Page 1

LTC4089/LTC4089-5

1

40895fb

HVIN

BOOST

HVEN

IN

SW

4.7µF

10µF

4.7µF

1µF

TIMER

CLPROG

LTC4089

GND PROG

HVOUT

HVPR

OUT

BAT

0.1µF

100k2k

5V (NOM)

FROM USB

CABLE V

BUS

HIGH (6V-36V)

VOLTAGE INPUT

Li-Ion BATTERY

+

1k

TO LDOs

R

EGS

, ETC.

4089 TAO1

VOUT (TYP)

V

BAT

+0.3V

5V

5V

V

BAT

AVAILABLE INPUT

HV INPUT (LTC4089)

HV INPUT (LTC4089-5)

USB ONLY

BAT ONLY

10µH

0.1µF

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

All other

trademarks are the property of their respective owners.

Burst Mode is a registered trademark

of Linear Technology Corporation.

Protected by U.S. Patents including 6522118 and 6700364.

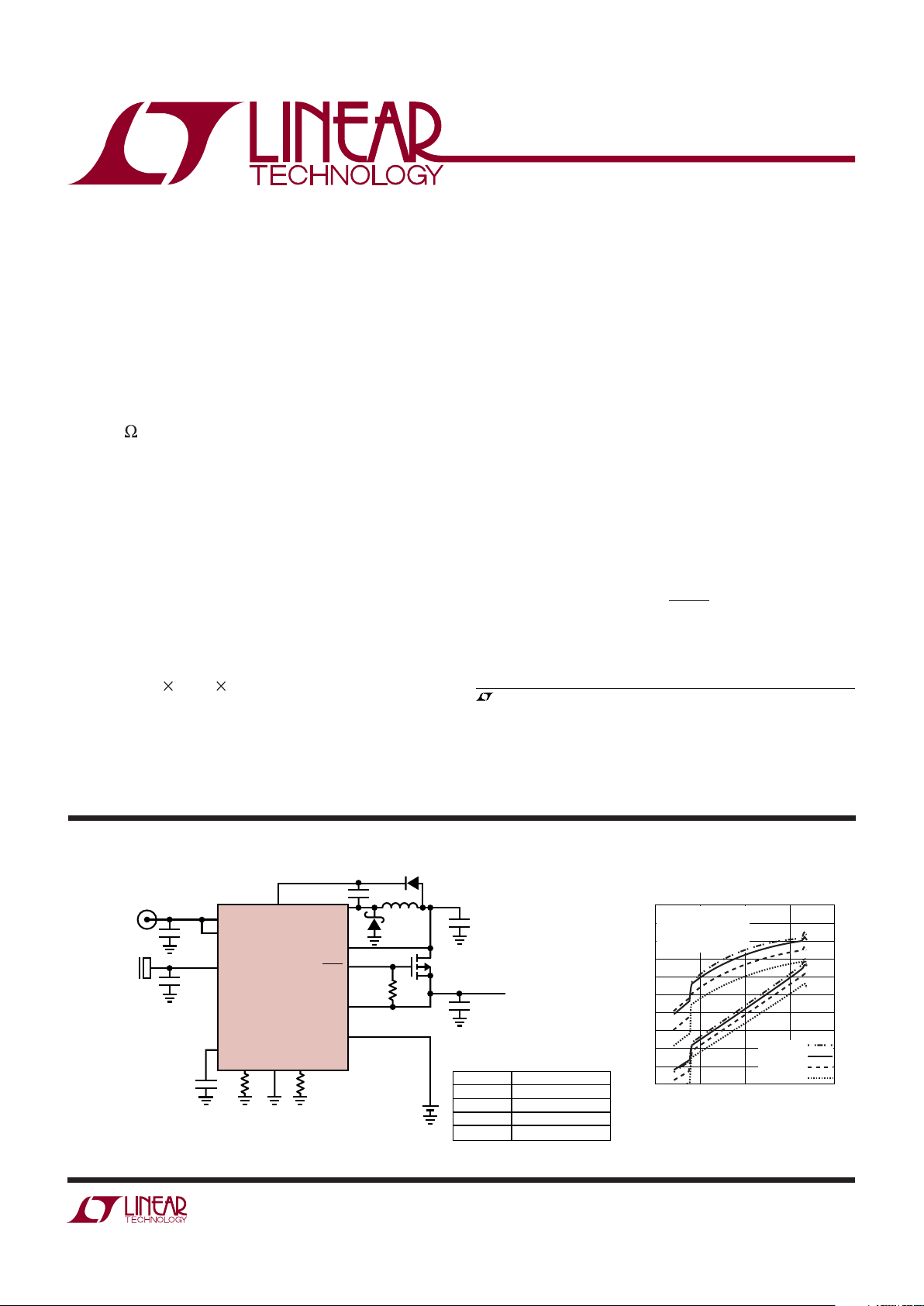

TYPICAL APPLICATIO

U

USB Power Manager with

High Voltage Switching Charger

The LTC®4089/LTC4089-5 are USB power managers plus

high voltage Li-Ion battery chargers. These devices control

the total current used by the USB peripheral for operation

and battery charging. Battery charge current is automatically reduced such that the sum of the load current and

the charge current does not exceed the programmed input

current limit. The LTC4089/LTC4089-5 also accommodate

high voltage power supplies, such as 12V AC-DC wall

adapters, FireWire, or automotive power.

The LTC4089 provides an adaptive output that tracks the

battery voltage for high effi ciency charging from the high

voltage input. The LTC4089-5 provides a fi xed 5V output

from the high voltage input to charge single cell Li-Ion

batteries. The charge current is programmable and an

end-of-charge status output (CHRG) indicates full charge.

Also featured is programmable total charge time, an NTC

thermistor input used to monitor battery temperature while

charging and automatic recharging of the battery.

■

Portable USB Devices—GPS Receivers, Cameras,

MP3 Players, PDAs

■

Seamless Transition Between Power Sources: Li-Ion

Battery, USB, and 6V to 36V External Supply

■

High Effi ciency 1.2A Charger from 6V to 36V Input

with Adaptive Output Control (LTC4089)

■

Load Dependent Charging from USB Input

Guarantees Current Compliance

■

215m Internal Ideal Diode plus Optional External

Ideal Diode Controller Provides Low Loss Power

Path When External Supply/USB Not Present

■

Constant-Current/Constant-Voltage Operation with

Thermal Feedback to Maximize Charging Rate

without Risk of Overheating

■

Selectable 100% or 20% Current Limit (e.g., 500mA/

100mA) from USB Input

■

Preset 4.2V Charge Voltage with 0.8% Accuracy

■

C/10 Charge Current Detection Output

■

NTC Thermistor Input for Temperature Qualifi ed

Charging

■

Tiny (6mm 3mm 0.75mm) 22-Pin DFN Package

APPLICATIO S

U

FEATURES

DESCRIPTIO

U

LTC4089 High Voltage

Battery Charger Effi ciency

BATTERY VOLTAGE (V)

2.5

40

EFFICIENCY (%)

45

55

60

65

90

75

3

3.5

4089 TA01b

50

80

85

70

4

4.5

HVIN = 8V

HVIN = 12V

HVIN = 24V

HVIN = 36V

CC CURRENT = 970mA

NO OUTPUT LOAD

FIGURE 10 SCHEMATIC

WITH R

PROG

= 52k

LTC4089-5

LTC4089

Page 2

LTC4089/LTC4089-5

2

40895fb

Terminal Voltage

BOOST ...................................................... –0.3V to 50V

BOOST above SW .....................................................25V

HVIN, HVEN .............................................. –0.3V to 40V

IN, OUT, HVOUT

t < 1ms and Duty Cycle < 1% .................. –0.3V to 7V

DC ............................................................ –0.3V to 6V

BAT .............................................................. –0.3V to 6V

NTC, TIMER, PROG, CLPROG .......–0.3V to (V

CC

+ 0.3V)

CHRG, HPWR, SUSP, HVPR ......................... –0.3V to 6V

Pin Current, DC

IN, OUT, BAT (Note 6) ..............................................2.5A

Operating Temperature Range

LTC4089E ................................................. –40°C to 85°C

Maximum Operating Junction Temperature .......... 110°C

Storage Temperature Range ................... –65°C to 125°C

(Notes 1, 2, 3, 4, 5)

The

● denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at TA = 25°C. HVIN = 12V, BOOST = 17V, VIN = 5V, V

BAT

= 3.7V, HVEN = 12V,

HPWR = 5V, R

PROG

= 100k, R

CLPROG

= 2k, SUSP = 0V, unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

USB Input Current Limit

V

IN

USB Input Supply Voltage IN

●

4.35 5.5 V

I

IN

Input Bias Current I

BAT

= 0 (Note 7)

Suspend Mode; SUSP = 5V

●

●

0.5

50

1

100

mA

µA

I

LIM

Current Limit R

CLPROG

= 2k, HPWR = 5V

R

CLPROG

= 2k, HPWR = 0V

●

●

475

90

500

100

525

110

mA

mA

I

IN(MAX)

Maximum Input Current Limit (Note 8) 2.4 A

R

ON

ON Resistance VIN to V

OUT

I

OUT

= 80mA Load 0.215

V

CLPROG

CLPROG Pin Voltage R

CLPROG

= 2k

R

CLPROG

= 1k

●

●

0.98

0.98

1.00

1.00

1.02

1.02

V

V

I

SS

Soft-Start Inrush Current IN 5 mA/µs

V

CLEN

Input Current Limit Enable

Threshold Voltage (V

IN

– V

OUT

)

(V

IN

– V

OUT

) VIN Rising

(V

IN

– V

OUT

) VIN Falling

20

–80

50

–50

80

–20

mV

mV

ELECTRICAL CHARACTERISTICS

ABSOLUTE AXI U RATI GS

W

WW

U

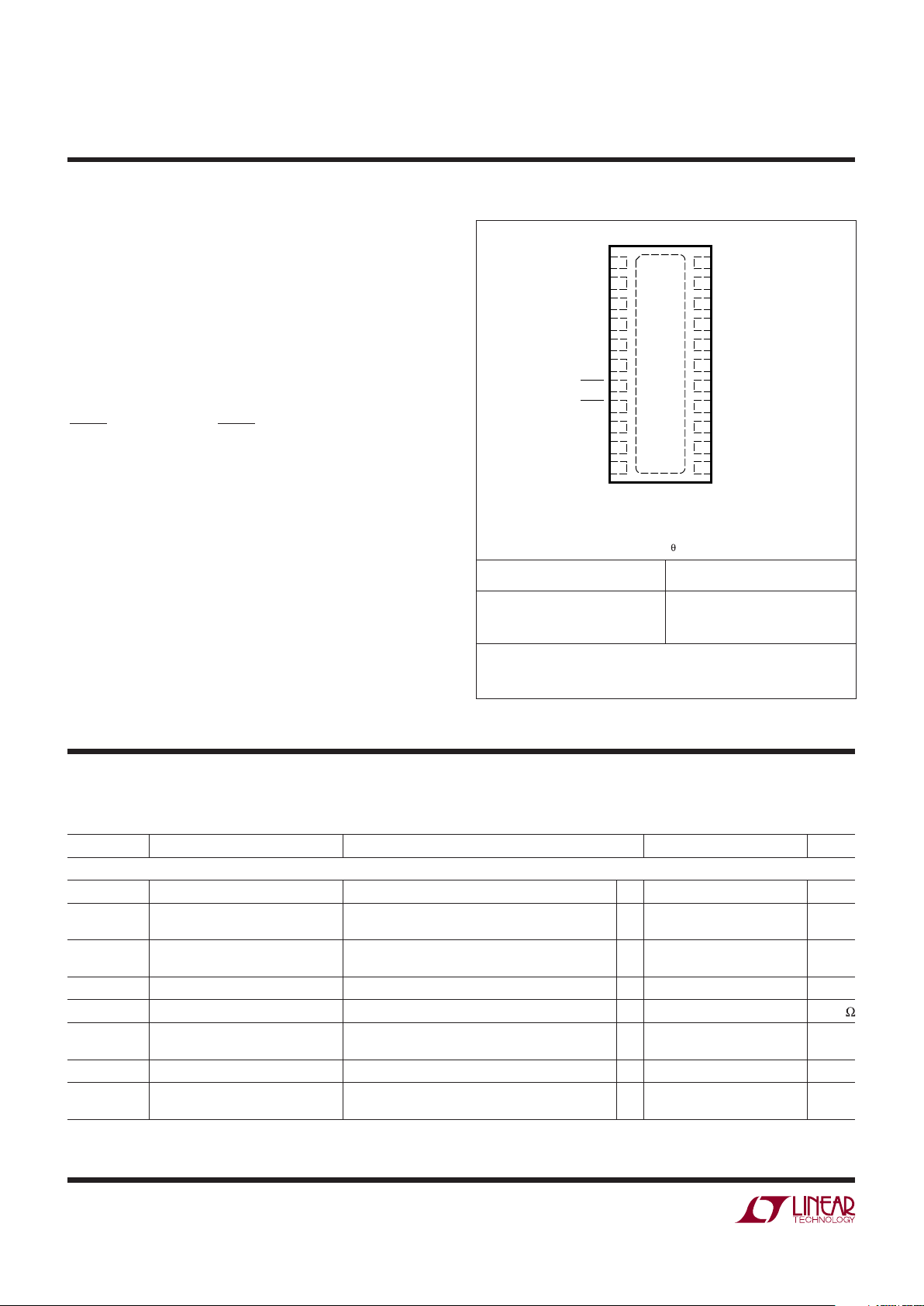

PACKAGE/ORDER I FOR ATIO

UUW

22

21

20

19

18

17

16

15

14

13

12

1

2

3

4

5

6

7

8

9

10

11

HVEN

HVIN

BOOST

SW

HVOUT

TIMER

SUSP

HPWR

CLPROG

OUT

IN

TOP VIEW

23

DJC PACKAGE

22-LEAD (6mm × 3mm) PLASTIC DFN

GND

GND

HVOUT

V

C

NTC

VNTC

HVPR

CHRG

PROG

GATE

BAT

EXPOSED PAD (PIN 23) IS GND

(MUST BE SOLDERED TO PCB)

T

JMAX

= 110°C, JA = 40°C/W

ORDER PART NUMBER DJC PART MARKING

LTC4089EDJC

LTC4089EDJC-5

4089

40895

Order Options Tape and Reel: Add #TR

Lead Free: Add #PBF Lead Free Tape and Reel: Add #TRPBF

Lead Free Part Marking: http://www.linear.com/leadfree/

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges.

Page 3

LTC4089/LTC4089-5

3

40895fb

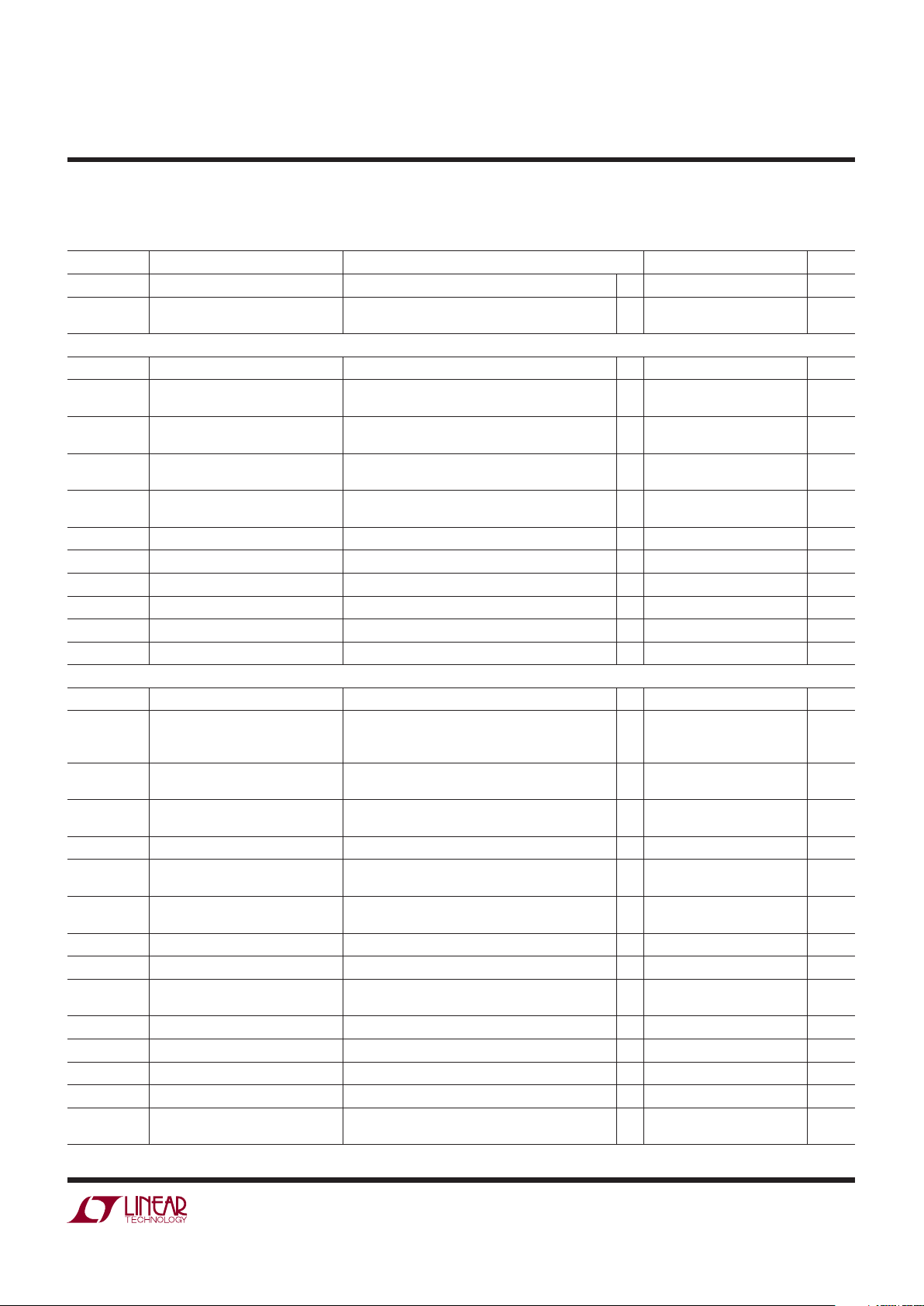

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

UVLO

Input Undervoltage Lockout VIN Powers Part, Rising Threshold

●

3.6 3.8 4 V

dV

UVLO

Input Undervoltage Lockout

Hysteresis

VIN Rising – VIN Falling 130 mV

High Voltage Regulator

V

HVIN

HVIN Supply Voltage 6 36 V

I

HVIN

HVIN Bias Current Not Switching

Shutdown; HVEN = 0V

1.9

0.01

2.5

2

mA

µA

V

OUT

Output Voltage with HVIN Present Assumes HVOUT to OUT Connection (LTC4089)

Assumes HVOUT to OUT Connection (LTC4089-5)

●

3.45

4.85

V

BAT

+0.354.6

5.15

V

V

V

HVUVLO

High Voltage Input Undervoltage

Lockout

V

HVIN

Rising 4.7 5 V

f

SW

Switching Frequency V

HVOUT

> 3.95V

V

HVOUT

= 0V

685 750

35

815 kHz

kHz

DC

MAX

Maximum Duty Cycle

●

88 95 %

I

SW(MAX)

Switch Current Limit (Note 9) 1.5 1.95 2.3 A

V

SAT

Switch V

CESAT

ISW = 1A 330 mV

I

LK

Switch Leakage Current 2µA

V

SWD

Minimum Boost Voltage Above SW ISW = 1A 1.85 2.2 V

I

BST

BOOST Pin Current ISW = 1A 30 50 mA

Battery Management

V

BAT

Input Voltage BAT 4.3 V

I

BAT

Battery Drain Current V

BAT

= 4.3V, Charging Stopped

Suspend Mode; SUSP = 5V

V

HVIN

= VIN = 0V, BAT Powers OUT, No Load

●

●

●

15

22

60

27

35

100

µA

µA

µA

V

FLOAT

Regulated Output Voltage I

BAT

= 2mA

I

BAT

= 2mA; (0°C – 85°C)

4.165

4.158

4.200

4.200

4.235

4.242

V

V

I

CHG

Current Mode Charge Current R

PROG

= 100k, No Load

R

PROG

= 50k, No Load; (0°C – 85°C)

●

465

900

500

1000

535

1080

mA

mA

I

CHG(MAX)

Maximum Charge Current (Note 8) 1.2 A

V

PROG

PROG Pin Voltage R

PROG

= 100k

R

PROG

= 50k

●

●

0.98

0.98

1.00

1.00

1.02

1.02

V

V

k

EOC

Ratio of End-of-Charge Current to

Charge Current

V

BAT

= V

FLOAT

(4.2V)

●

0.085 0.1 0.11 mA/mA

I

TRIKL

Trickle Charge Current V

BAT

= 2V, R

PROG

= 100k 35 50 60 mA

V

TRIKL

Trickle Charge Threshold Voltage

●

2.75 2.9 3 V

V

CEN

Charger Enable Threshold Voltage (V

OUT

– V

BAT

) Falling; V

BAT

= 4V

(V

OUT

– V

BAT

) Rising; V

BAT

= 4V

55

80

mV

mV

V

RECHRG

Recharge Battery Threshold Voltage V

FLOAT

- V

RECHRG

●

65 100 135 mV

t

TIMER

TIMER Accuracy V

BAT

= 4.3V –10 10 %

Recharge Time Percent of Total Charge Time 50 %

Low Battery Trickle Charge Time Percent of Total Charge Time, V

BAT

< 2.8V 25 %

T

LIM

Junction Temperature in Constant

Temperature Mode

105 °C

The ● denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at T

A

= 25°C. HVIN = 12V, BOOST = 17V, VIN = 5V, V

BAT

= 3.7V, HVEN = 12V,

HPWR = 5V, R

PROG

= 100k, R

CLPROG

= 2k, SUSP = 0V, unless otherwise noted.

ELECTRICAL CHARACTERISTICS

Page 4

LTC4089/LTC4089-5

4

40895fb

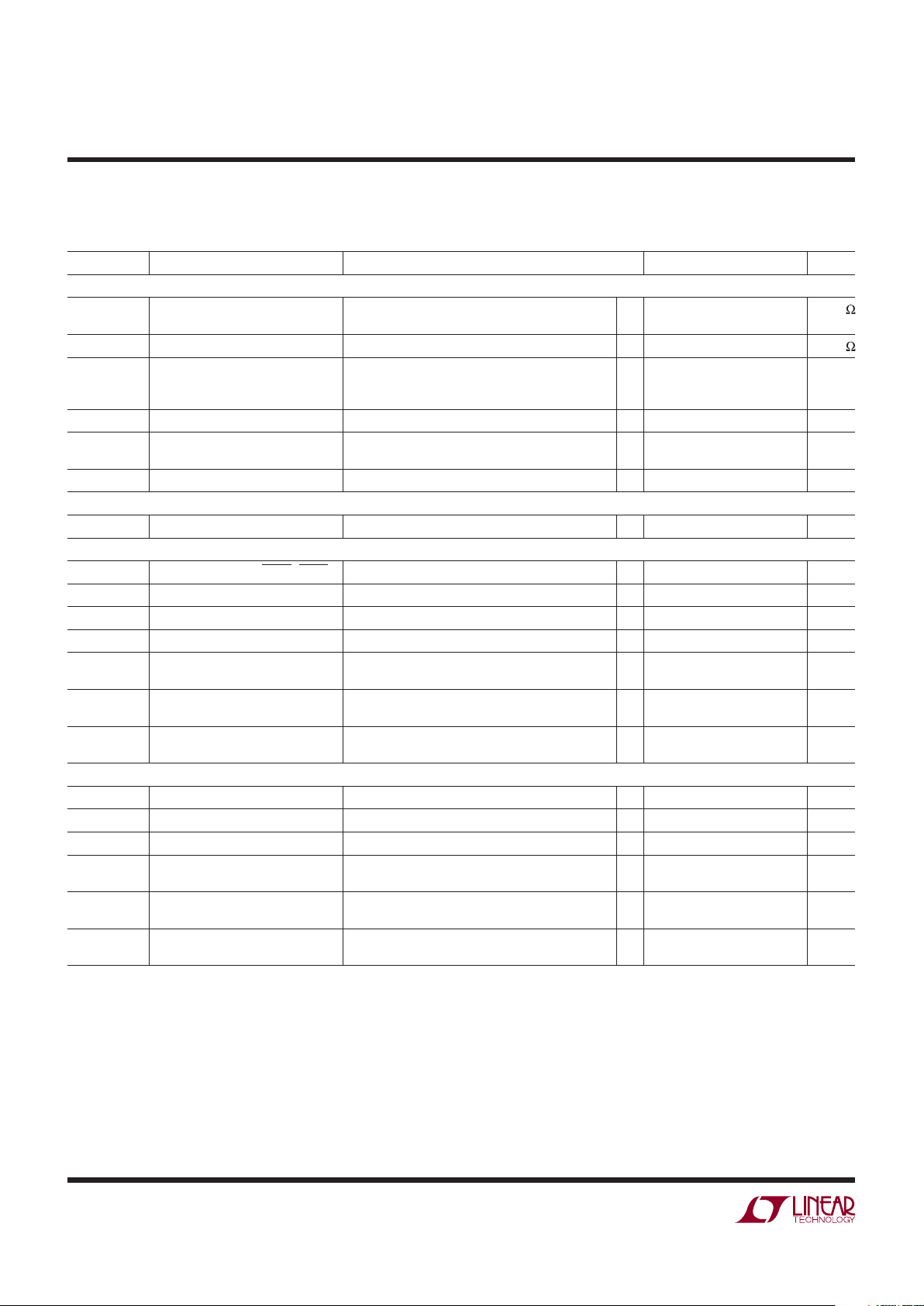

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Internal Ideal Diode

R

FWD

Incremental Resistance, VON

Regulation

I

BAT

= 100mA 125

m

R

DIO,ON

ON Resistance V

BAT

to V

OUT

I

BAT

= 600mA 215

m

V

FWD

Voltage Forward Drop (V

BAT

- V

OUT

)I

BAT

= 5mA

I

BAT

= 100mA

I

BAT

= 600mA

●

10 30

55

160

50 mV

mV

mV

V

OFF

Diode Disable Battery Voltage 2.8 V

I

FWD

Load Current Limit, for VON

Regulation

550 mA

I

D(MAX)

Diode Current Limit 2.2 A

External Ideal Diode

V

FWD, EXT

External Diode Forward Voltage 20 mV

Logic

V

OL

Output Low Voltage (CHRG, HVPR) I

SINK

= 5mA

●

0.1 0.4 V

V

IH

Input High Voltage HVEN, SUSP, HPWR Pin Low to High 2.3 V

V

IL

Input Low Voltage HVEN, SUSP, HPWR Pin High to Low 0.3 V

I

PULLDN

Logic Input Pull Down Current SUSP, HPWR 2 µA

I

HVEN

HVEN Pin Bias Current V

HVEN

= 2.3V

V

HVEN

= 0V

6

0.01

20

0.1

µA

µA

V

CHG,SD

Charger Shutdown Threshold

Voltage on TIMER

●

0.14 0.4 V

I

CHG,SD

Charger Shutdown Pull-Up Current

on TIMER

V

TIMER

= 0V

●

514 µA

NTC

I

VNTC

VNTC Pin Current V

VNTC

= 2.5V

●

1.4 2.5 3.5 mA

V

VNTC

VNTC Bias Voltage I

VNTC

= 500µA

●

4.4 4.85 V

I

NTC

NTC Input Leakage Current V

NTC

= 1V 0

±1

µA

V

COLD

Cold Temperature Fault Threshold

Voltage

Rising Threshold

Hysteresis

0.74•V

VNTC

0.02•V

VNTC

V

V

V

HOT

Hot Temperature Fault Threshold

Voltage

Falling Threshold

Hysteresis

0.29•V

VNTC

0.01•V

VNTC

V

V

V

DIS

NTC Disable Voltage NTC Input Voltage to GND (Falling)

Hysteresis

●

75 100

35

125 mV

mV

The ● denotes the specifi cations which apply over the full operating

temperature range, otherwise specifi cations are at T

A

= 25°C. HVIN = 12V, BOOST = 17V, VIN = 5V, V

BAT

= 3.7V, HVEN = 12V,

HPWR = 5V, R

PROG

= 100k, R

CLPROG

= 2k, SUSP = 0V, unless otherwise noted.

ELECTRICAL CHARACTERISTICS

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: V

CC

is the greater of VIN, V

OUT

or V

BAT

Note 3: All voltage values are with respect to GND.

Note 4: This IC includes over-temperature protection that is intended

to protect the device during momentary overload conditions. Junction

temperatures will exceed 110°C when over-temperature protection is

active. Continuous operation above the specifi ed maximum operating

junction temperature may result in device degradation or failure.

Note 5: The LTC4089/LTC4089-5 are guaranteed to meet specifi ed

performance from 0°C to 85°C and are designed, characterized and

expected to meet these extended temperature limits, but are not tested

at –40°C and 85°C.

Note 6: Guaranteed by long term current density limitations.

Note 7: Total input current is equal to this specifi cation plus 1.002 • I

BAT

where I

BAT

is the charge current.

Note 8: Accuracy of programmed current may degrade for currents greater

than 1.5A.

Note 9: Current limit guaranteed by design and/or correlation to static test.

Slope compensation reduces current limit at high duty cycle.

Page 5

LTC4089/LTC4089-5

5

40895fb

TIME (MIN)

0

V

BAT

, V

OUT

, V

CHRGB

(V)

I

BAT

(mA)

2

3

200

40895 G03

1

0

50

100

150

5

4

600

900

300

0

1500

1200

V

BAT

V

OUT

V

CHRGB

I

BAT

1250mAh

CELL

HVIN = 12V

R

PROG

= 50k

C/10

TERMINATION

I

BAT

(mA)

0

4.00

V

FLOAT

(V)

4.05

4.10

4.15

4.20

4.25

4.30

200 400 600 800

40895 G01

1000

R

PROG

= 34k

TEMPERATURE (°C)

–50

V

FLOAT

(V)

4.195

4.200

4.205

25

75

40895 G02

4.190

4.185

4.180

–25 0 50

4.210

4.215

4.220

100

VIN = 5V

I

BAT

= 2mA

V

BAT

(V)

0

0

I

BAT

(mA)

100

300

400

500

1

2

2.5 4.5

40895 G04

200

0.5 1.5

3

3.5

4

600

VIN = 5V

V

OUT

= NO LOAD

R

PROG

= 100k

R

CLPROG

= 2k

HPWR = 5V

HPWR = 0V

TEMPERATURE (°C)

–50

I

BAT

(mA)

400

500

600

25 75

40895 G05

300

200

–25 0

50 100 125

100

0

VIN = 5V

V

BAT

= 3.5V

θ

JA

= 50°C/W

V

FWD

(mV)

0

0

I

OUT

(mA)

100

300

400

500

1000

700

50

100

40895 G06

200

800

900

600

150

200

V

BAT

= 3.7V

V

IN

= 0V

–50°C

0°C

50°C

100°C

0

3000

4000

5000

80

4085 G17

2000

1000

2500

3500

4500

1500

500

0

20

40

60

100

V

FWD

(mV)

I

OUT

(mA)

V

BAT

= 3.7V

V

IN

= 0V

Si2333 PFET

–50°C

0°C

50°C

100°C

I

OUT

(A)

0

EFFICIENCY (%)

80

90

100

0.8

40895 G08

70

60

75

85

95

65

55

50

0.2

0.4

0.6

1.0

FIGURE 10 SCHEMATIC

V

BAT

= 4.21V (I

BAT

= 0)

HVIN = 8V

HVIN = 12V

HVIN = 36V

HVIN = 24V

I

OUT

(A)

0

EFFICIENCY (%)

80

90

100

0.8

40895 G09

70

60

75

85

95

65

55

50

0.2

0.4

0.6

1.0

FIGURE 10 SCHEMATIC

V

BAT

= 4.21V (I

BAT

= 0)

HVIN = 8V

HVIN = 12V

HVIN = 36V

HVIN = 24V

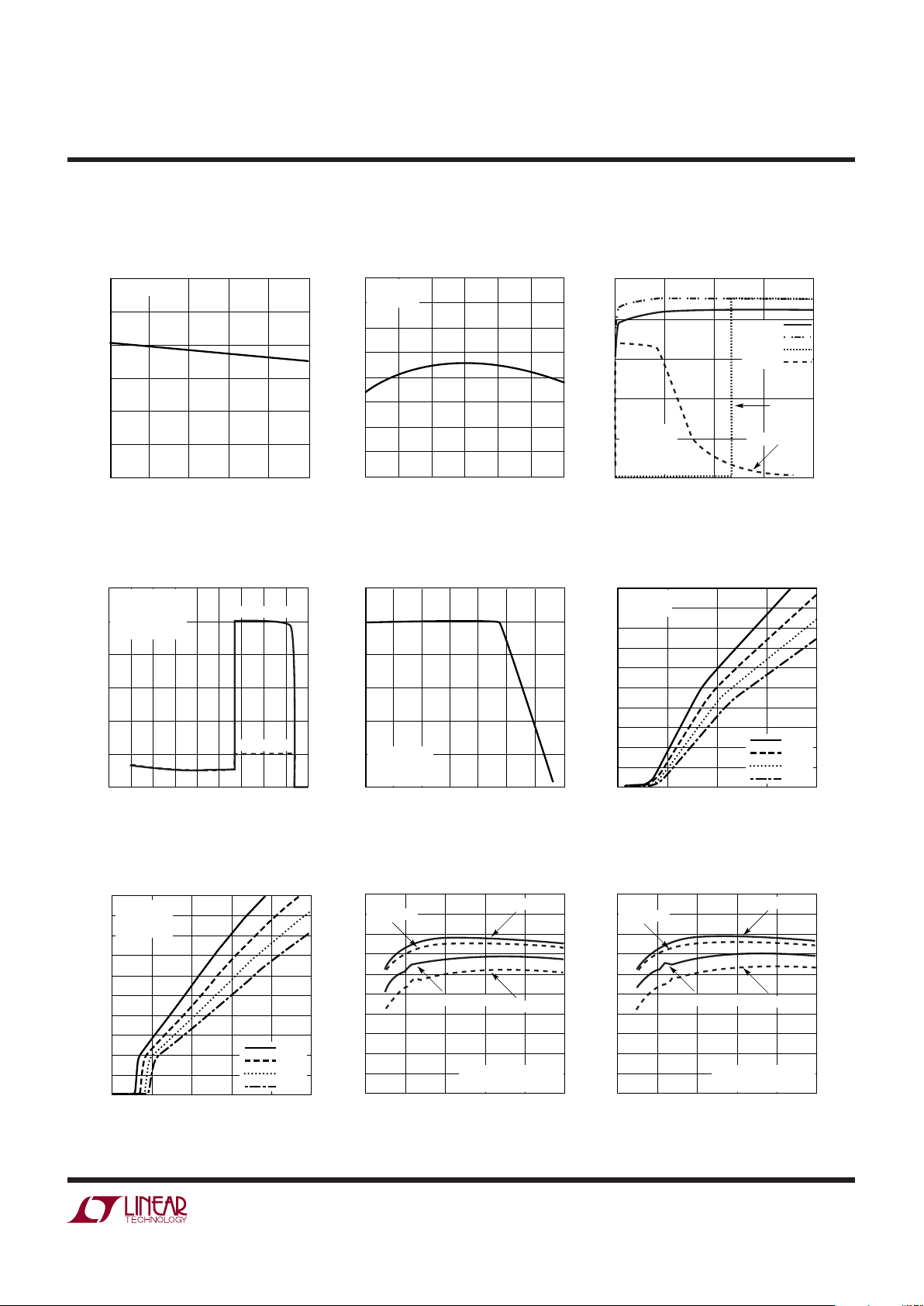

TYPICAL PERFORMANCE CHARACTERISTICS

V

FLOAT

Load Regulation

Battery Regulation (Float)

Voltage vs Temperature

Battery Current and Voltage vs

Time (LTC4089)

Charging from USB, I

BAT

vs V

BAT

Charge Current vs Temperature

(Thermal Regulation)

Ideal Diode Current vs Forward

Voltage and Temperature (No

External Device)

Ideal Diode Current vs Forward

Voltage and Temperature with

External Device

LTC4089 High Voltage Regulator

Effi ciency vs Output Load

LTC4089-5 High Voltage

Regulator Effi ciency vs Output

Load

T

A

= 25°C, unless otherwise specifi ed.

Page 6

LTC4089/LTC4089-5

6

40895fb

VIN (V)

5

1.6

1.5

1.4

1.3

1.2

1.1

1.0

0.9

20 30

40895 G10

10 15

25 35

I

OUT

(A)

MINIMUM

TYPICAL

VIN (V)

5

1.8

1.6

1.5

1.4

1.3

1.2

1.1

1.0

0.9

20 30

40895 G11

10 15

25 35

I

OUT

(A)

MINIMUM

TYPICAL

SWITCH CURRENT (A)

0

V

CE(SW)

(mV)

150

450

500

550

0.4

0.8

1.0

40895 G12

50

350

250

100

400

0

300

200

0.2

0.6

1.4

1.2

1.6

1.8

TA = 25°C

TA = 85°C

TA = –40°C

TEMPERATURE (°C)

FREQUENCY (kHz)

720

760

800

125

40895 G13

680

640

700

740

780

660

620

600

–25–50

250

75 100 150

50

FEEDBACK VOLTAGE (mV)

0

SWITCHING FREQUENCY (kHz)

400

600

800

40895 G14

200

0

200

400

600

100

300

500

700

800

300

500

100

700

SHDN PIN VOLTAGE (V)

0

0

SWITCH CURRENT LIMIT (A)

0.2

0.6

0.8

1.0

2.0

1.4

0.50 1 1.25

40895 G15

0.4

1.6

1.8

1.2

0.25 0.75 1.50 1.75 2

DUTY CYCLE (%)

0

CURRENT LIMIT (A)

1.6

1.8

2.0

80

40895 G16

1.4

1.2

1.5

1.7

1.9

1.3

1.1

1.0

2010

4030

60 70 90

50

100

TA = –40°C

T

A

= –5°C

T

A

= 25°C

T

A

= 90°C

LOAD CURRENT (mA)

1

5.8

INPUT VOLTAGE (V)

6.0

6.2

6.4

6.6

10 100 1000

40895 G17

5.6

5.4

5.2

5.0

6.8

7.0

TO START

TO RUN

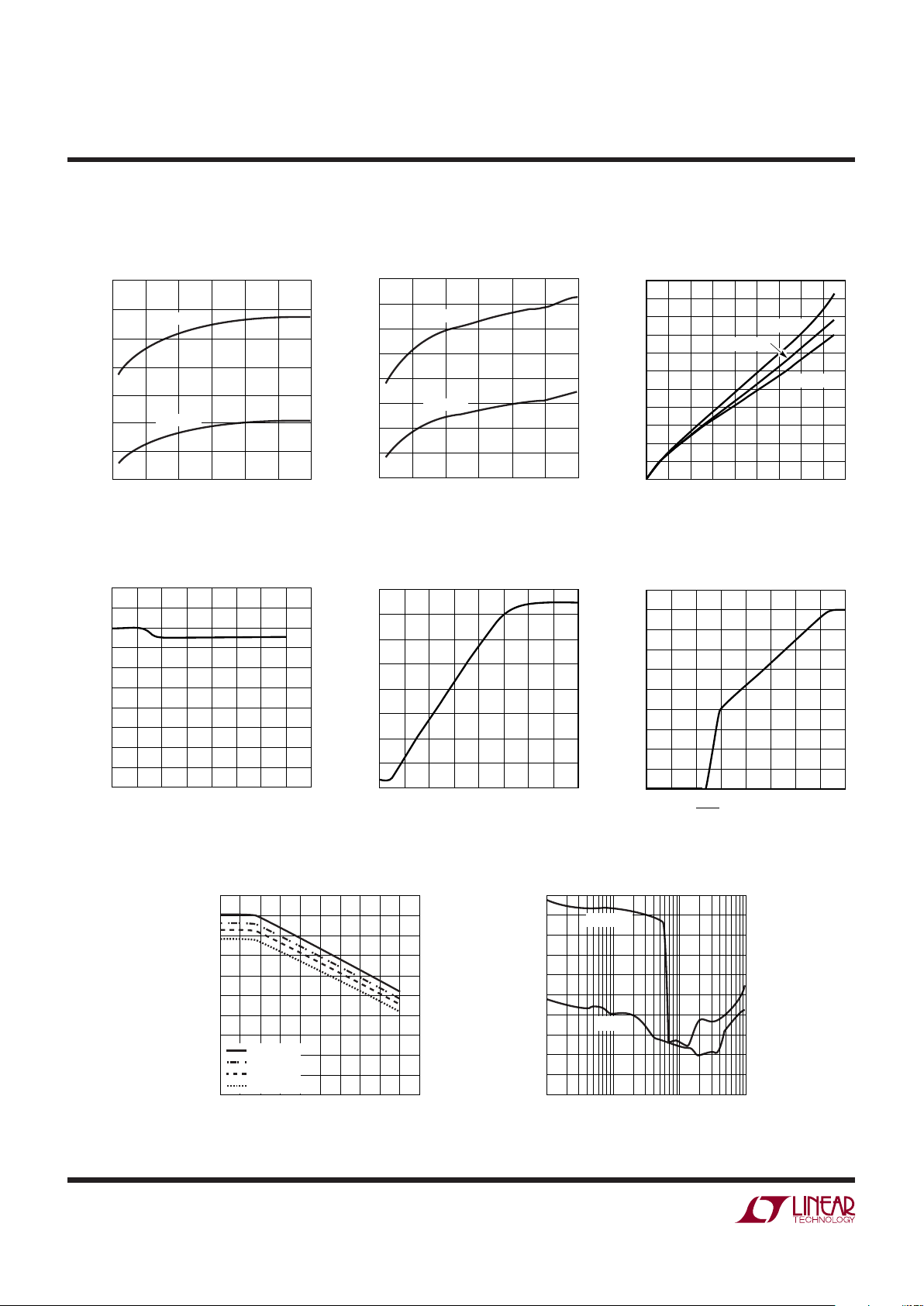

TYPICAL PERFORMANCE CHARACTERISTICS

High Voltage Regulator

Maximum Load Current, L = 10µH

High Voltage Regulator

Maximum Load Current, L = 33µH

High Voltage Regulator

Switch Voltage Drop

High Voltage Regulator

Switch Frequency

High Voltage Regulator

Frequency Foldback

High Voltage Regulator

Soft-Start

High Voltage Switch Current Limit

High Voltage Regulator

Typical Minimum Input Voltage

T

A

= 25°C, unless otherwise specifi ed.

Page 7

LTC4089/LTC4089-5

7

40895fb

1ms/DIV

V

IN

5V/DIV

V

OUT

5V/DIV

I

IN

0.5A/DIV

I

BAT

0.5A/DIV

40895 G18

V

BAT

= 3.85V

I

OUT

= 100mA

1ms/DIV

V

IN

5V/DIV

V

OUT

5V/DIV

I

IN

0.5A/DIV

I

BAT

0.5A/DIV

40895 G19

V

BAT

= 3.85V

I

OUT

= 100mA

100µs/DIV

HPWR

5V/DIV

I

IN

0.5A/DIV

I

BAT

0.5A/DIV

40895 G20

V

BAT

= 3.85V

I

OUT

= 50mA

1ms/DIV

WALL

5V/DIV

V

OUT

5V/DIV

I

WALL

0.5A/DIV

I

BAT

0.5A/DIV

40895 G21

V

BAT

= 3.85V

I

OUT

= 100mA

R

PROG

= 100k

1ms/DIV

WALL

5V/DIV

V

OUT

5V/DIV

I

WALL

0.5A/DIV

I

BAT

0.5A/DIV

40895 G22

V

BAT

= 3.85V

I

OUT

= 100mA

R

PROG

= 100k

100µs/DIV

SUSP

5V/DIV

V

OUT

5V/DIV

I

IN

0.5A/DIV

I

BAT

0.5A/DIV

40895 G23

V

BAT

= 3.85V

I

OUT

= 50mA

20µS/DIV

H

VOUT

50mV/DIV

I

OUT

0.5A/DIV

40895 G24

20µS/DIV

H

VOUT

50mV/DIV

I

L

0.5A/DIV

40895 G25

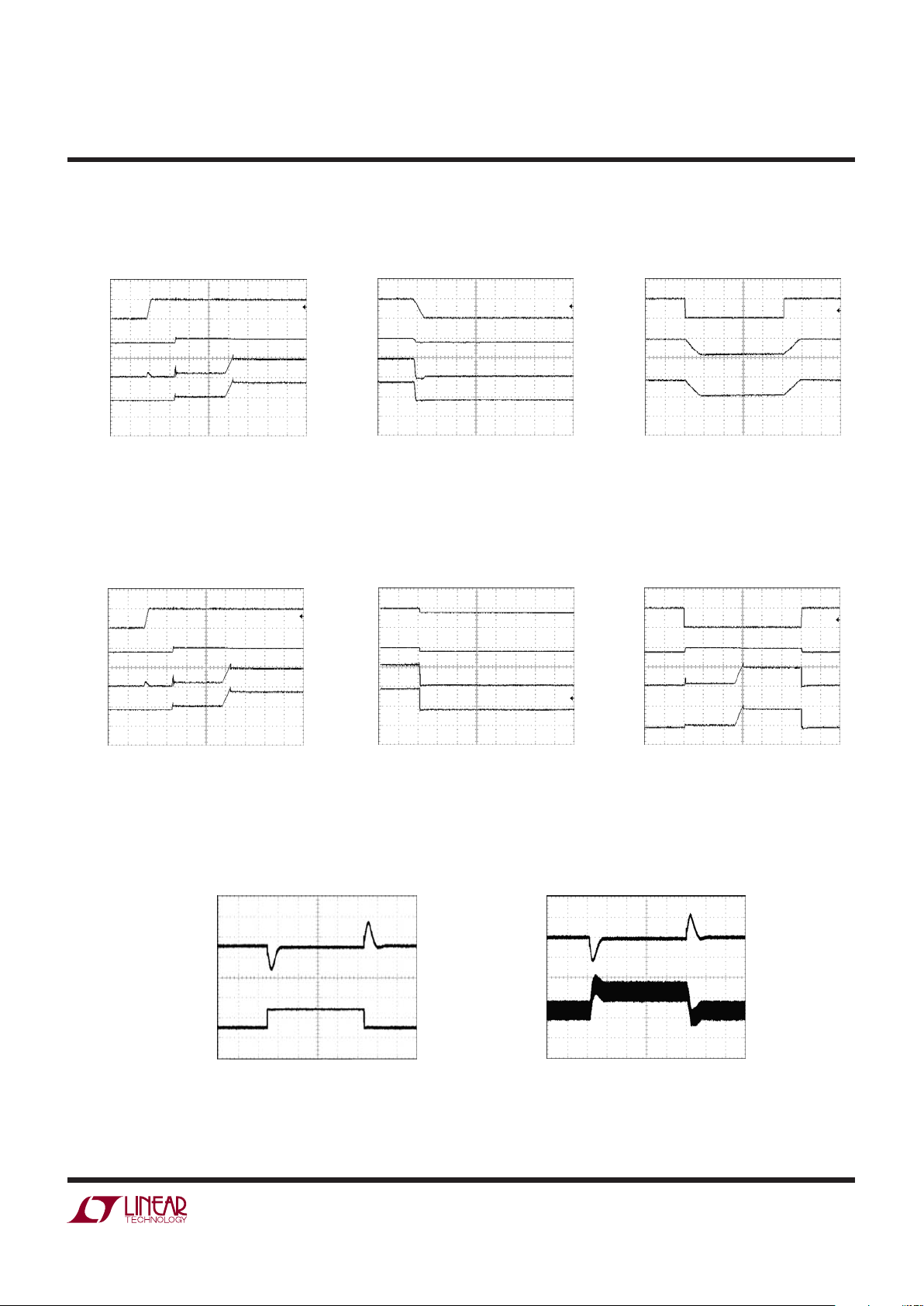

Input Connect Waveforms

TYPICAL PERFORMANCE CHARACTERISTICS

Input Disconnect Waveforms Response to HPWR

Wall Connect Waveforms

Wall Disconnect Waveforms Response to Suspend

High Voltage Regulator Load

Transient

High Voltage Regulator Load

Transient

T

A

= 25°C, unless otherwise specifi ed.

Page 8

LTC4089/LTC4089-5

8

40895fb

PI FU CTIO S

UUU

GND (Pins 1, 2): Ground. Tie the GND pin to a local ground

plane below the LTC4089 and the circuit components.

HVOUT (Pins 3, 18): Voltage Output of the High Voltage

Regulator. When suffi cient voltage is present at HVOUT,

the low voltage power path from IN to OUT will be disconnected and the HVPR pin will be pulled low to indicate

that a high voltage wall adapter has been detected. The

LTC4089 high voltage regulator will maintain just enough

differential voltage between HVOUT and BAT to keep the

battery charger MOSFET out of dropout (typically 300mV

from OUT to BAT). The LTC4089-5 high voltage regulator will provide a fi xed 5V output to the battery charger

MOSFET. HVOUT should be bypassed with at least 10µF

to GND. Connect pins 3 and 18 with a resistance no

greater than 1

.

V

C

(Pin 4): Leave the VC pin fl oating or bypass to ground

with a 10pF capacitor. This optional 10pF capacitor reduces

HVOUT ripple in discontinuous mode.

NTC (Pin 5): Input to the NTC Thermistor Monitoring

Circuits. Under normal operation, tie a thermistor from

the NTC pin to ground and a resistor of equal value from

NTC to VNTC. When the voltage on this pin is above 0.74

• V

VNTC

(Cold, 0°C) or below 0.29 • V

VNTC

(Hot, 50°C)

the timer is suspended but not cleared, the charging is

disabled and the CHRG pin remains in its former state.

When the voltage on NTC comes back between 0.74 •

V

VNTC

and 0.29 • V

VNTC

, the timer continues where it

left off and charging is re-enabled if the battery voltage

is below the recharge threshold. There is approximately

3°C of temperature hysteresis associated with each of the

input comparators.

Connect the NTC pin to ground to disable this feature. This

will disable all of the LTC4089 NTC functions.

VNTC (Pin 6): Output Bias Voltage for NTC. A resistor from

this pin to the NTC pin will bias the NTC thermistor.

HVPR (Pin 7): High Voltage Present Output. Active low

open drain output pin. A low on this pin indicates that the

high voltage regulator has suffi cient voltage to charge the

battery. This feature is disabled if no power is present on

HVIN, IN or BAT (i.e., below UVLO thresholds).

CHRG (Pin 8): Open-Drain Charge Status Output. When the

battery is being charged, the CHRG pin is pulled low by an

internal N-channel MOSFET. When the timer runs out or

the charge current drops below 10% of the programmed

charge current or the input supply is removed, the CHRG

pin is forced to a high impedance state.

PROG (Pin 9): Charge Current Program. Connecting a

resistor, R

PROG

, to ground programs the battery charge

current. The battery charge current is programmed

as follows:

IA

V

R

CHG

PROG

(),=

50 000

GATE (Pin 10): External ideal diode gate pin. This pin can

be used to drive the gate of an optional external PFET connected between BAT (drain) and OUT (source). By doing

so, the impedance of the ideal diode between BAT and

OUT can be reduced. When not in use, this pin should be

left fl oating. It is important to maintain a high impedance

on this pin and minimize all leakage paths.

BAT (Pin 11): Connect to a single cell Li-Ion battery. This

pin is used as an output when charging the battery and as

an input when supplying power to OUT. When the OUT pin

potential drops below the BAT pin potential, an ideal diode

function connects BAT to OUT and prevents V

OUT

from

dropping more than 100mV below V

BAT

. A precision internal

resistor divider sets the fi nal fl oat (charging) potential on

this pin. The internal resistor divider is disconnected when

IN and HVIN are in undervoltage lockout.

IN (Pin 12): Input Supply. Connect to USB supply, V

BUS

.

Input current to this pin is limited to either 20% or 100%

of the current programmed by the CLPROG pin as determined by the state of the HPWR pin. Charge current

(to the BAT pin) supplied through the input is set to the

current programmed by the PROG pin but will be limited

by the input current limit if charge current is set greater

than the input current limit.

Page 9

LTC4089/LTC4089-5

9

40895fb

PI FU CTIO S

UUU

OUT (Pin 13): Voltage Output. This pin is used to provide

controlled power to a USB device from either USB V

BUS

(IN), an external high voltage supply (HVIN), or the battery

(BAT) when no other supply is present. The high voltage

supply is prioritized over the USB V

BUS

input. OUT should

be bypassed with at least 4.7µF to GND.

CLPROG (Pin 14): Current Limit Program and Input Current Monitor. Connecting a resistor, R

CLPROG

, to ground

programs the input to output current limit. The current

limit is programmed as follows:

IA

V

R

CL

CLPROG

()=

1000

In USB applications, the resistor R

CLPROG

should be set

to no less than 2.1k. The voltage on the CLPROG pin is

always proportional to the current fl owing through the

IN to OUT power path. This current can be calculated

as follows:

IA

V

R

IN

CLPROG

CLPROG

() •= 1000

HPWR (Pin 15): High Power Select. This logic input is used

to control the input current limit. A voltage greater than

2.3V on the pin will set the input current limit to 100% of

the current programmed by the CLPROG pin. A voltage

less than 0.3V on the pin will set the input current limit to

20% of the current programmed by the CLPROG pin. A

2µA pull-down current is internally connected to this pin

to ensure it is low at power up when the pin is not being

driven externally.

SUSP (Pin 16): Suspend Mode Input. Pulling this pin

above 2.3V will disable the power path from IN to OUT.

The supply current from IN will be reduced to comply

with the USB specifi cation for suspend mode. Both the

ability to charge the battery from HVIN and the ideal diode

function (from BAT to OUT) will remain active. Suspend

mode will reset the charge timer if V

OUT

is less than V

BAT

while in suspend mode. If V

OUT

is kept greater than V

BAT

,

such as when the high voltage input is present, the charge

timer will not be reset when the part is put in suspend.

A 2µA pull-down current is internally applied to this pin

to ensure it is low at power-up when the pin is not being

driven externally.

TIMER (Pin 17): Timer Capacitor. Placing a capacitor,

C

TIMER

, to GND sets the timer period. The timer period is:

t hours

C R hours

µF k

TIMER

TIMER PROG

()

••

.•

=

3

0 1 100

Charge time is increased if charge current is reduced

due to undervoltage current limit, load current, thermal

regulation and current limit selection (HPWR).

Shorting the TIMER pin to GND disables the battery

charging functions.

SW (Pin 19): The SW pin is the output of the internal high

voltage power switch. Connect this pin to the inductor,

catch diode and boost capacitor.

BOOST (Pin 20): The BOOST pin is used to provide a

drive voltage, higher than the input voltage, to the internal

bipolar NPN power switch.

HVIN (Pin 21): The HVIN pin supplies current to the internal high voltage regulator and to the internal high voltage

power switch. The presence of a high voltage input takes

priority over the USB V

BUS

input (i.e., when a high voltage input supply is detected, the USB IN to OUT path is

disconnected). This pin must be locally bypassed.

HVEN (Pin 22): The HVEN pin is used to disable the high

voltage input path. Tie to ground to disable the high voltage

input or tie to at least 2.3V to enable the high voltage path.

If this feature is not used, tie to the HVIN pin. This pin can

also be used to soft-start the high voltage regulator; see

the Applications Information section.

EXPOSED PAD (Pin 23): Ground. The exposed package

pad is ground and must be soldered to the PC board for

proper functionality and for maximum heat transfer (use

several vias directly under the LTC4089).

Page 10

LTC4089/LTC4089-5

10

40895fb

BLOCK DIAGRA

W

–

+

SOFT-START

0.25V

SOFT-START2

–

+

–

+

–

+

–

+

15

TOO COLD

NTC

CURRENT LIMIT

TOO HOT

0.1V

NTC ENABLE

V

NTC

14

NTC

10k

100k

100k

–

+

13

HPWR

22

CLPROG

IN

23

PROG

CHG

1V

500mA/100mA

2µA

–

+

–

+

CURRENT CONTROL

OSCILLATOR

CHARGE CONTROL

CONTROL LOGIC

VOLTAGE DETECT

COUNTER

OSCILLATOR

TA

DIE

TEMP 105°C

I

LIM

2.8V

BATTERY

UVLO

4.1V

RECHARGE

UVLO

IN OUT BAT

I

CHG

BAT UV

RECHRG

HOLD

RESET

NTCERR

CLK

EOC

C/10

–

+

–

+

11

2µA

16

GND SUSP

2k

V

SET

IN

DRIVER

HVOUT

OUT

GATE

BATBAT

HVPR

21

TIMER

18

CHRG

STOP

4089 TA01

1V

CL

I

LIM

CNTL

ENABLE

–

+

EDA

19

D1

C3

L1

I

IN

1000

10

C4

R3

10pF

HVEN

HVIN

V

C

10

CC/CV REGULATOR

CHARGER

ENABLE

–

+

–

+

4.25V (RISING)

3.15V (FALLING)

–

+

21

21

21

1.8V

RSQ

10

C1

ENABLE

10

–

+

+

350mV

(LTC4089)

75mV (RISING)

25mV (FALLING)

GM

BOOST

Q1

D2

SW

25mV

25mV

IDEAL

DIODE

Q

DRIVER

+

–

+

–

+–+

–

PART NUMBER

LTC4089

LTC4089-5

V

SET

3.6V

5V

Page 11

LTC4089/LTC4089-5

11

40895fb

OPERATIO

U

The LTC4089/LTC4089-5 is a complete PowerPath™

controller for battery powered USB applications. The

LTC4089/LTC4089-5 is designed to receive power from a

low voltage source (e.g., USB or 5V wall adapter), a high

voltage source (e.g., FireWire/IEEE1394, automotive battery, 12V wall adapter, etc.), and a single-cell Li-Ion battery.

It can then deliver power to an application connected to the

OUT pin and a battery connected to the BAT pin (assuming

that an external supply other than the battery is present). Power supplies that have limited current resources

(such as USB V

BUS

supplies) should be connected to the

IN pin which has a programmable current limit. Battery

charge current will be adjusted to ensure that the sum of

the charge current and load current does not exceed the

programmed input current limit (see Figure 1).

An ideal diode function provides power from the battery

when output / load current exceeds the input current limit or

when input power is removed. Powering the load through

the ideal diode instead of connecting the load directly to

the battery allows a fully charged battery to remain fully

charged until external power is removed. Once external

power is removed the output drops until the ideal diode is

forward biased. The forward biased ideal diode will then

provide the output power to the load from the battery.

The LTC4089/LTC4089-5 also includes a high voltage

switching regulator which has the ability to receive power

from a high voltage input. This input takes priority over the

USB V

BUS

input (i.e., if both HVIN and IN are present, load

current and charge current will be delivered via the high

voltage path). When enabled, the high voltage regulator

regulates the HVOUT voltage using a 750kHz constant

frequency, current mode regulator. An external PFET between HVOUT (drain) and OUT (source) is turned on via

the HVPR pin allowing OUT to charge the battery and/or

supply power to the application. The LTC4089 maintains

approximately 300mV between the OUT pin and the BAT

pin, while the LTC4089-5 provides a fi xed 5V output.

Input Current Limit

Whenever the input power path is enabled (i.e., SUSP =

0V and HVIN = 0V) and power is available at IN, power

is delivered to OUT. The current limit and charger control

circuits of the LTC4089/LTC4089-5 are designed to limit

(Refer to Block Diagram)

HVOUT

OUT

GATE

BATBAT

OUT

HVPR

4089 F01

–

+

EDA

19

D1

L1

CC/CV REGULATOR

CHARGER

HIGH VOLTAGE

BUCK REGULATOR

USB CURRENT LIMIT

ENABLE

–

+

–

+

21

21

21

C1

HVIN

IN

Q1

SW

25mV

25mV

IDEAL

DIODE

4.25V (RISING)

3.15V (FALLING)

75mV (RISING)

25mV (FALLING)

+

LOAD

LI-ION

+

–

+

–

+

–

Figure 1. Simplifi ed PowerPath Block Diagram

PowerPath is a registered trademark of Linear Technology Corporation.

Page 12

LTC4089/LTC4089-5

12

40895fb

I

IN

I

LOAD(mA)

0

300

400

500

400 500300

4089 G01

200

100

100 200

0

CURRENT (mA)

I

LOAD

I

BAT

(CHARGING)

I

BAT

(IDEAL DIODE)

I

IN

I

LOAD(mA)

0

60

80

100

80 10060

4089 G02

40

20

20 40

0

CURRENT (mA)

I

LOAD

I

BAT

(CHARGING)

I

BAT

(IDEAL DIODE)

I

LOAD (mA)

0

300

400

500

400 500300

4089 G03

200

100

100 200

0

CURRENT (mA)

I

IN

I

LOAD

I

BAT

= I

CHG

I

BAT

= I

CL

= I

OUT

I

BAT

(CHARGING)

I

BAT

(IDEAL DIODE)

input current as well as control battery charge current

as a function of I

OUT

. The input current limit, ICL, can be

programmed using the following formula:

I

R

V

V

R

CL

CLPROG

CLPROG

CLPROG

=

⎡

⎣

⎢

⎤

⎦

⎥

=

1000 1000

•

where V

CLPROG

is the CLPROG pin voltage (typically 1V)

and R

CLPROG

is the total resistance from the CLPROG pin

to ground. For best stability over temperature and time,

1% metal fi lm resistors are recommended.

The programmed battery charge current, I

CHG

, is

defi ned as:

I

R

V

V

R

CHG

PROG

PROG

PROG

=

⎡

⎣

⎢

⎤

⎦

⎥

=

50 000 50 000,

•

,

Input current, IIN, is equal to the sum of the BAT pin

output current and the OUT pin output current. V

CLPROG

will typically servo to 1V, however, if I

OUT

+ I

BAT

< ICL

then V

CLPROG

will track the input current according to the

following equation:

II I

V

R

IN OUT BAT

CLPROG

CLPROG

=+= • 1000

The current limiting circuitry in the LTC4089/LTC4089-5

can and should be confi gured to limit current to 500mA

for USB applications (selectable using the HPWR pin and

programmed using the CLPROG pin).

OPERATIO

U

Figure 2. Input and Battery Currents as a Function of Load Current

The LTC4089/LTC4089-5 reduces battery charge current

such that the sum of the battery charge current and the

load current does not exceed the programmed input current

limit (one-fi fth of the programmed input current limit when

HPWR is low, see Figure 2). The battery charge current

goes to zero when load current exceeds the programmed

input current limit (one-fi fth of the limit when HPWR is

low). Even if the battery charge current is set to exceed

the allowable USB current, the USB specifi cation will not

be violated. The battery charger will reduce its current as

needed to ensure that the USB specifi cation is not exceeded.

If the load current is greater than the current limit, the

output voltage will drop to just under the battery voltage

where the ideal diode circuit will take over and the excess

load current will be drawn from the battery.

In USB applications, the minimum value for R

CLPROG

should be 2.1k. This will prevent the input current from

exceeding 500mA due to LTC4089/LTC4089-5 tolerances

and quiescent currents. A 2.1k CLPROG resistor will give a

typical current limit of 476mA in high power mode (HPWR

= 1) or 95mA in low power mode (HPWR = 0).

When SUSP is driven to a logic high, the input power

path is disabled and the ideal diode from BAT to OUT will

supply power to the application.

(a) High Power Mode/Full Charge

R

PROG

= 100k and R

CLPROG

= 2k

(b) Low Power Mode/Full Charge

R

PROG

= 100k and R

CLPROG

= 2k

(c) High Power Mode with

I

CL

= 500mA and I

CHG

= 250mA

R

PROG

= 200k and R

CLPROG

= 2k

Page 13

LTC4089/LTC4089-5

13

40895fb

High Voltage Step Down Regulator

The power delivered from HVIN to HVOUT is controlled

by a 750kHz constant frequency, current mode step down

regulator. An external P-channel MOSFET directs this

power to OUT and prevents reverse conduction from OUT

to HVOUT (and ultimately HVIN).

A 750kHz oscillator enables an RS fl ip-fl op, turning on the

internal 1.95A power switch Q1. An amplifi er and comparator monitor the current fl owing between the HVIN and SW

pins, turning the switch off when this current reaches a

level determined by the voltage at V

C

. An error amplifi er

servos the V

C

node to maintain approximately 300mV

between OUT and BAT (LTC4089). By keeping the voltage

across the battery charger low, effi ciency is optimized

because power lost to the battery charger is minimized

and power available to the external load is maximized. If

the BAT pin voltage is less than approximately 3.3V, then

the error amplifi er will servo the V

C

node to provide a

constant HVOUT output voltage of about 3.6V. An active

clamp on the V

C

node provides current limit. The VC node

is also clamped to the voltage on the HVEN pin; soft-start

is implemented by a voltage ramp at the HVEN pin using

an external resistor and capacitor.

An internal regulator provides power to the control circuitry.

This regulator includes an undervoltage lockout to prevent

switching when HVIN is less than about 4.7V. The HVEN

pin is used to disable the high voltage regulator. HVIN

input current is reduced to less than 2µA and the external

P-channel MOSFET disconnects HVOUT from OUT when

the high voltage regulator is disabled.

The switch driver operates from either the high voltage

input or from the BOOST pin. An external capacitor and

diode are used to generate a voltage at the BOOST pin that

is higher than the input supply. This allows the driver to

fully saturate the internal bipolar NPN power switch for

effi cient operation.

When HVOUT is below 3.95V the operating frequency

is reduced. This frequency foldback helps to control the

regulator output current during start-up and overload.

Ideal Diode from BAT to OUT

The LTC4089/LTC4089-5 has an internal ideal diode as

well as a controller for an optional external ideal diode. If

a battery is the only power supply available, or if the load

current exceeds the programmed input current limit, then

the battery will automatically deliver power to the load via

an ideal diode circuit between the BAT and OUT pins. The

ideal diode circuit (along with the recommended 4.7µF

capacitor on the OUT pin) allows the LTC4089/LTC4089-5

to handle large transient loads and wall adapter or USB

V

BUS

connect/disconnect scenarios without the need for

large bulk capacitors. The ideal diode responds within

a few microseconds and prevents the OUT pin voltage

from dropping signifi cantly below the BAT pin voltage.

A comparison of the I-V curve of the ideal diode and a

Schottky diode can be seen in Figure 3.

If the input current increases beyond the programmed

input current limit additional current will be drawn from the

battery via the internal ideal diode. Furthermore, if power

to IN (USB V

BUS

) or HVIN (high voltage input) is removed,

then all of the application power will be provided by the

battery via the ideal diode. A 4.7µF capacitor at OUT is

suffi cient to keep a transition from input power to battery

power from causing signifi cant output voltage droop. The

ideal diode consists of a precision amplifi er that enables a

large P-channel MOSFET transistor whenever the voltage

at OUT is approximately 20mV (V

FWD

) below the voltage

at BAT. The resistance of the internal ideal diode is approximately 200m

. If this is suffi cient for the application

OPERATIO

U

Figure 3. LTC4089/LTC4089-5 Versus

Schottky Diode Forward Voltage Drop

CONSTANT

I

0N

CONSTANT

R

0N

CONSTANT

V

0N

V

FWD

I

MAX

FORWARD VOLTAGE (V)

4089 F03

I

FWD

0

CURRENT (A)

SLOPE: 1/R

DIO(ON)

SLOPE: 1/R

FWD

SCHOTTKY

DIODE

LTC4089

Page 14

LTC4089/LTC4089-5

14

40895fb

then no external components are necessary. However,

if more conductance is needed, an external P-channel

MOSFET can be added from BAT to OUT. The GATE pin

of the LTC4089/LTC4089-5 drives the gate of the PFET for

automatic ideal diode control. The source of the external

MOSFET should be connected to OUT and the drain should

be connected to BAT. In order to help protect the external

MOSFET in over-current situations, it should be placed in

close thermal contact to the LTC4089/LTC4089-5.

Battery Charger

The battery charger circuits of the LTC4089/LTC4089-5

are designed for charging single cell lithium-ion batteries. Featuring an internal P-channel power MOSFET, the

charger uses a constant-current/constant-voltage charge

algorithm with programmable current and a programmable timer for charge termination. Charge current can be

programmed up to 1.2A. The fi nal fl oat voltage accuracy

is ±0.8% typical. No blocking diode or sense resistor is

required when powering either the IN or the HVIN pins.

The CHRG open-drain status output provides information

regarding the charging status of the LTC4089/LTC4089-5

at all times. An NTC input provides the option of charge

qualifi cation using battery temperature.

An internal thermal limit reduces the programmed charge

current if the die temperature attempts to rise above a

preset value of approximately 105°C. This feature protects

the LTC4089/LTC4089-5 from excessive temperature, and

allows the user to push the limits of the power handling

capability of a given circuit board without risk of damaging the LTC4089/LTC4089-5. Another benefi t of the

LTC4089/LTC4089-5 thermal limit is that charge current

can be set according to typical, not worst-case, ambient

temperatures for a given application with the assurance

that the charger will automatically reduce the current in

worst-case conditions.

The charge cycle begins when the voltage at the OUT

pin rises above the battery voltage and the battery voltage is below the recharge threshold. No charge current

actually fl ows until the OUT voltage is 100mV above

the BAT voltage. At the beginning of the charge cycle, if

the battery voltage is below 2.8V, the charger goes into

trickle charge mode to bring the cell voltage up to a safe

level for charging. The charger goes into the fast charge

constant-current mode once the voltage on the BAT pin

rises above 2.8V. In constant current mode, the charge

current is set by R

PROG

. When the battery approaches the

fi nal fl oat voltage, the charge current begins to decrease

as the LTC4089/LTC4089-5 switches to constant-voltage

mode. When the charge current drops below 10% of the

programmed charge current while in constant-voltage

mode the CHRG pin assumes a high impedance state.

An external capacitor on the TIMER pin sets the total

minimum charge time. When this time elapses the

charge cycle terminates and the CHRG pin assumes a

high impedance state, if it has not already done so. While

charging in constant current mode, if the charge current

is decreased by thermal regulation or in order to maintain

the programmed input current limit the charge time is

automatically increased. In other words, the charge time is

extended inversely proportional to the actual charge current

delivered to the battery. For Li-Ion and similar batteries that

require accurate fi nal fl oat potential, the internal bandgap

reference, voltage amplifi er and the resistor divider provide

regulation with ±0.8% accuracy.

Trickle Charge and Defective Battery Detection

At the beginning of a charge cycle, if the battery voltage is low (below 2.8V) the charger goes into trickle

charge reducing the charge current to 10% of the fullscale current. If the low battery voltage persists for one

quarter of the total charge time, the battery is assumed

to be defective, the charge cycle is terminated and the

CHRG pin output assumes a high impedance state. If

for any reason the battery voltage rises above ~2.8V the

charge cycle will be restarted. To restart the charge cycle

(i.e., when the dead battery is replaced with a discharged

battery), simply remove the input voltage and reapply it

or cycle the TIMER pin to 0V.

Programming Charge Current

The formula for the battery charge current is:

II

V

R

CHG PROG

PROG

PROG

==•, •,50 000 50 000

where V

PROG

is the PROG pin voltage and R

PROG

is the total

resistance from the PROG pin to ground. Keep in mind that

OPERATIO

U

Page 15

LTC4089/LTC4089-5

15

40895fb

when the LTC4089/LTC4089-5 is powered from the IN pin,

the programmed input current limit takes precedent over

the charge current. In such a scenario, the charge current

cannot exceed the programmed input current limit.

For example, if typical 500mA charge current is required,

calculate:

R

V

mA

k

PROG

==

1

500

50 000 100•,

For best stability over temperature and time, 1% metal fi lm

resistors are recommended. Under trickle charge conditions,

this current is reduced to 10% of the full-scale value.

The Charge Timer

The programmable charge timer is used to terminate the

charge cycle. The timer duration is programmed by an

external capacitor at the TIMER pin. The charge time is

typically:

t hours

C R hours

µF k

TIMER

TIMER PROG

()

••

.•

=

3

0 1 100

The timer starts when an input voltage greater than the

undervoltage lockout threshold level is applied or when

leaving shutdown and the voltage on the battery is less than

the recharge threshold. At power-up or exiting shutdown

with the battery voltage less than the recharge threshold

the charge time is a full cycle. If the battery is greater than

the recharge threshold the timer will not start and charging

is prevented. If after power-up the battery voltage drops

below the recharge threshold, or if after a charge cycle

the battery voltage is still below the recharge threshold,

the charge time is set to one-half of a full cycle.

The LTC4089/LTC4089-5 has a feature that extends charge

time automatically. Charge time is extended if the charge

current in constant current mode is reduced due to load

current or thermal regulation. This change in charge time

is inversely proportional to the change in charge current.

As the LTC4089/LTC4089-5 approaches constant voltage

mode the charge current begins to drop. This change in

charge current is due to normal charging operation and

does not affect the timer duration.

Consider, for example, a USB charge condition where

R

CLPROG

= 2k, R

PROG

= 100k and C

TIMER

= 0.1µF. This

corresponds to a three hour charge cycle. However, if the

HPWR input is set to a logic low, then the input current

limit will be reduced from 500mA to 100mA. With no additional system load, this means the charge current will

be reduced to 100mA. Therefore, the termination timer

will automatically slow down by a factor of fi ve until the

charger reaches constant voltage mode (i.e. V

BAT

= 4.2V)

or HPWR is returned to a logic high. The charge cycle is

automatically lengthened to account for the reduced charge

current. The exact time of the charge cycle will depend on

how long the charger remains in constant-current mode

and/or how long the HPWR pin remains a logic low.

Once a time-out occurs and the voltage on the battery is

greater than the recharge threshold, the charge current

stops, and the CHRG output assumes a high impedance

state if it has not already done so.

Connecting the TIMER pin to ground disables the battery

charger.

CHRG Status Output Pin

When the charge cycle starts, the CHRG pin is pulled to

ground by an internal N-channel MOSFET capable of driving an LED. When the charge current drops below 10%

of the programmed full charge current while in constant

voltage mode, the pin assumes a high impedance state,

but charge current continues to fl ow until the charge

time elapses. If this state is not reached before the end

of the programmable charge time, the pin will assume a

high impedance state when a time-out occurs. The CHRG

current detection threshold can be calculated by the following equation:

I

V

R

V

R

DETECT

PROG PROG

==

01

50 000

5000.

•,

For example, if the full charge current is programmed

to 500mA with a 100k PROG resistor the CHRG pin will

change state at a battery charge current of 50mA.

Note: The end-of-charge (EOC) comparator that monitors the charge current latches its decision. Therefore,

the fi rst time the charge current drops below 10% of the

programmed full charge current while in constant voltage mode, it will toggle CHRG to a high impedance state.

OPERATIO

U

Page 16

LTC4089/LTC4089-5

16

40895fb

If, for some reason the charge current rises back above

the threshold, the CHRG pin will not resume the strong

pull-down state. The EOC latch can be reset by a recharge

cycle (i.e., V

BAT

drops below the recharge threshold) or

toggling the input power to the part.

NTC Thermistor—Battery Temperature Charge

Qualifi cation

The battery temperature is measured by placing a negative temperature coeffi cient (NTC) thermistor close to the

battery pack. The NTC circuitry is shown in Figure 4.

To use this feature, connect the NTC thermistor (R

NTC

)

between the NTC pin and ground and a resistor (R

NOM

) from

the NTC pin to VNTC. R

NOM

should be a 1% resistor with

a value equal to the value of the chosen NTC thermistor at

25°C (this value is 10k for a Vishay NTHS0603N02N1002J

thermistor). The LTC4089/LTC4089-5 goes into hold mode

when the resistance (R

HOT

) of the NTC thermistor drops

to 0.41 times the value of R

NOM

, or approximately 4.1k,

which should be at 50°C. The hold mode freezes the timer

and stops the charge cycle until the thermistor indicates a

return to a valid temperature. As the temperature drops,

the resistance of the NTC thermistor rises. The LTC4089/

LTC4089-5 is designed to go into hold mode when the

value of the NTC thermistor increases to 2.82 times the

value of R

NOM

. This resistance is R

COLD

. For a Vishay

NTHS0603N02N1002J thermistor, this value is 28.2k

which corresponds to approximately 0°C. The hot and cold

comparators each have approximately 3°C of hysteresis

to prevent oscillation about the trip point. Grounding the

NTC pin will disable the NTC function.

Current Limit Undervoltage Lockout

An internal undervoltage lockout circuit monitors the

input voltage and disables the input current limit circuits

until V

IN

rises above the undervoltage lockout threshold.

The current limit UVLO circuit has a built-in hysteresis of

125mV. Furthermore, to protect against reverse current in

the power MOSFET, the current limit UVLO circuit disables

the current limit (i.e., forces the input power path to a high

impedance state) if V

OUT

exceeds VIN. If the current limit

UVLO comparator is tripped, the current limit circuits will

not come out of shutdown until V

OUT

falls 50mV below

the V

IN

voltage.

Charger Undervoltage Lockout

An internal undervoltage lockout circuit monitors the V

OUT

voltage and disables the battery charger circuits until

V

OUT

rises above the undervoltage lockout threshold. The

battery charger UVLO circuit has a built-in hysteresis of

125mV. Furthermore, to protect against reverse current

in the power MOSFET, the charger UVLO circuit keeps the

charger shut down if V

BAT

exceeds V

OUT

. If the charger

UVLO comparator is tripped, the charger circuits will

not come out of shutdown until V

OUT

exceeds V

BAT

by 50mV.

Suspend

The LTC4089/LTC4089-5 can be put in suspend mode by

forcing the SUSP pin greater than 2.3V. In suspend mode,

the ideal diode function from BAT to OUT is kept alive. If

power is applied to the HVIN pin, then charging will be

unaffected. Current drawn from the IN pin is reduced to

50µA. Suspend mode is intended to comply with the USB

power specifi cation mode of the same name.

OPERATIO

U

Figure 4. NTC Circuit

–

+

–

+

R

NOM

10k

R

NTC

10k

NTC

VNTC

6

0.1V

NTC_ENABLE

4089 F04

LTC4089

TOO_COLD

TOO_HOT

0.74 •

VNTC

0.29 • VNTC

–

+

5

Page 17

LTC4089/LTC4089-5

17

40895fb

USB and 5V Wall Adapter Power

Although the LTC4089/LTC4089-5 is designed to draw

power from a USB port, a higher power 5V wall adapter

can also be used to power the application and charge the

battery (higher voltage wall adapters can be connected

directly to HVIN). Figure 5 shows an example of combining

a 5V wall adapter and a USB power input. With its gate

grounded by 1k, P-channel MOSFET MP1 provides USB

power to the LTC4089/LTC4089-5 when 5V wall power is

not available. When 5V wall power is available, D1 both

supplies power to the LTC4089, pulls the gate of MN1 high

to increase the charge current (by increasing the input

current limit), and pulls the gate of MP1 high to disable it

and prevent conduction back to the USB port.

2k1k

MN1

2.87k

59k

IN

PROG

CLPROG

LTC4089

BAT

+

MP1

D1

I

CHG

Li-Ion

BATTERY

5V WALL

ADAPTER

850mA I

CHG

USB POWER

500mA I

CHG

4089 F05

Inductor Selection and Maximum Output Current

A good choice for the inductor value is L = 10µH. With this

value the maximum load current will be 1A. The RMS current

rating of the inductor must be greater than the maximum

load current and its saturation current should be about

30% higher. Note that the maximum load current

will be the programmed charge current plus the largest

expected application load current. For robust operation in

fault conditions, the saturation current should be ~2.3A. To

keep effi ciency high, the series resistance (DCR) should

be less than 0.1 . Table 1 lists several vendors and types

that are suitable.

Table 1: Inductor Vendors

VENDOR URL

PART

SERIES

INDUCTANCE

(µH)

SIZE

(mm)

Sumida www.sumida.com CDRH5D28 8.2, 10 6 6 3

CDRH6D38 10 7 7 4

TDK www.tdk.com SLF6028T 10 6 6 2.8

Toko www.toko.com D63LCB 10 6.3 6.3 3

Catch Diode

Depending on load current, a 1A to 2A Schottky diode is

recommended for the D1 catch diode. The diode must

have a reverse voltage rating equal to, or greater than,

the maximum input voltage. The ON Semiconductor

MBRM140 and the Diodes Inc. DFLS140/160/240 are

good choices.

High Voltage Regulator Capacitor Selection

Bypass the HVIN pin of the LTC4089/LTC4089-5 circuit

with a 1µF, or higher value ceramic capacitor of X7R or

X5R type. Y5V types have poor performance over temperature and applied voltage and should not be used. A 1µF

ceramic is adequate to bypass the high voltage input and

will easily handle the ripple current. However, if the input

power source has high impedance, or there is signifi cant

inductance due to long wires or cables, additional bulk

capacitance may be necessary. This can be provided with

a low performance electrolytic capacitor.

APPLICATIO S I FOR ATIO

WUU

U

Figure 5. USB or 5V Wall Adapter Power

Page 18

LTC4089/LTC4089-5

18

40895fb

The high voltage regulator output capacitor controls output

ripple, supplies transient load currents, and stabilizes the

regulator control loop. Ceramic capacitors have very low

equivalent series resistance (ESR) and provide the best

ripple performance. A good value is 10µF. Use X5R or

X7R types, and note that a ceramic capacitor biased with

V

HVOUT

will have less than its nominal capacitance. Table

2 lists several capacitor vendors.

Table 2: Capacitor Vendors

VENDOR PHONE URL

PART

SERIES

COM-

MENTS

Panasonic

(714) 373-7366

www.panasonic.com Ceramic,

Polymer,

Tantalum

EEF Series

Kemet

(864) 963-6300

www.kemet.com Ceramic,

Tantalum

T494,

T495

Sanyo

(408) 749-9714

www.sanyovideo.com Ceramic,

Polymer,

Tantalum

POSCAP

Murata

(404) 436-1300

www.murata.com Ceramic

AVX www.avxcorp.com Ceramic,

Tantalum

TPS

Series

Taiyo

Yuden

(864) 963-6300

www.taiyo-yuden.com Ceramic

BOOST Pin Considerations

Capacitor C3 and diode D2 (see Block Diagram) are used

to generate a boost voltage that is higher than the input

voltage. In most cases, a 0.1µF capacitor and fast-switching diode (such as the 1N4148 or 1N914) will work well.

The BOOST pin must be at least 2.2V above the SW pin

for proper operation.

High Voltage Regulator Soft-Start

The HVEN pin can be used to soft-start the high voltage

regulator and reduce the maximum input current during

start-up. A voltage ramp at the HVEN pin can be created

by driving the pin through an external RC fi lter (see Figure

6). By choosing a large RC time constant, the peak start-up

current will not overshoot the current that is required to

regulate the output. Choose the value of the resistor so that

it can supply 20µA when the HVEN pin reaches 2.3V.

RUN

15k

0.1µF

HVEN

GND

4089 F06

LTC4089

Alternate NTC Thermistors

The LTC4089/LTC4089-5 NTC trip points were designed

to work with thermistors whose resistance-temperature

characteristics follow Vishay Dale’s “R-T Curve 2.” The

Vishay NTHS0603N02N1002J is an example of such a

thermistor. However, Vishay Dale has many thermistor

products that follow the “R-T Curve 2” characteristic in a

variety of sizes. Furthermore, any thermistor whose ratio

of R

COLD

to R

HOT

is about 7.0 will also work (Vishay Dale

R-T Curve 2 shows a ratio of 2.815/0.4086 = 6.89).

Power conscious designs may want to use thermistors

whose room temperature value is greater than 10k. Vishay

Dale has a number of values of thermistor from 10k to 100k

that follow the “R-T Curve 2.” Using these as indicated

in the NTC Thermistor section will give temperature trip

points of approximately 3°C and 47°C, a delta of 44°C.

This delta in temperature can be moved in either direction by changing the value of R

NOM

with respect to R

NTC

.

APPLICATIO S I FOR ATIO

WUU

U

Figure 6. Using the HVEN Pin to Soft-Start the

High Voltage Regulator.

Page 19

LTC4089/LTC4089-5

19

40895fb

Increasing R

NOM

will move both trip points to lower

temperatures. Likewise, a decrease in R

NOM

with respect

to R

NTC

will move the trip points to higher temperatures.

To calculate R

NOM

for a shift to lower temperature, for

example, use the following equation:

R

R

RatC

NOM

COLD

NTC

=°

2 815

25

.

•

where R

COLD

is the resistance ratio of R

NTC

at the desired

cold temperature trip point. To shift the trip points to higher

temperatures use the following equation:

R

R

RatC

NOM

HOT

NTC

=°

0 4086

25

.

•

where R

HOT

is the resistance ratio of R

NTC

at the desired

hot temperature trip point.

The following example uses a 100K R-T Curve 1 Thermistor

from Vishay Dale. The difference between the trip points is

44°C, from before—and the desired cold trip point of 0°C,

would put the hot trip point at 44°C. The R

NOM

needed is

calculated as follows:

R

R

RatC

NOM

COLD

NTC

=°=

2 815

25

3 266

2 815

100

.

•

.

.

•kkkΩΩ= 116

The nearest 1% value for R

NOM

is 115k. This is the value

used to bias the NTC thermistor to get cold and hot trip

points of approximately 0°C and 44°C, respectively. To

extend the delta between the cold and hot trip points, a

resistor (R1) can be added in series with R

NTC

(see Figure

7). The values of the resistors are calculated as follows:

R

RR

R

NOM

COLD HOT

=

−

−

=

−

2 815 0 4086

1

0 4086

2 815 0

..

.

.

..•4086

⎡

⎣

⎢

⎤

⎦

⎥

−

[]

−RRR

COLD HOT HOT

where R

NOM

is the value of the bias resistor, R

HOT

and

R

COLD

are the values of R

NTC

at the desired temperature

trip points. Continuing the forementioned example with

a desired hot trip point of 50°C:

R

RR

k

NOM

COLD HOT

=

−

−

=

−

2 815 0 4086

100 3 266 0 3

..

•( . .

6602

2 815 0 4086

120 8 121 1

110

)

..

., %

−

=

=

k k nearest

R

00

0 4086

2 815 0 4086

3 266 0 3602

k•

.

..

•

..

−

⎛

⎝

⎜

⎞

⎠

⎟

−

()

−−

⎡

⎣

⎢

⎢

⎢

⎤

⎦

⎥

⎥

⎥

=

0 3602

13 3 13 3 1

.

., . %k k is nearest

The fi nal solution is shown in Figure 7, where

R

NOM

= 121k, R1 = 13.3k and R

NTC

= 100k at 25°C

–

+

–

+

R

NOM

121k

R

NTC

100k

R1

13.3k

NTC

VNTC

15

0.1V

NTC_ENABLE

4089 F07

TOO_COLD

TOO_HOT

0.74 •

VNTC

0.29 • VNTC

–

+

14

LTC4089

APPLICATIO S I FOR ATIO

WUU

U

Figure 7. Modifi ed NTC Circuit

Page 20

LTC4089/LTC4089-5

20

40895fb

Power Dissipation and High Temperature

Considerations

The die temperature of the LTC4089/LTC4089-5 must

be lower than the maximum rating of 110°C. This is

generally not a concern unless the ambient temperature

is above 85°C. The total power dissipated inside the

LTC4089/LTC4089-5 depends on many factors, including

input voltage (IN or HVIN), battery voltage, programmed

charge current, programmed input current limit, and load

current.

In general, if the LTC4089/LTC4089-5 is being powered

from IN the power dissipation can be calculated as follows:

PVV I VV I

D IN BAT BAT IN OUT OUT

=− +−()•()•

where PD is the power dissipated, I

BAT

is the battery

charge current, and I

OUT

is the application load current.

For a typical application, an example of this calculation

would be:

PVVAV VA

mW

D

=− +− =(.)•.(.)•.53704 547501

545

This example assumes VIN = 5V, V

OUT

= 4.75V, V

BAT

=

3.7V, I

BAT

= 400mA, and I

OUT

= 100mA resulting in slightly

more than 0.5W total dissipation.

If the LTC4089 is being powered from HVIN, the power

dissipation can be estimated by calculating the regulator

power loss from an effi ciency measurement, and subtracting the catch diode loss.

PVIIV

V

V

D HVOUT BAT OUT D

HVOUT

H

=− + −

−

( )•( •( )) •11η

VVIN

BAT OUT BAT

II VI

⎛

⎝

⎜

⎞

⎠

⎟

++•( ) . •03

where is the effi ciency of the high voltage regulator and

V

D

is the forward voltage of the catch diode at I = I

BAT

+ I

OUT

. The fi rst term corresponds to the power lost in

converting V

HVIN

to V

HVOUT

, the second term subtracts

the catch diode loss, and the third term is the power dis-

sipated in the battery charger. For a typical application,

an example of this calculation would be:

PVAAV

V

V

D

=− +

[]

−

−

⎛

⎝

( . )• •( . . ) . •1087 4 07 03 04

1

4

12

⎜⎜

⎞

⎠

⎟

++ =•( . . ) . • .07 03 03 07 463AA VA mW

This example assumes 87% effi ciency, V

HVIN

= 12V, V

BAT

= 3.7V (V

HVOUT

is about 4V), I

BAT

= 700mA, I

OUT

= 300mA

resulting in less than 0.5W total dissipation.

If the LTC4089-5 is being powered from HVIN, the power

dissipation can be estimated by calculating the regulator

power loss from an effi ciency measurement and subtracting the catch diode loss.

PVII

V

V

V

D BAT OUT

D

HVIN

=− +

−−

⎛

⎝

⎜

⎞

⎠

( )•( •( ))

•

15

1

5

η

⎟⎟

+

+−

•( )

()•

II

VV I

BAT OUT

BAT BAT

5

The difference between this equation and the LTC4089 is

the last term which represents the power dissipation in

the battery charger. For a typical application, an example

of this calculation would be:

PVAA

V

V

V

D

=− +

−−

(.)•(•(. .))

.•( )

1 0 87 5 0 7 0 3

04 1

5

12

••( . . )

(.)•.,

07 03

537071327

AA

VVA mW

+

+− =

Like the LTC4089 example, this example assumes 87%

effi ciency, V

HVIN

= 12V, V

BAT

= 3.7V, I

BAT

= 700mA, I

OUT

= 300mA resulting in 1.3W total dissipation.

To prevent power dissipation of this magnitude from

causing high die temperature, it is important to solder the

exposed backside of the package to a ground plane. This

ground should be tied to other copper layers below with

thermal vias; these layers will spread the heat dissipated

by the LTC4089. Additional vias should be placed near the

catch diodes. Adding more copper to the top and bottom

layers, and tying this copper to the internal planes with

vias, can reduce thermal resistance further. With these

steps, the thermal resistance from die (i.e., junction) to

ambient can be reduced to

JA

= 40°C/W.

APPLICATIO S I FOR ATIO

WUU

U

Page 21

LTC4089/LTC4089-5

21

40895fb

APPLICATIO S I FOR ATIO

WUU

U

The power dissipation in the other power components—catch diodes, MOSFETs, boost diodes and inductors—causes additional copper heating and can further

increase the “ambient” temperature of the IC.

Board Layout Considerations

As discussed in the previous section, it is critical that

the exposed metal pad on the backside of the LTC4089/

LTC4089-5 package be soldered to the PC board ground.

Furthermore, proper operation and minimum EMI requires

a careful printed circuit board (PCB) layout. Note that large,

switched currents fl ow in the power switch (between the

HVIN and SW pins), the catch diode and the HVIN input

capacitor. These components, along with the inductor and

output capacitor, should be placed on the same side of

the circuit board, and their connections should be made

on that layer. Place a local, unbroken ground plane below

these components. The loop formed by these components

should be as small as possible. Additionally, the SW and

BOOST nodes should be kept as small as possible. Figure

8 shows the recommended component placement with

trace and via locations.

High frequency currents, such as the high voltage input

current of the LTC4089, tend to fi nd their way along

the ground plane on a mirror path directly beneath the

incident path on the top of the board. If there are slits or

cuts in the ground plane due to other traces on that layer,