Page 1

32-Mbit, dual I/O, 4-Kbyte subsector erase,

serial Flash memory with 75 MHz SPI bus interface

Features

■ SPI bus compatible serial interface

■ 75 MHz (maximum) clock frequency

■ 2.7 V to 3.6 V single supply voltage

■ Dual input/output instructions resulting in an

equivalent clock frequency of 150 MHz:

– Dual Output Fast Read instruction

– Dual Input Fast Program instruction

■ 32 Mbit Flash memory

– Uniform 4-Kbyte subsectors

– Uniform 64-Kbyte sectors

■ Additional 64-byte user-lockable, one-time

programmable (OTP) area

■ Erase capability

– Subsector (4-Kbyte) granularity

– Sector (64-Kbyte) granularity

– Bulk Erase (32 Mbit) in 17 s (typical with

V

= 9 V)

PP

■ Write protections

– Software write protection applicable to

every 64-Kbyte sector (volatile lock bit)

– Har dware write protection: protected area

size defined by three non- volatile bit s (BP0,

BP1 and BP2)

■ Deep Power-down mode: 5 µA (typical)

■ Electronic signature

– JEDEC standard two-byte signature

(7116h)

– Unique ID code (UID) +16 byte of CFI data

■ More than 100 000 write cycles per sector

■ More than 20 year data retention

■ Packages

– ECOPACK® (RoHS compliant)

M25PX32

VFQFPN8 (MP)

6 × 5 mm

SO8W (MW)

208 mils

SO16 (MF)

300 mils

September 2007 Rev 4 1/63

www.st.com

1

Page 2

Contents M25PX32

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Signal descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Serial Data output (DQ1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Serial Data input (DQ0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Serial Clock (C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Chip Select (S

2.5 Hold (HOLD

2.6 Write Protect/Enhanced Program supply voltage (W

2.7 V

2.8 V

supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CC

ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SS

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

/VPP) . . . . . . . . . . . . 10

3 SPI modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Operating features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Page programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Dual Input Fast Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Subsector Erase, Sector Erase and Bulk Erase . . . . . . . . . . . . . . . . . . . . 13

4.4 Polling during a Write, Program or Erase cycle . . . . . . . . . . . . . . . . . . . . 13

4.5 Fast Bulk Erase mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.6 Active Power, Standby Power and Deep Power-down modes . . . . . . . . . 14

4.7 Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.8 Protection modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.8.1 Protocol-related protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.8.2 Specific hardware and software protection . . . . . . . . . . . . . . . . . . . . . . 16

4.9 Hold condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5 Memory organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6 Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1 Write Enable (WREN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2 Write Disable (WRDI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2/63

Page 3

M25PX32 Contents

6.3 Read Identification (RDID) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.4 Read Status Register (RDSR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.4.1 WIP bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.4.2 WEL bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.4.3 BP2, BP1, BP0 bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.4.4 TB bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.4.5 SRWD bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.5 Write Status Register (WRSR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.6 Read Data Bytes (READ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.7 Read Data Bytes at higher speed (FAST_READ) . . . . . . . . . . . . . . . . . . 33

6.8 Dual Output Fast Read (DOFR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.9 Read Lock Register (RDLR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.10 Read OTP (ROTP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.11 Page Program (PP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.12 Dual Input Fast Program (DIFP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.13 Program OTP instruction (POTP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.14 Write to Lock Register (WRLR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.15 Subsector Erase (SSE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.16 Sector Erase (SE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.17 Bulk Erase (BE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.18 Deep Power-down (DP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.19 Release from Deep Power-down (RDP) . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7 Power-up and power-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8 Initial delivery state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9 Maximum rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

10 DC and AC parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

11 Package mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

12 Part numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

13 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

3/63

Page 4

List of tables M25PX32

List of tables

Table 1. Signal names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2. Software protection truth table (Sectors 0 to 63, 64 Kbyte granularity) . . . . . . . . . . . . . . . 16

Table 3. Protected area sizes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 4. Memory organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 5. Instruction set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 6. Read Identification (RDID) data-out sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 7. Status Register format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 8. Protection modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 9. Lock Register out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 10. Lock Register in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 11. Power-up timing and VWI threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 12. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 13. Operating conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 14. AC measurement conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 2

Table 15. Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Table 16. DC characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Table 17. AC characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 18. VFQFPN8 (MLP8) 8-lead very thin fine pitch quad flat package no lead,

6 × 5 mm, package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 19. SO8W 8-lead plastic small outline, 208 mils body width, package

mechanical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 9

Table 20. SO16 wide - 16-lead plastic small outline, 300 mils body width, mechanical data. . . . . . . 60

Table 21. Ordering information scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 22. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4/63

Page 5

M25PX32 List of figures

List of figures

Figure 1. Logic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 2. VFQFPN and SO8 connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. SO16 connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. Bus Master and memory devices on the SPI bus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

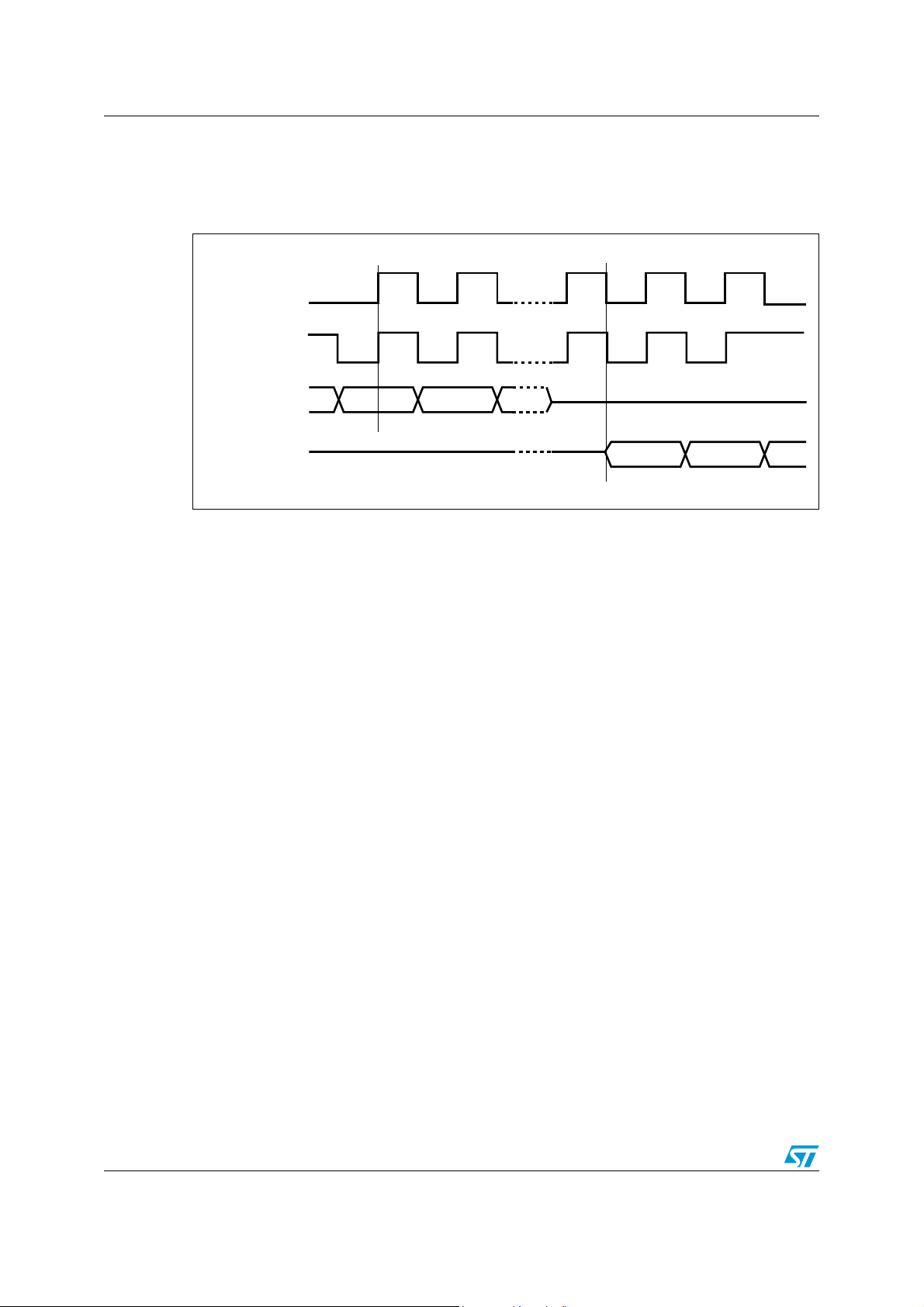

Figure 5. SPI modes supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

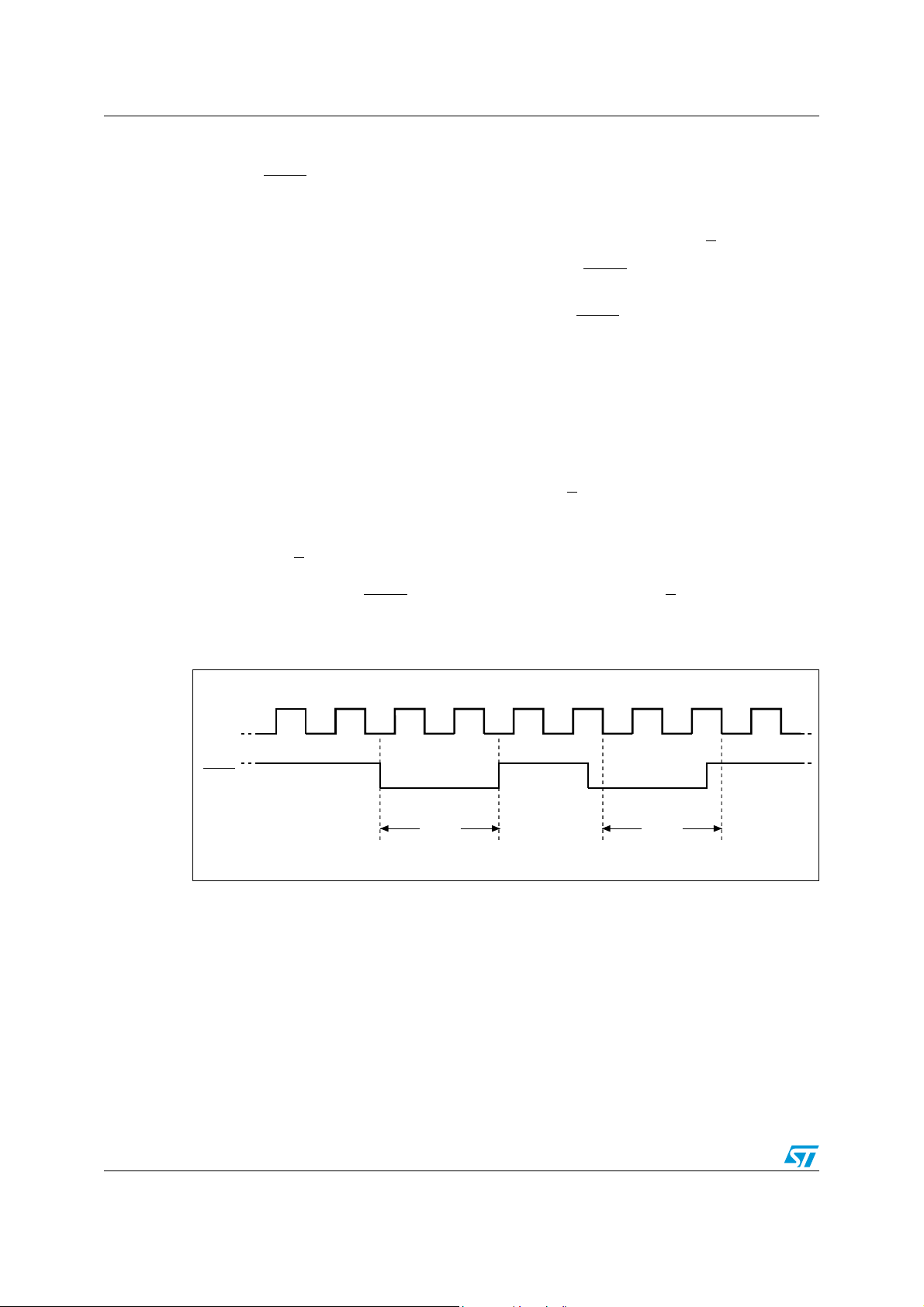

Figure 6. Hold condition activation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

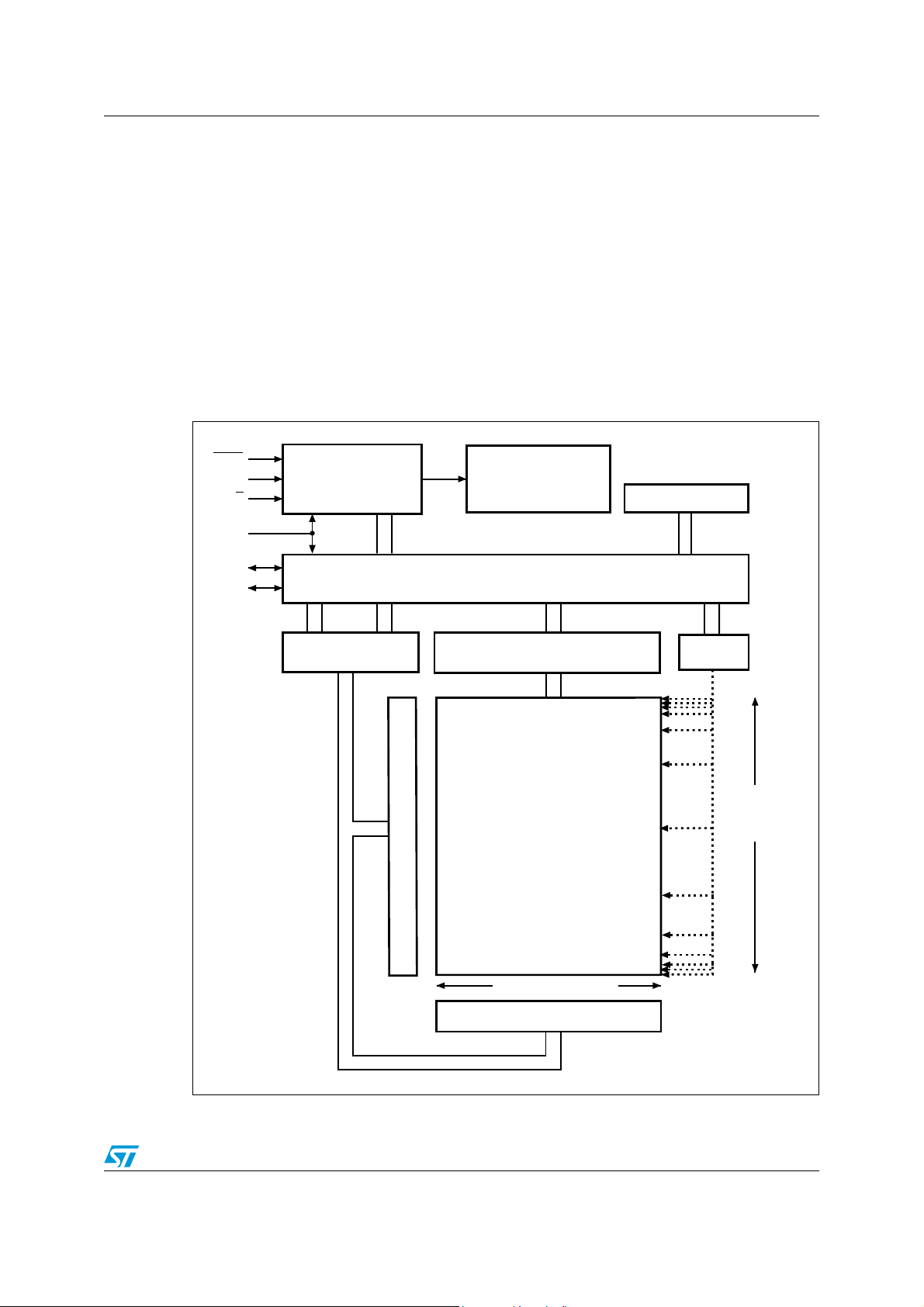

Figure 7. Block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 8. Write Enable (WREN) instruction sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 9. Write Disable (WRDI) instruction sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 10. Read Identification (RDID) instruction sequence and data-out sequence . . . . . . . . . . . . . 27

Figure 11. Read Status Register (RDSR) instruction sequence and data-out sequence . . . . . . . . . . 29

Figure 12. Write Status Register (WRSR) instruction sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 13. Read Data Bytes (READ) instruction sequence and data-out sequence . . . . . . . . . . . . . . 32

Figure 14. Read Data Bytes at higher speed (FAST_READ) instruction sequence

and data-out sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 15. Dual Output Fast Read instruction sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 16. Read Lock Register (RDLR) instruction sequence and data-out sequence . . . . . . . . . . . . 35

Figure 17. Read OTP (ROTP) instruction and data-out sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 18. Page Program (PP) instruction sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 19. Dual Input Fast Program (DIFP) instruction sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 20. Program OTP (POTP) instruction sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 21. How to permanently lock the 64 OTP bytes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 22. Write to Lock Register (WRLR) instruction sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 23. Subsector Erase (SSE) instruction sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 24. Sector Erase (SE) instruction sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 25. Bulk Erase (BE) instruction sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 26. Deep Power-down (DP) instruction sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 27. Release from Deep Power-down (RDP) instruction sequence. . . . . . . . . . . . . . . . . . . . . . 48

Figure 28. Power-up timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 29. AC measurement I/O waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 30. Serial input timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 31. Write Protect Setup and Hold timing during WRSR when SRWD=1 . . . . . . . . . . . . . . . . . 56

Figure 32. Hold timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 33. Output timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 34. V

Figure 35. VFQFPN8 (MLP8) 8-lead very thin fine pitch quad flat package no lead,

Figure 36. SO8W 8-lead plastic small outline, 208 mils body width, package outline. . . . . . . . . . . . . 59

Figure 37. SO16 wide - 16-lead plastic small outline, 300 mils body width, package outline . . . . . . . 60

timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

PPH

6 × 5 mm, package outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5/63

Page 6

Description M25PX32

1 Description

The M25PX32 is a 32 Mbit (4 Mb x 8) serial Flash memory, with advanced write protection

mechanisms, accessed by a high speed SPI-compatible bus.

The M25PX32 supports two new, high-performance dual input/output instructions:

● Dual Output Fast Read (DOFR) instruction used to read data a t up t o 75 MHz by using

both pin DQ1 and pin DQ0 as outputs

● Dual Input Fast Program (DIFP) instruction used to program data at up to 75 MHz by

using both pin DQ1 and pin DQ0 as inputs

These new instructions double the transfer bandwidth for read and program operations.

The memory can be programmed 1 to 256 bytes at a time, using the Page Program

instruction.

The memory is organized as 64 sectors that are further divided into 16 subsectors each

(1024 subsectors in total).

The memory can be erased a 4-Kbyte subsector at a time, a 64-Kbyte sect or at a time , or as

a whole. It can be Write Protected by software using a mix of volatile and non-volatile

protection features, depending on the application needs. The protection granularity is of 64

Kbytes (sector granularity).

An enhanced Fast Bulk Erase mode is available to speed up Bulk Erase operations in

factory environment. The device enters this mode whenever the V

the Write Protect/Enhanced Program supply voltage pin (W

/VPP).

voltage is applied to

PPH

The M25PX32 has 64 One-Time-Programmable bytes (OTP bytes) that can be read and

programmed using two dedicated instructions, Read OTP (ROTP) and Program OTP

(POTP), respectively. These 64 bytes can be permanently locked by a particular Program

OTP (POTP) sequence. Once they have been lock ed, they become read-only and this state

cannot be reverted.

Further features are available as additional security options. More information on these

security features is available, upon completion of an NDA (nondisclosure agreement), and

are, therefore, not described in this datasheet. For more details of this option contact your

nearest ST Sales office.

In order to meet environmental requirements, ST offers the M25PX32 in ECOPACK®

packages. ECOPACK® packages are Lead-free and RoHS compliant.

ECOPACK® is an ST trademark. ECOPACK® specifications are available at: www.st.com.

6/63

Page 7

M25PX32 Description

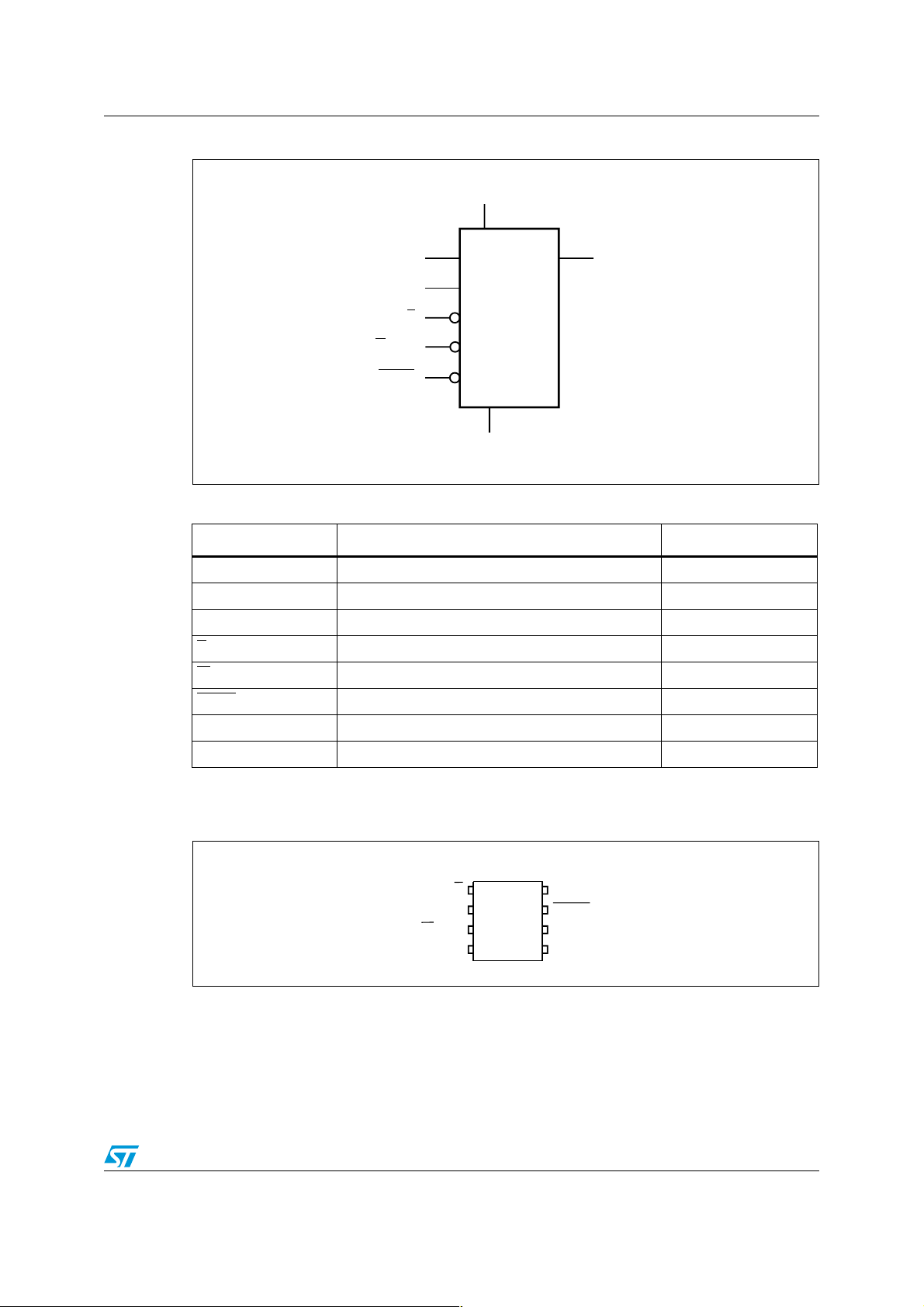

Figure 1. Logic diagram

V

CC

DQ0

DQ1

C

M25PX32

W/V

S

PP

HOLD

V

Table 1. Signal names

SS

AI14228

Signal name Function Direction

C Serial Clock Input

DQ0 Serial Data input I/O

DQ1 Serial Data output I/O

(1)

(2)

S Chip Select Input

/V

W

PP

HOLD

Write Protect/Enhanced Program supply voltage Input

Hold Input

V

CC

V

SS

1. Serves as an output during Dual Output Fast Read (DOFR) instructions.

2. Serves as an input during Dual Input Fast Program (DIFP) instructions.

Supply voltage

Ground

Figure 2. VFQFPN and SO8 connections

M25PX32

SV

1

2

W/V

1. There is an exposed central pad on the underside of the VFQFPN package. This is pulled, internally, to

V

, and must not be allowed to be connected to any other voltage or signal line on the PCB.

SS

2. See Package mechanical section for package dimensions, and how to identify pin-1.

PP

SS

3

4

7/63

8

CC

7

HOLDDQ1

6

C

5

DQ0V

AI13720b

Page 8

Description M25PX32

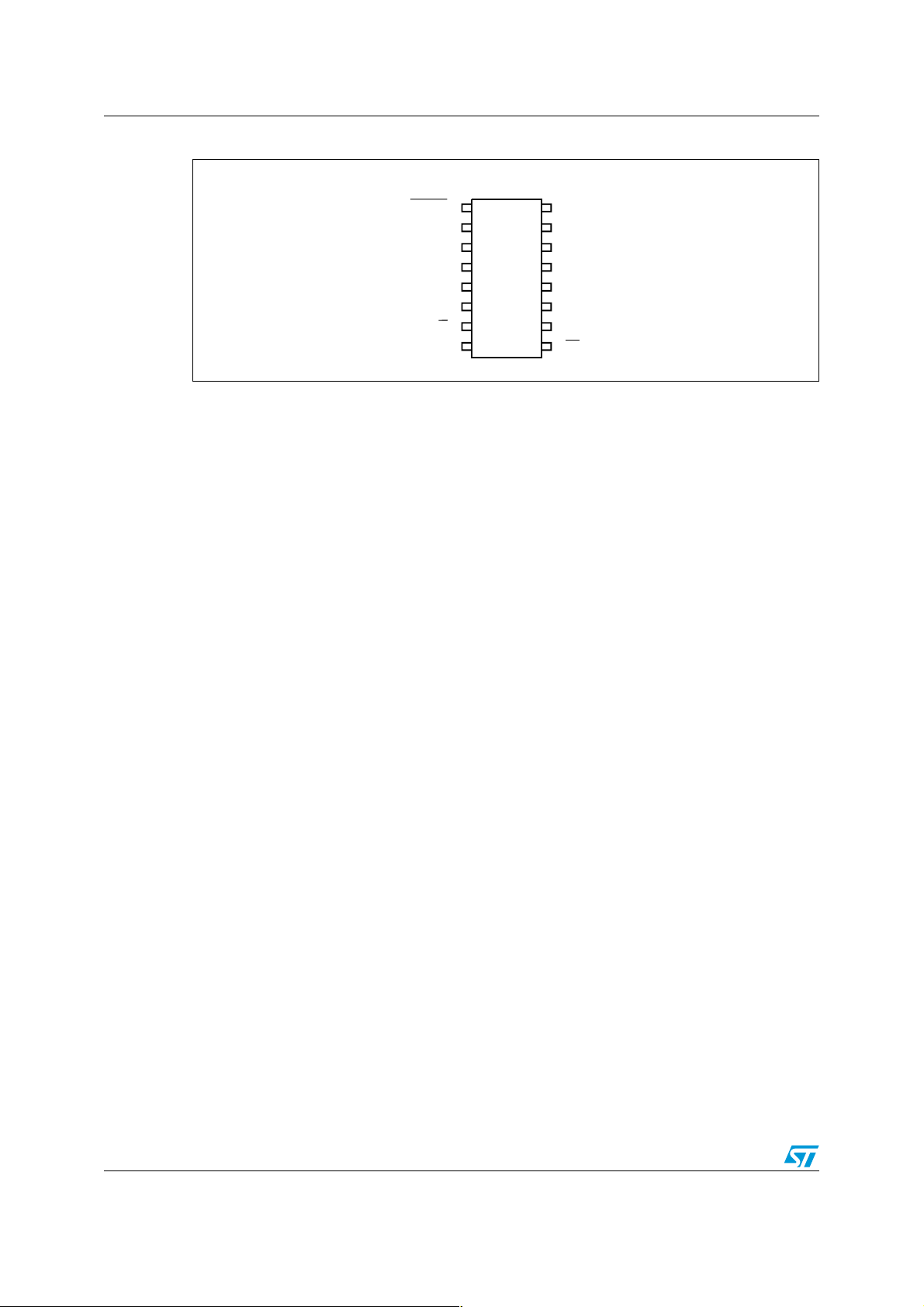

Figure 3. SO16 connections

M25PX32

HOLD

V

CC

DU

DU

DU

S

DQ1

1. DU = Don’t use.

2. See Package mechanical section for package dimensions, and how to identify pin-1.

16

1

2

3

4

5

6

7

8

15

14

13

12

11

10

C

DQ0

DUDU

DU

DU

DU

V

SS

9

W/V

PP

AI13721b

8/63

Page 9

M25PX32 Signal descriptions

2 Signal descriptions

2.1 Serial Data output (DQ1)

This output signal is used to transf er data serially out of the device. Data are shifted out on

the falling edge of Serial Clock (C).

During the Dual Input Fast Program (DIFP) instruction, pin DQ1 is used as an input. It is

latched on the rising edge of the Serial Clock (C).

2.2 Serial Data input (DQ0)

This input signal is used to transfer data serially into the device. It receives instructions,

addresses, and the data to be programmed. Values are latched on the rising edge of Serial

Clock (C).

During the Dual Output Fast Read (DOFR) instruction, pin DQ0 is used as an output. Data

are shifted out on the falling edge of the Serial Clock (C).

2.3 Serial Clock (C)

This input signal provides the timing of the serial interface. Instructions, addresses, or data

present at Serial Data input (DQ0) are latched on the rising edge of Serial Clock (C). Data

on Serial Data output (DQ1) changes after the falling edge of Serial Clock (C).

2.4 Chip Select (S)

When this input signal is High, the device is deselec ted and Serial Data output (DQ1) is at

high impedance. Unless an internal Program, Erase or Write Status Register cycle is in

progress, the device will be in the Standby Power mode (this is not the Deep Power-down

mode). Driving Chip Select (S

After Power-up, a falling edge on Chip Select (S

instruction.

2.5 Hold (HOLD)

The Hold (HOLD) signal is used to pause any serial communications with the de vice without

deselecting the device.

During the Hold condition, the Serial Data output (DQ1) is hi gh impe dance, and Serial Data

input (DQ0) and Serial Clock (C) are Don’t care.

To start the Hold condition, the device must be selected, with Chip Select (S

) Low enables the device, placing it in the Active Power mode .

) is required prior to the start of any

) driven Low.

9/63

Page 10

Signal descriptions M25PX32

2.6 Write Protect/Enhanced Program supply voltage (W/VPP)

W/VPP is both a control input and a power supply p in. The two functions ar e selected by the

voltage range app lied to the pin.

If the W

input. This input signal is used to freeze the size of the area of memory that is protected

against program or erase instructions (as specified by the values in the BP2, BP1 and BP0

bits of the Status Register. See Table 9).

If V

during the Bulk Erase cycle. In this case V

completed.

/V

input is kept in a low voltage range (0 V to VCC) the pin is seen as a control

PP

is in the range of V

PP

PPH

2.7 VCC supply voltage

VCC is the supply voltage.

2.8 VSS ground

VSS is the reference for the VCC supply voltage.

(as defined in Table 14) it acts as an additional power supply

must be stable until the Bulk Er ase algorithm is

PP

10/63

Page 11

M25PX32 SPI modes

3 SPI modes

These devices can be drive n by a microcontroller with its SPI peripheral running in either of

the two following modes:

● CPOL=0, CPHA=0

● CPOL=1, CPHA=1

For these two modes, input data is latched in on the rising edge of Serial Clock (C), and

output data is available from the falling edge of Serial Clock (C).

The difference between the two modes, as sho wn in Figure 5, is the clock polarity when the

bus master is in Standby mode and not transferring data:

● C remains at 0 for (CPOL=0, CPHA=0)

● C remains at 1 for (CPOL=1, CPHA=1)

Figure 4. Bus Master and memory devices on the SPI bus

V

SS

V

CC

R

SPI interface with

(CPOL, CPHA) =

(0, 0) or (1, 1)

SPI Bus Master

CS3 CS2 CS1

1. The Write Protect (W) and Hold (HOLD) signals should be driven, High or Low as appropriate.

SDO

SDI

SCK

device

V

CC

HOLD

W

C

V

SS

DQ1 DQ0

SPI memory

S

C

DQ1DQ0

RRR

SPI memory

S

device

V

CC

W

HOLD

C

V

SS

S

DQ1DQ0

SPI memory

device

W

V

CC

V

SS

HOLD

AI13725b

Figure 4 shows an exampl e of three de vices connected to an MCU, on an SPI bus. Only one

device is selected at a time, so only one device drives t he Serial Data ou tput ( DQ1) line a t a

time, the other devices are high impedance. Resistors R (represented in Figure 4) ensure

that the M25PX32 is not selected if the Bus Master leaves the S

line in the high impedance

state. As the Bus Master may enter a state where all inputs/outputs are in high impedance

at the same time (for example, when the Bus Master is reset), the clock line (C) must be

connected to an external pull-down resistor so that, when all inputs/outputs become high

impedance, the S

C do not become High at the same time, and so, that the t

typical value of R is 100 kΩ, assuming that the time constant R*C

line is pulled High while the C line is pulled Low (thus ensuring that S a nd

requirement is met). The

SHCH

(Cp = parasitic

p

capacitance of the bus line) is shorter than the time during which the Bus Master leaves the

SPI bus in high impedance.

11/63

Page 12

SPI modes M25PX32

Example: Cp = 50 pF, that is R*Cp = 5 µs <=> the application must ensure that the Bus

Master never leaves the SPI bus in the hig h impedance state for a time period shorter than

5µs.

Figure 5. SPI modes supported

CPHA

CPOL

C

0

0

1

1

C

DQ0

DQ1

MSB

MSB

AI13730

12/63

Page 13

M25PX32 Operating features

4 Operating features

4.1 Page programming

To program one data byte, two instructions are required: Write Enab le (WREN), which is one

byte, and a Page Program (PP) sequence, which consists of four bytes plus data. This is

followed by the internal Program cycle (of duration t

To spread this overhead, the P age Program (PP) instruction allows up to 256 bytes to be

programmed at a time (changing bits from 1 to 0), provided that they lie in consecutive

addresses on the same page of memory.

For optimized timings, it is recommended to use the Page Program (PP) instruction to

program all consecutive targeted bytes in a single sequence versus using several Page

Program (PP) sequences with each containing only a few bytes (see Page Program (PP)

and Table 17: AC characteristics).

4.2 Dual Input Fast Program

The Dual Input Fast Program (DIFP) instruction makes it possible to program up to 256

bytes using two input pins at the same time (by changing bits from 1 to 0).

PP

).

For optimized timings, it is recommended to use the Dual Input Fast Program (DIFP)

instruction to program all consecutive targeted bytes in a single sequence rather to using

several Dual Input Fast Program (DIFP) sequences each containing only a few bytes (see

Section 6.12: Dual Input Fast Program (DIFP)).

4.3 Subsector Erase, Sector Erase and Bulk Erase

The Page Program (PP) instruction allows bits to be reset from 1 to 0. Before this can be

applied, the bytes of memory need to have been erased to all 1s (FFh). This can be

achieved either a subsector at a time, using the Subsector Erase (SSE) instruction, a sector

at a time, using the Sector Erase (SE) instruction, or throughout the entire memory, using

the Bulk Erase (BE) instruction. This starts an internal Erase cycle (of duration t

t

).

BE

The Erase instruction must be preceded by a Write Enable (WREN) instruction.

4.4 Polling during a Write, Program or Erase cycle

A further improvement in the time to Write Status Register (WRSR), Program OTP (POTP),

Program (PP), Dual Input F ast Program (DIFP) or Erase (SSE, SE or BE) can be achieved

by not waiting for the worst case delay (t

(WIP) bit is provided in the Status Register so that the application program can monitor its

value, polling it to establish when the previous Write cycle, Program cycle or Erase cycle is

complete.

, tPP, t

W

, tSE, or tBE). The Write In Progress

SSE

SSE

, tSE or

13/63

Page 14

Operating features M25PX32

4.5 Fast Bulk Erase mode

The Fast Bulk Erase mode is used to speed up Bulk Erase operations. The device enters

the Fast Bulk Er ase mode d uring a Bulk Erase inst ruction whene v er a voltage equal to V

is applied to the W

/VPP pin.

PPH

The use of the Fast Bu lk Erase mode requires specific operating conditions in a ddition to the

normal ones (V

● the voltage applied to the W/V

● ambient temperature, T

● the cumulated time during which W/V

must be within the normal operating range):

CC

pin must be equal to V

PP

must be 25 °C ±10 °C,

A

is at V

PP

PPH

(see Table 13)

PPH

should be less than 80 hours.

4.6 Active Po wer, Standby Power and Deep Power-down modes

When Chip Select (S) is Low, the device is selected, and in the Active Power mode.

When Chip Select (S

) is High, the device is deselect ed, but coul d remain in the Activ e P o wer

mode until all internal cycles have completed (Program, Erase, Write Status Register). The

device then goes in to the Standby Power mode. The device consumption drops to I

The Deep Power-down mode is entered when the specific instruction (the Deep Powerdown (DP) instruction) is executed. The device consumption drops further to I

device remains in this mode until another specific instruction (the Release from Deep

Power-down (RDP) instruction) is executed.

While in the Deep Power-down mode, the device ignores all Write, Program and Erase

instructions (see Deep Power-down (DP)), this can be used as an extra software protection

mechanism, when the device is not in active use, to protect the device from inadvertent

Write, Program or Erase instructions.

4.7 Status Register

The Status Register contains a number of status a nd cont rol bits that can b e read or set (as

appropriate) by specific instructions. See Section 6.4: Read Status Register (RDSR) for a

detailed description of the Status Register bits.

CC2

CC1

. The

.

14/63

Page 15

M25PX32 Operating features

4.8 Protection modes

There are protocol-related and specific hardware and software protection modes. They are

described below.

4.8.1 Protocol-related protections

The environments where non-volatile memory devices are used can be very noisy. No SPI

device can operate correctly in the presence of excessive noise. To help combat this, the

M25PX32 features the following data protection mechanisms:

● P ower On Reset and an internal timer (t

changes while the power supply is outside the operating specification

● Program, Er ase and Write Status Register inst ructions are chec k ed tha t the y co nsist of

a number of clock pulses tha t is a multiple of eight, before they are accepted for

execution

● All instructions that modify data must be prec eded by a Write Enable (WREN)

instruction to set the Write Enable Latch (WEL) bit . This bit is re turned to its re set state

by the following events:

–Power-up

– Write Disable (WRDI) instruction completion

– Write Status Register (WRSR) instruction completion

– Write to Lock Register (WRLR) instruction completion

– Program OTP (POTP) instruction completion

– Page Program (PP) instruction completion

– Dual Input Fast Program (DIFP) instruction completion

– Subsector Erase (SSE) instruction completion

– Sector Erase (SE) instruction completion

– Bulk Erase (BE) instruction completion

● In addition to the lo w power consumption feature , the Deep Power-down mode offers

extra softw are protection, as all Write, Program and Erase instructions are ignored.

) can provide protection against inadvertent

PUW

15/63

Page 16

Operating features M25PX32

4.8.2 Specific hardware and software protection

There are two software protected modes , SPM1 and SPM2, that can b e combined to protect

the memory array as required. Th e SPM 2 can be lo cked by hardw are wit h th e help o f th e W

input pin.

SPM1 and SPM2

● The first software protected mode (SPM1) is managed by specific Lock Registers

assigned to each 64 Kbyte sector.

The Lock Registers can be read and written using the Read Loc k Register (RDLR) a nd

Write to Lock Register (WRLR) instructions.

In each Lock Register two bits control the protection of each sector: the Write Lock bit

and the Lock Down bit.

– Write Lock bit:

The Write Lock bit determines whether the contents of the sector can be modifi ed

(using the Write, Program or Erase instructions). When the Write Loc k b it is set to

‘1’, the sector is write protected – any operations t hat attempt to change the data

in the sector will fail. When the Write Lock bit is reset to ‘0’, the sector is not write

protected by the Lock Register, and may be modified.

– Lock Down bit:

The Lock Down bit pro vides a mechanism for protecting software da ta from simple

hacking and malicious attack. When the Lock Down bit is set, ‘1’, further

modification to the Write Lock and Lock Down bits cannot be performed. A powerup, is required before changes to these bits can be made. When the Lock Down bit

is reset, ‘0’, the Write Lock and Lock Down bits can be changed.

The definition of the Lock Register bits is given in Table 9: Lock Register out.

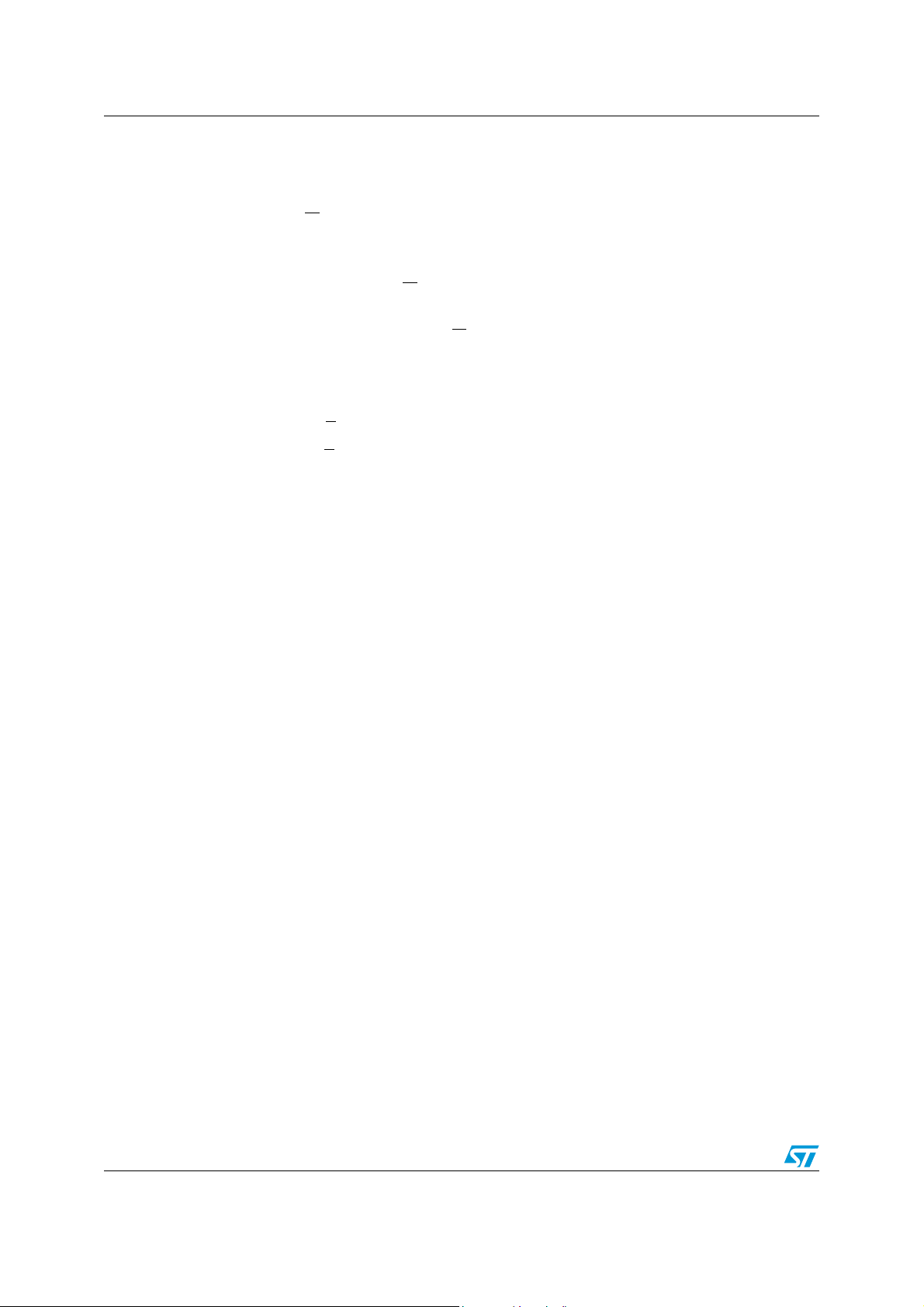

Table 2. Software protection truth table ( Sectors 0 to 63, 64 Kbyte granularity)

Sector Lock

Register

Protection status

Lock

Down bit

00

01

10

11

● the second software protected mode (SPM2) uses the Block Protect bits (see

Write

Lock bit

Sector unprotected from Program/Erase/Write operations, protection status

reversible

Sector protected from Program/Erase/Write operations, protection status

reversible

Sector unprotected from Program/Erase/Write operations,

Sector protection status cannot be changed except by a Power-up.

Sector protected from Program/Erase/Write operations,

Sector protection status cannot be changed except by a Power-up.

Section 6.4.3: BP2, BP1, BP0 bits) and the Top/Bottom bit (see Section 6.4.4: TB bit) to

allow part of the memory to be configured as read-only.

16/63

Page 17

M25PX32 Operating features

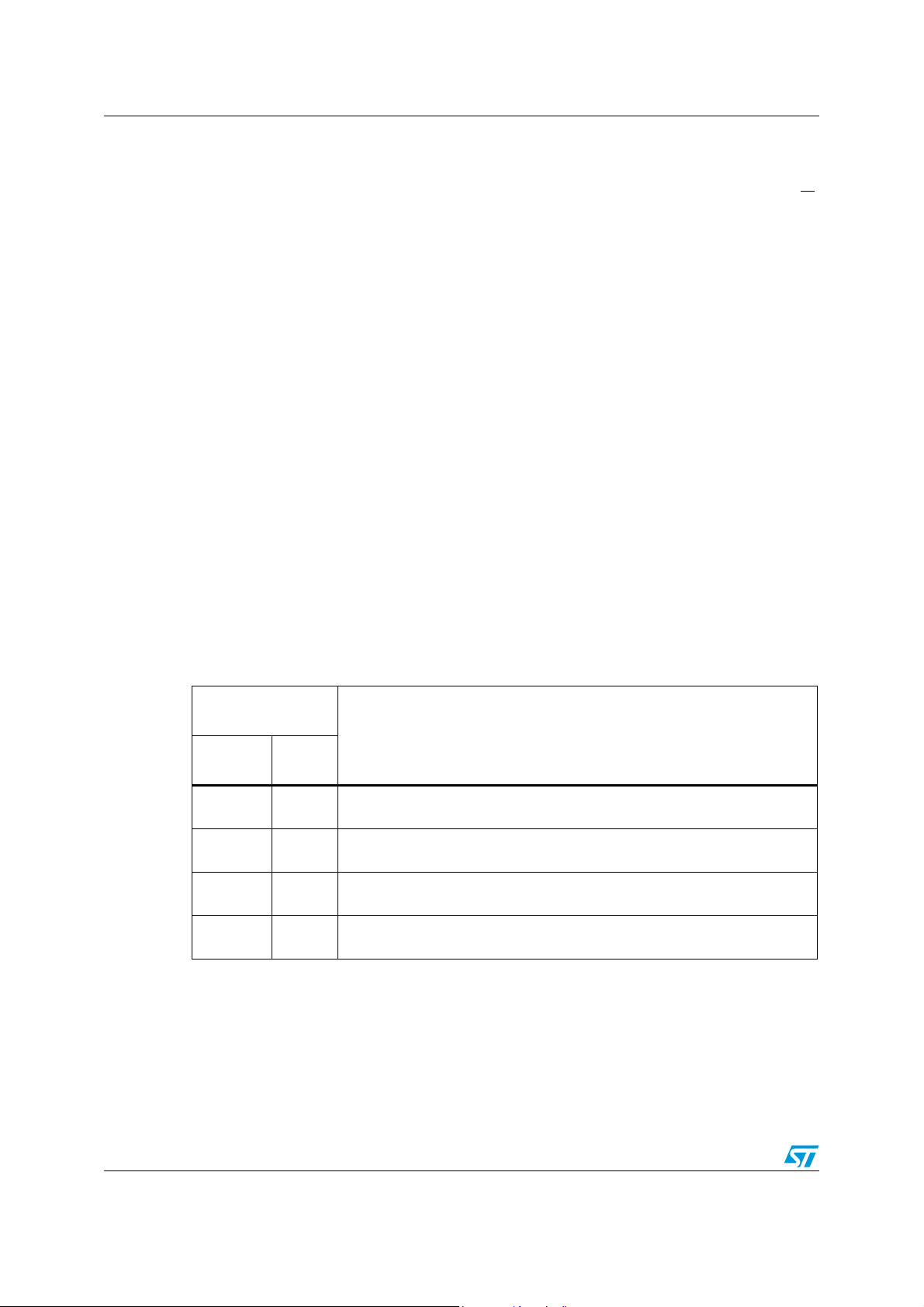

Table 3. Protected area sizes

Status Register

contents

TB

BP

BP

bit

bit 2

bit 1

BP

bit 0

Protected area Unprotected area

0 0 0 0 none All sectors

Memory content

(1)

(64 sectors: 0 to 63)

0 0 0 1 Upper 64th (Sector 63) Lower 63/64ths (63 sectors: 0 to 62)

0 0 1 0 Upper 32nd (two sectors: 62 and 63) Lower 31/32nds (62 sectors: 0 to 61)

0 0 1 1

0 1 0 0 Upper eighth (eight sectors: 56 to 63)

0 1 0 1

0 1 1 0

Upper sixteenth (four sectors: 60 to

63)

Upper quarter (sixteen sectors: 48 to

63)

Upper half (thirty-two sectors: 32 to

63)

Lower 15/16ths (60 sectors: 0 to 59)

Lower seven-eighths (56 sectors: 0

to 55)

Lower three-quarters (48 sectors: 0

to 47)

Lower half (32 sectors: 0 to 31)

0 1 1 1 All sectors (64 sectors: 0 to 63) none

(1)

1 0 0 0 none All sectors

(64 sectors: 0 to 63)

1 0 0 1 Lower 64th (sector 0) Upper 63/64ths (63 sectors: 1 to 63)

1 0 1 0 Lower 32nd (two sectors: 0 and 1) Upper 31/32ths (62 sectors: 2 to 63)

1 0 1 1 Lower 16th (four sectors: 0 to 3) Upper 15/16ths (60 sectors: 4 to 63)

1 1 0 0 Lower 8th (eight sectors: 0 to 7) Upper 7/8ths (56 sectors: 8 to 63)

1 1 0 1 Lower 4th (sixteen sectors: 0 to 15) Upper 3/4ths (48 sectors: 16 to 63)

1110

Lower half (thirty-two sectors: 0 to

31)

Upper half (32 sectors: 32 to 63)

1 1 1 1 All sectors (64 sectors: 0 to 63) none

1. The device is ready to accept a Bulk Erase instruction if, and only if, all Block Protect (BP2, B P1, BP0) are

0.

As a second level of protection, the Write Protect signal (applied on the W/VPP pin) can

freeze the Status Register in a read-only mode. In this mode, the Block Protect bits (BP2,

BP1, BP0) and the Status Register Write Disable bit (SRWD) are protected. For more

details, see Section 6.5: Write Status Register (WRSR).

17/63

Page 18

Operating features M25PX32

4.9 Hold condition

The Hold (HOLD) signal is used to pause any serial communications with the de vice without

resetting the clocking sequence. However, taking this signal Low does not terminate any

Write Status Register, Pro gram or Erase cycle that is currently in progress.

To enter the Hold condition, the device must be selected, with Chip Select (S

The Hold condition starts on the falling edge of the Hold (HOLD

) signal, provided that this

) Low.

coincides with Serial Clock (C) being Low (as shown in Figure 6).

The Hold condition ends on the rising edge of the Hold (HOLD

) signal, provided that this

coincides with Serial Clock (C) being Low.

If the falling edge does not coincide with Serial Clock (C) being Low, the Hold condition

starts after Serial Clock (C) next goes Low. Similarly, if the rising edge does not coincide

with Serial Clock (C) being Low, the Hold condition ends after Serial Clock (C) next goes

Low. (This is shown in Figure 6).

During the Hold condition, the Serial Data output (DQ1) is hi gh impe dance, and Serial Data

input (DQ0) and Serial Clock (C) are Don’t care.

Normally , the de vice is k ept selected, with Chip Select (S

) driven Low, for the whole dur ation

of the Hold condition. This is to ensure that the state of the internal logic remains unchanged

from the moment of entering the Hold condition.

If Chip Select (S

) goes High while the device is in the Hold condition, t his has the effect of

resetting the internal logic of the device. To restart communication with the device, it is

necessary to drive Hold (HOLD

) High, and then to drive Chip Select (S) Low. This prevents

the device from going back to the Hold condition.

Figure 6. Hold condition activation

C

HOLD

Hold

Condition

(standard use)

18/63

Hold

Condition

(non-standard use)

AI02029D

Page 19

M25PX32 Memory organization

5 Memory organization

The memory is organized as:

● 4 194 304 bytes (8 bits each)

● 1024 subsectors (4 Kbytes each)

● 64 sectors (64 Kbytes each)

● 16384 pages (256 bytes each)

● 64 OTP bytes located outside the main memory array

Each page can be individually prog rammed ( bits are prog rammed from 1 t o 0). The de vice is

Subsector, Sector or Bulk Erasable (bits are erased from 0 to 1) but not Page Erasable.

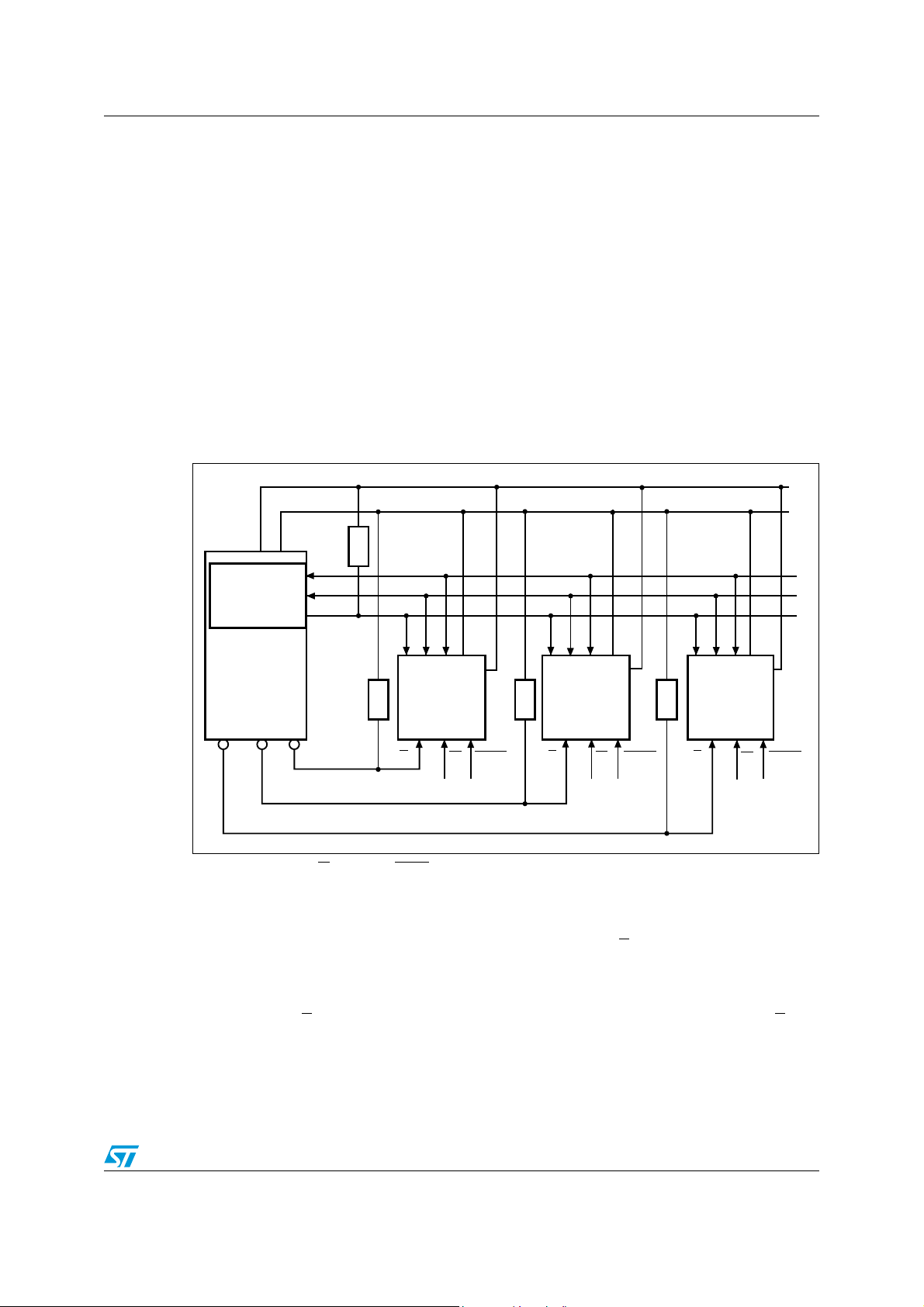

Figure 7. Block diagram

HOLD

V

DQ0

DQ1

PP

Control Logic

S

C

Address Register

and Counter

Y Decoder

High Voltage

Generator

I/O Shift Register

256 Byte

Data Buffer

64 OTP bytes

Status

Register

3FFFFFh

Configurable OTP

area in main

memory array

00000h

256 Bytes (Page Size)

X Decoder

000FFh

AI13722

19/63

Page 20

Memory organization M25PX32

Table 4. Memory organization

Sector Subsector Address range Sector Subsector Address range

63

62

61

60

59

58

57

56

55

54

53

1023 3FF000h 3FFFFFh

...

...

...

52

847 34F000h 34FFFFh

...

...

...

1008 3F0000h 3F0FFFh 832 340000h 340FFFh

1007 3EF000h 3EFFFFh

...

...

...

51

831 33F000h 33FFFFh

...

...

...

992 3E0000h 3E0FFFh 816 330000h 330FFFh

991 3DF000h 3DFFFFh

...

...

...

50

815 32F000h 32FFFFh

...

...

...

976 3D0000h 3D0FFFh 800 320000h 320FFFh

975 3CF000h 3CFFFFh

...

...

...

49

799 31F000h 31FFFFh

...

...

...

960 3C0000h 3C0FFFh 784 310000h 310FFFh

959 3BF000h 3BFFFFh

...

...

...

48

783 30F000h 30FFFFh

...

...

...

944 3B0000h 3B0FFFh 768 300000h 300FFFh

943 3AF000g 3AFFFFh

...

...

...

47

767 2FF000h 2FFFFFh

...

...

...

928 3A0000h 3A0FFFh 752 2F0000h 2F0FFFh

927 39F000h 39FFFFh

...

...

...

46

751 2EF000h 2EFFFFh

...

...

...

912 390000h 390FFFh 736 2E0000h 2E0FFFh

911 38F000h 38FFFFh

...

...

...

45

735 2DF000h 2DFFFFh

...

...

...

896 380000h 380FFFh 720 2D0000h 2D0FFFh

895 37F000h 37FFFFh

...

...

...

44

719 2CF000h 2CFFFFh

...

...

...

880 370000h 370FFFh 704 2C0000h 2C0FFFh

879 36F000h 36FFFFh

...

...

...

43

703 2BF000h 2BFFFFh

...

...

...

864 360000h 360FFFh 688 2B0000h 2B0FFFh

863 35F000h 35FFFFh

...

...

...

42

687 2AF000h 2AFFFFh

...

...

...

848 350000h 350FFFh 672 2A0000h 2A0FFFh

20/63

Page 21

M25PX32 Memory organization

Table 4. Memory organization (continued)

Sector Subsector Address range Sector Subsector Address range

41

40

39

38

37

36

671 29F000h 29FFFFh

...

656 290000h 290FFFh 480 1E0000h 1E0FFFh

655 28F000h 28FFFFh

...

640 280000h 280FFFh 464 1D0000h 1D0FFFh

639 27F000h 27FFFFh

...

624 270000h 270FFFh 448 1C0000h 1C0FFFh

623 26F000h 26FFFFh

...

608 260000h 260FFFh 432 1B0000h 1B0FFFh

607 25F000h 25FFFFh

...

592 250000h 250FFFh 416 1A0000h 1A0FFFh

591 24F000h 24FFFFh

...

576 240000h 240FFFh 400 190000h 190FFFh

...

...

...

...

...

...

...

...

...

...

...

...

30

29

28

27

26

25

495 1EF000h 1EFFFFh

...

479 1DF000h 1DFFFFh

...

463 1CF000h 1CFFFFh

...

447 1BF000h 1BFFFFh

...

431 1AF000h 1AFFFFh

...

415 19F000h 19FFFFh

...

...

...

...

...

...

...

...

...

...

...

...

...

35

34

33

32

31

575 23F000h 23FFFFh

...

560 230000h 230FFFh 384 180000h 180FFFh

559 22F000h 22FFFFh

...

544 220000h 220FFFh 368 170000h 170FFFh

543 21F000h 21FFFFh

...

528 210000h 210FFFh 352 160000h 160FFFh

527 20F000h 20FFFFh

...

512 200000h 200FFFh 336 150000h 150FFFh

511 1FF000h 1FFFFFh

...

496 1F0000h 1F0FFFh 320 140000h 140FFFh

...

...

...

...

...

...

...

...

...

...

24

23

22

21

20

399 18F000h 18FFFFh

...

383 17F000h 17FFFFh

...

367 16F000h 16FFFFh

...

351 15F000h 15FFFFh

...

335 14F000h 14FFFFh

...

...

...

...

...

...

...

...

...

...

...

21/63

Page 22

Memory organization M25PX32

Table 4. Memory organization (continued)

Sector Subsector Address range Sector Subsector Address range

19

18

17

16

15

14

319 13F000h 13FFFFh

...

304 130000h 130FFFh 128 80000h 80FFFh

303 12F000h 12FFFFh

...

288 120000h 120FFFh 112 70000h 70FFFh

287 11F000h 11FFFFh

...

272 110000h 110FFFh 96 60000h 60FFFh

271 10F000h 10FFFFh

...

256 100000h 100FFFh 80 50000h 50FFFh

255 FF000h FFFFFh

...

240 F0000h F0FFFh 64 40000h 40FFFh

239 EF000h EFFFFh

...

224 E0000h E0FFFh 48 30000h 30FFFh

...

...

...

...

...

...

...

...

...

...

...

...

8

7

6

5

4

3

143 8F000h 8FFFFh

...

127 7F000h 7FFFFh

...

111 6F000h 6FFFFh

...

95 5F000h 5FFFFh

...

79 4F000h 4FFFFh

...

63 3F000h 3FFFFh

...

...

...

...

...

...

...

...

...

...

...

...

...

13

12

11

10

223 DF000h DFFFFh

...

208 D0000h D0FFFh 32 20000h 20FFFh

207 CF000h CFFFFh

...

192 C0000h C0FFFh 16 10000h 10FFFh

191 BF000h BFFFFh

...

176 B0000h B0FFFh 4 04000h 04FFFh

175 AF000h AFFFFh 3 03000h 03FFFh

160 A0000h A0FFFh 1 01000h 01FFFh

159 9F000h 9FFFFh 0 00000h 00FFFh

9

...

144 90000h 90FFFh

...

...

...

...

...

...

...

...

2

1

0

47 2F000h 2FFFFh

...

31 1F000h 1FFFFh

...

15 0F000h 0FFFFh

...

2 02000h 02FFFh

...

...

...

...

...

...

22/63

Page 23

M25PX32 Instructions

6 Instructions

All instructions, addresses and data are shifted in and ou t of the device, most significant bit

first.

Serial Data input(s) DQ0 (DQ1) is (are) sampled on the first rising edge of Serial Cloc k (C)

after Chip Select (S

the device, most significant bit first, on Serial Data input(s) DQ0 (DQ1), each bit being

latched on the rising edges of Serial Clock (C).

The instruction set is listed in Table 5.

Every instruction sequence starts with a one-byte instruction code. Depending on the

instruction, this might be followed by address bytes, or by data bytes, or by both or none.

In the case of a Read Data Bytes (READ), Read Data Bytes at higher speed (Fast_Read),

Dual Output Fast Read (DOFR), Read OTP (ROTP), Read Lock Registers (RDLR), Read

Status Register (RDSR), Read Identification (RDID) or Release from Deep Power-do wn

(RDP) instruction, the shifted-in instruction sequence is followed by a data-out sequence.

Chip Select (S

out.

In the case of a Page Program (PP), Program OTP (POTP), Dual Input Fast Program

(DIFP), Subsector Erase (SSE), Sector Erase (SE), Bulk Erase (BE), Write Status Register

(WRSR), Write to Lock Register (WRLR), Write Enable (WREN), Write Disable (WRDI) or

Deep Power-down (DP) instruction, Chip Select (S

boundary, otherwise the instruction is rejected, and is not executed. That is, Chip Sele ct (S

must driven High when the number of clock pulses after Chip Select (S

an exact multiple of eight.

) is driven Low. Then, the one-byte instruction code m ust be shifted in to

) can be driven High after any bit of the data-out sequence is being shifted

) must be driven High exactly at a byte

) being driven Low is

)

All attempts to access the memory array during a Write Status Register cycle, Program

cycle or Erase cycle are ignored, and the internal Write Status Register cycle, Program

cycle or Erase cycle continues unaffected.

23/63

Page 24

Instructions M25PX32

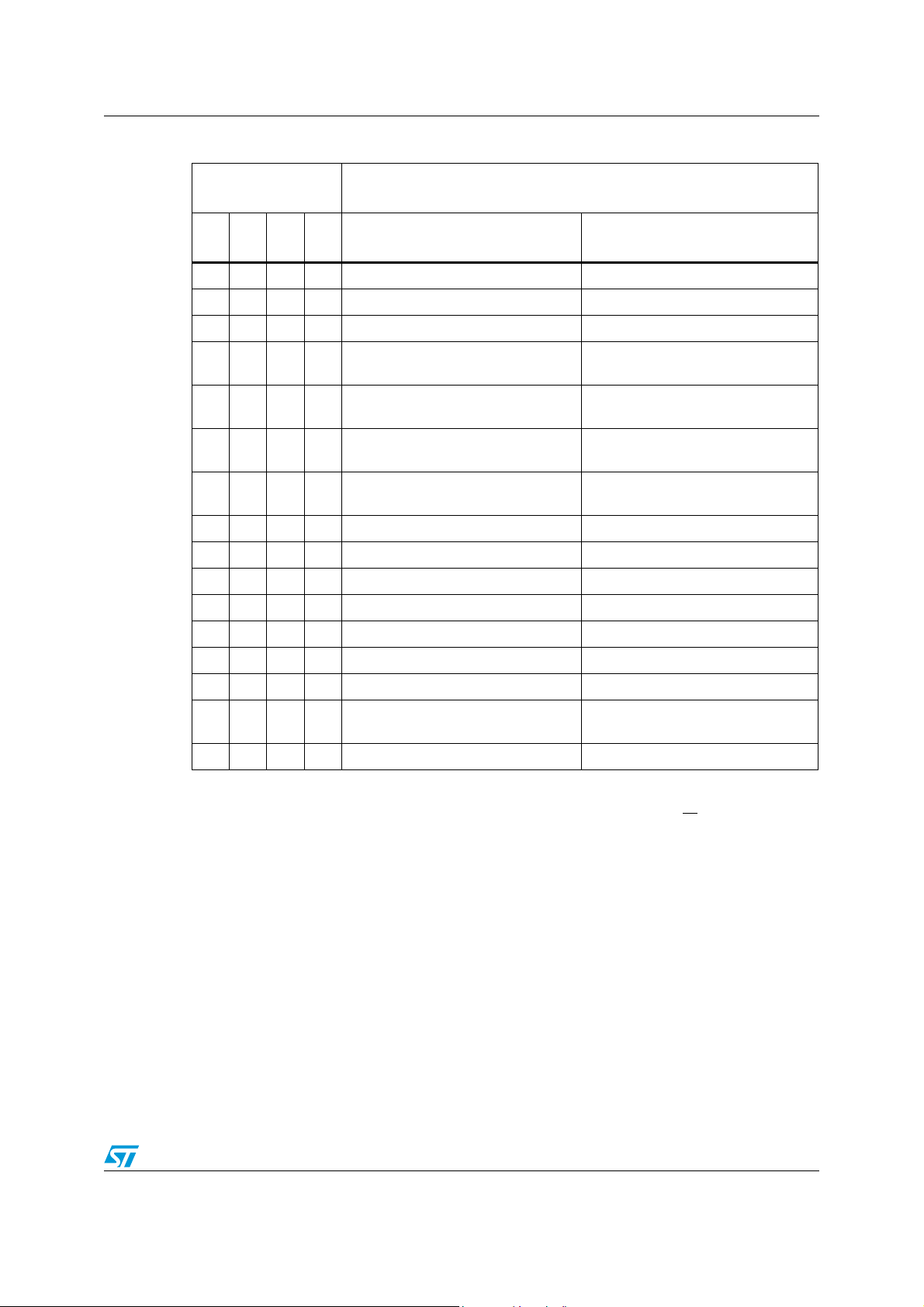

Table 5. Instruction set

Instruction Description

One-byte instruction

code

Address

bytes

Dummy

bytes

WREN Write Enable 0000 0110 06h 0 0 0

WRDI Write Disable 0000 0100 04h 0 0 0

1001 1111 9Fh 0 0 1 to 20

RDID Read Identification

1001 1110 9Eh 0 0 1 to 3

RDSR Read Status Register 0000 0101 05h 0 0 1 to ∞

WRSR Write Status Register 0000 0001 01h 0 0 1

WRLR Write to Lock Register 1110 0101 E5h 3 0 1

RDLR Read Lock Register 1110 1000 E8h 3 0 1

READ Read Data Bytes 0000 0011 03h 3 0 1 to ∞

FAST_READ

Read Data Bytes at higher

speed

0000 1011 0Bh 3 1 1 to ∞

DOFR Dual Output Fast Read 0011 1011 3Bh 3 1 1 to ∞

ROTP

POTP

Read OTP (Read 64 bytes of

OTP area)

Program OTP (Program 64

bytes of OTP area)

0100 1011 4Bh 3 1 1 to 65

0100 0010 42h 3 0 1 to 65

PP Page Program 0000 0010 02h 3 0 1 to 256

DIFP Dual Input Fast Program 1010 0010 A2h 3 0 1 to 256

SSE Subsector Erase 0010 0000 20h 3 0 0

Data

bytes

SE Sector Erase 1101 1000 D8h 3 0 0

BE Bulk Erase 1100 0111 C7h 0 0 0

DP Deep Power-down 1011 1001 B9h 0 0 0

RDP

Release from Deep Powerdown

1010 1011 ABh 0 0 0

24/63

Page 25

M25PX32 Instructions

6.1 Write Enable (WREN)

The Write Enable (WREN) instruction (Figure 8) sets the Write Enable Latch (WEL) bit.

The Write Enable Latch (WEL) bit must be set prior to e very Page Program (PP), Dual Input

Fast Prog ram (DIFP), Program OTP (POTP), Write to Lock Register (WRLR), Subsector

Erase (SSE), Sector Erase (SE), Bulk Erase (BE) and Write Status Register (WRSR)

instruction.

The Write Enable (WREN) instruction is entered by driving Chip Select (S

instruction code, and then driving Chip Select (S

) High.

Figure 8. Write Enable (WREN) instruction sequence

S

0

21 34567

C

Instruction

DQ0

High Impedance

DQ1

AI13731

) Low , send ing the

25/63

Page 26

Instructions M25PX32

6.2 Write Disable (WRDI)

The Write Disable (WRDI) instruction (Figure 9) resets the Write Enable Latch (WEL) bit.

The Write Disable (WRDI) instruction is entered by driving Chip Select (S

instruction code, and then driving Chip Select (S

) High.

The Write Enable Latch (WEL) bit is reset under the following conditions:

● Power-up

● Write Disable (WRDI) instruction completion

● Write Status Register (WRSR) instruction completion

● Write lo Lock Register (WRLR) instruction completion

● P age Program (PP) instruction completion

● Dual Input Fast Program (DIFP) instruction completion

● Program OTP (POTP) instruction completion

● Subsector Erase (SSE) instruction completion

● Sector Erase (SE) instruction completion

● Bulk Erase (BE) instruction completion

Figure 9. Write Disable (WRDI) instruction sequence

S

0

21 34567

C

Instruction

) Low , se nding the

DQ0

DQ1

High Impedance

AI13732

26/63

Page 27

M25PX32 Instructions

6.3 Read Identification (RDID)

The Read Identification (RDID) instruction allows to read the device identification data:

● Manufacturer identification (one byte)

● Device identification (two bytes)

● A Unique ID code (UID) followed by 16 bytes of CFI data

The manufacturer identification is assigned by JEDEC, and has the value 20h for

STMicroelectronics. The device identification is assigned by the device manufacturer, and

indicates the memory type in the first byte (71h), and the memory capacity of the device in

the second byte (16h). The UID is set to 10h and indicates that 16 bytes, related to the CFI

content, are following.

Any Read Identification (RDID) instruction while an Erase or Progr am cycle is in progress, is

not decoded, and has no effect on the cycle that is in progress.

The Read Identification (RDID) instruction should not be issued while the device is in Deep

Pow er-down mode.

The device is first selected by driving Chip Select (S

) Low. Then, the 8-bit instruction code

for the instruction is shifted in. After this, the 24-bit device identification, stored in the

memory, the 8-bit Unique ID code followed by 16 bytes of CFI content will be shifted out on

Serial Data output (DQ1). Each bit is shifted out during the falling edge of Serial Clock (C).

The instruction sequence is shown in Figure 10.

The Read Identification (RDID) instruction is terminated by driving Chip Select (S

any time during data output.

When Chip Select (S

) is driven High, the de vice is put in the Standby Power mode. Once in

the Standby P o wer m ode, the de vice w aits to be selected , so that it can receiv e, decode and

execute instructions.

Table 6. Read Identification (RDID) data-out sequence

Manufacturer identification

Device identification

UID CFI content

Memory type Memory capacity

20h 71h 16h 10h 16 bytes

Figure 10. Read Identification (RDID) instruction sequence and data-out sequence

S

0

213456789101112131415

C

Instruction

DQ0

16 17 18 28 29 30 31

) High at

DQ1

High Impedance

Manufacturer Identification

MSB

Device Identification

15

14 13 3 2 1 0

MSB

UID + CFI Data

MSB

AI06809d

27/63

Page 28

Instructions M25PX32

6.4 Read Status Register (RDSR)

The Read Status Register (RDSR) instruction allows the Status Register to be read. The

Status Register may be read at any time, even while a Program, Erase or Write Status

Register cycle is in progress. When one of these cycles is in progress, it is recommended to

check the Write In Progress (WIP) bit before sending a new instruction to the device. It is

also possible to read the Status Register continuously, as shown in Figure 11.

Table 7. Status Register format

b7 b0

SRWD 0 TB BP2 BP1 BP0 WEL WIP

Status Register Write Protect

Top/Bottom bit

Block Protect bits

Write Enable Latch bit

Write In Progress bit

The status and control bits of the Status Register are as follows:

6.4.1 WIP bit

The Write In Progress (WIP) bit indicates whether the memory is busy with a Write Status

Register, Program or Erase cycle. When set to 1, such a cycle is in progress, when reset to

0 no such cycle is in progress.

6.4.2 WEL bit

The Write Enable Latch (WEL) bit indicates the status of the internal Write Enable Latch.

When set to 1 the internal Write Enable Latch is set, when set to 0 the internal Write Enable

Latch is reset and no Write Status Register, Program or Erase instruction is accepted.

6.4.3 BP2 , BP1, BP0 bits

The Block Protect (BP2, BP1, BP0) bits are non-volatile. They define the size of the area to

be software protected against Program and Erase instructions. These bits are written with

the Write Status Register (WRSR) instruction. When one or more of the Block Protect (BP2,

BP1, BP0) bits is set to 1, the relevant memory area (as defined in Table 3) becomes

protected against Page Program (PP) and Sector Erase (SE) instructions. The Block Protect

(BP2, BP1, BP0) bits can be written provided that the Hardware Protected mode has not

been set. The Bulk Erase (BE) instruction is executed if, and only if, all Block Protect (BP2,

BP1, BP0) bits are 0.

28/63

Page 29

M25PX32 Instructions

6.4.4 TB bit

The Top/Bottom (TB) bit is non-volatile. It can be set and reset with the Write Status

Register (WRSR) instruction provided that the Write Enable (WREN) instruction has been

issued. The Top/Bottom (TB) bit is used in conjunction with the Block Protect (BP0, BP1,

BP2) bits to determine if the protected area defined by the Block Protect bits starts from the

top or the bottom of the memory array:

● When TB is reset to ‘0’ (default value), the area protected by the Block Protect bits

starts from the to p of th e me m ory array (see Table 3: Protected area sizes)

● When TB is set to ‘1’, the area prote cted by the Block Protect bits starts from the

bottom of the memory array (see Table 3: Protected area sizes)

The TB bit cannot be written when the SRWD bit is set to ‘1’ and t he W

6.4.5 SRWD bit

The Status Register Write Disable (SRWD) bit is operated in conjunction with the Write

Protect (W

(W

/VPP) signal allow the device to be put in the hardware protected mode (when the Status

Register Write Disable (SRWD) bit is set to ‘1’, and Write Protect (W

this mode, the non-volatile bits of the Status Register (SRWD, BP2, BP1, BP0) become

read-only bits and the Write Status Register (WRSR) instruction is no longer accepted for

execution.

Figure 11. Read Status Register (RDSR) instruction sequence and data-out

S

C

DQ0

DQ1

pin is driven Low.

/VPP) signal. The Status Register Write Disable (SRWD) bit and the Write Protect

/VPP) is driven Low). In

sequence

21 3456789101112131415

0

Instruction

High Impedance

Status Register Out

7 6543210

MSB

Status Register Out

7 6543210

MSB

7

AI13734

29/63

Page 30

Instructions M25PX32

6.5 Write Status Register (WRSR)

The Write Status Register (WRSR) instruction allows new values to be written to the Status

Register. Before it can be accepted, a Write Enable (WREN) instruction must previously

have been executed. After the Write Enable (WREN) instruction has been decoded and

executed, the device sets the Write Enable Latch (WEL).

The Write Status Register (WRSR) instruction is entered by driving Chip Select (S

) Low,

followed by the instruction code and the data byte on Serial Data inpu t (DQ0).

The instruction sequence is shown in Figure 12.

The Write Status Register (WRSR) instruction has no effect on b6, b1 and b0 of the Status

Register. b6 is always read as ‘0’.

Chip Select (S

) must be driven High after t he eighth bit of th e data b y te has bee n latched in .

If not, the Write Status Register (WRSR) instruction is not executed. As soon as Chip Select

(S

) is driven High, the self-timed Write Status Register cycle (whose duration is tW) is

initiated. While the Write Status Register cycle is in progress, the Status Register may still

be read to check the value of the Write In Progress (WIP) bit. The Write In Progress (WIP)

bit is 1 during the self-timed Write Status Register cycle, and is 0 when it is completed.

When the cycle is completed, the Write Enable Latch (WEL) is r eset.

The Write Status Register (WRSR) instruction allows the user to change the values of the

Block Protect (BP2, BP1, BP0) bits, to define the size of the area that is to be treated as

read-only, as defined in Table 3. The Write Status Register (WRSR) instruction also allows

the user to set and reset the Status Register Write Disable (SRWD) bit in accordance with

the Write Protect (W

Protect (W

/VPP) signal allow the device to be put in the hardware protected mode (HPM).

/VPP) signal. The Status Register Write Disable (SRWD) bit and Write

The Write Status Register (WRSR) instruction is not e xecuted once the hardware protected

mode (HPM) is entered.

Figure 12. Write Status Register (WRSR) instruction sequence

S

21 3456789101112131415

0

C

Instruction Status

DQ0

High Impedance

DQ1

30/63

Register In

765432 0

MSB

1

AI13735

Page 31

M25PX32 Instructions

Table 8. Protection modes

W/VPP

signal

10

00

11

01

1. As defined by the values in the Block Protect (BP2, BP1, BP0) bits of the Status Register, as shown in

Table 3.

SRWD

bit

Mode

Software

protected

(SPM)

Hardware

protected

(HPM)

Write Protection

of the Status

Register

Status Register is

Writable (if the

WREN instruction

has set the WEL

bit)

The values in the

SRWD, BP2, BP1

and BP0 bits can

be changed

Status Register is

hardware write

protected

The values in the

SRWD, BP2, BP1

and BP0 bits

cannot be changed

Protected area

Protected against

Page Program,

Sector Erase and

Bulk Erase

Protected against

Page Program,

Sector Erase and

Bulk Erase

Memory content

(1)

Unprotected area

Ready to accept

Page Program and

Sector Erase

instructions

Ready to accept

Page Program and

Sector Erase

instructions

(1)

The protection features of the device are summarized in Table 8.

When the Status Register Write Disable (SRWD) bit of the Status Register is 0 (its initial

delivery state), it is possible to write to the Status Register provid ed that the Write Enable

Latch (WEL) bit has previously been set by a Write Enable (WREN) instruction, regardless

of the whether Write Protect (W

/VPP) is driven High or Low.

When the Status Register Write Disable (SRWD) bit of the Status Register is set to 1, two

cases need to be considered, depending on the state of Write Protect (W

● If Write Protect (W/V

) is driven High, it is possible to write to the Status Register

PP

/VPP):

provided that the Write Enable Latch (WEL) bit has previously been set by a Write

Enable (WREN) instruction.

● If Write Protect (W/V

) is driven Low, it is not possible to write to the Status Register

PP

even if the Write Enable Latch (WEL) bit has previously been set by a Write Enable

(WREN) instruction. (Attempts to write to the Status Register are rejected, and are not

accepted for execution). As a consequence, all the data bytes in the memory area that

are software protected (SPM) by the Block Protect (BP2, BP1, BP0) bits of the Status

Register, are also hardware protected against data modification.

Regardless of the order of the two events, the Hardware Protected mode (HPM) can be

entered:

● by setting the Status Register Write Disable (SRWD) bit after driving Write Protect

(W

/VPP) Low

● or by driving Write Protect (W/V

) Low after setting the Status Register Write Disable

PP

(SRWD) bit.

The only way to exit the Hardware Protected mode (HPM) once entered is to pull Write

Protect (W

If Write Protect (W

/VPP) High.

/VPP) is permanently tied High, the Hardware Protected mode (HPM) can

never be activated, and only the Software Protected mode (SPM), using the Block Protect

(BP2, BP1, BP0) bits of the Status Register, can be used.

31/63

Page 32

Instructions M25PX32

6.6 Read Data Bytes (READ)

The device is first selected by driving Chip Select (S) Low. The instruction code for the Read

Data Bytes (READ) instruction is followed by a 3-byte address (A23-A0), each bit being

latched-in during the rising edge of Serial Clock (C). Then the memory contents, at that

address, is shifted out on Serial Data output (DQ1), each bit being shifted out, at a

maximum frequency f

The instruction sequence is shown in Figure 13.

The first byte addressed can be at any location. The address is automatically incremented

to the next higher address after each byte of data is shifted out. The whole memory can,

therefore, be read with a single Read Data Bytes (READ) instruction. When the highest

address is reached, the address counter rolls over to 000000h, allowing the read sequence

to be continued indefinitely.

, during the falling edge of Serial Clock (C).

R

The Read Data Bytes (READ) instruction is terminated by driving Chip Select (S

Select (S

) can be driven High at any time during data output. Any Read Data Bytes (READ)

) High. Chip

instruction, while an Erase, Program or Write cycle is in progress, is rejected without having

any effects on the cycle that is in progress.

Figure 13. Read Data Bytes (READ) instruction sequence and data-out sequence

S

21 345678910 2829303132333435

0

C

Instruction 24-bit address

DQ0

DQ1

1. Address bits A23 to A22 are Don’t care.

High Impedance

23

2221 3210

MSB

76543 1 7

MSB

36 37 38

Data Out 1

39

Data Out 2

2

0

AI13736

32/63

Page 33

M25PX32 Instructions

6.7 Read Data Bytes at higher speed (FAST_READ)

The device is first selected by driving Chip Select (S) Low. The instruction code for the Read

Data Bytes at higher speed (FAST_READ) instruction is followed by a 3-b yte address (A23A0) and a dummy byte, each bit being latched-in during the rising edge of Serial Clock (C).

Then the memory contents, at that address , are shif ted out o n Serial Data output (D Q1) at a

maximum frequency f

The instruction sequence is shown in Figure 14.

The first byte addressed can be at any location. The address is automatically incremented

to the next higher address after each byte of data is shifted out. The whole memory can,

therefore, be r ead with a single Read Data Bytes at higher speed (FAST_READ) instruction.

When the highest address is reached, the address counter rolls over to 000000h, allo wing

the read sequence to be continued indefinite ly.

The Read Data Bytes at higher speed (FAST_READ) instruction is terminated by driving

Chip Select (S

) High. Chip Select (S) can be driven High at any time du ring data output. An y

Read Data Bytes at higher speed (FAST_READ) instruction, while an Erase, Program or

Write cycle is in progress, is rejected without having any effects on the cycle that is in

progress.

Figure 14. Read Data Bytes at higher speed (FAST_READ) instruction sequence

and data-out sequence

, during the falling edge of Serial Clock (C).

C

DQ0

DQ1

S

C

DQ0

DQ1

21 345678910 28293031

0

Instruction 24-bit address

23

2221 3210

High Impedance

S

32 33 34 36 37 38 39 40 41 42 43 44 45 46

C

765432 0

35

Dummy byte

1

DATA OUT 1

765432 0

MSB

47

DATA OUT 2

7 6543210

1

MSB MSB

7

1. Address bits A23 to A22 are Don’t care.

AI13737

33/63

Page 34

Instructions M25PX32

6.8 Dual Output Fast Read (DOFR)

The Dual Output Fast Read (DOFR) instruction is very similar to the Read Data Bytes at

higher speed (FAST_READ) instruction, except that the data are shifted out on two pins (pin

DQ0 and pin DQ1) instead of only one. Outputting the data on two pins instead of one

doubles the data transfer bandwidth compared to the Read Data Bytes at higher speed

(FAST_READ) instruction.

The device is first selected by driving Chip Select (S

) Low . The instruction code for the Dual

Output Fast Read instruction is followed b y a 3-byte address (A23-A0) and a dummy byte,

each bit being latched-in during the rising edge of Serial Clock (C). Then the memory

contents, at that address, are shifted out on DQ0 and DQ1 at a maximum frequency f

,

C

during the falling edge of Serial Clock (C).

The instruction sequence is shown in Figure 15.

The first byte addressed can be at any location. The address is automatically incremented

to the next higher address after each byte of data is shifted ou t on DQ0 and DQ1. The whole

memory can, therefore, be read with a single Dual Output Fast Read (DOFR) instruction.

When the highest address is reached, the address counter rolls over to 00 0000h, so that

the read sequence can be continued indefinitely.

Figure 15. Dual Output Fast Read instruction sequence

S

DQ0

DQ1

C

Mode 3

Mode 2

21 345678910 282930310

Instruction 24-bit address

23 22 21 3 2 1 0

High Impedance

S

32 33 34 36 37 38 39 40 41 42 43 44 45 46

C

DQ0

DQ1

1. A23 to A22 are Don't care.

35

Dummy byte

642064 02

DATA OUT 1

753175 1

MSB

34/63

47

6420 64 02

DATA OUT 2 DATA OUT 3 DATA OUT n

7 531 7531

3

MSB MSB

MSB MSB

ai13574

Page 35

M25PX32 Instructions

6.9 Read Lock Register (RDLR)

The device is first selected by driving Chip Select (S) Low. The instruction code for the Read

Lock Register (RDLR) instruction is followed by a 3-byte address (A23-A0) pointing to any

location inside the concerned sector. Each ad dress bit is latched-in during the rising edge of

Serial Clock (C). Then the value of the Lock Register is shifted out on Serial Data outp u t

(DQ1), each bit being shifted out, at a maximum frequency f

Serial Clock (C).

The instruction sequence is shown in Figure 16.

, during the falling edge of

C

The Read Lock Register (RDLR) instruction is terminated by driving Chip Select (S

) High at

any time during data output.

Any Read Lock Register (RDLR) instruction, while an Erase, Program or Write cycle is in

progress, is rejected without having any effects on the cycle that is in progress.

Table 9. Lock Register out

Bit Bit name Value Function

b7-b2 Reserved

b1 Sector Lock Down

b0 Sector Write Lock

1. Values of (b1, b0) after Power-up are defined in Section 7: Power-up and power-down.

(1)

The Write Lock and Lock Down bits cannot be changed.

‘1’

Once a ‘1’ is written to the Lock Down bit it cannot be cleared

to ‘0’, except by a power-up.

The Write Lock and Lock Down bits can be changed by

‘0’

writing new values to them.

Write, Program and Erase operations in this sector will not be

‘1’

executed. The memory contents will not be changed.

Write, Program and Erase operations in this sector are

‘0’

executed and will modify the sector contents.

Figure 16. Read Lock Register (RDLR) instruction sequence and data-out sequence

S

DQ0

DQ1

21 345678910 2829303132333435

0

C

Instruction 24-bit address

23

2221 3210

MSB

High Impedance

Lock Register Out

76543 1

MSB

36 37 38

2

39

0

AI13738

35/63

Page 36

Instructions M25PX32

6.10 Read OTP (ROTP)

The device is first selected by driving Chip Select (S) Low. The instruction code for the Read

OTP (ROTP) instruction is f o llowed by a 3-byte ad dress (A23 - A0 ) and a dum my byte. Each

bit is latched in on the rising edge of Serial Clock (C).

Then the memory conte nt s at th at ad d re ss ar e sh ifte d ou t on Serial Data output (DQ1).

Each bit is shifted out at the maximum frequency, f

(C). The instruction sequence is shown in Figure 17.

The address is automatically incremented to the next higher address after each b yte of data

is shifted out.

There is no rollover mechanism with the Re ad OTP (ROT P) instruction. This means that the

Read OTP (ROTP) instruction must be sent with a maximum of 65 b ytes to read , since once

th

the 65

byte has been read, the same (65th) byte keeps being read on the DQ1 pin.

max, on the falling edg e of Serial Clock

C

The Read OTP (RO TP) instruction is terminated by driving Chip Select (S

(S

) can be driven High at any time during data output. Any Read OTP (ROTP) instruction

) High. Chip Select

issued while an Erase, Program or Write cycle is in progress, is rejected without having any

effect on the cycle that is in progress.

Figure 17. Read OTP (ROTP) instruction and data-out sequence

S

21 345678910 28293031

0

C

Instruction 24-bit address

23

DQ0

DQ1

High Impedance

S

32 33 34 36 37 38 39 40 41 42 43 44 45 46

C

35

2221 3210

47

Dummy byte

DQ0

DQ1

1. A23 to A7 are Don't care.

2. 1 ≤ n ≤ 65.

765432 0

1

765432 0

MSB

36/63

DATA OUT 1

DATA OUT n

1

7 6543210

MSB MSB

7

AI13573

Page 37

M25PX32 Instructions

6.11 Page Program (PP)

The Page Program (PP) instruction allows bytes to be progra mmed in the memory

(changing bits from 1 to 0). Before it can be accepted, a Write Enable (WREN) instruction

must previously have been executed. After the Write Enable (WREN) instruction has been

decoded, the device sets the Write Enable Latch (WEL).

The Page Program (PP) instruction is entered by driving Chip Select (S

the instruction code, three address bytes and at least one data byte on Serial Data input

(DQ0). If the 8 least significant address bits (A7-A0) are not all z ero , all tr ansmitted data that

goes beyond the end of the current page are programmed f rom the start address of the

same page (from the address whose 8 least significant bits (A7-A0) are all zero). Chip

Select (S

The instruction sequence is shown in Figure 18.

If more than 256 by tes ar e se nt t o the device, previo usly latche d data are discarded and the

last 256 data bytes are guaranteed t o be progr ammed correctly within the same page . If less

than 256 data bytes are sent to device, they are correctly programmed at the requested

addresses without having any effects on the other bytes of the same page.

For optimized timings, it is recommended to use the Page Program (PP) instruction to

program all consecutive targeted bytes in a single sequence versus using several Page

Program (PP) sequences with each containing only a few bytes (see Table 17: AC

characteristics).

Chip Select (S

latched in, otherwise the Page Program (PP) instruction is not ex ecuted.

As soon as Chip Select (S

duration is t

may be read to check the value of the Write In Progress (WIP) bit. The Write In Progress

(WIP) bit is 1 during the self-timed Page Program cycle, and is 0 when it is completed. At

some unspecified time before the cycle is completed, the Write Enable Latch (WEL) bit is

reset.

) must be driven Low for the entire duration of the sequence.

) must be driven High after the eighth bit of the last data byte has been

) is driven High, the self-timed Page Program cycle (whose

) is initiated. While the Page Program cycle is in progress , the Statu s Register

PP

) Low, followed by

A Page Progr am (PP) instruction applied to a page which is protected by the Block Protect

(BP2, BP1, BP0) bits (see Table 3 and Table 4) is not executed.

37/63

Page 38

Instructions M25PX32

Figure 18. Page Program (PP) instruction sequence

S

21 345678910 2829303132333435

0

C

Instruction 24-bit address

DQ0

S

4241 43 44 45 46 47 48 49 50 52 53 54 5540

C

Data byte 2

DQ0

765432 0

MSB MSB MSB

1

1. Address bits A23 to A22 are Don’t care.

23

2221 3210

MSB

51

Data byte 3 Data byte 256

765432 0

1

765432 0

MSB

2072

765432 0

Data byte 1

2074

2073

36 37 38

2076

2075

2077

1

1

2078

39

2079

AI13739

38/63

Page 39

M25PX32 Instructions

6.12 Dual Input Fast Program (DIFP)

The Dual Input Fast Program (DIFP) instruction is very similar to the Page Program (PP)

instruction, except that the data are entered on two pins (pin DQ0 and pin DQ1) instead of

only one. Inputting the data on two pins instead of one doubles the data transfer bandwidth

compared to the Pag e Program (PP) instruction.

The Dual Input Fast Program (DIFP) instruction is entered by driving Chip Select (S

followed by the instruction code, three address bytes and at least one data byte on Serial

Data input (DQ0).

If the 8 least significant address bits (A7-A0) are not all zero, all transmitted data that goes