Page 1

512 Kbit, Low Voltage, Serial Flash Memory

FEATURES SUMMARY

■ 512 Kbit of Flash Memory

■ Page Program (up to 256 Bytes) in 1.5ms

(typical)

■ Sector Erase (256 Kbit) in 2 s (typical)

■ Bulk Erase (512 Kbit) in 3 s (typical)

■ 2.7 V to 3.6 V Single Supply Voltage

■ SPI Bus Compatible Serial Interface

■ 25 MHz Clock Rate (maximum)

■ Deep Power-down Mode 1 µA (typical)

■ Electronic Signature (05h)

■ More than 100,000 Erase/Program Cycles per

Sector

■ More than 20 Year Data Retention

M25P05-A

With 25 MHz SPI Bus Interface

Figure 1. Packages

8

1

SO8 (MN)

150 mil width

ENHANCED VERSION OF THE M25P05

This device is an enhanced version of the

M25P05. The enhanced features include: larger

page size, shorter programming time, higher clock

frequency, specific electronic signature.

VFQFPN8 (MP)

(MLP8)

1/34December 2002

Page 2

M25P05-A

SUMMARY DESCRIPTION

The M25P05-A is a 512 Kbit (64K x 8) Serial Flash

Memory, with advanced write protection mechanisms, accessed by a high speed SPI -compatible

bus.

The memory can be programmed 1 to 256 bytes at

a time, using the Page Program instruction.

The memory is organized as 2 sec tors, each containing 128 pages . Each page is 25 6 bytes wide.

Thus, the whole memory can be viewed as consisting of 256 pages, or 65,536 bytes.

The whole memory can be eras ed using the B ulk

Erase instruction, or a sector at a time, us ing the

Sector Erase instruction.

Figure 2. Logi c D iagram

V

CC

Figure 3. SO Connect ions

M25P05-A

1

SV

2

3

W

4

SS

AI05758B

8

CC

7

HOLDQ

6

C

5

DV

D

C

S

W

HOLD

M25P05-A

V

SS

Table 1. Signal Names

C Serial Clock

D Serial Data Input

Q Serial Data Output

S

W

Write Protect

HOLD

Hold

Chip Select

Q

AI05757

V

V

2/34

CC

SS

Supply Voltage

Ground

Page 3

SIGNAL DESCRIPTION

Serial Data Output (Q). This output signal is

used to transfer data serially out of the device.

Data is shifted out on the falling edge of Serial

Clock (C).

Serial Data Input (D). This input signal is used to

transfer data serially into the device. It receives instructions, addresses, and the data to be programmed. Values are latched on the rising edge of

Serial Clock (C).

Serial Clock (C). This input signal provides the

timing of the serial interface. Instructions, addresses, or data present at Serial Data Input (D) are

latched on the rising edge of Serial Clock (C). Data

on Serial Data Output (Q) changes after the falling

edge of Serial Clock (C).

Chip Select (S

). When this input signal is High,

the device is des elected and Serial Data Output

(Q) is at high impedance. Unless an internal Program, Erase or Write Status Register cycle is in

progress, the device will b e in the Standby m ode

M25P05-A

(this is not the Deep Power-down mode). Driving

Chip Selec t ( S

in the active power mode.

After Power-up, a falling edge on Chip Select (S

is required prior to the start of any instruction.

Hold (HOLD

pause any serial communications with the device

without deselecting the device.

During the Hold condition, the Serial Data Output

(Q) is high impedanc e, and Serial D ata Input (D)

and Serial Clock (C) are Don’t Care.

To start the Hold condition, the device must be selected, wit h C hip S e lec t (S

Write Protect (W

put signal is to freeze the size of the area of memory that is protected against program or erase

instructions (as specified by the values in the BP1

and BP0 bits of the Status Register).

) Low enables the device, placing it

). The Hold (HOLD) signal is used to

) driven Low.

). The main purpose of this in-

)

3/34

Page 4

M25P05-A

SPI MODES

These devices can be drive n by a microcont roller

with its SPI peripheral running in either of the two

following modes:

– CPOL=0, CPHA=0

– CPOL=1, CPHA=1

For these two modes, input dat a is latched in on

the rising edge of Serial Clock (C), and output data

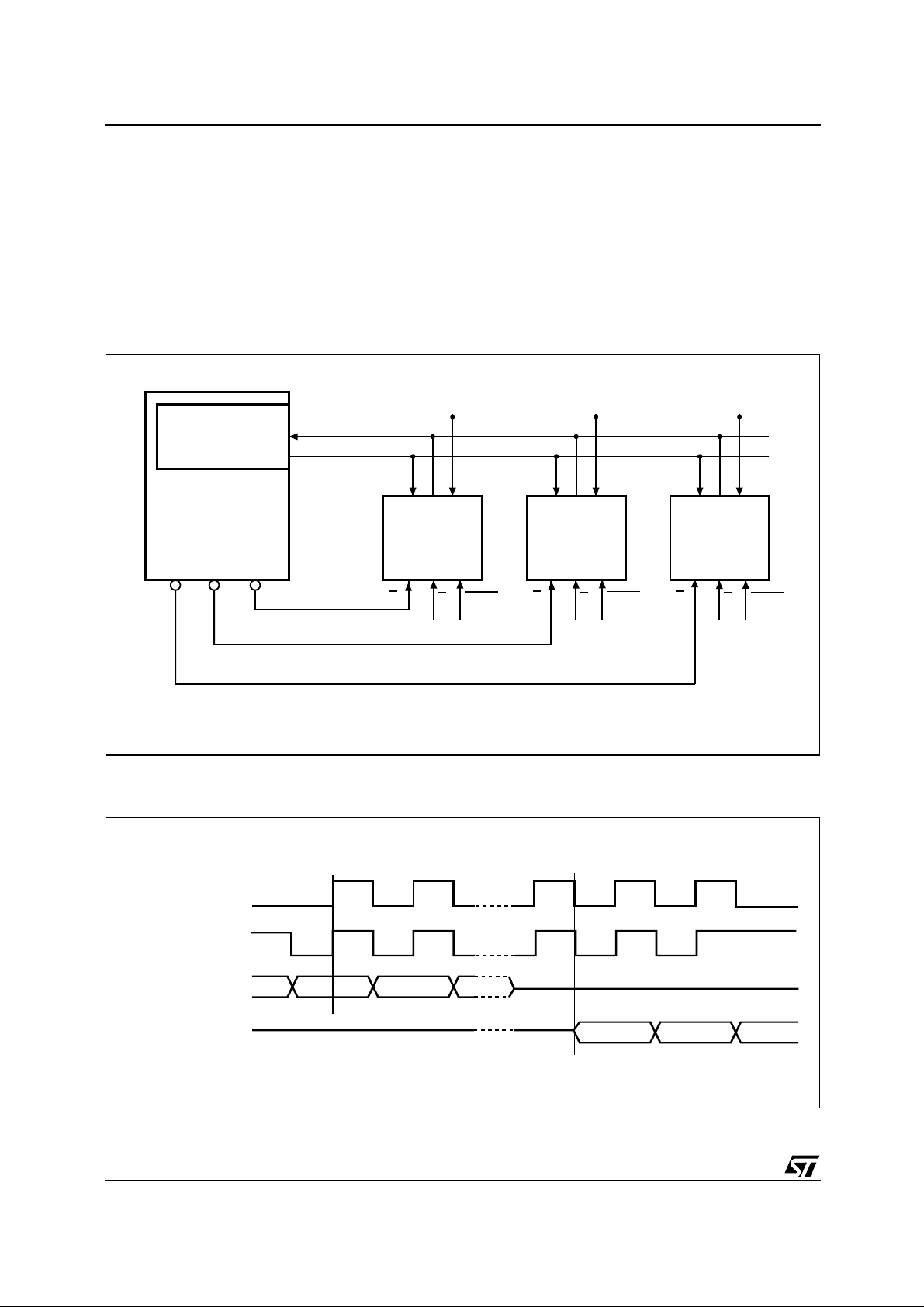

Figure 4. Bus Master and Memory Devices on the SPI Bus

is avai lable from the falling edge of Serial Cloc k

(C).

The difference between the two modes, as shown

in Figure 5, is the clock polarity when the bus master is in Stand-by mode and not transferring data:

– C remains at 0 for (CPOL=0, CPHA=0)

– C remains at 1 for (CPOL=1, CPHA=1)

SPI Interface with

(CPOL, CPHA) =

(0, 0) or (1, 1)

Bus Master

(ST6, ST7, ST9,

ST10, Others)

CS3 CS2 CS1

Note: 1. The Write Protect (W) a nd Hold (HOLD) signals should be driven, High or Low as appropriate.

SDO

SDI

SCK

CQD

SPI Memory

Device

S

CQD

SPI Memory

Device

HOLD

W

S

HOLD

W

Figure 5. SPI Modes Sup po r te d

CQD

SPI Memory

Device

S

W

AI03746D

HOLD

4/34

CPOL

0

1

CPHA

0

1

C

C

D

Q

MSB

MSB

AI01438B

Page 5

OPERATING FEATURES

Page Prog ram m i ng

To program one data byte, two instructions are required: Write Enable (WREN), which is one by te,

and a Page Program (PP) sequence, which consists of four bytes plus data. This is followed by the

internal Program cycle (of duration t

PP

).

To spread this overhead, the Page P rogram (PP)

instruction allows up to 256 bytes to be programmed at a time (changing bits from 1 to 0), provided that they lie in consecutive addresses on the

same page of memory.

Sector Erase and Bulk Erase

The Page Program (PP) instruction allows bits to

be reset from 1 to 0. Before this can be applied, the

bytes of memory need to have been e rased to a ll

1s (FFh). This can be achieved either a sector at a

time, using the Sector Erase (SE) instruction, or

throughout the entire memory, using the Bulk

Erase (BE) instruction. This starts an internal

Erase cycle (of duration t

or tBE).

SE

The Erase instruction must be preceeded by a

Write Enable (WREN) instruction.

Polling During a Write, Program or Erase Cycle

A further improvement in the time to Write Status

Register (WRSR), Program (PP) or Erase (SE or

BE) can be achieved by n ot waiting for the worst

case delay (t

, tPP, tSE, or tBE). The Write In

W

Progress (WIP) bit is provided in the Status Register so that the application program can monitor its

value, polling it to establish when the previous

Write cycle, Program cycle or Erase cycle is complete.

Active Power, Stand-by Power and De ep

Power-Down Modes

When Chip Select (S) is Low, the device is enabled, and in the Active Power mode.

When Chip Select (S

) is High, the device is dis-

abled, but could remain in the Active Power mode

M25P05-A

until all internal cycles have completed (Pro gram,

Erase, Write Status Register). The device then

goes in to the Stand-by P ower mode. T he device

consumption drops to I

The Deep Power-down mode is entered when the

specific instruction (the Enter Deep Power-down

Mode (DP) instruction) is executed. The device

consumption drops further to I

mains in this mode until another specific instruction (the Release from Deep Power-down Mode

and Read Electronic S ignature (RES ) instruction)

is executed.

All other instructions are ignored while the device

is in the Deep Power-down mode. This can be

used as an extra software protection mecha nism,

when the device is not in active use, to protect the

device from inadvertant Write, Program or Erase

instructions.

Status Register

The Status Register contains a num ber of status

and control bits, as shown in Table 5, that can be

read or set (as appropriate) by specific instructions.

WIP bit. The Write In Progress (WIP) bit indicates

whether the memory is busy with a Write Sta tus

Register, Program or Erase cycle.

WEL bit. Th e Write Enable Latch (WEL) bit indicates the status of the internal Write Enable Latch.

BP1, BP0 bits. The Block Protect (BP1, BP0) bits

are non-volatile. They define the size of the area to

be software protected against Program and Erase

instructions.

SRWD bit. The Status Register Write Disable

(SRWD) bit is operated in conjunction with the

Write Protect (W

) signal. The Status Register

Write Disable (SRWD) bit an d Write Protect (W

signal allow the device to be put in the Hardware

Protected mode. In this mode, the non-volatile bits

of the Status Register (SRWD, BP1, BP0) become

read-only bits.

CC1

.

. The device re-

CC2

)

5/34

Page 6

M25P05-A

Protection Modes

The environments where non-volatile memory devices are used can be v ery noisy. No SPI device

can operate correctly in the presence of excessive

noise. To help combat t his, t he M 25P 05-A b oas ts

the following data protection mechanisms:

■ Power-On Reset and an internal timer (t

can provide protection against inadvertant

changes while the power supply is outside the

operating specification.

■ Program, Erase and Write Status Register

instructions are checked that they consist of a

number of clock pulses that is a multiple of

eight, before they are accepted for execution.

■ All instructions that modify data must be

preceded by a Write Enable (WREN) instruction

to set the Write Enable Latch (WEL) bit . This bit

is returned to its reset state by the following

events:

– Power-up

– Write Disable (WRDI) instruction completion

PUW

)

– Write Status Register (WRSR) instruction

completion

– Page Program (PP) instruction completion

– Sector Erase (SE) instruction completion

– Bulk Erase (BE) instruction completion

■ The Block Protect (BP1, BP0) bits allow part of

the memory to be configured as read-only. This

is the Software Protected Mode (SPM).

■ The Write Protect (W) signal, in co-operation

with the Status Register Write Disabl e (SRWD)

bit, allows the Block Protect (BP1, BP0) bits and

Status Register Write Disable (SRWD) bit to be

write-protected. This is the Hardware Protected

Mode (HPM).

■ In addition to the low power consumption

feature, the Deep Power-down mode offers

extra software protection from inadvertant

Write, Program and Erase instructions, as all

instructions are ignored except one particular

instruction (the Release from Deep Powerdown instruction).

Table 2. Protected Area Sizes

Status Register

Content

BP1 Bit BP0 Bit Protected Area Unprotected Area

0 0 none All sectors (Sectors 0 and 1)

0 1

1 0

1 1 All sectors (Sectors 0 and 1) none

Note: 1. The device is ready to accept a Bulk Erase instru ct i on if, and only i f, bo th Block Protec t (BP1, BP0) are 0.

No protection against Page Program (PP) and Sector Erase (SE)

All sectors (Sectors 0 and 1) protected against Bulk Erase (BE)

Memory Content

6/34

Page 7

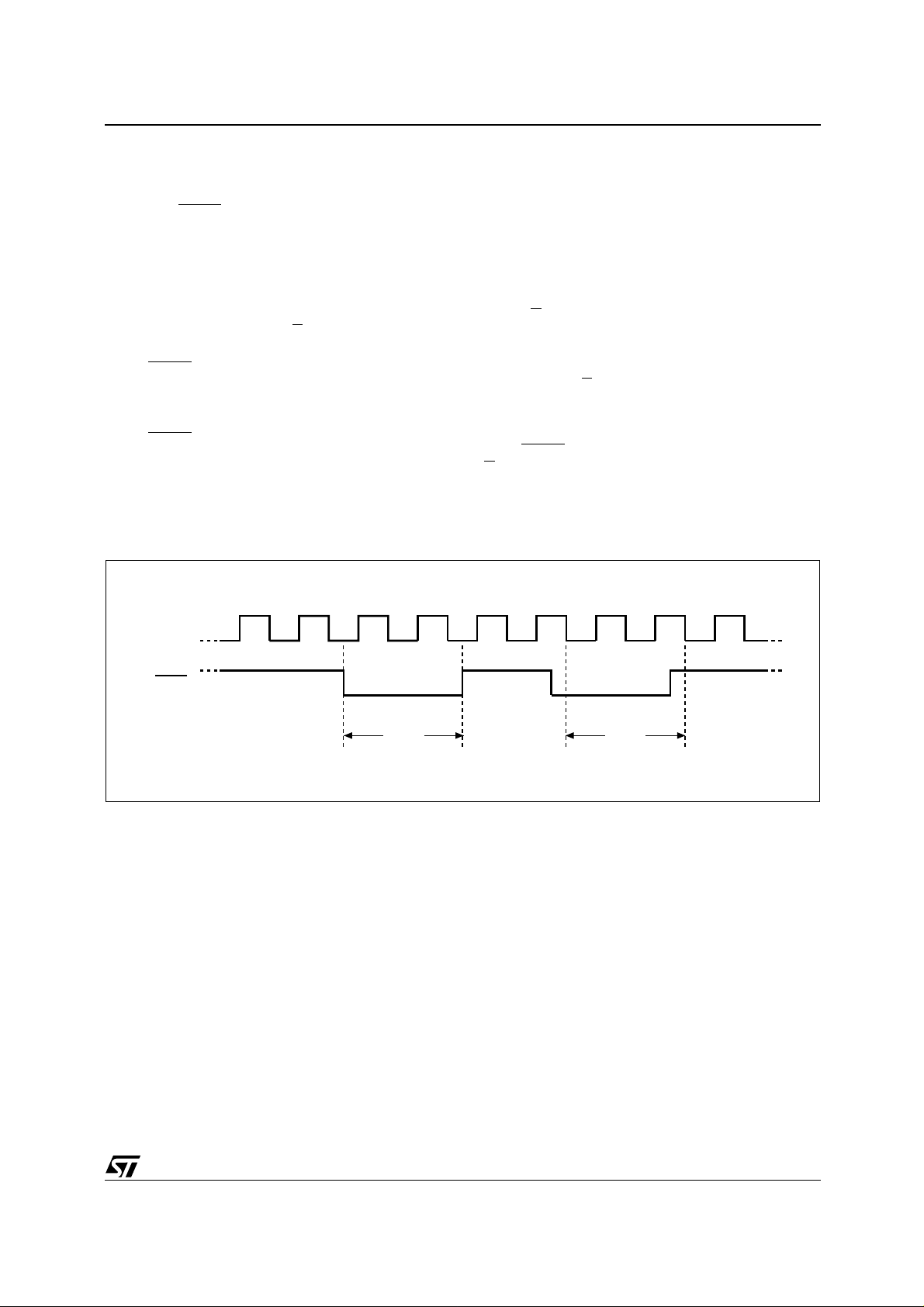

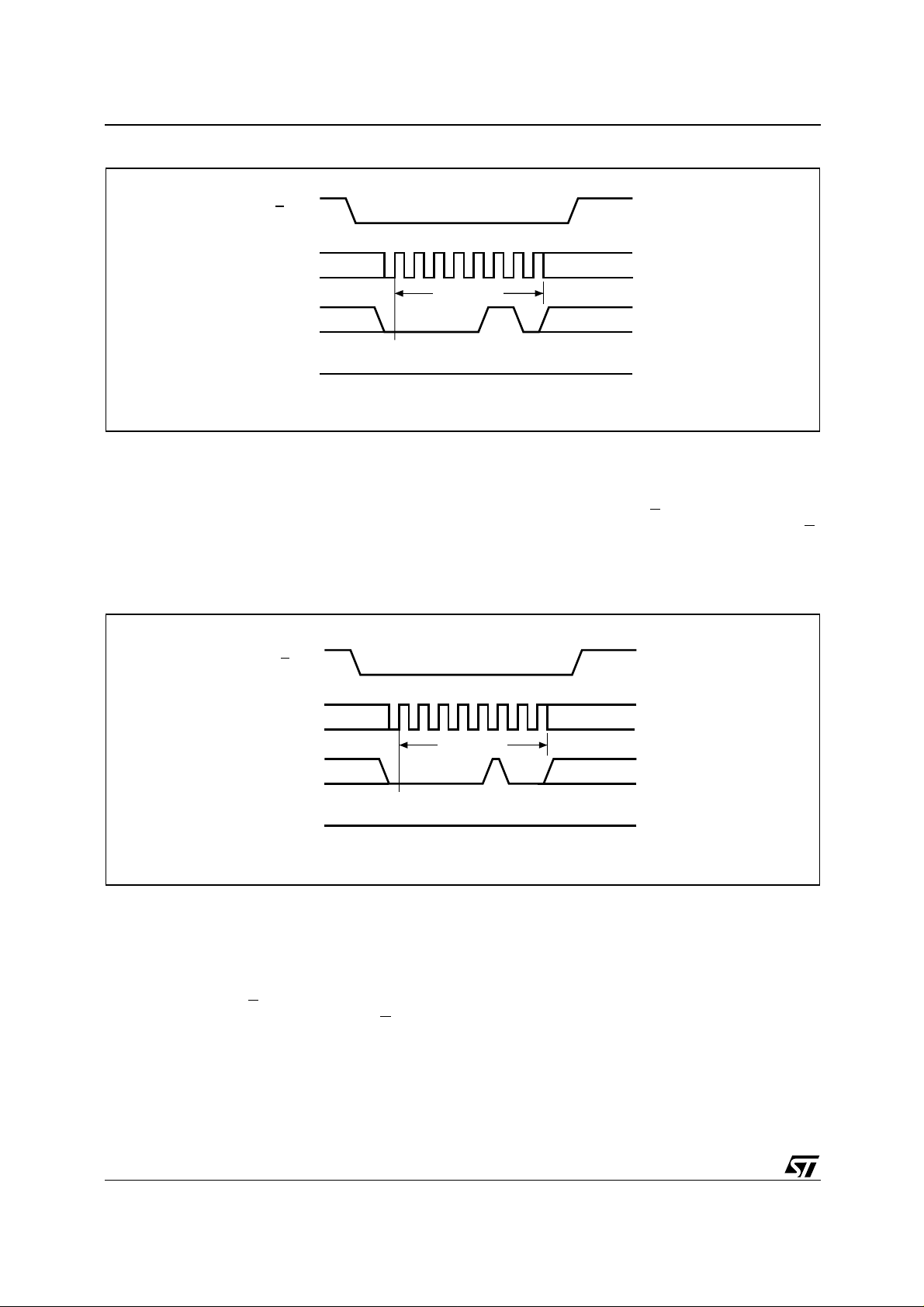

Hold Condition

The Hold (HOLD

) signal is used to pause any serial communications with the device without resetting the clocking sequence. However, taking this

signal Low does not terminate any Write Status

Register, Program or Erase cycle that is currently

in progress.

To enter the Hold condition, the device must be

selecte d, w it h C h ip Select ( S

) Low.

The Hold condition starts on the falling edge of the

Hold (HOLD

) signal, provided that this coincides

with Serial Clock (C) being Low (as shown in Figure 6).

The Hold condition ends on the rising edge of the

Hold (HOLD

) signal, provided that this coincides

with Serial Clock (C) being Low.

If the falling edge does not coincide with Serial

Clock (C) being Low, the Hold condition starts after Serial Clock (C) next goes Low. Similarly, if the

Figure 6. Hold Condition Activation

M25P05-A

rising edge does not coincide with Serial Clock (C)

being Low, the Hold condition ends after Serial

Clock (C) next goes Low. (This is shown in Figure

6).

During the Hold condition, the Serial Data Output

(Q) is high impedanc e, and Serial D ata Input (D)

and Serial Clock (C) are Don’t Care.

Normally, the device is kept selected, with Chip

Select (S

Hold condition. This is to en sure that the state of

the internal logic remains unchanged from the moment of entering the Hold condition.

If Chip Select (S

the Hold condition, this has the effect of reset ting

the internal logic of the device. To restart communication with the device, it is necessary to drive

Hold (HOLD

(S

to the Hold condition.

) driven Low, for the whole duration of the

) goes High while the d ev ice is in

) High, and then to drive Chip Select

) Low. This prevents the device from going back

HOLD

C

Hold

Condition

(standard use)

Hold

Condition

(non-standard use)

AI02029D

7/34

Page 8

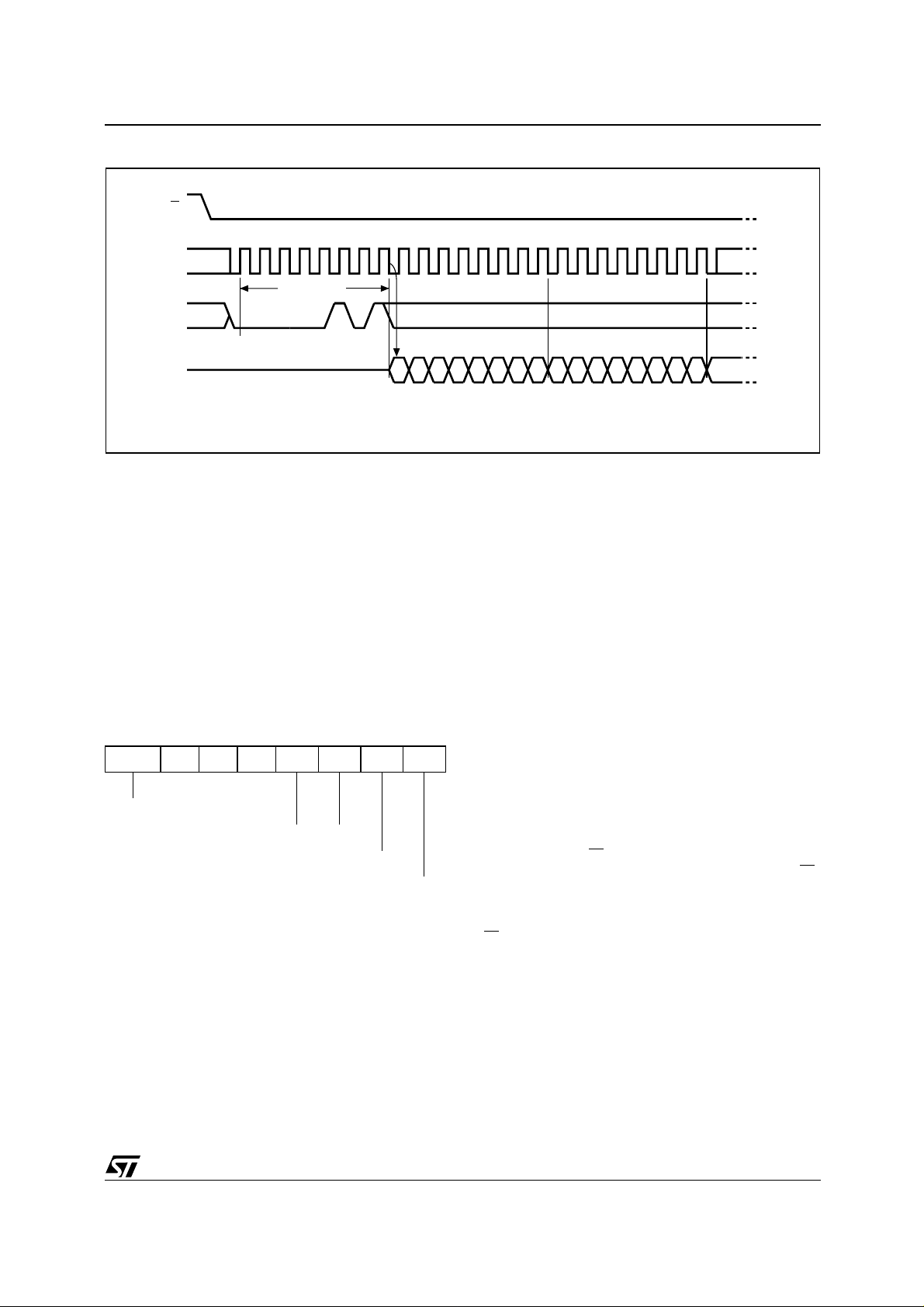

M25P05-A

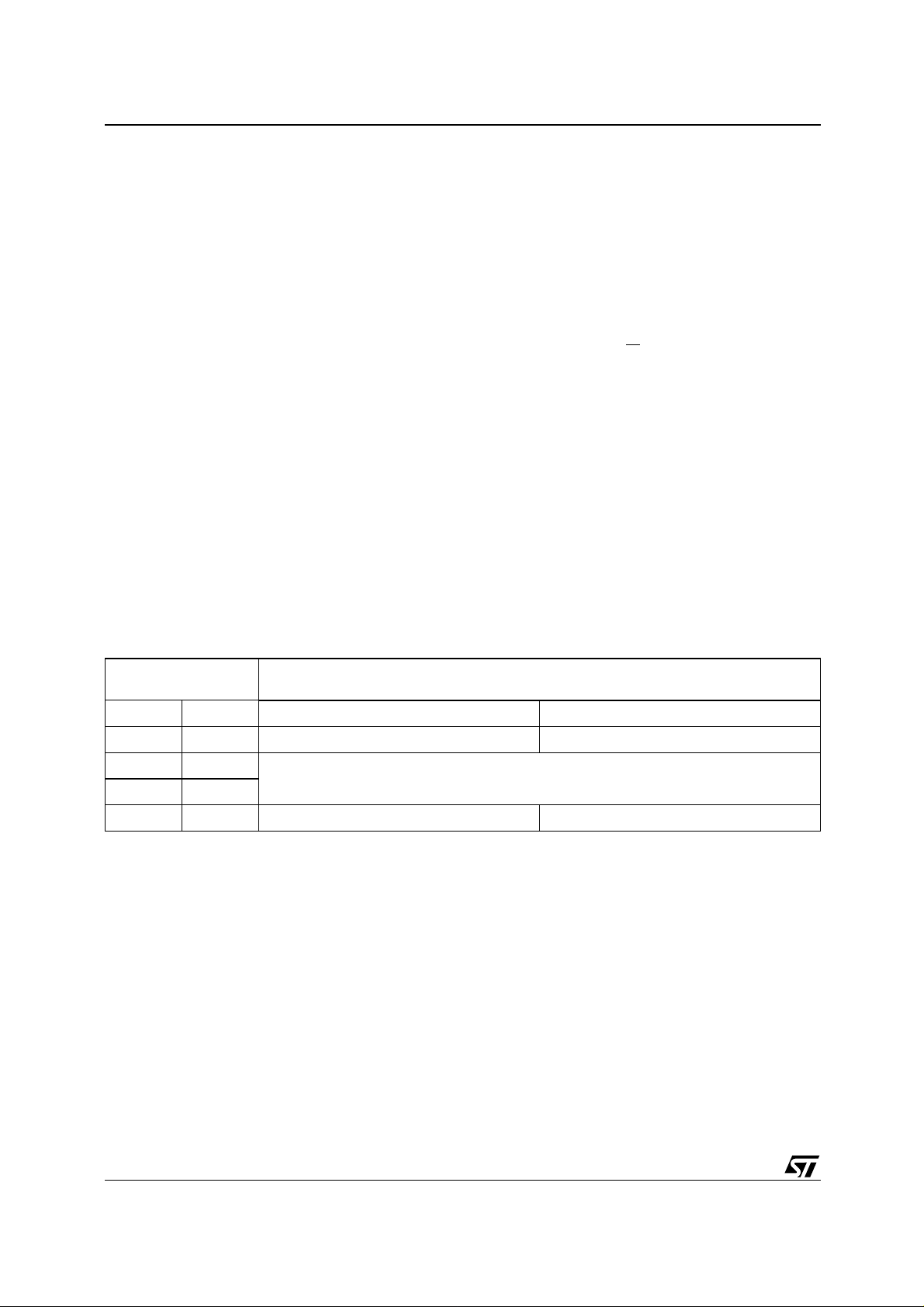

MEMORY OR GANIZATION

The memory is organized as:

■ 65,536 bytes (8 bits each)

■ 2 sectors (256 Kbits, 32768 bytes each)

■ 256 pages (256 bytes each).

Each page can be individually programmed (bits

are programmed from 1 to 0). The device is Sector

Figure 7. Block D ia gram

or Bulk Erasable (bits are erased from 0 to 1) but

not Page Erasable.

Table 3. Memory Organization

Sector Address Range

1 08000h 0FFFFh

0 00000h 07FFFh

HOLD

W

S

C

D

Q

Control Logic

Address Register

and Counter

08000h

Y Decoder

High Voltage

Generator

I/O Shift Register

256 Byte

Data Buffer

Status

Register

0FFFFh

Size of the

read-only

memory area

8/34

00000h

000FFh

256 Bytes (Page Size)

X Decoder

AI05759

Page 9

INSTRUCTIONS

All instructions, addresses and data are shifted in

and out of the device, most significant bit first.

Serial Data Input (D) is sampled on the first rising

edge of Serial Clock (C) a fter Chip Select (S

) is

driven Low. Then, the one-byte instruction code

must be shifted in to the device, most significant bit

first, on Serial Data Input (D), each bit being

latched on the rising edges of Serial Clock (C).

The instruction set is listed in Table 4.

Every instruction sequence starts with a one-byte

instruction code. Depending on the instruction,

this might be followed by address bytes, or by data

bytes, or by both or none. Chip Select (S

) must be

driven High after the last bit of the instruction sequence has been shifted in.

In the case of a Read Data Bytes (READ), Read

Data Bytes at Higher Speed (Fast_Read), Read

Status Register (RDSR) or Release from Deep

Power-down, and Read Electronic Signature

(RES) instruction, the shifted-in instruction sequence is followed by a data-out sequ ence. Chip

Selec t (S

) can be driven High after any bit of the

data-out sequence is being shifted out.

In the case of a Page Program (PP), Sector Erase

(SE), Bulk Erase (BE), Write Status Register

(WRSR), Write Enable (WREN), Write Disable

(WRDI) or Deep Power-down (DP) instruction,

Chip Sele ct (S

byte boundary, otherwise the inst ruction is rejected, and is not executed. That is, Chip Select (S

must driven High when the number of clock pulses

after Chip Select (S

multiple of eight.

All attempts to access the memory array during a

Write Status Register cycle, Program cycle or

Erase cycle are ignored, and the internal Write

Status Register cycle, Program cycle or Erase cycle continues unaffected.

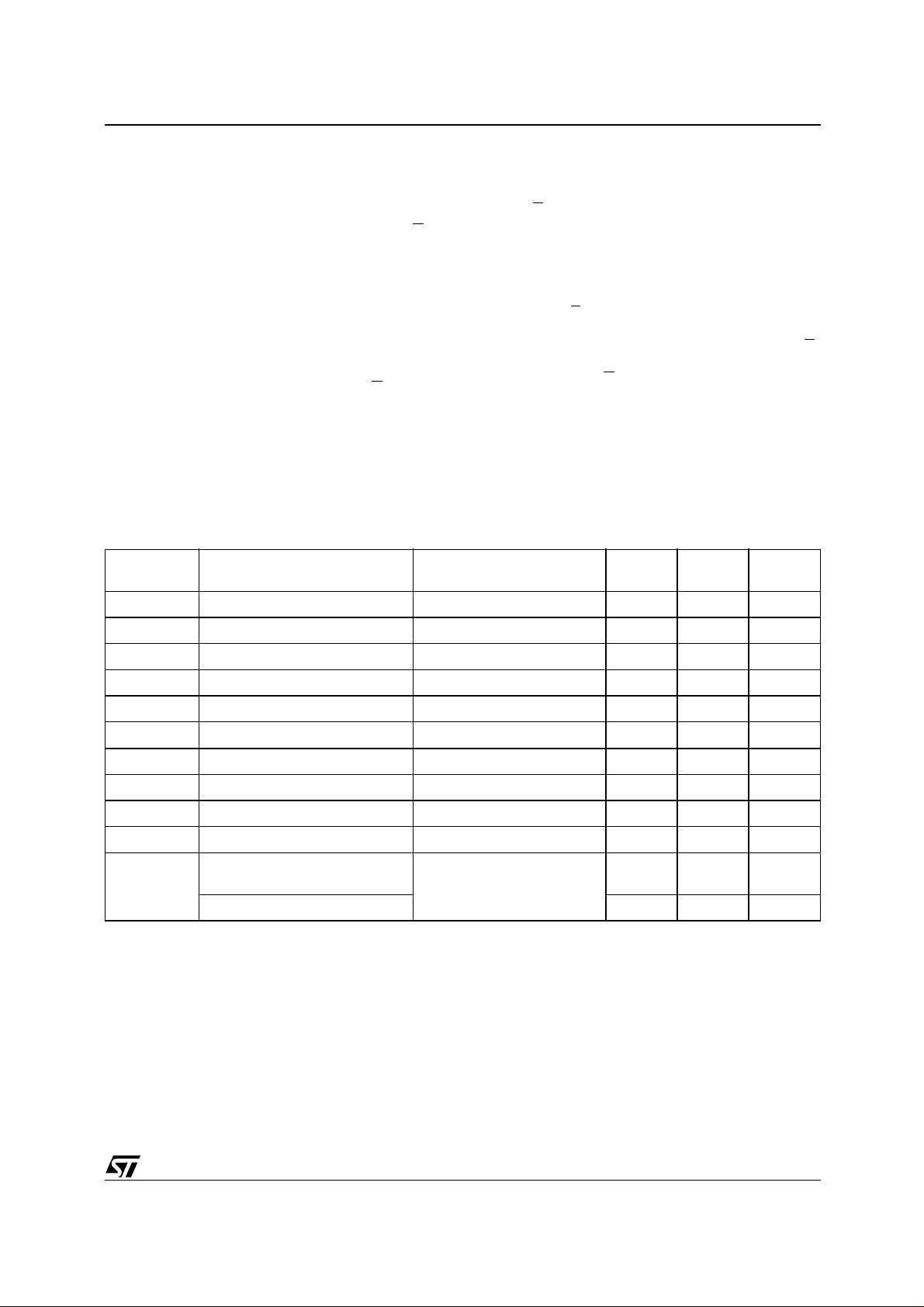

Table 4. Instruction Set

Instruction Description One-byte Instruction Code

M25P05-A

) must be driven High exactly at a

) being driven Low is an exact

Address

Bytes

Dummy

Bytes

Data

Bytes

)

WREN Write Enable 0000 0110 0 0 0

WRDI Write Disable 0000 0100 0 0 0

RDSR Read Status Register 0000 0101 0 0 1 to

WRSR Write Status Register 0000 0001 0 0 1

READ Read Data Bytes 0000 0011 3 0 1 to

FAST_READ Read Data Bytes at Higher Speed 0000 1011 3 1 1 to

PP Page Program 0000 0010 3 0 1 to 256

SE Sector Erase 1101 1000 3 0 0

BE Bulk Erase 1100 0111 0 0 0

DP Deep Power-down 1011 1001 0 0 0

RES

Release from Deep Power-down,

and Read Electronic Signature

Release from Deep Power-down 0 0 0

1010 1011

0 3 1 to

∞

∞

∞

∞

9/34

Page 10

M25P05-A

Figure 8. Write Enable (WREN) Instruction Sequenc e

S

21 34567

0

C

Instruction

D

High Impedance

Q

(SE), Bulk Erase (BE) and Write Status Register

Write Enable (WREN)

The Write Enable (WREN) instruction (Figure 8)

sets the Write Enable Latch (WEL) bit.

The Write Enable Latch (WEL) bit must be set prior to every Page Program (PP), Sector Erase

(WRSR) instruction.

The Write Enable (WREN) instruction is entered

by driving Chip Select (S

struction code, and then driving Chip Select (S

High.

AI02281E

) Low, sending the in-

)

Figure 9. Write Disable (WRDI) Instruction Sequence

S

21 34567

0

C

Instruction

D

High Impedance

Q

Write Disable (WRDI)

The Write Disable (WRDI) instruction (Figure 9)

resets the Write Enable Latch (WEL) bit.

The Write Disable (WRDI) instruction is entered by

driving Ch ip Select (S

tion code, and then driving Chip Select (S

) Low, sending the instruc-

) High.

The Write Enable Latch (WEL) bit is reset under

the following conditions:

AI03750D

– Power-up

– Write Disable (WRDI) instruction completion

– Write Status Register (WRSR) instruction com-

pletion

– Page Program (PP) instruction completion

– Sector Erase (SE) instruction completion

– Bulk Erase (BE) instruction completion

10/34

Page 11

Figure 10. Read Status Register (RDSR) Instruction Sequence and Data-Out Sequence

S

21 3456789101112131415

0

C

Instruction

D

M25P05-A

Q

High Impedance

Status Register Out

7 6543210

MSB

Read Status Register (RDSR)

The Read Status Register (RDSR) instruction allows the Status Register to be read. The Status

Register may be read at any time, even while a

Program, Erase or Write Status Register cycle is in

progress. When one of these cycl es i s in progress,

it is recommended to check the Write In Progress

(WIP) bit before sending a new instruction to the

device. It is also possible to read the Status Register continuously, as shown in Figure 10.

Table 5. Status Register Format

b7 b0

SRWD 0 0 0 BP1 BP0 WEL WIP

Status Register Write Protect

Block Protect Bits

Write Enable Latch Bit

Write In Progress Bit

The status and cont rol bits of t he Stat us Register

are as follows:

WIP bit. The Write In Progress (WIP) bit indicates

whether the memory is busy with a Write Status

Register, Program or Erase cycle. When set to 1,

such a cycle is in progress, when reset to 0 no

such cycle is in progres s.

Status Register Out

7 6543210

MSB

7

AI02031E

WEL bit. Th e Write Enable Latch (WEL) bit indicates the status of the internal Write Enable Latch.

When set to 1 the internal Write Enable Latch is

set, when set to 0 t he i nte rnal W rite E nabl e Latch

is reset and no Write S tatus Reg ister, Pr ogram or

Erase instruction is accepted.

BP1, BP0 bits. The Block Protect (BP1, BP0) bits

are non-volatile. They define the size of the area to

be software protected against Program and Erase

instructions. These bits are written with the Write

Status Register (WRSR) instruction. When one or

both of the Block Protec t (B P 1, B P0 ) bits i s s et t o

1, the relevant memory area (as defined in Table

2) becomes protected against Page Program (PP)

and Sector Erase (SE) instructions. The Block

Protect (BP1, BP0) bits can be written provided

that the Hardware Protect ed mode has not been

set. The Bulk Erase (BE) instruction is executed if,

and only if, both Block Protect (BP1, BP0) bits are

0.

SRWD bit. The Status Register Write Disable

(SRWD) bit is operated in conjunction with the

Write Protect (W

) signal. The Status Register

Write Disable (SRWD) bit an d Write Protect (W

signal allow the device to be put in the Hardware

Protected mode (when t he Status Register Write

Disable (SRWD) bit is set to 1, and Write Protect

(W

) is driven Low). In this mode, the non-volatile

bits of the Status Register (SRWD, BP1, BP0) become read-only bits and the Write Status Register

(WRSR) instruction is no longer accepted for execution.

)

11/34

Page 12

M25P05-A

Figure 11. Write Status Register (WRSR) Instruction Sequence

S

21 3456789101112131415

0

C

Instruction Status

D

High Impedance

Q

Write Status Register (WRSR)

The Write Status Register (WRSR) instruction allows new values to be written to the Status Register. Before it can be accepted, a Write Enable

(WREN) instruction must previously have been executed. After the Write Enable (WREN) instruction

has been decoded and ex ecuted, the device sets

the Write Enable Latch (WEL).

The Write Status Register (WRSR) instruction is

entered by driving Chip Select (S

) Low, followed

by the instruction code and the data byte on Serial

Data Input (D).

The instruction sequence is shown in Figure 11.

The Write Status Register (WRSR) instruction has

no effect on b6, b5, b4, b1 and b0 of the Status

Register. b6, b5 and b4 are always read as 0.

Chip Select (S

) must be driven High after the

eighth bit of the d ata byte has been latched in. If

not, the Write Status Register (WRSR) i nstruction

is not executed. As soon as Chip Select (S

) is driv-

en High, the self-timed Wri te S tatus Regi ster cycl e

Register In

765432 0

MSB

1

AI02282D

(whose duration is tW) is initiated . While the Writ e

Status Register cycle is in progress, the Status

Register may still be read to check the value of the

Write In Progress (WIP) bit. The Write In Progress

(WIP) bit is 1 during the self-timed Write Status

Register cycle, and is 0 wh en it is completed. At

some unspecifi ed time befo re the cycle i s completed, the Write Enable Latch (WEL) is reset.

The Write Status Register (WRSR) instruction allows the user to change the values of the Block

Protect (BP1, BP0) bits, to define the size of the

area that is to be trea ted as read-only, as defined

in Table 2. The Write Status Register (WRSR) instruction also allows the user to set or reset the

Status Register Write Disable (SRWD) bit in accordance with the Write Protect (W

) signal. The

Status Register Write Disable (SRWD) bit and

Write Protect (W

) signal allow the device to be put

in the Hardware Protected Mode (HPM). The Write

Status Register (WRSR) instruction is not executed once the Hardware P rotected Mode (HPM) is

entered.

12/34

Page 13

Table 6. Protection Modes

SRWD

W

Signal

Bit

Mode

Write Protection of the

Status Register

Memory Content

Protected Area

M25P05-A

1

Unprotected Area

1

10

00

11

01

Note: 1. As def i ned by the va lu es in the Block Pr otect (BP1, B P 0) bits of the Status Regist er, as shown i n T able 2.

Software

Protected

(SPM)

Hardware

Protected

(HPM)

Status Register is

Writable (if the WREN

instruction has set the

WEL bit)

The values in the SRWD,

BP1 and BP0 bits can be

changed

Status Register is

Hardware write protected

The values in the SRWD

BP1 and BP0 bits cannot

be changed

Protected against Page

Program, Sector Erase

and Bulk Erase

Protected against Page

Program, Sector Erase

and Bulk Erase

Ready to accept Page

Program and Sector

Erase instructions

Ready to accept Page

Program and Sector

Erase instructions

(Attempts to write to the Status Register are reThe protection features of t he de vic e are su mmarized in Table 6.

When the Status Register Write Disable (SRWD)

bit of the Status Register is 0 (its initial delivery

state), it is possible to write to the Status Register

provided that the Write Enable Latch (WEL) bit has

previously been set by a Write Enable (WREN) instruction, regardless of th e whether W rite Prote ct

) is driven High or Low.

(W

When the Status Register Write Disable (SRWD)

bit of the Status Register is set to 1, two cases

need to be considered, depending on the st ate of

Write Protect (W

– If Write Protect (W

):

) is driven High, it is possible

to write to the Status Register provided that the

Write Enable Latch (WEL) bit has previously

been set by a Write Enable (WREN) instruction.

– If Write Protect (W

) is driven Low, it is

sible to write to the Status Register

not

even

pos-

if the

Write Enable Latch (WEL) bit has previously

been set by a Write Enable (WREN) instruction.

jected, and are not accepted for ex ecution). As

a consequence, all the data bytes in the memory area that are software protected (SPM) by the

Block Protect (BP1, BP0) bits of the Status Register, are also hardware protected against data

modification.

Regardless of the order of the two events, the

Hardware Protected Mode (HPM) can be entered:

– by setting the Status Register Write Disable

(SRWD) bit after driving Write Protect (W

– or by driving Write Protect (W

the Status Register Write Disable (SRWD) bit.

The only way to exit the Hardware Protected Mode

(HPM) once entered is to pull W rite Protect (W

High.

If Write Protect (W

) is permanently tied High, t he

Hardware Protected Mode (HPM) can never be

activated, and only t he Software Protec ted Mode

(SPM), using the Block Protect (B P1, BP0) bi ts of

the Status Register, can be used.

) Low

) Low after setting

)

13/34

Page 14

M25P05-A

Figure 12. Read Data Bytes (READ) Instruction Sequence and Data-Out Sequence

S

21 345678910 2829303132333435

0

C

Instruction 24-Bit Address

23

D

High Impedance

Q

Note: 1. Address bits A23 to A16 must be set to 00h.

2221 3210

MSB

Read Data Bytes (READ)

The device is f irst s el ected by driving Chip S ele ct

) Low. The instruction code for the Read Data

(S

Bytes (READ) instruction is followed by a 3-byte

address (A23-A0), each bit being latched-in during

the rising edge of Serial Clock (C). Then the memory contents, at that address, is shifted out on Serial Data Output (Q), each bit being shifted o ut, at

a maximum frequency f

, during the falling edge of

R

Serial Clock (C).

The instruction sequence is shown in Figure 12.

The first byte addressed can be at any location.

The address is automatically incremented to the

36 37 38

Data Out 1

76543 1 7

MSB

next higher address after each byte of data is shifted out. The whole memory can, therefore, be read

with a single Read Data Bytes (REA D) i nstruction.

There is no address roll-over; when the highest

address (0FFFFh) is reached, the instruction

should be terminated.

The Read Data Bytes (READ) instruction is terminated by driving Chip Select (S

(S

) can be driven High at any time during data output. Any Read Data Bytes (READ) instruction,

while an Erase, Program or Write cycle is in

progress, is rejected without having any effects on

the cycle that is in progr es s.

39

2

0

) High. Chip Select

Data Out 2

AI03748D

14/34

Page 15

M25P05-A

Figure 13. Read Data Bytes at Higher Speed (FAST_READ) Instruction Sequence and Data-Out

Sequence

S

21 345678910 28293031

0

C

Instruction 24 BIT ADDRESS

23

D

High Impedance

Q

S

2221 3210

32 33 34 36 37 38 39 40 41 42 43 44 45 46

C

D

Q

Note: 1. Address bits A23 to A16 must be set to 00h.

765432 0

35

Dummy Byte

1

765432 0

MSB

Read Data Bytes at Higher Speed

(FAST_READ)

The device is f irst s el ected by driving Chip S ele ct

) Low. The instruction code for the Read Data

(S

Bytes at Higher Speed (FAST_READ) instruction

is followed by a 3-byte address (A23-A0) and a

dummy byte, each bit being latc hed-in during the

rising edge of Serial Clock (C). Then the memory

contents, at that address, is shifted out on Serial

Data Output (Q), each bit being s hifted out, at a

maximum frequency f

, during the falling edge of

C

Serial Clock (C).

The instruction sequence is shown in Figure 13.

The first byte addressed can be at any location.

The address is automatically incremented to the

47

DATA OUT 1

1

DATA OUT 2

7 6543210

MSB MSB

7

next higher address after each byte of data is shifted out. The whole memory can, therefore, be read

with a single Read Data Bytes at Higher Speed

(FAST_READ) instruction.

There is no address roll-over; when the highest

address (0FFFFh) is reached, the instruction

should be terminated.

The Read Data Bytes at Higher Speed

(FAST_READ) instruction is terminated by driving

Chip Select (S

) High. Chip Select (S) can be driven High at any time during data output. Any Read

Data Bytes at Higher Speed (FAST_READ) instruction, while an Erase, Program or Write cycle

is in progress, is rejected without having any effects on the cycle that is in progress.

AI04006

15/34

Page 16

M25P05-A

Figure 14. Page Program (PP) Instruction Sequence

S

21 345678910 2829303132333435

0

C

36 37 38

39

Instruction 24-Bit Address

23

D

S

4241 43 44 45 46 47 48 49 50 52 53 54 5540

C

Data Byte 2

D

Note: 1. Address bits A23 to A16 must be set to 00h.

765432 0

MSB MSB MSB

1

2221 3210

MSB

765432 0

Page Program (PP)

The Page Program (PP) instruction allows bytes to

be programmed in the memory (changing bits from

1 to 0). Before it can be accept ed, a Write Enable

(WREN) instruction must previously have been executed. After the Write Enable (WREN) instruction

has been decoded, the device sets the Write Enable Latch (WEL).

The Page Program (PP) instruction is entered by

driving Chip Select (S

) Low, followed by the instruction code, three address by tes and at least

one data byte on Serial Data Input (D). If the 8

least significant address bits (A7-A0) are not all

zero, all transmitted data that goes beyond the end

of the current page are programmed from the start

address of the same page (from the address

whose 8 least significant bits (A7-A0) are all zero).

Chip Selec t (S

) must be driven Low for the entire

duration of the sequence.

The instruction sequence is shown in Figure 14.

If more than 256 bytes are sent to the device, pre-

viously latched data are discarded and the last 256

Data Byte 1

765432 0

MSB

2074

2073

51

Data Byte 3 Data Byte 256

1

2072

765432 0

2075

2076

1

2077

1

2079

2078

AI04082B

data bytes are guaranteed to be programmed correctly within the same page. If less than 256 Data

bytes are sent to device, they are correctly programmed at the requested addresses without having any effects on the other bytes of the same

page.

Chip Select (S

) must be driven High after the

eighth bit of the last data byte has been latched in,

otherwise the Page Program (PP) instruction is not

executed.

As soon as Chip Select (S

) is driv en H i g h, t h e s e lf timed Page Program cycle (whose duration i s t

is initiated. While the Page Program cycle is in

progress, the Status Register may be read to

check the value of the Write In Progress (WIP) bit.

The Write In Progress (WIP) bit is 1 during the selftimed Page Program cycle, and is 0 when it is

completed. At some unspecified time before the

cycle is completed, the Write Enable Latch (WEL)

bit is reset .

A Page Program (PP) instruction applied to a page

which is protected by the Block Protect (BP1, BP0)

bits (see Tables 3 and 2) is not executed.

PP

)

16/34

Page 17

Figure 15. Sector Erase (SE) Instruction Sequence

S

21 3456789 293031

0

C

M25P05-A

Instruction

D

Note: 1. Address bits A23 to A16 must be set to 00h.

Sector Erase (SE)

The Sector Erase (SE) instruction sets t o 1 (FFh)

all bits inside the chosen sector. Before it ca n be

accepted, a Write Enable (WREN) instruction

must previously have been executed. After the

Write Enable (WREN) instruction has been decoded, the device sets the Write Enable Latch (WEL).

The Sector Erase (SE) instruction is entered by

driving Chip Select (S

) Low, followed by the instruction code, and three address by tes on Serial

Data Input (D). Any address inside the Sector (see

Table 3) is a valid address for the Sector Erase

(SE) instruction. Chip Select (S

) must be driven

Low for the entire duration of the sequence.

The instruction sequence is shown in Figure 15.

24 Bit Address

23 22 2 0

MSB

Chip Select (S

1

AI03751D

) must be driven High after the

eighth bit of the last address byte has been latched

in, otherwise the S ector Erase (SE) i nstruction is

not executed. As soon as Chip Select (S

High, the self -timed Sector E rase cycle (who se duration is t

) is initiated. While the Sector Erase cy-

SE

cle is in progress, the Status Register may be read

to check the value of the Write In Progress (WIP)

bit. The Write In Progress (WIP) bit is 1 during the

self-timed Sector Erase cycle, and is 0 when it is

completed. At some unspecified time before the

cycle is completed, the Write Enable Latch (WEL)

bit is reset .

A Sector Erase (S E) in struction applie d t o a page

which is protected by the Block Protect (BP1, BP0)

bits (see Tables 3 and 2) is not executed.

) is driven

17/34

Page 18

M25P05-A

Figure 16. Bulk Erase (BE) Instruction Sequence

S

21 345670

C

D

Bulk Erase (BE)

The Bulk Erase (BE) instruction sets all bits to 1

(FFh). Before it can be ac cepted, a Write Enable

(WREN) instruction must previously have been executed. After the Write Enable (WREN) instruction

has been decoded, the device sets the Write Enable Latch (WEL).

The Bulk Erase (BE) instruction is entered by driving Chip Select (S

code on Serial Data Input (D). Chip Select (S

must be driven Low for the entire duration of the

sequence.

The instruction sequence is shown in Figure 16.

Chip Select (S

eighth bit of the instruction code has been latched

) Low, followed by the instruction

)

) must be driven High after the

Instruction

AI03752D

in, otherwise the Bulk Erase instruction is not executed. As soon as Chip Select (S

) is driven High,

the self-ti med Bu lk Erase cycle (whose durat ion i s

t

) is initiate d. While the Bulk Erase cycle is in

BE

progress, the Status Register may be read to

check the value of the Write In Progress (WIP) bit.

The Write In Progress (WIP) bit is 1 during the selftimed Bulk Erase cycle, a nd is 0 when it is completed. At some unspecified time before the cycle

is completed, the Write Enable Latch (WEL) bit is

reset.

The Bulk Erase (BE) instruction is executed only if

both Block Protect (BP1, BP0) bits are 0. The Bulk

Erase (BE) instruction is ignored if one, or more,

sectors are protected.

18/34

Page 19

Figure 17. Deep Power-down (DP) Instruction Sequence

S

21 345670

C

Instruction

D

t

DP

M25P05-A

Deep Power-down (DP)

Executing the Deep Power-down (DP) instruction

is the only way to put the device in the lowest consumption mode (the Deep Power-down mode). It

can also be used as an extra s oftware protection

mechanism, while the device is not in active use,

since in this mod e, the device ign ores all Write,

Program and Erase instructions.

Driving Chip Select (S

) High deselects the device,

and puts the device in the S tandby m ode (if there

is no internal cycle currently in progress). But this

mode is not the Deep Power-down mode. The

Deep Power-down mode can only b e entered by

executing the Deep Power-down (DP ) instruction,

to reduce the standby current (from I

CC1

to I

CC2

as specified in Table 12).

Once the device has entered the Deep Power-

down mode, all instructions are ignored except the

Release from Deep Power-down and Read Electronic Signature (RES) instruction. This releases

the device from this mode. The Release from

Deep Power-down and Read Electronic Signature

(RES) instruction also allows the Electronic S igna-

Stand-by Mode

Deep Power-down Mode

ture of the device to be output on Serial Data Output (Q).

The Deep Power-down mode au tomatically stops

at Power-down, and the device always Powers-up

in the Standby mode.

The Deep Power-down (DP) instruction is entered

by driving Chip Select (S

) Low, followed by the in-

struction code on Serial Data Input (D). Chip Se-

) must be driven Low for the entire duration

lect (S

of the sequence.

The instruction sequence is shown in Figure 17.

Chip Select (S

) must be driven High after the

eighth bit of the instruction code has been latched

in, otherwise the Deep Power-down (DP) instruction is not executed. As soon as Chip Select (S

,

driven High, it requires a delay of t

supply current is reduced to I

DP

and the Deep

CC2

Power-down mode is entered.

Any Deep Power-down (DP) instruction, while an

Erase, Program or Write cycle is in progress, is rejected without havin g any effects on the cycle that

is in progress.

AI03753D

) is

before the

19/34

Page 20

M25P05-A

Figure 18. Release from Deep Power-d ow n and Read Electronic Sign atur e (RES) Instruction

Sequence a n d D at a- Out Sequ ence

S

21 345678910 2829303132333435

0

C

36 37 38

Instruction 3 Dummy Bytes

23

D

High Impedance

Q

2221 3210

MSB

Release from Deep Power-down and Read

Electronic Signature (RES)

Once the device has entered the Deep Powerdown mode, all instructions are ignored except the

Release from Deep Power-down and Read Electronic Signature (RES) instruction. Executing this

instruction takes the device out of the Deep Power-down mode. The instruction can also be used to

read, on Serial Data Output (Q), the 8-bit Electronic Signature of the device.

Except while an Erase, P rogram or Write Status

Register cycle is in progress, the Release from

Deep Power-down and Read Electronic Signature

(RES) instruction always provides access to the

Electronic Signature of the device, and can be applied even if the Deep Power-down mode has not

been entered.

Any Release from Deep Power-down and Read

Electronic Signature (RES) instruction while an

Erase, Program or Write Status Register cycle is in

progress, is not decoded, and has no effect on the

cycle that is in progress.

This instruction serves a second purpose. The device features an 8-bit Electronic Signature, whose

value for the M25P05-A is 05h. This can be read

using the Release from Deep Power-down and

Read Electronic Signature (RES) instruction.

t

RES2

Electronic Signature Out

765432 0

MSB

Deep Power-down Mode

1

Stand-by Mode

AI04047C

The device is f irst s el ected by driving Chip S el ect

) Low. The instruction code is followed by 3

(S

dummy bytes, each bit being latched-in on Serial

Data Input (D) during the rising edge of Serial

Clock (C). Then, the 8-bit Electronic Signature,

stored in the memory, is shifted out on Serial Data

Output (Q), each bit being shifted out during the

falling edge of Serial Clock (C).

The instruction sequence is shown in Figure 18.

The Release from Deep Power-down and Read

Electronic Signature (RES) instruction is terminated by driving Chip Select (S

) High after the Electronic Signature has been read at least once.

Sending additional clock cycles on Serial Clock

(C), while Chip Select (S

) is driven Low, cause the

Electronic Signature to be output repeatedly.

When Chip Select (S

) is driv en High, the device is

put in the Stand-by Power mode. If the device was

not previously in the Deep Power-down mode, the

transition to the Stand-by Power mode is imm ediate. If the device was previously in the Deep Power-down mode, though, the transition to the Standby Power mode is delayed by t

) must remain High for at least t

lect (S

, and Chip Se-

RES2

RES2

(max),

as specified in Table 13. Once in the Stand-by

Power mode, the device waits to be selected, so

that it can receive, decode and execute instructions .

20/34

Page 21

Figure 19. Release from Deep Power-d ow n (RES) Instruction Seq uen ce

S

t

21 345670

C

Instruction

D

High Impedance

Q

RES1

M25P05-A

Driving Chip Select (S

) High after the 8-bit instruction byte has been received by the device, but before the whole of the 8-bit Electronic Signature has

been transmitted for the first time (as shown in Figure 19), still insures that the device is put into

Stand-by Power mode. If the d evice was not previously in the Deep Power-down mode, the transition to the Stand-by Power mode is immediate. If

Deep Power-down Mode

Stand-by Mode

AI04078B

the device was previously in the Deep Powerdown mode, though, the transition to the Stand-by

Power mode is delayed by t

) must remain High for at least t

(S

, and Chip Selec t

RES1

RES1

(max), as

specified in Table 13. Once in the Stand-by Power

mode, the device waits to be selected, so that it

can receive, decode and execute instructions.

21/34

Page 22

M25P05-A

POWER-UP AND POWER-DOWN

At Power-up and Power-down, the device must

not be selected (that is Chip Select (S

the voltage applied on V

) until VCC reaches the

CC

correct value:

(min) at Power-up, and then for a further de-

–V

CC

lay of t

VSL

–VSS at Power-down

Usually a simple pull-up resistor on Chip Select (S

can be used to insure safe and proper Power-up

and Power-down.

To avoid data corruption and inadvertent write

operations during power up, a Power On Reset

(POR) circuit is included. The logic inside the

device is held reset while V

threshold value, V

– all operations are disabled,

WI

is less than the POR

CC

and the device does not respond to any

instruction.

Moreover, the device ignores all Write Enable

(WREN), Page Program (PP), Sector Erase (SE),

Bulk Erase (BE) and Write Status Register

(WRSR) instructions until a time delay of t

elapsed after the moment that V

V

threshold. However, the correct operation of

WI

the device is not guaranteed if, by this time, V

still below V

(min). No Write Status Register,

CC

Program or Erase instructions should be sent until

the later of:

) must follow

rises above the

CC

PUW

has

CC

is

–t

–t

after VCC passed the VWI threshold

PUW

afterVCC passed the VCC(min) level

VSL

These values are specified in Table 7.

If the delay, t

above V

CC

READ instructions even if the t

, has elapsed, after VCC has risen

VSL

(min), the device can be selected for

delay is not yet

PUW

fully elapsed.

)

At Power-up, the device is in the following state:

– The device is in the Standby mode (not the

Deep Power-down mode).

– The Write Enable Latch (WEL) bit is reset.

Normal precautions must be taken for supply rail

decoupling, to stablise the V

in a system should have the V

feed. Each device

CC

rail decoupled by

CC

a suitable capacitor close to the package pins.

(Generally, this capacitor is of the order of 0.1µF).

At Power-down, when V

drops from the

CC

operating voltage, to below the POR threshold

value, V

, all operations are disabled and the

WI

device does not respon d to any instruction. (The

designer needs to be aware that if a Power-down

occurs while a Write, Program or Erase cycle is in

progress, some data corruption can result.)

Figure 20. Power-up Timing

V

CC

VCC(max)

Program, Erase and Write Commands are Rejected by the Device

Chip Selection Not Allowed

VCC(min)

Reset State

of the

Device

V

WI

tVSL

tPUW

Read Access allowed Device fully

accessible

time

AI04009C

22/34

Page 23

M25P05-A

Table 7. Power-Up Timing and VWI Threshol d

Symbol Parameter Min. Max. Unit

1

t

VSL

t

PUW

V

Note: 1. These param eters are characteri zed only .

VCC(min) to S low

1

Time delay to Write instruction 1 10 ms

1

Write Inhibit Voltage 1 2 V

WI

INITIAL DELIVERY STATE

The device is delivered with the memory array

erased: all bits are set to 1 (each byte contains

FFh). The Status Register contains 00h (all Status

Register bits are 0).

10 µs

23/34

Page 24

M25P05-A

MAXIMUM RATI N G

Stressing the device above the rating l isted in the

Absolute Maximum Ratings" table may cause permanent damage to the device. These are stress

ratings only and operation of the device at t hese or

any other conditions ab ove those i ndicated in t he

Operating sections of this specificat ion is not im-

Table 8. Absolute Maximum Ratings

Symbol P arameter Min. Max. Unit

T

STG

T

LEAD

V

IO

V

CC

V

ESD

Note: 1. IPC/JEDEC J-STD- 020 A

2. JEDEC Std JESD 22-A114A (C1=100 pF, R1=1500

Storage Temperature –65 150 °C

Lead Temperature during Soldering

(20 seconds max.)

1

Input and Output Voltage (with respect to Ground) –0.6 4.0 V

Supply Voltage –0.6 4.0 V

Electrostatic Discharge Voltage (Human Body model)

Ω, R2=500 Ω)

plied. Exposure to Absolute Maximum Rating conditions for extended periods may affect device

reliability. Refer also to the STMicroelectronics

SURE Program and other relevant quality documents .

SO 235 °C

VFQFPN 235 °C

2

–2000 2000 V

24/34

Page 25

DC AND AC PARAMETERS

This section summarizes the operat ing and measurement conditions, and the DC and AC characteristics of the device. The parameters in the DC

and AC Characteristic tables that follow are derived from tests performed under the Measure-

ment Conditions summarized in the relevant

tables. Designers should check that the operating

conditions in their circuit matc h the measurem ent

conditions when relying on the quoted parameters.

Table 9. Operating Conditions

Symbol Parameter Min. Max. Unit

M25P05-A

V

CC

T

A

Supply Voltage 2.7 3.6 V

Ambient Operating Temperature –40 85 °C

Table 10. AC Measurement Conditions

Symbol Parameter Min. Max. Unit

C

L

Load Capacitance 30 pF

Input Rise and Fall Times 5 ns

to 0.8V

Input Pulse Voltages

Input and Output Timing Reference Voltages

Note: 1. Output Hi-Z is de fined as the point where da ta out is no longer driven .

0.2V

0.3V

CC

to 0.7V

CC

CC

CC

Figure 21. AC Measurement I/O Waveform

Input Levels

0.8V

CC

0.2V

CC

Input and Output

Timing Reference Levels

0.7V

CC

0.3V

CC

AI00825B

V

V

Table 11. Capacitance

Symbol Parameter Test Condition Min. Max. Unit

C

OUT

C

IN

Note: Sampled only, not 10 0% tested, at TA=25°C an d a frequency of 20 MHz.

Output Capacitance (Q) V

Input Capacitance (other pins) VIN = 0V 6 pF

= 0V 8 pF

OUT

25/34

Page 26

M25P05-A

Table 12. DC Characteristics

Symbol Parameter

Input Leakage Current ± 2 µA

I

LI

I

I

I

I

Output Leakage Current ± 2 µA

LO

Standby Current

CC1

Deep Power-down Current S = VCC, VIN= VSS or V

CC2

Operating Current (READ)

CC3

Test Condition

(in addition to those in Table 9)

S

= VCC, VIN= VSS or V

C = 0.1V

/ 0.9.VCC at 25 MHz,

CC

CC

CC

Q = open

Min. Max. Unit

50 µA

5µA

4mA

I

CC4

I

CC5

I

CC6

I

CC7

V

IL

V

IH

V

OL

V

OH

Operating Current (PP) S = V

Operating Current (WRSR) S = V

Operating Current (SE) S = V

Operating Current (BE)

S

= V

CC

CC

CC

CC

Input Low Voltage – 0.5

Input High Voltage

0.7V

CCVCC

Output Low Voltage IOL = 1.6 mA 0.4 V

I

Output High Voltage

= –100µAV

OH

CC

–0.2

15 mA

15 mA

15 mA

15 mA

0.3V

CC

+0.4

Table 13. AC Characteristics

Test conditions specified in Table 9 and Table 10

Symbol Alt. Parameter Min. Typ. Max. Unit

f

f

t

CH

t

CL

t

CLCH

t

CHCL

t

SLCH

t

CHSL

t

DVCH

t

CHDX

t

CHSH

t

SHCH

t

SHSL

t

SHQZ

t

CLQV

t

CLH

t

CLL

t

CSS

t

DSU

t

t

CSH

t

DIS

f

C

DH

t

V

C

R

1

1

2

2

2

Clock Frequency for the following instructions:

FAST_READ, PP, SE, BE, DP, RES,

D.C. 25 MHz

WREN, WRDI, RDSR, WRSR

Clock Frequency for READ instructions D.C. 20 MHz

Clock High Time 18 ns

Clock Low Time 18 ns

Clock Rise Time3 (peak to peak)

Clock Fall Time3 (peak to peak)

0.1 V/ns

0.1 V/ns

S Active Setup Time (relative to C) 10 ns

S Not Active Hold Time (relative to C) 10 ns

Data In Setup Time 5 ns

Data In Hold Time 5 ns

S Active Hold Time (relative to C) 10 ns

S Not Active Setup Time (relative to C) 10 ns

S Deselect Time 100 ns

Output Disable Time 15 ns

Clock Low to Output Valid 15 ns

V

V

V

26/34

Page 27

M25P05-A

Test conditions specified in Table 9 and Table 10

Symbol Alt. Parameter Min. Typ. Max. Unit

t

CLQX

t

HLCH

t

CHHH

t

HHCH

t

CHHL

2

t

HHQX

2

t

HLQZ

4

t

WHSL

4

t

SHWL

2

t

DP

2

t

RES1

2

t

RES2

t

W

t

PP

t

SE

t

BE

Note: 1. tCH + tCL must be greater than or equal to 1/ f

2. Value guarant eed by characteriza tion, not 100% tested in production .

3. Expressed as a slew-rate.

4. Only applicable as a constraint for a WRSR instruction when S RWD is set at 1.

t

HO

Output Hold Time 0 ns

HOLD Setup Time (relative to C) 10 ns

HOLD Hold Time (relative to C) 10 ns

HOLD Setup Time (relative to C) 10 ns

HOLD Hold Time (relative to C) 10 ns

t

LZ

t

HZ

HOLD to Output Low-Z 15 ns

HOLD to Output High-Z 20 ns

Write Protect Setup Time 20 ns

Write Protect Hold Time 100 ns

S High to Deep Power-down Mode 3

S High to Standby Mode without Electronic

Signature Read

S High to Standby Mode with Electronic

Signature Read

Write Status Register Cycle Time 5 15 ms

Page Program Cycle Time 1.5 5 ms

Sector Erase Cycle Time 2 3 s

Bulk Erase Cycle Time 3 6 s

C

3

1.8

s

µ

s

µ

s

µ

27/34

Page 28

M25P05-A

Figure 22. Serial Input Timing

S

C

tDVCH

tSLCH

tSHSL

tCHSHtCHSL

tSHCH

tCHCL

tCHDX

D

Q

MSB IN

High Impedance

tCLCH

LSB IN

Figure 23. Wri t e Pr otect Setup and Hold Ti m ing during WRSR when SRWD=1

W

tWHSL

S

C

AI01447C

tSHWL

28/34

D

High Impedance

Q

AI07439

Page 29

Figure 24. Hol d Timing

S

C

Q

D

HOLD

tCHHL

M25P05-A

tHLCH

tHHCH

tCHHH

tHHQXtHLQZ

AI02032

Figure 25. Output Timing

S

C

tCLQV

tCLQX

Q

ADDR.LSB IN

D

tCLQX

tCLQV

tCH

tCL

tQLQH

tQHQL

tSHQZ

LSB OUT

AI01449D

29/34

Page 30

M25P05-A

PACKAGE MECHANICAL

SO8 narrow – 8 lead Plastic Small Outline, 150 mils body width, Package Ou tline

h x 45˚

Note: Drawing is not to scale.

B

SO-a

A

e

D

N

1

CP

E

H

C

LA1 α

SO8 narrow – 8 lead Plastic Small Outline, 150 mils body width, Package Mechanical Data

Symb.

Typ. Min. Max. Typ. Min. Max.

A 1.35 1.75 0.053 0.069

mm inches

30/34

A1 0.10 0.25 0.004 0.010

B 0.33 0.51 0.013 0.020

C 0.19 0.25 0.007 0.010

D 4.80 5.00 0.189 0.197

E 3.80 4.00 0.150 0.157

e 1.27 – – 0.050 – –

H 5.80 6.20 0.228 0.244

h 0.25 0.50 0.010 0.020

L 0.40 0.90 0.016 0.035

α

0° 8° 0° 8°

N8 8

CP 0.10 0.004

Page 31

VFQFPN8 – 8-contact Very-thin Fine-pitch QFP No-lead, Package Outline

D

D1

E

E1

M25P05-A

eE2

b

A

Note: Drawing is not to scale.

A1

θ

A2

A3

D2

L

VFQFPN-01

VFQFPN8 – 8-contact Very-thin Fine-pitch QFP No-lead, Package Mecha nical Data

Symb.

Typ. Min. Max. Typ. Min. Max.

A 0.85 1.00 0.0 335 0.0394

A1 0 .00 0.05 0.0000 0.0020

A2 0.65 0.0256

A3 0.20 0.0079

b 0.40 0.35 0.48 0.0157 0.0138 0.0189

D 6.00 0.2362

mm inches

D1 5 .75 0.2264

D2 3 .40 3.20 3.60 0.1339 0.1260 0.1417

E 5.00 0.1969

E1 4.75 0.1870

E2 4.00 3.80 4.20 0.1575 0.1496 0.1654

e 1.27 0.0500

L 0.60 0.50 0.75 0.0236 0.0197 0.0295

θ

12° 12°

31/34

Page 32

M25P05-A

PART NUMBERING

Table 14. Ordering Information Scheme

Example: M25P05-A V MN 6 T

Device Type

M25P

Device Function

05-A = 512 Kbit (64K x 8) Enhanced Techology in line with

the M25P10-A, M25P20, M25P40, M25P80

Operating Voltage

V = V

Package

MN = SO8 (150 mil width)

MP = VFQFPN8 (MLP8)

Temperature Range

6 = –40 to 85 °C

= 2.7 to 3.6V

CC

Option

T = Tape & Reel Packing

For a list of available options (speed, package,

etc.) or for further information on any aspect of this

device, please contact your nearest ST Sales O ffice.

32/34

Page 33

REVISION HIST ORY

Table 15. Document Revision History

Date Rev. Description of Revision

25-Feb-2001 1.0 Document written

11-Apr-2002 1.1

12-Sep-2002 1.2 VFQFPN8 package (MLP8) added.

Clarification of descriptions of entering Stand-by Power mode from Deep Power-down mode,

and of terminating an instruction sequence or data-out sequence.

M25P05-A

13-Dec-2002 1.3

Typical Page Program time improved. Write Protect setup and hold times specified, for

applications that switch Write Protect to exit the Hardware Protection mode immediately before

a WRSR, and to enter the Hardware Protection mode again immediately after.

33/34

Page 34

M25P05-A

Information furnished is believed to be accurate and reliable. However, STMicroelec tronics as sumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or patent ri ghts of STM i croelectronics. Sp ecifications menti oned in thi s publicati on are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authoriz ed for use as critical components in li f e support dev i ces or systems wi thout exp ress written approval of STMicroe l ectronics.

The ST logo i s registered trademark of STMicro el ectronics

All other nam es are the pro perty of thei r respective owners

© 2002 STMicroelectronics - All Rights Reserved

STMicroelectron ic s group of companies

Austra lia - Brazil - Canada - China - F i nl and - France - Germany - Hong Kong -

India - Israel - Italy - Japan - Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switz erland - Un ited Kingdo m - United States.

www.st.com

34/34

Loading...

Loading...