Page 1

FEATURES

Final Electrical Specifications

LTC1756

Smart Card Interface

February 2000

U

DESCRIPTION

■

Fully ISO 7816-3 and EMV Compliant

■

Buck-Boost Charge Pump Generates 3V or 5V

■

2.7V to 5.5V Input Voltage Range

■

3V↔ 5V Signal Level Translator

■

>10kV ESD on All Smart Card Pins

■

Dynamic Pull-Ups Deliver Fast Signal Rise Times

■

Soft Start Limits Inrush Current at Turn On

■

Very Low Operating Current: 75µA

■

Shutdown Current: <2.5µA

■

Short-Circuit and Overtemperature Protected

■

Available in 16-Pin SSOP Package

U

APPLICATIONS

■

Handheld Payment Terminals

■

Pay Telephones

■

ATMs

■

Key Chain Readers

■

Smart Card Readers

The LTC®1756 universal Smart Card interface is fully

compliant with ISO 7816-3 and EMV specifications. It

provides the smallest and simplest interface circuit between a host microcontroller and general purpose Smart

Cards.

An internal charge pump DC/DC converter delivers regulated 3V or 5V to the Smart Card, while an on-chip level

shifter allows a connection to a low voltage controller. All

Smart Card contacts are rated for 10kV ESD, eliminating

the need for external ESD protection devices.

Input voltage may range from 2.7V to 5.5V, allowing direct

connection to a battery. Automatic DC/DC converter soft

start mitigates start-up problems that may result when the

input power is provided by another regulator.

Battery life is maximized by 75µA operating current and

2µA shutdown current. The 16-pin SSOP package mini-

mizes PCB area for compact portable systems.

, LTC and LT are registered trademarks of Linear Technology Corporation.

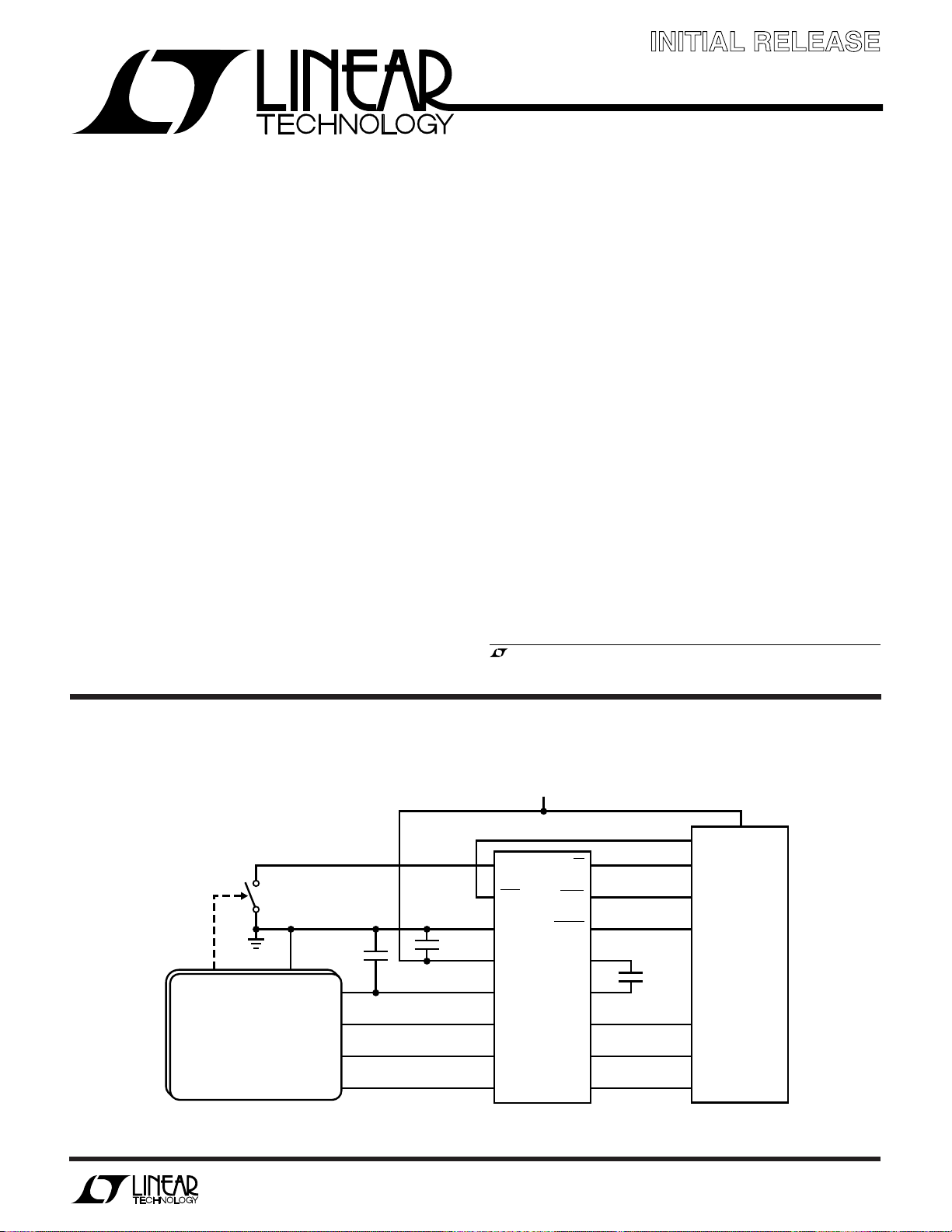

TYPICAL APPLICATION

SMART CARD

PRESENT SWITCH

N.O.

GND

SMART CARD

V

I/O

RST

CLK

U

CC

10µF

3.3V

1

PRES

2

PWR

3

C3

C2

10µF

GND

4

V

IN

LTC1756

5

V

CC

6

I/O

7

RST

8

CLK

5V/3V

CARD

READY

DATA

RIN

CIN

16

15

14

13

–

C

12

+

C

11

10

9

C1

0.68µF

µCONTROLLER

1756 TA01

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

1

Page 2

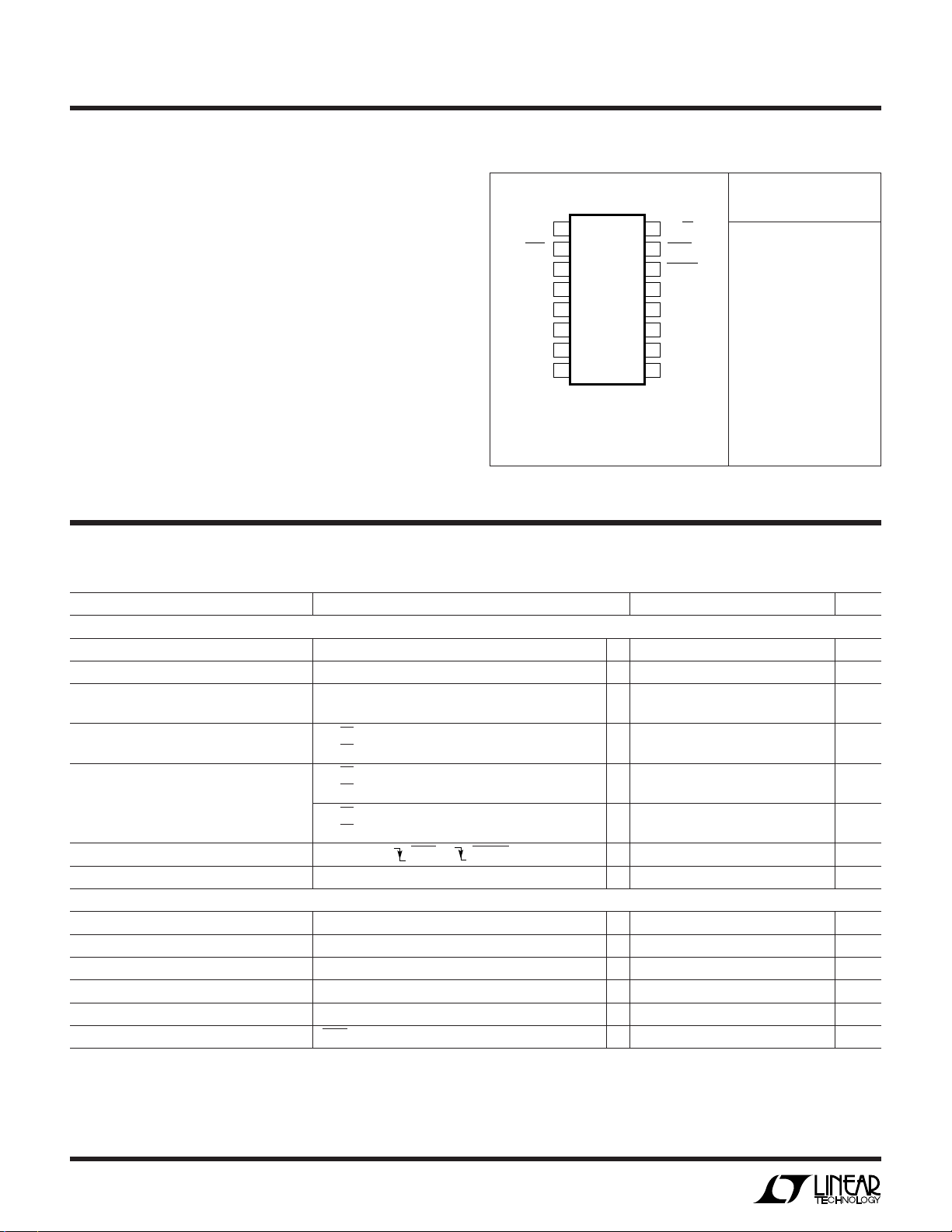

LTC1756

GN PACKAGE

16-LEAD NARROW PLASTIC SSOP

1

2

3

4

5

6

7

8

TOP VIEW

16

15

14

13

12

11

10

9

PRES

PWR

GND

V

IN

V

CC

I/O

RST

CLK

5V/3V

CARD

READY

C

–

C

+

DATA

RIN

CIN

WW

W

ABSOLUTE MAXIMUM RATINGS

U

PACKAGE

/

O

RDER I FOR ATIO

(Note 1)

VIN to GND............................................... –0.3V to 6.0V

VCC to GND .............................................. –0.3V to 5.5V

Digital Inputs to GND..................... –0.3V to VIN + 0.3V

CLK, RST, I/O to GND .....................–0.3V to VCC + 0.3V

VCC Short-Circuit Duration............................... Indefinite

Operating Temperature Range (Note 2) .. –40°C to 85°C

Storage Temperature Range ................ – 65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

T

= 125°C, θJA = 135°C/W

JMAX

Consult factory for Industrial and Military grade parts.

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specificatons are at TA = 25°C. VIN = 2.7V to 5.5V, unless otherwise noted.

The ● denotes specifications which apply over the full specified

WU

ORDER PART

NUMBER

LTC1756EGN

U

PARAMETER CONDITIONS MIN TYP MAX UNITS

Power Supply

VIN Operating Voltage ● 2.7 5.5 V

I

Operating Current ACTIVE State, I

VIN

I

Shutdown Current IDLE State, VIN ≤ 3.6V ● 2.5 µA

VIN

VCC Output Voltage 5V/3V = V

I

Output Current 5V/3V = 0V 3V ≤ VIN ≤ 5.5V ● 55 mA

VCC

VCC Turn-On Time C

VCC Discharge Time to 0.4V I

Controller Input/Output DATA

High Input Voltage Threshold (VIH) ● VIN – 0.6 0.5 • V

Low Input Voltage Threshold (VIL) ● 0.5 • V

High Level Output Voltage (VOH) Source Current = 20µA ● 0.7 • V

Low Level Output Voltage (VOL) Sink Current = –500µA (Note 3) ● 0.3 V

Output Rise/Fall Time Loaded with 30pF, 10% to 90% ● 0.5 µs

Input Current (IIH/IIL) PWR = V

2

= 0 ● 75 150 µA

VCC

IDLE State, 3.6V ≤ V

5V/3V = 0V

5V/3V = V

5V/3V = 0V 2.7V ≤ VIN ≤ 5.5V ● 55 mA

5V/3V = V

VCC

IN

IN

IN

= 10µF, PWR to READY ● 2.7 12 ms

OUT

= 0mA, VCC = 5V, C

IN

≤ 5.5V ● 10 µA

IN

● 4.75 5.00 5.25 V

● 2.80 3.00 3.20 V

3V ≤ VIN ≤ 5.5V ● 65 mA

2.7V ≤ VIN ≤ 5.5V ● 40 mA

= 10µF ● 100 250 µs

OUT

IN

0.3 V

IN

IN

● –1 1 µA

V

V

Page 3

LTC1756

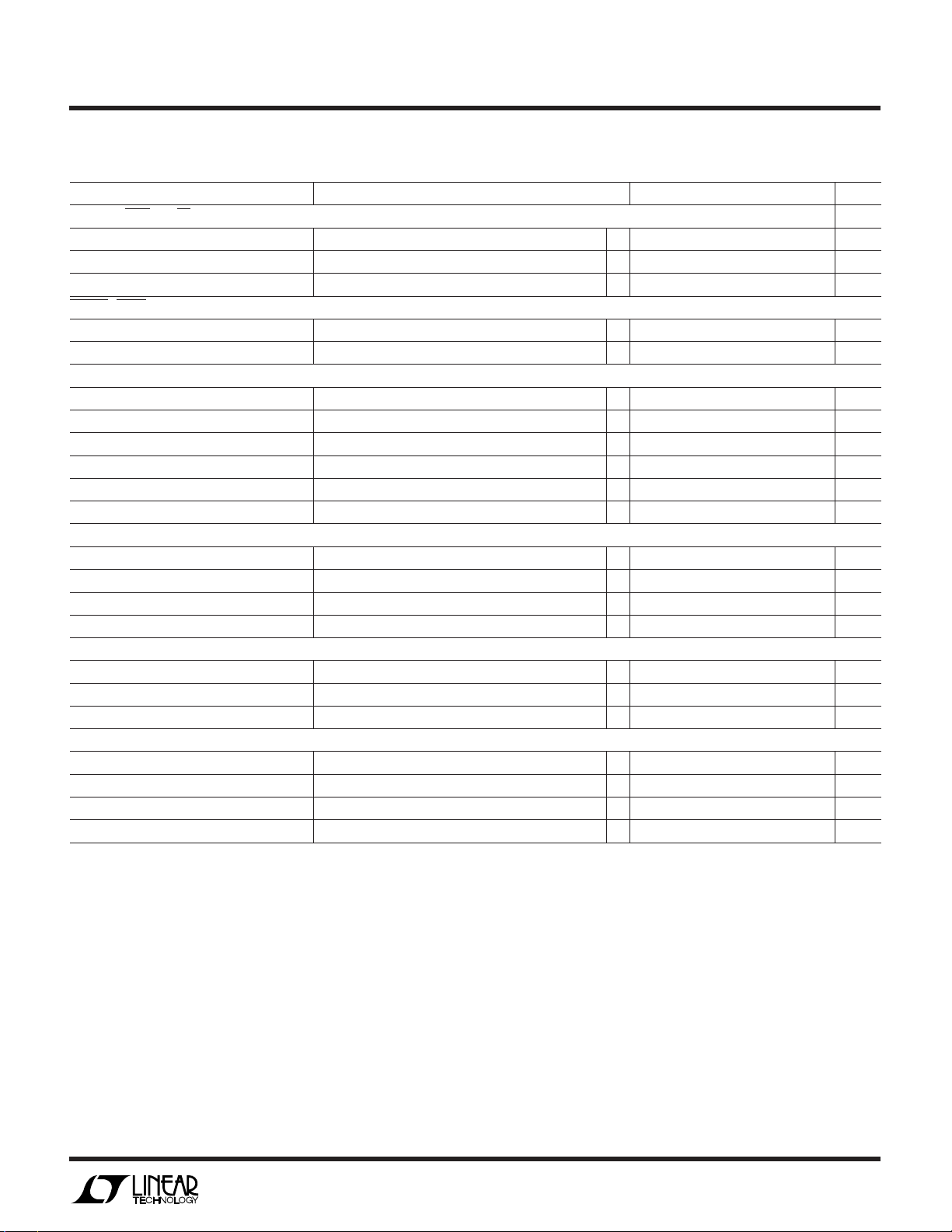

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full specified

temperature range, otherwise specificatons are at TA = 25°C. VIN = 2.7V to 5.5V, unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNITS

RIN, CIN, PWR, 5V/3V

High Input Voltage Threshold (VIH) ● 0.7 • VIN0.5 • V

Low Input Voltage Threshold (VIL) ● 0.5 • VIN0.2 • V

Input Current (IIH/IIL) ● –1 1 µA

READY, CARD

Pull-Up Current (IOH) ● 250 nA

Low Level Output Voltage (VOL) Sink Current = –20µA ● 0.3 V

Smart Card Input/Output I/O, VCC = 3V or 5V

High Input Voltage Threshold (VIH)I

Low Input Voltage Threshold (VIL)I

High Level Output Voltage (VOH) Source Current = 20µA, DATA = V

Low Level Output Voltage (VOL) Sink Current = –1mA, DATA = 0V (Note 3) ● 0.3 V

Rise/ Fall Time Loaded with 30pF, 10% to 90% ● 0.5 µs

Short-Circuit Current Shorted to V

CLK

High Level Output Voltage (VOH) Source Current = 100µA ● VCC – 0.5 V

Low Level Output Voltage (VOL) Sink Current = –200µA ● 0.3 V

CLK Rise/Fall Time CLK Loaded with 30pF ● 16 ns

CLK Frequency CLK Loaded with 30pF ● 5 MHz

RST

High Level Output Voltage (VOH) Source Current = 200µA ● 0.8 • V

Low Level Output Voltage (VOL) Sink Current = –200µA ● 0.3 V

RST Rise/Fall Time Loaded with 30pF ● 0.5 µs

PRES

High Input Voltage Threshold (VIH) ● 0.7 • VIN0.5 • V

Low Input Voltage Threshold (VIL) ● 0.5 • VIN0.2 • V

PRES Pull-Up Current V

PRES Debounce Time Proportional to the 0.68µF Charge Pump Capacitor ● 40 80 ms

= ±20µA ● 0.6 • VCC0.5 • V

IH(MAX)

= 1mA ● 0.5 • V

IL(MAX)

IN

CC

= 0V ● 0.5 1 µA

PRES

● 0.8 • V

● 3.5 5 mA

CC

CC

IN

CC

CC

IN

IN

0.8 V

IN

V

V

V

V

V

V

V

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC1756 is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the –40°C to 85°C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 3: The DATA and I/O pull-down drivers must sink up to 250µA

sourced by the internal current sources.

3

Page 4

LTC1756

UUU

PIN FUNCTIONS

PRES (Pin 1): (Input) Connects to the Smart Card acceptor’s

PRESENT indicator switch to detect if a card is inserted.

This pin has a pull-up current source so that a normally

open grounded switch can be detected with no external

components. The pull-up current source is nonlinear,

delivering higher current when the PRES pin is above 1V

but very little current below 1V. This helps resist false card

indications due to leakage current.

PWR (Pin 2): (Input) A low on the PWR pin places the

LTC1756 in the ACTIVE state enabling the charge pump.

The READY pin indicates when the card supply voltage

(VCC) has reached its final value and communication with

the Smart Card is possible. The reset and clock channels

are enabled after READY goes low. The I/O channel is also

enabled only after READY goes low.

The falling edge of PWR latches the state of the 5V/3V pin.

After PWR is low, changes on the 5V/3V pin are ignored.

GND (Pin 3): Ground Reference for the IC. This pin should

be connected to a low impedance ground plane. Bypass

capacitors for VIN and VCC should be in close proximity to

the GND pin.

VIN (Pin 4): Supply Voltage. May be between 2.7V and 5.5V.

A 10µF low ESR ceramic bypass capacitor is required on

this pin for optimum performance.

VCC (Pin 5): Regulated Smart Card Supply Voltage. This

pin should be connected to the Smart Card VCC contact.

The 5V/3V pin determines the VCC output voltage.

The VCC pin is protected against short circuits by comparing the actual output voltage with an internal reference

voltage. If VCC is below its correct level (for as little as 5µs)

the LTC1756 switches to the Alarm state (see the State

Diagram). The VCC pin requires a 10µF charge storage

capacitor to ground. For optimum performance a low ESR

ceramic capacitor should be used.

to the Smart Card I/O contact. The Smart Card I/O pin must

be able to sink up to 250µA when driving the I/O pin low

due to the pull-up current source. The I/O pin becomes a

low impedance to ground during the Idle state. It does not

become active until READY goes low indicating that VCC is

stable.

Once READY is low, the I/O pin is protected against short

circuits to VCC by current limiting to 5mA maximum.

The DATA-I/O channel is bidirectional for half-duplex

transmissions. Its idle state is H-H. Once an L is detected

on one side of the channel the direction of transmission is

established. Specifically, the side which received an L first

is now the input, and the opposite side is the output.

Transmission from the output side back to the input side

is inhibited, thereby preventing a latch condition. Once the

input side releases its L, both sides return to H, and the

channel is now ready for a new L to be transmitted in either

direction. If an L is forced externally on the output side, and

it persists until after the L on the input side is released, this

illegal input will not be transmitted to the input side

because the transmission direction will not have changed.

The direction of transmission can only be established from

the idle (H-H) state and is determined by the first receipt

of an L on either side.

RST (Pin 7): (Output) Level-Shifted Reset Output Pin. This

pin should be connected to the Smart Card RST contact.

The RST pin becomes a low impedance to ground during

the Idle state (see the State Diagram). The reset channel

does not become active until the READY signal goes low

indicating that VCC is stable.

Short-circuit protection is provided on the RST pin by

comparing RST with RIN. If these signals differ for several

microseconds then the LTC1756 switches to the Alarm

state. This fault checking is only performed after the VCC pin

has reached its final value (as indicated by the READY pin).

During the Idle and Alarm states the VCC pin is rapidly

discharged to ground to comply with the deactivation

requirements of the EMV and ISO-7816 specifications.

I/O (Pin 6): (Input/Output) Smart Card Side Data I/O Pin.

This pin is used for bidirectional data transfer between the

microcontroller and the Smart Card. It should be connected

4

CLK (Pin 8): (Output) Level-Shifted Clock Output Pin. This

pin should be connected to the Smart Card CLK contact.

The CLK pin becomes a low impedance to ground during

the Idle state (see the State Diagram). The clock channel

does not become active until the READY signal goes low

indicating that VCC is stable.

Page 5

UUU

PIN FUNCTIONS

LTC1756

Short-circuit protection is provided on the CLK pin by comparing CLK with CIN. If these signals differ for several microseconds then the LTC1756 switches to the Alarm state.

This fault checking is only performed after the VCC pin has

reached its final value (as indicated by the READY pin).

The clock channel is optimized for signal integrity in order

to meet the stringent duty cycle requirements of the EMV

specification. Therefore, to reduce power in low power

applications, clock stop mode is recommended when data

is not being exchanged.

CIN (Pin 9): (Input) Clock Input Pin from the Microcontroller. During the Active state this signal appears on the CLK

pin after being level-shifted and buffered.

RIN (Pin 10): (Input) Reset Input Pin from the Microcontroller. During the Active state this signal appears on the

RST pin after being level-shifted and buffered.

DATA (Pin 11): (Input/Output) Microcontroller Side Data

I/O Pin. This pin is used for bidirectional data transfer

between the microcontroller and the Smart Card. The

microcontroller data pin must be open drain and must be

able to sink up to 250µA when driving the DATA pin low

due to the pull-up current source. The DATA pin becomes

high impedance during the Idle state (see the State Diagram). It does not become active until the READY signal

goes low indicating that VCC is stable.

C+, C– (Pins 12, 13): Charge Pump Flying Capacitor

Terminals. Optimum values for the flying capacitor range

from 0.68µF to 1µF. Best performance is achieved with a

low ESR X7R ceramic capacitor.

READY (Pin 14): (Output) Readiness Indicator of the

Smart Card Supply Voltage (VCC). When the LTC1756 is

placed in the Active state the soft start feature slowly

ramps the VCC voltage. A low on the READY pin indicates

that VCC has reached its final value.

The READY pin is configured as an open-drain pull-down

with a weak pull-up current source.

The READY pin also indicates if the LTC1756 is in Alarm

mode. The LTC1756 detects faults such as VCC underrange

for at least 5µs, overtemperature shutdown, CLK or RST

invalid output levels and card removal during Active

state. CLK or RST invalid and overtemperature faults are

detected only after VCC has reached its final value. V

underrange and card removal during Active faults are

detected at any time during the Active period (i.e., once

PWR = 0V).

If the LTC1756 has been activated normally and VCC, the

card voltage, has reached its final value then READY will

go low indicating normal operation. If, following this, a

fault occurs and the LTC1756 enters the Alarm state, the

READY pin will return high.

In the event that a fault precedes the activation of VCC,

such as a direct short circuit from VCC to GND, the

LTC1756 will attempt to operate until the fault is detected

and then automatically shut down and enter the Alarm

state. In this case the READY pin will never go low after the

command to start the smart card is given (i.e., PWR = 0V).

If the LTC1756 enters the Alarm state it can only be

cleared by returning the PWR pin high.

CARD (Pin 15): (Output) Level-Shifted and Debounced

PRES Signal from the Smart Card Acceptor Switch. When

a valid card indication appears, this pin communicates the

presence of the Smart Card to the microcontroller. The

CARD pin has an open-drain active pull-down with a weak

pull-up current source. The debounce circuit ensures that

a card has been present for a continuous period of at least

40ms before asserting CARD low. The CARD pin returns

high within 50µs of card removal.

5V/3V (Pin 16):(Input) Controls the output voltage (VCC)

of the DC/DC converter during the Active state. A valid high

sets VCC to 5V. A valid low sets VCC to 3V. The 5V/3V pin

is latched on the falling edge of the PWR pin. When PWR

is low, changes on the 5V/3V pin are ignored. To change

the voltage on VCC the LTC1756 must first be returned to

the Idle state by bringing the PWR pin high.

CC

5

Page 6

LTC1756

BLOCK DIAGRA

W

V

IN

PRES 1

PWR 2

GND 3

V

IN

V

CC

I/O 6

τ

DC/DC CONVERTER

AND

CONTROL LOGIC

4

5

*

*

16

5V/3V

CARD

15

READY

14

–

C

13

+

C

12

DATA11

6

RST 7

CLK

8

DYNAMIC PULL-UP CURRENT SOURCE

*

1756 BD

RIN

10

CIN

9

Page 7

LTC1756

U

WUU

APPLICATIONS INFORMATION

10kV ESD Protection

All Smart Card pins (CLK, RST, I/O, VCC and GND) can

withstand over 10kV of human body model ESD in situ. In

order to ensure proper ESD protection, careful board

layout is required. The GND pin should be tied directly to

a ground plane. The VCC capacitor should be located very

close to the VCC pin and tied immediately to the ground

plane.

Capacitor Selection

The style and value of capacitors used with the LTC1756

determine several parameters such as output ripple voltage, charge pump strength, Smart Card switch debounce

time and VCC discharge rate.

Due to the switching nature of a capacitive charge pump,

low equivalent series resistance (ESR) capacitors are

recommended for the capacitors at VIN and VCC. Whenever the flying capacitor is switched to the VCC charge

storage capacitor, considerable current flows. The product of this high current and the ESR of the output capacitor

can generate substantial voltage spikes on the VCC output.

These spikes may cause problems with the Smart Card or

may interfere with the regulation loop of the LTC1756.

Therefore, ceramic or tantalum capacitors are recommended rather than higher ESR aluminum capacitors.

Between ceramic and tantalum, ceramic capacitors generally have the lowest ESR. Some manufacturers have

developed low ESR tantalum capacitors but they can be

expensive and may still have higher ESR than ceramic

types. Thus, while they cannot be avoided, ESR spikes will

typically be lowest when using ceramic capacitors.

For ceramic capacitors there are several different materials available to choose from. The choice of ceramic

material is generally based on factors such as available

capacitance, case size, voltage rating, electrical performance and cost. For example, capacitors made of Y5V

material have high packing density, which provides high

capacitance for a given case size. However, Y5V capacitors tend to lose considerable capacitance over the – 40°C

to 85°C temperature range. X7R ceramic capacitors are

more stable over temperature but don’t provide the high

packing density. Therefore, large capacitance values are

generally not available in X7R ceramic.

The value and style of the flying capacitor are important

not only for the charge pump but also because they

provide the large debounce time for the Smart Card

detection channel. A 0.68µF X7R capacitor is a good

choice for the flying capacitor because it provides fairly

constant capacitance over temperature and its value is not

prohibitively large.

The charge storage capacitor on the VCC pin determines

the ripple voltage magnitude and the discharge time of the

Smart Card voltage. To minimize ripple, generally, a large

value is needed. However, to meet the VCC discharge rate

specification, the value should not exceed 20µF. A 10µF

capacitor can be used but the ripple magnitude will be

higher leading to worse apparent DC load regulation.

Typically a 15µF to 18µF Y5V ceramic capacitor is the best

choice for the VCC charge storage capacitor. For best

performance, this capacitor should be connected as close

as possible to the VCC and GND pins. Note that most of the

electrostatic discharge (ESD) current on the Smart Card

pins is absorbed by this capacitor.

7

Page 8

LTC1756

U

WUU

APPLICATIONS INFORMATION

The bypass capacitor at VIN is also important. Large dips

on the input supply due to ESR may cause problems with

the internal circuitry of the LTC1756. A good choice for the

input bypass capacitor is a 10µF Y5V style ceramic

Dynamic Pull-Up Current Sources

The current sources on the bidirectional pins (DATA and

I/O) are dynamically activated to achieve a fast rise time

with a relatively small static current (Figure 1). Once a

bidirectional pin is relinquished, a small start-up current

begins to charge the node. An edge rate detector determines if the pin is released by comparing its slew rate with

an internal reference value. If a valid transition is detected,

a large pull-up current enhances the edge rate on the node.

The higher slew rate corroborates the decision to charge

the node thereby effecting a dynamic form of hysteresis.

Once the node has reached the power supply voltage the

internal comparator requires several hundred nanoseconds to reset. Pulling down on the pin before the reset

delay expires will result in a momentary contention and a

higher current flow. Therefore, the comparator delay sets

the upper limit on the maximum data rate of the bidirectional channels to about 500kHz.

Low Power Operation

The LTC1756 is inherently a low power device. When there

is no Smart Card present the supply current is less than

2.5µA. When a Smart Card is present the LTC1756 oper-

ates with a quiescent current of only 75µA, thus the

majority of power is consumed by charge pump losses

and the card itself. If the card can be made to consume less

power during idle times a significant power savings will be

achieved. Whenever possible Clock Stop Mode should be

used (or alternatively a very low “idling” clock speed).

Furthermore, in the Active state, the bidirectional pins

should all be relinquished whenever possible since there

is some static current flow when a bidirectional pin is

pulled down.

Overtemperature Fault Protection

An overtemperature circuit disables the chip and places

the LTC1765 in the Alarm state if the IC’s junction temperature exceeds 150°C.

V

OR V

CC

IN

+

I

START

–

δV

δt

BIDIRECTIONAL PIN

Figure 1. Dynamic Pull-Up Current Sources

1756 F01

V

REF

8

Page 9

LTC1756

U

WUU

APPLICATIONS INFORMATION

Self-Start Mode

By connecting the CARD pin to the PWR pin the LTC1756

can be made to start up automatically when a Smart Card

is detected (Figure 2). In this mode, the READY pin

becomes an interrupt signal indicating to the microcontroller that a Smart Card is present and that VCC, the charge

pump voltage, is at its final value. The Smart Card remains

powered as long as it is detected by the PRES pin. When

the Smart Card is removed the LTC1756 will automatically

be deactivated by the fault detection circuitry.

CARD

Figure 2. Self-Start Mode

PWR

READY

TO

MICROCONTROLLER

1756 F02

Deactivation Sequence

For maximum flexibility the Smart Card can be deactivated

either manually or automatically. In manual mode the

deactivation is controlled by explicitly manipulating the

LTC1756 input and control pins (DATA, RIN and CIN

followed by PWR). In automatic mode the PWR pin is used

to perform the built-in deactivation sequence. Once PWR

is brought high the built-in deactivation sequence occurs

as follows:

DEACTIVATION DIRECTIVE

V

CC

RST

CLK

I/O

RST = R

CLK = C

I/O = DATA

IN

IN

1755 F03

Figure 3. Deactivation Sequence

In the event of a fault, the LTC1756 automatically

implements the built-in deactivation sequence.

9

Page 10

LTC1756

U

WUU

APPLICATIONS INFORMATION

POWER OFF

State Definitions

IDLE/DEACTIVATION

VCC, RST, CLK, I/O = L

DEACTIVATION

PWR = V

DEACTIVATION

Figure 4. LTC1756 State Diagram

IDLE

IN

ALARM

PWR = 0V

PWR = V

PRES ≠ “0”

FAULT > 5µs

PRES ≠ “0”

IN

or

ACTIVE

NO

FAULT

FAULT

TIMEOUT

FAULT

1756 F04

ACTIVE

VCC = 3V or 5V (as determined by the 5V/3V pin)

READY, DATA = Z

CARD = PRES

Once the LTC1756 enters the Idle/Deactivation state the

deactivation sequence begins. The deactivation sequence

will continue until VCC is discharged to approximately 1V.

An activation command (PWR = 0V) will only be acknowledged once this occurs.

ALARM/DEACTIVATION

The only possible next state is Idle/Deactivation which is

achieved by disabling the LTC1756 via the PWR pin

(i.e., PWR = VIN).

The alarm indication can be cleared by rapidly cycling the

PWR pin. However, a new activation cycle will not begin

until VCC is or has dropped below approximately 1V.

RST = RIN, CLK = C

IN

I/O, DATA = Ready for data (after READY becomes low)

CARD = PRES

FAULT TIMEOUT

Same as Active except:

The duration of a fault is being measured. If the fault

duration exceeds 5µs then the Alarm/Deactivation state

follows. If the fault duration is less than 5µs, then the

device is returned to the Active state.

10

Page 11

PACKAGE DESCRIPTION

U

Dimensions in inches (millimeters) unless otherwise noted.

GN Package

16-Lead Plastic SSOP (Narrow 0.150)

(LTC DWG # 05-08-1641)

0.189 – 0.196*

(4.801 – 4.978)

16

15

14

12 11 10

13

LTC1756

0.009

(0.229)

9

REF

0.015

± 0.004

(0.38 ± 0.10)

0.007 – 0.0098

(0.178 – 0.249)

0.016 – 0.050

(0.406 – 1.270)

* DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

** DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

0° – 8° TYP

× 45°

0.229 – 0.244

(5.817 – 6.198)

0.053 – 0.068

(1.351 – 1.727)

0.008 – 0.012

(0.203 – 0.305)

12

0.150 – 0.157**

(3.810 – 3.988)

5

4

3

678

0.0250

(0.635)

BSC

0.004 – 0.0098

(0.102 – 0.249)

GN16 (SSOP) 1098

11

Page 12

LTC1756

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC1514/LTC1515 Micropower Step-Up/Step-Down Inductorless Regulated Output Up to 50mA, VIN from 2V to 10V, SO-8 Package

DC/DC Converters

LTC1516 Micropower Regulated 5V Charge Pump 5V/50mA Output from 2V to 5V Input, S0-8 Package

LTC1555/LTC1556 SIM Power Supply and Level Translator Step-Up/Step-Down Charge Pump + SIM Level Translators, >10kV ESD

LTC1754-5 5V Charge Pump with Shutdown in SOT-23 VIN from 2.7V to 5.5V, 50mA Output with VIN ≥ 3V

LTC1755 Smart Card Interface with C4, C8 Pins VIN from 2.7V to 6V, 10kV ESD On All Smart Card Pins,

60µA Operating Current

LTC1986 3V/5V SIM Power Supply in SOT-23 VIN from 2.6V to 4.4V, 3V/5V Output at 10mA

12

Linear T echnology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

1756i LT/TP 0200 4K • PRINTED IN USA

LINEAR TECHN OLOGY CORPORATION 2000

Loading...

Loading...