Datasheet LVT22V10-DN, LVT22V10-DD, LVT22V10-DA, LVT22V10-BN, LVT22V10-BD Datasheet (Philips)

...Page 1

LVT22V10

3V high speed, universal PLD device

Product specification

Supersedes data of 1996 Mar 12

IC13 Data Handbook

1998 Feb 10

INTEGRATED CIRCUITS

Page 2

Philips Semiconductors Product specification

LVT22V103V high speed, universal PLD device

2

1998 Feb 10 853-1759 18947

FEA TURES

•Fastest 3V PLD

•Supports 3/5V mixed systems

•Low ground bounce (<1.1V worst case)

•Live insertion/extraction permitted

•Bus-hold data inputs eliminate the need for external pull-up

resistors to hold unused inputs

•Metastable hardened device

•High output drive capability: 32mA/–16mA

•Varied product term distribution with up to 16 product terms per

output for complex functions

•Programmable output polarity

•Available in 300 mil-wide 24-pin Plastic Small Outline Package

•Design support provided for third party CAD development and

programming hardware

DESCRIPTION

The LVT22V10 is a versatile PAL device fabricated on the Philips

BiCMOS QUBiC process.

The QUBiC process produces very high speed 3V devices (7.5ns)

which have excellent noise characteristics. Ground bounce of an

output held low while the remaining 9 outputs switch from high to

low is typically less than 0.7V. V

CC

bounce of an output held high

while the remaining 9 outputs switch from low to high is typically less

than 1.0V .

The LVT22V10 was designed to support mixed 3/5V systems. The

inputs are capable of handling 7V while the outputs can be pulled up

to 7V .

The designer can interface directly from 5V outputs (CMOS full rail

or totem pole) to a 3V LVT input. A 3V LVT output can drive a 5V

TTL input directly , or in the case of a CMOS input, the LVT output

can interface with the use of an external pull-up resistor. Finally, no

external pull-up resistors are needed on unused input pins due to a

bus-hold data structure designed into the LVT input.

The LVT22V10 has been designed with high drive outputs (32mA

sink and 16mA source currents), which allows for direct connection

to a backplane bus. This feature eliminates the need for additional,

standalone bus drivers, which are traditionally required to boost the

drive of a standard PLDs.

The LVT22V10 outputs are designed to support Live

Insertion/Extraction into powered up systems. The output is

specially designed so that during V

CC

ramp, the output remains

3-Stated until V

CC

2.1V . At that time the outputs become fully

functional depending upon device inputs. (See DC Electrical

Characteristics, Symbol I

PU/PD,

Page 5). In addition when an

LVT22V10 output is tied to a 5V bus, no bus current is loaded.

The LVT22V10 uses the familiar AND/OR logic array structure,

which allows direct implementation of sum-of-products equations.

This device has a programmable AND array which drives a fixed OR

array. The OR sum of products feeds an “Output Macro Cell” (OMC)

which can be individually configured as a dedicated input, a

combinatorial output, or a registered output with internal feedback.

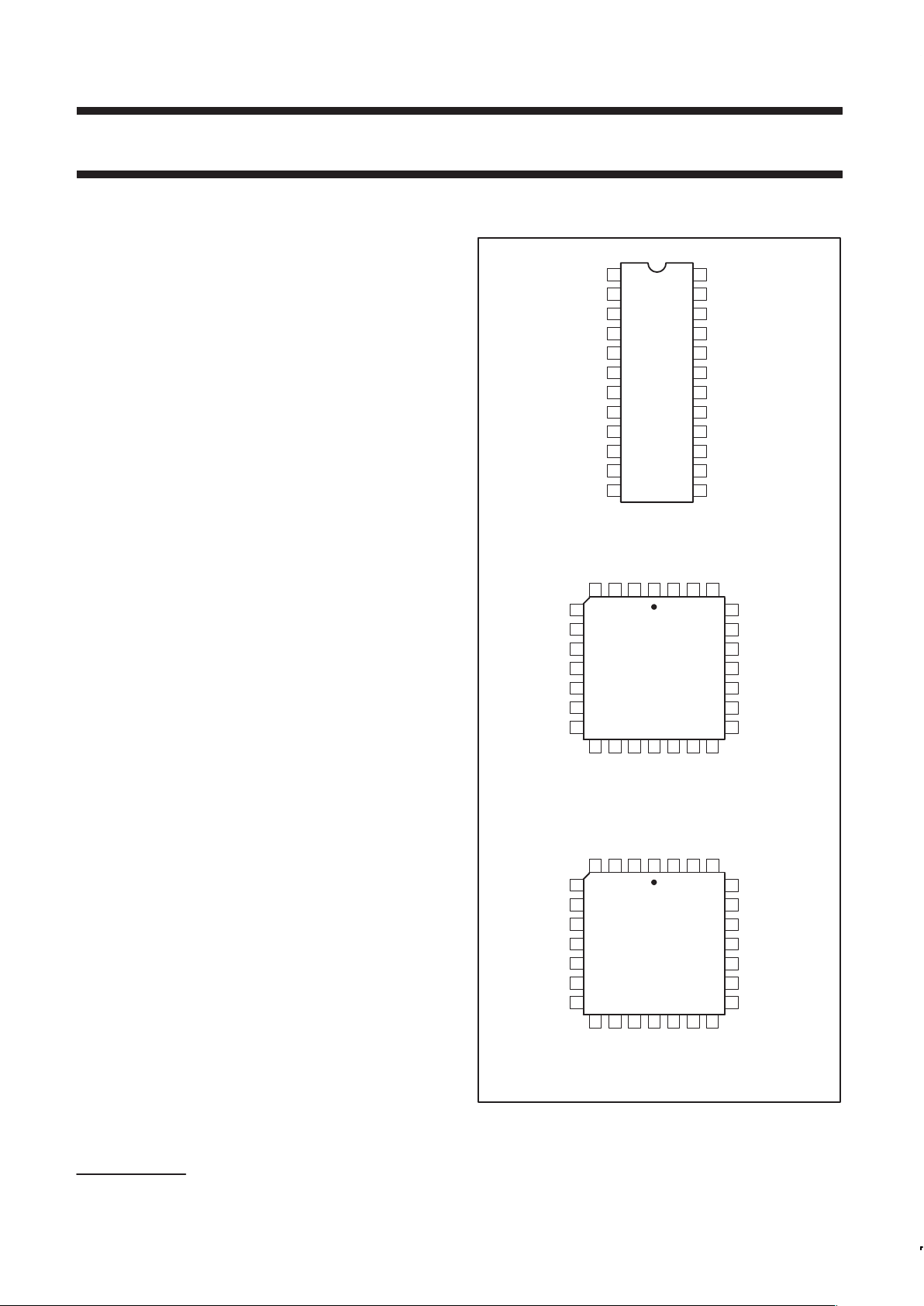

PIN CONFIGURATIONS

1234

5

6

7

8

9

10

11

12 13 14 15 16 17

18

19

20

21

22

23

24

25

262728

1

2

3

4

5

6

7

8

9

10

11

12 13

14

15

16

17

18

19

20

21

22

23

24

D and N Packages

I0/CLK

I1

I2

I3

I4

I5

I6

I7

I8

I9

I10

V

CC

F9

F8

F7

F6

F5

F4

F3

F2

F1

F0

I11

GND

NC

NC

A Package (standard)

NC

CLK/

I0

I1I2

I3

I4

I5

GND

I6

I8

I9 I10

GND

I11 F0 F1

F2

F3

F7

F6

F5

F4

F8F9V

CC

A = Plastic Leaded Chip Carrier

N = Plastic Dual In-Line Package (300mil-wide)

D = Plastic Small Outline Large (300mil-wide) Package

SP00436

NC

1234

5

6

7

8

9

10

11

12 13 14 15 16 17

18

19

20

21

22

23

24

25

262728

A Package (evolutionary)

CLK/

I0

I1I2

I3

I4

I5

I6

I8

I9 I10

GND

I11 F0 F1

F2

F3

F7

F6

F5

F4

F8F9V

CC

A = Plastic Leaded Chip Carrier

GND

V

CC

GND

GND

I7

PAL is a registered trademark of Advanced Micro Devices, Inc.

Page 3

Philips Semiconductors Product specification

LVT22V10

3V high speed, universal PLD device

1998 Feb 10

3

ORDERING INFORMATION

PACKAGES ORDER CODE DWG NUMBER

24-Pin Plastic DIP (300mil) LVT22V10-7N (8.0ns device) SOT222-1

28-Pin PLCC (standard pinout) LVT22V10B7A (7.5ns device) SOT261-3

28-Pin PLCC (evolutionary pinout) LVT22V10-7A (7.5ns device) SOT261-3

24-Pin Plastic SOL LVT22V10-7D (8.0ns device) SOT137-1

PIN LABEL DESCRIPTIONS

SYMBOL DESCRIPTION

I1 – I11 Dedicated Input

F0 – F9 Macro Cell Input/Output

CLK/I0 Clock Input/Dedicated Input

V

CC

Supply Voltage

GND Ground

NC No Connection

THERMAL RATINGS

TEMPERATURE

Maximum junction 150°C

Maximum ambient 75°C

Allowable thermal rise ambient to junction 75°C

OPERATING RANGES

RATINGS

SYMBOL

PARAMETER

MIN MAX

UNIT

V

CC

Supply voltage +3.0 +3.6 V

DC

T

amb

Operating free-air

temperature

0 +75 °C

ABSOLUTE MAXIMUM RATINGS

1

RATINGS

SYMBOL

PARAMETER

MIN MAX

UNIT

V

CC

Supply voltage

2

–0.5 +4.6 V

DC

V

IN

Input voltage

2

–0.5 7 V

DC

V

OUT

Output voltage

3

–0.5 5.5 V

DC

I

IN

Input currents –30 +30 mA

I

OUT

Output currents +100 mA

T

stg

Storage temperature range –65 +150 °C

NOTES:

1. Stresses above those listed may cause malfunction or permanent damage to the device. This is a stress rating only. Functional operation at

these or any other condition above those indicated in the operational and programming specification of the device is not implied.

2. Except in programming mode.

3. Outputs can be pulled up to 7V via external pull-up resistor.

Page 4

Philips Semiconductors Product specification

LVT22V10

3V high speed, universal PLD device

1998 Feb 10

4

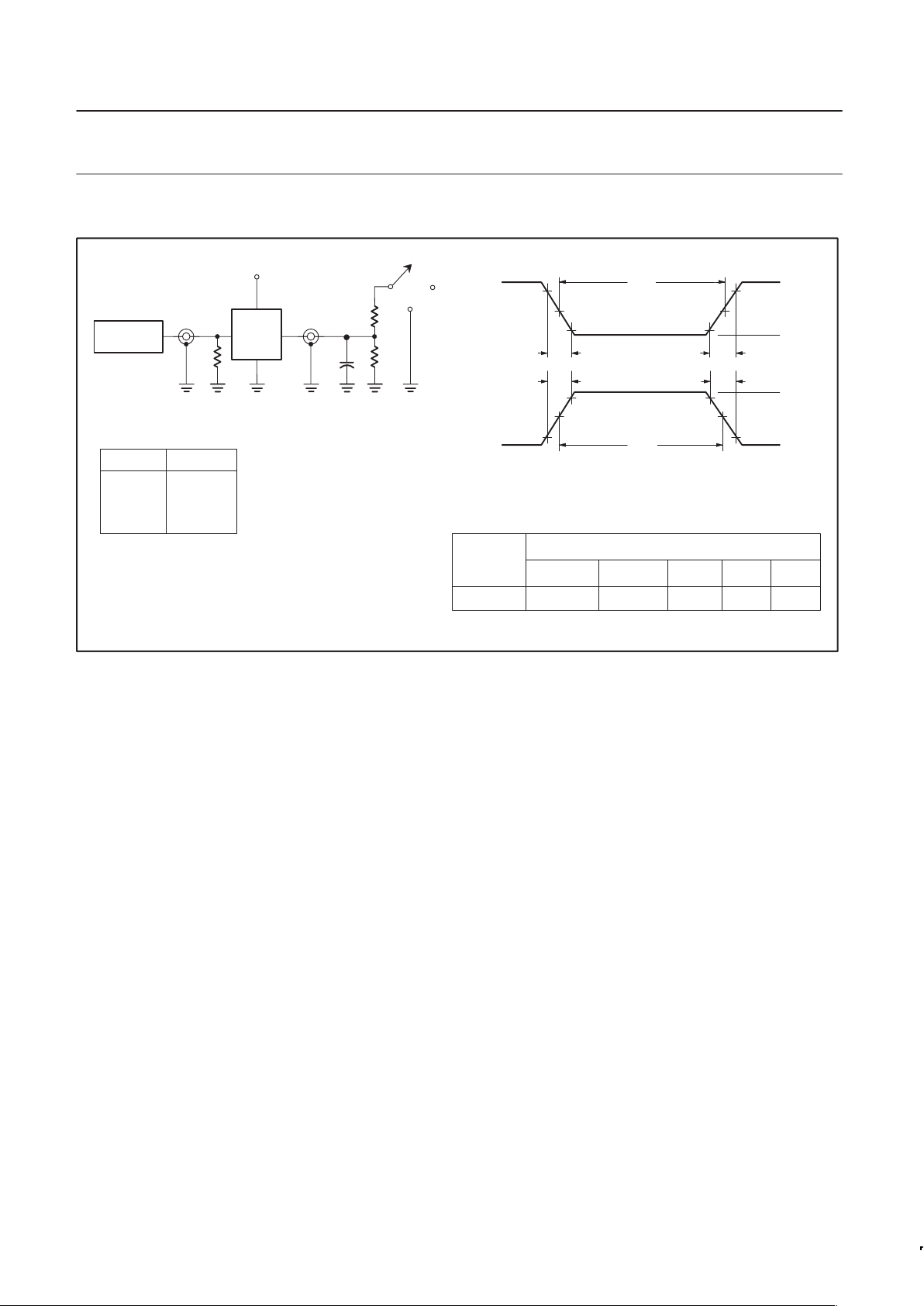

TEST CIRCUIT AND WAVEFORMS

V

M

V

M

t

W

AMP (V)

NEGATIVE

PULSE

10% 10%

90%

90%

0V

V

M

V

M

t

W

AMP (V)

POSITIVE

PULSE

90% 90%

10%

10%

0V

t

THL

(tF)

t

TLH

(tR)t

THL

(tF)

t

TLH

(tR)

VM = 1.5V

DEFINITIONS

R

L

=Load resistor; see AC CHARACTERISTICS for value.

C

L

= Load capacitance includes jig and probe capacitance;

see AC CHARACTERISTICS for value.

R

T

=Termination resistance should be equal to Z

OUT

of pulse

generators.

INPUT PULSE REQUIREMENTS

FAMILY

LVT

PULSE

GENERATOR

V

IN

D.U.T.

V

OUT

C

L

V

CC

R

L

Test Circuit for 3-State Outputs

6.0V

R

T

R

L

OPEN

GND

SWITCH POSITION

TEST SWITCH

t

PLH/tPHL

Open

t

PLZ/tPZL

6V

t

PHZ/tPZH

GND

SP00385

Input Pulse Definition

Amplitude Rep. Rate t

W

t

R

t

F

3.0V 10MHz 500ns 2.5ns 2.5ns

Page 5

Philips Semiconductors Product specification

LVT22V10

3V high speed, universal PLD device

1998 Feb 10

5

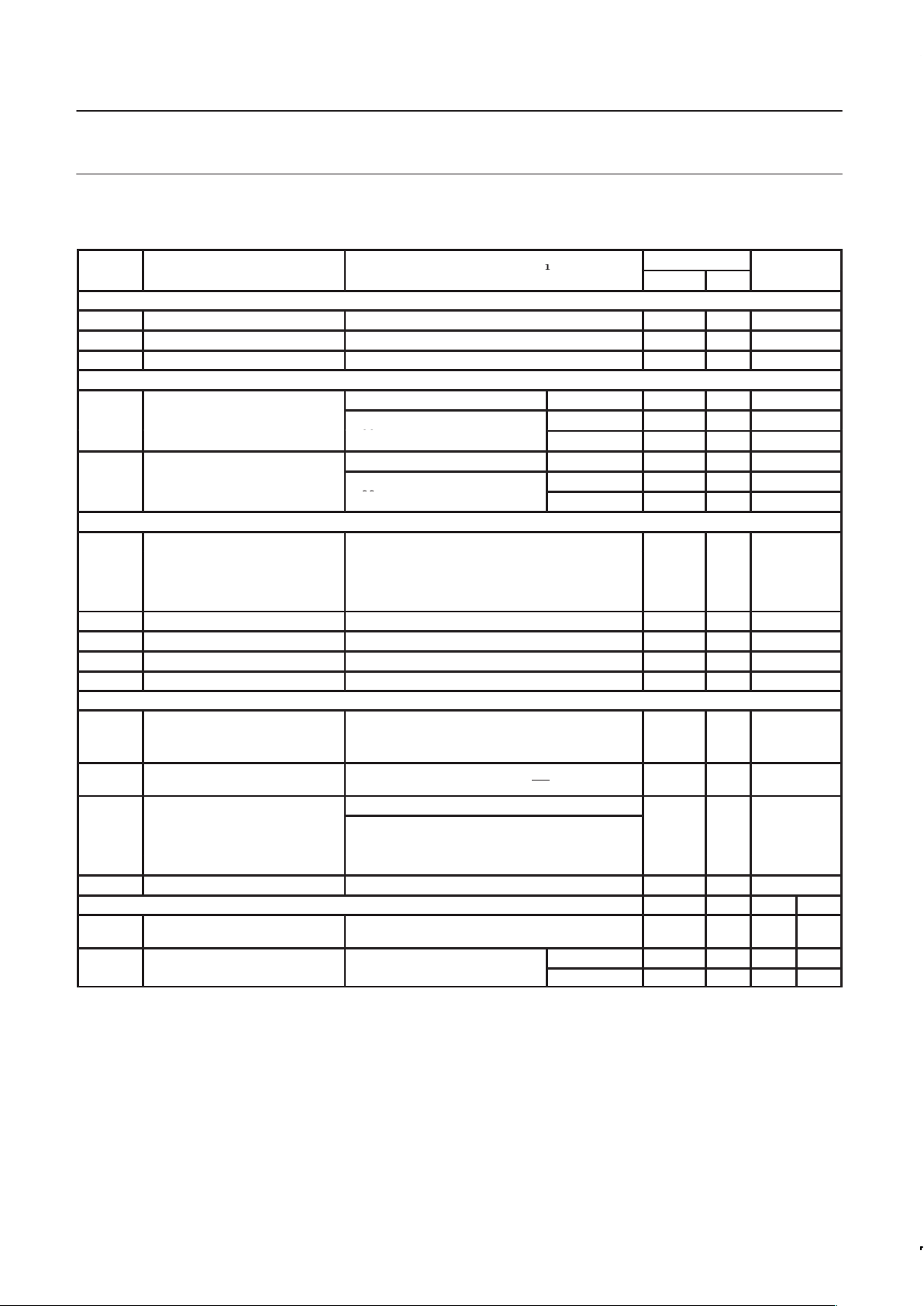

DC ELECTRICAL CHARACTERISTICS

Over operating ranges.

LIMITS

SYMBOL

PARAMETER

TEST CONDITIONS

1

MIN MAX

UNIT

Input voltage

V

IL

Low VCC = MIN 0.8 V

V

IH

High VCC = MAX 2.0 V

V

I

Clamp VCC = MIN, IIN = –18mA –1.2 V

Output voltage

VCC = MIN to MAX, VI = V

IH

or VILIOH = –100 µA VCC–0.2 V

V

OH

High-level output voltage

IOH = –16mA 2.0 V

V

CC

=

MIN, V

I

=

V

IH

or

V

IL

IOH = –5.5 mA 2.4 V

VCC = MIN to MAX, VI = VIH or VILIOL = 100µA 0.2 V

V

OL

Low-level output voltage

IOL = 32 mA 0.5 V

V

CC

=

MIN, V

I

=

V

IH

or

V

IL

IOL = 16 mA 0.4 V

Input current

I

IL

Low VCC = MAX, VIN = 0.0V –10 µA

I

IH

High VCC = MAX, VIN = V

CC

10 µA

I

I

Max input current VCC = MAX, VIN = 5.5V 10 µA

I

I

Pin 1 (program) VCC = MAX, VIN = 5.5V 20 µA

I

BHL

Bus hold low sustaining current

2

VCC = 3V, VI = 0.8V 75 µA

I

BHH

Bus hold high sustaining current

3

VCC = 3V, VI = 2V –75 µA

I

BHLO

Bus hold low overdrive current

4, 9

VCC = 3.6V 500 µA

I

BHHO

Bus hold high overdrive current

5, 9

VCC = 3.6V –500 µA

Output current

I

OFF

Output off current VCC = 0V, VI or VO = 0 to 4.5V ±10 µA

I

EX

Current into an output in high state

when VO > V

CC

VO = 5.5V, VCC = 3.0V ±100 µA

I

PU/PD

Power-up/down 3-State output

current

8

VCC <1.2V; VO = 0.5V to VCC;

VI = GND or VCC; OE/OE = X

100 µA

VCC = MAX

I

OZH

Output leakage

6

VIN = VIL or VIH, V

OUT

= 5.5V 10 µA

I

OZL

Output leakage

6

VIN = VIL or VIH, V

OUT

=0V –10 µA

I

SC

Short circuit

7

V

OUT

= 0.5V –30 –220 mA

I

CC

VCC supply current VCC = 3.6V, Outputs enabled, VI = VCC or GND; IO = 0 170 mA

Ground/VCC Bounce MIN TYP MAX UNIT

V

OHV

Maximum dynamic V

OH

VCC = 3.0V , 25°C,

CL = 50pF (including jig capacitance)

2.2 2.3 V

VCC = 3.3V , 25°C, CL = 50pF

LVT22V10-7 0.7 1.1 V

V

OLP

Maximum dynamic V

OL

CC

, ,

L

(including jig capacitance)

LVT22V10B7 1.0 1.1 V

NOTES:

1. These are absolute values with respect to device ground and all overshoots due to system or tester noise are included.

2. The bus hold circuit can sink at least the minimum low sustaining current at V

IL

MAX. I

BHL

should be measured after lowering VIN to GND

and then raising it to V

IL

MAX.

3. The bus hold circuit can source at least the minimum high sustaining current at V

IH

MIN. I

BHL

should be measured after raising VIN to V

CC

and then lowering it to V

IH MIN.

4. An external driver must source at least I

BHLO

to switch this node from low to high.

5. An external driver must sink at least I

BHHO

to switch this node from high to low.

6. I/O pin leakage is the worst case of I

OZX

or IIX (where X = H or L).

7. No more than one output should be tested at a time. Duration of the short-circuit test should not exceed one second. V

OUT

= 0.5V has been

chosen to avoid test problems caused by tester ground degradation.

8. This parameter is valid for any V

CC

between 0V and 1.2 V with a transition time up to 10 mS. From VCC = 1.2 to VCC = 3.3V ±0.3V a

transition time of 100 µS is permitted. X = Don’t care.

9. These parameters are not 100% tested, but are evaluated at initial characterization and at any time the design is modified where input

current may be affected.

Page 6

Philips Semiconductors Product specification

LVT22V10

3V high speed, universal PLD device

1998 Feb 10

6

AC ELECTRICAL CHARACTERISTICS

Over commercial operating temperature range.

LIMITS

SYMBOL

PARAMETER

TEST CONDITIONS

1

MIN TYP MAX

UNIT

Input or feedback to non-registered output

2

Active-LOW 7.5 ns

g

PLCC package

Active-HIGH 7.5 ns

t

PD

Input or feedback to non-registered output

2

Active-LOW 8.0 ns

g

DIP and SOL packages

Active-HIGH 8.0 ns

t

S

Setup time from input, feedback or SP to Clock 5.5 ns

t

H

Hold time 0 ns

t

CO

Clock to output 5.0 ns

t

CF

Clock to feedback

3

3.0 ns

t

AR

Asynchronous Reset to registered output 12.0 ns

t

ARW

Asynchronous Reset width 5.0 ns

t

ARR

Asynchronous Reset recovery time 5.0 ns

t

SPR

Synchronous Preset recovery time 5.0 ns

t

WL

Width of Clock LOW 3.0 ns

t

WH

Width of Clock HIGH 3.0 ns

Maximum frequency;

External feedback 1/(tS + tCO)

4

95 MHz

f

MAX

Maximum frequency;

Internal feedback 1/(tS + tCF)

4

118 MHz

t

EA

Input to Output Enable

5

8.5 ns

t

ER

Input to Output Disable

5

8.5 ns

Capacitance

6

Input Capacitance (Pin 1) VIN = 2.0V

=

6 pF

C

IN

Input Capacitance (Others) VIN = 2.0V

V

CC

= 3.3V,

T

amb

= 25°C,

6 pF

C

OUT

Output Capacitance V

OUT

= 2.0V

f = 1MHz

8 pF

NOTES:

1. Test Conditions: R

1

= 500Ω, R2 =500Ω

2. t

PD

is tested with switch S1 open and CL = 50pF (including jig capacitance). VIH = 3V, VIL = 0V, VT = 1.5V .

3. Calculated from measured f

MAX

internal.

4. These parameters are not 100% tested, but are calculated at initial characterization and at any time the design is modified where frequency

may be affected.

5. For 3-State output; output enable times are tested with CL = 50pF to the 1.5V level, and S1 is open for high-impedance to High tests and

closed for high-impedance to Low tests. Output disable times are tested with C

L

= 5pF. High-to-High impedance tests are made to an output

voltage of V

T

= (VOH – 0.3V) with S1 open, and Low-to-High impedance tests are made to the VT = (VOL + 0.3V) level with S1 closed.

6. These parameters are not 100% tested, but are evaluated at initial characterization and at any time the design is modified where

capacitance may be affected.

Page 7

Philips Semiconductors Product specification

LVT22V10

3V high speed, universal PLD device

1998 Feb 10

7

PRODUCT FEATURES

Low Ground Bounce

The Philips Semiconductors BiCMOS QUBiC process results in

exceptional noise immunity. Ground bounce is noise that is

generated on a non-switching active low output when other outputs

on the device switch from high to low. The worst case condition

occurs when 9 outputs simultaneously switch from high to low and

the tenth output is active low. The ground bounce on this tenth

output for Philips LVT22V10 is typically less than 0.7V.

VCC Bounce

VCC bounce occurs on a non-switching active high output when

other outputs are making a low to high transition. This specification

is important to consider in 3.3V designs because of the reduced

noise margin between V

CC

and VOH of only 1.3V relative to the

traditional 5V system’s noise margin of 3V. The Philips LVT22V10

V

CC

bounce of an output held high while the remaining 9 outputs

switch from low to high is typically less than 1.0V in magnitude.

Live Insertion/Extraction Capability

There are some inherent problems associated with inserting or

extracting an unpowered module from a powered-up, active system.

The LVT22V10 outputs have been designed such that any chance of

bus contention, glitching or clamping is eliminated.

Detailed information on this feature is provided in an application note

AN051:

Philips PLDs Support Live Insertion Applications

.

Bus Hold Input Structure

Bus Hold is a feature that maintains the input state of the device by

incorporating a weak latch into the input structure. This latch

maintains the input state until a minimum level of current (called the

overdrive current) is supplied to change the input state. This is

useful in bus applications where the bus is placed into a high

impedance state. The LVT22V10’s inputs, in this high impedance

situation, maintain valid logic levels until the bus is actively driven to

a new state.

Improved Fuse Verification Circuitry Increases

Reliability

Philips has developed a new means of testing the integrity of fuses,

both blown and intact fuses, which insures that all the fuses have

been correctly programmed and that each and every fuse – whether

“blown” or “intact” – is at the appropriate and optimal fuse

resistance. This dual verify scheme represents a significant

improvement over single reference voltage comparisons schemes

that have been used for bipolar devices since the late 1980s.

Detailed information on this feature is provided in an application note

entitled

Dual Verify Technique Increases Reliability of PLDs

.

Programmable 3-stage Outputs

Each output has a 3-Stage output buffer with 3-State control. A

product term controls the buffer, allowing enable and disable to be a

function of any product of device inputs or output feedback. The

combinatorial output provides a bidirectional I/O pin, and may be

configured as a dedicated input if the buffer is always disabled.

Programmable Output Polarity

The polarity of each macro cell output can be Active-HIGH or

Active-LOW, either to match output signal needs or to reduce

product terms. Programmable polarity allows Boolean expressions

to be written in their most compact form (true or inverted), and the

output can still be of the desired polarity. It can also save

“DeMorganizing” efforts.

Selection is controlled by programmable bit S

0

in the Output Macro

Cell, and affects both registered and combinatorial outputs.

Selection is automatic, based on the design specification and pin

definitions. If the pin definition and output equation have the same

polarity, the output is programmed to be Active-HIGH (S

0

= 1).

Preset/Reset

For initialization, the LVT22V10 has additional Preset and Reset

product terms. These terms are connected to all registered outputs.

When the Synchronous Preset (SP) product term is asserted high,

the output registers will be loaded with a HIGH on the next

LOW-to-HIGH clock transition. When the Asynchronous Reset (AR)

product term is asserted high, the output registers will be

immediately loaded with a LOW, independent of the clock.

Note that Preset and Reset control the flip-flop, not the output pin.

The output level is determined by the output polarity selected.

Power-Up Reset

All flip-flops power-up to a logic LOW for predictable system

initialization. Outputs of the LVT22V10 will depend on the

programmed output polarity. The V

CC

rise must be monotonic and

the reset delay time is 1–10µs maximum.

Security Fuse

After programming and verification, LVT22V10 designs can be

secured by programming the security fuse link. Once programmed,

this fuse defeats readback of the internal programmed pattern by a

device programmer, securing proprietary designs from competitors.

When the security fuse is programmed, the array will read as if

every fuse is programmed.

Quality and Testability

The LVT22V10 offers a very high level of built-in quality. Extra

programmable fuses provide a means of verifying performance of all

AC and DC parameters. In addition, this verifies programmability

and functionality of the device to provide the highest programming

and post-programming functional yields.

T echnology

The BiCMOS LVT22V10 is fabricated with the Philips

Semiconductors process known as QUBiC. QUBiC combines an

advanced, state-of-the-art 1.0µm (drawn feature size) CMOS

process with an ultra fast bipolar process to achieve superior speed

and drive capabilities. QUBiC incorporates three layers of Al/Cu

interconnects for reduced chip size, and our proven Ti-W fuse

technology ensures highest programming yields.

Programming

The LVT22V10 is fully supported by industry standard (JEDEC

compatible) PLD CAD tools, including Philips Semiconductors

SNAP design software package. ABEL

CUPL and PALASM 90

design software packages also support the LVT22V10 architecture.

All packages allow Boolean and state equation entry formats, SNAP,

ABEL and CUPL also accept, as input, schematic capture format.

ABEL is a trademark of Data I/O Corp.

CUPL is a trademark of Logical Devices, Inc.

PALASM is a registered trademark of AMD Corp.

Page 8

Philips Semiconductors Product specification

LVT22V10

3V high speed, universal PLD device

1998 Feb 10

8

Output Register Preload

The register on the LVT22V10 can be preloaded from the output

pins to facilitate functional testing of complex state machine designs.

This feature allows direct loading of arbitrary states, making it

unnecessary to cycle through long test vector sequences to reach a

desired state. In addition, transitions from illegal states can be

verified by loading illegal states and observing proper recovery. The

procedure for preloading follows:

1. Raise V

CC

to 3.3V ± 0.3V .

2. Set pin 2 or 3 to V

HH

to disable outputs and enable preload.

3. Apply the desired value (V

ILP/VIHP

) to all registered output pins.

Leave combinatorial output pins floating.

4. Clock Pin 1 from V

ILP

to V

IHP

.

5. Remove V

ILP/VIHP

from all registered output pins.

6. Lower pin 2 or 3 to V

ILP

.

7. Enable the output registers according to the programmed

pattern.

8. Verify V

OL/VOH

at all registered output pins. Note that the output

pin signal will depend on the output polarity.

PRELOAD SET -UP

LIMITS

SYMBOL PARAMETER MIN REC MAX UNIT

V

HH

Super-level input voltage 9.5 9.5 10 V

V

ILP

Low-level input voltage 0 0 0.8 V

V

IHP

High-level input voltage 2.4 3.3 3.6 V

t

D

Delay time 100 200 1000 ns

t

I/O

I/O valid after Pin 2 or 3 drops from VHH to V

ILP

100 ns

t

D

V

HH

V

IHP

V

OH

V

OL

V

ILP

V

IHP

V

ILP

t

I/O

PINS 2, 3

REGISTERED

OUTPUTS

CLOCK

t

D

t

D

t

D

t

D

Output Register Preload Waveform

DATA IN DATA OUT

V

ILP

SP00373

Page 9

Philips Semiconductors Product specification

LVT22V10

3V high speed, universal PLD device

1998 Feb 10

9

L VT22V10 TIMING CHARACTERIZATION

Normalized tCO vs Temperature

(V

CC

= 3.3V , output capacitance = 50pF, 5outputs switching)

Normalized t

PD

vs Temperature

(V

CC

= 3.3V , output capacitance = 50pF, 5 outputs switching)

Normalized t

CO

vs V

CC

(temp = 25°C, output capacitance = 50pF, 5 outputs switching)

Temperature (°C) Temperature (°C)

Supply Voltage (V) Supply Voltage (V)

Normalized t

CO

Normalized t

PD

Normalized t

CO

Normalized t

PD

1.20

1.10

1.00

0.90

0.80

RISE

FALL

Normalized tPD vs V

CC

(temp = 25°C, output capacitance = 50pF, 5 outputs switching)

The timing characterization represents the average values of a representative sample for each parameter.

The data can be used to derate the MAX AC CHARACTERIZATION based upon the specific user design.

Philips guarantees the MAX AC CHARACTERIZATION specifications.

SP00386

1.05

1.00

0.95

0.85

025 50 75

1.10

1.00

0.90

0.80

0255075

1.20

1.10

1.00

0.90

0.80

3.0 3.1 3.2 3.3 3.4 3.5

RISE

FALL

0.90

RISE

FALL

3.6

RISE

FALL

3.0 3.1 3.2 3.3 3.4 3.5 3.6

Page 10

Philips Semiconductors Product specification

LVT22V10

3V high speed, universal PLD device

1998 Feb 10

10

L VT22V10 TIMING CHARACTERIZATION

The timing characterization represents the average values of a representative sample for each parameter.

The data can be used to derate the MAX AC CHARACTERIZATION based upon the specific user design.

Philips guarantees the MAX AC CHARACTERIZATION specifications.

Delta t

CO

vs Number of Outputs Switching

(V

CC

= 3.3V , temp = 25°C, output capacitance = 50pF)

Delta t

PD

vs Number of Outputs Switching

(V

CC

= 3.3V , temp = 25°C, output capacitance = 50pF)

Delta t

CO

vs Output Capacitance

(VCC = 3.3V , temp = 25°C, 5 Outputs Switching)

Delta tPD vs Output Capacitance

(VCC = 3.3V , temp = 25°C, 5 Outputs Switching)

CO

PD

PD

100

–300

–500

–700

12345678910

Number of Outputs Switching Number of Outputs Switching

Output Capacitance Output Capacitance

Delta t (ns)

Delta t (ps)

Delta t (ns)

SP00387

–100

0.10

0.00

–0.20

–0.50

–0.60

–0.90

–1.10

1234 56 78910

–0.10

–0.40

–0.70

–1.00

10 50 100 200 400

5.00

4.00

1.00

–2.00

3.00

0.00

10 50 100 200 400

RISE

FALL

0

–400

–600

–200

RISE

FALL

–1.00

2.00

6.00

7.00

RISE

FALL

–0.30

–0.80

RISE

FALL

5.00

4.00

1.00

–2.00

3.00

0.00

–1.00

2.00

6.00

7.00

CO

Delta t (ns)

Page 11

Philips Semiconductors Product specification

LVT22V10

3V high speed, universal PLD device

1998 Feb 10

11

LOGIC DIAGRAM

NOTE:

Programmable connection.

1

1

0

0

0

1

0

1

D

AR

Q

Q

SP

0

1

Q

1

1

0

0

0

1

0

1

D

AR

Q

SP

0

1

Q

1

1

0

0

0

1

0

1

D

AR

Q

SP

0

1

Q

1

1

0

0

0

1

0

1

D

AR

Q

SP

0

1

Q

1

1

0

0

0

1

0

1

D

AR

Q

SP

0

1

Q

1

1

0

0

0

1

0

1

D

AR

Q

SP

0

1

Q

1

1

0

0

0

1

0

1

D

AR

Q

SP

0

1

Q

1

1

0

0

0

1

0

1

D

AR

Q

SP

0

1

Q

1

1

0

0

0

1

0

1

D

AR

Q

SP

0

1

Q

1

1

0

0

0

1

0

1

D

AR

Q

SP

0

1

AR

SP

0 3 4 7 8 1112 1516 1920 2324 2728 3132 3536 3940 43

0 3 4 7 8 1112 1516 1920 2324 2728 3132 3536 3940 43

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

CLK/I0

I1

I2

I3

I4

I5

I6

I7

I10

I8

I9

GND

I11

F0

F1

F2

F3

F4

F5

F6

F7

F8

F9

V

CC

0

1

9

10

20

21

33

34

48

49

65

66

82

83

97

98

110

111

121

122

130

131

SP00059

Page 12

Philips Semiconductors Product specification

LVT22V10

3V high speed, universal PLD device

1998 Feb 10

12

FUNCTIONAL DIAGRAM

OUTPUT

MACRO

CELL

CLK/I0 I1 – I11

F0 F1 F2 F3 F4 F5 F6 F7 F8 F9

PROGRAMMABLE AND ARRAY

(44 × 132)

1 11

81012141616141210 8

SP00060A

OUTPUT

MACRO

CELL

OUTPUT

MACRO

CELL

OUTPUT

MACRO

CELL

OUTPUT

MACRO

CELL

OUTPUT

MACRO

CELL

OUTPUT

MACRO

CELL

OUTPUT

MACRO

CELL

OUTPUT

MACRO

CELL

OUTPUT

MACRO

CELL

RESET

PRESET

Figure 1. Functional Diagram

FUNCTIONAL DESCRIPTION

The LVT22V10 allows the systems engineer to implement the

design on-chip, by opening fuse links to configure AND and OR

gates within the device, according to the desired logic function.

Product terms with all fuses opened assume the logical HIGH state;

product terms connected to both True and Complement of any

single input assume the logical LOW state.

The LVT22V10 has 12 inputs and 10 I/O Macro Cells (Figure 1). The

Macro Cell allows one of four potential output configurations,

registered output or combinatorial I/O, Active-HIGH or Active-LOW

(see Figure 2). The configuration choice is made according to the

user’s design specification and corresponding programming of the

configuration bits S

0

–S1. Multiplexer controls are connected to

ground (0) through a programmable fuse link, selecting the “0” path

through the multiplexer. Programming the fuse disconnects the

control line from GND and it floats to V

CC

(1), selecting the “1” path.

Page 13

Philips Semiconductors Product specification

LVT22V10

3V high speed, universal PLD device

1998 Feb 10

13

OUTPUT MACRO CELL

F

0

1

1

0

0

1

0

0

1CLK

1

AR

SP

S

1

S

0

S

1

S

0

OUTPUT CONFIGURATION

0 = Unprogrammed fuse

1 = Programmed fuse

DQ

Q

0

0

1

1

0

1

0

1

Registered/Active-LOW

Registered/Active-HIGH

Combinatorial/Active-LOW

Combinatorial/Active-HIGH

SP00375

Figure 2. Output Macro Cell Logic Diagram

F

CLK

AR

SP

S

0

= 0

S

1

= 0

DQ

Q

a. Registered/Active-LOW

F

CLK

AR

SP

S0 = 1

S

1

= 0

DQ

Q

b. Registered/Active-HIGH

F

S

0

= 0

S

1

= 1

c. Combinatorial/Active-LOW

d. Combinatorial/Active-HIGH

F

S

0

= 1

S

1

= 1

SP00376

Figure 3. Output Macro Cell Configurations

Registered Output Configuration

Each Macro Cell of the LVT22V10 includes a D-type flip-flop for data

storage and synchronization. The flip-flop is loaded on the

LOW-to-HIGH transition of the clock input. In the registered

configuration (S1 = 0), the array feedback is from Q of the flip-flop.

Combinatorial I/O Configuration

Any Macro Cell can be configured as combinatorial by selecting the

multiplexer path that bypasses the flip-flop (S

1

= 1). In the

combinatorial configuration, the feedback is from the pin.

Variable Input/Output Pin Ratio

The LVT22V10 has twelve dedicated input lines, and each Macro

Cell output can be an I/O pin. Buffers for device inputs have

complementary outputs to provide user-programmable input signal

polarity.

Page 14

Philips Semiconductors Product specification

LVT22V10

3V high speed, universal PLD device

1998 Feb 10

14

INTERFACING IN MIXED 3V/5V SYSTEMS

3V Logic Driving 5V Logic

The LVT family has outputs that swing virtually between the power

supply rails, thereby allowing direct interfacing with TTL switching

levels.

When interfacing the outputs of any of our 3V logic ICs with

standard TTL-level logic inputs (bipolar or CMOS HCT), the output

levels from the 3V logic are sufficient to directly drive the 5V logic.

When driving CMOS-level devices (such as HC or AC), the output

voltage from the 3V logic is insufficient to ensure reliable operation.

This problem can be easily resolved by using a pull-up resistor at

the interface.

5V Logic Driving 3V Logic

Since the LVT ICs do not have protection diodes between their

inputs and V

CC

, the inputs of these devices can therefore withstand

higher levels than the supply voltage, and they can be directly

connected to 5V CMOS logic outputs. For the LVT family, the

combination of low power dissipation with the live insertion feature,

bus hold and full 5V input/output capability make this logic ideal for

3.3V backplane interfacing.

INTERFACING 3 VOLT AND 5 VOLT LOGIC

FROM TO METHOD

3V

p

TTL Inputs Direct

to

5V

LVT Output

CMOS inputs Pull-up

5V

CMOS Rail LVT Input Direct

to

Totem-Pole L VT Input Direct

3V

Open Drain LVT Input Pull-up

LVT22V10 METASTABLE HARDENED

CHARACTERISTICS

Metastable Hardened Characteristics

What is metastable hardened? Philips Semiconductors uses the

term “metastable hardened” to describe a combination of two

characteristic features. The first is a patented Philips circuit that

prevents the outputs from glitching, oscillating, or remaining in the

linear region under any circumstances, including setup and hold

time violations. The second is the flip-flops’ inherent ability of

resolving the metastable condition. Philips provides complete data

on the LVT22V10’s metastable characteristics

With the LVT22V10, any tendency towards internal metastability is

resolved by Philips Semiconductors patented circuitry. If a

metastable event occurs within the flop, the only outward

manifestation of the event will be an increased clock-to-Q delay.

This delay is a function of the metastability characteristics of the

device, defined by τ and T

O

as described below. Since the outputs

never glitch, oscillate, or remain in the linear region, the only

metastable failure that can propagate further into the system is when

the next flip-flop in the system samples the LVT22V10’s output at

precisely the same time it is making a logic transition. By allowing

sufficient time for any increased clock-to-Q delay , propagation of

metastable failures can be avoided. The following design example

illustrates this concept.

Design Example

Suppose a designer wants to use the LVT22V10 for synchronizing

asynchronous data that is arriving at 2MHz (as measured by a

frequency counter), in a 3.3V system that has a clock frequency of

33MHz, at an ambient temperature of 25°C. She has decided that

she would like to sample the output of the LVT22V10 15ns after the

clock edge to ensure that any clock-to-Q delays that were the result

of the LVT22V10 internal metastability resolution circuitry have

completed and the outputs have transitioned. The MTBF for this

situation can be calculated by using the equation below:

MTBF = e(t’/τ )/T

OFCF1

In this formula, FC is the frequency of the clock, F1 is the average

input event frequency , and t’ is the time after the clock pulse that the

output is sampled (t’ > T

CO

). TO and τ are device parameters

provided by the semiconductor manufacturer (refer to the following

table for the LVT22V10 metastability specifications). T

O

and τ are

derived from tests and can be most nearly be defined as follows: τ is

a function of the rate at which a latch in a metastable state resolves

that condition. T

O

is a function of the measurement of the propensity

of a latch to enter a metastable state. T

O

is also a normalization

constant, which is a very strong function of the normal propagation

delay of the device.

In this situation the F

1

will be twice the data frequency, or 4MHz,

because input events consist of both of low and high transitions.

Thus, in this case, F

C

is 33MHz, F1 is 4MHz, τ is 317ps, t’ is 15ns,

and T

O

is 4.27 × 10-3 seconds. Using the above formula the actual

MTBF for this situation is 1.26 × 10

9

seconds or 39 years for the

LVT22V10.

Summary

The Philips LVT22V10 has on-chip circuitry that completely

eliminates any output glitches, oscillations, or other output

anomalies associated with metastable conditions. For outputs that

are then used to generate clocks, control signals or other

asynchronous data this represents an unparalleled level of reliability

in a PLD. In addition, a complete set of metastability data is

provided, that allows designers the ability to design robust systems

where data is synchronously pipelined.

L VT22V10 VALUES FOR τ AND T

O

0°C 25°C 75°C

V

CC

τ T

O

τ T

O

τ T

O

3.0V 829.00ps 1.16E–08 691.00ps 1.09E–07 429.00ps 2.27E–04

3.3V 358.00ps 2.36E–04 317.00ps 4.27E–03 329.00ps 5.75E–03

3.6V 237.00ps 2.66E–01 230.00ps 6.47E–01 250.00ps 1.13E+00

Page 15

Philips Semiconductors Product specification

LVT22V10

3V high speed, universal PLD device

1998 Feb 10

15

SWITCHING W AVEFORMS

t

S

Combinatorial Output

Registered Output

Clock to Feedback (f

MAX

Internal)

(See Path at Right)

Clock Width Input to Output Disable/Enable

Asynchronous Reset Synchronous Preset

t

PD

V

T

V

T

INPUT OR

FEEDBACK

COMBINATORIAL

OUTPUT

V

T

V

T

V

T

INPUT OR

FEEDBACK

CLOCK

REGISTERED

OUTPUT

t

S

t

H

t

CO

V

T

tS + t

CF

CLOCK

LOGIC REGISTER

CLK

t

S

t

CF

V

T

t

WH

CLOCK

t

WL

t

ER

t

EA

VOH – 0.3V

V

OL

+ 0.3V

INPUT

OUTPUT

V

T

V

T

V

T

V

T

V

T

t

ARW

t

AR

t

ARR

CLOCK

REGISTERED

OUTPUT

INPUT ASSERTING

ASYNCHRONOUS

RESET

t

H

V

T

V

T

V

T

V

T

t

SPR

INPUT ASSERTING

SYNCHRONOUS

PRESET

CLOCK

REGISTERED

OUTPUT

t

CO

SP00388

Clock to Feedback

NOTES:

1. V

T

= 1.5V .

2. Input pulse amplitude 0V to 3.0V.

3. Input rise and fall times 1.5ns max.

Page 16

Philips Semiconductors Product specification

LVT22V10

3V high speed, universal PLD device

1998 Feb 10

16

“AND” ARRAY – (I, B)

I, B

P, D

CODE

O

STATE

INACTIVE

1

CODESTATE CODESTATE CODESTATE

TRUE

HL—

P, D

I, B

I, B

P, D

I, B

I, B

P, D

I, B

I, B

I, B

COMPLEMENT DON’T CARE

SP00008

I, B I, B I, B I, B

NOTE:

1. This is the initial state.

POWER-UP RESET

The power-up reset feature ensures that all flip-flops will be reset to

LOW after the device has been powered up. The output state will

depend on the programmed pattern. This feature is valuable in

simplifying state machine initialization. A timing diagram and

parameter table are shown below. Due to the synchronous operation

of the power-up reset and the wide range of ways V

CC

can rise to its

steady state, two conditions are required to ensure a valid power-up

reset. These conditions are:

1. The V

CC

rise must be monotonic.

2. Following reset, the clock input must not be driven from LOW to

HIGH until all applicable input and feedback setup times are met.

t

WL

Power-Up Reset Waveform

2.7V

V

CC

t

S

t

PR

POWER

REGISTERED

ACTIVE-LOW

OUTPUT

CLOCK

SP00389

LIMITS

SYMBOL PARAMETER MIN MAX UNIT

t

PR

Power-up Reset Time 1 µs

t

S

Input or Feedback Setup Time See AC Electrical

t

WL

Clock Width LOW Characteristics

Page 17

Philips Semiconductors Product specification

L VT22V103V high speed, universal PLD device

1998 Feb 10

17

DIP24: plastic dual in-line package; 24 leads (300 mil) SOT222-1

Page 18

Philips Semiconductors Product specification

L VT22V103V high speed, universal PLD device

1998 Feb 10

18

PLCC28: plastic leaded chip carrer; 28 leads; pedestal SOT261-3

Page 19

Philips Semiconductors Product specification

L VT22V103V high speed, universal PLD device

1998 Feb 10

19

SO24: plastic small outline package; 24 leads; body width 7.5 mm SOT137-1

Page 20

Philips Semiconductors Product specification

L VT22V103V high speed, universal PLD device

1998 Feb 10

20

Definitions

Short-form specification — The data in a short-form specification is extracted from a full data sheet with the same type number and title. For

detailed information see the relevant data sheet or data handbook.

Limiting values definition — Limiting values given are in accordance with the Absolute Maximum Rating System (IEC 134). Stress above one

or more of the limiting values may cause permanent damage to the device. These are stress ratings only and operation of the device at these or

at any other conditions above those given in the Characteristics sections of the specification is not implied. Exposure to limiting values for extended

periods may affect device reliability.

Application information — Applications that are described herein for any of these products are for illustrative purposes only. Philips

Semiconductors make no representation or warranty that such applications will be suitable for the specified use without further testing or

modification.

Disclaimers

Life support — These products are not designed for use in life support appliances, devices or systems where malfunction of these products can

reasonably be expected to result in personal injury . Philips Semiconductors customers using or selling these products for use in such applications

do so at their own risk and agree to fully indemnify Philips Semiconductors for any damages resulting from such application.

Right to make changes — Philips Semiconductors reserves the right to make changes, without notice, in the products, including circuits, standard

cells, and/or software, described or contained herein in order to improve design and/or performance. Philips Semiconductors assumes no

responsibility or liability for the use of any of these products, conveys no license or title under any patent, copyright, or mask work right to these

products, and makes no representations or warranties that these products are free from patent, copyright, or mask work right infringement, unless

otherwise specified.

Philips Semiconductors

811 East Arques Avenue

P.O. Box 3409

Sunnyvale, California 94088–3409

Telephone 800-234-7381

Copyright Philips Electronics North America Corporation 1998

All rights reserved. Printed in U.S.A.

Date of release: 02-98

Document order number: 9397 750 03313

Data sheet

status

Objective

specification

Preliminary

specification

Product

specification

Product

status

Development

Qualification

Production

Definition

[1]

This data sheet contains the design target or goal specifications for product development.

Specification may change in any manner without notice.

This data sheet contains preliminary data, and supplementary data will be published at a later date.

Philips Semiconductors reserves the right to make chages at any time without notice in order to

improve design and supply the best possible product.

This data sheet contains final specifications. Philips Semiconductors reserves the right to make

changes at any time without notice in order to improve design and supply the best possible product.

Data sheet status

[1] Please consult the most recently issued datasheet before initiating or completing a design.

Loading...

Loading...