Page 1

FEATURES

LTC1734

Lithium-Ion Linear

Battery Charger in ThinSOT

U

DESCRIPTIO

■

Low Profile (1mm) ThinSOTTM Package

■

No Blocking Diode Required

■

No Sense Resistor Required

■

1% Accurate Preset Voltages: 4.1V or 4.2V

■

Charge Current Monitor Output

for Charge Termination

■

Programmable Charge Current: 200mA to 700mA

■

Automatic Sleep Mode with Input Supply Removal

■

Manual Shutdown

■

Negligible Battery Drain Current in Shutdown

■

Undervoltage Lockout

■

Self Protection for Overcurrent/Overtemperature

U

APPLICATIO S

■

Cellular Telephones

■

Handheld Computers

■

Digital Cameras

■

Charging Docks and Cradles

■

Low Cost and Small Size Chargers

■

Programmable Current Sources

The LTC®1734 is a low cost, single cell, constant-current/

constant-voltage Li-Ion battery charger controller. When

combined with a few external components, the SOT-23

package forms a very small, low cost charger for single cell

lithium-ion batteries.

The LTC1734 is available in 4.1V and 4.2V versions with

1% accuracy. Constant current is programmed using a

single external resistor between the PROG pin and ground.

Manual shutdown is accomplished by floating the program resistor while removing input power automatically

puts the LTC1734 into a sleep mode. Both the shutdown

and sleep modes drain near zero current from the battery.

Charge current can be monitored via the voltage on the

PROG pin allowing a microcontroller or ADC to read the

current and determine when to terminate the charge cycle.

The output driver is both current limited and thermally

protected to prevent the LTC1734 from operating outside

of safe limits. No external blocking diode is required.

The LTC1734 can also function as a general purpose

current source or as a current source for charging nickelcadmium (NiCd) and nickel-metal-hydride (NiMH) batteries using external termination.

, LTC and LT are registered trademarks of Linear Technology Corporation.

ThinSOT is a trademark of Linear Technology Corporation.

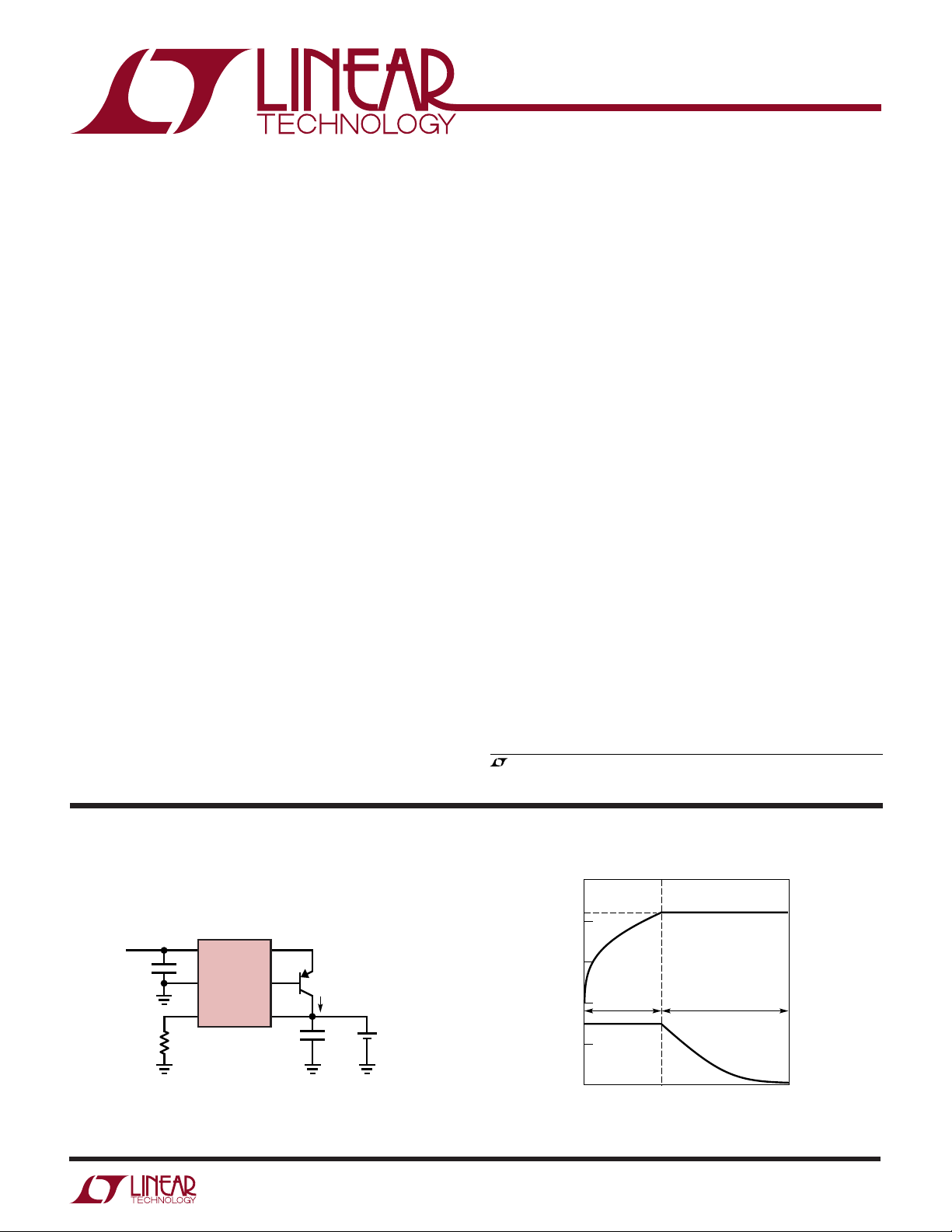

TYPICAL APPLICATIO

300mA Li-Ion Battery Charger

V

IN

5V

1µF

31

2

4

R

PROG

5k

V

CC

LTC1734

GND

PROG

I

SENSE

DRIVE

BAT

6

5

U

FMMT549

I

BAT

10µF

= 300mA

+

SINGLE

Li-Ion

BATTERY

1734 TA01

PROG Pin Indicates Charge Status

5V

V

(V)V

4V

BAT

V

3V

2V

1.5V

(V)

1V

PROG

0V

CHARGING

BEGINS

CONSTANT

CURRENT

BAT

V

CONSTANT

VOLTAGE

PROG

CHARGING

COMPLETE

1734 TA01b

1

Page 2

LTC1734

WW

W

ABSOLUTE MAXIMUM RATINGS

U

U

W

PACKAGE/ORDER INFORMATION

(Note 1)

Supply Voltage (VCC) ...................................–0.3V to 9V

Input Voltage (BAT, PROG) ........ –0.3V to (VCC + 0.3V)

Output Voltage (DRIVE) .............. –0.3V to (VCC + 0.3V)

Output Current (I

) ................................... –900mA

SENSE

Short-Circuit Duration (DRIVE) ...................... Indefinite

Junction Temperature.......................................... 125°C

Operating Ambient Temperature Range

(Note 2) ...............................................–40°C to 85°C

Operating Junction Temperature (Note 2) ............ 100°C

TOP VIEW

I

1

SENSE

GND 2

3

V

CC

S6 PACKAGE

6-LEAD PLASTIC SOT-23

T

= 125°C, θJA = 230°C/W

JMAX

6 DRIVE

5 BAT

4 PROG

ORDER PART

NUMBER

LTC1734ES6-4.1

LTC1734ES6-4.2

S6 PART MARKING

LTHD

LTRG

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VCC = 5V, GND = 0V and V

otherwise noted. All current into a pin is positive and current out of a pin is negative. All voltages are referenced to GND, unless

otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

VCC Supply

V

CC

I

CC

I

SHDN

I

BMS

I

BSL

V

UVLOI

V

UVLOD

V

UVHYS

Charging Performance

V

BAT

I

BAT1

I

BAT2

V

CM1

V

CM2

I

DSINK

Operating Supply Range (Note 5) ● 4.55 8 V

Quiescent VCC Pin Supply Current V

VCC Pin Supply Current in Manual Shutdown PROG Pin Open ● 450 900 µA

Battery Drain Current in Manual Shutdown PROG Pin Open ● –1 0 1 µA

(Note 3)

Battery Drain Current in Sleep Mode (Note 4) VCC = 0V ● –1 0 1 µA

Undervoltage Lockout Exit Threshold VCC Increasing ● 4.45 4.56 4.68 V

Undervoltage Lockout Entry Threshold VCC Decreasing ● 4.30 4.41 4.53 V

Undervoltage Lockout Hysteresis VCC Decreasing 150 mV

Output Float Voltage in Constant Voltage Mode 4.1V Version, I

Output Full-Scale Current When Programmed R

for 200mA in Constant Current Mode Pass PNP Beta > 50

Output Full-Scale Current When Programmed R

for 700mA in Constant Current Mode Pass PNP Beta > 50

Current Monitor Voltage on PROG Pin I

Current Monitor Voltage on PROG Pin I

Drive Output Current V

The ● denotes the specifications which apply over the full operating

= 5V, (Forces I

BAT

= 200µA,(7500Ω from PROG to GND)

I

PROG

4.2V Version, I

= 7500Ω, 4.55V ≤ VCC ≤ 8V, ● 155 200 240 mA

PROG

= 2143Ω, 4.55V ≤ VCC ≤ 8V, ● 620 700 770 mA

PROG

= 10% of I

BAT

4.55V ≤ V

≤ 85°C

0°C ≤ T

A

= 10% of I

BAT

4.55V ≤ V

0°C ≤ T

≤ 85°C

A

= 3.5V ● 30 mA

DRIVE

Consult LTC Marketing for parts specified with wider operating temperature ranges.

is equal to the float voltage unless

BAT

= I

DRIVE

= 10mA, 4.55V ≤ VCC ≤ 8V ● 4.059 4.10 4.141 V

BAT

= 10mA, 4.55V ≤ VCC ≤ 8V ● 4.158 4.20 4.242 V

BAT

, R

BAT1

BAT2

, R

PROG

PROG

≤ 8V, Pass PNP Beta > 50,

CC

≤ 8V, Pass PNP Beta > 50,

CC

= 0), ● 670 1150 µA

BAT

= 7500Ω, 0.045 0.15 0.28 V

= 2143Ω, 0.10 0.15 0.20 V

U

2

Page 3

LTC1734

TEMPERATURE (°C)

–50

190

I

BAT1

(mA)

200

210

0

50

75

1734 G03

–25

25

100

125

R

PROG

= 7.5k

PNP = FCX589

VCC = 4.55V AND 8V

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VCC = 5V, GND = 0V and V

The ● denotes the specifications which apply over the full operating

is equal to the float voltage unless

BAT

otherwise noted. All current into a pin is positive and current out of a pin is negative. All voltages are referenced to GND, unless

otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Charger Manual Control

V

MSDT

V

MSHYS

I

PROGPU

Protection

I

DSHRT

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC1734E is guaranteed to meet performance specifications

from 0°C to 70°C ambient temperature range and 0°C to 100°C junction

temperature range. Specifications over the –40°C to 85°C operating

ambient temperature range are assured by design, characterization and

correlation with statistical process controls.

Note 3: Assumes that the external PNP pass transistor has negligible B-C

reverse-leakage current when the collector is biased at 4.2V (V

base is biased at 5V (V

Manual Shutdown Threshold V

Manual Shutdown Hysteresis V

Programming Pin Pull-Up Current V

Drive Output Short-Circuit Current Limit V

).

CC

Increasing ● 2.05 2.15 2.25 V

PROG

Decreasing from V

PROG

= 2.5V –6 –3 –1.5 µA

PROG

= V

DRIVE

CC

MSDT

● 35 65 130 mA

90 mV

Note 4: Assumes that the external PNP pass transistor has negligible B-E

reverse-leakage current when the emitter is biased at 0V (V

base is biased at 4.2V (V

BAT

).

CC

Note 5: The 4.68V maximum undervoltage lockout (UVLO) exit threshold

must first be exceeded before the minimum V

Short duration drops below the minimum V

specification applies.

CC

specification of several

CC

microseconds or less are ignored by the UVLO. If manual shutdown is

entered, then VCC must be higher than the 4.68V maximum UVLO

) and the

BAT

threshold before manual shutdown can be exited. When operating near the

minimum V

, a suitable PNP transistor with a low saturation voltage

CC

must be used.

) and the

UW

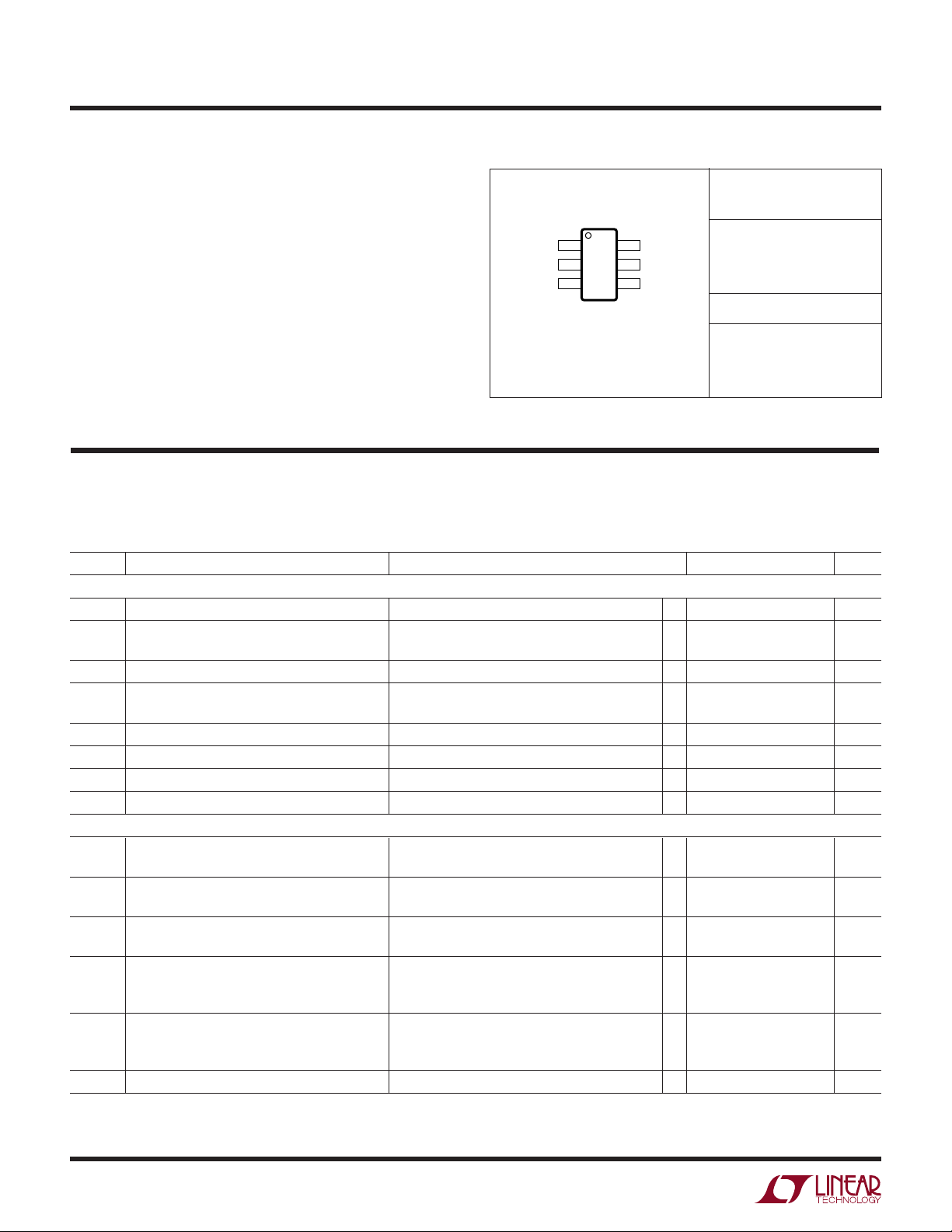

TYPICAL PERFOR A CE CHARACTERISTICS

Float Voltage vs Temperature

4.21

4.20

FLOAT VOLTAGE (V)

4.19

and Supply Voltage

I

= 10mA

BAT

PNP = FCX589

4.2V OPTION

V

= 4.55V

CC

25

–25

0

TEMPERATURE (°C)

–50

VCC = 8V

50

100

125

1734 G01

75

Float Voltage vs I

4.201

VCC = 5V

= 25°C

T

A

PNP = FCX589

4.2V OPTION

= 2150Ω

R

PROG

4.200

FLOAT VOLTAGE (V)

4.199

0

100

200

300

I

BAT

BAT

400

(mA)

500

600

1734 G02

700

I

vs Temperature

BAT1

and Supply Voltage

3

Page 4

LTC1734

TEMPERATURE (°C)

–50

140

V

PROG

(mV)

150

160

0

50

75

1734 G12

–25

25

100

125

R

PROG

= 2.15k

PNP = FCX589

VCC = 8V

V

CC

= 4.55V

UW

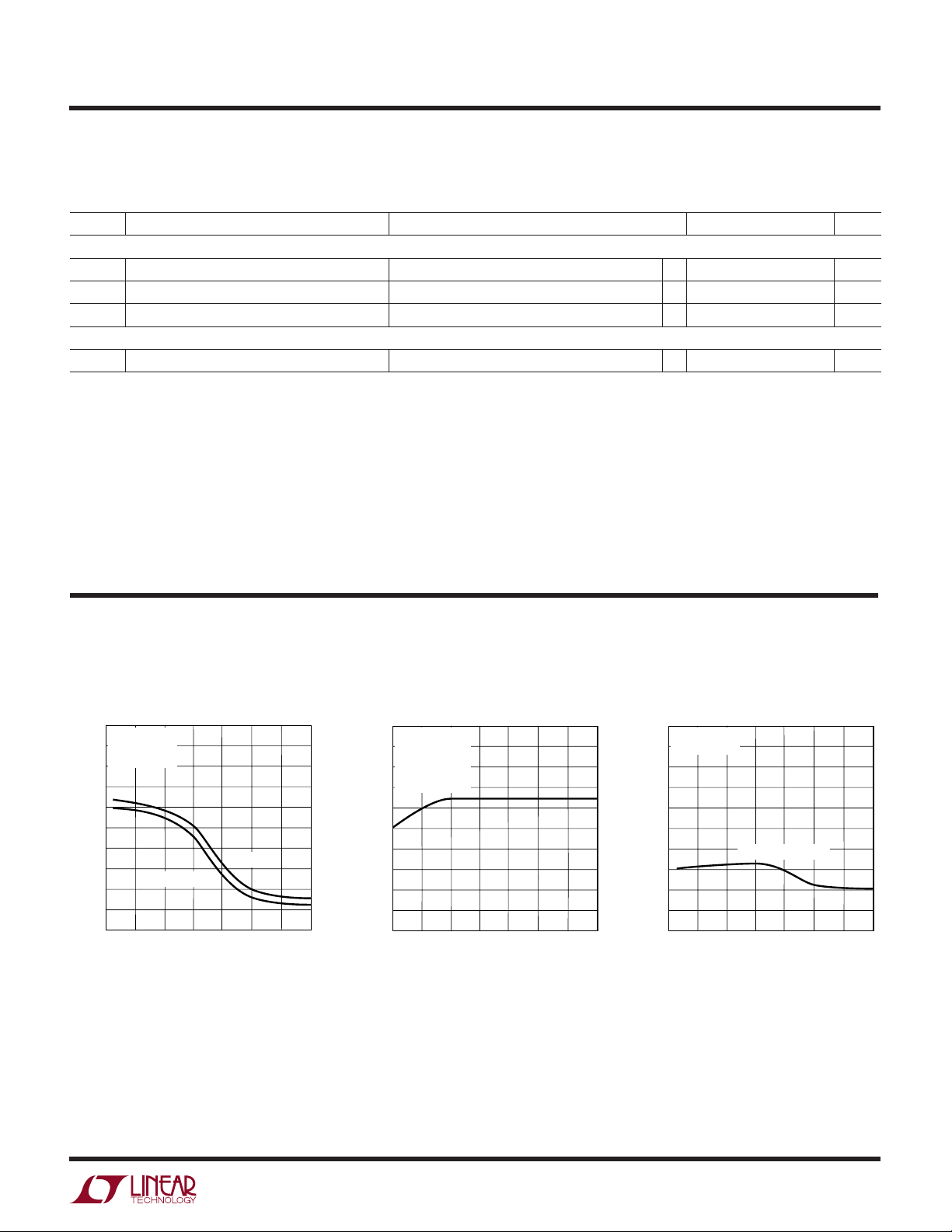

TYPICAL PERFOR A CE CHARACTERISTICS

I

vs Temperature

BAT2

and Supply Voltage

740

R

= 2.15k

PROG

PNP = FCX589

I

210

vs V

BAT1

VCC = 5V

T

= 25°C

A

= 7.5k

R

PROG

PNP = FCX589

BAT

I

750

vs V

BAT2

VCC = 5V

T

= 25°C

A

= 2.15k

R

PROG

PNP = FCX589

BAT

(mA)

700

BAT2

I

VCC = 4.55V AND 8V

660

–50

0

–25

TEMPERATURE (°C)

50

25

Program Pin Pull-Up Current vs

Temperature and Supply Voltage

3.6

V

= 2.5V

PROG

3.5

V

= 8V

3.4

(µA)

3.3

PROGPU

I

3.2

3.1

3.0

–50

–25 0

CC

VCC = 4.55V

50 100 125

25 75

TEMPERATURE (°C)

BAT PIN MUST BE DISCONNECTED

(mA)

200

BAT1

I

100

125

1734 G04

75

190

AND GROUNDED TO FORCE

CC MODE IN THIS REGION

1

0

3

4

2

V

(V)

BAT

5

1734 G05

Program Pin Pull-Up Current

vs V

PROG

3.6

VCC = 8V

= 25°C

T

A

3.4

3.2

(µA)

PROGPU

3.0

I

2.8

1734 G07

2.6

2

456

3

V

PROG

(V)

78

1635 G08

BAT PIN MUST BE DISCONNECTED

(mA)

BAT2

I

700

650

AND GROUNDED TO FORCE

CC MODE IN THIS REGION

1

0

2

V

BAT

Program Pin Voltage

vs Charge Current (200mA)

1.6

VCC = 5V

T

= 25°C

A

(V)

PROG

V

1.4

1.2

1.0

0.8

0.6

0.4

0.2

R

PROG

PNP = FCX589

0

0

= 7.5k

LIMITS AT 25mV DUE TO

PROGRAMMING PIN PULL-UP

CURRENT (I

I

100

BAT1

50

(V)

PROGPU

(mA)

3

4

5

1734 G06

)

150

200

1734 F09

4

Program Pin Voltage

vs Charge Current (700mA)

1.6

VCC = 5V

= 25°C

T

A

1.4

1.2

1.0

(V)

0.8

PROG

V

0.6

0.4

0.2

= 2.15k

R

PROG

PNP = FCX589

LIMITS AT 6mV DUE TO

PROGRAMMING PIN PULL-UP

0

0

CURRENT (I

100 200 400

300

I

BAT2

PROGPU

(mA)

)

500 600 700

1734 G10

Program Pin Voltage for I

BAT1

vs Temperature and Supply Voltage

160

(mV)

150

PROG

V

140

–50

–25

V

CC

= 4.55V

0

VCC = 8V

25

TEMPERATURE (°C)

50

R

PROG

PNP = FCX589

75

/10

= 7.5k

100

1734 G11

125

Program Pin Voltage for I

BAT2

/10

vs Temperature and Supply Voltage

Page 5

UUU

PIN FUNCTIONS

I

(Pin 1): Sense Node for Charge Current. Current

SENSE

from VCC passes through the internal current sense resistor and reappears at I

external PNP emitter. The PNP collector provides charge

current to the battery.

GND (Pin 2): Ground. Provides a reference for the internal

voltage regulator and a return for all internal circuits.

When in the constant voltage mode, the LTC1734 will

precisely regulate the voltage between the BAT and GND

pins. The battery ground should connect close to the GND

pin to avoid voltage drop errors.

VCC (Pin 3): Positive Input Supply Voltage. This pin

supplies power to the internal control circuitry and external PNP transistor through the internal current sense

resistor. This pin should be bypassed to ground with a

capacitor in the range of 1µF to 10µF.

PROG (Pin 4): Charge Current Programming, Charge

Current Monitor and Manual Shutdown Pin. Provides a

virtual reference voltage of 1.5V for an external resistor

(R

) tied between this pin and ground that programs

PROG

the battery charge current when the charger is in the

constant current mode. The typical charge current will be

1000 times greater than the current through this resistor

to supply current to the

SENSE

LTC1734

(I

= 1500/R

BAT

current to be monitored. The voltage on this pin is proportional to the charge current where 1.5V corresponds to the

full programmed currrent. Floating this pin allows an

internal current source to pull the pin voltage above the

shutdown threshold voltage. Because this pin is in a signal

path, excessive capacitive loading can cause AC instability. See the Applications Information section for more

details.

BAT (Pin 5): Battery Voltage Sense Input. A precision

internal resistor divider sets the final float voltage on this

pin. This divider is disconnected in the manual shutdown

or sleep mode. When charging, approximately 34µA

flows into the BAT pin. To minimize float voltage errors,

avoid excessive resistance between the battery and the

BAT pin. For dynamically stable operation, this pin usually

requires a minimum bypass capacitance to ground of 5µF

to frequency compensate for the high frequency inductive

effects of the battery and wiring.

DRIVE (Pin 6): Base Drive Output for the External PNP

Pass Transistor. Provides a controlled sink current that

drives the base of the PNP. This pin has current limiting

protection for the LTC1734.

). This pin also allows for the charge

PROG

BLOCK DIAGRA

VOLTAGE

REFERENCE

2.5V

UVLO

2.15V

C1

+

–

W

REF

SHUTDOWN

SHUTDOWN

V

IN

1µF

V

CC

3

I

/1000

BAT

60Ω 0.06Ω

1.5V

3µA

4

PROG

R

PROG

I

BAT

SHUTDOWN

+

–

A3

+

–

OUTPUT

DRIVER

TEMPERATURE AND

CURRENT LIMITING

A1A2

SHUTDOWN

2.5V

+

–

I

SENSE

1

DRIVE

6

I

BAT

BAT

5

10µF

1734 BD

2

GND

SINGLE

Li-Ion

CELL

5

Page 6

LTC1734

OPERATIO

U

The LTC1734 is a linear battery charger controller. Operation can best be understood by referring to the Block

Diagram. Charging begins when VCC rises above the

UVLO (Undervoltage Lockout) threshold V

external current programming resistor is connected between the PROG pin and ground. When charging, the

collector of the external PNP provides the charge current.

The PNP’s emitter current flows through the I

and through the internal 0.06Ω current sense resistor.

This current is close in magnitude, but slightly more than

the collector current since it includes the base current.

Amplifier A3, along with the P-channel FET, will force the

same voltage that appears across the 0.06Ω resistor to

appear across the internal 60Ω resistor. The scale factor

of 1000:1 in resistor values will cause the FET’s drain

current to be 1/1000 of the charge current and it is this

current that flows through the PROG pin. In the constant

current mode, amplifier A2 is used to limit the charge

current to the maximum that is programmed by R

The PROG pin current, which is 1/1000 of the charge

current, develops a voltage across the program resistor.

When this voltage reaches 1.5V, amplifier A2 begins

diverting current away from the output driver, thus limiting the charge current. This is the constant current mode.

The constant charge current is 1000 • (1.5V/R

As the battery accepts charge, its voltage rises. When it

reaches the preset float voltage of 4.2V (LTC1734-4.2

version), a precisely divided down version of this voltage

(2.5V) is compared to the 2.5V internal reference voltage

by amplifier A1. If the battery voltage attempts to exceed

UVLOI

SENSE

PROG

and an

pin

PROG

).

.

4.2V (2.5V at amplifier A1’s input) the amplifier will divert

current away from the output driver thus limiting charge

current to that which will maintain 4.2V on the battery. This

is the constant voltage mode.

When in the constant voltage mode, the 1000:1 current

ratio is still valid and the voltage on the PROG pin will

indicate the charge current as a proportion of the maximum current set by the current programming resistor.

The battery charge current is 1000 • (V

This feature allows a microcontroller with an ADC to easily

monitor charge current and if desired, manually shut down

the charger at the appropriate time.

When VCC is applied, the charger can be manually shut

down by floating the otherwise grounded end of R

An internal 3µA current source pulls the PROG pin above

the 2.15V threshold of voltage comparator C1 initiating

shutdown.

For charging NiMH or NiCd batteries, the LTC1734 can

function as a constant current source by grounding the

BAT pin. This will prevent amplifier A1 from trying to limit

charging current and only A2 will control the current.

Fault conditions such as overheating of the die or excessive DRIVE pin current are monitored and limited.

When input power is removed or manual shutdown is

entered, the charger will drain only tiny leakage currents

from the battery, thus maximizing battery standby time.

With VCC removed the external PNP’s base is connected to

the battery by the charger. In manual shutdown the base

is connected to VCC by the charger.

PROG/RPROG

) amps.

PROG

.

WUUU

APPLICATIO S I FOR ATIO

Charging Operation

Charging begins when an input voltage is present that

exceeds the undervoltage lockout threshold (V

Li-Ion battery is connected to the charger output and a

program resistor is connected from the PROG pin to

ground. During the first portion of the charge cycle, when

the battery voltage is below the preset float voltage, the

charger is in the constant current mode. As the battery

voltage rises and reaches the preset float voltage, the

UVLOI

), a

6

charge current begins to decrease and the constant

voltage portion of the charge cycle begins. The charge

current will continue to decrease exponentially as the

battery approaches a fully charged condition.

Should the battery be removed during charging, a fast

built-in protection circuit will prevent the BAT pin from rising above 5V, allowing the precision constant voltage

circuit time to respond.

Page 7

LTC1734

U

WUU

APPLICATIONS INFORMATION

Manual Shutdown

Floating the program resistor allows an internal 3µA

current source (I

PROGPU

2.15V shutdown threshold (V

the charger. In this mode, the LTC1734 continues to draw

some current from the supply (I

gible leakage current is delivered to the battery (I

Shutdown can also be accomplished by pulling the otherwise grounded end of the program resistor to a voltage

greater than 2.25V (V

1.5V, but the internal battery voltage resistor divider will

draw about 34µA from the battery until shutdown is

entered. Figure 1 illustrates a microcontroller configuration that can either float the resistor or force it to a voltage.

The voltage should be no more than 8V when high and

have an impedance to ground of less than 10% of the

program resistor value when low to prevent excessive

charge current errors. To reduce errors the program

resistor value may be adjusted to account for the impedance to ground. The programming resistor will prevent

potentially damaging currents if the PROG pin is forced

above VCC. Under this condition VCC may float, be loaded

down by other circuitry or be shorted to ground. If V

not shorted to ground the current through the resistor will

pull V

up somewhat.

CC

) to pull the PROG pin above the

), thus shutting down

MSDT

), but only a negli-

SHDN

BMS

Max). Charging will cease above

MSDT

).

CC

is

entering shutdown, but no more than 0.3V above V

CC

to

prevent damaging the LTC1734 from excessive PROG

pin current. An exception is if VCC is allowed to float with

no other circuitry loading VCC down. Then, because the

current will be low, it is allowable to have the PROG pin

shutdown voltage applied. A three-state logic driver with

sufficient pull-up current can be used to perform this

function by enabling the high impedance state to charge

or enabling the pull-up device to enter shutdown.

An NPN transistor or a diode can also be utilized to

implement shutdown from a voltage source. These have

the advantage of blocking current when the voltage source

goes low, thus automatically disconnecting the voltage

source for normal charging operation. The use of an NPN

allows for use of a weak voltage source due to the current

gain of the transistor. For an NPN connect the collector to

V

the base to the voltage source and the emitter to the

CC,

PROG pin. For a diode, connect the anode to the voltage

source and cathode to the PROG pin. An input high level

ranging from 3.3V to VCC should be adequate to enter

shutdown while a low level of 0.5V or less should allow for

normal charging operation. Use of inexpensive small

signal devices such as the 2N3904 or 1N914 is recommended to prevent excessive capacitive loading on the

PROG pin (see Stability section).

Another method is to directly switch the PROG pin to a

voltage source when shutdown is desired (Caution: pulling the PROG below 1.5V with VCC applied will cause

excessive and uncontrolled charge currents). The voltage source must be capable of sourcing the resulting

current through the program resistor. This has the advantage of not adding any error to the program resistor

during normal operation. The voltage on the PROG pin

must be greater than 2.25V (V

R

OPEN DRAIN

OR TOTEM

POLE OUTPUT

µC

ADC INPUT

Figure 1. Interfacing with a Microcontroller

PROG

MSDT(MAX)

PROG

LTC1734

) to ensure

1734 F01

Sleep Mode

When the input supply is disconnected, the IC enters the

sleep mode. In this mode, the battery drain current (I

BSL

)

is a negligible leakage current, allowing the battery to remain connected to the charger for an extended period of

time without discharging the battery. The leakage current

is due to the reverse-biased B-E junction of the external

PNP transistor.

Undervoltage Lockout

Undervoltage lockout (UVLO) keeps the charger off until

the input voltage exceeds a predetermined threshold level

(V

) that is typically 4.56V. Approximately 150mV of

UVLOI

hysteresis is built in to prevent oscillation around the

threshold level. In undervoltage lockout, battery drain

current is very low (<1µA).

7

Page 8

LTC1734

U

WUU

APPLICATIONS INFORMATION

Programming Constant Current

When in the constant current mode, the full-scale charge

current (C) is programmed using a single external resistor

between the PROG pin and ground. This charge current

will be 1000 times greater than the current through the

program resistor. The program resistor value is selected

by dividing the voltage forced across the resistor (1.5V)

by the desired resistor current.

The LTC1734 is designed for a maximum current of

approximately 700mA. This translates to a maximum

PROG pin current of 700µA and a minimum program

resistor of approximately 2.1k. Because the PROG pin is in

a closed-loop signal path, the pole frequency must be kept

high enough to maintain adequate AC stability by avoiding

excessive capacitance on the pin. See the Stability section

for more details.

The minimum full-scale current that can be reliably programmed is approximately 50mA, which requires a program resistor of 30k. Limiting capacitive loading on the

program pin becomes more important when high value

program resistors are used. In addition, the current

monitoring accuracy can degrade considerably at very

low current levels. If current monitoring is desired, a

minimum full-scale current of 200mA is recommended.

Different charge currents can be programmed by various

means such as by switching in different program resistors

as shown in Figures 2 and 3. A voltage DAC connected

through a resistor to the PROG pin or a current DAC

connected in parallel with a resistor to the PROG pin can

also be used to program current (the resistor is required

with the I

to maintain AC stability as discussed in the

DAC

Stability section). Another means is to use a PWM output

from a microcontroller to duty cycle the charger into and

out of shutdown to create an average current (see Manual

Shutdown section for interfacing examples). Because

chargers are generally slow to respond, it can take up to

approximately 300µs for the charger to fully settle after a

shutdown is deasserted. This delay must be accounted for

unless the minimum PWM low duration is about 3ms or

more. Shutdown occurs within a few microseconds of a

shutdown command. The use of PWM can extend the

average current to less than the normal 200mA minimum

constant current.

CHARGE

CURRENT

MONITOR

(FILTERED)

OPTIONAL FILTER

1k

0.1µF TO

0.5µF

Figure 2. Logic Control Programming of Output Current to 0mA, 200mA, 500mA or 700mA

PIN 4

CONTROL 1

CHARGE

CURRENT

MONITOR

(UNFILTERED)

V

IN

5V

1µF

3k

Q1

2N7002

CONTROL 2

V

IN

5V

1µF

3k

Q1

2N7002

CONTROL 1

Q2

2N7002

CONTROL 2

31

2

4

7.5k

V

CC

LTC1734

GND

PROG

I

SENSE

6

DRIVE

5

BAT

*OBSERVE MAXIMUM TEMPERATURE

31

2

4

7.5k

Q2

2N7002

V

CC

GND

PROG

I

SENSE

LTC1734

DRIVE

FZT549*

LOAD

BAT

I

LOAD

1734 F03

6

5

FZT549

I

BAT

10µF

CURRENT

0

200mA

500mA

700mA

CHARGE CURRENT

SINGLE

Li-Ion

BATTERY

1734 F02

CONTROL 1

LOW

LOW

HIGH

HIGH

0

200mA

500mA

700mA

CONTROL 2

LOW

HIGH

LOW

HIGH

CONTROL 1

LOW

LOW

HIGH

HIGH

CONTROL 2

LOW

HIGH

LOW

HIGH

8

Figure 3. Programmable Current Source with Output Current of 0mA, 200mA, 500mA or 700mA

Page 9

LTC1734

U

WUU

APPLICATIONS INFORMATION

Monitoring Charge Current

The voltage on the PROG pin indicates the charge current

as a proportion of the maximum current set by the

program resistor. The charge current is equal to 1000 •

(V

PROG/RPROG

ler with an ADC to easily monitor charge current and if

desired, manually shut down the charger at the appropriate time. See Figure 1 for an example. The minimum PROG

pin current is about 3µA (I

Errors in the charge current monitor voltage on the PROG

pin are inversely proportional to battery current and can be

statistically approximated as follows:

One Sigma Error(%) ≅ 1 + 0.3/I

Dynamic loads on the battery will cause transients to

appear on the PROG pin. Should they cause excessive

errors in charge current monitoring, a simple RC filter as

shown in Figure 2 can be used to filter the transients. The

filter will also quiet the PROG pin to help prevent inadvertent momentary entry into the manual shutdown mode.

Because the PROG pin is in a closed-loop signal path the

pole frequency must be kept high enough to maintain

adequate AC stability. This means that the maximum

resistance and capacitance presented to the PROG pin

must be limited. See the Stability section for more details.

Constant Current Source

The LTC1734 can be used as a constant current source by

disabling the voltage control loop as shown in Figure 3.

This is done by pulling the BAT pin below the preset float

voltages of 4.1V or 4.2V by grounding the BAT pin. The

program resistor will determine the output current. The

output current range can be between approximately 50mA

and 700mA, depending on the maximum power rating of

the external PNP pass transistor.

External PNP Transistor

The external PNP pass transistor must have adequate

beta, low saturation voltage and sufficient power dissipation capability (including any heat sinking, if required).

) amps. This feature allows a microcontrol-

PROGPU

).

BAT

(A)

used, more base current is required from the LTC1734.

This can result in the output drive current limit being

reached, or thermal shutdown due to excessive power

dissipation. Excessive beta can affect AC stability (see

Stability section)

With low supply voltages, the PNP saturation voltage

(V

than the minimum supply voltage minus the maximum

voltage drop across the internal sense resistor and bond

wires (0.1Ω) and battery float voltage. If the PNP transistor can not achieve the low saturation voltage required,

base current will dramatically increase. This is to be

avoided for a number of reasons: output drive may reach

current limit resulting in the charger’s characteristics to

go out of specifications, excessive power dissipation may

force the IC into thermal shutdown, or the battery could

become discharged because some of the current from the

DRIVE pin could be pulled from the battery through the

forward biased collector base junction.

For example, to program a charge current of 500mA with

a minimum supply voltage of 4.75V, the minimum operating VCE is:

The actual battery charge current (I

than the expected charge current because the charger

senses the emitter current and the battery charge current

will be reduced by the base current. In terms of β (IC/IB),

I

BAT

If β = 50, then I

be compensated for by increasing I

Another important factor to consider when choosing the

PNP pass transistor is the power handling capability. The

transistor’s data sheet will usually give the maximum rated

power dissipation at a given ambient temperature with a

power derating for elevated temperature operation. The

maximum power dissipation of the PNP when charging is:

) becomes important. The V

CESAT

V

CE(MIN)

can be calculated as follows:

I

BAT

P

D(MAX)

(V) = 4.75 – (0.5)(0.1) – 4.2 = 0.5V

(A) = 1000 • I

BAT

(W) = I

BAT (VDD(MAX)

[β/(β + 1)]

PROG

is 2% low. If desired, the 2% loss can

must be less

CESAT

) is slightly smaller

BAT

by 2%.

PROG

– V

BAT(MIN)

)

To provide 700mA of charge current with the minimum

available base drive of approximately 30mA requires a

PNP beta greater than 23. If lower beta PNP transistors are

V

DD(MAX)

the minimum battery voltage when discharged.

is the maximum supply voltage and V

BAT(MIN)

is

9

Page 10

LTC1734

U

WUU

APPLICATIONS INFORMATION

Table 1. PNP Pass Transistor Selection Guide

Maximum PD (W)

Mounted on Board

= 25°C Package Style ZETEX Part Number ROHM Part Number Comments

at T

A

0.5 SOT-23 FMMT549 Low V

0.625 SOT-23 FMMT720 Very Low V

1 SOT-89 FCX589 or BCX69

1.1 SOT-23-6 ZXT10P12DE6 Very Low V

1 to 2 SOT-89 FCX717 Very Low V

2 SOT-223 FZT589 Low V

2 SOT-223 BCP69 or FZT549

0.75 FTR 2SB822 Low V

1 ATV 2SB1443 Low V

2 SOT-89 2SA1797 Low V

10 (TC = 25°C) TO-252 2SB1182 Low V

Once the maximum power dissipation and V

CE(MIN)

known, Table 1 can be used as a guide in selecting some

PNPs to consider. In the table, very low V

0.25V, low V

is 0.25V to 0.5V and the others are 0.5V

CESAT

CESAT

is less than

to 0.8V all depending on the current. See the manufacturer’s

data sheet for details. All of the PNP transistors are rated

to carry at least 1A continuously as long as the power

dissipation is within limits. The Stability section addresses

caution in the use of high beta PNPs.

Should overheating of the PNP transistor be a concern,

protection can be achieved with a positive temperature

coefficient (PTC) thermistor, wired in series with the

current programming resistor and thermally coupled to

the transistor. The PTH9C chip series from Murata has a

steep resistance increase at temperature thresholds from

85°C to 145°C making it behave somewhat like a thermostat switch. For example, the model PTH9C16TBA471Q

thermistor is 470Ω at 25°C, but abruptly increase its

resistance to 4.7k at 125°C. Below 125°C, the device

exhibits a small negative TC. The 470Ω thermistor can be

added in series with a 1.6k resistor to form the current

programming resistor for a 700mA charger. Should the

thermistor reach 125°C, the charge current will drop to

238mA and inhibit any further increase in temperature.

are

CESAT

High Beta

CESAT,

High Beta, Small

CESAT,

High Beta

CESAT,

CESAT

CESAT

CESAT

CESAT

High Beta

CESAT,

constant voltage mode, a capacitor of at least 4.7µF is

usually required from BAT to ground. The battery and

interconnecting wires appear inductive at high frequencies, and since these are in the feedback loop, this capacitance may be necessary to compensate for the inductance.

This capacitor need not exceed 100µF and its ESR can

range from near zero to several ohms depending on the

inductance to be compensated. In general, compensation

is optimal with a capacitance of 4.7µF to 22µF and an ESR

of 0.5Ω to 1.5Ω.

Using high beta PNP transistors (>300) and very low ESR

output capacitors (especially ceramic) reduces the phase

margin, possibly resulting in oscillation. Also, using high

value capacitors with very low ESRs will reduce the phase

margin. Adding a resistor of 0.5Ω to 1.5Ω in series with

the capacitor will restore the phase margin.

In the constant current mode, the PROG pin is in the

feedback loop, not the battery. Because of this, capacitance on this pin must be limited. Locating the program

resistor near the PROG pin and isolating the charge

current monitoring circuitry (if used) from the PROG pin

with a 1k to 10k resistor may be necessary if the capacitance is greater than that given by the following equation:

Stability

The LTC1734 contains two control loops: constant voltage

and constant current. To maintain good AC stability in the

10

C

MAX pF

()

k

400

=

R

PROG

Page 11

LTC1734

V

CC

V

IN

*

1734 F06

LTC1734

*DRAIN-BULK DIODE OF FET

U

WUU

APPLICATIONS INFORMATION

Higher charge currents require lower program resistor

values which can tolerate more capacitive loading on the

PROG pin. Maximum capacitance can be as high as 50pF

for a charge current of 200mA (R

Figure 4 is a simple test circuit for checking stability in both

the constant current and constant voltage modes. With

input power applied and a near fully charged battery

connected to the charger, driving the PROG pin with a

pulse generator will cycle the charger in and out of the

manual shutdown mode. Referring to Figure 5, after a

short delay, the charger will enter the constant current

mode first, then if the battery voltage is near the programmed voltage of 4.1V or 4.2V, the constant voltage

mode will begin. The resulting waveform on the PROG pin

is an indication of stability.

The double exposure photo in Figure 5 shows the effects

of capacitance on the program pin. The middle waveform

is typical while the lower waveform indicates excessive

program pin capacitance resulting in constant current

mode instability. Although not common, ringing on the

constant voltage portion of the waveform is an indication

PROG

= 7.5k).

of instability due to any combination of extremely low ESR

values, high capacitance values of the output capacitor or

very high PNP transistor beta. To minimize the effect of the

scope probe capacitance, a 10k resistor is used to isolate

the probe from the program pin. Also, an adjustable load

resistor or current sink can be used to quickly alter the

charge current when a fully charged battery is used.

Reverse Input Voltage Protection

In some applications, protection from reverse voltage on

VCC is desired. If the supply voltage is high enough, a

series blocking diode can be used. In other cases, where

the voltage drop must be kept low, a P-channel FET as

shown in Figure 6 can be used.

Figure 6. Low Loss Reverse Voltage Protection

VCC Bypass Capacitor

TO SCOPE

2.5V

GENERATOR

(20pF ON PIN)

(200pF ON PIN)

10k

R

PROG

3k

0V

f = 1kHz

Figure 4. Setup for AC Stability Testing

5V

PULSE

0V

2V

PROG PIN

PROG PIN

1V

0V

2V

1V

0V

SHUT

DOWN

Figure 5. Stability Waveforms

PROG

*FULLY CHARGED CELL

DELAY CONSTANT

HORIZONTAL SCALE: 100µs/DIV

BAT

LTC1734

CURRENT

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

+

1734 F04

Li-Ion*

CONSTANT

VOLTAGE

6Ω TO

20Ω

Many types of capacitors with values ranging from 1µF to

10µF located close to the LTC1734 will provide adequate

input bypassing. However, caution must be exercised

when using multilayer ceramic capacitors. Because of the

self resonant and high Q characteristics of some types of

ceramic capacitors, high voltage transients can be generated under some start-up conditions, such as connecting

the charger input to a hot power source. To prevent these

transients from exceeding the absolute maximum voltage

rating, several ohms of resistance can be added in series

with the ceramic input capacitor.

Internal Protection

Internal protection is provided to prevent excessive DRIVE

pin currents (I

) and excessive self-heating of the

DSHRT

LTC1734 during a fault condition. The faults can be

generated from a shorted DRIVE pin or from excessive

DRIVE pin current to the base of the external PNP

transistor when it’s in deep saturation from too low a VCE.

This protection is not designed to prevent overheating of

the external pass transistor. Indirectly though, self-heating

of the PNP thermally conducting to the LTC1734 and

11

Page 12

LTC1734

U

WUU

APPLICATIONS INFORMATION

resulting in the IC’s junction temperature to rise above

150°C, thus cutting off the PNP’s base current. This

action will limit the PNP’s junction temperature to some

temperature well above 150°C. The temperature

U

PACKAGE DESCRIPTIO

S6 Package

6-Lead Plastic SOT-23

(LTC DWG # 05-08-1634)

(LTC DWG # 05-08-1636)

.20

(.008)

DATUM ‘A’

L

NOTE:

1. CONTROLLING DIMENSION: MILLIMETERS

2. DIMENSIONS ARE IN

3. DRAWING NOT TO SCALE

4. DIMENSIONS ARE INCLUSIVE OF PLATING

5. DIMENSIONS ARE EXCLUSIVE OF MOLD FLASH AND METAL BURR

6. MOLD FLASH SHALL NOT EXCEED .254mm

7. PACKAGE EIAJ REFERENCE IS:

SC-74A (EIAJ) FOR ORIGINAL

JEDEL MO-193 FOR THIN

MILLIMETERS

(INCHES)

.09 – .20

(.004 – .008)

(NOTE 2)

A2

A

(.074)

SOT-23

(Original)

.90 – 1.45

A

(.035 – .057)

.00 – 0.15

A1

(.00 – .006)

.90 – 1.30

A2

(.035 – .051)

.35 – .55

L

(.014 – .021)

depends on how well the IC and PNP are thermally

connected and on the transistor’s θJA. See the External

PNP Transistor section for information on protecting the

transistor from overheating.

2.80 – 3.10

(.110 – .118)

(NOTE 3)

1.90

REF

SOT-23

(ThinSOT)

1.00 MAX

(.039 MAX)

.01 – .10

(.0004 – .004)

.80 – .90

(.031 – .035)

.30 – .50 REF

(.012 – .019 REF)

A1

2.60 – 3.00

(.102 – .118)

1.50 – 1.75

(.059 – .069)

(NOTE 3)

.95

(.037)

REF

PIN ONE ID

.25 – .50

(.010 – .020)

(6PLCS, NOTE 2)

S6 SOT-23 0401

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT®1510-5 500kHz Constant-Current/Constant-Voltage Battery Charger Up to 1A Charge Current for Li-Ion, NiCd, NiMH or Lead-Acid

LT1571-1/LT1571-2 200kHz/500kHz Constant-Current/Constant-Voltage Battery Up to 1.5A Charge Current for 1-, 2- or Multiple Cell Li-Ion Batteries,

LT1571-5 Charger Family Preset and Adjustable Battery Voltages, C/10 Charge Detection

LTC1729 Li-Ion Battery Charger Termination Controller Can be Used with LTC Battery Chargers to Provide Charge Termina-

LTC1730 Li-Ion Battery Pulse Charger Minimizes Heat Dissipation, No Blocking Diode Required,

LTC1731 Linear Constant-Current/Constant-Voltage Charger Controller Simple Charger Uses External FET. Features Preset Voltages,

LTC1732 Linear Constant-Current/Constant-Voltage Charger Controller Simple Charger Uses External FET. Input Power Good Indication

LT1769 200kHz Constant-Current/Constant-Voltage Battery Charger Up to 2A Charge Current for Li-Ion, NiCd, NiMH or Lead-Acid

Linear Technology Corporation

12

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

Batteries

tion, Preset Voltages, C/10 Charge Detection and Timer Functions

Limits Maximum Current for Safety

C/10 Charge Detection and Programmable Timer

Features Preset Voltages, C/10 Charge Detection and Programmable Timer

Batteries with Input Current Limit

sn1734 1734fs LT/TP 0801 2K • PRINTED IN THE USA

LINEAR TECHNOLOGY CORPO RATION 2001

Loading...

Loading...