Datasheet LTC4210-2IS6, LTC4210-2CS6, LTC4210-1IS6, LTC4210-1CS6 Datasheet (Linear Technology)

Page 1

FEATURES

LTC4210-1/LTC4210-2

Hot Swap Controller in

6-Lead SOT-23 Package

U

DESCRIPTIO

■

Allows Safe Board Insertion and Removal

from a Live Backplane

■

Adjustable Analog Current Limit

with Circuit Breaker

■

Fast Response Limits Peak Fault Current

■

Automatic Retry or Latch Off On Current Fault

■

Adjustable Supply Voltage Power-Up Rate

■

High Side Drive for External MOSFET Switch

■

Controls Supply Voltages from 2.7V to 16.5V

■

Undervoltage Lockout

■

Adjustable Overvoltage Protection

■

Low Profile (1mm) SOT-23 (ThinSOTTM) Package

U

APPLICATIO S

■

Hot Board Insertion

■

Electronic Circuit Breaker

■

Industrial High Side Switch/Circuit Breaker

U

TYPICAL APPLICATIO

The LTC®4210 is a 6-pin SOT-23 Hot SwapTM controller

that allows a board to be safely inserted and removed from

a live backplane. An internal high side switch driver

controls the GATE of an external N-channel MOSFET for a

supply voltage ranging from 2.7V to 16.5V. The LTC4210

provides the initial timing cycle and allows the GATE to be

ramped up at an adjustable rate.

The LTC4210 features a fast current limit loop providing

active current limiting together with a circuit breaker

timer. The signal at the ON pin turns the part on and off and

is also used for the reset function.

This part is available in two options: the LTC4210-1 for

automatic retry on overcurrent fault and the LTC4210-2

for latch off on an overcurrent fault.

, LTC and LT are registered trademarks of Linear Technology Corporation.

ThinSOT and Hot Swap are trademarks of Linear Technology Corporation.

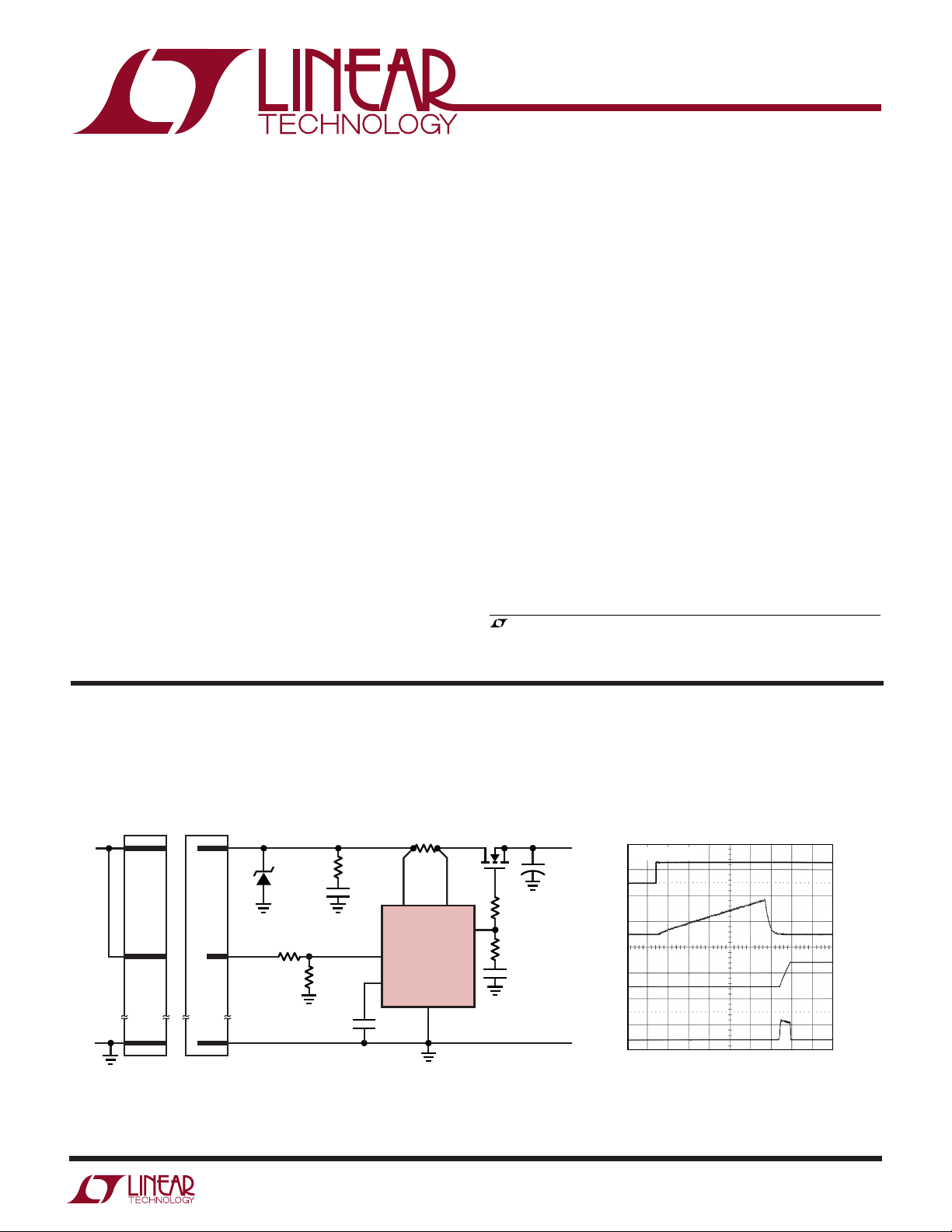

V

GND

IN

5V

BACKPLANE

CONNECTOR

(FEMALE)

Single Channel 5V Hot Swap Controller

PCB EDGE

CONNECTOR

(MALE)

LONG

R

R

10k

ON2

10Ω

X

C

X

0.1µF

Z1

OPTIONAL

R

ON1

SHORT

LONG

Z1: ISMA10A OR SMAJ10A

20k

R

0.01Ω

VCCSENSE

LTC4210

ON

TIMER

C

TIMER

0.22µF

SENSE

GND

GATE

Q1

Si4410DY

R

100Ω

R

100Ω

+

G

C

C

C

0.01µF

470µF

C

LOAD

4210 TA01

V

OUT

5V

4A

GND

Power-Up Sequence

C

= 470µF

LOAD

10ms/DIV

4210 TA02

V

ON

(2V/DIV)

V

TIMER

(1V/DIV)

V

OUT

(5V/DIV)

I

OUT

(0.5A/DIV)

421012f

1

Page 2

LTC4210-1/LTC4210-2

PACKAGE/ORDER I FOR ATIO

UU

W

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

Supply Voltage (VCC) ............................................... 17V

Input Voltage (SENSE, TIMER) .. –0.3V to (VCC + 0.3V)

Input Voltage (ON)..................................... –0.3V to 17V

Output Voltage (GATE) ........ Internally Limited (Note 3)

Operating Temperature Range

LTC4210-1C/LTC4210-2C ....................... 0°C to 70°C

LTC4210-1I/LTC4210-2I .................... –40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec)..................300°C

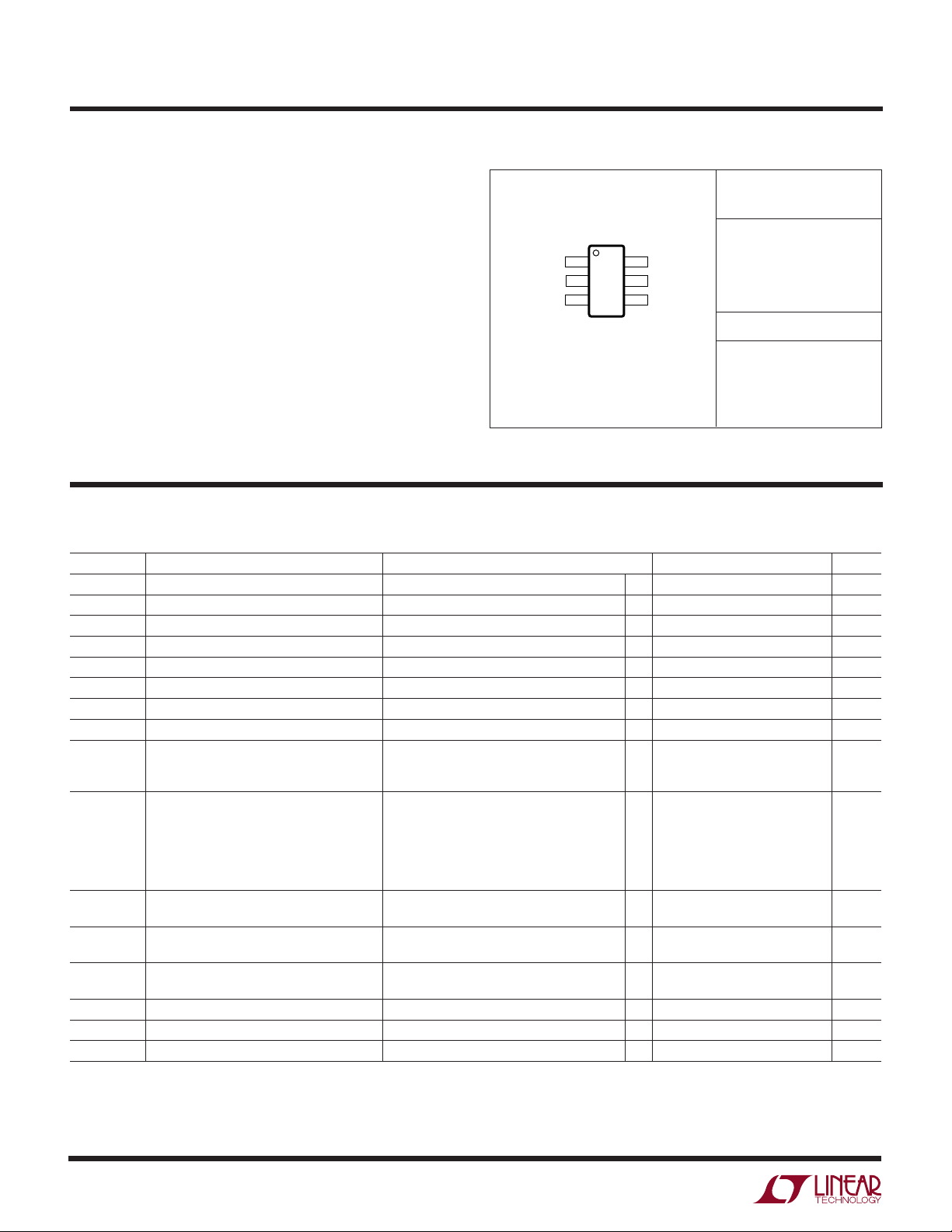

ORDER PART

NUMBER

TOP VIEW

TIMER 1

GND 2

ON 3

S6 PACKAGE

6-LEAD PLASTIC TSOT-23

T

= 125°C, θJA = 230°C/ W

JMAX

6 V

CC

5 SENSE

4 GATE

LTC4210-1CS6

LTC4210-2CS6

LTC4210-1IS6

LTC4210-2IS6

S6 PART MARKING

LTYW

LTYX

LTF5

LTF6

Consult LTC Marketing for parts specified with wider operating temperature ranges.

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating

temperature range, otherwise specifications are TA = 25°C. VCC = 5V, unless otherwise noted. (Note 2)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

CC

I

CC

V

LKOR

V

LKOHYST

I

INON

I

INSENSE

V

CB

I

GATEUP

I

GATEDN

∆V

GATE

I

TIMERUP

I

TIMERDN

V

TIMER

V

TMRHYST

V

ON

V

ONHYST

Supply Voltage ● 2.7 16.5 V

VCC Supply Current ● 0.65 3.5 mA

VCC Undervoltage Lockout Release VCC Rising ● 2.2 2.5 2.65 V

VCC Undervoltage Lockout Hysteresis 100 mV

ON Pin Input Current ● –10 0 10 µA

SENSE Pin Input Current V

Circuit Breaker Trip Voltage VCB = (VCC – V

GATE Pin Pull-Up Current V

GATE Pin Pull-Down Current V

External N-Channel Gate Drive V

TIMER Pin Pull-Up Current Initial Cycle, V

TIMER Pin Pull-Down Current After Current Fault Disappears, V

TIMER Pin Threshold High Threshold, TIMER Rising ● 1.22 1.3 1.38 V

TIMER Low Threshold Hysteresis 100 mV

ON Pin Threshold ON Threshold, ON Rising ● 1.22 1.3 1.38 V

ON Pin Threshold Hysteresis 80 mV

= V

SENSE

GATE

TIMER

V

ON

VCC – V

GATE

V

GATE

V

GATE

V

GATE

V

GATE

V

GATE

During Current Fault Condition, V

Under Normal Conditions, V

Low Threshold, TIMER Falling

CC

) ● 44 50 56 mV

SENSE

= 0V ● –5 –10 –15 µA

= 1.5V, V

= 0V, V

GATE

SENSE

– VCC, VCC = 2.7V ● 4.0 6.5 8 V

– VCC, VCC = 3V ● 4.5 7.5 10 V

– VCC, VCC = 3.3V ● 5.0 8.5 12 V

– VCC, VCC = 5V ● 10 12 16 V

– VCC, VCC = 12V ● 9.0 12 16 V

– VCC, VCC = 15V ● 6.0 11 18 V

= 3V or 25 mA

GATE

= 3V or

= 100mV, V

= 1V ● –2 –5 –8.5 µA

TIMER

= 3V

GATE

TIMER

TIMER

= 1V 100 µA

TIMER

● –10 5 10 µA

= 1V ● –25 –60 –100 µA

= 1V ● 2 3.5 µA

● 0.15 0.2 0.25 V

2

421012f

Page 3

LTC4210-1/LTC4210-2

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating

temperature range, otherwise specifications are TA = 25°C. VCC = 5V, unless otherwise noted. (Note 2)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

t

OFF(TMRHIGH)

t

OFF(ONLOW)

t

OFF(VCCLOW)

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: All currents into device pins are positive; all currents out of device

pins are negative. All voltages are referenced to ground unless otherwise

specified.

Turn-Off Time (TIMER Rise to GATE Fall) V

= 0V to 2V Step, VCC = VON = 5V 1 µs

TIMER

Turn-Off Time (ON Fall to GATE Fall) VON = 5V to 0V Step, VCC = 5V 30 µs

Turn-Off Time (VCC Fall to IC Reset) VCC = 5V to 2V Step, VON = 5V 30 µs

Note 3: An internal Zener on the GATE pin clamps the charge pump

voltage to a typical maximum voltage of 26V. External overdrive of the

GATE pin beyond the internal Zener voltage may damage the device.

Without a limiting resistor, the GATE capacitance must be <0.15µF at

maximum V

. If a lower GATE pin clamp voltage is desired, an external

CC

Zener diode may be used.

UW

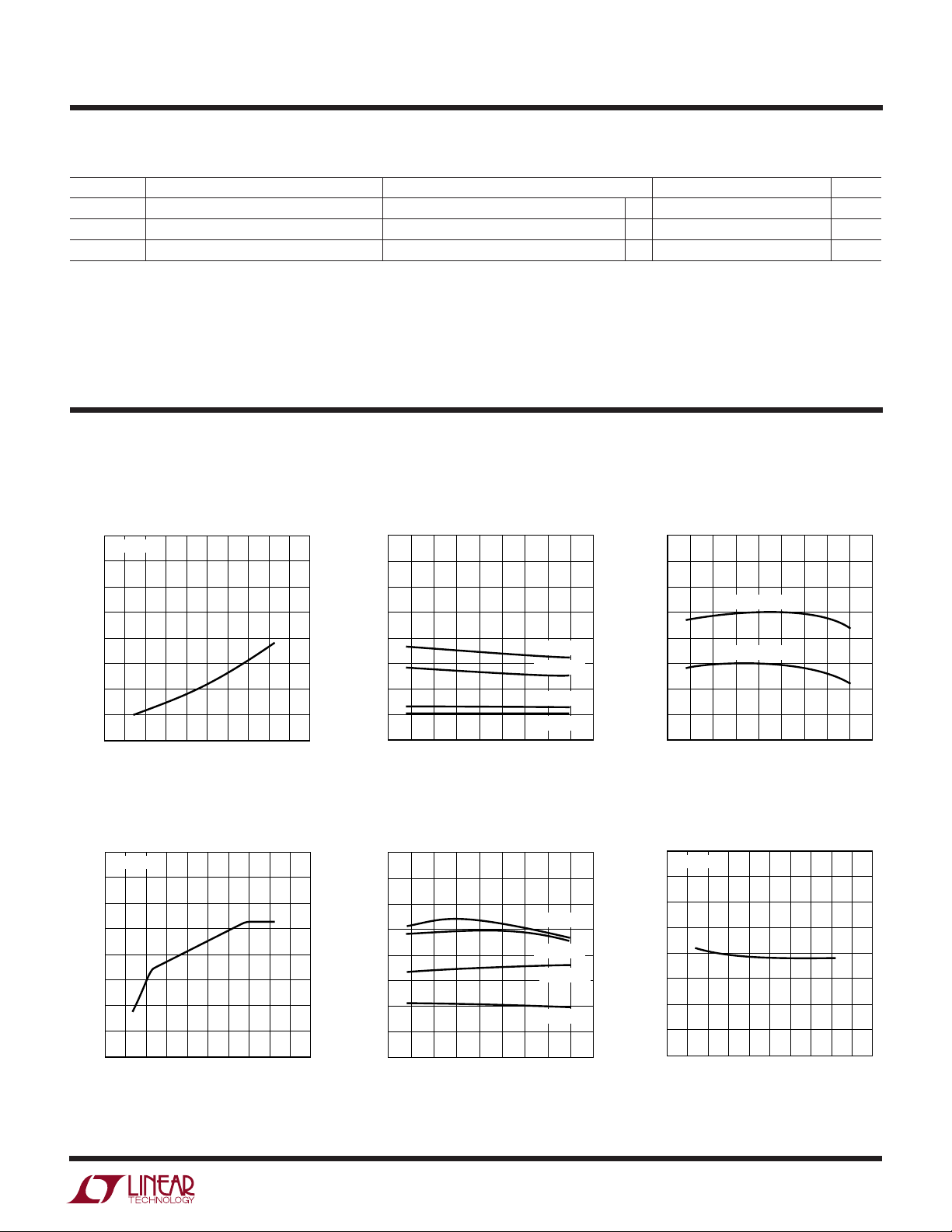

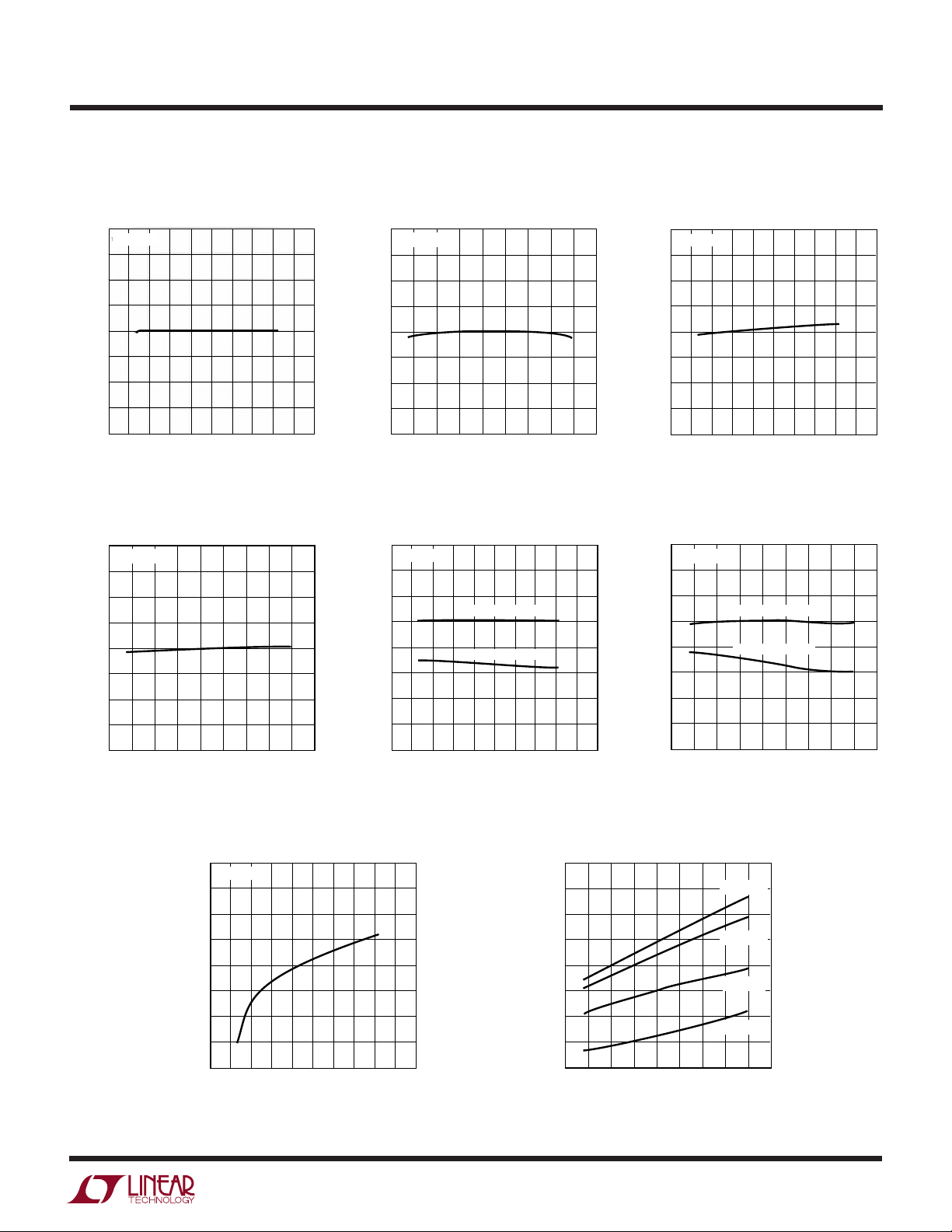

TYPICAL PERFOR A CE CHARACTERISTICS

Undervoltage Lockout Threshold

Supply Current vs Supply Voltage Supply Current vs Temperature

4.0

TA = 25°C

3.5

3.0

2.5

2.0

1.5

SUPPLY CURRENT (mA)

1.0

0.5

0

42 6 10 14 18

0

SUPPLY VOLTAGE (V)

12

16

8

20

4210 G01 4210 G02 4210 G03

4.0

3.5

3.0

2.5

2.0

1.5

SUPPLY CURRENT (mA)

1.0

0.5

0

–75

0 25 50 75 100 125

–25–50

TEMPERATURE (°C)

VCC = 15V

VCC = 12V

VCC = 5V

VCC = 3V

150

vs Temperature

2.65

2.60

2.55

2.50

2.45

2.40

2.35

2.30

UNDERVOLTAGE LOCKOUT THRESHOLD (V)

2.25

–75

VCC RISING

VCC FALLING

0 25 50 75 100 125

–25–50

TEMPERATURE (°C)

150

(V)

GATE

V

40

35

30

25

20

15

10

5

0

V

vs Supply Voltage V

GATE

TA = 25°C

42 6 10 14 18

0

SUPPLY VOLTAGE (V)

12

16

8

20

4210 G04 4210 G05 4210 G06

(V)

GATE

V

vs Temperature

GATE

40

35

30

25

20

15

10

5

0

–75

0 25 50 75 100 125

–25–50

TEMPERATURE (°C)

VCC = 15V

VCC = 12V

VCC = 5V

VCC = 3V

150

–8.0

–8.5

–9.0

–9.5

(µA)

–10.0

GATEUP

I

–10.5

–11.0

–11.5

–12.0

I

vs Supply Voltage

GATEUP

TA = 25°C

42 6 10 14 18

0

8

SUPPLY VOLTAGE (V)

12

16

20

421012f

3

Page 4

LTC4210-1/LTC4210-2

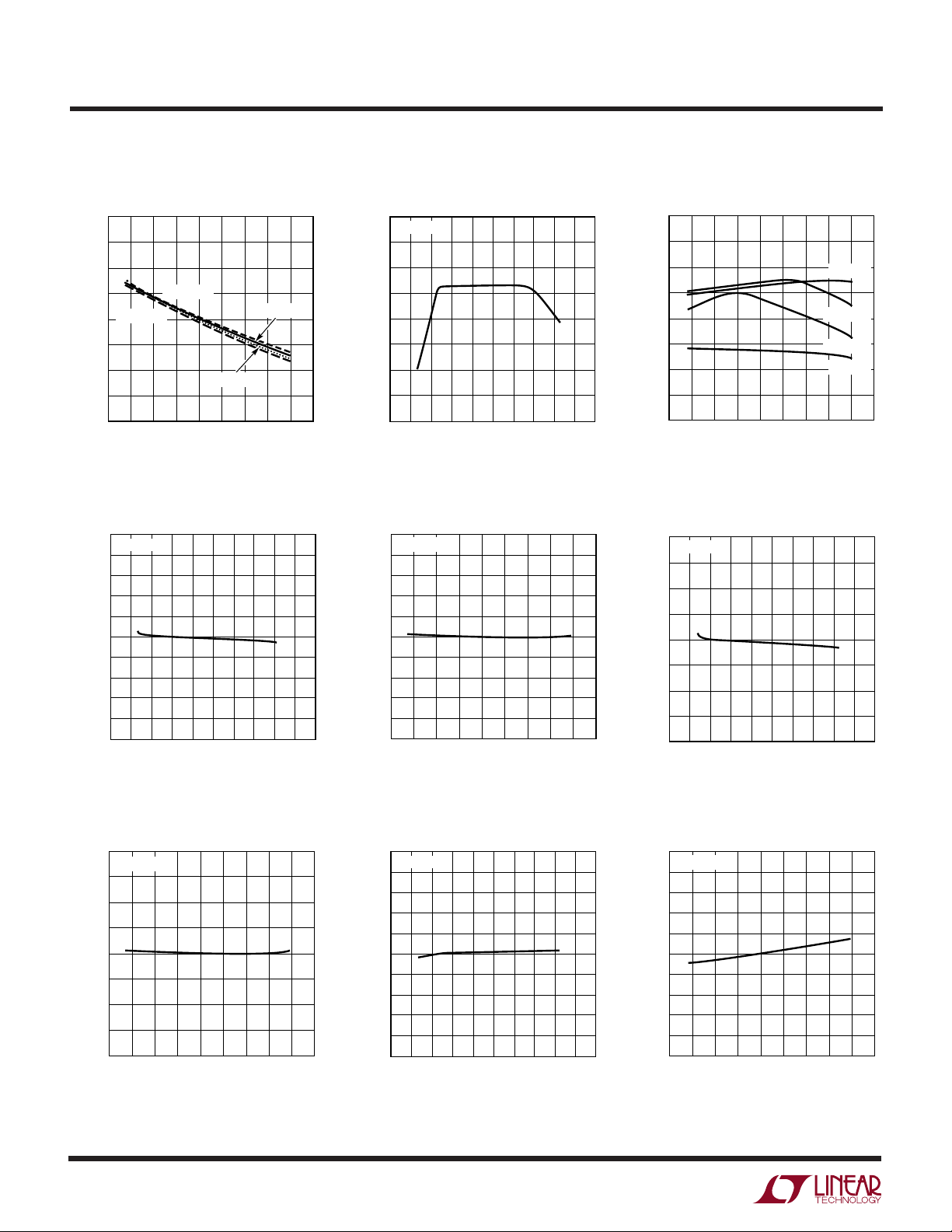

UW

TYPICAL PERFOR A CE CHARACTERISTICS

∆V

vs Supply Voltage

GATE

TA = 25°C

42 6 10 14 18

0

8

SUPPLY VOLTAGE (V)

12

16

–8.0

–8.5

–9.0

–9.5

(µA)

–10.0

GATEUP

I

–10.5

–11.0

–11.5

–12.0

I

GATEUP

–75

vs Temperature

VCC = 3V

VCC = 15V

0 25 50 75 100 125

–25–50

TEMPERATURE (°C)

VCC = 12V

VCC = 5V

4210 G07

150

(V)

GATE

∆V

18

16

14

12

10

8

6

4

2

4210 G08

∆V

vs Temperature

GATE

18

16

14

12

(V)

10

GATE

∆V

8

6

4

2

20

–75 150

0 25 50 75 100 125

–25–50

TEMPERATURE (°C)

VCC = 5V

VCC = 12V

VCC = 15V

VCC = 3V

4210 G09

I

(In Initial Cycle)

TIMERUP

vs Supply Voltage

0

TA = 25°C

–1

–2

–3

–4

(µA)

–5

–6

TIMERUP

I

–7

–8

–9

–10

42 6 10 14 18

0

I

TIMERUP

8

SUPPLY VOLTAGE (V)

(During Circuit Breaker

12

16

Delay) vs Temperature

–20

VCC = 5V

–30

–40

–50

(µA)

–60

TIMERUP

I

–70

–80

–90

–100

–75 150

0 25 50 75 100 125

–25–50

TEMPERATURE (°C)

I

vs Temperature

0

–1

–2

–3

–4

(µA)

–5

–6

TIMERUP

I

–7

–8

–9

–10

20

4210 G10 4210 G11 4210 G12

–75 150

I

vs Supply Voltage

3.0

2.8

2.6

2.4

2.2

(µA)

2.0

1.8

TIMERDN

I

1.6

1.4

1.2

1.0

0

4210 G13

(In Initial Cycle)

TIMERUP

VCC = 5V

0 25 50 75 100 125

–25–50

TEMPERATURE (°C)

(In Cool-Off Cycle)

TIMERDN

TA = 25°C

42 6 10 14 18

8

SUPPLY VOLTAGE (V)

I

(During Circuit Breaker

TIMERUP

Delay) vs Supply Voltage

–20

TA = 25°C

–30

–40

–50

(µA)

–60

TIMERUP

I

–70

–80

–90

–100

42 6 10 14 18

0

I

TIMERDN

8

SUPPLY VOLTAGE (V)

(In Cool-Off Cycle)

12

16

vs Temperature

3.0

VCC = 5V

2.8

2.6

2.4

2.2

(µA)

2.0

1.8

TIMERDN

I

1.6

1.4

1.2

1.0

12

16

20

4210 G14

–75 150

0 25 50 75 100 125

–25–50

TEMPERATURE (°C)

4210 G15

20

4

421012f

Page 5

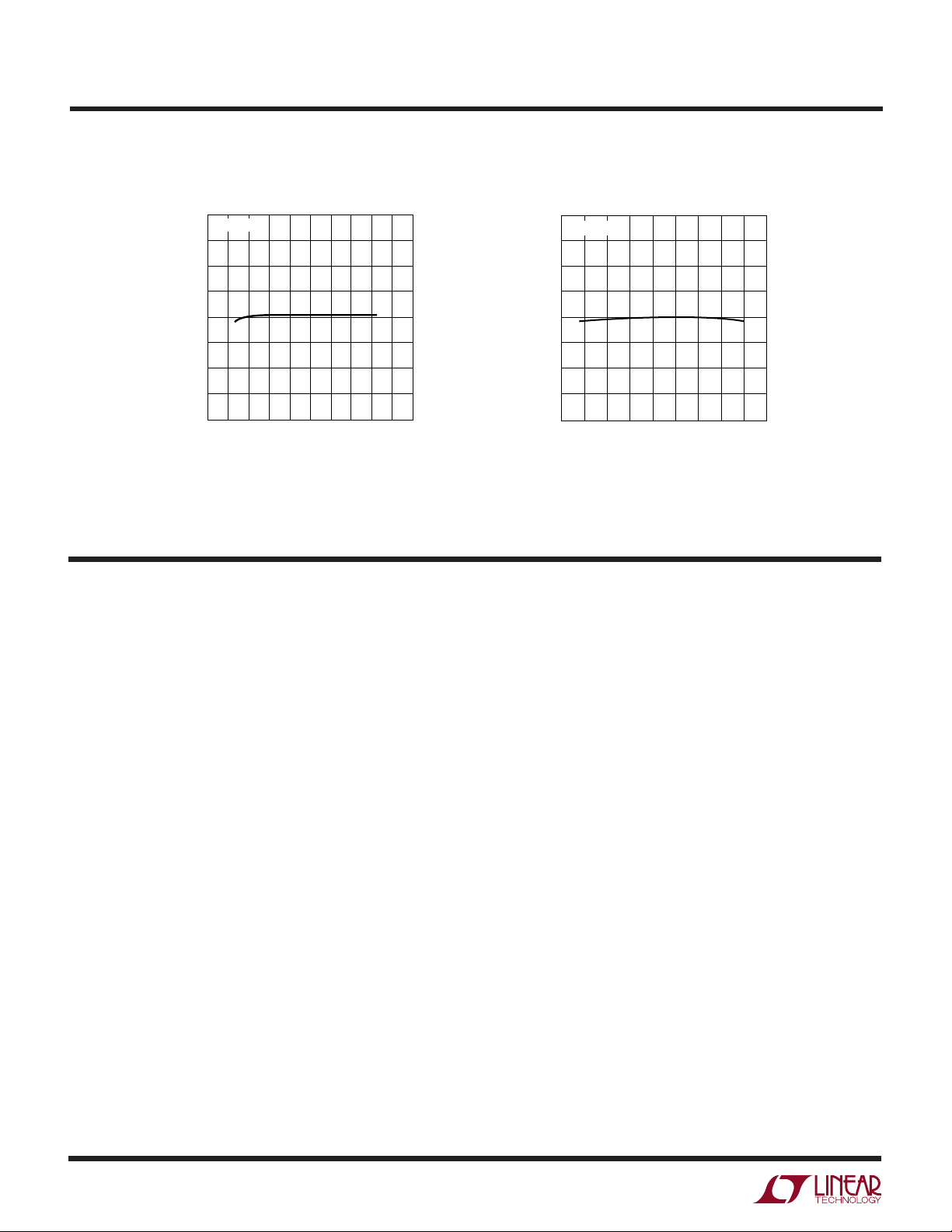

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LTC4210-1/LTC4210-2

TIMER High Threshold

vs Supply Voltage

1.38

TA = 25°C

1.36

1.34

1.32

1.30

1.28

1.26

TIMER HIGH THRESHOLD (V)

1.24

1.22

42 6 10 14 18

0

8

SUPPLY VOLTAGE (V)

12

16

20

4210 G16

TIMER Low Threshold

vs Temperature

0.24

VCC = 5V VCC = 5V

0.23

0.22

0.21

0.20

0.19

0.18

TIMER LOW THRESHOLD (V)

0.17

0.16

–75 150

0 25 50 75 100 125

–25–50

TEMPERATURE (°C)

4210 G19

TIMER High Threshold

vs Temperature

1.38

VCC = 5V

1.36

1.34

1.32

1.30

1.28

1.26

TIMER HIGH THRESHOLD (V)

1.24

1.22

–75 150

0 25 50 75 100 125

–25–50

TEMPERATURE (°C)

ON Pin Threshold

vs Supply Voltage

1.45

TA = 25°C

1.40

1.35

1.30

1.25

1.20

ON PIN THRESHOLD (V)

1.15

1.10

1.05

0

HIGH THRESHOLD

LOW THRESHOLD

42 6 10 14 18

SUPPLY VOLTAGE (V)

12

8

4210 G17

16

20

4210 G20

TIMER Low Threshold

vs Supply Voltage

0.24

TA = 25°C

0.23

0.22

0.21

0.20

0.19

0.18

TIMER LOW THRESHOLD (V)

0.17

0.16

42 6 10 14 18

0

8

SUPPLY VOLTAGE (V)

12

ON Pin Threshold

vs Temperature

1.45

1.40

1.35

1.30

1.25

1.20

ON PIN THRESHOLD (V)

1.15

1.10

1.05

–75 150

HIGH THRESHOLD

LOW THRESHOLD

0 25 50 75 100 125

–25–50

TEMPERATURE (°C)

16

20

4210 G18

4210 G21

t

OFF(ONLOW)

80

TA = 25°C

70

60

50

(µs)

40

30

OFF,ONLOW

t

20

10

0

016

vs Supply Voltage

42 6 10 14 18

SUPPLY VOLTAGE (V)

12

8

20

4210 G22

t

OFF(ONLOW)

80

70

60

50

(µs)

40

30

OFF,ONLOW

t

20

10

0

–75 150

vs Temperature

0 25 50 75 100 125

–25–50

TEMPERATURE (°C)

VCC = 15V

VCC = 12V

VCC = 5V

VCC = 3V

4210 G23

421012f

5

Page 6

LTC4210-1/LTC4210-2

UW

TYPICAL PERFOR A CE CHARACTERISTICS

VCB vs Supply Voltage

58

TA = 25°C

56

54

52

(mV)

50

CB

V

48

46

44

42

U

42 6 10 14 18

0

8

SUPPLY VOLTAGE (V)

UU

12

16

20

4210 G24

PI FU CTIO S

TIMER (Pin 1): Timer Input Pin. An external capacitor

C

µF circuit breaker delay. The GATE pin turns off whenever

the TIMER pin is pulled beyond the COMP2 threshold,

such as for overvoltage detection with an external zener.

GND (Pin 2): Ground Pin.

ON (Pin 3): ON Input Pin. The ON pin comparator has a

low-to-high threshold of 1.3V with 80mV hysteresis and a

glitch filter. When the ON pin is low, the LTC4210 is reset.

When the ON pin goes high, the GATE turns on after the

initial timing cycle.

GATE (Pin 4): GATE Output Pin. This pin is the high side

gate drive of an external N-channel MOSFET. An internal

charge pump provides a 10µA pull-up current with Zener

clamps to VCC and ground. In overload, the error amplifier

sets a 272.9ms/µF initial timing delay and a 21.7ms/

TIMER

VCB vs Temperature

58

VCC = 5V

56

54

52

(mV)

50

CB

V

48

46

44

42

–75 150

0 25 50 75 100 125

–25–50

TEMPERATURE (°C)

4210 G25

(EA) controls the external MOSFET to maintain a constant

load current. An external R-C compensation network

should be connected to this pin for current limit loop

stability.

SENSE (Pin 5): Current Limit Sense Input Pin. A sense

resistor between the VCC and SENSE pins sets the analog

current limit. In overload, the EA controls the external

MOSFET gate to maintain the SENSE pin voltage at 50mV

below VCC. When the EA is maintaining current limit, the

TIMER circuit breaker mode is activated. The current limit

loop/circuit breaker mode can be disabled by connecting

the SENSE pin to the VCC pin.

VCC (Pin 6): Positive Supply Input Pin. The operating

supply voltage range is between 2.7V to 16.5V. An undervoltage lockout (UVLO) circuit with a glitch filter resets the

LTC4210 when a low supply voltage is detected.

6

421012f

Page 7

BLOCK DIAGRA

LTC4210-1/LTC4210-2

W

1

2

TIMER

GND

5µA

INITIAL UP/LATCH OFF

60µA

0.2V

+

–

+

1.3V

–

INITIAL DOWN/NORMAL

100µA2µA

CURRENT LIMIT

COMP1

COMP2

LOGIC

6

V

UVLO

GLITCH

FILTER

GLITCH

FILTER

5

+

50mV

–

+

EA

SHUTDOWN

SENSE

CHARGE

PUMP

M5

10µA

Z2

26V

Z1

12V

GATE

4

CC

–

COOL OFF

–

1.3V

COMP3

+

ON

3

4210 BD

421012f

7

Page 8

LTC4210-1/LTC4210-2

WUUU

APPLICATIO S I FOR ATIO

Hot Circuit Insertion

When circuit boards are inserted into live backplanes, the

supply bypass capacitors can draw large transient currents from the backplane power bus as they charge. Such

transient currents can cause permanent damage to connector pins, glitches on the system supply or reset other

boards in the system.

The LTC4210 is designed to turn a printed circuit board’s

supply voltage ON and OFF in a controlled manner, allowing the circuit board to be safely inserted into or removed

from a live backplane. The LTC4210 can reside either on

the backplane or on the daughter board for hot circuit

insertion applications.

Overview

The LTC4210 is designed to operate over a range of

supplies from 2.7V to 16.5V. Upon insertion, an undervoltage lockout circuit determines if sufficient supply voltage

is present. When the ON pin goes high an initial timing

cycle assures that the board is fully seated in the backplane

before the MOSFET is turned on. A single timer capacitor

sets the periods for all of the timer functions. After the

initial timing cycle the LTC4210 can either start up in

current limit or with a lower load current. Once the external

MOSFET is fully enhanced and the supply has ramped up,

the LTC4210 monitors the load current through an external sense resistor. Overcurrent faults are actively limited

to 50mV/R

The LTC4210-1 will automatically retry after a current limit

fault while the LTC4210-2 latches off. The LTC4210-1

timer function limits the retry duty cycle to 3.8% for

MOSFET cooling.

Undervoltage Lockout

An internal undervoltage lockout (UVLO) circuit resets the

LTC4210 if the VCC supply is too low for normal operation.

for a specified circuit breaker timer limit.

SENSE

The UVLO has a low-to-high threshold of 2.5V, a 100mV

hysteresis and a high-to-low glitch filter of 30µs. Above

2.5V supply voltage, the LTC4210 will start if the ON pin

conditions are met. A short supply dip below 2.4V for less

than 30µs is ignored to allow for bus supply transients.

ON Function

The ON pin is the input to a comparator which has a lowto-high threshold of 1.3V, an 80mV hysteresis and a highto-low glitch filter of 30µs. A low input on the ON pin resets

the LTC4210 TIMER status and turns off the external

MOSFET by pulling the GATE pin to ground. A low-to-high

transition on the ON pin starts an initial cycle followed by

a start-up cycle. A 10k pull-up resistor connecting the ON

pin to the supply is recommended. The 10k resistor shunts

any potential static charge on the backplane and reduces

the overvoltage stress at the ON pin during live insertion.

Alternatively, an external resistor divider at the ON pin can

be used to program an undervoltage lockout value higher

than the internal UVLO circuit. An RC filter can be added at

the ON pin to increase the delay time at card insertion if the

internal glitch filter delay is insufficient.

GATE Function

During hot insertion of the PCB, an abrupt application of

supply voltage charges the external MOSFET drain/gate

capacitance. This can cause an unwanted gate voltage

spike. An internal proprietary circuit holds GATE low

before the internal circuitry wakes up. This reduces the

MOSFET current surges substantially at insertion. The

GATE pin is held low in reset mode and during the initial

timing cycle. In the start-up cycle the GATE pin is pulled up

by a 10µA current source. During an overcurrent fault

condition, the error amplifier servoes the GATE pin to

maintain a constant current to the load until the circuit

breaker trips. When the circuit breaker trips, the GATE pin

shuts down abruptly.

8

421012f

Page 9

SENSE RESISTOR

CURRENT FLOW

TO LOAD

TRACK WIDTH W:

0.03" PER AMP

ON 1 OZ COPPER

W

TO

V

CC

TO

SENSE

4210 F01

CURRENT FLOW

TO LOAD

WUUU

APPLICATIO S I FOR ATIO

Current Limit Circuit Breaker Function

The LTC4210 features a current limiting circuit breaker

instead of a traditional comparator circuit breaker. When

there is a sudden load current surge, such as a low

impedance fault, the bus supply voltage can drop significantly to a point where the power to an adjacent card is

affected, causing system malfunctions. The LTC4210 fast

response error amplifier (EA) instantly limits current by

reducing the external MOSFET GATE pin voltage. This

minimizes the bus supply voltage drop and permits power

budgeting and fault isolation without affecting neighboring cards. A compensation circuit should be connected to

the GATE pin for current limit loop stability.

LTC4210-1/LTC4210-2

Figure 1. Making PCB Connections to the Sense Resistor

Calculating Current Limit

Sense Resistor Consideration

The nominal fault current limit is determined by a sense

resistor connected between VCC and the SENSE pin as

given by Equation 1.

I

LIMIT NOM

()

V

CB NOM

==

()

R

SENSE NOM SENSE NOM

() ()

mV

50

R

(1)

The power rating of the sense resistor should be rated at

the fault current level. Table 2 in the Appendix lists some

common sense resistors.

For proper circuit breaker operation, Kelvin-sense PCB

connections between the sense resistor and the LTC4210

VCC and SENSE pins are strongly recommended. The

drawing in Figure 1 illustrates the connections between

the LTC4210 and the sense resistor. PCB layout should be

balanced and symmetrical to minimize wiring errors. In

addition, the PCB layout for the sense resistor should

include good thermal management techniques for optimal

sense resistor power dissipation.

For a selected R

, the nominal load current is given by

SENSE

Equation 1. The minimum load current is given by

Equation 2:

I

LIMIT MIN

()

V

CB MIN

==

()

R

SENSE MAX SENSE MAX

() ()

mV

44

R

(2)

where

R

RR

SENSE MAX SENSE

()

•=+

1

TOL

100

The maximum load current is given by Equation 3:

I

LIMIT MAX

()

V

CB MAX

==

()

R

SENSE MIN SENSE MIN

() ()

mV

56

R

(3)

where

R

RR

SENSE MIN SENSE

()

•–=

1

TOL

100

421012f

9

Page 10

LTC4210-1/LTC4210-2

WUUU

APPLICATIO S I FOR ATIO

If a 7mΩ sense resistor with ±1% tolerance is used for

current limiting, the nominal current limit is 7.14A. From

Equations 2 and 3, I

LIMIT(MIN)

= 6.22A and I

LIMIT(MAX)

=

8.08A. For proper operation, the minimum current limit

must exceed the circuit maximum operating load current

with margin. The sense resistor power rating must exceed

V

CB(MAX)

2

/R

SENSE(MIN)

.

Frequency Compensation

A compensation circuit should be connected to the GATE

pin for current limit loop stability.

Method 1

The simplest frequency compensation network consists

of RC and CC (Figure 2a). The total GATE capacitance is:

C

GATE

= C

ISS

+ C

C

(4)

Generally, the compensation value in Figure 2a is sufficient for a pair of input wires less than a foot in length.

Applications with longer input wires may require the RC or

CC value to be increased for better fault transient performance. For a pair of three foot input wires, users can start

with CC = 47nF and RC = 100Ω. Despite the wire length, the

general rule for AC stability required is CC ≥ 8nF and RC ≤

1kΩ.

Method 2

The compensation network in Figure 2b is similar to the

circuitry used in method 1 but with an additional gate resistor RG. The RG resistor helps to minimize high frequency

parasitic oscillations frequently associated with the power

MOSFET. In some applications, the user may find that R

G

helps in short-circuit transient recovery as well. However,

too large of an RG value will slow down the turn-off time.

The recommended RG range is between 5Ω and 500Ω.

Usually, method 2 is preferred when the input supply voltage is greater than 10V. RG limits the current flow into the

GATE pin’s internal zener clamp during transient events.

The recommended RC and CC values are the same as

method 1. The parasitic compensation capacitor CP is

required when 0.2µF < load capacitance CL < 9µF, other-

wise it is optional.

Parasitic MOSFET Oscillation

There are two possible parasitic oscillations when the

MOSFET operates as a source follower when ramping at

power-up or during current limiting. The first type of oscillation occurs at high frequencies, typically above 1MHz.

This high frequency oscillation is easily damped with RG as

mentioned in method 2.

The second type of oscillation occurs at frequencies between 200kHz and 800kHz due to the load capacitance

being between 0.2µF and 9µF, the presence of RG and R

C

resistance, the absence of a drain bypass capacitor, a combination of bus wiring inductance and bus supply output

impedance. There are several ways to prevent this second

type of oscillation. The simplest way is to avoid load capacitance below 10µF, the second choice is connecting an

external CP > 1.5nF.

10

V

5V

IN

V

R

SENSE

0.007ΩQ1Si4410DY

65

SENSE

CC

LTC4210*

GATE

4

(2a)

Method 1

R

C

100Ω

C

10nF

V

OUT

+

C

L

*ADDITIONAL DETAILS

OMITTED FOR CLARITY

IF 0.2µF < CL < 9µF,

**USE C

P

OTHERWISE NOT REQUIRED

C

Figure 2. Frequency Compensation

V

12V

IN

V

R

SENSE

0.007Ω

65

SENSE

CC

LTC4210*

GATE

(2b)

Method 2

Q1

Si4410DY

R

200Ω

4

R

100Ω

G

C

C

C

10nF

4210 F02

**

C

P

2.2nF

V

OUT

+

C

L

421012f

Page 11

WUUU

APPLICATIO S I FOR ATIO

LTC4210-1/LTC4210-2

Whichever method of compensation is used, board level

short-circuit testing is highly recommended as board

layout can affect transient performance. Beside frequency

compensation, the total gate capacitance C

determines the GATE start-up as in Equation 6. The C

GATE

also

GATE

should be kept below 0.15µF at high supply operation as

the capacitive energy ( 0.5 • C

GATE

• V

2

) is discharged

GATE

by the LTC4210 internal pull-down transistor. This prevents the internal pull-down transistor from overheating

when the GATE turns off and /or is servoing during current

limiting.

Timer Function

The TIMER pin handles several key functions with an

external capacitor, C

. There are two comparator

TIMER

thresholds: COMP1 (0.2V) and COMP2 (1.3V). The four

timing current sources are:

5µA pull-up

60µA pull-up

2µA pull-down

100µA pull-down

The 100µA is a nonideal current source approximating a

7k resistor below 0.4V.

ends. The 100µA current source then pulls down the

TIMER pin until it reaches 0.2V at time point 4. The initial

cycle delay (time point 2 to time point 4) is related to

C

by equation:

TIMER

t

INITIAL

≈ 272.9 • C

ms/µF (5)

TIMER

When the initial cycle terminates, a start-up cycle is

activated and the GATE pin ramps high. The TIMER pin

continues to be pulled down towards ground.

1

2345 6 7

>2.5V

V

IN

>1.3V

V

ON

COMP2

V

V

TIMER

GATE

V

OUT

RESET

MODE

5µA

INITIAL

CYCLE

100µA

COMP1

10µA

V

TH

START-UP

CYCLE

DISCHARGE

BY LOAD

4210 F03

NORMAL

CYCLE

Initial Timing Cycle

When the card is being inserted into the bus connector, the

long pins mate first which brings up the supply VIN at time

point 1 of Figure 3. The LTC4210 is in reset mode as the

ON pin is low. GATE is pulled low and the TIMER pin is

pulled low with a 100µA source. At time point 2, the short

pin makes contact and ON is pulled high. At this instant, a

start-up check requires that the supply voltage be above

UVLO, the ON pin be above 1.3V and the TIMER pin voltage

be less than 0.2V. When these three conditions are fulfilled, the initial cycle begins and the TIMER pin is pulled

high with 5µA. At time point 3, the TIMER reaches the

COMP2 threshold and the first portion of the initial cycle

Figure 3. Normal Operating Sequence

Start-Up Cycle Without Current Limit

The GATE is released with a 10µA pull-up at time point 4

of Figure 3. At time point 5, GATE reaches the external

MOSFET threshold VTH and V

ramp up. If the R

current is below the current limit,

SENSE

starts to follow the GATE

OUT

the GATE ramps at a constant rate of:

∆

V

GATE GATE

∆

where C

T

I

=

C

GATE

is the total capacitance at the GATE pin.

GATE

(6)

421012f

11

Page 12

LTC4210-1/LTC4210-2

tC

V

I

C

V

I

C

V

I

C

V

II

STARTUP GATE

TH

GATE

LOAD

IN

CLOAD

GATE

TH

GATE

LOAD

IN

RSENSE LOAD

=+

=+

••

••

–

WUUU

APPLICATIO S I FOR ATIO

The current through R

components; I

(C

LOAD

) and I

LOAD

due to the total load capacitance

CLOAD

due to the noncapacitive load elements.

can be divided into two

SENSE

The capacitive load typically dominates.

For a successful start-up without current limit, I

I

:

LIMIT

I

RSENSE

IC

RSENSE LOAD

= I

=

CLOAD

+ I

LOAD

V

∆

∆

< I

OUT

T

LIMIT

II

+<•

LOAD LIMIT

Due to the voltage follower configuration, the V

rate approximately tracks V

∆

V

OUT CLOAD

∆

I

=≈

T

C

LOAD

At time point 6, V

∆

V

is approximately VIN but GATE ramp-

OUT

:

GATE

GATE GATE

∆

T

I

=

C

GATE

RSENSE

OUT

<

(7)

ramp

(8)

up continues until it reaches a maximum voltage. This

maximum voltage is determined either by the charge

pump or the internal clamp.

V

TIMER

V

GATE

V

I

RSENSE

V

OUT

12 345 5A5B6 7

>2.5V

V

IN

>1.3V

ON

RESET

MODE

5µA

INITIAL

CYCLE

COMP2

100µA

COMP1

10µA

V

TH

REGULATED AT 50mV/R

START-UP

CYCLE

60µA

<10µA

2µA

10µA

SENSE

NORMAL

CYCLE

100µA

DISCHARGE

BY LOAD

4210 F04

Start-Up Cycle With Current Limit

If the duration of the current limit is brief during start-up

(Figure 4) and it did not last beyond the circuit breaker

function time out, the GATE behaves the same as in startup without current limit except for the time interval between time point 5A and time point 5B. The servo amplifier

limits I

RSENSE

II

RSENSE LIMIT

by decreasing the I

mV

==

50

R

SENSE

current (<10µA).

GATE

(9)

Equations 8 and 9 are applicable but with a lower GATE and

V

ramp rate.

OUT

Gate Start-Up Time

The start-up time without current limit is given by:

VV

+

tC

STARTUP GATE

tC

STARTUP GATE

=

=+

TH IN

•

I

GATE

V

TH

••

I

GATE

C

GATE

V

I

GATE

IN

(10)

Figure 4. Operating Sequence with

Current Limiting at Start-Up Cycle

During current limiting, the second term in Equation 10 is

partly modified from C

VIN/I

. The start-up time is now given by:

CLOAD

GATE

• VIN/I

GATE

to C

LOAD

•

(11)

For successful completion of current limit start-up cycle

there must be a net current to charge C

current limit duration must be less than t

and the

LOAD

CBDELAY

. The

second term in equation 11 has to fulfill equation 12.

V

C

LOAD

•

II

RSENSE LOAD

IN

t

<

–

CBDELAY

(12)

12

421012f

Page 13

WUUU

APPLICATIO S I FOR ATIO

LTC4210-1/LTC4210-2

Circuit Breaker Timer Operation

When a current limit fault is encountered at time point A in

Figure 5, the circuit breaker timing is activated with a 60µA

pull-up. The circuit breaker trips at time point B if the fault

is still present and the TIMER pin voltage reaches the

COMP2 threshold and the LTC4210 shuts down. For a

continuous fault, the circuit breaker delay is:

C

tV

CBDELAY

=µ1360.•

TIMER

A

(13)

Intermittent overloads may exceed the current limit as in

Figure 6, but if the duration is sufficiently short, the TIMER

pin may not reach the COMP2 threshold and the LTC4210

will not shut down. To handle this situation, the TIMER

discharges with 2µA whenever (VCC – SENSE) voltage is

below the 50mV limit and the TIMER voltage is between

the COMP1 and COMP2 thresholds. When the TIMER

voltage falls below the COMP1 threshold, the TIMER pin is

discharged with an equivalent 7k resistor (normal mode,

100µA source) when (VCC – SENSE) voltage is below the

50mV limit. If the TIMER pin does not drop below the

COMP1 threshold, any intermittent overload with an aggregate duty cycle of more than 3.8% will eventually trip

the circuit breaker. Figure 7 shows the circuit breaker

response time in seconds normalized to 1µF. The asym-

metric charging and discharging of TIMER is a fair gauge

of MOSFET heating.

V

TIMER

100µA

NORMAL

MODE

AB

COMP2

COMP1

FAULT

MODE

CIRCUIT BREAKER

TRIPS

LATCHED OFF (5µA PULL-UP)

OR RETRY (2µA PULL-DOWN)

60µA

4210 F05

Figure 5. A Continuous Fault Timing

A1 B1 A2 B2 A3 B3

~50mV/R

I

LOAD

COMP2

V

TIMER

V

GATE

60µA

10µA 10µA

CB

FAULT

60µA

2µA

CB

FAULT

60µA

2µA

LATCHED OFF (5µA PULL-UP)

OR RETRY (2µA PULL-DOWN)

CB

FAULT

SENSE

CIRCUIT BREAKER

TRIPS

COMP1

4210 F06

Figure 6. Mulitple Intermittent Overcurrent Conditon

1

C

TIMER

t

(s/µF) =

1.3V • 1µF

60µA • D – 2µA

C

TIMER

t

sF

(/ )

µ=

()

VF

13 1

.•

µ

AD A

60 2

•–

µ

µ

(14)

When the circuit breaker trips, the GATE pin is pulled low.

The TIMER enters latchoff mode with a 5µA pull-up for the

LTC4210-2 (latched-off version), while an autoretry “cooloff” cycle begins with a 2µA pull-down for the LTC4210-1

(autoretry version). An autoretry cool-off delay of the

LTC4210-1 between COMP2 and COMP1 thresholds takes:

C

tV

COOLOFF

=µ112.•

TIMER

A

(15)

0.1

NORMALIZED RESPONSE TIME (s/µF)

0.01

20 100

10

0

40

50

30

OVERLOAD DUTY CYCLE, D (%)

807060

90

4210 F07

Figure 7. Circuit Breaker Timer Response

for Intermittent Overload

421012f

13

Page 14

LTC4210-1/LTC4210-2

WUUU

APPLICATIO S I FOR ATIO

Autoretry After Current Fault (LTC4210-1)

Figure 8 shows the waveforms of the LTC4210-1 (autoretry

version) during a circuit breaker fault. At time point B1, the

TIMER trips the COMP2 threshold of 1.3V. The GATE pin

pulls to ground while TIMER begins a “cool-off” cycle with

a 2µA pull-down to the COMP1 threshold of 0.2V. At time

point C1, the TIMER pin pulls down with approximately a

7k resistor to ground and a GATE start-up cycle is initiated.

If the fault persists, the fault autoretry duty cycle is

approximately 3.8%. Pulling the ON pin low for more than

30µs will stop the autoretry function and put the LTC4210

in reset mode.

A1

B1 C1 A2 B2

2µA

COMP2

COMP1

V

TIMER

V

V

I

GATE

LOAD

60µA

OUT

REGULATING AT 50mV/R

2µA

60µA

100µA

SENSE

Latch-Off After Current Fault (LTC4210-2)

Figure 9 shows the waveforms of the LTC4210-2 (latch-off

version) during a circuit breaker fault. At time point B, the

TIMER trips the COMP2 threshold. The GATE pin pulls to

ground while the TIMER pin is latched high by a 5µA pull-

up. The TIMER pin eventually reaches the soft-clamped

voltage (V

) of 2.3V. To clear the latchoff mode, the

CLAMP

user can either pull the TIMER pin to below 0.2V externally

or cycle the ON pin low for more than 30µs.

AB C

V

CLAMP

V

TIMER

V

I

GATE

V

LOAD

60µA

OUT

REGULATING AT 50mV/R

SENSE

COMP2

COMP1

0V

0V

14

CB

FAULT

COOL OFF

CYCLE

4210 F08

NORMAL

MODE

CB

FAULT

COOL OFF

CYCLE

Figure 8. Automatic Retry After Overcurrent Fault

NORMAL

MODE

LATCHED OFF CYCLE

CB

FAULT

2410 F09

Figure 9. Latchoff After Overcurrent Fault

421012f

Page 15

WUUU

APPLICATIO S I FOR ATIO

LTC4210-1/LTC4210-2

Normal Mode/External Timer Control

Whenever the TIMER pin voltage drops below the COMP1

threshold, but is not in reset mode, the TIMER enters

normal (100µA source) mode with an equivalent 7k resis-

tive pull-down. Table 1 shows the relationship of t

t

CBDELAY

, t

COOLOFF

vs C

TIMER

.

INITIAL

,

If the TIMER pin is pulled beyond the COMP2 threshold,

the GATE pin is pulled to ground immediately. This allows

the TIMER pin to be used for overvoltage detection, see

Figure 11.

Externally forcing the TIMER pin below the COMP1 threshold will reset the TIMER to normal mode. During overvoltage detection, the TIMER’s 100µA pull-down current will

continue to be on if (VCC – SENSE) voltage is below 50mV.

If the (VCC – SENSE) voltage exceeds 50mV during the

overvoltage detection, the TIMER current will be the same

as described for latched-off or autoretry mode. See the

Table 1. t

C

TIMER

0.033 9.0 0.7 18.2

0.047 12.8 1 25.9

0.068 18.6 1.5 37.4

0.082 22.4 1.8 45.1

0.1 27.3 2.2 55

0.22 60.0 4.8 121

0.33 90.1 7.2 181.5

0.47 128.3 10.2 258.5

0.68 185.6 14.7 374

0.82 223.8 17.8 451

1 272.9 21.7 550

2.2 600.5 47.7 1210

3.3 900.7 71.5 1815

, t

INITIAL

(µF) t

CBDELAY

INITIAL

, t

COOLOFF

(ms) t

vs C

CBDELAY

TIMER

(ms) t

COOLOFF

(ms)

section OVERVOLTAGE DETECTION USING TIMER PIN

for details of the application.

Power-Off Cycle

The system can be reset by toggling the ON pin low for

more than 30µs as shown at time point 7 of Figure 3. The

GATE pin is pulled to ground. The TIMER capacitor is also

discharged to ground. C

discharges through the load.

LOAD

Alternatively, the TIMER pin can be externally driven above

the COMP2 threshold to turn off the GATE pin.

POWER MOSFET SELECTION

Power MOSFETs can be classified by R

at VGS gate

DSON

drive ratings of 10V, 4.5V, 2.5V and 1.8V. Use the typical

curves ∆VGATE vs Supply Voltage and ∆VGATE vs Temperature to determine whether the gate drive voltage is

adequate for the selected MOSFET at the operating voltage.

In addition, the selected MOSFET should fulfill two V

GS

criteria:

1. Positive VGS absolute maximum rating > LTC4210

maximum ∆V

GATE

, and

2. Negative VGS absolute maximum rating > supply

voltage. The gate of the MOSFET can discharge faster

than V

C

LOAD

when shutting down the MOSFET with a large

OUT

.

If one of the conditions cannot be met, an external Zener

clamp shown on Figure 10a or Figure 10b can be used. The

selection of RG should be within the allowed LTC4210

package dissipation when discharging V

via the Zener

OUT

clamp.

421012f

15

Page 16

LTC4210-1/LTC4210-2

WUUU

APPLICATIO S I FOR ATIO

V

GND

IN

5V

V

CC

BACKPLANE

CONNECTOR

(FEMALE)

R

SENSE

Q1

D1*

R

S

200Ω

GATE

(10a) (10b)

V

OUT

*USER SELECTED VOLTAGE CLAMP

(A LOW BIAS CURRENT ZENER DIODE

IS RECOMMENDED)

1N4688 (5V)

1N4692 (7V)

1N4695 (9V)

1N4702 (15V)

V

CC

Figure 10. Gate Protection Zener Clamp

PCB EDGE

CONNECTOR

(MALE)

LONG

R

X

10Ω

Z1

C

X

0.1µF

R

ON1

SHORT

LONG

20k

R

ON2

10k

Z1: SMAJ10A Z2: BZX84C6V2

R

10k

D1

1N4148

R

TIMER

18Ω

C

TIMER

0.22µF

B

3

1

Z2

R

SENSE

V

ON

TIMER

R

SENSE

0.01Ω

6

CC

LTC4210

Q1

GATE

GND

R

S

200Ω

SENSE

GATE

2

5

D2*D1*

Q1

Si4410DY

R

100Ω

4

R4

100Ω

G

C

C

10nF

V

OUT

V

OUT

5V

C

LOAD

470µF

4210 F11

4A

GND

+

16

Figure 11. Supply Side Overvoltage Protection

421012f

Page 17

WUUU

APPLICATIO S I FOR ATIO

LTC4210-1/LTC4210-2

A MOSFET with a VGS absolute maximum rating of ±20V

meets the two criteria for all the LTC4210 applications

ranges from 2.7V to 16.5V. Typically most 10V gate rated

MOSFETs have VGS absolute maximum ratings of ±20V or

greater, so no external VGS Zener clamp is needed. There

are 4.5V gate rated MOSFETs with VGS absolute maximum

ratings of ±20V.

In addition to the MOSFET gate drive rating and V

absolute maximum rating, other criteria such as V

I

D(MAX)

, R

DS(ON)

, PD, θJA, T

and maximum safe

J(MAX)

operating area should also be carefully reviewed. V

GS

BDSS

BDSS

,

should exceed the maximum supply voltage inclusive of

spikes and ringing. I

current limit, I

LIMIT

. R

which together with VCB yields an error in the V

should be greater than the

D(MAX)

determines the MOSFET V

DS(ON)

voltage.

OUT

DS

At 2.7V supply voltage, the total of VDS + VCB of 0.1V yields

3.7% V

OUT

error.

The maximum power dissipated in the MOSFET is

2

I

LIMIT

• R

and this should be less than the maxi-

DS(ON)

mum power dissipation, PD allowed in that package.

Given power dissipation, the MOSFET junction temperature, TJ can be computed from the operating temperature

(TA) and the MOSFET package thermal resistance (θJA).

The operating TJ should be less than the T

J(MAX)

specifi-

cation.

Next review the short-circuit condition under maximum

supply V

I

LIMIT(MAX)

t

CBDELAY

IN(MAX)

with the maximum safe operating area of the

conditions and maximum current limit,

during the circuit breaker time-out interval of

MOSFET. The operation during output short-circuit conditions must be well within the manufacturer’s recommended safe operating region with sufficient margin. To

ensure a reliable design, fault tests should be evaluated in

the laboratory.

VIN TRANSIENT PROTECTION

Unlike most circuits, Hot Swap controllers typically are

not allowed the good engineering practice of supply

bypass capacitors, since controlling the surge current to

bypass capacitors at plug-in is the primary motivation for

the Hot Swap controller. Although wire harness, backplane and PCB trace inductances are usually small, these

can create large spikes when large currents are suddenly

drawn, cut-off or limited. This can cause detrimental

damage to board components unless measures are taken.

Abrupt intervention can prevent subsequent damage

caused by a catastrophic fault but it does cause a large

supply transient. The energy stored in the lead/trace

inductance is easily controlled with snubbers and/or

transient voltage suppressors. Even when ferrite beads

are used for electromagnetic interference (EMI) control,

the low saturating current of ferrite will not pose a major

problem if the transient voltage suppressors with adequate ratings are used. The transient associated with the

GATE turn off can be controlled with a snubber and/or

transient voltage suppressor. Snubbers such as RC networks are effective especially at low voltage supplies. The

choice of RC is usually determined experimentally. The

value of the snubber capacitor is usually chosen between

10 to 100 times the MOSFET C

. The value of the

OSS

snubber resistor is typically between 3Ω to 100Ω. When

the supply exceeds 7V or EMI beads exist in the wire

harness, a transient voltage suppressor and snubber are

recommended to clip off large spikes and reduce the

ringing. For supply voltages of 6V or below, a snubber

network should be sufficient to protect against transient

voltages. In many cases, a simple short-circuit test can be

performed to determine the need of the transient voltage

suppressor.

OVERVOLTAGE DETECTION USING THE TIMER PIN

Figure 11 shows a supply side overvoltage detection

circuit. A Zener diode, a diode and COMP2 threshold sets

the overvoltage threshold. Resistor RB biases the Zener

diode voltage. Diode D1 blocks forward current in the

Zener during start-up or output short-circuit. R

C

sets the overload noise filter.

TIMER

TIMER

with

421012f

17

Page 18

LTC4210-1/LTC4210-2

U

APPE DIX

Table 2 lists some current sense resistors that can be used

with the circuit breaker. Table 3 lists some power MOSFETs

manufacturers. Since this information is subject to change,

please verify the part numbers with the manufacturer.

that are available. Table 4 lists the web sites of several

Table 2. Sense Resistor Selection Guide

CURRENT LIMIT VALUE PART NUMBER DESCRIPTION MANUFACTURER

1A LR120601R050 0.05Ω 0.5W 1% Resistor IRC-TT

2A LR120601R025 0.025Ω 0.5W 1% Resistor IRC-TT

2.5A LR120601R020 0.02Ω 0.5W 1% Resistor IRC-TT

3.3A WSL2512R015F 0.015Ω 1W 1% Resistor Vishay-Dale

5A LR251201R010F 0.01Ω 1.5W 1% Resistor IRC-TT

10A WSR2R005F 0.005Ω 2W 1% Resistor Vishay-Dale

Table 3. N-Channel Selection Guide

CURRENT LEVEL (A) PART NUMBER DESCRIPTION MANUFACTURER

0 to 2 MMDF3N02HD Dual N-Channel SO-8 ON Semiconductor

R

= 0.1Ω, C

DS(ON)

2 to 5 MMSF5N02HD Single N-Channel SO-8 ON Semiconductor

R

= 0.025Ω, C

DS(ON)

5 to 10 MTB50N06V Single N-Channel DD Pak ON Semiconductor

= 0.028Ω, C

R

DS(ON)

10 to 20 MTB75N05HD Single N-Channel DD Pak ON Semiconductor

R

= 0.0095Ω, C

DS(ON)

= 455pF

ISS

ISS

ISS

ISS

= 1130pF

= 1570pF

= 2600pF

Table 4. Manufacturers’ Web Sites

MANUFACTURER WEB SITE

TEMIC Semiconductor www.temic.com

International Rectifier www.irf.com

ON Semiconductor www.onsemi.com

Harris Semiconductor www.semi.harris.com

IRC-TT www.irctt.com

Vishay-Dale www.vishay.com

Vishay-Siliconix www.vishay.com

Diodes, Inc. www.diodes.com

18

421012f

Page 19

PACKAGE DESCRIPTIO

LTC4210-1/LTC4210-2

U

S6 Package

6-Lead Plastic TSOT-23

(Reference LTC DWG # 05-08-1636)

0.62

MAX

3.85 MAX

2.62 REF

RECOMMENDED SOLDER PAD LAYOUT

PER IPC CALCULATOR

0.20 BSC

DATUM ‘A’

NOTE:

1. DIMENSIONS ARE IN MILLIMETERS

2. DRAWING NOT TO SCALE

3. DIMENSIONS ARE INCLUSIVE OF PLATING

4. DIMENSIONS ARE EXCLUSIVE OF MOLD FLASH AND METAL BURR

5. MOLD FLASH SHALL NOT EXCEED 0.254mm

6. JEDEC PACKAGE REFERENCE IS MO-193

0.95

REF

1.22 REF

1.4 MIN

0.30 – 0.50 REF

2.80 BSC

0.09 – 0.20

(NOTE 3)

1.50 – 1.75

(NOTE 4)

1.00 MAX

0.95 BSC

0.80 – 0.90

2.90 BSC

(NOTE 4)

PIN ONE ID

1.90 BSC

0.30 – 0.45

6 PLCS (NOTE 3)

0.01 – 0.10

S6 TSOT-23 0302

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

421012f

19

Page 20

LTC4210-1/LTC4210-2

U

TYPICAL APPLICATIO

12V Hot Swap Application

PCB EDGE

CONNECTOR

(MALE)

LONG

SHORT

LONG

Z1: SMAJ12A

Z1

R

62k

ON1

R

10Ω

R

10k

X

C

X

0.1µF

ON2

VCCSENSE

3

ON

1

TIMER

C

TIMER

0.22µF

R

SENSE

0.01Ω

6

LTC4210

GND

Q1

Si4410DY

+

5

GATE

2

R

G

200Ω

4

R

C

100Ω

C

C

10nF

C

LOAD

470µF

4210 TA03

V

OUT

12V

4A

GND

V

12V

GND

BACKPLANE

CONNECTOR

(FEMALE)

IN

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC1421 Two Channel, Hot Swap Controller Operates from 3V to 12V and Supports –12V

LTC1422 Single Channel, Hot Swap Controller in SO-8 Operates from 2.7V to 12V, Reset Output

LT1640AL/LT1640AH Negative Voltage Hot Swap Controller in SO-8 Operates from –10V to –80V

LTC1642 Single Channel, Hot Swap Controller Overvoltage Protection to 33V, Foldback Current Limiting

LTC1643AL/LTC1643AH PCI Hot Swap Controller 3.3V, 5V, Internal FETs for ±12V

LTC1647 Dual Channel, Hot Swap Controller Operates from 2.7V to 16.5V, Separate ON pins for Sequencing

LTC4211 Single Channel, Hot Swap Controller 2.5V to 16.5V, Multifunction Current Control

LTC4230 Triple Channel, Hot Swap Controller 1.7V to 16.5V, Multifunction Current Control

LTC4251 –48V Hot Swap Controller in SOT-23 Floating Supply, Three-Level Current Limiting

LTC4252 –48V Hot Swap Controller in MSOP Floating Supply, Power Good, Three-Level Current Limiting

LTC4253 –48V Hot Swap Controller with Triple Supply Sequencing Floating Supply, Three-Level Current Limiting

20

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

421012f

LT/TP 0603 1K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 2002

Loading...

Loading...