Page 1

SOT-23 Comparator and Voltage

Reference for Battery Monitoring

FEATURES

■

High Accuracy Trip Voltage: 1% Max Error Using

External 1% Resistors

■

Adjustable Threshold Voltage and Hysteresis

■

Quiescent Current: 2.5µA Typ

■

Output Swings Rail-to-Rail

■

Thresholds Programmable from 2.5V to 3.25V

■

Output State Guaranteed for V

■

Low Profile (1mm) ThinSOT

BATT

TM

Package

≥ 1.5V

LTC1998

2.5µA, 1% Accurate

U

DESCRIPTIO

The LTC®1998 is a micropower comparator and a precision adjustable reference in a 6-pin SOT-23 package that

is optimized for lithium-ion low battery detection circuits.

The LTC1998 features a voltage detection circuit with an

adjustable threshold voltage and hysteresis. The threshold voltage can be programmed from 2.5V to 3.25V with

two external resistors. A 10mV to 750mV hysteresis can

be added with a third external resistor.

U

APPLICATIO S

■

Lithium-Ion Battery-Powered Equipment

PDAs

Cell Phones

Handheld Instruments

Battery Packs

Pagers

Palm Top Computers

POS Terminals

, LTC and LT are registered trademarks of Linear Technology Corporation.

ThinSOT is a trademark of Linear Technology Corporation.

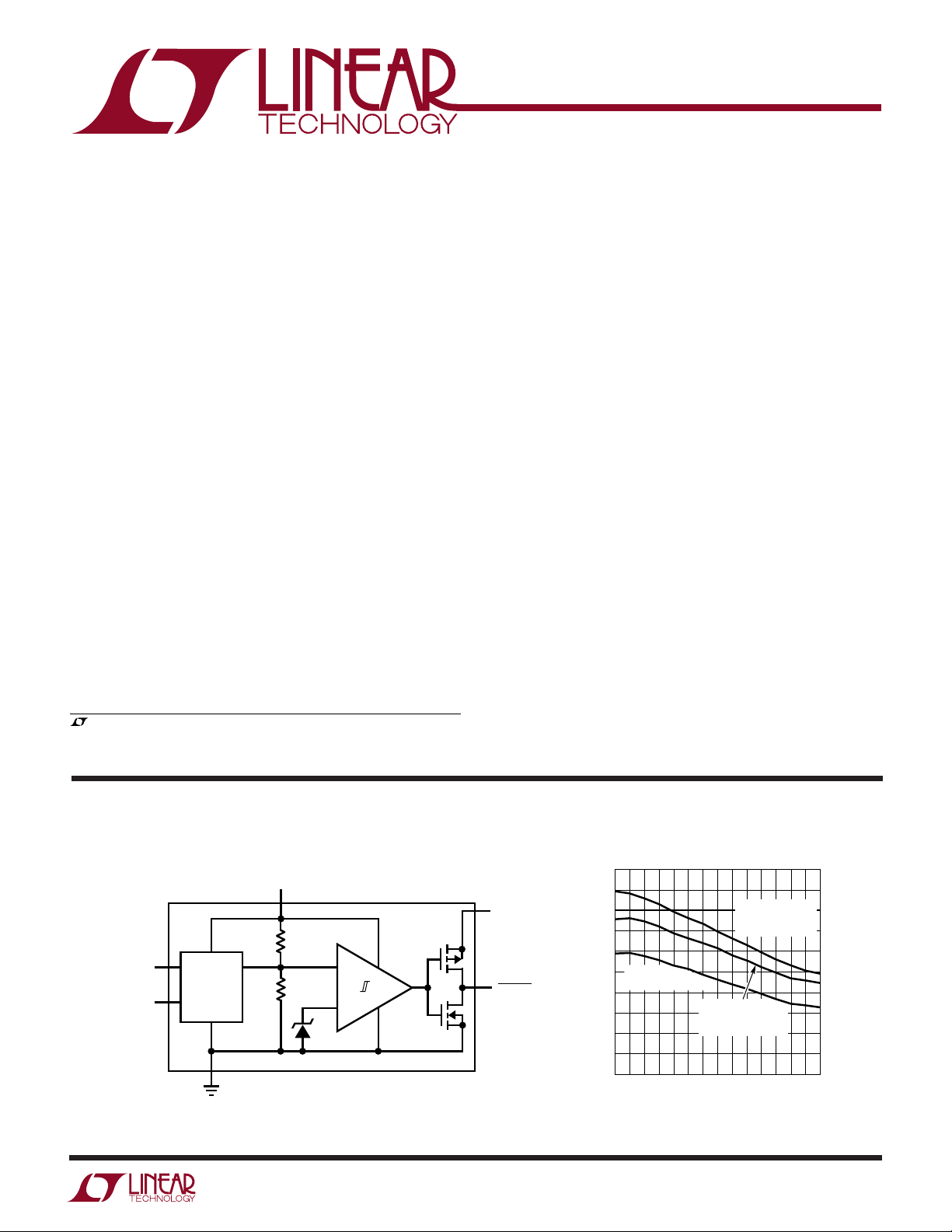

W

BLOCK DIAGRA

BATT

1.1R

V

HYST.A

V

TH.A

THRESHOLD

ADJUST

R

1.2V

A proprietary internal architecture maintains 1% threshold voltage accuracy over temperature with low cost 1%

external resistors.

A separate power supply pin, V

, allows the battery-

LOGIC

low logic output to operate below the battery voltage,

allowing compatibility with low voltage microprocessors

without a pull-up resistor. Power supply glitches are

eliminated by preventing the cross-conducting current

which occurs when the output changes state.

The LTC1998 operates with battery or supply voltages up

to 5.5V and its battery-low output is valid for battery

voltages above 1.5V.

Threshold Voltage Error vs Temperature

1.0

0.9

V

SET BY 1%

V

LOGIC

BATTLO

1998 BD

0.8

0.7

0.6

V

0.5

% ERROR

0.4

0.3

0.2

0.1

0

–45 15 55

1V

TH.A =

THRESHOLD = 3V

–25 –5

TEMPERATURE (°C)

TH.A

EXTERNAL R,

THRESHOLD = 3V

V

SHORTED

TH.A

TO GROUND,

THRESHOLD = 2.5V

35 75 95

1998 G05

1998f

1

Page 2

LTC1998

WW

W

ABSOLUTE AXI U RATI GS

U

UUW

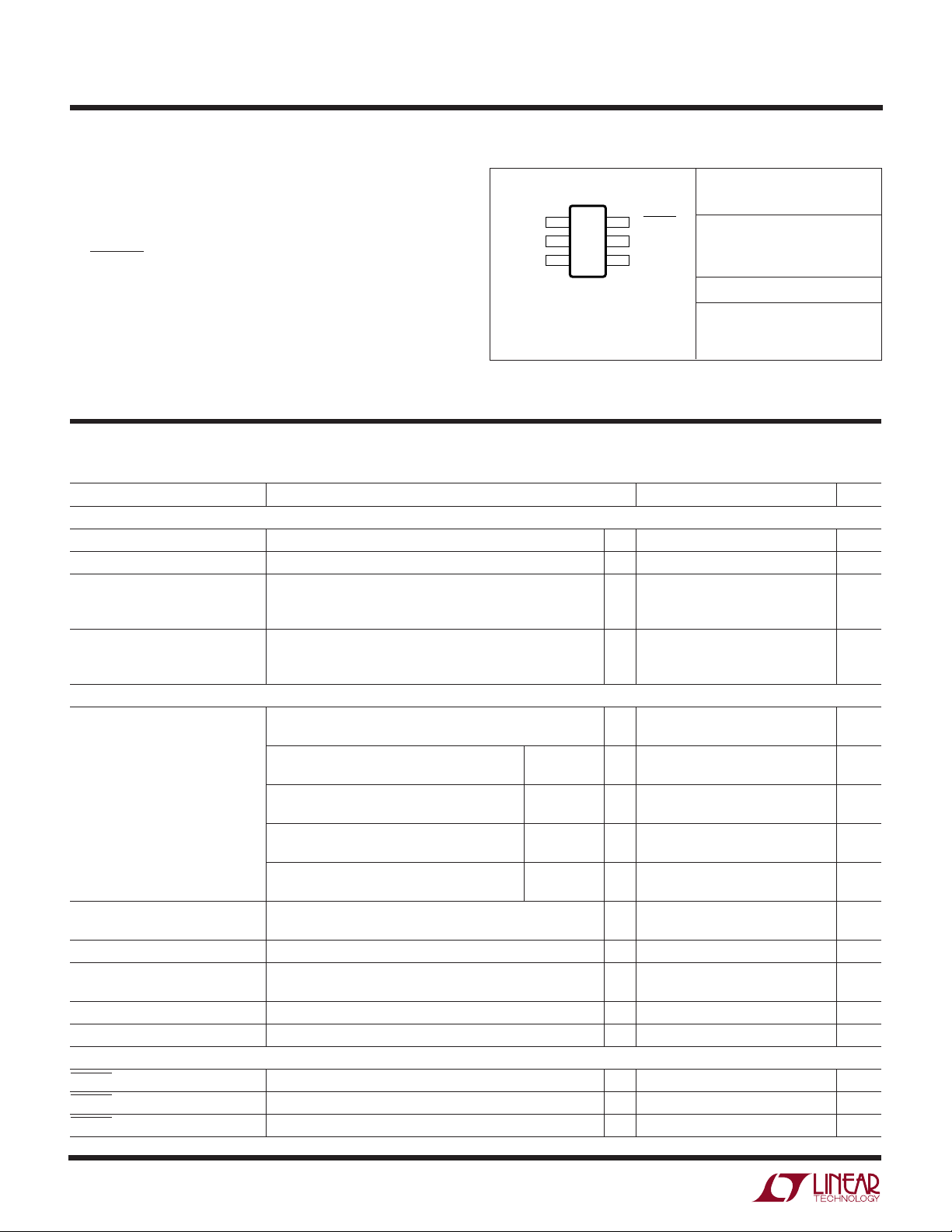

PACKAGE/ORDER I FOR ATIO

(Note 1)

ORDER PART

Total Supply Voltage (BATT or V

to GND) ......... 6V

LOGIC

Voltage

V

, V

TH.A

...........................

H.A

BATTLO ........................ V

BATT + 0.3V to GND – 0.3V

+ 0.3V to GND – 0.3V

LOGIC

Operating Temperature Range (Note 3) ...–40°C to 85°C

Specified Temperature Range (Note 4)

LTC1998C ...........................................–40°C to 85°C

BATT 1

GND 2

V

TH.A

TOP VIEW

3

S6 PACKAGE

6-LEAD PLASTIC SOT-23

T

= 150°C, θJA = 250°C/W

JMAX

6 BATTLO

5 V

LOGIC

4 V

H.A

NUMBER

LTC1998CS6

LTC1998IS6

S6 PART MARKING*

LTTY

LTC1998I.............................................–40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. V

PARAMETER CONDITIONS MIN TYP MAX UNITS

Power Supply

Supply Voltage Range-BATT ● 1.5 5.5 V

Supply Voltage Range-V

Supply Current, V

V

= 1.5V LTC1998CS6 ● 4.2 µA

TH.A

Supply Current, V

V

= 1.5V LTC1998CS6 ● 5.2 µA

TH.A

Monitor

Threshold Accuracy V

Hysteresis Accuracy V

Allowable Hysteresis Range (Note 2) ● 10 750 mV

Propagation Delay C

Threshold Adjust Pin Leakage, I

Hysteresis Adjust Pin Leakage, I

Output

BATTLO High Voltage I

BATTLO Low Voltage I

BATTLO Low Voltage I

LOGIC

= 3V, TA = 25°C 2.5 3.5 µA

BATT

LTC1998IS6 ● 4.5 µA

= 5.5V, TA = 25°C 3 4.3 µA

BATT

LTC1998IS6 ● 5.5 µA

= 2.5V, Pin 3 Shorted to Ground 0.6 0.85 %

BATT.Th

V

= 3V, Pin 3 Driven by Precision LTC1998C ● 0.5 0.61 %

BATT.Th

Voltage Source to 1V LTC1998I

V

= 3V, V

BATT.Th

Programmed with 1% Max External Resistors LTC1998I ● 0.9 1.1 %

V

BATT.Th

Voltage Source to 1.5V LTC1998I ● 0.7 0.85 %

V

BATT.Th

Programmed with1% Max External Resistors LTC1998I

≤ 250mV ● –5 5 mV

HYST

250mV ≤ V

= 100pF, Overdrive = 10mV 350 µs

OUT

TH.AVTH.A

H.AVH.A

≤ 1.5V ● 0.01 1 nA

≤ 1.5V ● 0.01 1 nA

= –1mA ● V

OUT

= 1mA, V

OUT

= 0.25mA, V

OUT

TH.A

= 3.25V, Pin 3 Diven by Precision LTC1998C ● 0.6 0.65 %

= 3.25V, V

TH.A

≤ 750mV ● ±5mV

HYST

Overdrive = 100mV 150 µs

≥ 2V ● 0.2 V

BATT

BATT

The ● denotes the specifications which apply over the full operating

= 1V (Note 5) LTC1998C ● 0.8 1 %

= 1.5V (Note 5) LTC1998C ● 0.9 1.1 %

= 1V ● 0.3 V

*The temperature grades are indentified by a label on the shipping container.

Consult LTC Marketing for parts specified with wider operating temperature ranges.

= 0V, unless otherwise noted.

GND

● 1V

● 0.8 1 %

● 0.6 0.71 %

● 1 1.3 %

– 0.3 V

LOGIC

BATT

1998f

V

2

Page 3

ELECTRICAL CHARACTERISTICS

LTC1998

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: Maximum allowable hysteresis depends on desired trip voltages.

See application notes for details.

Note 3: LTC1998C and LTC1998I are guaranteed functional over the

operating temperature range of –40°C to 85°C.

Note 4: The LTC1998C is guaranteed to meet specified performance from

0°C to 70°C. The LTC1998C is designed, characterized and expected to

meet specified performance from –40°C to 85°C but is not tested or QA

sampled at these temperatures. The LTC1998I is guaranteed to meet

specified performance from –40°C to 85°C.

Note 5: This parameter is not 100% tested.

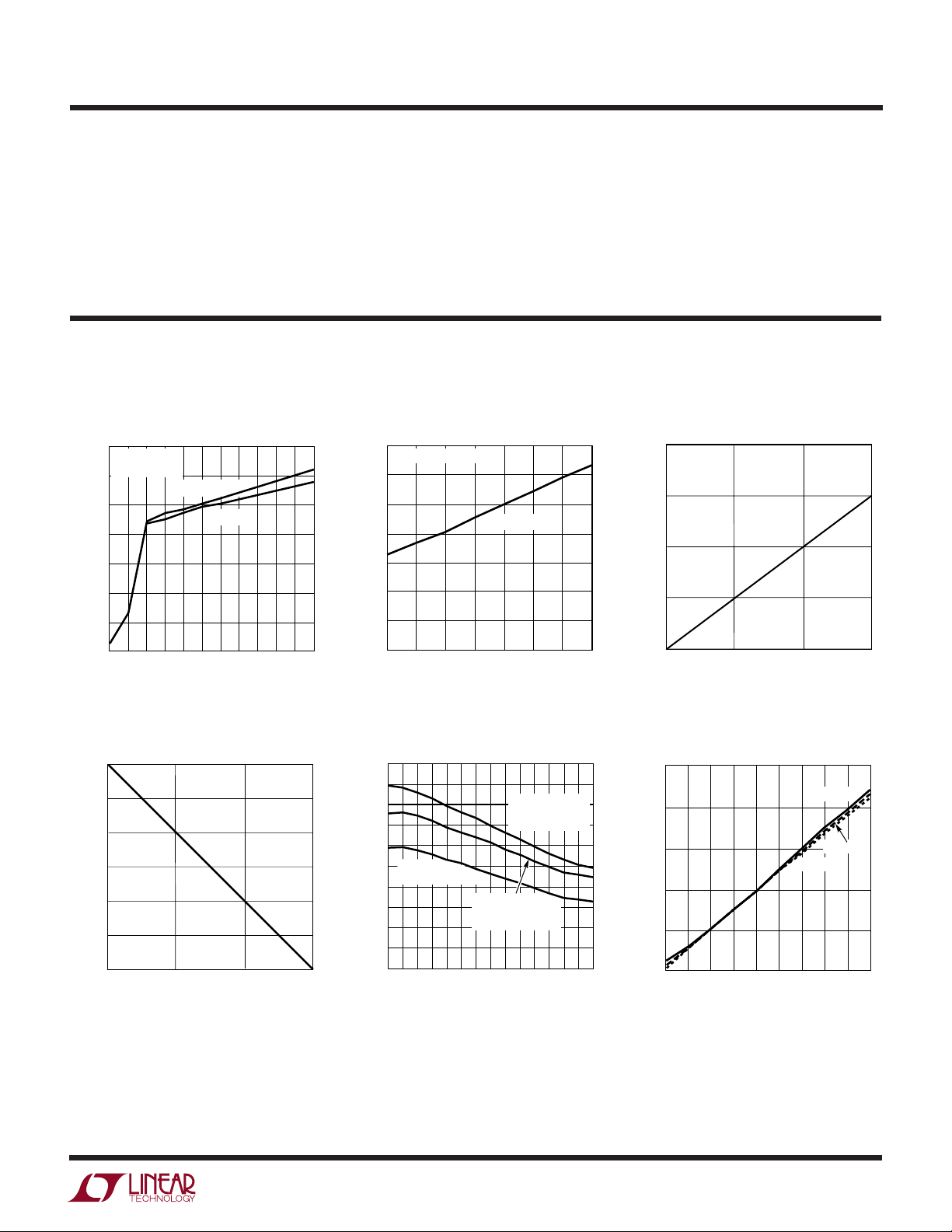

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Quiescent Supply Current vs

Supply Voltage

3.5

TA = 25°C

= V

V

LOGIC

3.0

2.5

2.0

1.5

1.0

SUPPLY CURRENT (µA)

0.5

BATT

V

= 1.5V

TH.A

V

TH.A

= 0V

Quiescent Supply Current vs

Temperature

3.5

V

= V

LOGIC

= 3V

V

BATT

3.0

2.5

2.0

1.5

1.0

SUPPLY CURRENT (µA)

0.5

TH.A

= 1.5V

Threshold Voltage vs Threshold

Adjust Voltage

3.5

3.0

THRESHOLD VOLTAGE (V)

0

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0

SUPPLY VOLTAGE (V)

Available Hysteresis vs

Threshold Voltage

750

500

250

AVAILABLE HYSTERESIS (mV)

0

2.5

2.75 3.0

LOW BATTERY THRESHOLD VOLTAGE (V)

1998 G01

1998 G04

3.25

0

–50 –30 –10 10 30 50 70 90

TEMPERATURE (°C)

Threshold Voltage Error vs

Temperature

1.0

0.9

V

SET BY 1%

0.8

0.7

0.6

V

0.5

% ERROR

0.4

0.3

0.2

0.1

0

–45 15 55

1V

TH.A =

THRESHOLD = 3V

–25 –5

TEMPERATURE (°C)

TH.A

EXTERNAL R,

THRESHOLD = 3V

V

SHORTED

TH.A

TO GROUND,

THRESHOLD = 2.5V

35 75 95

1998 G02

1998 G05

2.5

0

0.5 1.0

THRESHOLD ADJUST VOLTAGE (V)

Input Current vs Temperature

10000

1000

(pA)

H.A

, V

100

TH.A

10

1

INPUT CURRENT V

0.1

45 65

35

55

75

TEMPERATURE (°C)

1.5

1998 G03

VIN = 1.5V

VIN = 1V

VIN = 0.5V

105

85 125

115

95

1998 G06

1998f

3

Page 4

LTC1998

SUPPLY VOLTAGE (V)

1.0 1.5 2.5 3.5 4.5 5.5

CURRENT (mA)

120

100

80

60

40

20

0

2.0 3.0 4.0 5.0

1998 G09

6.0

SOURCE CURRENT,

BATTLO SHORTED TO GND

SINK CURRENT,

BATTLO SHORTED

TO V

LOGIC

TA = 25°C

V

BATT

= V

LOGIC

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Output Low Voltage vs Load

Current

0.6

TA = 25°C

= V

V

LOGIC

0.4

TA = 25°C

0.2

OUTPUT VOLTAGE (V)

0

1

= 3V

BATT

234

OUTPUT SINK CURRENT (mA)

U

TA = 85°C

TA = –40°C

5

1998 G07

UU

Output High Voltage vs Load

Current

0

(mV)

–50

BATT

–100

TA = –40°C

–150

–200

OUTPUT VOLTAGE RELATIVE TO V

–250

1

TA = 25°C

TA = 25°C

V

= V

LOGIC

BATT

234

OUTPUT SOURCE CURRENT (mA)

PI FU CTIO S

BATT (Pin 1): Battery Voltage to be monitored. Supply

current is also drawn from this pin. Board layout should

connect this pin to the battery(+) terminal, through a trace

that does not conduct load current.

GND (Pin 2): Ground should be connected to the battery

(–) terminal through a trace that does not conduct load

return current.

V

(Pin 3): Threshold Adjust Pin. Adjusts the low

TH.A

battery threshold voltage, V

V

can be supplied by a voltage source or a resistor

TH.A

BATT.Th

divider.

= 2.5V + (V

TH.A

/2).

Output Short-Circuit Current vs

Supply Voltage

TA = 85°C

TA = 25°C

TA = –40°C

TA = 85°C

BATT = 3V

BATT = 5V

5

1998 G08

V

(Pin 4): Hysteresis Adjust. Hysteresis threshold

H.A

voltage V

voltage source or resistor divider. V

programmed to a higher potential than V

voltage, V

V

LOGIC

= 2.5V + (V

TH2

= V

HYST

TH2

H.A

– V

/2). V

BATT.Th

can be supplied by a

H.A

must always be

H.A

. Hysteresis

TH.A

.

(Pin 5): Positive Supply Voltage for Output Driver.

This voltage can be driven from an external logic supply or

tied to BATT.

BATTLO (Pin 6): Output of Comparator. Low for BATT <

V

BATT.Th

guaranteed for V

(low battery threshold voltage). Output state

≥ 1.5V.

BATT

QUICK DESIG GUIDE

How to Calculate the External Resistor Values

The LTC1998 is a low battery warning indicator and is

especially designed for monitoring the voltage of singlecell Lithium-Ion batteries. The LTC1998 compares its

supply pin (BATT) to an accurate internal reference; if the

battery voltage falls below the programmed low battery

4

U

threshold voltage of the LTC1998, the battery low pin

(BATTLO) will change state, from high to low, to indicate

a low battery condition. The low battery threshold voltage

is programmed via the voltage threshold adjust pin (V

A hysteresis adjust pin (V

) will add hysteresis to the

H.A

TH.A

).

programmed value of the low battery threshold voltage.

1998f

Page 5

U

QUICK DESIG GUIDE

LTC1998

Typical Application

Table 1: Design Equations for R1, R2, R3, Figure 1

Choose desired values for:

• V

• V

BATT.Th

HYST

: Low Battery Threshold Voltage

: Hysteresis Voltage

• IR: Max Allowable Resistor Current

Solve:

V

42

V

5

+

.

.

.

I

R

1

R

11

RRRR

RR

RR

RR RR

=++ =

TOTAL

=

1

=

2

=

312

123

•–

TOTAL

TOTAL

TOTAL

VV

BATT Th HYST

V

5

•––

V

BATT Th

––

Example 1: A system using a 4.2V (fully charged) LithiumIon battery requires a low battery threshold of 2.7V,

100mV hysteresis and can allow up to 4.2µA maximum

resistor current.

R

= 1MΩ, R1 = 786k, R2 = 66k and R3 = 148k

TOTAL

Choose standard 1% values.

R1 = 787k, R2 = 66.5k, R3 = 147k

1.5V TO 4.2V

0.1µF

R1

+

1%

4

V

R2

1%

Li-Ion

R3

1%

Figure 1. Low Battery Threshold Detector with Hysteresis

H.A

3

V

TH.A

1

BATT

V

LTC1998

BATTLO

GND

2

REGULATOR

LOGIC

5

6

V

LOGIC

µP

1998 F01

WUUU

APPLICATIO S I FOR ATIO

LOW BATTERY THRESHOLD VOLTAGE AND

HYSTERESIS ADJUST

Low Battery Threshold Voltage Adjustment, Pin 3

The low battery threshold voltage is the battery voltage

which will trip the (BATTLO) pin high to low. It should be

adjusted via the threshold adjust pin (V

input impedance pin that senses an externally applied

voltage and programs the low battery threshold voltage

(V

BATT.Th

). The V

pin is designed to accommodate

TH.A

voltages from 0V to 1.5V with respect to ground. This

allows the low battery threshold voltage to be set to any

voltage between 2.5V and 3.25V, that is:

V

()

VV

BATT Th

.

=+25

TH A..

2

). This is a high

TH.A

For instance, if the applied voltage at pin 3, V

, is 1V the

TH.A

LTC1998 will indicate a low battery condition when the

battery voltage pin (BATT) falls below 3V.

The voltage at the threshold adjust pin (V

) can be set

TH.A

with any voltage source. This pin allows a continuous time

adjustment, that is, the low battery threshold voltage may

be changed at any time. The high input impedance of the

V

pin allows the use of a high valued resistive divider

TH.A

(to minimize current drain) from the battery to set the

battery low threshold voltage, Figure 2.

3

BATT

V

TH.A

LTC1998

1

2

1998 F02

+

R1

Li-Ion

R2

Figure 2. Resistor Divider Sets Threshold

1998f

5

Page 6

LTC1998

1998 F03

LTC1998

R1

R2

R3

V

H.A

V

TH.A

BATT

+

Li-Ion

1

4

3

WUUU

APPLICATIO S I FOR ATIO

The simple calculations of resistor values R1 and R2 are

illustrated below. Set a value for R1 + R2. This value will

affect the max amount of current drawn from the battery

when fully charged. For instance if R1 + R2 = 1M the

resistive divider will draw 4.1µA when the battery voltage

is 4.1V. Set the desired value of V

BATT.Th

(this value should

be between 2.5V and 3.25V) that is the value of the battery

voltage that will trip the internal circuitry of the LTC1998

and change the state of the battery low pin (BATTLO).

Solve for R R R

112

() –

V

BATT Th

V

5

1=+

.

Example: A Lithium-Ion battery is monitored and a battery

low signal should be issued when it discharges to 2.85V,

that is, V

BATT.Th

= 2.85V; if (R1 + R2) = 1M, then

R1 = 754.38k and R2 = 245.62k. Choose the closest 1%

value of R1 = 750k and R2 = 243k. Calculate the practical

value for V

BATT.Th

as it will be slightly different from 2.85V,

due to the use of standard 1% resistor values.

+

12

VV

BATT Th.

RR

()

++

112

RRR

=5

.=

2 849

V

The above low battery threshold of 2.849V is guaranteed

to within 1% even though 1% resistors are used to

program the V

For sake of completeness, the voltage at Pin 3 (V

be easily calculated by V

0.6972V (when V

voltage applied to Pin 3.

TH.A

= V

BATTERY

TH.A

= V

BATT.Th

BATT.Th

TH.A

(R2/(R1 + R2) =

).

) can

The programming of the hysteresis threshold adjust pin

(V

) is similar to the programming of the voltage thresh-

H.A

old adjust pin (V

) already described in the previous

TH.A

paragraph. Pin 4 effectively adjusts the threshold voltage

at which the low battery pin (BATTLO) changes state from

low to high. This threshold (V

V

()

VV

THHA2

25

=+.

.

2

) is defined as:

TH2

The actual hysteresis voltage is:

V

HYST

= V

TH2

– V

BATT.Th

It is imperative that the hysteresis threshold adjust voltage

at Pin 4 be set to a higher voltage than the low battery

threshold adjust voltage at Pin 3, at all times, to avoid

oscillation at the BATTLO output pin. The hysteresis

threshold adjust pin may be set with a voltage source or

with a resistor divider, just as with the low battery threshold adjust pin.

Combined Control of Threshold and Hysteresis

If a resistor divider is desired, then both threshold adjust

dividers can be combined in order to save current. This

simple technique also guarantees that the hysteresis threshold adjust voltage at Pin 4 is higher than the voltage at the

V

pin, Figure 3.

TH.A

Hysteresis Adjustment, Pin 4.

The LTC1998 has an adjustable hysteresis ranging from

10mV to 0.75V. A large hysteresis is useful in the event

that a low battery signal at the LTC1998’s BATTLO pin

causes the system to shed some battery load, thus inducing system confusion as the partially loaded battery recovers and changes the status of Pin 6 (BATTLO). The 2.5V to

3.25V programming window of low battery threshold

voltage includes the hysteresis. If, for instance, the low

battery threshold voltage is set to 2.5V, 750mV hysteresis

can be added on top of the 2.5V. If the low battery

threshold voltage is set to 3.15V, only 100mV hysteresis

can be applied.

6

Figure 3. Combined Resistor Divider

The calculation of the resistor values R1, R2 and R3 is

quite straightforward and similar to the procedure outlined in the previous paragraph.

Choose a value for the sum of R1 + R2 + R3 as well as the

values for low battery threshold and hysteresis.

Solve for resistor R1:

1998f

Page 7

WUUU

APPLICATIO S I FOR ATIO

LTC1998

RRRR

1123

=++

()–

5

V

TH

V

1

2

Solve for the sum of

V

()( ) –

RR RR R

12 123

V

BATT Th

5

1+=++

.

then solve for R2 and R3.

Example: A system needs to detect a low battery voltage of

3V (V

BATT.Th

= 3V) with 250mV hysteresis (V

= 3.25V).

TH2

Set the value of the resistor divider (R1 + R2 + R3) = 1M.

R1 = 539k, R1 + R2 = 667k, R2 = 128k, R3 = 333k. Choose

the closest 1% values, that is 536k, 332k, 127k. Figure 4

graphically shows the function of the LTC1998 as

described above.

VERSATILE OUTPUT DRIVER

V

, BATTLO (Pins 5,6)

LOGIC

The LTC1998 uses a CMOS push-pull output stage to drive

the low battery output signal. This output pin (BATTLO)

has a separate supply pin, (V

) that can be used to

LOGIC

provide an output voltage rail matching the VDD logic of

microprocessors. The V

lower than the voltage at the BATT pin. The V

also be tied to a voltage higher than V

pin may be tied to a voltage

LOGIC

LOGIC

via a series

BATT

pin may

resistor greater than 10kΩ. The output will then act as an

open-drain device.

In a given application, if it is possible for BATTLO to be

shorted to GND or a supply, a series resistor should be

added to limit the short-circuit current to 5mA.

3.25V

PROGRAMMED

HYSTERESIS

THRESHOLD

PROGRAMMED

LOW BATT

THRESHOLD

2.50V

V

LOGIC

BATTLO

PROGRAMMABLE

THRESHOLD RANGE

BATTERY

VOLTAGE

Figure 4. LTC1998 Function Plot

HYSTERESIS

BATTERY VOLTAGE

RECOVERS UNDER

REDUCED LOAD

1998 F04

PACKAGE DESCRIPTIO

3.85 MAX

2.62 REF

NOTE:

1. DIMENSIONS ARE IN MILLIMETERS

2. DRAWING NOT TO SCALE

3. DIMENSIONS ARE INCLUSIVE OF PLATING

4. DIMENSIONS ARE EXCLUSIVE OF MOLD

FLASH AND METAL BURR

5. MOLD FLASH SHALL NOT EXCEED 0.254mm

6. JEDEC PACKAGE REFERENCE IS MO-193

0.20 BSC

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

U

6-Lead Plastic TSOT-23

(Reference LTC DWG # 05-08-1636)

0.62

MAX

RECOMMENDED SOLDER PAD LAYOUT

PER IPC CALCULATOR

DATUM ‘A’

0.95

REF

0.30 – 0.50 REF

S6 Package

1.22 REF

1.4 MIN

2.80 BSC

0.09 – 0.20

(NOTE 3)

1.50 – 1.75

(NOTE 4)

1.00 MAX

0.95 BSC

0.80 – 0.90

PIN ONE ID

2.90 BSC

(NOTE 4)

1.90 BSC

0.30 – 0.45

6 PLCS (NOTE 3)

0.01 – 0.10

S6 TSOT-23 0302

1998f

7

Page 8

LTC1998

4

3

2

1

5

6

R4

909k

1%

R5

6.98k

1%

R6

76.8k

1%

LTC1998

V

H.A

V

TH.A

BATT

V

LOGIC

BATTLO

GND

4

3

2

1

5

6

R1

619k

1%

R2

6.04k

1%

R3

383k

1%

LTC1998

V

H.A

V

TH.A

BATT

V

LOGIC

BATTLO

GND

V

IN

NC

V

+

R7

1M

2N7002

WINDOW LOW THRESHOLD = 2.6V

HYSTERESIS = 10mV

WINDOW HIGH THRESHOLD = 3.1V

HYSTERESIS = 10mV

1998 TA06

V

OUT

V

OUT

= V+ WHEN

2.6V ≤ V

IN

≤ 3.1V

TYPICAL APPLICATIO S

U

Single Li-Ion Cell Low Battery Detector

=

V

BATT

1.5V TO 4.2V

R1

+

1%

R2

1%

Li-Ion

R3

1%

0.1µF

4

3

V

H.A

V

TH.A

1

BATT

V

LTC1998

BATTLO

GND

2

REGULATOR

5

LOGIC

6

Micropower 2.9V VCC Threshold

Detector with 15mV Hysteresis

3.3V

R1

715k

1%

R2

9.09k

1%

R3

274k

1%

4

3

V

H.A

V

TH.A

1

BATT

V

LTC1998

BATTLO

GND

2

LOGIC

5

6

V

LOGIC

1V TO 5V

OUT

Backup Battery Switchover Circuit

=

µP

1998 TA01

2.5V TO 4.2V

R1

787k

+

1%

4

R2

68.1k

Li-Ion

1%

3

R3

147k

1%

SWITCHES TO BACKUP BATTERY WHEN PRIMARY FALLS BELOW 2.7V.

SWITCHES BACK TO PRIMARY WHEN VOLTAGE RECOVERS TO ≥ 2.8V

V

H.A

V

TH.A

1

BATT

V

LOGIC

LTC1998

BATTLO

GND

2

5

6

BAT54C

R4

1M

BAT54C

MBRM120

+

V

OUT

Si2301

Si2301

3V

BACKUP

BATTERY

1998 TA04

High Accuracy Window Comparator

with Dual Hysteresis

LOW THRESHOLD = 2.9V

HYSTERESIS = 15mV

1998 TA03

Low Battery Load Reduction Circuit

R1

787k

+

1%

4

V

H.A

R2

68.1k

Li-Ion

1%

3

V

TH.A

R3

147k

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

1%

LOW THRESHOLD = 2.7V

HYSTERESIS = 100mV

LTC1440/LTC1540 Micropower Comparator with 1% Reference 1.182V ±1% Reference, ±10mV (Max) Input Offset

LTC1441/LTC1442 Micropower Dual Comparator with 1% Reference 1.182V ±1% Reference (LTC1442)

LTC1443/LTC1444/LTC1445 Micropower Quad Comparator with 1% Reference LTC1443 has 1.182V Reference, LTC1444/LTC1445 have 1.221V

8

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

1

BATT

V

LTC1998

BATTLO

GND

2

REGULATOR

LOGIC

5

6

Si2301

NONCRITICAL

CIRCUITRY

●

www.linear.com

CRITICAL

CIRCUITRY

1998 TA05

Reference and Adjustable Hysteresis

LT/TP 0802 2K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 2001

1998f

Loading...

Loading...