Page 1

FEATURES

■

Adaptive or Manual Delay Control for Zero Voltage

Switching Operation

■

Adjustable Synchronous Rectification Timing for

Highest Efficiency

■

Adjustable Maximum ZVS Delay

■

Adjustable System Undervoltage Lockout/Hysteresis

■

Programmable Leading Edge Blanking

■

Very Low Start-Up and Quiescent Currents

■

Current Mode (LTC3722-1) or Voltage Mode

(LTC3722-2) Operation

■

Programmable Slope Compensation

■

V

UVLO and 25mA Shunt Regulator

CC

■

50mA Output Drivers

■

Soft-Start, Cycle-by-Cycle Current Limiting and

Hiccup Mode Short-Circuit Protection

■

5V, 15mA Low Dropout Regulator

■

24-Pin Surface Mount GN Package

U

APPLICATIO S

■

Telecommunications, Infrastructure Power Systems

■

Distributed Power Architectures

■

Server Power Supplies

LTC3722-1/LTC3722-2

Synchronous Dual Mode

Phase Modulated

Full Bridge Controllers

U

DESCRIPTIO

The LTC®3722-1/LTC3722-2 phase shift PWM controllers

provide all of the control and protection functions necessary to implement a high efficiency, zero voltage switched

(ZVS), full bridge power converter. Adaptive ZVS circuitry

delays the turn-on signals for each MOSFET independent

of internal and external component tolerances. Manual

delay set mode enables secondary side control operation

or direct control of switch turn-on delays.

The LTC3722-1/LTC3722-2 feature adjustable synchronous rectifier timing for optimal efficiency. A UVLO program input provides accurate system turn-on and turn-off

voltages. The LTC3722-1 features peak current mode

control with programmable slope compensation and leading edge blanking, while the LTC3722-2 employs voltage

mode control with voltage feedforward capability.

The LTC3722-1/LTC3722-2 feature extremely low operating and start-up currents. Both devices include a full range

of protection features and are available in the 24-pin

surface mount GN package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

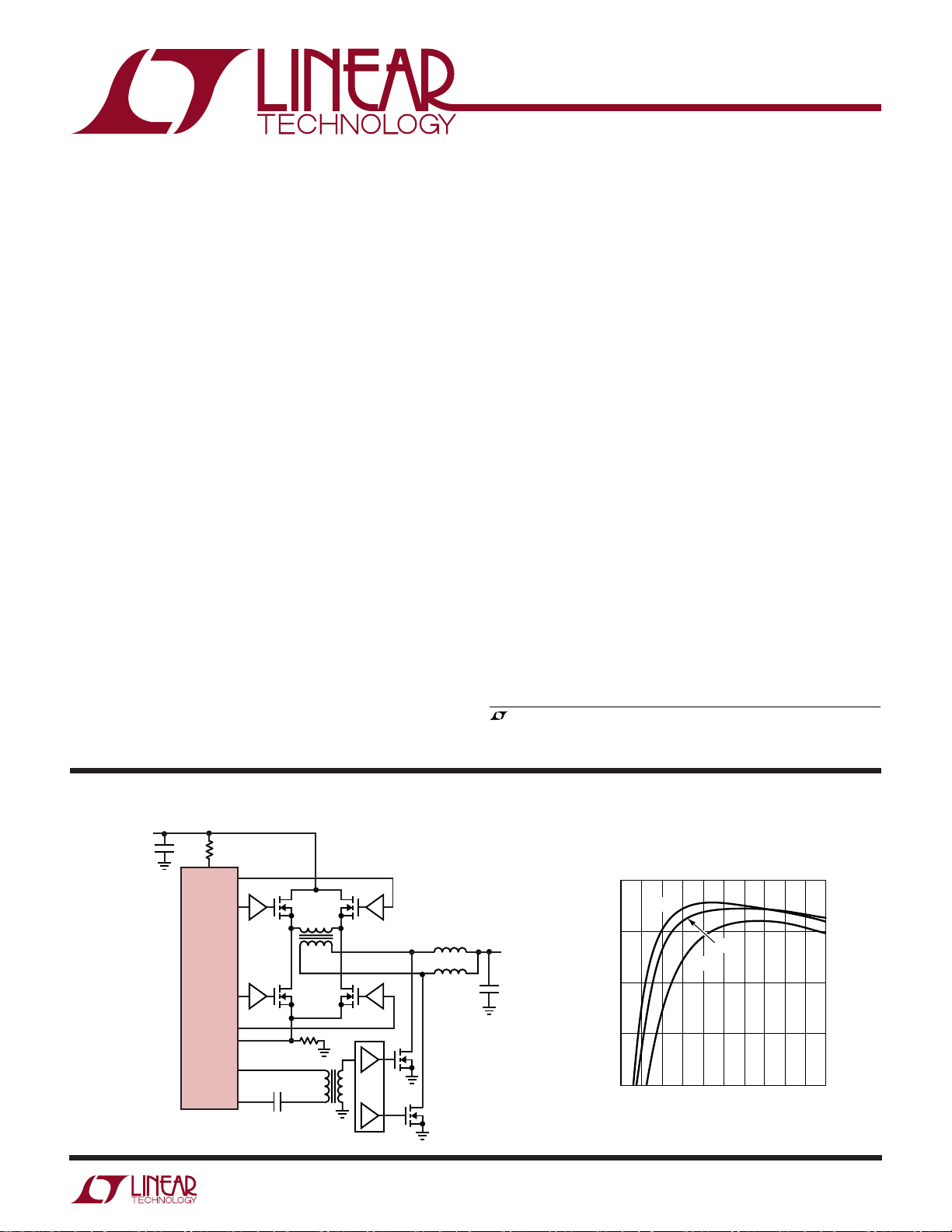

TYPICAL APPLICATIO

V

IN

36V TO 72V

C

IN

R1

U1 U2

LTC3722

U1, U2: LTC4440 GATE DRIVER

U3: LTC3901 GATE DRIVER

C1

U

MA

T1

MBMCMD

RCS

12V

, 240W Converter Efficiency

OUT

95

36V

IN

L1

L2

ME

T2

U3

MF

3722 • TA01A

V

OUT

12V

C

OUT

90

85

EFFICIENCY (%)

80

75

0

48V

IN

72V

IN

42 6 10 14 18

12

8

CURRENT (A)

16

3722 TA01b

20

372212f

1

Page 2

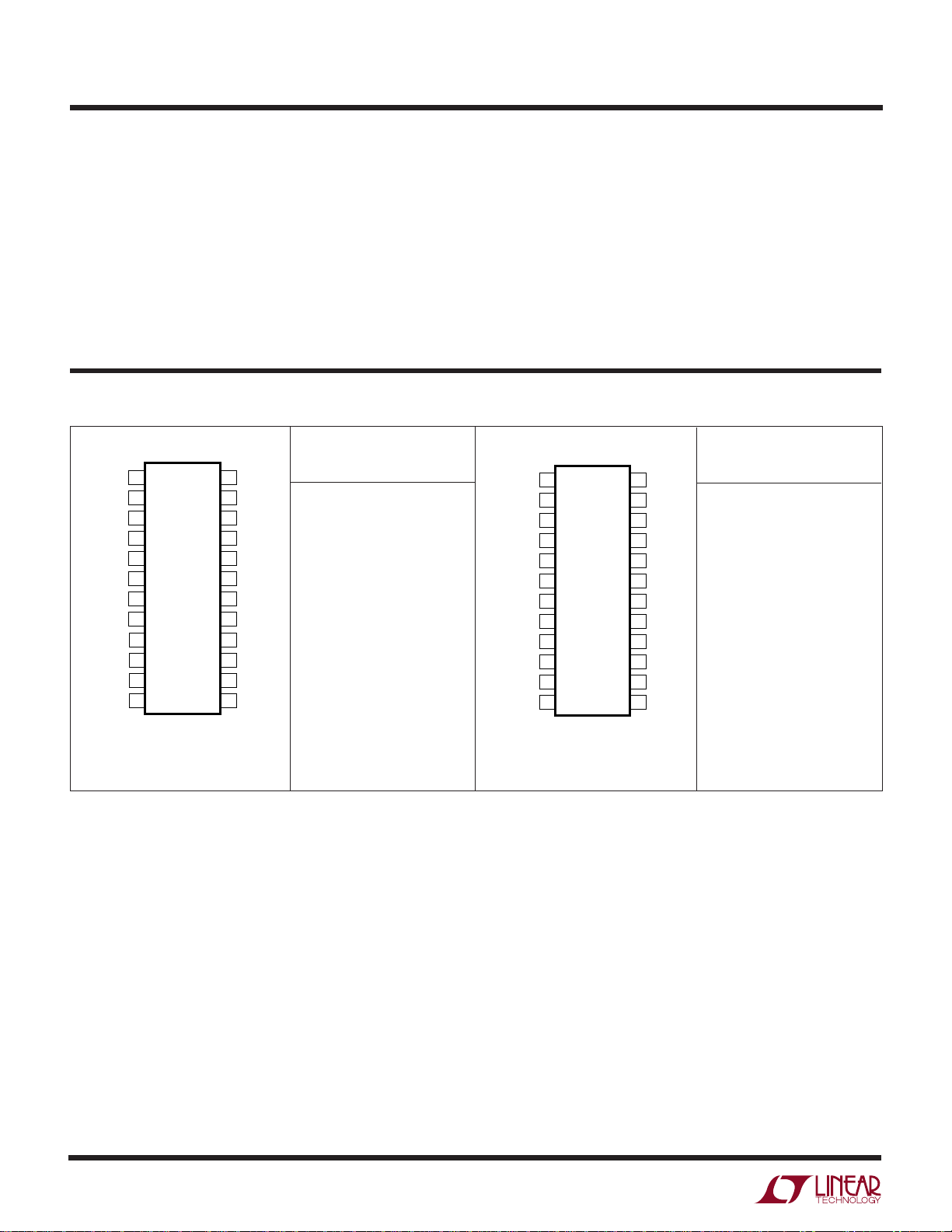

LTC3722-1/LTC3722-2

1

2

3

4

5

6

7

8

9

10

11

12

TOP VIEW

GN PACKAGE

24-LEAD NARROW PLASTIC SSOP

24

23

22

21

20

19

18

17

16

15

14

13

SYNC

RAMP

CS

COMP

DPRG

FB

SS

NC

PDLY

SBUS

ADLY

UVLO

C

T

GND

PGND

OUTA

OUTB

OUTC

V

CC

OUTD

OUTE

OUTF

V

REF

SPRG

WW

W

U

ABSOLUTE AXI U RATI GS

(Note 1)

VCC to GND (Low Impedance Source) ......... –0.3 to 10V

(Chip Self Regulates at 10.3V)

UVLO to GND................................................–0.3 to V

CC

All Other Pins to GND

(Low Impedance Source) ....................... –0.3 to 5.5V

VCC (Current Fed) ................................................. 25mA

UUW

PACKAGE/ORDER I FOR ATIO

ORDER PART

NUMBER

LTC3722EGN-1

SYNC

DPRG

COMP

RLEB

NC

PDLY

SBUS

ADLY

UVLO

TOP VIEW

1

2

3

CS

4

5

6

FB

7

SS

8

9

10

11

12

24

C

T

23

GND

22

PGND

21

OUTA

20

OUTB

19

OUTC

18

V

CC

17

OUTD

16

OUTE

15

OUTF

14

V

REF

13

SPRG

V

Output Current ................................ Self Regulated

REF

Outputs (A,B,C,D,E,F) Current .......................... ±100mA

Operating Temperature Range (Note 6)

LTC3722E........................................... –40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec)..................300°C

ORDER PART

NUMBER

LTC3722EGN-2

24-LEAD NARROW PLASTIC SSOP

T

JMAX

Consult LTC Marketing for parts specified with wider operating temperature ranges.

2

GN PACKAGE

= 125°C, θJA = 100°C/W

T

= 125°C, θJA = 100°C/W

JMAX

372212f

Page 3

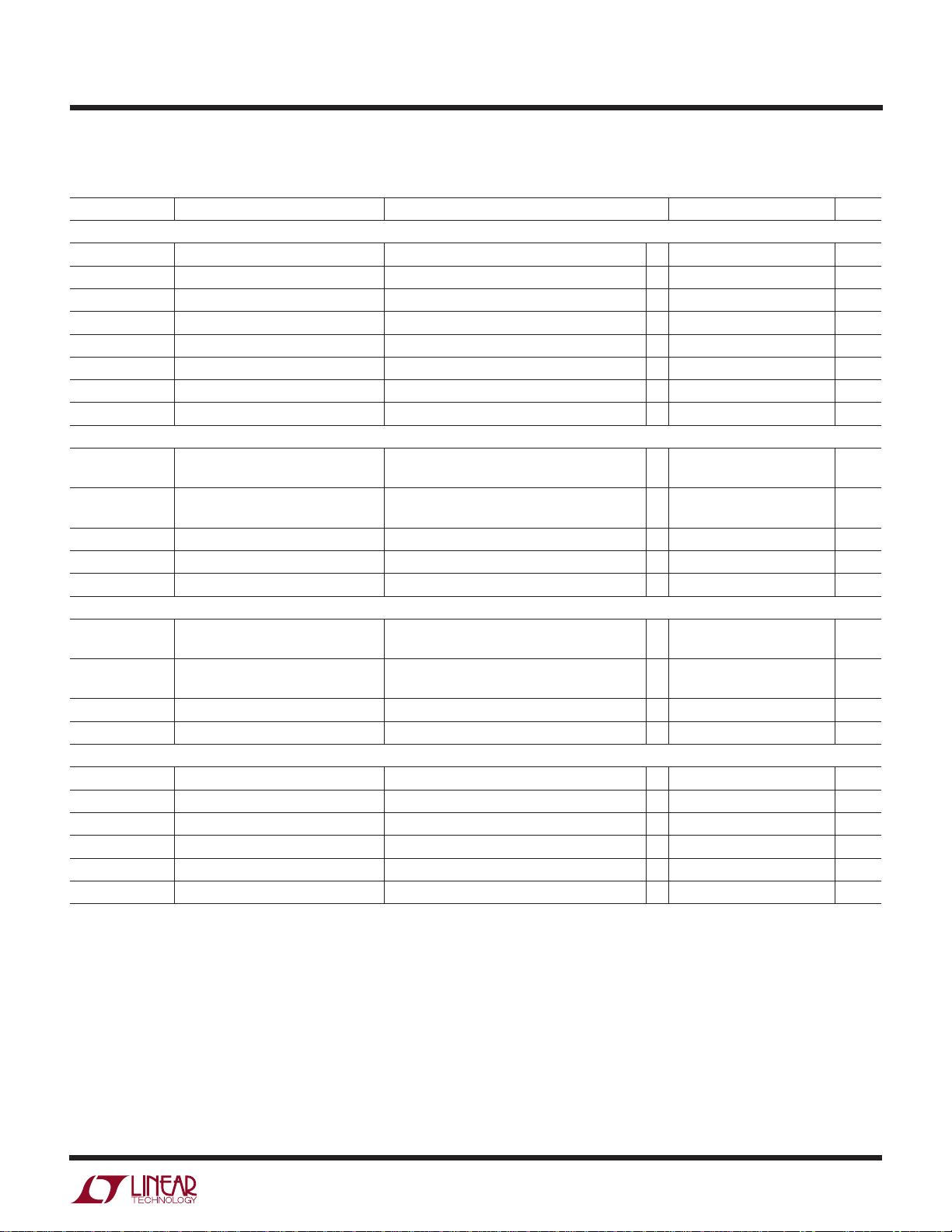

LTC3722-1/LTC3722-2

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VCC = 9.5V, CT = 270pF, R

The ● denotes the specifications which apply over the full operating

= 60.4k, R

DPRG

= 100k, unless otherwise

SPRG

noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Input Supply

V

CCUV

V

CCHY

I

CCST

I

CCRN

V

SHUNT

R

SHUNT

SUVLO System UVLO Threshold Measured on UVLO Pin, 10mA into V

SHYST System UVLO Hysteresis Current Current Flows Out of UVLO Pin 8.5 10 11.5 µA

Delay Blocks

DTHR Delay Pin Threshold SBUS = 1.5V ● 1.4 1.5 1.6 V

DHYS Delay Hysteresis Current SBUS = 1.5V, ADLY/PDLY = 1.7V 1.3 mA

DTMO Delay Timeout R

DFXT Fixed Delay Threshold Measured on SBUS 4 V

DFTM Fixed Delay Time ADLY,PDLY = 1V, SBUS = V

Phase Modulator

I

RMP

I

SLP

DC

MAX

DC

MIN

Oscillator

OSCI Initial Accuracy TA = 25°C, CT = 270pF 225 250 275 kHz

OSCT Total Variation VCC = 6.5V to 9.5V ● 215 250 285 kHz

OSCV CT Ramp Amplitude Measured on C

OSYT SYNC Threshold Measured on SYNC 1.6 1.9 2.2 V

OSYW Minimum SYNC Pulse Width Measured at Outputs (Note 2) 100 ns

OSYR SYNC Frequency Range Measured at Outputs (Note 2) 1000 kHz

VCC Under Voltage Lockout Measured on V

VCC UVLO Hysteresis Measured on V

Start-Up Current VCC = V

Operating Current No Load on Outputs 5 8 mA

Shunt Regulator Voltage Current into VCC = 10mA 10.3 10.8 V

Shunt Resistance Current into VCC = 10mA to 17mA 1.1 3.5 Ω

ADLY and PDLY SBUS = 2.25V

ADLY and PDLY

DPRG

Ramp Discharge Current RAMP = 1V, COMP = 0V, CT = 4V, 50 mA

LTC3722-1 Only

Slope Compensation Current Measured on CS, CT = 1V 30 µA

Maximum Phase Shift COMP = 4.5V ● 95 98.5 %

Minimum Phase Shift COMP = 0V ● 0 0.5 %

CC

CC

– 0.3V ● 145 230 µA

UVLO

CC

= 60.4K 100 ns

REF

= 2.25V 68 µA

C

T

T

3.8 4.2 V

4.8 5.0 5.2 V

● 2.1 2.25 2.4 V

10.25 10.5 V

70 ns

2.2 V

372212f

3

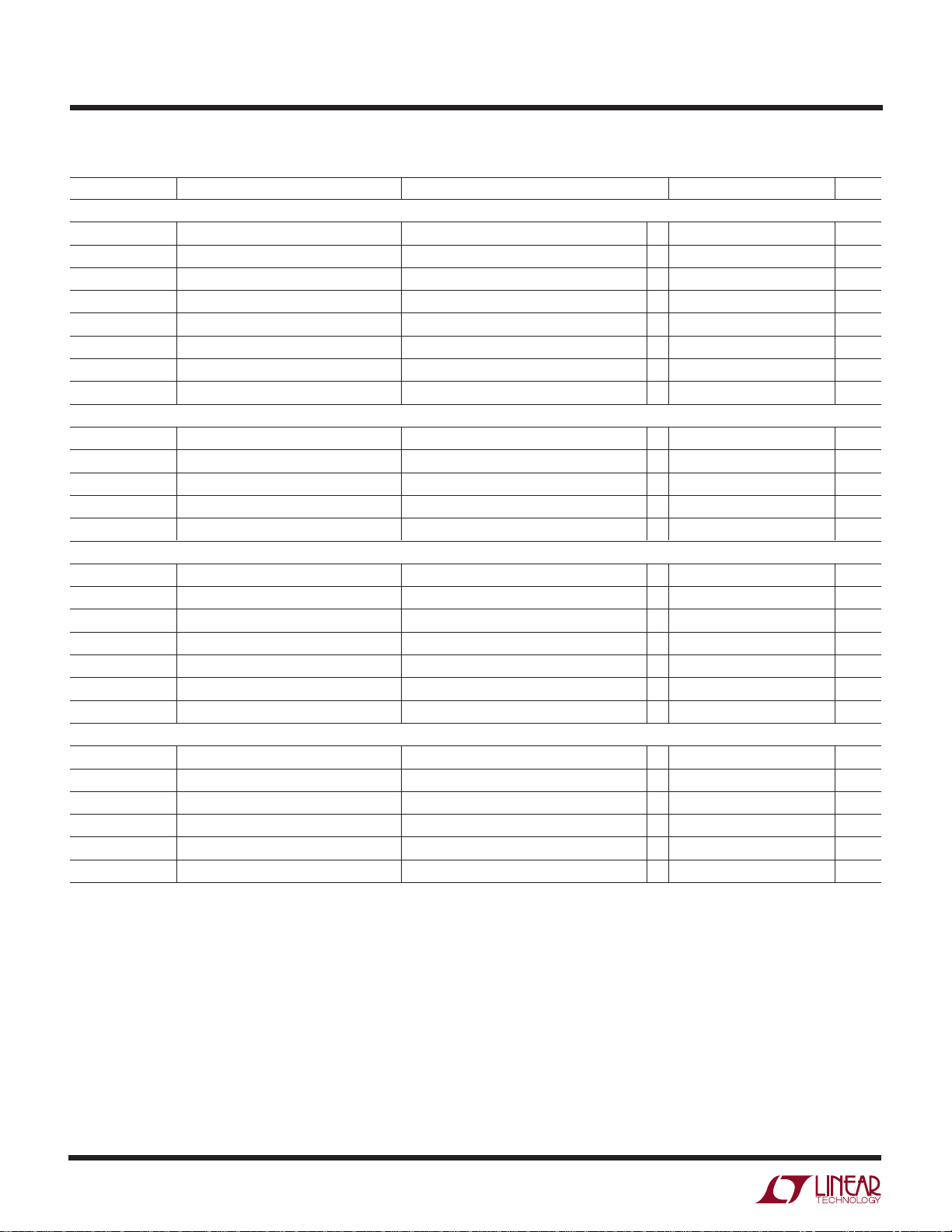

Page 4

LTC3722-1/LTC3722-2

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. VCC = 9.5V, unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Error Amplifier

V

FB

FBI FB Input Range Measured on FB (Note 5) –0.3 2.5 V

A

VOL

IIB Input Bias Current COMP = 2.5V (Note 4) 5 20 nA

V

OH

V

OL

I

SOURCE

I

SINK

Reference

V

REF

REFLD Load Regulation Load on V

REFLN Line Regulation VCC = 6.5V to 9.5V 0.9 10 mV

REFTV Total Variation Line, Load ● 4.900 5.000 5.100 V

REFSC Short-Circuit Current V

Outputs

OUTH(x) Output High Voltage I

OUTL(x) Output Low Voltage I

R

HI(x)

R

LO(x)

t

r(x)

t

f(x)

SDEL SYNC Driver Turn-0ff Delay R

Current Limit and Shutdown

CLPP Pulse by Pulse Current Limit Threshold Measured on CS 270 300 330 mV

CLSD Shutdown Current Limit Threshold Measured on CS 0.55 0.65 0.73 V

CLDEL Current Limit Delay to Output 100mV Overdrive on CS (Notes 3, 7) 80 ns

SSI Soft-Start Current SS = 2.5V 7 12 17 µA

SSR Soft-Start Reset Threshold Measured on SS 0.7 0.4 0.1 V

FLT Fault Reset Threshold Measured on SS 4.5 3.9 3.5 V

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: Sync amplitude = 5V

frequency = 1/2 sync frequency.

Note 3: Includes leading edge blanking delay, R

Note 4: FB is driven by a servo-loop amplifier to control V

tests.

Note 5: Set FB to –0.3V, 2.5V and insure that COMP does not phase

invert.

FB Input Voltage COMP = 2.5V (Note 4) 1.172 1.204 1.236 V

Open-Loop Gain COMP = 1V to 3V (Note 4) 70 90 dB

Output High Load on COMP = –100µA 4.7 4.92 V

Output Low Load on COMP = 100µA 0.18 0.4 V

Output Source Current COMP = 2.5V 400 800 µA

Output Sink Current COMP = 2.5V 2 5 mA

Initial Accuracy TA = 25°C, Measured on V

= 100µA to 5mA 2 15 mV

REF

Shorted to GND 18 30 45 mA

REF

= –50mA 7.9 8.4 V

OUT(x)

= 50mA 0.6 1 V

OUT(x)

Pull-Up Resistance I

Pull-Down Resistance I

Rise Time C

Fall Time C

= –50mA to –10mA 22 30 Ω

OUT(x)

= –50mA to –10mA 12 20 Ω

OUT(x)

= 50pF (Note 8) 5 15 ns

OUT(x)

= 50pF (Note 8) 5 15 ns

OUT(x)

= 100k 180 ns

SPRG

REF

4.925 5.00 5.075 V

Note 6: The LTC3722E-1/LTC3722E-2 are guaranteed to meet

performance specifications from 0°C to 85°C. Specifications over the

, pulse width = 50ns. Verify output (A-F)

P-P

= 20k.

LEB

for these

COMP

–40°C to 85°C operating temperature range are assured by design,

characterization and correlation with statistical process controls.

Note 7: Guaranteed by design, not tested in production.

Note 8: Rise time is measured from the 10% to 90% points of the rising

edge of the driver output signal. Fall time is measured from the 90% to

10% points of the falling edge of the driver output signal.

4

372212f

Page 5

UW

TEMPERATURE (°C)

FREQUENCY (kHz)

240

250

80

3722 • G03

230

220

–40–60 – 20 200 40 60 100

260

CT = 270pF

TEMPERATURE (°C)

V

REF

(V)

4.99

5.00

80

3722 • G06

4.98

4.97

–40–60 – 20 200 40 60 100

5.01

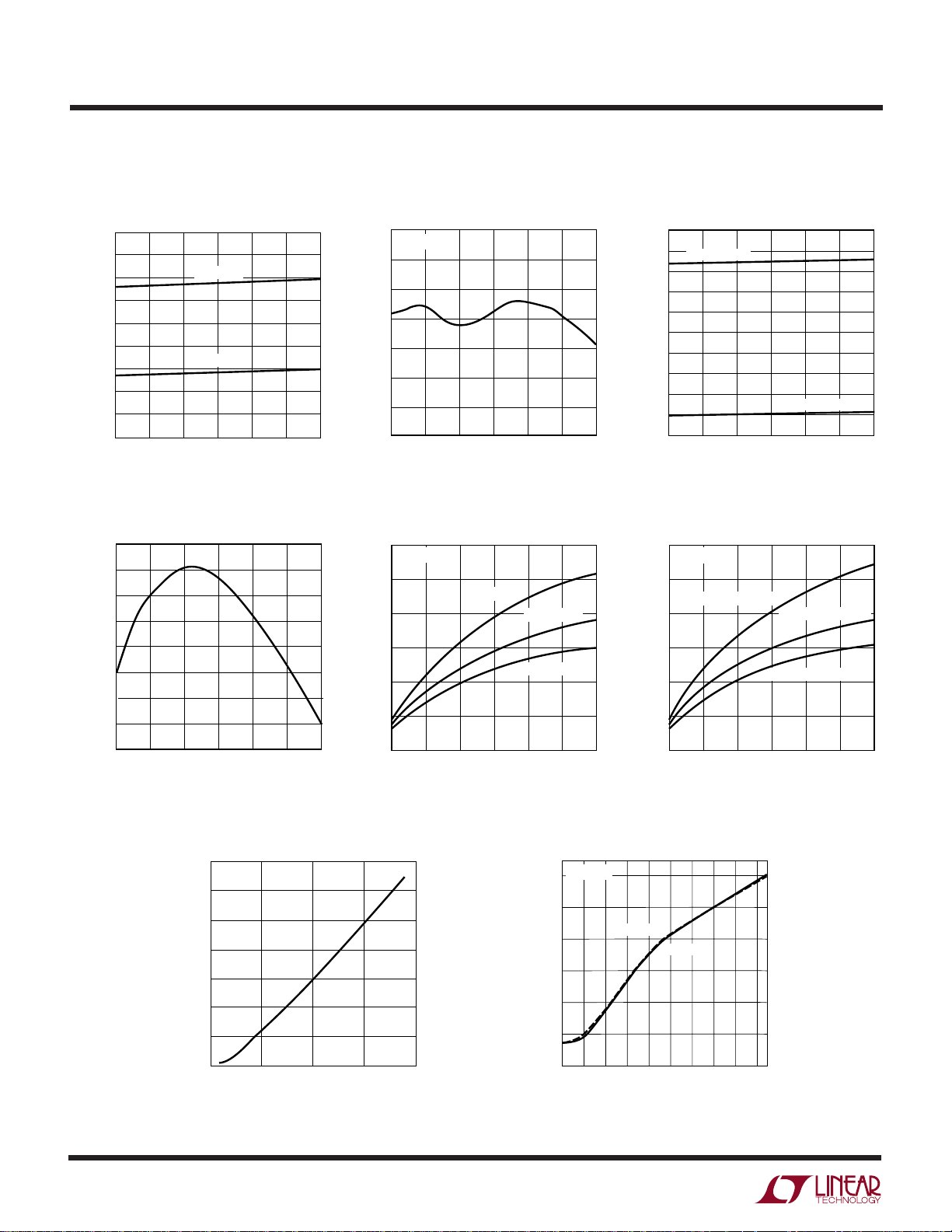

TYPICAL PERFOR A CE CHARACTERISTICS

Start-Up ICC vs V

200

TA = 25°C

CC

10.50

VCC vs I

TA = 25°C

SHUNT

LTC3722-1/LTC3722-2

Oscillator Frequency vs

Temperature

150

100

(µA)

CC

I

50

0

2

0

4

VCC (V)

Leading Edge Blanking Time

vs R

LEB

350

TA = 25°C

300

250

200

150

BLANK TIME (ns)

100

50

10.25

(V)

10.00

CC

V

9.75

(V)

REF

V

9.50

5.05

5.00

4.95

4.90

4.85

0

V

REF

10

vs I

TA = 25°C

REF

20

I

SHUNT

TA = 85°C

30

(mA)

TA = –40°C

40

50

3722 • G02

V

vs Temperature

REF

6

8

10

3722 • G01

GAIN (dB)PHASE (DEG)

0

0

40

2010 30 50 70 90

R

LEB

60 80

(kΩ)

Error Amplifier Gain/Phase

TA = 25°C

100

80

60

40

20

0

–180

–270

–360

10 1k100 10k 100k 10M

FREQUENCY (Hz)

3722 • G04

1M

100

3722 • G07

4.80

0

510

15 25 40

I

REF

Start-Up ICC vs Temperature

190

180

170

160

150

(µA)

140

CC

I

130

120

110

100

–25 5 35 95 12565

–55

TEMPERATURE (°C)

20

(mA)

30 35

3722 • G05

3722 • G08

Delay Hysteresis Current vs

Temperature

1.302

SBUS = 1.5V

1.300

1.298

1.296

1.294

1.292

1.290

1.288

1.286

HYSTERESIS CURRENT (mA)

1.284

1.282

1.280

–25 5 35 95 12565

–55

TEMPERATURE (°C)

3722 • G09

372212f

5

Page 6

LTC3722-1/LTC3722-2

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Slope Current vs Temperature

90

80

70

60

50

40

CURRENT (µA)

30

20

10

0

–25 5 35 95 12565

–55

CT = 2.25V

CT = 1V

TEMPERATURE (°C)

FB Input Voltage vs Temperature

1.205

1.204

1.203

1.202

1.201

1.200

FB VOLTAGE (V)

1.199

1.198

1.197

–25 5 35 95 12565

–55

TEMPERATURE (°C)

3722 • G10

3722 • G13

VCC Shunt Voltage vs

Temperature

10.5

ICC = 10mA

10.4

10.3

10.2

10.1

SHUNT VOLTAGE (V)

10.0

9.9

9.8

–25 5 35 95 12565

–55

Delay Timeout vs R

300

TA = 25°C

250

200

150

DELAY (ns)

100

50

0

10

60

TEMPERATURE (°C)

DPRG

SBUS = 2.25V

110 160 210

R

(kΩ)

DPRG

3722 • G11

SBUS = 1.5V

SBUS = 1.125V

260 310

3722 • G14

Delay Pin Threshold vs

Temperature

2.4

2.3

SBUS = 2.25V

2.2

2.1

2.0

1.9

1.8

THRESHOLD (V)

1.7

1.6

1.5

1.4

–25 5 35 95 12565

–55

TEMPERATURE (°C)

ZVS Delay in Fixed Mode,

SBUS = 5V

300

TA = 25°C

250

ADLY = PDLY = 2.25V

200

150

DELAY (ns)

100

50

0

10

110 160 210

60

SBUS = 1.5V

ADLY = PDLY = 1.5V

ADLY = PDLY = 1.125V

R

(kΩ)

DPRG

3722 • G12

260 310

3722 • G15

6

Synchronous Driver Turn-Off

Delay in Fixed Mode

350

TA = 25°C

300

250

200

150

DELAY (nS)

100

50

0

10

60 110 210

R

(kΩ)

SPRG

160

3722 • G16

Synchronous Driver Turn-Off Delay

in Adaptive Mode, SBUS = 1.5V

TA = 25°C

260

220

30

B HI-F LOW

70

50

R

90

SPRG

A HI-E LOW

130 170

110

(kΩ)

150

180

140

DELAY (ns)

100

60

20

10

190

3722 • G17

372212f

Page 7

LTC3722-1/LTC3722-2

U

PI FU CTIO S

SYNC (Pin 1/Pin 1): Synchronization Input/Output for the

Oscillator. The input threshold for SYNC is approximately

1.9V, making it compatible with both CMOS and TTL logic.

Terminate SYNC with a 5.1k resistor to GND.

DPRG (Pin 2/Pin 5): Programming Input for Default Zero

Voltage Transition (ZVS) Delay. Connect a resistor from

DPRG to V

outputs A, B, C, D. The nominal voltage on DPRG is 2V.

RAMP (NA/Pin 2): Input to Phase Modulator Comparator

for LTC3722-2 only. The voltage on RAMP is internally

level shifted by 650mV.

CS (Pin 3/Pin 3): Input to phase modulator for the

LTC3722-1. Input to Pulse by Pulse and Overload Current

Limit Comparators, Output of Slope Compensation Circuitry. The pulse by pulse comparator has a nominal

300mV threshold, while the overload comparator has a

nominal 650mV threshold.

COMP (Pin 4/Pin 4): Error Amplifier Output, Inverting

Input to Phase Modulator.

REF

UU

(LTC3722-1/LTC3722-2)

to set the maximum turn on delay for

SBUS (Pin 10/Pin 10): Line Voltage Sense Input. SBUS is

connected to the main DC voltage feed by a resistive

voltage divider when using adaptive ZVS control. The

voltage divider is designed to produce 1.5V on SBUS at

nominal VIN. If SBUS is tied to V

LTC3722-2 is configured for fixed mode ZVS control.

ADLY (Pin 11/Pin 11): Active Leg Delay Circuit Input.

ADLY is connected through a voltage divider to the right

leg of the bridge in adaptive ZVS mode. In fixed ZVS mode,

a voltage between 0V and 2.5V on ADLY, programs a fixed

ZVS delay time for the active leg transition.

UVLO (Pin 12/Pin 12): Input to Program System Turn-On

and Turn-Off Voltages. The nominal threshold of the UVLO

comparator is 5V. UVLO is connected to the main DC

system feed through a resistor divider. When the UVLO

threshold is exceeded, the LTC3722-1/LTC3722-2 commences a soft start cycle and a 10µA (nominal) current is

fed out of UVLO to program the desired amount of system

hysteresis. The hysteresis level can be adjusted by changing the resistance of the divider.

, the LTC3722-1/

REF

R

(Pin 5/NA): Timing Resistor for Leading Edge Blank-

LEB

ing. Use a 10k to 100k resistor to program from 40ns to

310ns of leading edge blanking of the current sense signal

on CS for the LTC3722-1. A ±1% tolerance resistor is

recommended. The LTC3722-2 has a fixed blanking time

of approximately 80ns.

FB (Pin 6/Pin 6): Error Amplifier Inverting Input. This is the

voltage feedback input for the LTC3722. The nominal

regulation voltage at FB is 1.204V.

SS (Pin 7/Pin 7): Soft-Start/Restart Delay Circuitry Timing

Capacitor. A capacitor from SS to GND provides a controlled ramp of the current command (LTC3722-1), or

duty cycle (LTC3722-2). During overload conditions SS is

discharged to ground initiating a soft-start cycle.

NC (Pin 8/Pin 8): No Connection. Tie this pin to GND.

PDLY (Pin 9/Pin 9): Passive Leg Delay Circuit Input. PDLY

is connected through a voltage divider to the left leg of the

bridge in adaptive ZVS mode. In fixed ZVS mode, a voltage

between 0V and 2.5V on PDLY, programs a fixed ZVS

delay time for the passive leg transition.

SPRG (Pin 13/Pin 13): A Resistor is connected between

SPRG and GND to set the turn-off delay for the synchronous rectifier driver outputs (OUTE and OUTF). The nominal voltage on SPRG is 2V.

V

(Pin 14/Pin 14): Output of the 5V Reference. V

REF

capable of supplying up to 18mA to external circuitry. V

should be decoupled to GND with a 1µF ceramic capacitor.

OUTF (Pin 15/Pin 15): 50mA Driver for Synchronous

Rectifier Associated with OUTB and OUTC.

OUTE (Pin 16/Pin 16): 50mA Driver for Synchronous

Rectifier Associated with OUTA and OUTD.

OUTD (Pin 17/Pin 17): 50mA driver for Low Side of the Full

Bridge Active Leg.

VCC (Pin 18/Pin 18): Supply Voltage Input to the

LTC3722-1/LTC3722-2 and 10.25V Shunt Regulator. The

chip is enabled after VCC has risen high enough to allow the

VCC shunt regulator to conduct current and the UVLO

comparator threshold is exceeded. Once the VCC shunt

regulator has turned on, VCC can drop to as low as 6V (typ)

and maintain operation.

REF

is

REF

372212f

7

Page 8

LTC3722-1/LTC3722-2

U

PI FU CTIO S

UU

(LTC3722-1/LTC3722-2)

OUTC (Pin 19/Pin 19): 50mA Driver for High Side of the

Full Bridge Active Leg.

OUTB (Pin 20/Pin 20): 50mA Driver for Low Side of the

Full Bridge Passive Leg.

OUTA (Pin 21/Pin 21): 50mA Driver for High Side of the

Full Bridge Passive Leg.

PGND (Pin 22/Pin 22): Power Ground for the LTC3722.

The output drivers of the LTC3722 are referenced to

W

BLOCK DIAGRA S

LTC3722-1 Current Mode SYNC Phase Shift PWM

FB

6

1.2V

COMP

4

+

–

V

CC

18 12 14

V

UVLO

CC

10.25V = ON

6V = OFF

–

+

ERROR

AMPLIFIER

650mV

UVLO V

REF AND LDO

REF GOOD

SYSTEM

+

UVLO

–

5V

R1

50k

–

+

R2

14.9k

REF

5V

1.2V

V

CC

GOOD

PHASE

MODULATOR

1 = ENABLE

0 = DISABLE

PGND. Connect the ceramic VCC bypass capacitor directly

to PGND.

GND (Pin 23/Pin 23): All circuits other than the output

drivers in the LTC3722 are referenced to GND. Use of a

ground plane is recommended but not absolutely

necessary.

CT (Pin 24/Pin 24): Timing Capacitor for the Oscillator.

Use a ±5% or better low ESR ceramic capacitor for best

results.

C

24

OSC

SYNC SPRG SBUSDPRG

T

T

QB

1 13 102

Q

PASSIVE

DELAY

SYNC

RECTIFIER

DRIVE

LOGIC

PDLY

9

OUTA

21

OUTB

20

OUTE

16

OUTF

15

8

M1

V

REF

SHUTDOWN

+

–

+

–

12µA

CURRENT

LIMIT

M2

PULSE BY PULSE

CURRENT LIMIT

SS

7

650mV

CS

3

BLANK

5

LEB

300mV

R

QB

R

S

Q

FAULT

LOGIC

SLOPE

COMPENSATION

/R

C

T

23

GND

OUTC

R

QB

S

ACTIVE

DELAY

19

OUTD

17

ADLY

11

PGND

22

3722 • BD01

372212f

Page 9

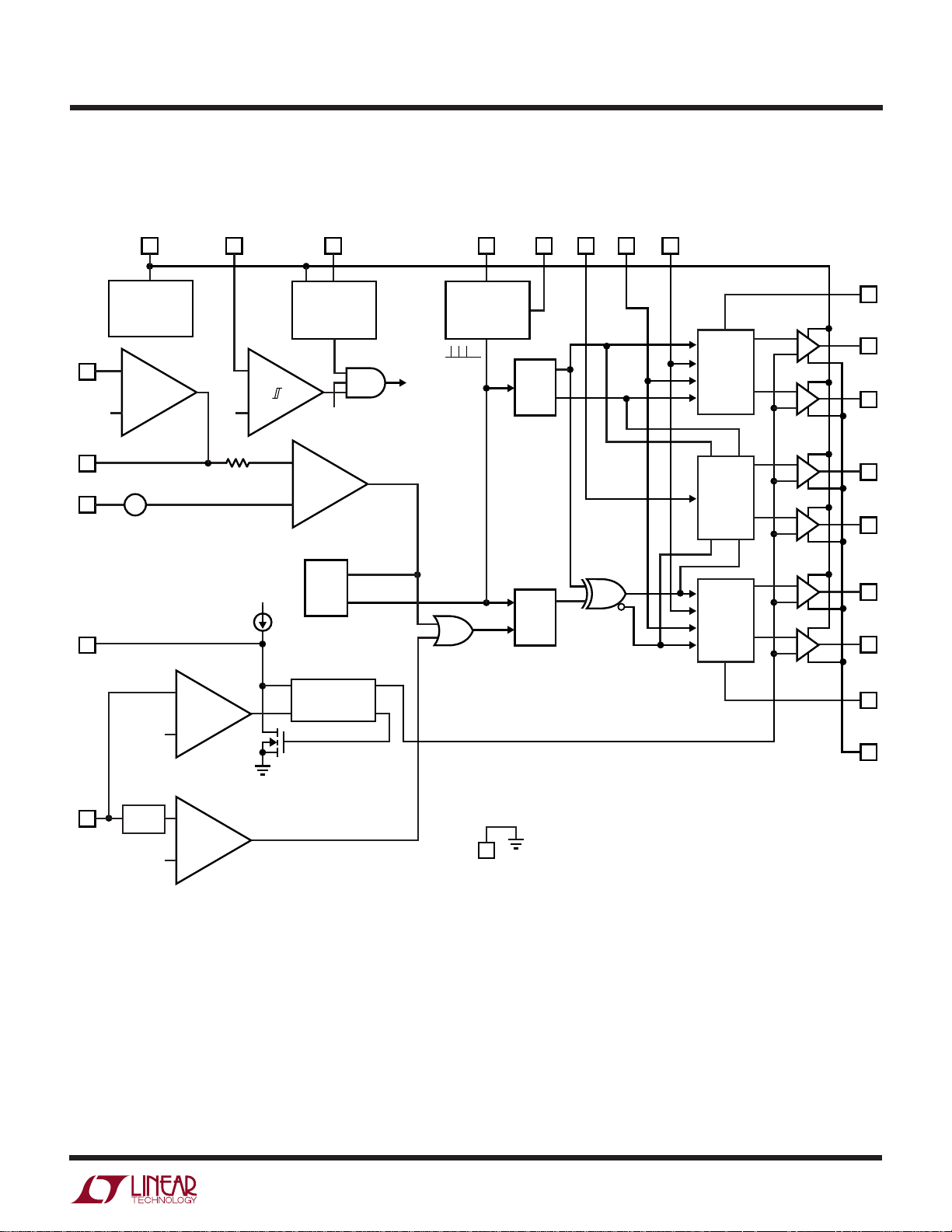

W

BLOCK DIAGRA S

LTC3722-1/LTC3722-2

LTC3722-2 Voltage Mode SYNC Phase Shift PWM

FB

6

1.2V

COMP

4

2

RAMP

SS

7

V

CC

18 12 14

V

UVLO

CC

10.25V = ON

6V = OFF

–

AMPLIFIER

+

+

–

650mV

UVLO V

ERROR

5V

R1

50k

12µA

SHUTDOWN

CURRENT

LIMIT

+

–

V

REF

+

REF AND LDO

REF GOOD

SYSTEM

UVLO

–

+

MODULATOR

QB

Q

REF

5V

1.2V

V

CC

GOOD

PHASE

FAULT

LOGIC

C

24

OSC

1 = ENABLE

0 = DISABLE

R

S

SYNC SPRG SBUSDPRG

T

T

QB

R

S

1 13 105

Q

QB

PASSIVE

DELAY

SYNC

RECTIFIER

DRIVE

LOGIC

ACTIVE

DELAY

PDLY

9

OUTA

21

OUTB

20

OUTE

16

OUTF

15

OUTC

19

OUTD

17

ADLY

11

650mV

CS

3

BLANK

300mV

–

+

–

M2

PULSE BY PULSE

CURRENT LIMIT

3722 • BD02

23

GND

PGND

22

372212f

9

Page 10

LTC3722-1/LTC3722-2

UWW

TI I G DIAGRA

OUTA

OUTB

OUTC

OUTD

RAMP

COMP

OUTE

OUTF

COMP

PASSIVE LEG

DELAY

SYNC TURN OFF

DELAY (PROGRAMMABLE)

SYNC TURN OFF

DELAY (PROGRAMMABLE)

ACTIVE LEG

DELAY

COMP

NOTE: SHADED AREAS CORRESPOND TO POWER DELIVERY PULSES.

U

OPERATIO

Phase Shift Full-Bridge PWM

Conventional full-bridge switching power supply topologies are often employed for high power, isolated DC/DC

and off-line converters. Although they require two additional switching elements, substantially greater power and

higher efficiency can be attained for a given transformer

size compared to the more common single-ended forward

and flyback converters. These improvements are realized

since the full-bridge converter delivers power during both

parts of the switching cycle, reducing transformer core

loss and lowering voltage and current stresses. The fullbridge converter also provides inherent automatic transformer flux reset and balancing due to its bidirectional

drive configuration. As a result, the maximum duty cycle

range is extended, further improving efficiency. Soft switching variations on the full-bridge topology have been proposed to improve and extend its performance and application. These zero voltage switching (ZVS) techniques

3722 TD

exploit the generally undesirable parasitic elements present

within the power stage. The parasitic elements are utilized

to drive near lossless switching transitions for all of the

external power MOSFETs.

LTC3722-1/LTC3722-2 phase shift PWM controllers provide enhanced performance and simplify the design task

required for a ZVS phase shifted full-bridge converter. The

primary attributes of the LTC3722-1/LTC3722-2 as compared to currently available solutions include:

1) Truly adaptive and accurate (DirectSenseTM technology)

ZVS with programmable timeout.

Benefit: higher efficiency, higher duty cycle capability,

eliminates external trim.

2) Fixed ZVS capability.

Benefit: enables secondary side control and simplifies

external circuit.

DirectSense is a trademark of Linear Technology Corporation.

372212f

10

Page 11

OPERATIO

LTC3722-1/LTC3722-2

U

3) Internally generated drive signals with programmable

turn-off for current doubler synchronous rectifiers.

Benefit: eliminates external glue logic, drivers, optimal

timing for highest efficiency.

4) Programmable (single resistor) leading edge blanking.

Benefit: prevents spurious operation, reduces external

filtering required on CS.

5) Programmable (single resistor) slope compensation.

Benefit: eliminates external glue circuitry.

6) Optimized current mode control architecture.

Benefit: eliminates glue circuitry, less overshoot at start-

up, faster recovery from system faults.

7) Programmable system undervoltage lockout and

hysteresis.

Benefit: provides an accurate turn-on voltage for power

supply and reduces external circuitry.

As a result, the LTC3722-1/LTC3722-2 makes the ZVS

topology feasible for a wider variety of applications, including those at lower power levels.

isolation barrier. Methods for providing drive to these

elements are detailed in this data sheet. The secondary

voltage of the transformer is the primary voltage divided

by the transformer turns ratio. Similar to a buck converter,

the secondary square wave is applied to an output filter

inductor and capacitor to produce a well regulated DC

output voltage.

Switching Transitions

The phase shifted full-bridge can be described by four

primary operating states. The key to understanding how

ZVS occurs is revealed by examining the states in detail.

Each full cycle of the transformer has two distinct periods

in which power is delivered to the output, and two “freewheeling” periods. The two sides of the external bridge

have fundamentally different operating characteristics that

become important when designing for ZVS over a wide

load current range. The left bridge leg is referred to as the

“passive” leg, while the right leg is referred to as the

“active” leg. The following descriptions provide insight as

to why these differences exist.

State 1 (Power Pulse 1)

The LTC3722-1/LTC3722-2 control four external power

switches in a full-bridge arrangement. The load on the

bridge is the primary winding of a power transformer. The

diagonal switches in the bridge connect the primary winding between the input voltage and ground every oscillator

cycle. The pair of switches that conduct are alternated by

an internal flip-flop in the LTC3722-1/LTC3722-2. Thus,

the voltage applied to the primary is reversed in polarity on

every switching cycle and each output drive signal is 1/2

the frequency of the oscillator. The on-time of each driver

signal is slightly less that 50%. The on-time overlap of the

diagonal switch pairs is controlled by the LTC3722-1/

LTC3722-2 phase modulation circuitry. (Refer to Block

and Timing Diagrams) This overlap sets the approximate

duty cycle of the converter. The LTC3722-1/LTC3722-2

driver output signals (OUTA to OUTF) are optimized for

interface with an external gate driver IC or buffer. External

power MOSFETs A and C require high side driver circuitry,

while B and D are ground referenced and E and F are

ground referenced but on the secondary side of the

As shown in Figure 1 on the following page, State 1 begins

with MA, MD and MF “ON” and MB, MC and ME “OFF.”

During the simultaneous conduction of MA and MD, the

full input voltage is applied across the transformer primary

winding and following the dot convention, VIN/N is applied

to the left side of LO1 allowing current to increase in LO1.

The primary current during this period is approximately

equal to the output inductor current (LO1) divided by the

transformer turns ratio plus the transformer magnetizing

current (VIN • tON/L

the end of State 1.

State 2 (Active Transition and Freewheel Interval)

MD turns off when the phase modulator comparator

transitions. At this instant, the voltage on the MD/MC

junction begins to rise towards the applied input voltage

(VIN). The transformer’s magnetizing current and the

reflected output inductor current propels this action. The

slew rate is limited by MOSFET MC and MD’s output

). MD turns off and ME turns on at

MAG

372212f

11

Page 12

LTC3722-1/LTC3722-2

U

OPERATIO

State 1

State 2

State 3

MA

MB

MA

MB

POWER PULSE 1

V

IN

ACTIVE

TRANSITION

PASSIVE

TRANSITION

MC

MD

IP ≈ I

MC

MD

/N + (VIN • T

L01

N:1

MF

MA

MB

OVL

)/L

MAG

L01

L02

ME

FREEWHEEL

INTERVAL

V

OUT

LOAD

+

PRIMARY AND

SECONDARY SHORTED

V

OUT

MC

LOAD

MD

MF

ME

State 4

MA

MB

MA

MB

POWER PULSE 2

MC

MD

MC

MD

MF

ME

Figure 1. ZVS Operation

V

OUT

LOAD

+

3722 F01

12

372212f

Page 13

OPERATIO

LTC3722-1/LTC3722-2

U

capacitance (C

former interwinding capacitance. The voltage transition

on the active leg from the ground reference point to VIN will

always occur, independent of load current as long as

energy in the transformer’s magnetizing and leakage inductance is greater than the capacitive energy. That is,

1/2 • (LM + LI) • I

occurs when the load current is zero. This condition is

usually easy to meet. The magnetizing current is virtually

constant during this transition because the magnetizing

inductance has positive voltage applied across it throughout the low to high transition. Since the leg is actively

driven by this “current source,” it is called the active or

linear transition. When the voltage on the active leg has

risen to VIN, MOSFET MC is switched on by the ZVS

circuitry. The primary current␣ now flows through the two

high side MOSFETs (MA and MC). The transformer’s

secondary windings are electrically shorted at this time

since both ME and MF are “ON”. As long as positive

current flows in LO1 and LO2, the transformer primary

(magnetizing) inductance is also shorted through normal

transformer action. MA and MF turn off at the end of

State 2.

State 3 (Passive Transition)

MA turns off when the oscillator timing period ends, i.e.,

the clock pulse toggles the internal flip-flop. At the instant

MA turns off, the voltage on the MA/MB junction begins to

decay towards the lower supply (GND). The energy available to drive this transition is limited to the primary leakage

inductance and added commutating inductance which

have (I

magnetizing and output inductors don’t contribute any

energy because they are effectively shorted as mentioned

previously, significantly reducing the available energy.

This is the major difference between the active and passive

transitions. If the energy stored in the leakage and commutating inductance is greater than the capacitive energy,

the transition will be completed successfully. During the

transition, an increasing reverse voltage is applied to the

leakage and commutating inductances, helping the overall

MAG

+ I

), snubbing capacitance and the trans-

OSS

2

> 1/2 • 2 • C

M

/2N) flowing through them initially. The

OUT

OSS

2

• V

— the worst case

IN

primary current to decay. The inductive energy is thus

resonantly transferred to the capacitive elements, hence,

the term passive or resonant transition. Assuming there is

sufficient inductive energy to propel the bridge leg to

GND, the time required will be approximately equal to

π • √LC/2. When the voltage on the passive leg nears GND,

MOSFET MB is commanded “ON” by the ZVS circuitry.

Current continues to increase in the leakage and external

series inductance which is opposite in polarity to the

reflected output inductor current. When this current is

equal in magnitude to the reflected output current, the

primary current reverses direction, the opposite secondary winding becomes forward biased and a new power

pulse is initiated. The time required for the current reversal

reduces the effective maximum duty cycle and must be

considered when computing the power transformer turns

ratio. If ZVS is required over the entire range of loads, a

small commutating inductor is added in series with the

primary to aid with the passive leg transition, since the

leakage inductance alone is usually not sufficient and

predictable enough to guarantee ZVS over the full load

range.

State 4 (Power Pulse 2)

During power pulse 2, current builds up in the primary

winding in the opposite direction as power pulse 1. The

primary current consists of reflected output inductor

current and current due to the primary magnetizing inductance. At the end of State 4, MOSFET MC turns off and an

active transition, essentially similar to State 2 but opposite

in direction (high to low), takes place.

Zero Voltage Switching (ZVS)

A lossless switching transition requires that the respective

full-bridge MOSFETs be switched to the “ON” state at the

exact instant their drain to source voltage is zero. Delaying

the turn-on results in lower efficiency due to circulating

current flowing in the body diode of the primary side

MOSFET rather than its low resistance channel. Premature

turn-on produces hard switching of the MOSFETs, increasing noise and power dissipation.

372212f

13

Page 14

LTC3722-1/LTC3722-2

U

OPERATIO

LTC3722-1/LTC3722-2 Adaptive Delay Circuitry

The LTC3722-1/LTC3722-2 monitors both the input supply and instantaneous bridge leg voltages, and commands

a switching transition when the expected zero voltage

condition is reached. DirectSense technology provides

optimal turn-on delay timing, regardless of input voltage,

output load, or component tolerances. The DirectSense

technique requires only a simple voltage divider sense

network to implement. If there is not enough energy to

fully commutate the bridge leg to a ZVS condition, the

LTC3722-1/LTC3722-2 automatically overrides the

DirectSense circuitry and forces a transition. The override

or default delay time is programmed with a resistor from

DPRG to V

REF

.

Adaptive Mode

The LTC3722-1/LTC3722-2 are configured for adaptive

delay sensing with three pins, ADLY, PDLY and SBUS.

ADLY and PDLY sense the active and passive delay legs

respectively via a voltage divider network as shown in

Figure 2.

V

IN

SBUS

PDLY

R2

R1

R3

1k

1k

A

R5

B

C

R6

D

R

CS

1922 F02

ADLY

R4

1k

ADLY and PDLY are connected through voltage dividers to

the active and passive bridge legs respectively. The lower

resistor in the divider is set to 1k. The upper resistor in the

divider is selected for the desired positive transition trip

threshold.

To set up the ADLY and PDLY resistors, first determine at

what drain to source voltage to turn-on the MOSFETs.

Finite delays exist between the time at which the LTC37221/LTC3722-2 controller output transitions, to the time at

which the power MOSFET switches on due to MOSFET

turn on delay and external driver circuit delay. Ideally, we

want the power MOSFET to switch at the instant there is

zero volts across it. By setting a threshold voltage for

ADLY and PDLY corresponding to several volts across the

MOSFET, the LTC3722-1/LTC3722-2 can “anticipate” a

zero voltage VDS and signal the external driver and switch

to turn-on. The amount of anticipation can be tailored for

any application by modifying the upper divider resistor(s).

The LTC3722-1/LTC3722-2 DirectSense circuitry sources

a trimmed current out of PDLY and ADLY after a low to

high level transition occurs. This provides hysteresis and

noise immunity for the PDLY and ADLY circuitry, and sets

the high to low threshold on ADLY or PDLY to nearly the

same level as the low to high threshold, thereby making

the upper and lower MOSFET VDS switch points virtually

identical, independent of VIN.

Example: V

= 48V nominal (36V to 72V)

IN

1. Set up SBUS: 1.5V is desired on SBUS with VIN = 48V.

Set divider current to 100µA.

R1 = 1.5V/100µA = 15k.

Figure 2. Adaptive Mode

The threshold voltage on PDLY and ADLY for both the

rising and falling transitions is set by the voltage on SBUS.

A buffered version of this voltage is used as the threshold

level for the internal DirectSense circuitry. At nominal VIN,

the voltage on SBUS is set to 1.5V by an external voltage

divider between VIN and GND, making this voltage directly

proportional to VIN. The LTC3722-1/LTC3722-2

DirectSense circuitry uses this characteristic to zero

voltage switch all of the external power MOSFETs, independent of input voltage.

14

R2 = (48V – 1.5V)/100µA = 465k.

An optional small capacitor (0.001µF) can be added

across R1 to decouple noise from this input.

2. Set up ADLY and PDLY: 7V of “anticipation” is desired

in this circuit to account for the delays of the external

MOSFET driver and gate drive components.

R3, R4 = 1k, sets a nominal 1.5mA in the divider

chain at the threshold.

R5, R6 = (48V – 7V – 1.5V)/1.5mA = 26.3k,

use (2) equal 13k segments.

372212f

Page 15

OPERATIO

LTC3722-1/LTC3722-2

U

Fixed Delay Mode

The LTC3722-1/LTC3722-2 provides the flexibility through

the SBUS pin to disable the DirectSense delay circuitry and

enable fixed ZVS delays. The level of fixed ZVS delay is

proportional to the voltage programmed through the voltage divider on the PDLY and ADLY pins. See Figure␣ 3 for

more detail.

V

REF

SBUS

PDLY

ADLY

R1

R2

R3

3722 F03

Figure 3. Setup for Fixed ZVS Delays

Programming Adaptive Delay Time-Out

The LTC3722-1/LTC3722-2 controllers include a feature

to program the maximum time delay before a bridge

switch turn on command is summoned. This function will

come into play if there is not enough energy to commutate

a bridge leg to the opposite supply rail, therefore bypassing the adaptive delay circuitry. The time delay can be set

with an external resistor connected between DPRG and

V

(see Figure 4). The nominal regulated voltage on

REF

DPRG is 2V. The external resistor programs a current

which flows into DPRG. The delay can be adjusted from

approximately 35ns to 300ns, depending on the resistor

value. If DPRG is left open, the delay time is approximately

400ns. The amount of delay can also be modulated based

on an external current source that feeds current into

DPRG. Care must be taken to limit the current fed into

DPRG to 350µA or less.

V

REF

Powering the LTC3722-1/LTC3722-2

The LTC3722-1/LTC3722-2 utilize an integrated VCC shunt

regulator to serve the dual purposes of limiting the voltage

applied to VCC as well as signaling that the chip’s bias

voltage is sufficient to begin switching operation (under

voltage lockout). With its typical 10.2V turn-on voltage

and 4.2V UVLO hysteresis, the LTC3722-1/LTC3722-2 is

tolerant of loosely regulated input sources such as an

auxiliary transformer winding. The VCC shunt is capable of

sinking up to 25mA of externally applied current. The

UVLO turn-on and turn-off thresholds are derived from an

internally trimmed reference making them extremely accurate. In addition, the LTC3722-1/LTC3722-2 exhibits

very low (145µA typ) start-up current that allows the use

of 1/8W to 1/4W trickle charge start-up resistors.

The trickle charge resistor should be selected as follows:

R

START(MAX)

= V

– 10.7V/250µA

IN(MIN)

Adding a small safety margin and choosing standard

values yields:

APPLICATION VIN RANGE R

DC/DC 36V to 72V 100k

Off-Line 85V to 270V

PFC Preregulator 390V

RMS

DC

START

430k

1.4M

VCC should be bypassed with a 0.1µF to 1µF multilayer

ceramic capacitor to decouple the fast transient currents

demanded by the output drivers and a bulk tantalum or

electrolytic capacitor to hold up the VCC supply before the

bootstrap winding, or an auxiliary regulator circuit takes

over.

C

HOLDUP

= (ICC + I

DRIVE

) • t

DELAY

/3.8V

(minimum UVLO hysteresis)

Regulated bias supplies as low as 7V can be utilized to

provide bias to the LTC3722-1/LTC3722-2. Figure 5 shows

various bias supply configurations.

R

DPRG

DPRG

+

2V

V

–

SBUS

+

–

Figure 4. Delay Timeout Circuitry

TURN-ON

OUTPUT

3722 F04

12V ±10%

1.5k

V

CC

V

< V

CC

UVLO

1N914

IN

R

START

0.1µF

1N5226

3V

0.1µF

V

BIAS

V

Figure 5. Bias Configurations

+

C

HOLD

3722 F04

372212f

15

Page 16

LTC3722-1/LTC3722-2

U

OPERATIO

Programming Undervoltage Lockout

The LTC3722-1/LTC3722-2 provides undervoltage lockout (UVLO) control for the input DC voltage feed to the

power converter in addition to the V

UVLO function

CC

described in the preceding section. Input DC feed UVLO is

provided with the UVLO pin. A comparator on UVLO

compares a divided down input DC feed voltage to the 5V

precision reference. When the 5V level is exceeded on

UVLO, the SS pin is released and output switching commences. At the same time a 10µA current is enabled which

flows out of UVLO into the voltage divider connected to

UVLO. The amount of DC feed hysteresis provided by this

current is: 10µA • R

threshold is: 5V • {(R

, see Figure 6. The system UVLO

TOP

TOP

+ R

BOTTOM

)/R

BOTTOM

}. If the

voltage applied to UVLO is present and greater than 5V

prior to the VCC UVLO circuitry activation, then the internal

UVLO logic will prevent output switching until the following three conditions are met: (1) VCC UVLO is enabled, (2)

V

is in regulation and (3) UVLO pin is greater than 5V.

REF

UVLO can also be used to enable and disable the power

converter. An open drain transistor connected to UVLO as

shown in Figure 6 provides this capability.

maintains decent regulation as the supply voltage varies,

and it does not require full safety isolation from the input

winding of the transformer. Some manufacturers include

a primary winding for this purpose in their standard

product offerings as well. A different approach is to add a

winding to the output inductor and peak detect and filter

the square wave signal (see Figure 7b). The polarity of this

winding is designed so that the positive voltage square

wave is produced while the output inductor is freewheeling. An advantage of this technique over the previous is

that it does not require a separate filter inductor and since

the voltage is derived from the well-regulated output

voltage, it is also well controlled. One disadvantage is that

this winding will require the same safety isolation that is

required for the main transformer. Another disadvantage

is that a much larger VCC filter capacitor is needed, since

it does not generate a voltage as the output is first starting

up, or during short-circuit conditions.

V

15V*

R

START

IN

+

C

HOLD

V

CC

2k

0.1µF

R

TOP

UVLO

ON OFF R

Figure 6. System UVLO Setup

BOTTOM

3722 F0A

Off-Line Bias Supply Generation

If a regulated bias supply is not available to provide V

CC

voltage to the LTC3722-1/LTC3722-2 and supporting

circuitry, one must be generated. Since the power requirement is small, approximately 1W, and the regulation is not

critical, a simple open-loop method is usually the easiest

and lowest cost approach. One method that works well is

to add a winding to the main power transformer, and post

regulate the resultant square wave with an L-C filter (see

Figure␣ 7a). The advantage of this approach is that it

*OPTIONAL

Figure 7a. Auxiliary Winding Bias Supply

V

IN

L

OUT

R

START

V

CC

Figure 7b. Output Inductor Bias Supply

0.1µF

ISO BARRIER

C

HOLD

1922 F05a

+

1922 F05b

V

OUT

Programming the LTC3722-1/LTC3722-2 Oscillator

The high accuracy LTC3722-1/LTC3722-2 oscillator circuit provides flexibility to program the switching frequency, slope compensation, and synchronization with

minimal external components. The LTC3722-1/LTC3722-2

16

372212f

Page 17

LTC3722

C

T

C

T

SYNC

5.1k

1k

3722 F06b

EXTERNAL

FREQUENCY

SOURCE

AMPLITUDE > 1.8V

100ns < PW < 0.4/ƒ

U

OPERATIO

oscillator circuitry produces a 2.2V peak-to-peak amplitude ramp waveform on CT and a narrow pulse on SYNC

that can be used to synchronize other PWM chips. Typical

maximum duty cycles of 98.5% are obtained at 300kHz

and 96% at 1MHz. A compensating slope current is

derived from the oscillator ramp waveform and sourced

out of CS.

The desired amount of slope compensation is selected

with single external resistor. A capacitor to GND on C

programs the switching frequency. The CT ramp discharge current is internally set to a high value (>10mA).

The dedicated SYNC I/O pin easily achieves synchronization. The LTC3722-1/LTC3722-2 can be set up to either

synchronize other PWM chips or be synchronized by

another chip or external clock source. The 1.8V SYNC

threshold allows the LTC3722-1/LTC3722-2 to be synchronized directly from all standard 3V and 5V logic

families.

T

LTC3722-1/LTC3722-2

OF SLAVE(S) IS

C

T

OF MASTER.

1.25 C

T

LTC3722

C

T

C

T

MASTER

Figure 8a. SYNC Output (Master Mode)

Figure 8b. SYNC Input from an External Source

SYNC

5.1k

•

•

•

UP TO

5 SLAVES

1k

1k

SYNC

5.1k

SYNC

5.1k

LTC3722

LTC3722

SLAVES

C

C

C

T

C

T

3722 F06a

T

T

Design Procedure:

1. Choose CT for the desired oscillator frequency. The

switching frequency selected must be consistent with the

power magnetics and output power level. This is detailed

in the Transformer Design section. In general, increasing

the switching frequency will decrease the maximum achievable output power, due to limitations of maximum duty

cycle imposed by transformer core reset and ZVS. Remember that the output frequency is 1/2 that of the

oscillator.

CT = 1/(13.4k • f

Example: Desired f

CT = 1/(13.4k • f

)

OSC

= 330kHz

OSC

) = 226pF, choose closest standard

OSC

value of 220pF. A 5% or better tolerance multilayer NPO

or X7R ceramic capacitor is recommended for best

performance.

2. The LTC3722-1/LTC3722-2 can either synchronize other

PWMs, or be synchronized to an external frequency source

or PWM chip. See Figure 8 for details.

3. Slope compensation is required for most peak current

mode controllers in order to prevent subharmonic oscillation of the current control loop. In general, if the system

duty cycle exceeds 50% in a fixed frequency, continuous

current mode converter, an unstable condition exists

within the current control loop. Any perturbation in the

current signal is amplified by the PWM modulator resulting in an unstable condition. Some common manifestations of this include alternate pulse nonuniformity and

pulse width jitter. Fortunately, this can be addressed by

adding a corrective slope to the current sense signal or by

subtracting the same slope from the current command

signal (error amplifier output). In theory, the current

doubler output configuration does not require slope

compensation since the output inductor duty cycles only

approach 50%. However, transient conditions can momentarily cause higher duty cycles and therefore, the

possibility for unstable operation. The exact amount of

required slope compensation is easily programmed by

the LTC3722-1/LTC3722-2 with the addition of a single

external resistor (see Figure 9). The LTC3722-1/LTC37222 generates a current that is proportional to the instantaneous voltage on CT, (33µA/V

). Thus, at the peak of

(CT)

CT, this current is approximately 82.5µA and is output

from the CS pin. A resistor connected between CS and the

external current sense resistor sums in the required

amount of slope compensation. The value of this resistor

is dependent on several factors including minimum VIN,

372212f

17

Page 18

LTC3722-1/LTC3722-2

U

OPERATIO

V

, switching frequency, current sense resistor value

OUT

and output inductor value. An illustrative example with

the design equation is provided below.

Example: VIN = 36V to 72V

V

= 3.3V

OUT

I

= 40A

OUT

L = 2.2µH

Transformer turns ratio (N) = V

V

␣=␣3

OUT

R

= 0.025Ω

CS

fSW = 300kHz, i.e., transformer f = fSW/2 = 150kHz

R

= VO • RCS/(2 • L • fT • 82.5µA • N) = 3.3V • 0.025/

SLOPE

(2 • 2.2µA • 100k • 82.5µA • 3)

R

to account for tolerances in I

= 505Ω, choose the next higher standard value

SLOPE

SLOPE

LTC3722

)

V(C

T

33k

I =

33k

CS

ADDED

SLOPE

CURRENT SENSE

WAVEFORM

C

T

Figure 9. Slope Compensation Circuitry

• D

IN(MIN)

MAX

, RCS, N and L.

R

SLOPE

/

BRIDGE

CURRENT

R

CS

3722 F07

Current Sensing and Overcurrent Protection

Current sensing provides feedback for the current mode

control loop and protection from overload conditions. The

LTC3722-1/LTC3722-2 are compatible with either resistive sensing or current transformer methods. Internally

connected to the LTC3722-1/LTC3722-2 CS pin are two

comparators that provide pulse-by-pulse and overcurrent

shutdown functions respectively. (See Figure 10)

The pulse-by-pulse comparator has a 300mV nominal

threshold. If the 300mV threshold is exceeded, the PWM

cycle is terminated. The overcurrent comparator is set

approximately 2x higher than the pulse-by-pulse level. If

the current signal exceeds this level, the PWM cycle is

terminated, the soft-start capacitor is quickly discharged

and a soft-start cycle is initiated. If the overcurrent condition persists, the LTC3722-1/LTC3722-2 halts PWM operation and waits for the soft-start capacitor to charge up

to approximately 4V before a retry is allowed. The softstart capacitor is charged by an internal 12µA current

source. If the fault condition has not cleared when softstart reaches 4V, the soft-start pin is again discharged and

a new cycle is initiated. This is referred to as hiccup mode

operation. In normal operation and under most abnormal

conditions, the pulse-by-pulse comparator is fast enough

to prevent hiccup mode operation. In severe cases, however, with high input voltage, very low R

DS(ON)

MOSFETs

and a shorted output, or with saturating magnetics, the

overcurrent comparator provides a means of protecting

the power converter.

18

–

+

+

–

Q

H = SHUTDOWN

Q

4.1V

0.4V

OUTPUTS

12µA

3722 F08

SS

C

SS

372212f

PWM

PULSE BY PULSE

CURRENT LIMIT

CS

300mV

R

CS

CURRENT LIMIT

650mV

φ

+

–

OVERLOAD

+

–

MOD

UVLO

ENABLE

LATCH

Q

S

SQ

R

PWM

LOGIC

UVLO

ENABLE

SQ

R

Figure 10. Current Sense/Fault Circuitry Detail

Page 19

OPERATIO

LTC3722-1/LTC3722-2

U

Leading Edge Blanking

The LTC3722-1/LTC3722-2 provides programmable leading edge blanking to prevent nuisance tripping of the

current sense circuitry. Leading edge blanking relieves the

filtering requirements for the CS pin, greatly improving the

response to real overcurrent conditions. It also allows the

use of a ground referenced current sense resistor or

transformer(s), further simplifying the design. With a

single 10k to 100k resistor from R

to GND, blanking

LEB

times of approximately 40ns to 320ns are programmed. If

not required, connecting R

LEB

to V

can disable leading

REF

edge blanking. Keep in mind that the use of leading edge

blanking will set a minimum linear control range for the

phase modulation circuitry.

Resistive Sensing

A resistor connected between input common and the

sources of MB and MD is the simplest method of current

sensing for the full-bridge converter. This is the preferred

method for low to moderate power levels. The sense

resistor should be chosen such that the maximum rated

output current for the converter can be delivered at the

lowest expected VIN. Use the following formula to calculate the optimal value for RCS.

LTC3722-1:

R

CS

I PEAK

()

P

mV A R

=

I

() ()

O MAX IN MAX MIN

=+ +

N EFF

••

2

VD

OMIN

LfN

OUT CLK

where: N = Transformer turns ratio

µ300 82 5–( . • )

I PEAK

()

P

(– )

1

••

SLOPE

VD

••

2

Lf

•

MAG CLK

N

P

=

N

S

LTC3722-2:

Current Transformer Sensing

A current sense transformer can be used in lieu of resistive

sensing with the LTC3722-1/LTC3722-2. Current sense

transformers are available in many styles from several

manufacturers. A typical sense transformer for this application will use a 1:50 turns ratio (N), so that the sense

resistor value is N times larger, and the secondary current

N times smaller than in the resistive sense case. Therefore,

the sense resistor power loss is about N times less with the

transformer method, neglecting the transformers core

and copper losses. The disadvantages of this approach

include, higher cost and complexity, lower accuracy, core

reset/max duty cycle limitations and lower speed. Nevertheless, for very high power applications, this method is

preferred. The sense transformer primary is placed in the

same location as the ground referenced sense resistor, or

between the upper MOSFET drains in the (MA, MC) and

VIN. The advantage of the high side location is a greater

immunity to leading edge noise spikes, since gate charge

current and reflected rectifier recovery current are largely

eliminated. Figure 11 illustrates a typical current sense

transformer based sensing scheme. RS in this case is

calculated the same as in the resistive case, only its value

is increased by the sense transformer turns ratio. At high

duty cycles, it may become difficult or impossible to reset

the current transformer. This is because the required

transformer reset voltage increases as the available time

for reset decreases to equalize the (volt • seconds) applied.

The interwinding capacitance and secondary inductance

of the current sense transformer form a resonant circuit

that limits the dV/dT on the secondary of the CS transformer. This in turn limits the maximum achievable duty

cycle for the CS transformer. Attempts to operate beyond

this limit will cause the transformer core to “walk” and

eventually saturate, opening up the current feedback loop.

Common methods to address this limitation include:

1. Reducing the maximum duty cycle by lowering the

power transformer turns ratio.

2. Reducing the switching frequency of the converter.

CS

300

=

I PEAK

()

P

R

mV

3. Employ external active reset circuitry.

372212f

19

Page 20

LTC3722-1/LTC3722-2

U

OPERATIO

4. Using two CS transformers summed together.

5. Choose a CS transformer optimized for high frequency

applications.

MB

SOURCE

R

RAMP

CS

SLOPE

OPTIONAL

FILTERING

R

N:1

S

Figure 11. Current Transformer Sense Circuitry

MD

SOURCE

CURRENT

TRANSFORMER

1922 F10

Phase Modulator (LTC3722-1)

The LTC3722-1 phase modulation control circuitry is

comprised of the phase modulation comparator and logic,

the error amplifier, and the soft-start amplifier (see Figure␣ 12). Together, these elements develop the required

phase overlap (duty cycle) required to keep the output

voltage in regulation. In isolated applications, the sensed

output voltage error signal is fed back to COMP across the

input to output isolation boundary by an optical coupler

and shunt reference/error amplifier (LT®1431) combination. The FB pin is connected to GND, forcing COMP high.

The collector of the optoisolator is connected to COMP

directly. The voltage COMP is internally attenuated by the

LTC3722-1. The attenuated COMP voltage provides one

input to the phase modulation comparator. This is the

current command. The other input to the phase modulation comparator is the RAMP voltage, level shifted by

approximately 650mV. This is the current loop feedback.

During every switching cycle, alternate diagonal switches

(MA-MD or MB-MC) conduct and cause current in an

output inductor to increase. This current is seen on the

primary of the power transformer divided by the turns

ratio. Since the current sense resistor is connected between GND and the two bottom bridge transistors, a

voltage proportional to the output inductor current will be

seen across R

connected to CS, usually through a small resistor (R

. The high side of R

SENSE

SENSE

is also

).

SLOPE

When the voltage on CS exceeds either (COMP/5.2)

–650mV, or 300mV, the overlap conduction period will

terminate. During normal operation, the attenuated COMP

voltage will determine the CS trip point. During start-up, or

slewing conditions following a large load step, the 300mV

CS threshold will terminate the cycle, as COMP will be

driven high, such that the attenuated version exceeds the

300mV threshold. In extreme conditions, the 650mV

threshold on CS will be exceeded, invoking a soft-start/

restart cycle.

20

COMP

R

LEB

TOGGLE

F/F

ERROR

V

REF

AMPLIFIER

–

+

SOFT-START

AMPLIFIER

+

–

BLANKING

50k

14.9k

PHASE

MODULATION

COMPARATOR

–

+

+

650mV

–

SQ

R

FB

1.2V

12µA

SS

CS

CLK

CLK

FROM

CURRENT

LIMIT

COMPARATOR

CLK

Q

Q

PHASE

MODULATION

LOGIC

SQ

R

A

B

C

D

3722 F11

Figure 12. Phase Modulation Circuitry (LTC3722-1)

372212f

Page 21

V I ESR

V ESR

Lf

DD

ORIPPLE RIPPLE

O

OSW

==•

•

••

(– )(– )

2

112

OPERATIO

LTC3722-1/LTC3722-2

U

Selecting the Power Stage Components

Perhaps the most critical part of the overall design of the

converter is selecting the power MOSFETs, transformer,

inductors and filter capacitors. Tremendous gains in efficiency, transient performance and overall operation can

be obtained as long as a few simple guidelines are followed

with the phase shifted full-bridge topology.

Power Transformer

Switching frequency, core material characteristics, series

resistance and input/output voltages all play an important

role in transformer selection. Close attention also needs to

be paid to leakage and magnetizing inductances as they

play an important role in how well the converter will

achieve ZVS. Planar magnetics are very well suited to

these applications because of their excellent control of

these parameters.

Turns Ratio

The required turns ratio for a current doubler secondary is

given below. Depending on the magnetics selected, this

value may need to be reduced slightly.

Turns ratio formula:

VD

IN MIN MAX

N

=

•

()

V

•2

OUT

where:

V

D

= Minimum VIN for operation

IN(MIN)

= Maximum duty cycle of controller (DC

MAX

MAX

)

maximized at high duty cycle and decreases as the duty

cycle reduces. This means that a current doubler converter requires less output capacitance for the same

performance as a conventional converter. By determining

the minimum duty cycle for the converter, worse-case

V

ripple can be derived by the formula given below.

OUT

where:

D = minimum duty cycle

f

= oscillator frequency

SW

LO= output inductance

ESR = output capacitor series resistance

The amount of bulk capacitance required is usually system

dependent, but has some relationship to output inductance value, switching frequency, load power and dynamic

load characteristics. Polymer electrolytic capacitors are

the preferred choice for their combination of low ESR,

small size and high reliability. For less demanding applications, or those not constrained by size, aluminum electrolytic capacitors are commonly applied. Most

DC/DC converters in the 100kHz to 300kHz range use 20µF

to 25µF of bulk capacitance per watt of output power.

Converters switching at higher frequencies can usually

use less bulk capacitance. In systems where dynamic

response is critical, additional high frequency capacitors,

such as ceramics, can substantially reduce voltage transients.

Output Capacitors

Output capacitor selection has a dramatic impact on ripple

voltage, dynamic response to transients and stability.

Capacitor ESR along with output inductor ripple current

will determine the peak-to-peak voltage ripple on the

output. The current doubler configuration is advantageous because it has inherent ripple current reduction.

The dual output inductors deliver current to the output

capacitor 180 degrees out of phase, in effect, partially

canceling each other’s ripple current. This reduction is

Power MOSFETs

The full-bridge power MOSFETs should be selected for

their R

DS(ON)

and BV

ratings. Select the lowest BV

DSS

DSS

rated MOSFET available for a given input voltage range

leaving at least a 20% voltage margin. Conduction losses

are directly proportional to R

. Since the full-bridge

DS(ON)

has two MOSFETs in the power path most of the time,

conduction losses are approximately equal to:

2 • R

• I2, where I = IO/2N

DS(ON)

372212f

21

Page 22

LTC3722-1/LTC3722-2

U

OPERATIO

Switching losses in the MOSFETs are dominated by the

power required to charge their gates, and turn-on and

turn-off losses. At higher power levels, gate charge power

is seldom a significant contributor to efficiency loss. ZVS

operation virtually eliminates turn-on losses. Turn-off

losses are reduced by the use of an external drain to source

snubber capacitor and/or a very low resistance turn-off

driver. If synchronous rectifier MOSFETs are used on the

secondary, the same general guidelines apply. Keep in

mind, however, that the BV

be greater than V

secondary is snubbed. Without snubbing, the secondary

voltage can ring to levels far beyond what is expected due

to the resonant tank circuit formed between the secondary

leakage inductance and the C

the synchronous rectifier MOSFETs.

Switching Frequency Selection

Unless constrained by other system requirements, the

power converter’s switching frequency is usually set as

high as possible while staying within the desired efficiency

target. The benefits of higher switching frequencies are

many including smaller size, weight and reduced bulk

capacitance. In the full-bridge phase shift converter, these

principles are generally the same with the added complication of maintaining zero voltage transitions, and therefore, higher efficiency. ZVS is achieved in a finite time

during the switching cycle. During the ZVS time, power is

not delivered to the output; the act of ZVS reduces the

maximum available duty cycle. This reduction is proportional to maximum output power since the parasitic capacitive element (MOSFETs) that increase ZVS time get

larger as power levels increase. This implies an inverse

relationship between output power level and switching

frequency. Table 1 displays recommended maximum

switching frequency vs power level for a 30V/75V in to

3.3V/5V out converter. Higher switching frequencies can

be used if the input voltage range is limited, the output

voltage is lower and/or lower efficiency can be tolerated.

IN(MAX)

rating needed for these can

DSS

/N, depending on how well the

(output capacitance) of

OSS

Table 1. Switching Frequency vs Power Level

<50W 600kHz

<100W 450kHz

<200W 300kHz

<500W 200kHz

<1kW 150kHz

<2kW 100kHz

Closing the Feedback Loop

Closing the feedback loop with the full-bridge converter

involves identifying where the power stage and other

system poles/zeroes are located and then designing a

compensation network around the converters error amplifier to shape the frequency response to insure adequate

phase margin and transient response. Additional modifications will sometimes be required in order to deal with

parasitic elements within the converter that can alter the

feedback response. The compensation network will vary

depending on the load current range and the type of output

capacitors used. In isolated applications, the compensation network is generally located on the secondary side of

the power supply, around the error amplifier of the

optocoupler driver, usually an LT1431 or equivalent. In

nonisolated systems, the compensation network is located around the LTC3722-1/LTC3722-2’s error amplifier.

In current mode control, the dominant system pole is

determined by the load resistance (VO/IO) and the output

capacitor 1/(2π • RO • CO). The output capacitors ESR

1/(2π • ESR • CO) introduces a zero. Excellent DC line and

load regulation can be obtained if there is high loop gain at

DC. This requires an integrator type of compensator

around the error amplifier. A procedure is provided for

deriving the required compensation components. More

complex types of compensation networks can be used to

obtain higher bandwidth if necessary.

Step 1. Calculate location of minimum and maximum

output pole:

22

372212f

Page 23

OPERATIO

LTC3722-1/LTC3722-2

U

F

P1(MIN)

F

P1(MAX)

= 1/(2π • R

= 1/(2π • R

O(MAX)

O(MIN)

• CO)

• CO)

Step 2. Calculate ESR zero location:

FZ1 = 1/(2π • R

ESR

• CO)

Step 3. Calculate the feedback divider gain:

RB/(RB + RT) or V

REF/VOUT

If Polymer electrolytic output capacitors are used, the ESR

zero can be employed in the overall loop compensation

and optimum bandwidth can be achieved. If aluminum

electrolytics are used, the loop will need to be rolled off

prior to the ESR zero frequency, making the loop response

slower. A linearized SPICE macromodel of the control loop

is very helpful tool to quickly evaluate the frequency

response of various compensation networks.

V

OUT

R

R

C

I

O

R

L

R

ESR

D

f

REF

–

+

2.5V

LT1431 OR EQUIVALENT

PRECISION ERROR

AMP AND REFERENCE

Polymer Electrolytic (see Figure 13) 1/(2πCCRI) sets a

low frequency pole. 1/(2πCCRF) sets the low frequency

zero. The zero frequency should coincide with the worstcase lowest output pole frequency. The pole frequency

and mid frequency gain (RF/RI) should be set such so that

the loop crosses over zero dB with a –1 slope at a

frequency lower than (fSW/8). Use a bode plot to graphically display the frequency response. An optional higher

frequency pole set by CP2 and Rf is used to attenuate

switching frequency noise.

Aluminum Electrolytic (see Figure 13) the goal of this

compensator will be to cross over the output minimum

pole frequency. Set a low frequency pole with CC and R

at a frequency that will cross over the loop at the output

pole minimum F, place the zero formed by CC and Rf at the

output pole F.

V

C

P2

OPTIONAL

C

C

COLL

OUT

OPTO

COMP

1922 F12

IN

Figure 13. Compensation for Polymer Electrolytic

372212f

23

Page 24

LTC3722-1/LTC3722-2

U

OPERATIO

Synchronous Rectification

The LTC3722-1/LTC3722-2 produces the precise timing

signals necessary to control current doubler secondary

side synchronous MOSFETs on OUTE and OUTF. Synchronous rectifiers are used in place of Schottky or Silicon

diodes on the secondary side of the power supply. As

MOSFET R

levels continue to drop, significant effi-

DS(ON)

ciency improvements can be realized with synchronous

rectification, provided that the MOSFET switch timing is

optimized. An additional benefit realized with synchronous rectifiers is bipolar output current capability. These

characteristics improve transient response, particularly

overshoot, and improve ZVS ability at light loads.

Programming the Synchronous Rectifier Turn-Off

Delay

The LTC3722-1/LTC3722-2 controllers include a feature

to program the turn-off edge of the secondary side synchronous rectifier MOSFETs relative to the beginning of a

SPRG

new primary side power delivery pulse. This feature provides optimized timing for the synchronous MOSFETs

which improves efficiency. At higher load currents it

becomes more advantageous to delay the turn-off of the

synchronous rectifiers until the transformer core has been

reset to begin the new power pulse. This allows for

secondary freewheeling current to flow through the synchronous MOSFET channel instead of its body diode.

The turn-off delay is programmed with a resistor from

SPRG to GND, see Figure 14. The nominal regulated

voltage on SPRG is 2V. The external resistor programs a

current which flows out of SPRG. The delay can be

adjusted from approximately 20ns to 200ns, with resistor

values of 10k to 200k. Do not leave SPRG floating. The

amount of delay can also be modulated based on an

external current source that sinks current out of SPRG.

Care must be taken to limit the current out of SPRG to

350µA or less.

R

SPRG

+

2V

V

–

Figure 14. Synchronous Delay Circuitry

+

–

TURN-OFF

SYNC OUT

3722 F0Y

24

372212f

Page 25

OPERATIO

LTC3722-1/LTC3722-2

U

Current Doubler

The current doubler secondary employs two output inductors that equally share the output load current. The

transformer secondary is not center-tapped. This configuration provides 2x higher output current capability

compared to similarly sized single output inductor modules, hence the name. Each output inductor is twice the

inductance value as the equivalent single inductor configuration and the transformer turns ratio is 1/2 that of a

single inductor secondary. The drive to the inductors is

180 degrees out of phase which provides partial ripple

current cancellation in the output capacitor(s). Reduced

capacitor ripple current lowers output voltage ripple and

1

NORMALIZED

OUTPUT RIPPLE

CURRENT

ATTENUATION

enhances the capacitors’s reliability. The amount of ripple

cancellation is related to duty cycle (see Figure 15).

Although the current doubler requires an additional inductor, the inductor core volume is proportional to LI2,

thus the size penalty is small. The transformer construction is simplified without a center-tap winding and the

turns ratio is reduced by 1/2 compared to a conventional

full wave rectifier configuration.

Synchronous rectification of the current doubler secondary requires two ground referenced N-channel MOSFETs.

The timing of the LTC3722-1/LTC3722-2 drive signals is

shown in the Timing Diagram.

NOTE: INDUCTOR(S) DUTY CYCLE