Page 1

LTC4002-4.2

Final Electrical Specifications

Standalone Li-Ion

Switch Mode Battery Charger

FEATURES

■

Wide Input Supply Range: 4.7V to 24V

■

High Efficiency Current Mode PWM Controller with

500kHz Switching Frequency

■

±1% Charge Voltage Accuracy

■

End-of-Charge Current Detection Output

■

3 Hour Charge Termination Timer

■

Constant Switching Frequency for Minimum Noise

■

±5% Charge Current Accuracy

■

Low 10µA Reverse Battery Drain Current

■

Automatic Battery Recharge

■

Automatic Shutdown When Input Supply is Removed

■

Automatic Trickle Charging of Low Voltage Batteries

■

Battery Temperature Sensing and Charge

Qualification

■

Stable with Ceramic Output Capacitor

■

8-Lead SO and 10-Lead DFN Packages

U

APPLICATIO S

■

Portable Computers

■

Charging Docks

■

Handheld Instruments

U

June 2003

DESCRIPTIO

The LTC®4002-4.2 is a complete battery charger controller

for single cell 4.2V lithium-ion batteries. With a 500kHz

switching frequency, the LTC4002-4.2 provides a small,

simple and efficient solution to fast charge Li-Ion batteries

from a wide range of supply voltages. An external sense

resistor sets the charge current with ±5% accuracy. An

internal resistor divider and precision reference set the

final float voltage to 4.2V with ±1% accuracy.

When the input supply is removed, the LTC4002-4.2

automatically enters a low current sleep mode, dropping

the battery drain current to 10µA. An internal comparator

detects the near end-of-charge condition while an internal

timer sets the total charge time and terminates the charge

cycle. After the charge cycle ends, if the battery voltage

drops below 4.05V, a new charge cycle will automatically

begin.

The LTC4002-4.2 is available in the 8-lead SO and 10-lead

DFN packages.

, LTC and LT are registered trademarks of Linear Technology Corporation.

TYPICAL APPLICATIO

BAT

2k

CHARGE

STATUS

2.2k

Figure 1. 1.5A Single Cell Li-Ion Battery Charger

0.1µF

CER

0.47µF

U

V

IN

5V TO 24V

B330B-13

2

V

CC

LTC4002ES8-4.2

5

CHRG

COMP

NTC GND

10k

T

NTC

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

3

GATE

7

SENSE

61

BAT

48

NTC: DALE NTHS-1206N02

Si6435ADQ

L1

6.8µH

68mΩ

22µF

CER

+

10µF

CER

B330B-13

Li-Ion

BATTERY

400242 F01

100

I

CHRG

R

SENSE

(CURVES INCLUDE

INPUT DIODE)

90

80

EFFICIENCY (%)

70

60

5

Efficiency vs Input Voltage

= 1.5A

= 68mΩ

= 4V

V

BAT

V

= 3.8V

BAT

10

15

INPUT VOLTAGE (V)

20

400242 TA02

25

400242i

1

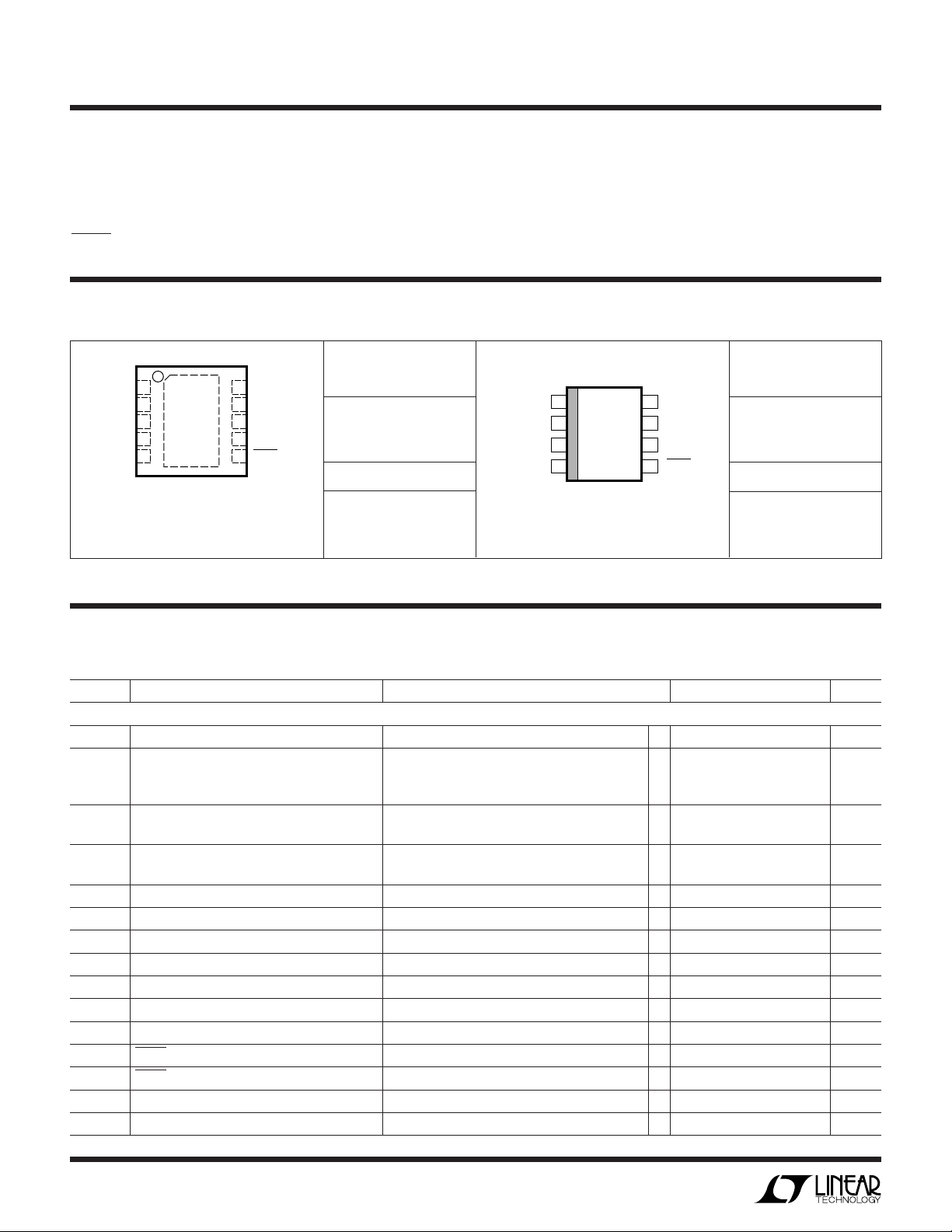

Page 2

LTC4002-4.2

1

2

3

4

8

7

6

5

TOP VIEW

NTC

SENSE

BAT

CHRG

COMP

V

CC

GATE

GND

S8 PACKAGE

8-LEAD PLASTIC SO

TOP VIEW

11

DD PACKAGE

10-LEAD (3mm × 3mm) PLASTIC DFN

10

9

6

7

8

4

5

3

2

1

NC

NTC

SENSE

BAT

CHRG

COMP

V

CC

GATE

PGND

SGND

WW

W

ABSOLUTE AXI U RATI GS

U

(Note 1)

Supply Voltage (VCC) .............................................. 24V

GATE .................................................. (VCC –8V) to V

CC

BAT, SENSE .............................................. –0.3V to 14V

CHRG, COMP, NTC ..................................... – 0.3V to 8V

UUW

PACKAGE/ORDER I FOR ATIO

ORDER PART

NUMBER

LTC4002EDD-4.2

DD PART MARKING

T

= 125°C, θJA = 43°C/W

JMAX

EXPOSED PAD IS GND (PIN 11)

MUST BE SOLDERED TO PCB

Consult LTC Marketing for parts specified with wider operating temperature ranges.

LAGG

Operating Temperature Range (Note 2) .. – 40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

ORDER PART

NUMBER

LTC4002ES8-4.2

S8 PART MARKING

T

= 125°C, θJA = 110°C/W

JMAX

400242

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VCC = 10V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

DC Characteristics

V

CC

I

CC

V

BAT

V

SNS(CHG)

V

SNS(TRKL)

V

TRKL

V

UV

∆V

UV

V

MSD

V

ASD

I

COMP

I

CHRG

V

CHRG

R

EOC

t

TIMER

2

VCC Supply Voltage ● 4.7 24 V

VCC Supply Current Current Mode 3 5 mA

Battery Regulated Float Voltage 5V ≤ VCC ≤ 24V (Note 2) 4.168 4.2 4.232 V

Constant Current Sense Voltage 3V ≤ V

Trickle Current Sense Voltage V

Trickle Charge Threshold Voltage V

VCC Undervoltage Lockout Threshold Voltage VCC Rising 3.9 4.2 4.5 V

VCC Undervoltage Lockout Hysteresis Voltage 200 mV

Manual Shutdown Threshold Voltage COMP Pin Falling 200 360 500 mV

Automatic Shutdown Threshold Voltage VCC – V

COMP Pin Output Current V

CHRG Pin Weak Pull-Down Current V

CHRG Pin Output Low Voltage I

End-of-Charge Ratio V

Charge Time Accuracy 10 %

The ● denotes the specifications which apply over the full operating

Shutdown Mode 3 5 mA

Sleep Mode 10 20 µA

● 4.158 4.242 V

≤ 4V (Note 3) 0°C ≤ TA ≤ 85°C ● 93 100 107 mV

BAT

= 0V (Note 3) 5 10 15 mV

BAT

Rising 2.75 2.9 3.05 V

BAT

BAT

= 1.2V 100 µA

COMP

= 1V 15 25 35 µA

CHRG

= 1mA 0.15 0.3 V

CHRG

SNS(EOC)/VSNS(CHG)

–40°C ≤ T

≤ 85°C ● 90 110 mV

A

250 mV

10 25 32 %

400242i

Page 3

LTC4002-4.2

TEMPERATURE (°C)

–50

f

OSC

(kHz)

25

400242 G03

500

–25 0 50

450

550

75 100 125

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VCC = 10V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

NTC

V

NTC-HOT

V

NTC-COLD

∆V

RECHRG

I

LEAK

Oscillator

f

OSC

DC Maximum Duty Cycle 100 %

Gate Drive

t

r

t

f

∆V

GATE

∆V

GATEHI

∆V

GATELO

Note 1: Absolute Maximum Rating are those values beyond which the life

of a device may be impaired.

NTC Pin Output Current V

NTC Pin Threshold Voltage (Hot) V

= 0.85V ● 75 85 95 µA

NTC

Falling ● 340 355 370 mV

NTC

Hysteresis 25 mV

NTC Pin Threshold Voltage (Cold) V

Rising ● 2.428 2.465 2.502 V

NTC

Hysteresis 170 mV

Recharge Battery Voltage Offset from Full V

BAT(FULLCHARGED)

– V

RECHRG

, V

Falling 100 150 200 mV

BAT

Charged Battery Voltage

CHRG Pin Leakage Current V

= 8V, Charging Stops 1 µA

CHRG

Switching Frequency 450 500 550 kHz

Rise Time C

Fall Time C

Output Clamp Voltage VCC – V

Output High Voltage ∆V

Output Low Voltage ∆V

= 2000pF, 10% to 90% 20 ns

GATE

= 2000pF, 90% to 10% 50 ns

GATE

, VCC ≥ 9V ● 8V

GATE

GATEHI

GATELO

= VCC – V

= VCC – V

, VCC ≥ 7V ● 0.3 V

GATE

, VCC ≥ 7V ● 4.5 V

GATE

Note 2: The LTC4002-4.2 is tested with Test Circuit 1.

Note 3: The LTC4002-4.2 is tested with Test Circuit 2.

UW

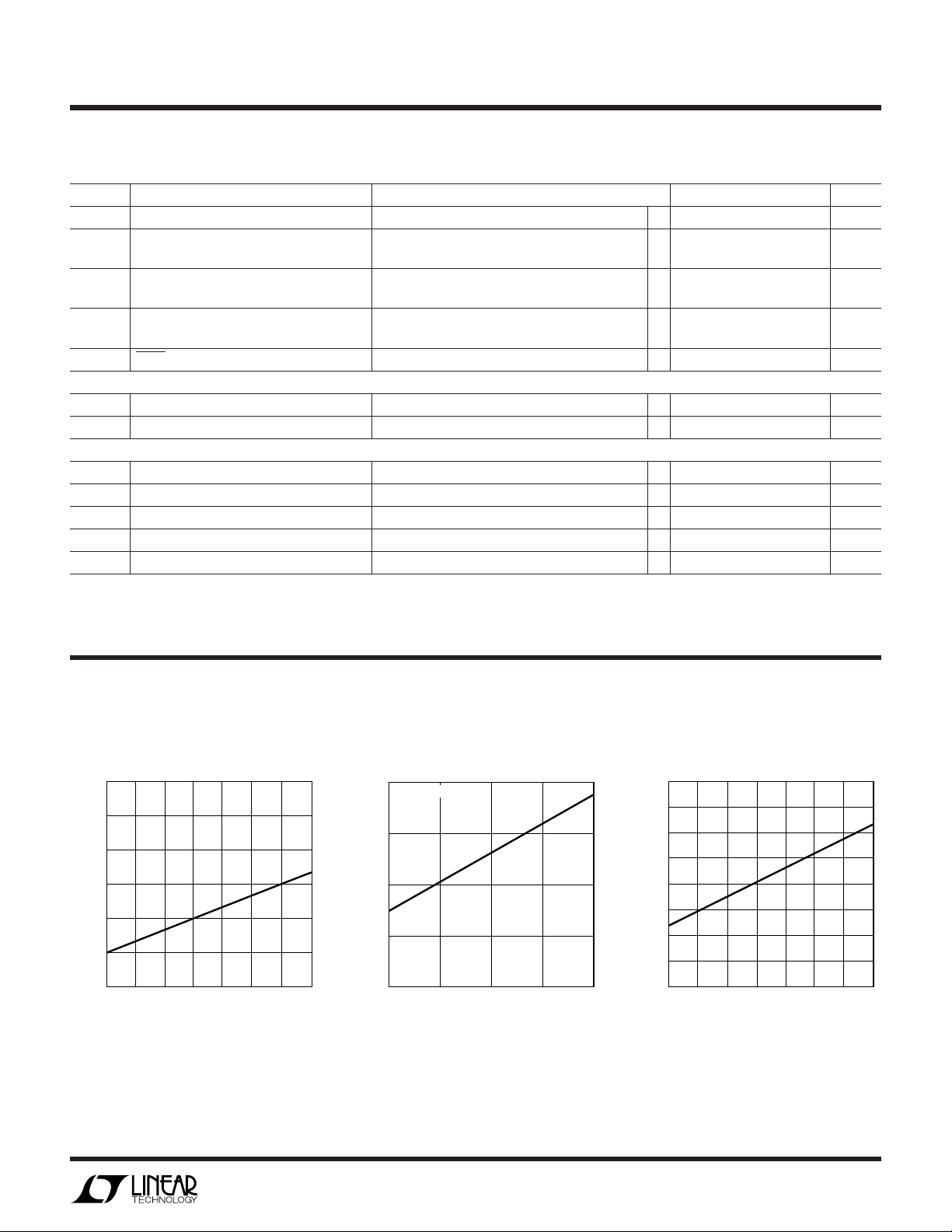

TYPICAL PERFOR A CE CHARACTERISTICS

Supply Current vs Temperature Supply Current vs V

4.0

3.5

(mA)

CC

I

3.0

2.5

–50

–25 0

50 100 125

25 75

TEMPERATURE (°C)

400242 G01

(mA)

CC

I

4

3

2

CURRENT MODE

5

10

15

VCC (V)

CC

20

TA = 25°C, VCC = 10V unless otherwise noted.

Oscillator Frequency

vs Temperature

25

400242 G02

400242i

3

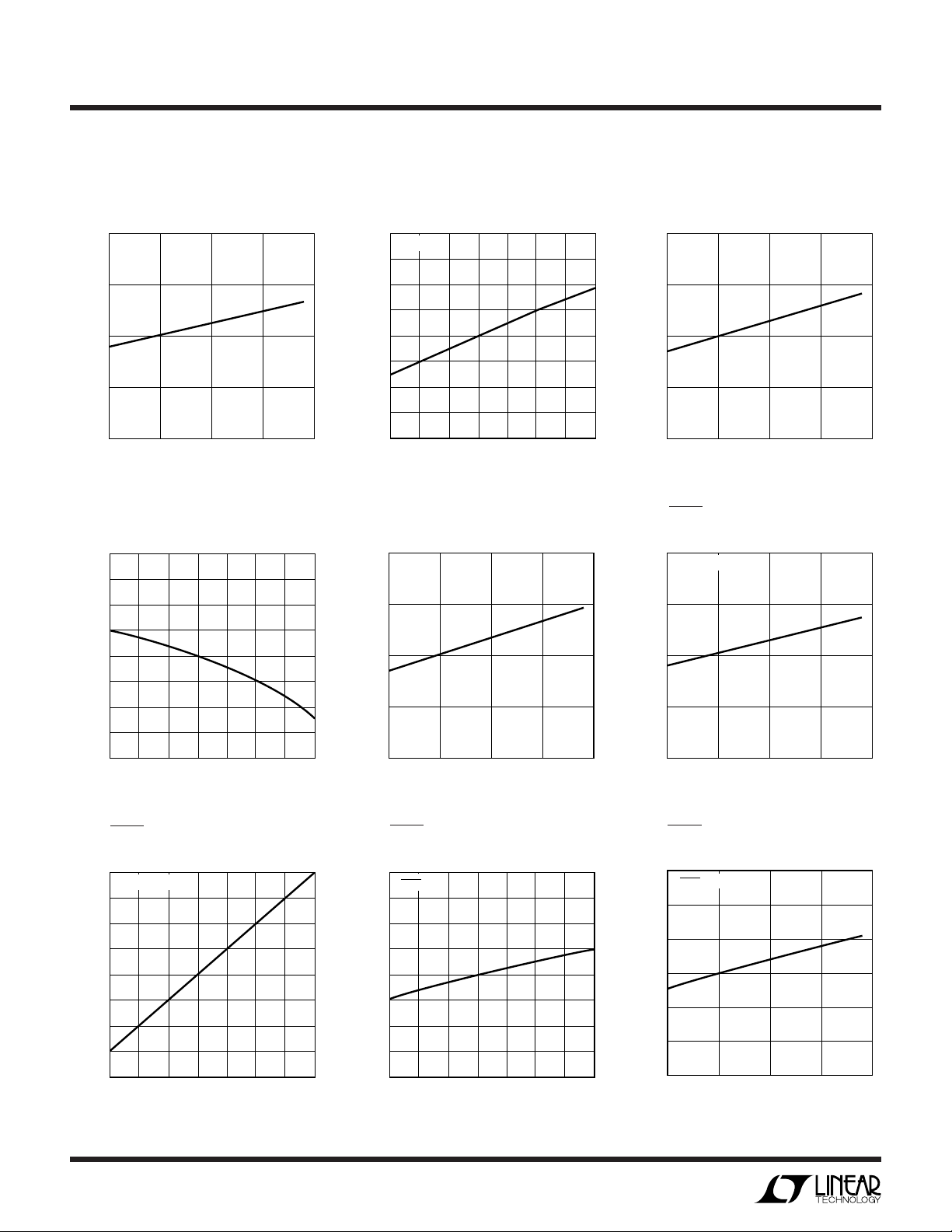

Page 4

LTC4002-4.2

VCC (V)

5

22

I

CHRG

(µA)

25

28

10 15 20 25

400242 G11

V

CHRG

= 8V

UW

TYPICAL PERFOR A CE CHARACTERISTICS

TA = 25°C, VCC = 10V unless otherwise noted.

Oscillator Frequency vs V

510

(kHz)

500

OSC

f

490

5

10

VCC (V)

Trickle Charge Voltage

vs Temperature

3.0

(V)

2.9

TRKL

V

Current Mode Sense Voltage

CC

15

20

25

400242 G04

vs Temperature

104

V

= 4V

BAT

(mV)

100

SNS

V

96

–25 0 50

–50

25

TEMPERATURE (°C)

75 100 125

400242 G05

Trickle Charge Voltage

vs V

CC

3.0

V

= 4V

BAT

(V)

2.9

TRKL

V

Current Mode Sense Voltage

vs V

CC

102

V

= 4V

BAT

(mV)

100

SNS

V

98

5

10

15

VCC (V)

CHRG Pin Output Low Voltage

vs V

CC

150

I

= 1mA

LOAD

(mV)

140

CHRG

V

20

25

400242 G04

2.8

–25 0 50

–50

25

TEMPERATURE (°C)

75 100 125

400242 G07

CHRG Pin Output Low Voltage

vs Temperature

180

I

= 1mA

LOAD

(mV)

140

CHG

V

100

–25 0 50

–50

4

25

TEMPERATURE (°C)

75 100 125

400242 G10

2.8

5

10

15

VCC (V)

CHRG Pin Weak Pull-Down

Current vs Temperature

29

V

= 8V

CHRG

(µA)

25

CHRG

I

21

–25 0 50

–50

25

TEMPERATURE (°C)

20

400242 G08

75 100 125

400242 G23

25

130

5

10

15

VCC (V)

20

25

400242 G09

CHRG Output Pin Weak Pull-Down

Current vs V

CC

400242i

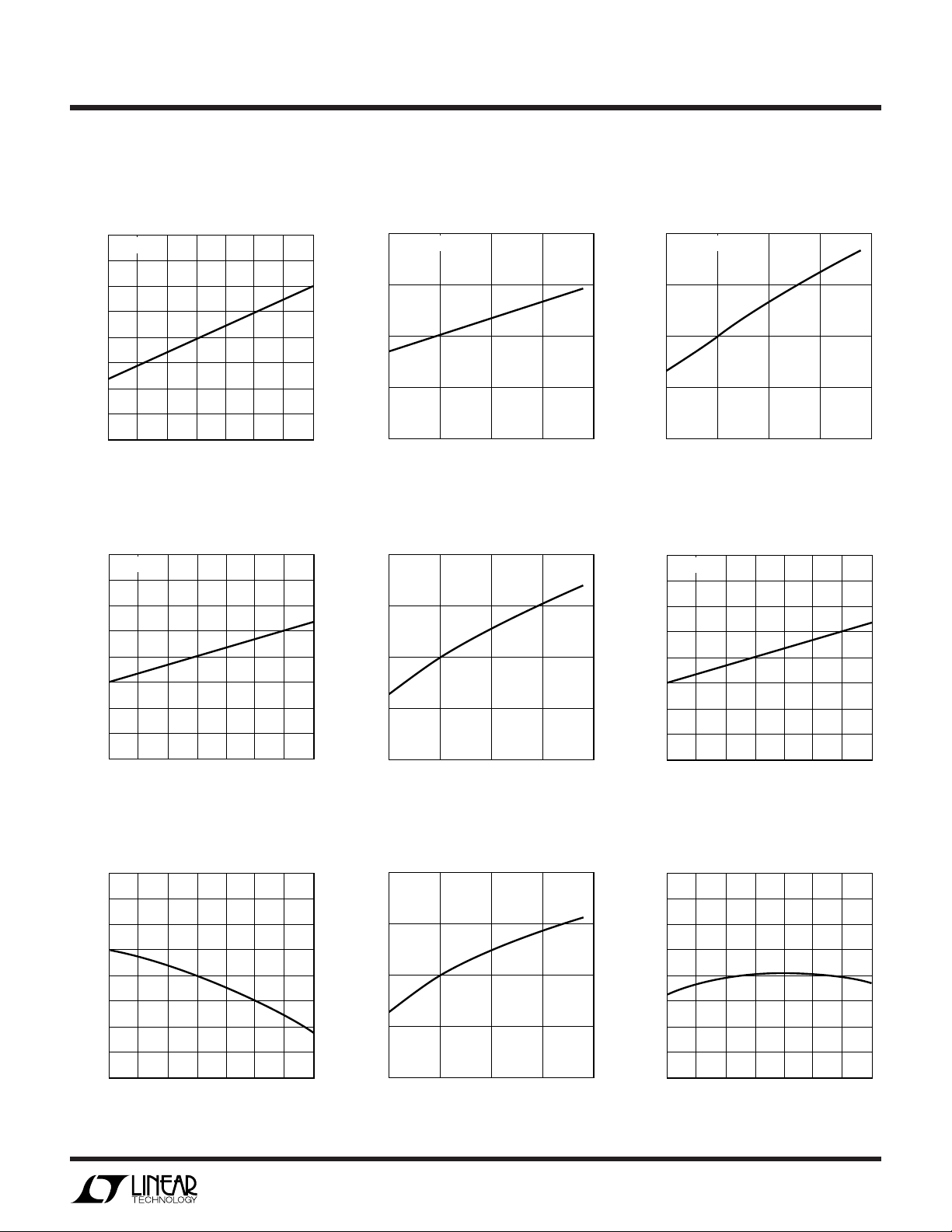

Page 5

TEMPERATURE (°C)

–50

I

NTC

(µA)

25

400242 G17

85

–25 0 50

81

89

75 100 125

V

NTC

= 0V

TEMPERATURE (°C)

–50

R

EOC

(%)

25

400242 G20

25

–25 0 50

21

29

75 100 125

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LTC4002-4.2

TA = 25°C, VCC = 10V unless otherwise noted.

Trickle Charge Sense Voltage

vs Temperature

10.4

V

= 2.5V

BAT

(mV)

10.0

SNS

V

9.6

–25 0 50

–50

25

TEMPERATURE (°C)

COMP Pin Output Current

vs Temperature

104

V

= 0V

COMP

75 100 125

400242 G12

Trickle Charge Sense Voltage

vs V

CC

11

V

= 2.5V

BAT

(mV)

10

SNS

V

9

5

10

15

V

(V)

CC

NTC Pin Output Current

vs V

CC

86

V

= 0V

NTC

COMP Pin Output Current

vs V

CC

102

V

= 0V

COMP

(µA)

100

COMP

I

20

25

400242 G13

98

5

10

15

VCC (V)

20

25

400242 G14

NTC Pin Output Current

vs Temperature

(µA)

100

COMP

I

96

–25 0 50

–50

25

TEMPERATURE (°C)

75 100 125

400242 G15

Recharge Voltage Offset from Full

Charged Voltage vs Temperature

190

(mV)

150

RECHRG

∆V

110

–25 0 50

–50

25

TEMPERATURE (°C)

75 100 125

400242 G18

(µA)

85

NTC

I

84

5

10

15

VCC (V)

Recharge Voltage Offset from Full

Charged Voltage vs V

160

(mV)

150

RECHRG

∆V

140

5

10

CC

15

VCC (V)

20

25

400242 G16

End-of-Charge Ratio

vs Temperature

20

25

400242 G19

400242i

5

Page 6

LTC4002-4.2

UW

TYPICAL PERFOR A CE CHARACTERISTICS

TA = 25°C, VCC = 10V unless otherwise noted.

End-of-Charge Ratio

vs V

CC

29

(%)

25

EOC

R

21

5

U

PI FU CTIO S

10 15 20 25

VCC (V)

400242 G21

UU

(DFN/SO-8)

COMP (Pin 1/Pin 1): Compensation, Soft-Start and Shut-

down Control Pin. The COMP pin is the control signal of the

inner loop of the current mode PWM. Charging begins when

the COMP pin reaches 800mV. The recommended compensation components are a 0.47µF (or larger) capacitor and

a 2.2k series resistor. A 100µA current into the compen-

sation capacitor also sets the soft-start slew rate. Pulling

the COMP pin below 350mV will shut down the charger.

VCC (Pin 2/Pin 2): Positive Supply Voltage Input. VCC can

range from 4.7V to 24V. A 0.1µF or higher capacitor is

required at the V

pin with the lead length kept to a mini-

CC

mum. A 10µF low ESR capacitor is also required at the

source pins of the power P-channel MOSFET.

GATE (Pin 3/Pin 3): Gate Drive Output. Driver Output for

the P-Channel MOSFET. The voltage at this pin is internally

clamped to 8V below VCC, allowing a low voltage MOSFET

with gate-to-source breakdown voltage of 8V or less to be

used.

PGND, SGND, Exposed Pad, GND (Pins 4, 5, 11/4): IC

Ground.

CHRG (Pin 6/Pin 5): Open-Drain Charge Status Output.

When the battery is being charged, the CHRG pin is pulled

low by an internal N-channel MOSFET. When the charge

current drops to 25% of the full-scale current for more than

Undervoltage Lockout Threshold

vs Temperature

4.4

VCC RISING

(V)

4.2

UV

V

4.0

–25 0 50

–50

25

TEMPERATURE (°C)

75 100 125

400242 G22

120µs, the N-channel MOSFET turns off and a 25µA cur-

rent source is connected from the CHRG pin to GND. When

the timer runs out or the input supply is removed, the 25µA

current source is turned off and the CHRG pin becomes high

impedance.

BAT (Pin 7/Pin 6): Battery Sense Input. A bypass capacitor of 22µF is required to minimize ripple voltage. An

internal resistor divider, which is disconnected in sleep

mode, sets the final float voltage at this pin. If the battery

connection is opened when charging, an overvoltage

circuit will limit the charger output voltage to 10% above

the programmed float voltage.

When V

is within 250mV of VCC, the LTC4002-4.2 is

BAT

forced into sleep mode, dropping ICC to 10µA.

SENSE (Pin 8/Pin 7): Current Amplifier Sense Input. A sense

resistor, R

, must be connected between the SENSE

SENSE

and BAT pins. The maximum charge current is equal to

100mV/R

SENSE

.

NTC (Pin 9/Pin 8): NTC (Negative Temperature Coefficient)

Thermistor Input. With an external 10kΩ NTC thermistor

to ground, this pin senses the temperature of the battery

pack and stops the charger when the temperature is out of

range. When the voltage at this pin drops below 350mV at

400242i

6

Page 7

LTC4002-4.2

U

PI FU CTIO S

UU

(DFN/SO-8)

hot temperature or rises above 2.465V at cold temperature,

charging is suspended and the internal timer stops. The

CHRG pin output is not affected during this hold state. To

W

BLOCK DIAGRA

COMP

M1

100µA

V

CC

CLK:

I

I

L

SLOP

–

C

PWM

+

R

SLOP

R

IL

disable the temperature qualification function, ground the

NTC pin.

NC (Pin 10/NA): No Connect.

S

Q

R

R

DRIVER

20mV

+

+

–

C

EOC

–

100mV

+

+

–

CA

–

GATE

SENSE

CHRG

+

BAT

M2

VA

4.2V

–

+

M3

90µA

C

LB

2.9V

–

+

C

350mV

OV

UVLO

4.2V

+

C

SD

–

Q4

Q5

25µA

SD

LOGIC

C/10

STOP

NTC_DISABLE

UV

EOC

RQ

TEMP

C

C

COLD

RQ

4.62V

–

+

4.05V

–

2.465V

+

–

85µA

V

CC

NTC

–

GND

C

HOT

+

350mV

+

50mV

–

400242 BD

400242i

7

Page 8

LTC4002-4.2

TEST CIRCUITS

1.5V

COMP

Test Circuit 1

15V

–

LT1006

+

0V

100µA

LTC4002-4.2

SENSE

–

R

CA

BAT

+

SENSE

10Ω

V

BAT

400242 TC01

1.5V

COMP

15V

–

LT1006

+

0V

100µA

LTC4002-4.2

Test Circuit 2

–

CA

+

–

VA

+

4.2V

SENSE

BAT

400242 TC02

R

SENSE

10Ω

1mA

8

400242i

Page 9

OPERATIO

LTC4002-4.2

U

The LTC4002 is a constant current, constant voltage

Li-Ion battery charger controller that uses a current mode

PWM step-down (buck) switching architecture. The charge

current is set by an external sense resistor (R

across the SENSE and BAT pins. The final battery float

voltage is internally set to 4.2V. For batteries like lithiumion that require accurate final float voltage, the internal

2.465V reference, voltage amplifier and the resistor divider provide regulation with ±1% accuracy.

A charge cycle begins when the voltage at the VCC pin rises

above the UVLO level (4.2V) and is 250mV or more greater

than the battery voltage. At the beginning of the charge

cycle, if the battery voltage is less than 2.9V, the charger

goes into trickle charge mode. The trickle charge current

is internally set to 10% of the full-scale current. If the

battery voltage stays low for 30 minutes, the battery is

considered faulty and the charge cycle is terminated.

When the battery voltage exceeds 2.9V, the charger goes

into the full-scale constant current charge mode. In constant current mode, the charge current is set by the

external sense resistor R

reference; I

When the battery voltage approaches the programmed

float voltage, the charge current will start to decrease.

= 100mV/R

BAT

and an internal 100mV

SENSE

.

SENSE

SENSE

)

When the current drops to 25% of the full-scale charge

current, an internal comparator turns off the internal pulldown N-channel MOSFET at the CHRG pin, and connects

a weak current source to ground to indicate a near end-ofcharge condition.

An internal 3 hour timer determines the total charge time.

After a time out occurs, the charge cycle is terminated

and the CHRG pin is forced high impedance. To restart

the charge cycle, remove and reapply the input voltage or

momentarily shut the charger down. Also, a new charge

cycle will begin if the battery voltage drops below the

recharge threshold voltage of 4.05V.

When the input voltage is present, the charger can be shut

down (ICC = 3mA) by pulling the COMP pin low. When the

input voltage is not present, the charger goes into sleep

mode, dropping ICC to 10µA. This will greatly reduce the

current drain on the battery and increase the standby time.

A 10kΩ NTC (negative temperature coefficient) thermistor

can be connected from the NTC pin to ground for battery

temperature qualification. The charge cycle is suspended

when the temperature is outside of the 0°C to 50°C

window (with DALE NTHS-1206N02).

400242i

9

Page 10

LTC4002-4.2

WUUU

APPLICATIO S I FOR ATIO

Undervoltage Lockout (UVLO)

An undervoltage lockout circuit monitors the input voltage

and keeps the charger off until VCC rises above 4.2V and

at least 250mV above the battery voltage. To prevent

oscillation around the threshold voltage, the UVLO circuit

has 200mV of built-in hysteresis.

Trickle Charge and Defective Battery Detection

At the beginning of a charge cycle, if the battery voltage is

below 2.9V, the charger goes into trickle charge mode with

the charge current reduced to 10% of the full-scale current. If the low-battery voltage persists for 30 minutes, the

battery is considered defective, the charge cycle is terminated and the CHRG pin is forced to be high impedance.

Shutdown

The LTC4002 can be shut down by pulling the COMP pin

to ground which pulls the GATE pin high and turns off the

external P-channel MOSFET. When the COMP pin is released, the internal timer is reset and a new charge cycle

starts. In shutdown, the output of the CHRG pin is high

impedance and the quiescent current remains at 3mA.

Removing the input power supply will put the charger

into sleep mode. If the voltage at the VCC pin drops below

(V

+ 250mV) or below the UVLO level (4.2V), the

BAT

LTC4002-4.2 goes into a low current (I

= 10µA) sleep

CC

mode, reducing the battery drain current.

CHRG Status Output Pin

When a charge cycle starts, the CHRG pin is pulled to

ground by an internal N-channel MOSFET which is capable

of driving an LED. When the charge current drops to 25%

of the full-scale current for more than 120µs, the N-channel

MOSFET turns off and a weak 25µA current source to

ground is connected to the CHRG pin. This weak 25µA

pull-down remains until the timer ends the charge cycle,

or the charger is in manual shutdown or sleep mode.

After a time out occurs (charge cycle ends), the pin will go

into high impedance. By using two different value resistors, a microprocessor can detect three states from this

pin (charging, end-of-charge and charging stopped) see

Figure␣ 2.

To detect the charge mode, force the digital output pin,

OUT, high and measure the voltage at the CHRG pin. The

N-channel MOSFET will pull the pin low even with a 2k

pull-up resistor. Once the charge current drops to 25% of

the full-scale current, the N-channel MOSFET is turned off

and a 25µA current source is connected to the CHRG pin.

The IN pin will then be pulled high by the 2k resistor

connected to OUT. Now force the OUT pin into a high

impedance state, the current source will pull the pin low

through the 400k resistor. When the internal timer has

expired, the CHRG pin changes to a high impedance state

and the 400k resistor will then pull the pin high to indicate

the charging has stopped.

10

V

CC

400k

2k

Figure 2. Microprocessor Interface

V

DD

µPROCESSORLTC4002-4.2

OUTCHRG

IN

400242 F02

400242i

Page 11

WUUU

APPLICATIO S I FOR ATIO

LTC4002-4.2

Gate Drive

The LTC4002-4.2 gate driver can provide high transient

currents to drive the external pass transistor. The rise and

fall times are typically 20ns and 50ns respectively when

driving a 2000pF load, which is typical for a P-channel

MOSFET with R

A voltage clamp is added to limit the gate drive to 8V below

VCC. For example, if VCC is 10V then the GATE output will

pull down to 2V max. This allows low voltage P-channel

MOSFETs with superior R

transistor thus increasing efficiency.

Stability

Both the current loop and the voltage loop share a common, high impedance, compensation node (COMP pin). A

series capacitor and resistor on this pin compensates both

loops. The resistor is included to provide a zero in the loop

response and boost the phase margin.

The compensation capacitor also provides a soft-start

function for the charger. Upon start-up, the COMP pin

voltage will quickly rise to 0.05V, due to the 2.2k series

resistor, then ramp at a rate set by the internal 100µA pull-

up current source and the external capacitor. Battery

charge current starts ramping up when the COMP pin

voltage reaches 0.8V and full current is achieved with the

COMP pin at 1.3V. With a 0.47µF capacitor, time to reach

full charge current is about 235ms. Capacitance can be

increased up to 1µF if a longer start-up time is needed.

in the range of 50mΩ.

DS(ON)

DS(ON)

to be used as the pass

Automatic Battery Recharge

After the 3 hour charge cycle is completed and both the

battery and the input power supply (wall adapter) are still

connected, a new charge cycle will begin if the battery

voltage drops below 4.05V due to self-discharge or external loading. This will keep the battery capacity at more than

80% at all times without manually restarting the charge

cycle.

Battery Temperature Detection

A negative temperature coefficient (NTC) thermistor

located close to the battery pack can be used to monitor

battery temperature and will not allow charging unless the

battery temperature is within an acceptable range.

Connect a 10kΩ thermistor (DALE NTHS-1206N02) from

the NTC pin to ground. If the temperature rises to 50°C, the

resistance of the NTC will be approximately 4.1kΩ. With

the 85µA pull-up current source, the Hot temperature

voltage threshold is 350mV. For Cold temperature, the

voltage threshold is set at 2.456V which is equal to 0°C

(R

≅ 28.4kΩ) with 85µA of pull-up current. If the

NTC

temperature is outside the window, the GATE pin will be

pulled up to VCC and the timer frozen while the output

status at the CHRG pin remains the same. The charge cycle

begins or resumes once the temperature is within the

acceptable range. Short the NTC pin to ground to disable

the temperature qualification feature.

400242i

11

Page 12

LTC4002-4.2

WUUU

APPLICATIO S I FOR ATIO

Input and Output Capacitors

Since the input capacitor is assumed to absorb all input

switching ripple current in the converter, it must have an

adequate ripple current rating. Worst-case RMS ripple current is approximately one-half of output charge current.

Actual capacitance value is not critical. Solid tantalum

capacitors have a high ripple current rating in a relatively

small surface mount package, but caution must be used

when tantalum capacitors are used for input bypass. High

input surge currents can be created when the adapter is

hot-plugged to the charger and solid tantalum capacitors

have a known failure mechanism when subjected to very

high turn-on surge currents. Selecting the highest possible voltage rating on the capacitor will minimize problems. Consult with the manufacturer before use.

The selection of output capacitor C

mined by the ESR required to minimize ripple voltage and

load step transients. The output ripple ∆V

mately bounded by:

∆≤∆ +

V I ESR

OUT L

Since ∆IL increases with input voltage, the output ripple is

highest at maximum input voltage. Typically, once the ESR

requirement is satisfied, the capacitance is adequate for

filtering and has the necessary RMS current rating.

1

fC

8

OSC OUT

is primarily deter-

OUT

is approxi-

OUT

Switching ripple current splits between the battery and the

output capacitor depending on the ESR of the output capacitor and the battery impedance. EMI considerations

usually make it desirable to minimize ripple current in the

battery leads. Ferrite beads or an inductor may be added

to increase battery impedance at the 500kHz switching

frequency. If the ESR of the output capacitor is 0.2Ω and

the battery impedance is raised to 4Ω with a bead or inductor, only 5% of the current ripple will flow in the battery.

Design Example

As a design example, take a charger with the following

specifications: V

1.5A, f

First, calculate the SENSE resistor :

R

Choose the inductor for about 65% ripple current at the

maximum VIN:

L

Selecting a standard value of 6.8µH results in a maximum

ripple current of :

∆=

= 500kHz, see Figure 1.

OSC

= 100mV/1.5A = 68mΩ

SENSE

500 0 65 1 5

()()()

L

500 6 8

()

= 5V to 24V, V

IN

4

V

kHz A

..

V

4

kHz H

.

µ

()

= 4V nominal, I

BAT

4

1

V

1

–.

4

–.

24

=µ

24

V

V

=I

980 4

V

6 838

BAT

H=

mA

=

12

400242i

Page 13

WUUU

APPLICATIO S I FOR ATIO

LTC4002-4.2

Next, choose the P-channel MOSFET. The Si6435ADQ in

a TSSOP-8 package with R

(max) offers a small solution. The maximum power dissipation with V

temperature is:

1 5 55 4

()

P

=

D

TJ = 50°C + (0.099W)(65°C/W) = 56.5°C

CIN is chosen for an RMS current rating of about 0.8A at

85°C. The output capacitor is chosen for an ESR similar to

the battery impedance of about 100mΩ. The ripple voltage

on the BAT pin is:

V

OUT RIPPLE

()

C1: Taiyo Yuden TMK325BJ106MM

C2: Taiyo Yuden JMK325BJ226MM

L1: TOKO B952AS-6R8N

The Schottky diode D2 shown in Figure 1 conducts current

when the pass transistor is off. In a low duty cycle case, the

current rating should be the same or higher than the

charge current. Also it should withstand reverse voltage as

high as VIN.

= 5V and V

IN

2

.

AmV

()()

V

5

∆

=

098 01

()

=

DS(ON)

Ω

I ESR

LMAX

()

2

..

A

()

2

= 42mΩ (nom), 55mΩ

= 4V at 50°C ambient

BAT

.

=

0 099

W

()

Ω

=

49

mV

Board Layout Suggestions

When laying out the printed circuit board, the following

considerations should be taken to ensure proper operation of the LTC4002-4.2.

GATE pin rise and fall times are 20ns and 50ns respectively

(with C

diode, pass transistor and the input bypass capacitor

traces should be kept as short as possible. The positive

side of the input capacitor should be close to the source of

the P-channel MOSFET; it provides the AC current to the

pass transistor. The connection between the catch diode

and the pass transistor should also be kept as short as

possible. The SENSE and BAT pins should be connected

directly to the sense resistor (Kelvin sensing) for best

charge current accuracy.

The compensation capacitor connected at the COMP pin

should return to the ground pin of the IC or as close to it

as possible. This will prevent ground noise from disrupting the loop stability. The ground pin also works as a heat

sink, therefore use a generous amount of copper around

the ground pin. This is especially important for high V

and/or high gate capacitance applications.

= 2000pF). To minimize radiation, the catch

GATE

CC

400242i

13

Page 14

LTC4002-4.2

PACKAGE DESCRIPTIO

U

DD Package

10-Lead Plastic DFN (3mm × 3mm)

(Reference LTC DWG # 05-08-1699)

0.675 ±0.05

3.50 ±0.05

1.65 ±0.05

(2 SIDES)2.15 ±0.05

PACKAGE

OUTLINE

0.25 ± 0.05

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

PIN 1

TOP MARK

(SEE NOTE 5)

0.200 REF

NOTE:

1. DRAWING TO BE MADE A JEDEC PACKAGE OUTLINE M0-229 VARIATION OF (WEED-2).

CHECK THE LTC WEBSITE DATA SHEET FOR CURRENT STATUS OF VARIATION ASSIGNMENT

2. ALL DIMENSIONS ARE IN MILLIMETERS

3. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

4. EXPOSED PAD SHALL BE SOLDER PLATED

5. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION ON THE

TOP AND BOTTOM OF PACKAGE

0.50

BSC

2.38 ±0.05

(2 SIDES)

3.00 ±0.10

(4 SIDES)

0.75 ±0.05

1.65 ± 0.10

(2 SIDES)

0.00 – 0.05

R = 0.115

TYP

2.38 ±0.10

(2 SIDES)

BOTTOM VIEW—EXPOSED PAD

106

15

0.50 BSC

0.38 ± 0.10

0.25 ± 0.05

(DD10) DFN 0403

14

400242i

Page 15

PACKAGE DESCRIPTIO

.050 BSC

U

S8 Package

8-Lead Plastic Small Outline (Narrow .150 Inch)

(Reference LTC DWG # 05-08-1610)

.189 – .197

.045 ±.005

(4.801 – 5.004)

8

NOTE 3

7

LTC4002-4.2

5

6

.245

MIN

.030 ±.005

TYP

RECOMMENDED SOLDER PAD LAYOUT

.010 – .020

(0.254 – 0.508)

.008 – .010

(0.203 – 0.254)

NOTE:

1. DIMENSIONS IN

2. DRAWING NOT TO SCALE

3. THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED .006" (0.15mm)

× 45°

.016 – .050

(0.406 – 1.270)

INCHES

(MILLIMETERS)

.160

±.005

.228 – .244

(5.791 – 6.197)

0°– 8° TYP

.053 – .069

(1.346 – 1.752)

.014 – .019

(0.355 – 0.483)

TYP

.150 – .157

(3.810 – 3.988)

NOTE 3

1

3

2

4

.004 – .010

(0.101 – 0.254)

.050

(1.270)

BSC

SO8 0303

400242i

15

Page 16

LTC4002-4.2

TYPICAL APPLICATIO

U

Single Cell 4.2V, 2A Li-Ion Battery Charger

100k

1/2 Si9933ADY

V

IN

5V TO 12V

B330-13

Li-Ion

BATTERY

400242 TA01

C1

10µF

CER

2.2k

0.1µF

CER

0.47µF

LTC4002ES8-4.2

5

CHRG

COMP

NTC GND

84

T

V

CC

10k

NTC

2

3

GATE

7

SENSE

61

BAT

NTC: DALE NTHS-1206N02

1/2 Si9933ADY

L1

6.8µH

R

SENSE

50mΩ

C2

+

22µF

CER

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC1732/LTC4050 Constant Voltage/Constant Current Li-Ion Linear Standalone Battery Charger, No uC or Firmware Required, Auto

Battery Chargers Recharge of Low Battery, 10-Pin MSOP, Input Supply Detection

LTC1733 Li-Ion Battery Charger with Termal Regulation Standalone Charger, Constant-Current/Constant-Voltage/

Constant-Temperature, Integrated MOSFET, No External Sense

Resistor or Blocking Diodes

LTC1734/LTC1734L SOT-23 Li-Ion Battery Chargers Need Only Two External Components, Monitors Charge Current, No

Reverse Diode or Sense Resistor Required, 50mA to 700mA

LTC1980 Combination Battery Charger and DC/DC Converter Wall Adapter May Be Above or Below Battery Voltage, Standalone,

1-, 2-Cell Li-Ion, Also for Charging NiMH and NiCd Batteries

LTC4006/LTC4007 4A Multiple Cell Li-Ion, NiCd, NiMH, Lead Acid 6V ≤ VIN ≤ 28V, High Efficiency ≥90%, V

LTC4008 Battery Chargers Digital Interface I/O, Small Inductor

LTC4052/LTC1730 Integrated Pulse Chargers for a 1-Cell Li-Ion Battery 0.35Ω Internal N-FET Requires No Blocking Diode,

Current Limit for Safety

LTC4053 USB Compatible Li-Ion Linear Battery Charger Charges from USB Input or AC/DC, 100mA/500mA Up to 1.25A,

Thermal Regulation, Fully Integrated

LTC4054 Standalone Linear Li-Ion Battery Charger Thermal Regulation Prevents Overheating, C/10 Termination,

with Integrated Pass Transistor in ThinSOT

TM

C/10 Indicator

LTC4056 Standalone SOT-23 Li-Ion Linear Battery Charger Charge Termination Included, ICH ≤ 700mA, 8-Lead ThinSOT Package

LTC4412 Low Loss PowerPathTM Controller in ThinSOT Automatic Switching Between DC Sources, Simplified Load Sharing

PowerPath and ThinSOT are trademarks of Linear Technology Corporation.

OUT

≤ 28V,

16

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

400242i

LT/TP 0603 1K PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 2003

Loading...

Loading...