Page 1

查询LTC1864ACMS8供应商

FEATURES

LTC1864/LTC1865

µPower, 16-Bit, 250ksps

1- and 2-Channel ADCs in MSOP

U

DESCRIPTIO

■

16-Bit 250ksps ADCs in MSOP Package

■

Single 5V Supply

■

Low Supply Current: 850µA (Typ)

■

Auto Shutdown Reduces Supply Current

to 2µA at 1ksps

■

True Differential Inputs

■

1-Channel (LTC1864) or 2-Channel (LTC1865)

Versions

■

SPI/MICROWIRETM Compatible Serial I/O

■

16-Bit Upgrade to 12-Bit LTC1286/LTC1298

■

Pin Compatible with 12-Bit LTC1860/LTC1861

U

APPLICATIO S

■

High Speed Data Acquisition

■

Portable or Compact Instrumentation

■

Low Power Battery-Operated Instrumentation

■

Isolated and/or Remote Data Acquisition

The LTC®1864/LTC1865 are 16-bit A/D converters that are

offered in MSOP and SO-8 packages and operate on a

single 5V supply. At 250ksps, the supply current is only

850µA. The supply current drops at lower speeds because

the LTC1864/LTC1865 automatically power down

between conversions. These 16-bit switched capacitor

successive approximation ADCs include sample-and-holds.

The LTC1864 has a differential analog input with an

adjustable reference pin. The LTC1865 offers a softwareselectable 2-channel MUX and an adjustable reference pin

on the MSOP version.

The 3-wire, serial I/O, small MSOP or SO-8 package and

extremely high sample rate-to-power ratio make these

ADCs ideal choices for compact, low power, high speed

systems.

These ADCs can be used in ratiometric applications or

with external references. The high impedance analog

inputs and the ability to operate with reduced spans down

to 1V full scale, allow direct connection to signal sources

in many applications, eliminating the need for external

gain stages.

, LTC and LT are registered trademarks of Linear Technology Corporation.

MICROWIRE is a trademark of National Semiconductor Corporation.

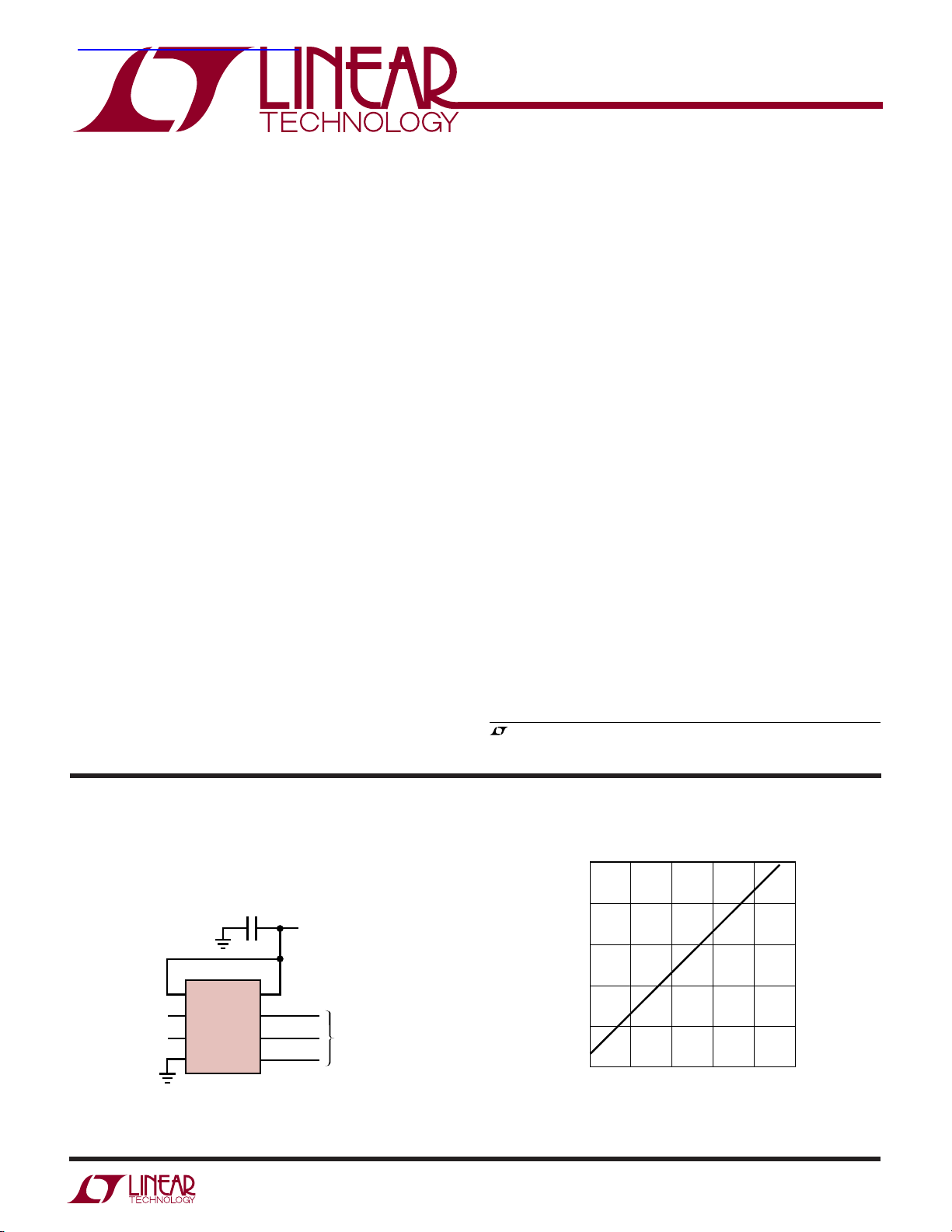

TYPICAL APPLICATIO

Single 5V Supply, 250ksps, 16-Bit Sampling ADC

1µF

LTC1864

ANALOG INPUT

0V TO 5V

1

V

REF

2

+

IN

3

–

IN

4

GND

V

SCK

SDO

CONV

8

CC

7

6

5

1864 TA01

U

5V

SERIAL DATA LINK TO

ASIC, PLD, MPU, DSP

OR SHIFT REGISTERS

Supply Current vs Sampling Frequency

1000

100

10

1

SUPPLY CURRENT (µA)

0.1

0.01

0.01

0.1

SAMPLING FREQUENCY (kHz)

10

1

100

1864 TA02

1000

sn18645 18645fs

1

Page 2

LTC1864/LTC1865

1

2

3

4

8

7

6

5

TOP VIEW

S8 PACKAGE

8-LEAD PLASTIC SO

CONV

CH0

CH1

GND

V

CC

SCK

SDO

SDI

1

2

3

4

5

CONV

CH0

CH1

AGND

DGND

10

9

8

7

6

V

REF

V

CC

SCK

SDO

SDI

TOP VIEW

MS PACKAGE

10-LEAD PLASTIC MSOP

WWWU

ABSOLUTE AXI U RATI GS

Supply Voltage (VCC) ................................................. 7V

Ground Voltage Difference

AGND, DGND LTC1865 MSOP Package ........... ±0.3V

Analog Input ............... (GND – 0.3V) to (V

Digital Input ................................ (GND – 0.3V) to 7V

Digital Output .............. (GND – 0.3V) to (V

Power Dissipation.............................................. 400mW

CC

CC

(Notes 1, 2)

+ 0.3V)

+ 0.3V)

Operating Temperature Range

LTC1864C/LTC1865C/

LTC1864AC/LTC1865AC ........................ 0°C to 70°C

LTC1864I/LTC1865I/

LTC1864AI/LTC1865AI ..................... –40°C to 85°C

Storage Temperature Range ................. – 65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

UU

W

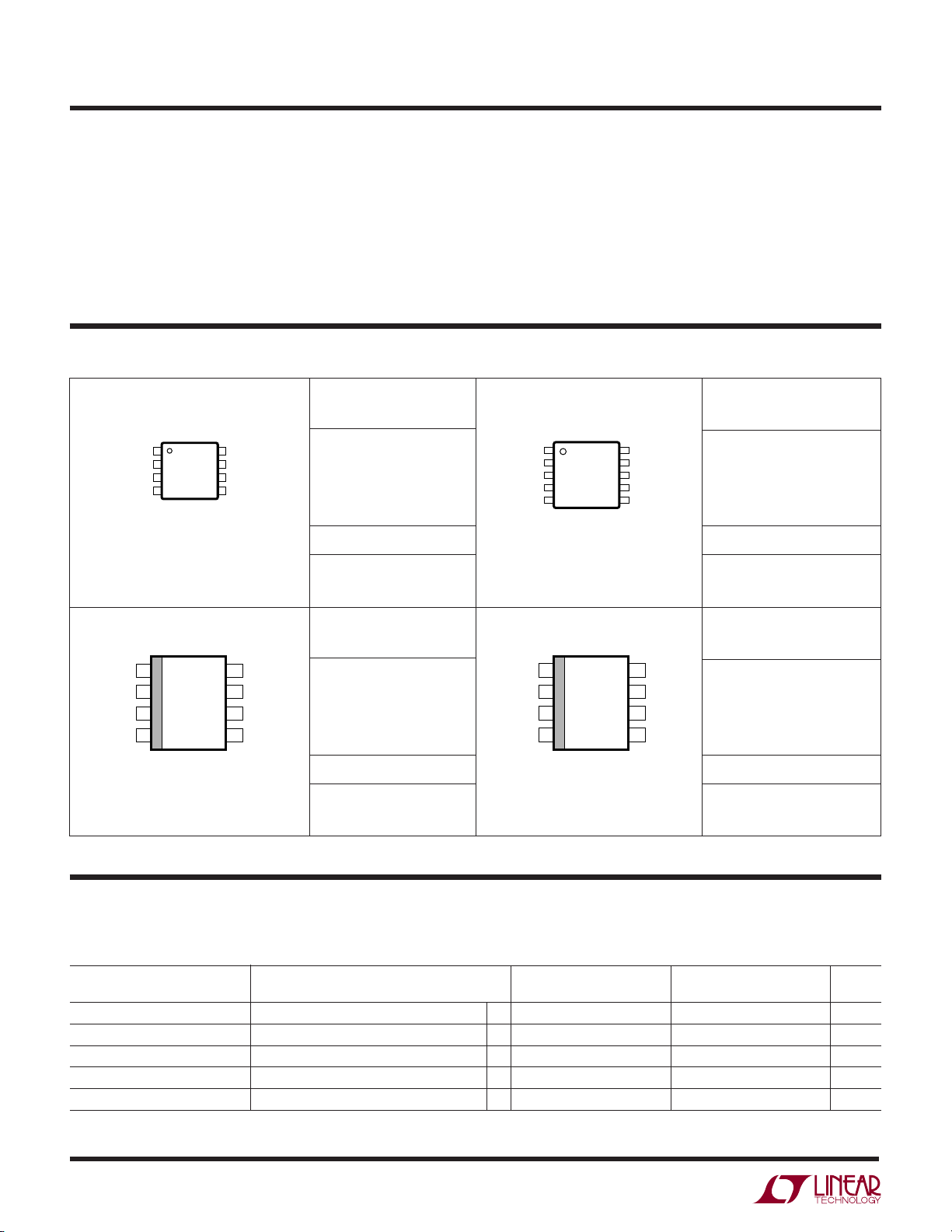

PACKAGE/ORDER I FOR ATIO

ORDER PART

TOP VIEW

V

1

REF

+

2

IN

3

IN¯

4

GND

MS8 PACKAGE

8-LEAD PLASTIC MSOP

= 150°C, θJA = 210°C/W

T

JMAX

TOP VIEW

1

V

REF

+

2

IN

–

3

IN

4

GND

S8 PACKAGE

8-LEAD PLASTIC SO

T

= 150°C, θJA = 175°C/W

JMAX

Consult LTC Marketing for parts specified with wider operating temperature ranges.

8

7

6

5

8

7

6

5

V

CC

SCK

SDO

CONV

V

SCK

SDO

CONV

CC

NUMBER

LTC1864CMS8

LTC1864IMS8

LTC1864ACMS8

LTC1864AIMS8

MS8 PART MARKING

LTHQ

ORDER PART

NUMBER

LTC1864CS8

LTC1864IS8

LTC1864ACS8

LTC1864AIS8

S8 PART MARKING

1864

1864I

1864A

1864AI

T

= 150°C, θJA = 210°C/W

JMAX

T

= 150°C, θJA = 175°C/W

JMAX

ORDER PART

NUMBER

LTC1865CMS

LTC1865IMS

LTC1865ACMS

LTC1865AIMS

MS PART MARKING

LTHS

ORDER PART

NUMBER

LTC1865CS8

LTC1865IS8

LTC1865ACS8

LTC1865AIS8

S8 PART MARKING

1865

1865I

1865A

1865AI

W

U

U

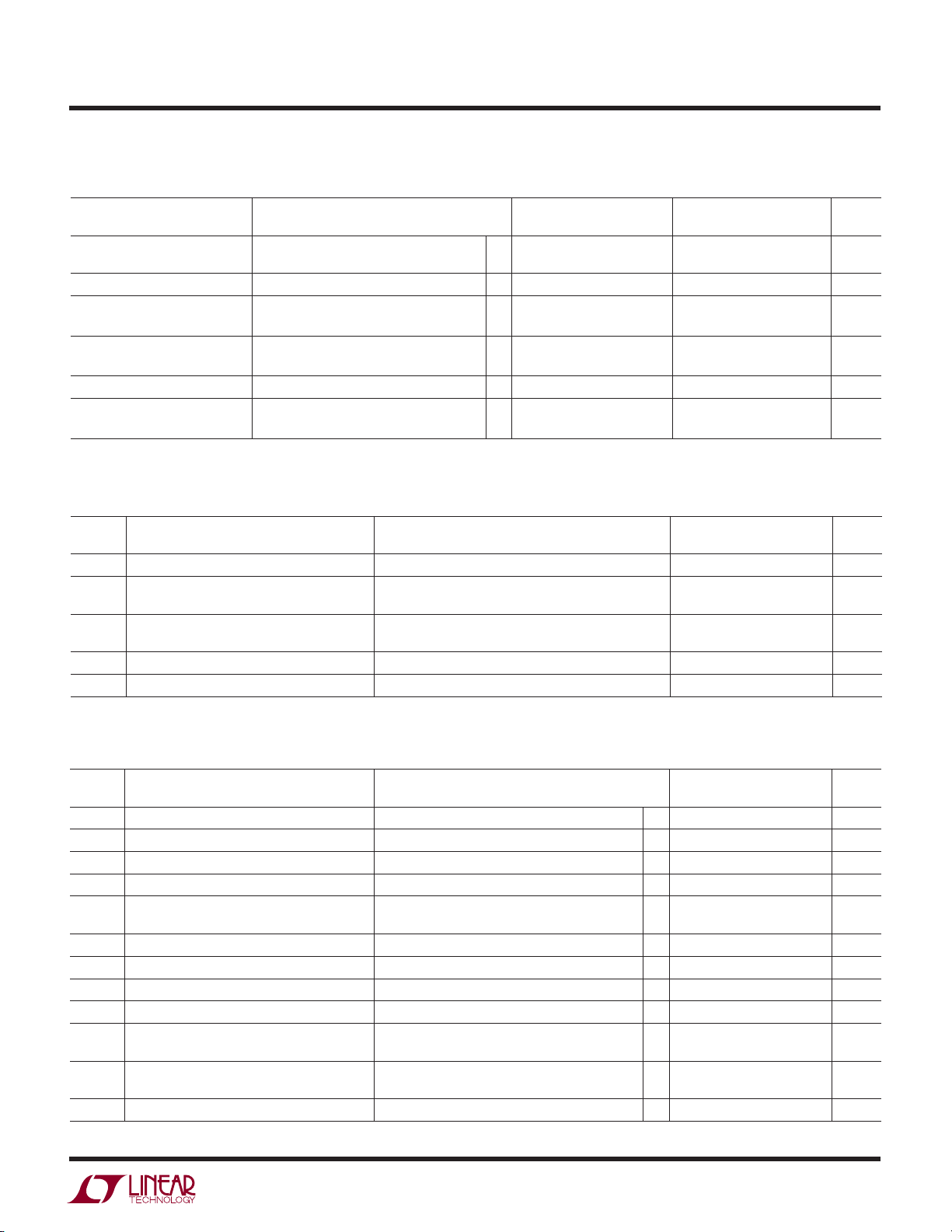

CO VERTER A D ULTIPLEXER CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

VCC = 5V, V

PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

Resolution ● 16 16 Bits

No Missing Codes Resolution ● 14 15 Bits

INL (Note 3) ● ±8 ±6 LSB

Transition Noise 1.1 1.1 LSB

Gain Error ● ±20 ±20 mV

2

REF

= 5V, f

SCK

= f

SCK(MAX)

as defined in Recommended Operating Conditions, unless otherwise noted.

LTC1864/LTC1865 LTC1864A/LTC1865A

RMS

sn18645 18645fs

Page 3

LTC1864/LTC1865

W

U

U

CO VERTER A D ULTIPLEXER CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

VCC = 5V, V

PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

Offset Error LTC1864 SO-8 and MSOP, LTC1865 MSOP ● ±2 ±5 ±2 ±5mV

Input Differential Voltage Range VIN = IN+ – IN

Absolute Input Range IN+ Input –0.05 VCC + 0.05 –0.05 VCC + 0.05 V

V

Input Range LTC1864 SO-8 and MSOP, 1 V

REF

Analog Input Leakage Current (Note 4) ● ±1 ±1 µA

CIN Input Capacitance In Sample Mode 12 12 pF

U

REF

= 5V, f

W

SCK

= f

SCK(MAX)

as defined in Recommended Operating Conditions, unless otherwise noted.

LTC1864/LTC1865 LTC1864A/LTC1865A

LTC1865 SO-8 ● ±3 ±7 ±3 ±7mV

–

–

Input –0.05 VCC/2 – 0.05 VCC/2 V

IN

LTC1865 MSOP

During Conversion 5 5 pF

● 0V

REF

CC

0V

1VCCV

REF

V

DY A IC ACCURACY

TA = 25°C. VCC = 5V, V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

SNR Signal-to-Noise Ratio 87 dB

S/(N + D) Signal-to-Noise Plus Distortion Ratio 10kHz Input Signal 83 dB

THD Total Hamonic Distortion Up to 5th Harmonic 10kHz Input Signal 88 dB

Full Power Bandwidth 20 MHz

Full Linear Bandwidth S/(N + D) ≥ 75dB 125 kHz

REF

= 5V, f

= 250kHz, unless otherwise noted.

SAMPLE

100kHz Input Signal 76 dB

100kHz Input Signal 77 dB

LTC1864/LTC1865

U

DIGITAL A D DC ELECTRICAL CHARACTERISTICS

over the full operating temperature range, otherwise specifications are TA = 25°C. VCC = 5V, V

SYMBOL PARAMETER CONDITION MIN TYP MAX UNITS

V

IH

V

IL

I

IH

I

IL

V

OH

V

OL

I

OZ

I

SOURCE

I

SINK

I

REF

I

CC

P

D

High Level Input Voltage VCC = 5.25V ● 2.4 V

Low Level Input Voltage VCC = 4.75V ● 0.8 V

High Level Input Current VIN = V

Low Level Input Current VIN = 0V ● –2.5 µA

High Level Output Voltage VCC = 4.75V, IO = 10µA ● 4.5 4.74 V

Low Level Output Voltage VCC = 4.75V, IO = 1.6mA ● 0.4 V

Hi-Z Output Leakage CONV = V

Output Source Current V

Output Sink Current V

Reference Current (LTC1864 SO-8 and CONV = V

MSOP, LTC1865 MSOP) f

Supply Current CONV = V

Power Dissipation f

CC

= 4.75V, IO = 360µA ● 2.4 4.72 V

V

CC

CC

= 0V –25 mA

OUT

= V

OUT

CC

CC

= f

SMPL

SMPL(MAX)

After Conversion ● 0.001 3 µA

CC

= f

f

SMPL

SMPL(MAX)

= f

SMPL

SMPL(MAX)

The ● denotes specifications which apply

= 5V, unless otherwise noted.

REF

LTC1864/LTC1865

● 2.5 µA

● ±3 µA

20 mA

● 0.001 3 µA

● 0.05 0.1 mA

● 0.85 1.3 mA

4.25 mW

sn18645 18645fs

3

Page 4

LTC1864/LTC1865

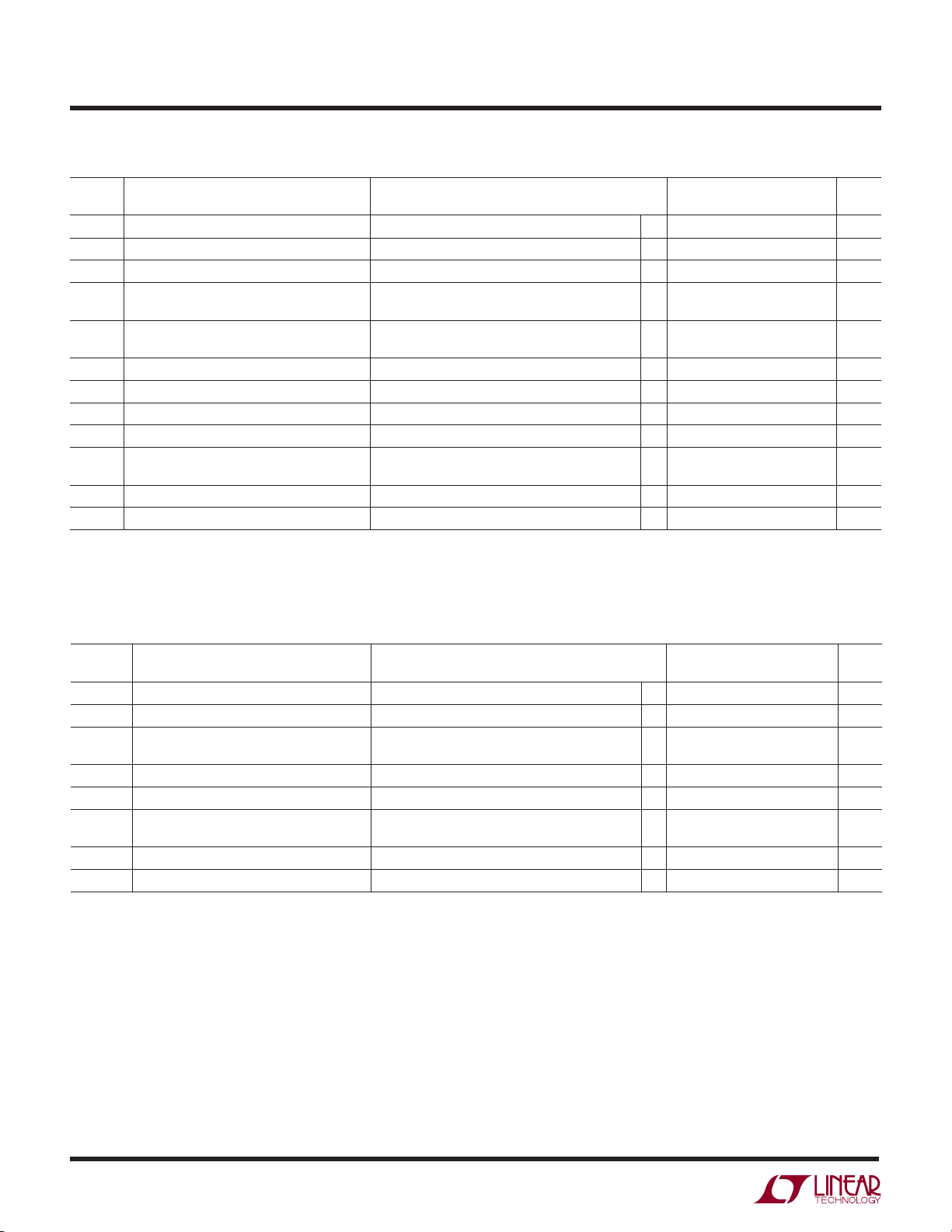

UUUUWW

RECO E DED OPERATI G CO DITIO S

SCK(MAX)

SCK(MAX)

= 25°C.

A

full operating temperature range, otherwise specifications are T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

CC

f

SCK

t

CYC

t

SMPL

t

suCONV

t

hDI

t

suDI

t

WHCLK

t

WLCLK

t

WHCONV

t

WLCONV

t

hCONV

Supply Voltage 4.75 5.25 V

Clock Frequency ● DC 20 MHz

Total Cycle Time 16 • SCK + t

Analog Input Sampling Time LTC1864 16 SCK

LTC1865 14 SCK

Setup Time CONV↓ Before First SCK↑ 30 ns

(See Figure 1)

Hold Time SDI After SCK↑ LTC1865 15 ns

Setup Time SDI Stable Before SCK↑ LTC1865 15 ns

SCK High Time f

SCK Low Time f

CONV High Time Between Data t

Transfer Cycles

CONV Low Time During Data Transfer 16 SCK

Hold Time CONV Low After Last SCK↑ 13 ns

SCK

SCK

= f

= f

The ● denotes specifications which apply over the

LTC1864/LTC1865

CONV

40% 1/f

40% 1/f

CONV

µs

SCK

SCK

µs

UW

TI I G CHARACTERISTICS

range, otherwise specifications are TA = 25°C. VCC = 5V, V

Conditions, unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

t

CONV

f

SMPL(MAX)

t

dDO

t

dis

t

en

t

hDO

t

r

t

f

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: All voltage values are with respect to GND.

Conversion Time (See Figure 1) ● 2.75 3.2 µs

Maximum Sampling Frequency ● 250 kHz

Delay Time, SCK↓ to SDO Data Valid C

Delay Time, CONV↑ to SDO Hi-Z ● 30 60 ns

Delay Time, CONV↓ to SDO Enabled C

Time Output Data Remains C

Valid After SCK↓

SDO Rise Time C

SDO Fall Time C

The ● denotes specifications which apply over the full operating temperature

= 5V, f

REF

= 20pF 15 20 ns

LOAD

= 20pF ● 30 60 ns

LOAD

= 20pF ● 510 ns

LOAD

= 20pF 8 ns

LOAD

= 20pF 4 ns

LOAD

= f

SCK

SCK(MAX)

Note 3: Integral nonlinearity is defined as deviation of a code from a

straight line passing through the actual endpoints of the transfer curve.

The deviation is measured from the center of the quantization band.

Note 4: Channel leakage current is measured while the part is in sample

mode.

as defined in Recommended Operating

LTC1864/LTC1865

● 25 ns

4

sn18645 18645fs

Page 5

UW

V

REF

(V)

0

REFERENCE CURRENT (µA)

60

50

40

30

20

10

0

1234

1864/65 G06

5

V

CC

= 5V

T

A

= 25°C

f

S

= 250kHz

TEMPERATURE (°C)

–50

ANALOG INPUT LEAKAGE (nA)

100

1864/65 G09

050

100

75

50

25

0

–25 25 75 125

VCC = 5V

V

REF

= 5V

CONV = 0V

TYPICAL PERFOR A CE CHARACTERISTICS

Supply Current vs Sampling

1000

SUPPLY CURRENT (µA)

0.01

100

10

1

0.1

0.01

Frequency

VCC = 5V

= 25°C

T

A

CONV LOW = 800ns

0.1

1.0

SAMPLING FREQUENCY (kHz)

10

100

1000

1864/65 G01

Supply Current vs Temperature

1000

800

600

400

SUPPLY CURRENT (µA)

200

0

–50

0

–25

TEMPERATURE (°C)

VCC = 5V

V

REF

f

SAMPLE

CONV HIGH = 3.2µS

50

25

= 5V

= 250kHz

75

100

1864/65 G02

125

LTC1864/LTC1865

Sleep Current vs Temperature

1000

CONV = V

900

800

700

600

500

400

300

SLEEP CURRENT (nA)

200

100

0

–50

= 5V

CC

0

–25

TEMPERATURE (°C)

50

25

75

100

125

1864/65 G03

Reference Current vs

Sampling Rate

60

VCC = 5V

= 25°C

T

A

50

= 5V

V

REF

CONV LOW = 800ns

40

30

20

REFERENCE CURRENT (µA)

10

0

0

50 100 150 200

SAMPLE RATE (kHz)

Typical INL Curve

4

VCC = 5V

= 25°C

T

A

= 5V

V

REF

2

1864/65 G04

250

Reference Current vs

Temperature

55

V

= 5V

CC

54

= 5V

V

REF

= 250kHz

f

S

53

52

51

50

49

48

REFERENCE CURRENT (µA)

47

46

45

–50

0

–25

TEMPERATURE (°C)

Typical DNL Curve

2

VCC = 5V

= 25°C

T

A

= 5V

V

REF

1

Reference Current vs

Reference Voltage

50

25

75

100

1864/65 G05

125

Analog Input Leakage Current vs

Temperature

0

INL ERROR (LSBs)

–2

–4

0

0

DNL ERROR (LSBs)

–1

16384

32768

CODE

49152

65536

1864/65 G07

–2

0 65536

3276816384

CODE

49152

1864/65 G08

sn18645 18645fs

5

Page 6

LTC1864/LTC1865

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Change in Offset Error vs

Reference Voltage

75

50

25

0

CHANGE IN OFFSET ERROR (LSB)

–25

1

0

2

REFERENCE VOLTAGE (V)

Change in Gain Error vs

Temperature

5

VCC = 5V

4

= 5V

V

REF

3

2

1

0

–1

–2

–3

CHANGE IN GAIN ERROR (LSB)

–4

–5

–50

–25

25

0

TEMPERATURE (°C)

Change in Gain Error vs

Change in Offset vs Temperature

5

VCC = 5V

= 25°C

T

A

3

4

5

1864/65 G10

VCC = 5V

4

= 5V

V

REF

3

2

1

0

–1

–2

CHANGE IN OFFSET (LSB)

–3

–4

–5

–50

–25

0

TEMPERATURE (°C)

50

25

75

100

1864/65 G11

125

Reference Voltage

20

VCC = 5V

= 25°C

T

15

A

10

5

0

–5

–10

CHANGE IN GAIN ERROR (LSB)

–15

–20

0

2

1

REFERENCE VOLTAGE(V)

4

3

5

1864/65 G12

Histogram of 4096 Conversions

of a DC Input Voltage

1800

127

729

1534

0

1178

1

CODE

1600

1400

1200

1000

800

FREQUENCY

600

400

200

00 1200

50

75

100

1864/65 G13

125

0

–4 –3 –2 –1

VCC = 5V

= 25°C

T

A

= 5V

V

REF

516

2345

1864/65 G14

4096 Point FFT Nonaveraged

0

fS = 203.125kHz

= 99.72763kHz

f

IN

–20

= 5V

V

CC

= 5V

V

REF

–40

= 25°C

T

A

–60

–80

AMPLITUDE (dB)

–100

–120

–140

0

40 60 80 100 120

20

FREQUENCY (kHz)

1864/65 G15

SINAD vs Frequency

100

90

80

70

60

50

SINAD (dB)

40

30

20

10

0

1

6

SNR

SINAD

VCC = 5V

= 5V

V

REF

= 25°C

T

A

= 0dB

V

IN

10 100 1000

FIN (kHz)

1864/5 G16

THD vs Frequency

0

–10

–20

–30

–40

–50

THD (dB)

–60

–70

–80

–90

–100

1

VCC = 5V

= 5V

V

REF

= 25°C

T

A

= 0dB

V

IN

10 100 1000

FIN (kHz)

1864/5 G17

SFDR vs Frequency

100

90

80

70

60

50

SFDR (dB)

40

30

20

10

0

1

VCC = 5V

= 5V

V

REF

= 25°C

T

A

= 0dB

V

IN

10 100 1000

FIN (kHz)

1864/5 G18

sn18645 18645fs

Page 7

LTC1864/LTC1865

U

UU

PI FU CTIO S

LTC1864

V

(Pin 1): Reference Input. The reference input defines

REF

the span of the A/D converter and must be kept free of

noise with respect to GND.

IN+, IN– (Pins 2, 3): Analog Inputs. These inputs must be

free of noise with respect to GND.

GND (Pin 4): Analog Ground. GND should be tied directly

to an analog ground plane.

CONV (Pin 5): Convert Input. A logic high on this input

starts the A/D conversion process. If the CONV input is left

high after the A/D conversion is finished, the part powers

LTC1865 (MSOP Package)

CONV (Pin 1): Convert Input. A logic high on this input

starts the A/D conversion process. If the CONV input is left

high after the A/D conversion is finished, the part powers

down. A logic low on this input enables the SDO pin,

allowing the data to be shifted out.

CH0, CH1 (Pins 2, 3): Analog Inputs. These inputs must

be free of noise with respect to AGND.

AGND (Pin 4): Analog Ground. AGND should be tied

directly to an analog ground plane.

DGND (Pin 5): Digital Ground. DGND should be tied

directly to an analog ground plane.

down. A logic low on this input enables the SDO pin,

allowing the data to be shifted out.

SDO (Pin 6): Digital Data Output. The A/D conversion

result is shifted out of this pin.

SCK (Pin 7): Shift Clock Input. This clock synchronizes the

serial data transfer.

V

(Pin 8):

CC

free of noise and ripple by bypassing directly to the

analog ground plane.

SDO (Pin 7): Digital Data Output. The A/D conversion

result is shifted out of this output.

SCK (Pin 8): Shift Clock Input. This clock synchronizes the

serial data transfer.

VCC (Pin 9):

free of noise and ripple by bypassing directly to the

analog ground plane.

V

(Pin 10): Reference Input. The reference input de-

REF

fines the span of the A/D converter and must be kept free

of noise with respect to AGND.

Positive Supply. This supply must be kept

Positive Supply. This supply must be kept

SDI (Pin 6):

word is shifted into this input.

LTC1865 (SO-8 Package)

CONV (Pin 1): Convert Input. A logic high on this input

starts the A/D conversion process. If the CONV input is left

high after the A/D conversion is finished, the part powers

down. A logic low on this input enables the SDO pin,

allowing the data to be shifted out.

CH0, CH1 (Pins 2, 3): Analog Inputs. These inputs must

be free of noise with respect to GND.

GND (Pin 4): Analog Ground. GND should be tied directly

to an analog ground plane.

Digital Data Input. The A/D configuration

SDI (Pin 5):

word is shifted into this input.

SDO (Pin 6): Digital Data Output. The A/D conversion

result is shifted out of this output.

SCK (Pin 7): Shift Clock Input. This clock synchronizes the

serial data transfer.

VCC (Pin 8):

free of noise and ripple by bypassing directly to the

analog ground plane. V

Digital Data Input. The A/D configuration

Positive Supply. This supply must be kept

is tied internally to this pin.

REF

sn18645 18645fs

7

Page 8

LTC1864/LTC1865

SDO

WAVEFORM 1

(SEE NOTE 1)

V

IH

t

dis

90%

10%

SDO

WAVEFORM 2

(SEE NOTE 2)

CONV

NOTE 1: WAVEFORM 1 IS FOR AN OUTPUT WITH INTERNAL CONDITIONS SUCH

THAT THE OUTPUT IS HIGH UNLESS DISABLED BY THE OUTPUT CONTROL

NOTE 2: WAVEFORM 2 IS FOR AN OUTPUT WITH INTERNAL CONDITIONS SUCH

THAT THE OUTPUT IS LOW UNLESS DISABLED BY THE OUTPUT CONTROL

1864 TC05

UU

W

FUNCTIONAL BLOCK DIAGRA

PIN NAMES IN

PARENTHESES

IN

(CH0)

IN

(CH1)

+

–

REFER TO LTC1865

GND

CONVERT

CLK

+

–

V

CC

BIAS AND

SHUTDOWN

16-BIT

SAMPLING

ADC

V

REF

DATA IN

DATA OUT

CONV

(SDI) SCK

SERIAL

PORT

16 BITS

SDO

1864/65 BD

TEST CIRCUITS

Load Circuit for t

TEST POINT

SDO

3k

20pF

Voltage Waveforms for t

CONV

SDO

Voltage Waveforms for SDO Delay Times, t

8

SCK

SDO

t

V

hDO

IL

t

dDO

dDO

, tr, tf, t

t

en

VCC t

t

dis

and t

dis

WAVEFORM 2, t

dis

WAVEFORM 1

en

dDO

en

1864 TC03

and t

1864 TC02

1864 TC01

Voltage Waveforms for SDO Rise and Fall Times, tr, t

SDO

en

t

r

Voltage Waveforms for t

dis

t

f

1864 TC04

f

V

OH

V

OL

hDO

V

OH

V

OL

sn18645 18645fs

Page 9

WUUU

APPLICATIO S I FOR ATIO

LTC1864/LTC1865

LTC1864 OPERATION

Operating Sequence

The LTC1864 conversion cycle begins with the rising edge

of CONV. After a period equal to t

, the conversion is

CONV

finished. If CONV is left high after this time, the LTC1864

goes into sleep mode drawing only leakage current. On the

falling edge of CONV, the LTC1864 goes into sample mode

and SDO is enabled. SCK synchronizes the data transfer

with each bit being transmitted from SDO on the falling

SCK edge. The receiving system should capture the data

from SDO on the rising edge of SCK. After completing the

data transfer, if further SCK clocks are applied with CONV

low, SDO will output zeros indefinitely. See Figure 1.

CONV

SCK

t

CONV

SLEEP MODE

Analog Inputs

The LTC1864 has a unipolar differential analog input. The

converter will measure the voltage between the “IN+” and

“IN–” inputs. A zero code will occur when IN+ minus IN

–

equals zero. Full scale occurs when IN+ minus IN– equals

V

minus 1LSB. See Figure 2. Both the “IN+” and

REF

“IN–” inputs are sampled at the same time, so common

–

mode noise on the inputs is rejected by the ADC. If “IN

is grounded and V

is tied to VCC, a rail-to-rail input span

REF

”

will result on “IN+” as shown in Figure 3.

Reference Input

The voltage on the reference input of the LTC1864 defines

the full-scale range of the A/D converter. The LTC1864 can

operate with reference voltages from VCC to 1V.

t

SMPL

16151413121110987654321

SDO

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0

•

•

•

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Hi-Z

B14 B12 B10 B8 B6 B4 B2 B0*

B15

*AFTER COMPLETING THE DATA TRANSFER, IF FURTHER SCK CLOCKS ARE

APPLIED WITH CONV LOW, THE ADC WILL OUTPUT ZEROS INDEFINITELY

B11 B9 B7 B5 B3 B 1

B13

Hi-Z

1854 F01

Figure 1. LTC1864 Operating Sequence

1µF

V

CC

LTC1864

1

V

REF

2

VIN = 0V TO V

VIN*

0V

1LSB

*V

IN

= IN+ – IN

V

REF

–

– 2LSB

V

REF

– 1LSB

V

REF

1864 F02

CC

+

IN

3

–

IN

4

GND

V

SCK

SDO

CONV

8

CC

7

6

5

1864 F03

SERIAL DATA LINK TO

ASIC, PLD, MPU, DSP

OR SHIFT REGISTERS

Figure 3. LTC1864 with Rail-to-Rail Input SpanFigure 2. LTC1864 Transfer Curve

sn18645 18645fs

9

Page 10

LTC1864/LTC1865

MUX ADDRESS

Table 1. Multiplexer Channel Selection

SGL/DIFF

1

1

0

0

ODD/SIGN

0

1

0

1

CHANNEL #

0

+

+

–

1

+

–

+

GND

–

–

1864 TBL1

SINGLE-ENDED

MUX MODE

DIFFERENTIAL

MUX MODE

WUUU

APPLICATIO S I FOR ATIO

LTC1865 OPERATION

Operating Sequence

The LTC1865 conversion cycle begins with the rising edge

of CONV. After a period equal to t

, the conversion is

CONV

finished. If CONV is left high after this time, the LTC1865

goes into sleep mode drawing only leakage current. The

LTC1865’s 2-bit data word is clocked into the SDI input on

the rising edge of SCK after CONV goes low. Additional

inputs on the SDI pin are then ignored until the next CONV

cycle. The shift clock (SCK) synchronizes the data transfer

with each bit being transmitted on the falling SCK edge and

captured on the rising SCK edge in both transmitting and

receiving systems. The data is transmitted and received

simultaneously (full duplex). After completing the data

transfer, if further SCK clocks are applied with CONV low,

SDO will output zeros indefinitely. See Figure 4.

Analog Inputs

The two bits of the input word (SDI) assign the MUX

configuration for the next requested conversion. For a

given channel selection, the converter will measure the

voltage between the two channels indicated by the “+”

and “–” signs in the selected row of the following table. In

single-ended mode, all input channels are measured with

respect to GND. A zero code will occur when the “+” input

minus the “–” input equals zero. Full scale occurs when

the “+” input minus the “–” input equals V

REF

minus

1LSB. See Figure 5. Both the “+” and “–” inputs are

sampled at the same time so common mode noise is

rejected. The input span in the SO-8 package is fixed at

V

= VCC. If the “–” input in differential mode is

REF

grounded, a rail-to-rail input span will result on the “+”

input.

Reference Input

The reference input of the LTC1865 SO-8 package is

internally tied to VCC. The span of the A/D converter is

therefore equal to VCC. The voltage on the reference input

of the LTC1865 MSOP package defines the span of the

A/D converter. The LTC1865 MSOP package can operate

with reference voltages from 1V to VCC.

CONV

SDI

SCK

SDO

10

t

CONV

Hi-Z

SLEEP MODE

S/D O/S

B14 B12 B10 B8 B6 B 4 B 2

B15

*AFTER COMPLETING THE DATA TRANSFER, IF FURTHER SCK CLOCKS ARE

APPLIED WITH CONV LOW, THE ADC WILL OUTPUT ZEROS INDEFINITELY

Figure 4. LTC1865 Operating Sequence

t

SMPL

DON’T CAREDON’T CARE

B11 B9 B7 B5 B3 B 1

B13

16151413121110987654321

B0*

Hi-Z

1864 F04

sn18645 18645fs

Page 11

WUUU

APPLICATIO S I FOR ATIO

LTC1864/LTC1865

GENERAL ANALOG CONSIDERATIONS

Grounding

The LTC1864/LTC1865 should be used with an analog

ground plane and single point grounding techniques. Do

not use wire wrapping techniques to breadboard and

evaluate the device. To achieve the optimum performance,

use a printed circuit board. The ground pins (AGND and

DGND for the LTC1865 MSOP package and GND for the

LTC1864 and LTC1865 SO-8 package) should be tied

directly to the analog ground plane with minimum lead

length.

Bypassing

For good performance, the VCC and V

of noise and ripple. Any changes in the VCC/V

pins must be free

REF

voltage

REF

with respect to ground during the conversion cycle can

induce errors or noise in the output code. Bypass the V

and V

pins directly to the analog ground plane with a

REF

CC

minimum of 1µF tantalum. Keep the bypass capacitor

leads as short as possible.

Analog Inputs

Because of the capacitive redistribution A/D conversion

techniques used, the analog inputs of the LTC1864/

LTC1865 have capacitive switching input current spikes.

These current spikes settle quickly and do not cause a

problem if source resistances are less than 200Ω or high

speed op amps are used (e.g., the LT

®

1211, LT1469,

LT1807, LT1810, LT1630, LT1226 or LT1215). But if large

source resistances are used, or if slow settling op amps

drive the inputs, take care to ensure the transients caused

by the current spikes settle completely before the conversion begins.

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0

•

•

•

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

0V

1LSB

*V

= (SELECTED “+” CHANNEL) –

IN

(SELECTED “–” CHANNEL)

REFER TO TABLE 1

Figure 5. LTC1865 Transfer Curve

V

CC

– 2LSB

V

CC

– 1LSB

V

CC

1864 F05

*

V

IN

sn18645 18645fs

11

Page 12

LTC1864/LTC1865

WUUU

APPLICATIO S I FOR ATIO

40383634323028262422201816141210864

J4

3201S40G1

393735333129272523211917151311

C14

0.1µF

DIG

5V

C13

0.1µF

DIG

5V

C26

DIG

5V

R4

2Ω

AN

5V

3

OUT

V

IN

V

1

15V

LTC1864 Evaluation Circuit Schematic

C2

10µF

GND

1µF

C1

6.3V

2

5V

10V

0.1µF

1234567

QB

QC

CC

QAAOENB

V

U4

74HC595ADT

16151413121110

DIG

5V

1206

C4

0.1µF

AN

C3

6.3V

10µF

0805

QD

1206

RN1

QE

330

876

123

QF

QG

LCLK

SCLK

876

123

CC

V

SCK

REF

V

IN+IN–GND

R5

C8

8

QH

RESET

9

402Ω, 1%

5

SDO

4

1000pF

C7

GND

SQH

U8A

C21

5

4

CONV

OPT

390pF

1234567

QB

QC

CC

QAAOENB

V

16151413121110

74AC14

R6

47pF

U3

LTC1864CMS8

C10

680pF

OPT

C9

180pF

2

97531

QF

QE

QD

QG

QH

LCLK

SCLK

RESET

U8B

74AC14

1%

C22

402Ω

47pF

ANALOG GROUND PLANE

C12

1000pF

OPT

C11

390pF

CONV

DGND

DGND

DOUT

CLKOUT

ENABLE

C25

DATA

E2

E3

E7

E6

E4

2

1

JP5

U8F

74AC14

U8E

74AC14

0.1µF

DIG

5V

8

CLR

8

CLR

GND

PRE

GND

PRE

U8D

74AC14

C17

0.1µF

DIG

5V

C16

0.1µF

DIG

5V

DIG

5V

C15

0.1µF

DIG

5V

U9D

74AC00

8

U9C

0.1µF

DIG

0.1µF

DIG

U5

74HC595ADT

16

U12B

74AC109

16

U12A

74AC109

74AC00

21

JP4

10

9

Q

Q

CC

V

JKCLK

1413121511

6

7

Q

Q

CC

V

JKCLK

23415

GND

SQH

9

C24

5V

C23

5V

CLKIN

J3

E5

C18

0.1µF

DIG

5V

10k

R12

16151413121110

CC

V

RESET

U7

74HC163AD

1234567

R9

51Ω

C19

0.1µF

DIG

5V

JP7

2

1

JP6

5

OUT

V+GND

U10

LTC1799

123

Q0Q1Q2

RCO

CLKP0P1P2P3

U13D

U13A

3

21

3

4

DIV

SET

R10

Q3

ENT

ENP

74AC32

74AC32

U8C

20k

9

LO

GND

8

74AC14

1864/65 AI1

NOTES: UNLESS OTHERWISE SPECIFIED

INSTALL SHUNTS ON JP1, JP3-JP7 PIN 1 AND PIN2;

ON JP8 AND JP9 PIN 2 AND PIN 4, PIN 3 AND PIN 5.

U13C

74AC32

CLK

U13B

74AC32

12

R2

510Ω

2

1

JP3

U9B

C6

0.1µF

–15V

–

IN

R8

51Ω

0PT

E9

J2

–

IN

74AC00

U9A

74AC00

DIG

5V

DIG

5V

16151413121110

CC

V

RCO

RESET

CLKP0P1P2P3

U6

74HC163AD

1234567

JP8

246

Q0Q1Q2

135

Q3

ENT

ENP

246

9

LO

GND

8

JP9

135

JP1

C5

R1

510Ω

21

JP2

0.1µF

U2

0PT

OPT

+

–

E8

AGND

15V

R7

51Ω

R3

2Ω

21

U1

LT1021-5

6

OUT

V

4

GND

IN

V

2

C27

0.1µF

+

IN

15V

J1

E1

15V

+

IN

sn18645 18645fs

Page 13

WUUU

APPLICATIO S I FOR ATIO

Component Side Silk Screen for LTC1864 Evaluation Circuit

LTC1864/LTC1865

Component Side Showing Traces

(Note Wider Traces on Analog Side)

Ground Layer with Separate Analog and Digital Grounds Supply Layer with 5V Digital Supply and Analog Ground Repeated

(Note Almost No Analog Traces on Board Bottom)

Bottom Side Showing Traces

sn18645 18645fs

13

Page 14

LTC1864/LTC1865

WUUU

APPLICATIO S I FOR ATIO

5V

DIG

U9B

74AC00

U9A

74AC00

U6

74HC163AD

1

RESET

2

CLK

3

P0

4

P1

5

P2

6

P3

7

ENP

8

GND

V

RCO

ENT

U11

15V

LT1121CST-5

1

VINV

GND

5V

AN

1V to 5V REFERENCE

0V to V

INPUT

REF

10µF

6.3V

1206

C3

0.1µF

1

V

REF

2

+

IN

3

–

IN

4

GND

U3

LTC1864CMS8

C4

RN1

330

8

V

SCK

SDO

CONV

CC

1

7

6

5

8

2

7

3

6

4

5

ANALOG GROUND PLANE

V

CC

J

K

v

CLK

CLR

PRE

DIG

C16

0.1µF

U7

74HC163AD

RESET

CLK

P0

P1

P2

P3

ENP

GND

U13B

74AC32

16

C23

0.1µF

GND

V

RCO

Q0

Q1

Q2

Q3

ENT

LO

5V

DIG

U12B

CLK

74AC109

14

13

12

15

11

5V

DIG

6

Q

7

Q

8

5V

DIG

C17

0.1µF

16

CC

15

14

13

100k

12

11

10

9

5V

DIG

U12A

74AC109

2

3

4

1

5

5V

5V

DIG

16

CC

15

14

Q0

13

Q1

12

Q2

11

Q3

10

9

LO

1

2

3

4

5

6

7

8

J

K

v

CLK

CLR

PRE

U10

LTC1799

1

V

2

GND

3

SET

C24

0.1µF

16

10

V

CC

Q

9

Q

8

GND

C18

0.1µF

OUT

DIV

5

4

+

1

5V

5

MC74VHC1G66

U13C

74AC32

4

5V

AN

3

OUT

2

2

500Ω

3

5V

DIG

R4

2Ω

5V

DIG

1

2

3

4

LTC1485

RO

RE

DE

DI

PRE

D

v

CLK

CLR

PRE

D

v

CLK

CLR

C26

10µF

6.3V

1206

5V

15V

DIG

8

V

CC

7

B

6

A

5

GND

5V

DIG

74AC74

5V

DIG

74AC74

120Ω

4 CONDUCTOR

TELEPHONE WIRES

TO RECEIVER

74AC86

Q

Q

Q

Q

1864/65 AI2

14

Figure 6. LTC1864 Manchester Transmitter

sn18645 18645fs

Page 15

WUUU

APPLICATIO S I FOR ATIO

LTC1864/LTC1865

V

CC

DATA IN

CLK

RECEIVE CLOCK AT

CLOCK FREQUENCY

IC1A

74AC74

4

PRE

2

D

3

v

CLK

1

CLR

8 X TRANSMIT

4 CONDUCTOR

TELEPHONE WIRES

TO TRANSMITTER

Q

Q

V

CC

5

6

CLK

15V SUPPLY TO

10

PRE

12

D

11

v

CLK

13

CLR

IC1B

74AC74

U1

LTC1485

1

RO

2

RE

3

DE

4

DI

TRANSMITTER

V

GND

R1

120Ω

V

CC

IC3A

74AC74

4

PRE

2

D

CLK

3

v

CLK

1

CLR

V

IC3B

CC

74AC74

10

PRE

12

D

CLK

11

v

CLK

13

CLR

IC8

74AC595

14

SER

11

SCK

10

SCL

V

CC

12

v

RCK

13

8

V

CC

IC9

74AC595

14

SER

11

SCK

10

SCL

10

9

12

v

RCK

13

8

5

Q

6

Q

9

Q

STROBE

8

Q

15

QA

D15

1

QB

D14

2

QC

D13

3

QD

D12

4

QE

D11

5

QF

D10

6

QG

D9

7

QH

D8

9

QH

IN

15

QA

D7

1

QB

D6

2

QC

D5

3

QD

D4

4

QE

D3

5

QF

D2

6

QG

D1

7

QH

D0

9

QH

IN

5

6

CLK

STROBE

DATA

V

CC

IC2B

74AC74

10

PRE

12

D

11

v

CLK

13

CLR

IC6C

74LS32D

IC4D

74AC08

OPTIONAL SERIAL TO

PARALLEL CONVERTER

11

14

12

13

15

9

Q

8

Q

IC4C

74AC08

IC7B

74AC109

PRE

J

v

CLK

K

CLR

IC4B

74AC08

Q

Q

V

CC

CLK

4

2

3

1

IC2A

74AC74

PRE

D

v

CLK

CLR

Q

Q

IC5C

74AC86

9

Q

8

DATA

Q

DATA

V

CC

8

CC

7

B

6

A

5

IC6D

74AC32

IC4A

74AC08

Figure 7. LTC1864 Manchester Receiver

1864/65 AI3

sn18645 18645fs

15

Page 16

LTC1864/LTC1865

WUUU

APPLICATIO S I FOR ATIO

Transmit LTC1864 Data Over Modular Telephone Wire

Using Simple Transmitter/Receiver

Figure 6 shows a simple Manchester encoder and differential transmitter suitable for use with the LTC1864. This

circuit allows transmission of data over inexpensive telephone wire. This is useful for measuring a remote sensor,

particularly when the cost of preserving the analog signal

over a long distance is high.

Manchester encoding is a clock signal that is modulated

by exclusive ORing with the data signal. The resulting

signal contains both clock and data information and has an

average duty cycle of 50%, that also allows transformer

coupling. In practice, generating a Manchester encoded

signal with an XOR gate will often produce glitches due to

the skew between data and clock transitions. The D flipflops in this encoder retime the clock and data such that

the respective edges are closely aligned, effectively suppressing glitches. The retimed data and clock are then

XORed to produce the Manchester encoded data, which is

interfaced to telephone wire with an LTC1485 RS485

transceiver.

In order to synchronize to incoming data, the receiver

needs a sequence to indicate the start of a data word. The

transmitter schematic shows logic that will produce 31

zeros, a start bit, followed by the 16 data bits (one sample

every 48 clock cycles) at a clock frequency of 1MHz set by

the LTC1799 oscillator. Sending at least 18 zeros before

each start bit ensures that if synchronization is lost, the

receiver can resynchronize to a start bit under all conditions. The serial to parallel converter shown in Figure 7

requires 18 zeros to avoid triggering on data bits.

The Manchester receiver shown in Figure 7 was adopted

from Xilinx application note 17-30 and would typically be

implemented in an FPGA. The decoder clock frequency is

nominally 8 times the transmit clock frequency and is very

tolerant of frequency errors. The outputs of the decoder

are data and a strobe that indicates a valid data bit. The data

can be deserialized using shift registers as shown. The

start bit resets the J-K/flip-flop on its way into the first shift

register. When it appears at the QH

shift register, it sets the flip-flop that loads the parallel data

into the output register.

With AC family CMOS logic at 5V the receiver clock

frequency is limited to 20MHz; the corresponding transmitter clock frequency is 2.5MHz. If the receiver is implemented in an FPGA that can be clocked at 160MHz, the

LTC1864 can be clocked at its rated clock frequency of

20MHz.

output of the second

IN

16

sn18645 18645fs

Page 17

PACKAGE DESCRIPTIO

LTC1864/LTC1865

U

MS8 Package

8-Lead Plastic MSOP

(Reference LTC DWG # 05-08-1660)

5.23

(.206)

MIN

0.42 ± 0.04

(.0165 ± .0015)

TYP

RECOMMENDED SOLDER PAD LAYOUT

PLANE

3.00 ± 0.102

(.118 ± .004)

(NOTE 3)

4.88

± 0.1

(.192 ± .004)

0.22 – 0.38

(.009 – .015)

1.10

(.043)

MAX

0.889 ± 0.127

(.035 ± .005)

3.2 – 3.45

(.126 – .136)

0.65

(.0256)

BSC

NOTE:

1. DIMENSIONS IN MILLIMETER/(INCH)

2. DRAWING NOT TO SCALE

3. DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH, PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

4. DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

5. LEAD COPLANARITY (BOTTOM OF LEADS AFTER FORMING) SHALL BE 0.102mm (.004") MAX

GAUGE PLANE

0.18

(.077)

0.254

(.010)

DETAIL “A”

DETAIL “A”

° – 6° TYP

0

0.53 ± 0.015

(.021 ± .006)

SEATING

8

12

0.65

(.0256)

BCS

0.52

5

4

(.206)

REF

3.00 ± 0.102

(.118 ± .004)

NOTE 4

0.86

(.034)

REF

0.13 ± 0.05

(.005 ± .002)

MSOP (MS8) 1001

7

6

3

sn18645 18645fs

17

Page 18

LTC1864/LTC1865

PACKAGE DESCRIPTIO

0.889 ± 0.127

(.035 ± .005)

U

MS Package

10-Lead Plastic MSOP

(Reference LTC DWG # 05-08-1661)

3.00 ± 0.102

(.118 ± .004)

(NOTE 3)

0.497 ± 0.076

8910

(.0196 ± .003)

7

6

REF

5.23

(.206)

MIN

0.305 ± 0.038

(.0120 ± .0015)

TYP

RECOMMENDED SOLDER PAD LAYOUT

NOTE:

1. DIMENSIONS IN MILLIMETER/(INCH)

2. DRAWING NOT TO SCALE

3. DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH, PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

4. DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

5. LEAD COPLANARITY (BOTTOM OF LEADS AFTER FORMING) SHALL BE 0.102mm (.004") MAX

3.2 – 3.45

(.126 – .136)

0.50

(.0197)

BSC

GAUGE PLANE

0.18

(.007)

0.254

(.010)

DETAIL “A”

DETAIL “A”

0° – 6° TYP

0.53 ± 0.01

(.021 ± .006)

SEATING

PLANE

4.88 ± 0.10

(.192 ± .004)

(.043)

0.17 – 0.27

(.007 – .011)

1.10

MAX

12

0.50

(.0197)

TYP

3

3.00 ± 0.102

(.118 ± .004)

NOTE 4

45

0.86

(.034)

REF

0.13 ± 0.05

(.005 ± .002)

MSOP (MS) 1001

18

sn18645 18645fs

Page 19

PACKAGE DESCRIPTIO

U

S8 Package

8-Lead Plastic Small Outline (Narrow .150 Inch)

(Reference LTC DWG # 05-08-1610)

0.189 – 0.197*

(4.801 – 5.004)

7

8

6

LTC1864/LTC1865

5

0.228 – 0.244

(5.791 – 6.197)

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

×

°

45

0.016 – 0.050

(0.406 – 1.270)

0°– 8° TYP

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

TYP

0.150 – 0.157**

(3.810 – 3.988)

SO8 1298

1

3

2

4

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

BSC

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

sn18645 18645fs

19

Page 20

LTC1864/LTC1865

TYPICAL APPLICATIO

Sample Two Channels Simultaneously with a Single Input ADC

0.1µF

f

(0V TO 0.66V)

4.096V

REF

28.7k

10k

(0V TO 2V)

1

1µF

0.1µF

f

2

+

1/2

LT1492

–

5k

10k

5k

+

LT1492

–

1/2

20k

5pF

5V

0.1µF

8

4

U

100Ω

100pF

100Ω

100pF

4096 Point FFT of Output

5V

4.096V

REF

81

V

CC

2

+

IN

–

IN

3

LTC1864

GND

REF

SCK

SDO

CONV

4

0.1µF1µF

0.1µF

7

6

5

1µF

1860 TA03

0

10

20

30

40

50

60

70

80

AMPLITUDE (dB)

90

100

110

120

130

f1 = 7.507324kHz AT 530mV

f2 = 45.007324kHz AT 1.7V

fS = 100kHz

0 5 10 15 20 25 30 35 40 45 50

FREQUENCY (kHz)

P-P

P-P

1864/65 TA03b

RELATED PARTS

PART NUMBER SAMPLE RATE POWER DISSIPATION DESCRIPTION

14-Bit Serial I/O ADCs

LTC1417 400ksps 20mW 16-Pin SSOP, Unipolar or Bipolar, Reference, 5V or ±5V

LTC1418 200ksps 15mW Serial/Parallel I/O, Internal Reference, 5V or ±5V

16-Bit Serial I/O ADCs

LTC1609 200ksps 65mW Configurable Bipolar or Unipolar Input Ranges, 5V

References

LT1460 Micropower Precision Series Reference Bandgap, 130µA Supply Current, 10ppm/°C, Available in SOT-23

LT1790 Micropower Low Dropout Reference 60µA Supply Current, 10ppm/°C, SOT-23

Op Amps

LT1468/LT1469 Single/Dual 90MHz, 16-Bit Accurate Op Amps 22V/µs Slew Rate, 75µV/125µV Offset

LT1806/LT1807 Single/Dual 325MHz Low Noise Op Amps 140V/µs Slew Rate, 3.5nV/√Hz Noise, – 80dBc Distortion

LT1809/LT1810 Single/Dual 180MHz Low Distortion Op Amps 350V/µs Slew Rate, –90dBc Distortion at 5MHz

20

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

sn18645 18645fs

LT/TP 0502 2K • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2001

Loading...

Loading...