Page 1

1

LTC4001

4001f

■

Handheld Battery-Powered Devices

■

Handheld Computers

■

Charging Docks and Cradles

■

Digital Cameras

■

Smart Phones

2A Single Cell Li-Ion Battery Charger

2A Synchronous

Buck Li-Ion Charger

■

Low Power Dissipation

■

2A Maximum Charge Current

■

No External MOSFETs, Sense Resistor or Blocking

Diode Required

■

Remote Sensing at Battery Terminals

■

Programmable Charge Termination Timer

■

Preset 4.2V Float Voltage with ±0.5% Accuracy

■

Programmable Charge Current Detection/Termination

■

Automatic Recharge

■

Thermistor Input for Temperature Qualified Charging

■

Compatible with Current Limited Wall Adapters

■

Low Profile 16-Lead (4mm × 4mm) QFN Package

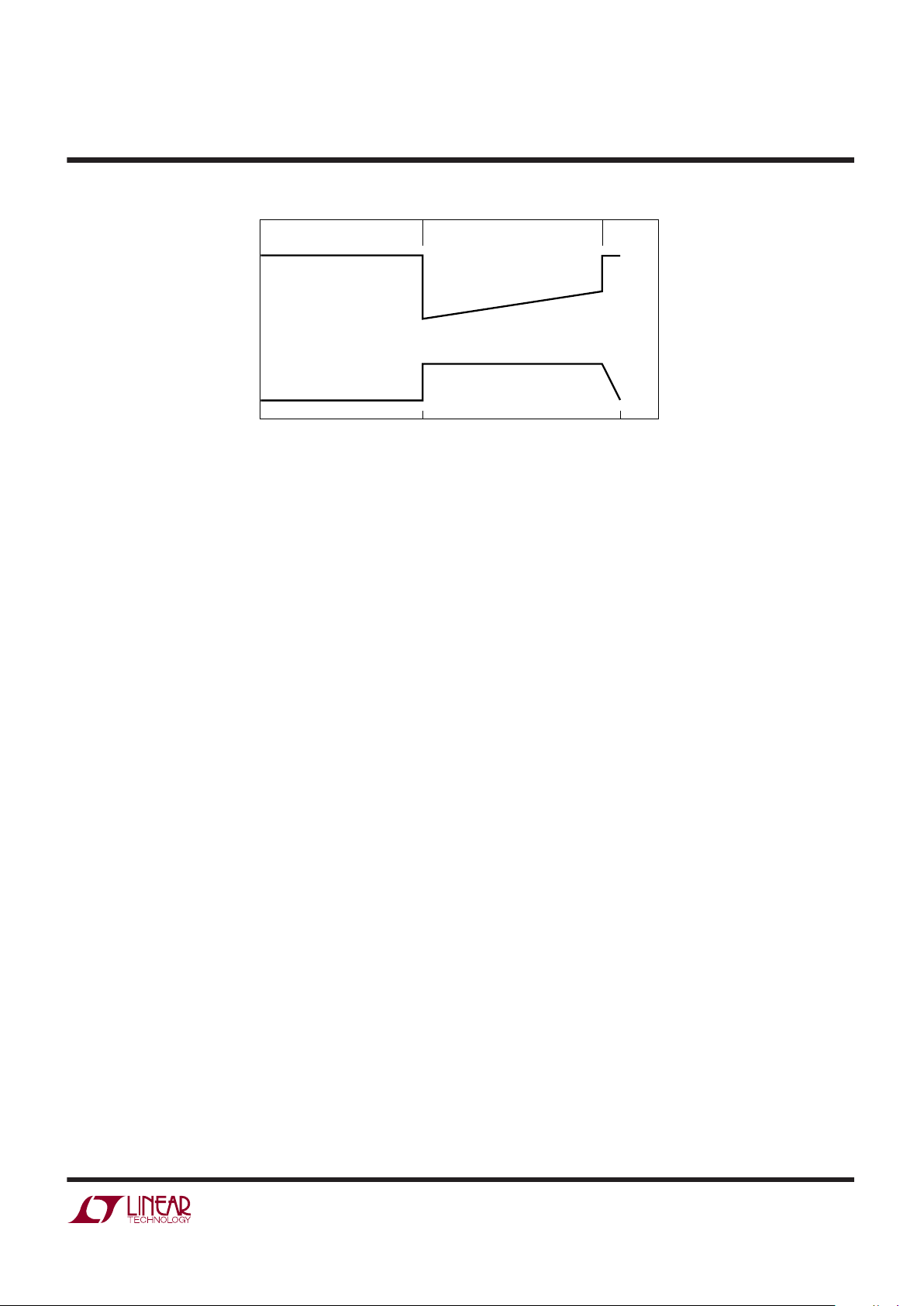

Power Loss vs V

BAT

Charging (PWM Mode)

FEATURES

DESCRIPTIO

U

APPLICATIO S

U

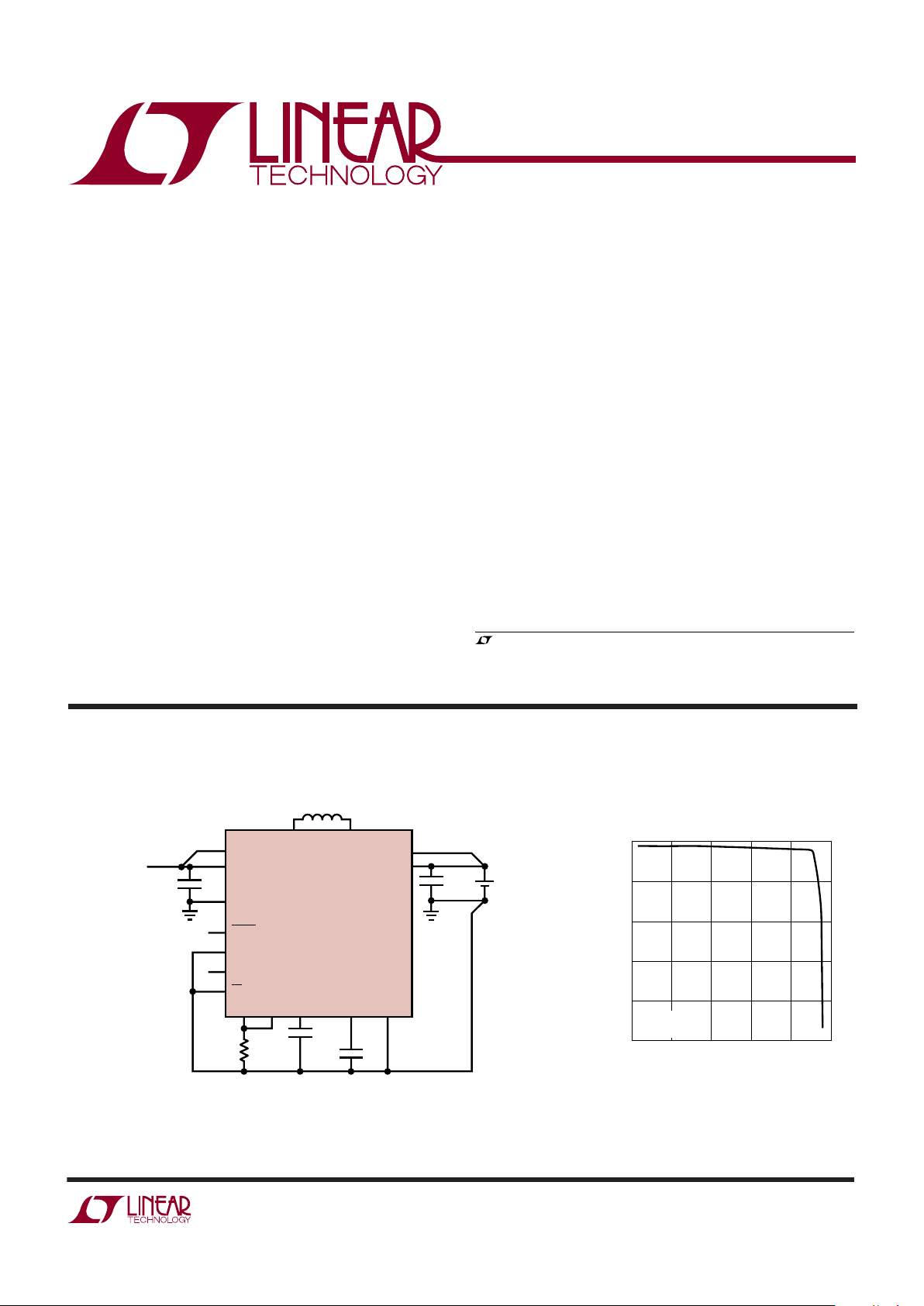

TYPICAL APPLICATIO

U

The LTC®4001 is a 2A Li-Ion battery charger intended for

5V wall adapters. It utilizes a 1.5MHz synchronous buck

converter topology to reduce power dissipation during

charging. Low power dissipation, an internal MOSFET and

sense resistor allow a physically small charger that can be

embedded in a wide range of handheld applications. The

LTC4001 includes complete charge termination circuitry,

automatic recharge and a ±1% 4.2V float voltage. Input

short-circuit protection is included so no blocking diode is

required.

Battery charge current, charge timeout and end-of-charge

indication parameters are set with external components.

Additional features include shorted cell detection, temperature qualified charging and overvoltage protection. The

LTC4001 is available in a low profile (0.75mm) 16-lead

(4mm × 4mm) QFN package.

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

+

PROG

EN

FAULT

NTC

CHRG

PGND

PV

IN

V

INSENSE

BAT

BATSENS

IDET TIMER

274Ω

0.22µF

10µF

4001 TA01a

4.2V

Li-Ion

10µF

V

IN

4.5V TO 5.5V

0.1µF

SS

SW SENSE

LTC4001

1.5µH

GNDSENS

V

BAT

(V)

3

TOTAL APPLICATION CIRCUIT POWER

DISSIPATION (W)

0.75

1.00

1.25

4

4001 TA01b

0.50

0.25

0

3.25

3.5

3.75

4.25

VIN = 5V

2A CHARGER

Page 2

2

LTC4001

4001f

Consult LTC Marketing for parts specified with wider operating temperature ranges.

ABSOLUTE AXI U RATI GS

WWWU

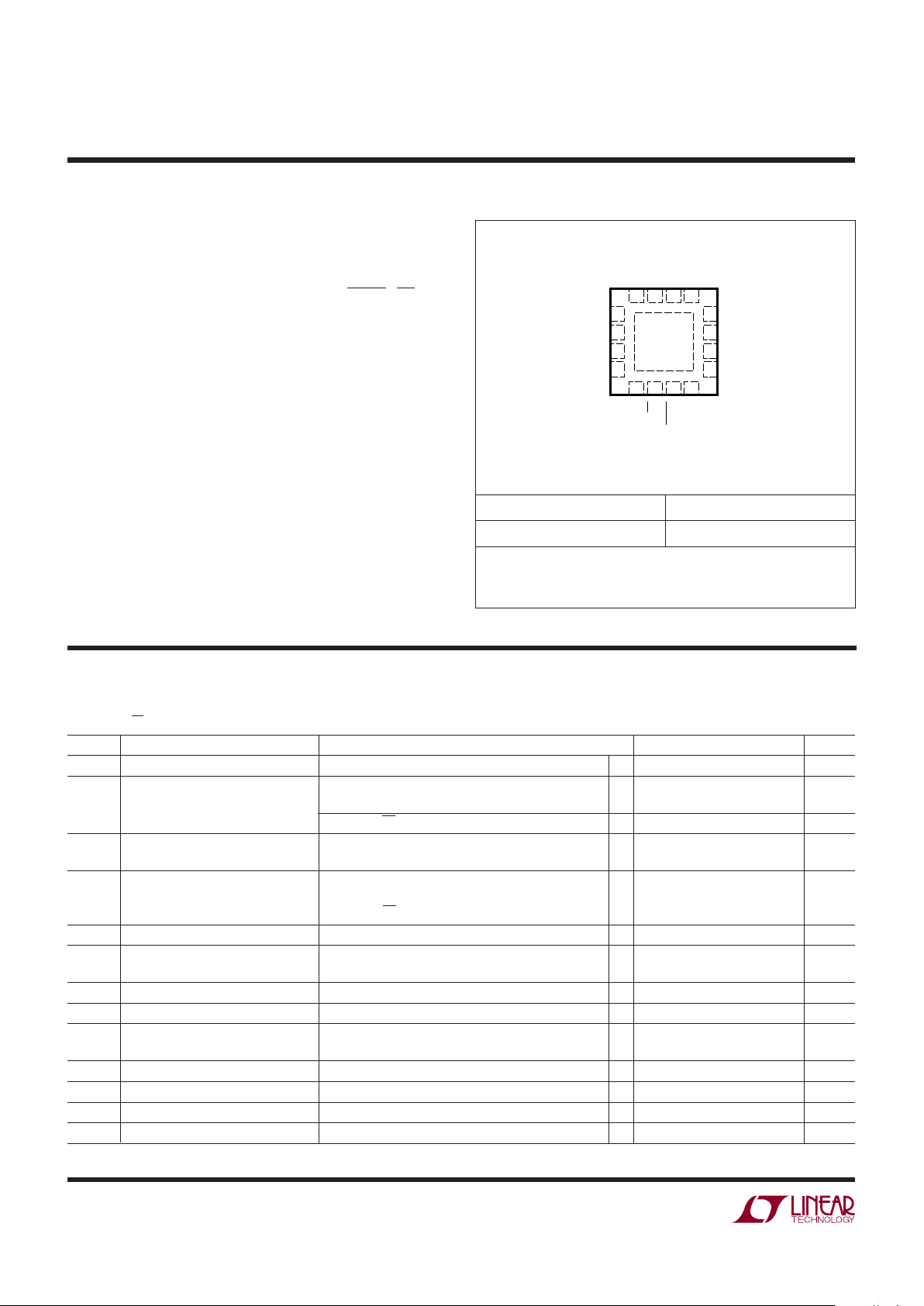

PACKAGE/ORDER I FOR ATIO

UU

W

(Note 1)

LTC4001EUF

ORDER PART NUMBER UF PART MARKING

4001

T

JMAX

= 125°C, θJA = 37°C/W

EXPOSED PAD (PIN 17) IS GND, MUST BE SOLDERED TO PCB

16 15 14 13

5 6 7 8

TOP VIEW

17

UF PACKAGE

16-LEAD (4mm × 4mm) PLASTIC QFN

9

10

11

12

4

3

2

1BAT

SENSE

PGND

GNDSENS

PROG

NTC

FAULT

V

INSENSE

BATSENS

TIMERSSIDET

SW

EN

CHRG

PV

IN

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IN

Supply Voltage (Note 2) 4 5.5 V

I

IN

PVIN Connected to V

INSENSE

, PROG and IDET 2 mA

Pins Open, Charger On

Shutdown, EN = V

IN

50 µA

V

FLOATVBAT

Regulated Float Voltage Measured from BATSENS to GNDSENS

●

4.158 4.2 4.242 V

4.179 4.2 4.221 V

I

BAT

Current Mode Charge Current R

PROG

= 549Ω, V

BAT

= 3.5V 1.8 2 2.2 A

R

PROG

= 1.10k, V

BAT

= 3.5V 0.9 1 1.1 A

Shutdown, EN = V

IN

±5 µA

I

TRIKL

Trickle Charge Current V

BAT

= 2V 35 50 65 mA

V

TRIKL

Trickle Charge Threshold V

BAT

Rising 3.05 3.1 3.20 V

V

BAT

Falling 2.85 3.0 3.05 V

V

UVL

VIN Undervoltage Lockout Voltage VIN Rising, Measured from V

INSENSE

to GNDSENS 2.7 2.82 V

∆V

UVL

VIN Undervoltage Lockout Hysteresis Measured from V

INSENSE

to GNDSENS 100 mV

V

ASD

Automatic Shutdown Threshold V

INSENSE

– V

BATSENS

Rising (Turn-On), V

BATSENSE

= 4V 200 250 300 mV

Voltage V

INSENSE

– V

BATSENS

Falling (Turn-Off), V

BATSENSE

= 4V 15 30 60 mV

f

OSC

Oscillator Frequency 1.3 1.5 1.7 MHz

D Maximum Duty Factor 100 %

R

PFET

R

DS(ON)

of P-Channel MOSFET Measured from PVIN to SW 127 mΩ

R

NFET

R

DS(ON)

of N-Channel MOSFET Measured from SW to PGND 121 mΩ

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

V

IN

= 5V, VEN = 0V, R

PROG

= 549Ω, R

IDET

= 549Ω, unless otherwise specified.

ELECTRICAL CHARACTERISTICS

Order Options Tape and Reel: Add #TR

Lead Free: Add #PBF Lead Free Tape and Reel: Add #TRPBF

Lead Free Part Marking: http://www.linear.com/leadfree/

PVIN, V

INSENSE

t < 1ms, DC < 1% .................................... –0.3V to 7V

Steady State ............................................ –0.3V to 6V

SW, SENSE, BAT, BATSENS, SS, FAULT, CHRG, EN,

NTC, PROG, IDET, TIMER Voltage .............. – 0.3V to 6V

Operating Temperature Range (Note 3) .. –40°C to 85°C

Operating Junction Temperature

(Note 5) ............................................... – 40°C to 125°C

Storage Temperature Range ................ –65°C to 125°C

Page 3

3

LTC4001

4001f

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

t

TIMER

Timer Accuracy C

TIMER

= 0.22µF ±10 %

V

EN

Enable Input Threshold Voltage VEN Rising 0.6 0.8 1 V

∆V

EN

Enable Input Hysteresis 100 mV

V

PROG

PROG Pin Voltage R

PROG

= 549Ω 1.213 V

V

IDET

IDET Pin Voltage R

IDET

= 549Ω 1.213 V

I

IDET

IDET Threshold R

IDET

= 549Ω 150 200 250 mA

I

CHRG

CHRG Pin Weak Pull-Down Current V

CHRG

= 1V 15 30 50 µA

V

CHRG

CHRG Pin Output Low Voltage I

CHRG

= 5mA 0.2 0.4 V

V

OL

FAULT Pin Output Low Voltage 1mA Load 0.4 V

V

OH

FAULT Pin Output High Voltage 1mA Load 4.6 V

V

RECHRG

Recharge Battery Threshold Voltage V

FLOAT

– V

RECHRG VBAT

Falling 50 100 135 mV

t

RB

Recharge Filter Time Constant 4 ms

t

RECHRG

Recharge Time Percent of Total Charge Time 50 %

t

TRIKL

Low-Battery Trickle Charge Time Percent of Total Charge Time, V

BAT

< 2.8V, 25 %

Measured Using BATSENS and GNDSENS Pins

I

SS

Soft-Start Ramp Current V

BAT

< V

FLOAT

– 100mV, V

BAT

Across BATSENS 6 12.8 16 µA

and GNDSENS Pins

V

COLD

NTC Pin Cold Temperature Fault From NTC to GNDSENS Pin

Threshold Rising Threshold 0.74 V

INSENSE

V

Falling Threshold 0.72 V

INSENSE

V

V

HOT

NTC Pin Hot Temperature Fault From NTC to GNDSENS Pin

Threshold Falling Threshold 0.29 V

INSENSE

V

Rising Threshold 0.30 V

INSENSE

V

V

DIS

NTC Disable Threshold (Falling) From NTC to GNDSENS Pin 0.015 • 0.02 • 0.025 • V

V

INSENSEVINSENSEVINSENSE

∆V

DIS

NTC Disable Hysteresis From NTC to GNDSENS Pin 0.01 • V

INSENSE

V

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

V

IN

= 5V, VEN = 0V, R

PROG

= 549Ω, R

IDET

= 549Ω, unless otherwise specified.

ELECTRICAL CHARACTERISTICS

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: Operation with current limited wall adapters is allowed down to the

undervoltage lockout threshold.

Note 3: The LTC4001E is guaranteed to meet performance specifications

from 0°C to 85°C. Specifications over the –40°C to 85°C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 4: T

J

is calculated from the ambient temperature TA and power

dissipation P

D

according to the following formula:

T

J

= TA + (PD • 37°C/W)

Note 5: This IC includes overtemperature protection that is intended to

protect the device during momentary overload. Junction temperature will

exceed 125°C when overtemperature protection is active. Continuous

operation above the specified maximum operating junction temperature

my impair device reliability.

Page 4

4

LTC4001

4001f

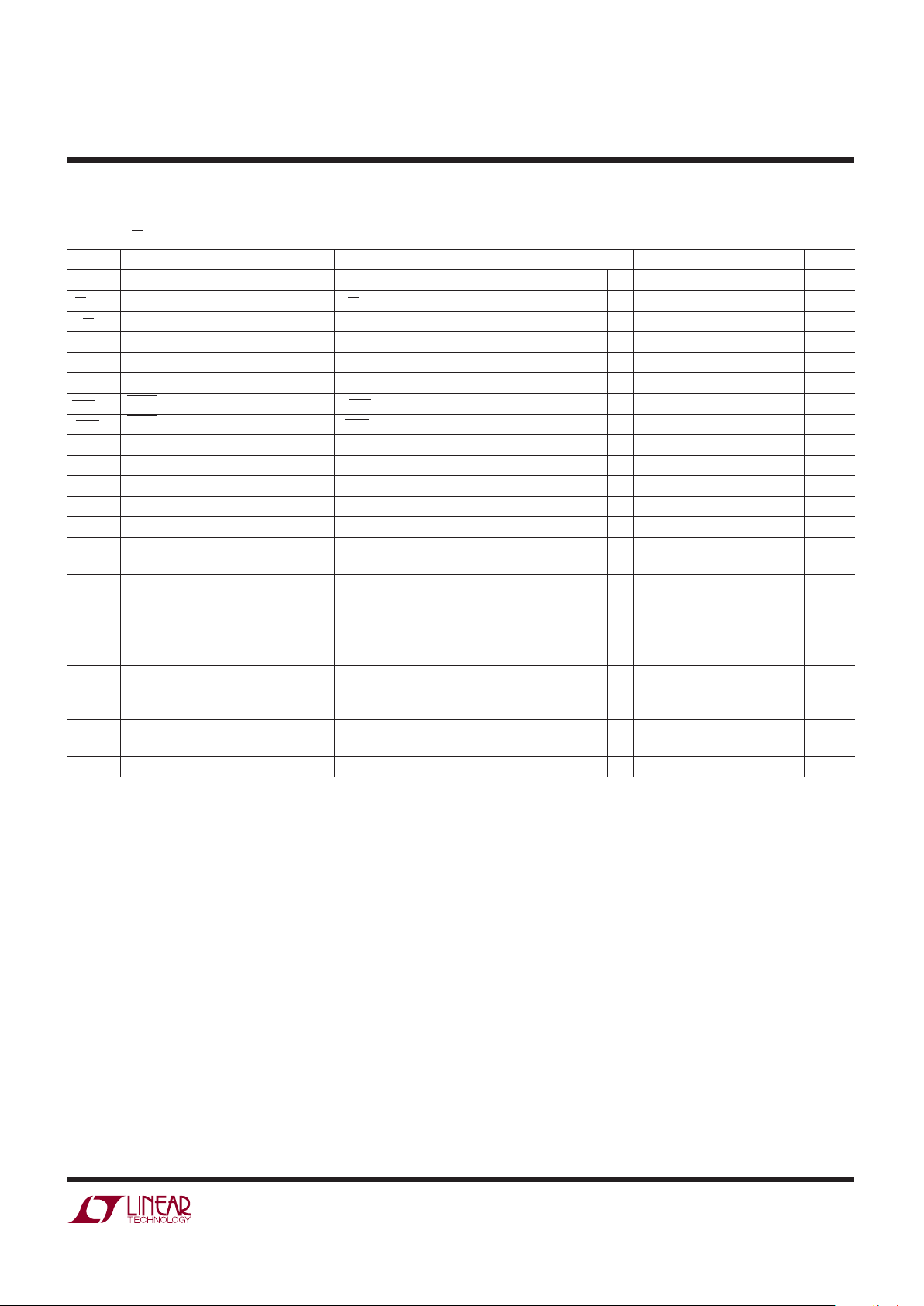

TYPICAL PERFOR A CE CHARACTERISTICS

UW

Oscillator Frequency vs V

IN

Oscillator Frequency

vs Temperature

Dissipation of Figure 8 Circuit

vs I

BAT

PROG Pin Characteristic

(V

PROG

vs I

PROG

)

Dissipation of Figure 8 Circuit

vs V

IN

Trickle Charge Current vs V

BAT

V

FLOAT

and Recharge Battery

Threshold Voltage vs Temperature

Output Charging Characteristic

Showing Constant Current and

Constant Voltage Operation

(T

A

= 25°C unless otherwise noted)

VIN (V)

3

PERCENT VARIATION (%)

–0.25

0

0.25

4.5

5.5

4001 G01

–0.50

–0.75

–1.00

3.5 4 5

0.50

0.75

1.00

6

V

BAT

= 3.2V

V

SS

= 1V

I

PROG

(mA)

0

0.8

1.0

15

4001 G05

0.6

0.4

510 20

0.2

0

1.2

V

PROG

(V)

VIN = 5V

V

BAT

= 3.2V V

BAT

= 4V

V

BAT

= 3.5V

V

BAT

= 3.7V

V

BAT

(V)

0

0

I

BAT

(A)

0.5

1.0

1.5

2.0

0.5 1 1.5 2

4001 G06

2.5 3 3.5 4

V

BAT

(V)

0

40

I

BAT

(mA)

45

50

55

0.5 1 1.5 2

4001 G07

2.5 3

VIN = 5.5V

VIN = 5V

VIN = 4V

VIN = 4.5V

TEMPERATURE (°C)

–50

FREQUENCY VARIATION FROM 25°C (%)

0.4

0.6

0.8

110

4001 G02

0.2

0

–0.2

–30 –10 10

30 50

70 90 130

150

VIN = 5V

V

BAT

= 3.2V

V

SS

= 1V

I

BAT

(mA)

500

TOTAL APPLICATION CIRCUIT POWER

DISSIPATION (W)

0.50

0.75

4001 G03

0.25

0

1000

1500

2000

1.25

1.00

V

IN

= 5V

V

BAT

= 4V

VIN (V)

4.25

1.0

1.2

1.4

5.25

4001 G04

0.8

0.6

4.5 4.75 5 5.5

0.4

0.2

0

TOTAL APPLICATION CIRCUIT POWER

DISSIPATION (W)

I

BAT

= 2A

V

BAT

= 4V

I

BAT

= 1.5A

I

BAT

= 1A

I

BAT

= 500mA

TEMPERATURE (°C)

4.0

FLOAT AND RECHARGE VOLTAGES (V)

4.1

4.2

4.3

–10 30 70 110

4001 G08

150–30–50 10 50 90 130

V

FLOAT

V

RECHARGE

(V

BAT

FALLING)

Page 5

5

LTC4001

4001f

TYPICAL PERFOR A CE CHARACTERISTICS

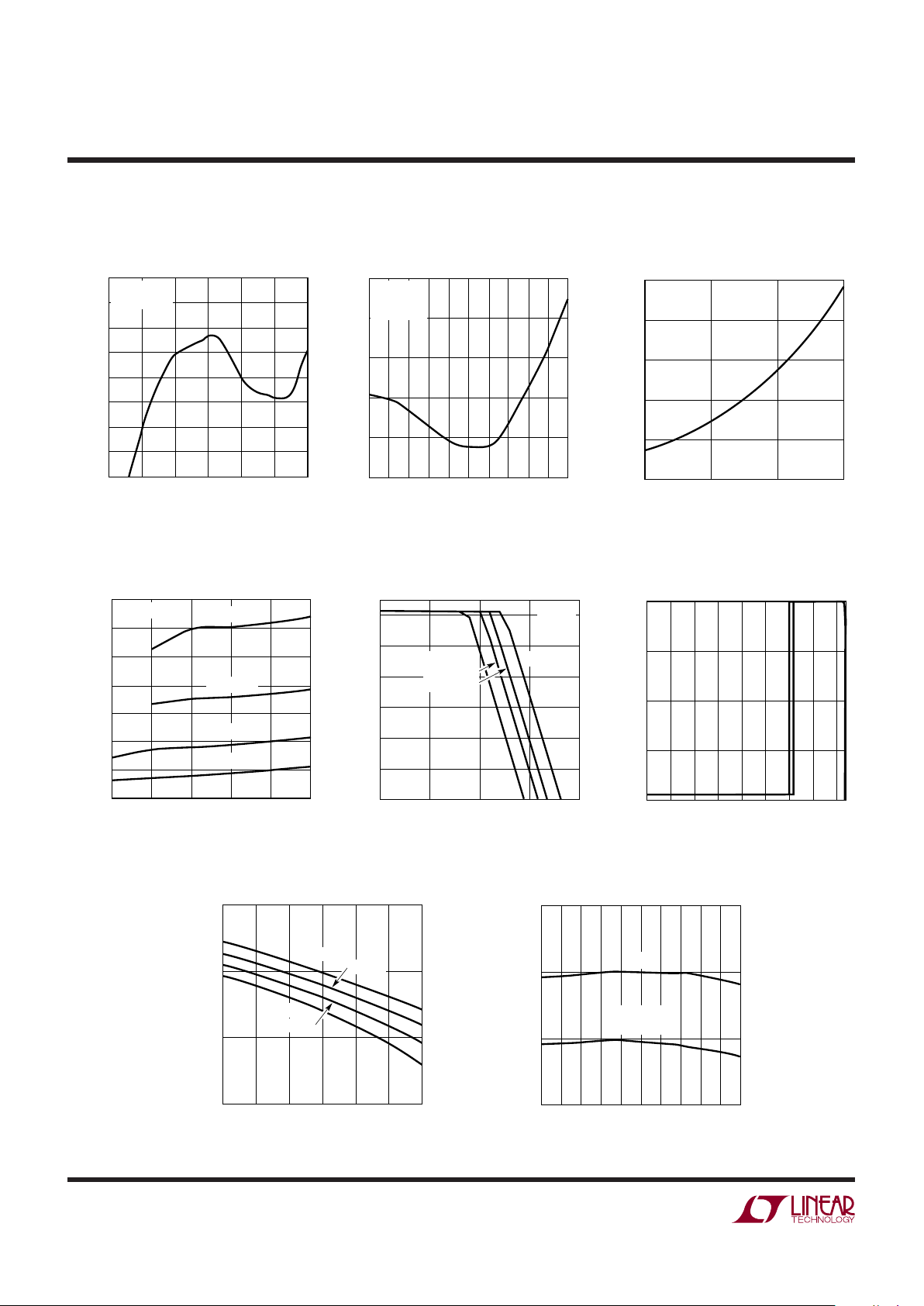

UW

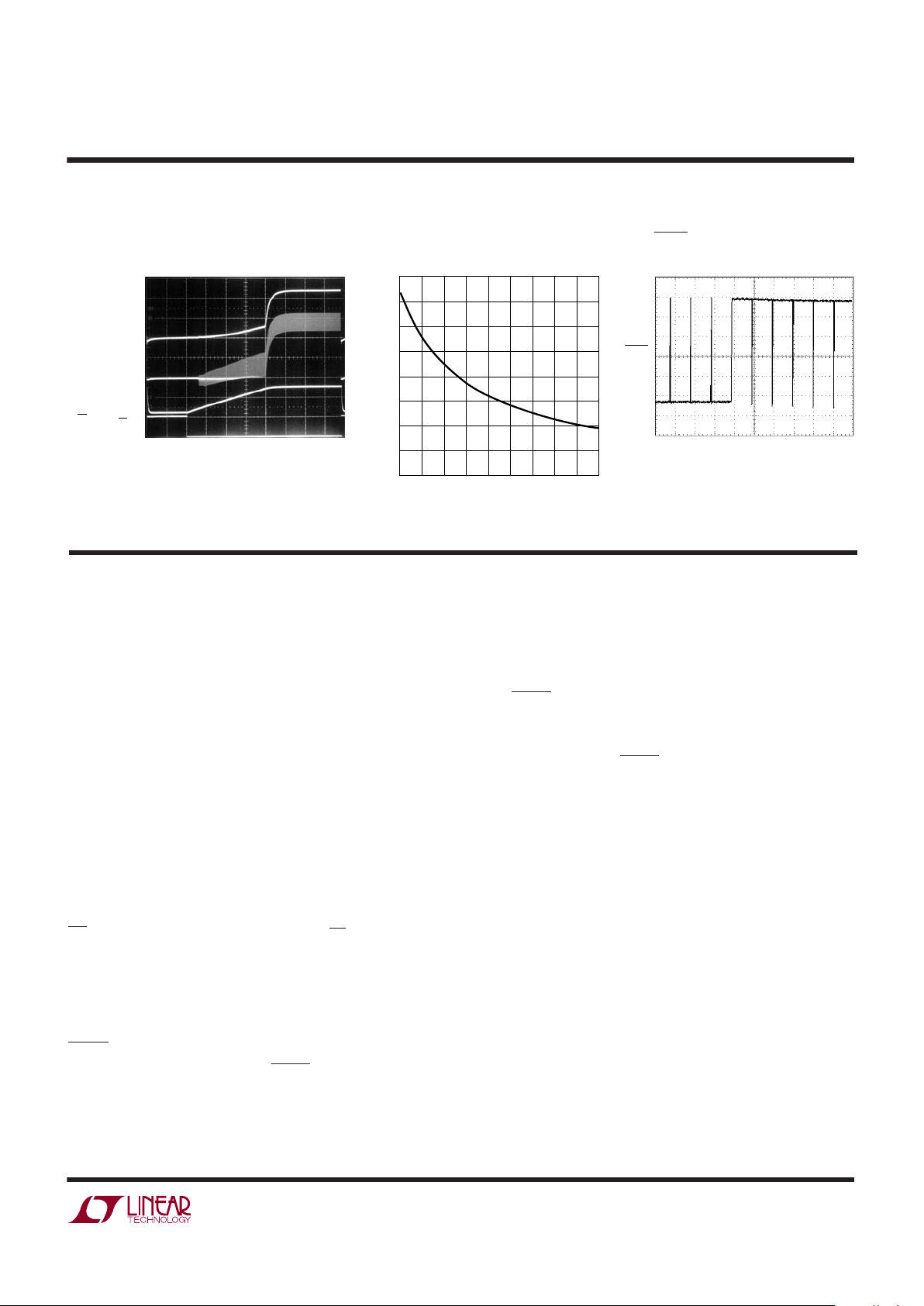

Soft-Start (PWM Mode)

IDET Threshold vs R

IDET

for

R

PROG

= 549Ω

UU

U

PI FU CTIO S

BAT (Pin 1): Battery Charger Output Terminal. Connect a

10µF ceramic chip capacitor between BAT and PGND to

keep the ripple voltage small.

SENSE (Pin 2): Internal Sense Resistor. Connect to external inductor.

PGND (Pin 3): Power Ground.

GNDSENS (Pin 4): Ground Sense. Connect this pin to the

negative battery terminal. GNDSENS provides a Kelvin

connection for PGND and must be connected to PGND

schematically.

SW (Pin 5): Switch Node Connection. This pin connects to

the drains of the internal main and synchronous power

MOSFET switches. Connect to external inductor.

EN (Pin 6): Enable Input Pin. Pulling the EN pin high places

the LTC4001 into a low power state where the BAT drain

current drops to less than 3µA and the supply current is

reduced to less than 50µA. For normal operation, pull the

pin low.

CHRG (Pin 7): Open-Drain Charge Status Output. When

the battery is being charged, CHRG is pulled low by an

internal N-channel MOSFET. When the charge current

drops below the IDET threshold (set by the R

IDET

programming resistor) for more than 5milliseconds, the N-channel

MOSFET turns off and a 30µA current source is connected

from CHRG to ground. (This signal is latched and is reset

by initiating a new charge cycle.) When the timer runs out

or the input supply is removed, the current source will be

disconnected and the CHRG pin is forced to a high impedance state. A temperature fault causes this pin to blink.

PV

IN

(Pin 8): Positive Supply Voltage Input. This pin

connects to the power devices inside the chip. V

IN

ranges

from 4V to 5.5V for normal operation. Operation down to

the undervoltage lockout threshold is allowed with current

limited wall adapters. Decouple with a 10µF or larger

surface mounted ceramic capacitor.

V

INSENSE

(Pin 9): Positive Supply Sense Input. This pin

connects to the inputs of all input comparators (UVL, V

IN

to V

BAT

). It also supplies power to the controller portion of

this chip. When the BATSENS pin rises to within 30mV of

V

INSENSE

, the LTC4001 enters sleep mode, dropping IIN to

50µA. Tie this pin directly to the terminal of the PV

IN

decoupling capacitor.

CHRG Pin Temperature Fault

Behavior (Detail)

0

INPUT

CURRENT (I

IN

)

0.5A/DIV

INDUCTOR

CURRENT (I

L

)

0.5A/DIV

SOFT-START

VOLTAGE (V

SS

)

1V/DIV

EN PIN (V

EN

)

5V/DIV

0

0

0

2ms/DIVV

BAT

= 3.5V

V

IN

= 5V

4001 G09

R

IDET

(Ω)

300

IDET (mA)

200

250

300

1100

4001 G10

150

100

0

500

700

900

400 1200

600

800

1000

50

400

350

CHRG

1V/DIV

TIME (20µs/DIV)

4001 G11

Page 6

6

LTC4001

4001f

FAULT (Pin 10): Battery Fault. This pin is a logic high if a

shorted battery is detected or if a temperature fault is

detected. A temperature fault occurs with the temperature

monitor circuit enabled and the thermistor temperature is

either below 0°C or above 50°C (typical).

NTC (Pin 11): Input to the NTC (Negative Temperature

Coefficient) Thermistor Temperature Monitoring Circuit.

Under normal operation, tie a thermistor from the NTC pin

to the GNDSENS pin and a resistor of equal value from NTC

to VIN. When the voltage on this pin is above 0.74VIN (Cold,

0°C) or below 0.29V

IN

(Hot, 50°C), charging is disabled

and the CHRG pin blinks. When the voltage on NTC comes

back between 0.74V

IN

and 0.29VIN, the timer continues

where it left off and charging resumes. There is approximately 3°C of temperature hysteresis associated with

each of the input comparators. If the NTC function is not

used connect the NTC pin to GNDSENS. This will disable

all of the NTC functions. NTC should never be pulled above

VIN.

PROG (Pin 12): Charge Current Program. The R

PROG

resistor connects from this pin to GNDSENS, setting the

current:

R

k

I

PROG

BAT AMPS

=

1 110.

()

where I

BAT

is the high rate battery charging current.

UU

U

PI FU CTIO S

IDET (Pin 13): Charge Rate Detection Threshold. Connecting a resistor, R

IDET

to GNDSENS programs the charge

rate detection threshold. If R

IDET

= R

PROG

, CHRG provides

an I

BAT

/10 indication. For other thresholds see the Appli-

cations Information section.

SS (Pin 14): Soft-Start/Compensation. Provides soft-start

function and compensation for the float voltage control

loop and compensation for the charge current control

loop. Tie a soft-start/compensation capacitor between this

pin and GNDSENS.

TIMER (Pin 15): Timer Capacitor. The timer period is set

by placing a capacitor, C

TIMER

, to GNDSENS. Set C

TIMER

to:

C

TIMER

= Time (Hrs) • 0.0733 (µF)

where time is the desired charging time.

Connect this pin to IDET to disable the timer. Connect this

pin to GNDSENS to end battery charging when I

BAT

drops

below the IDET charge rate threshold.

BATSENS (Pin 16): Battery Sense Input. An internal resistor divider sets the final float voltage at this pin. The

resistor divider is disconnected in sleep mode or when

EN = H to reduce the battery drain current. Connect this pin

to the positive battery terminal.

Exposed Pad (Pin 17): Ground. This pin must be soldered

to the PCB ground (PGND) for electrical contact and rated

thermal performance.

Page 7

7

LTC4001

4001f

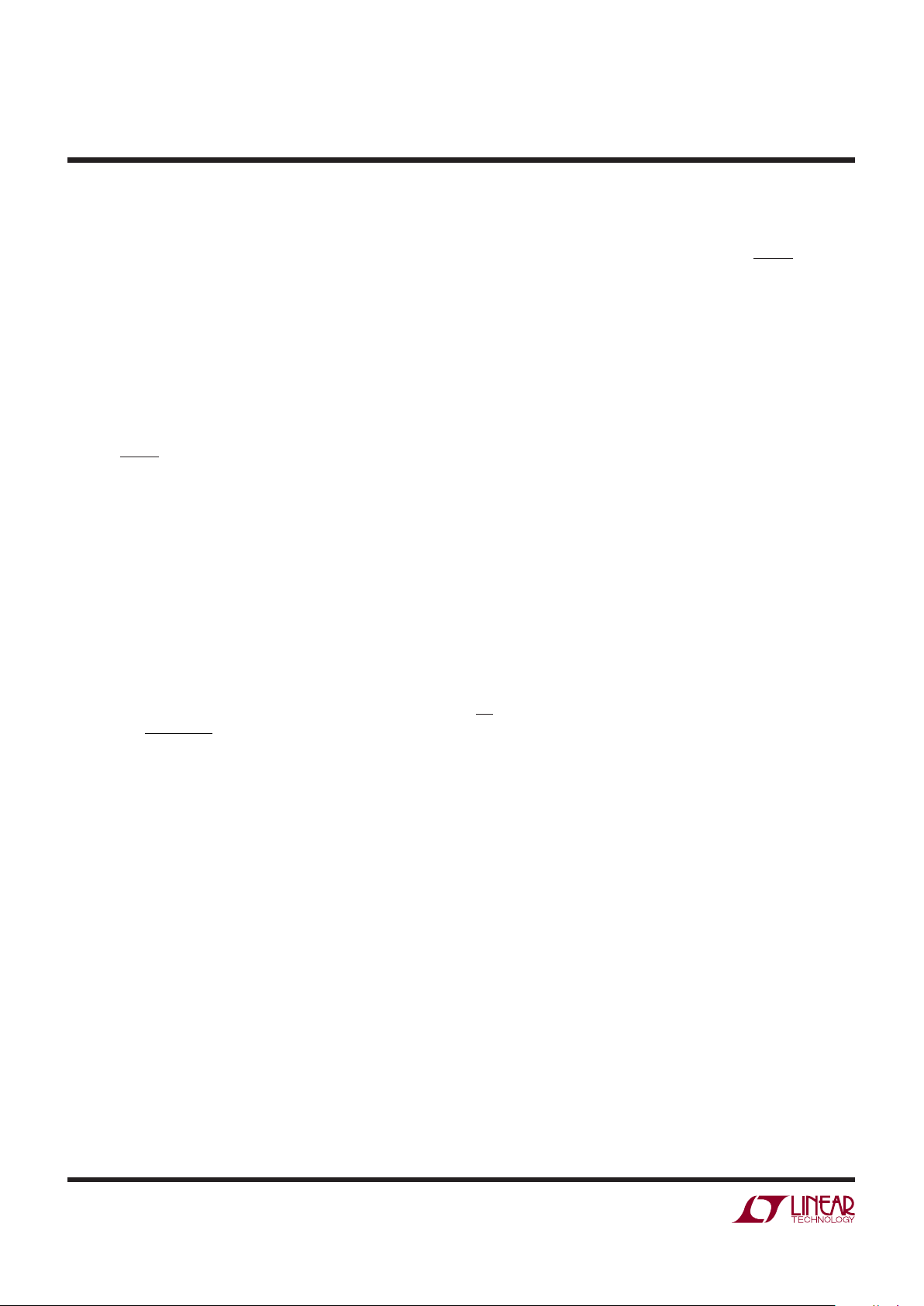

BLOCK DIAGRA

W

BATTERY

OVERVOLTAGE

COMPARATOR

VOLTAGE

REFERENCE

+

–

UNDERVOLTAGE

COMPARATOR

FLOAT VOLTAGE

ERROR AMP

RECHARGE

COMPARATOR

LOW-BATTERY

COMPARATOR

SHUTDOWN

COMPARATOR

OVERCURRENT

COMPARATOR

CURRENT

REVERSAL

COMPARATOR

+

–

+

–

CHARGE CURRENT

ERROR AMP

PROG

ERROR

AMP

PROG SHORT

COMPARATOR

+

–

IDET

COMPARATOR

+

–

1.2V

150mV

GNDSENS

4001 BD

+

–

+

–

SOFT-START

COPMPARATOR

+

–

1.1V

1.2V

LOW CURRENT

V

IN

GOOD

RECHARGE

DISCHARGE SS

PROG SHORTED

SS LOW

OVERVOLTAGE

CHIP OVER TEMP

CHIP

OVERTEMP

COMPARATOR

CONNECT

PWM ON

TRICKLE ON

OVERCURRENT

SHUTDOWN

LOW BATTERY

+

–

+

–

+

–

4

PROGIDET

12

13

GND

17

50mA

BAT

9

V

INSENSE

16

BATSENSSENSE

2

SW

5

+

–

1

+

–

+

–

PGND

DRIVER

PWM

COMPARATOR

OSCILLATOR

Q

S

SS

RD

3

PV

IN

8

11

CLK

RAMP

+

–

TFAULT

NTC

NTC

COMPARATOR

15

TIMER

TIMER

10

FAULT

LOGIC

FAULT

7

CHRG

CHRG

6

EN

EN

14

SS

Page 8

8

LTC4001

4001f

OPERATIO

U

The LTC4001 is a constant current, constant voltage

Li-Ion battery charger based on a synchronous buck

architecture. Low power dissipation makes continuous

high rate (2A) battery charging practical. The battery DC

charge current is programmed by a resistor R

PROG

(or a

DAC output current) at the PROG pin. The final battery float

voltage is internally set to 4.2V.

Charging begins when the VIN voltage rises above the

UVLO level (approximately 2.75V), V

IN

is 250mV greater

than the battery voltage and EN is low. At the beginning of

the charge cycle, if the battery voltage is less than the

trickle charge threshold, 3V, the charger goes into trickle

charge mode and delivers approximately 50mA to the

battery using a linear charger. If the battery voltage stays

low for more than one quarter of the charge time, the

battery is considered faulty, the charge cycle is terminated

and the FAULT pin produces a logic high output.

When the battery voltage exceeds the trickle charge threshold, the low rate linear charger is turned off and the high

rate PWM charger ramps up (based on the SS pin capacitance) reaching its full-scale constant current (set via the

PROG pin). When the battery approaches the float voltage,

the charge current will start to decrease. When the charge

current drops below the charge rate detection threshold

(set via the IDET pin) for more than 5ms, an internal

comparator turns off the internal pull-down N-channel

MOSFET at the CHRG pin, and connects a weak current

source (30µA typical) to ground to indicate a near end-of-

charge condition.

Total charge time is set by an external capacitor connected

to the timer pin. After timeout occurs, the charge cycle is

terminated and the CHRG pin is forced to a high impedance state. To restart the charge cycle, remove and reapply

the input voltage, or momentarily shut the charger down

via the EN pin. Also, a new charge cycle will begin if the

battery voltage drops below the recharge threshold voltage (100mV below the float voltage). A recharge cycle

lasts only one-half of the normal charge time.

A negative temperature coefficient (NTC) thermistor located close to the battery pack can be used to monitor

battery temperature and suspend charging when battery

temperature is outside the 0°C to 50°C window. A temperature fault drives the FAULT pin high and makes the

CHRG pin blink. When the input voltage (V

IN

) is present,

the charger can be shut down by pulling the EN pin up.

IDET Blanking

The IDET comparator provides an end-of-charge indication by sensing when battery charge current is less than

the IDET threshold. To prevent a false end-of-charge

indication from occurring during soft-start, this comparator is blanked until the battery voltage approaches the float

voltage.

Automatic Battery Recharge

After the charge cycle is completed and if both the battery

and the input power supply (wall adapter) are still connected, a new charge cycle will begin if the battery voltage

drops below 4.1V due to self-discharge or external loading. This will keep the battery near maximum capacity at all

times without manually restarting the charge cycle.

In some applications such as battery charging in GPRS

cellphones, large load current transients may cause battery voltage to momentarily drop below the recharge

threshold. To prevent these transients from initiating a

recharge cycle when it is not needed, the output of the

recharge comparator is digitally qualified. Only if the

battery voltage stays below the recharge threshold for at

least 4ms will battery recharging occur. (GPRS qualification is available even if timeout is disabled.)

Undervoltage Lockout and Automatic Shutdown

Internal undervoltage lockout circuits monitor V

IN

and

keep the charger circuits shut down until V

IN

rises above

the undervoltage lockout threshold (3V). The UVLO has a

built-in hysteresis of 100mV. Furthermore, to protect

against reverse current, the charger also shuts down if V

IN

is less than V

BAT

. If automatic shutdown is tripped, V

IN

must increase to more than 250mV above V

BAT

to allow

charging.

Page 9

9

LTC4001

4001f

OPERATIO

U

Overvoltage, Chip Overtemperature and Short-Circuit

Current Protection

The LTC4001 includes overvoltage, chip overtemperature

and several varieties of short-circuit protection.

A comparator turns off both chargers (high rate and

trickle) if battery voltage exceeds the float voltage by

approximately 5%. This may occur in situations where the

battery is accidentally disconnected while battery charging is underway.

A comparator continuously monitors on-chip temperature

and will shut off the battery charger when chip temperature

exceeds approximately 160°C. Battery charging will be

enabled again when temperature drops to approximately

150°C.

Short-circuit protection is provided in several different

ways. First, a hard short on the battery terminals will

cause the charge to enter trickle charge mode, limiting

charge current to the trickle charge current (typically

50mA). Second, PWM charging is prevented if the high

rate charge current is programmed far above the 2A

maximum recommended charge current (via the PROG

pin). Third, an overcurrent comparator monitors the peak

inductor current.

Page 10

10

LTC4001

4001f

APPLICATIO S I FOR ATIO

WUUU

Soft-Start and Compensation Capacitor Selection

The LTC4001 has a low current trickle charger and a

PWM-based high current charger. Soft-start is used whenever the high rate charger is initially turned on, preventing

high start-up current. Soft-start ramp rate is set by the

internal 12.8µA pull-up current and an external capacitor.

The control range on the SS pin is approximately 0.3V to

1.6V. With a 0.1µF capacitor, the time to ramp up to

maximum duty cycle is approximately 10ms.

The external capacitor on the SS pin also sets the compensation for the current control loop and the float voltage

control loop. A minimum capacitance of 10nF is required.

Charge Current and IDET Programming

The LTC4001 has two different charge modes. If the

battery is severely depleted (battery voltage less than

2.9V) a 50mA trickle current is initially used. If the battery

voltage is greater than the trickle charge threshold, high

rate charging is used.

This higher charge current is programmable and is approximately 915 times the current delivered by the PROG

pin. This current is usually set with an external resistor

from PROG to GNDSENS, but it may also be set with a

current output DAC connected to the PROG pin. The

voltage on the PROG pin is nominally 1.213V.

For 2A charge current:

R

V

A

PROG

= ≅Ω

915 1 213

2

554 9•..

The IDET threshold (a charge current threshold used to

determine when the battery is nearly fully charged) is

programmed in much the same way as the PROG pin,

except that the IDET threshold is 91.5 times the current

delivered by the IDET pin. This current is usually set with

an external resistor from IDET to ground, but it may also

be set with a current output DAC. The voltage on the PROG

pin is nominally 1.213V.

For 200mA IDET current (corresponding to C/10 for a

2AHr battery):

R

V

A

IDET

= ≅Ω

91 5 1 213

02

554 9

.•.

.

.

1.10kΩ programs approximately 100mA and 274Ω approximately 400mA.

For applications where IDET is set to one tenth of the high

rate charge current, and slightly poorer charger current

and IDET threshold accuracy is acceptable, the PROG and

IDET pins may be tied together and a single resistor, R1,

can program both (Figure 1).

R

I

CHARGE

1

457 5 1 213

=

.•.

and

IDET

I

CHARGE

=

10

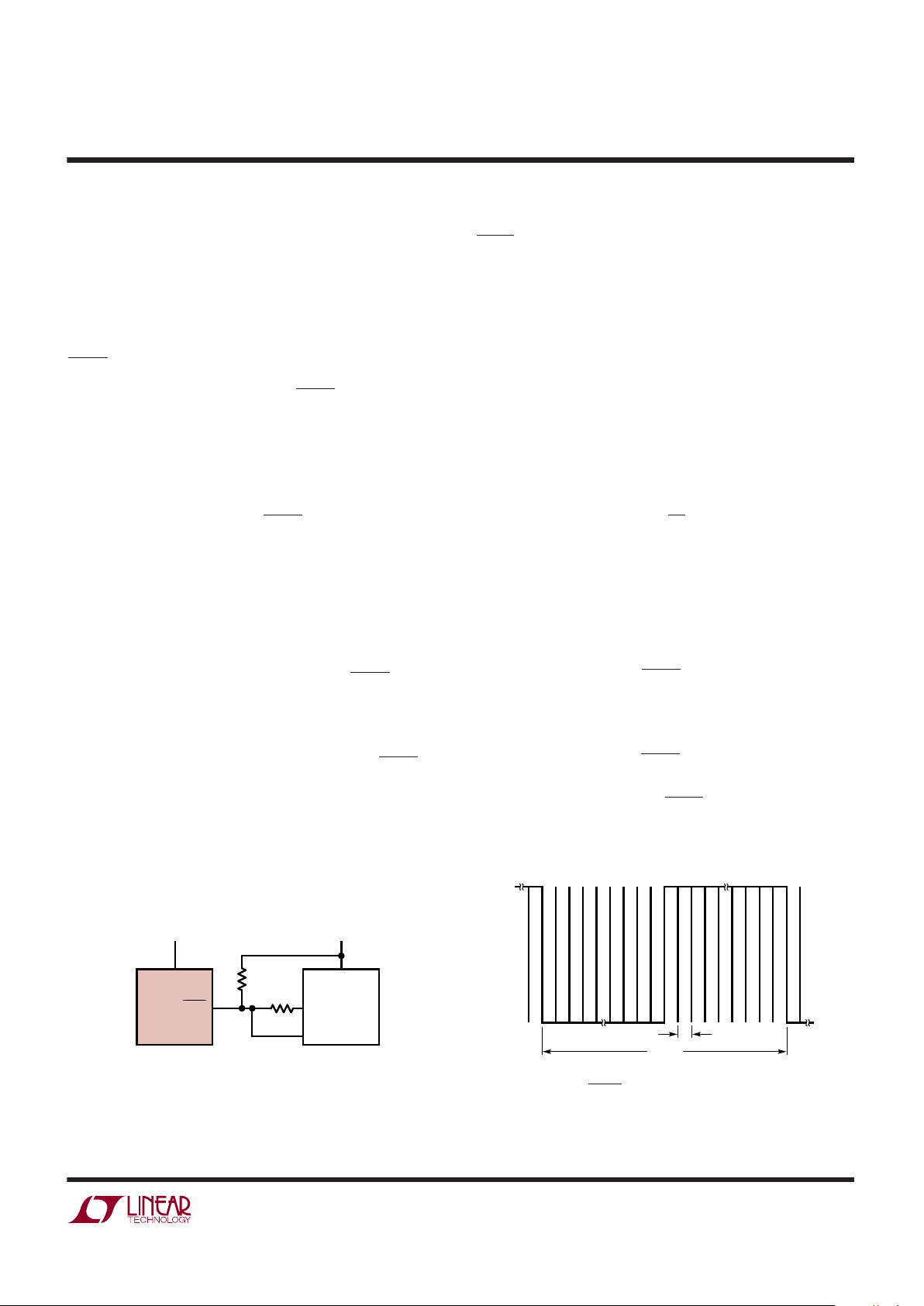

Figure 1. Programming Charge Current and IDET Threshold

with a Single Resistor

PROG

LTC4001

IDET

R1

274Ω FOR 2A

GNDSENS

4001 F01

Page 11

11

LTC4001

4001f

The equations for calculating R1 (used in single resistor

programming) differ from the equations for calculating

R

PROG

and R

IDET

(2-resistor programming) and reflect the

fact that the current from both the IDET and PROG pins

must flow through a single resistor R1 when a single

programming resistor is used.

CHRG Status Output Pin

When a charge cycle starts, the CHRG pin is pulled to

ground by an internal N-channel MOSFET which is capable

of driving an LED. When the charge current drops below

the end-of-charge (IDET) threshold for at least 4ms, and

the battery voltage is close to the float voltage, the N-channel

MOSFET turns off and a weak 30µA current source to

ground is connected to the CHRG pin. This weak pulldown remains until the charge cycle ends. After charging

ends, the pin will become high impedance. By using two

different value resistors, a microprocessor can detect

three states from this pin (charging, end-of-charge and

charging stopped). See Figure 2.

To detect the charge mode, force the digital output pin,

OUT, high and measure the voltage on the CHRG pin. The

N-channel MOSFET will pull the pin low even with a 2k pullup resistor. Once the charge current drops below the endof-charge threshold, the N-channel MOSFET is turned off

and a 30µA current source is connected to the CHRG pin.

The IN pin will then be pulled high by the 2k resistor

connected to OUT. Now force the OUT pin into a high

impedance state, the current source will pull the pin low

through the 390k resistor. When charging stops, the

CHRG pin changes to a high impedance state and the 390k

resistor will then pull the pin high to indicate charging has

stopped.

Charge Termination

Battery charging may be terminated several different ways,

depending on the connections made to the TIMER pin. For

time-based termination, connect a capacitor between the

TIMER pin and GNDSENS (C

TIMER

= Time(Hrs) 0.0733µF).

Charging may be terminated when charge current drops

below the IDET threshold by tying TIMER to GNDSENS.

Finally, charge termination may be defeated by tying

TIMER to IDET. In this case, an external device can

terminate charging by pulling the EN pin high.

Battery Temperature Detection

When battery temperature is out of range (either too hot or

too cold) charging is temporarily halted and the FAULT pin

is driven high. In addition, if the battery is still charging at

a high rate (greater than the IDET current) when a temperature fault occurs, the CHRG pin NMOS turns on and off

at approximately 50kHz, alternating between a high and

low duty factor at an approximate rate of 1.5Hz (Figure 3).

This provides a low rate visual indication (1.5Hz) when

driving an LED from the CHRG pin while providing a fast

temperature fault indication (20useconds typical) to a

microprocessor by tying the CHRG pin to an interrupt line.

Serrations within this pulse are typically 500ns wide.

APPLICATIO S I FOR ATIO

WUUU

Figure 2. Microprocessor Interface

Figure 3. CHRG Temperature Fault Waveform

LTC4001

V

IN

V

DD

IN

OUT

µPROCESSOR

CHRG

R2

2k

R1

390k

4001 F02

20µs

4001 F03

667ms

Page 12

12

LTC4001

4001f

The battery temperature is measured by placing a negative

temperature coefficient (NTC) thermistor close to the

battery pack. To use this feature, connect the NTC thermistor, R

NTC

, between the NTC pin and GNDSENS and the

resistor, R

NOM

, from the NTC pin to V

INSENSE

. R

NOM

should be a 1% resistor with a value equal to the value of

the chosen NTC thermistor at 25°C. The LTC4001 goes

into hold mode when the resistance, R

HOT

, of the NTC

thermistor drops to 0.41 times the value of R

NOM

. For

instance for R

NTC

= 10k. (The value for a Vishay

NTHS0603N02N1002J thermistor at 25°C) hold occurs at

approximately 4.1k, which occurs at 50°C. The hold mode

freezes the timer and stops the charge cycle until the

thermistor indicates a return to a valid temperature. As the

temperature drops, the resistance of the NTC thermistor

rises. The LTC4001 is designed to go into hold mode when

the value of the NTC thermistor increases to 2.82 times the

value of R

NOM

. This resistance is R

COLD

. For the Vishay 10k

thermistor, this value is 28.2k, which corresponds to

approximately 0°C. The hot and cold comparators each

have approximately 3°C of hysteresis to prevent oscillation about the trip point. Grounding the NTC pin disables

the NTC function.

Thermistors

The LTC4001 NTC trip points were designed to work with

thermistors whose resistance temperature characteristics

follow Vishay Dale’s “R-T Curve 2.” However, any thermistor whose ratio of R

COLD

to R

HOT

is about 7 will also

work (Vishay Dale R-T Curve 2 shows a ratio of R

COLD

to

R

HOT

of 2.815/0.4086 = 6.89).

Power conscious designs may want to use thermistors

whose room temperature value is greater than 10k. Vishay

Dale has a number of values of thermistor from 10k to

100k that follow the “R-T Curve 1.” Using these as indicated in the NTC Thermistor section will give temperature

trip points of approximately 3°C and 47°C, a delta of 44°C.

This delta in temperature can be moved in either direction

by changing the value of R

NOM

with respect to R

NTC

.

Increasing R

NOM

will move the trip points to higher tem-

peratures. To calculate R

NOM

for a shift to lower tempera-

ture for example, use the following equation:

R

R

RatC

NOM

COLD

NTC

=°

2 81525.

•

where R

COLD

is the resistance ratio of R

NTC

at the desired

cold temperature trip point. If you want to shift the trip

points to higher temperatures use the following equation:

R

R

RatC

NOM

HOT

NTC

=°

0 4086

25

.

•

where R

HOT

is the resistance ratio of R

NTC

at the desired

hot temperature trip point.

Here is an example using a 100k R-T Curve 1 thermistor

from Vishay Dale. The difference between trip points is

44°C, from before, and we want the cold trip point to be

0°C, which would put the hot trip point at 44°C. The R

NOM

needed is calculated as follows:

R

R

RatC

kk

NOM

COLD

NTC

=°

==

2 815

25

3 266

2 815

100 116

.

•

.

.

•

The nearest 1% value for R

NOM

is 115k. This is the value

used to bias the NTC thermistor to get cold and hot trip

points of approximately 0°C and 44°C respectively. To

extend the delta between the cold and hot trip points a

resistor, R1, can be added in series with R

NTC

(see

Figure 4). The values of the resistors are calculated as

follows:

R

RR

RRRR

NOM

COLD HOT

COLD HOT HOT

=

=

()

–

.–.

.

.–.

•––

2 815 0 4086

1

0 4086

2 815 0 4086

APPLICATIO S I FOR ATIO

WUUU

Page 13

13

LTC4001

4001f

where R

NOM

is the value of the bias resistor, R

HOT

and

R

COLD

are the values of R

NTC

at the desired temperature

trip points. Continuing the example from before with a

desired hot trip point of 50°C:

R

RR

k

k k is nearest

Rk

k k is nearest

NOM

COLD HOT

==

()

=

=

()

⎛

⎝

⎜

⎞

⎠

⎟

=

–

.–.

•. –.

.–.

., %

•

.

.–.

• . –. –.

., . %

2 815 0 4086

100 3 2636 0 3602

2 815 0 4086

120 8 121 1

1 100

0 4086

2 815 0 4086

3 266 0 3602 0 3602

13 3 13 3 1

The final solution is as shown if Figure 4 where R

NOM

=

121k, R1 = 13.3k and R

NTC

= 100k at 25°C.

Input and Output Capacitors

The LTC4001 uses a synchronous buck regulator to provide high battery charging current. A 10µF chip ceramic

APPLICATIO S I FOR ATIO

WUUU

capacitor is recommended for both the input and output

capacitors because it provides low ESR and ESL and can

handle the high RMS ripple currents. However, some high

Q capacitors may produce high transients due to selfresonance under some start-up conditions, such as connecting the charger input to a hot power source. For more

information, refer to Application Note 88.

EMI considerations usually make it desirable to minimize

ripple current in the battery leads, and beads or inductors

may be added to increase battery impedance at the 1.5MHz

switching frequency. Switching ripple current splits between the battery and the output capacitor depending on

the ESR of the output capacitor and the battery impedance.

If the ESR of the output capacitor is 0.1Ω and the battery

impedance is raised to 2Ω with a bead or inductor, only 5%

of the ripple current will flow in the battery. Similar

techniques may also be applied to minimize EMI from the

input leads.

Figure 4. Extending the Delta Temperature

TOO COLD

LTC4001 NTC BLOCK

TOO HOT

0.29 • V

INSENSE

0.74 • V

INSENSE

R

NOM

121k

V

INSENSE

0.02 • V

INSENSE

NTC ENABLE

4001 F04

–

+

–

+

–

+

R1

13.3k

R

NTC

100k

9

NTC

11

GNDSENS

4

Page 14

14

LTC4001

4001f

Inductor Selection

A high (1.5MHz) operating frequency was chosen for the

buck switcher in order to minimize the size of the inductor.

However, take care to use inductors with low core losses

at this frequency. A good choice is the IHLP-2525AH-01

from Vishay Dale.

To calculate the inductor ripple current:

∆ =I

V

V

V

Lf

L

BAT

BAT

IN

–

•

2

where V

BAT

is the battery voltage, VIN is the input voltage,

L is the inductance and f is the PWM oscillator frequency

(typically 1.5MHz). Maximum inductor ripple current occurs at maximum VIN and V

BAT

= VIN/2.

Peak inductor current will be:

I

PK

= I

BAT

+ 0.5 • ∆I

L

where I

BAT

is the maximum battery charging current.

When sizing the inductor make sure that the peak current

will not exceed the saturation current of the inductors.

Also, ∆IL should never exceed 0.4(I

BAT

) as this may

interfere with proper operation of the output short-circuit

protection comparator. 1.5µH provides reasonable induc-

tor ripple current in a typical application. With 1.5µH and

2A charge current:

∆ =

µ

=I

V

V

V

HMHz

A

LP

285

285

55

15 15

061

2

.–

.

.

.•.

.

-P

and

I

PK

= 2.31A

APPLICATIO S I FOR ATIO

WUUU

Remote Sensing

For highest float voltage accuracy, tie GNDSENS and

BATSENS directly to the battery terminals. In a similar

fashion, tie BAT and PGND directly to the battery terminals. This eliminates IR drops in the GNDSENS and

BATSENS lines by preventing charge current from flowing

in them.

Operation with a Current Limited Wall Adapter

Wall adapters with or without current limiting may be used

with the LTC4001, however, lowest power dissipation

battery charging occurs with a current limited wall adapter.

To use this feature, the wall adapter must limit at a current

smaller than the high rate charge current programmed

into the LTC4001. For example, if the LTC4001 is programmed to charge at 2A, the wall adapter current limit

must be less than 2A.

To understand operation with a current limited wall adapter,

assume battery voltage, V

BAT

, is initially below V

TRIKL

, the

trickle charge threshold (Figure 5). Battery charging begins at approximately 50mA, well below the wall adapter

current limit so the voltage into the LTC4001 (VIN) is the

wall adapter’s rated output voltage (V

ADAPTER

). Battery

voltage rises eventually reaching V

TRIKL

. The linear charger

shuts off, the PWM (high rate) charger turns on and a softstart cycle begins. Battery charging current rises during

the soft-start cycle causing a corresponding increase in

wall adapter load current. When the wall adapter reaches

current limit, the wall adapter output voltage collapses and

the LTC4001 PWM charger duty cycle ramps up to 100%

(the topside PMOS switch in the LTC4001 buck regulator

stays on continuously). As the battery voltage approaches

V

FLOAT

, the float voltage error amplifier commands the

PWM charger to deliver less than I

LIMIT

. The wall adapter

exits current limit and the V

IN

jumps back up to V

ADAPTER

.

Page 15

15

LTC4001

4001f

Battery charging current continues to drop as the V

BAT

rises, dropping to zero at V

FLOAT.

Because the voltage drop

in the LTC4001 is very low when charge current is highest,

power dissipation is also very low.

Thermal Calculations (PWM and Trickle Charging)

The LTC4001 operates as a linear charger when conditioning (trickle) charging a battery and operates as a high rate

buck battery charger at all other times. Power dissipation

should be determined for both operating modes.

For linear charger mode:

PD = (VIN – V

BAT

) • I

TRIKL

+ VIN • I

IN

where IIN is VIN current consumed by the IC.

Worst-case dissipation occurs for V

BAT

= 0, maximum VIN,

and maximum quiescent and trickle charge current. For

example with 5.5V maximum input voltage and 65mA

worst case trickle charge current, and 2mA worst-case

chip quiescent current:

P

D

= (5.5 – 0) • 65mA + 5.5 • 2mA = 368.5mW

LTC4001 power dissipation is very low if a current limited

wall adapter is used and allowed to enter current limit.

When the wall adapter is in current limit, the voltage drop

across the LTC4001 charger is:

V

DROP

= I

LIMIT

• R

PFET

where I

LIMIT

is the wall adapter current limit and R

PFET

is

the on resistance of the topside PMOS switch.

The total LTC4001 power dissipation during current limited charging is:

PD = (V

BAT

+ V

DROP

) • (IIN + IP) + V

DROP

• I

LIMIT

where I

IN

is the chip quiescent current and IP is total

current flowing through the IDET and PROG programming

pins. Maximum dissipation in this mode occurs with the

highest V

BAT

that keeps the wall adapter in current limit

(which is very close to V

FLOAT

), highest quiescent current

I

IN

, highest PMOS on resistance R

PFET

, highest I

LIMIT

and

highest programming current I

P

.

Assume the LTC4001 is programmed for 2A charging and

200mA IDET and that a 1.5A wall adapter is being used:

I

LIMIT

= 1500mA, R

PFET

= 127mΩ, I

IN

= 2mA, IP = 4mA and

V

BAT

≈ V

FLOAT

= 4.242V

then:

V

DROP

= 1500mA • 127mΩ = 190.5mV

and:

P

D

= (4.242V + 0.1905V) • (2mA + 4mA) + 0.1905V

• 1500mA = 312mW

Power dissipation in buck battery charger mode may be

estimated from the dissipation curves given in the Typical

Performance Characteristics section of the data sheet.

This will slightly overestimate chip power dissipation

because it assumes all loss, including loss from external

components, occurs within the chip.

APPLICATIO S I FOR ATIO

WUUU

Figure 5. Charging Characteristic

LINEAR CHARGING

V

ADAPTER

V

IN

V

TRIKL

V

FLOAT

4001 F05

V

BAT

I

BAT

I

TRICKLE

WALL ADAPTER IN CURRENT LIMIT

V

BAT

+ V

DROP

I

LIMIT

PWM

CHARGING

Page 16

16

LTC4001

4001f

APPLICATIO S I FOR ATIO

WUUU

Insert the highest power dissipation figure into the following equation to determine maximum junction temperature:

T

J

= TA + (PD • 37°C/W)

The LTC4001 includes chip overtemperature protection. If

junction temperature exceeds 160°C (typical), the chip

will stop battery charging until chip temperature drops

below 150°C.

Using the LTC4001 in Applications Without a Battery

The LTC4001 is normally used in end products that only

operate with the battery attached (Figure 6). Under these

conditions the battery is available to supply load transient

currents. For indefinite operation with a powered wall

adapter there are only two requirements—that the average current drawn by the load is less than the high rate

charge current, and that V

BAT

stays above the trickle

charge threshold when the load is initially turned on and

during other load transients. When making this determination take into account battery impedance. If battery

voltage is less than the trickle charge threshold, the

system load may be turned off until V

BAT

is high enough

to meet these conditions.

The situation changes dramatically with the battery removed (Figure 7). Since the battery is absent, V

BAT

begins

at zero when a powered wall adapter is first connected to

the battery charger.

With a maximum load less than the

LTC4001 trickle charge current

, battery voltage will ramp

up until V

BAT

crosses the trickle charge threshold. When

this occurs, the LTC4001 switches over from trickle charge

to high rate (PWM) charge mode but initially delivers zero

current (because the soft-start pin is at zero). Battery

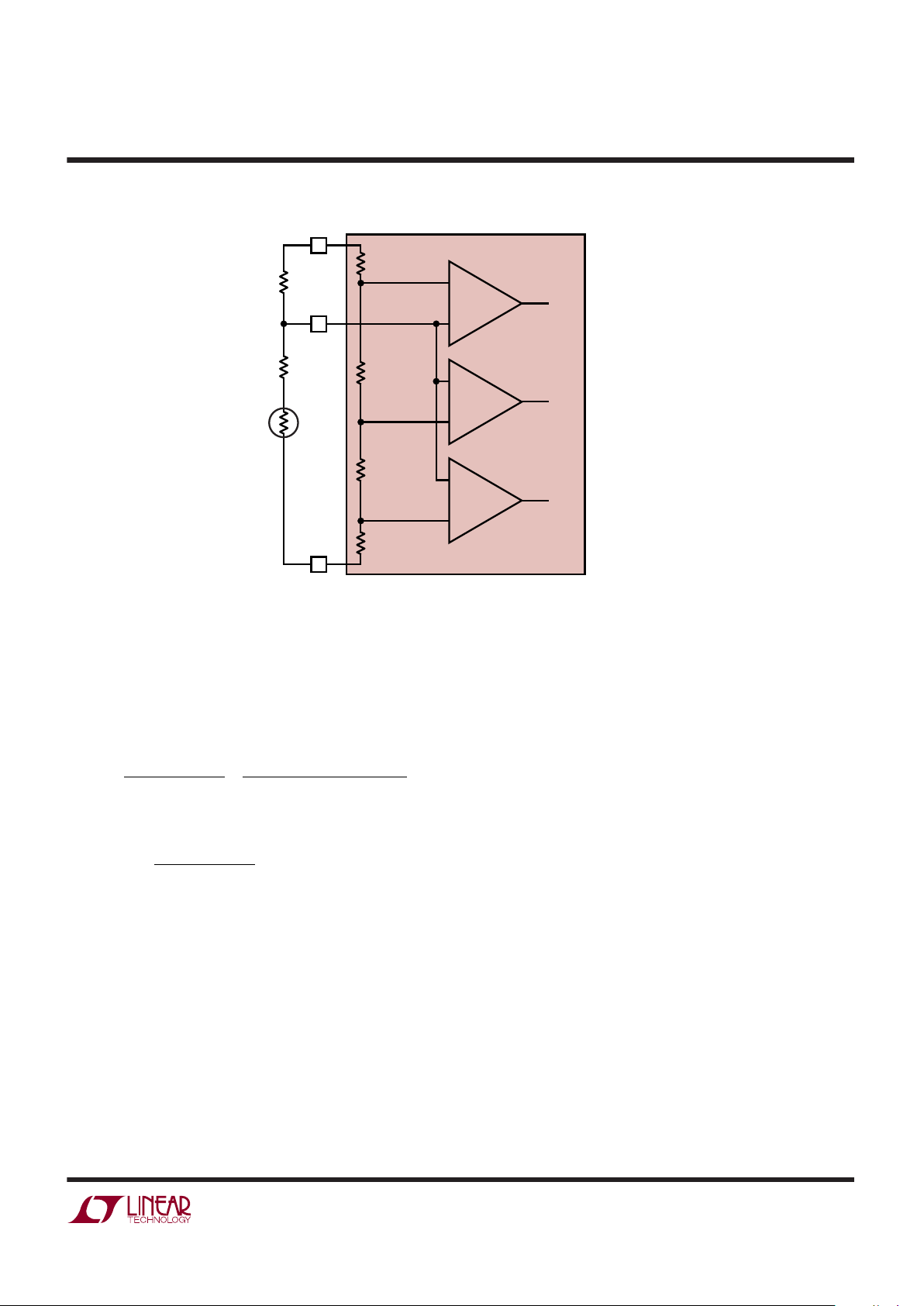

voltage drops as a result of the system load, crossing

below the trickle charge threshold. The charger re-enters

trickle charge mode and the battery voltage ramps up

again until the battery charger re-enters high rate mode.

The soft-start voltage is slightly higher this time around

(than in the previous PWM cycle). Every successive time

that the charger enters high rate (PWM) charge mode, the

soft-start pin is at a slightly higher voltage. Eventually high

rate charge mode begins with a soft-start voltage that

causes the PWM charger to provide more current than the

system load demands, and V

BAT

rapidly rises until the float

voltage is reached.

For battery-less operation, system load current should be

restricted to less than the worst case trickle charge current

(preferably less than 30mA) when V

BAT

is less than 3.15V

(through an undervoltage lockout or other means). Above

V

BAT

= 3.15V, system load current less than or equal to the

high rate charge current is allowed. If operation without a

battery is required, additional low-ESR output filtering

improves start-up and other load transients. Battery-less

start-up is also improved if a 10k resistor is placed in

series with the soft-start capacitor.

Figure 6. Typical Application

+

WALL

ADAPTER

LTC4001

BATTERY

CHARGER

SYSTEM

LOAD

Li-Ion

BATTERY

4001 F06

Page 17

17

LTC4001

4001f

APPLICATIO S I FOR ATIO

WUUU

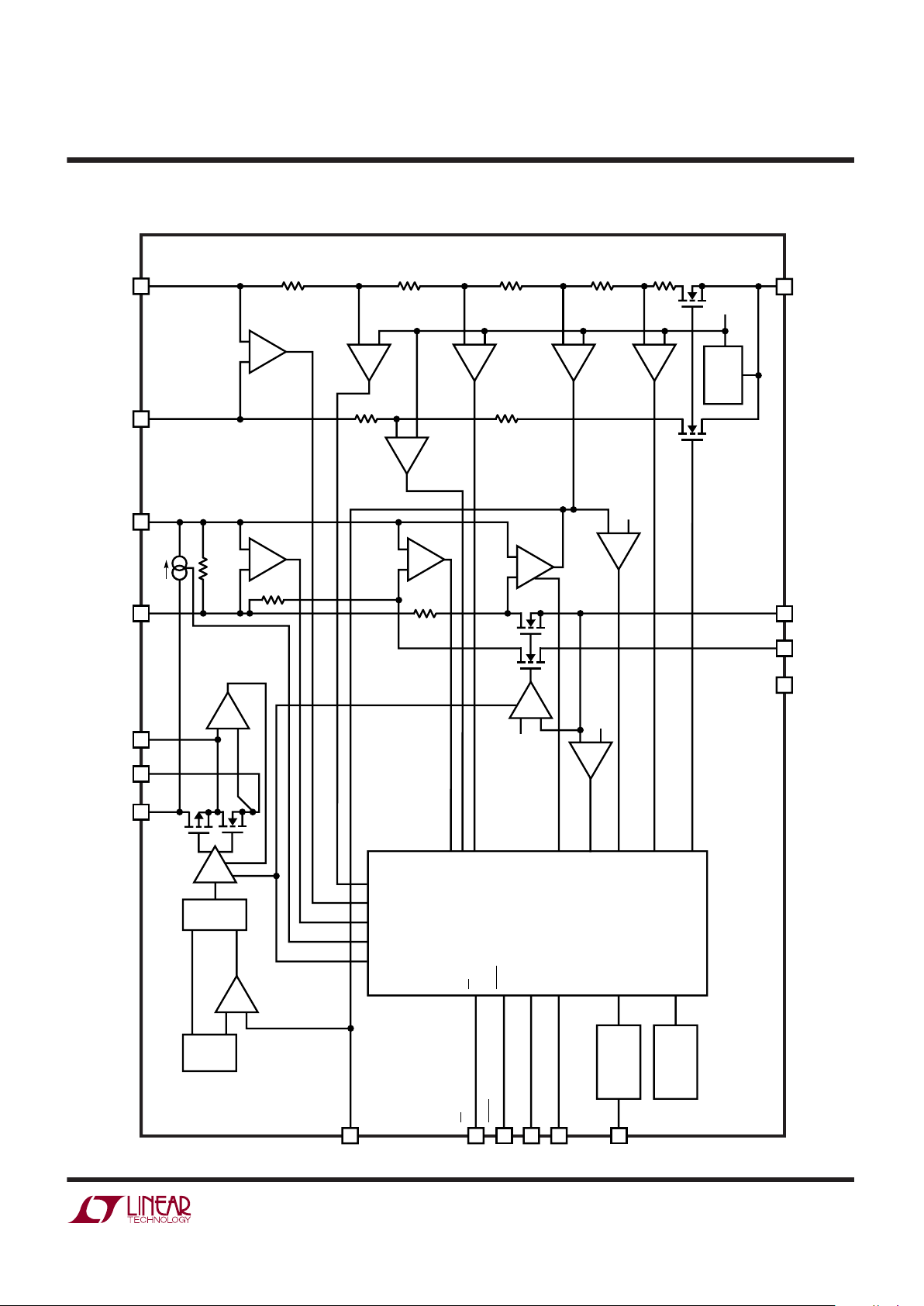

Figure 7. Battery-Less Start-Up

024681012

TIME (ms)

14 16 18 20 22 24

4

3

2

1

0

V

BAT

(V)

024681012

TIME (ms)

14 16 18 20 22 24

500

250

0

V

SS

(mV)

024681012

TIME (ms)

4001 F07

14 16 18 20 22 24

PWM

CHARGE

TRICKLE

CHARGE

Page 18

18

LTC4001

4001f

Layout Considerations

Switch rise and fall times are kept under 5ns for maximum

efficiency. To minimize radiation, the SW pin and input

bypass capacitor leads (between PVIN and PGND) should

be kept as short as possible. A ground plane should be

used under the switching circuitry to prevent interplane

coupling. The Exposed Pad must be connected to the

ground plane for proper power dissipation. The other

paths contain only DC and/or 1.5MHz tri-wave ripple

current and are less critical.

Figure 8. 2A Li-Ion Battery Charger with 3Hr Timer, Temperature

Qualification, Soft-Start, Remote Sensing and C/10 Indication

With the exception of the input and output filter capacitors

(which should be connected to PGND) all other components that return to ground should be connected to

GNDSENS.

Recommended Components Manufacturers

For a list of recommend component manufacturers, contact the Linear Technology application department.

APPLICATIO S I FOR ATIO

WUUU

+

PROG

EN

FAULTTO µP

FROM µP

NTC

CHRG

PGND

PV

IN

V

INSENSE

BAT

BATSENS

IDET TIMER

R4

549Ω

C2

0.22µF

C3

0.1µF

L1: VISHAY DALE IHLP-2525AH-01

R3: NTC VISHAY DALE NTHS0603N02N1002J

C4

10µF

4001 F08

2AHr

4.2V

Li-Ion

C1

10µF

D1

LED

V

IN

4.5V TO 5.5V

SS

SW SENSE

LTC4001

L1

1.5µH

GNDSENS

R2

1k

R1

10k

R3

10k

AT 25°C

R5

549Ω

Page 19

19

LTC4001

4001f

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

U

PACKAGE DESCRIPTIO

UF Package

16-Lead Plastic QFN (4mm × 4mm)

(Reference LTC DWG # 05-08-1692)

4.00 ± 0.10

(4 SIDES)

NOTE:

1. DRAWING CONFORMS TO JEDEC PACKAGE OUTLINE MO-220 VARIATION (WGGC)

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION

ON THE TOP AND BOTTOM OF PACKAGE

PIN 1

TOP MARK

(NOTE 6)

0.55 ± 0.20

1615

1

2

BOTTOM VIEW—EXPOSED PAD

2.15 ± 0.10

(4-SIDES)

0.75 ± 0.05

R = 0.115

TYP

0.30 ± 0.05

0.65 BSC

0.200 REF

0.00 – 0.05

(UF16) QFN 10-04

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

0.72 ±0.05

0.30 ±0.05

0.65 BSC

2.15 ± 0.05

(4 SIDES)

2.90 ± 0.05

4.35 ± 0.05

PACKAGE OUTLINE

PIN 1 NOTCH R = 0.20 TYP

OR 0.35 × 45° CHAMFER

Page 20

20

LTC4001

4001f

LT 0406 • PRINTED IN THE USA

PART NUMBER DESCRIPTION COMMENTS

LT®1511 3A Constant Current/Constant Voltage Battery Charger High Efficiency, Minimum External Components to Fast Charge Lithium,

NIMH and NiCd Batteries, 24-Lead SO Package

LT1513 SEPIC Constant or Programmable Current/Constant Charger Input Voltage May Be Higher, Equal to or Lower Than Battery

Voltage Battery Charger Voltage, 500kHz Switching Frequency, DD Pak and TO-220 Packages

LT1571 1.5A Switching Charger 1- or 2-Cell Li-Ion, 500kHz or 200kHz Switching Frequency,

Termination Flag, 16- and 28-Lead SSOP Packages

LTC1729 Li-Ion Battery Charger Termination Controller Trickle Charge Preconditioning, Temperature Charge Qualification,

Time or Charge Current Termination, Automatic Charger and Battery

Detection, and Status Output, MS8 and SO-8 Packages

LT1769 2A Switching Charger Constant Current/Constant Voltage Switching Regulator, Input Current

Limiting Maximizes Charge Current, 20-Lead TSSOP and 28-Lead SSOP

Packages

LTC4002 Standalone Li-Ion Switch Mode Battery Charger Complete Charger for 1- or 2-Cell Li-Ion Batteries, Onboard Timer

Termination, Up to 4A Charge Current, 10-Lead DFN and SO-8 Packages

LTC4006 Small, High Efficiency, Fixed Voltage Li-Ion Battery Complete Charger for 2-, 3- or 4-Cell Li-Ion Batteries, AC Adapter

Charger with Termination Current Limit and Thermistor Sensor, 16-Lead Narrow SSOP Package

LTC4007 High Efficiency, Programmable Voltage Battery Complete Charger for 3- or 4-Cell Li-Ion Batteries, AC Adapter Current

Charger with Termination Limit, Thermistor Sensor and Indicator Outputs, 24-Lead SSOP Package

LTC4008 4A, High Efficiency, Multi-Chemistry Battery Charger Complete Charger for 2- to 6-Cell Li-Ion Batteries or 4- to 18-Cell Nickel

Batteries, Up to 96% Efficiency, 20-Lead SSOP Package

RELATED PARTS

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

© LINEAR TECHNOLOGY CORPORATION 2006

Loading...

Loading...