Page 1

FEATURES

■

Low Output Noise: 60µV

■

Adjustable or Fixed Boosted Output

■

Adjustable Output Voltage Range: 2.5V to 5.5V

■

Fixed Output Voltages: 3.3V, 5V

■

Wide Input Voltage Range: 1.8V to 4.4V

■

Uses Small Ceramic Capacitors

■

No Inductors Required

■

Output Current up to 50mA

■

550kHz Switching Frequency

■

Low Operating Current: 150µA

■

Low Shutdown Current: 1µA

■

Internal Thermal Shutdown and Current Limiting

■

Available in 8-Pin MSOP and SO Packages

(100kHz BW)

RMS

U

APPLICATIO S

■

VCO Power Supplies in Cellular Phones

■

2-Way Pagers

■

Wireless PCMCIA Cards

■

Portable Medical Instruments

■

Low Power Data Acquisition

■

Remote Transmitters

LTC1682/LTC1682-3.3/LTC1682-5

Doubler Charge Pumps with

Low Noise Linear Regulator

U

DESCRIPTIO

The LT C®1682/LTC1682-3.3/LTC1682-5 are doubler charge

pumps with an internal low noise, low dropout (LDO) linear

regulator. These parts are designed to provide a low noise

boosted supply voltage for powering noise sensitive devices

such as high frequency VCOs in wireless applications.

An internal doubler charge pump converts a 1.8V to 4.4V

input to a boosted output, while the internal LDO regulator

converts the boosted voltage to a low noise regulated output.

The adjustable version allows the user to set V

resistors connected to FB. The regulator is capable of supplying up to 50mA of output current. Shutdown reduces the

supply current to < 5µA, removes the load from VIN by

disabling the regulator and discharges V

through a 100Ω switch.

The LTC1682 LDO regulator is stable with only 2µF on the

output. Small ceramic capacitors can be used, reducing PC

board area.

The LTC1682/LTC1682-3.3/LTC1682-5 are short-circuit and

over temperature protected. The parts are available in 8-pin

MSOP and SO packages.

, LTC and LT are registered trademarks of Linear Technology Corporation.

via external

OUT

to ground

OUT

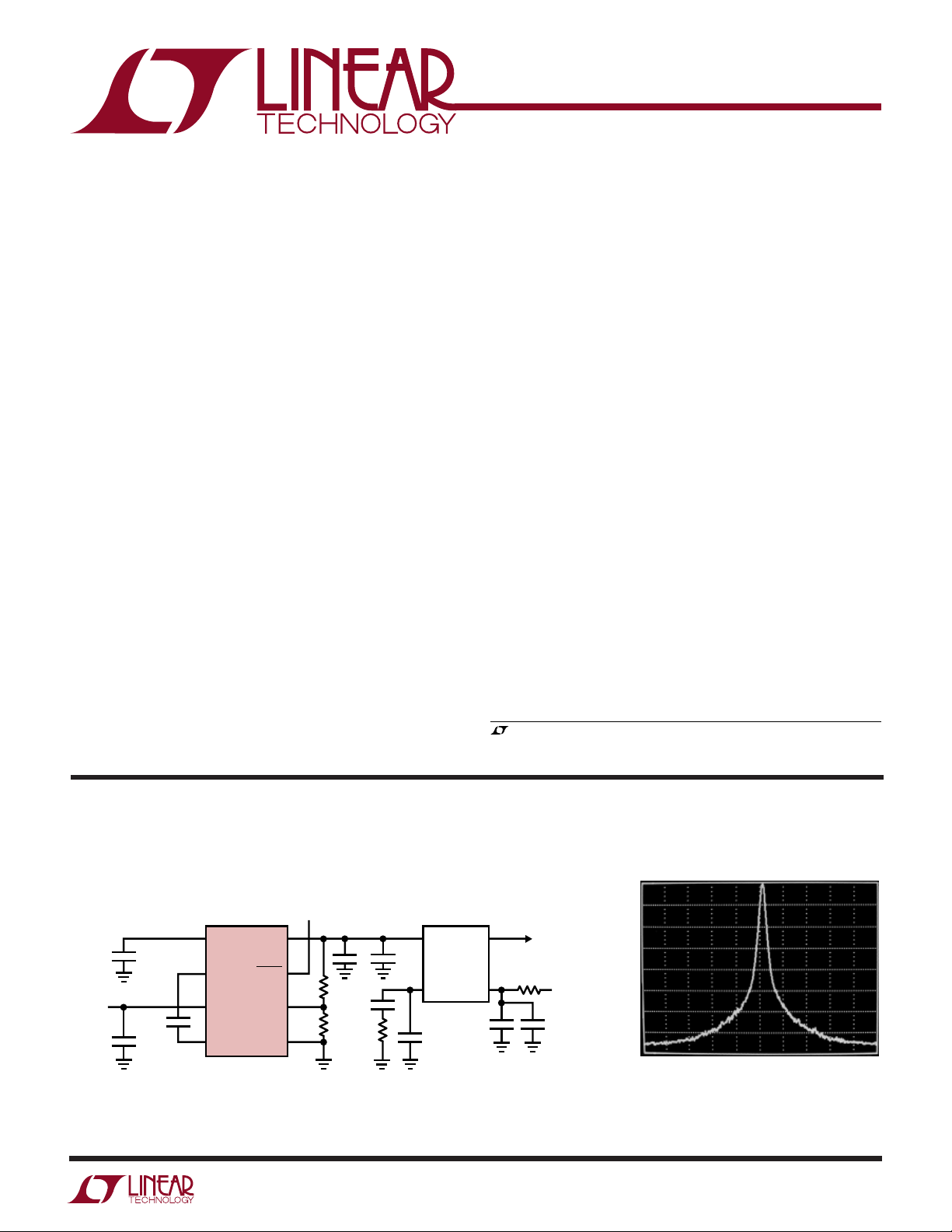

TYPICAL APPLICATIO

4.2V VCO Power Supply, VIN = 2.5V to 4.4V

SHUTDOWN

V

2.5V TO

4.4V

8

CPO

4.7µF

IN

0.22µF

4.7µF

7

C

6

V

5

C

+

LTC1682

IN

–

V

OUT

SHDN

GND

FB

U

Open-Loop Close-In Phase Noise

4.2V

1

2

3

4

36k

15k

4.7µF

1µF

1k

1000pF

B

VCO

MURATA

MQE001-902

M

1000pF

1000pF

P

C

100k

f

OUT

902MHz

V

4.7µF

1682 TA01

C

AMPLITUDE

10dB/DIV

CENTER = 902MHz RES BW = 1kHz

SPAN = 100kHz VBW = 30Hz

SWP = 10 sec REF = 0dBm

1682 TA02

1

Page 2

LTC1682/LTC1682-3.3/LTC1682-5

TOP VIEW

S8 PACKAGE

8-LEAD PLASTIC SO

1

2

3

4

8

7

6

5

V

OUT

SHDN

FILT/FB*

GND

CPO

C

+

V

IN

C

–

*PIN3 = FILT FOR LTC1682-3.3/LTC1682-5

= FB FOR LTC1682

WW

W

ABSOLUTE MAXIMUM RATINGS

U

(Note 1)

VIN to Ground ..............................................–0.3V to 5V

V

Voltage................................................–0.3V to 6V

OUT

CPO to Ground ........................................................ 10V

SHDN, FILT/FB Voltage to

Ground ..................................... – 0.3V to (VIN + 0.3V)

V

Short-Circuit Duration............................ Indefinite

OUT

I

...................................................................... 90mA

OUT

UUW

PACKAGE/ORDER INFORMATION

ORDER PART

NUMBER

TOP VIEW

V

1

OUT

2

SHDN

3

FILT/FB*

4

GND

MS8 PACKAGE

8-LEAD PLASTIC MSOP

*PIN3 = FILT FOR LTC1682-3.3/LTC1682-5

= FB FOR LTC1682

T

= 125°C, θJA = 140°C/ W

JMAX

8

CPO

+

7

C

V

6

IN

–

C

5

LTC1682CMS8

LTC1682CMS8-3.3

LTC1682CMS8-5

LTC1682IMS8

LTC1682IMS8-3.3

LTC1682IMS8-5

MS8 PART MARKING

LTER

LTGT

LTGV

LTHM

LTGU

LTGW

Operating Temperature Range

Commercial ............................................ 0°C to 70°C

Extended Commercial (Note 2)........... – 40°C to 85°C

Industrial ........................................... –40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec)..................300°C

Maximum Junction Temperature..........................125°C

ORDER PART

NUMBER

LTC1682CS8

LTC1682CS8-3.3

LTC1682CS8-5

LTC1682IS8

LTC1682IS8-3.3

LTC1682IS8-5

S8 PART MARKING

= 125°C, θJA = 120°C/W

T

JMAX

1682

168233

16825

1682I

1682I33

1682I5

Consult factory for Military grade parts.

ELECTRICAL CHARACTERISTICS

range, otherwise specifications are TA = 25°C. SHDN = VIN = 3V; C1 = 0.22µF; C2, C3, C4 = 4.7µF, unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNITS

VIN Operating Voltage LTC1682 ● 1.8 4.4 V

I

Shutdown Current SHDN = 0V ● 15 µA

VIN

I

Operating Current I

VIN

FB Input Current LTC1682, FB = 1.235V ● –50 50 nA

FB Voltage LTC1682 ● 1.210 1.235 1.260 V

Regulated Output Voltage LTC1682-3.3, I

V

Temperature Coefficient ±50 ppm

OUT

Charge Pump Oscillator Frequency I

Burst Mode is a trademark of Linear Technology Corporation.

2

The ● denotes specifications that apply over the full operating temperature

LTC1682-3.3

LTC1682-5

= 0mA, Burst Mode

OUT

0°C to 70°C

–40°C to 85°C

LTC1682-5, I

> 200µA, VIN = 1.8V to 4.4V ● 480 550 620 kHz

OUT

OUT

OUT

TM

Operation

= 1mA ● 3.23 3.30 3.37 V

= 1mA ● 4.9 5.0 5.1 V

● 2 4.4 V

● 2.7 4.4 V

● 150 250 µA

● 150 300 µA

Page 3

LTC1682/LTC1682-3.3/LTC1682-5

ELECTRICAL CHARACTERISTICS

The ● denotes specifications that apply over the full operating temperature

range, otherwise specifications are TA = 25°C. SHDN = VIN = 3V; C1 = 0.22µF; C2, C3, C4 = 4.7µF, unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNITS

CPO (Charge Pump Output) VIN = 1.8V, I

Output Resistance V

V

Dropout Voltage (Note 3) LTC1682, I

OUT

= 3V, I

IN

= 4.4V, I

V

IN

LTC1682/LTC1682-3.3, I

LTC1682/LTC1682-5, I

V

Enable Time I

OUT

V

Output Noise Voltage LTC1682 I

OUT

= 10mA 2 ms

OUT

LTC1682-3.3 I

LTC1682-5 I

V

Line Regulation VIN = 3V to 4V, I

OUT

V

Load Regulation I

OUT

V

Shutdown Resistance SHDN = 0V, Resistance Measured to Ground, VIN = 1.8V ● 150 350 Ω

OUT

= 1mA to 10mA ● 310 mV

OUT

I

= 1mA to 50mA (Note 4) 10 mV

OUT

SHDN = 0V, Resistance Measured to Ground, V

SHDN Input Threshold VIN = 1.8V to 4.4V ● 0.4 1 1.6 V

SHDN Input Current SHDN = V

SHDN = 0V

= 10mA ● 18 30 Ω

OUT

= 10mA ● 13 20 Ω

OUT

= 10mA ● 11 17 Ω

OUT

= 10mA, V

OUT

IN

OUT

I

OUT

OUT

I

OUT

OUT

I

OUT

= 0mA (Note 6) ● 520 mV

OUT

= 2.57V (Note 5) ● 100 160 mV

OUT

= 10mA, V

OUT

= 10mA, V

OUT

= 10mA, 10Hz ≤ f ≤ 100kHz, V

= 10mA, 10Hz ≤ f ≤ 2.5MHz, V

= 10mA, 10Hz ≤ f ≤ 100kHz, C

= 10mA, 10Hz ≤ f ≤ 2.5MHz, C

= 10mA, 10Hz ≤ f ≤ 100kHz, C

= 10mA, 10Hz ≤ f ≤ 2.5MHz, C

= 3.3V ● 75 120 mV

OUT

= 5V ● 50 90 mV

OUT

= 5V 88 µV

OUT

= 5V 800 µV

OUT

= 1nF 58 µV

FILT

= 1nF 500 µV

FILT

= 1nF 64 µV

FILT

= 1nF 600 µV

FILT

= 4.4V ● 50 150 Ω

IN

● –1 1 µA

● –1 1 µA

RMS

P-P

RMS

P-P

RMS

P-P

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC1682C is guaranteed to meet specified performance from

0°C to 70°C and is designed, characterized and expected to meet these

extended temperature limits, but is not tested at –40°C and 85°C. The

LTC1682I is guaranteed to meet the extended temperature limits.

Note 3: Dropout voltage is the minimum input/output voltage required to

maintain regulation at the specified output current. In dropout the output

voltage will be equal to: V

CPO

– V

DROPOUT

(see Figure 4).

Note 4: Operating conditions are limited by maximum junction

temperature. The regulated output specification will not apply for all

possible combinations of input voltage and output current. When

operating at maximum input voltage, the output current range may be

limited. When operating at maximum output current, the input voltage

range may be limited.

Note 5: Limited by the LDO disable switch point of 1.45V

.

IN

Note 6: The LTC1682 is set to 5V. The feedback current is 25µA.

3

Page 4

LTC1682/LTC1682-3.3/LTC1682-5

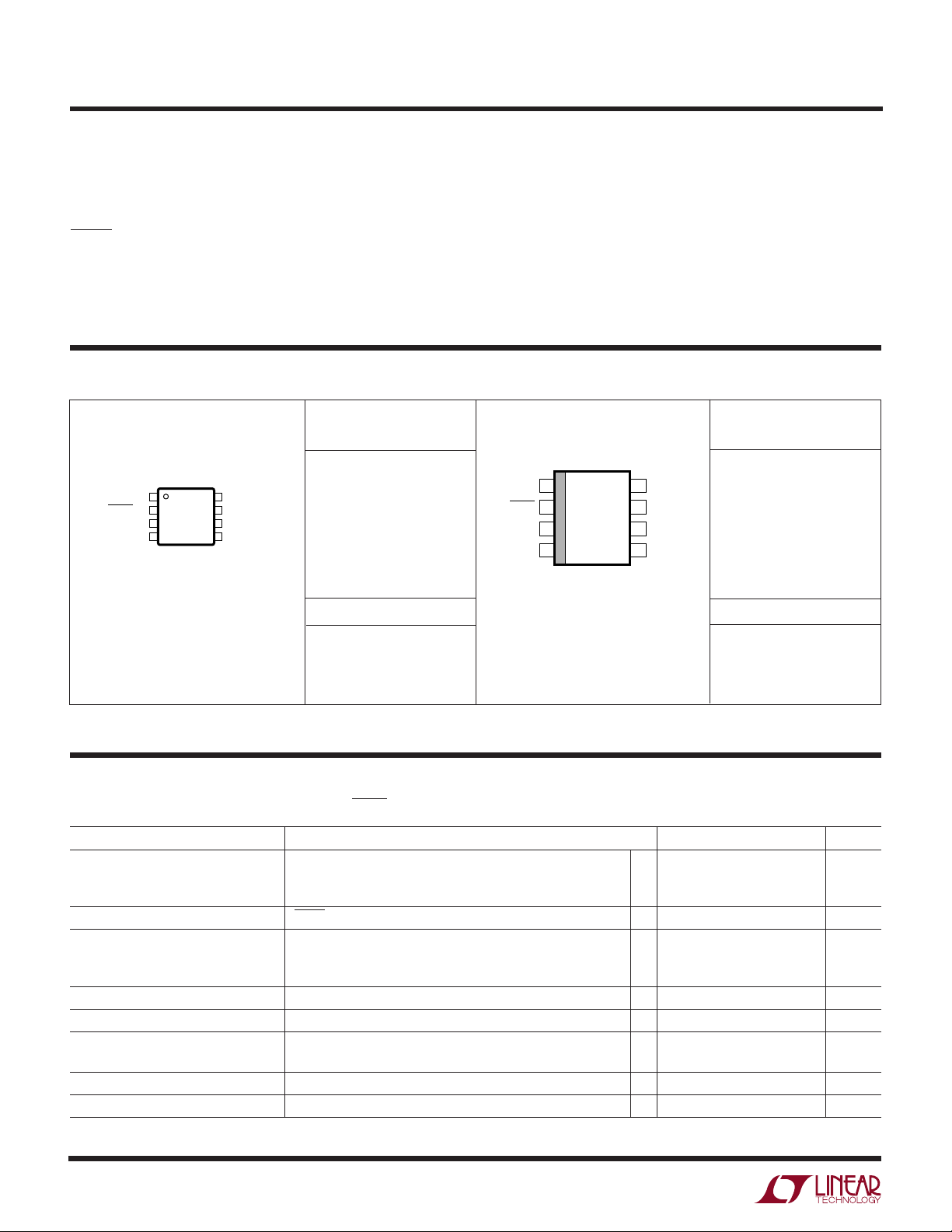

UW

TYPICAL PERFOR A CE CHARACTERISTICS

CPO Output Resistance vs V

35

30

25

(Ω)

20

CPO

R

15

10

5

1.5

2.5 3.0 3.5

2.0

VIN (V)

LTC1682-5 Output Noise

(BW = 10Hz to 2.5MHz)

IN

TA = 25°C

C1 = 0.22µF

= 10mA

I

OUT

4.0 4.5

1682 G01

Min and Max V

9

TA = 25°C

8

7

6

(V)

CPO

V

5

4

3

1.5

(A) THE MAXIMUM GENERATED NO LOAD

(B) THE MINIMUM ALLOWABLE CPO VOLTAGE,

V

2.5 3.0 3.5

2.0

CPO VOLTAGE

AT FULL LOAD, TO ENSURE THAT THE LDO

IS NOT DISABLED

Shutdown to Enable Timing

CPO

vs V

CPO

= 2(VIN)

(A)

V

VIN (V)

IN

(B)

= 1.45(VIN)

CPO

4.0 4.5

1682 G02

V

Transient Response

OUT

10

5

(mV)I

0

OUT

TA = 25°C

∆V

(mA)

OUT

V

–5

IN

V

OUT

C

–10

OUT

15

10

5

0

050

= 3V

= 4V

= 10µF

100 200150

TIME (µs)

Enable to Shutdown Timing

250

300

1682 G02

V

OUT

200µV/DIV

C

= C

CPO

= 10mA TA = 25°C

I

OUT

= 3V C

V

IN

100µs/DIV 1682 G04

= 4.7µFV

OUT

Oscillator Frequency vs

Temperature

565

VIN = 3V

560

555

550

545

540

OSCILLATION FREQUENCY (kHz)

535

530

–50

= 5V

OUT

= 1nF

FILT

–25 0

50 100 125

25 75

TEMPERATURE (°C)

SHDN (V)V

(V)

OUT

2

0

4

3

2

1

0

1682 G07

TA = 25°C

= 3V

V

IN

= 4V

V

OUT

= 10mA

I

OUT

= C

C

CPO

OUT

= 10µF

200µs/DIV

1682 G05

Operating Current vs V

(No Load)

220

TA = 25°C

200

180

160

140

120

100

OPERATING CURRENT (µA)

80

60

1.5

LTC1682-3.3

LTC1682-5

2.5 3.0 3.5 4.0 4.5

2.0

2

0

SHDN (V)V

4

3

(V)

2

OUT

1

0

VIN (V)

NO LOAD

= 25°C

T

A

= 3V

V

IN

= 4V

V

OUT

= 10µF

C

OUT

IN

LTC1682

1ms/DIV

1682 G06

1682 G08

4

Page 5

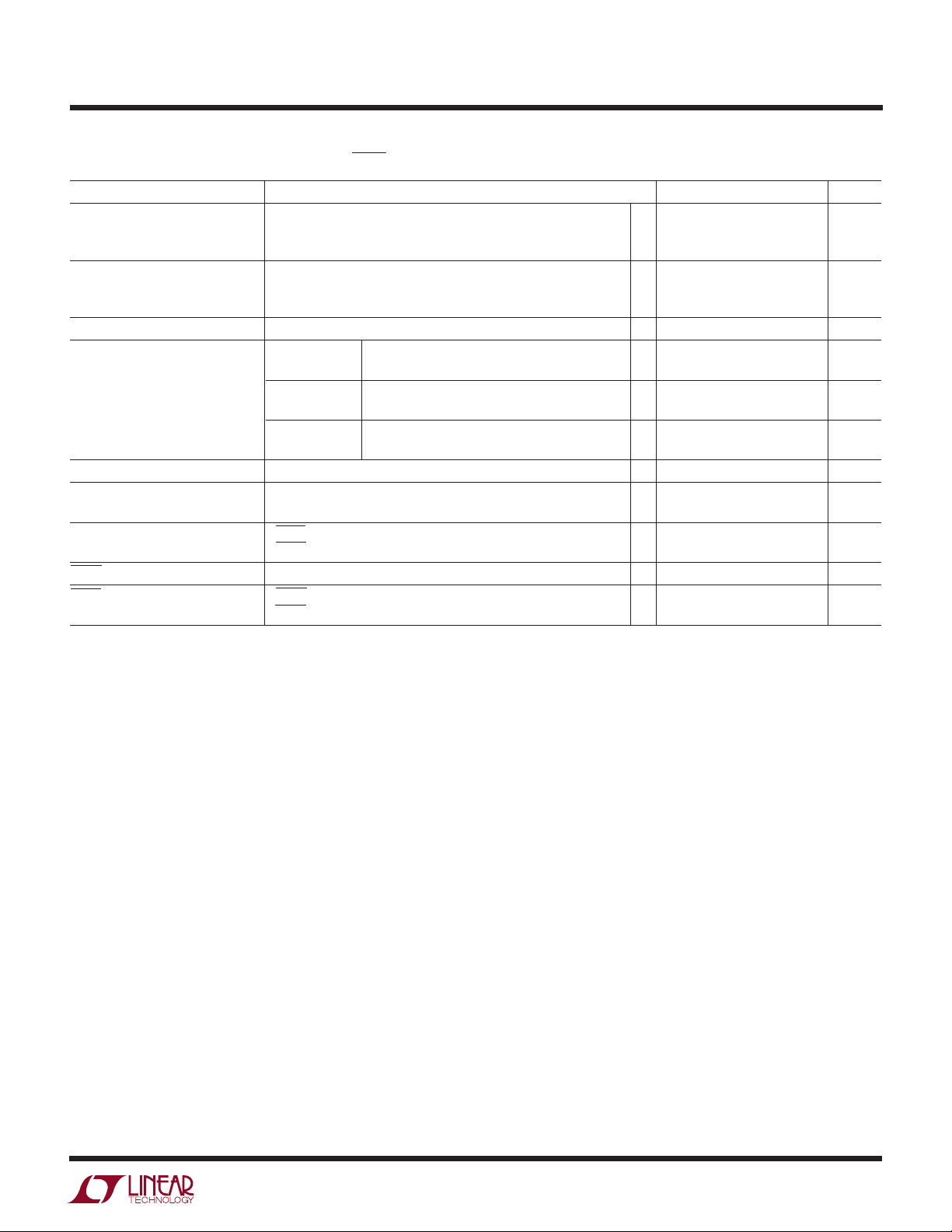

LTC1682/LTC1682-3.3/LTC1682-5

UW

TYPICAL PERFOR A CE CHARACTERISTICS

V

Voltage vs Temperature

OUT

5.030

V

5.020

I

OUT

5.010

5.000

4.990

3.340

3.330

3.320

3.310

VOLTAGE (V)

3.300

OUT

V

3.290

1.240

1.238

1.236

1.234

–50

IN

= 3V

= 10mA

LTC1682-3.3

0

–25

TEMPERATURE (°C)

LTC1682-5

LTC1682

25

75

50 125

100

1682 G09

5.000

4.999

4.998

4.997

4.996

4.995

4.994

4.993

VOLTAGE (V)

3.300

OUT

3.299

V

3.298

3.297

3.296

3.295

3.294

UUU

PIN FUNCTIONS

V

Voltage vs Output Current

OUT

LTC1682-5

LTC1682-3.3

20

0

15 25 40 45 50

510

OUTPUT CURRENT (mA)

30 35

VIN = 3.3V

= 25°C

T

A

1682 G10

V

(Pin 1): Low Noise Regulated Output Voltage. V

OUT

OUT

should be bypassed with a ≥2µF low ESR capacitor as

close to the pin as possible for best performance. The V

OUT

range is 2.5V to 5.5V.

SHDN (Pin 2): Shutdown Input. A logic low on the SHDN

pin puts the part in shutdown mode. A logic high enables

the part. To continuously enable the part connect SHDN to

VIN. When the part is in shutdown, V

will be connected

OUT

to ground via a 100Ω switch and CPO will be high

impedance disconnected from VIN.

FB (Pin 3) (LTC1682): The voltage on this pin is compared

to the internal reference voltage (1.235V) by the error

amplifier to keep the output in regulation. An external

resistor divider is required between V

and FB to adjust

OUT

the output voltage.

FILT (Pin 3) (LTC1682-3.3/LTC1682-5): This pin is used

to filter the internal voltage reference. Typically a 1nF

capacitor is connected from FILT to ground.

GND (Pin 4): System Ground.

C– (Pin 5): Flying Capacitor Negative Input.

VIN (Pin 6): Input Voltage, 1.8V to 4.4V. VIN should be

bypassed with a ≥2µF low ESR capacitor as close to the

pin as possible for best performance. A minimum capacitance value of 0.1µF is required.

C+ (Pin 7): Flying Capacitor Positive Input.

CPO (Pin 8): Unregulated Charge Pump Output Voltage.

Approximately 1.95(VIN) at low loads. Bypass with a ≥2µF

low ESR capacitor. If a minimum V

required, the CPO capacitor should be 2× the V

enable time is

OUT

OUT

capacitor.

5

Page 6

LTC1682/LTC1682-3.3/LTC1682-5

W

BLOCK DIAGRA SM

C1

0.22µF

+

C

V

IN

C4

4.7µF

6

CHARGE PUMP

AND

SLEW CONTROL

57

CLK1

–

C

CPO

ENB

8

–

275k

C3

4.7µF

+

38k

1:100

+

–

328k

1

SD

100Ω

C2

4.7µF

V

OUT

SHDN

POWER-

2

ON

RESET

SD

REGEN

ENB

550kHz

OSCILLATOR

REG B

–

V

REF

= 1.235V

V

IN

+

LDO

REGEN

1µA/2µA

6

FB

34

GND

Figure 1. LTC1682 Block Diagram

R1

R2

1682 F01

Page 7

W

BLOCK DIAGRA SM

C1

0.22µF

LTC1682/LTC1682-3.3/LTC1682-5

V

IN

4.7µF

C4

SHDN

1nF

FILT

+

C

6

CHARGE PUMP

AND

SLEW CONTROL

57

CLK1

–

C

CPO

ENB

8

–

275k

C3

4.7µF

+

38k

1:100

+

–

328k

1

SD

100Ω

V

C2

4.7µF

OUT

POWER-

2

3

ON

RESET

REGEN

ENB

200k

V

SD

REF

= 1.235V

550kHz

OSCILLATOR

V

IN

RA

120k/65.5k

REG B

RB

200k

–

+

LDO

REGEN

1µA/2µA

4

GND

Figure 2. LTC1682-3.3/LTC1682-5 Block Diagram

1682 F02

7

Page 8

LTC1682/LTC1682-3.3/LTC1682-5

U

WUU

APPLICATIONS INFORMATION

Operation

The LTC1682 uses a switched-capacitor charge pump to

generate a CPO voltage of approximately 2(VIN). CPO

powers an internal low dropout linear regulator that supplies a regulated output at V

used to sense CPO and VIN voltages for power-up conditioning. The output current is sensed to determine the

charge pump operating mode. A trimmed internal bandgap

is used as the voltage reference and a trimmed internal

oscillator is used to control the charge pump switches.

The charge pump is a doubler configuration that uses one

external flying capacitor. When enabled, a 2-phase

nonoverlapping clock controls the charge pump switches.

At start-up, the LDO is disabled and the load is removed

from CPO. When CPO reaches 1.75(VIN) the LDO is

enabled. If CPO falls below 1.45(VIN) the LDO will be

disabled. Generally, the charge pump runs open loop with

continuous clocking for low noise. If CPO is greater than

1.95(VIN)

and

I

is less than 100µA, the charge pump

OUT

will operate in Burst Mode operation for increased efficiency but slightly higher output noise. In Burst Mode

operation, the clock is disabled when CPO reaches 1.95(VIN)

and enabled when CPO droops by about 100mV. The

switching frequency is precisely controlled to ensure that

the frequency is above 455kHz and at the optimum rate to

ensure maximum efficiency. The switch edge rates are

also controlled to minimize noise. The effective output

resistance at CPO is dependent on the voltage at VIN, CPO

and the junction temperature. A low ESR capacitor of ≥2µF

should be used at CPO for minimum noise.

. Internal comparators are

OUT

The LDO is used to filter the ripple on CPO and to set an

output voltage independent of CPO. V

is set by an

OUT

external or internal resistor divider. The LDO requires a

capacitor on V

for stability and improved load transient

OUT

response. A low ESR capacitor of ≥2µF should be used.

Output Voltage Selection

The LTC1682-3.3/LTC1682-5 versions have internal

resistor networks to set the regulated output voltage. The

LTC1682 output voltage is set using an external resistor

divider (see Figure 3). The output voltage is determined

using the following formula:

V

= 1.235V(1 + R1/R2)

OUT

The output voltage range is 2.5V to 5.5V.

Maximum V

OUT

and I

Calculations

OUT

The maximum available output voltage and current can be

calculated based on the open circuit CPO voltage, the

dropout voltage of the LDO and the effective output

resistance of the charge pump. The open circuit CPO

voltage is approximately 2(VIN) (see Figure 4).

R

+

2V

IN

–

CPO

V

CPO

Figure 4. Equivalent Circuit

R

DROPOUT

+

V

DROPOUT

C

CPO

V

OUT

–

I

LOAD

1682 F04

8

EXTERNAL LDO

C3

4.7µF

IN

3.3V

OUT

C5

GND

V

3.6V

IN

4.7µF

C4

0.22µF

8

CPO

7

+

C

LTC1682

6

V

C1

IN

5

–

C

V

OUT

SHDN

GND

1

2

R1

56k

3

FB

4

R2

18k

V

OUT

1682 F03

5.1V

V

= 800µV

RIPPLE

C2

4.7µF

= 1.235V(1 + R1/R2)

P-P

Figure 3. Powering an Auxiliary Regulator from CPO

Page 9

LTC1682/LTC1682-3.3/LTC1682-5

U

WUU

APPLICATIONS INFORMATION

The following formula can be used to find the maximum

output voltage that may be programmed for a given

minimum input voltage and output current load:

V

OUT(MAX)

with the condition that (I

Example:

V

IN(MIN)

I

= 10mA

OUT

R

CPO(MAX)

Max unloaded CPO voltage = 6V

Loaded CPO voltage = 6V – (10mA)(20Ω) = 5.8V

V

DROPOUT(MAX)

V

OUT(MAX)

V

< 5.5V and (I

OUT

For minimum noise applications, the LDO must be kept out

of dropout to prevent CPO noise from coupling into V

External CPO Loading

= (2)(V

IN(MIN)

OUT

) – (I

)(R

)(R

OUT

) < 0.55VIN.

CPO

= 3V

= 20Ω

= 0.08V

= (6V) – (0.2V) – (0.08V) = 5.72V

)(R

OUT

) < 0.55VIN, 0.2V < 1.65V.

CPO

CPO

) – V

DROPOUT

OUT

.

instantaneous currents which may induce ripple onto

a common voltage rail. C4 should be ≥2µF and a spike

reducing resistor of 2.2Ω may be required between

VIN and the supply.

A low ESR ceramic capacitor is recommended for the

flying capacitor C1 with a value of 0.22µF. At low load or

high VIN a smaller capacitor could be used to reduce ripple

on CPO which would reflect as lower ripple on V

OUT

.

If a minimum enable time is required, the CPO output filter

capacitor should be at least 2× the V

filter capacitor.

OUT

When the LDO is first enabled, the CPO capacitor will

dump a large amount of charge into the V

capacitor. If

OUT

the drop in the CPO voltage falls below 1.45(VIN), the LDO

will be disabled and the CPO voltage will have to charge up

to 1.75(VIN) to enable the LDO. The resulting cycling

extends the enable time.

A 1nF filter capacitor for the LTC1682-3.3/LTC1682-5

should be connected between the FILT pin and ground for

optimum noise performance.

The CPO output can drive an external load (an LDO, for

example). The current required by this additional load will

reduce the available current from V

requires 5mA, then the maximum available current at V

. If the external load

OUT

OUT

will be reduced by 5mA.

Short-Circuit and Thermal Protection

V

can be shorted to ground indefinitely. Internal cir-

OUT

cuitry will limit the output current. If the junction temperature exceeds 150°C, the part will shut down. Excessive

power dissipation due to heavy loads will also cause the

part to shut down when the junction temperature exceeds

150°C. The part will become enabled when the junction

temperature drops below 140°C. If the fault condition

remains in place, the part will cycle between the shutdown

and enabled states.

Capacitor Selection

For best performance it is recommended that low ESR

capacitors be used for C2, C3 and C4 in Figure 1 to

reduce noise and ripple. C2 must be ≥2µF and C3 must

be equal to or greater than C2. C4 is dependent on the

source impedance. The charge pump demands large

Output Ripple

The output noise and ripple on CPO includes a spike

component from the charge pump switches and a droop

component which is dependent on the load current and the

value of C3. The charge pump has been carefully designed

to minimize the spike component; however, low ESR

capacitors are essential to reduce the remaining spike

energy effect on the CPO voltage. C3 should be increased

for high load currents to minimize the droop component.

Ripple components on CPO are greatly reduced at V

OUT

by

the LDO; however, C2 should also be a low ESR capacitor

to improve filtering of the CPO noise.

Shutdown

When SHDN pin is pulled low (<0.4V), the part will be in

shutdown, the supply current will be < 5µA and V

OUT

will

be connected to ground through a 100Ω switch. In addition, CPO will be high impedance and disconnected from

VIN.

If shutdown is not required, connect SHDN to VIN which

will continuously enable the part.

9

Page 10

LTC1682/LTC1682-3.3/LTC1682-5

U

WUU

APPLICATIONS INFORMATION

Power-On Reset

Upon initial power-up, a power-on reset circuit ensures

that the internal functions are correctly initialized when

power is applied. Once VIN reaches approximately 1V, the

power-on reset circuit will enable the part as long as the

SHDN pin is held high.

Thermal Considerations

The power handling capability of the device will be limited

by the maximum rated junction temperature (125°C). The

device power dissipation PD = I

VIN(4mA). The device dissipates the majority of its heat

through its pins, especially GND (Pin 4). Thermal resistance to ambient can be optimized by connecting GND to

a large copper region on the PCB, which serves as a heat

sink. Applications which operate the LTC1682 near maximum power levels should maximize the copper area at all

pins except C+, C– and FILT/FB and ensure that there is

some airflow over the part to carry away excess heat.

(2VIN – V

OUT

OUT

) +

General Layout Considerations

Due to the high switching frequency and high transient

currents produced by the device, careful board layout is a

must. A clean board layout using a ground plane and short

connections to all capacitors will improve noise performance and ensure proper regulation (Figure 5).

The FILT pin on the LTC1682-3.3/LTC1682-5 is a high

impedance node. Leakage currents at this pin must be

minimized.

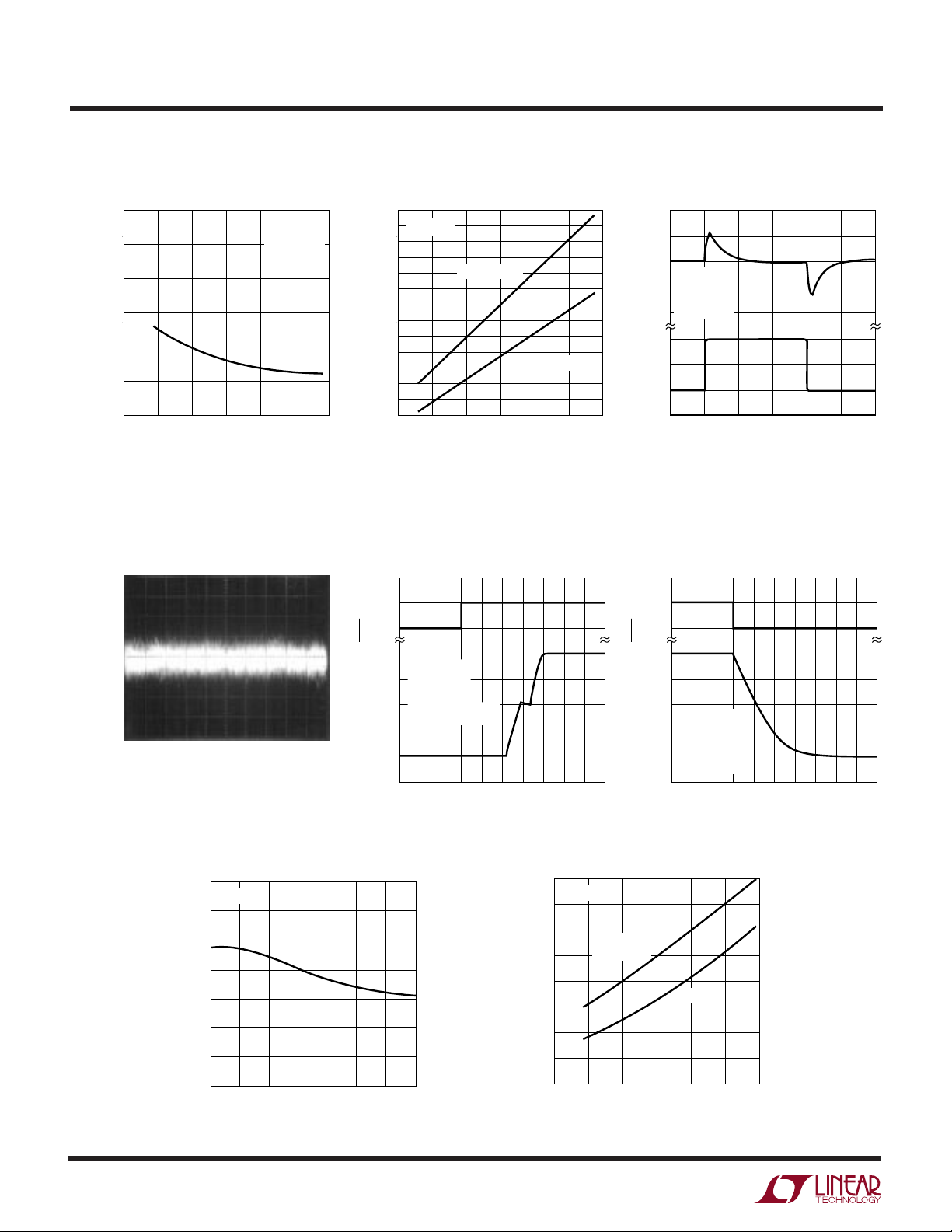

Measuring Output Noise

Measuring the LTC1682 low noise levels requires care.

Figure 6 shows a test setup for taking the measurement.

Good connection and signal handling technique should

yield about 500µV

over a 2.5MHz bandwidth. The noise

P-P

measurement involves AC coupling the LTC1682 output

into the test setup’s input and terminating this connection

with 50Ω. Coaxial connections must be maintained to

preserve measurement integrity.

BATTERY OR

LOW NOISE DC

POWER SUPPLY

R

LOAD

GROUND TERMINAL E5

BNC CABLES

OR COUPLERS

LTC1682

DEMO

BOARD

CONNECT BNC AND

GROUND TO THE

OUTPUT CAPACITOR

SHDN

COUPLING

CAPACITOR

V

OUT

R

LOAD

PLACE COUPLING

CAPACITOR IN SHIELDED

BOX WITH COAXIAL

CONNECTOR

V

OUT

C2

1

2

LTC1682-3.3/5

GND

3

4

C1

C

FILT

C3

8

V

IN

7

6

5

C4

1682 F05

Figure 5

PREAMPLIFIER

1822

+

R*

20dB

–

R*

*50Ω TERMINATIONS

HP-11048C OR

EQUIVALENT

BANDWIDTH

FILTER

R*

NOTE: KEEP BNC CONNECTIONS

AS SHORT AS POSSIBLE

INPUT

OSCILLOSCOPE

PLACE BANDWIDTH FILTER

COMPONENTS IN SHIELDED BOX

WITH COAXIAL CONNECTORS

1682 F06

10

Figure 6. LTC1682 Noise Measurement Test Setup

Page 11

TYPICAL APPLICATION

(

LTC1682/LTC1682-3.3/LTC1682-5

U

3.3V to Low Noise 3.3V Converter

SHUTDOWN

C3

4.7µF

V

IN

3.3V

C4

4.7µF

0.22µF

PACKAGE DESCRIPTION

0.007

(0.18)

0.021

± 0.006

(0.53 ± 0.015)

* DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS. MOLD FLASH,

PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

** DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.006"

° – 6° TYP

0

8

CPO

7

+

C

LTC1682-3.3

6

V

C1

IN

5

–

C

V

OUT

SHDN

FILT

GND

1

2

3

C

FILT

1nF

4

1682 TA03

C2

4.7µF

3.3V

V

RIPPLE

= 500µV

P-P

U

Dimensions in inches (millimeters) unless otherwise noted.

MS8 Package

8-Lead Plastic MSOP

(LTC DWG # 05-08-1660)

0.118 ± 0.004*

(3.00 ± 0.102)

0.040

SEATING

PLANE

± 0.006

(1.02 ± 0.15)

0.012

(0.30)

0.0256

REF

(0.65)

TYP

0.152mm) PER SIDE

0.034 ± 0.004

(0.86 ± 0.102)

0.006 ± 0.004

(0.15 ± 0.102)

0.192 ± 0.004

(4.88 ± 0.10)

8

7

12

6

5

0.118 ± 0.004**

(3.00 ± 0.102)

MSOP (MS8) 1197

4

3

8-Lead Plastic Small Outline (Narrow 0.150)

0.010 – 0.020

(0.254 – 0.508)

0.008 – 0.010

(0.203 – 0.254)

*

DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**

DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

× 45°

0.016 – 0.050

0.406 – 1.270

0.053 – 0.069

(1.346 – 1.752)

0°– 8° TYP

0.014 – 0.019

(0.355 – 0.483)

S8 Package

(LTC DWG # 05-08-1610)

0.004 – 0.010

(0.101 – 0.254)

0.050

(1.270)

TYP

0.228 – 0.244

(5.791 – 6.197)

0.189 – 0.197*

(4.801 – 5.004)

7

8

1

2

5

6

0.150 – 0.157**

(3.810 – 3.988)

SO8 0996

3

4

11

Page 12

LTC1682/LTC1682-3.3/LTC1682-5

U

TYPICAL APPLICATION

Wide Input Range VCO Supply (VIN > 4.4V)

V

IN

3V TO 6V

Q1

FMMT3904

8

7

6

5

CPO

+

C

LTC1682-5

V

IN

–

C

(REQUIRED FOR

START-UP)

C3

4.7µF

D1

1N4148

3V

C4

4.7µF

0.22µF

C1

V

OUT

SHDN

FILT

GND

1

2

3

4

R1

470Ω

SHUTDOWN

C

1nF

FILT

LOW NOISE

C2

4.7µF

5V

VCO

1682 ta04

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LTC1340 Low Noise, Voltage-Boosted Varactor Driver Generates 5V Varactor Drive from 3V Supply

LTC1517-X Micropower, Regulated Charge Pump Doubler in SOT-23 ICC = 6µA; Short Circuit/Thermal Protected

LT1521 300mA Low Dropout Regulator Micropower; Good Transient Response

LTC1522 Micropower, Regulated 5V Charge Pump Ultralow Power: Typical Operating ICC = 6µA

LT1761 Series 100mA Low Noise LDO Regulator in SOT-23 ICC = 20µA; 20µV

Output Noise

RMS

12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

128235fs, sn128235 LT/TP 0799 4K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1999

Loading...

Loading...