

Erase is set-up by writing 20h to the command

register, the erasure is started by repeating this

writecycle. EraseVerifyis set-upby writingA0h to

the command registertogetherwith theaddress of

the byte to be verified. The subsequent read cycle

reads the data which is compared to FFh. Erase

Verify begins at address 0000h and continues to

the last addressoruntilthe comparisonof the data

to 0FFhfails. If this occurs, the addressof the last

byte checked is stored and a new Erase operation

performed. Erase Verify then continues from the

address of the stored location.

PRESTOF PROGRAMALGORITHM

ThePRESTO F ProgrammingAlgorithm applies a

series of 10µs programmingpulses to a byte until

a correct verify occurs. Up to 25 programming

operations are allowed for one byte. Program is

set-upby writing 40h to the command register, the

programming is started after the next write cycle

which also latches the address and data to be

programmed. Program Verify is set-up by writing

C0h to the command register, followed by a read

cycle and a compare of the data read to the data

expected.During Program and ProgramVerify operations a MARGIN MODE circuit is activated to

guaranteethatthecellis programmedwitha safety

margin.

17/23

Page 18

M28F101

ORDERING INFORMATION SCHEME

Example: M28F101 -70 X N 1 TR

Operating Voltage

F5V

Speed

-70 70ns

-90 90ns

-100 100ns

-120 120ns

-150 150ns

-200 200ns

Power Supplies

blank V

XV

± 10%

CC

± 5%

CC

Package

P PDIP32

K PLCC32

N TSOP32

8 x 20mm

Devicesare shippedfrom the factorywith the memory content erased (toFFh).

Option

R Reverse Pinout

TR Tape& Reel

Packing

Temp.Range

1 0 to 70 °C

3 –40 to 125 °C

6 –40 to 85 °C

For a listof availableoptions(Speed,Package,etc...)orfor furtherinformationon anyaspectofthisdevice,

please contact the SGS-THOMSON Sales Officenearest to you.

18/23

Page 19

PDIP32 - 32 pin Plastic DIP, 600 mils width

M28F101

Symb

Typ Min Max Typ Min Max

A 4.83 0.190

A1 0.38 – 0.015 –

A2––––––

B 0.41 0.51 0.016 0.020

B1 1.14 1.40 0.045 0.055

C 0.20 0.30 0.008 0.012

D 41.78 42.04 1.645 1.655

E 15.24 15.88 0.600 0.625

E1 13.46 13.97 0.530 0.550

e1 2.54 – – 0.100 – –

eA 15.24 – – 0.600 – –

L 3.18 3.43 0.125 0.135

S 1.78 2.03 0.070 0.080

α 0° 15° 0° 15°

N32 32

PDIP32

mm inches

Drawing is not to scale.

B1 B e1

D

S

N

1

A2A1A

L

Cα

eA

E1 E

PDIP

19/23

Page 20

M28F101

PLCC32 - 32 lead Plastic Leaded Chip Carrier,rectangular

Symb

Typ Min Max Typ Min Max

A 2.54 3.56 0.100 0.140

A1 1.52 2.41 0.060 0.095

B 0.33 0.53 0.013 0.021

B1 0.66 0.81 0.026 0.032

D 12.32 12.57 0.485 0.495

D1 11.35 11.56 0.447 0.455

D2 9.91 10.92 0.390 0.430

E 14.86 15.11 0.585 0.595

E1 13.89 14.10 0.547 0.555

E2 12.45 13.46 0.490 0.530

e 1.27 – – 0.050 – –

N32 32

Nd 7 7

Ne 9 9

CP 0.10 0.004

PLCC32

mm inches

Ne E1 E

Drawing is not to scale.

20/23

PLCC

D

D1

1N

Nd

D2/E2

A1

B1

e

B

A

CP

Page 21

M28F101

TSOP32 Normal Pinout - 32 lead Plastic Thin Small Outline, 8 x 20mm

Symb

Typ Min Max Typ Min Max

A 1.04 1.24 0.041 0.049

A1 0.05 0.20 0.002 0.008

A2 0.95 1.06 0.037 0.042

B 0.15 0.27 0.006 0.011

C 0.10 0.21 0.004 0.008

D 19.90 20.12 0.783 0.792

D1 18.24 18.49 0.718 0.728

E 7.90 8.10 0.311 0.319

e 0.50 – – 0.020 – –

L 0.30 0.70 0.012 0.028

α 0° 5° 0° 5°

N32 32

CP 0.10 0.004

TSOP32

mm inches

Drawing is not to scale.

1N

E

N/2

D1

D

DIE

TSOP-a

A2

e

B

A

CP

C

LA1 α

21/23

Page 22

M28F101

TSOP32 Reverse Pinout - 32 lead Plastic Thin Small Outline, 8 x 20mm

Symb

Typ Min Max Typ Min Max

A 1.04 1.24 0.041 0.049

A1 0.05 0.20 0.002 0.008

A2 0.95 1.06 0.037 0.042

B 0.15 0.27 0.006 0.011

C 0.10 0.21 0.004 0.008

D 19.90 20.12 0.783 0.792

D1 18.24 18.49 0.718 0.728

E 7.90 8.10 0.311 0.319

e 0.50 – – 0.020 – –

L 0.30 0.70 0.012 0.028

α 0° 5° 0° 5°

N32 32

CP 0.10 0.004

TSOP32

mm inches

Drawing is not to scale.

1N

E

N/2

D1

D

DIE

TSOP-b

A2

e

B

A

CP

C

LA1 α

22/23

Page 23

M28F101

Information furnished is believed to be accurate and reliable.However, SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use of such informationnor for any infringementof patents or other rights ofthird parties which may result from its use.No

license is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specificationsmentioned

in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied.

SGS-THOMSON Microelectronics products are not authorized for use as critical componentsin life supportdevices or systemswithout express

written approval of SGS-THOMSON Microelectronics.

1997 SGS-THOMSON Microelectronics - All Rights Reserved

Australia - Brazil - Canada- China - France - Germany - Hong Kong - Italy -Japan - Korea- Malaysia -Malta - Morocco - The Netherlands -

Singapore- Spain - Sweden - Switzerland - Taiwan- Thailand - United Kingdom- U.S.A.

SGS-THOMSON Microelectronics GROUP OF COMPANIES

23/23

Loading...

Loading...