Page 1

FEATURES

Final Electrical Specifications

■

Trickle Charge Preconditioning If Cell <2.7V

■

Charging Enabled When 0°C < T < 50°C

■

Built-In Termination: 3-Hour Time-Out

■

C/10 Detection with Status Indicator

■

Automatic Charger Present Detection

■

Automatic Battery Present Detection

■

1- or 2-Cell, 4.1V/Cell or 4.2V/Cell Options

■

Precision Internal 0.2% Voltage Feedback Divider

■

Compatible with LT1505/LT1510/LT1511/

LT1512/LT1513/LT1769

■

Small Footprint/Low Profile

U

APPLICATIONS

■

Cellular Phones

■

PDAs

■

Cradle Chargers

■

Camcorders

LTC1729 Series

Li-Ion Battery Charger

Termination Controllers

October 1999

U

DESCRIPTION

The LTC®1729 series is a family of smart

controllers for lithium-ion battery chargers. These ICs

provide trickle charge preconditioning, temperature charge

qualification, time or charge current termination, automatic charger and battery detection and status output.

Combining the LTC1729 series part with the LT®1510

(1.5A), LT1769 (2A), LT1511 (3A) and LT1505 (>4A)

step-down chargers is a simple operation. Connecting six

pins from the LTC1729 series part to the step-down

chargers completes the integration. The LTC1729 termination controllers are also compatible with step-down/

step-up (SEPIC) chargers, including the LT1512 (2A switch)

and LT1513 (3A switch).

The LTC1729 series is available in the 8-pin MSOP and SO

packages.

, LTC and LT are registered trademarks of Linear Technology Corporation.

termination

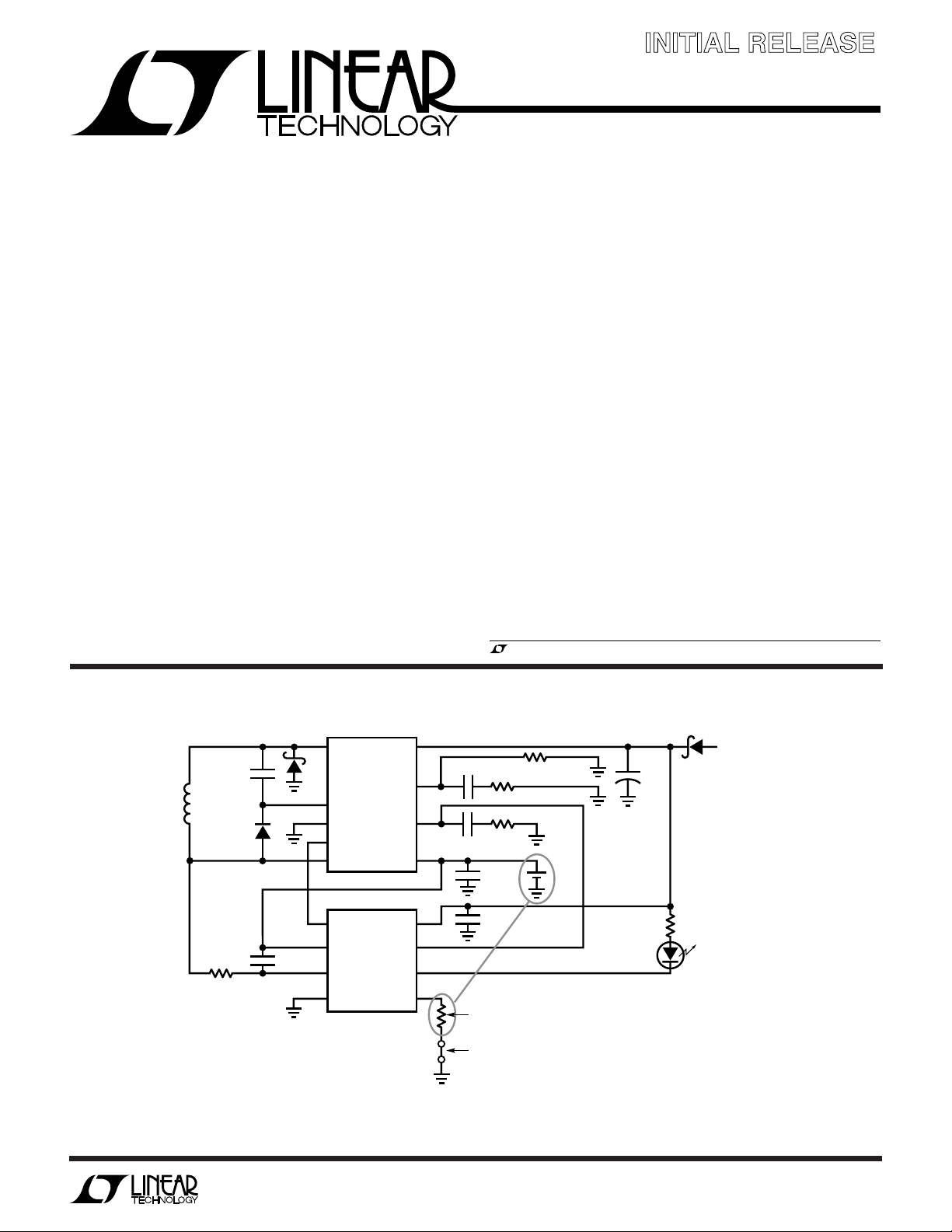

TYPICAL APPLICATION

MBRM120T3

0.22µF

L1**

10µH

MMBD914L

200Ω

* TOKIN OR MARCON SURFACE MOUNT

** COILTRONICS TP3-100, 10µH, 2.2mm HEIGHT

(0.8A CHARGING CURRENT)

COILTRONICS TP1 SERIES, 10µH, 1.8mm

HEIGHT (<0.5A CHARGING CURRENT)

*** PANASONIC EEFCD1B220

†

LUMEX SML-LX0805GW-TR

1µF

U

SW

LT1510-5

BOOST

GND

OVP

SENSE

1

OVP

2

BAT

LTC1729-4.2

3

SENSE

4

GND

Figure 1. 500kHz Li-Ion Cell Phone Charger (0.8A)

V

PROG

BAT

V

STATUS

NTC

CC

1µF

V

C

0.1µF

8

CC

7

V

C

6

5

10k NTC THERMISTOR, NTHS1206N02 VISHAY/DALE

NOTE: EITHER A THERMISTOR OR 10k RESISTOR MUST BE PRESENT

OPTION: TIE RESISTOR TO STATUS FOR

CHARGE TERMINATION AT

LOW CHARGING CURRENT

300Ω

C

OUT

22µF

0.1µF

6.19k

1k

+

***

4.2V

+

MBRM120T3

CIN*

10µF

1729 F01

1.4k

†

D1

CHARGE STATUS

INPUT POWER

8.2V TO 20V

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

1

Page 2

LTC1729 Series

WW

W

ABSOLUTE MAXIMUM RATINGS

U

(Note 1)

VCC......................................................................... 30V

SENSE, V

, NTC .................................... –0.3V to 15V

BAT

VC............................................................. –0.3V to 15V

OVP ............................................................ –0.3V to 5V

U

W

U

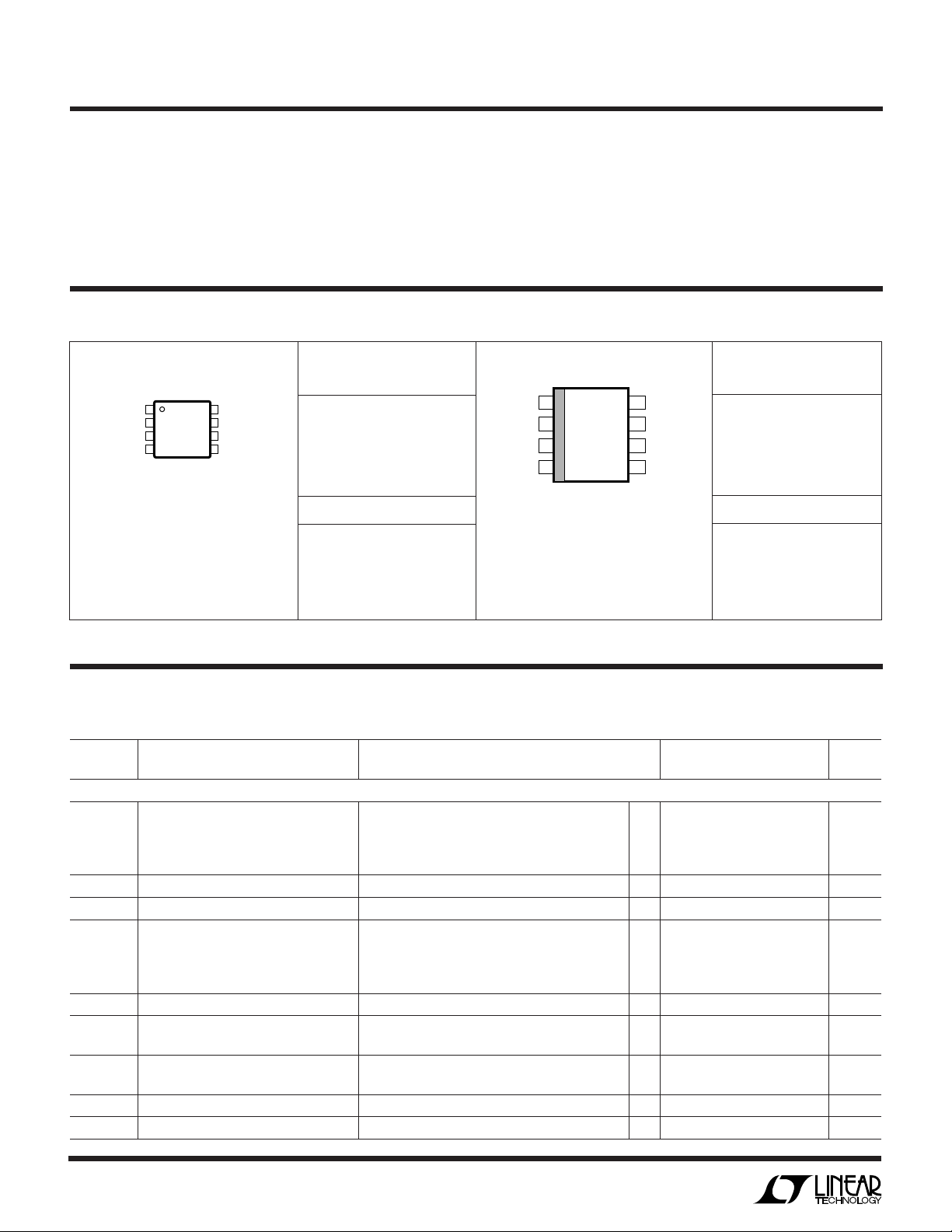

PACKAGE/ORDER INFORMATION

ORDER PART

TOP VIEW

OVP

1

BAT

2

SENSE

3

GND

4

MS8 PACKAGE

8-LEAD PLASTIC MSOP

T

= 150°C, θJA = 200°C/W

JMAX

8

V

7

V

6

STATUS

5

NTC

CC

C

NUMBER

LTC1729CMS8-4.1

LTC1729CMS8-4.2

LTC1729CMS8-8.2

LTC1729CMS8-8.4

MS8 PART MARKING

LTLY

LTJH

LTLZ

LTJG

STATUS .................................................... –0.3V to 30V

Operating Temperature Range .................... 0°C to 70°C

Storage Temperature Range ................ –65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

ORDER PART

1

OVP

BAT

2

SENSE

3

GND

4

8-LEAD PLASTIC SO

T

= 150°C, θJA = 150°C/W

JMAX

TOP VIEW

S8 PACKAGE

8

7

6

5

V

CC

V

C

STATUS

NTC

NUMBER

LTC1729CS8-4.1

LTC1729CS8-4.2

LTC1729CS8-8.2

LTC1729CS8-8.4

S8 PART MARKING

172941

172942

172982

172984

Consult factory for Industrial and Military grade parts.

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C, VIN = 8V.

LTC1729-4.1/LTC1729-4.2

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

DC CHARACTERISTICS

I

VIN

V

LKOH

V

LKOL

I

VBAT

V

CLAMP

V

MAX

V

MIN

I

SENSE

V

C10

VCC Supply Current VIN = 5V (Below UVLO) ● 1512 µA

V

= 8V, 200µA Pull-Up on V

IN

= 8V, V

V

IN

VIN = 8V, V

VIN Undervoltage Lockout High ● 5.5 6.5 7.5 V

VIN Undervoltage Lockout Low ● 5.0 6.0 7.0 V

V

Current VIN = 5V (Below UVLO), V

BAT

V

Clamp No Bat (External 200µA Pull-Up on V

BAT

High V

Low V

SENSE Pin Current Charge State, V

SENSE Pin C/10 Offset Charge State, V

Threshold High Going Threshold ● 4.25 4.51 4.75 V

BAT

Threshold High Going Threshold ● 2.55 2.7 2.85 V

BAT

= 8V, V

V

IN

= 8V, V

V

IN

VIN = 8V, V

Low Going Threshold ● 4.25 4.50 4.75 V

Low Going Threshold ● 2.45 2.6 2.75 V

= 2.5V Trickle 10 17 21 mA

BAT

= 3.5V Charge ● 0.5 3.0 5.0 mA

BAT

= 4.25V No Bat ● 40 73 120 µA

BAT

= 2.5V Trickle – 19 –16 –9.5 mA

BAT

= 3.5V Charge ● –2.7 – 1.3 – 0.5 mA

BAT

= 3V ● 85 100 115 µA

SENSE

= (V

C10

BAT

(4.5V) No Bat ● 1.0 1.4 2.0 mA

BAT

= 4.2V ● –1 –0.1 1 µA

BAT

) ● 4.25 4.5 4.75 V

BAT

– V

) ● ±1 ±2.5 mV

SENSE

2

Page 3

LTC1729 Series

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C, VIN = 8V.

LTC1729-4.1/LTC1729-4.2

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

NTC

V

NTC-RESET

V

NTC-HOT

V

NTC-COLD

V

OVP

V

OL-ST

V

OL-VC

I

SOFT

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C,

VIN = 12V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

DC CHARACTERISTICS

I

VIN

V

LKOH

V

LKOL

I

VBAT

V

CLAMP

V

MAX

V

MIN

I

SENSE

V

C10

I

NTC

V

NTC-RESET

V

NTC-HOT

V

NTC-COLD

V

OVP

V

OL-ST

V

OL-VC

I

SOFT

NTC Pin Current V

= 1V ● 90 100 110 µA

NTC

Thermistor Pin Reset Threshold ● 0.160 0.206 0.240 V

Thermistor Pin Hot Hold Threshold High Going Threshold ● 0.460 0.486 0.510 V

Low Going Threshold ● 0.380 0.405 0.430 V

Thermistor Pin Cold Hold Threshold High Going Threshold ● 2.70 2.79 2.90 V

Low Going Threshold ● 2.10 2.23 2.35 V

OVP Pin Voltage V

= 4.1V or V

BAT

= 4.2V ● 2.455 2.465 2.475 V

BAT

2.460 2.465 2.470 V

Output Low Voltage-STATUS Pin IO = 3mA ● 0.5 0.9 1.2 V

Output Low Voltage-VC Pin IO = 1mA ● 0.35 0.6 0.75 V

Status Soft Pull-Down Current V

= 4.5V ● 40 50 65 µA

STATUS

LTC1729-8.2/LTC1729-8.4

VCC Supply Current VIN = 9V (Below UVLO) ● 1612 µA

V

= 12V, 200µA Pull-Up on V

IN

= 12V, V

V

IN

VIN = 12V, V

= 5V Trickle 10 17 21 mA

BAT

= 7V Charge ● 0.5 3.0 5.0 mA

BAT

(9V) No Bat ● 1.0 1.4 2.0 mA

BAT

VIN Undervoltage Lockout High ● 9.5 10.4 11.4 V

VIN Undervoltage Lockout Low ● 8.5 9.6 10.5 V

V

Current VIN = 9V (Below UVLO), V

BAT

V

Clamp No Bat (External 200µA Pull-Up on V

BAT

High V

Threshold High Going Threshold ● 8.5 9.013 9.5 V

BAT

= 12V, V

V

IN

= 12V, V

V

IN

VIN = 12V, V

= 8.5V No Bat ● 60 95 140 µA

BAT

= 5V Trickle – 19 – 16 –9.5 mA

BAT

= 7V Charge ● –2.7 – 1.3 – 0.5 mA

BAT

= 8.4V ● –1 –0.1 1 µA

BAT

) ● 8.5 9 9.5 V

BAT

Low Going Threshold ● 8.5 9 9.5 V

Low V

Threshold High Going Threshold ● 5.1 5.4 5.7 V

BAT

Low Going Threshold ● 4.9 5.2 5.5 V

SENSE Pin Current Charge State, V

SENSE Pin C/10 Offset Charge State, V

NTC Pin Current V

= 1V ● 90 100 110 µA

NTC

= 7V ● 85 100 115 µA

SENSE

= (V

C10

BAT

– V

) ● ±1 ±2.5 mV

SENSE

Thermistor Pin Reset Threshold ● 0.160 0.206 0.240 V

Thermistor Pin Hot Hold Threshold High Going Threshold ● 0.460 0.486 0.510 V

Low Going Threshold ● 0.380 0.405 0.430 V

Thermistor Pin Cold Hold Threshold High Going Threshold ● 2.70 2.79 2.90 V

Low Going Threshold ● 2.10 2.23 2.35 V

OVP Pin Voltage V

= 8.2V or V

BAT

= 8.4V ● 2.455 2.465 2.475 V

BAT

2.460 2.465 2.470 V

Output Low Voltage-STATUS Pin IO = 3mA ● 0.5 0.9 1.2 V

Output Low Voltage-VC Pin IO = 1mA ● 0.35 0.6 0.75 V

Status Soft Pull-Down Current V

= 4.5V ● 40 50 65 µA

STATUS

3

Page 4

LTC1729 Series

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C. (Note 2)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

AC CHARACTERISTICS

TIMER1 Timer for Trickle-Charge Preconditioning ● 0.869 1 1.305 Hr

TIMER2 Timer for Charging ● 2.61 3 3.55 Hr

TIMER3 Timer for V

TIMER4 Timer for V

T

OSC

Oscillator Period ● 6.66 7.63 9.09 µs

Filter ● 0.764 0.859 1.043 sec

MAX

Filter ● 3.055 3.5 4.17 sec

C/10

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

UUU

PIN FUNCTIONS

OVP (Pin 1): Output from an Internal Precision Resistor

Divider Used as a Voltage Feedback Monitor for ConstantVoltage Mode Charging.

BAT (Pin 2): Input to Battery Monitor Circuits and OVP

Resistor Divider. The battery monitor circuits activate

trickle charge preconditioning, battery present detection

and C/10 current detection. This pin is in a high impedance

state when VCC is below the undervoltage lockout threshold. During trickle charge preconditioning and charging

the BAT pin sources 16mA and 1.3mA respectively. The

current sources are clamped from driving the BAT pin

above 4.5V/cell with an internal pull-down transistor.

In the No Bat, Done and Pause states or the Hold and Reset

modes, the current sources are turned off, leaving only the

55k OVP divider as a load on the BAT pin. Most chargers

have a 200µA current source that will compensate for this

50µA to 80µA load.

SENSE (Pin 3): Input to C/10 Current Detection Circuit.

This pin sinks 100µA during the Charge state which is used

to program the C/10 current threshold.

GND (Pin 4): Ground.

NTC (Pin 5): Input to the NTC Thermistor Monitoring

Circuits. When the voltage on this pin is above 2.79V

(cold) or below 0.405V (hot), the state machine is locked

in the present state and the timer is stopped. This is called

the Hold mode. While in the Hold mode, the charger is

turned off via the VC pin and the current sources on BAT

and SENSE pins are turned off. The STATUS pin is not

affected.

Note 2: VIN = 8V for LTC1729-4.1/LTC1729-4.2; VIN = 12V for

LTC1729-8.2/LTC1729-8.4

If the NTC pin is below 0.2V, the state machine is forced

in the reset mode with all the timers cleared to zero. The

current sources on the BAT pin and SENSE pin are

disabled leaving the 55k OVP divider. The STATUS pin is

pulled low in the Reset mode.

There is a 100µA current source on the NTC pin to bias the

NTC thermistor. This current source is active while the V

CC

is greater than the undervoltage lockout threshold.

STATUS (Pin 6): Open-Drain Output for C/10 Charge

Termination Detection Circuit. When in the Charge state,

this pin is pulled low. Once the charge current drops below

the C/10 current threshold for three seconds, the pulldown transistor is disabled, and a 50µA pull-down current

sink remains activated until the 1- or 3-hour time-out or

the battery or wall adapter is removed.

VC (Pin 7): Open-Drain Output for turning off the charger.

When this pin is open circuit, the charger is active.

Normally this pin allows the charger to be active for three

hours.

VCC (Pin 8): Input Supply. For 4.1V or 4.2V single cell

operation, VCC should be between 8V and 28V with the IC

turning off when VCC drops below 6V. For 2-cell applications, the undervoltage lockout is 10.4V with a minimum

VCC of 12V. Removing the wall adapter will trigger an

undervoltage lockout and put the part in a high impedance

condition. When the supply is connected, the part is

initialized in the Reset mode with the state machine forced

in the Charge state with all the timers set to zero.

4

Page 5

BLOCK DIAGRA

3

SENSE

–

COMP1

+

BAT

2

UVLO

M1

2.465V

OVP

1

W

1.3mA

100µA

UVLO

16mA

4.5V/CELL

CLAMP

4.5V/CELL

2.7V/CELL

+

–

+

–

COMP2

COMP3

C/10

V

MAX

V

MIN

HOLD

LOGIC

AND

TIMER

LTC1729 Series

V

7

C

M2

6

STATUS

M3

50µA

NTC

100µA

5

2.79V

0.405V

0.2V

+

–

+

–

+

–

COMP4

COMP5

COMP6

Figure 2. Block Diagram

U

WUU

APPLICATIONS INFORMATION

Overview

The LTC1729 is a charge termination controller for the

LT1505/LT1510/LT1511/LT1512/LT1513/LT1769 constant-voltage/constant-current battery charger family.

Table 1 details these chargers. The primary function of this

IC is to stop the charger after three hours of constantvoltage/constant-current charging. The secondary function of this controller includes an indication when the

charge current (during constant-voltage mode) drops

below a user-selected threshold. A 500kHz Li-Ion cell

phone charger is shown in Figure 1. The LTC1729 only

needs six external components when combined with the

RESET

1729 F02

standard LT1510 application. The LTC1729 provides a

complete and tiny solution for cellular phones and other

portable applications.

Table 1. Battery Chargers

LT1505 4A Step-Down Charger with Input Current Limit

LT1510 1.5A Step-Down Charger

LT1510-5 1.5A 500kHz Step-Down Charger

LT1511 3A Step-Down Charger with Input Current Limit

LT1512 2A Switch SEPIC Charger

LT1513 3A Switch SEPIC Charger

LT1769 2A Step-Down Charger with Input Current Limit

5

Page 6

LTC1729 Series

U

WUU

APPLICATIONS INFORMATION

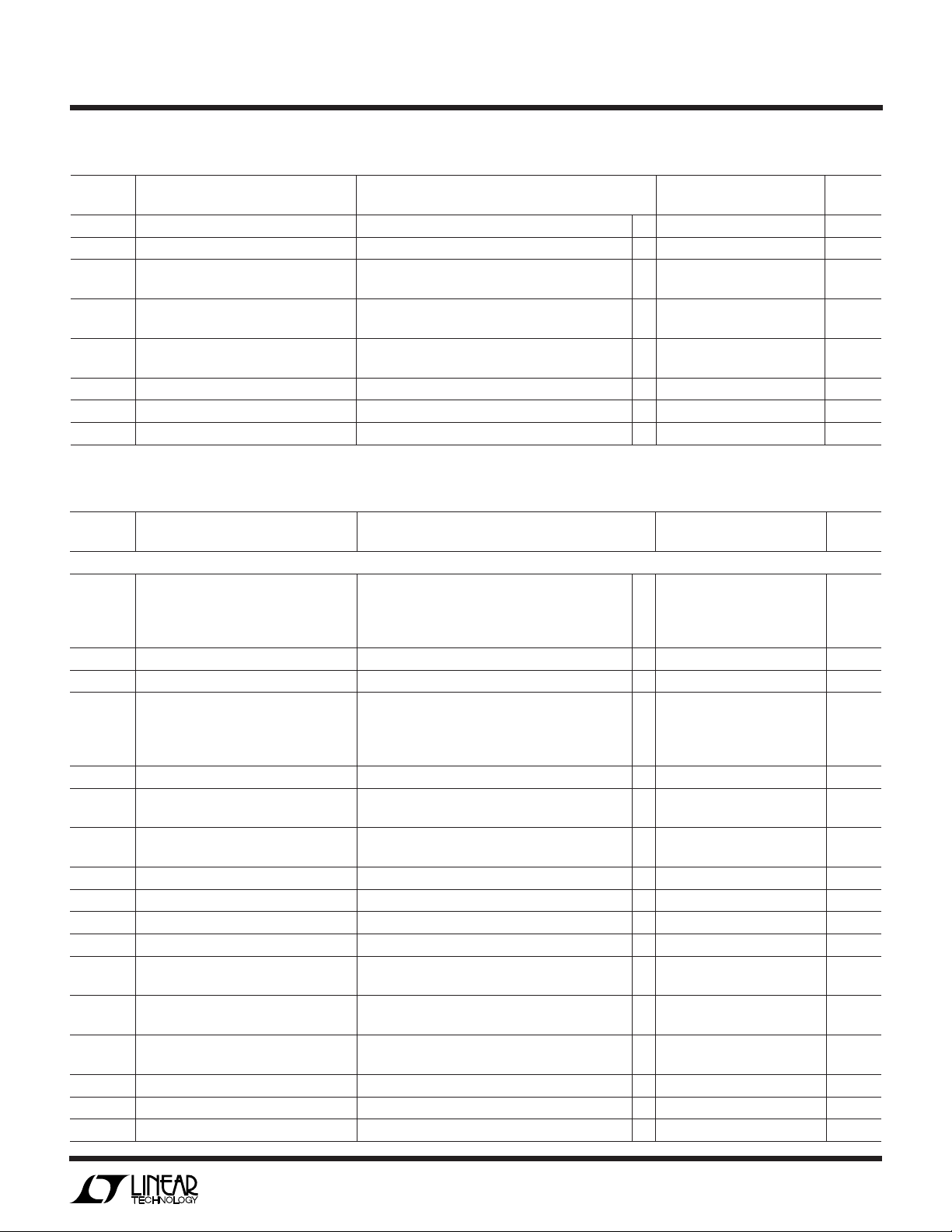

Block Diagram

Figure 2 shows the block diagram of the LTC1729. The IC

consists of six comparators, a resistive divider, a UVLO

block and a logic and timer block.

The comparator COMP1 is used to indicate C/10 charge

current threshold. (“C” is a term used to indicate the

Ampere-hour capacity of a cell.) Figure 3 details the C/10

detection circuit. The resistor and capacitor on the SENSE

pin filter the signal from the 0.2Ω current sense resistor

R1. The 100µA current sink on the SENSE pin develops

20mV across the 200Ω resistor R2. This sets a 20mV

offset on COMP1 that sense resistor R1 must equal before

C/10 current is indicated. The C/10 is not recognized by the

logic until it passes through a 3-second digital filter.

For cases where there are multiple batteries to be charged,

the LTC1729 detects when a battery is removed and resets

the timers for the next charge cycle. The battery present

detection is the primary function of comparator COMP2.

When the battery is disconnected from the LTC1729, the

voltage at the BAT pin will begin ramping upward. This is

due to a current source inside the charger or an external

pull-up resistor. Once the voltage on the BAT pin exceeds

the 4.5V/cell limit, COMP2 signals a V

logic and turns on a transistor that clamps the voltage.

There is the possibility of an overvoltage transient at the

charging terminals. This occurs if the battery protection

circuit, which is often included in the battery pack, opens

the connection to the battery during high current charging

(constant-current mode). This is a result of energy storage

in the inductor. COMP2 senses the overvoltage and clamps

= true to the

MAX

the VC pin, reducing the duty cycle of the charger. If the

battery protection circuit quickly returns battery connection to the charger (in less than one second), then the

LTC1729 continues charging without resetting the timers.

For a battery that has been over-discharged, the LTC1729

provides a 16mA start-up current. This preconditioning

trickle charge begins when the battery voltage drops

below 2.7V/cell. Comparator COMP3 is used to determine

when this condition exists. The battery operating range is

summarized in Figure 4.

With a 10k negative TC thermistor connected to the NTC

pin, the LTC1729 will disable charging if the temperature

is not in the 0°C to 50°C range. A thermistor must be

present at this pin, or if the temperature qualification

feature is not used, a 10k resistor must be used in its place.

This pin should not be left open. The NTC thermistor

monitoring circuits consist of COMP4, COMP5 and COMP6.

The NTC pin voltage range is shown in Figure 5.

Comparators COMP4 and COMP5 signal the logic when

the temperature is below 0°C or above 50°C. The 100µA

bias current through the 10kΩ thermistor will generate

2.79V at 0°C and 0.405V at 50°C. The voltage hysteresis

on COMP4 and COMP5 is designed to give 10°C of

temperature hysteresis. If the voltage on the NTC pin

drops below 0.2V, the comparator COMP6 generates a

reset to the logic and timer block.

To provide accurate charge voltages, the internal resistor

divider is trimmed to provide a precise ±0.2% voltage of

2.465V at the OVP pin for the four battery voltage options

of 4.1V, 4.2V, 8.2V and 8.4V.

6

20mV

+

–

CHARGING

CURRENT

R1

0.2Ω

+

20mV

R2

200Ω

V

CC

I

BIAS

C1

1µF

SENSE

BAT

Figure 3. C/10 Detection Circuit

–

–

COMP1

+

100µA

3-SEC

FILTER

LOGIC

AND

TIMERS

LTC1729

STATUS

50µA

CHARGE

LED

1729 F03

Page 7

LTC1729 Series

RESET MODE

I

BAT

= 0

STATUS = PULL-DOWN

V

C

= PULL-DOWN

PAUSE

I

BAT

= 0

STATUS = PULL-DOWN

V

C

= PULL-DOWN

DONE

I

BAT

= 0

STATUS = OPEN

V

C

= PULL-DOWN

NO BAT

I

BAT

= 0

STATUS = OPEN

V

C

= PULL-DOWN

HOLD MODE

I

BAT

= 0

STATUS = PREVIOUS STATUS

V

C

= PULL-DOWN

PRECONDITION

I

BAT

= 16mA

STATUS = PULL-DOWN

V

C

= PULL-DOWN

t

MAX

= 1HR

V

BAT

< V

MIN

V

BAT

> V

MIN

V

BAT

> V

MAX

TIME > t

MAX

1729 F06

NOTE: FOR STATUS

PULL-DOWN = HARD:

FOR CURRENT > C/10

PULL-DOWN = 50µA:

FOR CURRENT < C/10 FOR 3SEC

V

BAT

< V

MAX

FOR MORE THAN 1SEC

V

BAT

< V

MAX

FOR MORE THAN 1SEC

V

BAT

> V

MAX

FOR MORE THAN 1SEC

V

BAT

> V

MAX

FOR MORE THAN 1SEC

V

NTC

> 2.79V OR

V

NTC

< 0.405V

V

NTC

< 2.79V AND

V

NTC

> 0.405V

V

BAT

> V

MIN

V

BAT

< V

MIN

CHARGER “ON”

I

BAT

= 1.3mA

STATUS = PULL-DOWN

V

C

= OPEN

t

MAX

= 3HR

CHARGE

U

WUU

APPLICATIONS INFORMATION

V

= 1V

= 0V

= 0V

= 0V

= 0V

= 1V

BATTERY CLAMP

PULL-DOWN

ON

NORMAL CHARGE

TRICKLE CHARGE

PRECONDITIONING

1729 F04

MAX

V

MIN

4.5V/CELL

V

MAX

V

MIN

2.7V/CELL

BATTERY VOLTAGE

V

MAX

V

MIN

Figure 4. BAT Voltage Operating Range

HOLD MODE

2.79V

NORMAL CHARGE

Figure 5. NTC Voltage Operating Range

When the input supply is removed in step-down charger

designs, the VCC pin does not drop to 0V, but is held to a

diode drop below the battery voltage. This is due to the

internal parasitic diode from the SW pin to the VCC pin that

is present in the LT1510, LT1511, LT1769, and the body

diode of the top MOSFET in the LT1505 charger. Removing

the input supply will result in the VCC pin dropping below

the UVLO threshold, thus shutting down the LTC1729 and

minimizing battery drain. Once the input supply is connected, the LTC1729 resets the timers and begins another

charge cycle. There is a disconnect transistor that will

remove the OVP resistor divider from the battery when the

VCC voltage drops below the UVLO threshold.

0.405V

HOLD MODE

THERMISTOR VOLTAGE

0.2V

RESET MODE

1729 F05

Figure 6. State Diagram

The logic and timer block consists of a state machine,

oscillator and counter. The state machine will be discussed in detail in the next section. The oscillator is

internally trimmed to 131kHz. The counter is composed of

a chain of 25 flip-flops that includes self-test circuitry.

State Machine

The state machine is responsible for the following items:

1. When to start and stop the charger. The internal timer

must be initialized every time a new battery is installed

or when the input supply is applied.

2. When a battery is installed, the state machine must

determine if it is a new battery or if the previous battery

has been reinstalled.

7

Page 8

LTC1729 Series

U

WUU

APPLICATIONS INFORMATION

3. When a heavily discharged battery is installed, trickle

charge conditioning must take place before the full

charge current.

The state machine diagram is shown in Figure 6. Note that

the Charge state includes the Precondition state, the

charger “ON” state and the Reset mode.

Reset and Hold are the two modes that will cause the

charger to stop charging (VC pin pulled low) and ignore the

state machine. The Reset mode clears all the timers and

forces the state machine to begin in the Charge state

(STATUS pin pulled low). This mode is only activated

momentarily at power-up or when the NTC pin is below the

Reset threshold. The other interrupt condition is called the

Hold mode. When the voltage on the NTC pin is above

2.79V (cold) or below 0.405V (hot), the state machine is

locked in the present state until the NTC pin voltage returns

to the proper range. While in the Hold mode, the charging

is disabled and the timers are frozen.

The charger is enabled only during the charger “ON” state.

There are three ways that the state machine can exit the

charger “ON” state. The first is for a 3-hour time-out which

is denoted as the time > t

Second, if the battery is removed from the charger, the

V

signal is activated as mentioned in the Block Dia-

MAX

gram section. This causes the state machine to make the

V

> V

BAT

exit the charger “ON” state is with a V

to the Precondition state. The battery will need to drop

below 2.6V/cell to be less than V

scenario.

transition to the Pause state. The third way to

MAX

transition to the Done state.

MAX

< V

BAT

. This is not a likely

MIN

transition

MIN

requirement for this transition is for the BAT pin voltage to

exceed V

assumes that the battery has been removed.

From the No Bat state, there is only one possible transition.

The No Bat state can move to the Charge state if the voltage

on the BAT pin remains less than V

LTC1729 will now work on the assumption that a new

battery has been installed.

Although the Precondition and Charger “ON” both reside

in the Charge state, there are differences between these

states. The main purpose of the Precondition state is to

slowly bring a heavily discharged battery up to a minimum

level before full charge current begins. The Precondition

state uses a 16mA current source to trickle charge the

battery with a 1-hour time-out transition to the Done state.

The Charger “ON” state enables the external charger and

the time-out is increased to three hours. For the entire

time in the Precondition state, the STATUS pin uses a hard

pull-down. In the Charger “ON” state the STATUS pin uses

two types of pull-down: hard pull-down and soft 50µA

pull-down.

The STATUS pin is designed to provide an indication that

the battery is charging. Once the current drops below the

C/10 threshold, the battery is close to being fully charged.

The LTC1729 turns off the hard pull-down once the

C/10 comparator is active for more than three seconds.

The 50µA soft pull down remains in effect until the 3-hour

time-out is completed or the input power is removed.

Terminate at C/10 Current

for more than one second. The IC now

MAX

for one second. The

MAX

Once in the Pause state, there are two ways to proceed.

The first is to go to the No Bat state. This requires that the

V

remain greater than V

BAT

second. From these conditions, the LTC1729 interprets

that a battery has been removed. If the voltage on the BAT

pin stays less than V

the state machine returns to the Charge state (Precondition and charger “ON”). This is interpreted as a momentary

open caused by the battery pack protection circuitry or

loose contact.

The Done state can only proceed to the No Bat state. From

outside the LTC1729 this transition is undetectable. The

for more than one second, then

MAX

for more than one

MAX

8

Charging can also be terminated using C/10 detection

rather than the 3-hour time-out. By connecting the low

side of the NTC thermistor to the STATUS pin instead of

ground, the NTC pin will float to 5V as soon as the Status

pull-down is open. This will force the state machine into

the Hold mode. The VC pin is pulled low which turns off the

charger. This circuit is shown in Figure 7.

In order to restart the charging process for a new battery,

the NTC pin will need to be momentarily brought below

0.2V or the VCC pin brought below the UVLO threshold.

The automatic battery detection features are disabled

during the Hold mode.

Page 9

LTC1729 Series

U

WUU

APPLICATIONS INFORMATION

LTC1729-4.2

1

1µF

2

3

4

OVP

BAT

SENSE

GND

OVP

BAT

SENSE

200Ω

Figure 7. Terminate Charging at C/10

Using Status as a Charging Indicator

In many applications circuits shown in this data sheet, the

STATUS pin is used to indicate when C/10 has occurred

(charge current has dropped to 10% of the full charge

current). This C/10 number is not fixed, but is set by an

external resistor connected to the LTC1729 SENSE pin. A

100µA bias current through this resistor develops a volt-

age which is compared with the voltage across the charge

current sense resistor. When these voltages are equal, the

8

V

CC

7

V

V

C

C

6

STATUS

5

NTC

10k NTC THERMISTOR

NTHS1206N02 VISHAY/DALE

0.1µF

1729 F07

V

CC

open-drain STATUS pin turns off. Connecting an LED to

the STATUS pin will give a visual indication during the

precondition trickle charge and the portion of the main

charge before C/10 has occurred.

By reducing the LTC1729 SENSE pin resistor to 0Ω, the

STATUS pin function can be changed to a

tor

(Figure 8). The LED on the STATUS pin will always go

charging indica-

off after the 3-hour charge cycle is completed, regardless

of the C/10 circuitry.

CHARGE

CURRENT

I

BIAS

+

–

SENSE

RESISTOR

SENSE

BAT

–

COMP1

+

Figure 8. Modify C/10 Indication to Create Charging Indicator

LTC1729

100µA

1729 F08

U

TYPICAL APPLICATIONS

V

IN

LT1512

V

C

STATUS

R5

1k

L1A**

V

V

I

C5

0.1µF

V

NTC

SW

FB

FB

CC

V

C

INPUT POWER

4V TO 9V

R7

C6

100Ω

1µF

22µF

C3

S/S

GND

OVP

BAT

LTC1729-4.2

SENSE

GND

SEPIC Charger with 0.5A Output Current

C2*

2.2µF

R4, 24Ω

C4

0.22µF

D1

MBRS130LT3

L1B**

R3

0.2Ω

C7

10µF

R8

10k NTC THERMISTOR, NTHS1206N02 VISHAY/DALE

NOTE: EITHER A THERMISTOR OR 10k RESISTOR MUST BE PRESENT

OPTION: TIE R8 TO STATUS FOR

CHARGE TERMINATION AT

LOW CHARGING CURRENT

R6

0.2Ω

C1

22µF

R1

29.4k

R2

12.4k

R

PULLUP

10k

R9

1k

†

D4

+

* TOKIN CERAMIC 1E225ZY5U-C203-F

** L1A, L1B ARE TWO 33µH WINDINGS ON A

SINGLE INDUCTOR; COILTRONICS CTX33-3

†

LUMEX SML-LX0805GW-TR SIZE R9 FOR

20mA TYPICAL

BOOST

CAP

4.2V

GND

CAP

FOR 3.5V TO 14V USE LTC1144

+

LTC1044

–

V

OSC

OUT

+

V

LV

1/2 BAT85S

+

D2

1/2 BAT85S

C8

10µF

D3

1729 F11

9

Page 10

LTC1729 Series

TYPICAL APPLICATIONS

TO

V

(FROM

ADAPTER)

IN

5.1k

DBODY

M3

Si4435

R7

500Ω

R5

3k

R6

R

0.025Ω

1µF

C6

0.1µF

C1

S4

SYSTEM

POWER

R1

1k

C7

0.68µF

C

*

IN

47µF

V

35V

CC

CLN

CLP

INFET

UV

SYNC

SHDN

FLAG

CAP

COMP1

BAT2 BAT SENSE SPIN

U

4A, 2-Cell Lithium-Ion Battery Charger

BOOST

LT1505

BOOSTC

GBIAS

TGATE

BGATE

PROG

3 CELL

AGND

PGND

SW

V

4.2V

4.1V

V

C

FB

C3

2.2µF

R

4.93k

1%

5Ω

MMSD4148

PROG

D2

R3

300Ω

C

1µF

R4

3k

PROG

C5

0.33µF

M1

Si4412

M2

Si4412

C4

0.1µF

D3

MMSD4148

D4

MBRS140

C2

0.68µF

L1**

15µH

R

S1

0.025Ω

R

S2

200Ω

1%

R

S3

200Ω

1%

C

OUT

22µF

× 2

***

+

8.4V

R8

100Ω

* SANYO OS-CON

** SUMIDA CDRH127-150

*** AVX TPSD226L025R0200

†

LUMEX SML-LX0805GW-TR

C8

0.1µF

OVP

BAT

LTC1729-8.4

SENSE

GND

V

STATUS

NTC

R

PULL-UP

10k

CC

V

C

C9

0.1µF

10k NTC THERMISTOR, NTHS1206N02 VISHAY/DALE

NOTE: EITHER A THERMISTOR OR 10k RESISTOR MUST BE PRESENT

OPTION: TIE RESISTOR TO STATUS FOR

CHARGE TERMINATION AT

LOW CHARGING CURRENT

R9

1.4k

†

D5

1729 F09

10

Page 11

PACKAGE DESCRIPTION

(

0.007

(0.18)

0.021 ± 0.006

(0.53 ± 0.015)

* DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS. MOLD FLASH,

PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

** DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.006"

0° – 6° TYP

U

Dimensions in inches (millimeters) unless otherwise noted.

MS8 Package

8-Lead Plastic MSOP

(LTC DWG # 05-08-1660)

0.118 ± 0.004*

(3.00 ± 0.102)

0.193 ± 0.006

(4.90 ± 0.15)

SEATING

PLANE

0.040 ± 0.006

(1.02 ± 0.15)

0.012

(0.30)

0.0256

REF

(0.65)

BSC

0.152mm) PER SIDE

0.034 ± 0.004

(0.86 ± 0.102)

0.006 ± 0.004

(0.15 ± 0.102)

LTC1729 Series

8

7

6

5

0.118 ± 0.004**

(3.00 ± 0.102)

MSOP (MS8) 1098

12

4

3

S8 Package

8-Lead Plastic Small Outline (Narrow 0.150)

(LTC DWG # 05-08-1610)

0.228 – 0.244

(5.791 – 6.197)

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

× 45°

0°– 8° TYP

0.016 – 0.050

(0.406 – 1.270)

0.053 – 0.069

(1.346 – 1.752)

0.014 – 0.019

(0.355 – 0.483)

TYP

0.189 – 0.197*

(4.801 – 5.004)

7

8

1

2

5

6

0.150 – 0.157**

(3.810 – 3.988)

3

4

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

BSC

SO8 1298

11

Page 12

LTC1729 Series

TYPICAL APPLICATION

3A (LT1511) Or 2A (LT1769), 2-Cell Lithium-Ion Battery Charger

U

0.47µF

L1**

22µH

100Ω

R

S4

0.05Ω

R7

1.4k

D5

D1

SS24

†

D2

SS24

R5

3k

R6

5.1K

INPUT POWER

11.5V TO 28V

TO MAIN

SYSTEM

POWER

R1

C

1µF

R3

300Ω

8.4V

PROG

510Ω

R

4.93k

PROG

GND CLP

R

S1

STATUS

CLN

V

PROG

BATSENSE

V

CC

V

CC

UV

V

C

R

S3

200Ω

1%

C

+

C1*

15µF

C4

0.33µF

R2

1k

C7***

22µF

C6

0.1µF

+

SW

D3

MBR0540T

D4

SS24

C3

200pF

C5

1µF

200Ω

LT1511 OR LT1769

BOOST

COMP1

SPIN

OVP

R

S2

0.05Ω

1%

OVP

BAT

LTC1729-8.4

SENSE

C2

R4

* TOKIN C55Y5U1E156Z

** SUMIDA CDRH125-220MC

*** AVX TPSD226K025R0200

†

LUMEX SML-LX0805GW-TR

D1, D2, D4: GENERAL SEMICONDUCTOR

GND

NTC

10k NTC THERMISTOR, NTHS1206N02 VISHAY/DALE

NOTE: EITHER A THERMISTOR OR 10k RESISTOR MUST BE PRESENT

OPTION: TIE RESISTOR TO STATUS FOR

CHARGE TERMINATION AT

LOW CHARGING CURRENT

1729 F10

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1505 High Efficiency Constant-Voltage/Constant-Current Battery Charger Uses External Synchronous N-Channel FETs

LT1510 Constant-Voltage/Constant-Current Battery charger Up to 1.5A Charge Current for Lithium-Ion, NiCd and

NiMH Batteries, Internal R

LT1511 3A Constant-Voltage/Constant-Current Battery Charger Charges Lithium, NiCd and NiMH Batteries

LT1512 SEPIC Battery Charger VIN Can Be Higher or Lower Than Battery Voltage, 2A Switch

LT1513 SEPIC Battery Charger VIN Can Be Higher or Lower Than Battery Voltage, 3A Switch

LTC1759 SMBus-Controlled Smart Battery Charger LT1505 Charger Functionality with SMBus Control

LT1769 2A Constant-Voltage/Constant-Current Battery Charger In 28-Pin SSOP Package

SENSE

12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

1729i LT/TP 1099 4K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1999

Loading...

Loading...