Page 1

LTC2424/LTC2428

Final Electrical Specifications

4-/8-Channel 20-Bit µPower

TM

No Latency ∆Σ

ADCs

FEATURES

■

Pin Compatible 4-/8-Channel 20-Bit ADCs

■

8ppm INL, No Missing Codes at 20 Bits

■

4ppm Full-Scale Error and 0.5ppm Offset

■

1.2ppm Noise

■

Digital Filter Settles in a Single Cycle. Each

Conversion is Accurate, Even After Changing

Channels

■

Fast Mode: 16-Bit Noise, 12-Bit TUE at 100sps

■

Internal Oscillator—No External Components

Required

■

110dB Min, 50Hz/60Hz Notch Filter

■

Reference Input Voltage: 0.1V to V

■

Live Zero—Extended Input Range Accommodates

CC

12.5% Overrange and Underrange

■

Single Supply 2.7V to 5.5V Operation

■

Low Supply Current (200µA) and Auto Shutdown

■

Can Be Interchanged with 24-Bit LTC2404/LTC2408

if ZS

Pin is Grounded

SET

U

APPLICATIO S

■

Weight Scales

■

Direct Temperature Measurement

■

Gas Analyzers

■

Strain-Gage Transducers

■

Instrumentation

■

Data Acquisition

■

Industrial Process Control

■

4-Digit DVMs

U

March 2000

DESCRIPTIO

The LTC®2424/LTC2428 are 4-/8-channel 2.7V to 5.5V

micropower 20-bit A/D converters with an integrated

oscillator, 8ppm INL and 1.2ppm RMS noise. They use

delta-sigma technology and provide single cycle digital

filter settling time (no latency delay) for multiplexed

applications. The first conversion after the channel is

changed is always valid. Through a single pin the LTC2424/

LTC2428 can be configured for better than 110dB rejection at 50Hz or 60Hz ±2%, or can be driven by an external

oscillator for a user defined rejection frequency in the

range 1Hz to 800Hz. The internal oscillator requires no

external frequency setting components.

The converters accept any external reference voltage from

0.1V to VCC. With their extended input conversion range of

–12.5% V

LTC2424/LTC2428

overrange problems of preceding sensors or signal conditioning circuits.

The

LTC2424/LTC2428

4-wire digital interface which is compatible with SPI and

MICROWIRETM protocols.

, LTC and LT are registered trademarks of Linear Technology Corporation.

No Latency ∆Σ is a trademark of Linear Technology Corporation.

MICROWIRE is a trademark of National Semiconductor Corporation.

to 112.5% V

REF

(V

REF

REF

= FS

SET

– ZS

SET

) the

smoothly resolve the offset and

communicate through a flexible

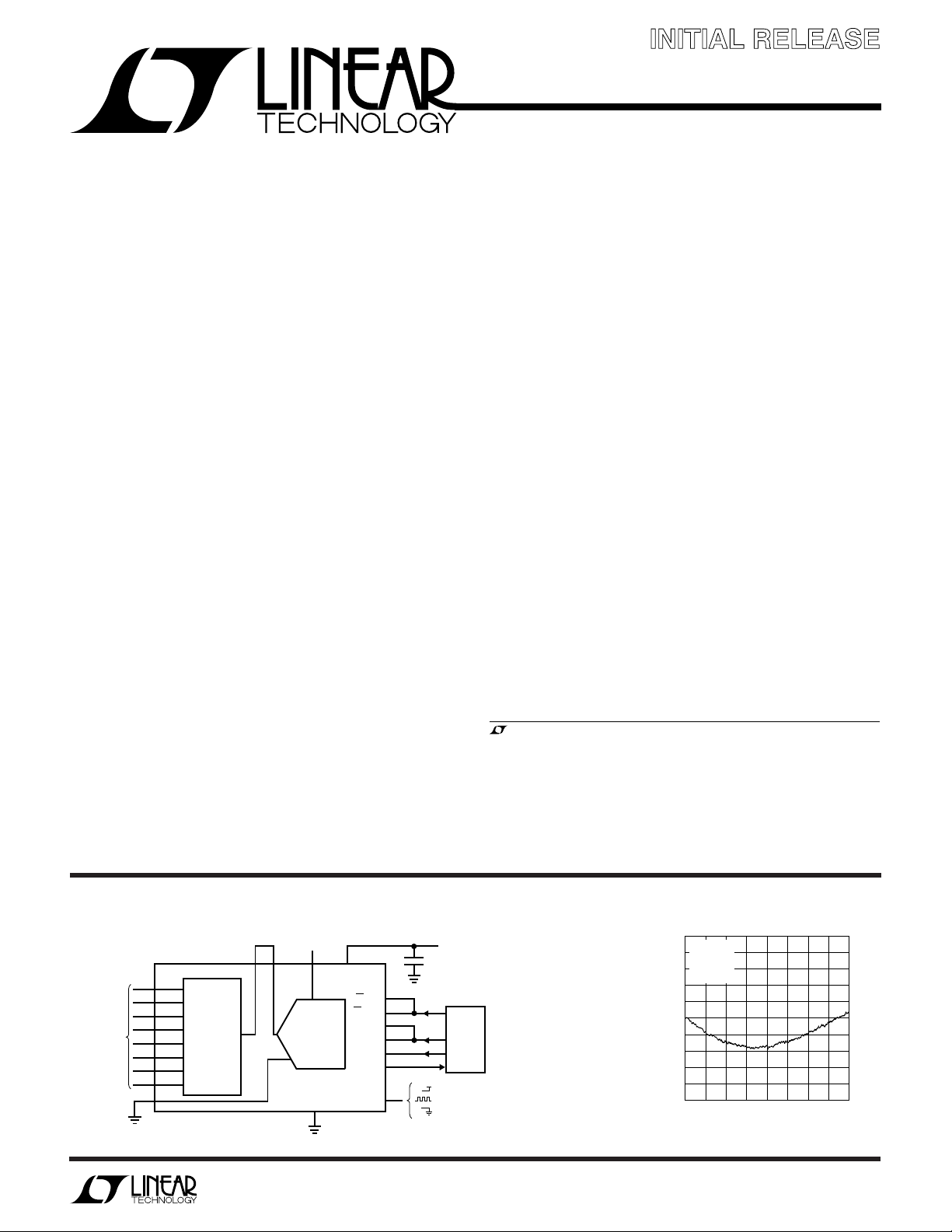

TYPICAL APPLICATIO

9

CH0

10

CH1

11

ANALOG

INPUTS

TO

–0.12V

REF

1.12V

REF

CH2

12

CH3

4-/8-CHANNEL

13

CH4*

CH5*

CH6*

CH7*

MUX

SET

14

15

17

5ZS

*THESE PINS ARE NO CONNECTS ON THE LTC2404

U

0.1V TO V

7 4 3 2, 8

ADCINMUXOUT

1, 6, 16, 18, 22, 27, 28

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

CC

FS

SETVCC

20-BIT

+

∆∑ ADC

–

LTC2424/LTC2428

GND

CSADC

CSMUX

SCK

CLK

SDO

24248 TA01

23

20

25

19

21

D

IN

24

26

F

O

2.7V TO 5.5V

1µF

SERIAL DATA LINK

MICROWIRE AND

SPI COMPATABLE

MPU

V

CC

= INTERNAL OSC/50Hz REJECTION

= EXTERNAL CLOCK SOURCE

= INTERNAL OSC/60Hz REJECTION

Total Unadjusted Error vs Output Code

10

VCC = 5V

8

V

= 5V

REF

T

= 25°C

A

6

F

= LOW

O

4

2

0

–2

–4

LINEARITY ERROR (ppm)

–6

–8

–10

0 8,338,608 16,777,215

OUTPUT CODE (DECIMAL)

24248 TA02

1

Page 2

LTC2424/LTC2428

WW

W

U

ABSOLUTE MAXIMUM RATINGS

(Notes 1, 2)

Supply Voltage (VCC) to GND.......................– 0.3V to 7V

Analog Input Voltage to GND ....... –0.3V to (VCC + 0.3V)

Reference Input Voltage to GND .. –0.3V to (VCC + 0.3V)

Digital Input Voltage to GND........ –0.3V to (VCC + 0.3V)

Digital Output Voltage to GND ..... –0.3V to (VCC + 0.3V)

U

W

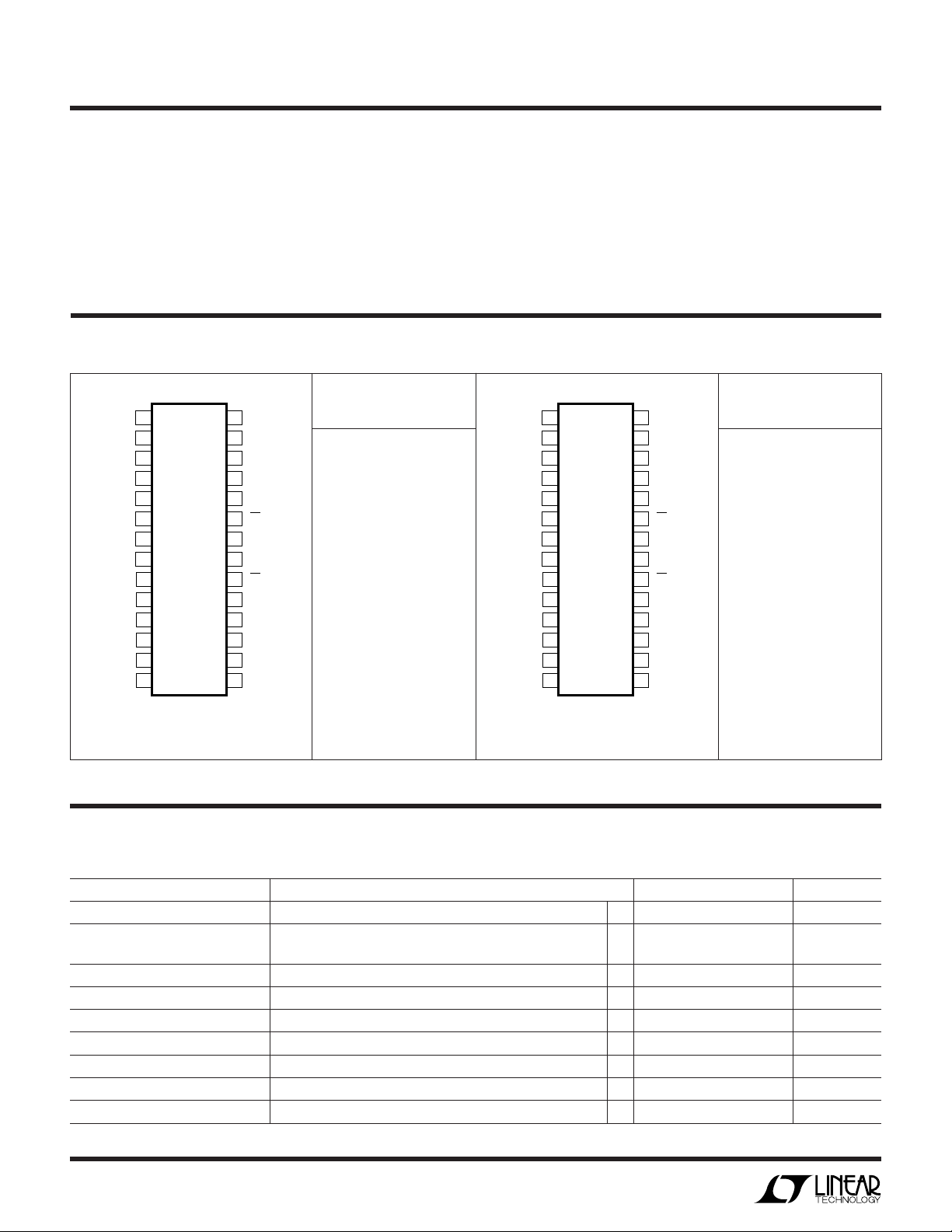

PACKAGE/ORDER INFORMATION

ORDER

PART NUMBER

LTC2424CG

LTC2424IG

GND

V

FS

SET

ADCIN

ZS

SET

GND

MUXOUT

V

CH0

CH1

CH2

CH3

NC

NC

TOP VIEW

1

2

CC

3

4

5

6

7

8

CC

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

GND

GND

F

O

SCK

SDO

CSADC

GND

D

IN

CSMUX

CLK

GND

NC

GND

NC

Operating Temperature Range

LTC2424C/LTC2428C ..............................0°C to 70°C

LTC2424I/LTC2428I ........................... – 40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

U

ORDER

PART NUMBER

LTC2428CG

LTC2428IG

GND

V

FS

SET

ADCIN

ZS

SET

GND

MUXOUT

V

CH0

CH1

CH2

CH3

CH4

CH5

TOP VIEW

1

2

CC

3

4

5

6

7

8

CC

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

GND

GND

F

O

SCK

SDO

CSADC

GND

D

IN

CSMUX

CLK

GND

CH7

GND

CH6

G PACKAGE

28-LEAD PLASTIC SSOP

T

= 125°C, θJA = 130°C/W

JMAX

G PACKAGE

28-LEAD PLASTIC SSOP

T

= 125°C, θJA = 130°C/W

JMAX

Consult factory for Military grade parts.

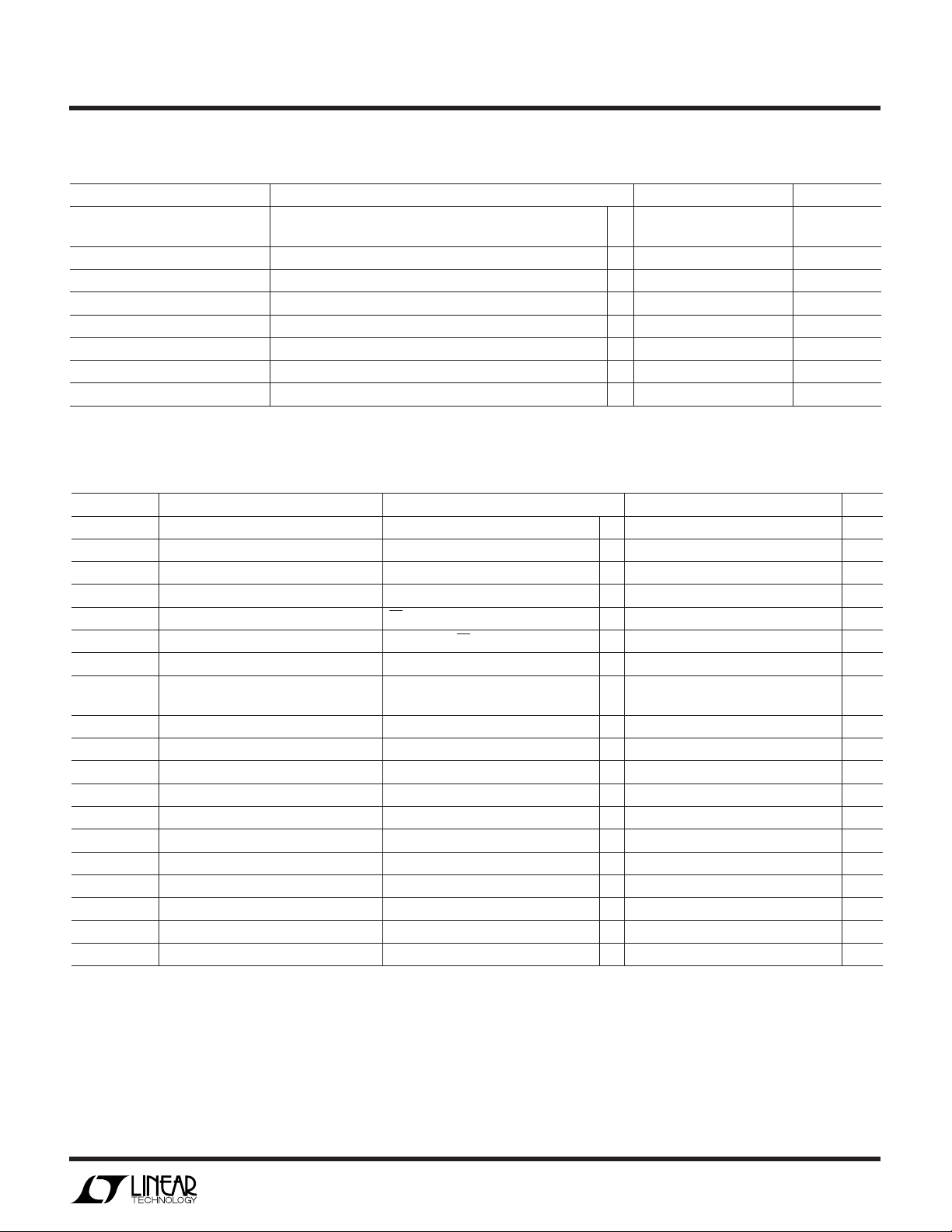

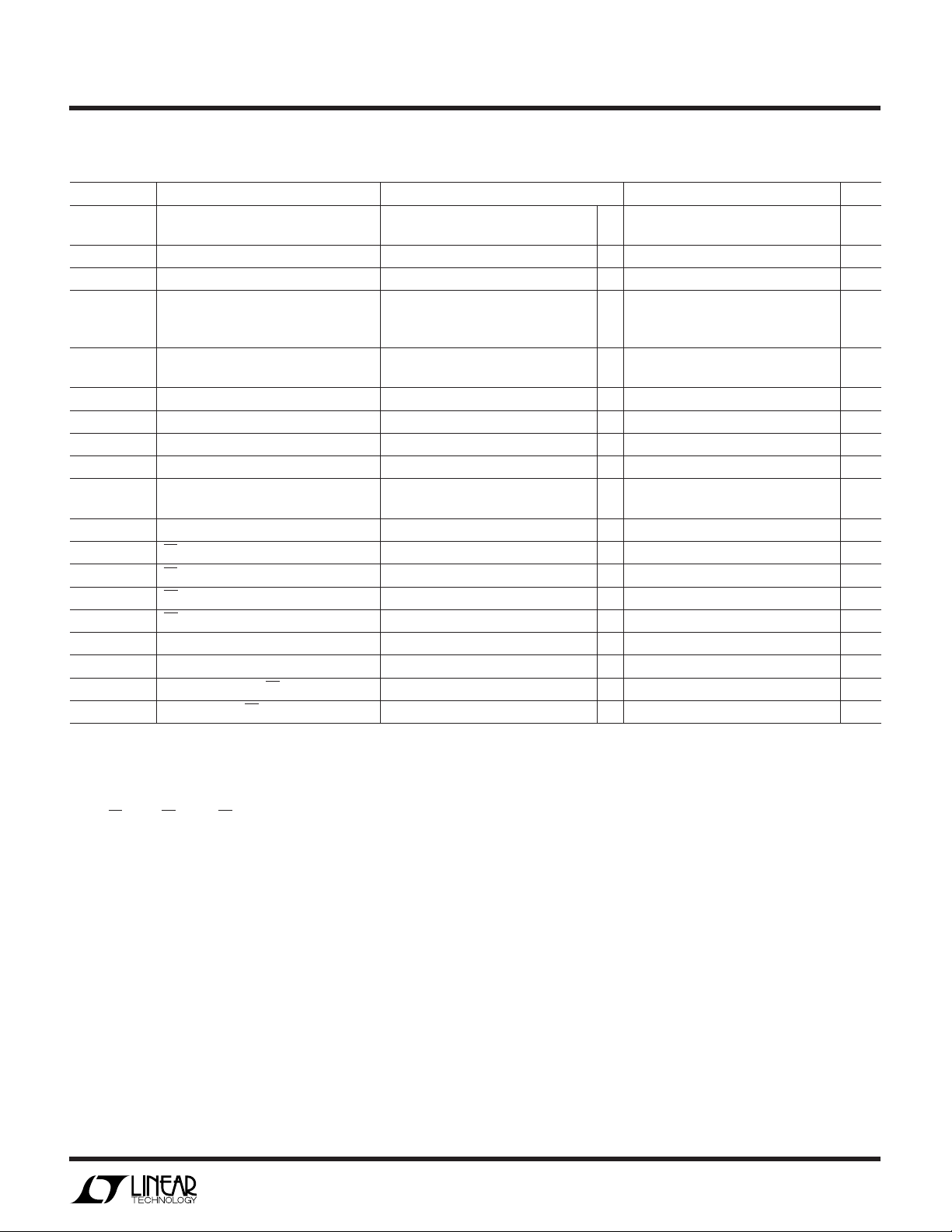

U

CONVERTER CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. (Notes 3, 4)

PARAMETER CONDITIONS MIN TYP MAX UNITS

Resolution (No Missing Codes) 0.1V ≤ V

Integral Nonlinearity V

REF

V

REF

Integral Nonlinearity (Fast Mode) 2.5V < V

Offset Error 2.5V ≤ V

Offset Error (Fast Mode) 2.5V < V

Offset Error Drift 2.5V ≤ V

Full-Scale Error 2.5V ≤ V

Full-Scale Error (Fast Mode) 2.5V < V

Full-Scale Error Drift 2.5V ≤ V

≤ VCC, (Note 5) ● 20 Bits

REF

= 2.5V (Note 6) ● 4 10 ppm of V

= 5V (Note 6) ● 8 20 ppm of V

< VCC, 100 Samples/Second, fO = 2.048MHz ● 40 250 ppm of V

REF

≤ V

REF

CC

< 5V, 100 Samples/Second, fO = 2.048MHz 3 ppm of V

REF

≤ V

REF

CC

≤ V

REF

CC

< 5V, 100 Samples/Second, fO = 2.048MHz 10 ppm of V

REF

≤ V

REF

CC

The ● denotes specifications which apply over the full operating

● 0.5 10 ppm of V

0.04 ppm of V

● 4 15 ppm of V

0.04 ppm of V

REF

REF

REF

REF

REF

REF

REF

/°C

REF

REF

/°C

2

Page 3

LTC2424/LTC2428

U

CONVERTER CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. (Notes 3, 4)

PARAMETER CONDITIONS MIN TYP MAX UNITS

Total Unadjusted Error V

Output Noise VIN = 0V, V

Output Noise (Fast Mode) V

Normal Mode Rejection 60Hz ±2% (Note 7) ● 110 130 dB

Normal Mode Rejection 50Hz ±2% (Note 8) ● 110 130 dB

Power Supply Rejection, DC V

Power Supply Rejection, 60Hz ±2% V

Power Supply Rejection, 50Hz ±2% V

= 2.5V 8 ppm of V

REF

V

= 5V 16 ppm of V

REF

= 5V (Note 13) 6 µV

REF

= 5V, 100 Samples/Second, fO = 2.048MHz 20 µV

REF

= 2.5V, VIN = 0V 100 dB

REF

= 2.5V, VIN = 0V, (Notes 7, 16) 110 dB

REF

= 2.5V, VIN = 0V, (Notes 8, 16) 110 dB

REF

The ● denotes specifications which apply over the full operating

REF

REF

RMS

RMS

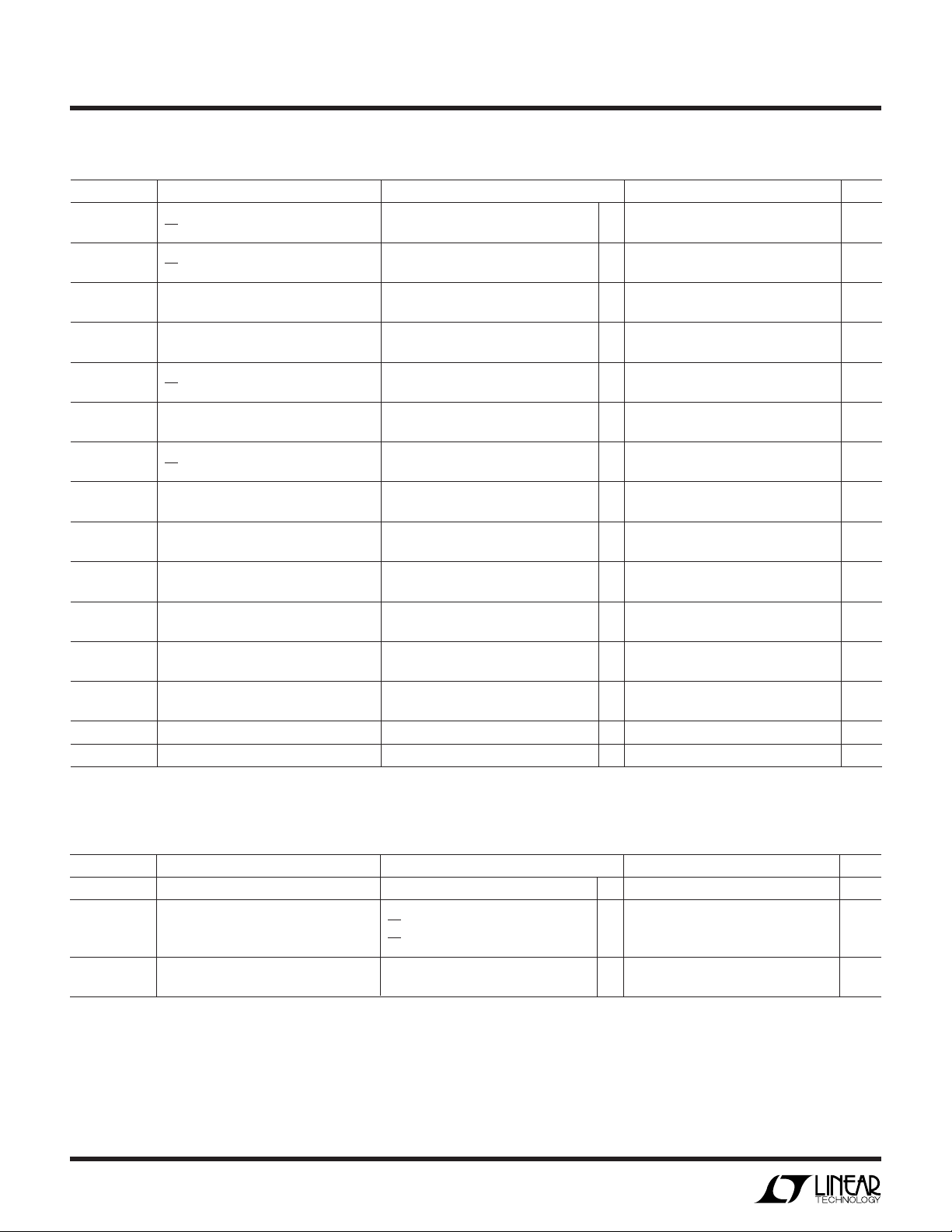

UU

U

A ALOG I PUT A D REFERE CE

U

The ● denotes specifications which apply over the full operating

temperature range, otherwise specifications are at TA = 25°C. (Note 3)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IN

V

REF

C

S(IN)

C

S(REF)

I

IN(LEAK)

I

REF(LEAK)

I

IN(MUX)

R

ON

I

S(OFF)

I

D(OFF)

t

OPEN

t

ON

t

OFF

QIRR MUX Off Isolation VIN = 2V

QINJ Charge Injection RS = 0Ω, CL = 1000pF, VS = 1V ±1pC

C

S(OFF)

C

D(OFF)

Input Voltage Range (Note 14) ● –0.125 • V

Reference Voltage Range ● 0.1 V

Input Sampling Capacitance 1 pF

Reference Sampling Capacitance 1.5 pF

Input Leakage Current CS = V

Reference Leakage Current V

On Channel Leakage Current VS = 2.5V (Note 15) ● ±20 nA

MUX On-Resistance I

MUX ∆RON vs Temperature 0.5 %/°C

∆RON vs VS (Note 15) 20 %

MUX Off Input Leakage Channel Off, VS = 2.5V ● ±20 nA

MUX Off Output Leakage Channel Off, VD = 2.5V ● ±20 nA

MUX Break-Before-Make Interval 290 ns

Enable Turn-On Time VS = 1.5V, RL = 3.4k, CL = 15pF 490 ns

Enable Turn-Off Time VS = 1.5V, RL = 3.4k, CL = 15pF 190 ns

Input Off Capacitance (MUX) 10 pF

Output Off Capacitance (MUX) 10 pF

CC

= 2.5V, CS = V

REF

= 1mA, VCC = 2.7V ● 250 300 Ω

OUT

I

= 1mA, VCC = 5V ● 120 250 Ω

OUT

P-P

CC

, RL = 1k, f = 100kHz 70 dB

● –100 1 100 nA

● –100 1 100 nA

REF

1.125 • V

CC

REF

V

V

3

Page 4

LTC2424/LTC2428

UU

DIGITAL I PUTS A D DIGITAL OUTPUTS

operating temperature range, otherwise specifications are at TA = 25°C. (Note 3)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IH

V

IL

V

IH

V

IL

I

IN

I

IN

C

IN

C

IN

V

OH

V

OL

V

OH

V

OL

I

OZ

VIN H

VIN L

MUX

MUX

High Level Input Voltage 2.7V ≤ VCC ≤ 5.5V ● 2.5 V

CS, F

O

Low Level Input Voltage 4.5V ≤ VCC ≤ 5.5V ● 0.8 V

CS, F

O

High Level Input Voltage 2.7V ≤ VCC ≤ 5.5V (Note 9) ● 2.5 V

SCK 2.7V ≤ V

Low Level Input Voltage 4.5V ≤ VCC ≤ 5.5V (Note 9) ● 0.8 V

SCK 2.7V ≤ V

Digital Input Current 0V ≤ VIN ≤ V

CS, F

O

Digital Input Current 0V ≤ VIN ≤ VCC (Note 9) ● –10 10 µA

SCK

Digital Input Capacitance 10 pF

CS, F

O

Digital Input Capacitance (Note 9) 10 pF

SCK

High Level Output Voltage IO = –800µA ● VCC – 0.5V V

SDO

Low Level Output Voltage IO = 1.6mA ● 0.4V V

SDO

High Level Output Voltage IO = –800µA (Note 10) ● VCC – 0.5V V

SCK

Low Level Output Voltage IO = 1.6mA (Note 10) ● 0.4V V

SCK

High-Z Output Leakage ● –10 10 µA

SDO

MUX High Level Input Voltage V+ = 3V ● 2V

MUX Low Level Input Voltage V+ = 2.4V ● 0.8 V

2.7V ≤ VCC ≤ 3.3V 2.0 V

2.7V ≤ VCC ≤ 5.5V 0.6 V

≤ 3.3V (Note 9) 2.0 V

CC

≤ 5.5V (Note 9) 0.6 V

CC

CC

The ● denotes specifications which apply over the full

● –10 10 µA

WU

POWER REQUIRE E TS

otherwise specifications are at TA = 25°C. (Note 3)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

CC

I

CC

I

CC(MUX)

Supply Voltage ● 2.7 5.5 V

Supply Current (Pin 2)

Conversion Mode CS = 0V (Note 12)

Sleep Mode CS = V

Multiplexer Supply Current (Pin 8) All Logic Inputs Tied Together ● 15 40 µA

The ● denotes specifications which apply over the full operating temperature range,

● 200 300 µA

(Note 12) ● 20 30 µA

CC

= 0V or 5V

V

IN

4

Page 5

LTC2424/LTC2428

UW

TI I G CHARACTERISTICS

otherwise specifications are at TA = 25°C. (Note 3)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

f

EOSC

t

HEO

t

LEO

t

CONV

f

ISCK

D

ISCK

f

ESCK

t

LESCK

t

HESCK

t

DOUT_ISCK

t

DOUT_ESCK

t

1

t

2

t

3

t

4

t

KQMAX

t

KQMIN

t

5

t

6

External Oscillator Frequency Range 20-Bit Effective Resolution ● 2.56 307.2 kHz

External Oscillator High Period ● 0.5 390 µs

External Oscillator Low Period ● 0.5 390 µs

Conversion Time FO = 0V ● 130.66 133.33 136 ms

Internal SCK Frequency Internal Oscillator (Note 10) 19.2 kHz

Internal SCK Duty Cycle (Note 10) 45 55 %

External SCK Frequency Range (Note 9) ● 2000 kHz

External SCK Low Period (Note 9) ● 250 ns

External SCK High Period (Note 9) ● 250 ns

Internal SCK 24-Bit Data Output Time Internal Oscillator (Notes 10, 12) ● 1.23 1.25 1.28 ms

External SCK 24-Bit Data Output Time (Note 9) ● 24/f

CS ↓ to SDO Low Z ● 0 150 ns

CS ↑ to SDO High Z ● 0 150 ns

CS ↓ to SCK ↓ (Note 10) ● 0 150 ns

CS ↓ to SCK ↑ (Note 9) ● 50 ns

SCK ↓ to SDO Valid ● 200 ns

SDO Hold After SCK ↓ (Note 5) ● 15 ns

SCK Set-Up Before CS ↓ ● 50 ns

SCK Hold After CS ↓ ● 50 ns

The ● denotes specifications which apply over the full operating temperature range,

12-Bit Effective Resolution

= V

F

O

CC

External Oscillator (Note 11)

External Oscillator (Notes 10, 11) f

External Oscillator (Notes 10, 11)

● 2.56k 2.048M Hz

● 156.80 160 163.20 ms

● 20480/f

● 192/f

(in kHz) ms

EOSC

/8 kHz

EOSC

(in kHz) ms

EOSC

(in kHz) ms

ESCK

Note 1: Absolute Maximum Ratings are those values beyond which the

life of the device may be impaired.

Note 2: All voltage values are with respect to GND.

Note 3: V

is 0Ω. CSADC = CSMUX = CS. V

= 2.7 to 5.5V unless otherwise specified, source input

CC

REF

= FS

SET

– ZS

SET

.

Note 4: Internal Conversion Clock source with the FO pin tied

to GND or to V

f

= 153600Hz unless otherwise specified.

EOSC

or to external conversion clock source with

CC

Note 5: Guaranteed by design, not subject to test.

Note 6: Integral nonlinearity is defined as the deviation of a code from

a straight line passing through the actual endpoints of the transfer

curve. The deviation is measured from the center of the quantization

band.

Note 7: FO = 0V (internal oscillator) or f

= 153600Hz ±2%

EOSC

(external oscillator).

Note 8: F

= VCC (internal oscillator) or f

O

= 128000Hz ±2%

EOSC

(external oscillator).

Note 9: The converter is in external SCK mode of operation such that

the SCK pin is used as digital input. The frequency of the clock signal

driving SCK during the data output is f

and is expressed in kHz.

ESCK

Note 10: The converter is in internal SCK mode of operation such that

the SCK pin is used as digital output. In this mode of operation the

SCK pin has a total equivalent load capacitance C

Note 11: The external oscillator is connected to the F

oscillator frequency, f

, is expressed in kHz.

EOSC

= 20pF.

LOAD

pin. The external

O

Note 12: The converter uses the internal oscillator.

F

= 0V or FO = VCC.

O

Note 13: The output noise includes the contribution of the internal

calibration operations.

Note 14: For reference voltage values V

of –0.125 • V

to 1.125 • V

REF

is limited by the absolute maximum

REF

rating of the Analog Input Voltage pin (Pin 3). For 2.5V < V

0.267V + 0.89 • V

For 0.267V + 0.89 • V

+ 0.3V.

to V

CC

the input voltage range is –0.3V to 1.125 • V

CC

< V

CC

≤ VCC the input voltage range is –0.3V

REF

> 2.5V the extended input

REF

REF

≤

REF

Note 15: VS is the voltage applied to a channel input. VD is the voltage

applied to the MUX output.

Note 16: V

CC(DC)

= 4.1V, V

CC(AC)

= 2.8V

P-P

.

.

5

Page 6

LTC2424/LTC2428

U

UU

PIN FUNCTIONS

GND (Pins 1, 6, 16, 18, 22, 27, 28): Ground. Should be

connected directly to a ground plane through a minimum

length trace or it should be the single-point-ground in a

single-point grounding system.

VCC (Pins 2, 8): Positive Supply Voltage. 2.7V ≤ VCC ≤

5.5V. Bypass to GND with a 10µF tantalum capacitor in

parallel with 0.1µF ceramic capacitor as close to the part

as possible.

FS

(Pin 3): Full-Scale Set Input. This pin defines the

SET

full-scale input value. When VIN = FS

full scale (FFFFFH). The total reference voltage (V

FS

– ZS

SET

ADCIN (Pin 4): Analog Input. The input voltage range is

–0.125 • V

voltage range may be limited by the pin absolute maximum rating of –0.3V to VCC + 0.3V.

ZS

(Pin 5): Zero-Scale Set Input. This pin defines the

SET

zero-scale input value. When VIN = ZS

zero scale (00000H). For pin compatibility with the LTC2404/

LTC2408 this pin must be grounded.

MUXOUT (Pin 7): MUX Output. This pin is the output of the

multiplexer. Tie to ADCIN for normal operation.

.

SET

to 1.125 • V

REF

REF

. For V

, the ADC outputs

SET

> 2.5V the input

REF

, the ADC outputs

SET

REF

) is

CSMUX (Pin 20): MUX Chip Select Input. A logic high on

this input allows the MUX to receive a channel address. A

logic low enables the selected MUX channel and connects

it to the MUXOUT pin for A/D conversion. For normal

operation, drive this pin in parallel with CSADC.

DIN (Pin 21): Digital Data Input. The multiplexer address

is shifted into this input on the last four rising CLK edges

before CSMUX goes low.

CSADC (Pin 23): ADC Chip Select Input. A low on this pin

enables the SDO digital output and following each conversion, the ADC automatically enters the Sleep mode and

remains in this low power state as long as CSADC is high.

A high on this pin also disables the SDO digital output. A

low-to-high transition on CSADC during the Data Output

state aborts the data transfer and starts a new conversion.

For normal operation, drive this pin in parallel with CSMUX.

SDO (Pin 24): Three-State Digital Output. During the data

output period this pin is used for serial data output. When

the chip select CSADC is high (CSADC = VCC), the SDO pin

is in a high impedance state. During the Conversion and

Sleep periods, this pin can be used as a conversion status

output. The conversion status can be observed by pulling

CSADC low.

CH0 (Pin 9): Analog Multiplexer Input.

CH1 (Pin 10): Analog Multiplexer Input.

CH2 (Pin 11): Analog Multiplexer Input.

CH3 (Pin 12): Analog Multiplexer Input.

CH4 (Pin 13): Analog Multiplexer Input. No connect on the

LTC2424.

CH5 (Pin 14): Analog Multiplexer Input. No connect on the

LTC2424.

CH6 (Pin 15): Analog Multiplexer Input. No connect on the

LTC2424.

CH7 (Pin 17): Analog Multiplexer Input. No connect on the

LTC2424.

CLK (Pin 19): Shift Clock for Data In. This clock synchro-

nizes the serial data transfer into the MUX. For normal

operation, drive this pin in parallel with SCK.

SCK (Pin 25): Shift Clock for Data Out. This clock synchronizes the serial data transfer of the ADC data output. Data

is shifted out of SDO on the falling edge of SCK. For normal

operation, drive this pin in parallel with CLK.

FO (Pin 26): Digital input which controls the ADC’s notch

frequencies and conversion time. When the FO pin is

connected to VCC (FO = VCC), the converter uses its internal

oscillator and the digital filter first null is located at 50Hz.

When the FO pin is connected to GND (FO = OV), the

converter uses its internal oscillator and the digital filter

first null is located at 60Hz. When FO is driven by an

external clock signal with a frequency f

uses this signal as its clock and the digital filter first null is

located at a frequency f

word rate is f

EOSC

/20480.

/2560. The resulting output

EOSC

, the converter

EOSC

6

Page 7

LTC2424/LTC2428

3.4k

SDO

24248 TC02

Hi-Z TO V

OL

VOH TO V

OL

VOL TO Hi-Z

C

LOAD

= 20pF

V

CC

UU

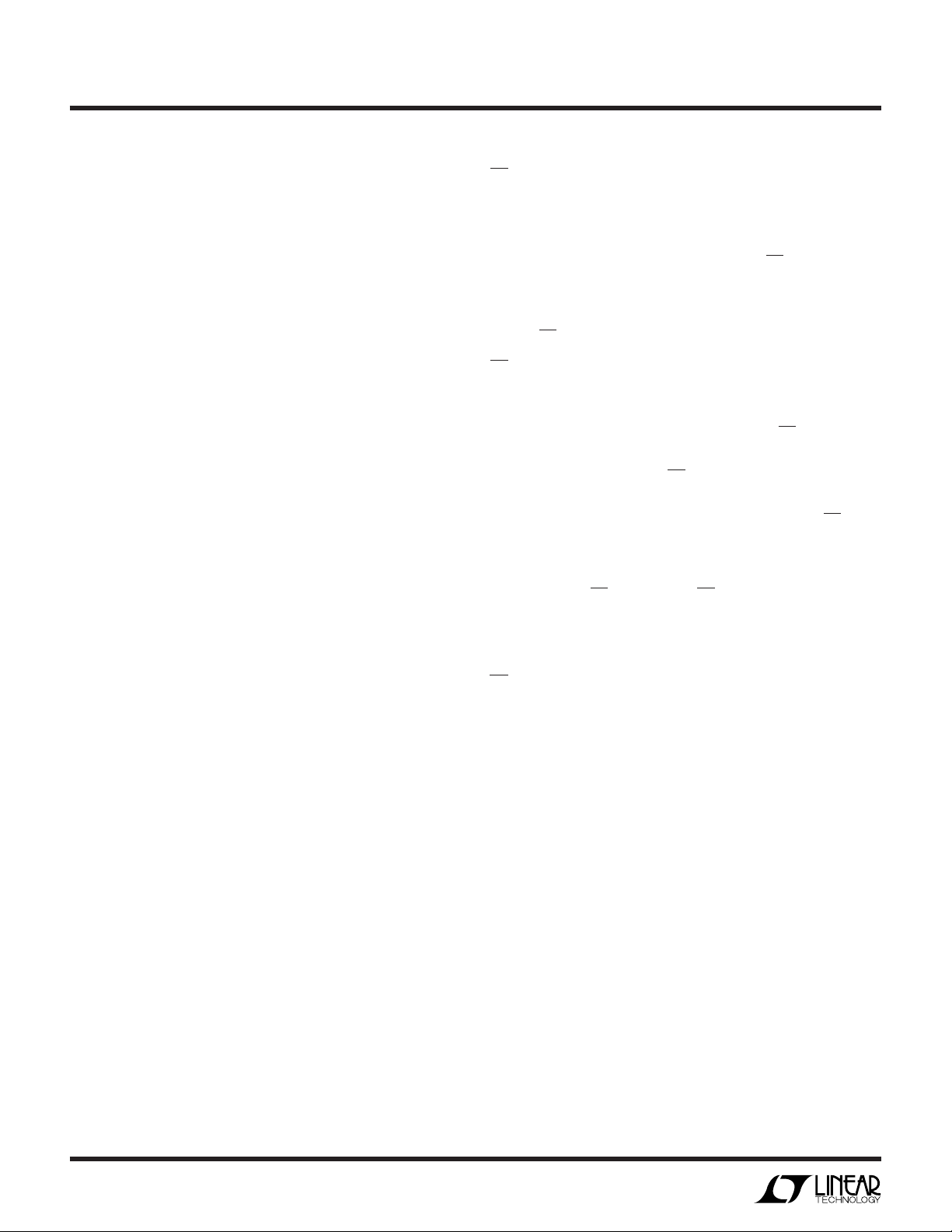

W

FU CTIO AL BLOCK DIAGRA

V

CC

GND

CH0

CH1

CH2

CH3

CH4

CH5

CH6

CH7

ZS

FS

SET

8-CHANNEL MUX

SET

DAC

∫∫∫

∑

ADC

AUTOCALIBRATION

AND CONTROL

DECIMATING FIR

INTERNAL

OSCILLATOR

SERIAL

INTERFACE

CHANNEL

SELECT

(INT/EXT)

24248 BD

F

O

SDO

SCK

CSADC

CSMUX

D

IN

CLK

TEST CIRCUITS

SDO

3.4k

Hi-Z TO V

VOL TO V

VOH TO Hi-Z

U

OH

OH

= 20pF

C

LOAD

24248 TC01

WUU

APPLICATIONS INFORMATION

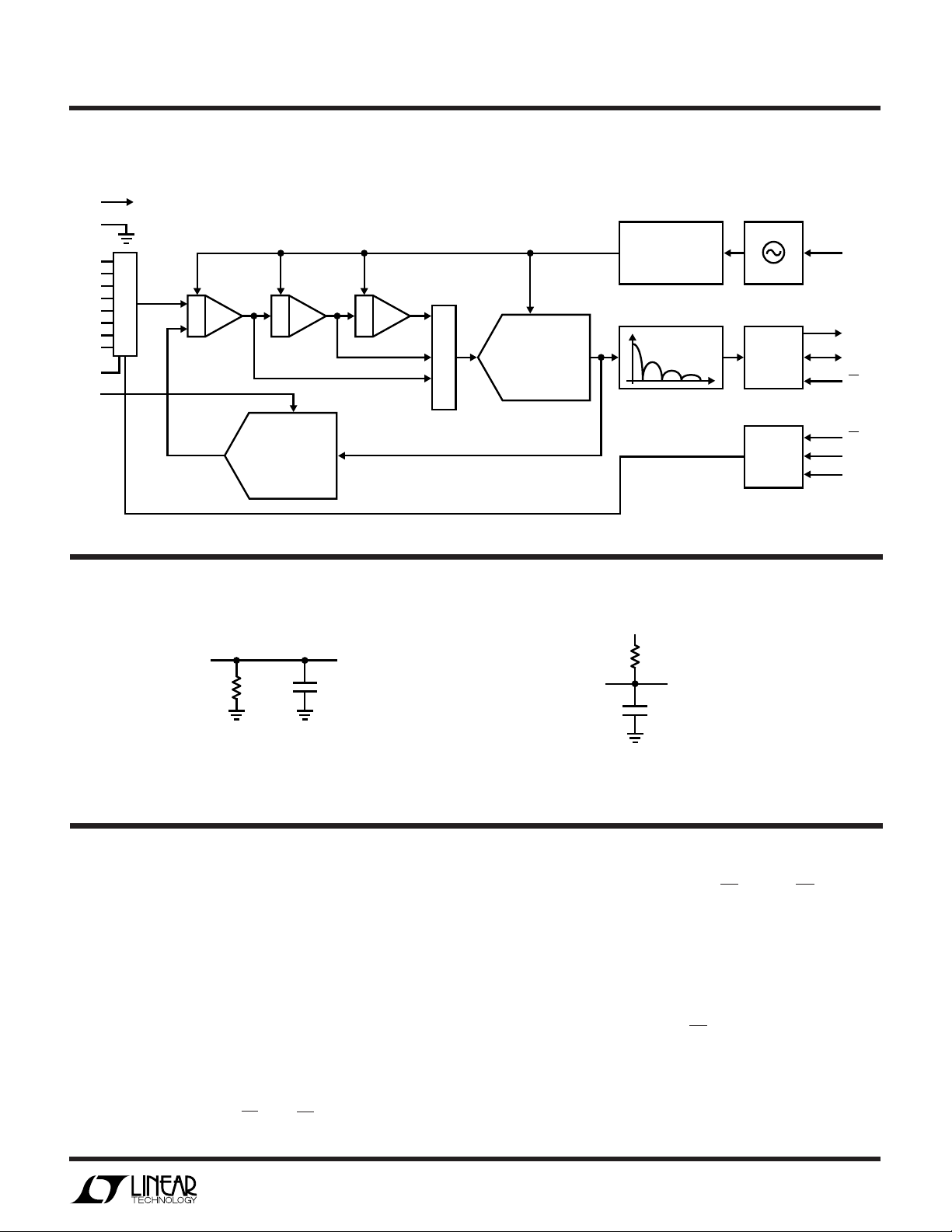

Converter Operation Cycle

The LTC2424/LTC2428 are low power, 4-/8-channel deltasigma analog-to-digital converters with easy-to-use

4-wire interfaces. Their operation is simple and made up

of four states. The converter operation begins with the

conversion, followed by a low power sleep state and

concluded with the data output (see Figure 1). Channel

selection may be performed while the device is in the sleep

state or at the conclusion of the data output state. The

interface consists of serial data output (SDO), serial clock

(CLK/SCK), chip select (CSADC/CSMUX) and data input

(DIN). By tying SCK to CLK and CSADC to CSMUX, the

interface requires only four wires.

Initially, the LTC2424 or LTC2428 performs a conversion.

Once the conversion is complete, the device enters the

sleep state. While in the sleep state, power consumption

is reduced by an order of magnitude. The part remains in

the sleep state as long as CSADC is logic HIGH. The

conversion result is held indefinitely in a static shift

register while the converter is in the sleep state.

Channel selection for the next conversion cycle is performed while the device is in the sleep state or at the end

7

Page 8

LTC2424/LTC2428

U

WUU

APPLICATIONS INFORMATION

CONVERT

CHANNEL SELECT

(SLEEP)

SLEEP

CSADC

1

AND

SCK

0

DATA OUTPUT

(CHANNEL SELECT)

Figure 1. LTC2428 State Transition Diagram

of the data output state. A specific channel is selected by

applying a 4-bit serial word to the DIN pin on the rising edge

of CLK while CSMUX is HIGH, see Figure 4 and Table 3. The

channel is selected based on the last four bits clocked into

the DIN pin before CSMUX goes low. If DIN is all 0’s, the

previous channel remains selected.

In the example, Figure 4, the MUX channel is selected

during the sleep state, just before the data output state

begins. Once the channel selection is complete, the device

remains in the sleep state as long as CSADC remains

HIGH.

Once CSADC is pulled low, the device begins outputting

the conversion result. There is no latency in the conversion

result. Since there is no latency, the first conversion

following a change in input channel is valid and corresponds to that channel. The data output corresponds to

the conversion just performed. This result is shifted out on

the serial data output pin (SDO) under the control of the

serial clock (SCK). Data is updated on the falling edge of

SCK allowing the user to reliably latch data on the rising

edge of SCK, see Figure 4. The data output state is

concluded once 24 bits are read out of the ADC or when

CSADC is brought HIGH. The device automatically initiates

a new conversion and the cycle repeats.

Through timing control of the CSADC and SCK pins, the

LTC2424/LTC2428 offer two modes of operation: internal

24248 F01

or external SCK. These modes do not require programming configuration registers; moreover, they do not disturb the cyclic operation described above. These modes of

operation are described in detail in the Serial Interface

Timing Modes section.

Conversion Clock

A major advantage delta-sigma converters offer over

conventional type converters is an on-chip digital filter

(commonly known as Sinc or Comb filter). For high

resolution, low frequency applications, this filter is typically designed to reject line frequencies of 50 or 60Hz plus

their harmonics. In order to reject these frequencies in

excess of 110dB, a highly accurate conversion clock is

required. The LTC2424/LTC2428 incorporate an on-chip

highly accurate oscillator. This eliminates the need for

external frequency setting components such as crystals or

oscillators. Clocked by the on-chip oscillator, the LTC2424/

LTC2428 reject line frequencies (50 or 60Hz ±2%) a

minimum of 110dB.

Ease of Use

The LTC2424/LTC2428 data output has no latency, filter

settling or redundant data associated with the conversion

cycle. There is a one-to-one correspondence between the

conversion and the output data. Therefore, multiplexing

an analog input voltage is easy.

The LTC2424/LTC2428 perform offset and full-scale calibrations every conversion cycle. This calibration is transparent to the user and has no effect on the cyclic operation

described above. The advantage of continuous calibration

is extreme stability of offset and full-scale readings with

respect to time, supply voltage change and temperature

drift.

Power-Up Sequence

The LTC2424/LTC2428 automatically enter an internal

reset state when the power supply voltage VCC drops

below approximately 2.2V. When the VCC voltage rises

above this critical threshold, the converter creates an

internal power-on-reset (POR) signal with duration of

approximately 0.5ms. The POR signal clears all internal

registers within the ADC and initiates a conversion. At

8

Page 9

LTC2424/LTC2428

U

WUU

APPLICATIONS INFORMATION

power-up, the multiplexer channel is disabled and should

be programmed once the device enters the sleep state.

The results of the first conversion following a POR are not

valid since a multiplexer channel was disabled.

Reference Voltage Range

The LTC2424/LTC2428 can accept a reference voltage

from 0V to VCC. The converter output noise is determined

by the thermal noise of the front-end circuits, and as such,

its value in microvolts is nearly constant with reference

voltage. A decrease in reference voltage will not significantly improve the converter’s effective resolution. On the

other hand, a reduced reference voltage will improve the

overall converter INL performance. The recommended

range for the LTC2424/LTC2428 voltage reference is

100mV to VCC.

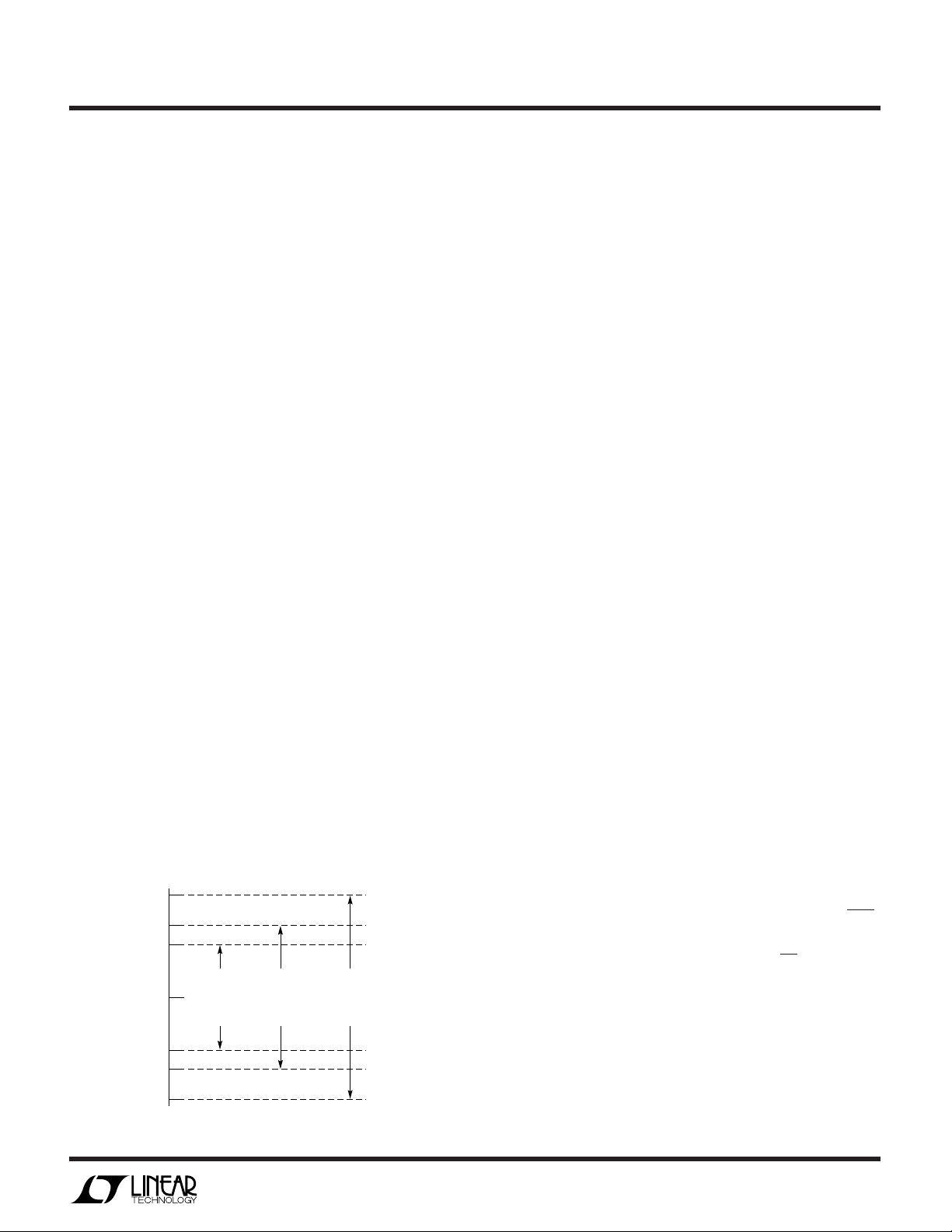

Input Voltage Range

The converter is able to accommodate system level offset

and gain errors as well as system level overrange

situations due to its extended input range, see Figure 2.

The LTC2424/LTC2428 converts input signals within the

extended input range of –0.125 • V

(V

= FS

REF

For large values of V

SET

– ZS

).

SET

this range is limited to a voltage

REF

range of – 0.3V to (VCC + 0.3V). Beyond this range the input

ESD protection devices begin to turn on and the errors due

to the input leakage current increase rapidly.

Input signals applied to VIN may extend below ground by

– 300mV and above VCC by 300mV. In order to limit any fault

current, a resistor of up to 5k may be added in series with

VCC + 0.3V

to 1.125 • V

REF

REF

any channel input pin (CH0 to CH7) without affecting the

performance of the device. In the physical layout, it is important to maintain the parasitic capacitance of the connection between this series resistance and the channel input

pin as low as possible; therefore, the resistor should be

located as close as practical to the channel input pin. The

effect of the series resistance on the converter accuracy can

be evaluated from the curves presented in the Analog Input/Reference Current section. In addition, a series resistor will introduce a temperature dependent offset error due

to the input leakage current. A 1nA input leakage current

will develop a 1ppm offset error on a 5k resistor if V

REF

=

5V. This error has a very strong temperature dependency.

Output Data Format

The LTC2424/LTC2428 serial output data stream is 24 bits

long. The first 4 bits represent status information indicating the sign, input range and conversion state. The next 20

bits are the conversion result, MSB first.

The LTC2424/LTC2428 can be interchanged with the

LTC2404/LTC2408. The two devices are designed to allow

the user to incorporate either device in the same design as

long as ZS

of the LTC2424/LTC2428 is tied to ground.

SET

While the LTC2424/LTC2428 output word lengths are 24

bits (as opposed to the 32-bit output of the LTC2404/

LTC2408), their output clock timing can be identical to the

LTC2404/LTC2408. As shown in Figure 3, the LTC2424/

LTC2408 data output is concluded on the falling edge of the

24th serial clock (SCK). In order to maintain drop-in compatibility with the LTC2404/LTC2408, it is possible to clock

the LTC2424/LTC2428 with an additional 8 serial clock

pulses. This results in 8 additional output bits which are

always logic HIGH.

9/8V

REF

V

REF

NORMAL

1/2V

REF

0

–1/8V

REF

–0.3V

Figure 2. LTC2424/LTC2428 Input Range

INPUT

RANGE

EXTENDED

INPUT

RANGE

ABSOLUTE

MAXIMUM

INPUT

RANGE

24248 F02

Bit 23 (first output bit) is the end of conversion (EOC)

indicator. This bit is available at the SDO pin during the

conversion and sleep states whenever the CS pin is LOW.

This bit is HIGH during the conversion and goes LOW

when the conversion is complete.

Bit 22 (second output bit) is a dummy bit (DMY) and is

always LOW.

Bit 21 (third output bit) is the conversion result sign indicator (SIG). If VIN is >0, this bit is HIGH. If VIN is <0, this

bit is LOW. The sign bit changes state during the zero code.

9

Page 10

LTC2424/LTC2428

U

WUU

APPLICATIONS INFORMATION

CSADC

8 8 8 8 (OPTIONAL)

SCK

SDO

EOC = 1

CONVERSION SLEEP

Figure 3. LTC2424/LTC2428 Compatible Timing with the LTC2404/LTC2408

Bit 20 (forth output bit) is the extended input range (EXR)

indicator. If the input is within the normal input range

0␣ ≤␣VIN ≤ V

normal input range, VIN > V

, this bit is LOW. If the input is outside the

REF

or VIN < 0, this bit is HIGH.

REF

The function of these bits is summarized in Table 1.

Table 1. LTC2424/LTC2428 Status Bits

Bit 23 Bit 22 Bit 21 Bit 20

Input Range EOC DMY SIG EXR

VIN > V

REF

0 < VIN ≤ V

VIN = 0+/0

VIN < 0 0 001

REF

–

0 011

0 010

0 0 1/0 0

Bit 19 (fifth output bit) is the most significant bit (MSB).

Bits 19-0 are the 20-bit conversion result MSB first.

Bit 0 is the least significant bit (LSB).

Data is shifted out of the SDO pin under control of the serial

clock (SCK), see Figure 4. Whenever CSADC is HIGH, SDO

remains high impedance and any SCK clock pulses are

ignored by the internal data out shift register.

In order to shift the conversion result out of the device,

CSADC must first be driven LOW. EOC is seen at the SDO

pin of the device once CSADC is pulled LOW. EOC changes

real time from HIGH to LOW at the completion of a

conversion. This signal may be used as an interrupt for an

external microcontroller. Bit 23 (EOC) can be captured on

the first rising edge of SCK. Bit 22 is shifted out of the

device on the first falling edge of SCK. The final data bit (Bit

0) is shifted out on the falling edge of the 23rd SCK and

may be latched on the rising edge of the 24th SCK pulse.

On the falling edge of the 24th SCK pulse, SDO goes HIGH

EOC = 0

4 STATUS BITS 20 DATA BITS

indicating a new conversion cycle has been initiated. This

bit serves as EOC (Bit 23) for the next conversion cycle.

Table 2 summarizes the output data format.

As long as the voltage on the VIN pin is maintained within

the –0.3V to (VCC + 0.3V) absolute maximum operating

range, a conversion result is generated for any input value

from –0.125 • V

greater than 1.125 • V

to the value corresponding to 1.125 • V

voltages below –0.125 • V

clamped to the value corresponding to –0.125 • V

Channel Selection

Typically, CSADC and CSMUX are tied together or CSADC

is inverted and drives CSMUX. SCK and CLK are tied

together and driven with a common clock signal. During

channel selection, CSMUX is HIGH. Data is shifted into the

DIN pin on the rising edge of CLK, see Figure 4. Table 3

shows the bit combinations for channel selection. In order

to enable the multiplexer output, CSMUX must be pulled

LOW. The multiplexer should be programmed after the

previous conversion is complete. In order to guarantee the

conversion is complete, the multiplexer addressing should

be delayed a minimum t

60Hz notch) after the data out is read.

While the multiplexer is being programmed, the ADC is in

a low power sleep state. Once the MUX addressing is

complete, the data from the preceding conversion can be

read. A new conversion cycle is initiated following the data

read cycle with the analog input tied to the newly selected

channel.

DATA OUT

CONVERSION

EOC = 1

LAST 8 BITS ALWAYS 1

to 1.125 • V

REF

, the conversion result is clamped

REF

CONV

DATA OUTPUT

REF.

, the conversion result is

REF

24248 F03

For input voltages

. For input

REF

.

REF

(approximately 133ms for a

10

Page 11

LTC2424/LTC2428

U

WUU

APPLICATIONS INFORMATION

t

CONV

CSMUX/CSADC

SDO

SCK/CLK

D

IN

Hi-Z

D2EN D1 D0

EOC “0”

BIT 22BIT 23 BIT 0

MSB LSB

EXTSIG

DON’T CARE

Figure 4. Typical Data Input/Output Timing

Table 2. LTC2424/LTC2428 Output Data Format

Bit 23 Bit 22 Bit 21 Bit 20 Bit 19 Bit 18 Bit 17 Bit 16 Bit 15 … Bit 0

Input Voltage EOC DMY SIG EXR MSB LSB

VIN > 9/8 • V

9/8 • V

V

REF

V

REF

3/4V

3/4V

1/2V

1/2V

1/4V

1/4V

0+/0

–1LSB 0 0 0111 1 11...1

–1/8 • V

VIN < –1/8 • V

*The sign bit changes state during the 0 code.

REF

REF

+ 1LSB 0 0 1100 0 00...0

+ 1LSB 0 01011 0 00...0

REF

REF

+ 1LSB 0 01010 0 00...0

REF

REF

+ 1LSB 0 01001 0 00...0

REF

REF

–

REF

REF

0 01100 0 11...1

0 01100 0 11...1

0 01011 1 11...1

0 01010 1 11...1

0 01001 1 11...1

0 01000 1 11...1

0 0 1/0* 0 0 0 0 0 0 ... 0

0 00111 1 00...0

0 00111 1 00...0

Hi-Z

24248 F04

Table 3. Logic Table for Channel Selection

CHANNEL STATUS EN D2 D1 D0

All Off 0 X X X

CH0 1 0 0 0

CH1 1 0 0 1

CH2 1 0 1 0

CH3 1 0 1 1

CH4* 1 1 0 0

CH5* 1 1 0 1

CH6* 1 1 1 0

CH7* 1 1 1 1

*Not used for the LTC2424.

Frequency Rejection Selection (FO Pin Connection)

The LTC2424/LTC2428 internal oscillator provides better

than 110dB normal mode rejection at the line frequency

and all its harmonics for 50Hz ±2% or 60Hz ±2%. For

60Hz rejection, FO (Pin 26) should be connected to GND

(Pin 1) while for 50Hz rejection the FO pin should be

connected to V

(Pin␣ 2).

CC

The selection of 50Hz or 60Hz rejection can also be made

by driving FO to an appropriate logic level. A selection

change during the sleep or data output states will not

disturb the converter operation. If the selection is made

11

Page 12

LTC2424/LTC2428

U

WUU

APPLICATIONS INFORMATION

during the conversion state, the result of the conversion in

progress may be outside specifications but the following

conversions will not be affected.

When a fundamental rejection frequency different from

50Hz or 60Hz is required or when the converter must be

synchronized with an outside source, the LTC2424/

LTC2428 can operate with an external conversion clock.

The converter automatically detects the presence of an

external clock signal at the FO pin and turns off the internal

oscillator. The frequency f

be at least 2560Hz (1Hz notch frequency) to be detected.

The external clock signal duty cycle is not significant as

long as the minimum and maximum specifications for the

high and low periods t

HEO

While operating with an external conversion clock of a

frequency f

, the LTC2424/LTC2428 provide better

EOSC

than 110dB normal mode rejection in a frequency range

f

/2560 ±4% and its harmonics. The normal mode

EOSC

rejection as a function of the input frequency deviation

from f

/2560 is shown in Figure 5.

EOSC

Whenever an external clock is not present at the FO pin the

converter automatically activates its internal oscillator

and enters the Internal Conversion Clock mode. The

LTC2424/LTC2428 operation will not be disturbed if the

change of conversion clock source occurs during the

sleep state or during the data output state while the

of the external signal must

EOSC

and t

are observed.

LEO

converter uses an external serial clock. If the change

occurs during the conversion state, the result of the

conversion in progress may be outside specifications but

the following conversions will not be affected. If the

change occurs during the data output state and the

converter is in the Internal SCK mode, the serial clock duty

cycle may be affected but the serial data stream will

remain valid.

Table 4 summarizes the duration of each state as a

function of FO.

–60

–70

–80

–90

–100

–110

REJECTION (dB)

–120

–130

–140

–12–8–404812

INPUT FREQUENCY DEVIATION FROM NOTCH FREQUENCY (%)

24248 F05

Figure 5. LTC2424/LTC2428 Normal Mode Rejection When

Using an External Oscillator of Frequency f

EOSC

Table 4. LTC2424/LTC2428 State Duration

State Operating Mode Duration

CONVERT Internal Oscillator FO = LOW (60Hz Rejection) 133ms

FO = HIGH (50Hz Rejection) 160ms

External Oscillator FO = External Oscillator 20480/f

with Frequency f

(f

/2560 Rejection)

EOSC

SLEEP As Long As CSADC = HIGH Until CSADC = 0 and SCK

DATA OUTPUT Internal Serial Clock FO = LOW/HIGH As Long As CSADC = LOW But Not Longer Than 1.67ms

(Internal Oscillator) (32 SCK cycles)

FO = External Oscillator with As Long As CSADC = LOW But Not Longer Than 256/f

MAXIMUM OUTPUT

WORD RATE (OWR)

Frequency f

External Serial Clock with As Long As CSADC = LOW But Not Longer Than 32/f

Frequency f

kHz (32 SCK cycles)

SCK

EOSC

kHz

EOSC

kHz (32 SCK cycles)

OWR

(In Seconds)

EOSC

=

tt

CONVERT DATAOUTPUT

1

+

inHz

EOSC

SCK

ms

12

ms

Page 13

LTC2424/LTC2428

U

WUU

APPLICATIONS INFORMATION

Operation at Higher Data Output Rates

The LTC2424/LTC2428 typically operate with an internal

oscillator of 153.6kHz. This corresponds to a notch frequency of 60Hz and an output rate of 7.5 samples/second.

The internal oscillator is enabled if the FO pin is logic LOW

(logic HIGH for a 50Hz notch). It is possible to drive the F

pin with an external oscillator for higher data output rates.

As shown in Figure 6, an external clock of 2.048MHz

applied to the FO pin results in a notch frequency of 800Hz

with a data output rate of 100 samples/second.

Figure 7 shows the total unadjusted error (Offset Error +

Full-Scale Error + INL + DNL) as a function of the output

LTC2424

1

GND

2

V

CC

3

FS

SET

4

ADCIN

5

ZS

SET

6

GND

7

MUXOUT

8

V

CC

9

CH0

10

CH1

11

CH2

12

CH3

13

NC

14

NC

Figure 6. Selectable 100 Sample/Second Turbo Mode

28

GND

27

GND

26

F

O

25

SCK

24

SDO

23

CSADC

22

GND

21

D

IN

20

CSMUX

19

CLK

18

GND

17

NC

16

GND

15

NC

256

V

REF

224

192

160

128

96

64

TOTAL UNADJUSTED ERROR (ppm)

32

0

0

Figure 7. Total Error vs Output Rate (V

R9 1k

SWITCH

HCO4

6

12

10

89

= 5V

50 100

OUTPUT RATE (SAMPLES/SEC)

10 TVEN POT

C9

0.1µF

5

13

11

10k

C8 5pF

5V

HCO4

3421

7

12 BITS

13 BITS

14 BITS

16 BITS

24248 F07

REF

R6 47k

24248 F06

150

= 5V)

R8 1k

R7 5k

C6

270pF

C7

10pF

O

+

data rate with a 5V reference. The relationship between the

output data rate (ODR) and the frequency applied to the F

O

pin (FO) is:

ODR = FO/20480

For output data rates up to 50 samples/second, the total

unadjusted error (TUE) is better than 16 bits, and better

than 12 bits at 100 samples/second. As shown in Figure 8,

for output data rates of 100 samples/second, the TUE is

better than 15 bits for V

below 2.5V. Figure 9 shows an

REF

unaveraged total unadjusted error for the LTC2424 or

LTC2428 operating at 100 samples/second with V

REF

=

2.5V. Figure 10 shows the same device operating with a 5V

reference and an output data rate of 7.5 samples/second.

256

OUTPUT RATE = 100sps

224

192

160

128

96

64

TOTAL UNADJUSTED ERROR (ppm)

32

0

1.5

1.0

2.0

REFERENCE VOLTAGE (V)

Figure 8. Total Error vs V

10

5

0

–5

–10

–15

–20

–25

–30

TOTAL UNADJUSTED ERROR (ppm)

–35

–40

0

3.0

2.5

REF

INPUT VOLTAGE (V)

Figure 9. Total Unadjusted Error at

100 Samples/Second (No Averaging)

12 BITS

13 BITS

14 BITS

15 BITS

3.5

4.0

4.5

24248 F08

5.0

(Output Rate = 100sps)

VCC = 5V

= 2.5V

V

REF

2.5

24248 F09

13

Page 14

LTC2424/LTC2428

U

WUU

APPLICATIONS INFORMATION

6

4

2

0

–2

–4

–6

TOTAL UNADJUSTED ERROR (ppm)

–8

–10

0

INPUT VOLTAGE (V)

Figure 10. Total Unadjusted Error at

7.5 Samples/Second (No Averaging)

At 100 samples/second, the LTC2424/LTC2428 can be

used to capture transient data. This is useful for monitoring settling or auto gain ranging in a system. The LTC2424/

LTC2428 can monitor signals at an output rate of 100

samples/second. After acquiring 100 samples/second data,

the FO pin may be driven LOW enabling 60Hz rejection to

110dB and the highest possible DC accuracy. The no

latency architecture of the LTC2424/LTC2428 allows consecutive readings (one at 100 samples/second the next at

7.5 samples/second) without interaction between the two

readings.

As shown in Figure 11, the LTC2424/LTC2428 can capture transient data with 90dB of dynamic range (with a

VCC = 5V

= 5V

V

REF

24248 F10

5

300mV

performance of

input signal at 2Hz). The exceptional DC

P-P

the LTC2424/LTC2428 enables signals to

be digitized independent of a large DC offset. Figures 12a

and 12b show the dynamic performance with a 15Hz

signal superimposed on a 2V DC level. The same signal

with no DC level is shown in Figures 12c and 12d.

SERIAL INTERFACE

The LTC2424/LTC2428 transmit the conversion results,

program the channel selection, and receive the start of

conversion command through a synchronous 4-wire interface (SCK = CLK, CSADC = CSMUX). During the conversion and sleep states, this interface can be used to assess

the converter status. While in the sleep state this interface

may be used to program an input channel. During the data

output state, it is used to read the conversion result.

ADC Serial Clock Input/Output (SCK)

The serial clock signal present on SCK (Pin 25) is used to

synchronize the data transfer. Each bit of data is shifted out

of the SDO pin on the falling edge of the serial clock.

In the Internal SCK mode of operation, the SCK pin is an

output and the LTC2424/LTC2428 creates its own serial

clock by dividing the internal conversion clock by 8. In the

External SCK mode of operation, the SCK pin is used as

input. The internal or external SCK mode is selected on

power-up and then reselected every time a HIGH-to-LOW

transition is detected at the CSADC pin. If SCK is HIGH or

14

0.20

0.15

0.10

0.05

–0.05

–0.10

–0.15

ADC OUTPUT (NORMALIZED TO VOLTS)

–0.20

500ms

0

0.5 1 1.5 2 2.5

TIME (SEC)

f

= 2Hz

IN

24248 F11a

Figure 11. Transient Signal Acquisition

0

–20

–40

–60

MAGNITUDE (dB)

–80

–100

–120

Figure 11b. Output FFTFigure 11a. Digitized Waveform

25 500

FREQUENCY (Hz)

2Hz

100sps

0V OFFSET

24248 F11b

Page 15

LTC2424/LTC2428

U

WUU

APPLICATIONS INFORMATION

2.20

= 300mV

V

IN

2.15

2.10

2.05

2.00

1.95

1.90

1.85

ADC OUTPUT (NORMALIZED TO VOLTS)

1.80

0.20

= 300mV

V

IN

0.15

0.10

0.05

0.00

–0.05

–0.10

–0.15

ADC OUTPUT (NORMALIZED TO VOLTS)

–0.20

+ 2V DC

P-P

TIME (SEC)

+ 0V DC

P-P

TIME (SEC)

1.5 2 2.50.5 1

24248 F12a

1.5 2 2.510.5

24248 F12c

0

–20

–40

–60

MAGNITUDE (dB)

–80

–100

–120

Figure 12b. FFT Waveform with 2V DC OffsetFigure 12a. Digitized Waveform with 2V DC Offset

0

–20

–40

–60

MAGNITUDE (dB)

–80

–100

–120

Figure 12d. FFT Waveform with No OffsetFigure 12c. Digitized Waveform with No Offset

25 500

FREQUENCY (Hz)

25 500

FREQUENCY (Hz)

15Hz

100sps

2V OFFSET

24248 F12b

15Hz

100sps

0V OFFSET

24248 F12d

Figure 12. Using the LTC2424/LTC2428’s High Accuracy Wide Dynamic Range

to Digitize a 300mV

15Hz Waveform with a Large DC Offset (VCC = 5V, V

P-P

floating at power-up or during this transition, the converter

enters the internal SCK mode. If SCK is LOW at power-up

or during this transition, the converter enters the external

SCK mode.

Multiplexer Serial Input Clock (CLK)

Generally, this pin is externally tied to SCK for 4-wire operation. On the rising edge of CLK (Pin 19) with CSMUX held

HIGH, data is serially shifted into the multiplexer. If CSMUX

is LOW the CLK input will be disabled and the channel

selection unchanged.

Serial Data Output (SDO)

The serial data output pin, SDO (Pin 24), drives the serial

data during the data output state. In addition, the SDO pin

= 5V)

REF

is used as an end of conversion indicator during the

conversion and sleep states.

When CSADC (Pin 23) is HIGH, the SDO driver is switched

to a high impedance state. This allows sharing the serial

interface with other devices. If CSADC is LOW during the

convert or sleep state, SDO will output EOC. If CSADC is

LOW during the conversion phase, the EOC bit appears

HIGH on the SDO pin. Once the conversion is complete,

EOC goes LOW. The device remains in the sleep state until

the first rising edge of SCK occurs while CSADC = 0.

ADC Chip Select Input (CSADC)

The active LOW chip select, CSADC (Pin 23), is used to test

the conversion status and to enable the data output

transfer as described in the previous sections.

15

Page 16

LTC2424/LTC2428

U

WUU

APPLICATIONS INFORMATION

In addition, the CSADC signal can be used to trigger a new

conversion cycle before the entire serial data transfer has

been completed. The LTC2424/LTC2428 will abort any

serial data transfer in progress and start a new conversion

cycle anytime a LOW-to-HIGH transition is detected at the

CSADC pin after the converter has entered the data output

state (i.e., after the first rising edge of SCK occurs with

CSADC = 0).

Multiplexer Chip Select (CSMUX)

For 4-wire operation, this pin is tied directly to CSADC or

the output of an inverter tied to CSADC. CSMUX (Pin 20)

is driven HIGH during selection of a multiplexer channel.

On the falling edge of CSMUX, the selected channel is

enabled and drives MUXOUT.

Data Input (DIN)

The data input to the multiplexer, DIN (Pin 21), is used to

program the multiplexer. The input channel is selected by

serially shifting a 4-bit input word into the DIN pin under

the control of the multiplexer clock, CLK. Data is shifted

into the multiplexer on the rising edge of CLK. Table 3

shows the logic table for channel selection. In order to

select or change a previously programmed channel, an

enable bit (DIN = 1) must proceed the 3-bit channel select

serial data. The user may set DIN = 0 to continually convert

on the previously selected channel.

SERIAL INTERFACE TIMING MODES

The LTC2424/LTC2428’s 4-wire interface is SPI and

MICROWIRE compatible. This interface offers two modes

of operation. These include an internal or external serial

clock. The following sections describe both of these serial

interface timing modes in detail. For both cases the

converter can use the internal oscillator (FO = LOW or F

= HIGH) or an external oscillator connected to the FO pin.

Refer to Table 5 for a summary.

O

External Serial Clock (SPI/MICROWIRE Compatible)

This timing mode uses an external serial clock (SCK) to

shift out the conversion result, see Figure 13. This same

external clock signal drives the CLK pin in order to program the multiplexer. A single CS signal drives both the

multiplexer CSMUX and converter CSADC inputs. This

common signal is used to monitor and control the state of

the conversion as well as enable the channel selection.

The serial clock mode is selected on the falling edge of

CSADC. To select the external serial clock mode, the serial

clock pin (SCK) must be LOW during each CSADC falling

edge.

The serial data output pin (SDO) is HI-Z as long as CSADC

is HIGH. At any time during the conversion cycle, CSADC

may be pulled LOW in order to monitor the state of the

converter. While CSADC is LOW, EOC is output to the SDO

pin. EOC = 1 while a conversion is in progress and EOC =

0 if the device is in the sleep state. Independent of CSADC,

the device automatically enters the low power sleep state

once the conversion is complete.

While the device is in the sleep state, prior to entering the

data output state, the user may program the multiplexer.

As shown in Figure 13, the multiplexer channel is selected

by serial shifting a 4-bit word into the DIN pin on the rising

edge of CLK (CLK is tied to SCK). The first bit is an enable

bit that must be HIGH in order to program a channel. The

next three bits determine which channel is selected, see

Table 3. On the falling edge of CSMUX, the new channel is

selected and will be valid for the first conversion performed

following the data output state. Clock signals applied to the

CLK pin while CSMUX is LOW (during the data output

state) will have no effect on the channel selection. Furthermore, if DIN is held LOW or CLK is held LOW during the

sleep state, the channel selection is unchanged.

When the device is in the sleep state (EOC = 0), its

conversion result is held in an internal static shift regis

ter.

Table 5. LTC2424/LTC2428 Interface Timing Modes

Conversion Data Connection

Configuration Source Control Control Waveforms

External SCK External CSADC and SCK CSADC and SCK Figures 7, 8, 9

Internal SCK Internal CSADC ↓ CSADC ↓ Figures 10, 11

SCK Cycle Output and

16

Page 17

LTC2424/LTC2428

U

WUU

APPLICATIONS INFORMATION

–0.12V

TO 1.12V

CSADC/

CSMUX

SCK/CLK

SDO

D

TEST EOC

DON’T CARE DON’T CAREEN D2 D1 D0

IN

TEST EOC

Hi-ZHi-Z

Figure 13. External Serial Clock Timing Diagram

2.7V TO 5.5V

0.1V

TO V

CC

REF

REF

V

CC

LTC2424/LTC2428

FS

CH0

TO CH7

MUXOUT

ADCIN

ZS

GND

CSMUX

SET

CSADC

SET

EXRSIG

SCK

CLK

D

SDO

F

IN

MSB

V

CC

= 50Hz REJECTION

O

= EXTERNAL OSCILLATOR

= 60Hz REJECTION

CS

SCK

BIT4BIT19 BIT18BIT20BIT21BIT22BIT23

BIT0

LSB

Hi-Z

TEST EOC

24248 F13

The device remains in the sleep state until the first rising

edge of SCK is seen while CSADC is LOW. Data is

shifted

out the SDO pin on each falling edge of SCK. This enables

external circuitry to latch the output on the rising edge of

SCK. EOC can be latched on the first rising edge of SCK

and the last bit of the conversion result can be latched on

the 24th rising edge of SCK. On the 24th falling edge of

SCK, the device begins a new conversion. SDO goes HIGH

(EOC = 1) indicating a conversion is in progress.

At the conclusion of the data cycle, CSADC may remain

LOW and EOC monitored as an end-of-conversion interrupt. Alternatively, CSADC may be driven HIGH setting

SDO to HI-Z. As described above, CSADC may be pulled

LOW at any time in order to monitor the conversion status.

For each of these operations, CSMUX may be tied to

CSADC without affecting the selected channel.

At the conclusion of the data output cycle, the converter

enters a user transparent calibration cycle prior to actually

performing a conversion on the selected input channel.

This enables a 66ms (for 60Hz notch frequency) look ahead

time for the multiplexer input. Following the data output

cycle, the multiplexer input channel may be selected any

time in this 66ms window by pulling CSADC HIGH and

serial shifting data into the DIN pin, see Figure 14.

While the device is performing the internal calibration, it is

sensitive to ground current disturbances. Error currents

flowing in the ground pin may lead to offset errors. If the

SCK pin is toggling during the calibration, these ground

disturbances will occur. The solution is to either drive the

multiplexer clock input (CLK) separately from the ADC

clock input (SCK), or program the multiplexer in the first

1ms following the data output cycle. The remaining 65ms

may be used to allow the input signal to settle.

Typically, CSADC remains LOW during the data output

state. However, the data output state may be aborted by

pulling CSADC HIGH anytime between the first rising edge

and the 24th falling edge of SCK, see Figure 15. On the

rising edge of CSADC, the device aborts the data output

state and immediately initiates a new conversion. This is

useful for systems not requiring all 24 bits of output data,

aborting an invalid conversion cycle or synchronizing the

start of a conversion.

Internal Serial Clock

This timing mode uses an internal serial clock to shift out

the conversion result and program the multiplexer, see

Figure 16. A CS signal directly drives the CSADC input,

while the inverse of CS drives the CSMUX input. The CS

17

Page 18

LTC2424/LTC2428

U

WUU

APPLICATIONS INFORMATION

CSADC/

CSMUX

SCK/CLK

SDO

CONVERTER

STATE

TEST EOC

D

IN

CONV SLEEP DATA OUTPUT INTERNAL CALIBRATION

TEST EOC

Hi-Z

EXRSIG

DON’T CARE DON’T CAREEN D2 D1 D0

Figure 14. Use of Look Ahead to Program Multiplexer After Data Output

–0.12V

TO 1.12V

MSB

2.7V TO 5.5V

0.1V

TO V

CC

REF

REF

BIT4BIT19BIT18BIT20BIT21BIT22BIT23

V

CC

LTC2424/LTC2428

FS

CH0

TO CH7

MUXOUT

ADCIN

ZS

GND

SET

SET

CSMUX

CSADC

SCK

CLK

D

SDO

BIT0

LSB

CONVERSION ON SELECTED CHANNEL

66ms LOOK AHEAD

133ms CONVERSION CYCLE (OUTPUT RATE = 7.5Hz)

V

CC

= 50Hz REJECTION

F

O

IN

= EXTERNAL OSCILLATOR

= 60Hz REJECTION

CS

SCK

66ms CONVERT

24248 F14

CSADC/

CSMUX

SCK/CLK

SDO

D

IN

TEST EOC

DON’T CARE DON’T CAREEN D2 D1 D0

TEST EOC

Hi-ZHi-Z

Figure 15. External Serial Clock with Reduced Data Output Length Timing Diagram

signal is used to monitor and control the state of the

conversion cycles as well as enable the channel selection.

The multiplexer is programmed during the data output

state. The internal serial clock (SCK) generated by the ADC

is applied to the multiplexer clock input (CLK).

In order to select the internal serial clock timing mode, the

serial clock pin (SCK) must be floating (HI-Z) or pulled

HIGH prior to the falling edge of CSADC. The device will not

enter the internal serial clock mode if SCK is driven LOW

on the falling edge of CSADC. An internal weak pull-up

BIT8BIT9BIT19 BIT18BIT20BIT21BIT22BIT23

MSB

EXRSIG

24248 F15

resistor is active on the SCK pin during the falling edge of

CSADC; therefore, the internal serial clock timing mode is

automatically selected if SCK is not externally driven.

The serial data output pin (SDO) is HI-Z as long as CSADC

is HIGH. At any time during the conversion cycle, CSADC

may be pulled LOW in order to monitor the state of the

converter. Once CSADC is pulled LOW, SCK goes LOW

and EOC is output to the SDO pin. EOC = 1 while a

conversion is in progress and EOC = 0 if the device is in the

sleep state.

18

Page 19

LTC2424/LTC2428

U

WUU

APPLICATIONS INFORMATION

TO V

–0.12V

TO 1.12V

CSMUX

t

EOCtest

CSADC

SCKCLK

TEST EOC

SDO

Hi-Z Hi-ZHi-Z

2.7V TO 5.5V

0.1V

CC

REF

REF

MSB

EXRSIG

V

CC

LTC2424/LTC2428

FS

CH0

TO CH7

MUXOUT

ADCIN

ZS

GND

SET

CSMUX

CSADC

SET

SCK

CLK

D

SDO

V

CC

= 50Hz REJECTION

F

O

IN

= EXTERNAL OSCILLATOR

= 60Hz REJECTION

CS

10k

BIT0BIT4 BIT3 BIT2 BIT1BIT19 BIT18BIT20BIT21BIT22BIT23

LSB

TEST EOCTEST EOC

D

IN

DON’T CARE DON’T CAREEN D2 D1 D0

Figure 16. Internal Serial Clock Timing Diagram

When testing EOC, if the conversion is complete (EOC = 0),

the device will exit the sleep state and enter the data output

state if CSADC remains LOW. In order to prevent the

device from exiting the low power sleep state, CSADC

must be pulled HIGH before the first rising edge of SCK. In

the internal SCK timing mode, SCK goes HIGH and the

device begins outputting data at time t

falling edge of CSADC (if EOC = 0) or t

EOCtest

EOCtest

after the

after EOC

goes LOW (if CSADC is LOW during the falling edge of

EOC). The value of t

is 23µs if the device is using its

EOCtest

internal oscillator (F0 = logic LOW or HIGH). If FO is driven

by an external oscillator of frequency f

3.6/f

. If CSADC is pulled HIGH before time t

EOSC

EOSC

, then t

EOCtest

EOCtest

, the

is

device remains in the sleep state. The conversion result is

held in the internal static shift register.

If CSADC remains LOW longer than t

, the first rising

EOCtest

edge of SCK will occur and the conversion result is serially

shifted out of the SDO pin. The data output cycle begins on

this first rising edge of SCK and concludes after the 24th

rising edge. Data is shifted out the SDO pin on each falling

24248 F16

edge of SCK. The internally generated serial clock is output

to the SCK pin. This signal may be used to shift the

conversion result into external circuitry. EOC can be

latched on the first rising edge of SCK and the last bit of the

conversion result on the 24th rising edge of SCK. After the

24th rising edge, SDO goes HIGH (EOC = 1), SCK stays

HIGH, and a new conversion starts.

While operating in the internal serial clock mode, the SCK

output of the ADC may be used as the multiplexer clock

(CLK). DIN is latched into the multiplexer on the rising

edge of CLK. As shown in Figure 16, the multiplexer

channel is selected by serial shifting a 4-bit word into the

DIN pin on the rising edge of CLK. The first bit is an enable

bit which must be HIGH in order to program a channel. The

next three bits determine which channel is selected, see

Table 3. On the rising edge of CSADC (falling edge of

CSMUX), the new channel is selected and will be valid for

the next conversion. If DIN is held LOW during the data

output state, the previous channel selection remains valid.

19

Page 20

LTC2424/LTC2428

U

WUU

APPLICATIONS INFORMATION

Typically, CSADC remains LOW during the data output

state. However, the data output state may be aborted by

pulling CSADC HIGH anytime between the first and 24th

rising edge of SCK, see Figure 17. On the rising edge of

CSADC, the device aborts the data output state and

immediately initiates a new conversion. This is useful for

systems not requiring all 24 bits of output data, aborting

an invalid conversion cycle, or synchronizing the start of

a conversion. If CSADC is pulled HIGH while the converter is driving SCK LOW, the internal pull-up is not

available to restore SCK to a logic HIGH state. This will

cause the device to exit the internal serial clock mode on

the next falling edge of CSADC. This can be avoided by

adding an external 10k pull-up resistor to the SCK pin or

by never pulling CSADC HIGH when SCK is LOW.

Whenever SCK is LOW, the LTC2424/LTC2428’s internal

pull-up at pin SCK is disabled. Normally, SCK is not

externally driven if the device is in the internal SCK timing

mode. However, certain applications may require an external driver on SCK. If this driver goes HI-Z after outputting

a LOW signal, the LTC2424/LTC2428’s internal pull-up

remains disabled. Hence, SCK remains LOW. On the next

falling edge of CSADC, the device is switched to the

external SCK timing mode. By adding an external 10k pullup resistor to SCK, this pin goes HIGH once the external

driver goes HI-Z. On the next CSADC falling edge, the

device will remain in the internal SCK timing mode.

A similar situation may occur during the sleep state when

CSADC is pulsed HIGH-LOW-HIGH in order to test the

conversion status. If the device is in the sleep state

(EOC = 0), SCK will go LOW. Once CSADC goes HIGH

(within the time period defined above as t

EOCtest

), the

internal pull-up is activated. For a heavy capacitive load

on the SCK pin, the internal pull-up may not be adequate

to return SCK to a HIGH level before CSADC goes LOW

again. This is not a concern under normal conditions

CSMUX

CSADC

SCKCLK

SDO

TEST EOC

t

EOCtest

2.7V TO 5.5V

V

CC

0.1V

TO V

CC

–0.12V

REF

TO 1.12V

REF

TEST EOC TEST EOC

Hi-Z Hi-ZHi-Z

EXRSIG

LTC2424/LTC2428

FS

SET

CH0

TO CH7

MUXOUT

ADCIN

ZS

SET

GND

MSB

CSMUX

CSADC

SCK

CLK

D

SDO

F

O

IN

V

CC

= 50Hz REJECTION

= EXTERNAL OSCILLATOR

= 60Hz REJECTION

CS

10k

BIT8BIT12 BIT11 BIT10 BIT9BIT19BIT18BIT20BIT21BIT22BIT23

D

IN

20

DON’T CARE DON’T CAREEN D2 D1 D0

24248 F17

Figure 17. Internal Serial Clock with Reduced Data Output Length Timing Diagram

Page 21

LTC2424/LTC2428

U

WUU

APPLICATIONS INFORMATION

where CSADC remains LOW after detecting EOC = 0. This

situation is easily avoided by adding an external 10k pullup resistor to the SCK pin.

DIGITAL SIGNAL LEVELS

The LTC2424/LTC2428’s digital interface is easy to use.

Its digital inputs (FO, CSADC, CSMUX, CLK, DIN and SCK

in External SCK mode of operation) accept standard TTL/

CMOS logic levels and can tolerate edge rates as slow as

100µs. However, some considerations are required to take

advantage of exceptional accuracy and low supply current.

The digital output signals (SDO and SCK in Internal SCK

mode of operation) are less of a concern because they are

not generally active during the conversion state.

In order to preserve the accuracy of the LTC2424/LTC2428,

it is very important to minimize the ground path impedance which may appear in series with the input and/or

reference signal and to reduce the current which may flow

through this path. The ZS

nected directly to the signal ground.

The power supply current during the conversion state

should be kept to a minimum. This is achieved by restricting the number of digital signal transitions occurring

during this period.

While a digital input signal is in the 0.5V to (VCC␣ –␣ 0.5V)

range, the CMOS input receiver draws additional current

from the power supply. It should be noted that, when any

one of the digital input signals (FO, CSADC, CSMUX, DIN,

CLK and SCK in External SCK mode of operation) is within

this range, the LTC2424/LTC2428 power supply current

may increase even if the signal in question is at a valid logic

level. For micropower operation and in order to minimize

the potential errors due to additional ground pin current,

it is recommended to drive all digital input signals to full

CMOS levels [VIL < 0.4V and VOH > (VCC – 0.4V)].

pin (Pin 6) should be con-

SET

For reference, on a regular FR-4 board, signal propagation velocity is approximately 183ps/inch for internal

traces and 170ps/inch for surface traces. Thus, a driver

generating a control signal with a minimum transition

time of 1ns must be connected to the converter pin

through a trace shorter than 2.5 inches. This problem

becomes particularly difficult when shared control lines

are used and multiple reflections may occur. The solution

is to carefully terminate all transmission lines close to

their characteristic impedance.

Parallel termination near the LTC2424/LTC2428 input

pins will eliminate this problem but will increase the driver

power dissipation. A series resistor between 27Ω and 56Ω

placed near the driver or near the LTC2424/LTC2428 pin

will also eliminate this problem without additional power

dissipation. The actual resistor value depends upon the

trace impedance and connection topology.

Driving the Input and Reference

The analog input and reference of the typical delta-sigma

analog-to-digital converter are applied to a switched capacitor network. This network consists of capacitors switching between the analog input (ADCIN), ZS

the reference (FS

seen at both ADCIN and V

circuit is shown in Figure 18.

The key to understanding the effects of this dynamic input

current is based on a simple first order RC time constant

model. Using the internal oscillator, the internal switched

capacitor network of the LTC2424/LTC2428 is clocked at

153,600Hz corresponding to a 6.5µs sampling period.

Fourteen time constants are required each time a capacitor

is switched in order to achieve 1ppm settling accuracy.

Therefore, the equivalent time constant at VIN and V

should be less than 6.5µs/14 = 460ns in order to achieve

1ppm accuracy.

). The result is small current spikes

SET

. A simplified input equivalent

REF

(Pin 6) and

SET

REF

Severe ground pin current disturbances can also occur

due to the undershoot of fast digital input signals. Undershoot and overshoot can occur because of the impedance mismatch at the converter pin when the transition

time of an external control signal is less than twice the

propagation delay from the driver to LTC2424/LTC2428.

Input Current (VIN)

If complete settling occurs on the input, conversion results will be unaffected by the dynamic input current. If the

settling is incomplete, it does not degrade the linearity

performance of the device. It simply results in an offset/

21

Page 22

LTC2424/LTC2428

U

WUU

APPLICATIONS INFORMATION

FS

SET

MUXV

CC

I

IN(MUX)

I

IN(MUX)

(PIN 8)

R

SW

75Ω

±I

DC

ADCINMUXOUT

ZS

SET

Figure 18. LTC2424/LTC2428 Equivalent Analog Input Circuit

SELECTED

CHANNEL

CHX

f

= 50Hz, INTERNAL OSCILLATOR: f = 128kHz

OUT

= 60Hz, INTERNAL OSCILLATOR: f = 153.6kHz

f

OUT

EXTERNAL OSCILLATOR: 2.56kHz ≤ f ≤ 307.2kHz

full-scale shift, see Figure 19. To simplify the analysis of

input dynamic current, two separate cases are assumed:

large capacitance at VIN (CIN > 0.01µF) and small capaci-

tance at VIN (CIN < 0.01µF).

If the total capacitance at VIN (see Figure 20) is small

(<0.01µF), relatively large external source resistances (up

to 20k for 20pF parasitic capacitance) can be tolerated

without any offset/full-scale error.

TUE

ADCV

CC

(PIN 2)

R

ADCV

(PIN 2)

SW

5k

CC

R

SW

5k

R

SW

5k

AVERAGE INPUT CURRENT:

= 0.25(VIN – 0.5 • V

I

DC

C

1pF (TYP)

24248 F18

) • f • C

REF

EQ

EQ

I

I

I

IN(LEAK)

I

IN(LEAK)

REF

REF

ANTIALIASING

One of the advantages delta-sigma ADCs offer over conventional ADCs is on-chip digital filtering. Combined with

a large oversampling ratio, the LTC2424/LTC2428 significantly simplify antialiasing filter requirements.

The digital filter provides very high rejection except at

integer multiples of the modulator sampling frequency

(fS), see Figure 21. The modulator sampling frequency is

256 • FO, where FO is the notch frequency (typically 50Hz

or 60Hz). The bandwidth of signals not rejected by the

digital filter is narrow (≈0.2%) compared to the bandwidth

of the frequencies rejected.

0

22

0

V

/2

REF

V

IN

Figure 19. Offset/Full-Scale Shift

R

SOURCE

INTPUT

SIGNAL

SOURCE

C

C

IN

PAR

≅20pF

Figure 20. An RC Network at CH0 to CH7

CH0 TO

CH7

LTC2424/

LTC2428

24248 F20

V

REF

24248 F19

–20

–40

–60

–80

REJECTION (dB)

–100

–120

–140

0

fS/2 f

INPUT FREQUENCY

Figure 21. Sync4 Filter Rejection

S

24248 F21

Page 23

LTC2424/LTC2428

U

WUU

APPLICATIONS INFORMATION

As a result of the oversampling ratio (256) and the digital

filter, minimal (if any) antialias filtering is required in front

of the LTC2424/LTC2428. If passive RC components are

placed in front of the LTC2424/LTC2428, the input dynamic current should be considered. In cases where large

effective RC time constants are used, an external buffer

amplifier may be required to minimize the effects of input

dynamic current.

The modulator contained within the LTC2424/LTC2428

can handle large-signal level perturbations without saturating. Signal levels up to 40% of V

analog modulator. These signals are limited by the input

ESD protection to 300mV below ground and 300mV above

VCC.

The LTC2428’s Resolution and Accuracy Allows You

to Measure Points in a Ladder of Sensors

In many industrial processes, for example, cracking towers in petroleum refineries, a group of temperature measurements must be related to one another. A series of

platinum RTDs that sense slow changing temperatures

do not saturate the

REF

5V

R2300µA