Page 1

FEATURES

LTC1873

Dual 550kHz Synchronous

2-Phase Switching Regulator

Controller with 5-Bit VID

U

DESCRIPTIO

■

Two Independent PWM Controllers in One Package

■

Side 1 Output Is Compliant with Intel Desktop

VRM 8.4 Specifications (Includes 5-Bit VID DAC)

■

1.3V to 3.5V Output Voltage with 50mV/100mV Steps

■

Two Sides Run Out-of-Phase to Minimize C

■

All N-Channel External MOSFET Architecture

■

No External Current Sense Resistors Required

■

Precison Internal 0.8V ±1% Reference

■

550kHz Switching Frequency Minimizes External

IN

Component Size

■

Very Fast Transient Response

■

Up to 25A Output Current per Channel

■

Low Shutdown Current: < 100µA

■

Small 28-Pin SSOP Package

U

APPLICATIO S

■

Microprocessor Core and I/O Supplies

■

Multiple Logic Supply Generator

■

High Efficiency Power Conversion

■

Chipset Power Supply

The LTC®1873 is a dual switching regulator controller optimized for high efficiency with low input voltages. It includes

two complete, on-chip, independent switching regulator controllers. Each is designed to drive a pair of external

N-channel MOSFETs in a voltage mode feedback, synchronous buck configuration. The LTC1873 includes digital output voltage adjustment on side 1 that conforms to the Intel

Desktop VID specification. A constant-frequency, true PWM

design minimizes external component size and cost and

optimizes load transient performance. The synchronous buck

architecture automatically shifts to discontinuous and then to

Burst ModeTM operation as the output load decreases, ensuring maximum efficiency over a wide range of load currents.

The LTC1873 features an onboard reference trimmed to 1%

and delivers better than 1.5% regulation at the converter

outputs over all combinations of line, load and temperature.

Each channel can be enabled independently; with both channels disabled, the LTC1873 shuts down and supply current

drops below 100µA.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Burst Mode is a trademark of Linear Technology Corporation.

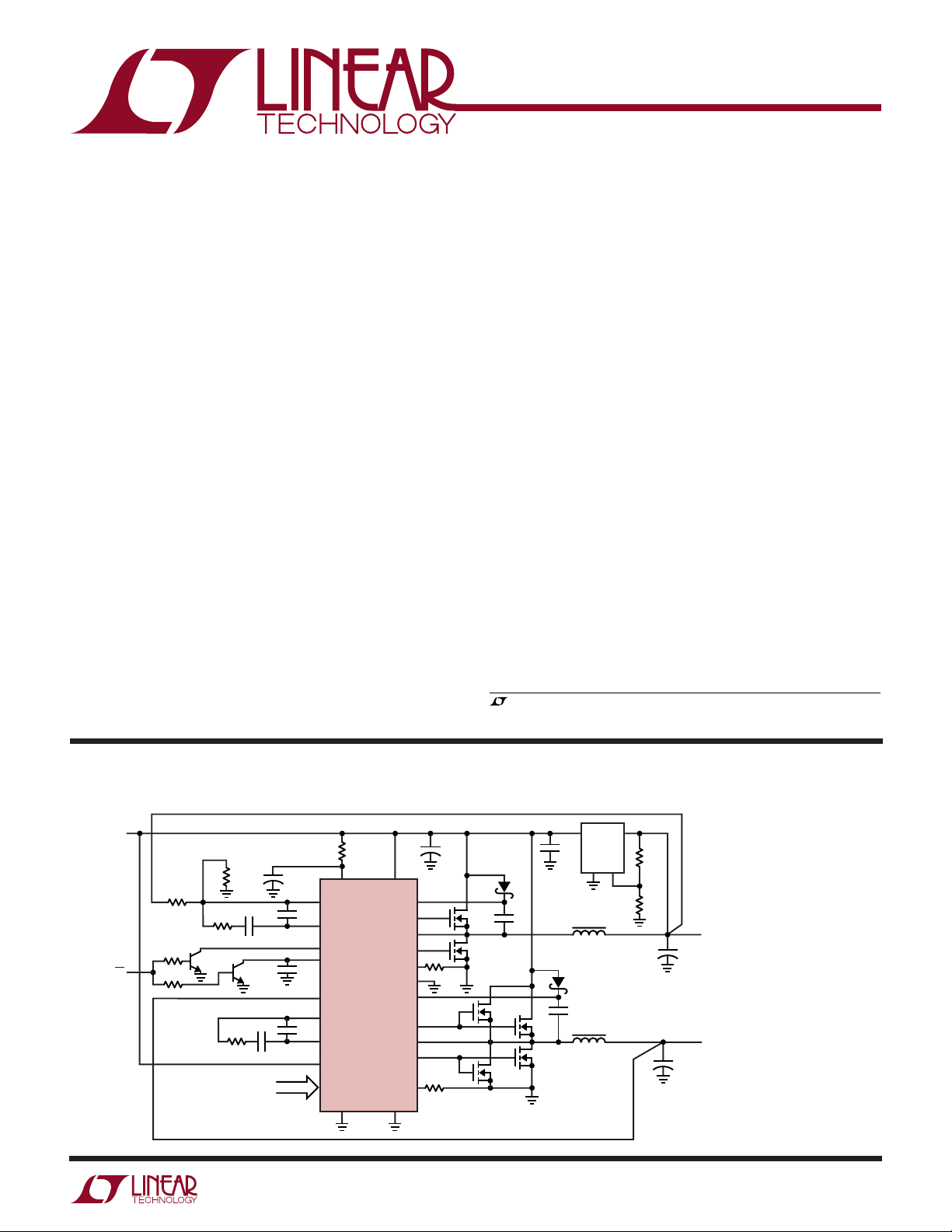

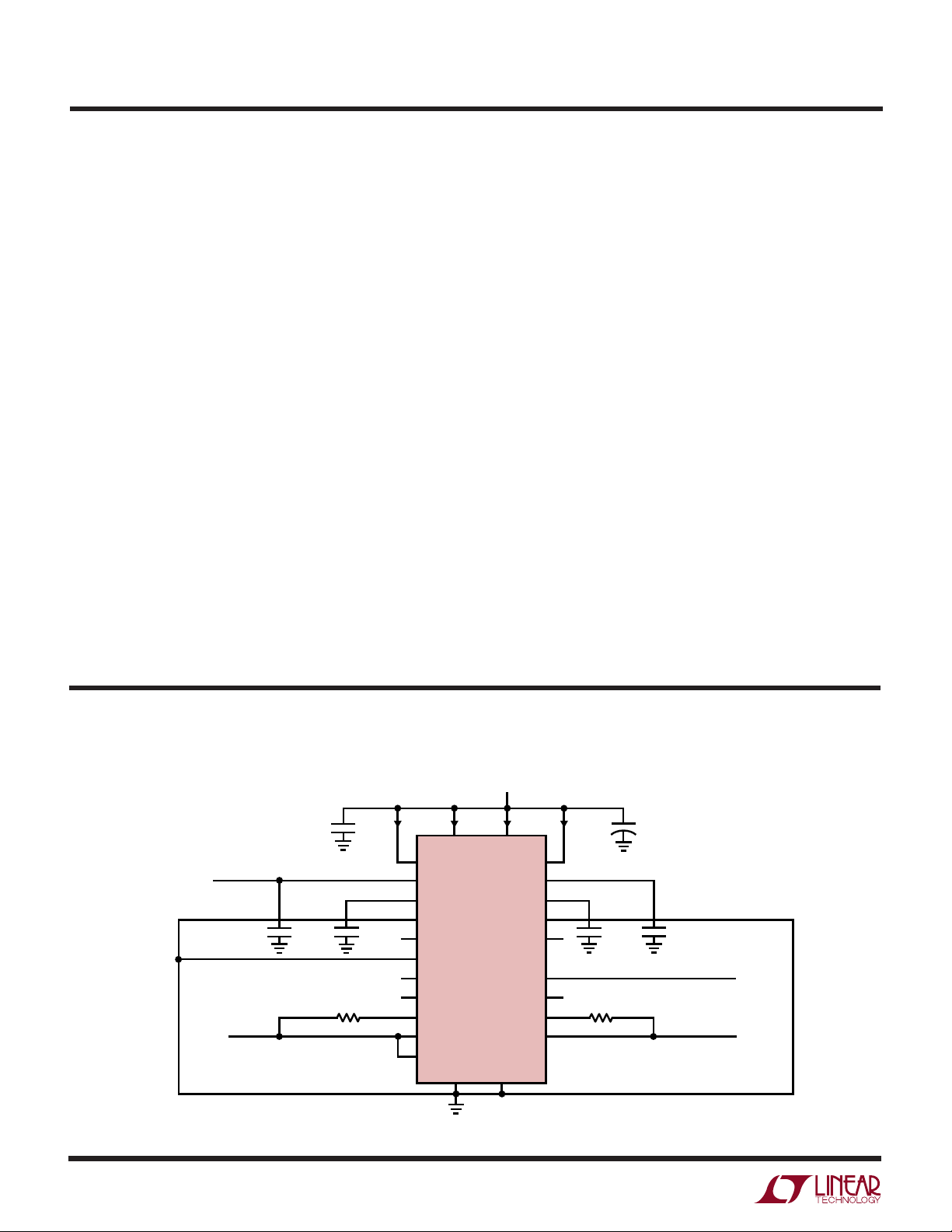

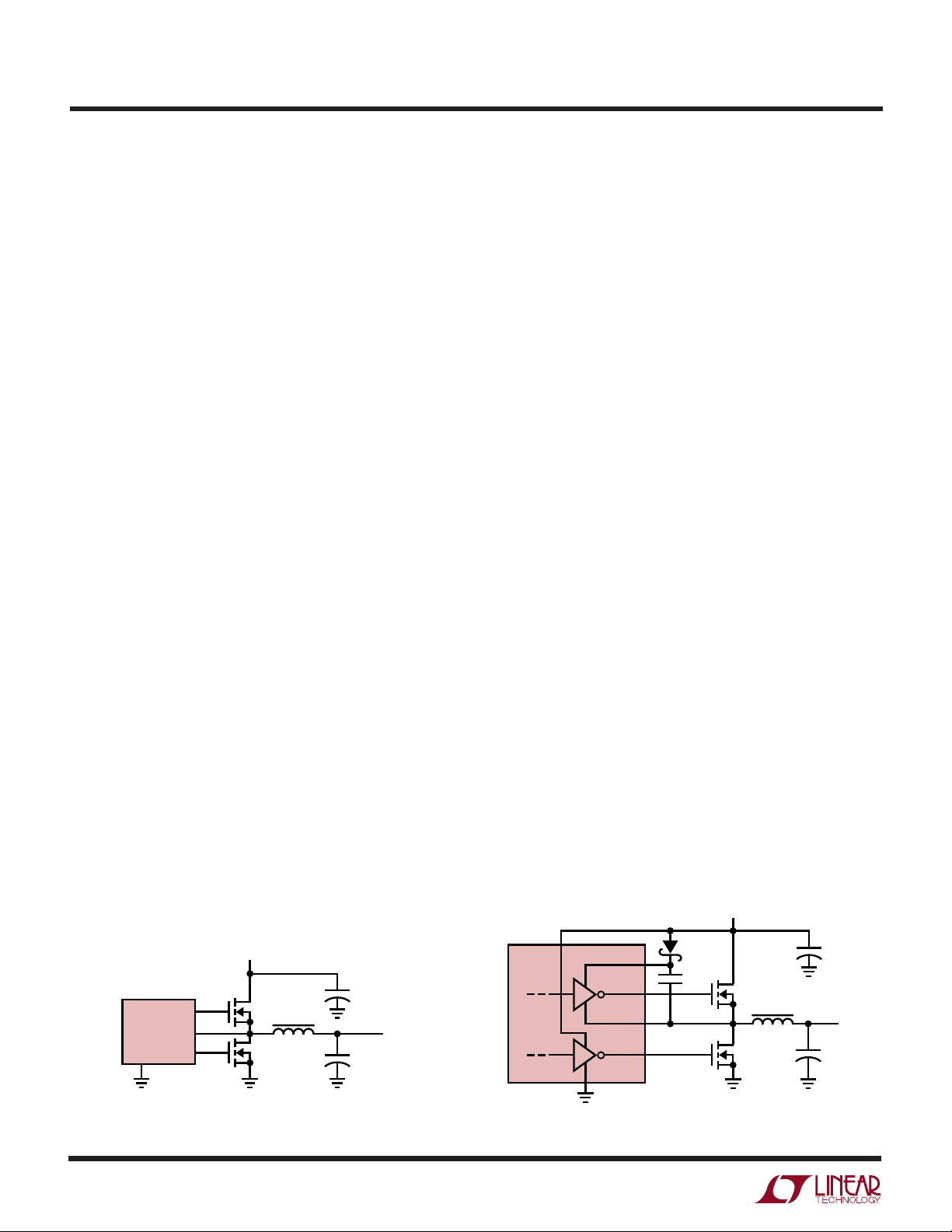

TYPICAL APPLICATIO

4.5V TO 5.5V

+

STBY/ON

10k

0.1%

1k

1k

QSS1

68k

4.75k

0.1%

330pF

56k

5-BIT VID

10µF

QSS2

220pF

U

Low Cost Desktop CPU Supply with RDRAM Keepalive

1µF

MBR0530T

1µF

IN OUT

LT1761

GND

ADJ

L2

L1

56pF

0.1µF

39pF

FB2

COMP2

RUN/SS2

RUN/SS1

SENSE

FB1

COMP1

FCB

VID4:0

10Ω

V

SGND PGND

CC

LTC1873

PV

BOOST2

I

FAULT

BOOST1

I

CC

TG2

SW2

BG2

MAX2

TG1

SW1

BG1

MAX1

+

C

IN

MBR0530T

1µF

QT2

QB2

47k

QT1B

QT1A

QB1A

33k

QB1B

16.2k

0.1%

16.9k

0.1%

1873 TA01

V

RDRAM

2.5V/7A

+

2.45V/100mA STANDBY

C

OUT2

V

CORE

1.3V TO 3.5V

+

20A

C

C

= SANYO 10MV1200GX (6 IN PARALLEL)

OUT1

IN

= SANYO 6MV1500GX (8 IN PARALLEL)

C

OUT1

= SANYO 6MV1500GX (3 IN PARALLEL)

C

OUT2

L1: 1µH SUMIDA CEP125-1R0MC-H

L2: 2.2µH COILTRONICS UP2B-2R2

QSS1, QSS2: MOTOROLA MMBT3904LT1

QT1A, QT1B, QB1A, QB1B: FAIRCHILD FDS6670A

QT2, QB2: 1/2 SILICONIX Si4966

1

Page 2

LTC1873

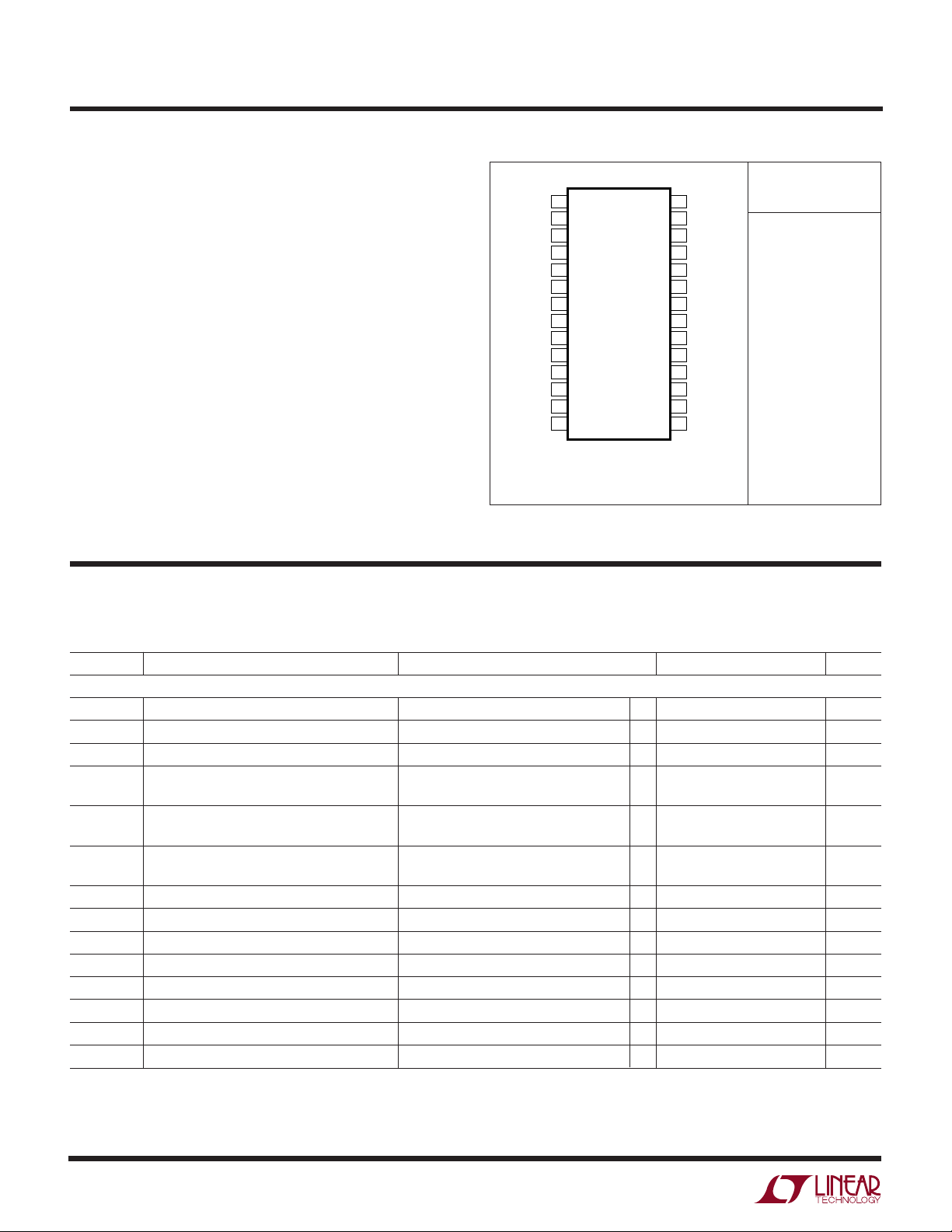

PACKAGE/ORDER I FOR ATIO

UU

W

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

Supply Voltage

V

...........................................................................................

CC

BOOST

n...............................................................

BOOSTn – SWn.................................................... 7V

Input Voltage

SWn.......................................................... –1V to 8V

VIDn....................................................... –0.3V to 7V

All Other Inputs ......................... – 0.3V to VCC + 0.3V

Peak Output Current < 10µs

TGn, BGn............................................................... 5A

Operating Temperature Range

(Note 2) ............................................. – 40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

7V

15V

PV

BOOST1

BG1

TG1

SW1

I

MAX1

FCB

RUN/SS1

COMP1

SGND

FB1

SENSE

VID0

VID1

TOP VIEW

1

CC

2

3

4

5

6

7

8

9

10

11

12

13

14

G PACKAGE

28-LEAD PLASTIC SSOP

T

= 125°C, θJA = 55°C/W

JMAX

28

27

26

25

24

23

22

21

20

19

18

17

16

15

I

MAX2

BOOST2

BG2

TG2

SW2

PGND

FAULT

RUN/SS2

COMP2

FB2

V

CC

VID4

VID3

VID2

ORDER PART

LTC1873EG

Consult factory for Industrial and Military grade parts.

NUMBER

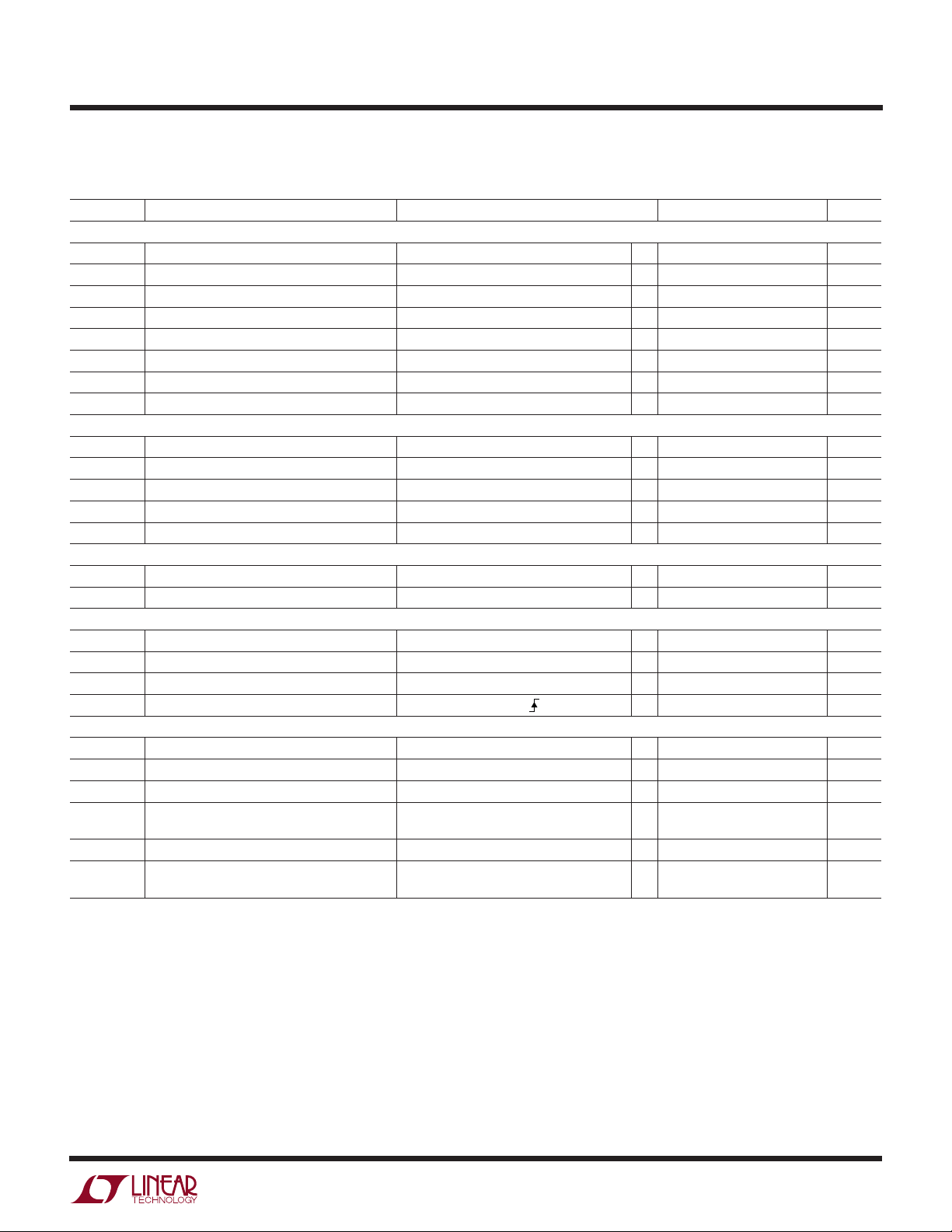

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

VCC = 5V unless otherwise specified. (Note 4)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Main Control Loop

V

CC

PV

CC

BV

CC

I

CC

IPV

I

BOOST

V

FB

∆V

FB

I

FB

V

FCB

∆V

FCB

I

FCB

V

RUN

I

SS

CC

VCC Supply Voltage ● 37V

PVCC Supply Voltage (Note 3) ● 37V

BOOST Pin Voltage V

– VSW (Note 3) ● 2.7 7 V

BOOST

VCC Supply Current Test Circuit 1 ● 2.2 8 mA

RUN/SS1 = RUN/SS2 = 0V (Note 6)

● 30 100 µA

PVCC Supply Current Test Circuit 1 (Note 5) ● 2.2 6 mA

RUN/SS1 = RUN/SS2 = 0V (Note 6)

● 6 100 µA

BOOST Pin Current Test Circuit 1 (Note 5) ● 1.3 3 mA

RUN/SS1 = RUN/SS2 = 0V

● 0.1 10 µA

Feedback Voltage Test Circuit 1 ● 0.790 0.800 0.810 V

Feedback Voltage Line Regulation VCC = 3V to 7V ● ±0.005 ±0.05 %/V

Feedback Current FB2 Only (Note 7) ● ±0.001 ±1 µA

FCB Threshold ● 0.75 0.8 0.85 V

FCB Feedback Hysteresis 20 mV

FCB Pin Current ● ±0.001 ±1 µA

RUN/SS Pin RUN Threshold ● 0.45 0.55 0.65 V

Soft Start Source Current RUN/SSn = 0V –1.5 –3.5 –5.5 µA

2

Page 3

LTC1873

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

VCC = 5V unless otherwise specified. (Note 4)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Switching Characteristics

V

OSC

f

OSC

Φ

OSC2

DC

MIN1

DC

MIN2

DC

MAX

t

NOV

tr, t

f

Feedback Amplifier

A

VFB

GBW FB Gain Bandwidth 25 MHz

I

ERR

V

MIN

V

MAX

Current Limit Loop

A

VILIM

I

IMAX

Status Outputs

V

FAULT

V

OLF

I

FAULT

t

FAULT

VID Inputs

R1 Resistance Between SENSE and FB1 Side 1 Only 20 kΩ

V

Error % Output Voltage Accuracy Programmed from 1.3V to 3.5V ● –1.5 1.5 %

OUT

R

PULLUP

VID

T

I

VID-LEAK

V

PULLUP

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC1873 is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the –40°C to 85°C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 3: PV

the external MOSFETs used to ensure proper operation.

Note 4: All currents into device pins are positive; all currents out of device

pins are negative. All voltages are referenced to ground unless otherwise

specified.

Oscillator Amplitude 1V

P-P

Oscillator Frequency Test Circuit 1 ● 475 550 750 kHz

Controller 2 Oscillator Phase Relative to Controller 1 180 DEG

Minimum Duty Cycle VFB < V

Minimum Duty Cycle VFB > V

MAX

MAX

● 710 %

● 0%

Maximum Duty Cycle ● 87 90 93 %

Driver Nonoverlap Test Circuit 1 (Note 9) ● 40 100 ns

Driver Rise/Fall Time Test Circuit 1 (Note 9) ● 12 80 ns

FB DC Gain ● 74 85 dB

FB Sink/Source Current COMPN Output ● ±3 ±10 mA

MIN Comparator Threshold ● 760 785 mV

MAX Comparator Threshold ● 815 840 mV

I

Gain 40 dB

LIM

I

Source Current I

MAX

FAULT Trip Point VFB Relative to Regulated V

FAULT Output Low Voltage I

FAULT Output Current V

FAULT Delay Time VFB > V

VID Input Pull-Up Resistance V

= 0V ● –7 –10 –14 µA

MAX

OUT

= 1mA ● 0.03 0.1 V

FAULT

= 0V –10 µA

FAULT

to FAULT (Note 9) 25 µs

FAULT

= 0.6V (Note 8) 40 kΩ

DIODE

● +10 +15 +20 %

VID Input Voltage Threshold VIL (2.7V ≤ VCC ≤ 5.5V) 0.4 V

(2.7V ≤ VCC ≤ 5.5V) 1.6 V

V

IH

VID Input Leakage Current VCC < VID < 7V (Note 8) 0.01 ±1 µA

VID Pull-Up Voltage VCC = 3.3V 2.8 V

= 5V 4.5 V

V

CC

Note 5: Supply current in normal operation is dominated by the current

needed to charge and discharge the external MOSFET gates. This current

will vary with supply voltage and the external MOSFETs used.

Note 6: Supply current in shutdown is dominated by external MOSFET

leakage and may be significantly higher than the quiescent current drawn

by the LTC1873, especially at elevated temperature.

and BVCC (V

CC

– VSW) must be greater than V

BOOST

GS(ON)

of

Note 7: Feedback current at FB1 will be higher due to internal VID

resistors.

Note 8: Each built-in pull-up resistor attached to the VID inputs also has a

series diode connected to V

to allow input voltages higher than the V

CC

CC

supply without damage or clamping. (See Block Diagram.)

Note 9: Rise and fall times are measured at 20% to 80% levels. Delay and

nonoverlap times are measured using 50% levels.

3

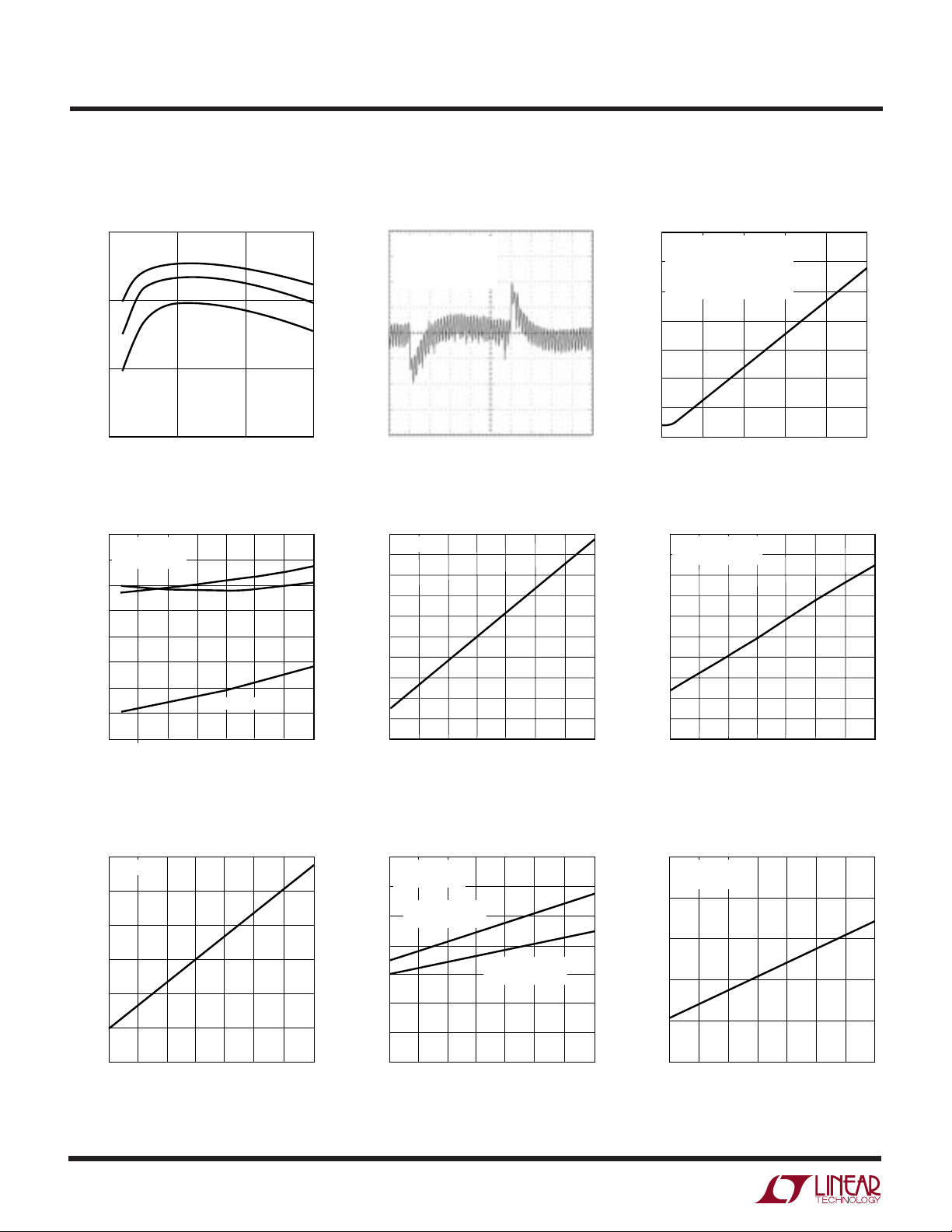

Page 4

LTC1873

TEMPERATURE (°C)

–50

0.4

R

ON

(Ω)

0.5

0.7

0.8

0.9

1.4

1.1

0

50

75

1873 G06

0.6

1.2

1.3

1.0

–25

25

100

125

V

PVCC

= 5V

V

BOOST

– VSW = 5V

GATE CAPACITANCE (pF)

0

25

30

35

6000 8000

1873 G03

20

15

2000 4000 10000

10

5

0

DRIVER SUPPLY CURRENT (mA)

TEST CIRCUIT 1

ONE DRIVER LOADED

MULTIPLY BY # OF ACTIVE

DRIVERS TO OBTAIN TOTAL

DRIVER SUPPLY CURRENT

TEMPERATURE (°C)

–50 –25

12

RISE/FALL TIME (ns)

12

15

0

50

75

1873 G09

11

14

13

25

100

125

TEST CIRCUIT 1

C

L

= 2000pF

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Efficiency vs Load Current

100

= 5V

V

IN

90

EFFICIENCY (%)

80

V

OUT

V

OUT

V

OUT

= 3.3V

= 2.5V

= 1.6V

Transient Response

VIN = 5V

= 1.8V

V

OUT

I

= 0A-10A-0A

LOAD

±2.2% MAX DEVIATION

20mV/

DIV

MOSFET Driver Supply Current

vs Gate Capacitance

70

0

Supply Current vs Temperature

2.6

TEST CIRCUIT 1

= 0pF

C

2.4

L

2.2

2.0

1.8

1.6

SUPPLY CURRENT (mA)

1.4

1.2

1.0

–25 0 50

–50

RUN/SS Source Current

vs Temperature

5.0

VCC = 5V

4.5

4.0

3.5

3.0

SOURCE CURRENT (µA)

2.5

2.0

–50

–25 0

4

510

LOAD CURRENT (A)

PV

CC

V

CC

BOOST1, BOOST2

25

TEMPERATURE (°C)

50 100 125

25 75

TEMPERATURE (°C)

15

1873 G01

75 100 125

1873 G04

1873 G07

10µs/DIV

Frequency Drift vs Temperature

2.5

VCC = 5V

2.0

1.5

1.0

0.5

0

–0.5

–1.0

FREQUENCY DRIFT (%)

–1.5

–2.0

–2.5

–50

–25

0

TEMPERATURE (°C)

50

25

1873 G02

Driver RON vs Temperature

100

125

1873 G05

75

Nonoverlap Time vs Temperature Driver Rise/Fall vs Temperature

70

TEST CIRCUIT 1

C

= 2000pF

L

60

TG FALLING EDGE

50

BG RISING EDGE

40

30

20

NONOVERLAP TIME (ns)

10

0

–50

–25 0

BG FALLING EDGE

TG RISING EDGE

50 100 125

25 75

TEMPERATURE (°C)

1873 G08

Page 5

LTC1873

U

UU

PI FU CTIO S

PVCC (Pin 1): Driver Power Supply Input. PVCC provides

power to the two BGn output drivers. PVCC must be

connected to a voltage high enough to fully turn on the

external MOSFETs QB1 and QB2. PVCC should generally

be connected directly to VIN. PVCC requires at least a 1µF

bypass capacitor directly to PGND.

BOOST1 (Pin 2): Controller 1 Top Gate Driver Supply. The

BOOST1 pin supplies power to the floating TG1 driver.

BOOST1 should be bypassed to SW1 with a 1µF capacitor.

An additional Schottky diode from VIN to BOOST1 pin will

create a complete floating charge-pumped supply at

BOOST1. No other external supplies are required.

BG1 (Pin 3): Controller 1 Bottom Gate Drive. The BG1 pin

drives the gate of the bottom N-channel synchronous

switch MOSFET, QB1. BG1 is designed to drive up to

10,000pF of gate capacitance directly. If RUN/SS1 goes

low, BG1 will go low, turning off QB1. If FAULT mode is

tripped, BG1 will go high and stay high, keeping QB1 on

until the power is cycled.

TG1 (Pin 4): Controller 1 Top Gate Drive. The TG1 pin

drives the gate of the top N-channel MOSFET, QT1. The

TG1 driver draws power from the BOOST1 pin and returns

to the SW1 pin, providing true floating drive to QT1. TG1

is designed to drive up to 10,000pF of gate capacitance

directly. In shutdown or fault modes, TG1 will go low.

SW1 (Pin 5): Controller 1 Switching Node. SW1 should be

connected to the switching node of converter 1. The TG1

driver ground returns to SW1, providing floating gate

drive to the top N-channel MOSFET switch, QT1. The

voltage at SW1 is compared to I

comparator while the bottom MOSFET, QB1, is on.

I

(Pin 6): Controller 1 Current Limit Set. The I

MAX1

pin sets the current limit comparator threshold for

controller 1. If the voltage drop across the bottom MOSFET,

QB1, exceeds the magnitude of the voltage at I

controller 1 will go into current limit. The I

internal 10µA current source pull-up, allowing the current

threshold to be set with a single external resistor to PGND.

This current setting resistor should be Kelvin connected to

the source of QB1. See the Current Limit Programming

section for more information on choosing R

by the current limit

MAX1

MAX1

IMAX

MAX1

MAX1

pin has an

.

,

FCB (Pin 7): Force Continuous Bar. The FCB pin forces

both converters to maintain continuous synchronous

operation regardless of load when the voltage at FCB

drops below 0.8V. FCB is normally tied to VCC. To force

continuous operation, tie FCB to SGND. FCB can also be

connected to a feedback resistor divider from a secondary

winding on one converter’s inductor to generate a third

regulated output voltage. Do not leave FCB floating.

RUN/SS1 (Pin 8): Controller 1 Run/Soft-Start. Pulling

RUN/SS1 to SGND will disable controller 1 and turn off

both of its external MOSFET switches. Pulling both

RUN/SS pins down will shut down the entire LTC1873,

dropping the quiescent supply current below 50µA. A

capacitor from RUN/SS1 to SGND will control the turn-on

time and rate of rise of the controller 1 output voltage at

power-up. An internal 3.5µA current source pull-up at

RUN/SS1 pin sets the turn-on time at approximately

50ms/µF.

COMP1 (Pin 9): Controller 1 Loop Compensation. The

COMP1 pin is connected directly to the output of the first

controller’s error amplifier and the input to the PWM

comparator. An RC network is used at the COMP1 pin to

compensate the feedback loop for optimum transient

response.

SGND (Pin 10): Signal Ground. All internal low power

circuitry returns to the SGND pin. Connect to a low

impedance ground, separated from the PGND node. All

feedback, compensation and soft-start connections should

return to SGND. SGND and PGND should connect only at

a single point, near the PGND pin and the negative plate of

the CIN bypass capacitor.

FB1 (Pin 11): Controller 1 Feedback Input. The loop

compensation network for controller 1 should be connected to FB1. FB1 is connected internally to the VID

resistor network to set the output voltage at side 1.

SENSE (Pin 12): Output Sense. Connect to V

VID0 to VID4 (Pins 13 to 17): VID Programming Inputs.

These are logic inputs that set the output voltage at side 1

to a preprogrammed value (see Table 1). VID4 is the MSB,

VID0 is the LSB. The codes selected by the VIDn inputs

correspond to the Intel Desktop VID specification. Each

OUT1

.

5

Page 6

LTC1873

U

UU

PI FU CTIO S

VIDn pin includes an on-chip 40kΩ pull-up resistor in

series with a diode (see Block Diagram).

VCC (Pin 18): Power Supply Input. All internal circuits

except the output drivers are powered from this pin. V

should be connected to a low noise power supply voltage

between 3V and 7V and should be bypassed to SGND with

at least a 1µF capacitor in close proximity to the LTC1873.

FB2 (Pin 19): Controller 2 Feedback Input. FB2 should be

connected through a resistor divider network to V

set the ouput voltage. The loop compensation network for

controller 2 also connects to FB2.

COMP2 (Pin 20): Controller 2 Loop Compensation. See

COMP1.

RUN/SS2 (Pin 21): Controller 2 Run/Soft-Start. See RUN/

SS1.

FAULT (Pin 22): Output Overvoltage Fault (Latched). The

FAULT pin is an open-drain output with an internal 10µA

pull-up. If either regulated output voltage rises more than

15% above its programmed value for more than 25µs, the

FAULT output will go high and the entire LTC1873 will be

OUT2

CC

to

disabled. When FAULT is high, both BG pins will go high,

turning on the bottom MOSFET switches and pulling down

the high output voltage. The LTC1873 will remain latched

in this state until the power is cycled. When FAULT mode

is active, the FAULT pin will be pulled up with an internal

10µA current source. Tying FAULT directly to SGND will

disable latched FAULT mode and will allow the LTC1873 to

resume normal operation when the overvoltage fault is

removed.

PGND (Pin 23): Power Ground. The BGn drivers return to

this pin. Connect PGND to a high current ground node in

close proximity to the sources of external MOSFETs, QB1

and QB2, and the VIN and V

bypass capacitors.

OUT

SW2 (Pin 24): Controller 2 Switching Node. See SW1.

TG2 (Pin 25): Controller 2 Top Gate Drive. See TG1.

BG2 (Pin 26): Controller 2 Bottom Gate Drive. See BG1.

BOOST2 (Pin 27): Controller 2 Top Gate Driver Supply.

See BOOST1.

I

(Pin 28): Controller 2 Current Limit Set. See I

MAX2

MAX1

.

TEST CIRCUIT

f

OSC

MEASURED

V

FB1

Test Circuit 1

5V

I

0.1µF

2k

BOOST1ICC

V

CC

BOOST1

TG1

BG1

2000pF2000pF 2000pF

SW1

I

MAX1

LTC1873

FCB

NC

VID0:4

RUN/SS1

NC NC

COMP1

FB1

SENSE

GND PGND

I

PVCC

PV

CC

BOOST2

SW2

I

MAX2

FAULT

RUN/SS2

COMP2

TG2

BG2

FB2

I

BOOST2

2000pF

2k

+

100µF

V

V

FAULT

FB2

1873 TC

6

Page 7

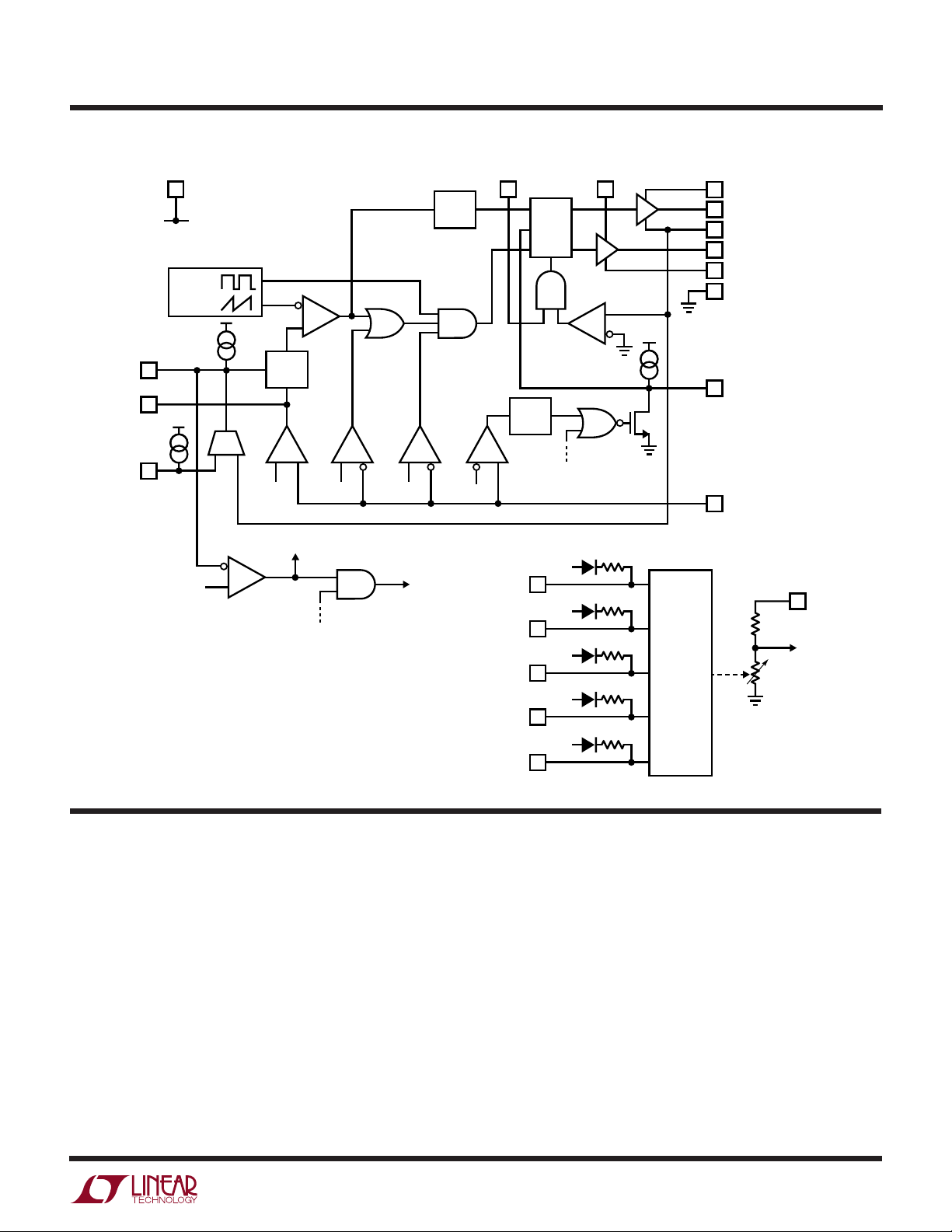

BLOCK DIAGRA

V

CC

OSC

550kHz

3.5µA

RUN/SS1,2

COMP1,2

I

LIM

800mV 760mV 840mV

SHUTDOWN TO

THIS CONTROLLER

I

MAX1,2

10µA

500mV

W

90% DUTY CYCLE

SOFT

START

FB

+

–

FROM

OTHER

CONTROLLER

MIN MAX

BURST

LOGIC

920mV

SHUTDOWN TO

ENTIRE CHIP

FLT

0V

FCB

VID0

VID1

VID2

VID3

VID4

DRIVE

LOGIC

25µs

DELAY

CONTROLLER

FROM

OTHER

V

CC

V

CC

V

CC

V

CC

V

CC

DIS

LTC1873

PV

40k

40k

40k

40k

40k

CC

10µA

SWITCH

CONTROL

LOGIC

BOOST1,2

TG1,2

SW1,2

BG1,2

PGND

SGND

FAULT

FB1,2

R11

20k

R

SENSE

TO FB1

B1

1873 BD

WUUU

APPLICATIO S I FOR ATIO

OVERVIEW

The LTC1873 is a dual, step-down (buck), voltage mode

feedback switching regulator controller. It is designed to

be used in a synchronous switching architecture with two

external N-channel MOSFETs per channel. It is intended to

operate from a low voltage input supply (7V maximum)

and provide a high power, high efficiency, precisely regulated output voltage. Several features make it particularly

suited for microprocessor supply regulation. Output regulation is extremely tight, with DC line and load regulation

and initial accuracy better than 1.5%, and total regulation

including transient response inside of 3.5% with a prop-

erly designed circuit. The 550kHz switching frequency

allows the use of physically small, low value external

components without compromising performance. An

onboard DAC sets the output voltage at channel 1, consistent with the Intel desktop VID specification (Table 1).

The LTC1873’s internal feedback amplifier is a 25MHz

gain-bandwidth op amp, allowing the use of complex

multipole/zero compensation networks. This allows the

feedback loop to maintain acceptable phase margin at

higher frequencies than traditional switching regulator

controllers allow, improving stability and maximizing transient response. The 800mV internal reference at channel

2

7

Page 8

LTC1873

WUUU

APPLICATIO S I FOR ATIO

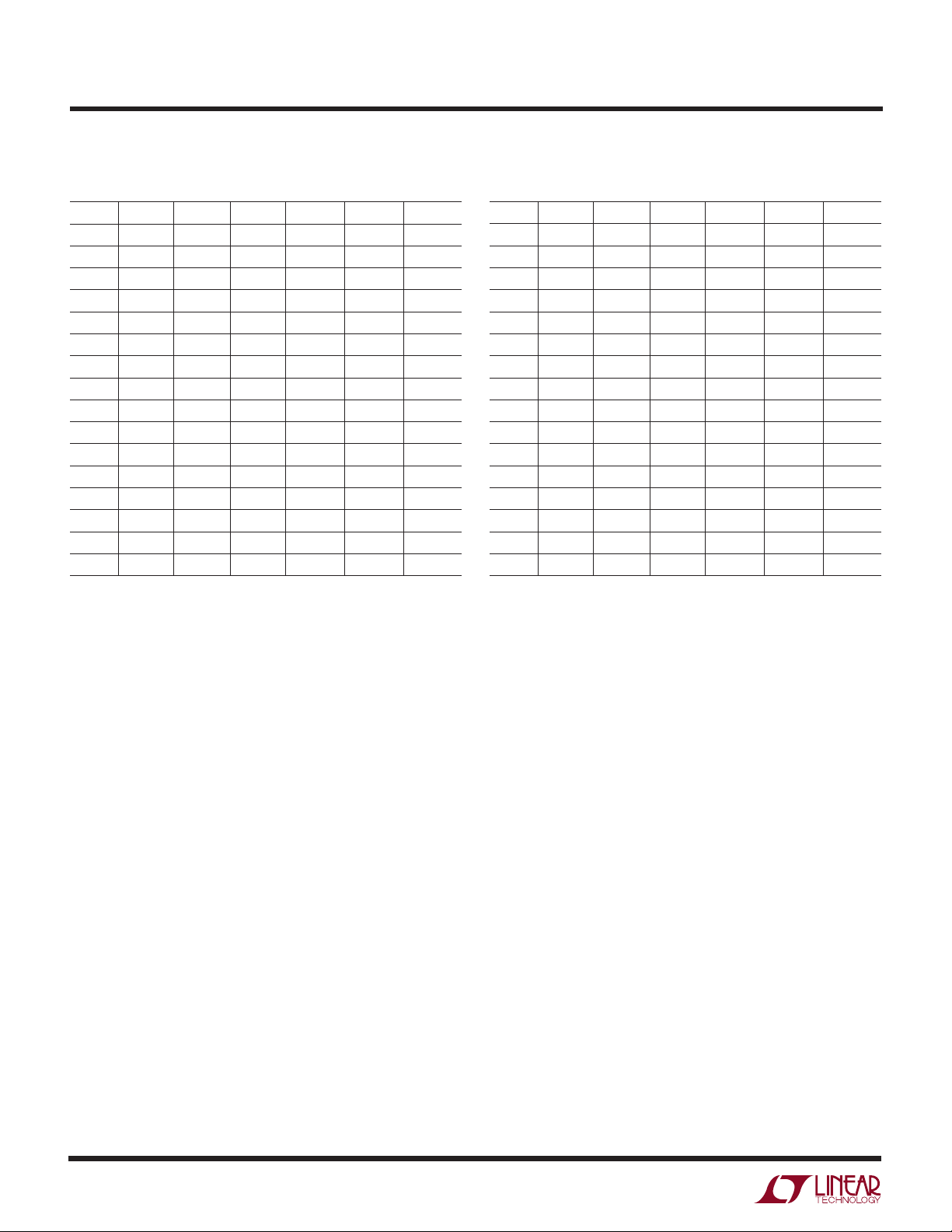

Table 1. VID Inputs and Corresponding Output Voltage for

Channel 1

CODE VID4 VID3 VID2 VID1 VID0 V

00000 GND GND GND GND GND 2.05V

00001 GND GND GND GND Float 2.00V

00010 GND GND GND Float GND 1.95V

00011 GND GND GND Float Float 1.90V

00100 GND GND Float GND GND 1.85V

00101 GND GND Float GND Float 1.80V

00110 GND GND Float Float GND 1.75V

00111 GND GND Float Float Float 1.70V

01000 GND Float GND GND GND 1.65V

01001 GND Float GND GND Float 1.60V

01010 GND Float GND Float GND 1.55V

01011 GND Float GND Float Float 1.50V

01100 GND Float Float GND GND 1.45V

01101 GND Float Float GND Float 1.40V

01110 GND Float Float Float GND 1.35V

01111 GND Float Float Float Float 1.30V

* 11111 is defined by Intel to signify “no CPU.” The LTC1873

will generate the output voltage shown when this codes is selected.

OUT1

CODE VID4 VID3 VID2 VID1 VID0 V

10000 Float GND GND GND GND 3.50V

10001 Float GND GND GND Float 3.40V

10010 Float GND GND Float GND 3.30V

10011 Float GND GND Float Float 3.20V

10100 Float GND Float GND GND 3.10V

10101 Float GND Float GND Float 3.00V

10110 Float GND Float Float GND 2.90V

10111 Float GND Float Float Float 2.80V

11000 Float Float GND GND GND 2.70V

11001 Float Float GND GND Float 2.60V

11010 Float Float GND Float GND 2.50V

11011 Float Float GND Float Float 2.40V

11100 Float Float Float GND GND 2.30V

11101 Float Float Float GND Float 2.20V

11110 Float Float Float Float GND 2.10V

11111* Float Float Float Float Float 2.00V

OUT1

allows regulated output voltages as low as 800mV without

external level shifting amplifiers.

The LTC1873’s synchronous switching logic transitions

automatically into Burst Mode operation, maximizing efficiency with light loads. An onboard overvoltage (OV) fault

flag indicates when an OV fault has occurred. The OV flag

can be set to latch the device off when an OV fault has

occurred, or to automatically resume operation when the

fault is removed.

2-Phase Operation

The LTC1873 dual switching regulator controller offers

considerable benefits using 2-phase operation. Circuit

benefits include lower input filtering requirements,

reduced electromagnetic interference (EMI) and increased

efficiency associated with 2-phase operation.

Why the need for 2-phase operation? Until recently, constant-frequency dual switching regulators operated both

channels in phase (i.e., single-phase operation). This

means that both topside MOSFETs turned on at the same

time, causing current pulses of up to twice the amplitude

of those for one regulator to be drawn from the input

capacitor. These large amplitude current pulses increased

the total RMS current flowing from the input capacitor,

requiring the use of more expensive input capacitors and

increasing both EMI and losses in the input capacitor and

input power supply.

With 2-phase operation, the two channels of the LTC1873

are operated 180 degrees out of phase. This effectively

interleaves the current pulses coming from the switches,

greatly reducing the overlap time where they add together.

The result is a significant reduction in total RMS input

current, which in turn allows less expensive input capacitors to be used, reduces shielding requirements for EMI

and improves real world operating efficiency.

Figure 7 shows example waveforms for a single switching

regulator channel versus a 2-phase LTC1873 system with

both sides switching. A single-phase dual regulator with

both sides operating would exhibit double the single side

numbers. In this example, 2-phase operation reduced the

RMS input current from 9.3A

4.8A

. While this is an impressive reduction in itself,

RMS

remember that the power losses are proportional to I

(2 × 4.66A

RMS

RMS

) to

RMS

2

,

meaning that the actual power wasted is reduced by a

8

Page 9

WUUU

APPLICATIO S I FOR ATIO

LTC1873

factor of 3.75. The reduced input ripple voltage also means

less power is lost in the input power path, which could

include batteries, switches, trace/connector resistances

and protection circuitry. Improvements in both conducted

and radiated EMI also directly accrue as a result of the

reduced RMS input current and voltage.

Small Footprint

The LTC1873 operates at a 550kHz switching frequency,

allowing it to use low value inductors without generating

excessive ripple currents. Because the inductor stores

less energy per cycle, the physical size of the inductor can

be reduced without risking core saturation, saving PCB

board space. The high operating frequency also means

less energy is stored in the output capacitors between

cycles, minimizing their required value and size. The

remaining components, including the SSOP-28 LTC1873,

are tiny, allowing an entire dual-output LTC1873 circuit to

be constructed in 1.5in2 of PCB space. Further, this space

is generally located right next to the microprocessor or in

some similarly congested area, where PCB real estate is at

a premium.

Fast Transient Response

The voltage mode feedback loop and MOSFET VDS current

limit sensing remove the need for an external current

sense resistor, eliminating an external component and a

source of power loss in the high current path. Properly

designed circuits using low gate charge MOSFETs are

capable of efficiencies exceeding 90% over a wide range

of output voltages.

VID Programming

The LTC1873 includes an onboard feedback network that

programs the output voltage at side 1 in accordance with

the Intel Desktop VID specification (Table 1). The network

includes a 20k resistor (R1) connected from SENSE to

FB1, and a variable value resistor (RB) from FB1 to SGND,

with the value set by the digital code present at the VID0:4

pins. SENSE should be connected to V

network to monitor the output voltage. No additional

feedback components are required to set the output voltage at controller 1, although loop compensation components are still required. Each VIDn pin includes an internal

40k pull-up resistor, allowing it to float high if left unconnected. The pull-up resistors are connected to VCC through

diodes (see Block Diagram), allowing the VIDn pins to be

pulled above VCC without damage.

to allow the

OUT1

The LTC1873 uses a fast 25MHz GBW op amp as an error

amplifier. This allows the compensation network to be

designed with several poles and zeros in a more flexible

configuration than with a typical gm feedback amplifier.

The high bandwidth of the amplifier, coupled with the high

switching frequency and the low values of the external

inductor and output capacitor, allow very high loop crossover frequencies. The low inductor value is the other half

of the equation—with a typical value on the order of 1µH,

the inductor allows very fast di/dt slew rates. The result is

superior transient response compared with conventional

solutions.

High Efficiency

The LTC1873 uses a synchronous step-down (buck)

architecture, with two external N-channel MOSFETs per

output. A floating topside driver and a simple external

charge pump provide full gate drive to the upper MOSFET.

Note that code 11111, defined by Intel to indicate “no CPU

present,” does generate an output voltage at V

Note also that controller 2 on the LTC1873 is not connected to the VID circuitry, and works independently from

controller 1.

ARCHITECTURE DETAILS

The LTC1873 dual switching regulator controller includes

two independent regulator channels. The two sides of the

chip and their corresponding external components act

independently of each other with the exception of the

common input bypass capacitor, the VID circuitry at side

1, and the FCB and FAULT pins, which affect both channels. In the following discussions, when a pin is referred

to without mentioning which side is involved, that discussion applies equally to both sides.

OUT1

(2.00V).

9

Page 10

LTC1873

+

TG

BOOST

SW

BG

PGND

PV

CC

D

CP

C

IN

+

C

OUT

1873 F02

V

OUT

L

EXT

V

IN

QT

QB

C

CP

1µF

LTC1873

WUUU

APPLICATIO S I FOR ATIO

Switching Architecture

Each half of the LTC1873 is designed to operate as a

synchronous buck converter (Figure 1). Each channel

includes two high power MOSFET gate drivers to control

external N-channel MOSFETs QT and QB. These drivers

have 0.5Ω output impedances and can carry well over an

amp of continuous current with peak currents up to 5A to

slew large MOSFET gates quickly. The external MOSFETs

are connected with the drain of QT attached to the input

supply and the source of QT at the switching node SW. QB

is the synchronous rectifier with its drain at SW and its

source at PGND. SW is connected to one end of the

inductor, with the other end connected to V

capacitor is connected from V

to PGND.

OUT

. The output

OUT

When a switching cycle begins, QB is turned off and QT is

turned on. SW rises almost immediately to VIN and the

inductor current begins to increase. When the PWM pulse

finishes, QT turns off and one nonoverlap interval later, QB

turns on. Now SW drops to PGND and the inductor current

decreases. The cycle repeats with the next tick of the

master clock. The percentage of time spent in each mode

is controlled by the duty cycle of the PWM signal, which in

turn is controlled by the feedback amplifier. The master

clock runs at a 550kHz rate and turns QT once every 1.8µs.

In a typical application with a 5V input and a 1.5V output,

the duty cycle will be set at 1.5/5 × 100% or 30% by the

feedback loop. This will give roughly a 540ns on-time for

QT and a 1.26µs on-time for QB.

This constant frequency operation brings with it a couple

of benefits. Inductor and capacitor values can be chosen

with a precise operating frequency in mind and the feedback loop components can be similarly tightly specified.

Noise generated by the circuit will always be in a known

frequency band with the 550kHz frequency designed to

leave the 455kHz IF band free of interference. Subharmonic

oscillation and slope compensation, common headaches

with constant frequency current mode switchers, are

absent in voltage mode designs like the LTC1873.

During the time that QT is on, its source (the SW pin) is at

VIN. VIN is also the power supply for the LTC1873. However, QT requires VIN + V

at its gate to achieve

GS(ON)

minimum RON. This presents a problem for the LTC1873—

it needs to generate a gate drive signal at TG higher than

its highest supply voltage. To accomplish this, the TG

driver runs from floating supplies, with its negative supply

attached to SW and its power supply at BOOST. This

allows

it to slew up and down with the source of QT. In combination

with a simple external charge pump (Figure 2),

this allows

the LTC1873 to completely enhance the gate of QT without

requiring an additional, higher supply voltage.

The two channels of the LTC1873 run from a common

clock, with the phasing chosen to be 180° from side 1 to

side 2. This has the effect of doubling the frequency of the

switching pulses seen by the input bypass capacitor,

significantly lowering the RMS current seen by the capacitor and reducing the value required (see the 2-Phase

section).

Feedback Amplifier

Each side of the LTC1873 senses the output voltage at

V

with an internal feedback op amp (see Block Dia-

OUT

gram). This is a real op amp with a low impedance output,

85dB open-loop gain and 25MHz gain-bandwidth product.

The positive input is connected internally to an 800mV

reference, while the negative input is connected to the FB

10

V

IN

TG

1/2

SW

LTC1873

PGND

BG

Figure 1. Synchronous Buck Architecture

QT

L

EXT

QB

+

C

IN

V

+

OUT

C

OUT

1873 F01

Figure 2. Floating TG Driver Supply

Page 11

WUUU

APPLICATIO S I FOR ATIO

LTC1873

pin. The output is connected to COMP, which is in turn

connected to the soft-start circuitry and from there to the

PWM generator.

Unlike many regulators that use a resistor divider connected to a high impedance feedback input, the LTC1873

is designed to use an inverting summing amplifier topology with the FB pin configured as a virtual ground. This

allows flexibility in choosing pole and zero locations not

available with simple gm configurations. In particular, it

allows the use of “type 3” compensation, which provides

a phase boost at the LC pole frequency and significantly

improves loop phase margin (see Figure 3). The Feedback

Loop/Compensation section contains a detailed explanation of type 3 feedback loops. Note that side 1 of the

LTC1873 includes R1 and RB internally as part of the VID

DAC circuitry.

C3

R3

R1

B

V

OUT

COMP

0.8V

+

FB

–

C2

R2

FB

R

C1

1873 F03

to resume normal operation when the fault is removed.

The overvoltage protection circuit can optionally be set to

latch the output off permanently (see the Overvoltage Fault

section).

The MIN comparator (see Block Diagram) trips whenever

FB is more than 5% below 800mV and immediately forces

the switch duty cycle to 90% to bring the output voltage

back into range. It releases when FB is within the 5%

window. MIN is disabled when the soft-start or current

limit circuits are active—the only two times that the

output should legitimately be below its regulated value.

Notice that the FB pin is the virtual ground node of the

feedback amplifier. A typical compensation network does

not include local DC feedback around the amplifier, so that

the DC level at FB will be an accurate replica of the output

voltage, divided down by R1 and RB (Figure 3). However,

the compensation capacitors will tend to attenuate AC

signals at FB, especially with low bandwidth type 1 feedback loops. This creates a situation where the MIN and

MAX comparators do not respond immediately to shifts in

the output voltage, since they monitor the output at FB.

Maximizing feedback loop bandwidth will minimize these

delays and allow MIN and MAX to operate properly. See

the Feedback Loop/Compensation section.

Figure 3. “Type 3” Feedback Loop (Side 2 Shown)

MIN/MAX COMPARATORS

Two additional feedback loops keep an eye on the primary

feedback amplifier and step in if the feedback node moves

±5% from its nominal 800mV value. The MAX comparator

(see Block Diagram) activates whenever FB rises more

than 5% above 800mV. It immediately turns the top

MOSFET (QT) off and the bottom MOSFET (QB) on and

keeps them that way until FB falls back within 5% of its

nominal value. This pulls the output down as fast as

possible, preventing damage to the (often expensive)

load. If FB rises because the output is shorted to a higher

supply, QB will stay on until the short goes away, the

higher supply current limits or QB dies trying to save the

load. This behavior provides maximum protection against

overvoltage faults at the output, while allowing the circuit

SHUTDOWN/SOFT-START

Each half of the LTC1873 has a RUN/SS pin. The RUN/SS

pins perform two functions: when pulled to ground, each

shuts down its half of the LTC1873, and each acts as a

conventional soft-start pin, enforcing a maximum duty

cycle limit proportional to the voltage at RUN/SS. An

internal 3.5µA current source pull-up is connected to each

RUN/SS pin, allowing a soft-start ramp to be generated

with a single external capacitor to ground. The 3.5µA

current sources are active even when the LTC1873 is shut

down, ensuring the device will start when any external

pull-down at RUN/SS is released. Either side can be shut

down without affecting the operation of the other side. If

both sides are shut down at the same time, the LTC1873

goes into a micropower sleep mode, and quiescent current drops typically below 50µA. Entering sleep mode also

resets the FAULT latch, if it was set.

11

Page 12

LTC1873

WUUU

APPLICATIO S I FOR ATIO

Each RUN/SS pin shuts down its half of the LTC1873 when

it falls below about 0.5V (Figure 4). Between 0.5V and

about 1V, that half is active, but the maximum duty cycle

is limited to 10%. The maximum duty cycle limit increases

linearly between 1V and 2.5V, reaching its final value of

90% when RUN/SS is above 2.5V. Somewhere before this

point, the feedback amplifier will assume control of the

loop and the output will come into regulation. When RUN/

SS rises to 0.5V below VCC, the MIN feedback comparator

is enabled, and the LTC1873 is in full operation.

CURRENT LIMIT

The LTC1873 includes an onboard current limit circuit that

limits the maximum output current to a user-programmed

level. It works by sensing the voltage drop across QB

during the time that QB is on and comparing that voltage

to a user-programmed voltage at I

. Since QB looks like

MAX

a low value resistor during its on-time, the voltage drop

across it is proportional to the current flowing in it. In a

buck converter, the average current in the inductor is equal

to the output current. This current also flows through QB

during its on-time. Thus, by watching the voltage across

QB, the LTC1873 can monitor the output current.

Any time QB is on and the current flowing to the output is

reasonably large, the SW node at the drain of QB will be

somewhat negative with respect to PGND. The LTC1873

senses this voltage and inverts it to allow it to compare the

sensed voltage with a positive voltage at the I

I

pin includes a trimmed 10µA pull-up, enabling the

MAX

user to set the voltage at I

with a single resistor, R

MAX

MAX

pin. The

IMAX

,

to ground. The LTC1873 compares the two inputs and

begins limiting the output current when the magnitude of

the negative voltage at the SW pin is greater than the

voltage at I

The current limit detector is connected to an internal g

MAX

.

m

amplifier that pulls a current from the RUN/SS pin proportional to the difference in voltage magnitudes between the

SW and I

pins. This current begins to discharge the

MAX

soft-start capacitor at RUN/SS, reducing the duty cycle

and controlling the output voltage until the current drops

below the limit. The soft-start capacitor needs to move a

fair amount before it has any effect on the duty cycle,

adding a delay until the current limit takes effect (Figure 4).

This allows the LTC1873 to experience brief overload

conditions without affecting the output voltage regulation.

The delay also acts as a pole in the current limit loop to

V

RUN/SS

V

OUT

0V

5V

2.5V 2.5V

1.0V

0.5V

0V

LTC1873 ENABLED

RUN/SS CONTROLS

DUTY CYCLE

START-UP NORMAL OPERATION CURRENT LIMIT

Figure 4. Soft-Start Operation in Start-Up and Current Limit

4.5V

RUN/SS CONTROLS

DUTY CYCLE

COMP CONTROLS DUTY CYCLE

MIN COMPARATOR ENABLED

1873 F04

12

Page 13

WUUU

APPLICATIO S I FOR ATIO

LTC1873

enhance loop stability. Larger overloads cause the softstart capacitor to pull down quickly, protecting the output

components from damage. The current limit gm amplifier

includes a clamp to prevent it from pulling RUN/SS below

0.5V and shutting off the device.

Power MOSFET R

limiting the accuracy obtainable from the LTC1873 current

limit loop. Additionally, ringing on the SW node due to

parasitics can add to the apparent current, causing the

loop to engage early. The LTC1873 current limit is

designed primarily as a disaster prevention, “no blow up”

circuit, and is not useful as a precision current regulator.

It should typically be set around 50% above the maximum

expected normal output current to prevent component

tolerances from encroaching on the normal current range.

See the Current Limit Programming section for advice on

choosing a valve for R

DISCONTINUOUS/Burst Mode OPERATION

Theory of operation

The LTC1873 switching logic has three modes of operation. Under heavy loads, it operates as a fully synchronous, continuous conduction switching regulator. In this

mode of operation (“continuous” mode), the current in the

inductor flows in the positive direction (toward the output)

during the entire switching cycle, constantly supplying

current to the load. In this mode, the synchronous switch

(QB) is on whenever QT is off, so the current always flows

through a low impedance switch, minimizing voltage drop

and power loss. This is the most efficient mode of operation at heavy loads, where the resistive losses in the power

devices are the dominant loss term.

Continuous mode works efficiently when the load current

is greater than half of the ripple current in the inductor. In

a buck converter like the LTC1873, the average current in

the inductor (averaged over one switching cycle) is equal

to the load current. The ripple current is the difference

between the maximum and the minimum current during a

switching cycle (see Figure 5a). The ripple current

depends on inductor value, clock frequency and output

voltage, but is constant regardless of load as long as the

LTC1873 remains in continuous mode. See the Inductor

varies from MOSFET to MOSFET,

DS(ON)

.

IMAX

Selection section for a detailed description of ripple

current.

As the output load current decreases in continuous mode,

the average current in the inductor will reach a point where

it drops below half the ripple current. At this point, the

current in the inductor will reverse during a portion of the

switching cycle, or begin to flow from the output back to

the input. This does not adversely affect regulation, but

does cause additional losses as a portion of the inductor

current flows back and forth through the resistive power

switches, giving away a little more power each time and

lowering the efficiency. There are some benefits to allowing this reverse current flow: the circuit will maintain

regulation even if the load current drops below zero (the

load supplies current to the LTC1873) and the output

ripple voltage and frequency remain constant at all loads,

easing filtering requirements. Circuits that take advantage

of this behavior can force the LTC1873 to operate in

continuous mode at all loads by tying the FCB (Force

Continuous Bar) pin to ground.

Discontinuous Mode

To minimize the efficiency loss due to reverse current flow

at light loads, the LTC1873 switches to a second mode of

operation: discontinuous mode (Figure 5b). In discontinuous mode, the LTC1873 detects when the inductor current

approaches zero and turns off QB for the remainder of the

switch cycle. During this time, the voltage at the SW pin

will float about V

be zero, and the inductor current remains zero until the

next switching cycle begins andQT turns on again. This

prevents current from flowing backwards in QB, eliminating that power loss term. It also reduces the ripple current

in the inductor as the output current approaches zero.

The LTC1873 detects that the inductor current has reached

zero by monitoring the voltage at the SW pin while QB is

on. Since QB acts like a resistor, SW should ideally be right

at 0V when the inductor current reaches zero. In reality, the

SW node will ring to some degree immediately after it is

switched to ground by QB, causing some uncertainty as to

the actual moment the average current in QB goes to zero.

The LTC1873 minimizes this effect by ignoring the SW

node for a fixed 50ns after QB turns on when the ringing

, the voltage across the inductor will

OUT

13

Page 14

LTC1873

WUUU

APPLICATIO S I FOR ATIO

is most severe, and by including a few millivolts offset in

the comparator that monitors the SW node. Despite these

precautions, some combinations of inductor and layout

parasitics can cause the LTC1873 to enter discontinuous

mode erratically. In many cases, the time that QB turns off

will correspond to a peak in the ringing waveform at the

SW pin (Figure 6). This erratic operation isn’t pretty, but

retains much of the efficiency benefit of discontinuous

mode and maintains regulation at all times.

I

RIPPLE

I

AVERAGE

INDUCTOR CURRENT

TIME

Figure 5a. Continuous Mode

I

RIPPLE

INDUCTOR CURRENT

TIME

1873 F05a

I

AVERAGE

1873 F05b

Burst Mode Operation

Discontinuous mode removes a loss term due to resistive

drop in QB, but the LTC1873 is still switching QT and QB

on and off once a cycle. Each time an external MOSFET is

turned on, the internal driver must charge its gate to VCC.

Each time it is turned off, that charge is lost to ground. At

the high switching frequencies that the LTC1873 operates

at, the charge lost to the gates can add up to tens of

milliamps from VCC. As the load current continues to drop,

this quickly become the dominant power loss term, reducing efficiency once again.

Once again, the LTC1873 switches to a new mode to

minimize efficiency loss: Burst Mode operation. As the

circuit goes deeper and deeper into discontinuous mode,

the total time QT and QB are on reduces. However, the ratio

of the time that QT is on to the time that QB is on must

remain constant for the output to stay in regulation. An

internal timer circuit forces QT to stay on for at least 10%

of a normal switching cycle. When the load drops to the

point that the output requires less than 10% on-time at QT,

the output voltage will begin to rise. The LTC1873 senses

this rise and shuts both QT and QB off completely, skipping several switching cycles until the output falls back

into range. It then resumes switching in discontinuous

mode with QT at 10% duty cycle and the burst sequence

repeats. The total deviation from the regulated output is

within the 1.5% regulation tolerance of the LTC1873.

14

Figure 5b. Discontinuous Mode

DISCONTINUOUS

COMPARATOR

V

SW

0V

5V

V

BG

0V

Figure 6. Ringing at SW Causes Discontinuous

Comparator to Trip Early

TURNS OFF BG

50ns

BLANK

TIME

TIME

TIME

1873 F06

In Burst Mode operation, both resistive loss and switching

loss are minimized while keeping the output in regulation.

The ripple current will be set by the 10% QT on-time and

the input supply voltage and is the lowest of all three

operating modes. As the load current falls to zero in Burst

Mode operation, the most significant loss term becomes

the 3mA quiescent current drawn by each side of the

LTC1873—usually much less than the minimum load

current in a typical low voltage logic system. Burst Mode

operation maximizes efficiency at low load currents, but

can cause low frequency ripple in the output voltage as the

cycle-skipping circuitry switches on and off.

Page 15

WUUU

APPLICATIO S I FOR ATIO

LTC1873

FCB Pin

In some circumstances, it is desirable to control or disable

discontinuous and Burst Mode operations. The FCB (Force

Continuous Bar) pin allows the user to do this. When the

FCB pin is high, the LTC1873 is allowed to enter discontinuous and Burst Mode operations at either side as

required. If FCB is taken low, discontinuous and Burst

Mode operations are disabled and both sides of the

LTC1873 run in continuous mode regardless of load. This

does not affect output regulation but does reduce efficiency at low output currents. The FCB pin threshold is

specified at 0.8V ±50mV, and includes 20mV of hysteresis, allowing it to be used as a precision small-signal

comparator.

Paralleling Outputs

Synchronous regulators (like the LTC1873) are known for

their bullheadedness when their outputs are paralleled

with other regulators. In particular, a synchronous regulator paralleled with another regulator whose output is

slightly higher (perhaps just by millivolts) will happily sink

amps of current attempting to pull its own output back

down to what it thinks is the right value.

The LTC1873 discontinuous mode allows it to be paralleled with another regulator without fighting. A typical

system might use the LTC1873 as a primary regulator and

a small LDO as a backup regulator to keep SRAM alive

when the main power is off. When the LTC1873 is shut

down (by pulling RUN/SS to ground), both QT and QB turn

off and the output goes into a high impedance state,

allowing the smaller regulator to support the output voltage. However, if the LTC1873 is powered back up in

continuous mode, it will begin a soft-start cycle with a low

duty cycle, pulling the output down and corrupting the

data stored in SRAM. The solution is to tie FCB high,

allowing the device to start in discontinuous mode. Any

reverse current flow in QB will trip the discontinuous mode

circuitry, preventing the LTC1873 from pulling down the

output.

OVERVOLTAGE FAULT

The LTC1873 includes a single overvoltage fault flag for

both channels: FAULT. FAULT is an open-drain output

with an internal 10µA pull-up. If either FB pin rises more

than 15% above the nominal 800mV value for more than

25µs, the overvoltage comparator will trip, setting an

internal latch. This latch releases the pull-down at FAULT,

allowing the 10µA pull-up to take it high. When FAULT

goes high, the LTC1873 stops all switching, turns both QB

(bottom synchronous) MOSFETs on continuously and

remains in this state until both RUN/SS pins are pulled low

simultaneously, the power supply is recycled, or the

FAULT pin is pulled low externally. This behavior is

intended to protect a potentially expensive load from

overvoltage damage at all costs. Under some conditions,

this behavior can cause the output voltage to undershoot

below ground. If latched FAULT mode is used, a Schottky

diode should be added with its cathode at the output and

its anode at ground to clamp the negative voltage to a safe

level and prevent possible damage to the load and the

output capacitors.

Note that in overvoltage conditions, the MAX comparator

will kick in at just +5%, turning QB on continuously long

before the output reaches +15%. Under most fault conditions, this is adequate to bring the output back down

without firing the fault latch. Additionally, if MAX successfully keeps the output below +15%, the LTC1873 will

resume normal regulation as soon as the output overvoltage fault is resolved.

In some circuits, the OV latch can be a liability. Consider

a circuit where the output voltage at one channel may be

changed on the fly by changing the VID code or switching

in different feedback resistors. A downward adjustment

of greater than 15% will fire the fault latch, disabling both

sides of the LTC1873 until the power is recycled. In

circuits such as this, the fault latch can be disabled by

grounding the FAULT pin. The internal latch will still be set

the first time the output exceeds +15%, but the 10µA

current source pull-up will not be able to pull FAULT high,

and the LTC1873 will ignore the latch and continue

15

Page 16

LTC1873

WUUU

APPLICATIO S I FOR ATIO

normal opera

turning on QB until output is within range and then

allowing the loop to resume normal operation. FAULT can

also be pulled down with external open-collector logic to

restart a fault-latched LTC1873 as an alternative to recycling the power. Note that this will not reset the internal

latch; if the external pull-down is released, the LTC1873

will reenter FAULT mode. To reset the latch, pull both RUN/

SS pins low simultaneously or cycle the power.

VID Considerations

Some applications change the VID codes at channel 1 on

the fly. This is possible with the LTC1873, but care must

be taken to avoid tripping the overvoltage fault circuit.

Stepping the voltage upwards abruptly is safe, but stepping down quickly by more than 15% can leave the system

in a state where the output voltage is still at the old higher

level, but the feedback node is set to expect a new,

substantially lower voltage. If this condition persists for

more than 25µs, the overvoltage fault circuitry will activate

and latch off the LTC1873.

The simplest solution is to disable the fault circuit by

grounding the FAULT pin. Systems that must keep the

fault circuit active should ensure that the output voltage is

never programmed to step down by more than 15% in any

single step. A safe strategy is to step the output down by

10% or less at a time and wait for the output to settle to the

new value before taking subsequent steps. Regardless of

the state of the FAULT pin, the load is always protected

against overvoltage faults by the +5% MAX comparator.

EXTERNAL COMPONENT SELECTION

POWER MOSFETs

Getting peak efficiency out of the LTC1873 depends strongly

on the external MOSFETs used. The LTC1873 requires at

least two external MOSFETs per side—more if one or

more of the MOSFETs are paralleled to lower on-resistance. To work efficiently, these MOSFETs must exhibit

low R

DS(ON)

is 3.3V) to minimize resistive power loss while they are

conducting current. They must also have low gate charge

to minimize transition losses during switching. On the

tion. The MAX comparator will act as usual,

at 5V VGS (3.3V VGS if the PVCC input supply

other hand, voltage breakdown requirements in a typical

LTC1873 circuit are pretty tame: the 7V maximum input

voltage limits the VDS and VGS the MOSFETs can see to

safe levels for most devices.

Low R

DS(ON)

R

the resistance from the drain to the source of the MOSFET

when the gate is fully on. Many MOSFETs have R

specified at 4.5V gate drive—this is the right number to

use in LTC1873 circuits running from a 5V supply. As

current flows through this resistance while the MOSFET is

on, it generates I2R watts of heat, where I is the current

flowing (usually equal to the output current) and R is the

MOSFET R

MOSFET is on. When it is off, the current is zero and the

power lost is also zero (and the other MOSFET is busy

losing power).

This lost power does two things: it subtracts from the

power available at the output, costing efficiency, and it

makes the MOSFET hotter—both bad things. The effect is

worst at maximum load when the current in the MOSFETs

and thus the power lost are at a maximum. Lowering

R

additional gate charge (usually) and more cost (usually).

Proper choice of MOSFET R

between tolerable efficiency loss, power dissipation and

cost. Note that while the lost power has a significant effect

on system efficiency, it only adds up to a watt or two in a

typical LTC1873 circuit, allowing the use of small, surface

mount MOSFETs without heat sinks.

Gate Charge

Gate charge is the amount of charge (essentially, the

number of electrons) that the LTC1873 needs to put into

the gate of an external MOSFET to turn it on. The easiest

way to visualize gate charge is to think of it as a capacitance

from the gate pin of the MOSFET to SW (for QT) or to PGND

(for QB). This capacitance is composed of MOSFET channel charge, actual parasitic drain-source capacitance and

Miller-multiplied gate-drain capacitance, but can be

approximated as a single capacitance from gate to source.

Regardless of where the charge is going, the fact remains

calculations are pretty straightforward. R

DS(ON)

. This heat is only generated when the

DS(ON)

improves heavy load efficiency at the expense of

DS(ON)

becomes a trade-off

DS(ON)

DS(ON)

DS(ON)

is

16

Page 17

WUUU

APPLICATIO S I FOR ATIO

LTC1873

that it all has to come out of VCC to turn the MOSFET gate

on, and when the MOSFET is turned back off, that charge

all ends up at ground. In the meanwhile, it travels through

the LTC1873’s gate drivers, heating them up. More power

lost!

In this case, the power is lost in little bite-sized chunks, one

chunk per switch per cycle, with the size of the chunk set

by the gate charge of the MOSFET. Every time the MOSFET

switches, another chunk is lost. Clearly, the faster the

clock runs, the more important gate charge becomes as a

loss term. Old-fashioned switchers that ran at 20kHz could

pretty much ignore gate charge as a loss term; in the

550kHz LTC1873, gate charge loss can be a significant

efficiency penalty. Gate charge loss can be the dominant

loss term at medium load currents, especially with large

MOSFETs. Gate charge loss is also the primary cause of

power dissipation in the LTC1873 itself.

TG Charge Pump

There’s another nuance of MOSFET drive that the LTC1873

needs to get around. The LTC1873 is designed to use

N-channel MOSFETs for both QT and QB, primarily

because N-channel MOSFETs generally cost less and have

lower R

QB on is no big deal since the source of QB is attached to

PGND; the LTC1873 just switches the BG pin between

PGND and VCC. Driving QT is another matter. The source

of QT is connected to SW which rises to VCC when QT is

on. To keep QT on, the LTC1873 must get TG one MOSFET

V

GS(ON)

with the negative lead of the driver attached to SW (the

source of QT) and the VCC lead of the driver coming out

separately at BOOST. An external 1µF capacitor (CCP)

connected between SW and BOOST (Figure 2) supplies

power to BOOST when SW is high, and recharges itself

through DCP when SW is low. This simple charge pump

keeps the TG driver alive even as it swings well above VCC.

The value of the bootstrap capacitor CCP needs to be at

least 100 times that of the total input capacitance of the

topside MOSFET(s). For very large external MOSFETs (or

multiple MOSFETs in parallel), CCP may need to be

increased beyond the 1µF value.

than similar P-channel MOSFETs. Turning

DS(ON)

above VCC. It does this by utilizing a floating driver

INPUT SUPPLY

The BiCMOS process that allows the LTC1873 to include

large MOSFET drivers on-chip also limits the maximum

input voltage to 7V. This limits the practical maximum

input supply to a loosely regulated 5V or 6V rail. The

LTC1873 will operate properly with input supplies down to

about 3V, so a typical 3.3V supply can also be used if the

external MOSFETs are chosen appropriately (see the Power

MOSFETs section).

At the same time, the input supply needs to supply several

amps of current without excessive voltage drop. The input

supply must have regulation adequate to prevent sudden

load changes from causing the LTC1873 input voltage to

dip. In most typical applications where the LTC1873 is

generating a secondary low voltage logic supply, all of

these input conditions are met by the main system logic

supply when fortified with an input bypass capacitor.

INPUT BYPASS CAPACITOR

A typical LTC1873 circuit running from a 5V logic supply

might provide 1.6V at 10A at one of its outputs. 5V to 1.6V

implies a duty cycle of 32%, which means QT is on 32%

of each switching cycle. During QT’s on-time, the current

drawn from the input equals the load current and during

the rest of the cycle, the current drawn from the input is

near zero. This 0A to 10A, 32% duty cycle pulse train adds

up to 4.7A

last about 1.8µs—most system logic supplies have no

hope of regulating output current with that kind of speed.

A local input bypass capacitor is required to make up the

difference and prevent the input supply from dropping

drastically when QT kicks on. This capacitor is usually

chosen for RMS ripple current capability and ESR as well

as value.

The input bypass capacitor in an LTC1873 circuit is

common to both channels. Consider our 10A example

case with the other side of the LTC1873 disabled. The input

bypass capacitor gets exercised in three ways: its ESR

must be low enough to keep the initial drop as QT turns on

within reason (100mV or so); its RMS current capability

must be adequate to withstand the 4.7A

at the input and the capacitance must be large enough to

at the input. At 550kHz, switching cycles

RMS

ripple current

RMS

17

Page 18

LTC1873

WUUU

APPLICATIO S I FOR ATIO

maintain the input voltage until the input supply can make

up the difference. Generally, a capacitor that meets the

first two parameters will have far more capacitance than is

required to keep capacitance-based droop under control.

In our example, we need 0.01Ω ESR to keep the input drop

under 100mV with a 10A current step and 4.7A

RMS

ripple

current capacity to avoid overheating the capacitor. These

requirements can be met with multiple low ESR tantalum

or electrolytic capacitors in parallel, or with a large monolithic ceramic capacitor.

The two sides of the LTC1873 run off a single master clock

and are wired 180° out of phase with each other to

significantly reduce the total capacitance/ESR needed at

the input. Assuming 100mV of ripple and 10A output

current, we needed an ESR of 0.01Ω and 4.7A ripple

current capability for one side. Now, assume both sides

are running simultaneously with identical loading. If the

two sides switched in phase, all the loading conditions

would double and we’d need enough capacitance for

9.4A

phase, the input current is 4.8A

and 0.005Ω ESR. With the two sides out of

RMS

—barely larger than

RMS

the single case (Figure 7)! The peak current deltas are still

only 10A, requiring the same 0.01Ω ESR rating. As long

as the capacitor we chose for the single side application

can support the slightly higher 4.8A

current, we can

RMS

add the second channel without changing the input capacitor at all. As a general rule, an input bypass capacitor

capable of supporting the larger output current channel

10A

6.8A

–3.2A

32%

0

32%

0

68%

68%

QT CURRENT, SIDE 1 ONLY

(FOR 1-PHASE, 2 SIDES:

MULTIPLY CURRENT BY 2)

CIN

RMS

= 9.3A

, SIDE 1 ONLY

IN

, (1-PHASE,

RMS

)

CURRENT IN C

I

= 4.66A

CIN

2 SIDES: I

Calculating RMS Current in C

IN

A buck regulator like the LTC1873 draws pulses of

current from the input capacitor during normal operation. The input capacitor sees this as AC current, and

dissipates power proportional to the RMS value of the

input current waveform. To properly specify the capacitor, we need to know the RMS value of the input current.

Calculating the approximate RMS value of a pulse train

with a fixed duty cycle is straightforward, but the LTC1873

complicates matters by running two sides simultaneously

and out of phase, creating a complex waveform at the

input.

To calculate the approximate RMS value of the input

current, we first need to calculate the average DC value

with both sides of the LTC1873 operating at maximum

load. Over a single period, the system will spend some

time with one top switch on and the other off, perhaps

some time with both switches on, and perhaps some

time with both switches off. During the time each top

switch is on, the current will equal that side’s full load

output current. When both switches are on, the total

current will be the sum of the two full load currents, and

when both are off, the current is effectively zero. Multiply

each current value by the percentage of the period that

the current condition lasts, and sum the results—this is

the average DC current value.

As an example, consider a circuit that takes a 5V input

and generates 3.3V at 3A at side 1 and 1.6V at 10A at

side 2. When a cycle starts, TG1 turns on and 3A flows

13

10

50% 16% 16% 18%

10A

0

3.6A

0

–6.4A

18

32% 18%

32% 18%

18%

18%32%

32%

Figure 7. Current Waveforms

QT1 CURRENT

QT2 CURRENT

BOTH SIDES EQUAL LOAD

2-PHASE OPERATION

RMS

,

IN

1873 F07

CURRENT IN C

BOTH SIDES EQUAL LOAD

= 4.8A

I

CIN

1873 SB1

I

AVE

5.2

INPUT CURRENT (A)

3

0

0ABCD

TIME

Figure SB1. Average Current Calculation

Page 19

WUUU

APPLICATIO S I FOR ATIO

from

CIN (time point A). 50% of the way through, TG2

turns on and the total current is 13A (time point B).

Shortly thereafter, TG1 turns off and the current drops to

10A (time point C). Finally, TG2 turns off and the current

spends a short time at 0 before TG1 turns on again (time

point D).

305 13016

IA A

AVG

•. •.

=

()

+

()

+

LTC1873

current and resistive losses, but this approximate value

is adequate for input capacitor calculation purposes.

I

RMS

22

–. •. . • .

218 05 782 016

()

=

=

455

22

.•. –.•.

482 016 518 018

()

.

A

RMS

+

()

+

()

+

10 016 0 018 518

•. •. .

AA A

()

Now we can calculate the RMS current. Using the same

waveform we used to calculate the average DC current,

subtract the average current from each of the DC values.

Square each current term and multiply the squares by the

same period percentages we used to calculate the average DC current. Sum the results and take the square root.

The result is the approximate RMS current as seen by the

input capacitor with both sides of the LTC1873 at full

load. Actual RMS current will differ due to inductor ripple

7.8

4.8

0

–2.2

AC INPUT CURRENT (A)

– 5.2

0ABCD

Figure SB2. AC Current Calculation

+

()

50% 16% 16% 18%

TIME

=

1873 SB2

If the circuit is likely to spend time with one side operating

and the other side shut down, the RMS current will need

to be calculated for each possible case (side 1 on, side 2

off; side 1 off, side 2 on; both sides on). The capacitor

must be sized to withstand the largest RMS current of the

three—sometimes this occurs with one side shut down!

Side only

1

:

IA A A

IA

Side only

IAA A

I

Consider the case where both sides are operating at the

same load, with a 50% duty cycle at each side. The RMS

current with both sides running is near zero, while the

RMS current with one side active is 1/2 the total load

current of that side.

=

3 0 67 0 0 33 2 01

AVE

1

RMS RMS

1

2

AVE

2

RMS

2

•. •. .

()

22

1 0 67 2 0 33 1 42

=

()

:

10 032 0 068 32

=

()

68 032 32 068

.•. –.•.

=

()

= 4466 455..AA

+

()

•. – •. .

•. •. .

22

+

()

+

()

+

()

>

RMS RMS

=

=

=

can sup

the 2-Phase Operation section for more information).

Details on how to calculate the maximum RMS input

current can be found in Application Note 77.

Tantalum capacitors are a popular choice as input capacitors for LTC1873 applications, but they deserve a special

caution here. Generic tantalum capacitors have a destructive failure mechanism when they are subjected to large

RMS currents (like those seen at the input of a LTC1873).

port both channels running simultaneously (see

At some random time after they are turned on, they can

blow up for no apparent reason. The capacitor manufacturers are aware of this and sell special “surge tested”

tantalum capacitors specifically designed for use with

switching regulators. When choosing a tantalum input

capacitor, make sure that it is rated to carry the RMS

current that the LTC1873 will draw. If the data sheet

doesn’t give an RMS current rating, chances are the

capacitor isn’t surge tested. Don’t use it!

19

Page 20

LTC1873

WUUU

APPLICATIO S I FOR ATIO

OUTPUT BYPASS CAPACITOR

The output bypass capacitor has quite different requirements from the input capacitor. The ripple current at the

output of a buck regulator like the LTC1873 is much lower

than at the input, due to the fact that the inductor current

is constantly flowing at the output whenever the LTC1873

is operating in continuous mode. The primary concern at

the output is capacitor ESR. Fast load current transitions

at the output will appear as voltage across the ESR of the

output bypass capacitor until the feedback loop in the

LTC1873 can change the inductor current to match the

new load current value. This ESR step at the output is often

the single largest budget item in the load regulation

calculation. As an example, our hypothetical 1.6V, 10A

switcher with a 0.01Ω ESR output capacitor would experience a 100mV step at the output with a 0 to 10A load

step—a 6.3% output change!

inductor should be rated to withstand 15A + 1/2 I

RIPPLE

,

or 16.5A without saturating.

FEEDBACK LOOP/COMPENSATION

1

Feedback Loop Types

In a typical LTC1873 circuit, the feedback loop consists of

the modulator, the external inductor and output capacitor,

and the feedback amplifier and its compensation network.

All of these components affect loop behavior and need to

be accounted for in the loop compensation. The modulator

consists of the internal PWM generator, the output MOSFET

drivers and the external MOSFETs themselves. From a

feedback loop point of view, it looks like a linear voltage

transfer function from COMP to SW and has a gain roughly

equal to the input voltage. It has fairly benign AC behavior

at typical loop compensation frequencies with significant

phase shift appearing at half the switching frequency.

Usually the solution is to parallel several capacitors at the

output. For example, to keep the transient response inside

of 3% with the previous design, we’d need an output ESR