Page 1

FEATURES

■

Guaranteed

■

Guaranteed

■

Typ Offset Drift: 0.01µV/°C

■

Excellent Long Term Stability: 100nV/√Month

■

Guaranteed

■

Over Operating Temperature Range:

Guaranteed

Guaranteed

Guaranteed

■

Single Supply Operation: 4.75V to 16V

Max Offset: 5µV

Max Offset Drift: 0.05µV/°C

Max Input Bias Current: 30pA

Min Gain: 120dB

Min CMRR: 120dB

Min PSRR: 120dB

(Input Voltage Range Extends to Ground)

■

External Capacitors can be Returned to V– with No

Noise Degradation

U

APPLICATIO S

■

Thermocouple Amplifiers

■

Strain Gauge Amplifiers

■

Low Level Signal Processing

■

Medical Instrumentation

LTC1052/LTC7652

Zero-Drift

Operational Amplifier

U

DESCRIPTIO

The LTC®1052 and LTC7652 are low noise zero-drift op

amps manufactured using Linear Technology’s enhanced

LTCMOSTM silicon gate process. Chopper-stabilization

constantly corrects offset voltage errors. Both initial offset

and changes in the offset due to time, temperature and

common mode voltage are corrected. This, coupled with

picoampere input currents, gives these amplifiers

unmatched performance.

Low frequency (1/f) noise is also improved by the

chopping technique. Instead of increasing continuously

at a 3dB/octave rate, the internal chopping causes noise to

decrease at low frequencies.

The chopper circuitry is entirely internal and completely

transparent to the user. Only two external capacitors

are required to alternately sample-and-hold the offset

correction voltage and the amplified input signal. Control

circuitry is brought out on the 14-pin and 16-pin versions

to allow the sampling of the LTC1052 to be synchronized

with an external frequency source.

, LTC and LT are registered trademarks of Linear Technology Corporation.

LTCMOS is a trademark of Linear Technology Corporation.

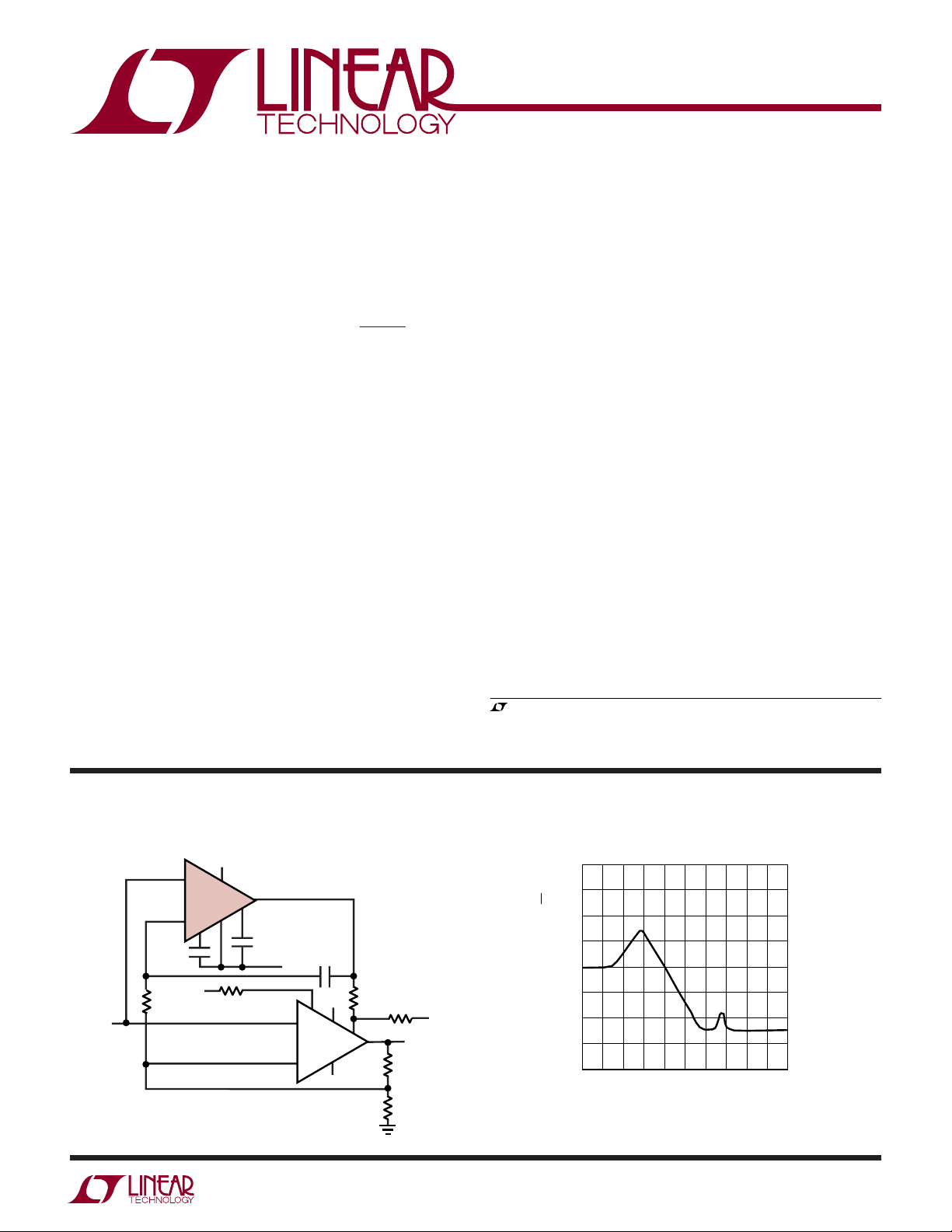

TYPICAL APPLICATIO

Ultralow Noise, Low Drift Amplifier Noise Spectrum

5V

INPUT

3

2

0.1µF

100k

V

OS = 3µV

V

OS∆T = 50nV/°C

NOISE = 0.06µV

+

LTC1052

–

1

5V

7

6

8

4

0.1µF

3K

0.1Hz TO 10Hz

P-P

–5V

3

2

0.1µF

1

+

LT®1007

–

U

–5V

160

140

120

100

80

VOLTAGE NOISE DENSITY (nV/√Hz)

60

40

20

0

0

FREQUENCY (Hz)

400100 200 300 500

LTC1052/7652 • TA02

1052fa

68k

5V

7

4

1.5k

8

6

5V

OUTPUT

100k

100Ω

LTC1052/7652 • TA01

1

Page 2

LTC1052/LTC7652

WWWU

ABSOLUTE AXI U RATI GS

(Notes 1 and 2)

Total Supply Voltage (V+ to V–) ............................... 18V

+

Input Voltage ........................ (V

+ 0.3V) to (V– – 0.3V)

Output Short Circuit Duration .......................... Indefinite

Storage Temperature Range .................. –55°C to 150°C

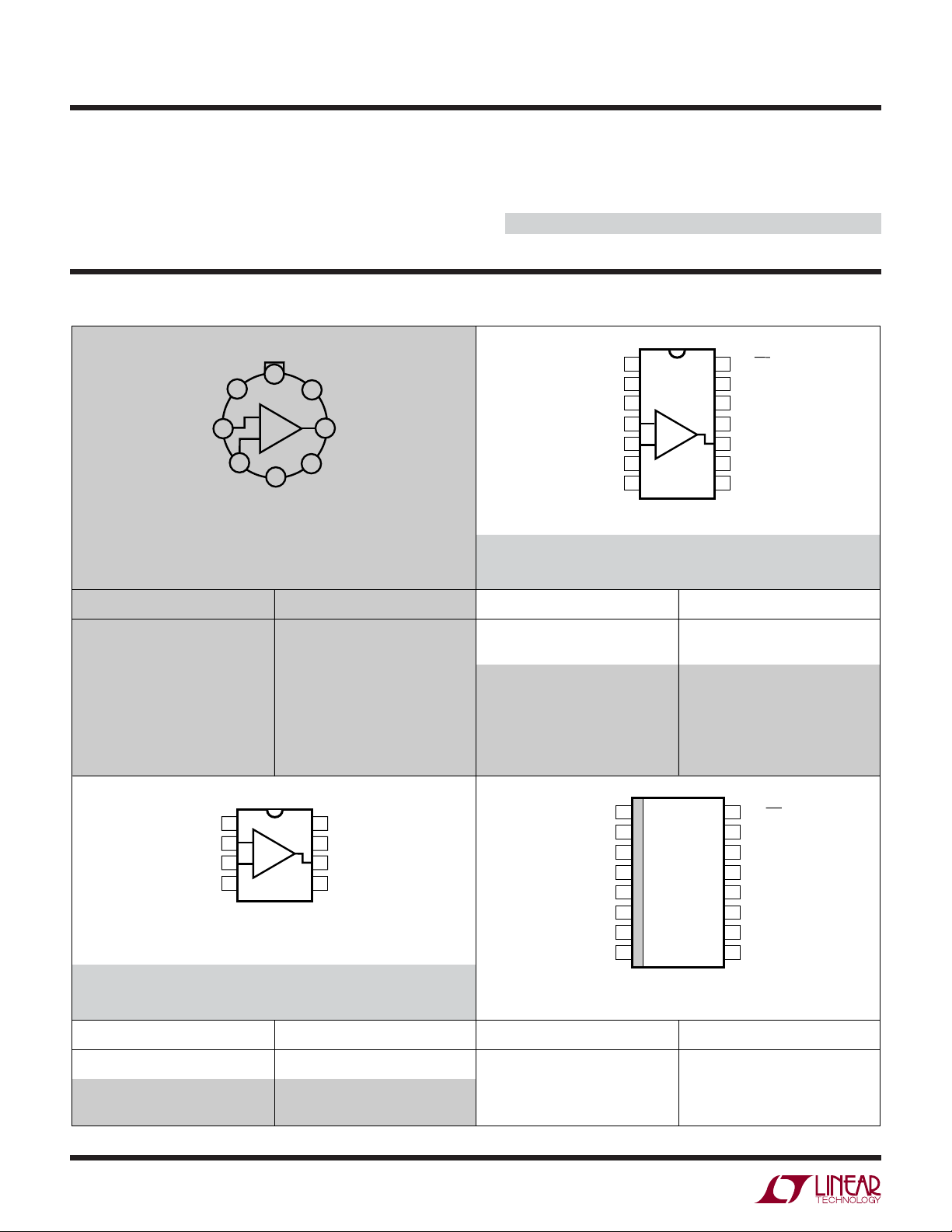

UU

W

PACKAGE/ORDER I FOR ATIO

TOP VIEW

C

EXTB

C

1

EXTA

2

–IN

3

+IN

METAL CAN H PACKAGE

OBSOLETE PACKAGE

ORDER PART NUMBER

8

–

+

4

–

V

+

V

/CASE

7

OUTPUT

6

5

LTC1052 OUTPUT CLAMP

LTC7652 C

RETURN

REPLACES

Operating Temperature Range

LTC1052C/LTC7652C ..........................–40°C to 85°C

LTC1052M (OBSOLETE).....................–55°C to 125°C

Lead Temperature (Soldering, 10 sec).................. 300°C

TOP VIEW

C

EXTB

C

EXTA

NC (GUARD)

–IN

+IN

NC (GUARD)

V–

1

2

3

4

–

5

+

6

7

N PACKAGE, 14-LEAD CERDIP

T

= 110°C, θJA = 130°C/W

JMAX

J PACKAGE, 14-LEAD CERDIP

INT/EXT

14

CLK IN

13

12

CLK OUT

V+

11

OUTPUT

10

OUTPUT CLAMP

9

C

RETURN

8

OBSOLETE PACKAGE

Consider the N14 Package for Alternate SourceConsider the N8 Package for Alternate Source

ORDER PART NUMBER

REPLACES

LTC7652CH

ICL7652CTV

ICL7652ITV

ICL7650CTV-1

ICL7650ITV-1

LTC1052CH

ICL7650CTV

ICL7650ITV

LTC1052MH

C

EXTA

–

IN

+N

–

V

T

J8 PACKAGE, 8-LEAD CERDIP

TOP VIEW

1

–

2

3

+

4

N8 PACKAGE

8-LEAD PDIP

= 110°C, θJA = 150°C/W

JMAX

ICL7650MTV

C

EXTB

8

+

V

7

6

OUTPUT

OUTPUT

5

CLAMP

OBSOLETE PACKAGE

Consider the N8 Package for Alternate Source

ORDER PART NUMBER

LTC1052CN8

LTC1052CJ8

LTC1052MJ8

Consult LTC Marketing for parts specified with wider operating temperature ranges.

REPLACES

ICL7650CPA

ICL7650IJA

ORDER PART NUMBER

LTC1052CN

LTC1052CJ

LTC1052MJ

C

1

EXTB

2

C

EXTA

NC (GUARD)

NC (GUARD)

3

4

–IN

5

+IN

6

7

V–

8

NC

16-LEAD PLASTIC (WIDE) SO

T

JMAX

LTC1052CSW

TOP VIEW

16

15

14

13

12

11

10

SW PACKAGE

= 110°C, θJA = 150°C/W

ICL7652CPD

ICL7650CPD

ICL7652IJD

ICL7650IJD

ICL7650MJD

INT/EXT

CLK IN

CLK OUT

V+

OUTPUT

OUTPUT CLAMP

C

RETURN

9

NC

REPLACES

LTC1052CS

1052fa

2

Page 3

LTC1052/LTC7652

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VS = ±5V, test circuit TC1, unless otherwise noted.

LTC1052M LTC1052C/LTC7652C

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

V

OS

∆VOS/∆Temp Average Input Offset Drift (Note 3) ● ± 0.01 ±0.05 ±0.01 ±0.05 µV/°C

∆VOS/∆Time Long-Term Offset Voltage Stability 100 100 nV/√Month

I

OS

I

B

e

nP-P

I

n

CMRR Common Mode Rejection Ratio VCM = V– to 2.7V ● 120 140 120 140 dB

PSRR Power Supply Rejection Ratio V

A

VOL

V

OUT

SR Slew Rate RL = 10k, CL = 50pF 4 4 V/µs

GBW Gain Bandwidth Product 1.2 1.2 MHz

I

S

f

S

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: Connecting any terminal to voltages greater than V

–

, may cause destructive latch-up. It is recommended that no sources

V

operating from external supplies be applied prior to power-up of the

LTC1052/LTC7652.

Note 3: These parameters are guaranteed by design. Thermocouple effects

preclude measurement of the voltage levels in high speed automatic

Input Offset Voltage (Note 3) ±0.5 ± 5 ±0.5 ± 5 µV

Input Offset Current ±30 ±90 ±30 ±90 pA

● ±2000 ±350 pA

Input Bias Current ±1 ±30 ±1 ±30 pA

● ±1000 ±175 pA

Input Noise Voltage RS = 100Ω, DC to 10HZ, TC3 1.5 1.5 µV

RS = 100Ω, DC to 1HZ, TC3 0.5 0.5 µV

P-P

P-P

Input Noise Current f = 10Hz (Note 5) 0.6 0.6 fA/√Hz

= ±2.375V to ±8V ● 120 150 120 150 dB

SUPPLY

Large-Signal Voltage Gain RL = 10k, V

= ±4V ● 120 150 120 150 dB

OUT

Maximum Output Voltage Swing RL = 10k ● ±4.7 ±4.85 ±4.7 ±4.85 V

(Note 4) R

= 100k ±4.95 ±4.95 V

L

Supply Current No Load 1.7 2.0 1.7 2.0 mA

● 3.0 3.0 mA

Internal Sampling Frequency 330 330 Hz

Clamp On Current RL = 100k ● 25 100 25 100 µA

Clamp Off Current –4V < V

< 4V 10 100 10 100 pA

OUT

+

, or less than

● 21nA

testing. V

capability. Voltages on C

is measured to a limit determined by test equipment

OS

EXTA

and C

EXTB

, A

, CMRR and PSRR are

VOL

measured to insure proper operation of the nulling loop to ensure meeting

the V

and V

OS

drift specifications. See Package-Induced VOS in the

OS

Applications Information section.

Note 4: Output clamp not connected.

Note 5: Current noise is calculated from the formula: i

q = 1.6 • 10

–19

coulomb.

n

= (2q IB)

1/2

, where

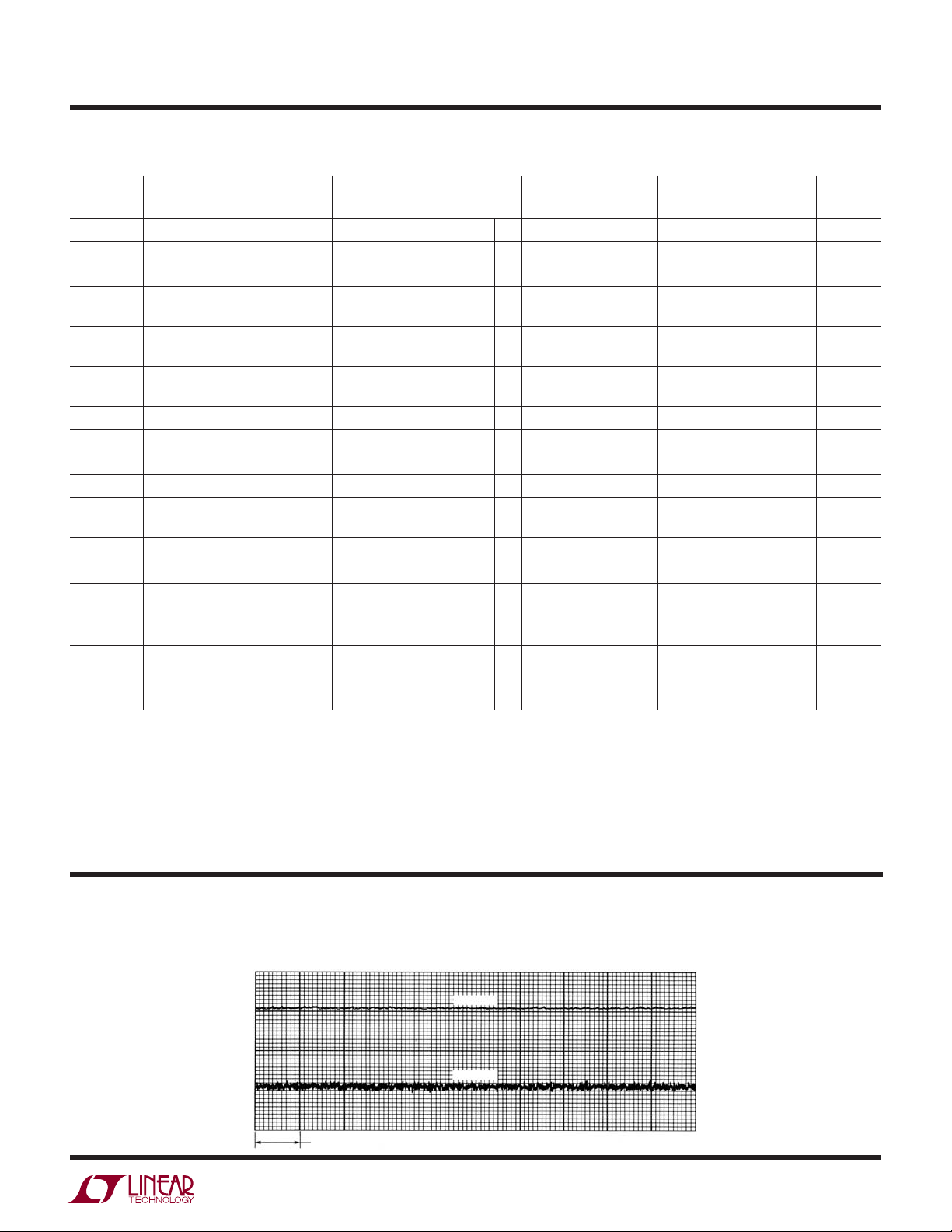

UW

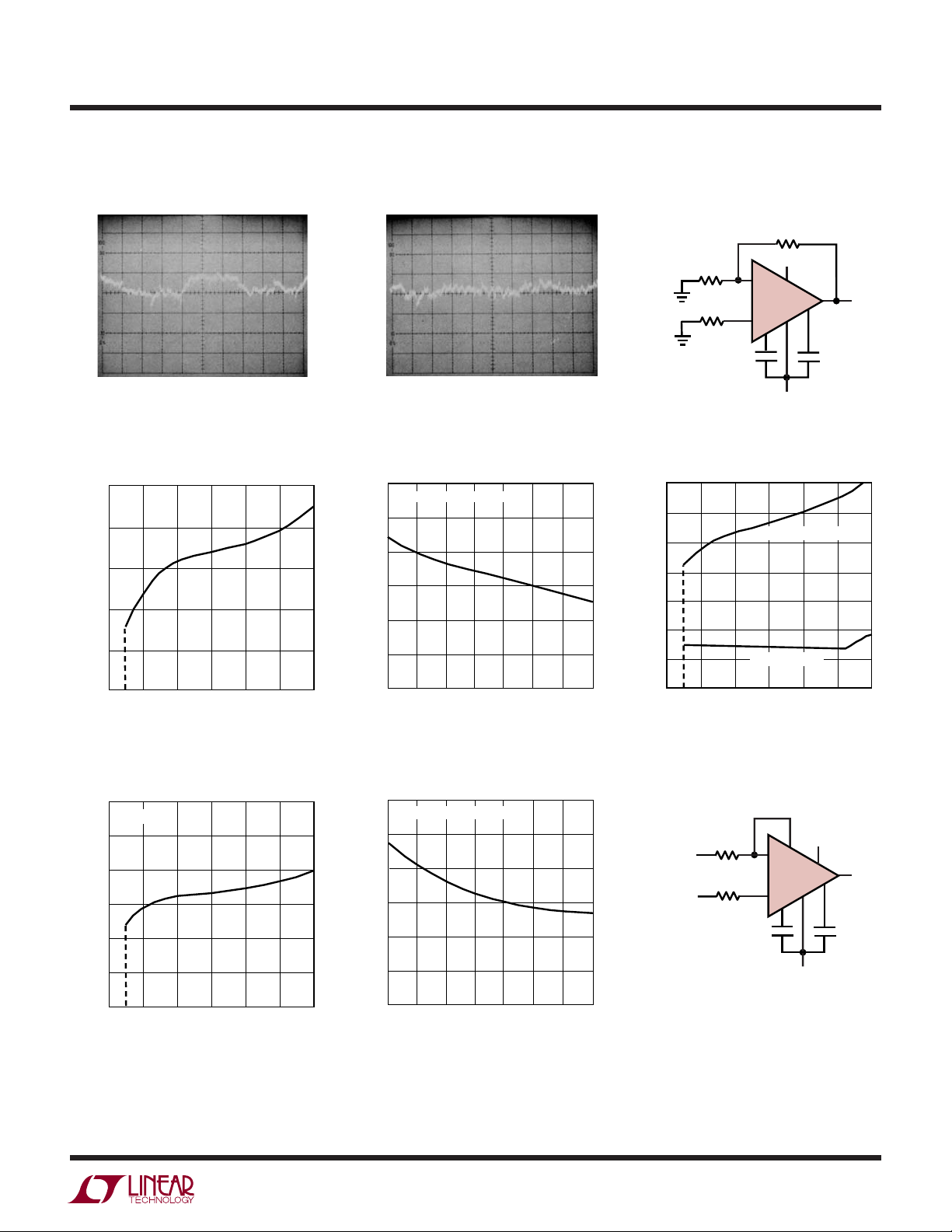

TYPICAL PERFOR A CE CHARACTERISTICS

Input Noise Voltage

5µV

0

5µV

0

10 SEC.

VS = ±5V, TEST CIRCUIT (TC3)

DC TO 1Hz

DC TO 10Hz

1052fa

3

Page 4

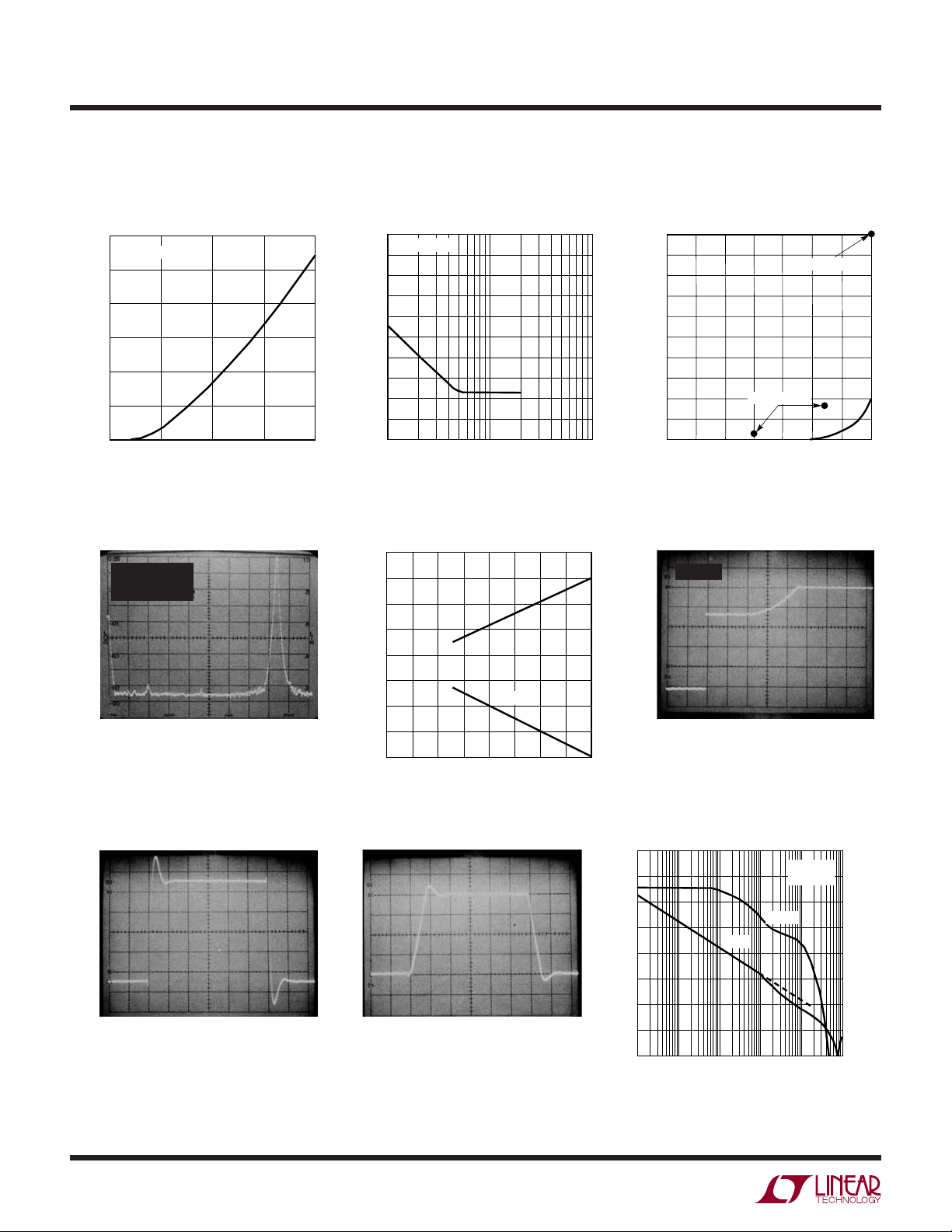

LTC1052/LTC7652

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Offset Voltage vs Sampling

Frequency

12

V

SUPPLY= ±5V

10

8

(µV)

6

OS

V

4

2

0

0

500 1000 1500 2000

SAMPLING FREQUENCY, fS (Hz)

Aliasing Error

VS = ±5V

AV = –1

TEST CIRCUIT TC2

(3Hz BANDWIDTH)

OUTPUT SPECTRUM (dB)

fI–f

S

50Hz/DIV

LTC1052/7652 • TPC01

f

S

1OHz

Frequency

5

4

3

2

1

10Hz PEAK-TO-PEAK NOISE (µV)

0

100

Common Mode Input Range vs

Supply Voltage

8

6

4

2

0

–2

–4

COMMON MODE RANGE (V)

f

I

–6

–8

0

Noise vs Sampling

P-P

V

SUPPLY= ± 5V

SAMPLING FREQUENCY, fS (Hz)

1

2

1k 10k

4

3

SUPPLY VOLTAGE (±V)

VCM = V

5

LTC1052/7652 • TPC02

–

6

7

Input Bias Current vs

Temperature

1000

900

800

(pA)

B

700

600

500

400

300

200

INPUT BIAS CURRENT, I

100

0

–50

0

–25

AMBIENT TEMPERATURE, TA(°C)

GUARANTEED

25

50

GUARANTEED

75

100

LTC1052/7652 • TPC03

125

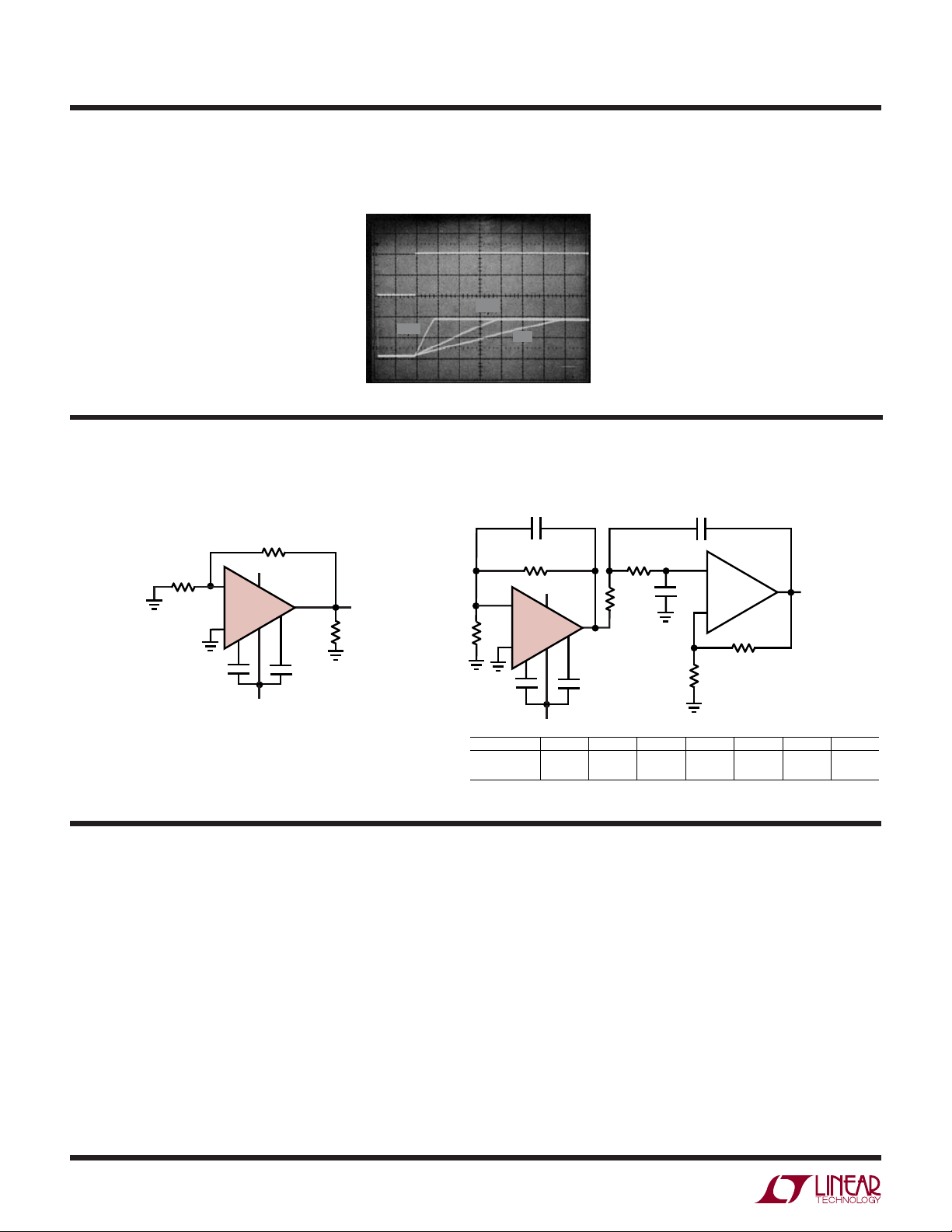

Overload Recovery

(Output Clamp Not Used)

VS = ±5V

IV/DIV

OVERDRIVE

REMOVED

AV = –100

8

50ms/DIV

LTC1052/7652 • TPC04

Small-Signal Transient Response* Gain Phase vs Frequency

OUTPUT VOLTAGE (20mV/DIV)

AV = 1

RL = 10k

CL = 100pF

VS = ±5V

*RESPONSE IS NOT DEPENDENT ON PHASE OF CLOCK

2µs/DIV

Large-Signal Transient Response*

OUTPUT VOLTAGE (2mV/DIV)

AV = 1

RL = 10k

CL = 100pF

VS = ±5V

2µs/DIV

120

100

80

60

40

20

VOLTAGE GAIN (dB)

0

–20

–40

100 10

3

10

GAIN

4

FREQUENCY (Hz)

4

10

PHASE

5

VS= ±5V

= 100pF

C

L

6

10

LTC1052/LTC7652 • TPC06

60

80

PHASE SHIFT (DEGREES)

100

120

140

160

180

200

220

7

10

1052fa

Page 5

UW

0.1µF

0.1µF

1k

V

REF

*

3

2

7

6

8

4

1

–5V

1k

5V

+

–

LTC1052

LTC1052/7652 • TPC13

V

IN

* – 5V ≤ V

REF

≤ 2.7V

5

TYPICAL PERFOR A CE CHARACTERISTICS

LTC1052/LTC7652

Broadband Noise, C

(5µV/DIV)

INPUT REFERRED NOISE

AV = –1000 1ms/DIV

EXT

= 0.1µF

Supply Current vs Supply Voltage

2.5

2.0

(mA)

S

1.5

1.0

SUPPLY CURRENT, I

0.5

0

6581012

4

TOTAL SUPPLY VOLTAGE, V+ TO V– (V)

LTC1052/LTC7652 • TPC08

14 16

Broadband Noise, C

(5µV/DIV)

INPUT REFERRED NOISE

AV = –1000 1ms/DIV

3.0

SUPPLY VOLTAGE = ± 5V

(mA)

S

2.0

1.0

SUPPLY CURRENT, I

0

–50

–25 0

AMBIENT TEMPERATURE, TA (°C)

= 1.0µF Broadband Noise Test Circuit (TC2)

EXT

50 100 125

25 75

LTC1052/LTC7652 • TPC09

R2

1M

R1

1k

R3

1k

C

EXTA

2

3

5V

–

LTC1052

+

1

–5V

Output Short-Circuit Current vs

Supply VoltageSupply Current vs Temperature

8

6

OUT (mA)

4

2

0

–10

–20

SHORT-CIRCUIT OUTPUT CURRENT, I

–30

5

4

68

TOTAL SUPPLY VOLTAGE, V+ TO V– (V)

I

SOURCE VOUT

I

SINK VOUT

10 14

7

6

8

4

C

EXTB

LTC1052/7652 • TPC07

–

= V

+

= V

12 16

LTC1052/LTC7652 • TPC10

Sampling Frequency vs Voltage Comparator Operation

600

500

(Hz)

S

400

300

200

SAMPLING FREQUENCY, f

100

0

4

TA = 25°C

5

681012

TOTAL SUPPLY VOLTAGE, V+ TO V– (V)

LTC1052/LTC7652 • TPC11

14 16

Sampling Frequency vs

Temperature

600

SUPPLY VOLTAGE = ± 5V

500

(Hz)

S

400

300

200

SAMPLING FREQUENCY, f

100

0

–50

–25 0

AMBIENT TEMPERATURE, TA (°C)

50 100 125

25 75

LT1052/LTC7652 • TPC12

1052fa

5

Page 6

LTC1052/LTC7652

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Response Time vs Overdrive

V

+ OVERDRIVE

REF

INPUT

{

OUTPUT

– 1mV

V

REF

10µV

5µV

20ms/DIV

{

–5V

5V

50µV

TEST CIRCUITS

Electrical Characteristics Test Circuit (TC1) DC to 10Hz and DC to 1HZ Noise Test Circuit (TC3)

C2

R2

1M

R1

0.1µF

2

3

10Hz

1Hz

R2

–

LTC1052

+

1

V

V

+

7

4

–

16.2Ω

16.2Ω

2

3

–

LTC1052

+

1

+

V

7

6

8

4

0.1µF

–

V

OUTPUT

R

L

LTC1052/7652 • TC01

BANDWIDTH

R1

1k

0.1µF

C3

R4

R3

6

8

0.1µF

R1

R2

162k

162k

R3

16.2k

162k

3

+

C4

LT1001

2

–

34k

R4

16.2k

162k

34k

C2

0.1µF

1.0µF

6

OUTPUT

(NOISE x 20,000)

C3

1.0µF

1.0µF

C4

1.0µF

1.0µF

LTC1052/7652 • TC02

U

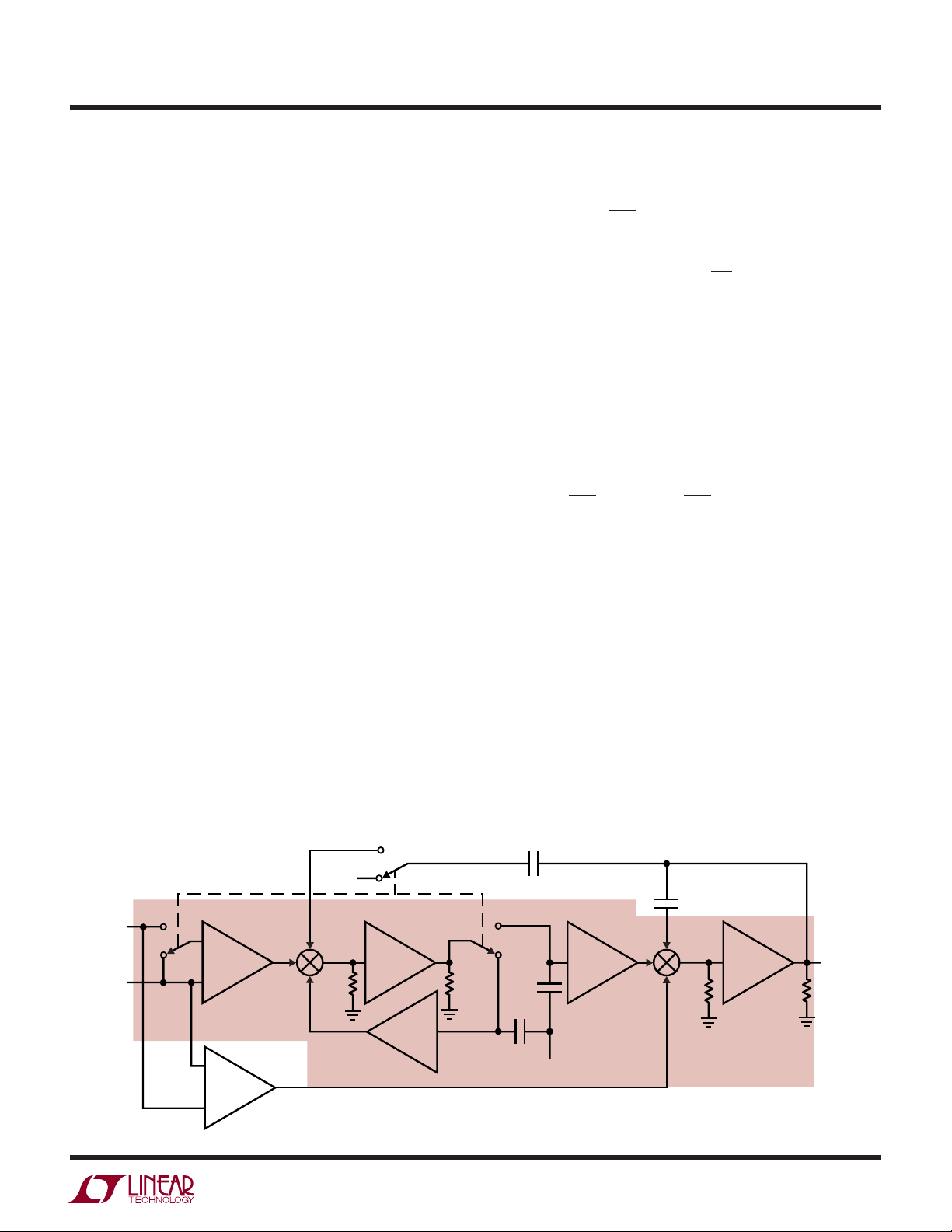

THEORY OF OPERATIO

DC OPERATION

The shaded portion of the LTC1052 block diagram

(Figure 1a) entirely determines the amplifier’s DC

characteristics. During the auto zero portion of the cycle,

the g

inputs are shorted together and a feedback path is

m1

closed around the input stage to null its offset. Switch S2

and capacitor C

act as a sample-and-hold to store the

EXTA

nulling voltage during the next step—the sampling cycle.

In the sampling cycle, the zeroed amplifier is used to

amplify the differential input voltage. Switch S2 connects

the amplified input voltage to C

and the output gain

EXTB

6

stage. C

and S2 act as a sample-and-hold to store the

EXTB

amplified input signal during the auto zero cycle.

By switching between these two states at a frequency

much higher than the signal frequency, a continuous

output results.

Notice that during the auto zero cycle the g

inputs are

m1

not only shorted together, but are also shorted to the

inverting input. This forces nulling with the common mode

voltage present and accounts for the extremely high

CMRR of the LTC1052. In the same fashion, variations in

1052fa

Page 7

THEORY OF OPERATIO

LTC1052/LTC7652

U

power supply are also nulled. For nulling to take place, the

offset voltage, common mode voltage and power supply

must not change at a frequency which is high compared to

the frequency response of the nulling loop.

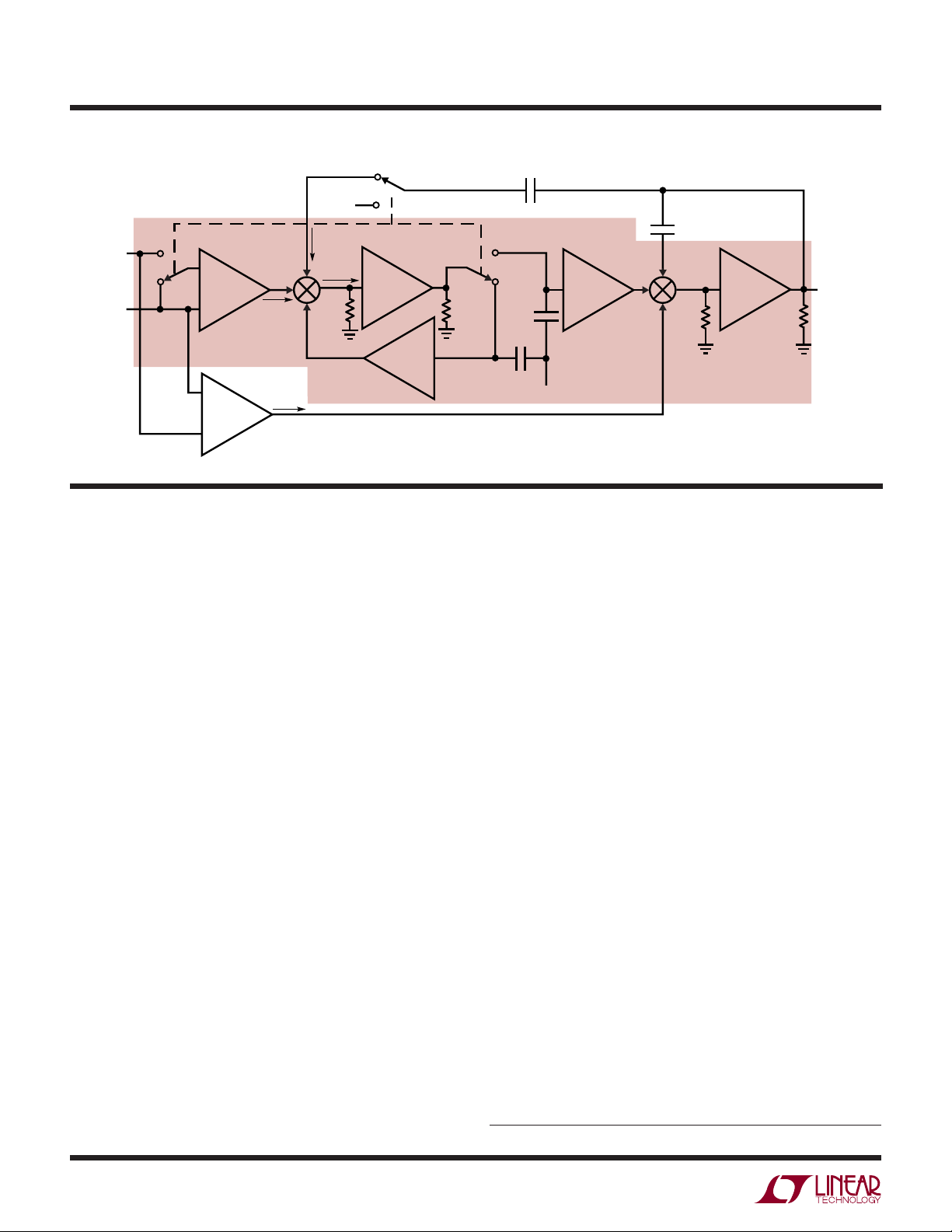

AC OPERATION AND ALIASING ERRORS

So far, the DC performance of the LTC1052 has been

explained. As the input signal frequency increases, the

problem of aliasing must be addressed. Aliasing is the

spurious formation of low and high frequency signals

caused by the mixing of the input signal with the sampling

frequency, fS. The frequency of the error signals, fE, is:

fE = fS ±f

I

where fI = input signal frequency.

Normally it is the difference frequency (fS – fI ) which is of

concern because the high frequency (fS + fI) can be easily

filtered. As the input frequency approaches the sampling

frequency, the difference frequency approaches zero and

will cause DC errors—the exact problem that the zero-drift

amplifier is meant to eliminate.

The solution is simple; filter the input so the sampling loop

never sees any frequency near the sampling frequency.

At a frequency well below the sampling frequency, the

LTC1052 forces I1 to equal I2 (see Figure 1b). This makes

δ l zero, thus the gain of the sampling loop zero at this and

higher frequencies (i.e., a low pass filter). The corner

frequency of this low pass filter is set by the output stage

pole (1/RL4 gm5 RL5 C2).

S3

V

REF

+IN

–IN

S1

+

g

m1

–

–

+

–

R

L1

g

m2

R

L2

V

g

m3

NULL

For frequencies above this pole, I2 is:

I2 = VIN gm6 •

1

• SC1

SC2

and

I1 – I2 = VIN gm1 – VIN gm6 •

The LTC1052 is very carefully designed so that gm1 = g

C1

C2

m6

and C1 = C2. Substituting these values in the above equation shows I1 – I2 = 0.

The gm6 input stage, with Cl and C2, not only filters the

input to the sampling loop, but also acts as a high

frequency path to give the LTC1052 good high frequency

response. The unity-gain cross frequencies for both the

DC path and high frequency path are identical

[f3dB =

1

(gm1/C1) =

2π

1

(gm6/C2)]

2π

thereby making the frequency response smooth and continuous while eliminating sampling noise in the output as

the loop transitions from the high gain DC loop to the high

frequency loop.

The typical curves show just how well the amplifier works.

The output spectrum shows that the difference frequency

(fI–fS = 100Hz) is down by 80dB and the frequency

response curve shows no abnormalities or perturbations.

Also note the well-behaved small and large-signal step

responses and the absence of the sampling frequency in

the output spectrum. If the dynamics of the amplifier

(i.e., slew rate and overshoot), depend on the sampling

clock, the sampling frequency will appear in the output

spectrum.

C1

C2

S2

g

m4

C

EXT B

C

EXT A

–

+

+

R

L4

g

m5

V

OUT

R

L5

–

g

m6

+

Figure 1a. LTC1052 Block Diagram

Auto Zero Cycle

V–

LTC1052/7652 • TPC13

1052fa

7

Page 8

LTC1052/LTC7652

U

THEORY OF OPERATIO

S3

V

REF

l

+IN

–IN

S1

+

g

m1

–

–

g

m6

+

2

δl

–

+

–

l

1

R

L1

l

3

Figure 1b. LTC1052 Block Diagram

WUUU

APPLICATIO S I FOR ATIO

g

m2

g

m3

Sampling Cycle

C1

C2

S2

g

m4

R

L2

C

EXT B

C

EXT A

–

V

–

+

+

R

L4

g

m5

LTC1052/7652 • TO02

V

OUT

R

L5

EXTERNAL CAPACITORS

C

EXTA

and C

are the holding elements of a sample-

EXTB

and-hold circuit. The important capacitor characteristics

are leakage current and dielectric absorption. A high

quality film-type capacitor such as mylar or polypropylene

provides excellent performance. However, low grade

capacitors such as ceramic are suitable in many

applications.

Capacitors with very high dielectric absorption (ceramic)

can take several seconds to settle after power is first

turned on. This settling appears as clock ripple on the

output and, as the capacitor settles, the ripple gradually

disappears. If fast settling after power turn-on is

important, mylar or polypropylene is recommended.

Above 85°C, leakage, both from the holding capacitors

and the printed circuit board, becomes important. To

maintain the capabilities of the LTC1052 it may be

necessary to use PTFE capacitors and PTFE standoffs

when operating at 125°C (see Achieving Picoampere/

Microvolt Performance).

C

EXTA

and C

are normally in the range of 0.1µF

EXTB

to 1.0µF. All specifications are guaranteed with 0.1µF and

the broadband noise (refer to Typical Performance Characteristics) is only very slightly degraded with 0.1µF.

Output clock ripple is not present for capacitors of 0.1µF

or greater at any temperature.

On competitive devices, connecting C

EXTA

and C

EXTB

to

V– causes an increase in amplifier noise. Design changes

have eliminated this problem on the LTC1052. On the

14-pin LTC1052 and 8-pin LTC7652, the capacitors can

be returned to V– or C

RETURN

with no change in noise

performance.

ACHIEVING PICOAMPERE/MICROVOLT PERFORMANCE

Picoamperes

In order to realize the picoampere level of accuracy of the

LTC1052, proper care must be exercised. Leakage

currents in circuitry external to the amplifier can

significantly degrade performance. High quality insulation

should be used (e.g., PTFE, Kel-F); cleaning of all

insulating surfaces to remove fluxes and other residues

will probably be necessary—particularly for high

temperature performance. Surface coating may be

necessary to provide a moisture barrier in high humidity

environments.

Board leakage can be minimized by encircling the input

connections with a guard ring operated at a potential

close to that of the inputs: in inverting configurations, the

guard ring should be tied to ground; in noninverting

1052fa

8

Page 9

WUUU

APPLICATIO S I FOR ATIO

LTC1052/LTC7652

connections, to the inverting input. Guarding both sides

of the printed circuit board is required. Bulk leakage

reduction depends on the guard ring width.

Microvolts

Thermocouple effects must be considered if the LTC1052’s

ultralow drift is to be fully utilized. Any connection

of dissimilar metals forms a thermoelectric junction

producing an electric potential which varies with

temperature (Seebeck effect). As temperature sensors,

thermocouples exploit this phenomenon to produce

useful information. In low drift amplifier circuits the effect

is a primary source of error.

Figure 2 is an example of the introduction of an

unnecessary resistor to promote differential thermal

balance. Maintaining compensating junctions in close

physical proximity will keep them at the same temperature

and reduce thermal EMF errors.

NOMINALLY UNNECESSARY

RESISTOR USED TO

THERMALLY BALANCE OTHER

INPUT RESISTOR

RESISTOR LEAD, SOLDER,

COPPER TRACE JUNCTION

Figure 2

LEAD WIRE/SOLDER/COPPER

TRACE JUNCTION

+

LTC1052

–

OUTPUT

LTC1052/7652 • AI03

When connectors, switches, relays and/or sockets are

necessary they should be selected for low thermal EMF

activity. The same techniques of thermally balancing and

coupling the matching junctions are effective in reducing

the thermal EMF errors of these components.

Connectors, switches, relay contacts, sockets, resistors,

solder, and even copper wire are all candidates for

thermal EMF generation. Junctions of copper wire from

different manufacturers can generate thermal EMFs of

200nV/°C—4 times the maximum drift specification of

the LTC1052. The copper/kovar junction, formed when

wire or printed circuit traces contact a package lead, has

a thermal EMF of approximately 35µV/°C–700 times the

maximum drift specification of the LTC1052.

Minimizing thermal EMF-induced errors is possible if

judicious attention is given to circuit board layout and

component selection. It is good practice to minimize the

number of junctions in the amplifier’s input signal path.

Avoid connectors, sockets, switches and relays where

possible. In instances where this is not possible, attempt

to balance the number and type of junctions so that

differential cancellation occurs. Doing this may involve

deliberately introducing junctions to offset unavoidable

junctions.

Resistors are another source of thermal EMF errors.

Table 1 shows the thermal EMF generated for different

resistors. The temperature gradient across the resistor is

important, not the ambient temperature. There are two

junctions formed at each end of the resistor and if these

junctions are at the same temperature, their thermal EMFs

will cancel each other. The thermal EMF numbers are

approximate and vary with resistor value. High values give

higher thermal EMF.

Table 1. Resistor Thermal EMF

RESISTOR TYPE THERMAL EMF/°C GRADIENT

Tin Oxide ~mV/’C

Carbon Composition ~450µV/°C

Metal Film ~20µV/°C

Wire Wound

Evenohm ~2µV/°C

Manganin ~2µV/°C

1052fa

9

Page 10

LTC1052/LTC7652

WUUU

APPLICATIO S I FOR ATIO

When all of these errors are considered, it may seem

impossible to take advantage of the extremely low drift

specifications of the LTC1052. To show that this is not the

case, examine the temperature test circuit of Figure 3. The

lead lengths of the resistors connected to the amplifier’s

inputs are identical. The thermal capacity and thermal

resistance each input sees is balanced because of the

symmetrical connection of resistors and their identical

size. Thermal EMF-induced shifts are equal in phase and

amplitude, thus cancellation occurs.

50k

–

LTC1052

+

5V

7

6

8

4

V

• 1000

1

OS

0.1µF

LTC1052/7652 • AI04

2

0.1µF

100Ω

50k

3

0.1µF

–5V

Figure 3. Offset Drift Test Circuit

Figure 4 shows the response of this circuit under

temperature transient conditions. Metal film resistors and

an 8-pin DIP socket were used. Care was taken in the

construction to thermally balance the inputs to the

amplifier. The units were placed in an oven and allowed to

stabilize at 25°C. The recording was started and after

100 seconds the oven, preset to 125°C, was switched on.

The test was first performed on an 8-pin plastic package

and then was repeated for a TO-5 package plugged into the

same test board. It is significant that the change in VOS,

even under these severe thermal transient conditions,

is quite good. As temperature stabilizes, note that the

steady-state change of VOS is well within the maximum

±0.05µV/°C drift specification.

Very slight air currents can still affect even this

arrangement. Figure 5 shows strip charts of output noise

both with the circuit covered and with no cover in “still” air.

This data illustrates why it is often prudent to enclose the

LTC1052 and its attendant components inside some form

of thermal baffle.

0 MIN 25 MIN20 MIN5 MIN

10

25°C TO 125°C

0

(10µV/DIV)

OS

10

OFFSET VOLTAGE, V

0

OVEN SWITCHED

ON (25°C)

PLASTIC

25°C TO 125°C

METAL CAN

OVEN STABILIZED

AT 12 MIN

100 SECONDS/IN

±0.05µV/°C

±0.05µV/°C

Figure 4. Transient Response of Offset Drift Test Circuit with 100°C Temperature Step

10

1052fa

Page 11

WUUU

APPLICATIO S I FOR ATIO

#1 COVERED

1µV

Figure 5. DC to 1Hz (Test Circuit TC3)

LTC1052/LTC7652

#1 UNCOVERED

#2 UNCOVERED

20 SEC

PACKAGE-INDUCED OFFSET VOLTAGE

Since the LTC1052 is constantly fixing its own offset, it

may be asked why there is any error at all, even under

transient temperature conditions. The answer is simple.

The LTC1052 can only fix offsets inside its own nulling

loop. There are many thermal junctions outside this loop

that cannot be distinguished from legitimate signals.

Some have been discussed previously, but the package

thermal EMF effects are an important source of errors.

Notice the difference in the thermal response curves of

Figure 4. This can only be attributed to the package since

everything else is identical. In fact, the VOS specification is

set by the package-induced warm-up drift, not by the

LTC1052. TO-99 metal cans exhibit the worst warm-up

drift and Linear Technology sample tests TO-99 lots to

minimize this problem.

Two things make 100% screening costly: (1) The extreme

precision required on the LTC1052 and (2) the thermal

time constant of the package is 0.5 to 3 minutes, depending on package type. The first precludes the use of automatic handling equipment and the second takes a long

time. Bench test equipment is available to 100% test for

warmed-up drift if offsets of less than ±5µV are required.

CLOCK

The LTC1052 has an internal clock, setting the nominal

sampling frequency at 330Hz. On 8-pin devices, there is

no way to control the clock externally. In some applications it may be desirable to control the sampling clock and

this is the function of the 14-pin device.

CLK IN, CLK OUT and INT/EXT are provided to accomplish

this. With no external connection, an internal pull-up holds

INT/EXT at the V+ supply and the 14-pin device selfoscillates at 330Hz. In this mode there is a signal on the

CLK IN pin of 660Hz (2 times sampling frequency) with a

30% duty cycle. A divide-by-two drives the CLK OUT pin

and sets the sampling frequency.

To use an external clock, connect INT/EXT to V– and the

external clock to CLK IN. The logic threshold of CLK IN is

2.5V below the positive supply; this allows CMOS logic to

drive it directly with logic supplies of V+ and ground. CLK

IN can be driven from V+ to V– if desired. The duty cycle of

the external clock is not particularly critical but should be

kept between 30% and 60%.

Capacitance between CLK IN and CLK OUT (pins 13 and

12) can cause the divide-by-two circuit to malfunction. To

avoid this, keep this capacitance below 5pF.

1052fa

11

Page 12

LTC1052/LTC7652

WUUU

APPLICATIO S I FOR ATIO

OUTPUT CLAMP

If the LTC1052 is driven into saturation, the nulling loop,

attempting to force the differential input voltage to zero,

will drive C

EXTA

and C

to a supply rail. After the

EXTB

saturating drive is removed, the capacitors take a finite

time to recover—this is the overload recovery time. The

overload recovery is longest when the capacitors are

driven to the negative rail (refer to Overload Recovery in

the Typical Performance Characteristics section). The

overload recovery time in this case is typically 225ms. In

the opposite direction (i.e., C

EXTA

and C

at positive

EXTB

rail), it is about ten times faster (25ms). The overload

recovery time for the LTC1052 is much faster than competitive devices; however, if a faster overload recovery

time is necessary, the output clamp function can be used.

When the output clamp is connected to the negative input

it prevents the amplifier from saturating, thus keeping

C

EXTA

and C

at their nominal voltages. The output

EXTB

clamp is a switch that turns on when the output gets to

within approximately 1V of either supply rail. This switch

is in parallel with the amplifier’s feedback resistor. As the

output moves closer to the rail, the switch on

resistance decreases, reducing the closed loop gain. The

output swing is reduced when the clamp function is used.

How much current the output clamp leaks when off

is important because, when used, it is connected to the

amplifier’s negative input. Any current acts like input bias

current and will degrade accuracy. At the other extreme,

the maximum current the clamp conducts when on determines how much overdrive the clamp will take, and still

keep the amplifier from saturating. Both of these numbers

are guaranteed in the Electrical Characteristics section.

LOW SUPPLY OPERATION

The minimum supply voltage for proper operation of the

LTC1052 is typically 4.0V (±2.0V). In single supply

applications, PSRR is guaranteed down to 4.7V (±2.35V).

This assures proper operation down to the minimum TTL

specified voltage of 4.75V.

U

TYPICAL APPLICATIO S

5V Powered Ultraprecision Instrumentation Amplifier Fast Precision Inverter

+IN

–IN

5V

4

11

12

LTC1043

2

3

0.0047µF

8

C1

C3

1µF

C2

1µF1µF

R1

14

5

15

16

100

+

C4

1µF

CIRCUITRY WITHIN DASHED LINES MAY BE DELETED IF OUTPUT

DOES NOT HAVE TO SWING ALL THE WAY TO GROUND

DRIFT = 50nV/°C

V

= 3µV

OS

R2

GAIN =

+ 1

R1

CMRR = >120dB DC – 20kHz

BANDWIDTH =10Hz

7

13

5V

43k

1N914

6

18

17

3

2

0.1µF

≈ – 0.5V

R2

100k

+

LTC1052

–

4

5V

1

0.22µF

10k*

7

6

8

0.1µF

10k

V

OUT

LTC1052/7652 • TA03

INPUT

10k

0.1µF

10k

1N4148

300pF

5V

2

7

+

LTC1052

3

8

–

4

1

–5V

*1% METAL FILM

FULL POWER BANDWIDTH = 2MHz

SLEW RATE = 40V/µs

SETTLING (10V STEP) = 12µs TO 0.01%

BIAS CURRENT DC = 30pA

OFFSET DRIFT = 50nV/°C

OFFSET VOLTAGE = 5µV

6

0.1µF

10k

1000pF

2

+

3

–

10k*

8pF

5V

LT318A

–5V

7

6

OUTPUT

4

LTC1052/7652 • TA04

1052fa

12

Page 13

TYPICAL APPLICATIO S

+

COMPARATOR

INPUTS

GROUND OR

INPUT COMMON-

MODE VOLTAGE

–

U

14 13

8

LTC1043

5

Offset Stabilized Comparator

5V

4

12

11

7

1M

6

2

3

0.1µF

2

3

2

3

+

LTC1052

–

1

1µF

5V

+

–

–5V

7

4

5V

8

LT1011

4

8

1

6

0.1µF

LTC1052/LTC7652

150Ω330Ω

2k

6

7

5

10k

COMPARATOR

OUTPUT (± 5V)

5V

ZERO COMMAND

5V =ZERO

–5V=COMPARE

1HZ to 1.25MHz Voltage-to-Frequency Converter (5V Supply)

5V

3

7

+

LTC1052

2

–

0.1µF 0.1µF

FULL-SCALE TRIM

30.1k*

V

IN

OV TO 5V

TRW MTR–5/ +1200ppm/°C

*

POLYSTYRENE–WESCO #32–P/ – 120ppm/°C

**

±0.05%

>120dB

0.01Hz/°C

20ppm/°C

LINEARITY

DYNAMIC RANGE

ZERO POINT DRIFT

GAIN DRIFT

4

1

10k

(1.25MHz)

6

8

0.22µF

15 18

16

17

–5V

3.3k

0.01µF

2k

8

14 13

10k

470Ω

330pF

1/2

470Ω

Q1

2N2907

5V

4

11

100pF**

12

LTC1043

17

–5V

0.01µF

5V

10k

7

LT1004-1.2V

16

74C04

5V

3.3pF

10k

0.1µF

STATUS OUTPUT

OV = ZERO

5V = COMPARE

LTC1052/7652 • TA05

LTC1052/7652 • TA06

NC

2N3904

OUTPUT

1H to 1.25MHz

1052fa

13

Page 14

LTC1052/LTC7652

TYPICAL APPLICATIO S

No VOS Adjust* CMOS DAC Buffer—Single Supply Air Flow Detector

15V

R

FB

12–BIT CMOS DAC

43k

6 5

1N914

15

1pF

16

l

OUT2

l

OUT1

1/2

15V

4

11

+

12

LTC1043

17

C

0.1µF

*

F

1k

15

5

2

+

LTC1052

3

–

1

0.1µF

1µF

NON POLARIZED

≈ – 0.5V

15V

4

U

7

8

LTC1052/7652 • TA07

6

0.1µF

V

OUT

FOR HIGHER SPEED, REFER TO

“FAST PRECISION INVERTER”

UNDER TYPICAL APPLICATIONS

10k

*OFFSET VOLTAGE CAUSES

NONLINEARITY ERRORS.

SEE: “APPLICATION GUIDE

TO CMOS MULTIPLYING D/A

CONVERTERS,”

ANALOG DEVICES, INC.

100k

± 1%

LT1004-1.2

43.2Ω

± 1%

AMBIENT

TEMPERATURE

STILL AIR

10k

1k

0.1µF

–

+

3

2

+

LTC1052

–

1

5V

5

7

6

5V = NO AIR FLOW

0V = AIR FLOW

8

4

0.1µF

–

TYPE K

LTC1052/7652 • TA08

+

AIR FLOW

240Ω

OV TO 3V

1Hz TRIM

IN

STABILIZING

AMP

3

2

0.1µF

16.2k*

5V

10k

–5V

+

LTC1052

–

100k

100k

1

2k

30MHz

TRIM

1000M

–5V

1Hz to 30MHz Voltage-to-Frequency Converter

5V

120Ω

CURRENT

7

6

8

4

0.1µF

0.0.1µF

10k

0.22µF

CHARGE

8

†

100pF

14

1/2

SOURCE

7.5k

PUMP

11

12

LTC1043

12k

2N3906

7

0.22µF

10

13

16

120Ω

100pF

5V

11

0.1µF

2k

LT1004–1.2V

5V

5

7490

10

1

1

12

FET BUFFER

2N5486

50Ω

2N5486

50Ω

–5V

14

5

5V

74S741/2

74S132

14

7

5V

TRIGGER

HP5082-2810

3

NC

RESET DIODE

2N3904

*TRW MTR-5/ + 120ppm/°C

†WESCO #32-P/ – 120ppm/°C

0.3Hz/°C ZERO-DRIFT

±0.08% LINEARITY

20ppm/°C GAIN DRIFT

150dB DYNAMIC RANGE

1Hz TO 30MHz

OUTPUT

LTC1052/7652 • TA09

OUT

14

1052fa

Page 15

100k

LOAD

5k

2.5k

1k

220Ω

6

7

2

8

4

2000pF

1

3

5V

100Ω

LTC1052/7652 • TA11

OUTPUT

INPUT

10k

+

–

LTC1052

OUTPUT SWING

± 4.92V

± 4.84V

± 4.65V

± 3.65V

5V

220pF

74C04

10k

0.1µF 0.1µF

TYPICAL APPLICATIO S

±100mA Output Drive Increasing Output Current

100k

V

IN

0.1µF

5V

2

7

3

–

LTC1052

+

1

6

8

4

0.1µF

–5V

VOS=5µV

/∆T=50µV/°C

V

OS

GAIN =10

FULL POWER BANDWIDTH =1kHz

100pF

LTC1010

Single 5V Thermocouple Amplifier with Cold Junction Compensation

U

–5V

LTC1052/LTC7652

5V

1M

V

OUT

±100mA

R

L

LTC1052/7652 • TA10

5V

100k

LT1004-1.2

1690Ω

187Ω

43k

5V

R1

1820Ω

IN914

0.0047µF

5k AT 25°C

7

13

6

18

16

5V

†

11

12

+

LTC1043

17

+

V

T

–

4

8

1µF

14

5

2

1µF

3

15

1k

5V

3

7

–

LTC1052

2

+

1

1µF

1µF

†

*CHOOSE C

0.1µF

NONPOLARIZED

≈– 0.5V

YELLOW SPRINGS INST. CO. PART #44007

10k

TO FILTER NOISE

F

8

4

LTC1052/7652 • TA12

6

0.1µF

R

F

R

V

OUT

CF*

l

THERMOCOUPLE

TYPE

J

K

T

S

R

F

= VT1+

()

R

l

R1

232k

301k

301k

2.1M

1052fa

15

Page 16

LTC1052/LTC7652

TYPICAL APPLICATIO S

U

Increasing Output Current and Voltage (V

7V

2N3904

INPUT

3k

STABLE FOR ALL GAINS, INVERTING

AND NONINVERTING, OBSERVE

LTC1052 COMMON MODE INPUT LIMITS

2

3

–

LTC1052

+

1

–7V

0.1µF

7

4

0.1µF

NC

3

6

8

0.1µF0.1µF

2N3904

NC

+

LT318A

2

–

Precision Multiplexed Differential Thermocouple Amplifier

COLD JUNCTION

COMPENSATOR

LT1004–1.2V

1690Ω

187Ω

100k

R1

1820Ω

5k AT

25°C

†

SUPPLY

15V

30k 33pF

7

6

4

–15V

= ±15V) DC Stabilized FET Probe

INPUT CAPACITANCE BOOTSTRAP

5V

FAST SOURCE

FOLLOWER

OUTPUT

±12V AT 20mA | LIMIT

3k

1k

LTC1052/7652 • TA13

4

7

11

12

1µF

INPUT

0.1µF

3

0.1µF

2

–

LTC1052

+

8

1µF

10M

Q2

2N2222

100Ω

–5V

DC STABILIZATION

5V

7

4

1

–5V

Q1

2N5486

1N4148

DRAIN CURRENT SINK

10k

0.01µF

2000pF

1k

6

8

0.1µF

1M

LT1010

–5V

V

OUT

0.1µF

5V

0.1µF

6

8

BANDWIDTH: 20MHz

†

DELAY: 5ns

= 1001 • V

+

V

7

+

LTC1052

–

4

1

: 100ns

RISE

THERMOCOUPLE

OUTPUT

10M

3

0.1µF

2

0.1µF

LTC1052/7652 • TA14

16

5V

16

12

1

14

5

15

2

11

4

78

–5V

13

3

9

10

CD4052B

13

6

18

LTC1043

16

0.0047µF

–5V

ADDRESS

14

TYPE

K

T

S

1k

J

R1

232k

301k

301k

2.1M

LTC1052/7652 • TA15

1052fa

5

2

1µF

3

15

17

1µF

†

YELLOW SPRINGS INST. CO. PART #44007

THERMOCOUPLE

Page 17

TYPICAL APPLICATIO S

–

+

FILTER-AND-OVERLOAD

TYPE K

THERMOCOUPLE 41.4µV/°C

CLAMP

50k

60°C TRIM

A

187Ω*

†

1N914

COLD JUNCTION BIAS

100k

1µF

OPTIONAL INPUT

STABILIZING AMP

150k**

33k**

1µF

487Ω*

3

2

0.1µF

301k*

U

Direct Thermocouple-to-Frequency Converter

R

+

LTC1052

–

1

5

100pF

5V

7

4

–5V

3300pF

LTC1043

T

1.8k*

33k

6

8

0.1µF

16

6

0.1µF

2

COLD JUNCTION TEMPERATURE TRACKING

1N4148

A

74C04

0.68µF

5V

74C04

F

–5V

4.75k*

1k*

LT1004–1.2V

LTC1052/LTC7652

470Ω

C10k B

820pF

5V

3k

0.01% FILM-TRW MAR-6

*

TRW/MTR/5/ + 120

**

= YELLOW SPRINGS INST. #44007

R

T

100pF = POLYSTYRENE

†

FOR GENERAL PURPOSE (1mV FULL-SCALE)

10-BIT A-TO-D, REMOVE THERMOCOUPLE—

COLD JUNCTION NETWORK, GROUND POINT A,

AND DRIVE LTC1052 POSITIVE INPUT

E

D

5V

74C903

OUTPUT

0Hz TO 600Hz

0°C TO 60°C

LTC1052/7652 • TA16

3

2

1000pF

1

+

LM301A

–

5V

8

4

7

–5V

BRIDGE DRIVE

Direct 10-Bit Strain Gauge Digitizer

5V

5V

20Ω

STRAIN GAUGE

1N4148

1N4148

TRANSDUCER

= 350Ω

Z

IN

= 350Ω

Z

OUT

7

3.3M

13

22.3k*

470k*

1/2 LTC1043

SW1

SW2

20Ω

1k

6

2N2905

–5V

28k

1000pF

3.3MΩ*

11

16

12

14

–5V

INTEGRATOR

2

–

LTC1052

3

+

0.01µF

8

1k*

74C00

14k

CLOCK

5V

7

6

8

4

1

0.01µF

–5V

CONNECT DIRECTLY

ACROSS BRIDGE

DRIVE POINTS

+

33µF

2

0.003µF

5V

1/2 74C74

7

–5V

4114

10k

5V

10k

3

5

6

*0.1% METAL FILM TRW MAR-5

100k

1/2 74C903

5V

–5V

OUTPUT

GATING

OUT A

DATA OUTPUT =

SW1 =MAIN CURRENT SWITCH

SW2 =CURRENT LOADING COMPENSATION SWITCH

CONNECT TO BRIDGE

END OF 470k RESISTOR

TRANSDUCER ZERO NETWORK

= 1000 COUNTS FULL-SCALE

OUT B

(OPTIONAL)

LTC1052/7652 • TA17

FREQUENCY

OUT B

FREQUENCY

OUT A

1052fa

17

Page 18

LTC1052/LTC7652

TYPICAL APPLICATIO S

U

16-Bit A/D Converter

74C00

E

OV TO 5V

IN

10k

FULL-SCALE

TRIM

95k*

0.1µF

2

3

28k

0.01µF

–

LTC 1052

+

1

2N4338

5V

4

–5V

7

A2

8

INTEGRATOR

75k*

14k

CLOCK

6

2

1/2

0.1µF

5V

7

6

LTC1052

8

4

–5V

CURRENT SINK

5V

24114

74C74

5

76

3

+

2

–

1

0.1µF0.1µF

820pF

10pF

1k

LT1009

5V

B

OUT

10k

1/3

74C903

5V

A

OUT

–5V

5V

16

13

1µF39pF

20k

–5V

0.01µF

LINEARITY

TRIM

7

18

4

14

12

11

8

15

18

A

DATA OUTPUT =

100,000 COUNTS FULL-SCALE

NO ZERO TRIM

20ppm/°C GAIN DRIFT

*VISHAY S-102 RESISTOR

OUT

B

OUT

CURRENT SWITCH

3

LTC1043

17

–5V

LTC1052/7652 • TA18

1052fa

Page 19

TYPICAL APPLICATIO S

LTC1052/LTC7652

U

Precision Isolation Amplifier

INPUT

FLOATING

SUPPLY

OUTPUTS

100k

– 15V

25mA

15V

25mA

NC

4

–

5

+

11

NC

2N3904

+

2.2µF

FLOATING COMMON

LTC1052

14–PIN

13

10

2

7

1

14

11

74C90 74C90

2N3904

2.2µF

+

0.1µF0.1µF

55

14

11

1

1N4148

100k*

1010

1k*

10k

2N5434

14

÷10÷10

2k

1212

1

2k

1N4148 1N4148

11k

DALE TC–10–11

4.3k

10k

L1

4

5

7

8

OUTPUT SIDEINPUT SIDE

1

2N5434

2

L2

STANCOR PCT-39

2N54342N5434

36

15V

1.8k

1

2N2222

POWER

DRIVER

15V

2

2N2222

39

10k

68pF

1k

74C04

10k

100pF

68pF

– 15V

1000pF

74C04

330Ω

ZERO TRIM

100k

74C04

1000pF

20k

20k

22M

15V

3

2

IN4148

10M

(SELECT)

1

+

LTC1052

–

15V

– 15V

30pF

7

– 15V

20k

4

8

6

1k GAIN TRIM

13.3k*

10k*

OUT

250V ISOLATION

0.03% ACCURACY

*1% FILM RESISTOR

1.8k

15V

1k

LTC1052/7652 • TA19

1052fa

19

Page 20

LTC1052/LTC7652

PACKAGE DESCRIPTIO

SEATING

PLANE

(0.254 – 1.143)

45°TYP

U

H Package

8-Lead TO-5 Metal Can (.200 Inch PCD)

(Reference LTC DWG # 05-08-1320)

.335 – .370

(8.509 – 9.398)

DIA

.305 – .335

(7.747 – 8.509)

.016 – .021**

(0.406 – 0.533)

PIN 1

.010 – .045*

.028 – .034

(0.711 – 0.864)

.040

(1.016)

MAX

.050

(1.270)

MAX

.027 – .045

(0.686 – 1.143)

GAUGE

PLANE

.200

(5.080)

TYP

.165 – .185

(4.191 – 4.699)

.500 – .750

(12.700 – 19.050)

REFERENCE

PLANE

.110 – .160

(2.794 – 4.064)

INSULATING

STANDOFF

*

LEAD DIAMETER IS UNCONTROLLED BETWEEN THE REFERENCE PLANE

AND THE SEATING PLANE

**

FOR SOLDER DIP LEAD FINISH, LEAD DIAMETER IS

.016 – .024

(0.406 – 0.610)

OBSOLETE PACKAGE

H8(TO-5) 0.200 PCD 0801

20

1052fa

Page 21

PACKAGE DESCRIPTIO

U

J Package

14-Lead CERDIP (Narrow .300 Inch, Hermetic)

(Reference LTC DWG # 05-08-1110)

.785

12

(19.939)

MAX

11 891013

.005

(0.127)

MIN

14

LTC1052/LTC7652

.025

(0.635)

RAD TYP

.300 BSC

(7.62 BSC)

.008 – .018

(0.203 – 0.457)

NOTE: LEAD DIMENSIONS APPLY TO SOLDER DIP/PLATE

OR TIN PLATE LEADS

0° – 15°

1

.045 – .065

(1.143 – 1.651)

OBSOLETE PACKAGE

234

.014 – .026

(0.360 – 0.660)

56

7

.100

(2.54)

BSC

.220 – .310

(5.588 – 7.874)

.200

(5.080)

MAX

.015 – .060

(0.381 – 1.524)

.125

(3.175)

MIN

J14 0801

1052fa

21

Page 22

LTC1052/LTC7652

PACKAGE DESCRIPTIO

U

J8 Package

8-Lead CERDIP (Narrow .300 Inch, Hermetic)

(Reference LTC DWG # 05-08-1110)

CORNER LEADS OPTION

(4 PLCS)

.023 – .045

(0.584 – 1.143)

HALF LEAD

.045 – .068

(1.143 – 1.650)

FULL LEAD

OPTION

.300 BSC

(7.62 BSC)

.008 – .018

(0.203 – 0.457)

NOTE: LEAD DIMENSIONS APPLY TO SOLDER DIP/PLATE

OR TIN PLATE LEADS

OPTION

0° – 15°

OBSOLETE PACKAGE

8-Lead PDIP (Narrow .300 Inch)

(Reference LTC DWG # 05-08-1510)

.005

(0.127)

MIN

.025

(0.635)

RAD TYP

.045 – .065

(1.143 – 1.651)

.014 – .026

(0.360 – 0.660)

N8 Package

.405

(10.287)

MAX

87

12

65

3

4

.220 – .310

(5.588 – 7.874)

.015 – .060

(0.381 – 1.524)

.100

(2.54)

BSC

.200

(5.080)

MAX

.125

3.175

MIN

J8 0801

22

87 6

.255 ± .015*

(6.477 ± 0.381)

1234

.300 – .325

(7.620 – 8.255)

.065

(1.651)

.008 – .015

(0.203 – 0.381)

+.035

.325

–.015

+0.889

8.255

()

–0.381

NOTE:

1. DIMENSIONS ARE

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED .010 INCH (0.254mm)

INCHES

MILLIMETERS

TYP

.045 – .065

(1.143 – 1.651)

.100

(2.54)

BSC

.400*

(10.160)

MAX

5

.130 ± .005

(3.302 ± 0.127)

.120

(3.048)

MIN

.018 ± .003

(0.457 ± 0.076)

.020

(0.508)

MIN

N8 1002

1052fa

Page 23

PACKAGE DESCRIPTIO

U

N Package

14-Lead PDIP (Narrow .300 Inch)

(Reference LTC DWG # 05-08-1510)

14

.255 ± .015*

(6.477 ± 0.381)

1213

.770*

(19.558)

MAX

11

LTC1052/LTC7652

8910

.300 – .325

(7.620 – 8.255)

.008 – .015

(0.203 – 0.381)

+.035

.325

–.015

+0.889

8.255

()

–0.381

NOTE:

1. DIMENSIONS ARE

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED .010 INCH (0.254mm)

INCHES

MILLIMETERS

.020

(0.508)

MIN

.130 ± .005

(3.302 ± 0.127)

.120

(3.048)

MIN

.005

(0.125)

MIN

2

31

.045 – .065

(1.143 – 1.651)

.100

(2.54)

BSC

6

7

.065

(1.651)

TYP

.018 ± .003

(0.457 ± 0.076)

N14 1002

5

4

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

1052fa

23

Page 24

LTC1052/LTC7652

PACKAGE DESCRIPTIO

.030 ±.005

TYP

N

U

SW Package

16-Lead Plastic Small Outline (Wide .300 Inch)

(Reference LTC DWG # 05-08-1620)

.050 BSC

.045 ±.005

16

N

.398 – .413

(10.109 – 10.490)

15 14

NOTE 4

13

12

10 9

11

.420

MIN

123 N/2

RECOMMENDED SOLDER PAD LAYOUT

.291 – .299

(7.391 – 7.595)

NOTE 4

.010 – .029

.005

(0.127)

RAD MIN

.009 – .013

(0.229 – 0.330)

NOTE:

1. DIMENSIONS IN

2. DRAWING NOT TO SCALE

3. PIN 1 IDENT, NOTCH ON TOP AND CAVITIES ON THE BOTTOM OF PACKAGES ARE THE MANUFACTURING OPTIONS.

THE PART MAY BE SUPPLIED WITH OR WITHOUT ANY OF THE OPTIONS

4. THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED .006" (0.15mm)

(0.254 – 0.737)

NOTE 3

INCHES

(MILLIMETERS)

× 45°

.016 – .050

(0.406 – 1.270)

.325 ±.005

0° – 8° TYP

NOTE 3

.093 – .104

(2.362 – 2.642)

(1.270)

1

.050

BSC

(0.356 – 0.482)

2345

.014 – .019

TYP

6

.394 – .419

(10.007 – 10.643)

N/2

78

.037 – .045

(0.940 – 1.143)

.004 – .012

(0.102 – 0.305)

S16 (WIDE) 0502

24

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

1052fa

LW/TP 1202 1K REV A • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1985

Loading...

Loading...