Page 1

查询LTC2445IUHF供应商

Selectable Multiple Reference Inputs

FEATURES

■

Five Selectable Differential Reference Inputs

■

Four Differential/Eight Single-Ended Inputs

■

4-Way MUX for Multiple Ratiometric

Measurements

■

Up to 8kHz Output Rate

■

Up to 4kHz Multiplexing Rate

■

Selectable Speed/Resolution:

2µV

200nV

Noise at 1.76kHz Output Rate

RMS

Noise at 13.8Hz Output Rate with

RMS

Simultaneous 50/60Hz Rejection

■

Guaranteed Modulator Stability and Lock-Up

Immunity for any Input and Reference Conditions

■

0.0005% INL, No Missing Codes

■

Autosleep Enables 20µA Operation at 6.9Hz

■

<5µV Offset (4.5V < VCC < 5.5V, – 40°C to 85°C)

■

Differential Input and Differential Reference with

GND to V

■

No Latency Mode, Each Conversion is Accurate Even

Common Mode Range

CC

After a New Channel is Selected

■

Internal Oscillator—No External Components

■

LTC2447 Includes MUXOUT/ADCIN for External

Buffering or Gain

■

Tiny QFN 5mm x 7mm Package

U

APPLICATIO S

■

Flow

■

Weight Scales

■

Pressure

■

Direct Temperature Measurement

■

Gas Chromatography

LTC2446/LTC2447

24-Bit High Speed

8-Channel ∆Σ ADCs with

U

DESCRIPTIO

The LTC®2446/LTC2447 4-terminal switching enables

multiplexed ratiometric measurements. Four sets of selectable differential inputs coupled with four sets of differential reference inputs allow multiple RTDs, bridges and

other sensors to be digitized by a single converter. A fifth

differential reference input can be selected for any input

channel not requiring ratiometric measurements (thermocouples, voltages, current sense, etc.). The flexible

input multiplexer allows single-ended or differential inputs coupled with a slaved reference input or a universal

reference input.

A proprietary delta-sigma architecture results in absolute

accuracy (offset, full-scale, linearity) of 15ppm, noise as

low as 200nV

simple 4-wire interface, ten speed/resolution combinations can be selected. The first conversion following a

speed, resolution, channel change or reference change is

valid since there is no settling time between conversions,

enabling scan rates of up to 4kHz. Additionally, a 2x mode

can be selected for any speed-enabling output rates up to

8kHz with one cycle of latency.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Protected by U.S. Patents, including 6140950, 6169506, 6208279, 6411242, 6639526

and speeds as high as 8kHz. Through a

RMS

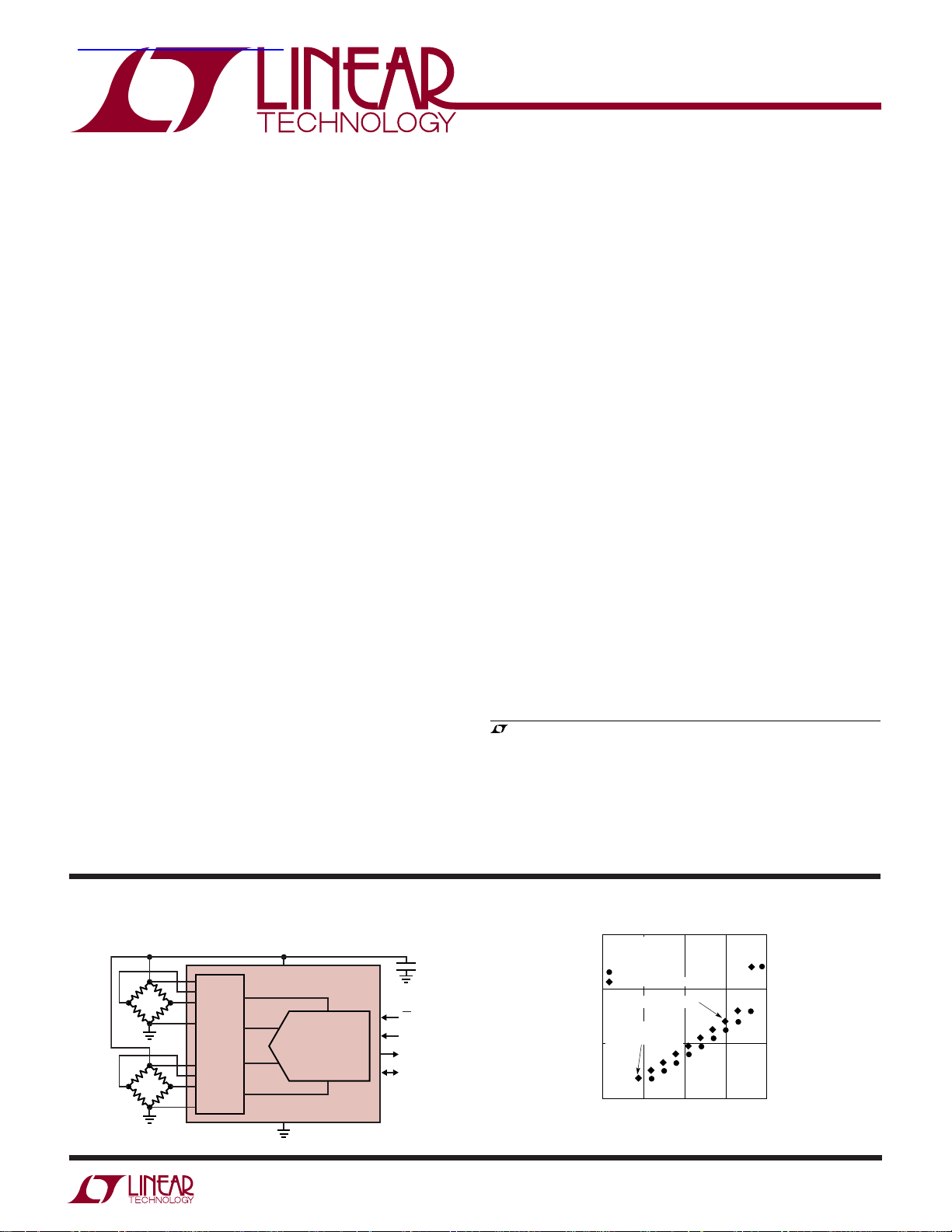

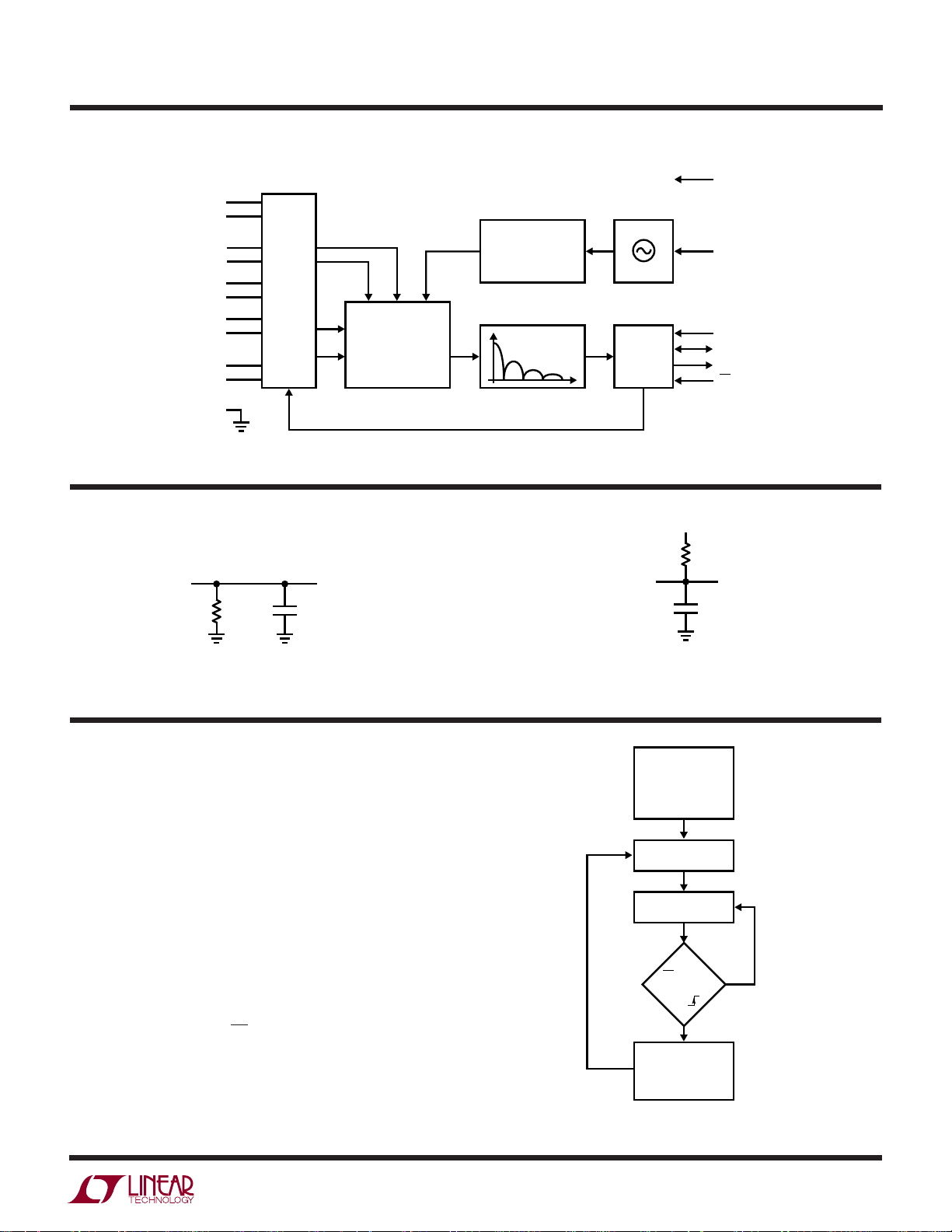

TYPICAL APPLICATIO

Multiple Ratiometric Measurement System

V

CC

+

REF

+

IN

IN

REF

+

–

–

–

•

19-INPUT

•

4-OUTPUT

•

MUX

U

LTC2446

VARIABLE SPEED/

RESOLUTION 24-BIT

∆Σ ADC

24467 TA01

CS

SDI

SDO

SCK

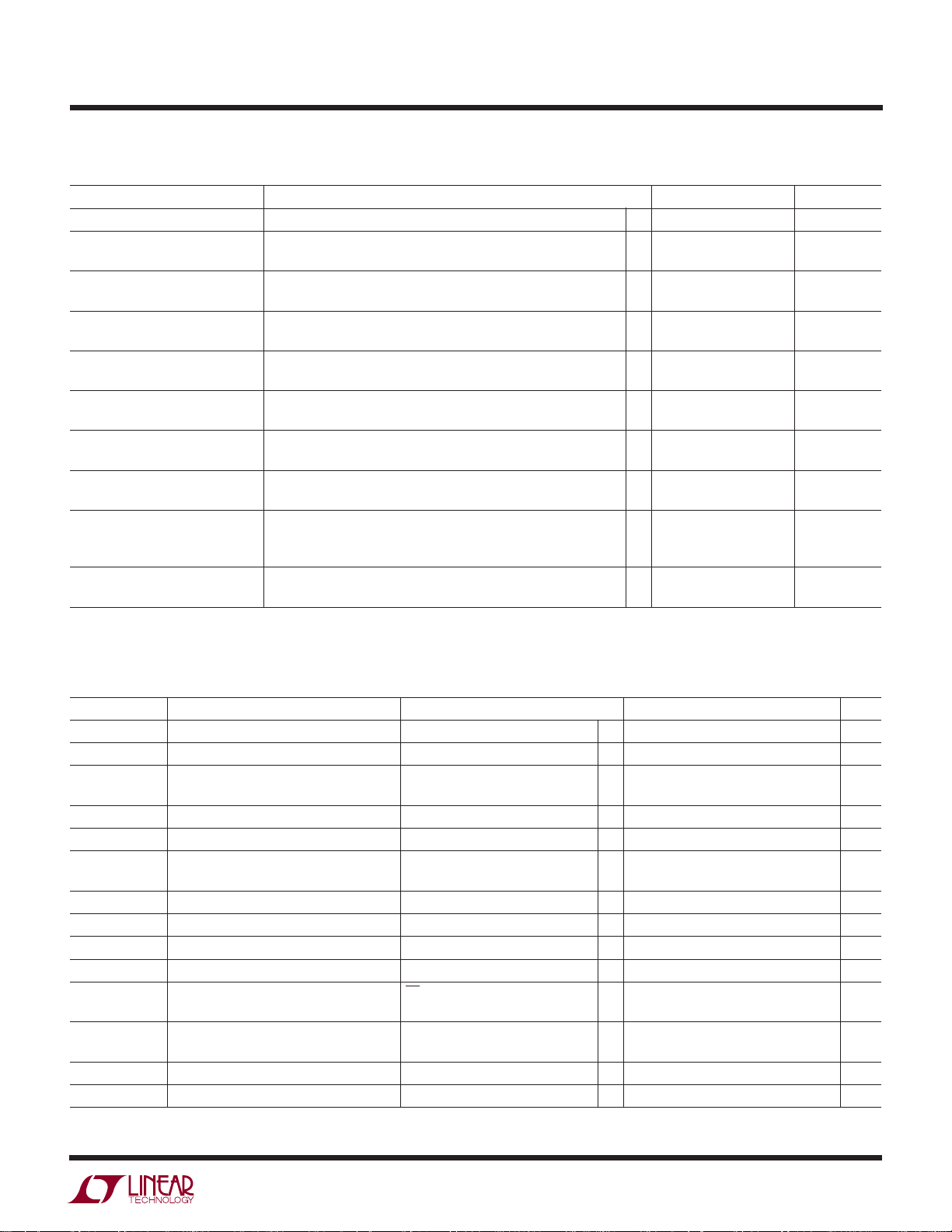

LTC2446 Speed vs RMS Noise

100

VCC = 5V

= 5V

V

REF

+

–

= V

= 0V

V

IN

IN

2x SPEED MODE

NO LATENCY MODE

10

RMS NOISE (µV)

1

0.1

2.8µV AT 880Hz

280nV AT 6.9Hz

(50/60Hz REJECTION)

1

10 100

CONVERSION RATE (Hz)

1000 10000

24467 TA02

24467fa

1

Page 2

LTC2446/LTC2447

WW

W

ABSOLUTE AXI U RATI GS

U

(Notes 1, 2)

Supply Voltage (VCC) to GND.......................–0.3V to 6V

Analog Input Pins Voltage

to GND .................................... – 0.3V to (V

+ 0.3V)

CC

Reference Input Pins Voltage

to GND .................................... – 0.3V to (V

Digital Input Voltage to GND ........ –0.3V to (V

+ 0.3V)

CC

+ 0.3V)

CC

UUW

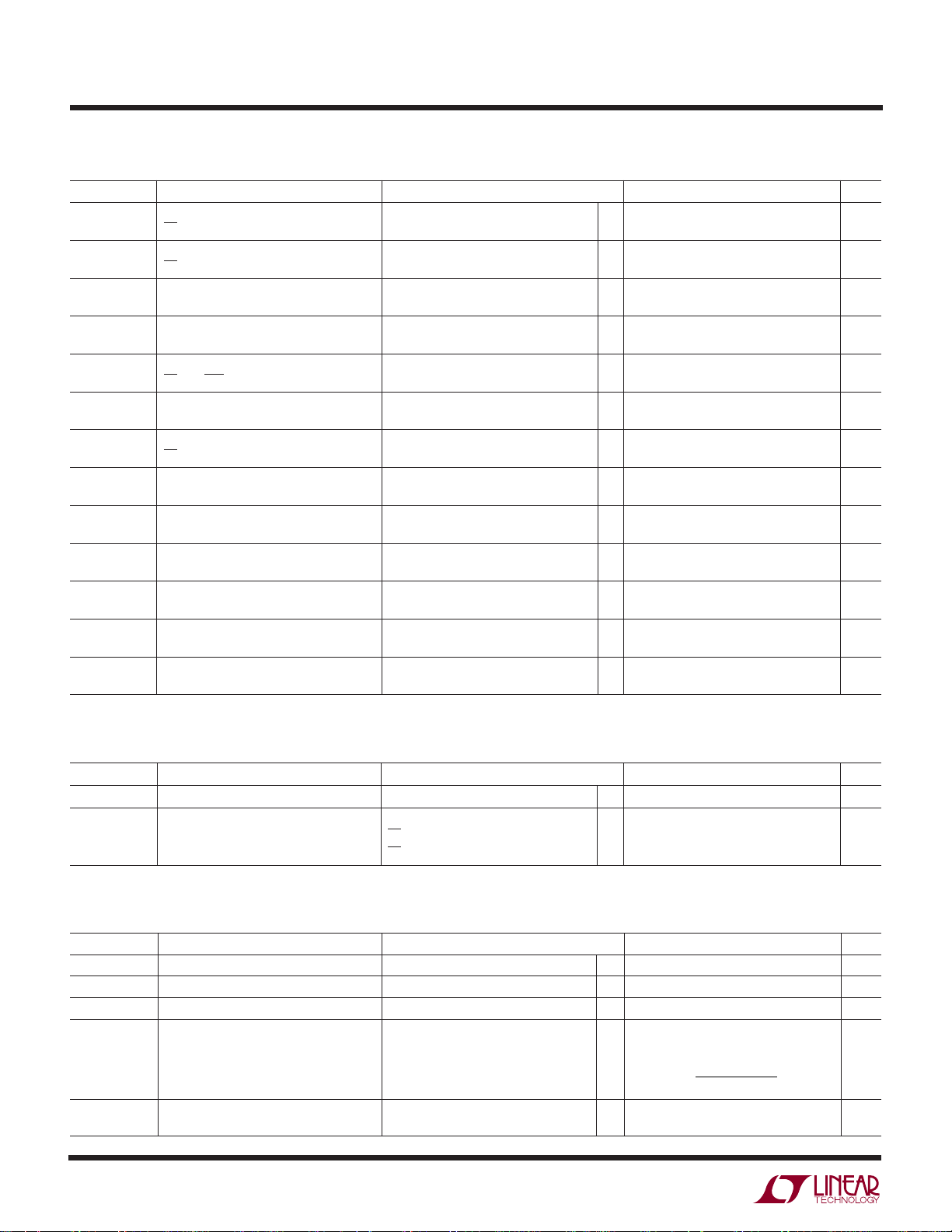

PACKAGE/ORDER I FOR ATIO

TOP VIEW

SCK

SDOCSFOSDI

38 37 36 35 34 33 32

1GND

BUSY

2

EXT

3

GND

4

GND

5

GND

6

COM

7

CH0

8

CH1

9

–

V

10

REF01

+

V

11

REF01

CH2

12

13 14 15 16

–

CH3

REF23

V

38-LEAD (5mm × 7mm) PLASTIC QFN

UHF PACKAGE

T

= 125°C, θJA = 34°C/W

JMAX

EXPOSED PAD (PIN 39) IS GND

MUST BE SOLDERED TO PCB

+

V

REF23

39

CH4

GND

17 18 19

–

CH5

REF45

V

GND

+

REF45

V

31

GND

–

REFG

30

+

REFG

29

V

28

CC

NC

27

NC

26

NC

25

NC

24

+

V

23

REF67

–

22

V

REF67

21

CH7

20

CH6

Digital Output Voltage to GND ..... – 0.3V to (V

+ 0.3V)

CC

Operating Temperature Range

LTC2446C/LTC2447C .............................. 0°C to 70°C

LTC2446I/LTC2447I ........................... – 40°C to 85°C

Storage Temperature Range ................. –65°C to 125°C

TOP VIEW

SCK

SDOCSFOSDI

38 37 36 35 34 33 32

1GND

BUSY

2

EXT

3

GND

4

GND

5

GND

6

COM

7

CH0

8

CH1

9

–

V

10

REF01

+

V

11

REF01

CH2

12

13 14 15 16

_

CH3

REF23

V

38-LEAD (5mm × 7mm) PLASTIC QFN

UHF PACKAGE

T

= 125°C, θJA = 34°C/W

JMAX

EXPOSED PAD (PIN 39) IS GND

MUST BE SOLDERED TO PCB

+

VREF23

39

CH4

GND

17 18 19

–

CH5

REF45

V

+

GND

REF45

V

31

30

29

28

27

26

25

24

23

22

21

20

GND

–

REFG

+

REFG

V

CC

MUXOUTN

ADCINN

ADCINP

MUXOUTP

+

V

REF67

–

V

REF67

CH7

CH6

ORDER PART

NUMBER

LTC2446CUHF

LTC2446IUHF

QFN PART

MARKING*

2446

ORDER PART

NUMBER

LTC2447CUHF

LTC2447IUHF

QFN PART

MARKING*

2447

Order Options Tape and Reel: Add #TR Lead Free: Add #PBF Lead Free Tape and Reel: Add #TRPBF

Lead Free Part Marking: http://www.linear.com/leadfree/

*The temperature grade is identified by a label on the shipping container. Consult LTC Marketing for parts specified with wider operating temperature ranges.

24467fa

2

Page 3

LTC2446/LTC2447

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at T

The ● denotes specifications which apply over the full operating

= 25°C. (Notes 3, 4)

A

PARAMETER CONDITIONS MIN TYP MAX UNITS

Resolution (No Missing Codes) 0.1V ≤ V

Integral Nonlinearity VCC = 5V, REF+ = 5V, REF– = GND, V

REF+ = 2.5V, REF– = GND, V

Offset Error 2.5V ≤ REF+ ≤ VCC, REF– = GND,

GND ≤ IN

Offset Error Drift 2.5V ≤ REF+ ≤ VCC, REF– = GND, 20 nV/°C

GND ≤ IN

Positive Full-Scale Error REF+ = 5V, REF– = GND, IN+ = 3.75V, IN– = 1.25V

REF+ = 2.5V, REF– = GND, IN+ = 1.875V, IN– = 0.625V

Positive Full-Scale Error Drift 2.5V ≤ REF+ ≤ VCC, REF– = GND, 0.2 ppm of V

IN

+

Negative Full-Scale Error REF+ = 5V, REF– = GND, IN+ = 1.25V, IN– = 3.75V

REF+ = 2.5V, REF– = GND, IN+ = 0.625V, IN– = 1.875V

Negative Full-Scale Error Drift 2.5V ≤ REF+ ≤ VCC, REF– = GND, 0.2 ppm of V

IN

+

Total Unadjusted Error 5V ≤ VCC ≤ 5.5V, REF+ = 2.5V, REF– = GND, V

5V ≤ VCC ≤ 5.5V, REF+ = 5V, REF– = GND, V

REF+ = 2.5V, REF– = GND, V

Input Common Mode Rejection DC 2.5V ≤ REF+ ≤ VCC, REF– = GND, 120 dB

GND ≤ IN

≤ VCC, –0.5 • V

REF

+

= IN– ≤ VCC (Note 12)

+

= IN– ≤ V

CC

= 0.75REF+, IN– = 0.25 • REF

≤ VIN ≤ 0.5 • V

REF

= 1.25V, (Note 6) 3 ppm of V

INCM

+

= 0.25 • REF+, IN– = 0.75 • REF

= 1.25V, (Note 6) 15 ppm of V

INCM

–

= IN+ ≤ V

CC

= 2.5V, (Note 6)

INCM

+

INCM

, (Note 5)

REF

= 1.25V 15 ppm of V

INCM

●

24 Bits

●

●

●

●

●

●

5 15 ppm of V

2.5 5 µV

10 50 ppm of V

10 50 ppm of V

10 50 ppm of V

10 50 ppm of V

= 2.5V 15 ppm of V

REF

REF

REF

REF

REF

REF

/°C

REF

REF

/°C

REF

REF

REF

UUU

A ALOG I PUT AUD REFERE CE

temperature range, otherwise specifications are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

+

IN

–

IN

V

IN

+

REF

–

REF

V

REF

C

S(IN+)

C

S(IN–)

C

S(REF+)

C

S(REF–)

I

DC_LEAK(IN+, IN–,

REF+, REF–)

I

SAMPLE(IN+, IN–,

REF+, REF–)

t

OPEN

QIRR MUX Off Isolation VIN = 2V

Absolute/Common Mode IN+ Voltage

Absolute/Common Mode IN– Voltage

Input Differential Voltage Range

+

(IN

– IN–)

Absolute/Common Mode REF+ Voltage

Absolute/Common Mode REF– Voltage

Reference Differential Voltage Range

+

(REF

– REF–)

IN+ Sampling Capacitance 2 pF

IN– Sampling Capacitance 2 pF

REF+ Sampling Capacitance 2 pF

REF– Sampling Capacitance 2 pF

Leakage Current, Inputs and Reference CS = VCC, IN+ = GND, IN– = GND,

Average Input/Reference Current Varies, See Applications Section nA

During Sampling

MUX Break-Before-Make 50 ns

= 25°C. (Note 3)

A

REF+ = 5V, REF– = GND

The ● denotes specifications which apply over the full operating

●

GND – 0.3V VCC + 0.3V V

●

GND – 0.3V VCC + 0.3V V

●

–V

/2 V

REF

●

●

●

●

DC to 1.8MHz 120 dB

P-P

0.1 V

GND VCC – 0.1V V

0.1 V

–15 1 15 nA

/2 V

REF

CC

CC

V

V

24467fa

3

Page 4

LTC2446/LTC2447

UU

DIGITAL I PUTS A D DIGITAL OUTPUTS

operating temperature range, otherwise specifications are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IH

V

IL

V

IH

V

IL

I

IN

I

IN

C

IN

C

IN

V

OH

V

OL

V

OH

V

OL

I

OZ

High Level Input Voltage 4.5V ≤ VCC ≤ 5.5V

CS, F

O

Low Level Input Voltage 4.5V ≤ VCC ≤ 5.5V

CS, F

O

High Level Input Voltage 4.5V ≤ VCC ≤ 5.5V (Note 8)

SCK

Low Level Input Voltage 4.5V ≤ VCC ≤ 5.5V (Note 8)

SCK

Digital Input Current 0V ≤ VIN ≤ V

, EXT, SOI

CS, F

O

Digital Input Current 0V ≤ VIN ≤ VCC (Note 8)

SCK

Digital Input Capacitance 10 pF

CS, F

O

Digital Input Capacitance (Note 8) 10 pF

SCK

High Level Output Voltage IO = –800µA

SDO, BUSY

Low Level Output Voltage IO = 1.6mA

SDO, BUSY

High Level Output Voltage IO = –800µA (Note 9)

SCK

Low Level Output Voltage IO = 1.6mA (Note 9)

SCK

Hi-Z Output Leakage

SDO

= 25°C. (Note 3)

A

CC

The ● denotes specifications which apply over the full

●

●

●

●

●

●

●

●

●

●

●

2.5 V

0.8 V

2.5 V

0.8 V

–10 10 µA

–10 10 µA

VCC – 0.5V V

0.4V V

VCC – 0.5V V

0.4V V

–10 10 µA

WU

POWER REQUIRE E TS

otherwise specifications are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

CC

I

CC

Supply Voltage

Supply Current

Conversion Mode CS = 0V (Note 7)

Sleep Mode CS = V

= 25°C. (Note 3)

A

The ● denotes specifications which apply over the full operating temperature range,

(Note 7)

CC

●

●

●

4.5 5.5 V

811 mA

830 µA

UW

TI I G CHARACTERISTICS

range, otherwise specifications are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

f

EOSC

t

HEO

t

LEO

t

CONV

f

ISCK

External Oscillator Frequency Range

External Oscillator High Period

External Oscillator Low Period

Conversion Time OSR = 256

Internal SCK Frequency Internal Oscillator (Note 9)

= 25°C. (Note 3)

A

The ● denotes specifications which apply over the full operating temperature

●

●

●

●

OSR = 32768

External Oscillator (Notes 10, 13)

External Oscillator (Notes 9, 10) f

●

●

●

0.1 20 MHz

25 10000 ns

25 10000 ns

0.99 1.13 1.33 ms

126 145 170 ms

40 • OSR +170

f

(kHz)

EOSC

0.8 0.9 1 MHz

/10 Hz

EOSC

24467fa

ms

4

Page 5

LTC2446/LTC2447

WU

TI I G CHARACTERISTICS

range, otherwise specifications are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

D

ISCK

f

ESCK

t

LESCK

t

HESCK

t

DOUT_ISCK

t

DOUT_ESCK

t

1

t

2

t

3

t

4

t

KQMAX

t

KQMIN

t

5

t

6

t

7

t

8

Note 1: Absolute Maximum Ratings are those values beyond which the life

of the device may be impaired.

Note 2: All voltage values are with respect to GND.

Note 3: V

= REF+ – REF–, V

V

REF

reference input, REF

= (IN+ + IN–)/2.

V

INCM

Note 4: F

= 10MHz unless otherwise specified.

f

EOSC

Note 5: Guaranteed by design, not subject to test.

Note 6: Integral nonlinearity is defined as the deviation of a code from a

straight line passing through the actual endpoints of the transfer curve.

The deviation is measured from the center of the quantization band.

Internal SCK Duty Cycle (Note 9)

External SCK Frequency Range (Note 8)

External SCK Low Period (Note 8)

External SCK High Period (Note 8)

Internal SCK 32-Bit Data Output Time Internal Oscillator (Notes 9, 11)

External SCK 32-Bit Data Output Time (Note 8)

CS ↓ to SDO Low Z (Note 12)

CS ↑ to SDO High Z (Note 12)

CS ↓ to SCK ↓ (Note 9) 5 µs

CS ↓ to SCK ↑ (Notes 8, 12)

SCK ↓ to SDO Valid

SDO Hold After SCK ↓ (Note 5)

SCK Setup Before CS ↓

SCK Hold After CS ↓

SDI Setup Before SCK ↑ (Note 5)

SDI Hold After SCK ↑ (Note 5)

= 4.5V to 5.5V unless otherwise specified.

CC

pin tied to GND or to external conversion clock source with

O

= (REF+ + REF–)/2; REF+ is the positive

REFCM

–

is the negative reference input; VIN = IN+ – IN–,

= 25°C. (Note 3)

A

The ● denotes specifications which apply over the full operating temperature

External Oscillator (Notes 9, 10)

Note 7: The converter uses the internal oscillator.

Note 8: The converter is in external SCK mode of operation such that the

SCK pin is used as a digital input. The frequency of the clock signal driving

SCK during the data output is f

Note 9: The converter is in internal SCK mode of operation such that the

SCK pin is used as a digital output. In this mode of operation, the SCK pin

has a total equivalent load capacitance of C

Note 10: The external oscillator is connected to the F

oscillator frequency, f

Note 11: The converter uses the internal oscillator. F

Note 12: Guaranteed by design and test correlation.

Note 13: There is an internal reset that adds an additional 1µs (typ) to the

conversion time.

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

EOSC

45 55 %

20 MHz

25 ns

25 ns

41.6 35.3 30.9 µs

320/f

EOSC

32/f

ESCK

025ns

025ns

25 ns

25 ns

15 ns

50 ns

50 ns

10 ns

10 ns

and is expressed in Hz.

ESCK

= 20pF.

LOAD

pin. The external

, is expressed in Hz.

O

= 0V.

O

s

s

U

UU

PI FU CTIO S

GND (Pins 1, 4, 5, 6, 31, 32, 33): Ground. Multiple

ground pins internally connected for optimum ground

current flow and VCC decoupling. Connect each one of

these pins to a common ground plane through a low

impedance connection. All seven pins must be connected

to ground for proper operation.

BUSY (Pin 2): Conversion in Progress Indicator. This pin

is HIGH while the conversion is in progress and goes LOW

indicating the conversion is complete and data is ready. It

remains LOW during the sleep and data output states. At

the conclusion of the data output state, it goes HIGH

indicating a new conversion has begun.

EXT (Pin 3): Internal/External SCK Selection Pin. This pin

is used to select internal or external SCK for outputting/

inputting data. If EXT is tied low, the device is in the

external SCK mode and data is shifted out of the device

under the control of a user applied serial clock. If EXT is

tied high, the internal serial clock mode is selected. The

device generates its own SCK signal and outputs this on

the SCK pin. A framing signal BUSY (Pin 2) goes low

indicating data is being output.

COM (Pin 7): The common negative input (IN

–

) for all

single ended multiplexer configurations. The voltage on

CH0-CH7 and COM pins can have any value between GND

24467fa

5

Page 6

LTC2446/LTC2447

UUU

PI FU CTIO S

– 0.3V to V

inputs (IN

+

– IN–) from –0.5 • V

IN

+ 0.3V. Within these limits, the two selected

CC

+

and IN–) provide a bipolar input range (VIN =

to 0.5 • V

REF

. Outside this input

REF

range, the converter produces unique over-range and

under-range output codes.

CH0 to CH7 (Pins 8, 9, 12, 13, 16, 17, 20, 21): Analog

Inputs. May be programmed for Single-ended or Differential mode.

V

REF01

V

REF23

V

REF67

+

(Pin 11), V

–

(Pin 14), V

+

(Pin 23), V

REF67

–

(Pin 10) V

REF01

+

(Pin 19), V

REF45

–

(Pin 22): Differential Reference

REF23

REF45

+

(Pin 15),

–

(Pin 18),

Inputs. The voltage on these pins can be anywhere

between 0V and V

+

input (V

EF01

, V

the corresponding negative reference input (V

–

V

REF23

, V

REF45

as long as the positive reference

CC

REF23

–

, V

+

, V

REF67

+

, V

REF45

–

) by at least 100mV.

+

) is greater than

REF67

REF01

–

,

NC (Pins 24, 25, 26, 27): LTC2446 No Connect. These

pins can either be tied to ground or left floating.

MUXOUTP (Pin 24): LTC2447 Positive Input Channel

Multiplexer Output. Used to drive the input to an external

buffer/amplifier for the selected positive input signal (IN

+

).

ADCINP (Pin 25): LTC2447 Positive ADC Input. Tie to

output of buffer/amplifier driven by MUXOUTP.

ADCINN (Pin 26): LTC2447 Negative ADC Input. Tie to

output of buffer/amplifier driven by MUXOUTN.

MUXOUTN (Pin 27): LTC2447 Negative Input Channel

Multiplexer Output. Used to drive the input to an external

buffer/amplifier for the selected negative input signal

(IN–).

VCC (Pin 28): Positive Supply Voltage. Bypass to GND with

a 10µF tantalum capacitor in parallel with a 0.1µF ceramic

capacitor as close to the part as possible.

V

REFG

+

(Pin 29), V

–

(Pin 30): Global Reference Input.

REFG

This differential reference input can be used for any input

channel selected through a single bit in the digital input word.

SDI (Pin 34): Serial Data Input. This pin is used to select

the speed, 1x or 2x mode, resolution, input channel and

reference input for the next conversion cycle. At initial

power-up, the default mode of operation is CH0-CH1,

, OSR of 256, and 1x mode. The serial data input

V

REF01

contains an enable bit which determines if a new channel/

speed is selected. If this bit is low the following conversion

remains at the same speed and selected channel. The

serial data input is applied to the device under control of

the serial clock (SCK) during the data output cycle. The

first conversion following a new channel/speed is valid.

FO (Pin 35): Frequency Control Pin. Digital input that

controls the internal conversion clock. When F

nected to V

or GND, the converter uses its internal

CC

is con-

O

oscillator running at 9MHz. The conversion rate is determined by the selected OSR such that t

OSR + 170)/f

at 8/t

CONV

(kHz). The first digital filter null is located

OSC

, 7kHz at OSR = 256 and 55Hz (Simultaneous 50/

(ms) = (40 •

CONV

60Hz) at OSR = 32768. This pin may be driven with a

maximum external clock of 10.24MHz resulting in a maximum 8kHz output rate (OSR = 64, 2x Mode).

CS (Pin 36): Active Low Chip Select. A LOW on this pin

enables the SDO digital output and wakes up the ADC.

Following each conversion the ADC automatically enters

the sleep mode and remains in this low power state as long

as CS is HIGH. A LOW-to-HIGH transition on CS during the

Data Output aborts the data transfer and starts a new

conversion.

SDO (Pin 37): Three-State Digital Output. During the data

output period, this pin is used as serial data output. When

the chip select CS is HIGH (CS = V

) the SDO pin is in a

CC

high impedance state. During the conversion and sleep

periods, this pin is used as the conversion status output.

The conversion status can be observed by pulling CS

LOW. This signal is HIGH while the conversion is in

progress and goes LOW once the conversion is complete.

SCK (Pin 38): Bidirectional Digital Clock Pin. In internal

serial clock operation mode, SCK is used as a digital output

for the internal serial interface clock during the data output

period. In the external serial clock operation mode, SCK is

used as the digital input for the external serial interface

clock during the data output period. The serial clock

operation mode is determined by the logic level applied to

the EXT pin.

Exposed Pad (Pin 39): Ground. The exposed pad on the

bottom of the package must be soldered to the PCB ground.

For Prototyping purposes, this pin may remain floating.

24467fa

6

Page 7

LTC2446/LTC2447

1.69k

SDO

24467 TA04

Hi-Z TO V

OL

VOH TO V

OL

VOL TO Hi-Z

C

LOAD

= 20pF

V

CC

UU

W

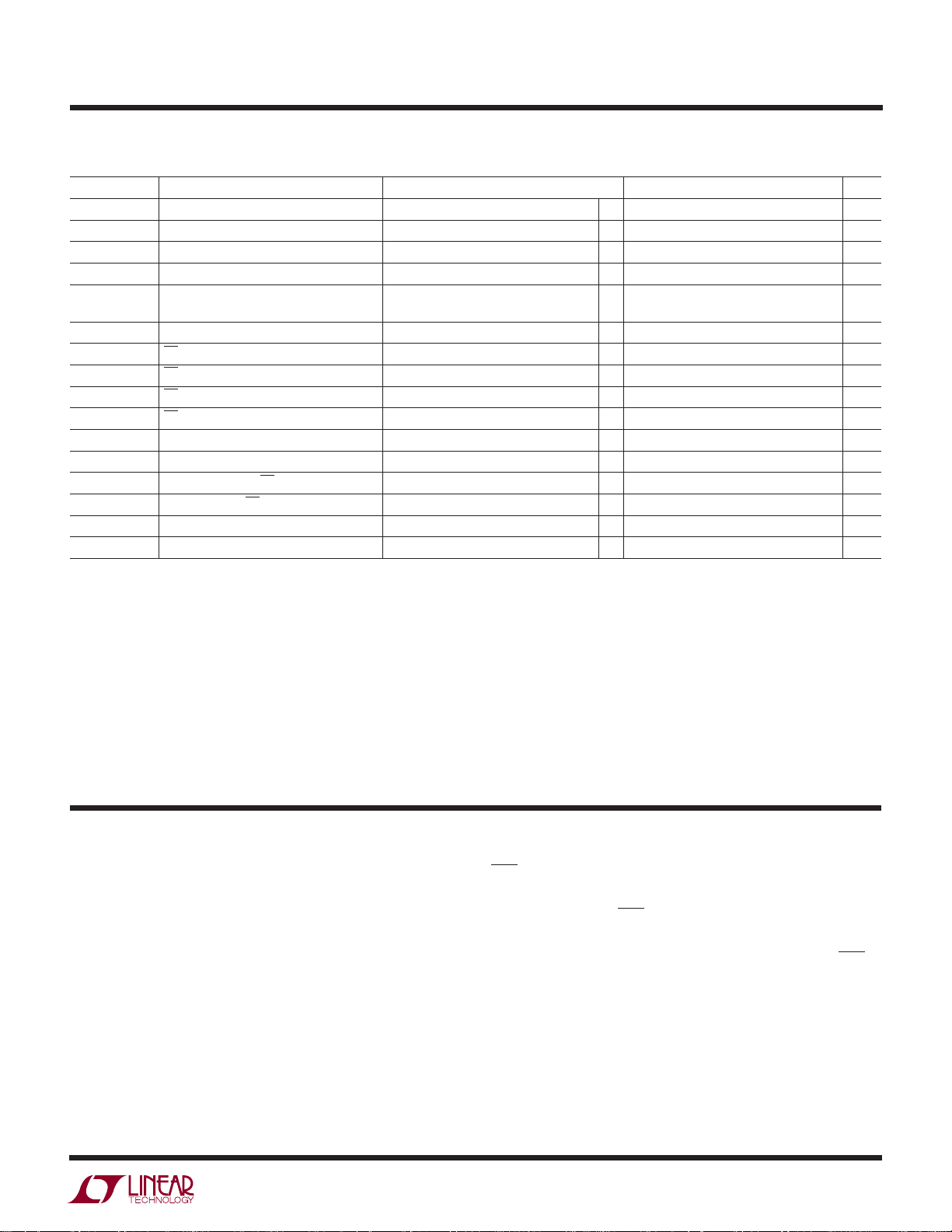

FU CTIO AL BLOCK DIAGRA

+

V

REF01

–

V

REF01

V

REF67

V

REF67

V

V

REFG

REFG

CH0

CH1

CH7

COM

GND

•

•

•

+

–

+

–

•

•

•

+

REF

–

REF

+

IN

INPUT/REFERENCE MUX

IN

–

∆Σ MODULATOR

DIFFERENTIAL

3RD ORDER

Figure 1. Functional Block Diagram

TEST CIRCUITS

AUTOCALIBRATION

AND CONTROL

DECIMATING FIR

ADDRESS

INTERNAL

OSCILLATOR

SERIAL

INTERFACE

24467 F01

V

CC

F

O

(INT/EXT)

SDI

SCK

SDO

CS

SDO

1.69k

Hi-Z TO V

VOL TO V

VOH TO Hi-Z

OH

OH

U

C

LOAD

= 20pF

24467 TA03

WUU

APPLICATIO S I FOR ATIO

CONVERTER OPERATION

Converter Operation Cycle

The LTC2446/LTC2447 are multichannel, multireference

high speed, delta-sigma analog-to-digital converters with

an easy to use 3- or 4-wire serial interface (see Figure 1).

Their operation is made up of three states. The converter

operating cycle begins with the conversion, followed by

the low power sleep state and ends with the data output/

input (see Figure 2). The 4-wire interface consists of serial

data input (SDI), serial data output (SDO), serial clock

(SCK) and chip select (CS). The interface, timing, operation cycle and data out format is compatible with Linear’s

entire family of ∆Σ converters.

Initially, the LTC2446/LTC2447 perform a conversion.

Once the conversion is complete, the device enters the

POWER UP

+

=CH0, IN–=CH1

IN

+

REF

REF

OSR=256,1X MODE

CONVERT

CS = LOW

AND

CHANNEL SELECT

REFERENCE SELECT

SPEED SELECT

DATA OUTPUT

= V

–

= V

SLEEP

SCK

REFO1

REF01

YES

+

,

–

24467 F02

NO

Figure 2. LTC2446/LTC2447 State Transition Diagram

24467fa

7

Page 8

LTC2446/LTC2447

U

WUU

APPLICATIO S I FOR ATIO

sleep state. While in this sleep state, power consumption

is reduced below 10µA. The part remains in the sleep state

as long as CS is HIGH. The conversion result is held

indefinitely in a static shift register while the converter is

in the sleep state.

Once CS is pulled LOW, the device begins outputting the

conversion result. There is no latency in the conversion

result while operating in the 1x mode. The data output corresponds to the conversion just performed. This result is

shifted out on the serial data out pin (SDO) under the control of the serial clock (SCK). Data is updated on the falling

edge of SCK allowing the user to reliably latch data on the

rising edge of SCK (see Figure 3). The data output state is

concluded once 32 bits are read out of the ADC or when CS

is brought HIGH. The device automatically initiates a new

conversion and the cycle repeats.

Through timing control of the CS, SCK and EXT pins, the

LTC2446/LTC2447 offer several flexible modes of operation (internal or external SCK). These various modes do

not require programming configuration registers; moreover, they do not disturb the cyclic operation described

above. These modes of operation are described in detail in

the Serial Interface Timing Modes section.

Ease of Use

The LTC2446/LTC2447 data output has no latency, filter

settling delay or redundant data associated with the

conversion cycle while operating in the 1x mode. There

is a one-to-one correspondence between the conversion

and the output data. Therefore, multiplexing multiple

analog voltages and references is easy. Speed/resolution

adjustments may be made seamlessly between two

conversions without settling errors.

The LTC2446/LTC2447 perform offset and full-scale calibrations every conversion cycle. This calibration is transparent to the user and has no effect on the cyclic operation

described above. The advantage of continuous calibration

is extreme stability of offset and full-scale readings with respect to time, supply voltage change and temperature drift.

Power-Up Sequence

The LTC2446/LTC2447 automatically enter an internal

reset state when the power supply voltage V

drops

CC

below approximately 2.2V. This feature guarantees the

integrity of the conversion result and of the serial interface mode selection.

When the VCC voltage rises above this critical threshold,

the converter creates an internal power-on-reset (POR)

signal with a duration of approximately 0.5ms. The POR

signal clears all internal registers. The conversion immediately following a POR is performed on the input channel

+

IN

= CH0, IN– = CH1, REF+ = V

REF01

+

, REF– V

REF01

–

at an

OSR = 256 in the 1x mode. Following the POR signal, the

LTC2446/LTC2447 start a normal conversion cycle and

follow the succession of states described above. The first

conversion result following POR is accurate within the

specifications of the device if the power supply voltage is

restored within the operating range (4.5V to 5.5V) before

the end of the POR time interval.

Reference Voltage Range

These converters accept truly differential external reference voltages. Each set of five reference inputs may be

independently driven to any common mode voltage over

the entire supply range of the device (GND to V

CC

). For

correct converter operation, each positive reference pin

REF

+

(V

REF01

+

, V

REF23

+

, V

REF45

+

, V

REF67

+

, V

REFG

+

) must

be more positive than its corresponding negative reference pin REF

–

V

) by at least 100mV.

REFG

–

(V

REF01

–

, V

REF23

–

, V

REF45

–

, V

REF67

–

,

The LTC2446/LTC2447 can accept a differential reference

from 0.1V to V

on each set of reference input pins. The

CC

converter output noise is determined by the thermal noise

of the front-end circuits, and as such, its value in microvolts is nearly constant with reference voltage. A decrease

in reference voltage will not significantly improve the

converter’s effective resolution. On the other hand, a

reduced reference voltage will improve the converter’s

overall INL performance.

Input Voltage Range

The analog input is truly differential with an absolute/

common mode range for the CH0-CH7 and COM input

pins extending from GND – 0.3V to V

+ 0.3V. Outside

CC

these limits, the ESD protection devices begin to turn on

and the errors due to input leakage current increase

rapidly. Within these limits, the LTC2446/LTC2447

24467fa

8

Page 9

LTC2446/LTC2447

U

WUU

APPLICATIO S I FOR ATIO

c

onvert the bipolar differential input signal, VIN = IN+ –

–

(where IN+ and IN– are the selected input channels),

IN

from –FS = –0.5 • V

+

REF

– REF– (REF+ and REF– are the selected references).

Outside this range, the converter indicates the overrange

or the underrange condition using distinct output codes.

MUXOUT/ADCIN

There are two differences between the LTC2446 and the

LTC2447. The first is the RMS noise performance. For a

given OSR, the LTC2447 noise level is approximately √2

times lower (0.5 effective bits)than that of the LTC2446.

The second difference is the LTC2447 includes MUXOUT/

ADCIN pins. These pins enable an external buffer or gain

block to be inserted between the selected input channel of

the multiplexer and the input to the ADC. Since the buffer

is driven by the output of the multiplexer, only one circuit

is required for all 8 input channels. Additionally, the

transparent calibration feature of the LTC244X family

automatically removes the offset errors of the external

buffer.

In order to achieve optimum performance, the MUXOUT

and ADCIN pins should not be shorted together. In applications where the MUXOUT and ADCIN need to be shorted

together, the LTC2446 should be used because the

MUXOUT and ADCIN are internally connected for optimum performance.

to +FS = 0.5 • V

REF

where V

REF

REF

=

Bit 31 (first output bit) is the end of conversion (EOC)

indicator. This bit is available at the SDO pin during the

conversion and sleep states whenever the CS pin is LOW.

This bit is HIGH during the conversion and goes LOW

when the conversion is complete.

Bit 30 (second output bit) is a dummy bit (DMY) and is

always LOW.

Bit 29 (third output bit) is the conversion result sign indicator (SIG). If V

is >0, this bit is HIGH. If VIN is <0, this

IN

bit is LOW.

Bit 28 (fourth output bit) is the most significant bit (MSB)

of the result. This bit in conjunction with Bit 29 also

provides the underrange or overrange indication. If both

Bit 29 and Bit 28 are HIGH, the differential input voltage is

above +FS. If both Bit 29 and Bit 28 are LOW, the

differential input voltage is below –FS.

The function of these bits is summarized in Table 1.

Table 1. LTC2446/LTC2447 Status Bits

BIT 31 BIT 30 BIT 29 BIT 28

INPUT RANGE EOC DMY SIG MSB

VIN ≥ 0.5 • V

0V ≤ VIN < 0.5 • V

–0.5 • V

VIN < – 0.5 • V

REF

≤ VIN < 0V 0001

REF

REF

REF

0011

0010

0000

Bits 28-5 are the 24-bit conversion result MSB first.

Output Data Format

The LTC2446/LTC2447 serial output data stream is 32 bits

long. The first 3 bits represent status information indicating the sign and conversion state. The next 24 bits are the

conversion result, MSB first. The remaining 5 bits are sub

LSBs beyond the 24-bit level that may be included in

averaging or discarded without loss of resolution. In the

case of ultrahigh resolution modes, more than 24 effective

bits of performance are possible (see Table 4). Under

these conditions, sub LSBs are included in the conversion

result and represent useful information beyond the 24-bit

level. The third and fourth bit together are also used to

indicate an underrange condition (the differential input

voltage is below –FS) or an overrange condition (the

differential input voltage is above +FS).

Bit 5 is the least significant bit (LSB).

Bits 4-0 are sub LSBs below the 24-bit level. Bits 4-0 may

be included in averaging or discarded without loss of

resolution.

Data is shifted out of the SDO pin under control of the serial

clock (SCK), see Figure 3. Whenever CS is HIGH, SDO

remains high impedance and SCK is ignored.

In order to shift the conversion result out of the device, CS

must first be driven LOW. EOC is seen at the SDO pin of the

device once CS is pulled LOW. EOC changes real time from

HIGH to LOW at the completion of a conversion. This

signal may be used as an interrupt for an external

microcontroller. Bit 31 (EOC) can be captured on the first

24467fa

9

Page 10

LTC2446/LTC2447

U

WUU

APPLICATIO S I FOR ATIO

CS

1234567891011121314 32

SCK

SDI

Hi-Z

SDO

BUSY

rising edge of SCK. Bit 30 is shifted out of the device on the

first falling edge of SCK. The final data bit (Bit 0) is shifted

out on the falling edge of the 31st SCK and may be latched

on the rising edge of the 32nd SCK pulse. On the falling

edge of the 32nd SCK pulse, SDO goes HIGH indicating the

initiation of a new conversion cycle. This bit serves as EOC

(Bit 31) for the next conversion cycle. Table 2 summarizes

the output data format.

As long as the voltage on the IN

within the –0.3V to (V

operating range, a conversion result is generated for any

differential input voltage V

+FS = 0.5 • V

. For differential input voltages greater than

REF

1 0 EN SGL GLBL A1 A0 OSR3 OSR2 OSR1 OSR0 TWOXODD

BIT 31

EOC

BIT 30

“0”

BIT 28 BIT 27 BIT 26 BIT 25 BIT 24 BIT 23 BIT 22 BIT 21 BIT 20 BIT 19 BIT 0

BIT 29

MSB

SIG

Figure 3. SDI Speed/Resolution, Channel Selection, and Data Output Timing

+

and IN– pins is maintained

+ 0.3V) absolute maximum

CC

from –FS = –0.5 • V

IN

REF

to

LSB

Hi-Z

24467 F03

+FS, the conversion result is clamped to the value corresponding to the +FS + 1LSB. For differential input voltages

below –FS, the conversion result is clamped to the value

corresponding to –FS – 1LSB.

SERIAL INTERFACE PINS

The LTC2446/LTC2447 transmit the conversion results

and receive the start of conversion command through a

synchronous 3- or 4-wire interface. During the conversion and sleep states, this interface can be used to assess

the converter status and during the data output state it is

used to read the conversion result and program the

speed, resolution and input channel.

10

Table 2. LTC2446/LTC2447 Output Data Format

Differential Input Voltage Bit 31 Bit 30 Bit 29 Bit 28 Bit 27 Bit 26 Bit 25 … Bit 0

* EOC DMY SIG MSB

V

IN

VIN* ≥ 0.5 • V

0.5 • V

REF

0.25 • V

REF

0.25 • V

REF

0 0 0100 0 0…0

–1LSB 0 0011 1 1…1

–0.25 • V

–0.25 • V

–0.5 • V

VIN* < –0.5 • V

*The differential input voltage VIN = IN+ – IN–. **The differential reference voltage V

** 0 0110 0 0…0

REF

** – 1LSB 00101 1 1…1

** 0 0101 0 0…0

** – 1LSB 00100 1 1…1

** 00011 0 0…0

REF

** – 1LSB 00010 1 1…1

REF

** 0 0010 0 0…0

REF

** 0 0001 1 1…1

REF

= REF+ – REF–.

REF

24467fa

Page 11

WUUU

APPLICATIO S I FOR ATIO

LTC2446/LTC2447

Serial Clock Input/Output (SCK)

The serial clock signal present on SCK (Pin 38) is used to

synchronize the data transfer. Each bit of data is shifted out

the SDO pin on the falling edge of the serial clock.

In the Internal SCK mode of operation, the SCK pin is an

output and the LTC2446/LTC2447 create their own serial

clock. In the External SCK mode of operation, the SCK pin

is used as input. The internal or external SCK mode is

selected by tying EXT (Pin 3) LOW for external SCK and

HIGH for internal SCK.

Serial Data Output (SDO)

The serial data output pin, SDO (Pin 37), provides the

result of the last conversion as a serial bit stream (MSB

first) during the data output state. In addition, the SDO pin

is used as an end of conversion indicator during the

conversion and sleep states.

When CS (Pin 36) is HIGH, the SDO driver is switched to

a high impedance state. This allows sharing the serial

interface with other devices. If CS is LOW during the

convert or sleep state, SDO will output EOC. If CS is LOW

during the conversion phase, the EOC bit appears HIGH on

the SDO pin. Once the conversion is complete, EOC goes

LOW. The device remains in the sleep state until the first

rising edge of SCK occurs while CS = LOW.

Chip Select Input (CS)

The active LOW chip select, CS (Pin 36), is used to test the

conversion status and to enable the data output transfer as

described in the previous sections.

In addition, the CS signal can be used to trigger a new

conversion cycle before the entire serial data transfer has

been completed. The LTC2446/LTC2447 will abort any

serial data transfer in progress and start a new conversion

cycle anytime a LOW-to-HIGH transition is detected at the

CS pin after the converter has entered the data output

state.

Serial Data Input (SDI)

The serial data input (SDI, Pin 34) is used to select the

speed/resolution input channel and reference of the

LTC2446/LTC2447. SDI is programmed by a serial input

data stream under the control of SCK during the data

output cycle, see Figure 3.

Initially, after powering up, the device performs a conversion with IN

V

REF01

speed mode (no Latency). Once this first conversion is

complete, the device enters the sleep state and is ready to

output the conversion result and receive the serial data input

stream programming the speed/resolution, input channel

and reference for the next conversion. At the conclusion of

each conversion cycle, the device enters this state.

In order to change the speed/resolution, reference or input

channel, the first 3 bits shifted into the device are 101. This

is compatible with the programming sequence of the

LTC2414/LTC2418/LTC2444/LTC2445/LTC2448/

LTC2449. If the sequence is set to 000 or 100, the following input data is ignored (don’t care) and the previously

selected speed/resolution, channel and reference remain

valid for the next conversion. Combinations other than 101,

100, and 000 of the 3 control bits should be avoided.

If the first 3 bits shifted into the device are 101, then the

following 5 bits select the input channel/reference for the

following conversion (see Table 3). The next 5 bits select

the speed/resolution and mode 1x (no Latency) 2x (double

output rate with one conversion latency), see Table 4. If

these 5 bits are set to all 0’s, the previous speed remains

selected for the next conversion. This is useful in applications requiring a fixed output rate/resolution but need to

change the input channel or reference. In this case, the

timing and input sequence is compatible with the LTC2414/

LTC2418.

When an update operation is initiated (the first 3 bits are

101) the next 5 bits are the channel/reference address. The

first bit, SGL, determines if the input selection is differential (SGL = 0) or single-ended (SGL = 1). For SGL = 0, two

adjacent channels can be selected to form a differential

input. For SGL = 1, one of 8 channels is selected as the

positive input. The negative input is COM for all single

ended operations. The global V

determine which reference is selected. GLBL = 0 selects

the individual reference slaved to a given channel. Each set

of channels has a corresponding differential input reference. If GLBL = 1, a global reference V

selected. The global reference input may be used for any

input channel selected. Table 3 shows a summary of input/

reference selection. The remaining bits (ODD, A1, A0)

determine which channel is selected.

+

= CH0, IN– = CH1, REF+ = V

–

, OSR = 256 (output rate nominally 880Hz), and 1x

bit (GLBL) is used to

REF

REF01

REFG

+

, REF– =

+

/V

REFG

–

is

24467fa

11

Page 12

LTC2446/LTC2447

U

WUU

APPLICATIO S I FOR ATIO

Table 3. Channel Selection for the LTC2446/LTC2447

MUX ADDRESS CHANNEL INPUT REFERENCE INPUT

ODD/

SGL SIGN GLBL A1 A0 0 1 2 3 4 5 6 7 COM 01

*0 0 0 0 0 IN+IN

00001 IN+IN

00010 IN+IN

00011 IN+IN

01000IN–IN

01001 IN–IN

01010 IN–IN

01011 IN–IN

10000IN

10001 IN

10010 IN

–

–

–

–

+

+

+

+

+

+

+

10011 IN+IN– REF+REF

11000 IN

11001 IN

11010 IN

+

+

+

11011 IN+IN

00100IN+IN

00101 IN+IN

00110 IN+IN

00111 IN+IN

01100IN–IN

01101 IN–IN

01110 IN–IN

01111 IN–IN

10100IN

10101 IN

10110 IN

–

–

–

–

+

+

+

+

+

+

+

10111 IN+IN

11100 IN

11101 IN

11110 IN

+

+

+

11111 IN+IN

*Default at power up

+01–23+23–45+45–67+67–G+G–

REF+REF

–

REF+REF

–

REF+REF

–

REF+REF

REF+REF

–

REF+REF

–

REF+REF

–

REF+REF

IN–REF+REF

–

IN

–

IN

IN–REF+REF

–

IN

–

IN

–

–

IN

–

IN

–

IN

–

–

IN

–

IN

–

IN

–

–

REF+REF

–

REF+REF

–

REF+REF

–

REF+REF

–

–

REF+REF

–

–

–

–

REF+REF

REF+REF

REF+REF

REF+REF

REF+REF

REF+REF

REF+REF

REF+REF

REF+REF

REF+REF

REF+REF

REF+REF

REF+REF

REF+REF

REF+REF

REF+REF

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

12

24467fa

Page 13

WUUU

APPLICATIO S I FOR ATIO

Table 4. LTC2446/LTC2447 Speed/Resolution Selection

CONVERSION RATE

INTERNAL EXTERNAL RMS RMS

9MHz 10.24MHz NOISE NOISE ENOB ENOB

OSR3 OSR2 OSR1 OSR0 TWOX CLOCK CLOCK LTC2446 LTC2447 LTC2446 LTC2447 OSR LATENCY

00000 Keep Previous Speed/Resolution

000103.52kHz 4kHz 23µV23µV 17 17 64 None

001001.76kHz 2kHz 4.4µV 3.5µV 20.1 20.1 128 None

00110880Hz 1kHz 2.8µV2µV 20.8 21.3 256 None

01000440Hz 500Hz 2µV 1.4µV 21.3 21.8 512 None

01010220Hz 250Hz 1.4µV1µV 21.8 22.4 1024 None

01100110Hz 125Hz 1.1µV 750nV 22.1 22.9 2048 None

0111055Hz 62.5Hz 720nV 510nV 22.7 23.4 4096 None

1000027.5Hz 31.25Hz 530nV 375nV 23.2 24 8192 None

1001013.75Hz 15.625Hz 350nV 250nV 23.8 24.4 16384 None

111106.875Hz 7.8125Hz 280nV 200nV 24.1 24.6 32768 none

00001 Keep Previous Speed/Resolution

000117.04kHz 8kHz 23µV23µV 17 17 64 1 Cycle

001013.52kHz 4kHz 4.4µV 3.5µV 20.1 20.1 128 1 Cycle

001111.76kHz 2kHz 2.8µV2µV 20.8 21.3 256 1 Cycle

01001880Hz 1kHz 2µV 1.4µV 21.3 21.8 512 1 Cycle

01011440Hz 500Hz 1.4µV1µV 21.8 22.4 1024 1 Cycle

01101220Hz 250Hz 1.1µV 750nV 22.1 22.9 2048 1 Cycle

01111110Hz 125Hz 720nV 510nV 22.7 23.4 4096 1 Cycle

1000155Hz 62.5Hz 530nV 375nV 23.2 24 8192 1 Cycle

1001127.5Hz 31.25Hz 350nV 250nV 23.8 24.4 16384 1 Cycle

1111113.75Hz 15.625Hz 280nV 200nV 24.1 24.6 32768 1 Cycle

LTC2446/LTC2447

24467fa

13

Page 14

LTC2446/LTC2447

WUUU

APPLICATIO S I FOR ATIO

Speed Multiplier Mode

In addition to selecting the speed/resolution, a speed

multiplier mode is used to double the output rate while

maintaining the selected resolution. The last bit of the 5-bit

speed/resolution control word (TWOX, see Table 4) determines if the output rate is 1x (no speed increase) or 2x

(double the selected speed).

While operating in the 1x mode, the device combines two

internal conversions for each conversion result in order to

remove the ADC offset. Every conversion cycle, the offset

and offset drift are transparently calibrated greatly simplifying the user interface. The conversion result has no

latency. The first conversion following a newly selected

speed/resolution and/or input/reference is valid. This is

identical to the operation of the LTC2440, LTC2444,

LTC2445, LTC2448, LTC2449, LTC2414 and LTC2418.

While operating in the 2x mode, the device performs a

running average of the last two conversion results. This

automatically removes the offset and drift of the device

while increasing the output rate by 2x. The resolution

(noise) remains the same as the 1x mode. If a new

channel/reference is selected, the conversion result is

valid for all conversions after the first conversion (one

cycle latency). If a new speed/resolution is selected, the

first conversion result is valid but the resolution (noise) is

a function of the running average. All subsequent conversion results are valid. If the mode is changed from either

1x to 2x or 2x to 1x without changing the resolution or

channel, the first conversion result is valid.

If an external buffer/amplifier circuit is used for the

LTC2447, the 2x mode can be used to increase the settling

time of the amplifier between readings. While operating in

the 2x mode, the multiplexer output (input to the external

buffer/amplifier) is switched at the end of each conversion

cycle. Prior to concluding the data out/in cycle, the analog

multiplexer output is switched. This occurs at the end of

the conversion cycle (just prior to the data output cycle)

for auto calibration. The time required to read the conversion enables more settling time for the external buffer/

amplifier. The offset/offset drift of the external amplifiers

are automatically removed by the converter’s auto calibration sequence for both the 1x and 2x speed modes.

While operating in the 1x mode, if a new input channel/

reference is selected the multiplexer is switched on the

falling edge of the 14th SCK (once the complete data input

word is programmed). The remaining data output sequence time can be used to allow the external buffer/

amplifier to settle.

BUSY

The BUSY output (Pin 2) is used to monitor the state of

conversion, data output and sleep cycle. While the part is

converting, the BUSY pin is HIGH. Once the conversion is

complete, BUSY goes LOW indicating the conversion is

complete and data out is ready. The part now enters the

LOW power sleep state. BUSY remains LOW while data is

shifted out of the device and SDI is shifted into the device.

It goes HIGH at the conclusion of the data input/output

cycle indicating a new conversion has begun. This rising

edge may be used to flag the completion of the data read

cycle.

SERIAL INTERFACE TIMING MODES

The LTC2446/LTC2447’s 3- or 4-wire interface is SPI and

MICROWIRE compatible. This interface offers several flexible modes of operation. These include internal/external

serial clock, 3- or 4-wire I/O, single cycle conversion and

autostart. The following sections describe each of these

serial interface timing modes in detail. In all these cases,

the converter can use the internal oscillator (F

an external oscillator connected to the FO pin. Refer to

Table 5 for a summary.

= LOW) or

O

Table 5. LTC2446/LTC2447 Interface Timing Modes

CONVERSION DATA CONNECTION

SCK CYCLE OUTPUT AND

CONFIGURATION SOURCE CONTROL CONTROL WAVEFORMS

External SCK, Single Cycle Conversion External CS and SCK CS and SCK Figures 4, 5

External SCK, 3-Wire I/O External SCK SCK Figure 6

Internal SCK, Single Cycle Conversion Internal CS ↓ CS ↓ Figures 7, 8

Internal SCK, 3-Wire I/O, Continuous Conversion Internal Continuous Internal Figure 9

14

24467fa

Page 15

WUUU

APPLICATIO S I FOR ATIO

LTC2446/LTC2447

External Serial Clock, Single Cycle Operation

(SPI/MICROWIRE Compatible)

This timing mode uses an external serial clock to shift out

the conversion result and a CS signal to monitor and

control the state of the conversion cycle, see Figure 4.

The serial clock mode is selected by the EXT pin. To select

the external serial clock mode, EXT must be tied low.

The serial data output pin (SDO) is Hi-Z as long as CS is

HIGH. At any time during the conversion cycle, CS may be

pulled LOW in order to monitor the state of the converter.

While CS is pulled LOW, EOC is output to the SDO pin.

EOC = 1 (BUSY = 1) while a conversion is in progress and

EOC = 0 (BUSY = 0) if the device is in the sleep state.

Independent of CS, the device automatically enters the low

power sleep state once the conversion is complete.

4.5V TO 5.5V

1µF

28

USER SELECTABLE

REFERENCES

0.1V TO V

ANALOG

INPUTS

V

29

REFG

30

REFG

11

REF01

10

CC

REF01

24

REF67

23

REF67

8

CH0

9

CH1

12

CH2

22

CH7

7

COM

CC

LTC2446

+

–

.

.

.

.

.

.

F

O

+

–

+

SDI

–

SCK

SDO

CS

BUSY

GND

When the device is in the sleep state (EOC = 0), its

conversion result is held in an internal static shift register. The device remains in the sleep state until the first

rising edge of SCK is seen. Data is

shifted out the SDO pin

on each falling edge of SCK. This enables external circuitry

to latch the output on the rising edge of SCK. EOC can be

latched on the first rising edge of SCK and the last bit of

the conversion result can be latched on the 32nd rising

edge of SCK. On the 32nd falling edge of SCK, the device

begins a new conversion. SDO goes HIGH (EOC = 1) and

BUSY goes HIGH indicating a conversion is in progress.

At the conclusion of the data cycle, CS may remain LOW

and EOC monitored as an end-of-conversion interrupt.

Alternatively, CS may be driven HIGH setting SDO to Hi-Z

and BUSY monitored for the completion of a conversion.

35

34

38

37

36

2

1,4,5,6,31,32,33

= EXTERNAL OSCILLATOR

= INTERNAL OSCILLATOR

4-WIRE

SPI INTERFACE

CS

TEST EOC TEST EOC

SCK

(EXTERNAL)

SDI

SDO

BUSY

CONVERSION SLEEP DATA OUTPUT CONVERSION

1234567891011121314 32

1 0 EN SGL GLBL A1 A0 OSR3 OSR2 OSR1 OSR0 TWOXODD

BIT 28 BIT 27 BIT 26 BIT 25 BIT 24 BIT 23 BIT 22 BIT 21 BIT 20 BIT 19 BIT 0

BIT 29

BIT 30

BIT 31

Hi-Z

EOC

“0”

SIG

MSB

Figure 4. External Serial Clock, Single Cycle Operation

LSB

Hi-Z

24467 F04

24467fa

15

Page 16

LTC2446/LTC2447

U

WUU

APPLICATIO S I FOR ATIO

As described above, CS may be pulled LOW at any time in

order to monitor the conversion status on the SDO pin.

Typically, CS remains LOW during the data output state.

However, the data output state may be aborted by pulling

CS HIGH anytime between the fifth falling edge and the

32nd falling edge of SCK, see Figure 5. On the rising edge

of CS, the device aborts the data output state and immediately initiates a new conversion.

data bits are required in order to properly program the

speed/resolution and input/reference channel. If the data

Thirteen serial input

4.5V TO 5.5V

1µF

USER SELECTABLE

REFERENCES

0.1V TO V

CC

ANALOG

INPUTS

28

V

CC

29

REFG

30

REFG

11

REF01

10

REF01

24

REF67

23

REF67

8

CH0

9

CH1

12

CH2

.

.

.

22

CH7

7

COM

LTC2446

+

–

+

–

.

.

.

+

–

SDI

SCK

SDO

CS

BUSY

GND

F

O

output sequence is aborted prior to the 13th rising edge of

SCK, the new input data is ignored, and the previously

selected speed/resolution and channel are used for the

next conversion cycle.

This is useful for systems not

requiring all 32 bits of output data, aborting an invalid

conversion cycle or synchronizing the start of a conversion. If a new channel is being programmed, the rising

edge of CS must come after the 14th falling edge of SCK

in order to store the data input sequence.

35

34

38

37

36

2

1,4,5,6,31,32,33

= EXTERNAL OSCILLATOR

= INTERNAL OSCILLATOR

4-WIRE

SPI INTERFACE

16

CS

SCK

(EXTERNAL)

SDI

SDO

BUSY

CONVERSION

12345615

BIT 30

“0”

DON'T CARE

BIT 28 BIT 27 BIT 26 BIT 25

BIT 29

MSB

SIG

CONVERSION

DON'T CARE DON'T CARE

BIT 31

Hi-Z Hi-Z

EOC

DATA OUTPUT DATA OUTPUT

SLEEP

CONVERSION

Figure 5. External Serial Clock, Reduced Output Data Length

TEST EOC

SLEEP

24467 F05

24467fa

Page 17

LTC2446/LTC2447

U

WUU

APPLICATIO S I FOR ATIO

External Serial Clock, 3-Wire I/O

This timing mode utilizes a 3-wire serial I/O interface. The

conversion result is shifted out of the device by an externally generated serial clock (SCK) signal, see Figure 6. CS

may be permanently tied to ground, simplifying the user

interface or isolation barrier. The external serial clock

mode is selected by tying EXT LOW.

Since CS is tied LOW, the end-of-conversion (EOC) can be

continuously monitored at the SDO pin during the convert

and sleep states. Conversely, BUSY (Pin 2) may be used

to monitor the status of the conversion cycle. EOC or BUSY

may be used as an interrupt to an external controller

4.5V TO 5.5V

1µF

28

USER SELECTABLE

REFERENCES

0.1V TO V

ANALOG

INPUTS

V

29

REFG

30

REFG

11

REF01

10

CC

REF01

24

REF67

23

REF67

8

CH0

9

CH1

12

CH2

22

CH7

7

COM

CC

LTC2446

+

–

.

.

.

.

.

.

F

O

+

–

+

SDI

–

SCK

SDO

CS

BUSY

GND

indicating the conversion result is ready. EOC = 1

(BUSY = 1) while the conversion is in progress and

EOC = 0 (BUSY = 0) once the conversion enters the low

power sleep state. On the falling edge of EOC/BUSY, the

conversion result is loaded into an internal static shift

register. The device remains in the sleep state until the

first rising edge of SCK. Data is shifted out the SDO pin

on each falling edge of SCK enabling external circuitry to

latch data on the rising edge of SCK. EOC can be latched

on the first rising edge of SCK. On the 32nd falling edge

of SCK, SDO and BUSY go HIGH (EOC = 1) indicating a

new conversion has begun.

35

34

38

37

36

2

1,4,5,6,31,32,33

= EXTERNAL OSCILLATOR

= INTERNAL OSCILLATOR

3-WIRE

SPI INTERFACE

SCK

(EXTERNAL)

SDI

SDO

BUSY

CS

CONVERSION

1234567891011121314 32

1 0 EN SGL GLBL A1 A0 OSR3 OSR2 OSR1 OSR0 TWOXODD

BIT 28 BIT 27 BIT 26 BIT 25 BIT 24 BIT 23 BIT 22 BIT 21 BIT 20 BIT 19 BIT 0

BIT 29

BIT 30

BIT 31

MSB

SIG

“0”

EOC

SLEEP

DATA OUTPUT

Figure 6. External Serial Clock, CS = 0 Operation (3-Wire)

DON'T CAREDON'T CARE

LSB

CONVERSION

24467 F06

24467fa

17

Page 18

LTC2446/LTC2447

WUUU

APPLICATIO S I FOR ATIO

Internal Serial Clock, Single Cycle Operation

This timing mode uses an internal serial clock to shift out

the conversion result and a CS signal to monitor and

control the state of the conversion cycle, see Figure 7.

In order to select the internal serial clock timing mode, the

EXT pin must be tied HIGH.

The serial data output pin (SDO) is Hi-Z as long as CS is

HIGH. At any time during the conversion cycle, CS may be

pulled LOW in order to monitor the state of the converter.

Once CS is pulled LOW, SCK goes LOW and EOC is output

to the SDO pin. EOC = 1 while a conversion is in progress

and EOC = 0 if the device is in the sleep state. Alternatively,

BUSY (Pin 2) may be used to monitor the status of the

conversion in progress. BUSY is HIGH during the conver-

4.5V TO 5.5V

1µF

28

V

CC

LTC2446

29

+

REFG

30

–

REFG

11

+

REF01

10

–

REF01

.

.

.

24

+

REF67

23

–

REF67

8

CH0

9

CH1

12

CH2

.

.

.

22

CH7

7

COM

CS

TEST EOC TEST EOC

SCK

USER SELECTABLE

REFERENCES

0.1V TO V

CC

ANALOG

INPUTS

<t

EOC(TEST)

1234567891011121314 32

sion and goes LOW at the conclusion. It remains LOW until

the result is read from the device.

When testing EOC, if the conversion is complete (EOC = 0),

the device will exit the sleep state and enter the data output

state if CS remains LOW. In order to prevent the device

from exiting the low power sleep state, CS must be pulled

HIGH before the first rising edge of SCK. In the internal

SCK timing mode, SCK goes HIGH and the device begins

outputting data at time t

(if EOC = 0) or t

after EOC goes LOW (if CS is LOW

EOCtest

during the falling edge of EOC). The value of t

500ns. If CS is pulled HIGH before time t

after the falling edge of CS

EOCtest

EOCtest

EOCtest

, the device

remains in the sleep state. The conversion result is held in

the internal static shift register.

= EXTERNAL OSCILLATOR

= INTERNAL OSCILLATOR

4-WIRE

SPI INTERFACE

SDI

SCK

SDO

BUSY

GND

F

O

CS

35

34

38

37

36

2

1,4,5,6,31,32,33

is

SDI

SDO

BUSY

CONVERSION

18

DON'T CARE DON'T CARE

Hi-Z

SLEEP DATA OUTPUT CONVERSION

1 0 EN SGL GLBL A1 A0 OSR3 OSR2 OSR1 OSR0 TWOXODD

BIT 28 BIT 27 BIT 26 BIT 25 BIT 24 BIT 23 BIT 22 BIT 21 BIT 20 BIT 19 BIT 0

BIT 29

BIT 30

BIT 31

MSB

SIG

“0”

EOC

LSB

Figure 7. Internal Serial Clock, Single Cycle Operation

Hi-Z

244676 F07

24467fa

Page 19

LTC2446/LTC2447

U

WUU

APPLICATIO S I FOR ATIO

If CS remains LOW longer than t

edge of SCK will occur and the conversion result is serially

shifted out of the SDO pin. The data output cycle begins on

this first rising edge of SCK and concludes after the 32nd

rising edge. Data is shifted out the SDO pin on each falling

edge of SCK. The internally generated serial clock is output

to the SCK pin. This signal may be used to shift the

conversion result into external circuitry. EOC can be

latched on the first rising edge of SCK and the last bit of the

conversion result on the 32nd rising edge of SCK. After the

32nd rising edge, SDO goes HIGH (EOC = 1), SCK stays

HIGH and a new conversion starts.

Typically, CS remains LOW during the data output state.

However, the data output state may be aborted by pulling

CS HIGH anytime between the first and 32nd rising edge

<t

EOC(TEST)

CS

, the first rising

EOCtest

USER SELECTABLE

REFERENCES

0.1V TO V

ANALOG

4.5V TO 5.5V

1µF

INPUTS

28

V

CC

LTC2446

29

+

REFG

30

–

REFG

11

REF01

10

REF01

CC

.

.

.

24

REF67

23

REF67

8

CH0

9

CH1

12

CH2

.

.

.

22

CH7

7

COM

of SCK, see Figure 8. On the rising edge of CS, the device

aborts the data output state and immediately initiates a

new conversion. This is useful for systems not requiring

all 32 bits of output data, aborting an invalid conversion

cycle, or synchronizing the start of a conversion. Thirteen

serial input data bits are required in order to properly

program the speed/resolution and input channel. If the

data output sequence is aborted prior to the 13th rising

edge of SCK, the new input data is ignored, and the

previously selected speed/resolution and channel are used

for the next conversion cycle.

If a new channel is being

programmed, the rising edge of CS must come after the

14th falling edge of SCK in order to store the data input

sequence.

= EXTERNAL OSCILLATOR

= INTERNAL OSCILLATOR

4-WIRE

SPI INTERFACE

<t

EOC(TEST)

+

–

+

–

SDI

SCK

SDO

BUSY

GND

F

O

CS

35

34

38

37

36

2

1,4,5,6,31,32,33

SCK

SDI

SDO

BUSY

CONVERSION

12345615

DON'T CARE DON'T CARE DON'T CARE

BIT 31

BIT 30

Hi-Z Hi-Z

DATA OUTPUT DATA OUTPUT

SLEEP

CONVERSION

EOC

“0”

BIT 28 BIT 27 BIT 26 BIT 25

BIT 29

MSB

SIG

CONVERSION

Figure 8. Internal Serial Clock, Reduced Data Output Length

TEST EOC

SLEEP

24467 F08

24467fa

19

Page 20

LTC2446/LTC2447

U

WUU

APPLICATIO S I FOR ATIO

Internal Serial Clock, 3-Wire I/O,

Continuous Conversion

This timing mode uses a 3-wire, all output (SCK and SDO)

interface. The conversion result is shifted out of the device

by an internally generated serial clock (SCK) signal, see

Figure 9. CS may be permanently tied to ground, simplifying the user interface or isolation barrier. The internal

serial clock mode is selected by tying EXT HIGH.

During the conversion, the SCK and the serial data output

pin (SDO) are HIGH (EOC = 1) and BUSY = 1. Once the

conversion is complete, SCK, BUSY and SDO go LOW

(EOC = 0) indicating the conversion has finished and the

4.5V TO 5.5V

1µF

28

V

CC

LTC2446

29

+

REFG

30

–

REFG

11

USER SELECTABLE

REFERENCES

0.1V TO V

ANALOG

INPUTS

CC

+

REF01

10

–

REF01

.

.

.

24

+

REF67

23

–

REF67

8

CH0

9

CH1

12

CH2

.

.

.

22

CH7

7

COM

device has entered the low power sleep state. The part

remains in the sleep state a minimum amount of time

(≈500ns) then immediately begins outputting data. The

data output cycle begins on the first rising edge of SCK and

ends after the 32nd rising edge. Data is shifted out the SDO

pin on each falling edge of SCK. The internally generated

serial clock is output to the SCK pin. This signal may be

used to shift the conversion result into external circuitry.

EOC can be latched on the first rising edge of SCK and the

last bit of the conversion result can be latched on the 32nd

rising edge of SCK. After the 32nd rising edge, SDO goes

HIGH (EOC = 1) indicating a new conversion is in progress.

SCK remains HIGH during the conversion.

= EXTERNAL OSCILLATOR

= INTERNAL OSCILLATOR

3-WIRE

SPI INTERFACE

SDI

SCK

SDO

BUSY

GND

F

O

CS

35

34

38

37

36

2

1,4,5,6,31,32,33

CS

SCK

SDI

SDO

BUSY

20

CONVERSION

1234567891011121314 32

1 0 EN SGL GLBL A1 A0 OSR3 OSR2 OSR1 OSR0 TWOXODD

BIT 28 BIT 27 BIT 26 BIT 25 BIT 24 BIT 23 BIT 22 BIT 21 BIT 20 BIT 19 BIT 0

BIT 29

BIT 30

BIT 31

MSB

SIG

“0”

EOC

SLEEP

DATA OUTPUT

DON'T CAREDON'T CARE

LSB

Figure 9. Internal Serial Clock, Continuous Operation

CONVERSION

24467 F09

24467fa

Page 21

LTC2446/LTC2447

U

WUU

APPLICATIO S I FOR ATIO

Normal Mode Rejection and Antialiasing

One of the advantages delta-sigma ADCs offer over conventional ADCs is on-chip digital filtering. Combined with

a large oversampling ratio, the LTC2446/LTC2447 significantly simplify antialiasing filter requirements.

The LTC2446/LTC2447’s speed/resolution is determined

by the over sample ratio (OSR) of the on-chip digital filter.

The OSR ranges from 64 for 3.5kHz output rate to 32,768

for 6.9Hz (in 1x mode) output rate. The value of OSR and

the sample rate f

device. The first NULL of the digital filter is at f

multiples of fN where fN = fS/OSR, see Figure 10 and Table

6. The rejection at the frequency f

80dB, see Figure 11.

–20

–40

–60

–80

–100

NORMAL MODE REJECTION (dB)

–120

–140

Figure 10. LTC2446/LTC2447

Normal Mode Rejection (Internal Oscillator)

determine the filter characteristics of the

S

±14% is better than

N

0

SINC4 ENVELOPE

0

60 120 240

DIFFERENTIAL INPUT SIGNAL FREQUENCY (Hz)

180

24467 F10

and

N

Table 6. OSR vs Notch Frequency (fN) (with Internal Oscillator

Running at 9MHz)

OSR NOTCH (fN)

64 28.16kHz

128 14.08kHz

256 7.04kHz

512 3.52kHz

1024 1.76kHz

2048 880Hz

4096 440Hz

8192 220Hz

16384 110Hz

32768* 55Hz

*Simultaneous 50/60Hz rejection

If FO is grounded, fS is set by the on-chip oscillator at

1.8MHz ±5% (over supply and temperature variations). At

an OSR of 32,768, the first NULL is at fN = 55Hz and the no

latency output rate is fN/8 = 6.9Hz. At the maximum OSR,

the noise performance of the device is 280nV

(LTC2446) and 200nV

(LTC2447) with better than

RMS

RMS

80dB rejection of 50Hz ±2% and 60Hz ±2%. Since the OSR

is large (32,768) the wide band rejection is extremely large

and the antialiasing requirements are simple. The first

multiple of fS occurs at 55Hz • 32,768 = 1.8MHz, see

Figure 12.

The first NULL becomes fN = 7.04kHz with an OSR of 256

(an output rate of 880Hz) and FO grounded. While the

NULL has shifted, the sample rate remains constant. As a

result of constant modulator sampling rate, the linearity,

–80

–90

–100

–110

–120

NORMAL MODE REJECTION (dB)

–130

–140

47

DIFFERENTIAL INPUT SIGNAL FREQUENCY (Hz)

51 55

49 53

59

57

61

24467 F11

63

Figure 11. LTC2446/LTC2447

Normal Mode Rejection (Internal Oscillator)

0

–20

–40

–60

–80

–100

NORMAL MODE REJECTION (dB)

–120

–140

0

DIFFERENTIAL INPUT SIGNAL FREQUENCY (Hz)

REJECTION > 120dB

1000000 2000000

1.8MHz

24467 F12

Figure 12. LTC2446/LTC2447

Normal Mode Rejection (Internal Oscillator)

24467fa

21

Page 22

LTC2446/LTC2447

WUUU

APPLICATIO S I FOR ATIO

offset and full-scale performance remain unchanged as

does the first multiple of f

The sample rate f

and NULL fN, may also be adjusted by

S

.

S

driving the FO pin with an external oscillator. The sample

rate is fS = f

/5, where f

EOSC

is the frequency of the

EOSC

clock applied to FO. Combining a large OSR with a reduced

sample rate leads to notch frequencies fN near DC while

maintaining simple antialiasing requirements. A 100kHz

clock applied to FO results in a NULL at 0.6Hz plus all

harmonics up to 20kHz, see Figure 13. This is useful in

applications requiring digitalization of the DC component

of a noisy input signal and eliminates the need of placing

a 0.6Hz filter in front of the ADC.

0

–20

–40

–60

–80

–100

NORMAL MODE REJECTION (dB)

–120

–140

246 10

0

DIFFERENTIAL INPUT SIGNAL FREQUENCY (Hz)

8

24467 F13

Figure 13. LTC2446/LTC2447 Normal

Mode Rejection (External Oscillator at 90kHz)

An external oscillator operating from 100kHz to 20MHz

can be implemented using the LTC1799 (resistor set

SOT-23 oscillator), see Figure 14. By floating pin 4 (DIV)

of the LTC1799, the output oscillator frequency is:

OSC

10

=

f MHz

⎛

⎜

⎝

10

10••

⎞

k

⎟

⎠

R

SET

The normal mode rejection characteristic shown in

Figure 13 is achieved by applying the output of the LTC1799

(with R

= 100k) to the FO pin on the LTC2446/LTC2447

SET

with SDI tied HIGH (OSR = 32768).

Multiple Ratiometric and Absolute Measurements

The LTC2446/LTC2447 combine a high precision, high

speed delta-sigma converter with a versatile front-end

4.5V TO 5.5V

1µF

USER SELECTABLE

REFERENCES

0.1V TO V

ANALOG

INPUTS

28

V

CC

LTC2446

29

+

REFG

30

–

REFG

11

10

CC

24

23

12

22

8

9

7

REF01

REF01

.

.

.

REF67

REF67

CH0

CH1

CH2

.

.

.

CH7

COM

+

–

+

–

SDI

SCK

SDO

BUSY

GND

F

O

CS

35

34

38

37

36

2

1,4,5,6,31,32,33

NC

24467 F14

OUT

DIV SET

4-WIRE

SPI INTERFACE

LTC1799

GND

+

V

R

SET

0.1µF

Figure 14. Simple External Clock Source

multiplexer. The unique no latency architecture allows

seamless changes in both input channel and reference

while the absolute accuracy ensures excellent matching

between both analog input channels and reference channels. Any set of inputs (differential or single-ended) can

perform a conversion with one of two references. For

Bridges, RTDs and other ratiometric devices, each set of

channels can perform a conversion with respect to a

unique reference voltage. For Thermocouples, voltage

sense, current sense and other absolute sensors, each set

of channels can perform a conversion with respect to a

single global reference voltage (see Figure 15). This allows

users to measure both multiple absolute and multiple ratio

metric sensors with the same device in such applications

as flow, gas chromatography, multiple RTDs or bridges,

or universal data acquisition.

Average Input Current

The LTC2446 switches the input and reference to a 2pF

capacitor at a frequency of 1.8MHz. A simplified equivalent

circuit is shown in Figure 16. The sample capacitor for the

LTC2447 is 4pF, and its average input current is externally

buffered from the input source.

The average input and reference currents can be expressed in terms of the equivalent input resistance of the

sample capacitor, where: Req = 1/(f

SW

• Ceq).

24467fa

22

Page 23

LTC2446/LTC2447

U

WUU

APPLICATIO S I FOR ATIO

RTD

RATIOMETRIC

RTD

BRIDGE

V

CC

V

REF

V

REFG

V

REFO1

V

REFO1

CH0

CH1

V

REF23

V

REF23

CH2

CH3

CH4

V

REF45

CH5

V

REF45

+

+

–

+

REF

+

+

–

IN

–

IN

+

REF

–

+

–

–

10µF

VARIABLE SPEED

RESOLUTION

24-BIT ∆Σ ADC

LTC2446

CS

SDI

SDO

SCK

I

V

VIN+

VIN–

I

V

REF

REF

IIN+

IIN–

REF

REF

ABSOLUTE

vs V